Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

21 results about "Pressure control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressure control (PC) is a mode of mechanical ventilation alone and a variable within other modes of mechanical ventilation. Pressure control is used to regulate pressures applied during mechanical ventilation. Air delivered into the patients lungs (breaths) are currently regulated by Volume Control or Pressure Control. In pressure controlled breaths a tidal volume achieved is based on how much volume can be delivered before the pressure control limit is reached.

Valve

ActiveUS8397758B2Reduce partEasy to adaptServomotor componentsMultiple way valvesFuel tankEngineering

A valve, particularly a proportional pressure control valve for controlling fluid flows, includes a valve housing (10) having at least three fluid-conducting connections in the form of a pump connection (P), a use connection (A) and of a tank (T) connection. To connect the pump connection (T) to the use connection (A) and the use connection (A) to the tank connection (T), a control piston (18) can be guided in a longitudinally displaceable manner inside the valve housing (10). This control piston is provided for establishing a fluid-conducting connection between at least one of the connections (P) and a pilot chamber (20) of a pilot valve (22) having a connecting channel (24). A valve part (40) of the pilot valve (22) is guided in the pilot chamber (20) in a longitudinally displaceable manner. The connecting channel (24) has a throttle in the direction of the pilot chamber (20) of the pilot valve (22) with its valve part. A guiding device (38) oriented toward the pilot chamber (20) and provided for guiding the fluid flow is provided next to the throttle to divert the fluid flow, conveyed inside the connecting channel (24) and flowing toward the valve part (40), at least partially away from this valve part.

Owner:HYDAC FLUITECHNIK GMBH

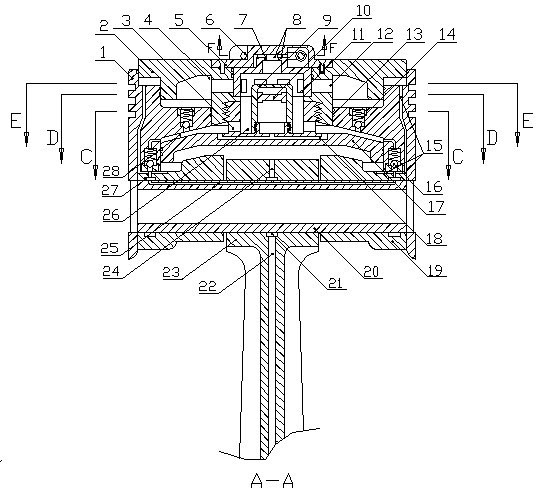

Adaptive variable compression engine piston

ActiveCN102330617ANo significant volume changeActual replacement installationEngine controllersMachines/enginesCombustionCheck valve

Owner:安徽格太信控科技有限公司

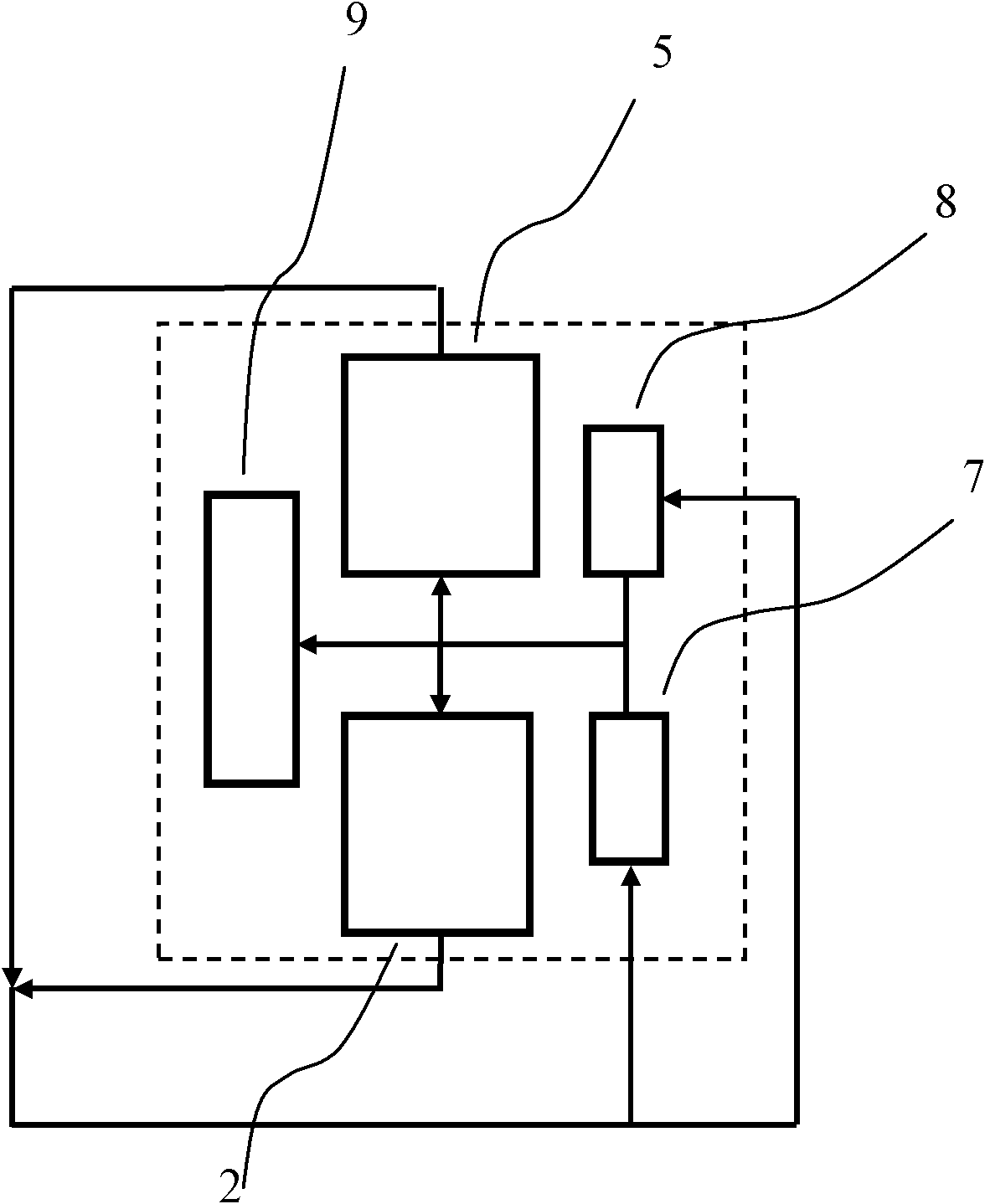

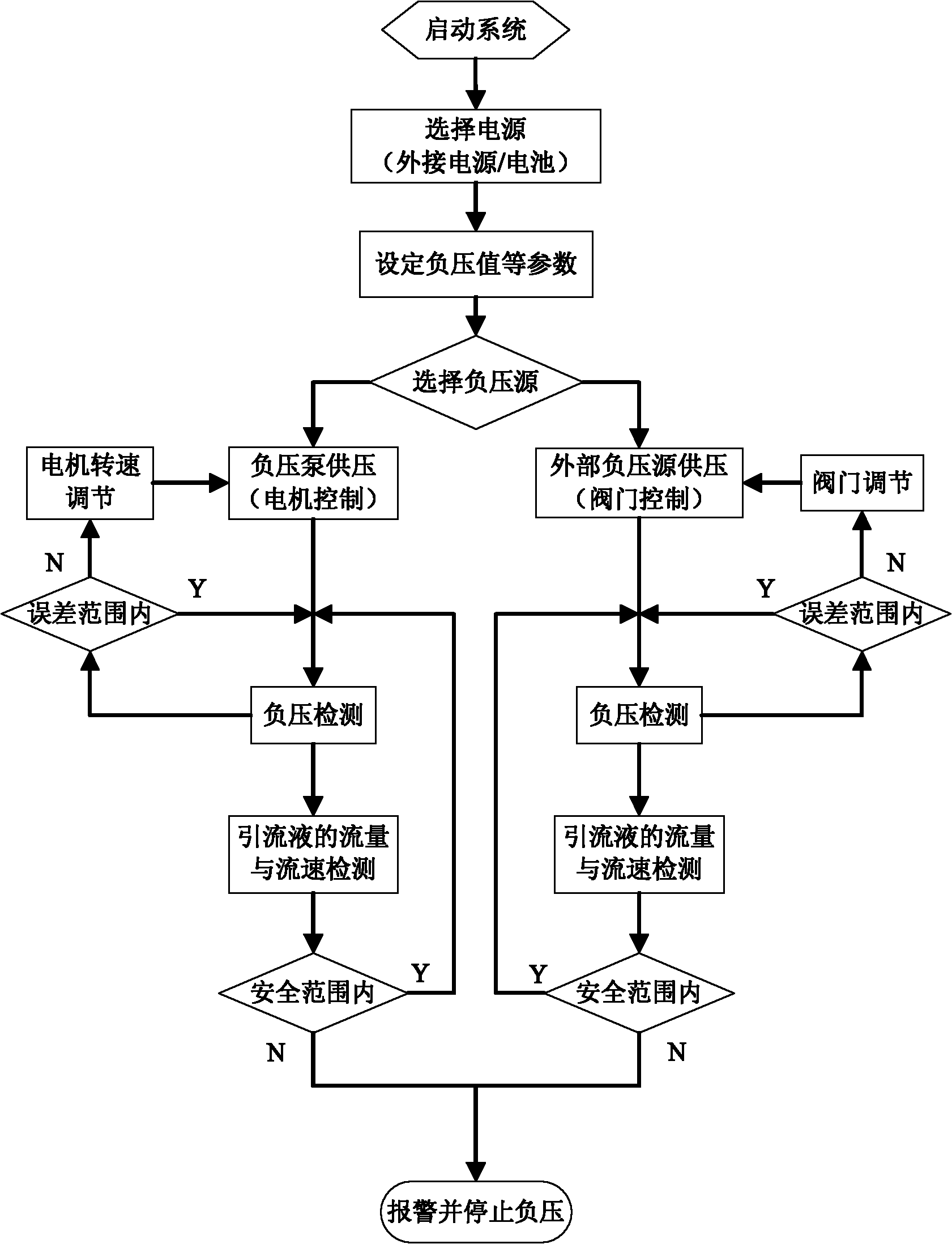

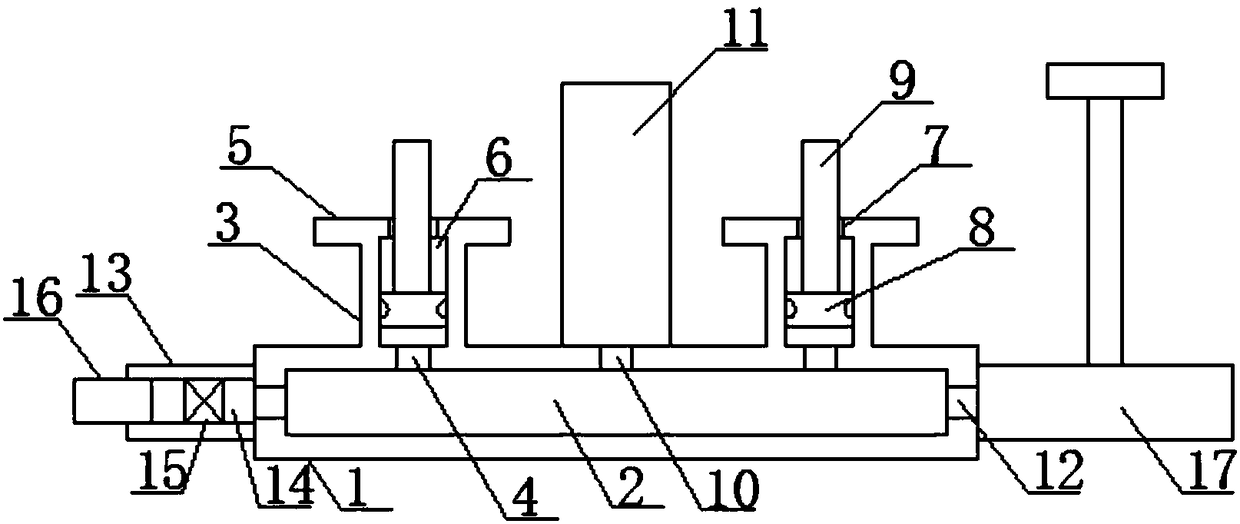

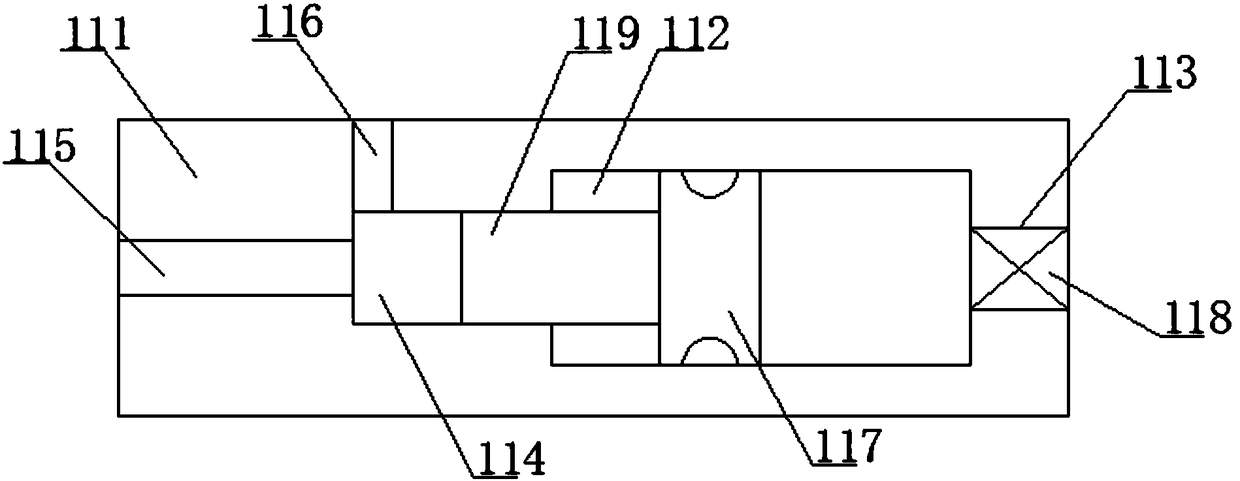

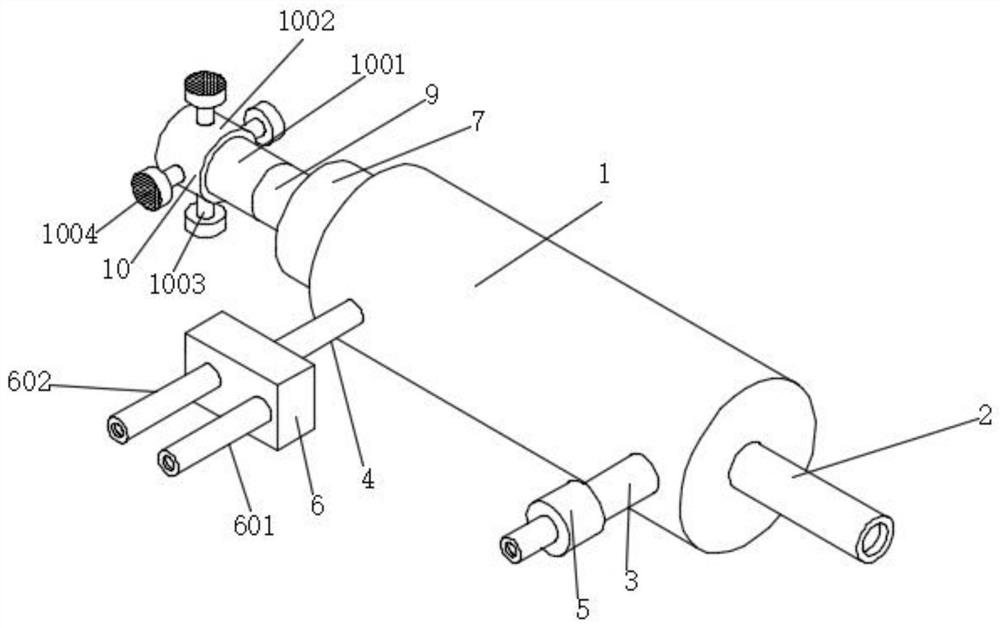

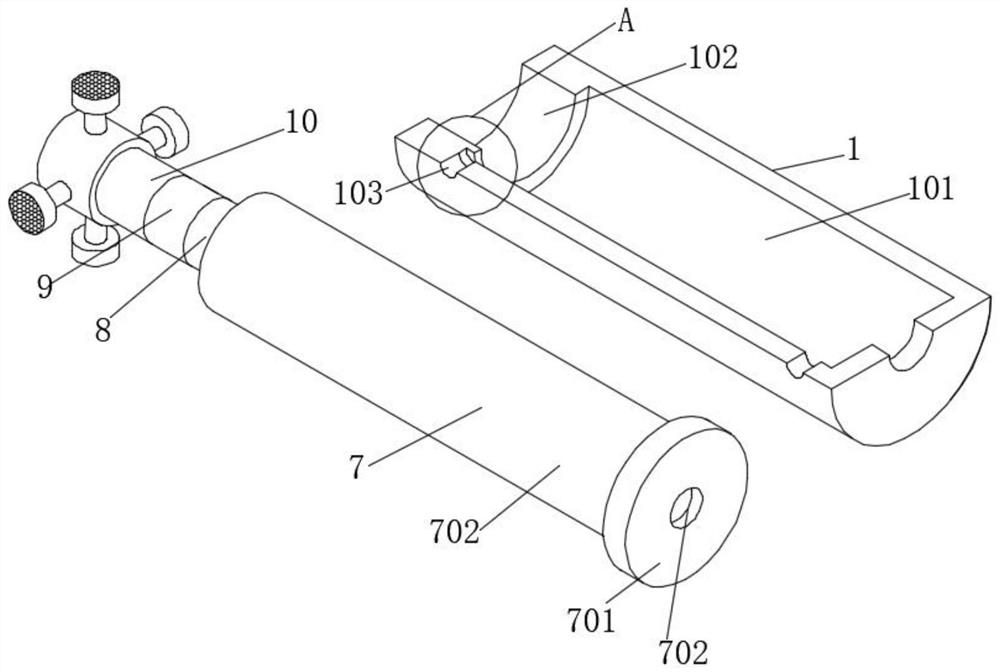

Dual negative pressure adjustable wound negative pressure therapy device based on microprocessor core

Owner:BEIHANG UNIV

Four-way switching valve

InactiveUS6860294B2Operating means/releasing devices for valvesAir-treating devicesSolenoid valveReciprocating motion

To provide a four-way solenoid valve having a three-way solenoid valve of which non-concentricity between a valve element and a valve hole is small, if any. A core of a three-way solenoid is integrally formed with a refrigerant passage extending axially therethrough, an annular projection forming a valve seat, and a guide for guiding reciprocating motion of a needle forming a valve element. A plug closing a cylinder of a body to define the pressure control chamber is also integrally formed with a valve seat and a guide for guiding reciprocating motion of a needle forming a valve element associated with the valve seat. This causes the needles to be seated on the valve seats associated therewith in respective states guided by the guides substantially concentric with the valve holes, which makes it possible to impart sufficient sealing properties to the valve portions when each valve is closed.

Owner:TGK

Gas-type road limit device

Owner:张礼国

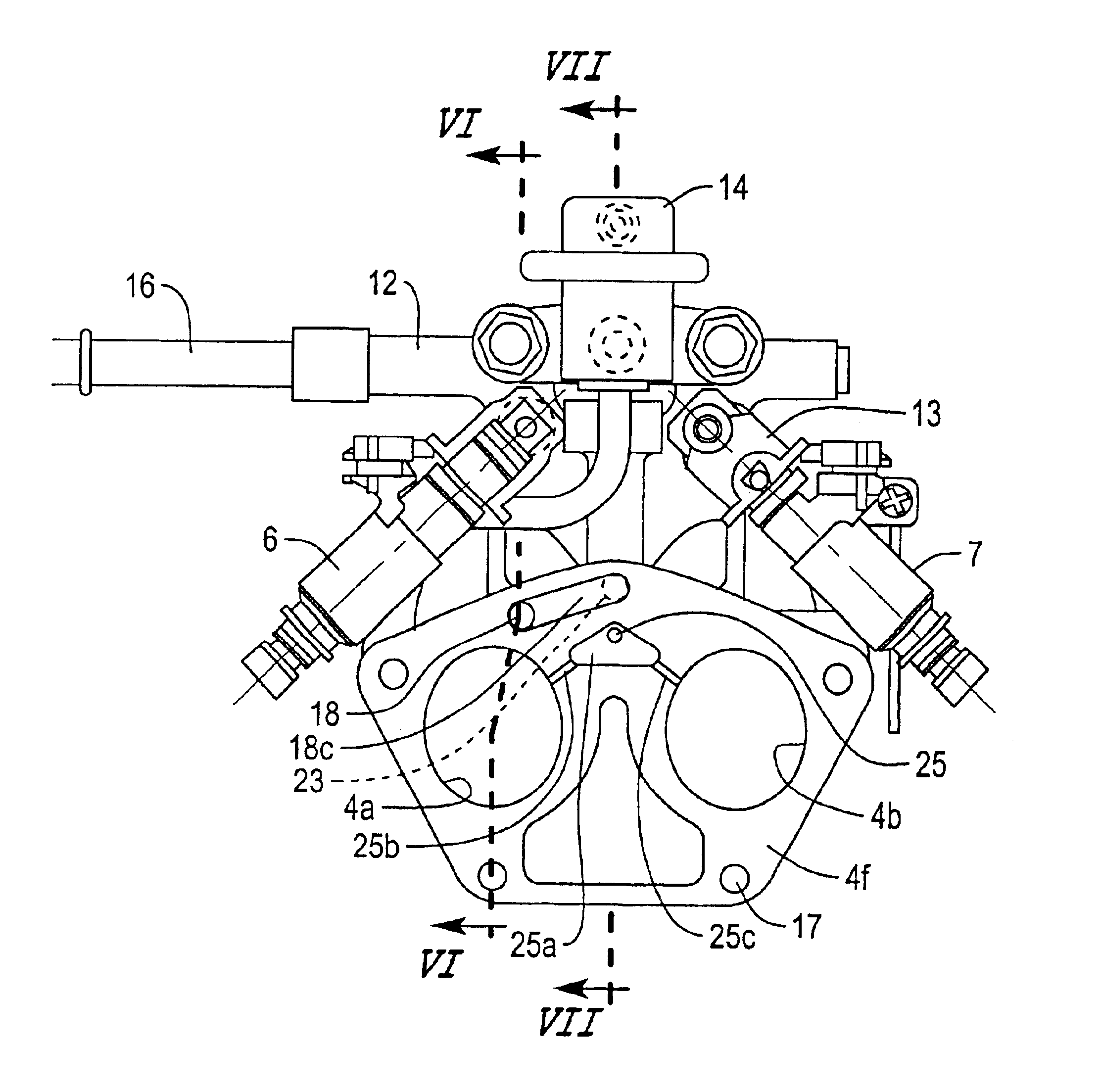

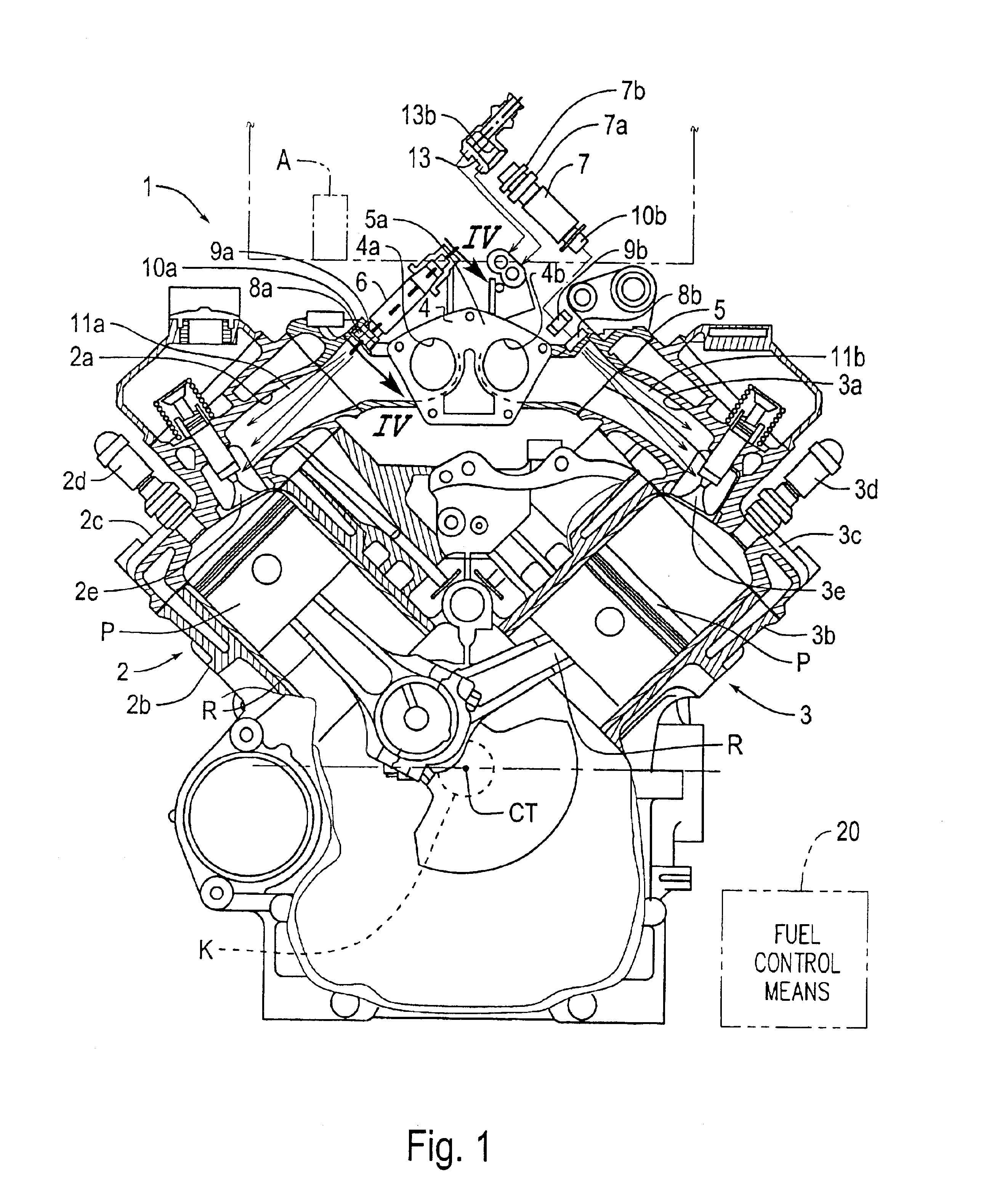

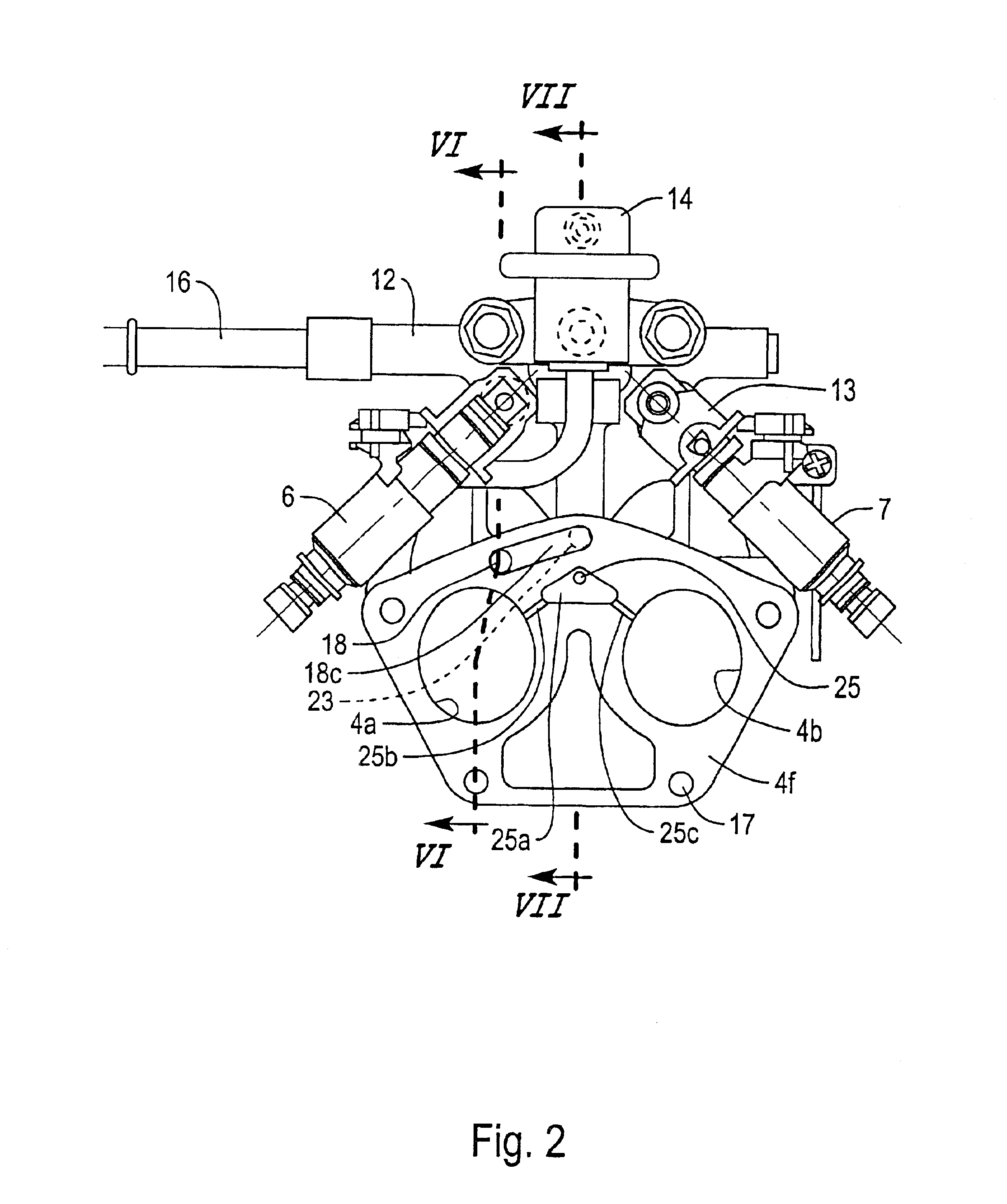

Multiple cylinder engine

InactiveUS6837220B2Limit air-fuel ratioAccurate detectionElectrical controlLow-pressure fuel injectionShuttle valvePressure control

Owner:KAWASAKI HEAVY IND LTD

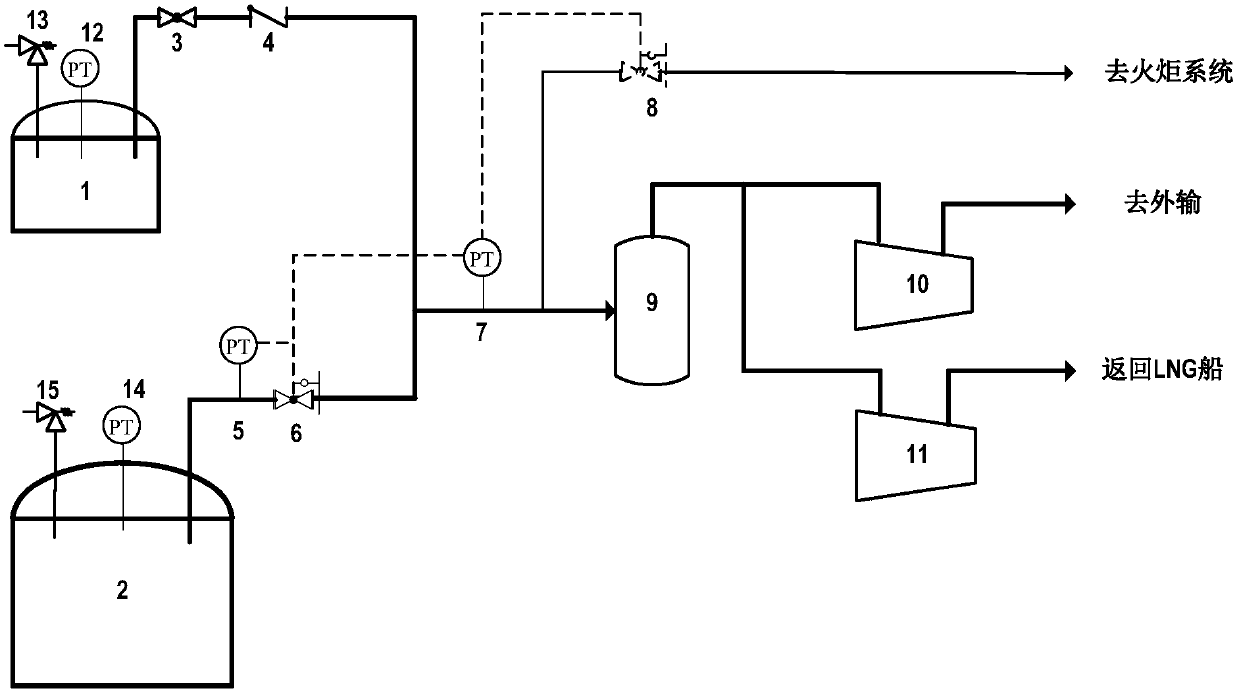

BOG treatment system and method of LNG storage tanks applicable to different design pressures

Owner:CHINA HUANQIU CONTRACTING & ENG CO LTD

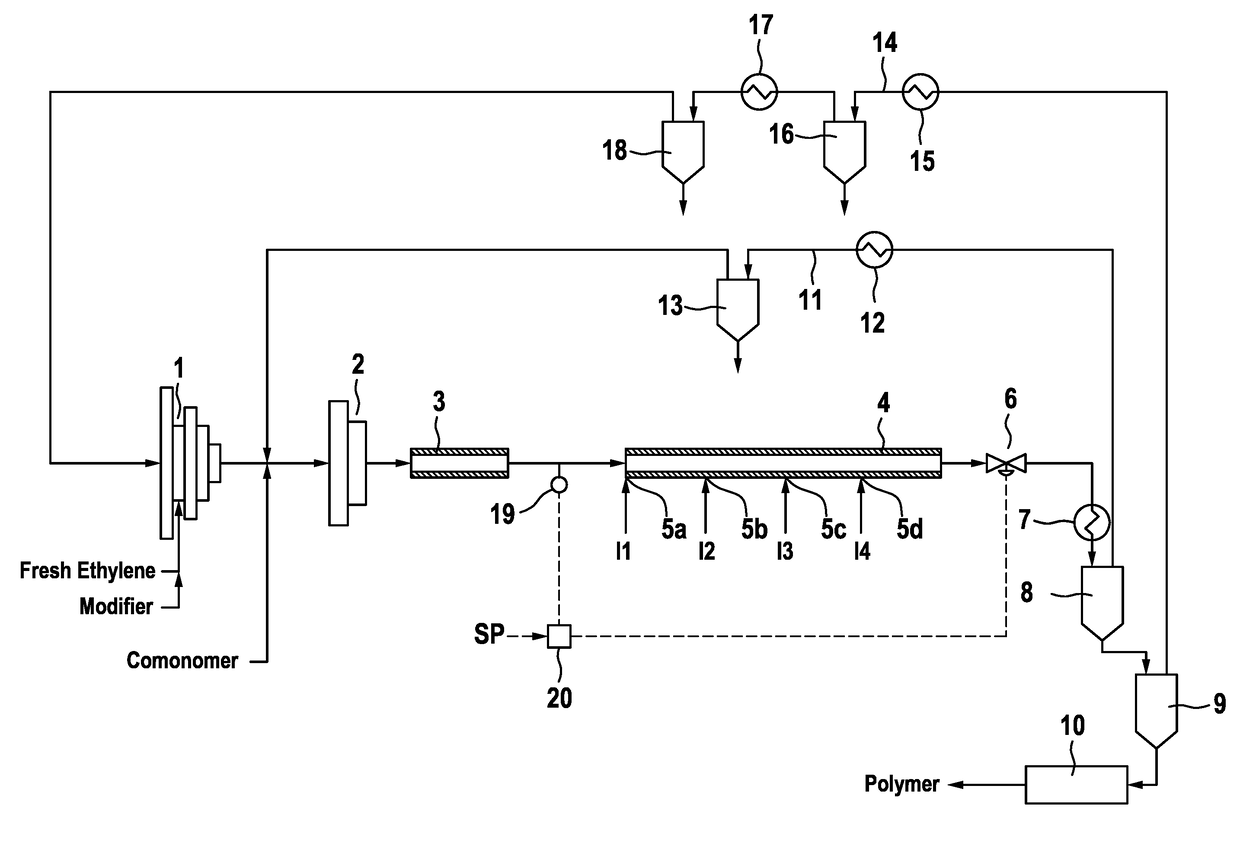

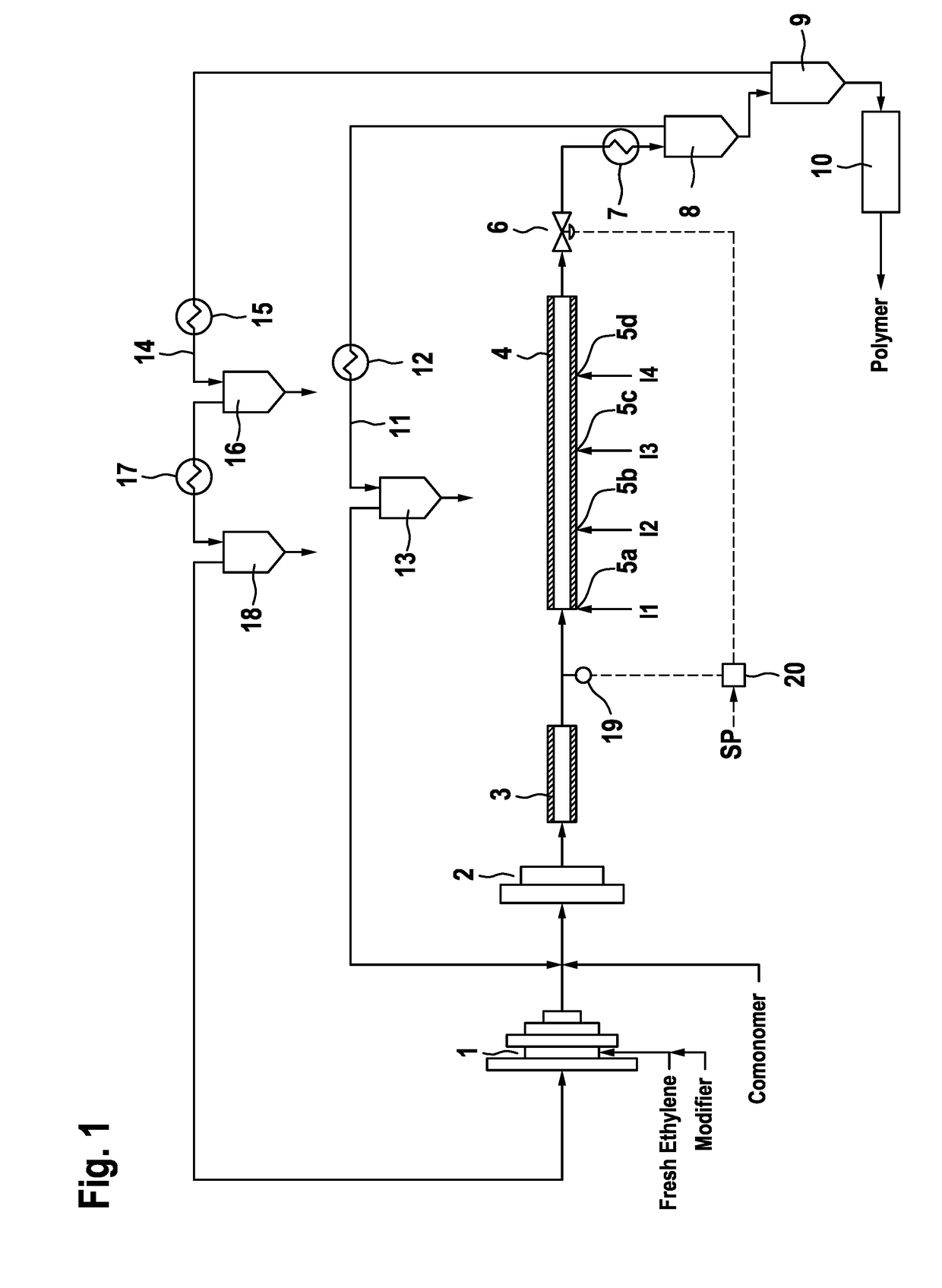

High-pressure polymerization process of ethylenically unsaturated monomers

ActiveUS20180030160A1Process control/regulationFluid pressure measurementDecreased pressureControl valves

Owner:BASELL POLYOLEFINE GMBH

Fluid handling device

A fluid handling device and a method for implementing the fluid handling device is provided, wherein the fluid handling device includes a pressure control device configurable to generate at least one of a positive pressure and a negative pressure; and a flow control device having a flow control device output, wherein the flow control device is configurably associated with the pressure control device such that at least one of the positive pressure and the negative pressure is in flow communication with the flow control device output.

Owner:BRISTOL MYERS SQUIBB CO

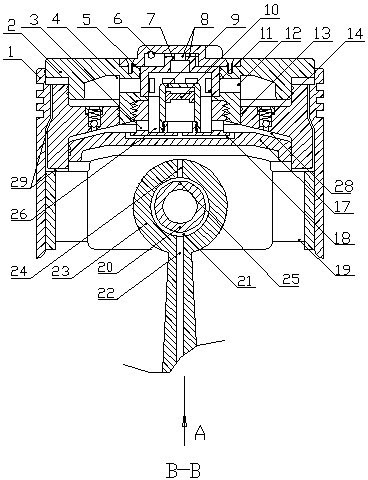

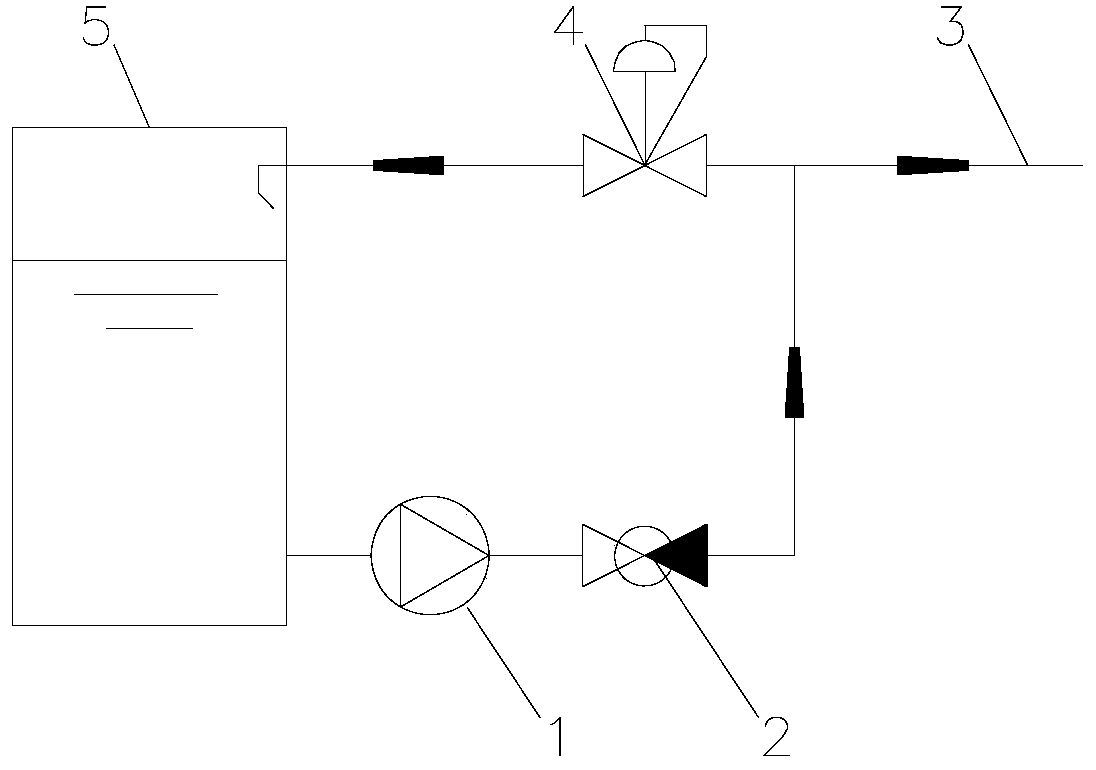

Control system and control method for turbocharger

InactiveCN103089343APrecise and stable controlIngenious designInternal combustion piston enginesEngine componentsControl systemTurbocharger

The invention relates to a control system and a control method for a turbocharger. A pressure control mechanism is used for controlling an exhaust gas valve of the turbocharger. The pressure control mechanism comprises a compression medium source, a shut-off valve, a pilot decompression valve, a first pressure regulating valve and a second pressure regulating valve which are arranged in a control pipeline. The shut-off valve is arranged at an outlet of the compression medium source for opening and shutting off the output of the compression medium source; the pilot decompression valve and the first pressure regulating valve are arranged on the lower course of the shut-off valve successively, the pilot decompression valve is provided with a first pressure gage and reduces pressure when pressure of compression media is too high, and the first pressure regulating valve is provided with a second pressure gage; and the second pressure gage is communicated with a lower course pipeline of the first pressure gage and the external environment, and the lower course of a control pipeline is connected with a mechanical actuator of the exhaust gas valve. The control system and the control method are applicable to development tests of turbochargers, and the boost pressure of a motor can be controlled easily, accurately and stably; and the design is ingenious, and the manufacture cost is low.

Owner:SAIC MOTOR

Calibrating device for fire extinguishing agent concentration measuring system

InactiveCN105424876AEnsure final calibration accuracyEnsure consistencyMaterial analysisEngineeringControl valves

Owner:CHINA HELICOPTER RES & DEV INST

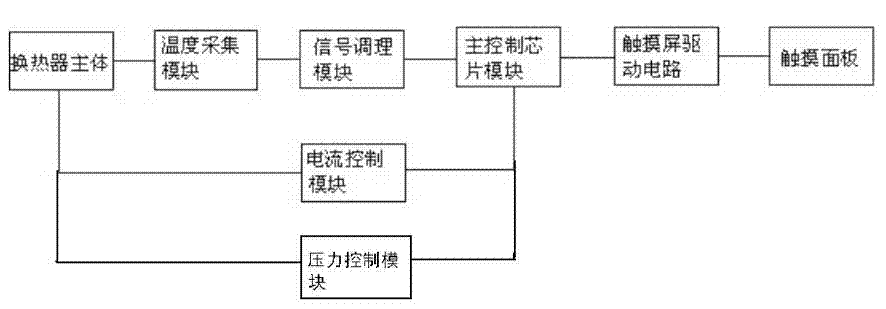

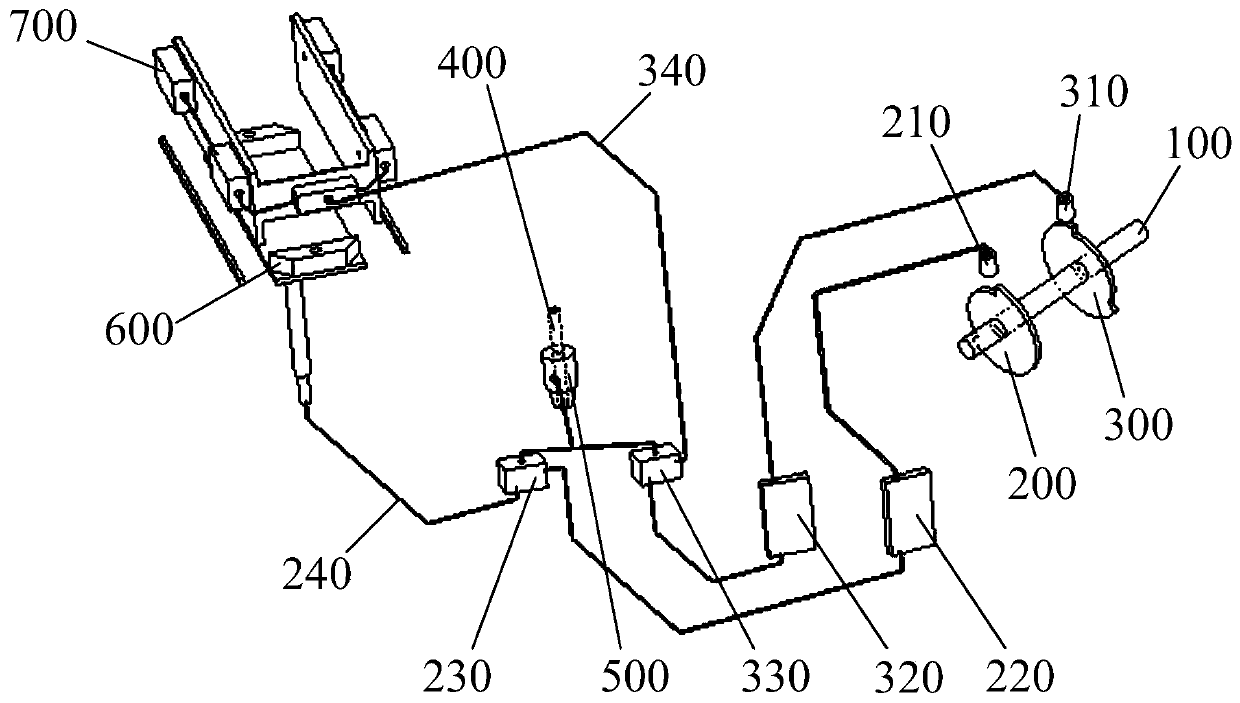

Heat exchanger

InactiveCN103808199AControl flow rateControl flowHeat exchange apparatusPower flowPlate heat exchanger

Owner:WUXI ACC HEAT EXCHANGER

Negative pressure control device of proximity type CV carton transparent paper packaging machine and packaging machine

PendingCN111003273APrevent immersionGuaranteed uptimeWrapping material feeding apparatusPackaging machinesCartonControl valves

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Systems and methods for air mattress pressure control

The disclosed technology includes a pressure-controlled air mattress for enabling a user to set a desired firmness or pressure level of the air mattress. The pressure-controlled air mattress may automatically maintain the desired pressure by replacing leaked air with air from a pressurized air reservoir.

Owner:POLYGROUP MACAU BVI

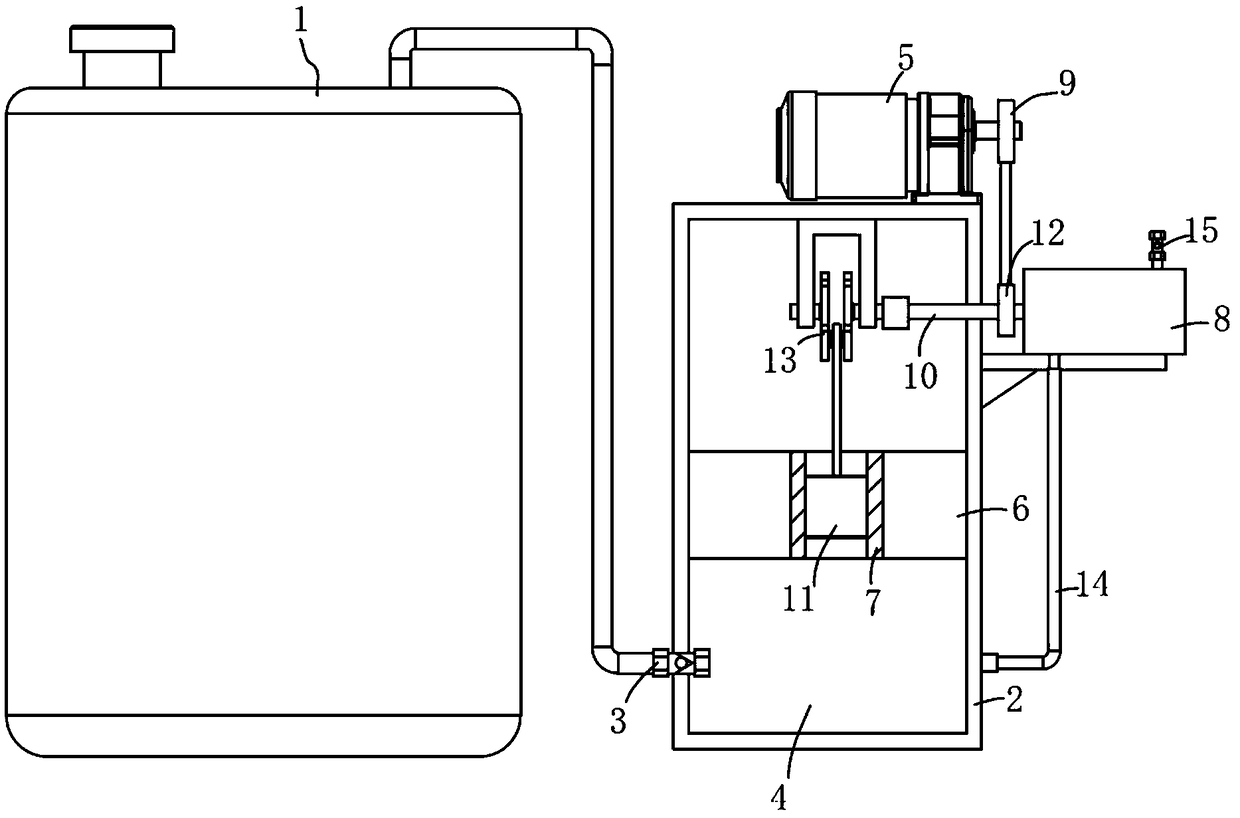

Pure pump type pressure water supply device

InactiveCN111572708AOptimize layoutReduce in quantitySelf-bailing equipments/scuppersVessel partsFrequency changerEngineering

Owner:708TH RES INST OF CSSC

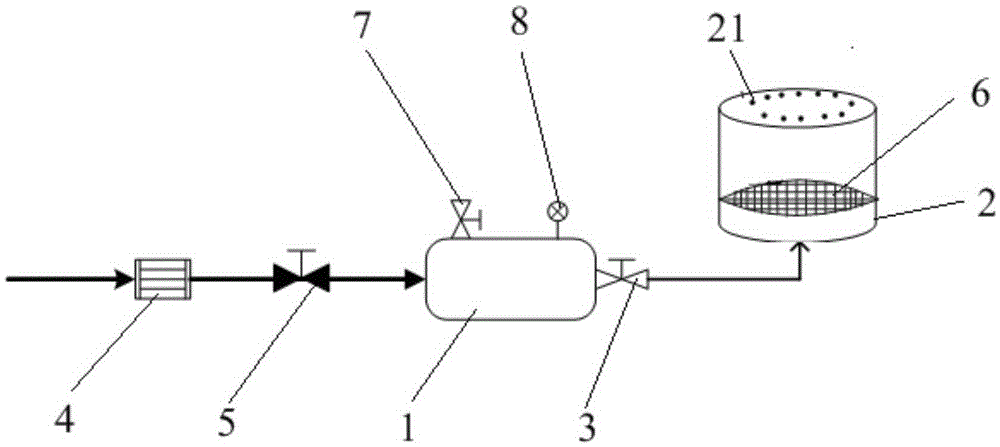

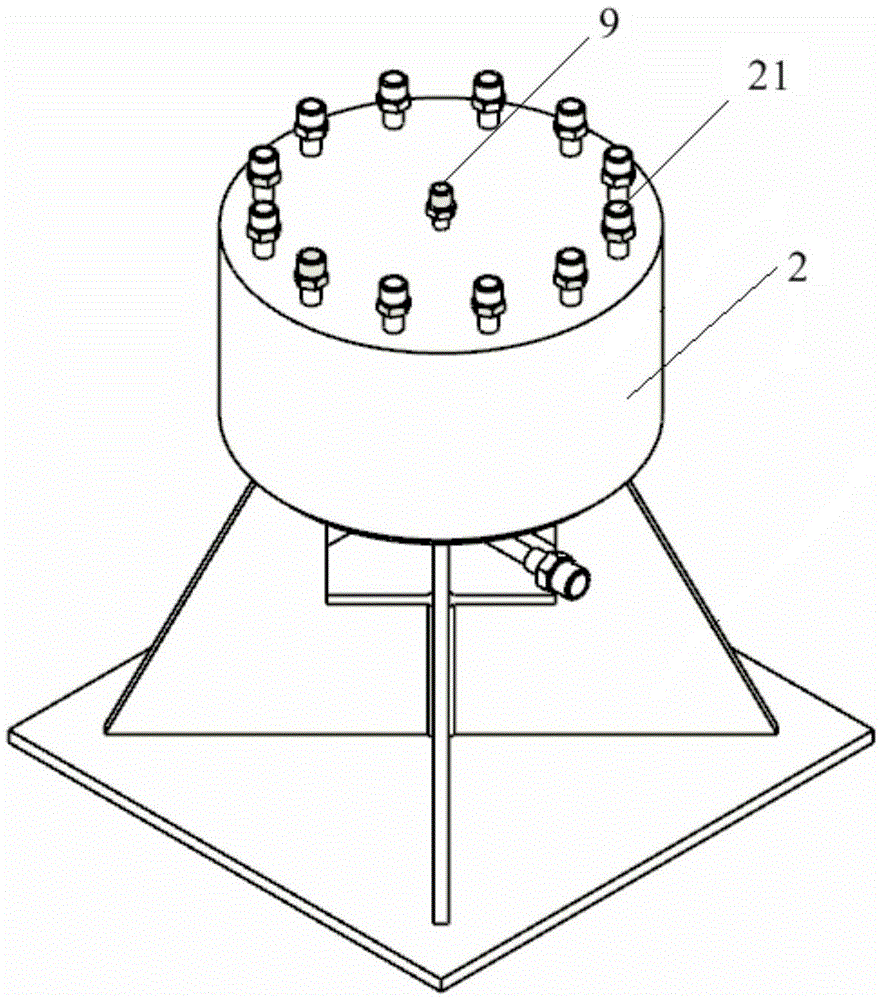

High-precision ink pressure control device for three-dimensional additive printer

ActiveCN109177173AStable ink pressureGuaranteed printing effectAdditive manufacturing apparatus3D object support structuresEngineeringPressure controlled ventilation

Owner:HEFEI AIRWREN AUTOMATIC EQUIP CO LTD

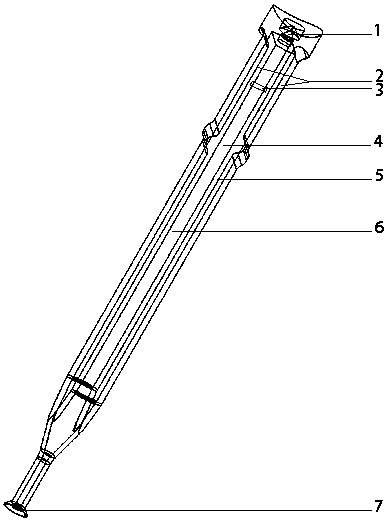

Telescopic spraying device for electroplating inner wall of conveying cylinder

ActiveCN112626578ARealize the scaling functionImprove cleaning efficiencyEngineeringStructural engineering

Owner:常德嘉腾电镀有限公司

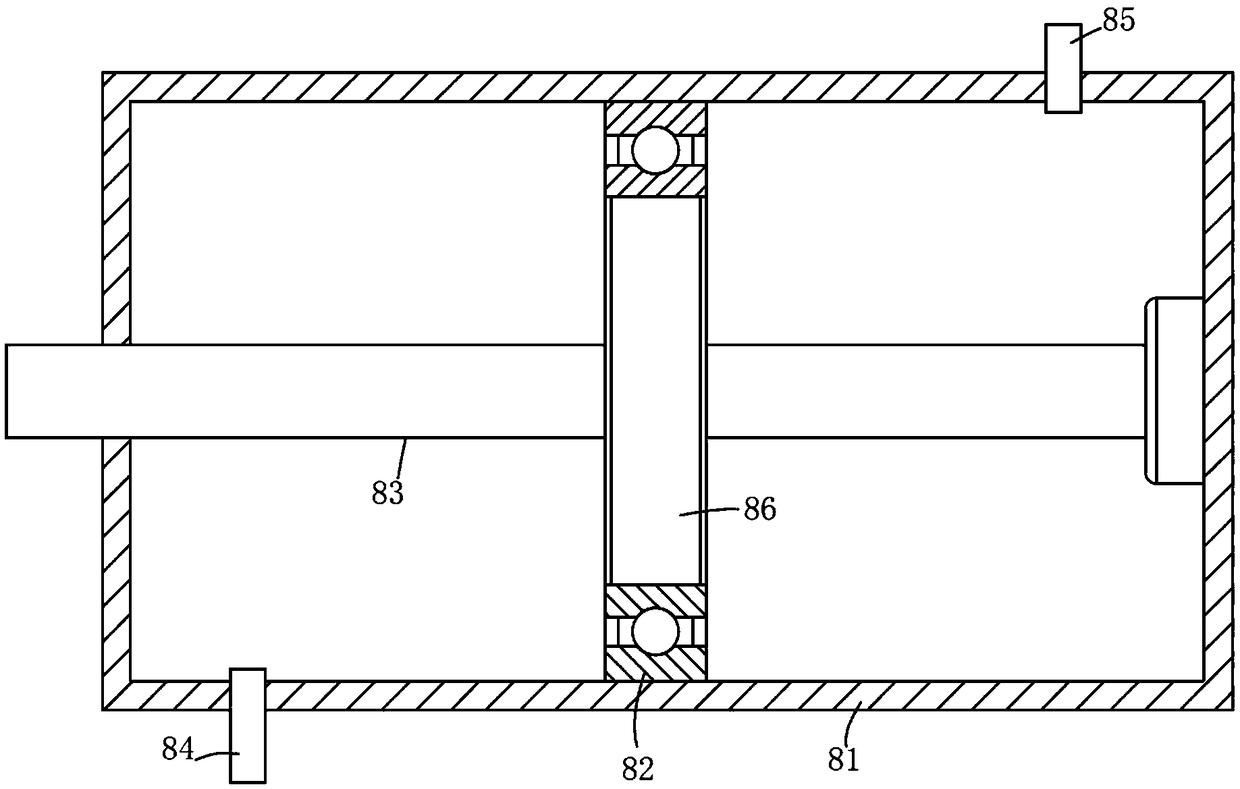

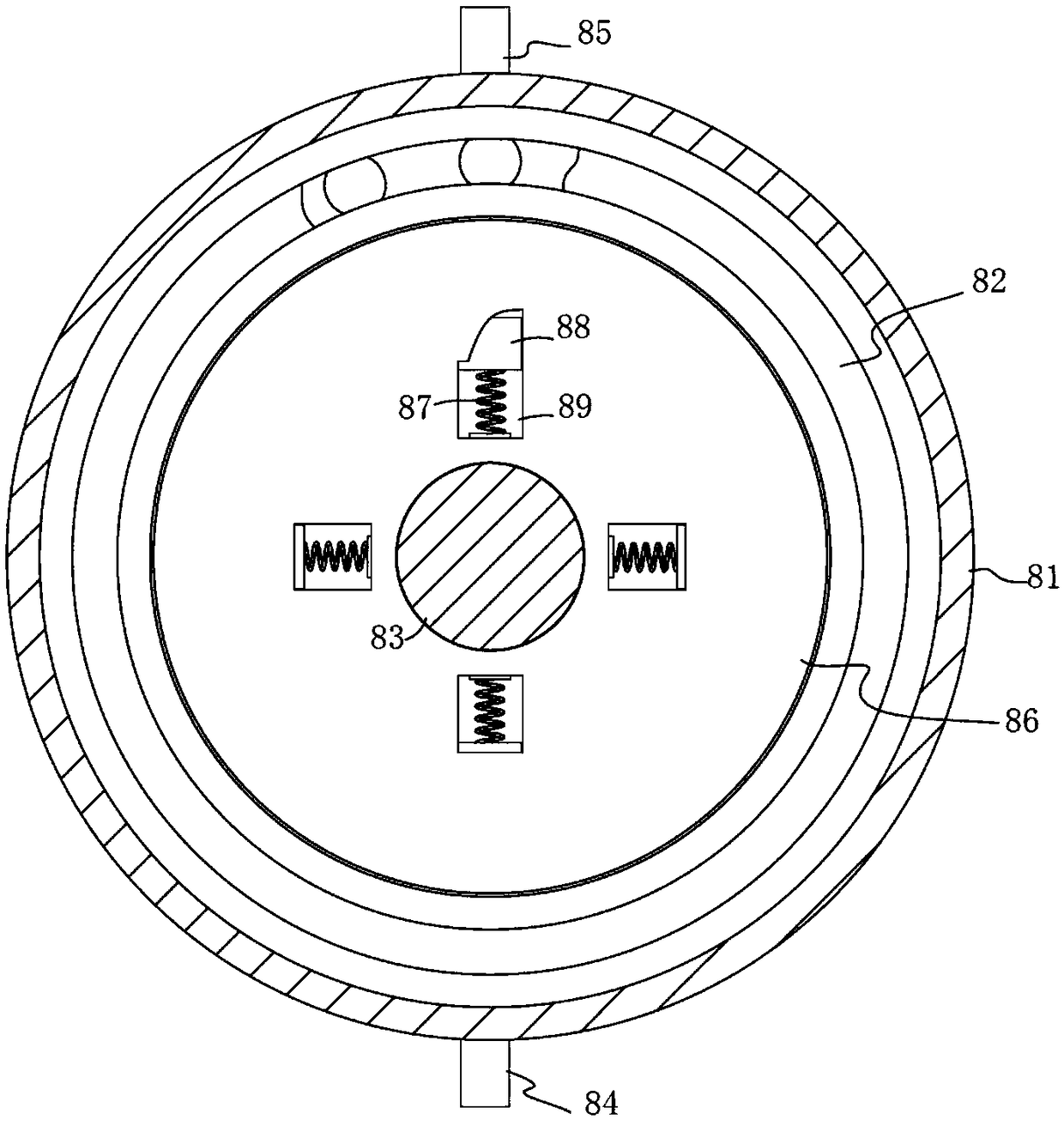

Electric control plug valve

ActiveCN107255173BSmall opening and closing torqueImprove sealingPlug valvesElectrical controlElectric control

The invention relates to an electric control cock valve comprising a valve body, a cock body and a valve rod. The electric control cock valve is mainly characterized in that a valve seat is mounted in an annular cavity in the outer side of an inlet-outlet channel of the valve body in a motive seal mode; a pressure control cavity is formed between the back face of the valve seat and the bottom face of the annular cavity and connected with a pressure control mechanism through a pressure channel; the pressure control mechanism is composed of a piston control mechanism and an electrical control circuit; under control of the pressure control mechanism, the negative pressure is generated in the pressure control cavity when the valve is opened or closed, and the valve seat is made to contract into the pressure control cavity; and after the valve is opened or closed in place, the pressure is injected into the pressure control cavity, and the valve seat is pushed out of the pressure control cavity to be in compressed seal fit with the cock body. The electric control cock valve has the characteristics of small open-close torque, reliable sealing performance, long service life of a product, high using pressure and the like, and is applied to the high-pressure medium working condition.

Owner:YONGJIA XINCHENG TECH SERVICE CO LTD

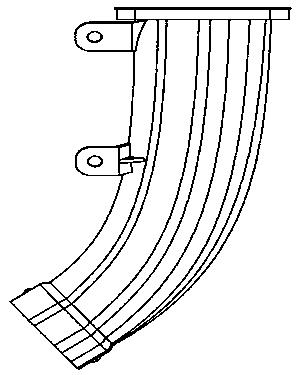

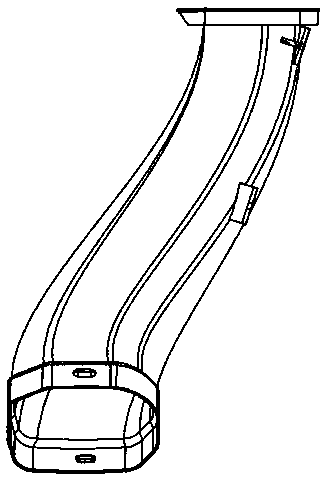

Manufacturing method of blow molding and foaming air channel

Owner:JIANGSU XINGCHENXING AUTO ACCESSORIES

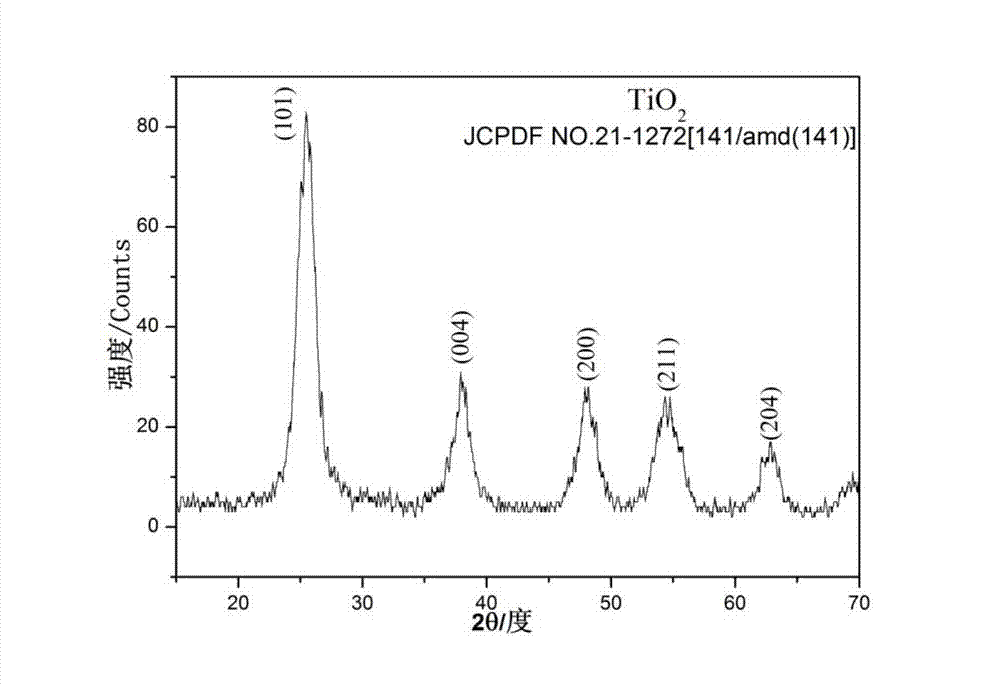

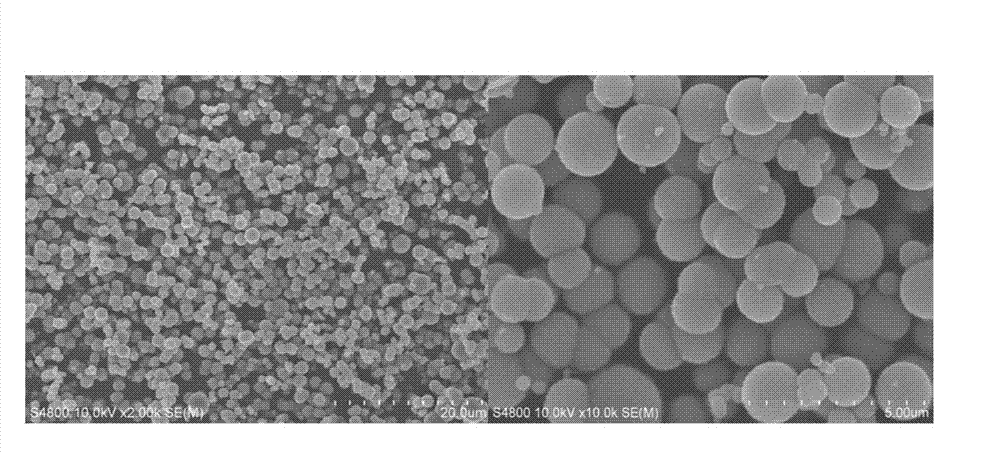

Method for preparing blue-shifting TiO2 microspheres

InactiveCN102923769AGood repeatabilityHigh temperature and high repeatabilityTitanium dioxideMicrosphereTemperature control mode

Owner:SHAANXI UNIV OF SCI & TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap