Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Ingenious design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

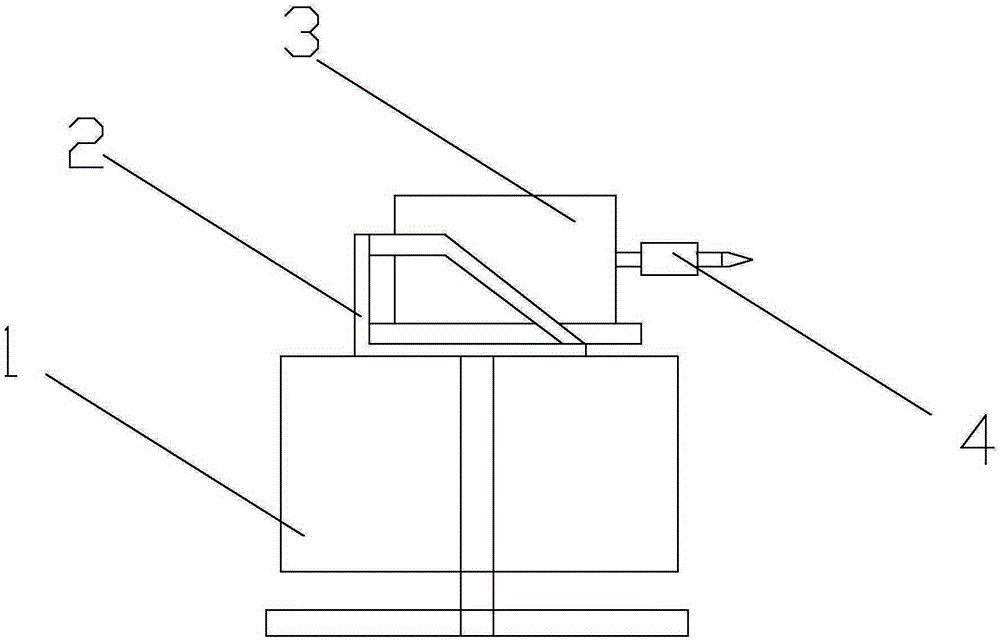

Blowing pollinator and method for using same to carry out blowing pollination

The invention relates to the field of cross breeding, in particular to a blowing pollinator and a method for using the same to carry out blowing pollination. The blowing pollinator comprises a fan and an air guide; the air outlet of the fan is connected with the air guide, and the air outlet end of the air guide is connected with two air nozzles; each air nozzle is an adjustable air nozzle, and can adjust the angle between the jetted airflow and the horizontal plane; each air nozzle is perpendicular to the air outlet end of the air guide, i.e., the flowing direction is changed by 90 degrees after the airflow enters the air nozzle via the air guide; the two air nozzles respectively face up at the left and the right of the air outlet end of the air guide; and the fan is connected with a storage battery for supplying power and a flow velocity regulator for regulating the velocity of the airflow. The blowing pollinator and the blowing pollination method provided by the invention can utilize the airflow to directly blow the mature pollen of male parents into the air over a male parent area, the pollen then spontaneously falls to finish the pollination process, and thereby the setting rate of the cross breeding can be remarkably increased.

Owner:SICHUAN CHUANLONG TRACTORS MFG CO LTD

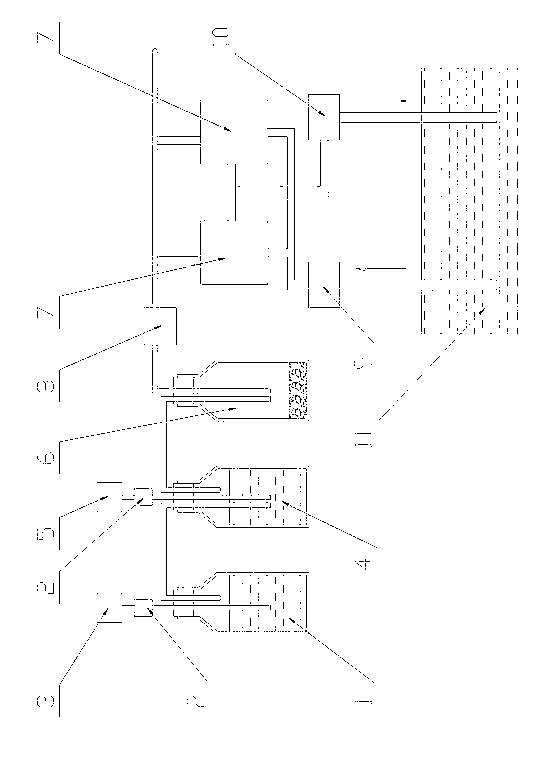

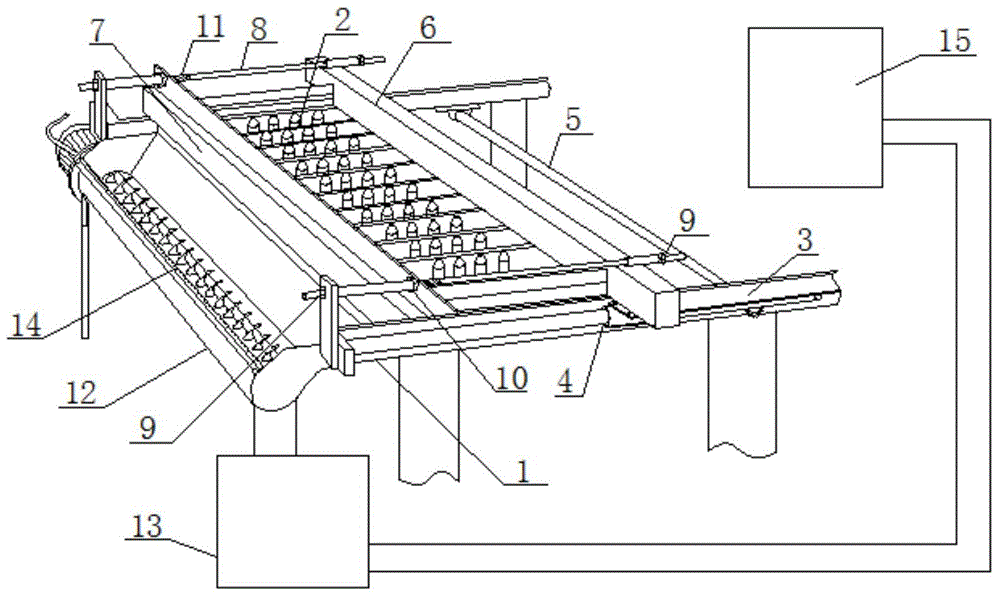

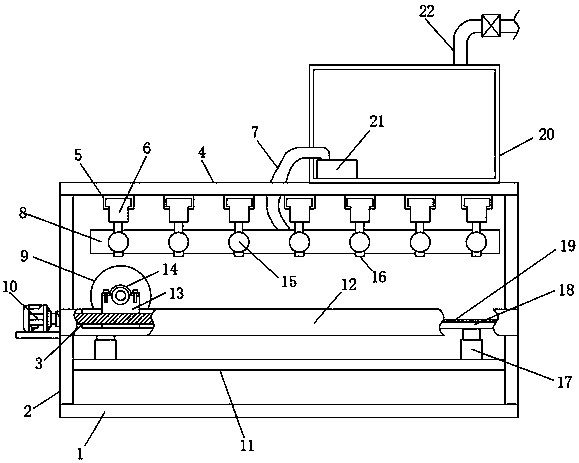

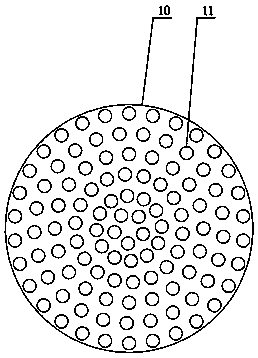

Online chip cleaning and drying equipment

ActiveCN102820242ASimple structureIngenious designDrying using combination processesSemiconductor/solid-state device manufacturingEngineeringVacuum chamber

The invention discloses online chip cleaning and drying equipment which comprises an automatic feeding mechanism, a spray type cleaning device, vacuum drying equipment and a positioning table. The vacuum drying equipment comprises a frame; a pair of drying conveying belts which are connected with a cleaning machine, support the two sides of a chip and horizontally move are arranged in the middle of the frame; a push plate which controls and supports the chip to move up and down through mechanical power is arranged on the frame below the part between the drying conveying belts; a first vacuum chamber provided with a vacuum sucker and an infrared heating tube is arranged right over the push plate; a second vacuum chamber which is movably connected with the first vacuum chamber through a connecting rod mechanism and provided with a sealing structure matched with the lower end of the first vacuum chamber is arranged on one side of the first vacuum chamber; and a vacuum adsorption hole corresponding to the chip is formed on one side of the second vacuum chamber corresponding to the first vacuum chamber and provided with the sealing structure. The equipment is simple in structure and skillful in design, automatically picks up chips, performs spray type cleaning and vacuum drying on the chip, dries the chip through thermal power in the vacuum environment, and prevents the chips from being damaged.

Owner:TONGLING TAIYANGDAO AGRI TECH CO LTD

Enhanced information system of AR glasses

Owner:南京水晶视界文化科技有限公司

Full-automatic pipe cutting machine

ActiveCN111036982AIngenious designShorten the timeMetal sawing devicesFully automatedIndustrial engineering

Owner:KUNSHAN JUNQIAN PRECISION MACHINERY CO LTD

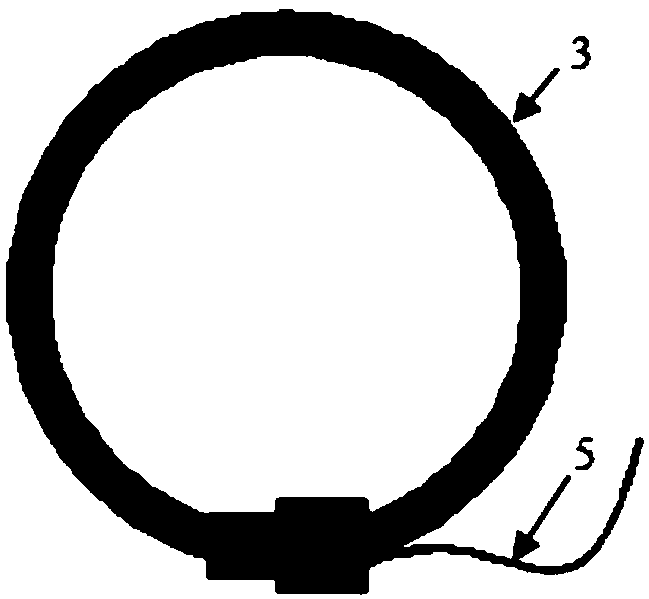

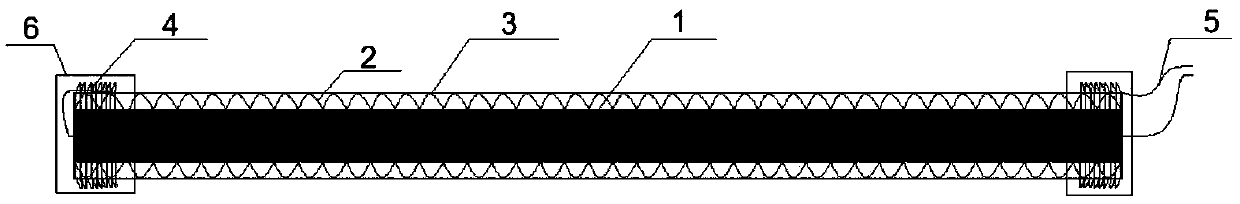

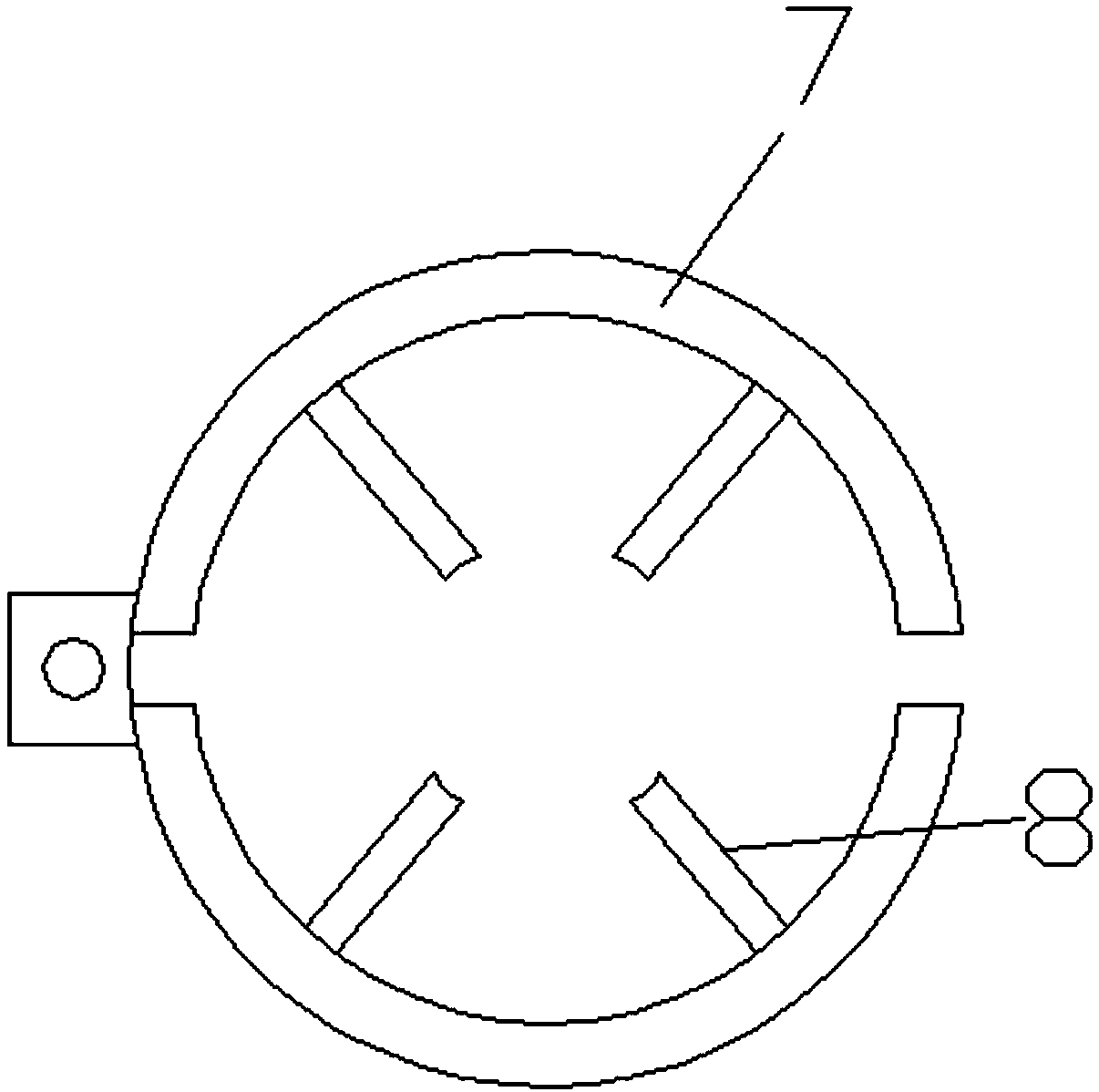

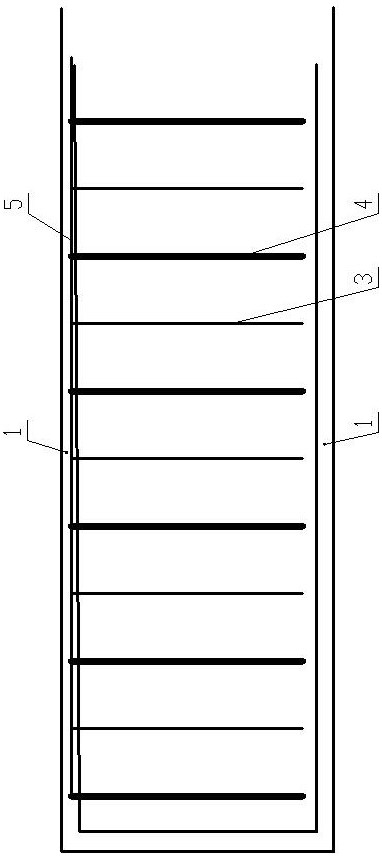

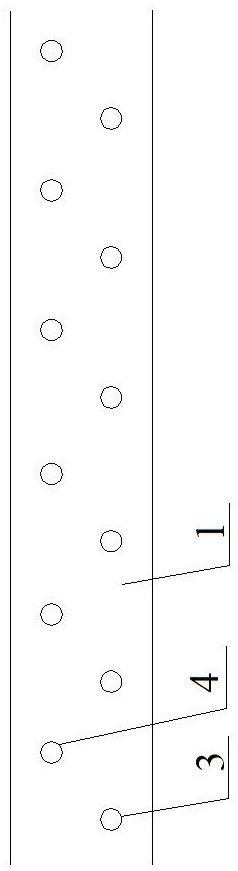

High-precision Rogowski coil

ActiveCN109613319AIngenious designSimple structureVoltage/current isolationCoilsRogowski coilEngineering

Owner:JIANGYIN SPARK ELECTRONICS TECH

Hidden-type ceiling projection screen box

Owner:NANJING LISHUI HIGH-TECH VENTURE CAPITAL MANAGEMENT CO LTD

Shoe washing system capable of washing more cleanly

Owner:QUANZHOU ZHENJIANG SPORTS GOODS CO LTD

Atomization device of electronic cigarette and electronic cigarette

Owner:CHINA TOBACCO HUNAN INDAL CORP

Drilling machine

InactiveCN105397137AExtended service lifeIngenious designBoring/drilling componentsBoring/drilling machinesCouplingDrill bit

Owner:JIASHAN BORAN BEARING CO LTD

Dual-purpose fuel injection system and fuel injection control method

InactiveCN106050495AIngenious designPracticalEngine controllersFuel injection apparatusAlcoholDual purpose

Owner:十堰科纳汽车电子股份有限公司

Novel paper roll holder

Owner:徐州嘉隆玻璃制品有限公司

Ocean acidification research experiment device

Owner:DALIAN OCEAN UNIV

Water distribution pipe in chilled water storage system

InactiveCN104913422AIngenious designAir conditioning systemsDucting arrangementsChilled waterCold storage

Owner:许文辉

Storage shoe cabinet with variable inner space

InactiveCN108813994AIngenious designSimple structureApparel holdersFittingComplex problemsEngineering

Owner:皮子远

Automatic excess material recycling device for gypsum block production equipment

InactiveCN104647579AIncrease productivityIngenious designAuxillary shaping apparatusCeramic shaping plantsGypsum blockMaterial recycling

Owner:济南留安石膏机械设备制造有限公司

Agricultural ditching membrane-coating soil-covering device

InactiveCN107360910AIngenious designVersatileFurrow making/coveringPlant protective coveringsAgricultural engineeringAgricultural machinery

Owner:黑龙江省农业机械运用研究所

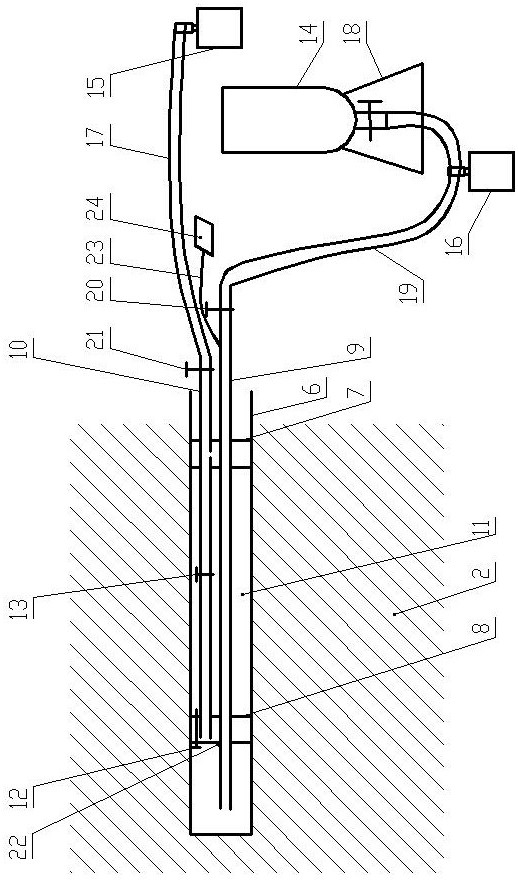

Freezing fracturing type permeability improving and drainage promoting method for coal body

InactiveCN112412419AImprove breathabilityImprove the extraction effectLiquid/gas jet drillingInsulationCoalDrill hole

The invention provides a freezing fracturing type permeability improving and drainage promoting method for a coal body. The method comprises the following steps that bedding drilling is conducted on the coal body from a working face crossheading, and any two adjacent drill holes are named as a liquid injection hole and a drainage hole correspondingly; drainage pipes are mounted in the drainage holes and the liquid injection holes for hole sealing, and after sealing, an underground drainage system is connected for gas drainage; high-pressure water is injected into the liquid injection holes; special hole sealers are fed into the drainage pipes in the liquid injection holes and perform hole sealing; liquid nitrogen is injected into the liquid injection holes through the special hole sealersto freeze the coal body around the liquid injection holes; under the effect of the ground temperature, the liquid nitrogen is slowly sublimated into nitrogen, and the nitrogen effectively replaces anddisplaces gas in the coal body; and the drainage pipes in the liquid injection holes are connected with the drainage system for gas drainage work. The principle is scientific, design is ingenious, hole sealing is tight, the method can be widely applied to work such as cross-cut coal uncovering, fault crossing and anti-reflection and drainage-promoting of a mining working face, the anti-reflectionand drainage-promoting effects are good, and the application prospects are wide.

Owner:HENAN POLYTECHNIC UNIV

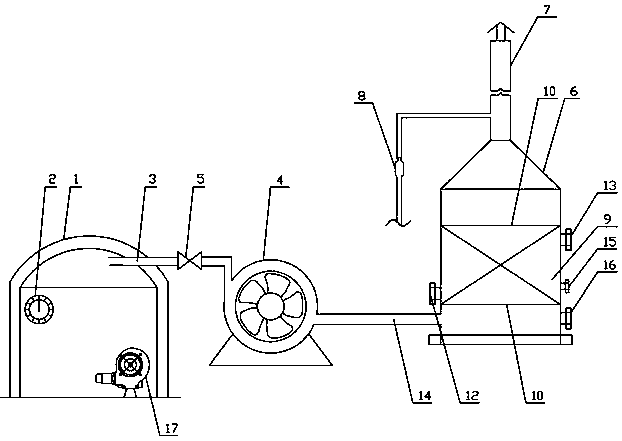

Control system and control method for turbocharger

InactiveCN103089343APrecise and stable controlIngenious designInternal combustion piston enginesEngine componentsControl systemTurbocharger

The invention relates to a control system and a control method for a turbocharger. A pressure control mechanism is used for controlling an exhaust gas valve of the turbocharger. The pressure control mechanism comprises a compression medium source, a shut-off valve, a pilot decompression valve, a first pressure regulating valve and a second pressure regulating valve which are arranged in a control pipeline. The shut-off valve is arranged at an outlet of the compression medium source for opening and shutting off the output of the compression medium source; the pilot decompression valve and the first pressure regulating valve are arranged on the lower course of the shut-off valve successively, the pilot decompression valve is provided with a first pressure gage and reduces pressure when pressure of compression media is too high, and the first pressure regulating valve is provided with a second pressure gage; and the second pressure gage is communicated with a lower course pipeline of the first pressure gage and the external environment, and the lower course of a control pipeline is connected with a mechanical actuator of the exhaust gas valve. The control system and the control method are applicable to development tests of turbochargers, and the boost pressure of a motor can be controlled easily, accurately and stably; and the design is ingenious, and the manufacture cost is low.

Owner:SAIC MOTOR

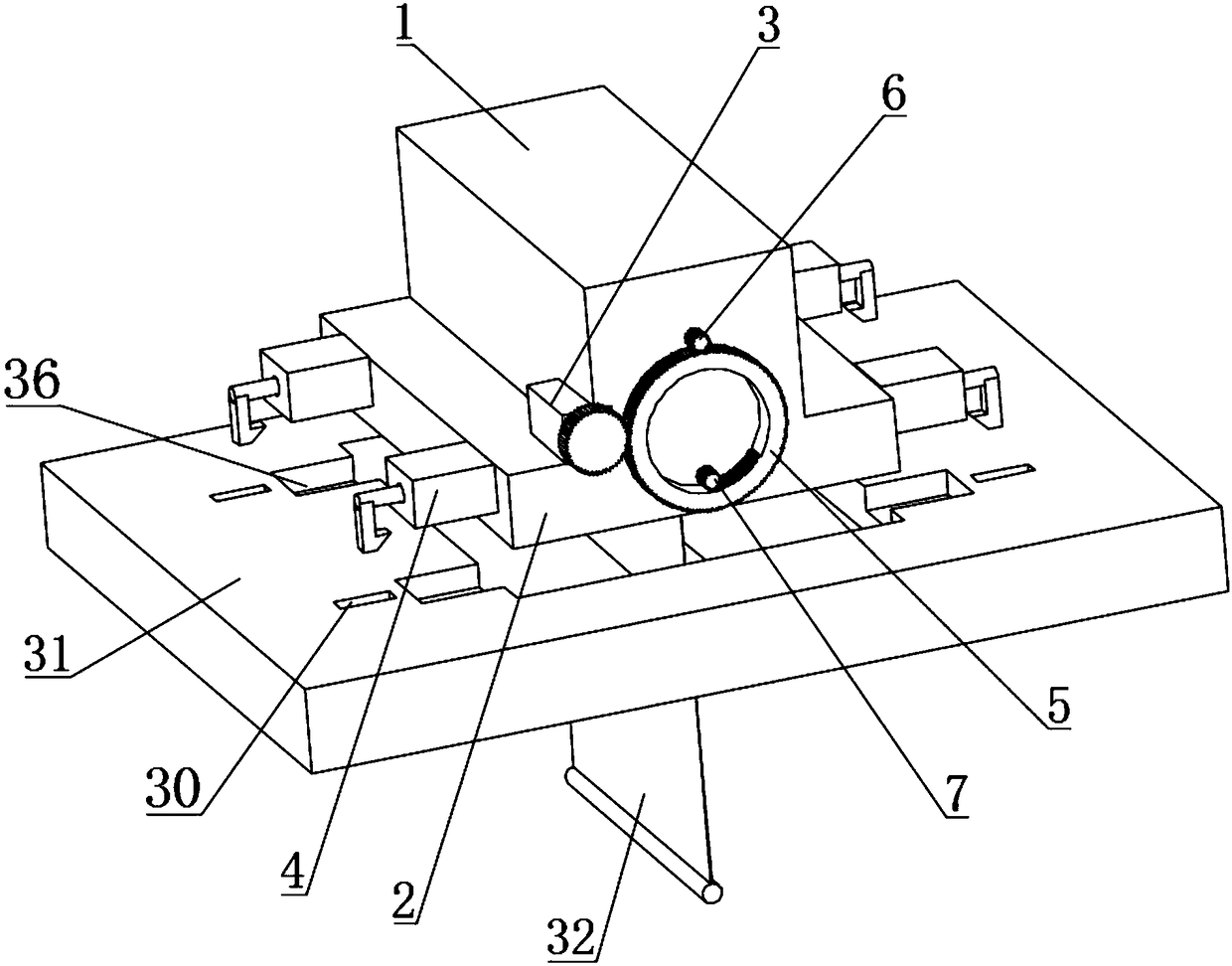

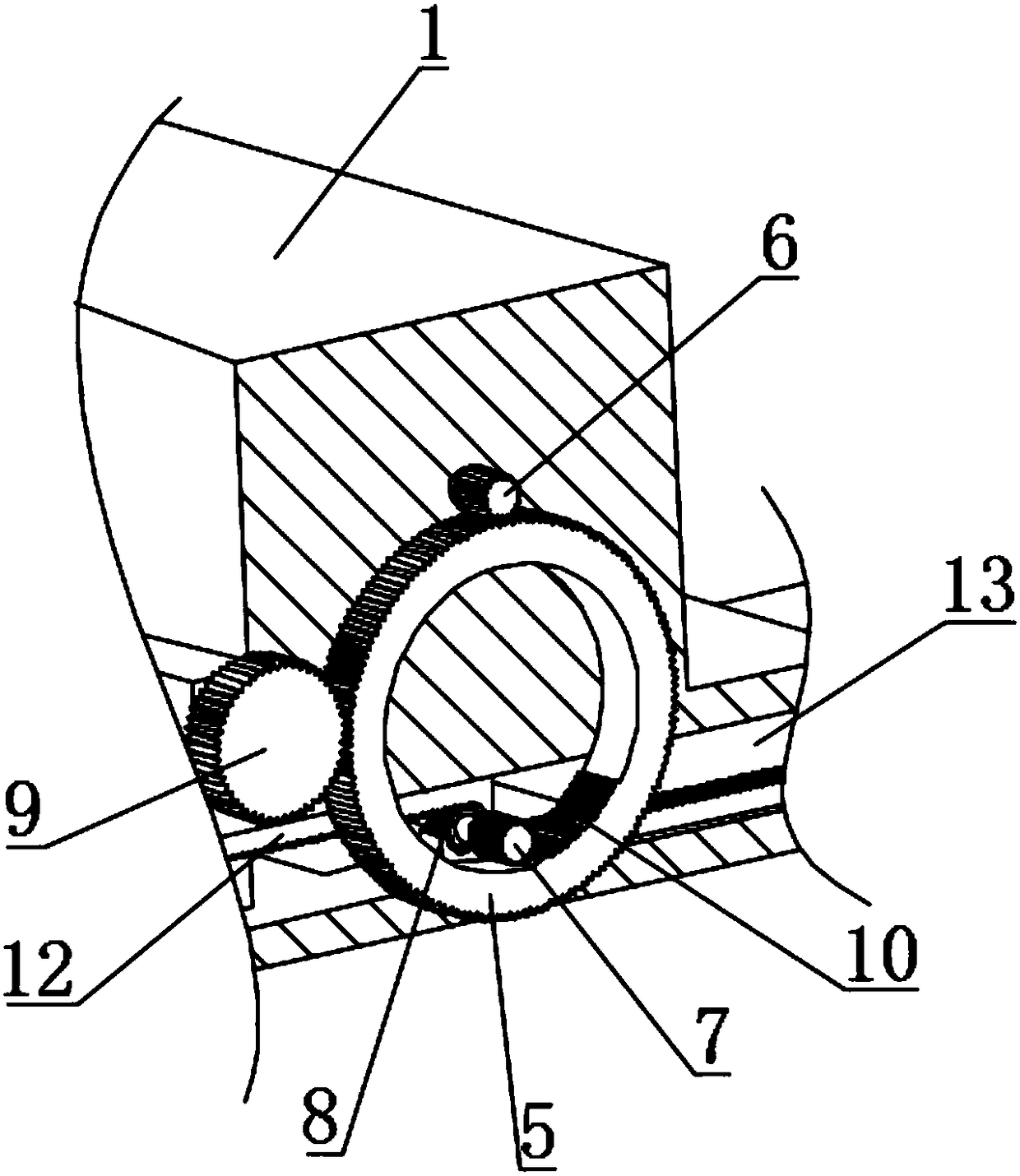

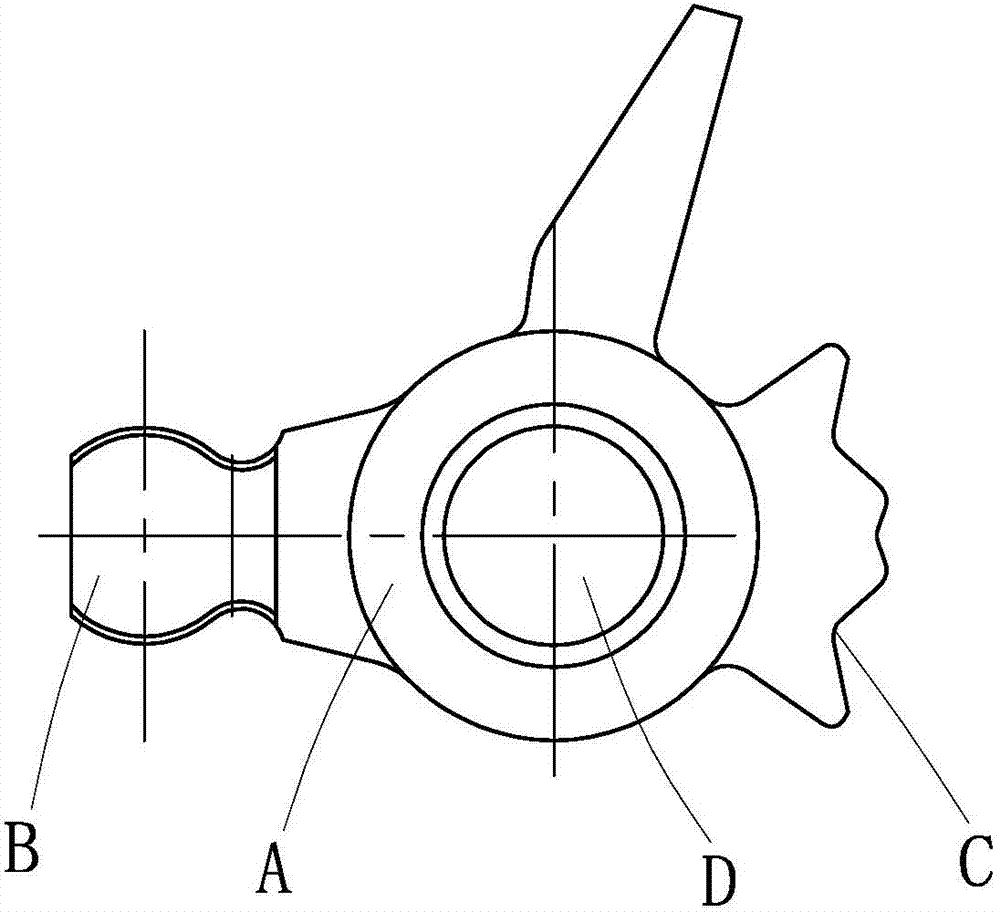

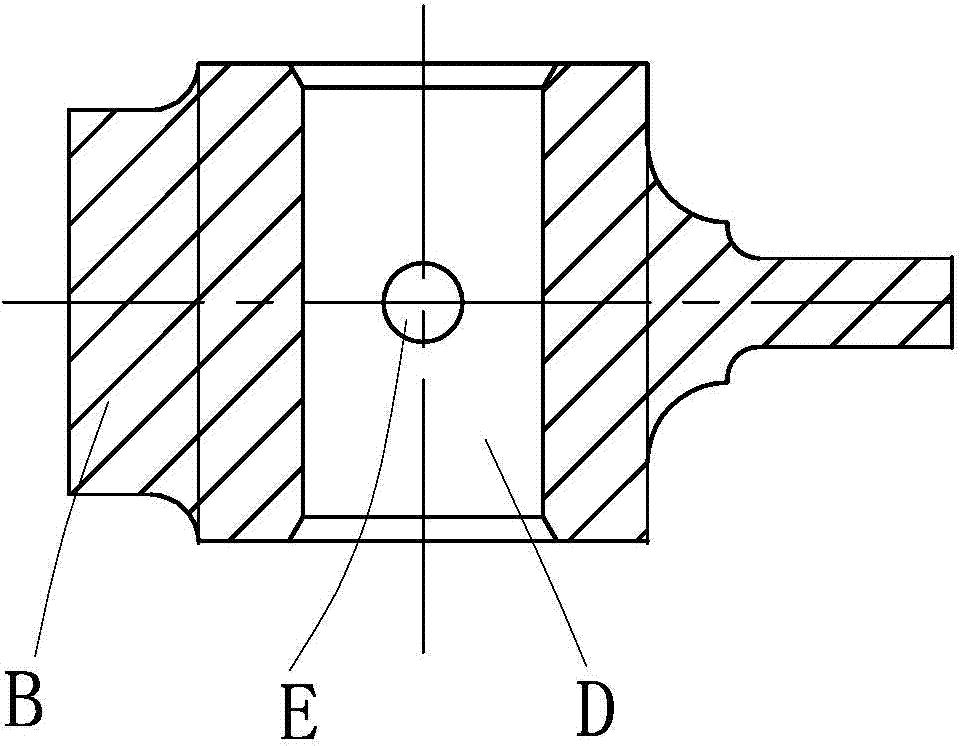

Machine for removing burrs in through hole of gear-shifting oscillating bar of transmission

The invention discloses a machine for removing burrs in a through hole of a gear-shifting oscillating bar of a transmission. The machine comprises a base, a supporting column, a driving motor, a feeding and retracting driving cylinder, a rotating hard alloy file and a sliding supporting plate; an automobile oscillating bar sleeve column and an automobile oscillating bar anti-rotation block are fixedly arranged above the sliding supporting plate; a hand-operated oscillating bar is hinged to the middle position of the front sidewall of the sliding supporting plate; two bearings arranged left and right at an interval are arranged on the front and rear sides of the sliding supporting plate to guide the left-and-right movement of the sliding supporting plate; limiting plates are arranged on the left and right sides of the neck of the sliding supporting plate to limit the left-and-right movement of the sliding supporting plate. The machine for removing burrs in the through hole of the gear-shifting oscillating bar of the transmission is novel in design, ingenious in design, convenient to operate, and high in degree of automation, and worthy of wide popularization; besides, the production efficiency and the product consistency are remarkably improved.

Owner:重庆市广角机械制造有限公司

Waterproof textile

InactiveCN106042462AGood air permeabilityIngenious designSynthetic resin layered productsEngineeringFiber layer

Owner:XINCHANG COUNTY XINLIANXING TEXTILE CO LTD

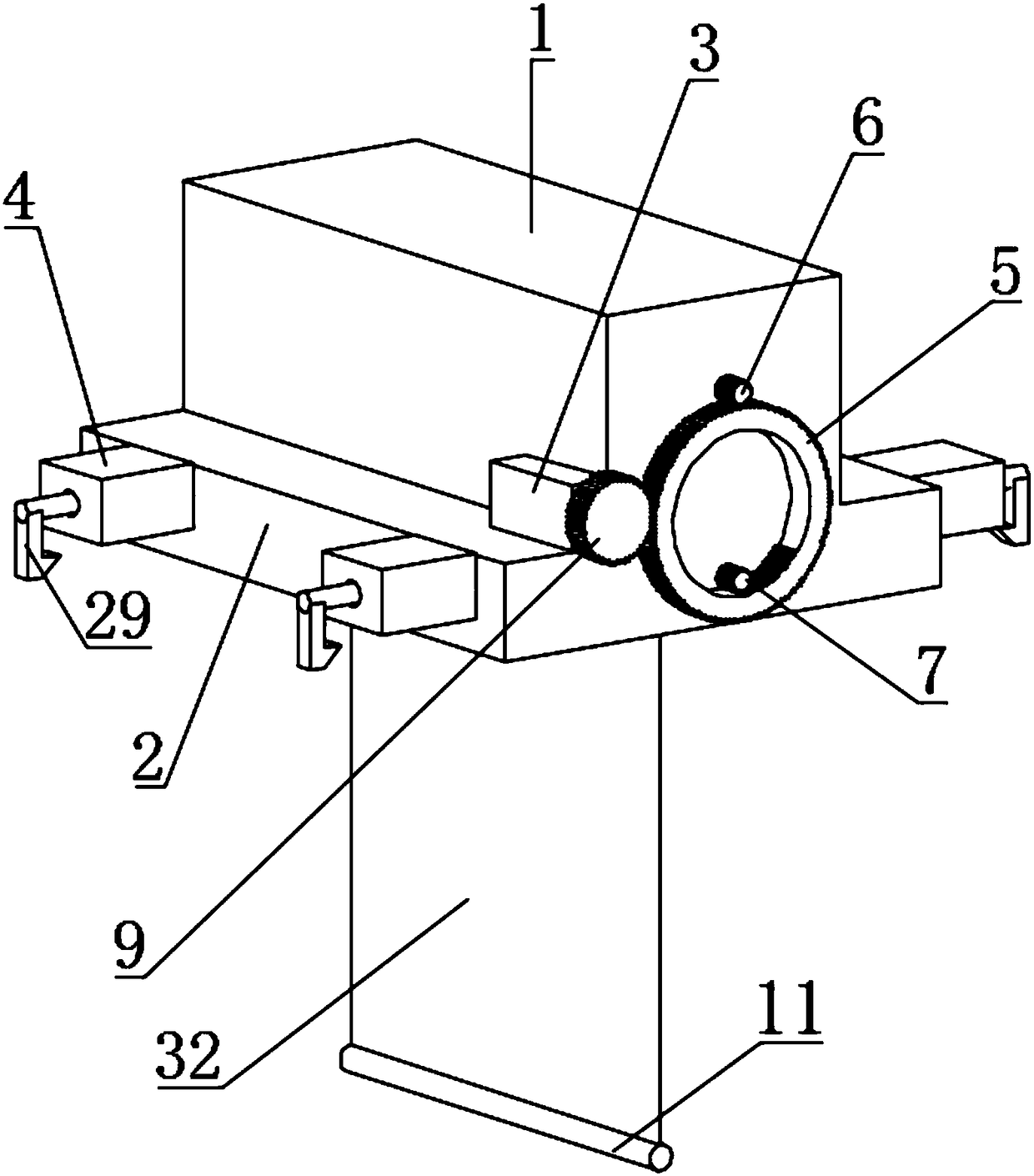

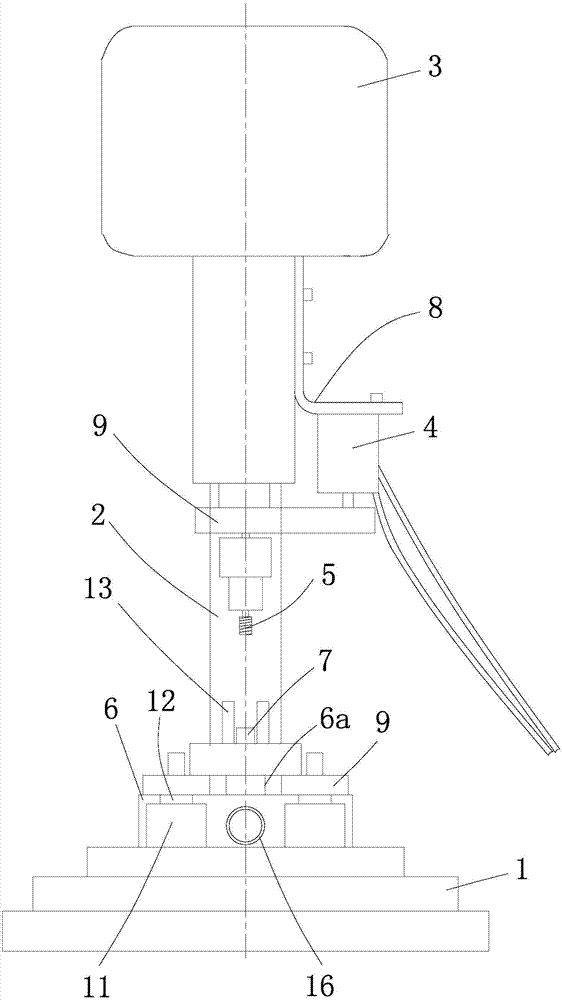

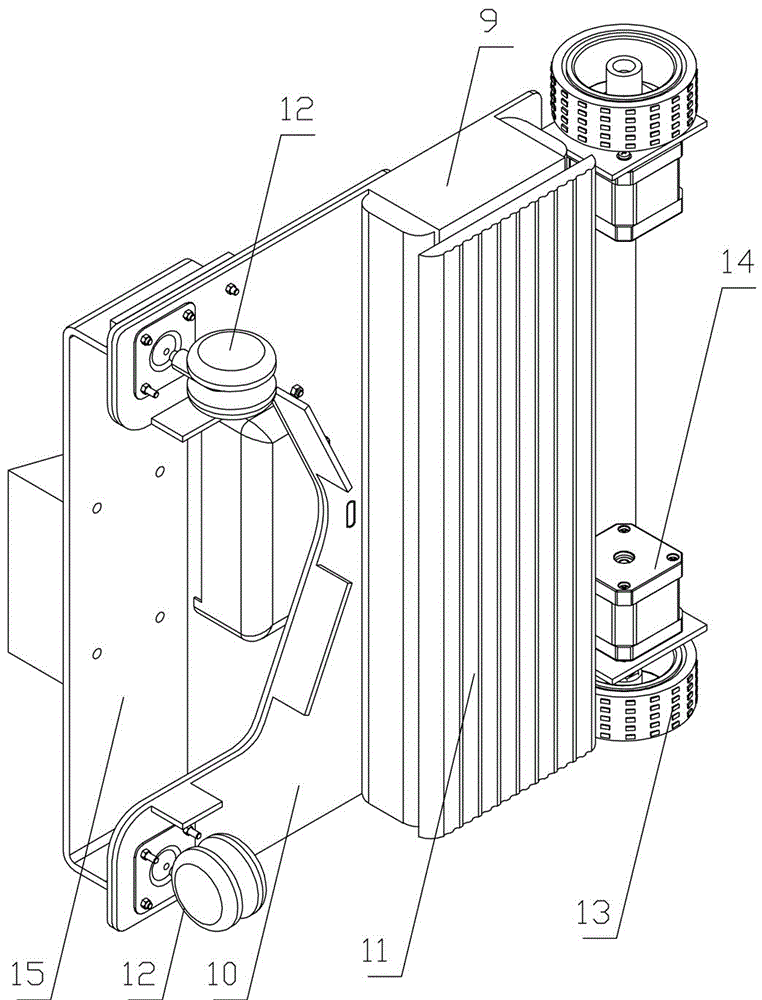

Horizontal planing machine for machining internal hole spline grooves of long shaft parts

The invention discloses a horizontal planing machine for machining internal hole spline grooves of long shaft parts. The horizontal planing machine comprises a horizontal planing machine body (11) and is characterized in that the horizontal planing machine body (11) is provided with a tool, a first clamp and a second clamp. According to the horizontal planing machine, the clamps and the tool are improved on the basis of a common horizontal planing machine body, and therefore the internal hole spline grooves of the long shaft parts can be machined efficiently, easily and conveniently, the functions of the horizontal planing machine can be expanded, and the machining cost can be lowered.

Owner:XUZHOU UNE INNOVATIVE TECH CO LTD

Connecting piece trolley for automobile side wall conveying system

InactiveCN109383999AAccuracy meetsHigh degree of automationMechanical conveyorsAssistive device/technologyEngineering

The invention relates to the technical field of auxiliary equipment for automobile production, in particular to a connecting piece trolley for an automobile side wall conveying system. The connectingpiece trolley is provided with a walking base frame mounted on a conveying track, a power device for driving the connecting piece trolley to move along a connecting piece track is mounted on the walking base frame, a plurality of pairs of connecting piece devices are mounted on each of the two sides of the walking base frame in the direction of the connecting piece trolley, gas grabbing devices are also mounted at the bottom of the walking base frame, and positioning block devices matched with the gas grabbing devices are arranged on the connecting piece track at least at starting and ending points where the connecting piece trolley walks. The connecting piece trolley provided by the invention has the benefits that the starting point of displacement of the connecting piece trolley is accurately positioned by adopting pneumatic grabs and the positioning block devices, so that the accuracy of a joint between the connecting piece trolley and an upper piece trolley and the accuracy of a joint between the connecting piece trolley and a lower piece trolley are better met; and the degree of automation is high, no manual intervention is required for transportation of connecting pieces on the side walls, the performance is stable, and the labor cost is greatly reduced, and therefore, an application prospect is good.

Owner:HUANGSHI DINGXIN ELECTROMECHANICAL CO LTD

Split type cleaning trolley

InactiveCN104586323ASimple structureIngenious designMachine detailsFloor sweeping machinesEngineeringWireless

A split type cleaning trolley is composed of a main body and an auxiliary body. The main body is composed of a trolley body, a garbage can, a guiding groove and a bucket. A storage battery, a first single chip microcomputer, a second single chip microcomputer and a wireless communication module are installed on the trolley body. A V-shaped guiding device is arranged at the front end of a chassis of the trolley body. The auxiliary body is located under the guiding groove. Two PS-2 mouse modules, two ultrasonic modules and a third single chip microcomputer are installed on the auxiliary body. A V-shaped guiding plate is arranged behind a chassis of the auxiliary body. The V-shaped guiding plate of the auxiliary body is matched with the V-shaped guiding device of the main body. The split type cleaning trolley is simple in structure and ingenious in design, separation and combination of the auxiliary body and the main body of the cleaning trolley can be achieved through control programs of the single chip microcomputers, meanwhile, garbage in the open indoor space and narrow corner slits can be cleaned away, the intelligence is high, the labor intensity of residents is lowered, a large amount of cleaning time is saved, and the high practical value is achieved.

Owner:HUBEI POLYTECHNIC UNIV

Automatic washing device for anilox roller of cigarette case printer

Owner:GUIZHOU XINIUWANG PRINTING

Pipeline surface treatment device of pressure controller

PendingCN110328596AEasy to useIngenious designGrinding bedsGrinding carriagesCopper tubingCopper wire

Owner:NAN TONG HUAGUAN ELECTRIC CO LTD

Cloth bag dust removal device with cleaning function

InactiveCN112206603ASimple structureIngenious designDispersed particle filtrationTransportation and packagingElectric machineryEngineering

Owner:湖南正志商贸有限公司

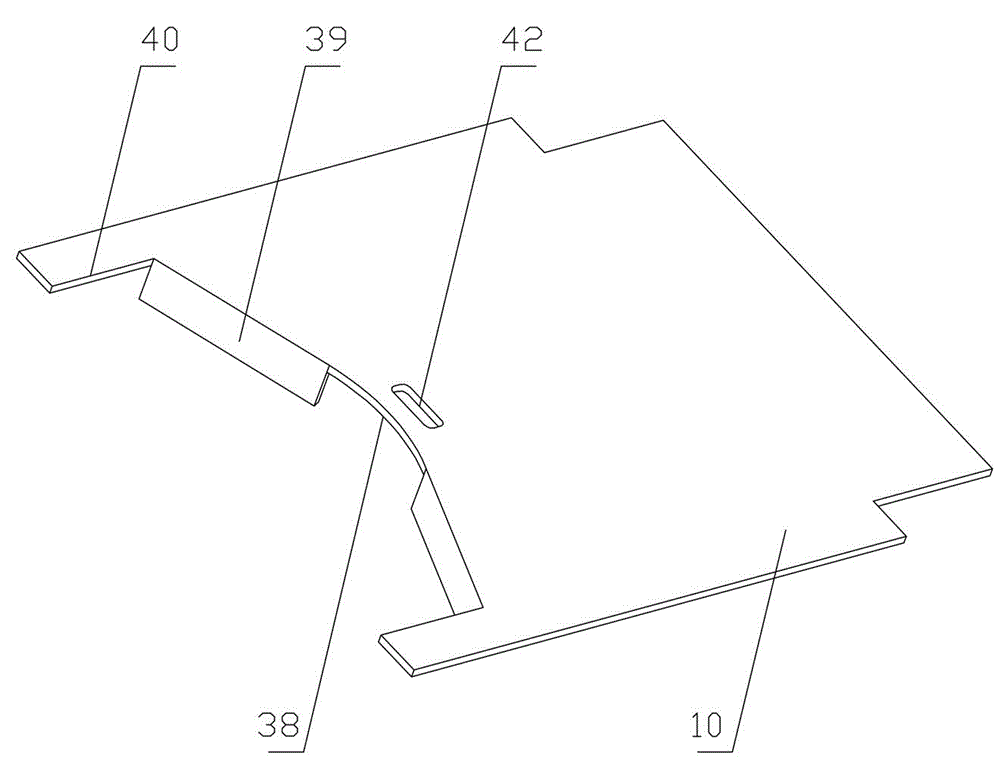

Main board material holding disc for circuit boards

The invention discloses a main board discharge tray for circuit boards, comprising: a main board discharge frame and a main board discharge part arranged in the main board discharge frame; the main board discharge frame is composed of a first fixed plate, a second fixed plate, Surrounded by the third fixed plate and the fourth fixed plate, the first fixed plate, the second fixed plate, the third fixed plate and the fourth fixed plate form a mainboard placement space, and the mainboard discharge part is arranged in the mainboard placement space. The main board discharge tray of the present invention can place materials on the main board discharge part by being provided with a main board discharge part, and by being provided with a first bump, a second bump, a third bump, and a fourth bump It forms a certain height with another mainboard discharge tray, so that there is a certain discharge space between the two mainboard discharge trays; at the same time, it is convenient for users to take materials by providing a through hole for taking materials. The main board discharging tray of the present invention has simple structure and ingenious design, can effectively increase the quantity of circuit board discharging, and save the space for circuit board discharging.

Owner:钟立朋

Large conveyor loading and unloading platform car

InactiveCN109534027AAvoid secondary loading and unloadingFlexible shippingTractor-trailer combinationsTractorsVehicle frameRemote control

The invention relates to the field of material loading and unloading equipment, in particular to a large conveyor loading and unloading platform car. The large conveyor loading and unloading platformcar comprises a saddle tractor, and a loading and unloading platform; the middle front section of the loading and unloading platform is fixed on the saddle tractor through a saddle; and the saddle tractor is totally mounted under the loading and unloading platform. The length of the saddle tractor is to guarantee that the saddle tractor is totally covered by the loading and unloading platform in atraction state. A car shell is provided with a frame, a power system, a hydraulic system, an electric remote control system and a steering system inside; the power system, the hydraulic system and the electric remote control system are all mounted on the frame; the steering system comprises wheels, a front axle and a rear axle; and the frame is stretched over the front axle and the rear axle. Thesaddle tractor is mounted at the bottom of the loading and unloading platform car, so that the requirements on the road space during steering are reduced, and the space is applied to the greatest extent. The saddle tractor can directly tow a goods car through a traction bolt at the back end, so that the transportation is flexible and various, the secondary loading and unloading of goods are prevented, the manpower is saved, and the working efficiency is improved.

Owner:SINOTRUK QINGDAO HEAVY IND

City domestic sewage low-energy-consumption treatment device

InactiveCN109231557AEasy maintenanceImprove practicalityTreatment involving filtrationMultistage water/sewage treatmentSewageEngineering

The invention discloses a city domestic sewage low-energy-consumption treatment device. The city domestic sewage low-energy-consumption treatment device comprises a machine body and a sewer sealing machine body installed on the end face of the right end of the machine body. The circumferential outer surface of the sewer sealing machine body is internally provided with a fan-shaped groove which isoutwards opened and centrosymmetric. The inner wall of the right end of the fan-shaped groove is internally provided with an annular groove. The inner wall of the bottom of the annular groove is internally provided with a first cavity. A fan-shaped sealing block is slidably and cooperatively connected into the annular groove. The fan-shaped sealing block is internally provided with a fan-shaped sliding chute of which an opening is backwards steered along a principal plane. A permanent magnet compensation sealing fan-shaped block is slidably and cooperatively connected into the fan-shaped sliding chute. The inner wall of one end of the fan-shaped sliding chute is internally provided with an electromagnetic block which is in power connection with the permanent magnet compensation sealing fan-shaped block. An internal gear cylinder is rotatably and cooperatively connected into the annular groove.

Owner:李冬兰

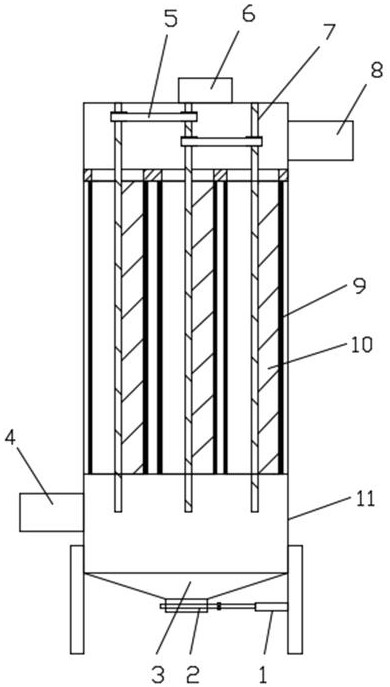

Biological organic fertilizer fermentation deodorization device

InactiveCN110386834ASimple structureIngenious designGas treatmentDispersed particle separationChemistryActivated carbon

The invention relates to a biological organic fertilizer fermentation deodorization device. The biological organic fertilizer fermentation deodorization device is provide with a fermentation library,wherein a vacuum negative pressure meter is arranged in the fermentation library, and an odor outlet is formed in the top 1 / 3-1 / 2 of the fermentation library, and the odor outlet is provided with an induced draft fan, a gas valve for adjusting the air flow conveniently is arranged between the odor outlet and the induced draft fan, a deodorization tower is arranged at an outlet of the induced draftfan, a chimney is arranged at the top of the deodorization tower, a sampler is arranged in the middle of the chimney, an adsorption section filled with activated carbon is arranged on the middle partof the deodorization tower, partition plates used for fixing the activated carbon are arranged at the bottom and the top of the adsorption section, through holes are formed in the partition plates, the diameter of the through holes is smaller than the diameter of the activated carbon, a discharge hole is formed in the lower part of the adsorption section, a material filling hole is formed in theupper part of the adsorption section, the discharging hole is arranged opposite to the material filling hole, and an air inlet pipe is arranged on the lower part of the discharging hole. The biological organic fertilizer fermentation deodorization device is simple in structure, ingenious in design and good in deodorization effect. The pollution of odor to the living environment is effectively avoided, and good application and promotion prospects are achieved.

Owner:HUBEI GUANJUN BIOTECH DEV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap