Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

18 results about "Vacuum chamber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A vacuum chamber is a rigid enclosure from which air and other gases are removed by a vacuum pump. This results in a low-pressure environment within the chamber, commonly referred to as a vacuum. A vacuum environment allows researchers to conduct physical experiments or to test mechanical devices which must operate in outer space (for example) or for processes such as vacuum drying or vacuum coating. Chambers are typically made of metals which may or may not shield applied external magnetic fields depending on wall thickness, frequency, resistivity, and permeability of the material used. Only some materials are suitable for vacuum use.

Extreme ultraviolet light source

InactiveUS20050230645A1Improve efficiencyImprove performanceNanoinformaticsSemiconductor/solid-state device manufacturingAtomic elementLight energy

The present invention provides a reliable, high-repetition rate, production line compatible high energy photon source. A very hot plasma containing an active material is produced in vacuum chamber. The active material is an atomic element having an emission line within a desired extreme ultraviolet (EUV) range. A pulse power source comprising a charging capacitor and a magnetic compression circuit comprising a pulse transformer, provides electrical pulses having sufficient energy and electrical potential sufficient to produce the EUV light at an intermediate focus at rates in excess of 5 Watts. In preferred embodiments designed by Applicants in-band, EUV light energy at the intermediate focus is 45 Watts extendable to 105.8 Watts.

Owner:CYMER INC

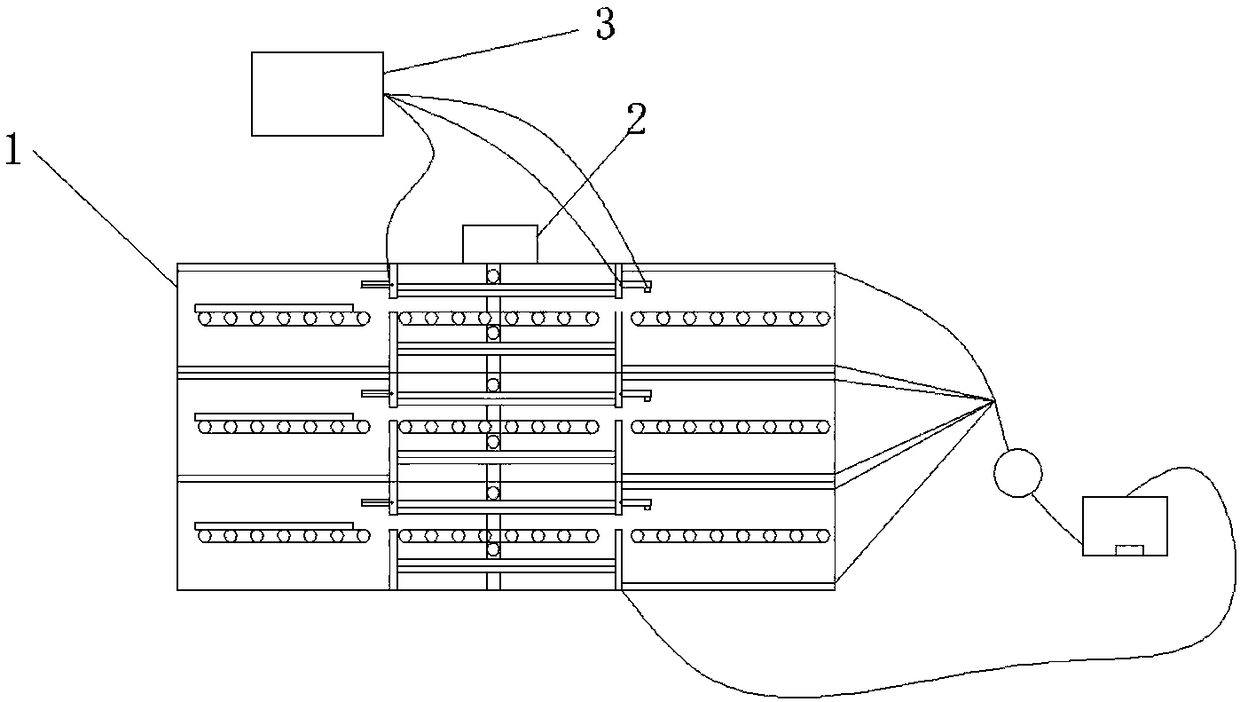

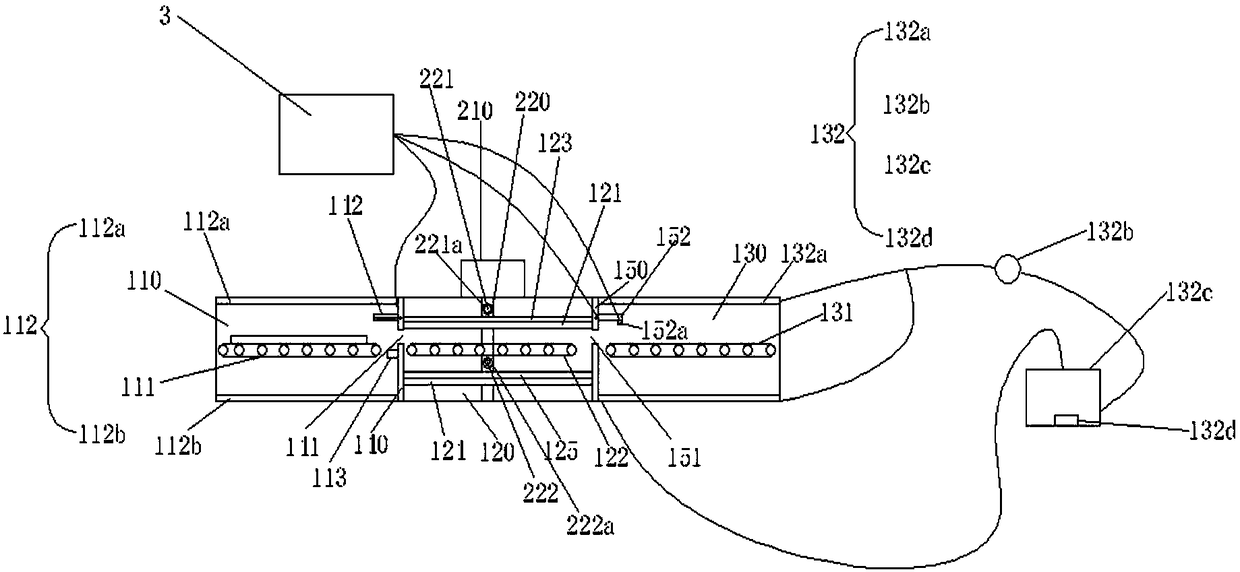

Online chip cleaning and drying equipment

ActiveCN102820242ASimple structureIngenious designDrying using combination processesSemiconductor/solid-state device manufacturingEngineeringVacuum chamber

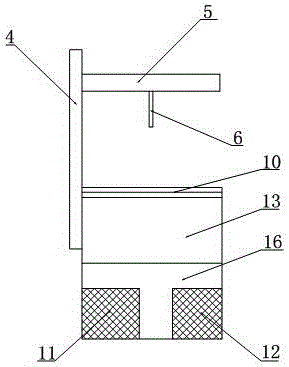

The invention discloses online chip cleaning and drying equipment which comprises an automatic feeding mechanism, a spray type cleaning device, vacuum drying equipment and a positioning table. The vacuum drying equipment comprises a frame; a pair of drying conveying belts which are connected with a cleaning machine, support the two sides of a chip and horizontally move are arranged in the middle of the frame; a push plate which controls and supports the chip to move up and down through mechanical power is arranged on the frame below the part between the drying conveying belts; a first vacuum chamber provided with a vacuum sucker and an infrared heating tube is arranged right over the push plate; a second vacuum chamber which is movably connected with the first vacuum chamber through a connecting rod mechanism and provided with a sealing structure matched with the lower end of the first vacuum chamber is arranged on one side of the first vacuum chamber; and a vacuum adsorption hole corresponding to the chip is formed on one side of the second vacuum chamber corresponding to the first vacuum chamber and provided with the sealing structure. The equipment is simple in structure and skillful in design, automatically picks up chips, performs spray type cleaning and vacuum drying on the chip, dries the chip through thermal power in the vacuum environment, and prevents the chips from being damaged.

Owner:TONGLING TAIYANGDAO AGRI TECH CO LTD

Device for expanding thermal shrinkage tube

ActiveCN101327645AExtended service lifePlay a lubricating roleTubular articlesShrinkage rateCooling effect

Owner:CHANGYUAN ELECTRONICS DONGGUAN +3

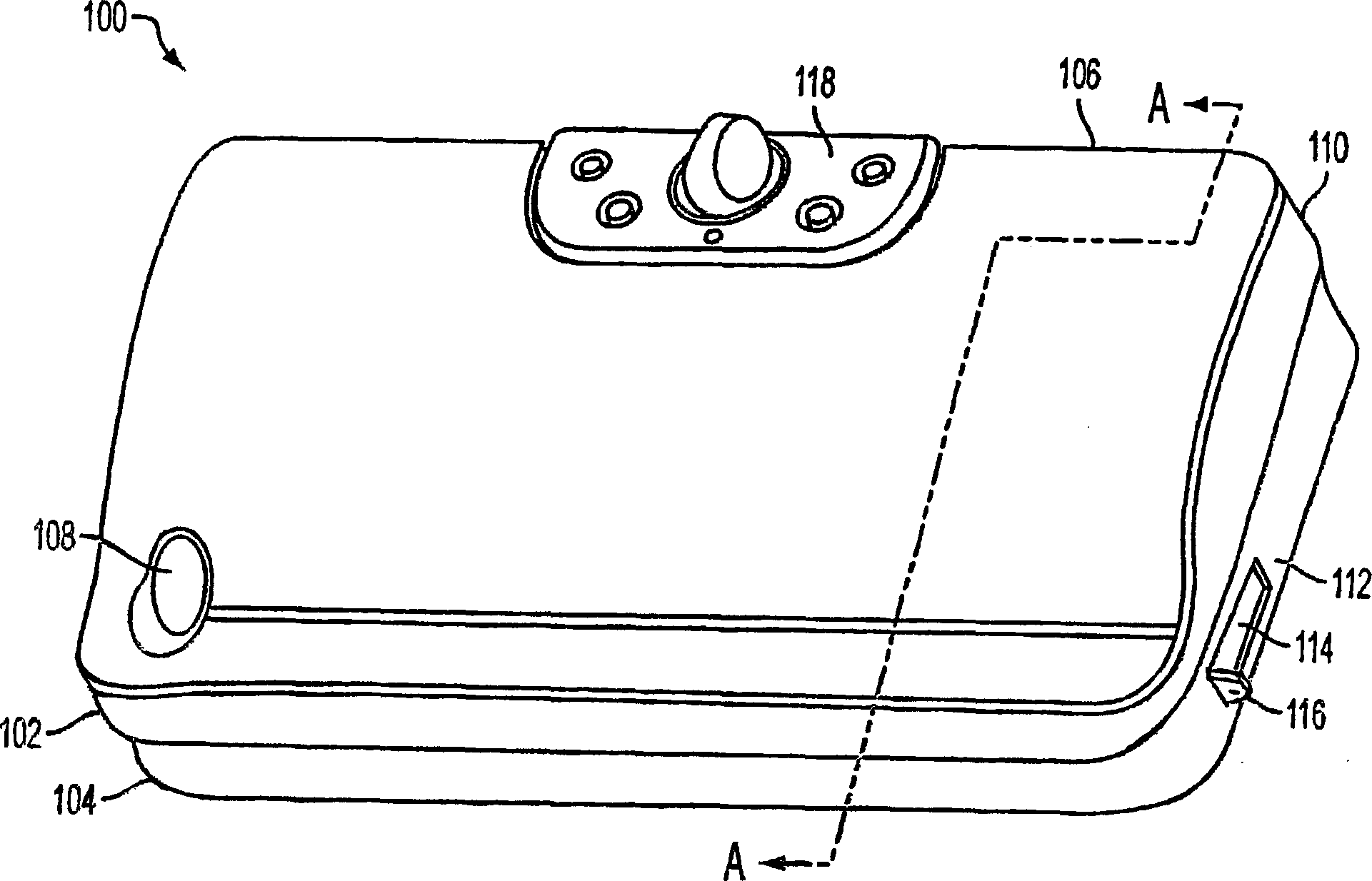

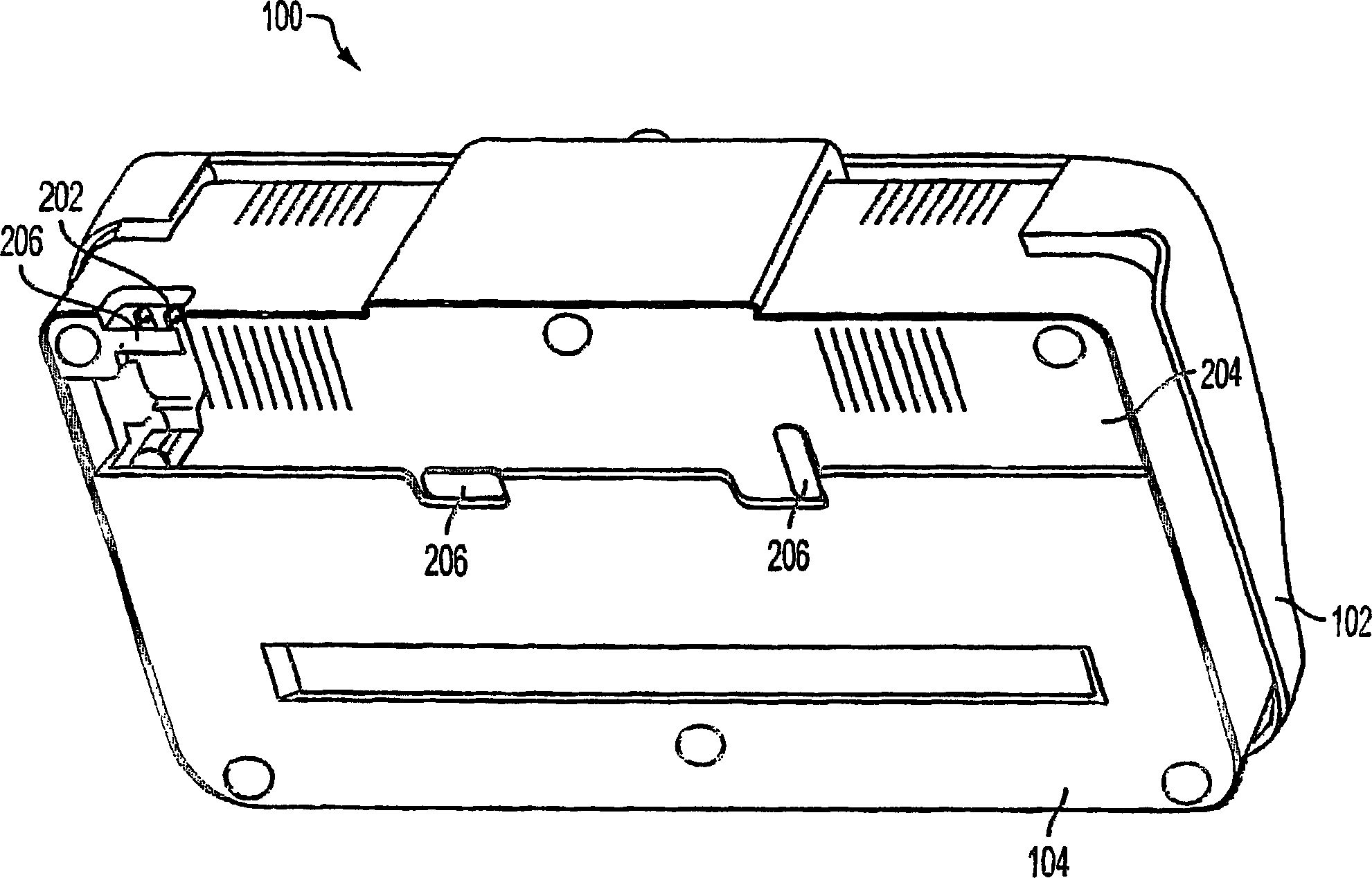

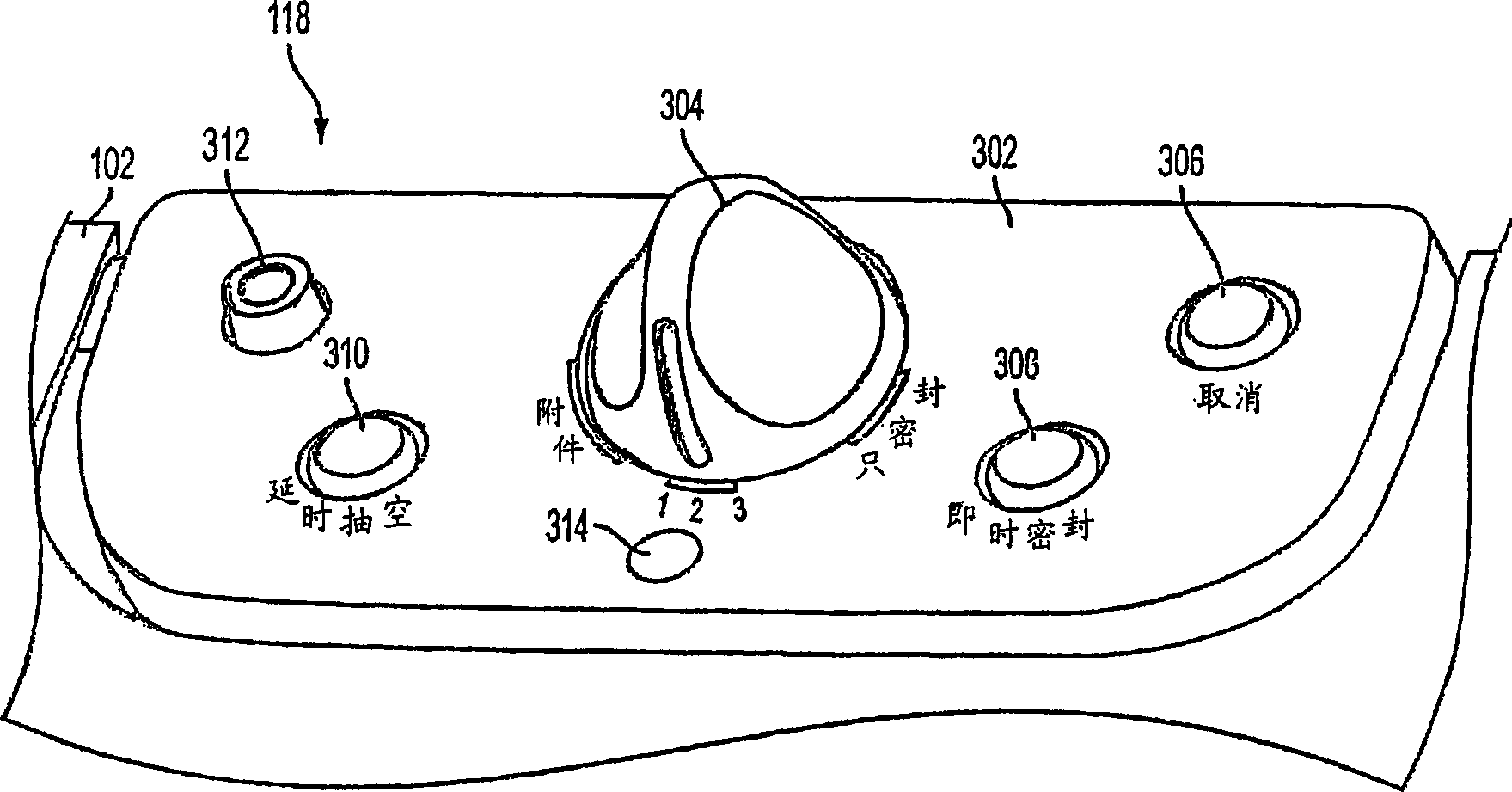

Vacuum packaging appliance with slidable channel

InactiveCN1777534AClear featuresClear advantagePackaging by pressurising/gasifyingPackaging under vacuum/special atmosphereMechanical engineeringVacuum chamber

Owner:TILIA INT INC

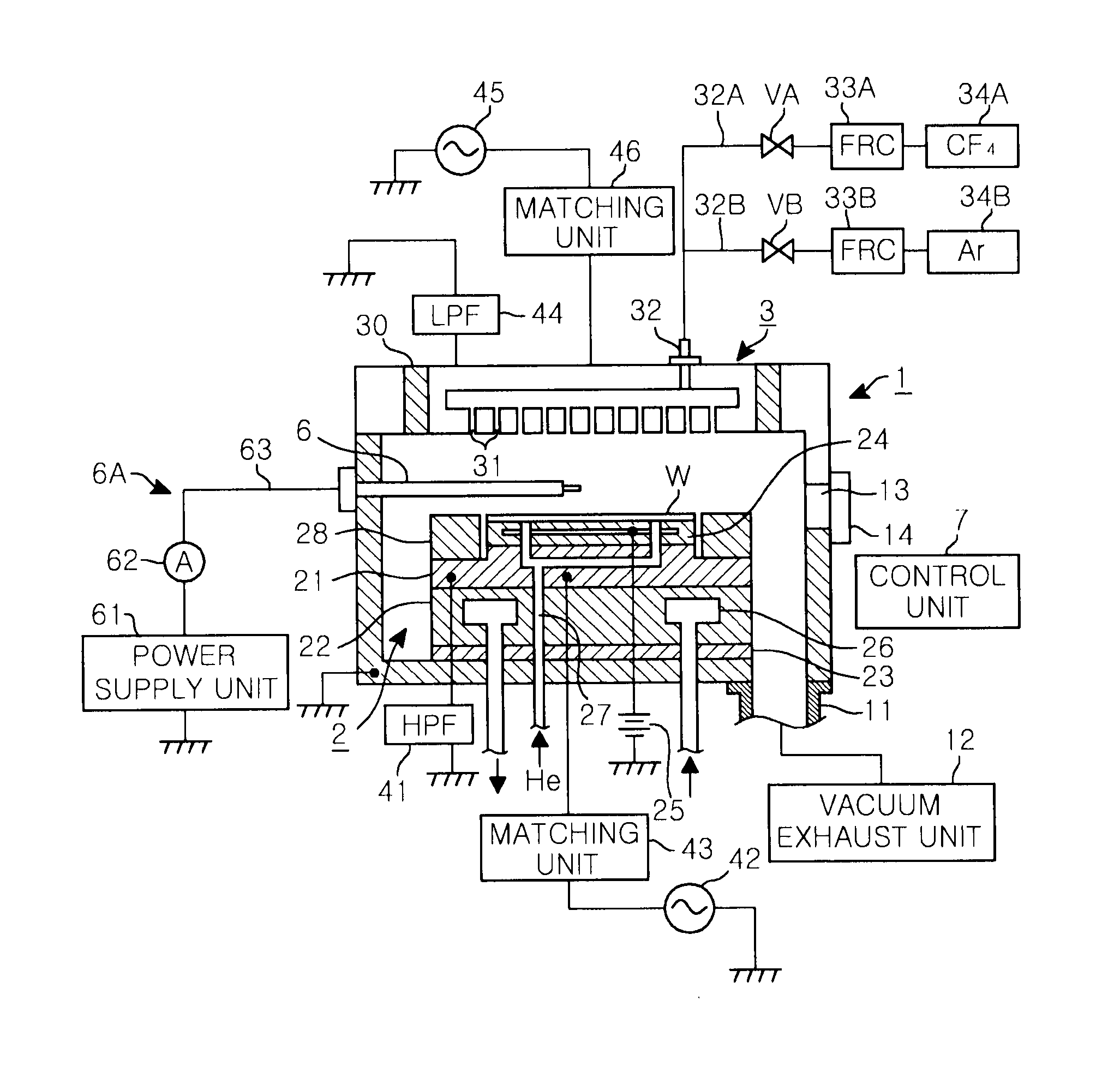

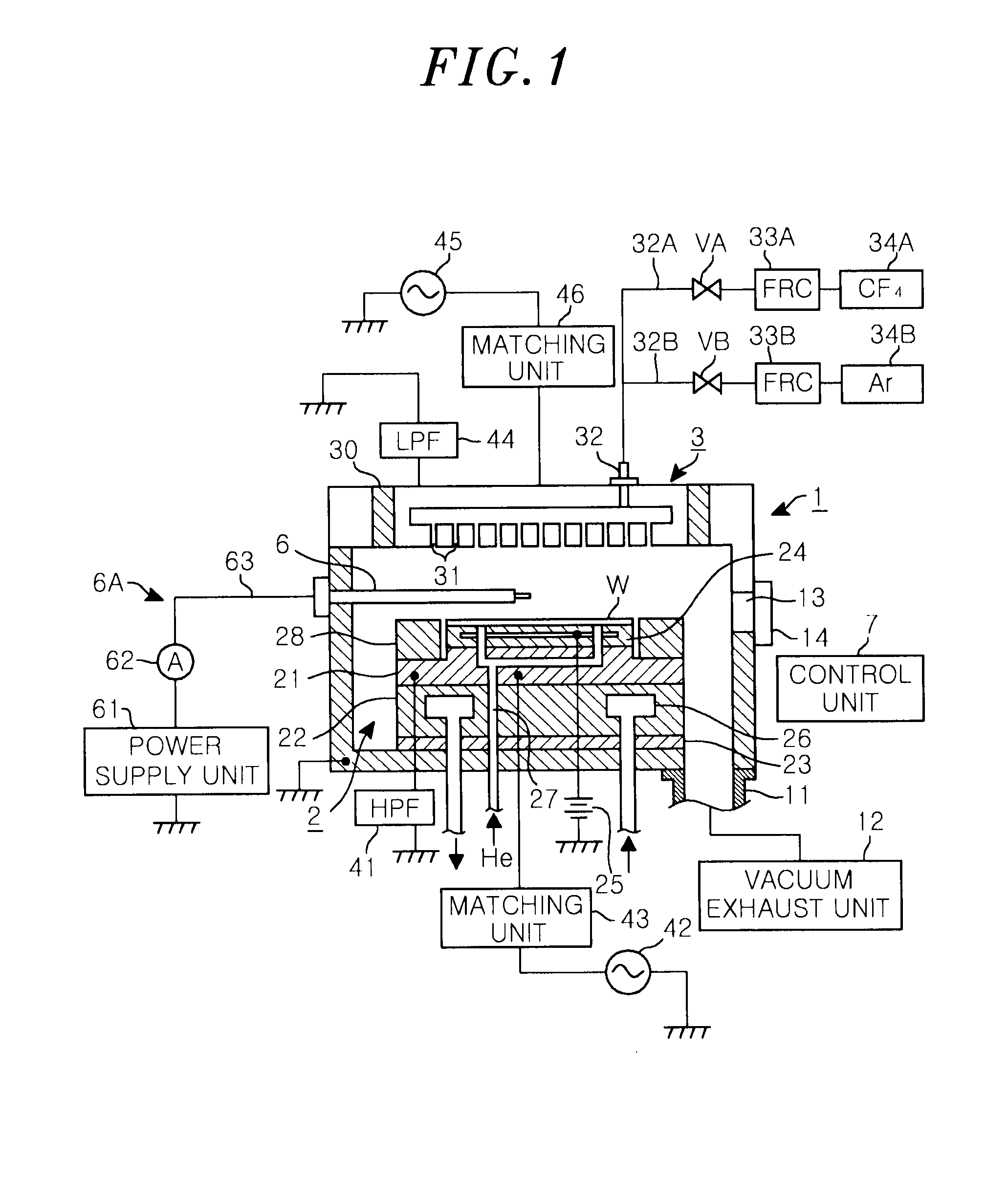

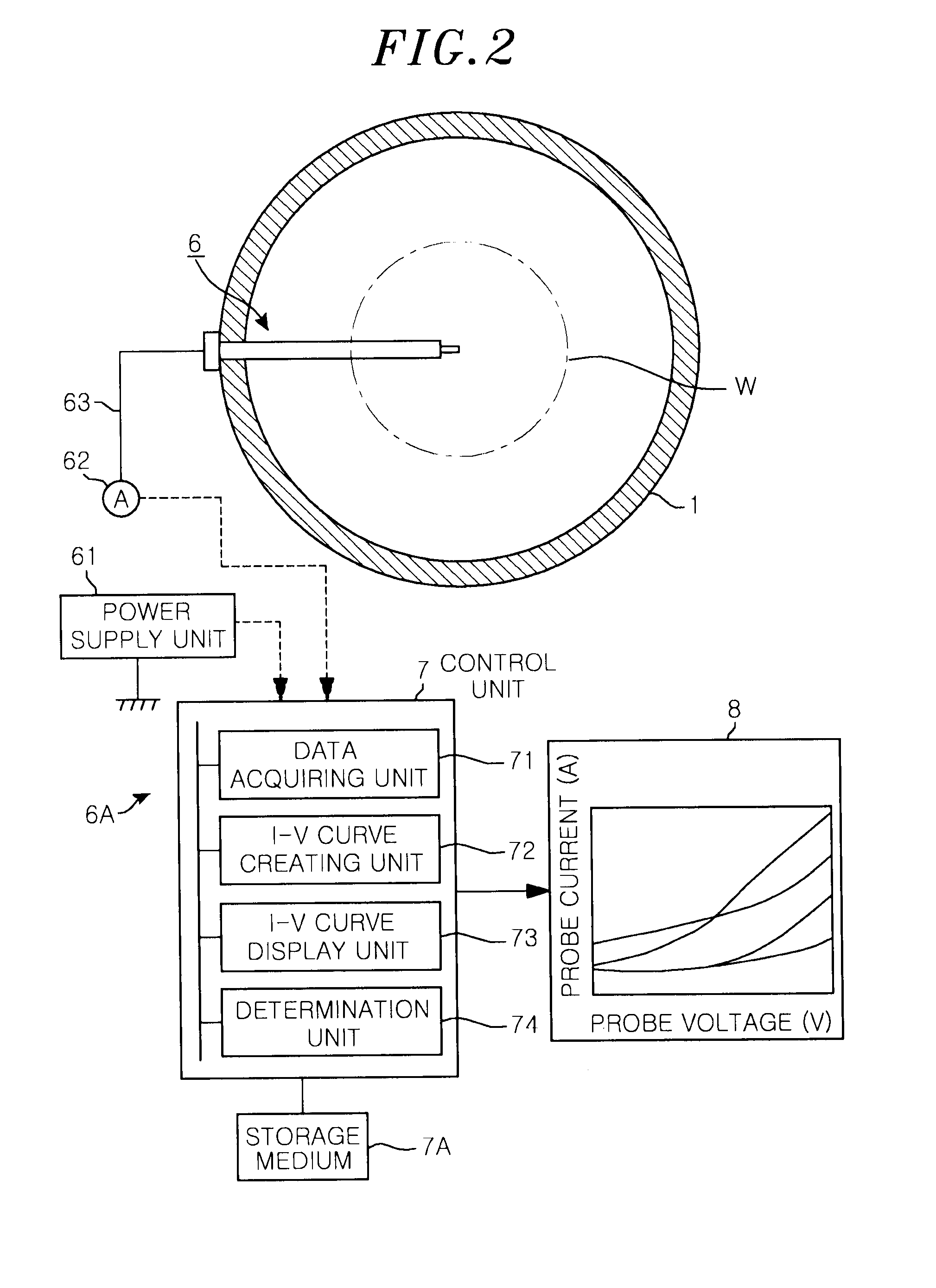

Plasma measuring method, plasma measuring device and storage medium

InactiveUS20100321029A1Easy to optimizeHighly effectiveElectric discharge tubesMaterial analysis by electric/magnetic meansElectricityCurrent voltage

Owner:TOKYO ELECTRON LTD

Device for measuring thermoelectric performance in wide temperature range

InactiveCN1837801AGuaranteed accuracyAvoid mutationElectrical testingMaterial analysis by electric/magnetic meansElectricityMeasurement device

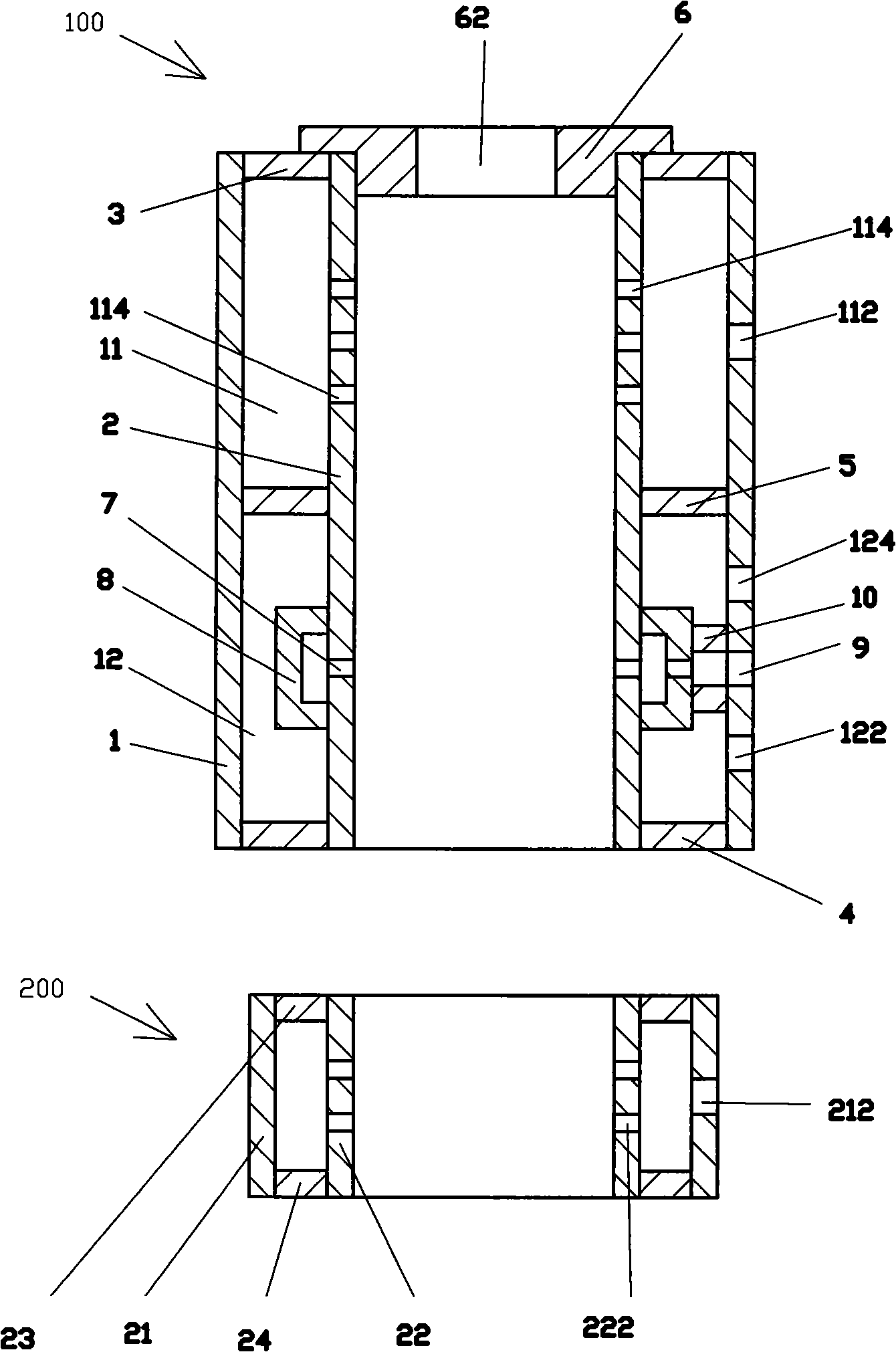

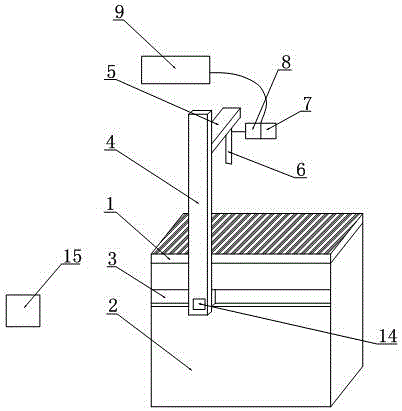

This invention relates to a device for measuring thermoelectric performance in wide temperature range, which comprises a measuring platform (5); a sealed vacuum chamber (2) with a vacuumizing device, a heater (9) and a liquid nitrogen cavity (7) connected to the lower ends of an inlet pipe (4) and an outlet pipe (6). Wherein. Both upper ends of (4) and (6) are outside of the chamber (2); there is an insulating layer (8) between (5) and (7). This invention can measure property continually.

Owner:ZHEJIANG UNIV

Laminated glass forming device

Owner:黄山市歙县凯旋工贸有限公司

Self rotation device for vacuum cavity

ActiveCN103807119ASolve the sealing problemTroubleshoot spinning crafting issuesSpring motorMachines/enginesGear wheelEngineering

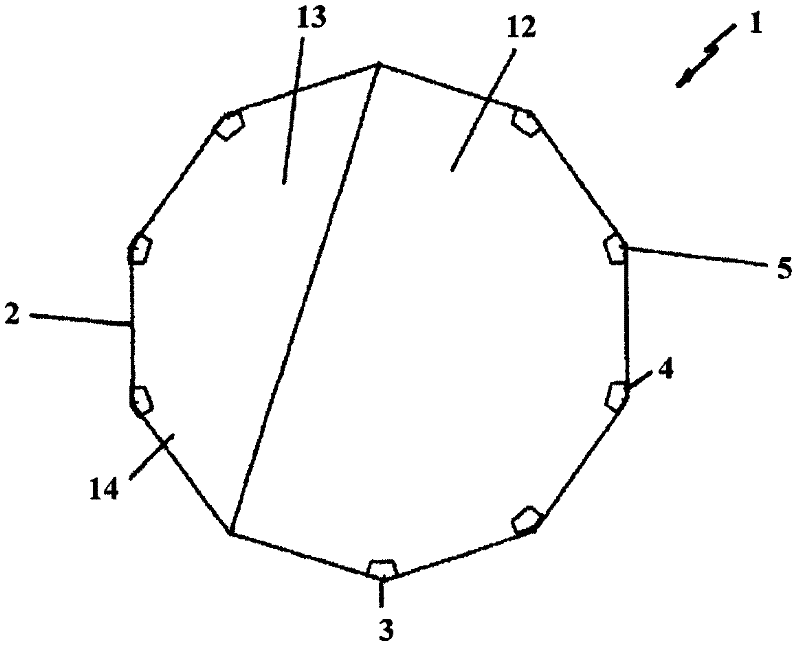

The invention discloses a self rotation device for a vacuum cavity. The self rotation device comprises a rotation tray, a casing and a spiral clockwork spring, an internal and outer inclined tooth gear, a directional rotation fork and a rotating shaft, wherein the internal and outer inclined tooth gear is an annular wheel, internal and external inclined teeth are respectively arranged on the inner and outer side surfaces of the annular wheel, the inclination directions of the internal and external inclined teeth are opposite, the upper end of the rotating shaft is fixedly arranged on the rotation tray, the lower end of the rotating shaft sequentially passes through the internal and external inclined tooth gear, the clockwork spring and a case, the directional rotation fork comprises a plurality of stop parts, the center of the directional rotation fork is fixed onto the rotating shaft, the tail ends of the stop parts are respectively butted with the internal inclined teeth, the internal end of the spiral clockwork spring is fixedly arranged on the rotating shaft, the outer end of the spiral clockwork spring is fixedly arranged on the casing, a plurality of pallets are arranged on the inner side surface of the casing, and the tail ends of the pallets are butted with the external inclined teeth. The self rotation device for the vacuum cavity has the advantages that the structure is simple, and in addition, the rotation smoothness and the airtightness requirement during the rotation can be met.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Vacuum slit valve

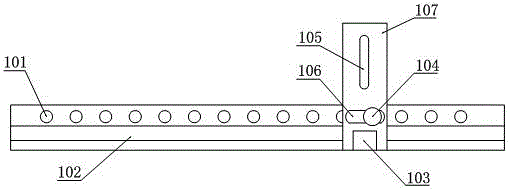

The invention relates to a vacuum slit valve which comprises a valve body. The valve body is provided with a channel for conveying a strip, and a vacuum accommodating cavity is disposed in the valve body. A valve body assembly and a valve plate assembly are placed in the vacuum accommodating cavity, and an executor connected with the valve plate assembly is arranged outside the valve body assembly. The valve body assembly is provided with a channel for conveying the strip, and the channel arranged on the valve body assembly is communicated with the channel arranged on the valve body, an included angle between the sealing surface of the valve body assembly and the working direction of the strip is 10-45 degrees, and at least one compressible sealing element surrounds a channel outlet of the sealing surface of the valve body assembly. An included angle between the sealing surface of the valve plate assembly and the working direction of the strip is 10-45 degrees, and the sealing surface of the valve plate assembly is provided with compressible sealing elements corresponding to the sealing elements on the sealing surface of the valve body assembly. According to the vacuum slit valve, under the conditions that the strip is not damaged, vacuum sealing of different vacuum chamber parts is achieved.

Owner:XIAORUI VACUUM EQUIP (JIAXING) CO LTD

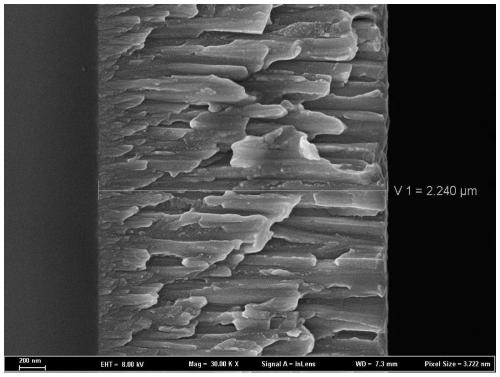

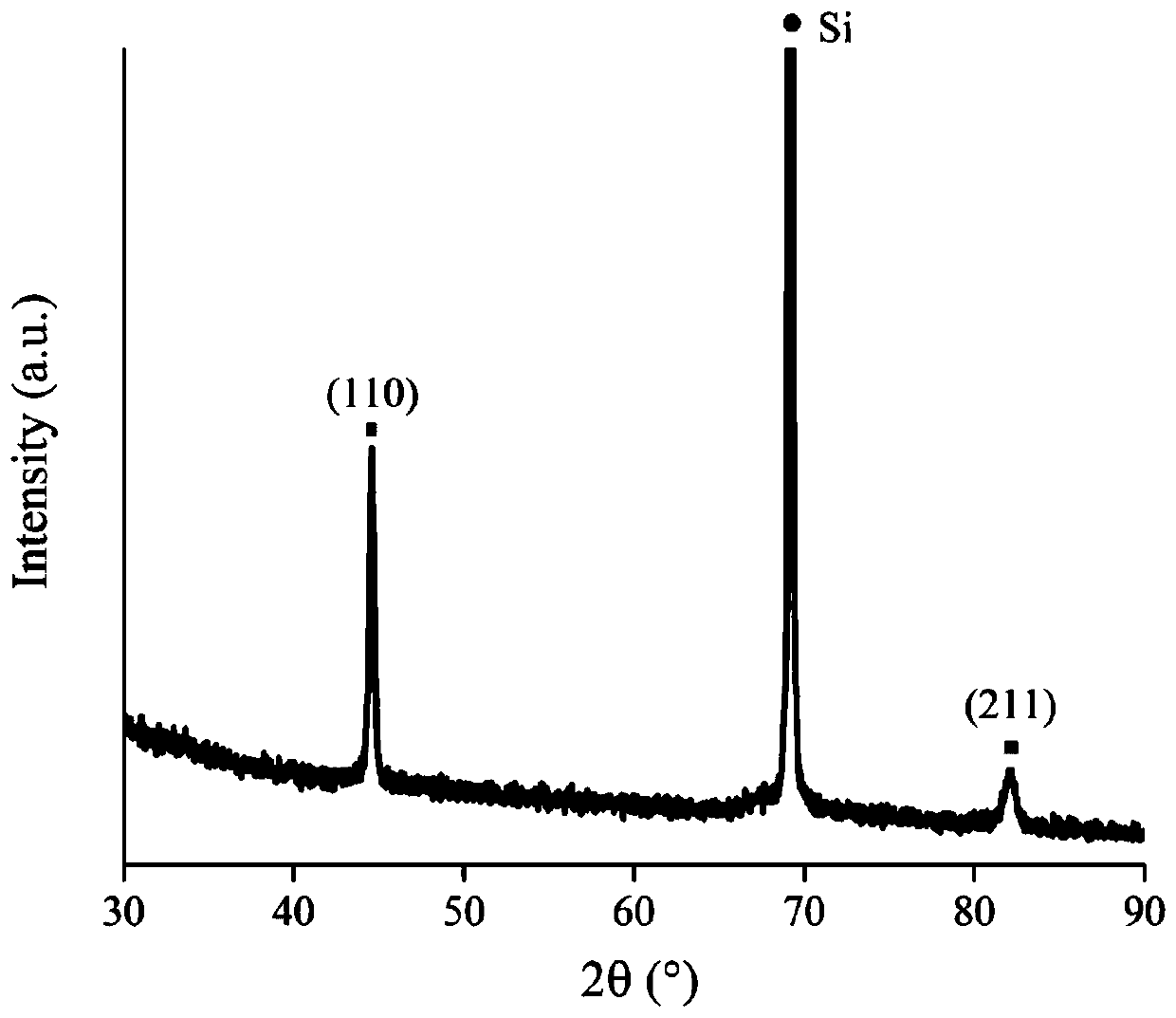

High-resistivity high-entropy alloy film and preparation method thereof

ActiveCN110129732AIncrease temperatureHigh hardnessVacuum evaporation coatingSputtering coatingSputteringHigh entropy alloys

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

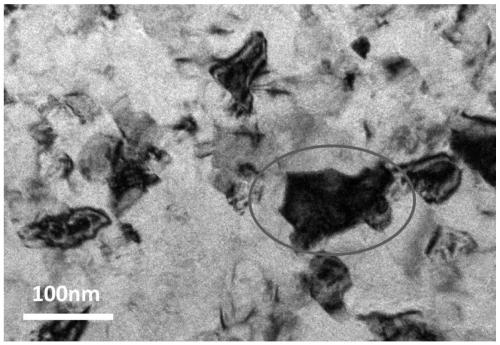

Particle imaging method

PendingCN109115660AShort cooldownEffective aggregationMaterial analysisLiquid storage tankCombined method

Owner:JINHUA VOCATIONAL TECH COLLEGE

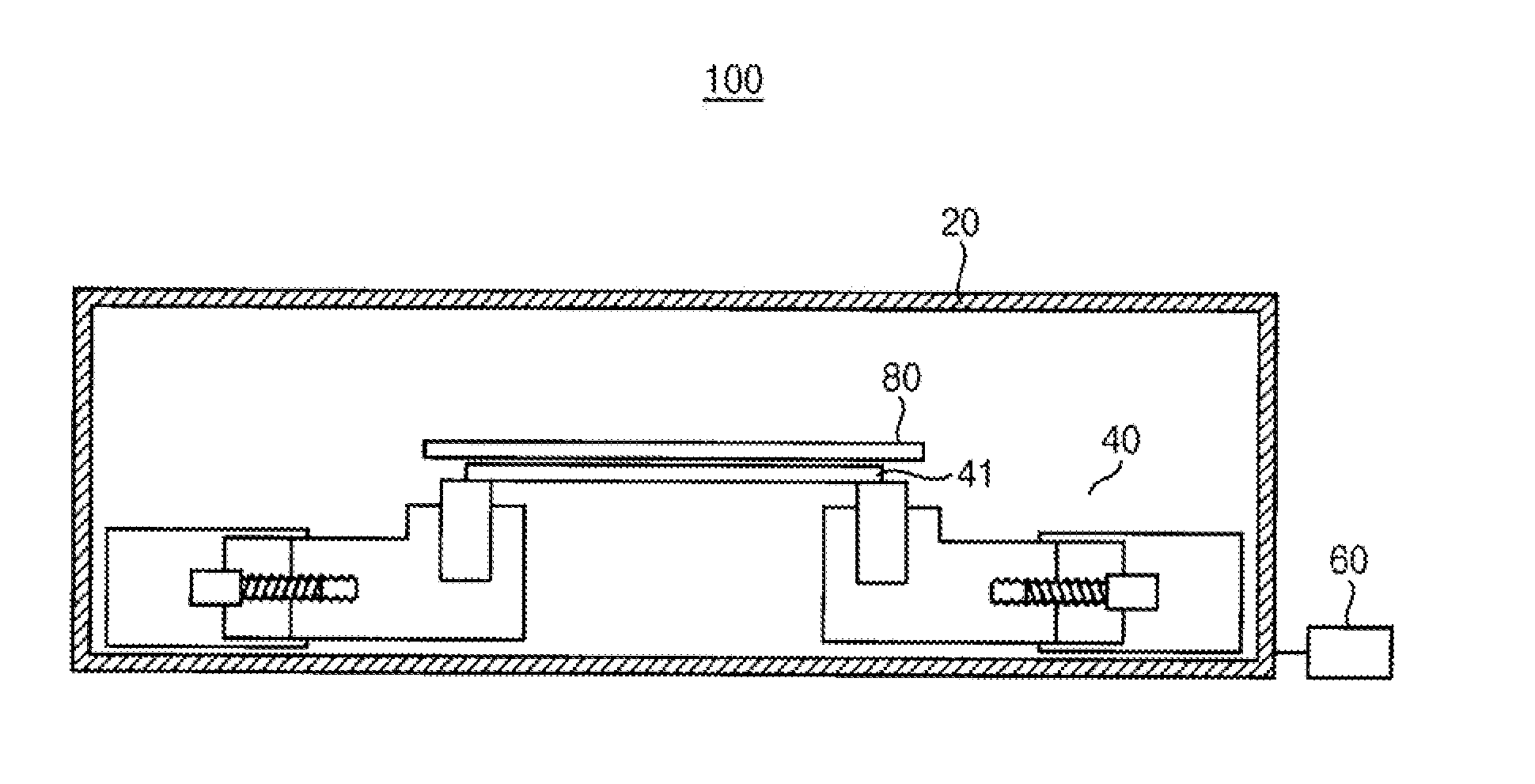

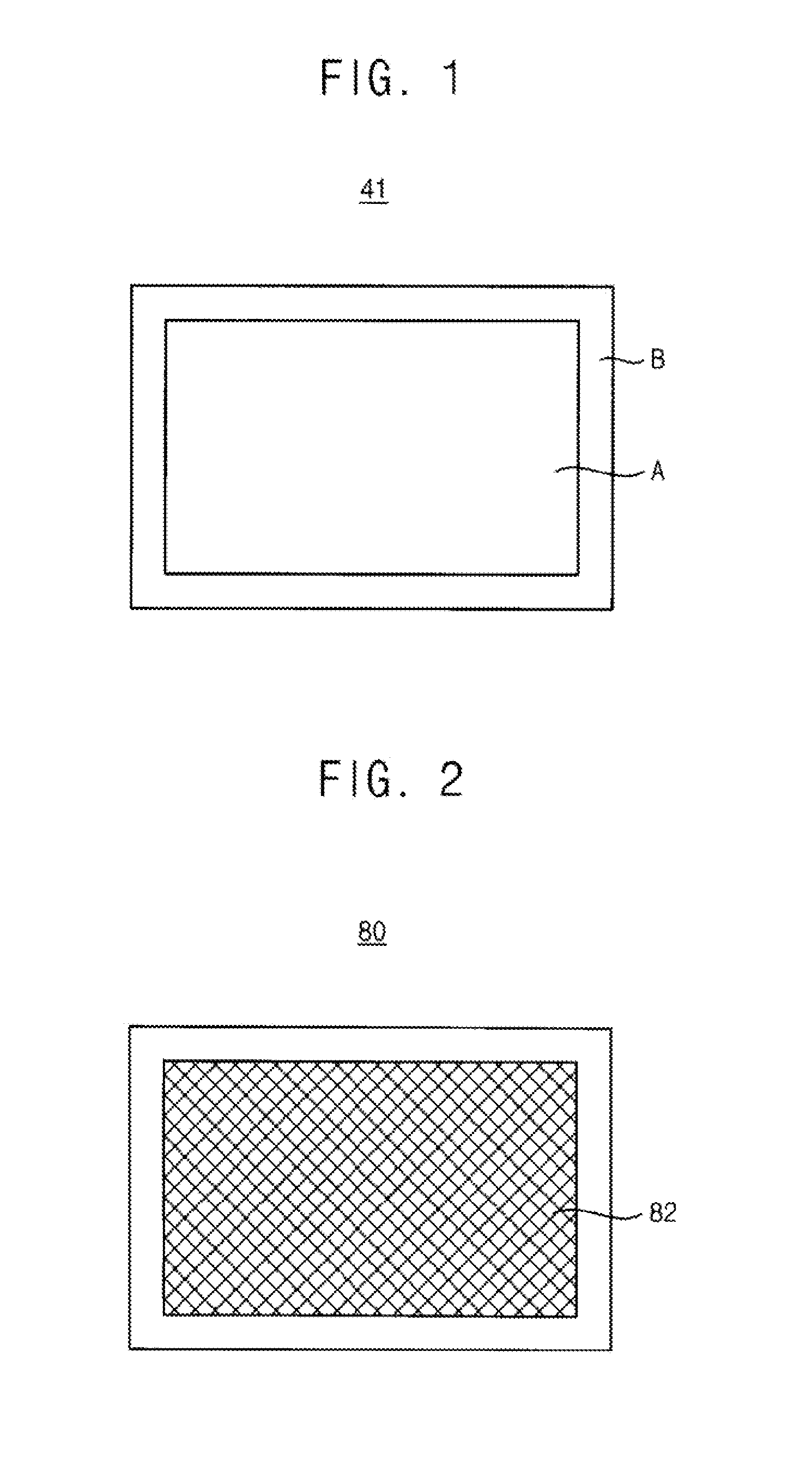

Vacuum deposition apparatus and method using the same

InactiveUS20150011075A1Replacing period can be delayedReduce material costsSolid-state devicesVacuum evaporation coatingVacuum chamberVacuum deposition

Owner:SAMSUNG DISPLAY CO LTD

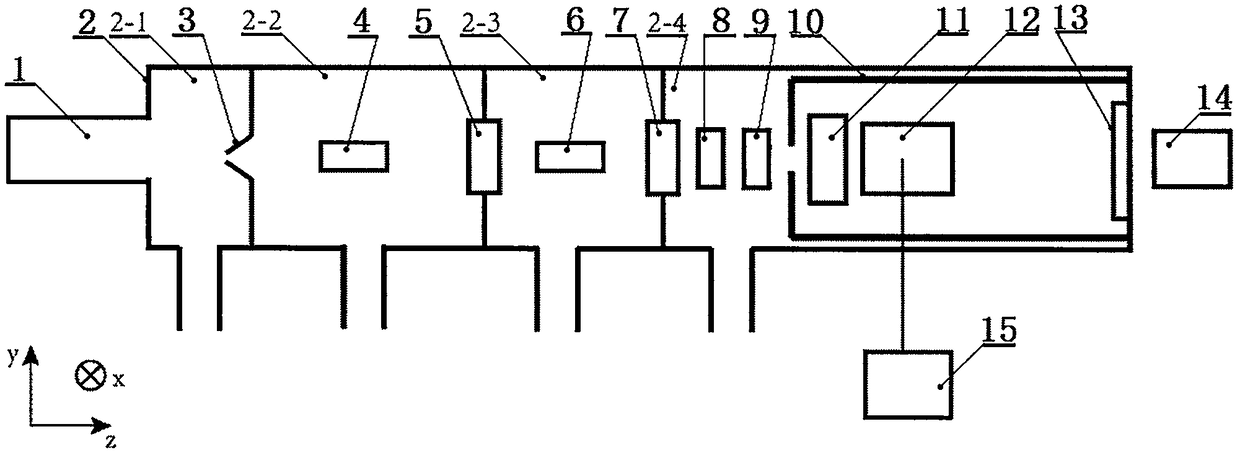

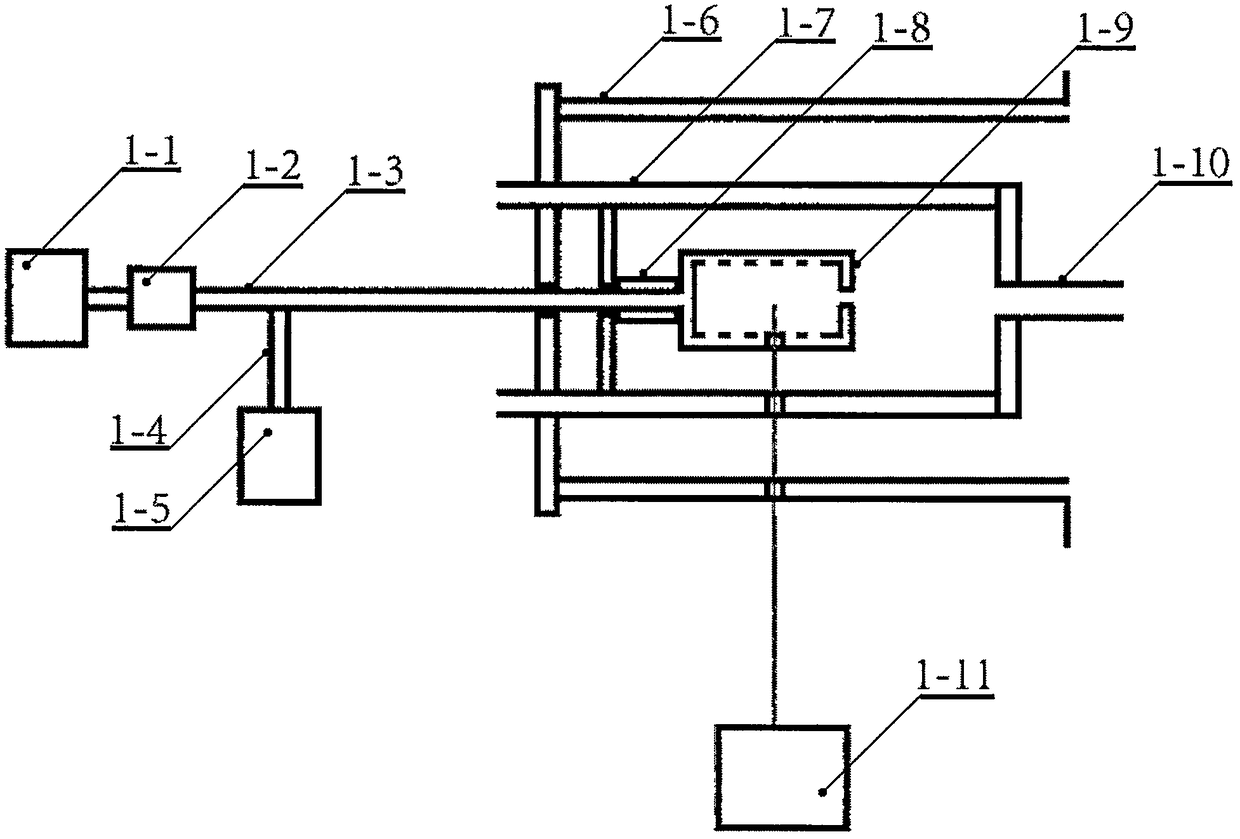

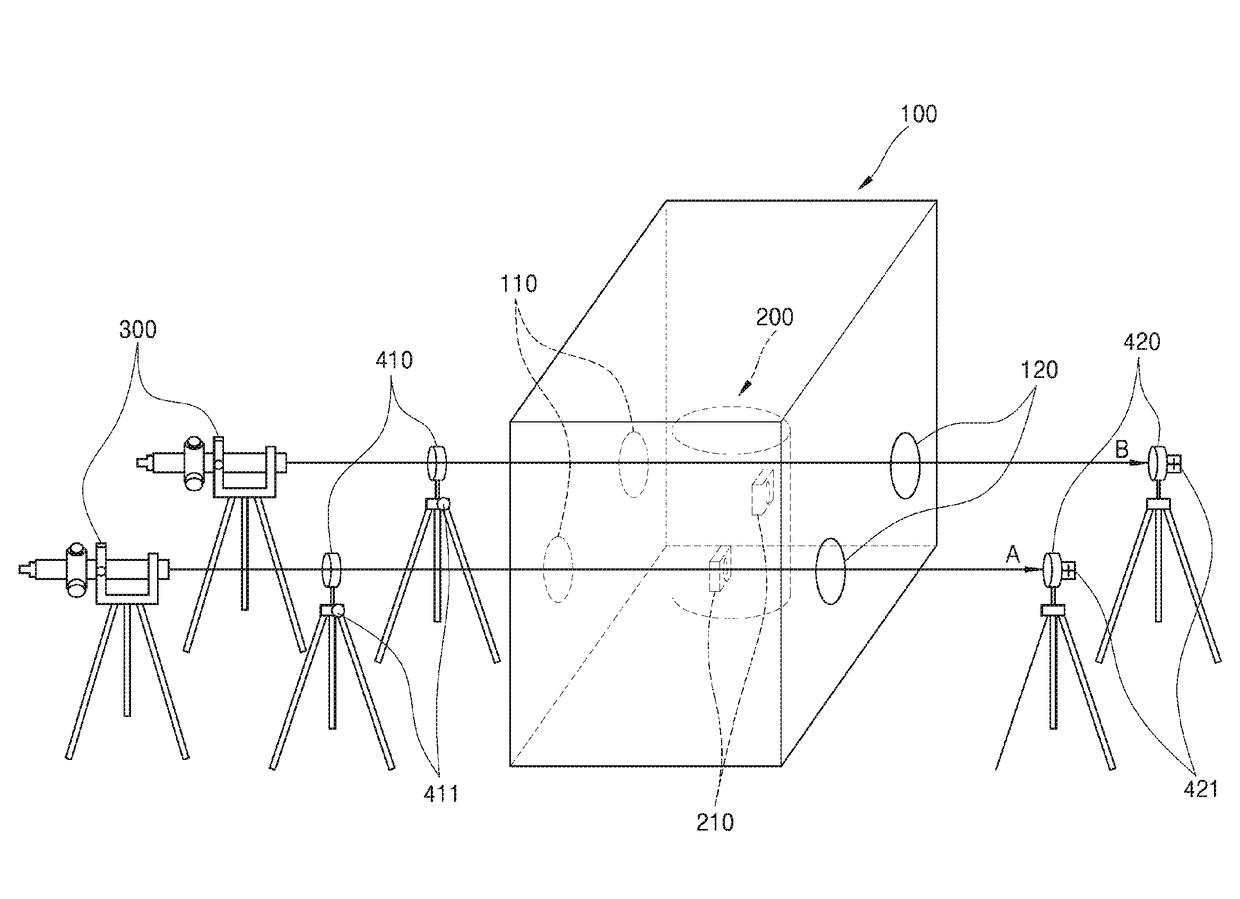

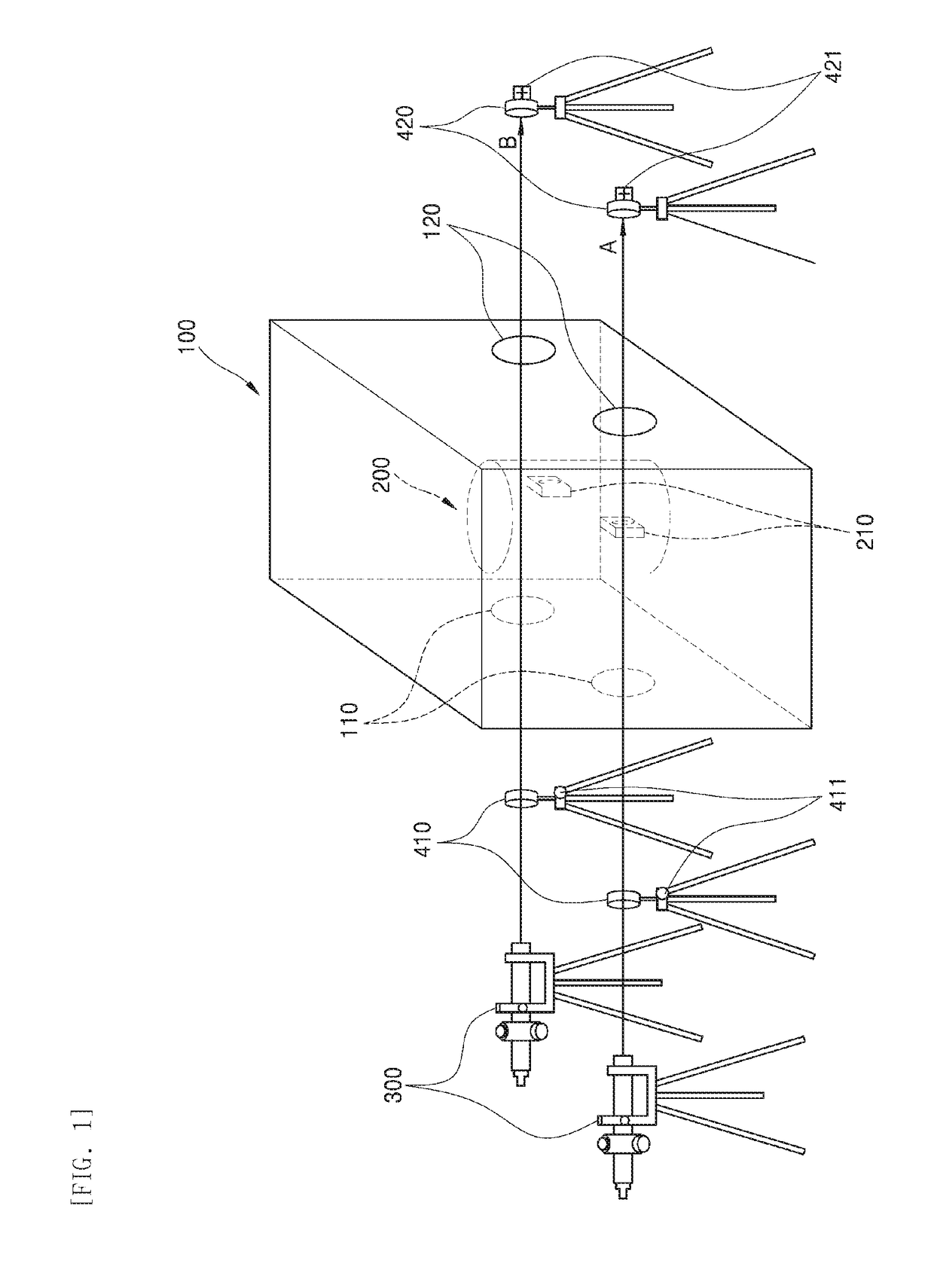

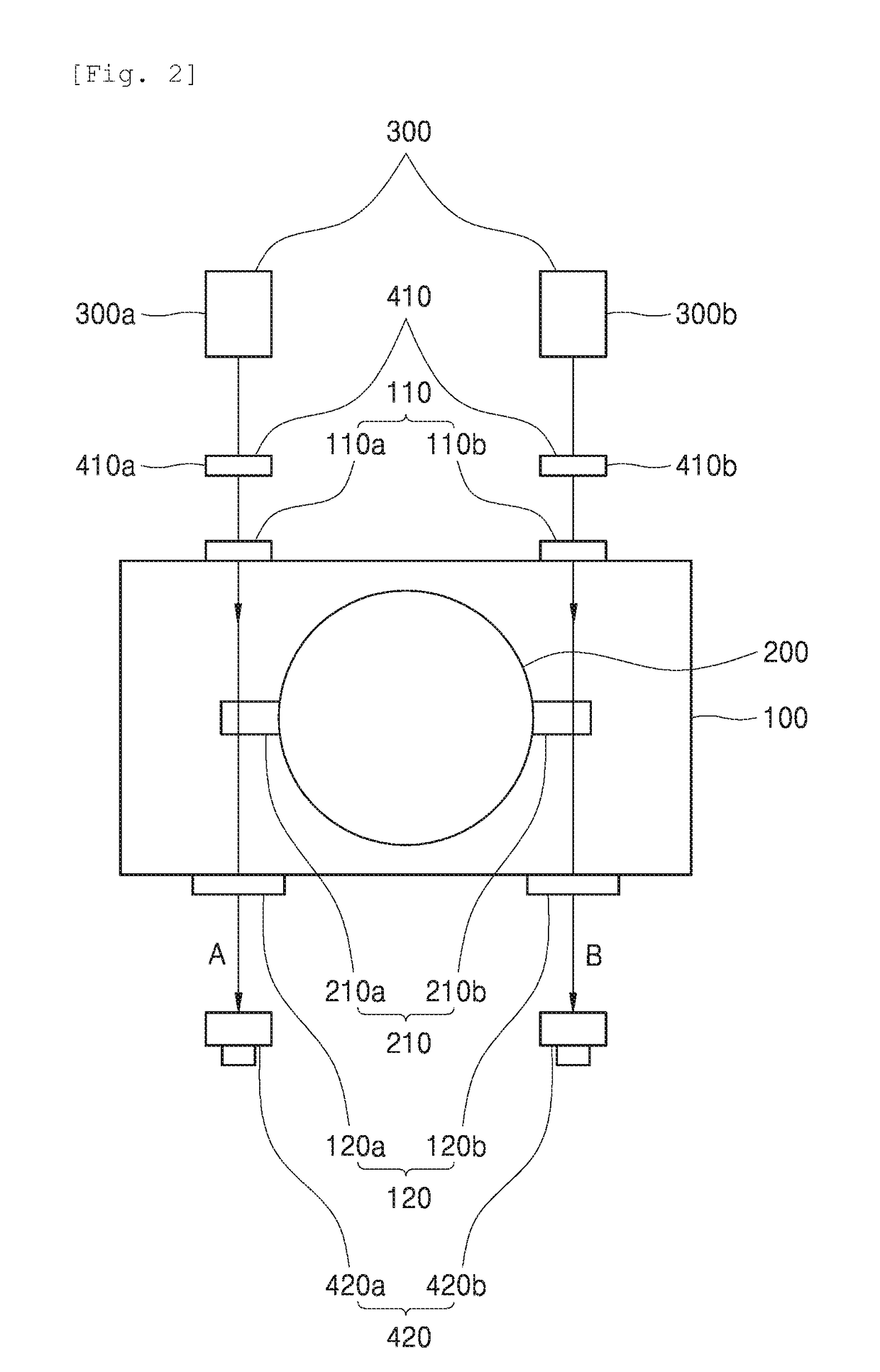

System for measuring displacement of accelerating tube in high-vacuum chamber by using micro-alignment telescope and method thereof

Owner:INST FOR BASIC SCI

Automatic spraying device applied to SPE film and achieving method of automatic spraying device

ActiveCN105772252AImprove permeabilityAvoid deformationSpray nozzlesTemperature controlControl system

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Ion filling and depositing combined treatment method of rolling bearing ring raceways

ActiveCN104018115AIncreased working surface hardnessImprove wear resistanceSolid state diffusion coatingEngineeringHardness

Owner:HUANGSHAN MINGMINGDE BEARING

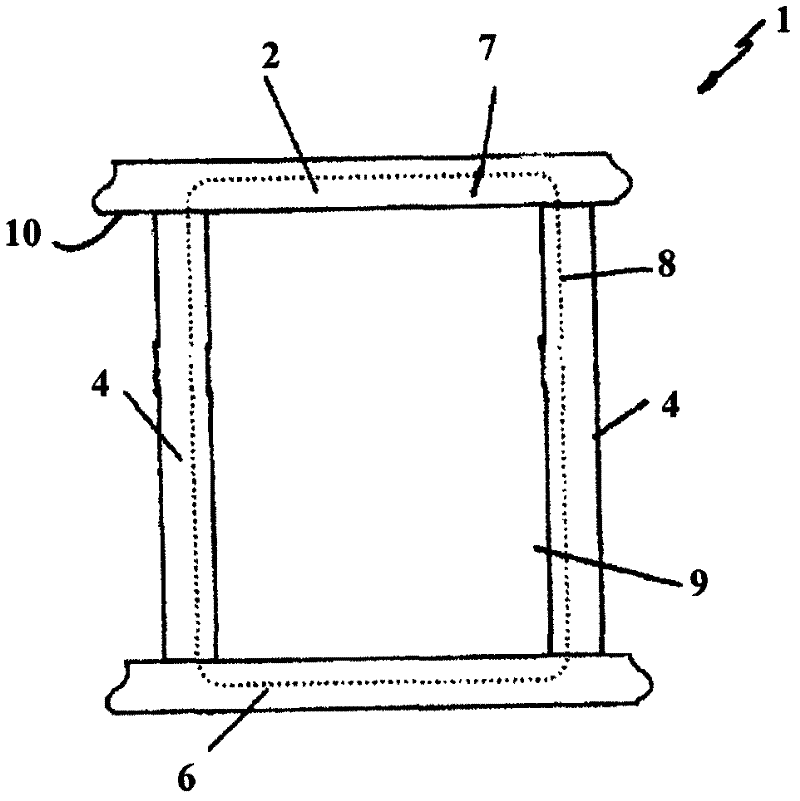

Vacuum chamber for coating equipment and method for manufacturing a vacuum chamber for coating equipment

InactiveCN102292149AReduce manufacturing costVacuum evaporation coatingSputtering coatingEngineeringFront edge

Owner:OERLIKON TRADING AG TRUEBBACH

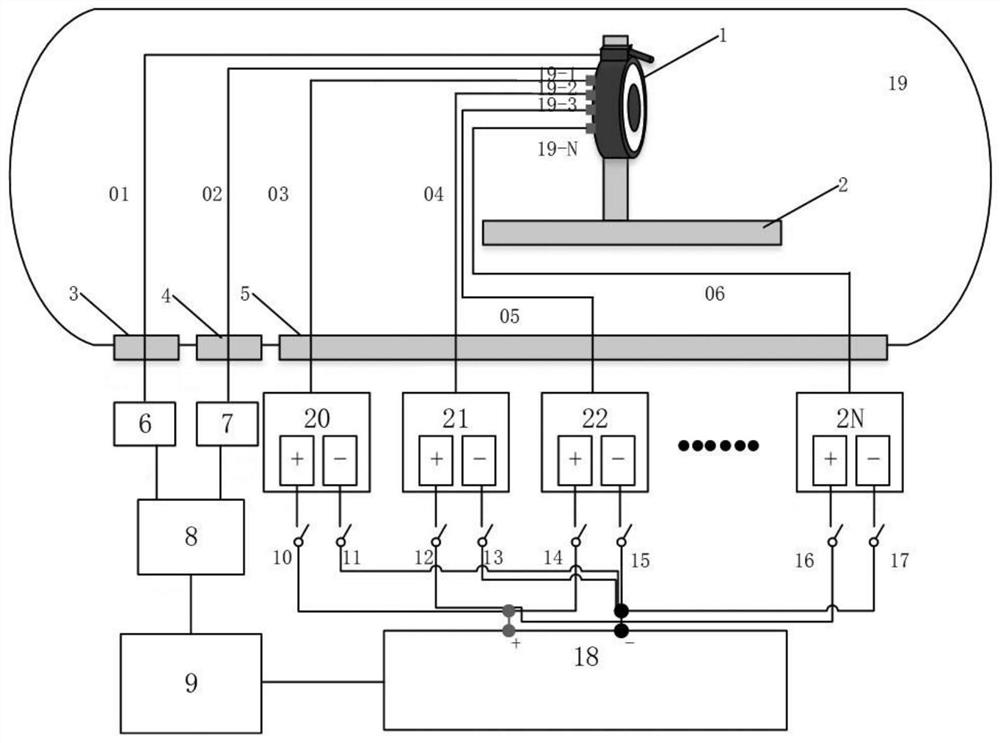

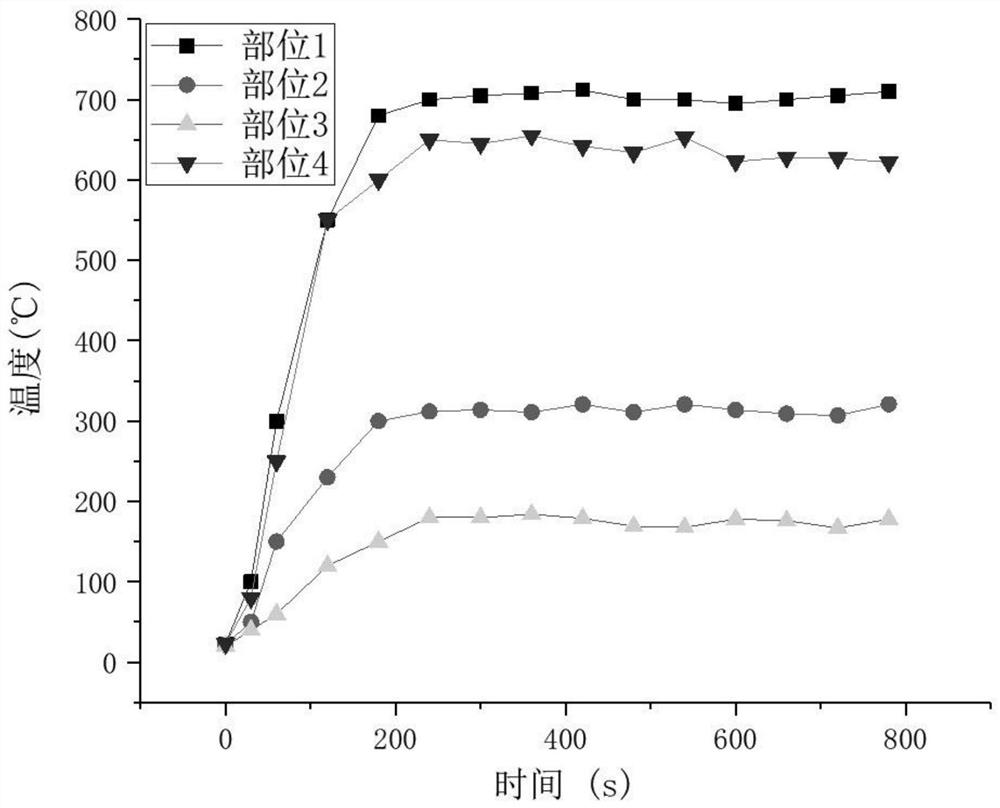

Single-display-unit multi-channel online temperature acquisition system

PendingCN112985643AReduce in quantitySimple structureThermometer applicationsTransient stateThermodynamics

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

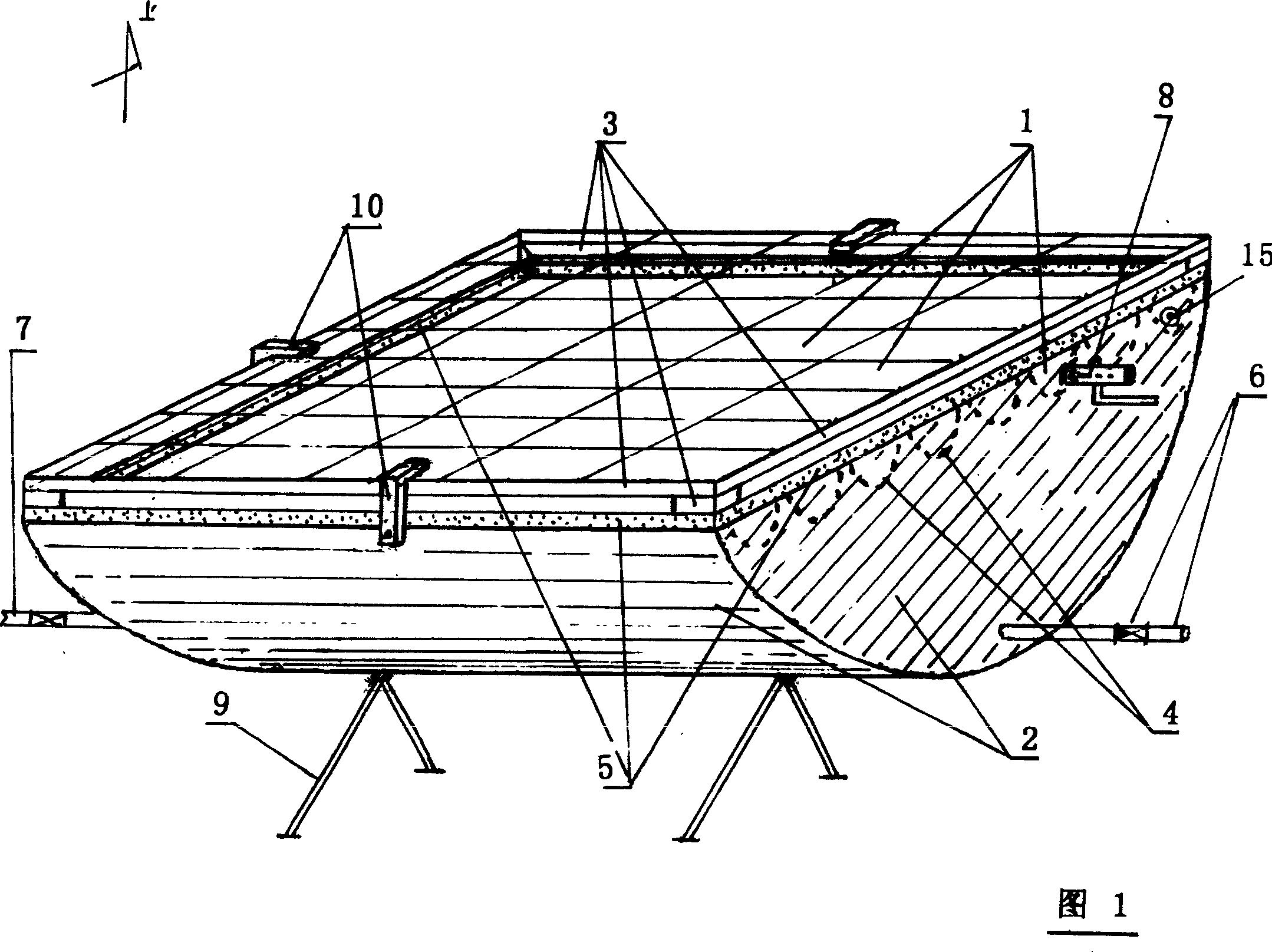

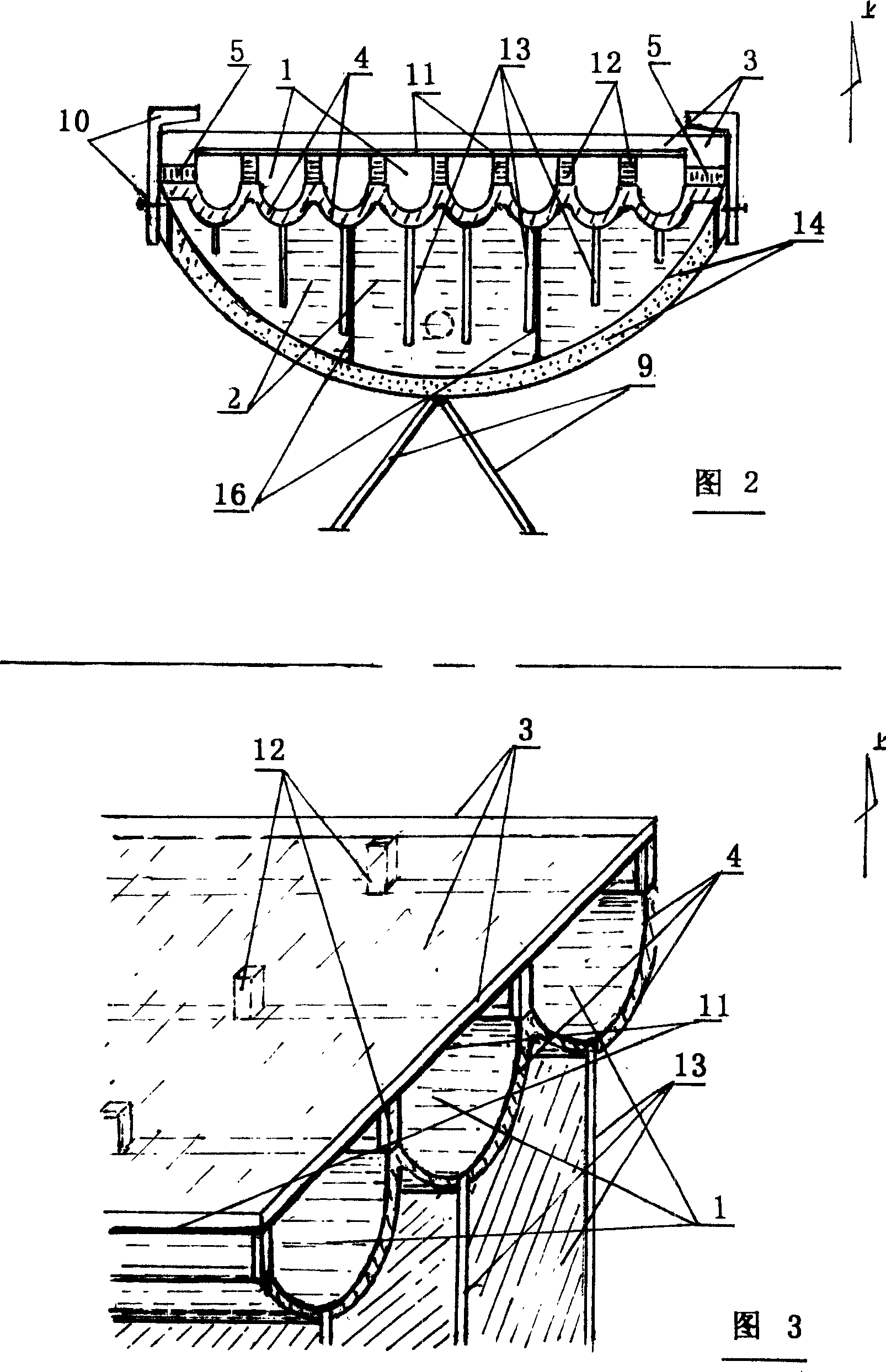

Detachable press-sealing vacuum chamber solar energy heat collection exchanger

InactiveCN101012968AEven by forceReasonable shapeSolar heat devicesSolar thermal energy generationGlass coverEngineering

Owner:孙正维

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap