System for measuring displacement of accelerating tube in high-vacuum chamber by using micro-alignment telescope and method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]The terminology and words used herein and accompanying claims should be not interpreted as the meanings of commonly used dictionaries, but interpreted as having meanings according to the technical sprit of the present invention on the principle that the concepts of the terminology and the words can be defined by the inventor in order to explain the present invention in the best mode.

[0027]Throughout the whole specification, when a predetermined part “includes” a predetermined component, the predetermined part does not exclude other components, but may further include other components unless the context clearly indicates otherwise. In addition, the terms “part”, “machine”, “module”, “device”, or “step” refer to units to process at least one function or operation, and is realized. by hardware or software, or the combination of the hardware and the software.

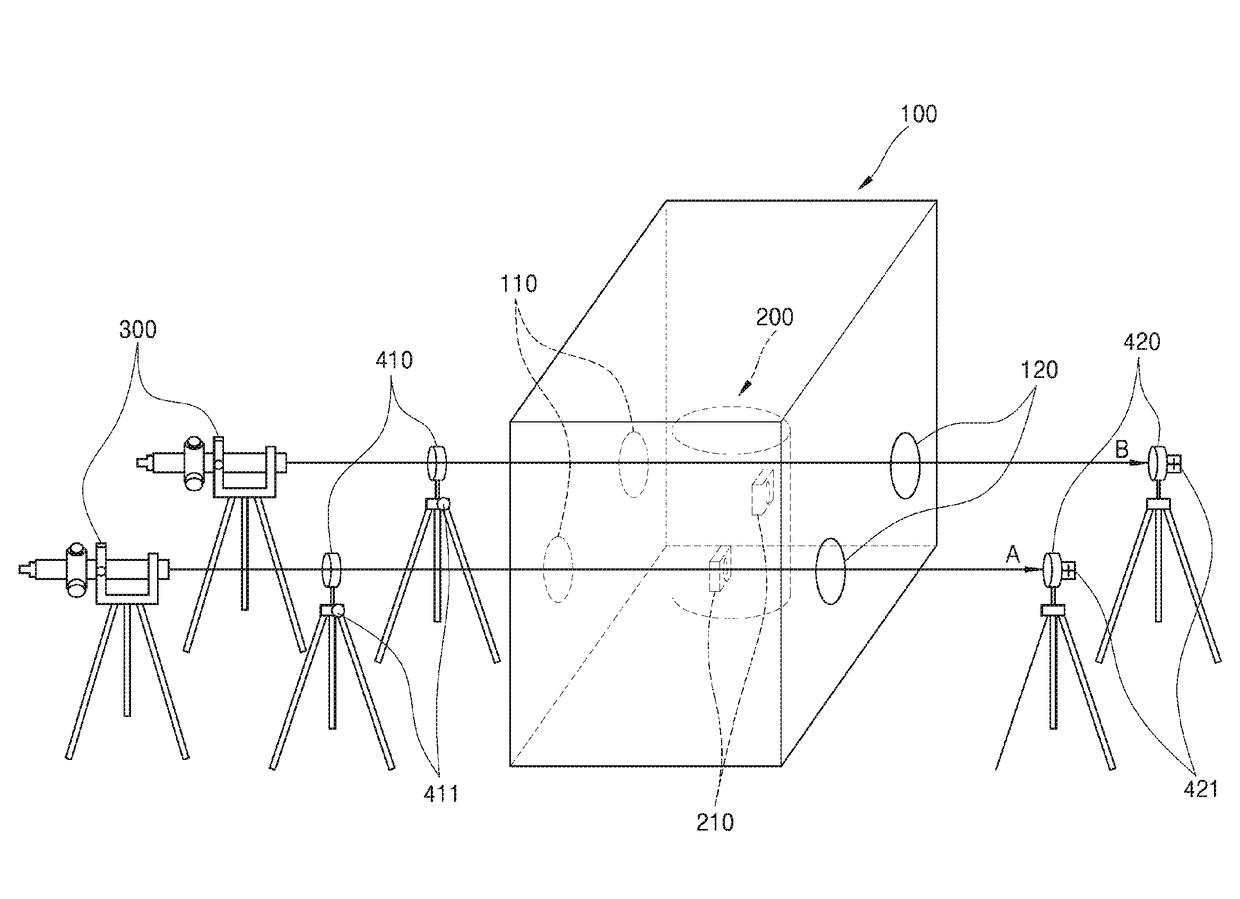

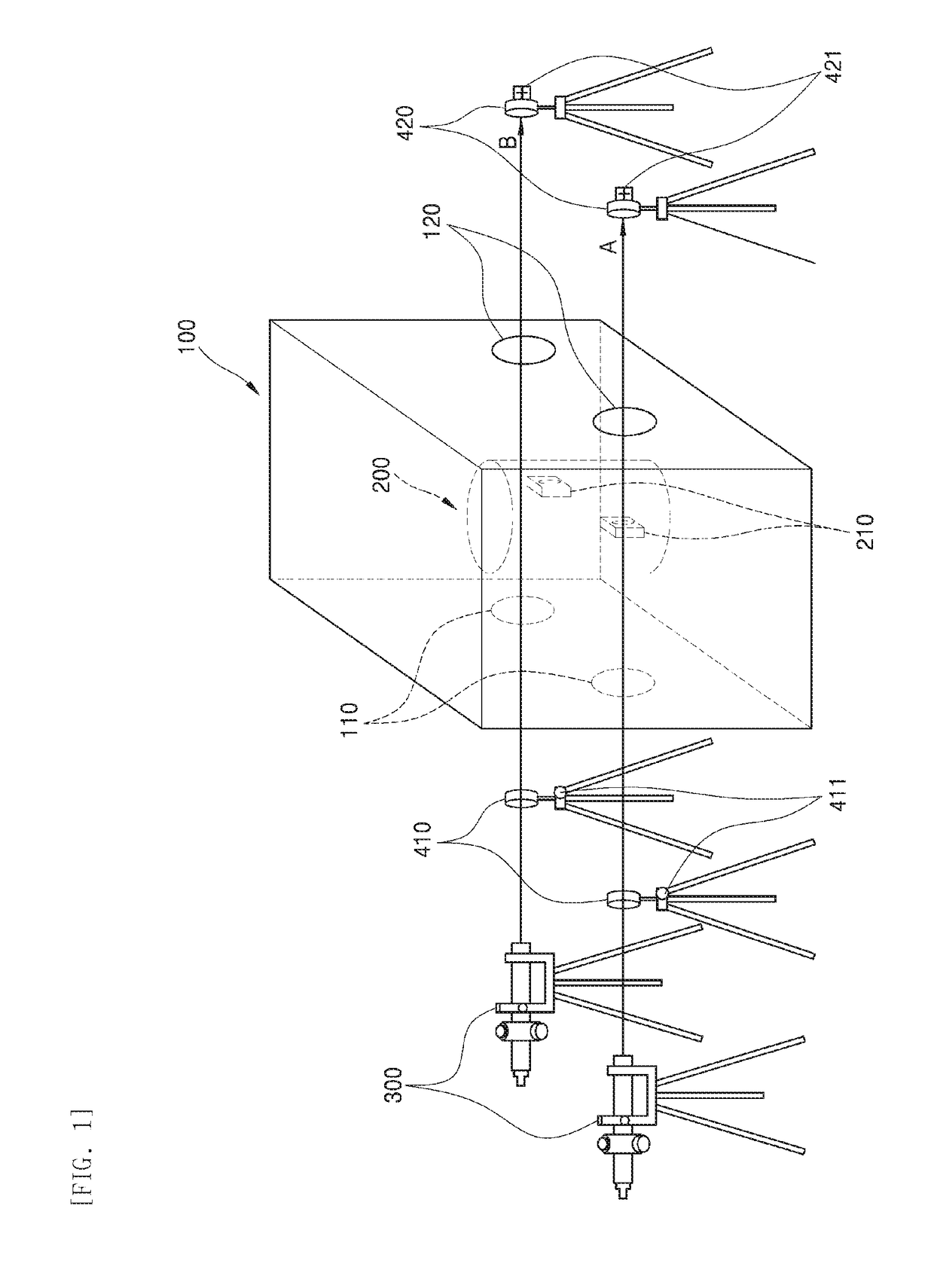

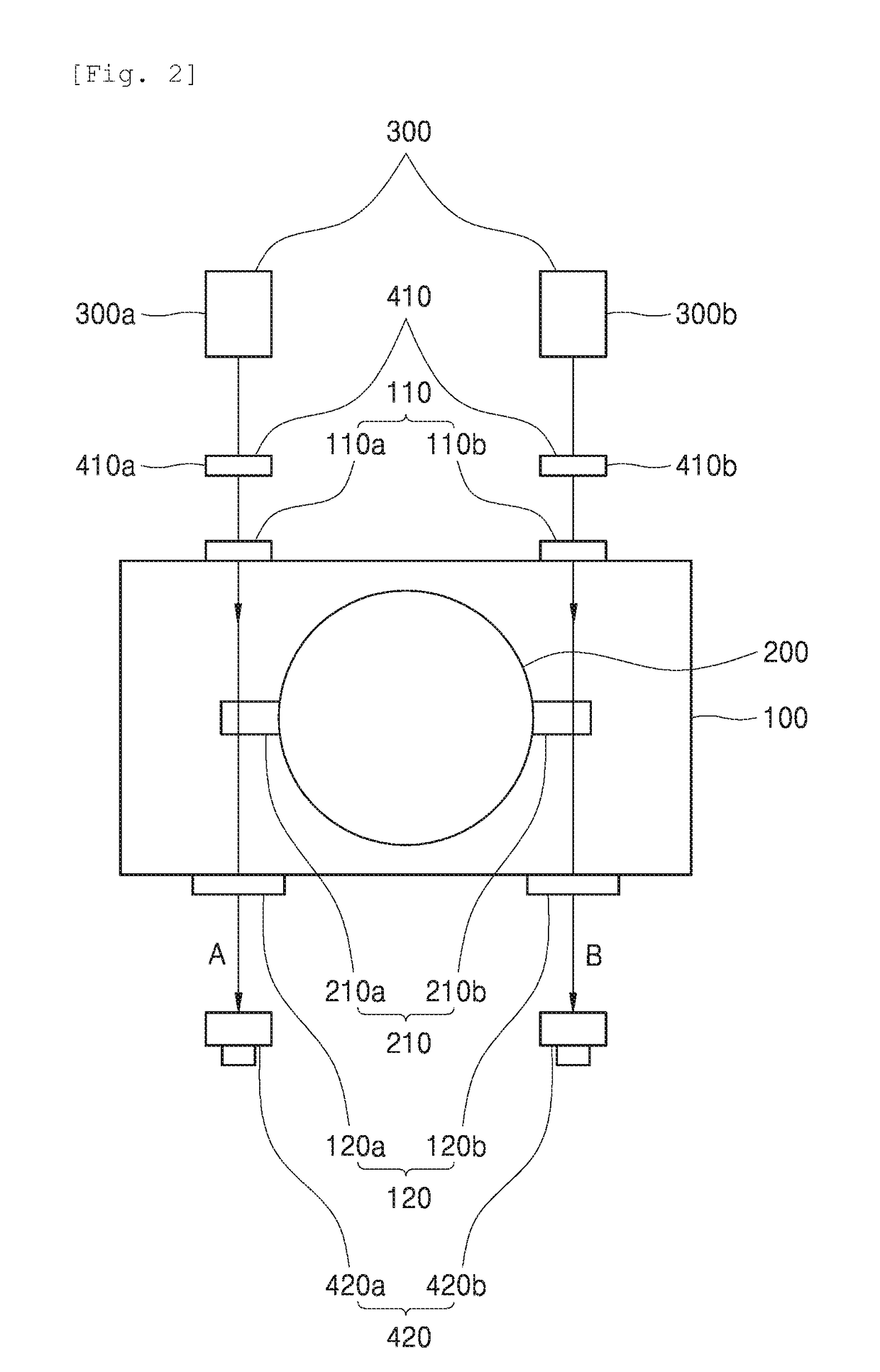

[0028]Hereinafter, a system for measuring displacement of an accelerating tube in a high-vacuum chamber by using a micro-alignm

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap