Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97results about "Electric discharge tubes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light emitting diode illumination apparatus

ActiveUS20060232974A1Effective lightingEfficient heatingCoupling device connectionsPoint-like light sourceLight-emitting diodeMetal substrate

The present invention describes a light emitting diode illumination apparatus made of a light bulb base, a heat dissipating device, a plastic lid, a drive substrate, a metal substrate, a circular insulated base and a casing, and the heat dissipating device is in contact with the metal substrate in normal conditions, such that the heat source produced by each light emitting diode is conducted to the heat dissipating device through the metal substrate and then conducted from the heat dissipating device to the light bulb base for effectively dispersing the heat source and maintaining the light emitting efficiency of each light emitting diode.

Owner:TAIWAN OASIS TECH CO LTD

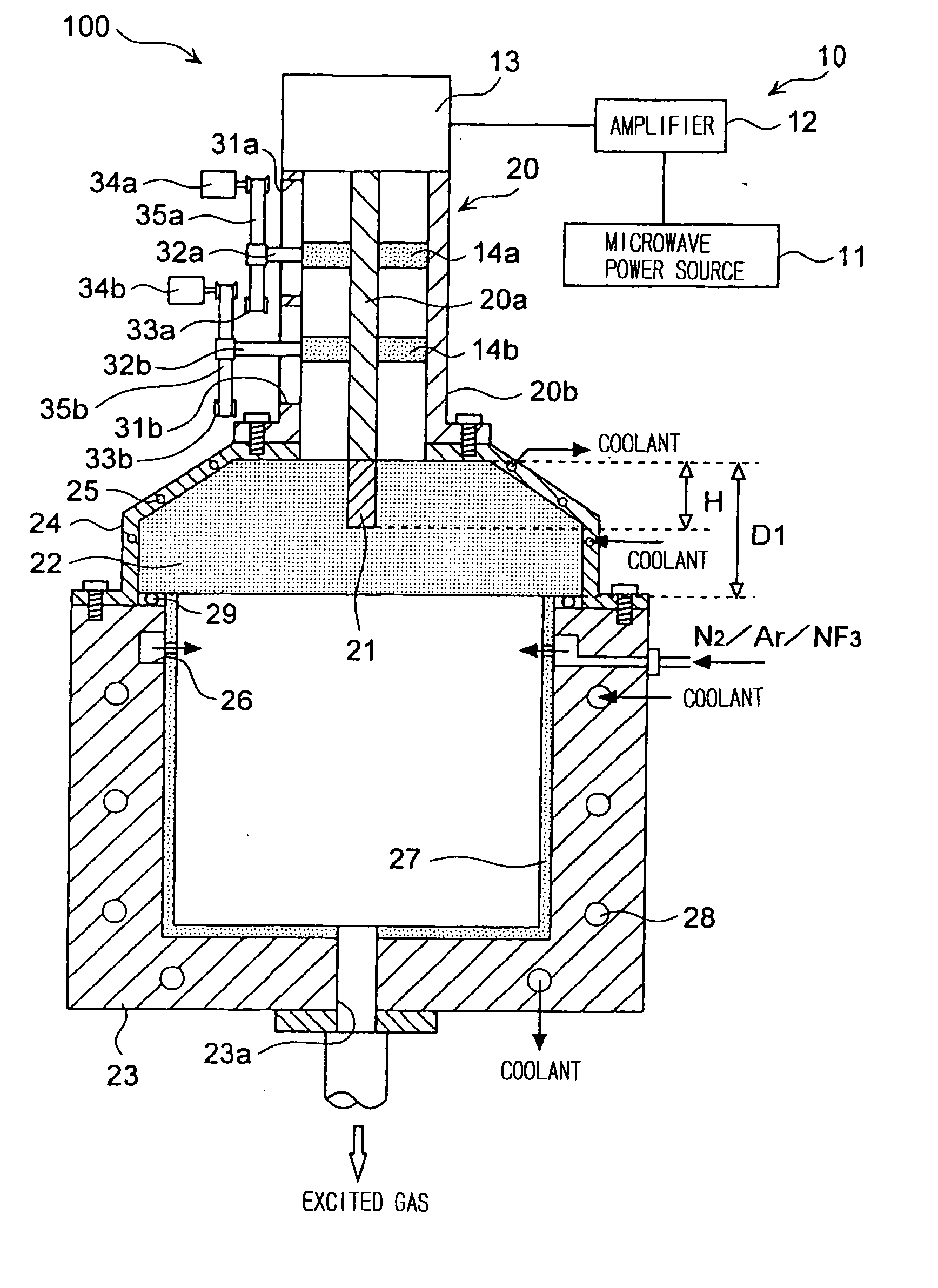

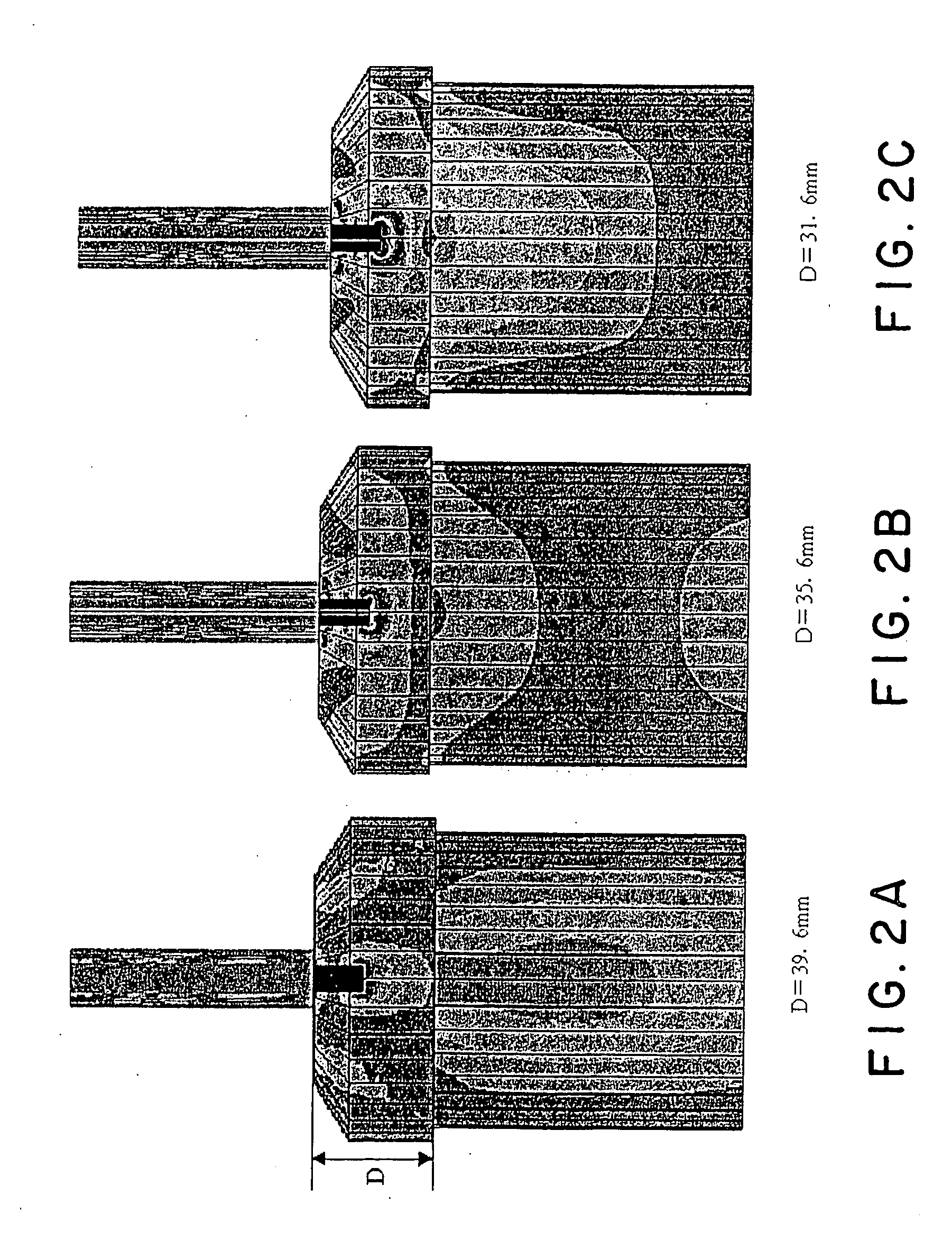

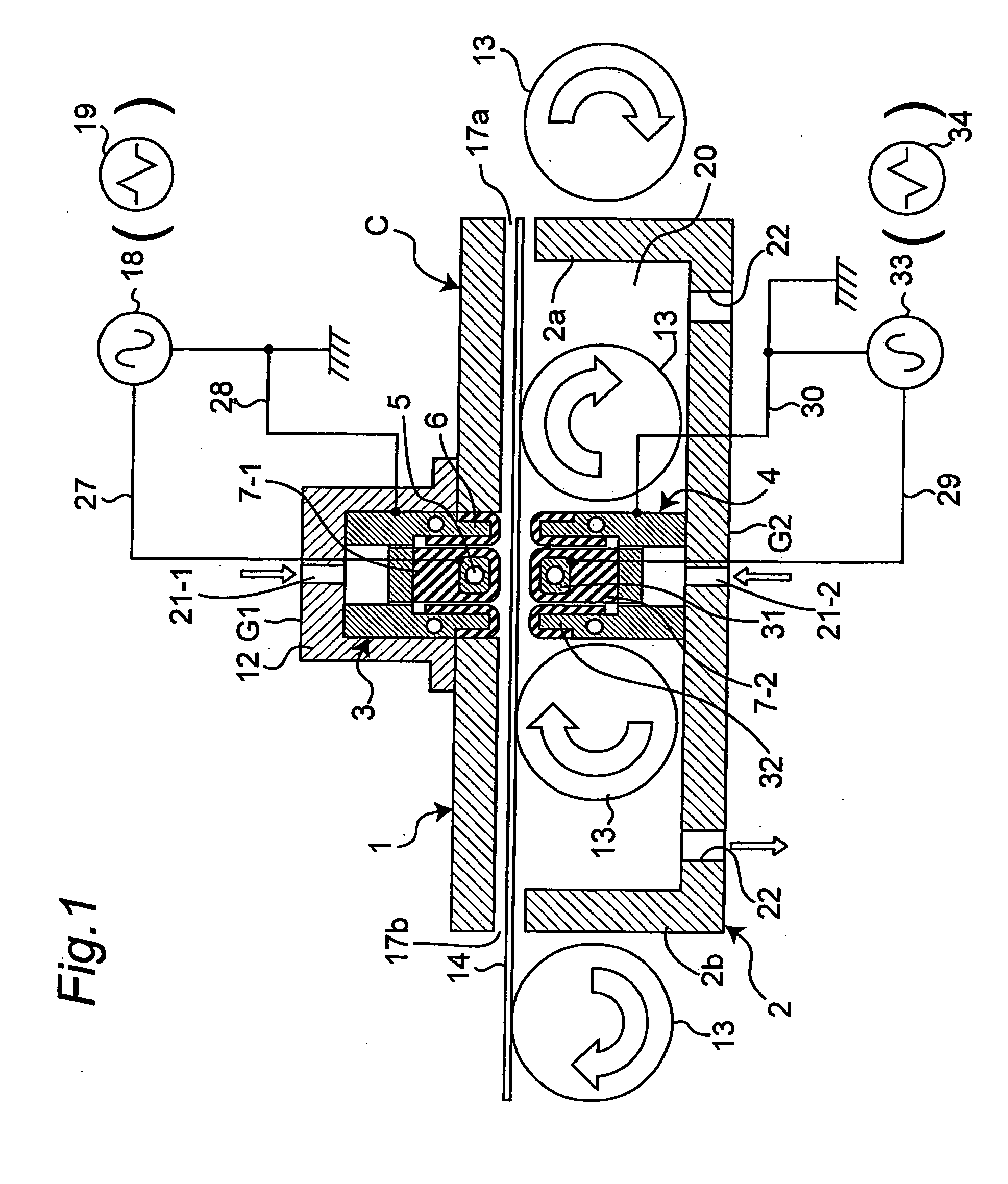

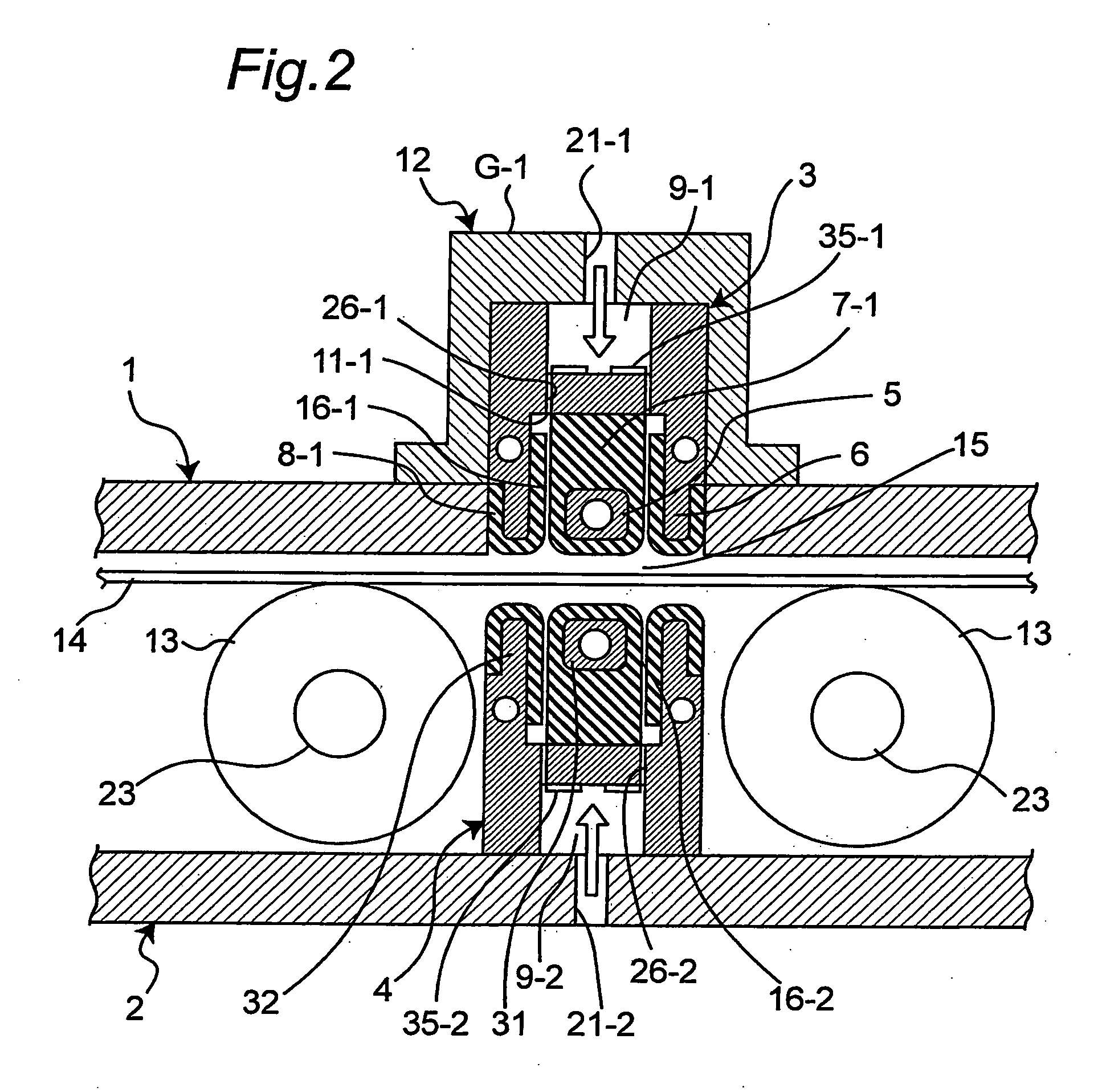

Plasma generating apparatus, plasma generating method and remote plasma processing apparatus

InactiveUS20060137613A1Improve plasma excitation efficiencySmall sizeElectric discharge tubesChemical vapor deposition coatingRemote plasmaCoaxial waveguides

Owner:TOKYO ELECTRON LTD

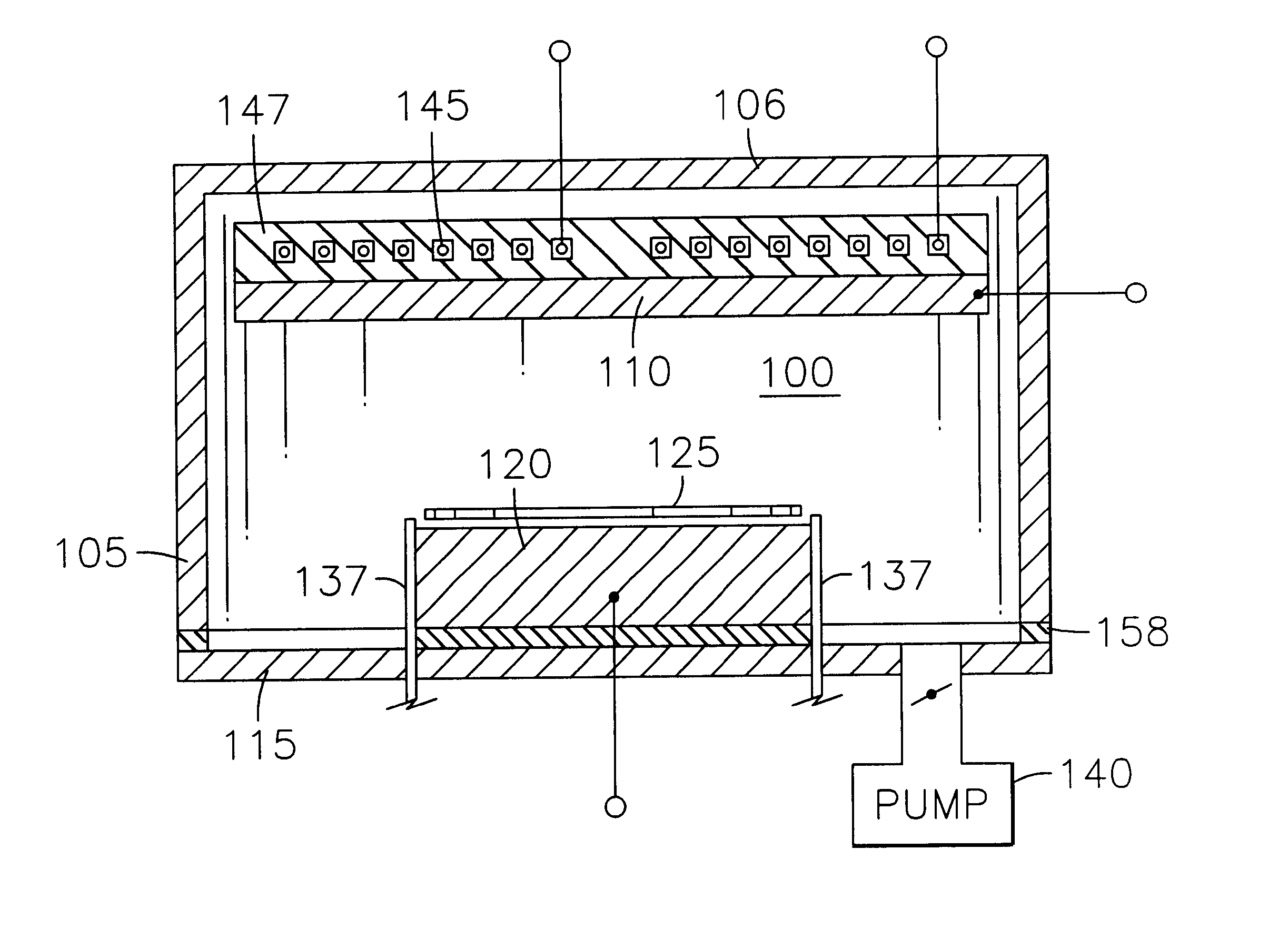

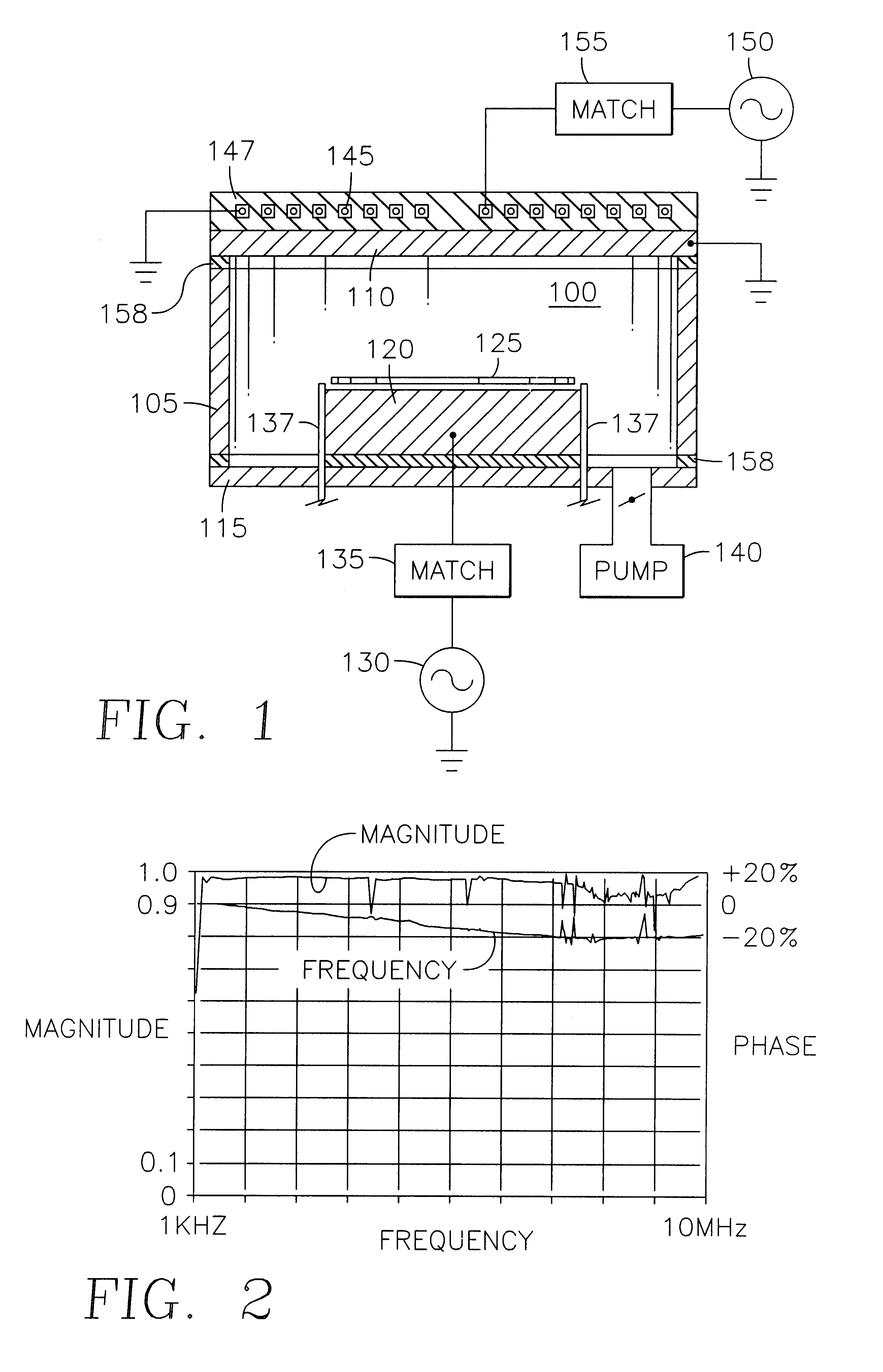

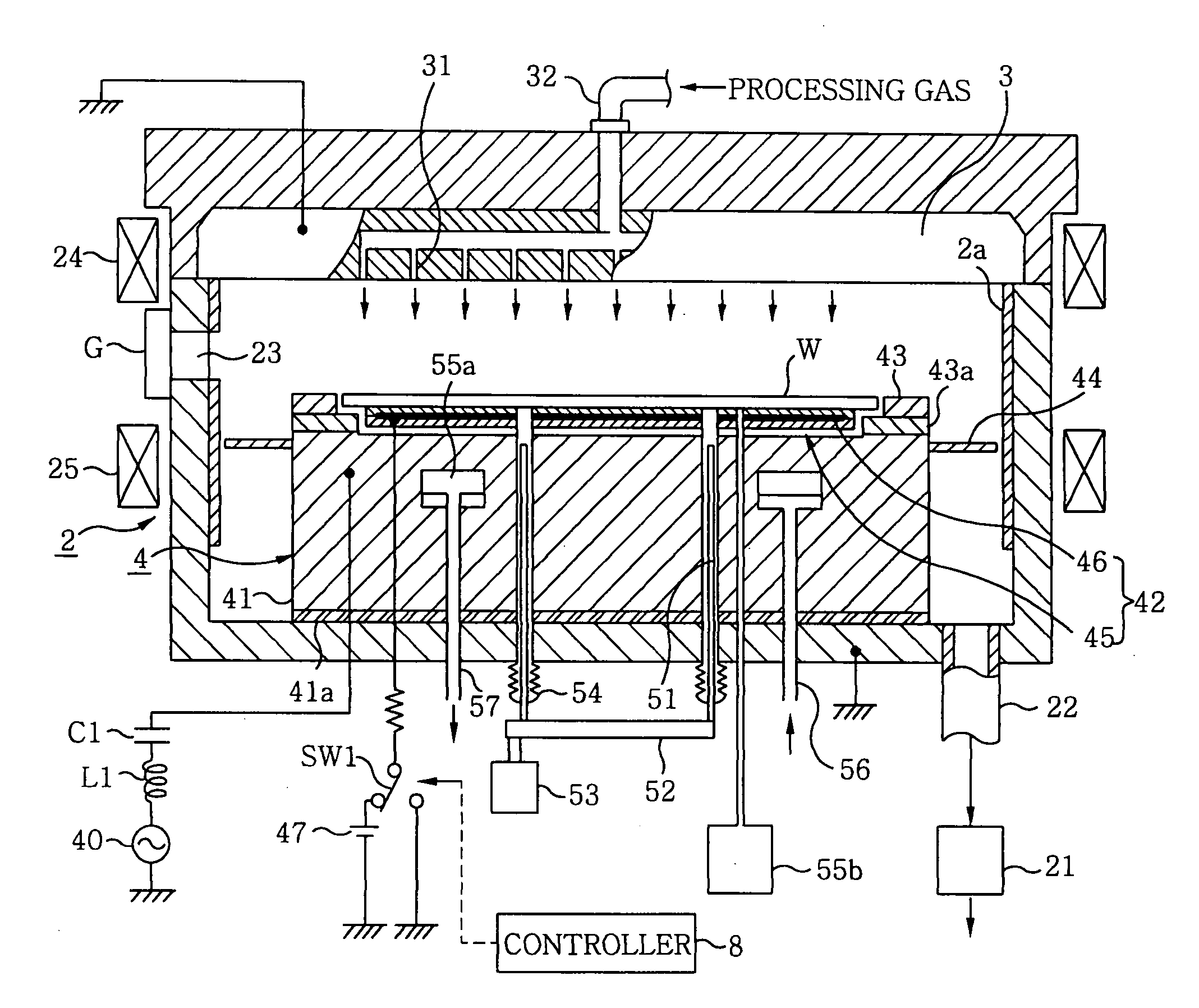

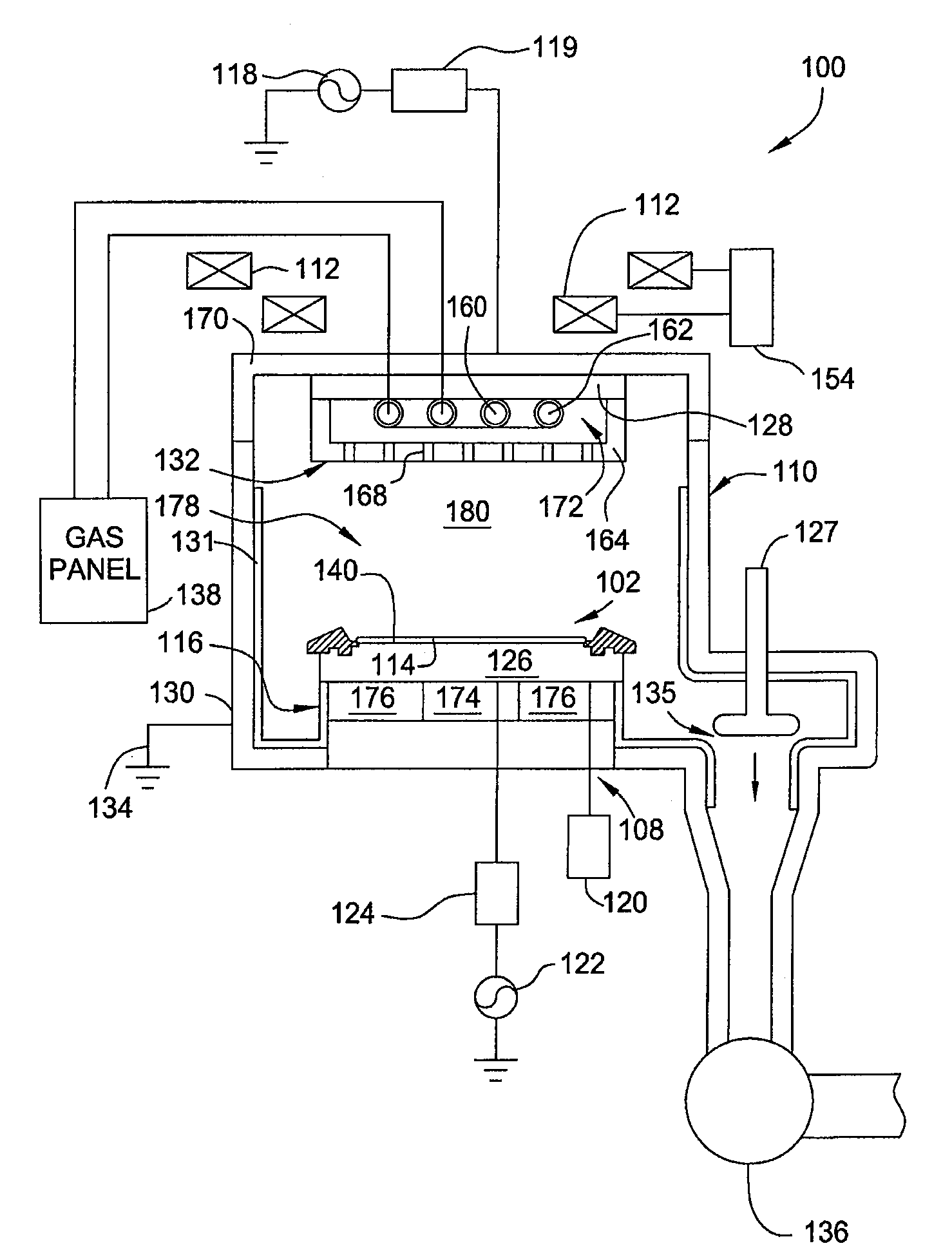

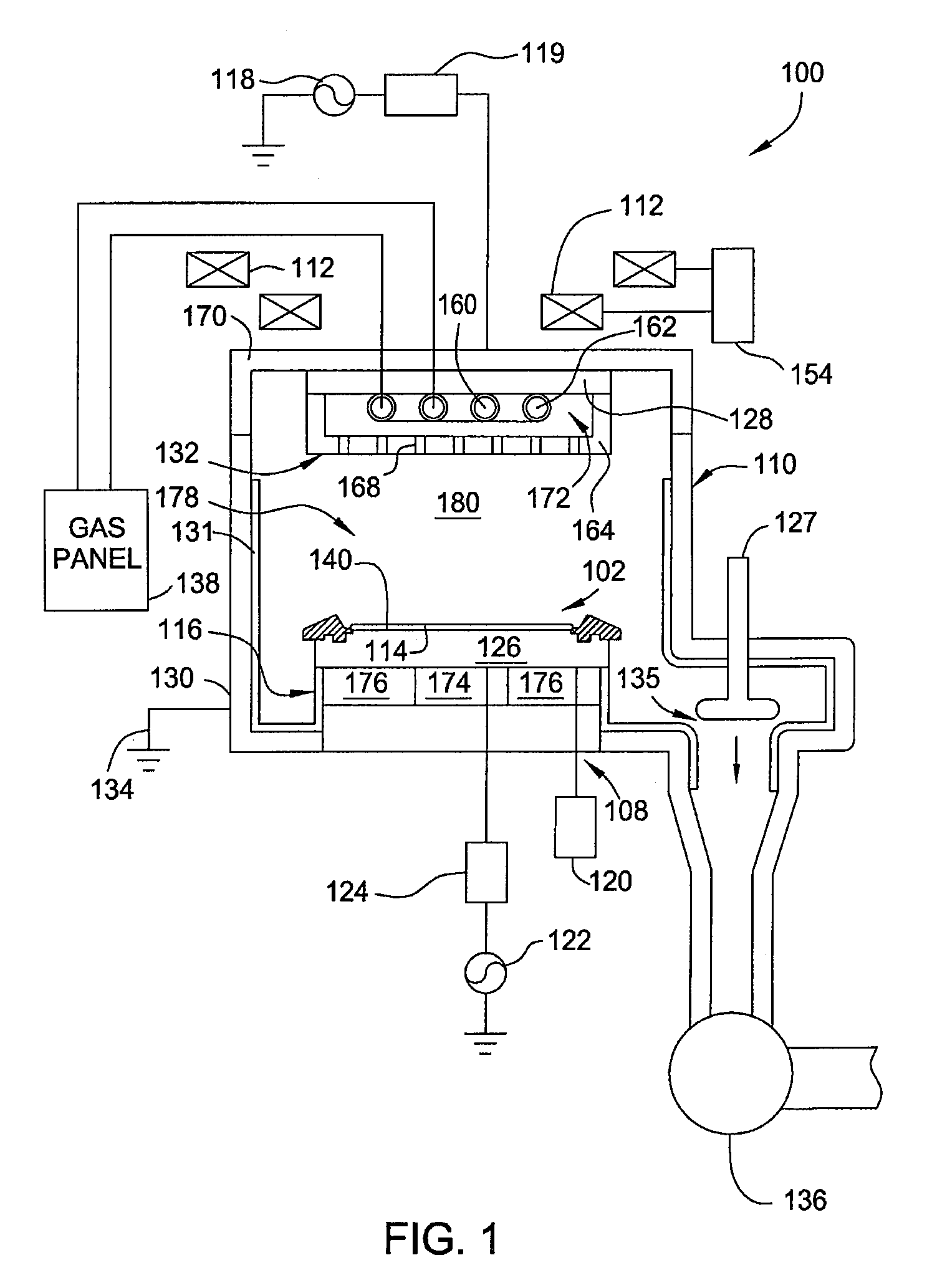

Plasma reactor having an inductive antenna coupling power through a parallel plate electrode

Owner:APPLIED MATERIALS INC

Copper or copper alloy target/copper alloy backing plate assembly

Owner:JX NIPPON MINING& METALS CORP

Power receptacle device with rotatable sockets

A power receptacle device has a stationary base and at least one rotating base. The at least one rotating base is mounted rotatably in the stationary base and has at least one socket. The at least one socket is covered when the rotating base is rotated to a position to prevent users from touching the at least one socket and getting electric shock. Further, because the at least one rotating base is rotatable, the at least one socket on the at least one rotating base is exposed and accessible when the at least one rotating base is turned out from the at least one rotating base.

Owner:RITE TECH INDAL

Internal member of a plasma processing vessel

ActiveUS7780786B2Prevent peelingLiquid surface applicatorsMolten spray coatingThermal sprayingMetallurgy

Owner:TOKYO ELECTRON LTD

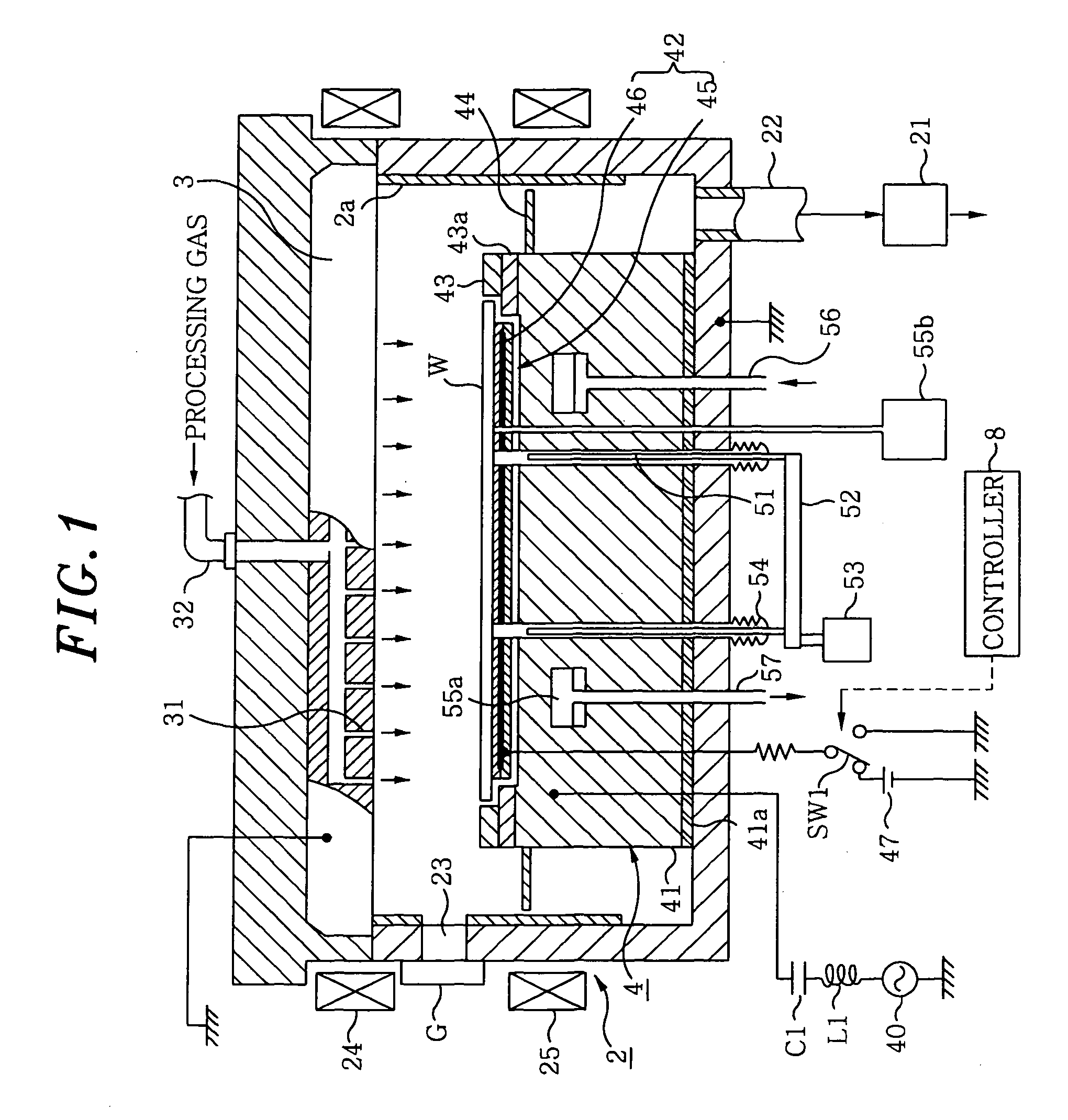

Plasma processing apparatus

InactiveUS20050217798A1Plasma discharge can be stabilizedLow running costElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringMaterials science

Owner:SHARP KK

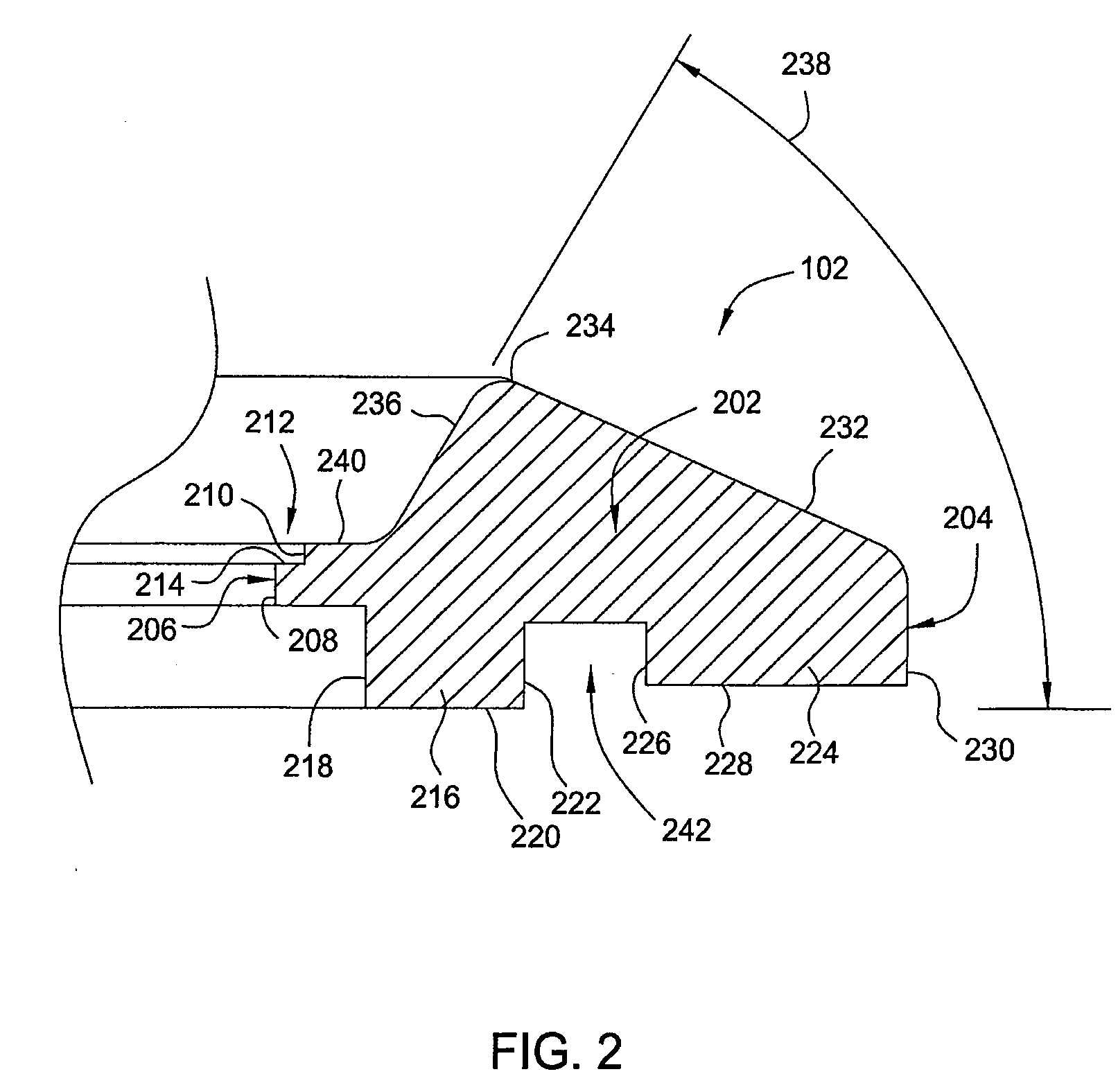

Low sloped edge ring for plasma processing chamber

ActiveUS20100059181A1Electric discharge tubesSemiconductor/solid-state device manufacturingEngineeringYttrium

Owner:APPLIED MATERIALS INC

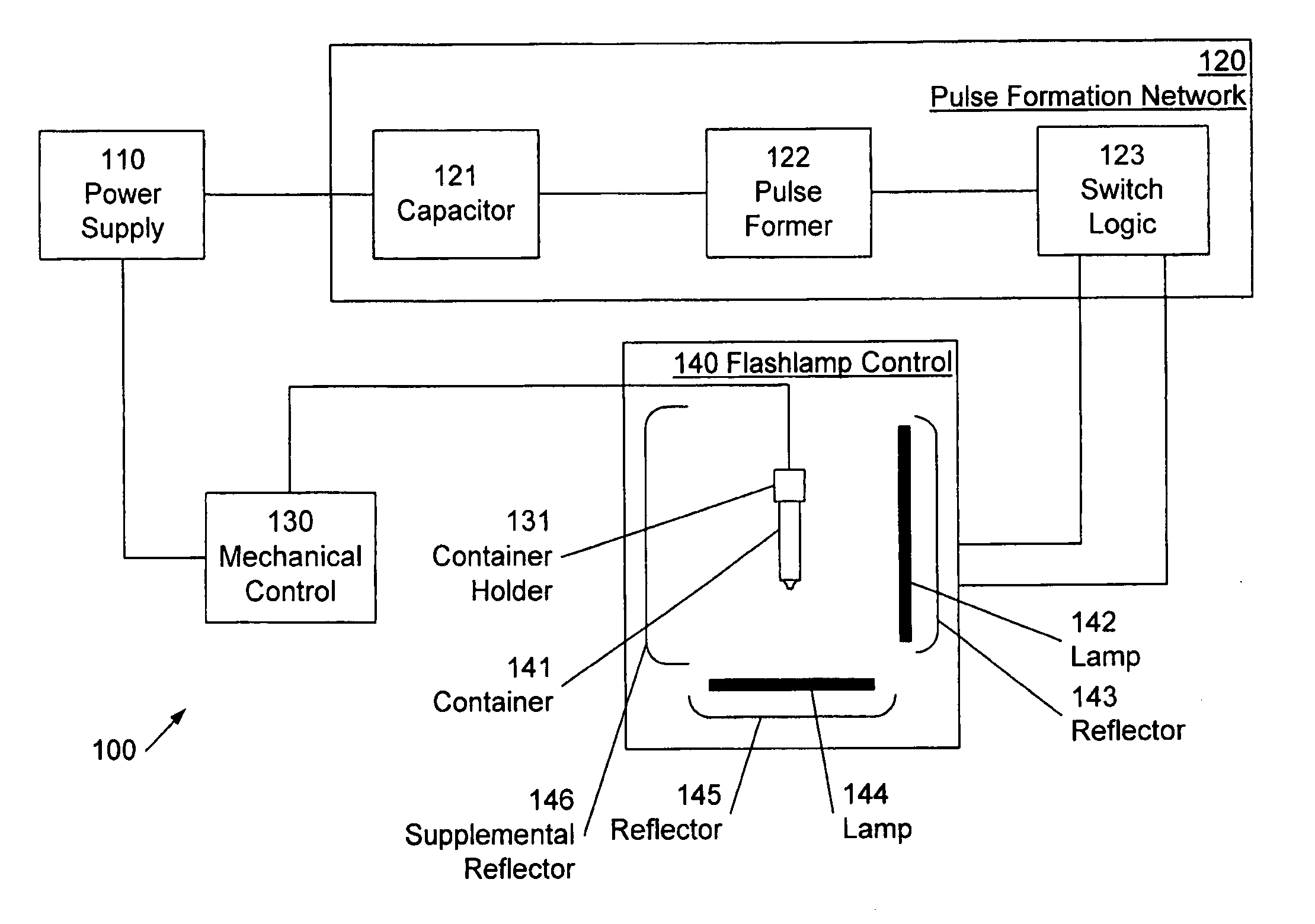

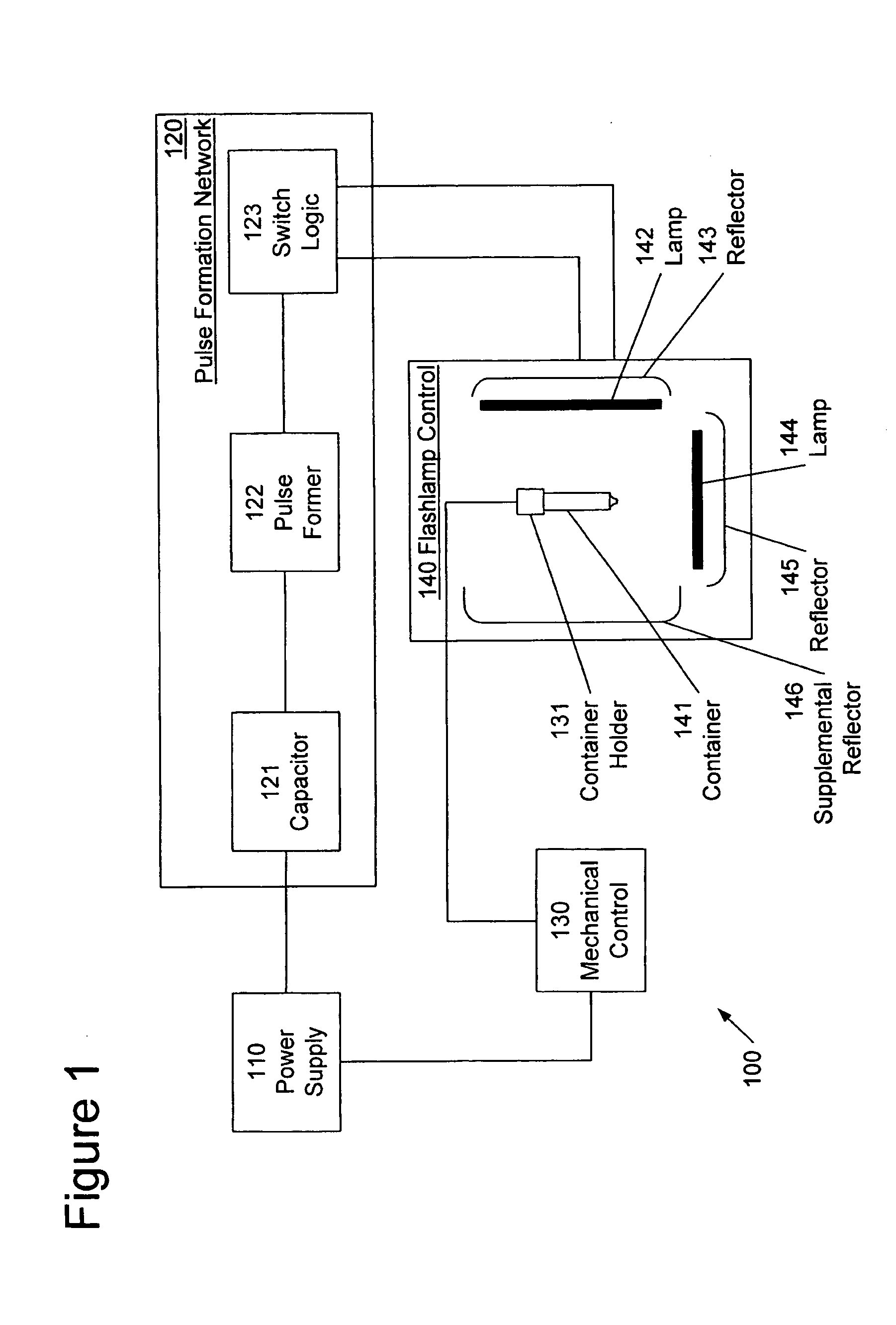

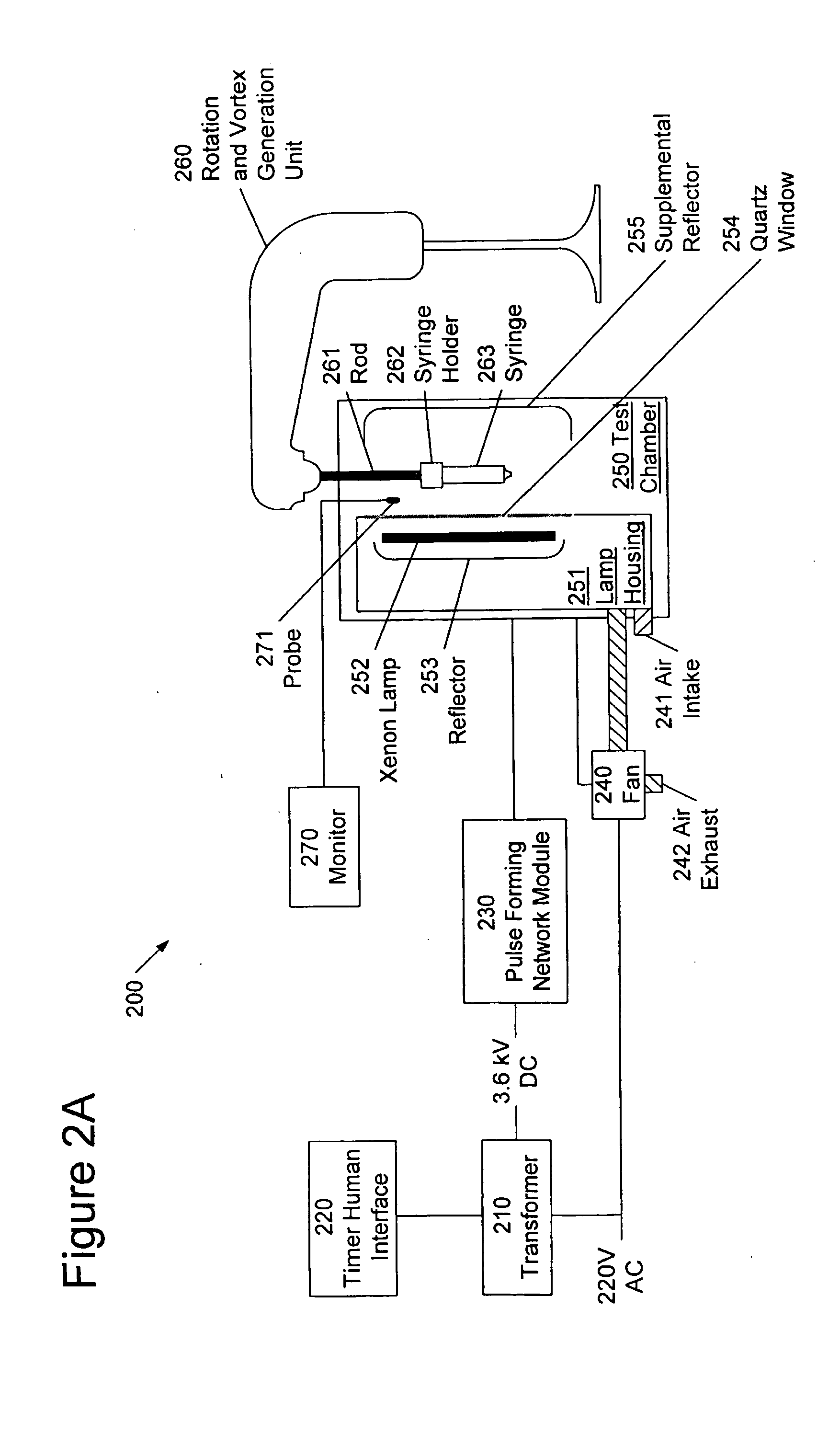

Pulsed high-intensity light sterilization

InactiveUS20060228251A1Material analysis using wave/particle radiationElectric discharge tubesBroad spectrumHigh intensity light

Owner:JAGAJI HLDG

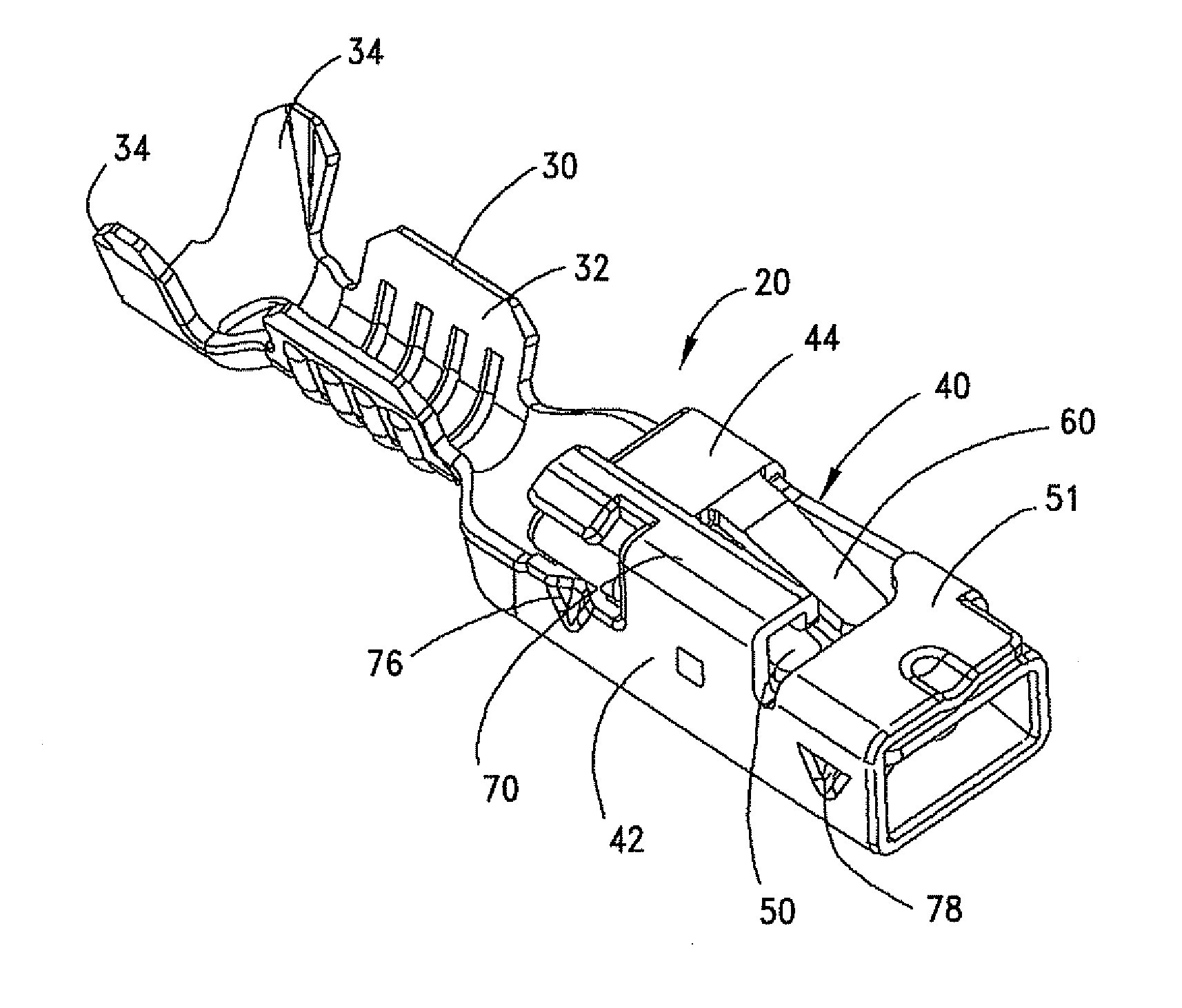

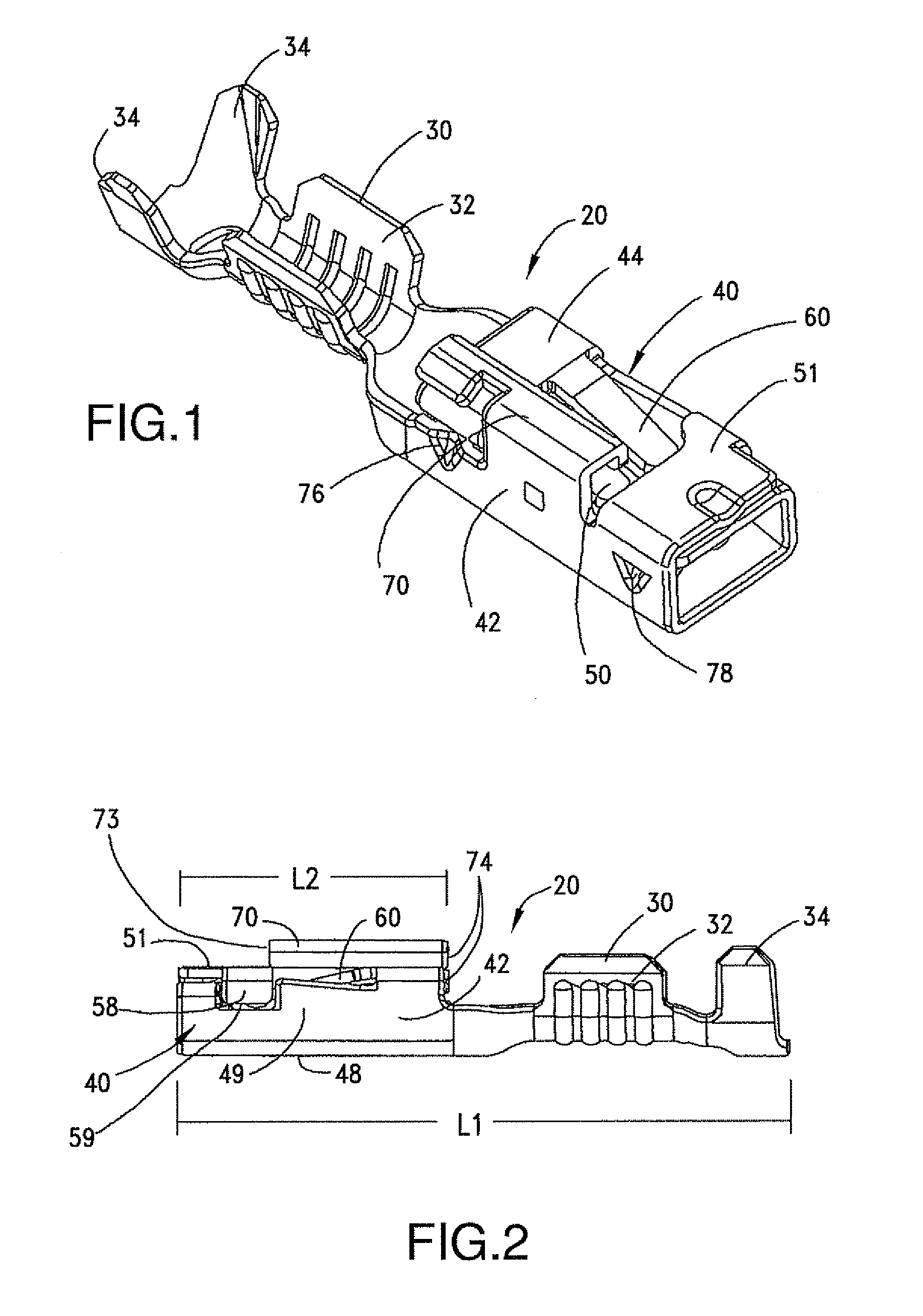

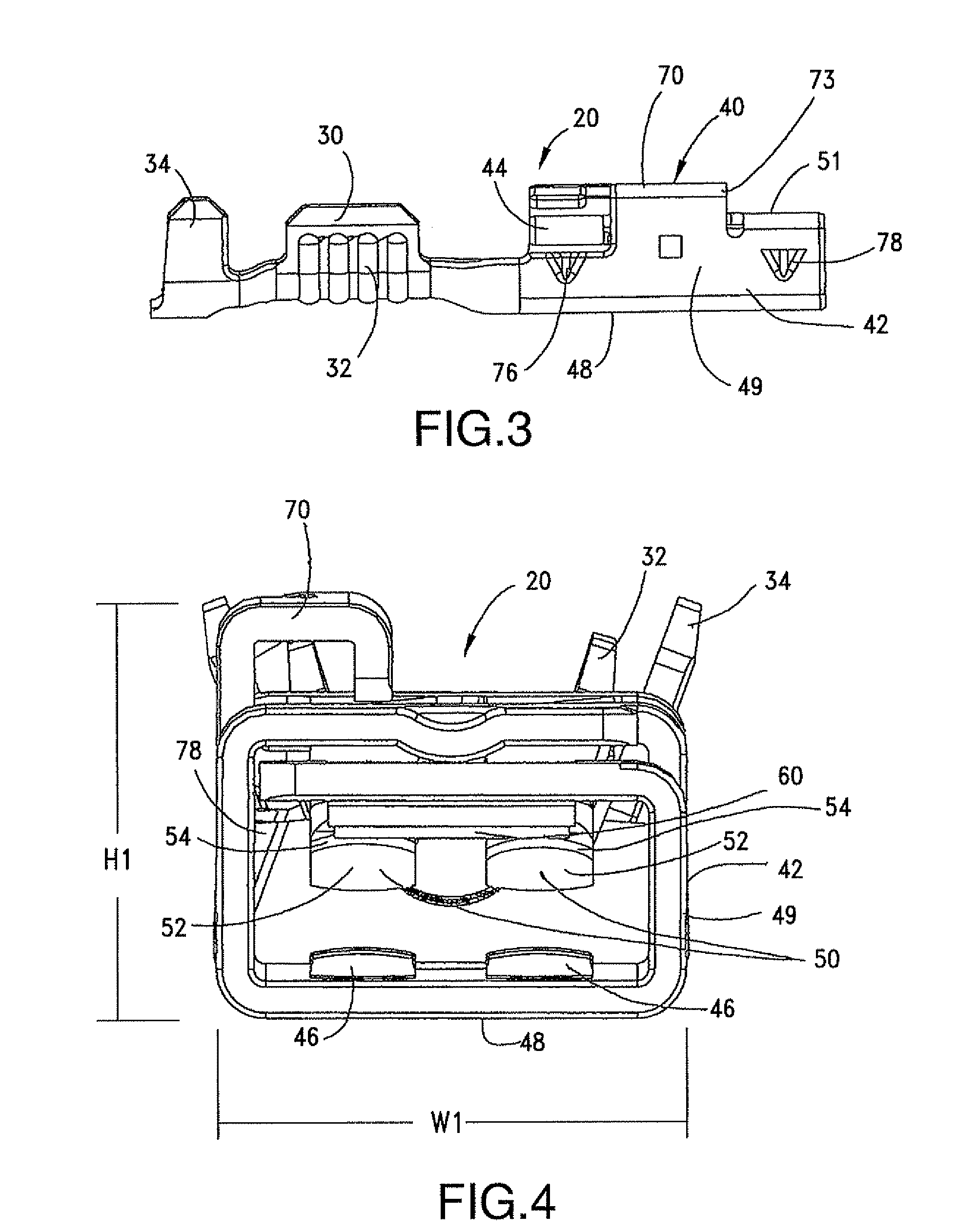

Miniature receptacle terminals

ActiveUS20120244756A1Good manufacturing controlMinimizes contact force variationElectric discharge tubesCoupling contact membersPRIMARY CONTACTEngineering

Owner:MOLEX INC

Socket

InactiveUS6848928B2Easy to installEasy to operateEngagement/disengagement of coupling partsElectric discharge tubesEngineeringCompression member

Owner:LTI HLDG INC

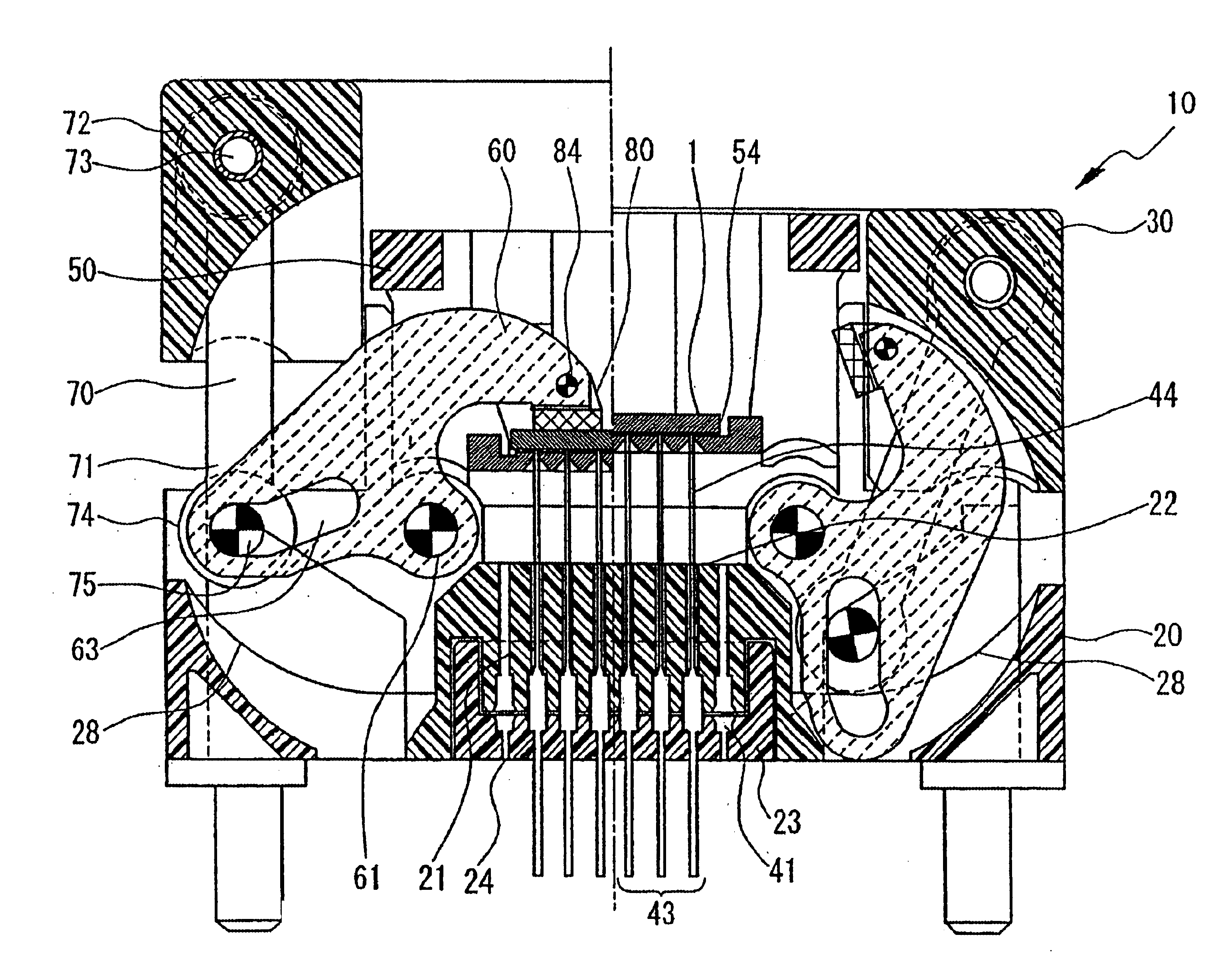

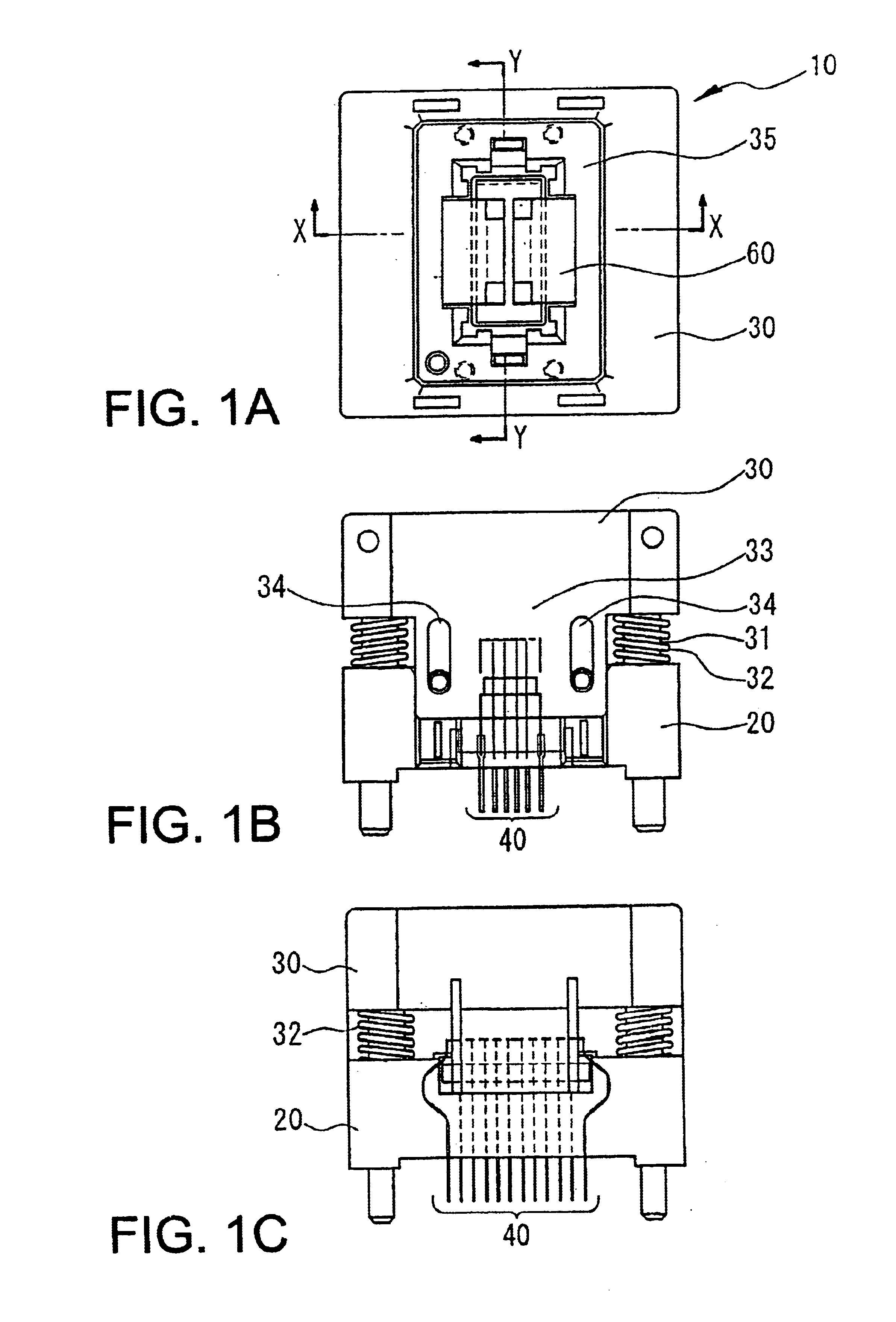

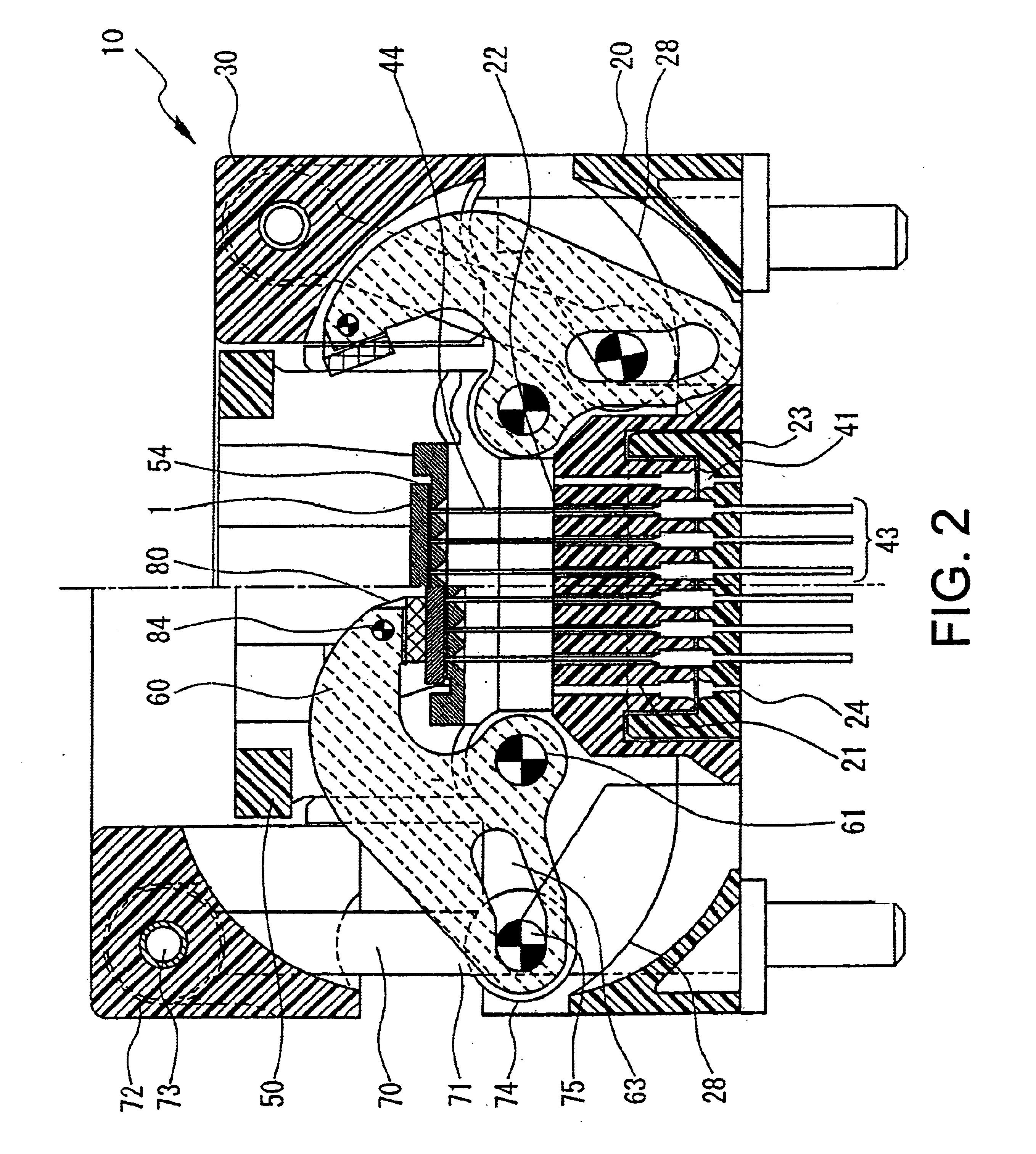

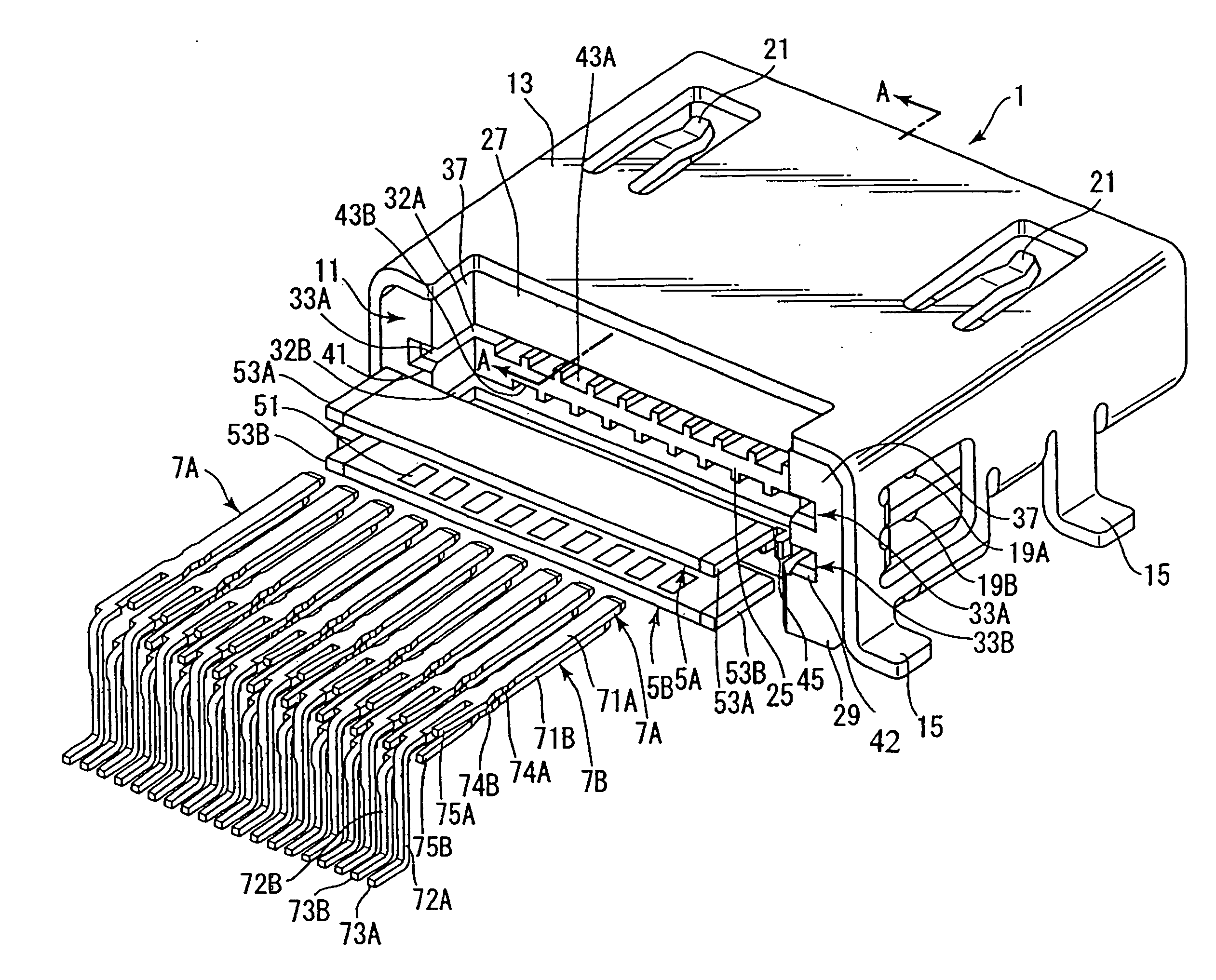

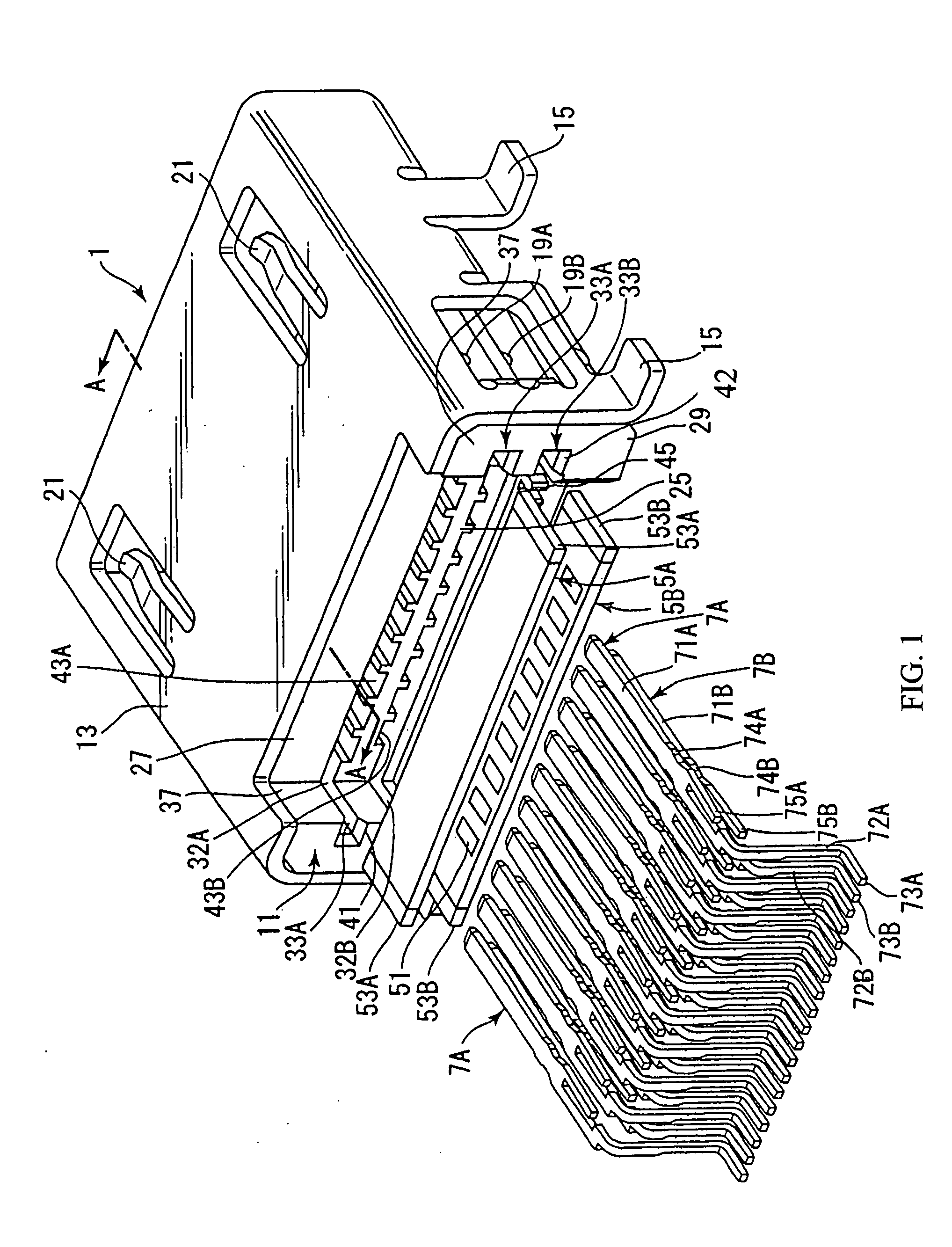

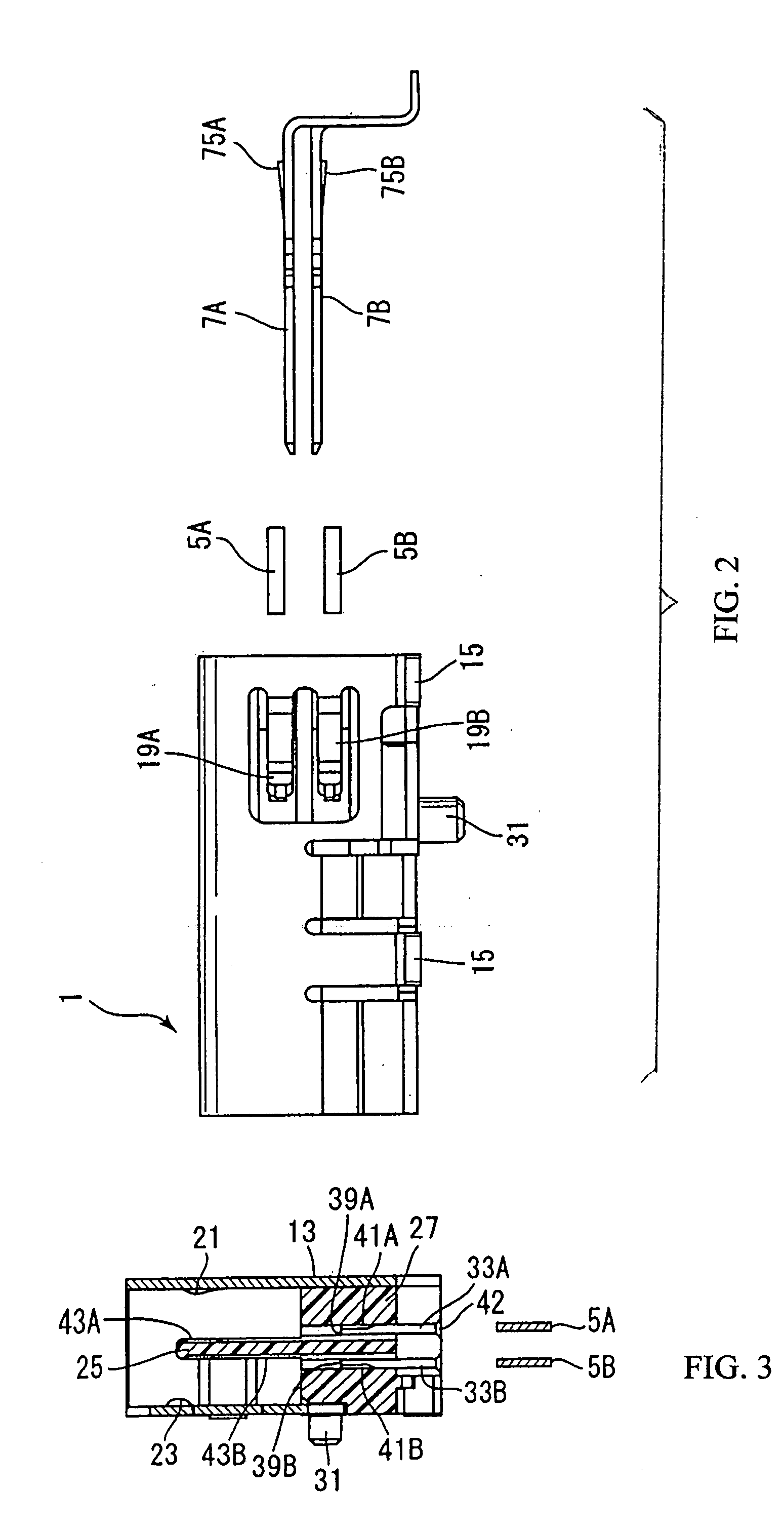

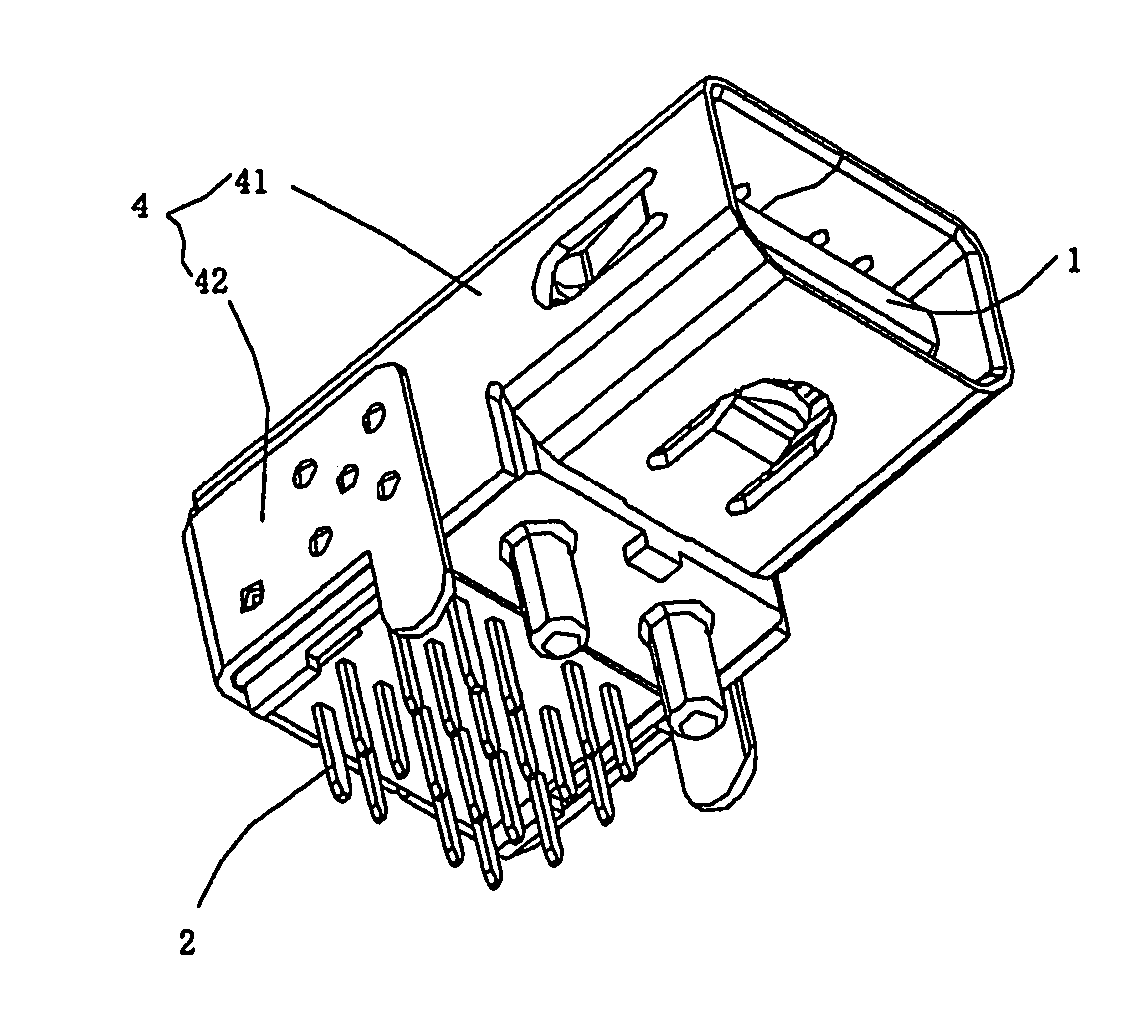

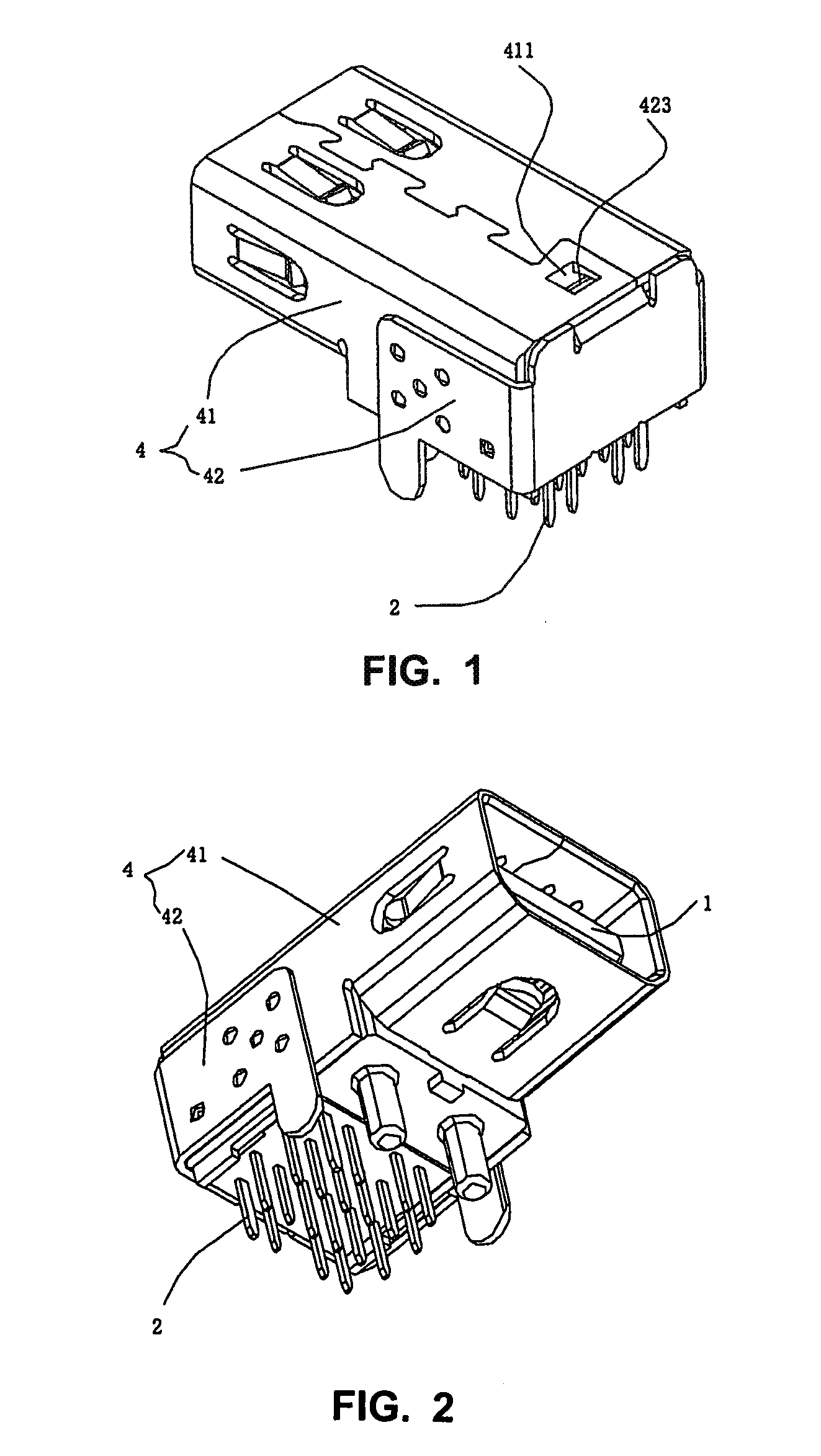

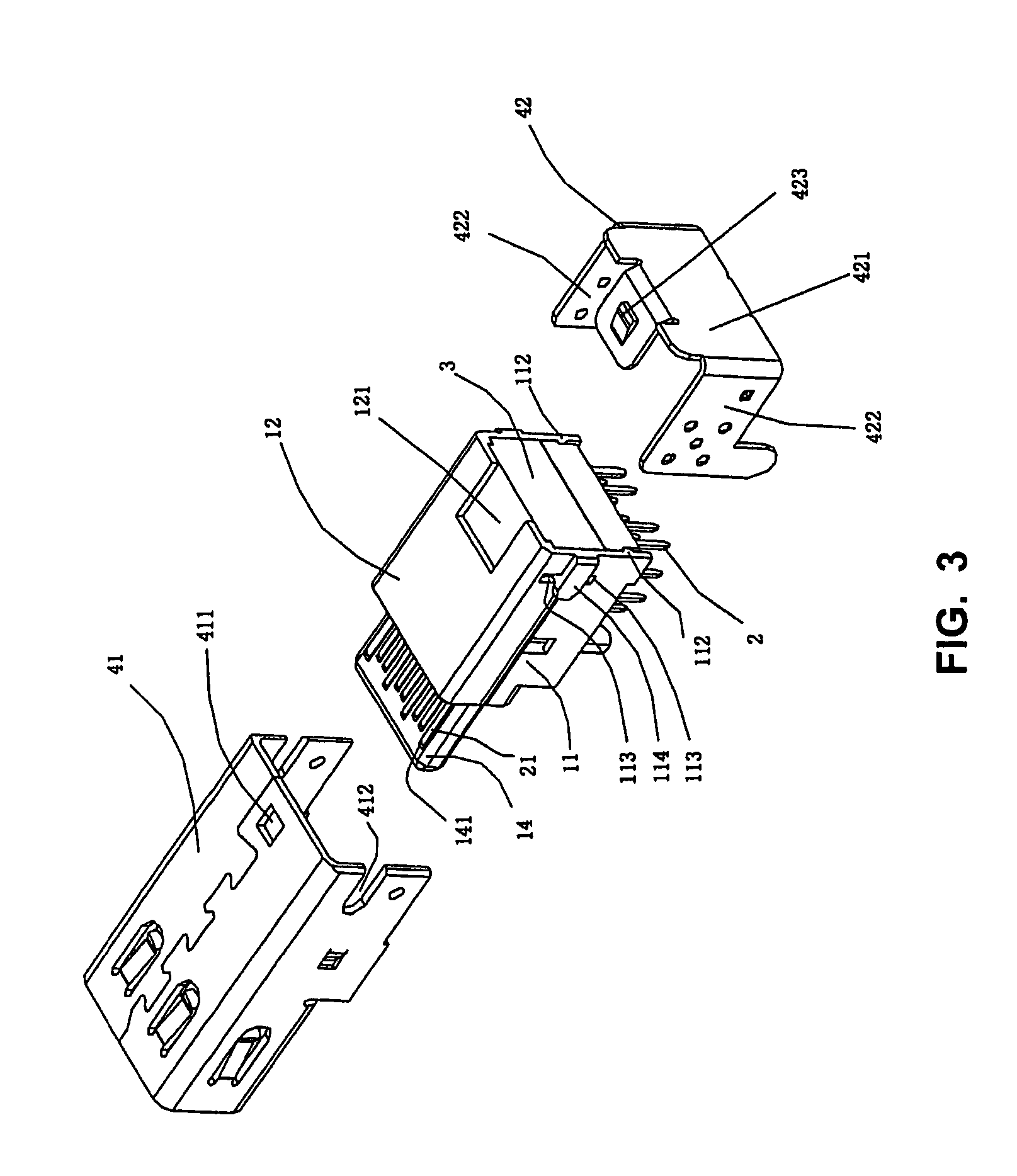

Connector with built-in substrate and its assembling method

InactiveUS20060040562A1Easy to assembleLess numberLine/current collector detailsElectric discharge tubesEngineeringElectrical and Electronics engineering

Owner:HIROSE ELECTRIC GROUP

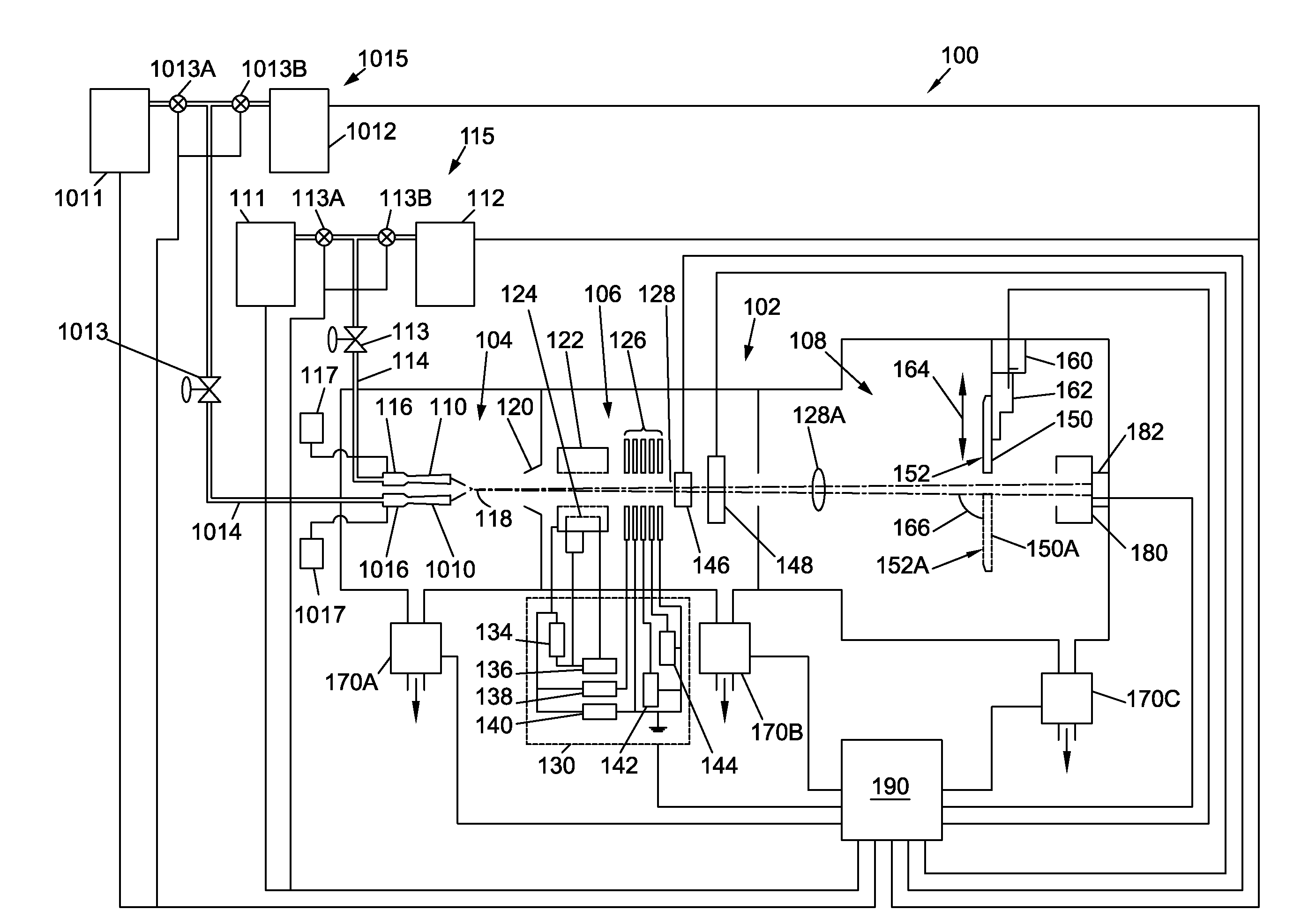

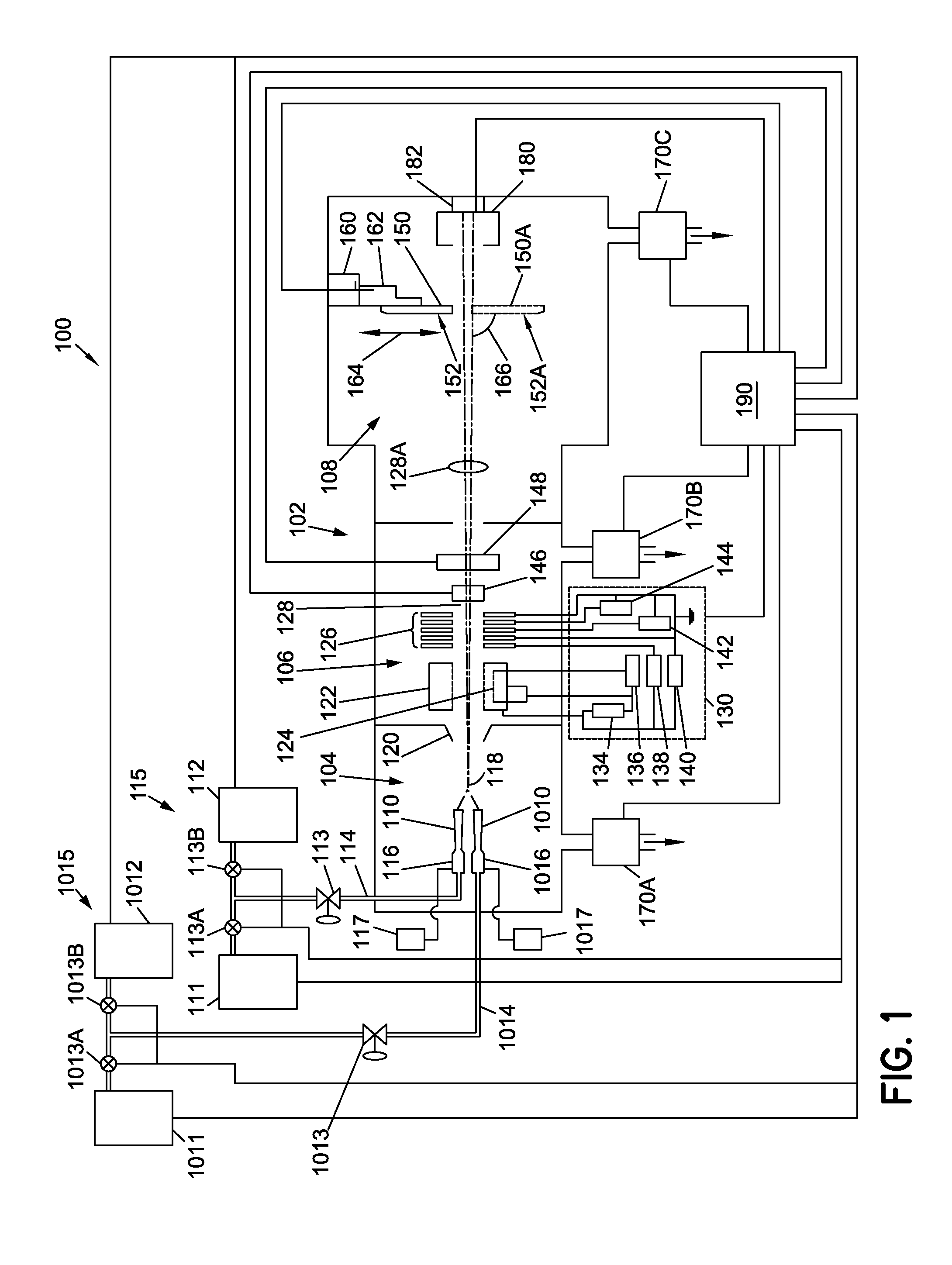

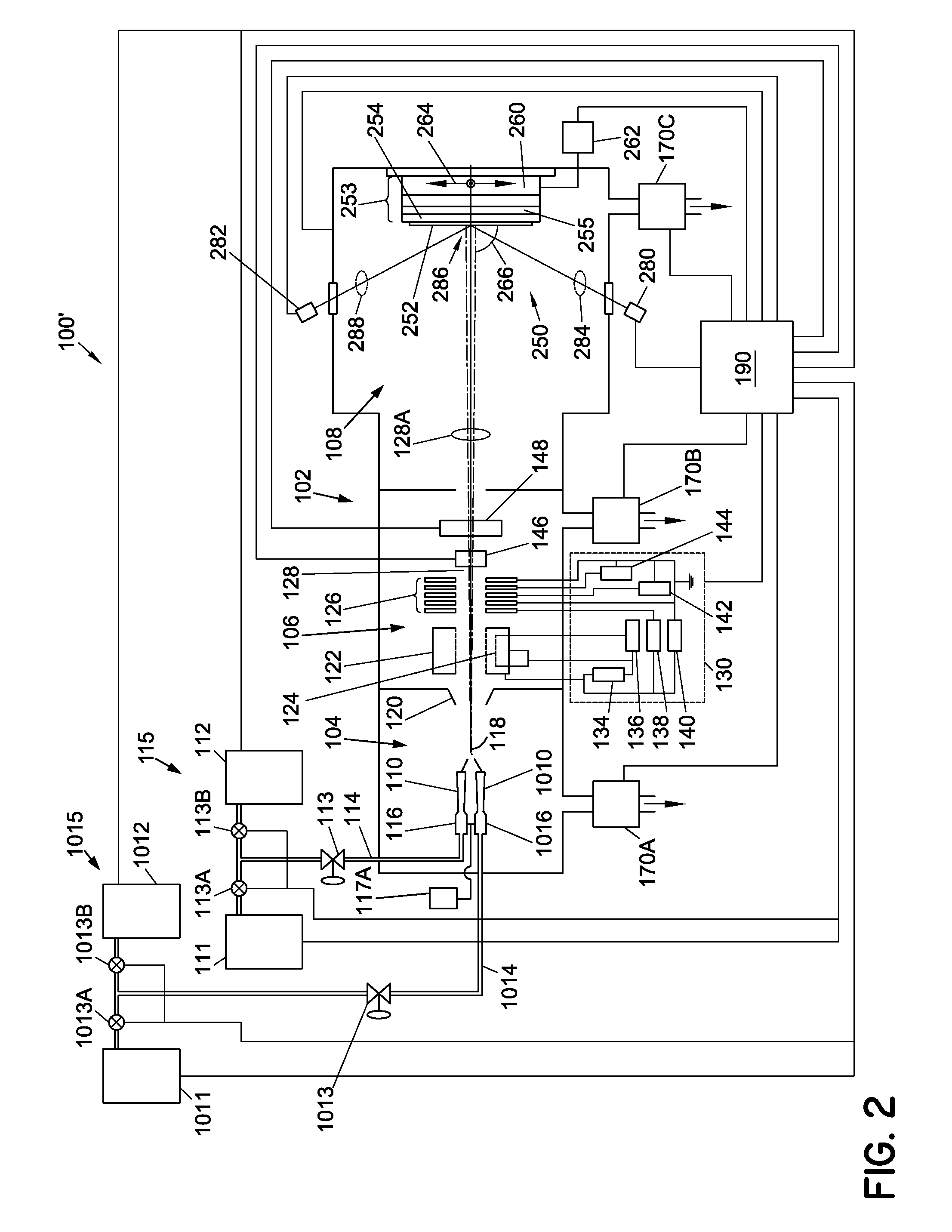

Gas cluster ion beam system with cleaning apparatus

ActiveUS20110272593A1Easy to cleanElectric discharge tubesSemiconductor/solid-state device manufacturingGas cluster ion beamSpray nozzle

Owner:TEL EPION

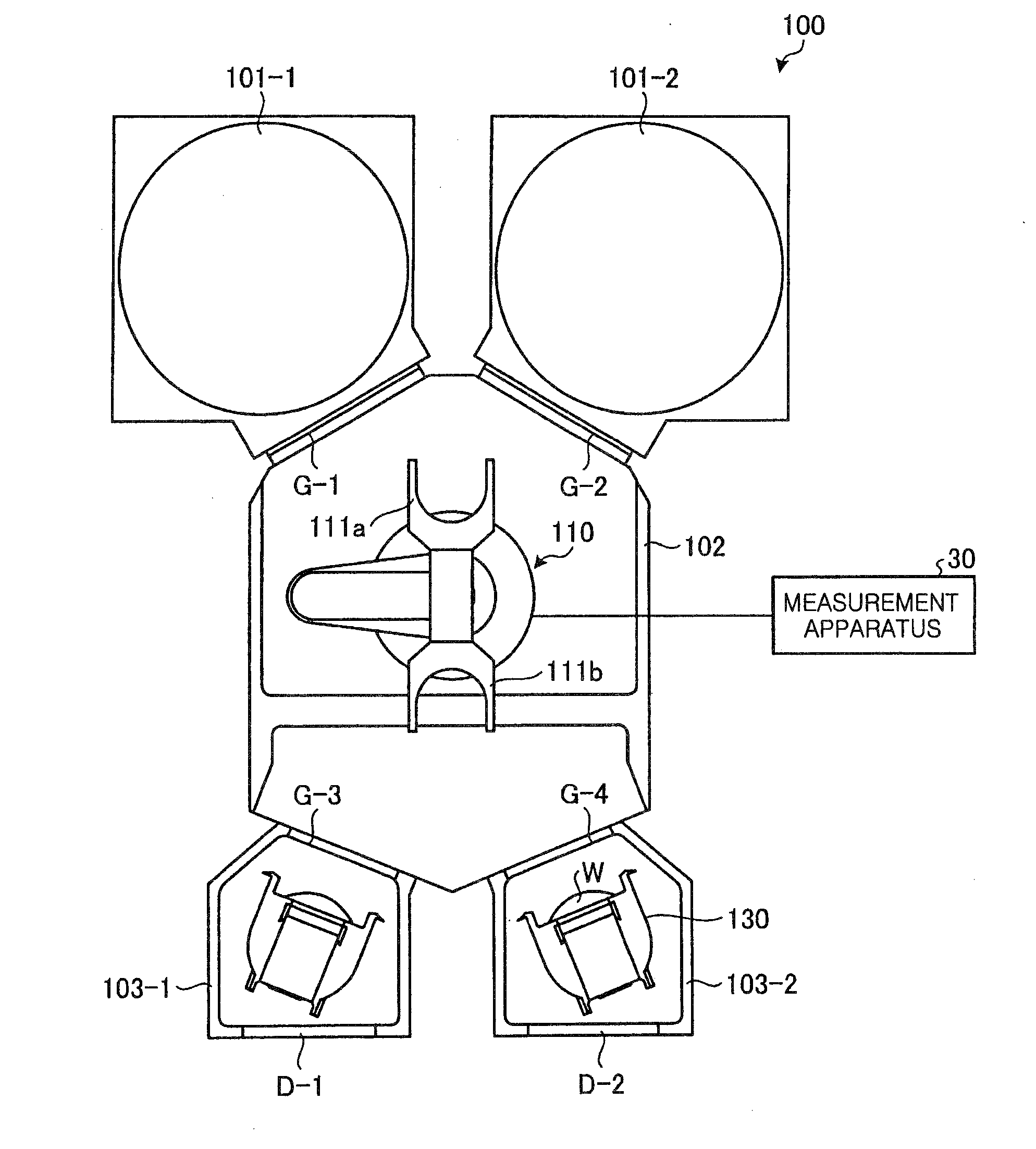

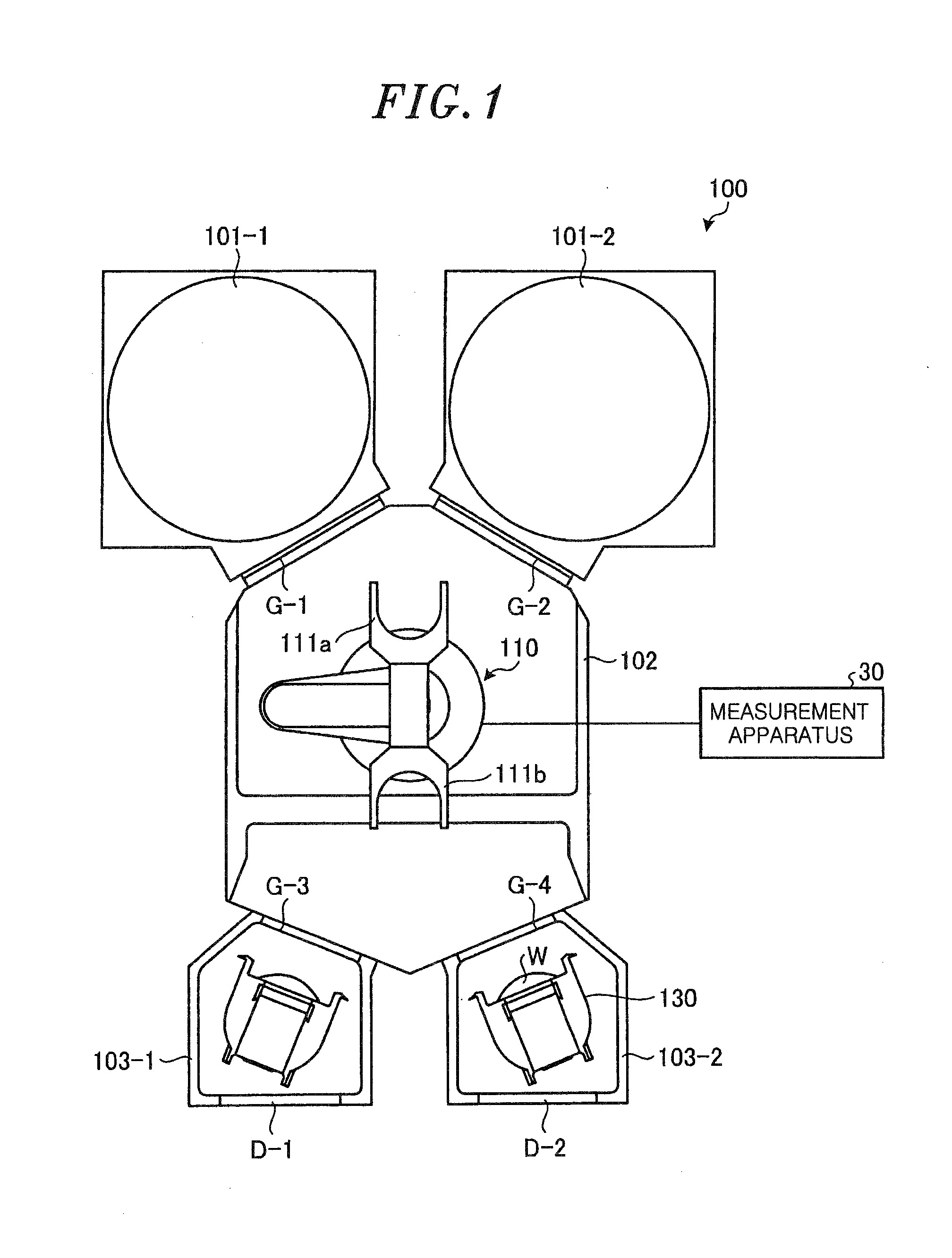

Measurement system and measurement method

ActiveUS20160141154A1Electric discharge tubesResistance/reactance/impedenceDistance sensorsEngineering

Owner:TOKYO ELECTRON LTD

CCFL device with a solid heat-dissipation means

InactiveUS20060273720A1Cost-effective assemblyElectric discharge tubesLow-pressure discharge lampsElectrical ballastEngineering

A CCFL device using a heat-conductive compound that may also be light-transmitting to embed both its heat generating components, i.e., the electronic driver and the CCFL filament, so that there is no air trapped between these two heat sources and the outer surface of the device. The heat-conductive compound also forms its own surfaces that are exposed directly to air, so that the heat generated by the CCFL filament and the electronic driver is dissipated swiftly into the atmosphere. One embodiment of the present invention attaches the lamp filament support member to the integral ballast assembly, so it is no longer connected to the light-transmitting container in order to support the CCFL filament, thereby simplifies the manufacturing process significantly.

Owner:KWONG HENRY YUK HO

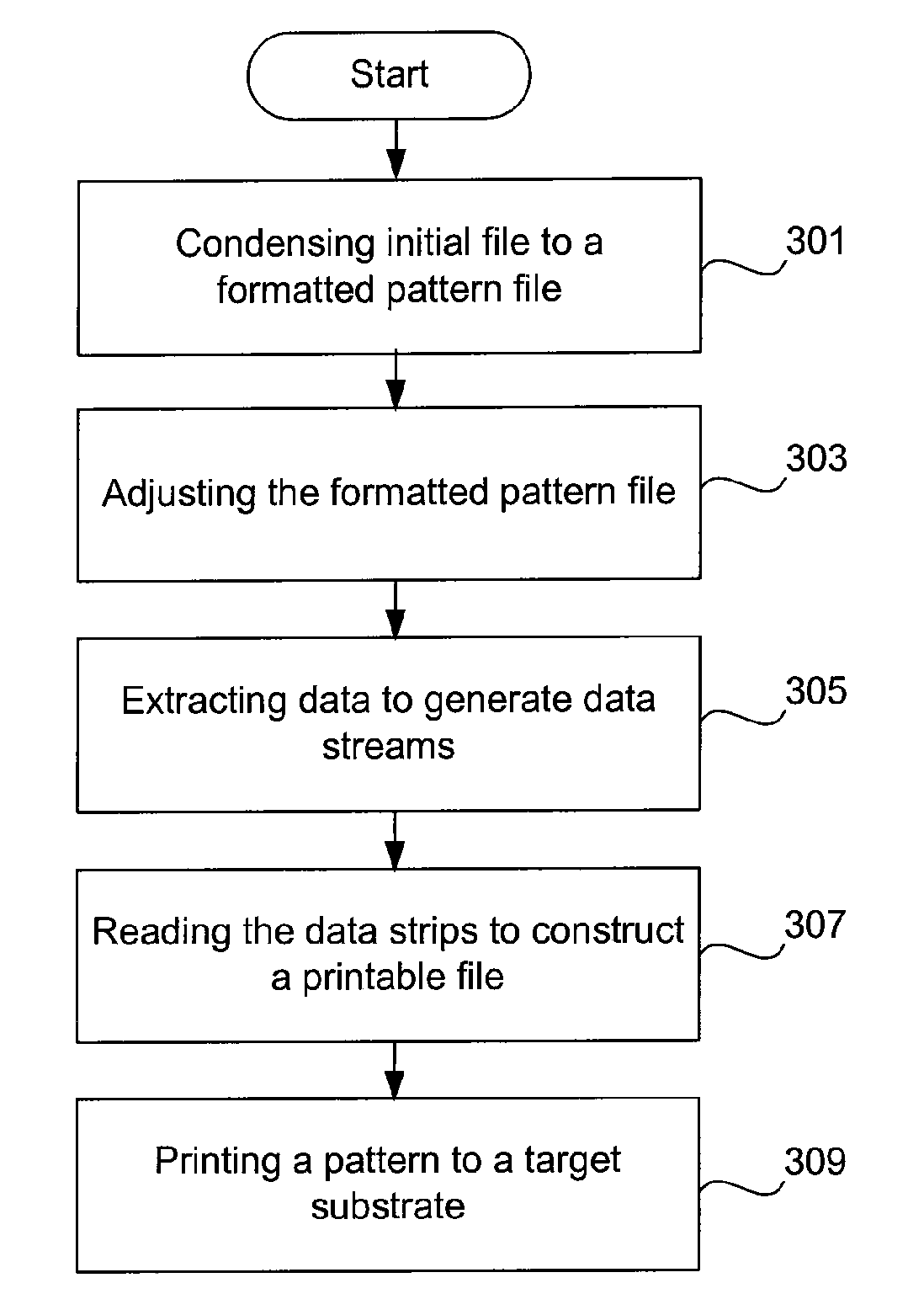

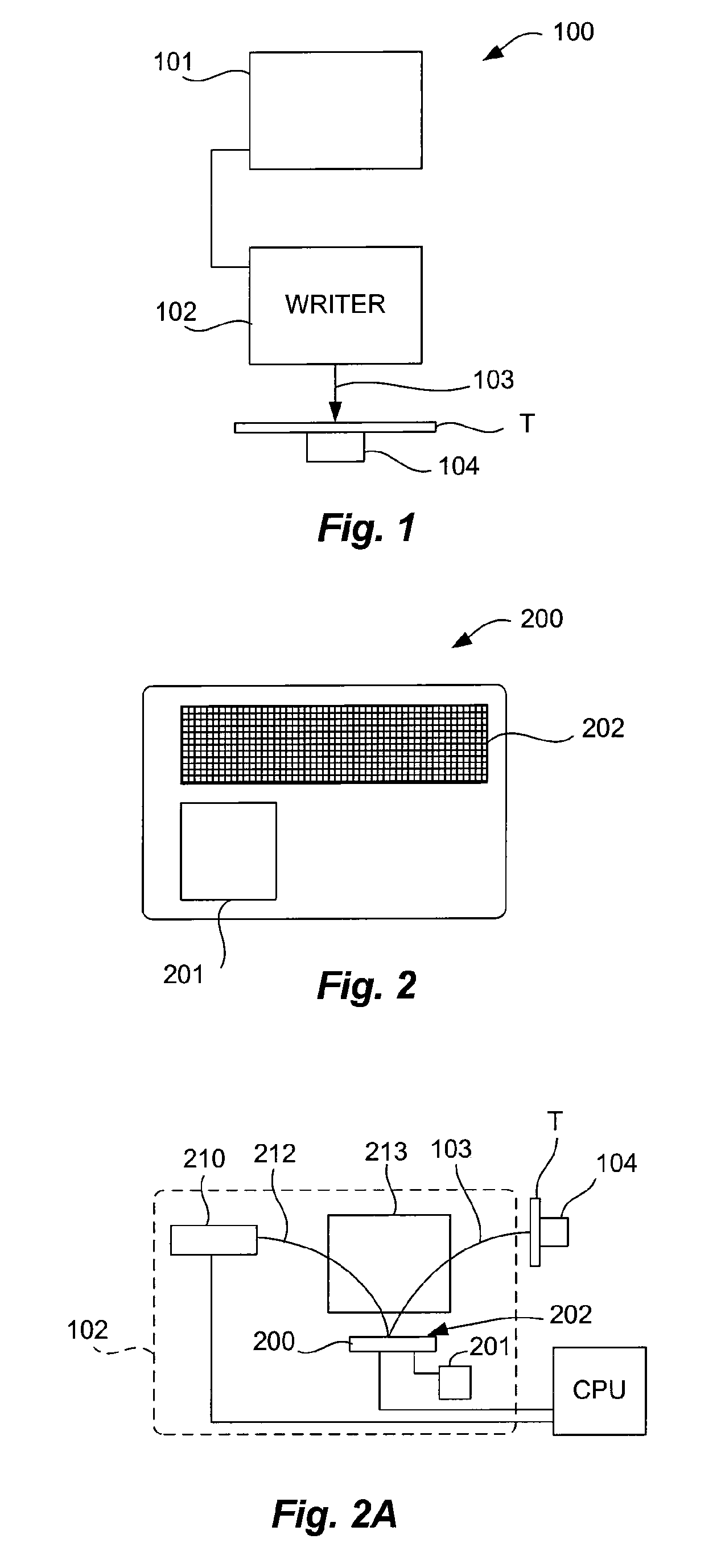

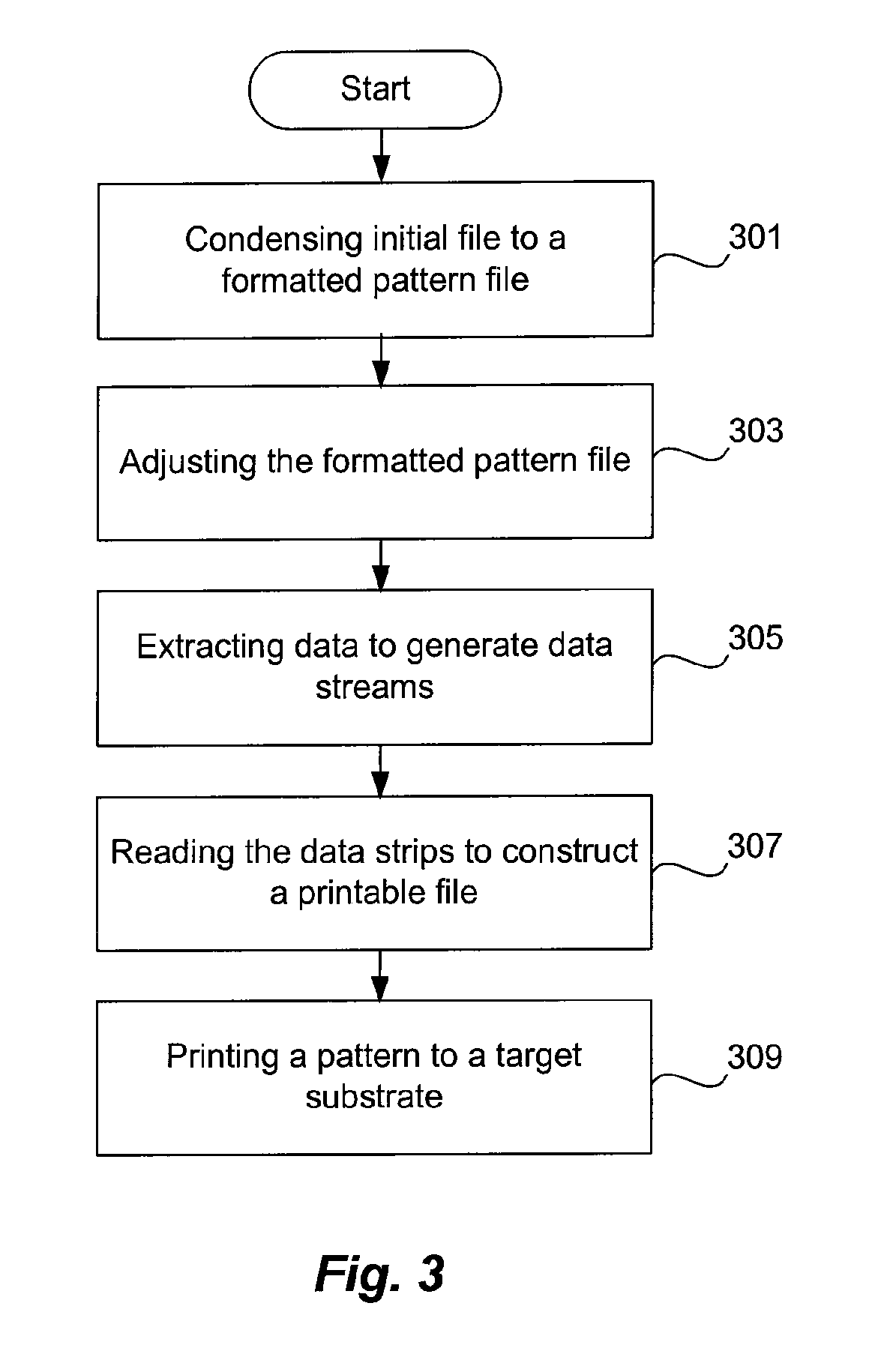

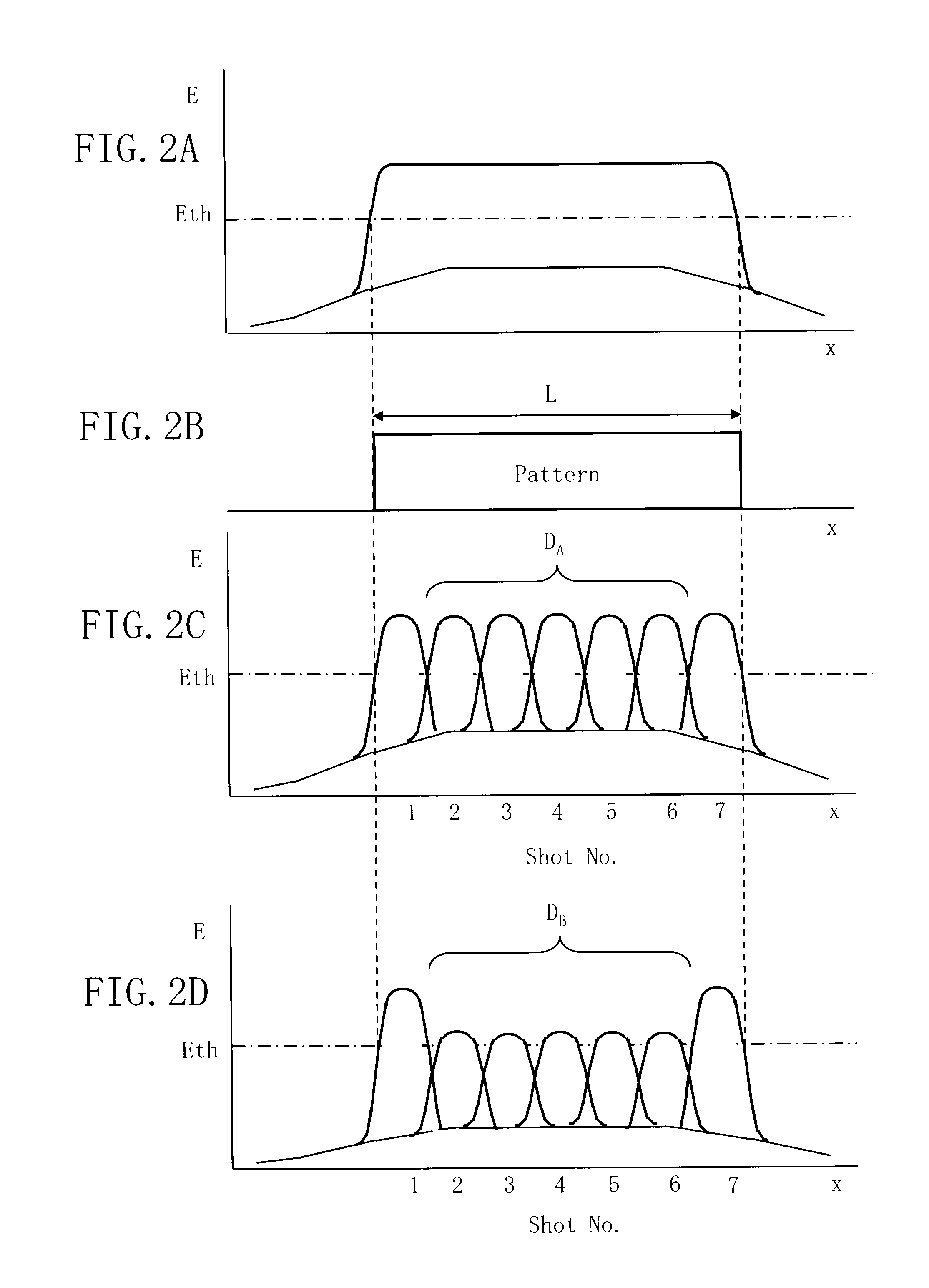

Method of data encoding, compression, and transmission enabling maskless lithography

InactiveUS20080145767A1Electric discharge tubesRadiation applicationsPattern recognitionLithographic artist

Owner:KLA TENCOR TECH CORP

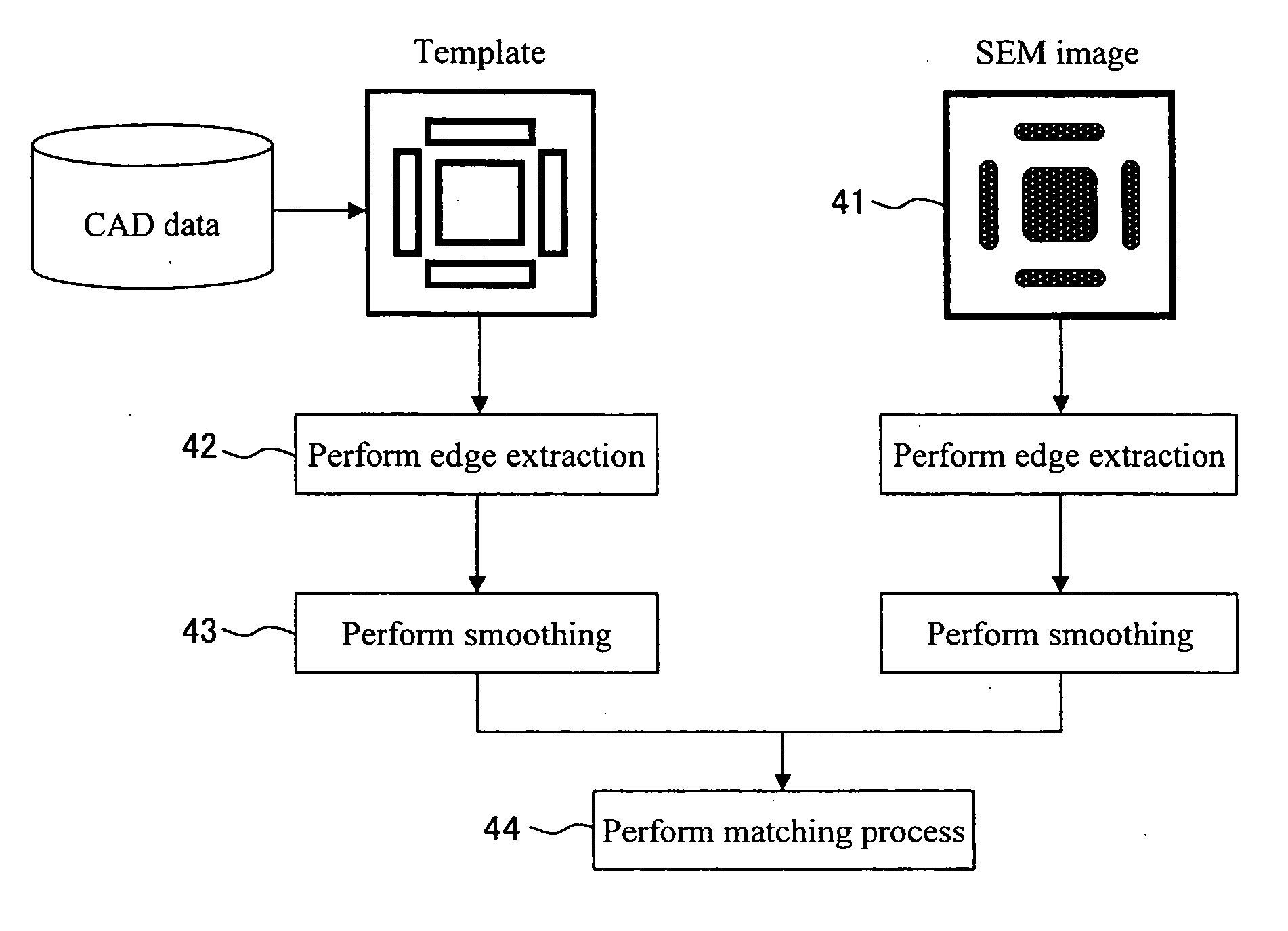

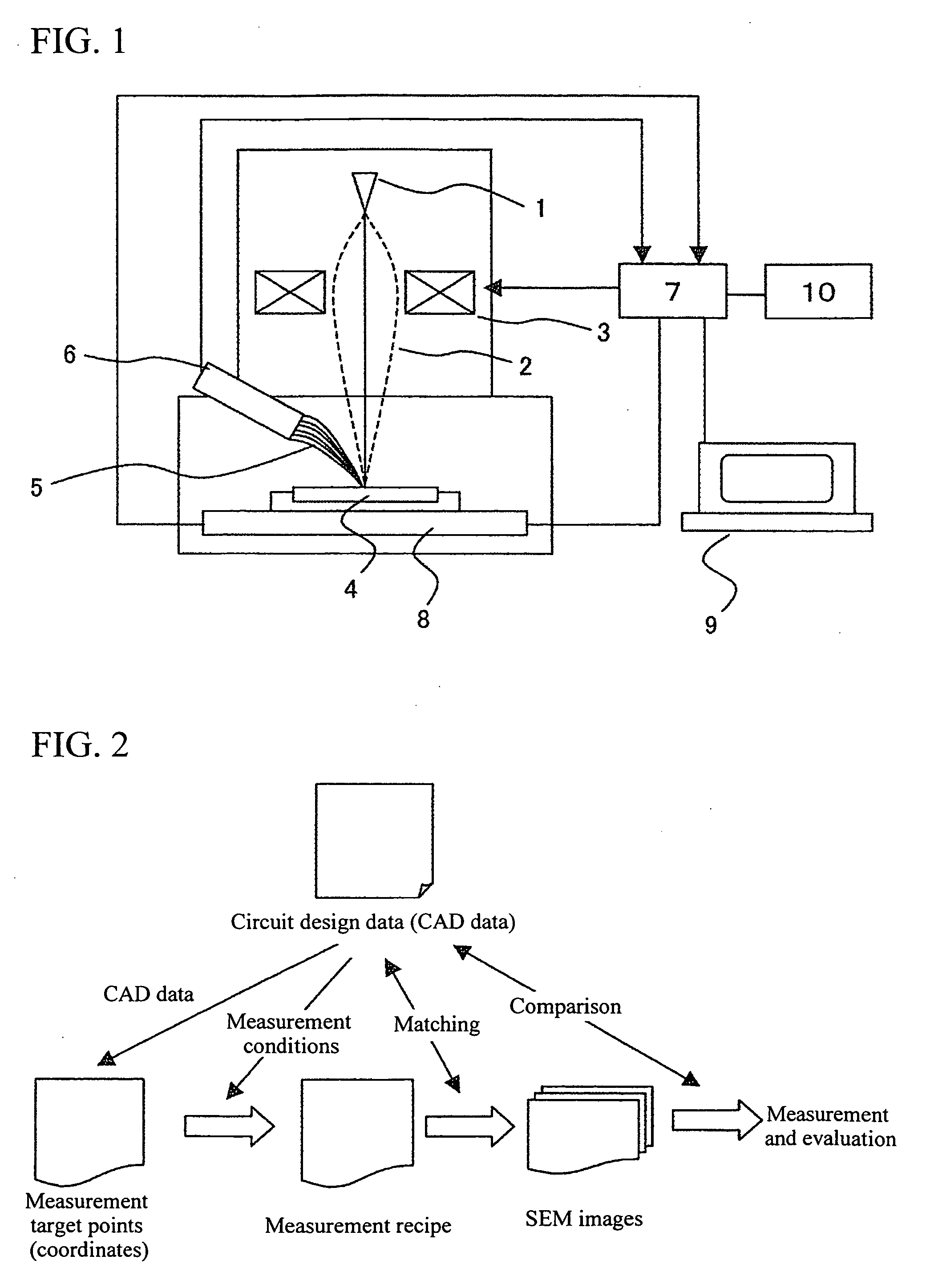

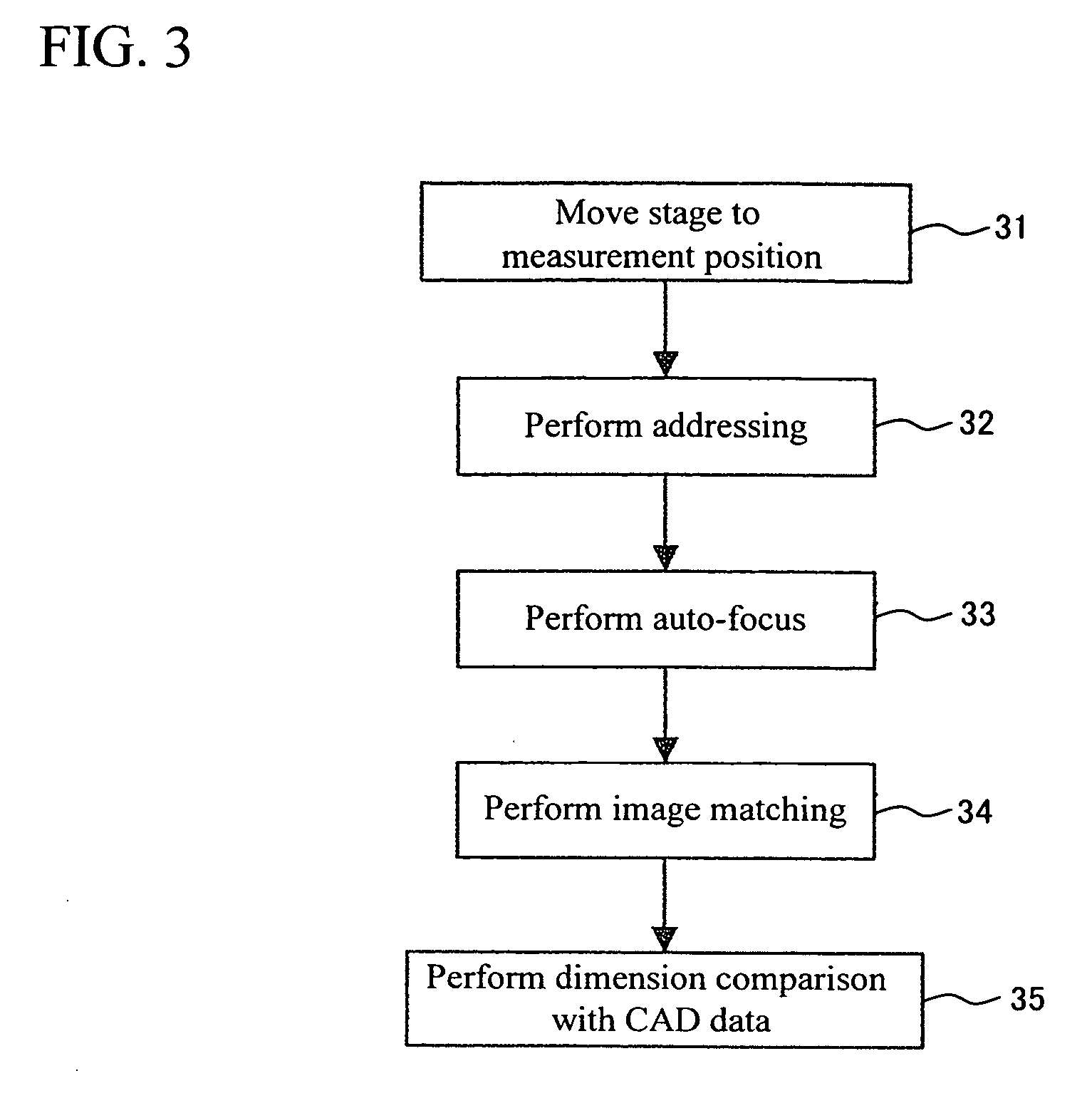

Pattern measurement methods and pattern measurement equipment

ActiveUS20090238443A1Highly accurate pattern matchingElectric discharge tubesSemiconductor/solid-state device testing/measurementComputer graphics (images)Magnification

Owner:HITACHI HIGH-TECH CORP

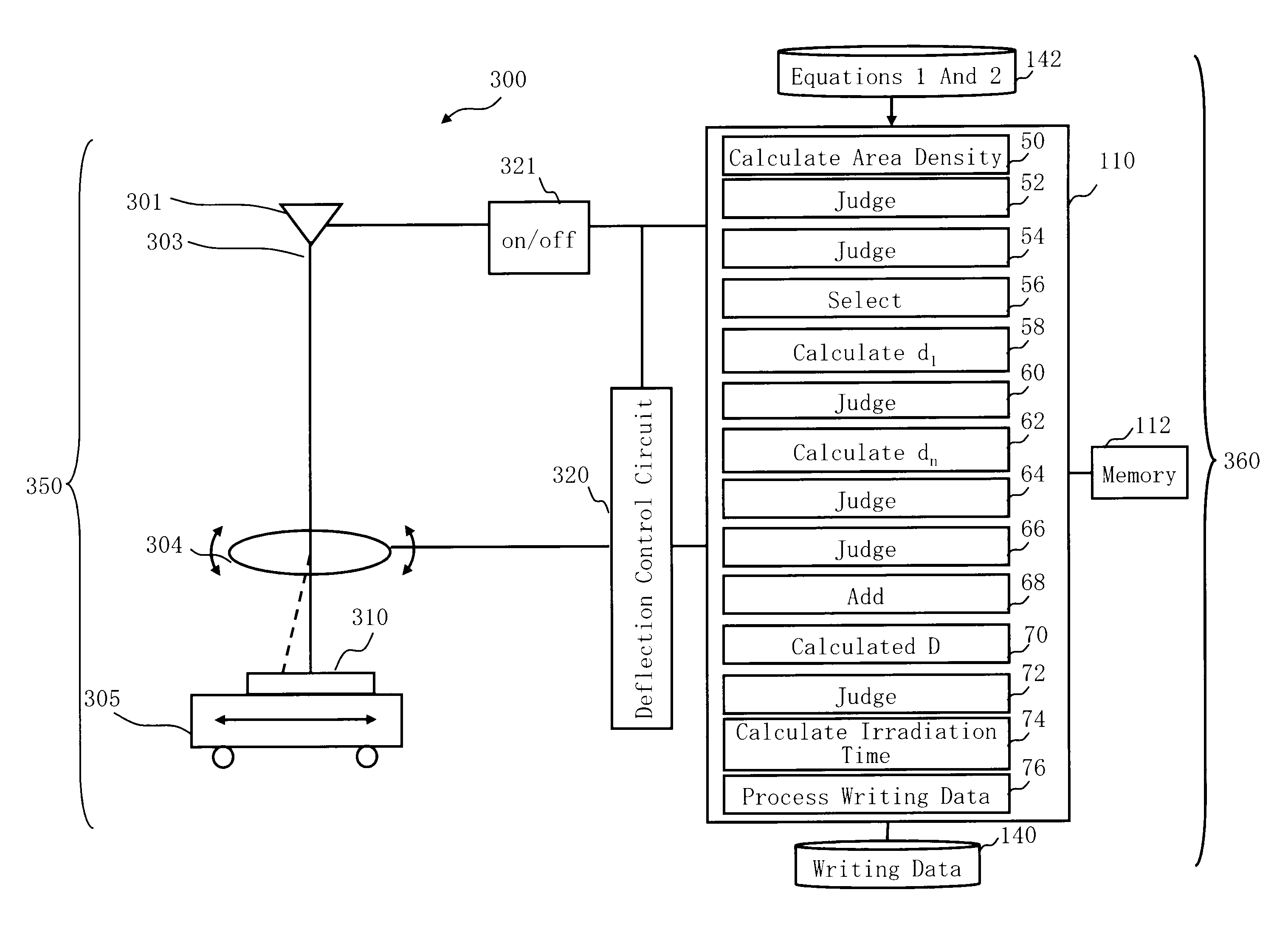

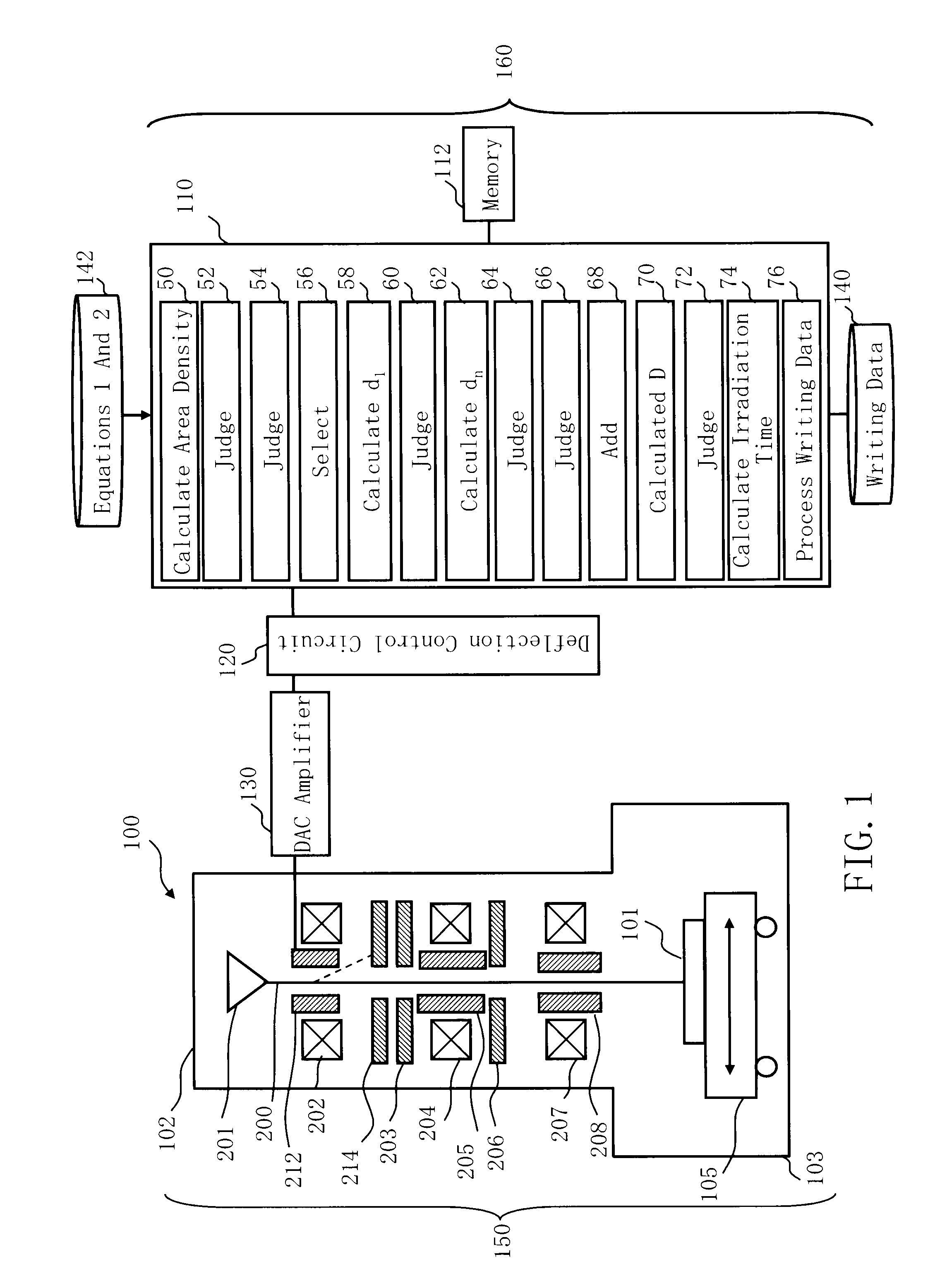

Charged particle beam writing apparatus and charged particle beam writing method

Owner:NUFLARE TECH INC

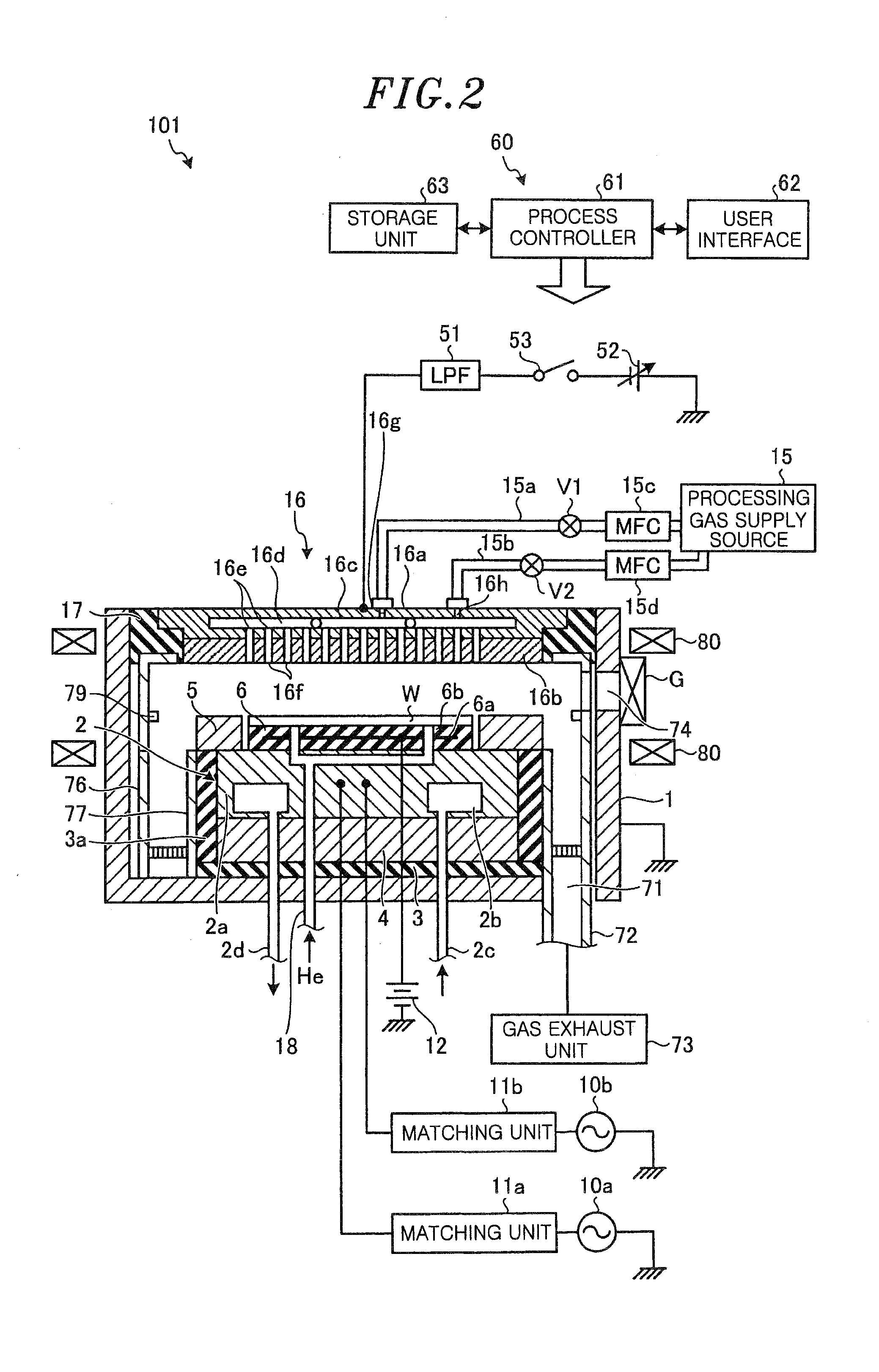

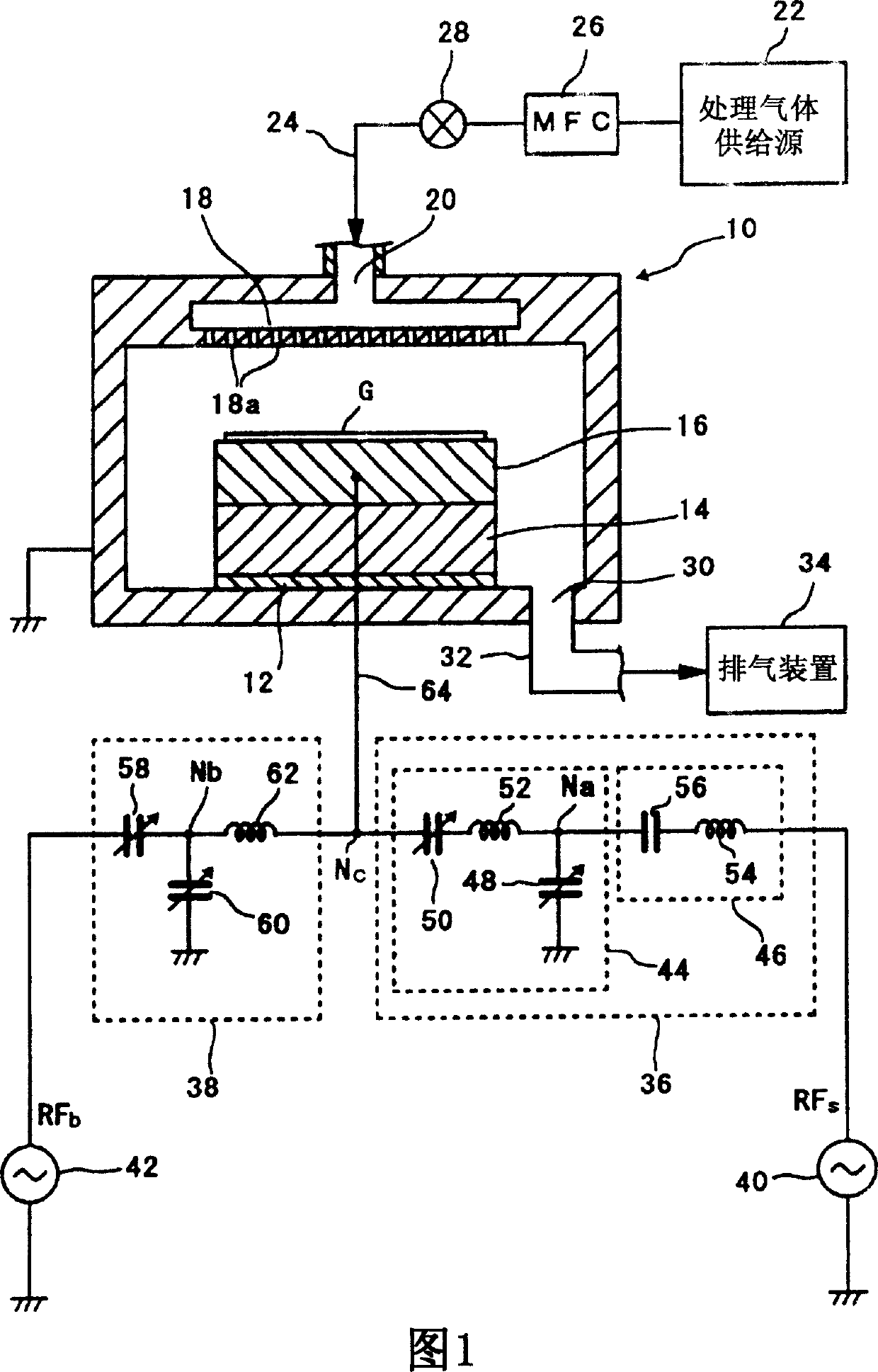

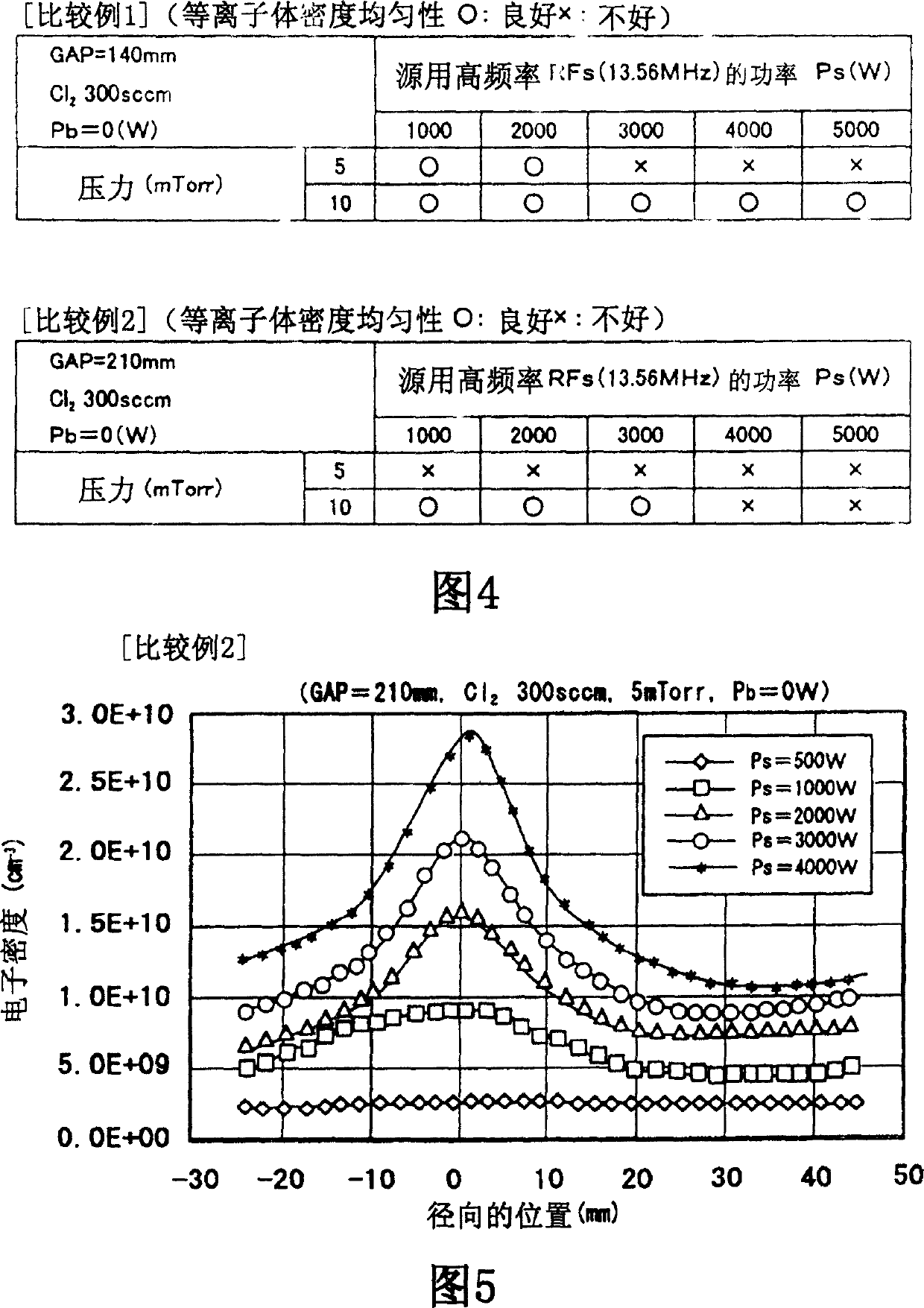

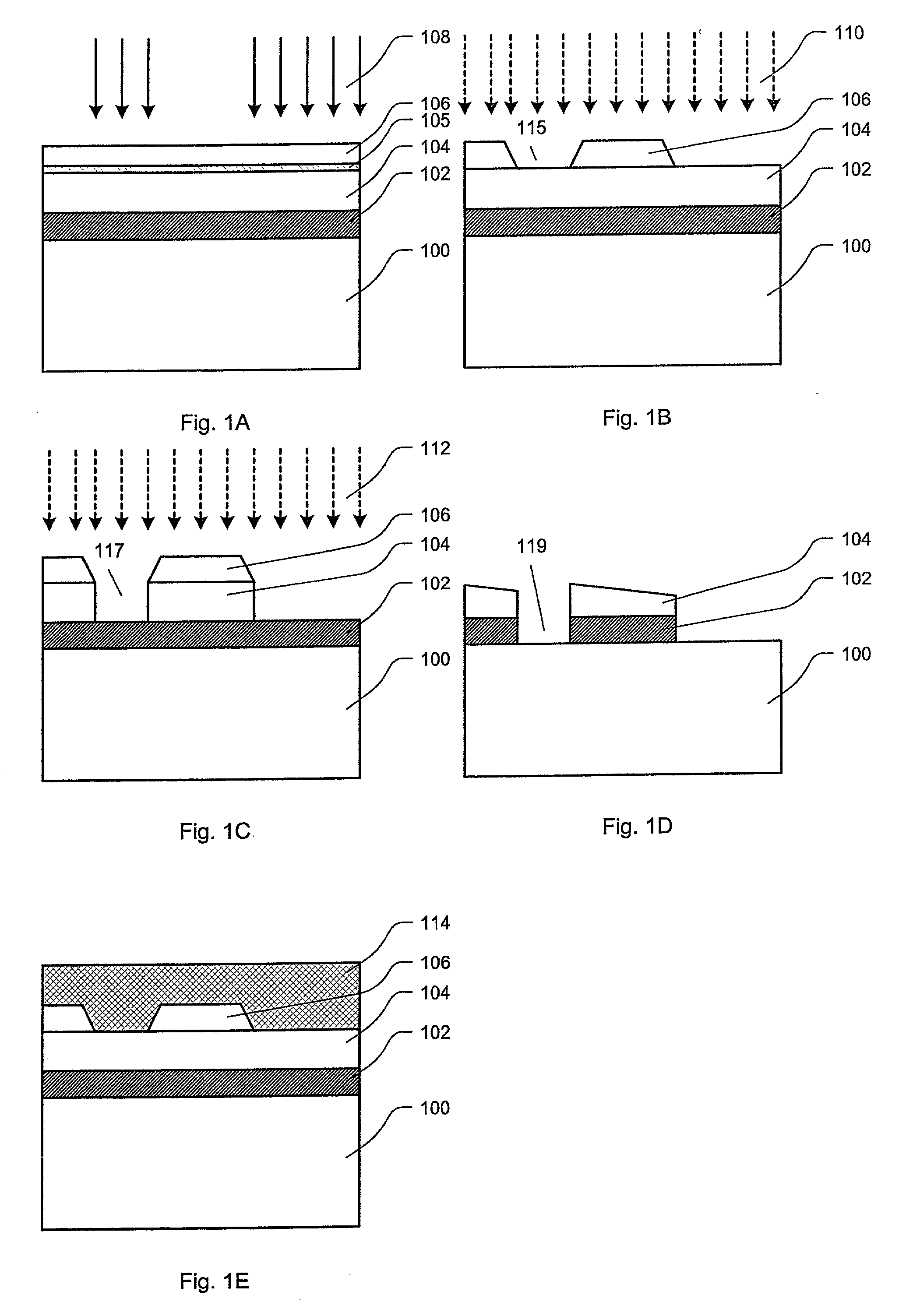

Plasma etching method and plasma treatment apparatus

ActiveCN1581445AMiniaturizationImprove etching effectElectric discharge tubesSemiconductor/solid-state device manufacturingRadio frequencyPhysics

To realize reduction in size and low cost of a matching circuit in the double-frequency superimposing and impressing system. In this plasma etching apparatus, an upper electrode 18 is connected (grounded) to the ground potential via a chamber 10, while a lower electrode 16 is electrically connected to a first radio frequency power source 40 (for example, 13.56 MHz) and a second radio frequency power source 42 (for example, 3.2 MHz) via a first matching unit 36 and a second matching unit 38. The second matching unit 38 in the lower frequency side is formed of a T-type circuit in which a coil 62 is provided in the final output stage and the coil 62 is also operated as a high-cut filter for shielding the radio frequency (13.56 MHz) from the first radio frequency power source 40.

Owner:TOKYO ELECTRON LTD

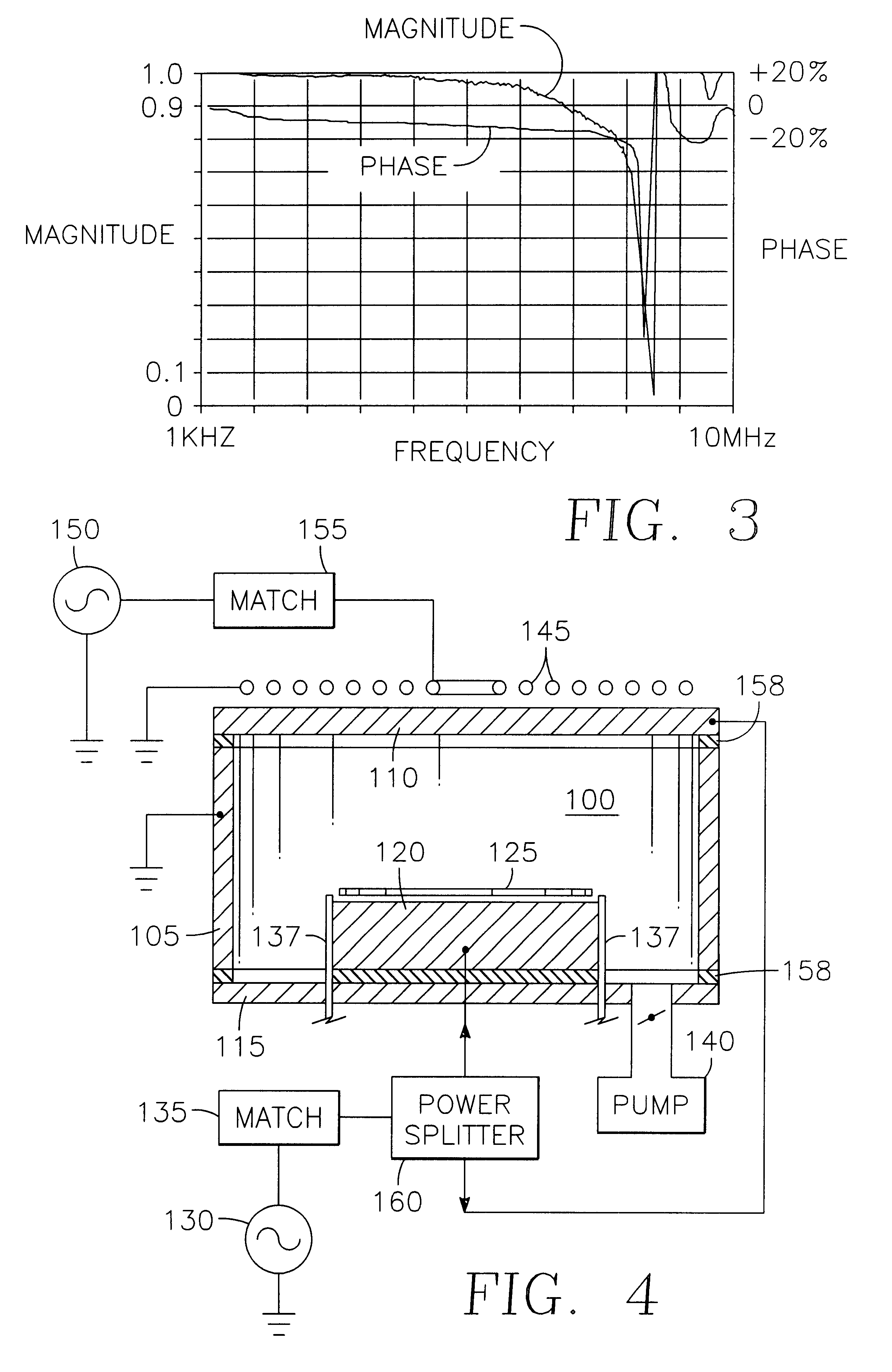

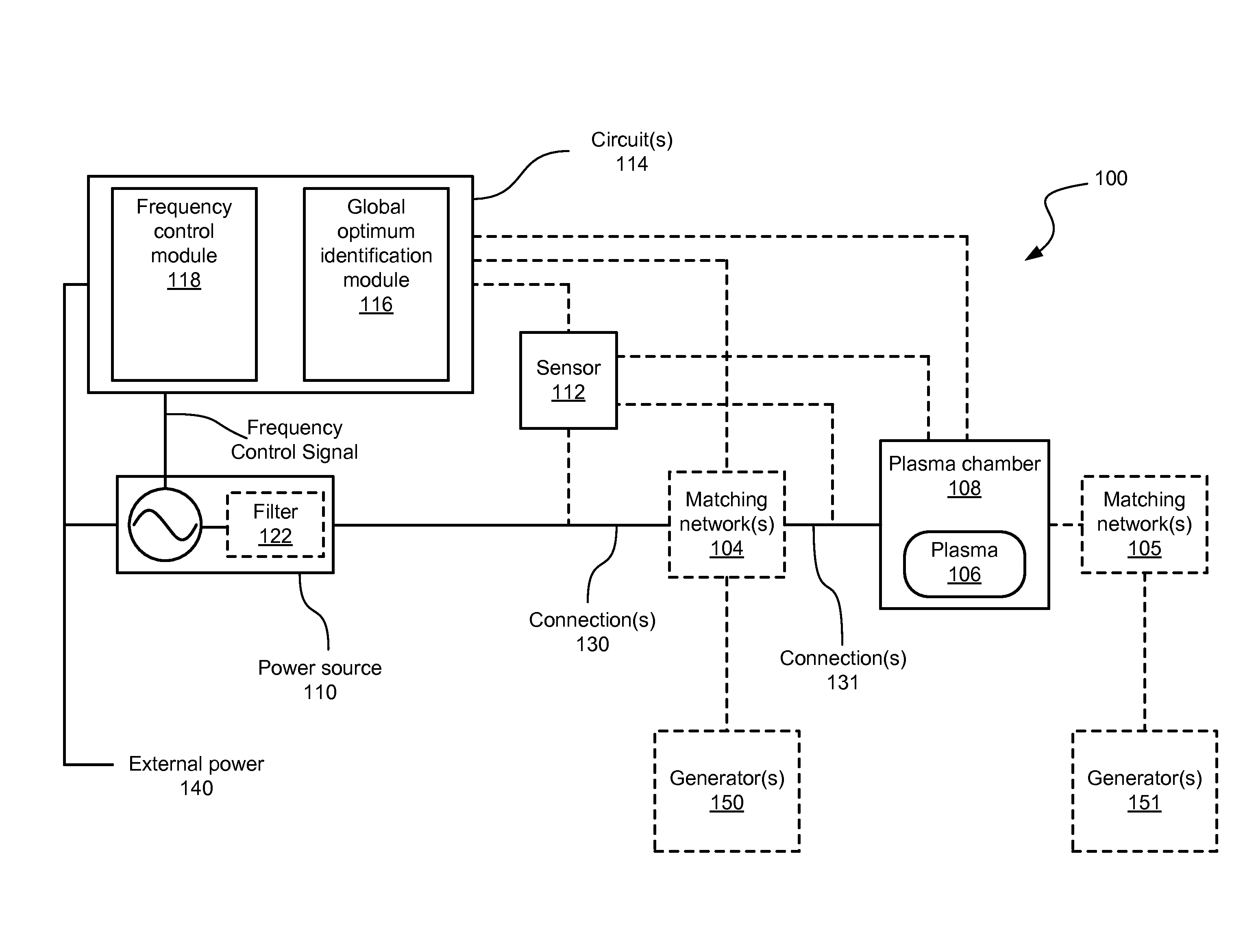

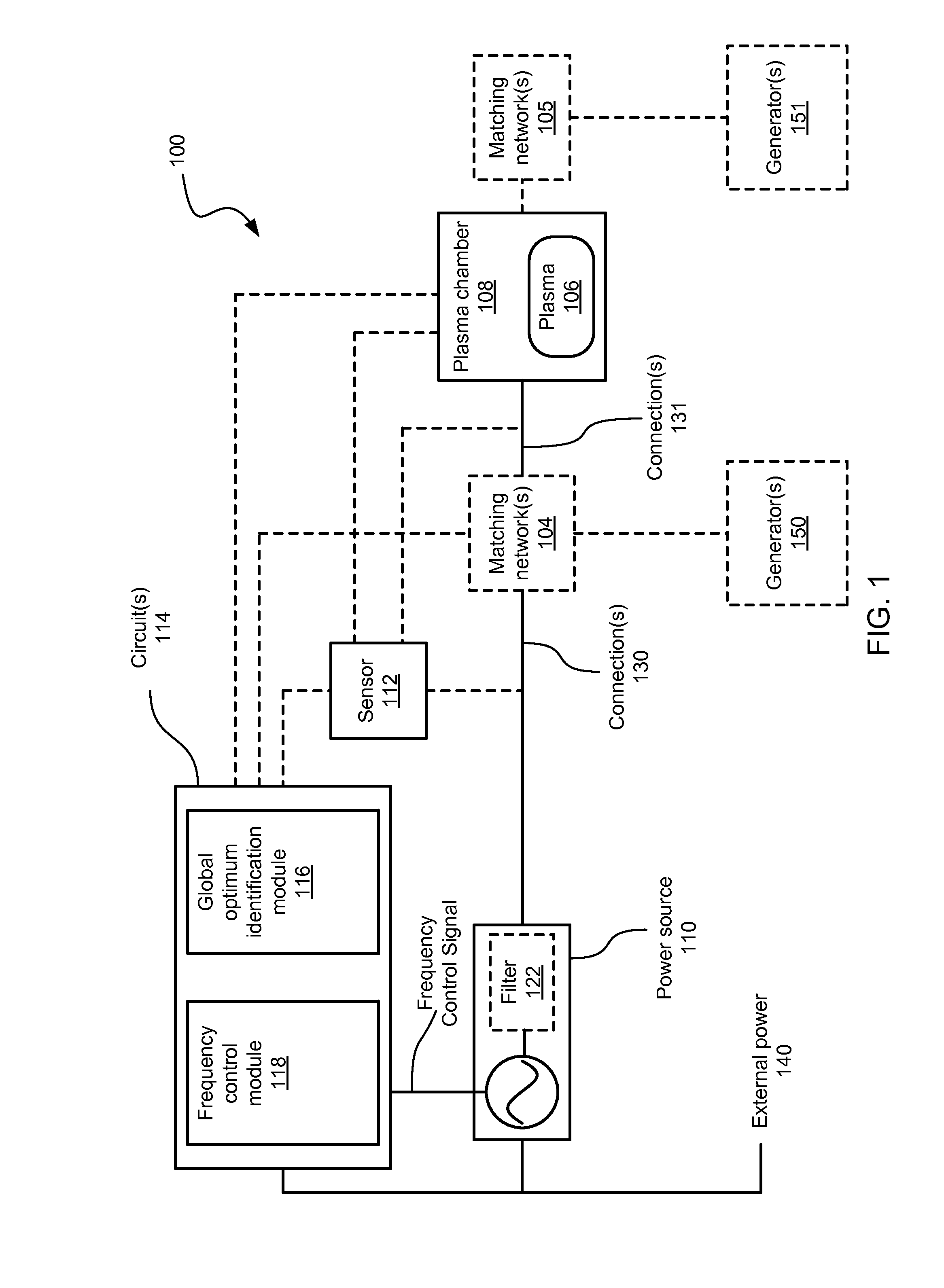

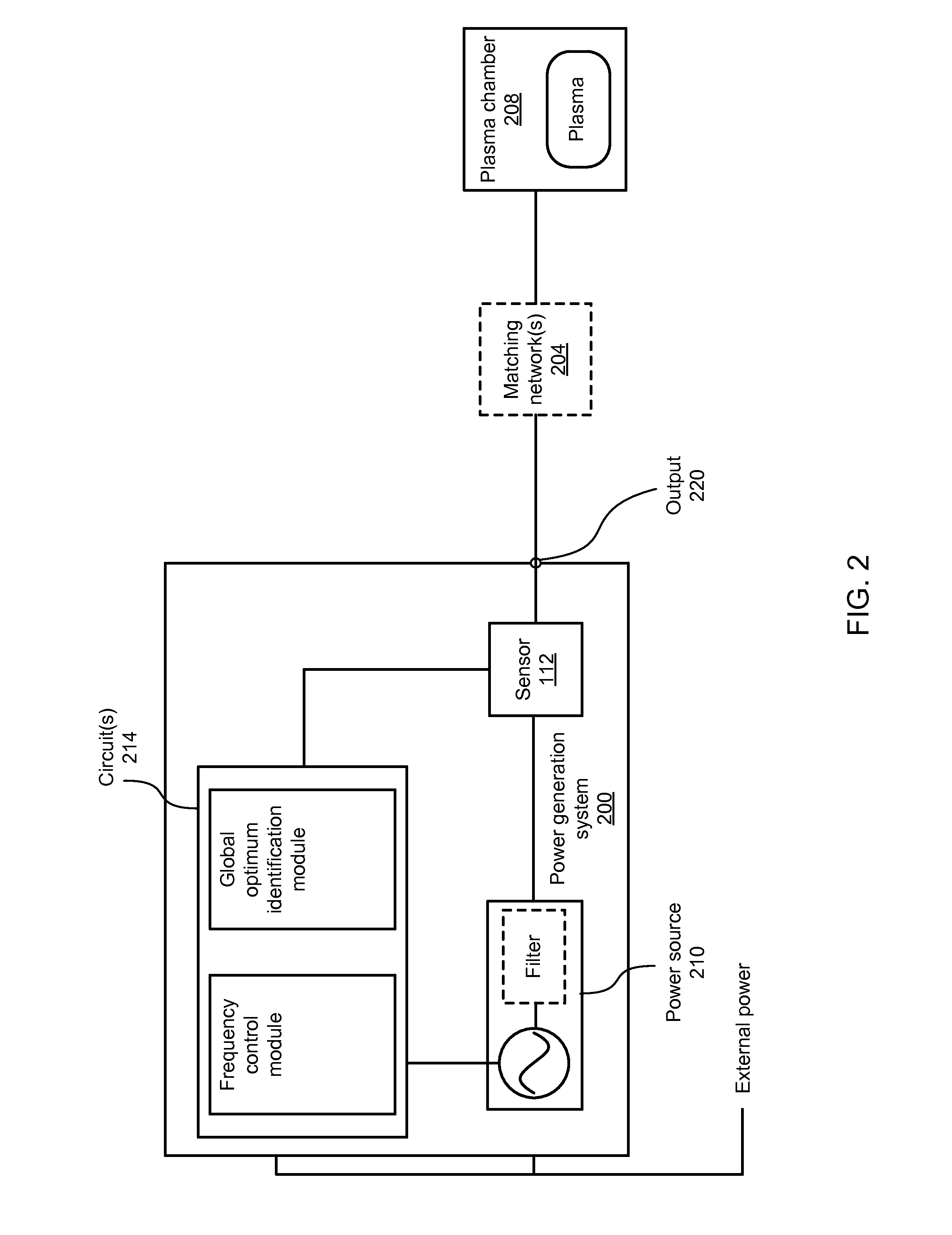

Noise based frequency tuning and identification of plasma characteristics

Owner:AES GLOBAL HLDG PTE LTD

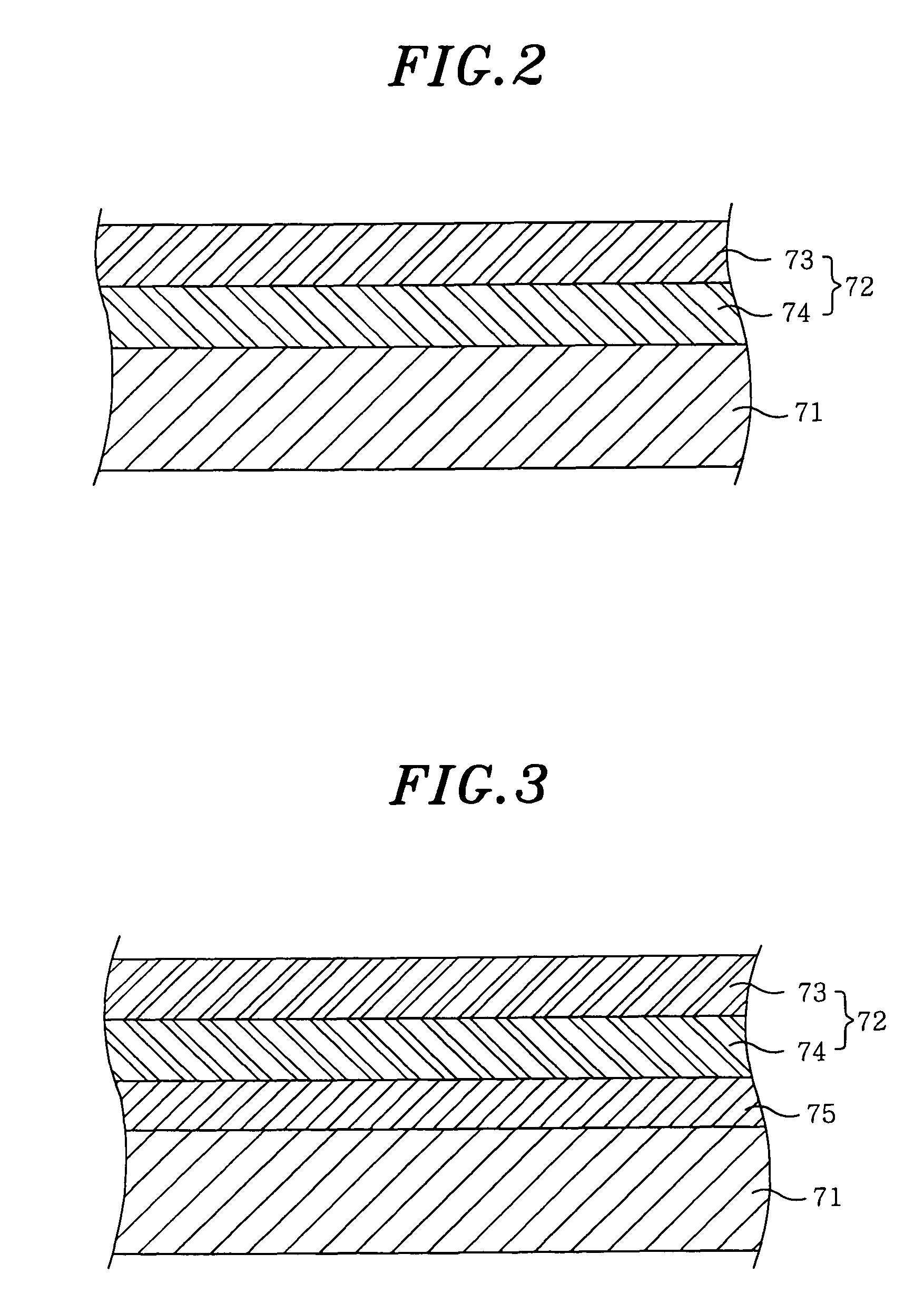

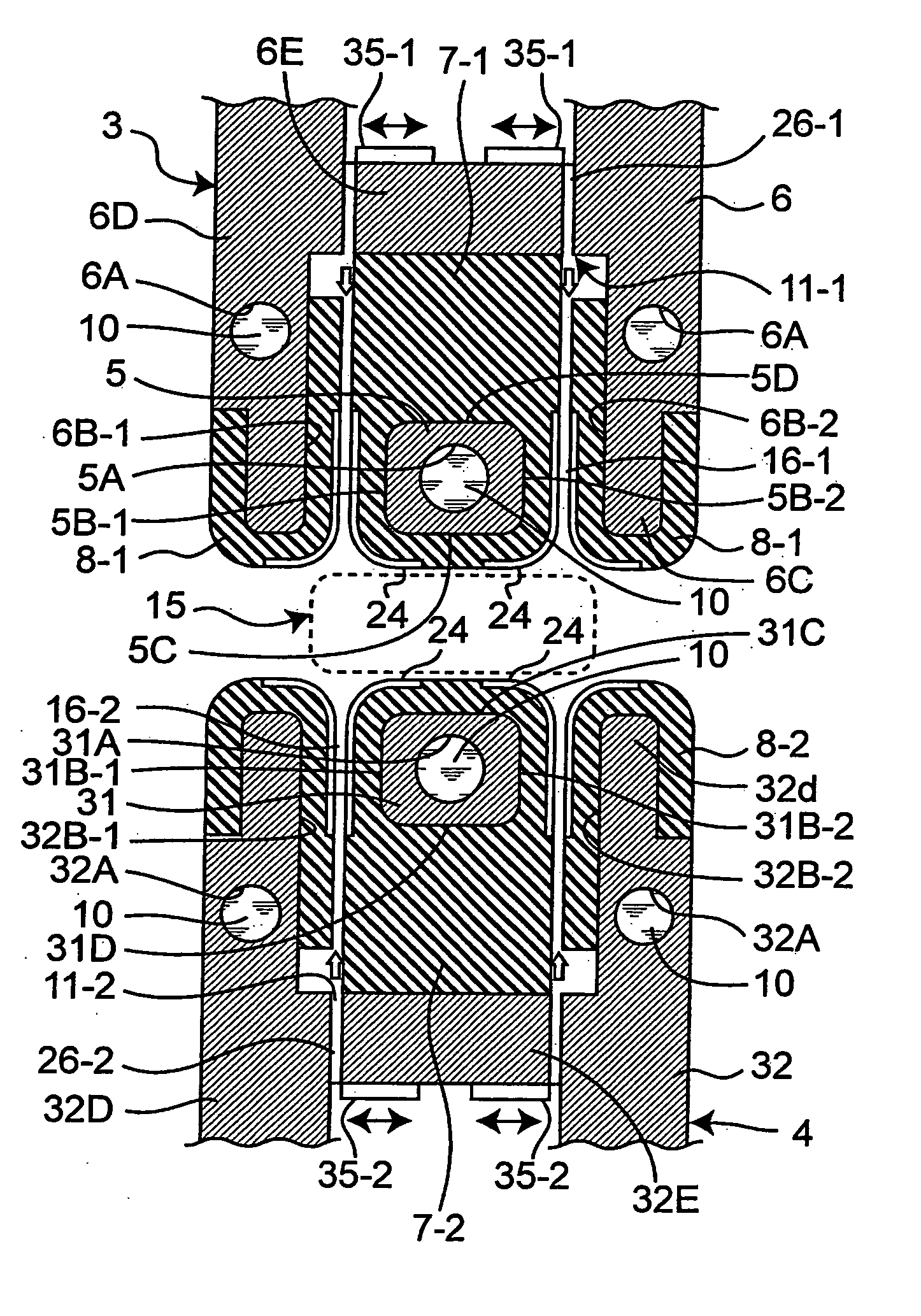

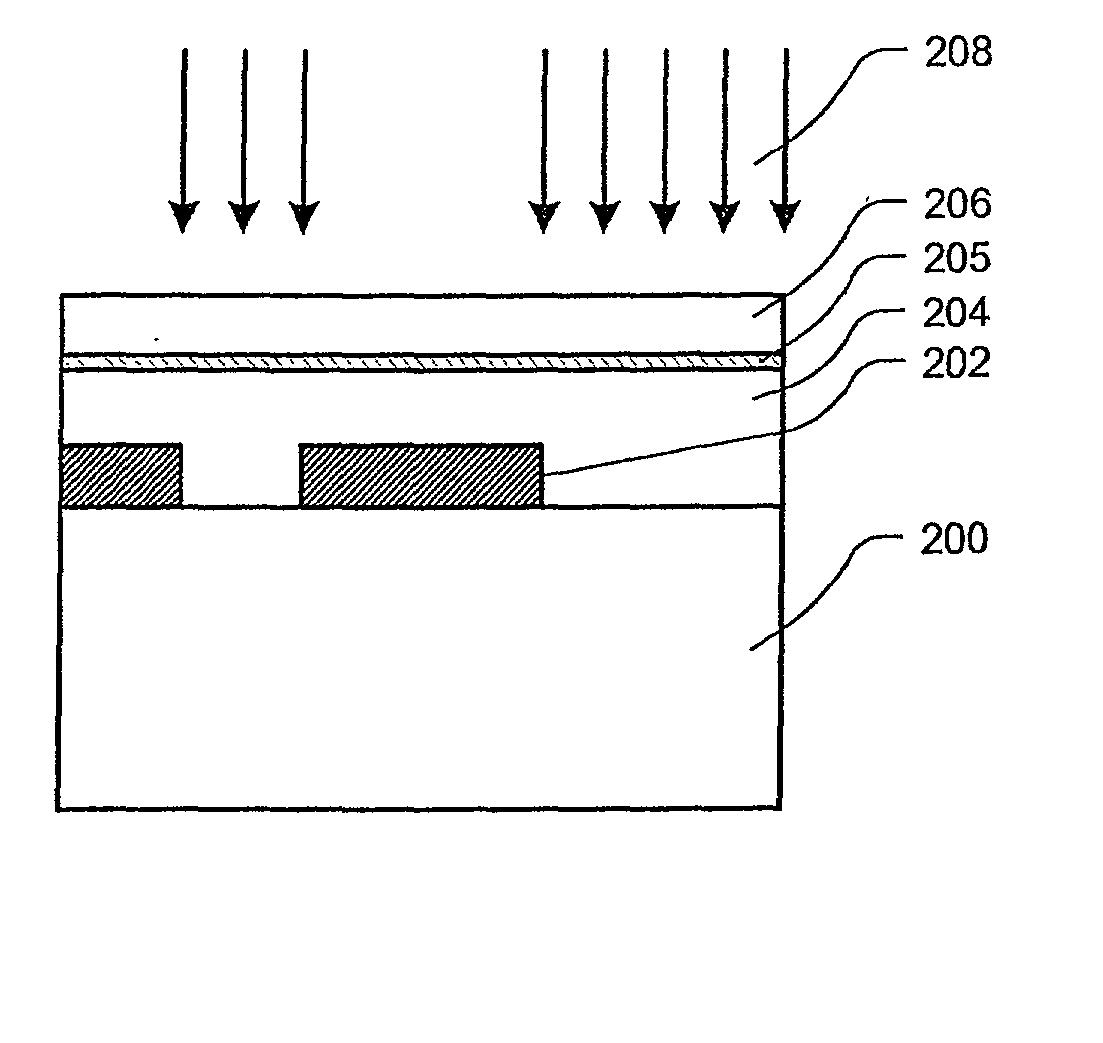

Thin film forming device for forming silicon thin film having crystallinity

InactiveUS6192828B1Electric discharge tubesSemiconductor/solid-state device manufacturingElectric dischargeSilicon thin film

An insulating member is interposed between a film formation chamber container and a plasma chamber container. Both containers are adjacent to and communicated with each other. In the film formation chamber container, a base material holder is provided for holding the base material. Raw material gas is introduced into the plasma chamber container and ionized by high frequency electric discharge, to generate plasma. A high frequency electrode and a high frequency electric power source are provided as a plasma generating unit. There is provided a porous electrode 30, the electric potential of which is the same as that of the plasma chamber container 24, between both chambers 22, 24 to partition both chambers. A pulse electric powder source for impressing bipolar pulse voltage, in which a positive polarity portion and a negative polarity portion are alternately repeated, is provided between the base material holder and both of the plasma chamber container and the porous electrode 30, the electric potential of which is the same as that of the plasma chamber container 24.

Owner:NISSIN ELECTRIC CO LTD

Ceramic nanofibers for liquid or gas filtration and other high temperature (> 1000 °c) applications

In accordance with the invention there are devices and processes for making ceramic nanofiber mats and ceramic filters for use in high temperature and in corrosive environments. The process for forming a ceramic filter can include electrospinning a preceramic polymer solution into a preceramic polymer fiber having a diameter from about 10 nm to about 1 micron and forming a preceramic polymer fiber web from the preceramic polymer fiber onto a collector. The process can also include pyrolyzing the preceramic polymer fiber web to form a ceramic nanofiber mat having a diameter less than the diameter of the preceramic polymer fiber, the ceramic nanofiber mat comprising one or more of an oxide ceramic and a non-oxide ceramic such that the ceramic fiber mat can withstand temperature greater than about 1000° C.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Display device and a televsion receiver having the same

InactiveUS20090231506A1Electric discharge tubesPrinted circuit aspectsDisplay deviceElectrical element

A display device is capable of efficiently cooling electronic or electrical components disposed therein without installing a cooling element or member on the electronic or electrical components. In the display device, a ceramic or ceramic-containing layer is formed on any one of a surface of a member placed in proximity to the electronic or electrical component, the surface facing at least the electronic or electrical component, a surface of the member placed in proximity to the electronic or electrical component, the surface opposite to the surface facing the electronic or electrical component, a surface of the electronic or electrical component, and a surface of a circuit board, the surface opposite to a surface of the circuit board on which the electronic or electrical component is mounted.

Owner:SHARP KK

Dual layer reticle blank and manufacturing process

Owner:ASML NETHERLANDS BV

Ion beam emission source for outputting single ionic energy

Owner:XIAN TECHNOLOGICAL UNIV

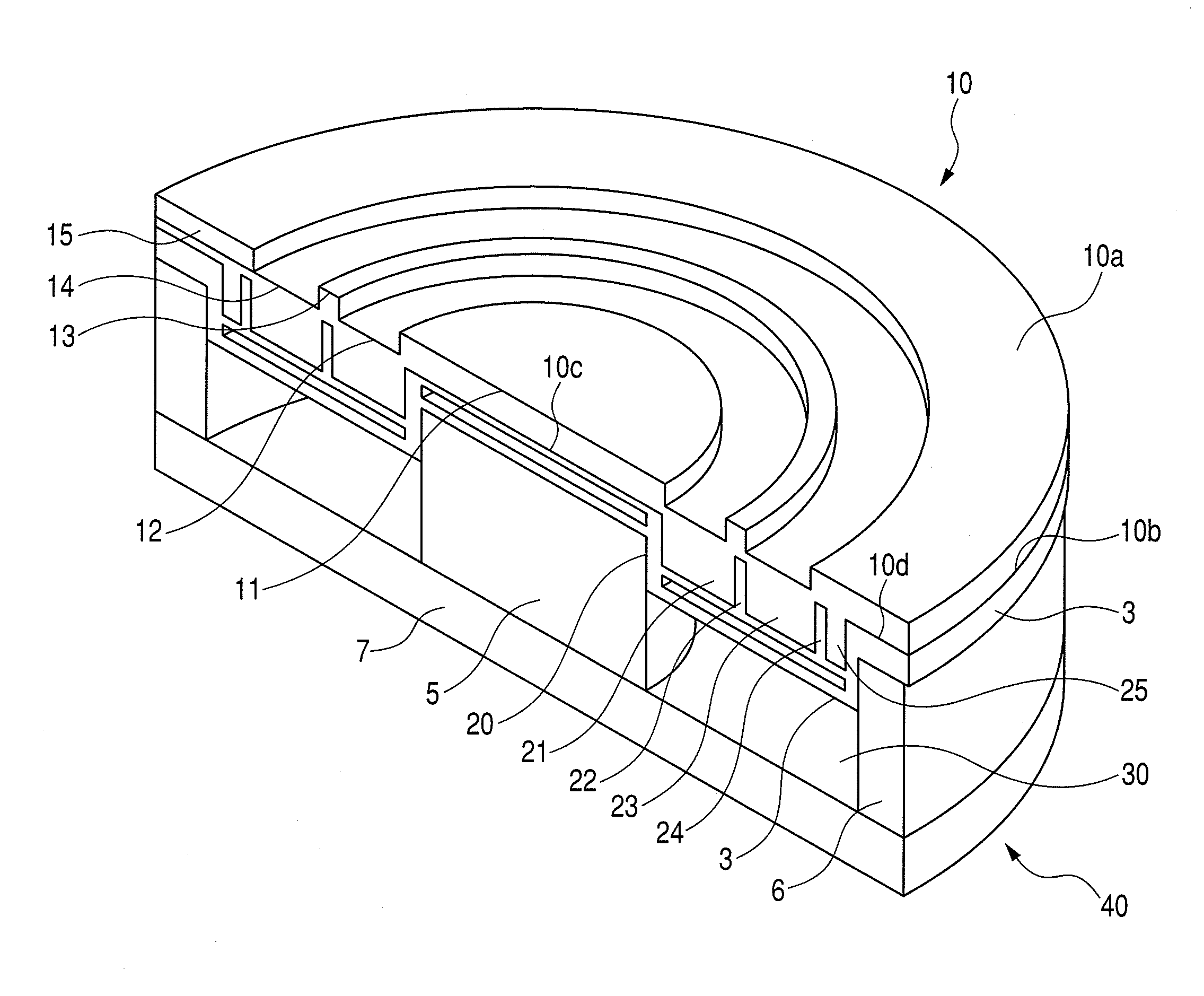

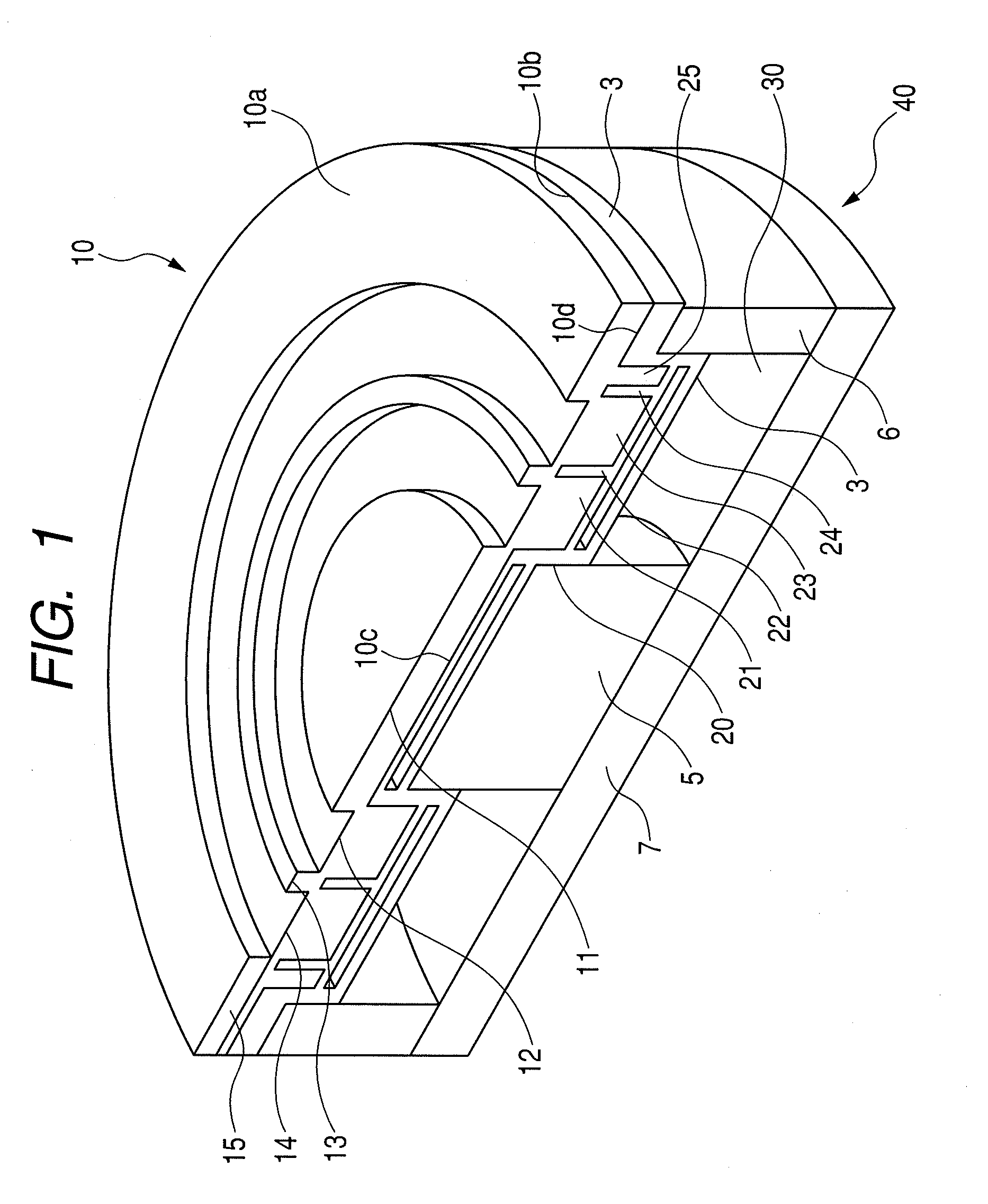

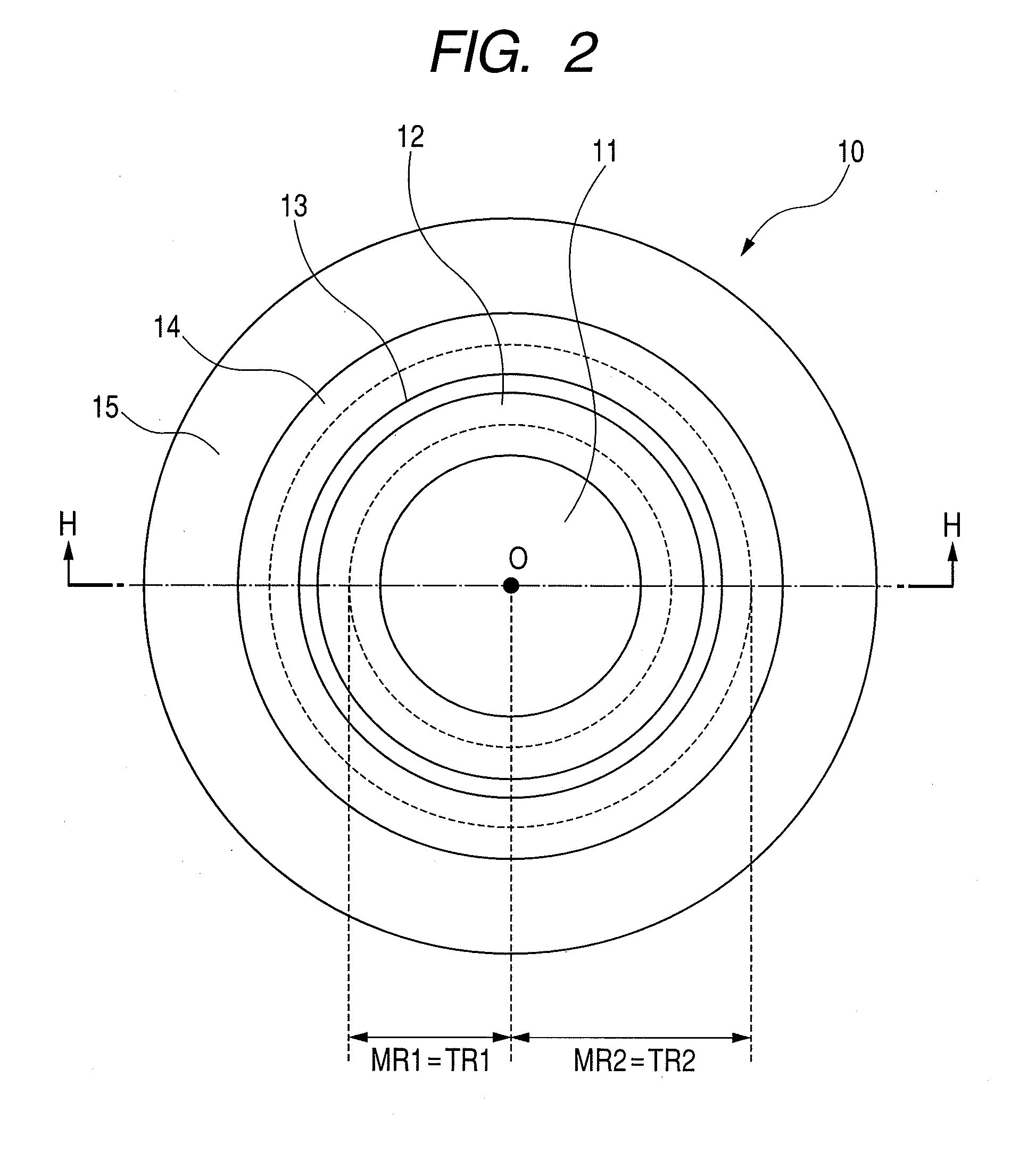

Magnetron sputtering cathode, magnetron sputtering apparatus, and method of manufacturing magnetic device

Owner:CANON ANELVA CORP

Mini Receptacle

ActiveUS20100210139A1Avoid short circuit failureAvoid failureContact member assembly/disassemblyElectric discharge tubesElectrical connectorShort circuit

Owner:MOLEX INC

Semiconductor processing equipment and process control method thereof

ActiveCN111489949AImprove yieldImprove accuracyElectric discharge tubesFinal product manufactureWaferProcess engineering

The embodiment of the invention provides semiconductor processing equipment and a process control method thereof. The semiconductor processing equipment comprises a cavity, a lifting assembly, a baseand a temperature measuring assembly, wherein the base and the temperature measuring assembly are arranged in the cavity; the lifting assembly is used for bearing and driving wafers to be selectivelylocated at multiple stations above the base, the multiple stations correspond to the multiple target temperature values in a one-to-one mode, and the distance between each station and an upper surfaceof the base is inversely proportional to the corresponding target temperature value; and the temperature measuring assembly is arranged at positions where the lifting assembly is in contact with thewafers and is used for acquiring actual measurement temperature values of the wafers in real time. According to the embodiment of the invention, the purpose of adjusting the target temperature value according to different types of wafers and different processes is achieved, and the requirement for temperature change in the process can be met such that the yield of the wafers is effectively improved, and the process efficiency is greatly improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

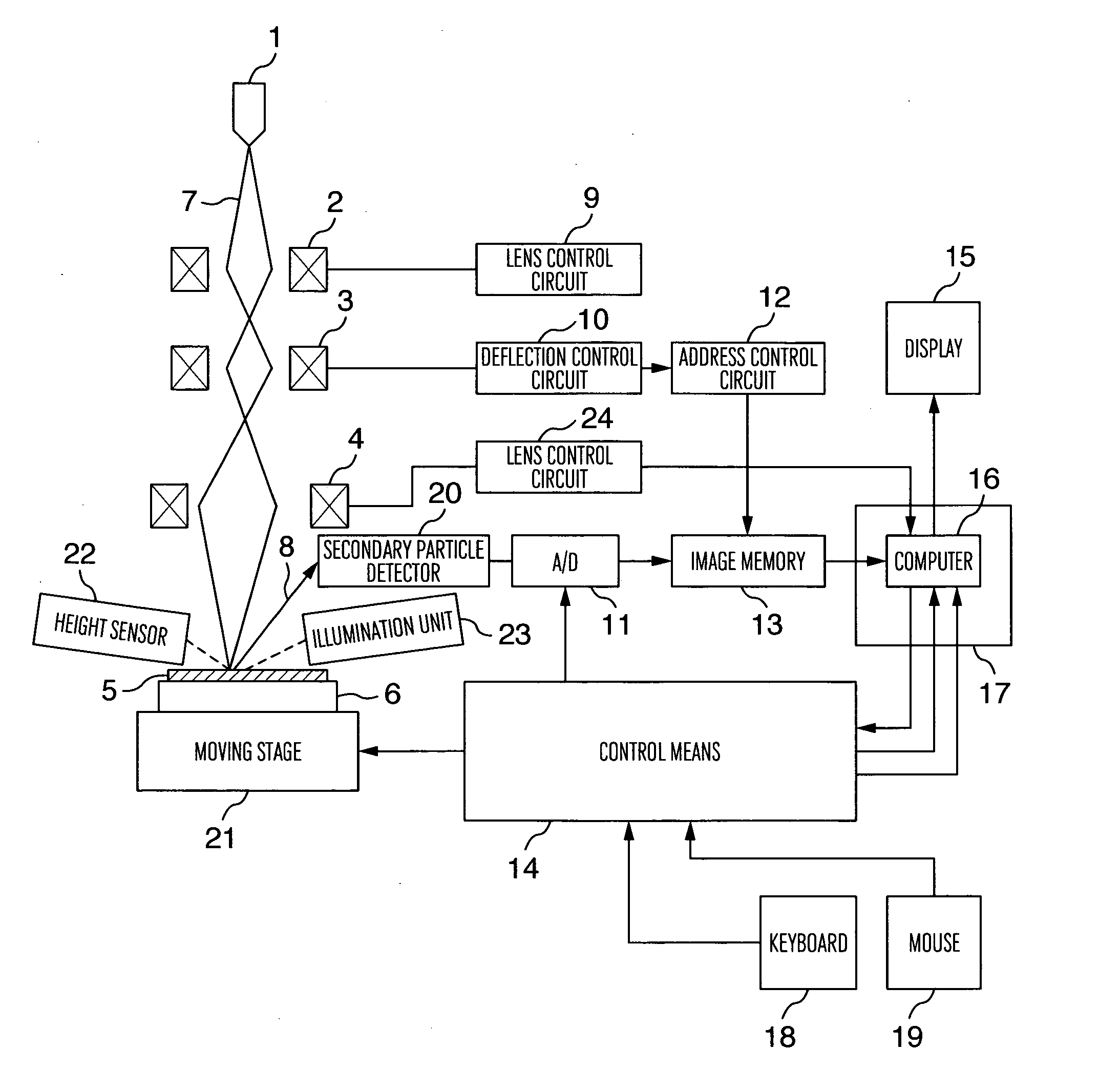

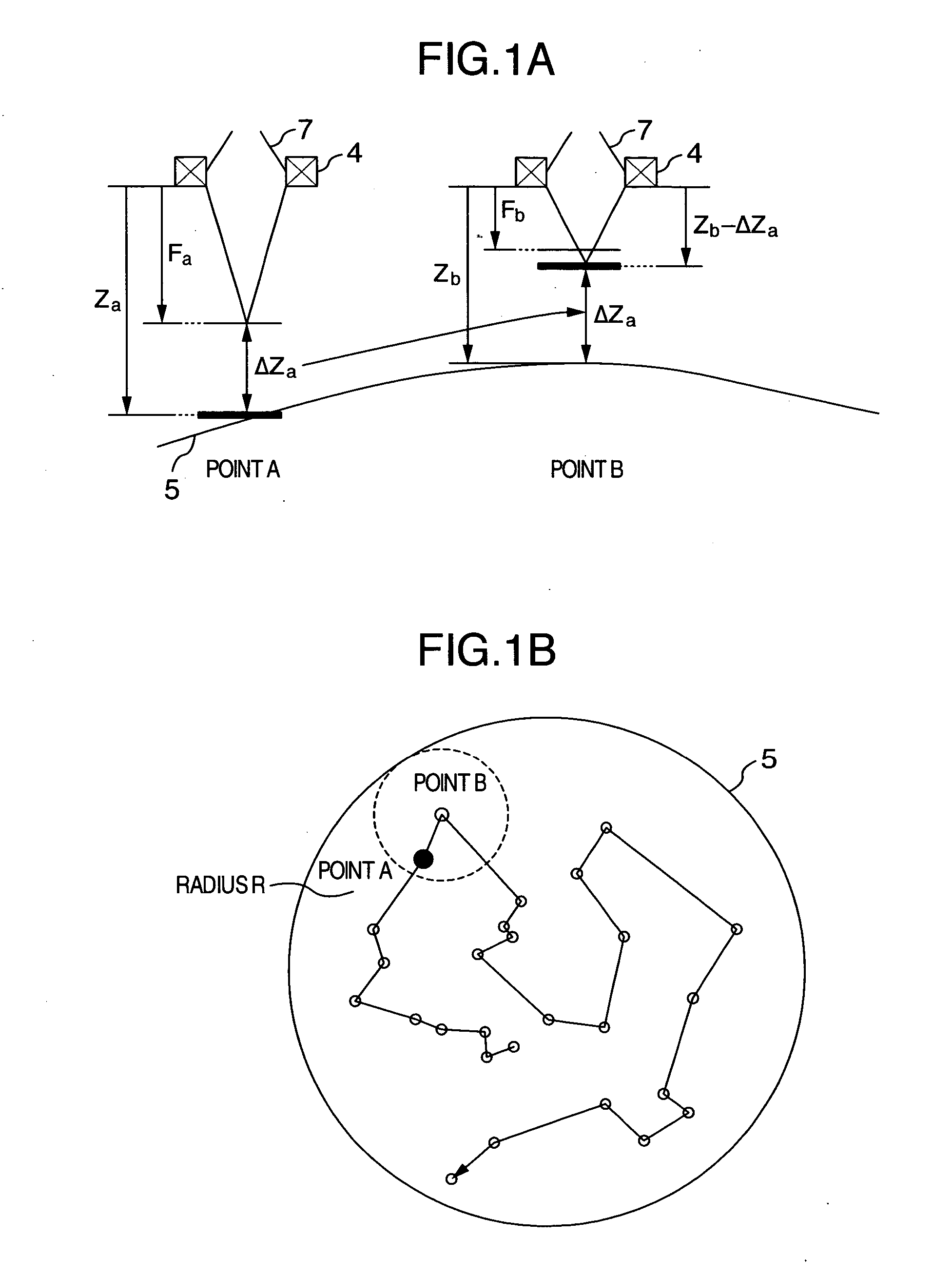

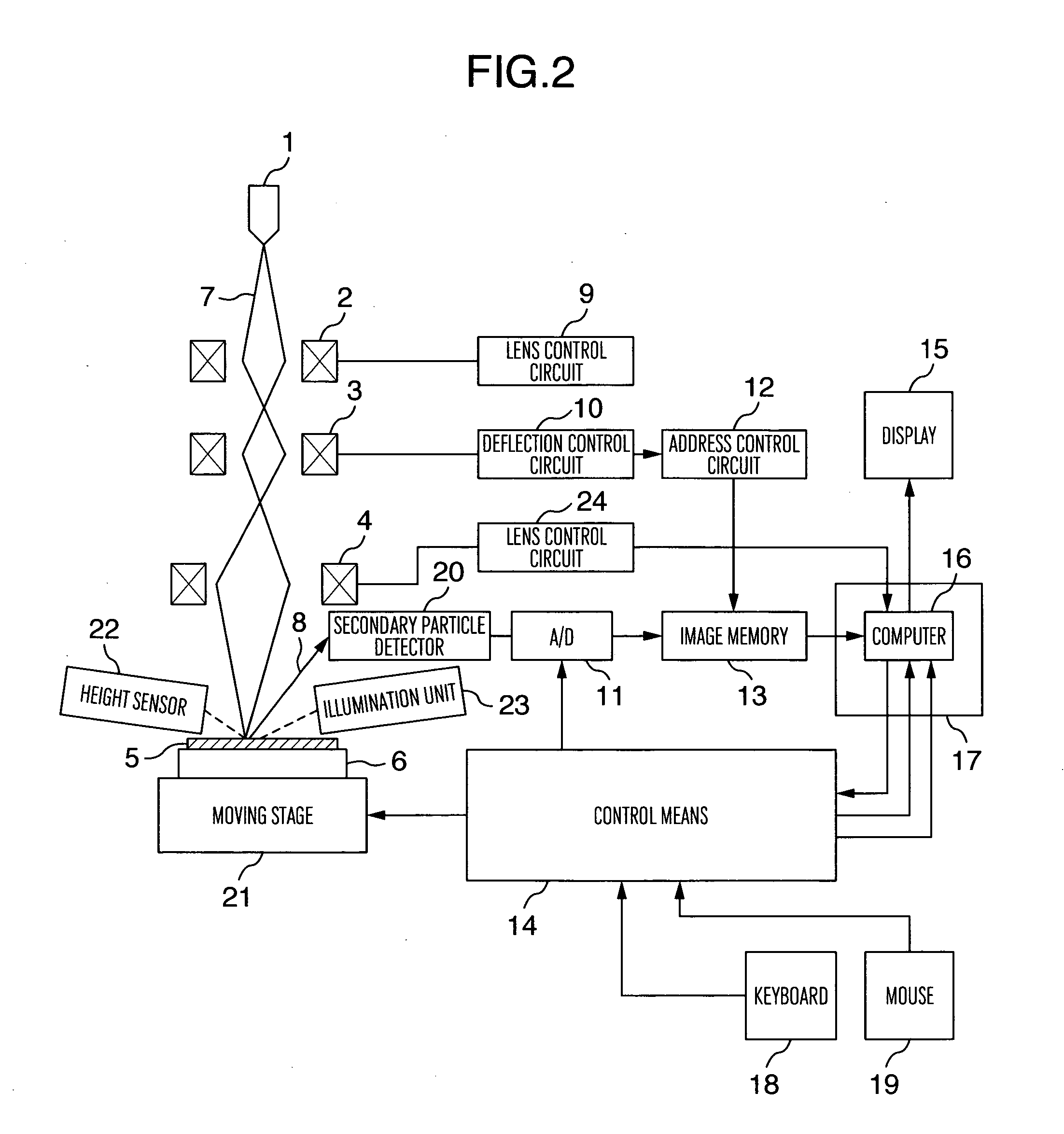

Scanning electron microscope

ActiveUS20060043294A1Increase speedMaterial analysis using wave/particle radiationElectric discharge tubesMeasurement pointElectron microscope

Owner:HITACHI HIGH-TECH CORP

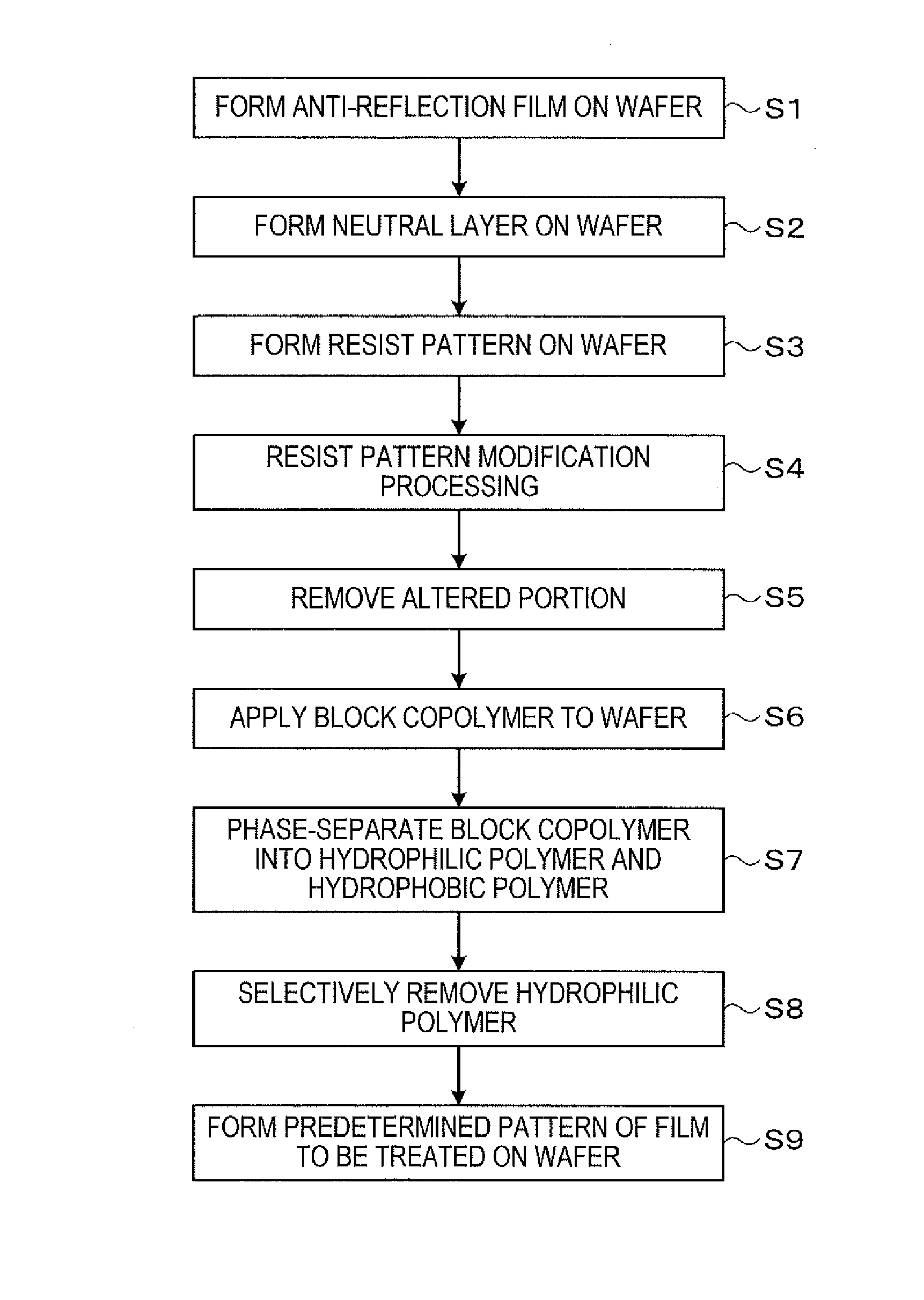

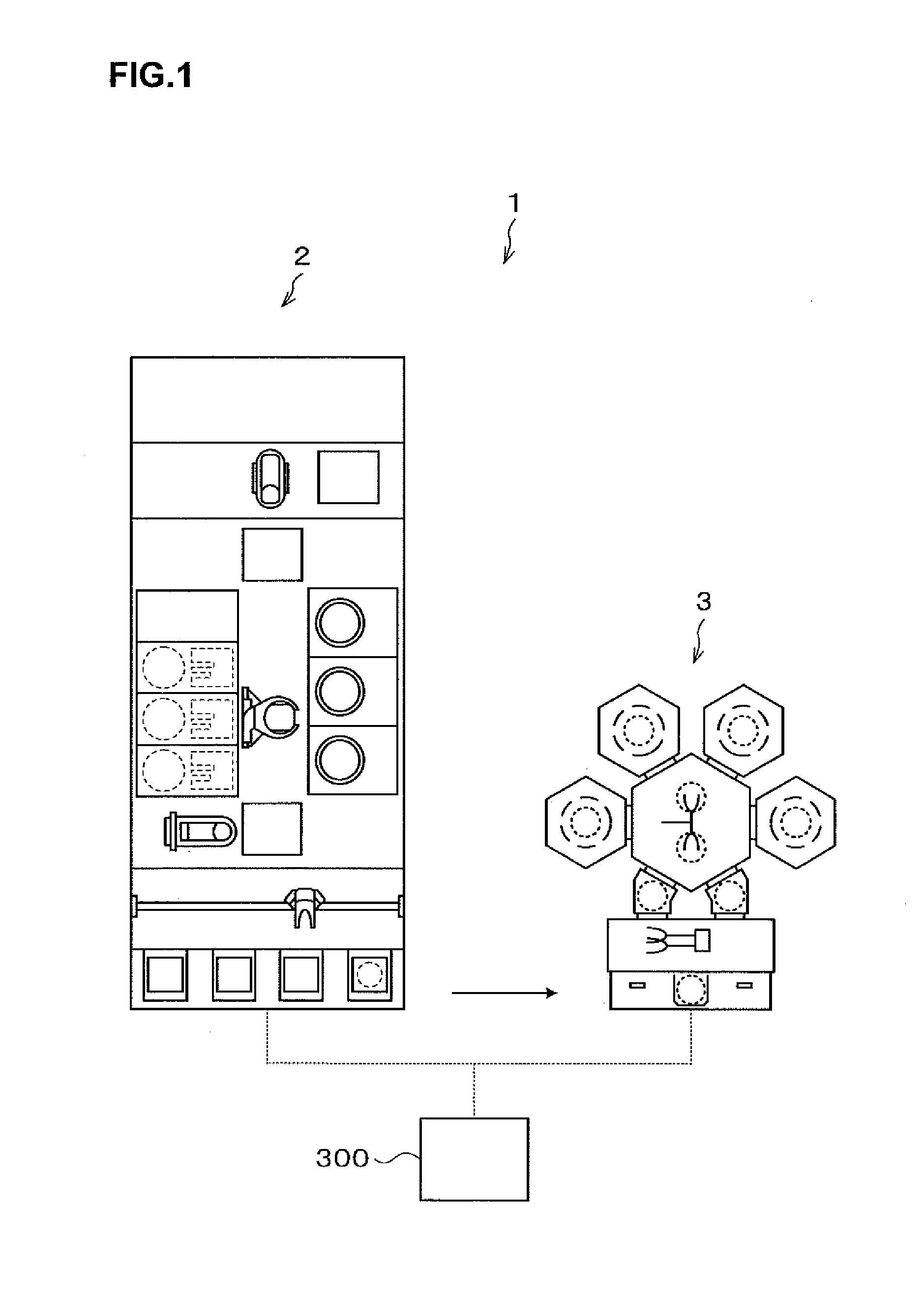

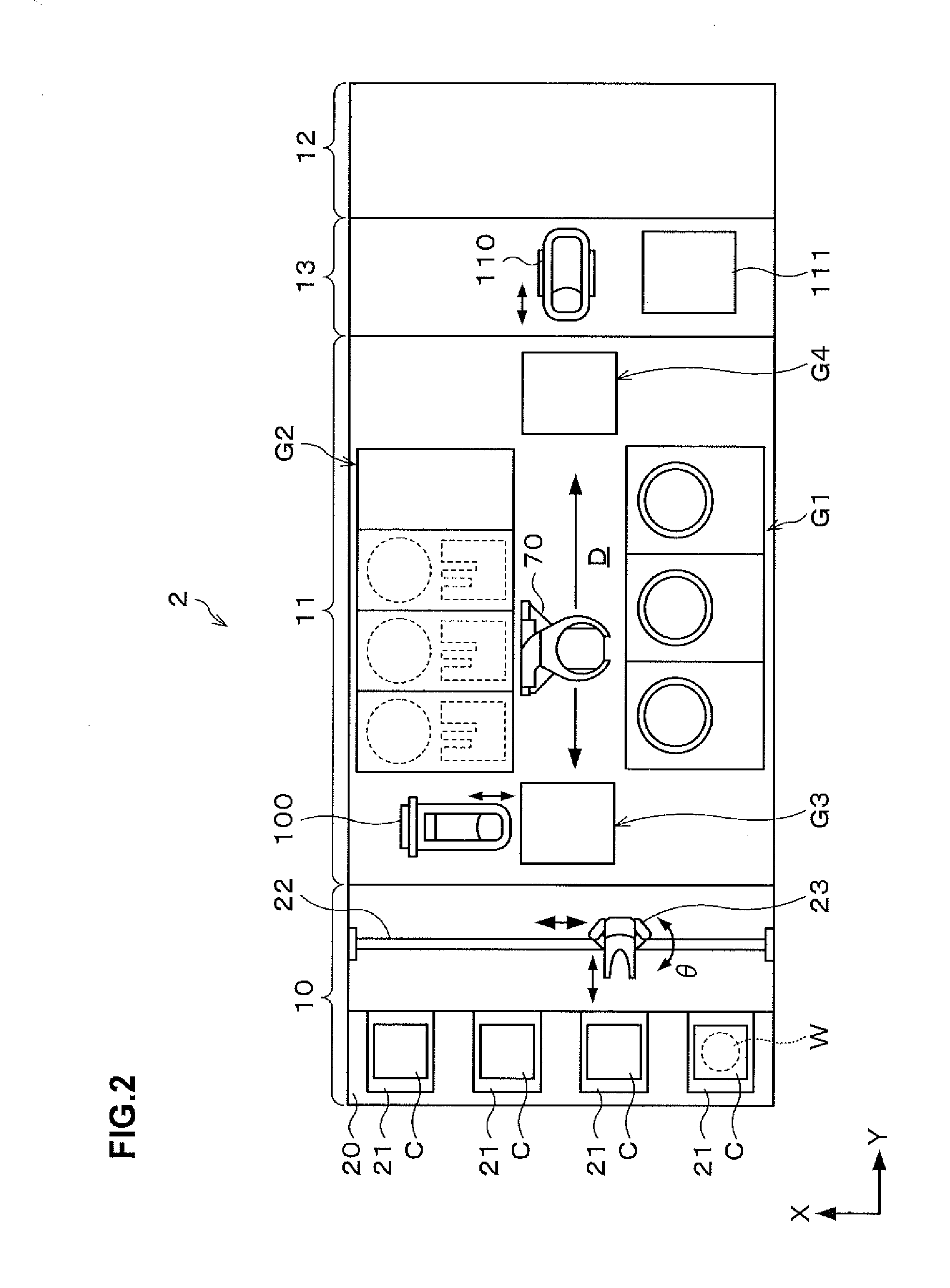

Substrate treatment method, computer storage medium, and substrate treatment system

ActiveUS20150255271A1Electric discharge tubesSemiconductor/solid-state device manufacturingResistHydrophilic polymers

Owner:TOKYO ELECTRON LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap