Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

91results about "Chemical vapor deposition coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organoaminosilane Precursors and Methods for Depositing Films Comprising Same

Owner:VERSUM MATERIALS US LLC

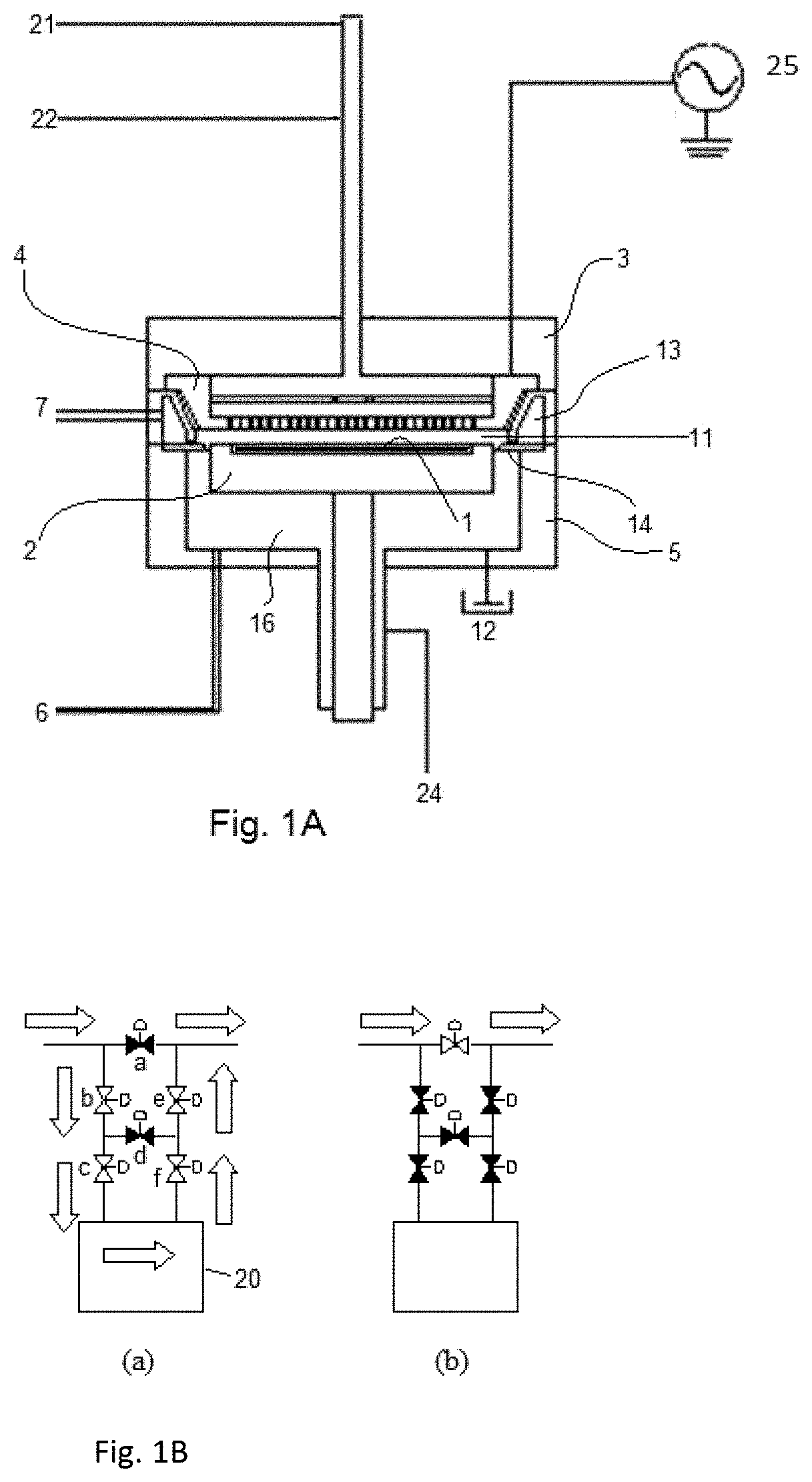

Method for depositing silicon-free carbon-containing film as gap-fill layer by pulse plasma-assisted deposition

ActiveUS20200013612A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingPolymer scienceWafering

A film having filling capability is deposited by forming a viscous polymer in a gas phase by striking an Ar, He, or N2 plasma in a chamber filled with a volatile hydrocarbon precursor that can be polymerized within certain parameter ranges which define mainly partial pressure of precursor during a plasma strike, and wafer temperature.

Owner:ASM IP HLDG BV

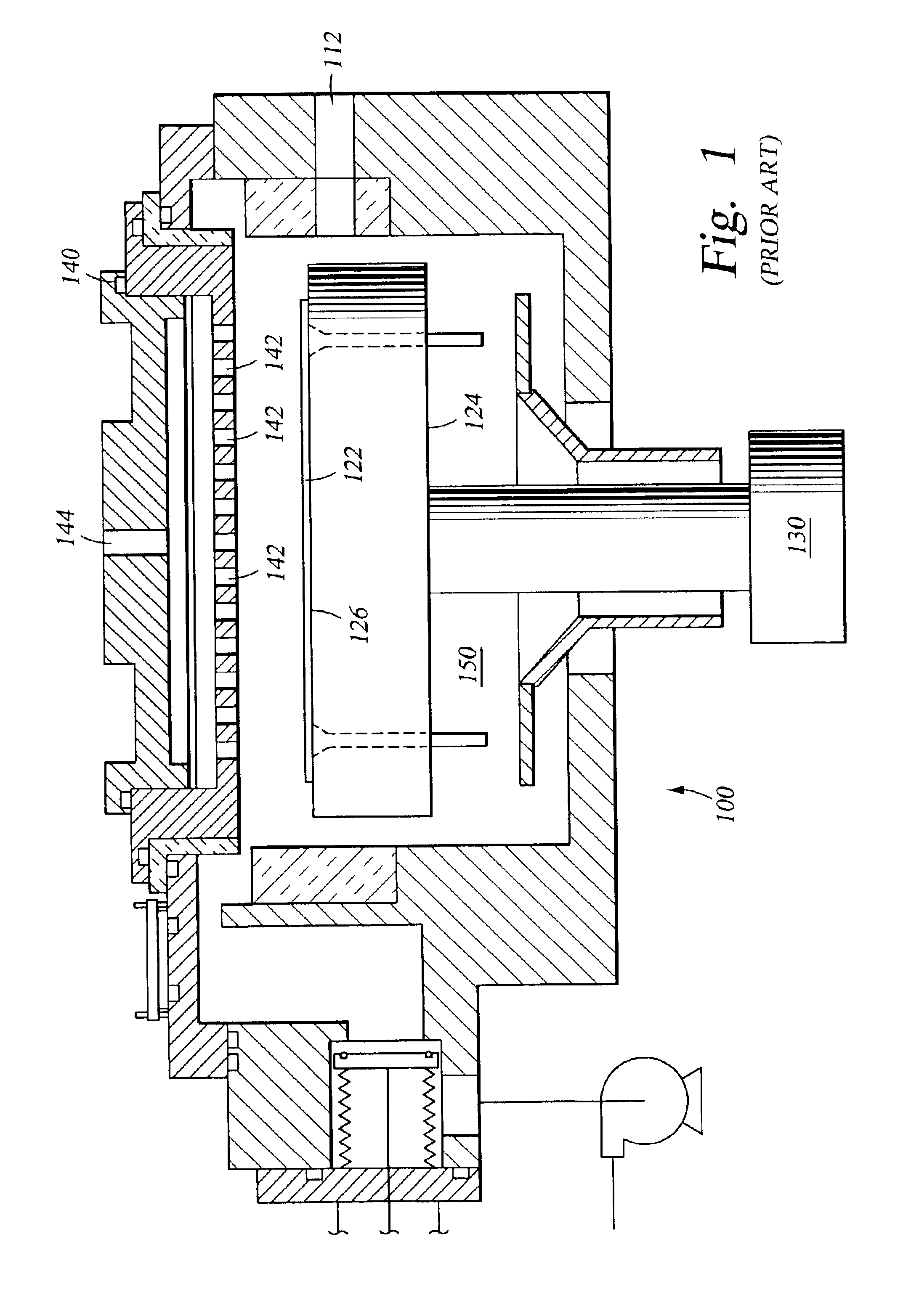

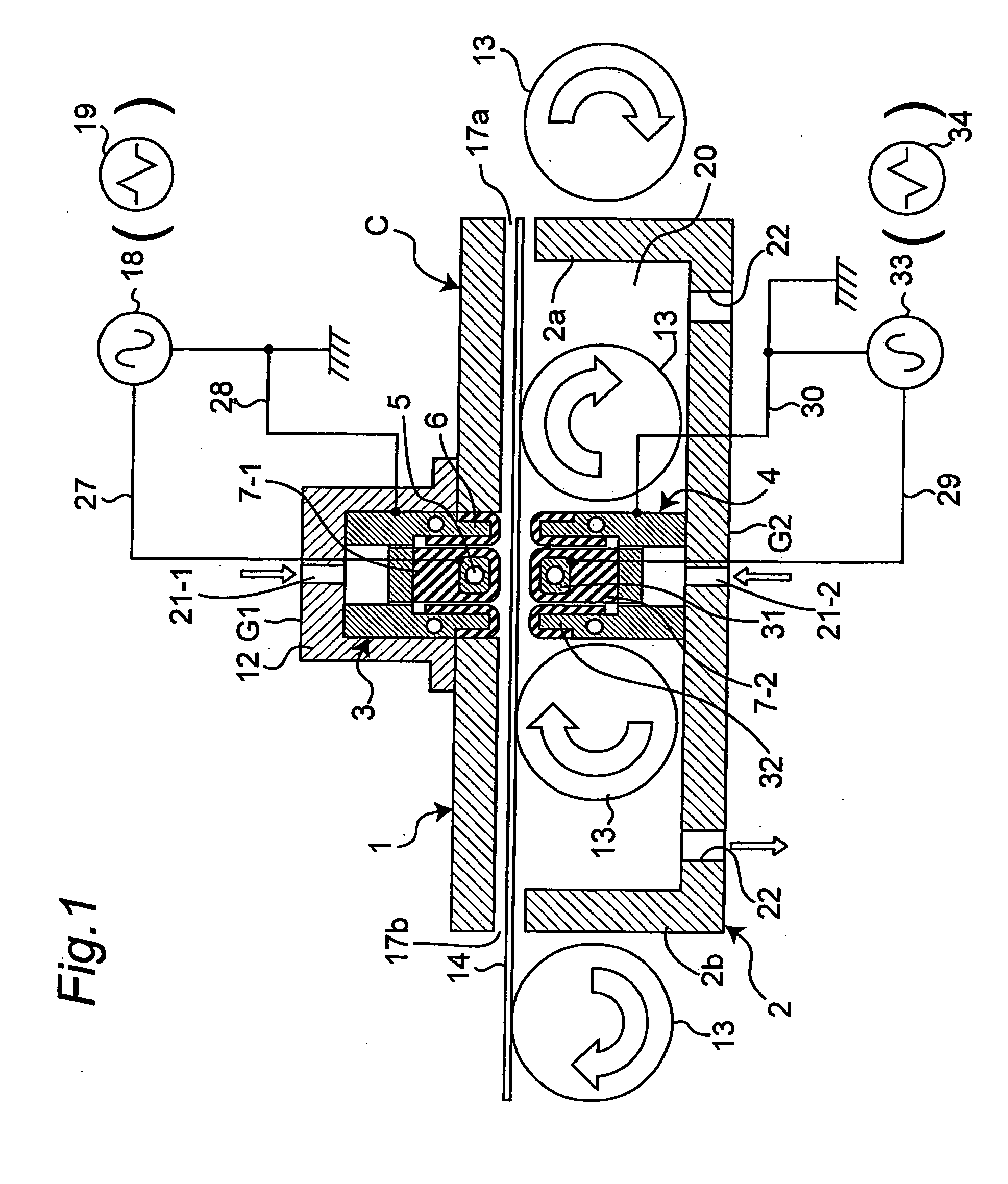

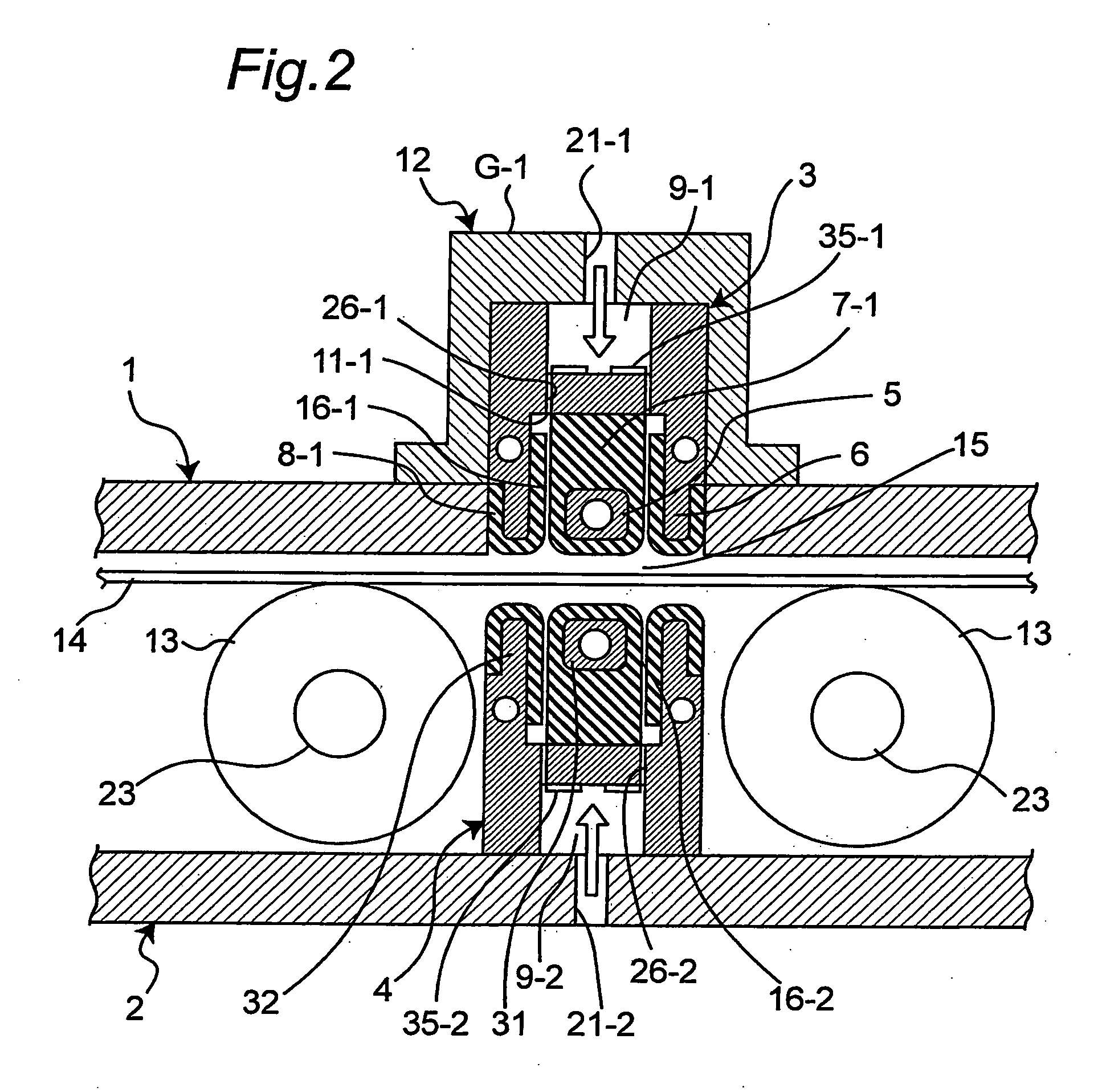

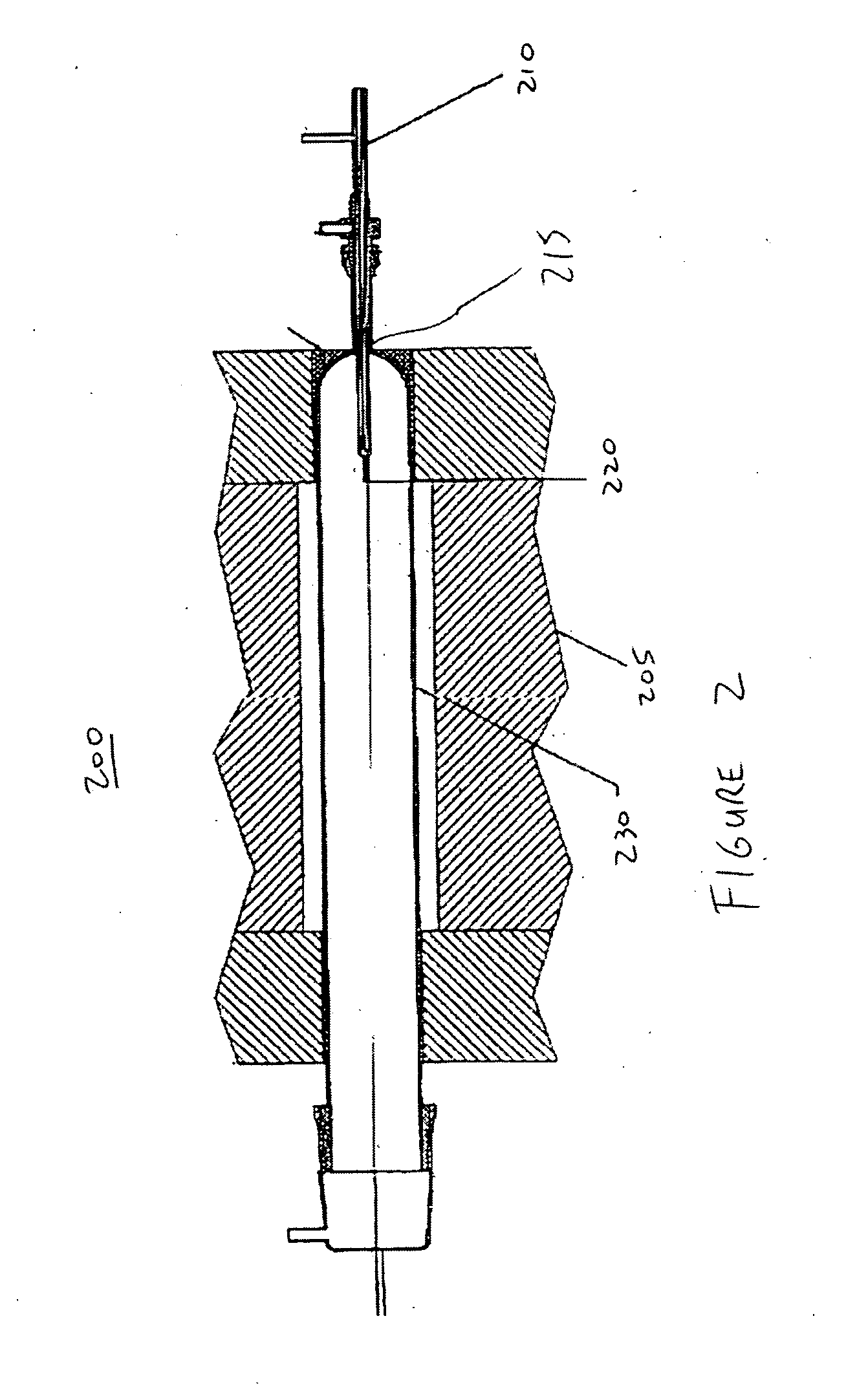

Reactor and method of processing a semiconductor substrate

InactiveUSRE37546E1Accurately determineEliminate needThermometer detailsRadiation pyrometryGas syringeEngineering

Owner:KOKUSAI SEMICON EQUIP CORP

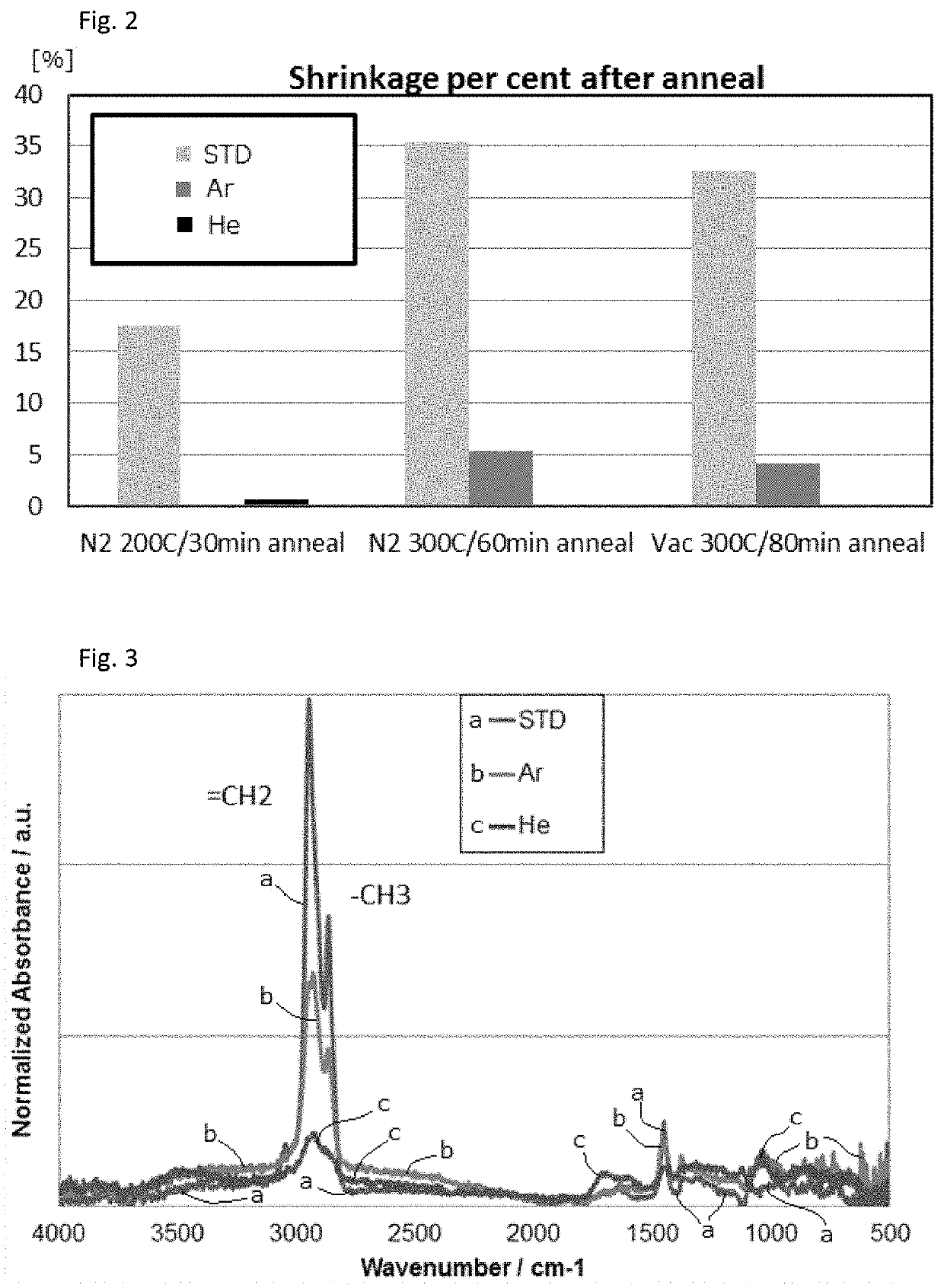

Method for reforming amorphous carbon polymer film

ActiveUS20210043444A1Improve thermal stabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingCarbon filmThin membrane

Owner:ASM IP HLDG BV

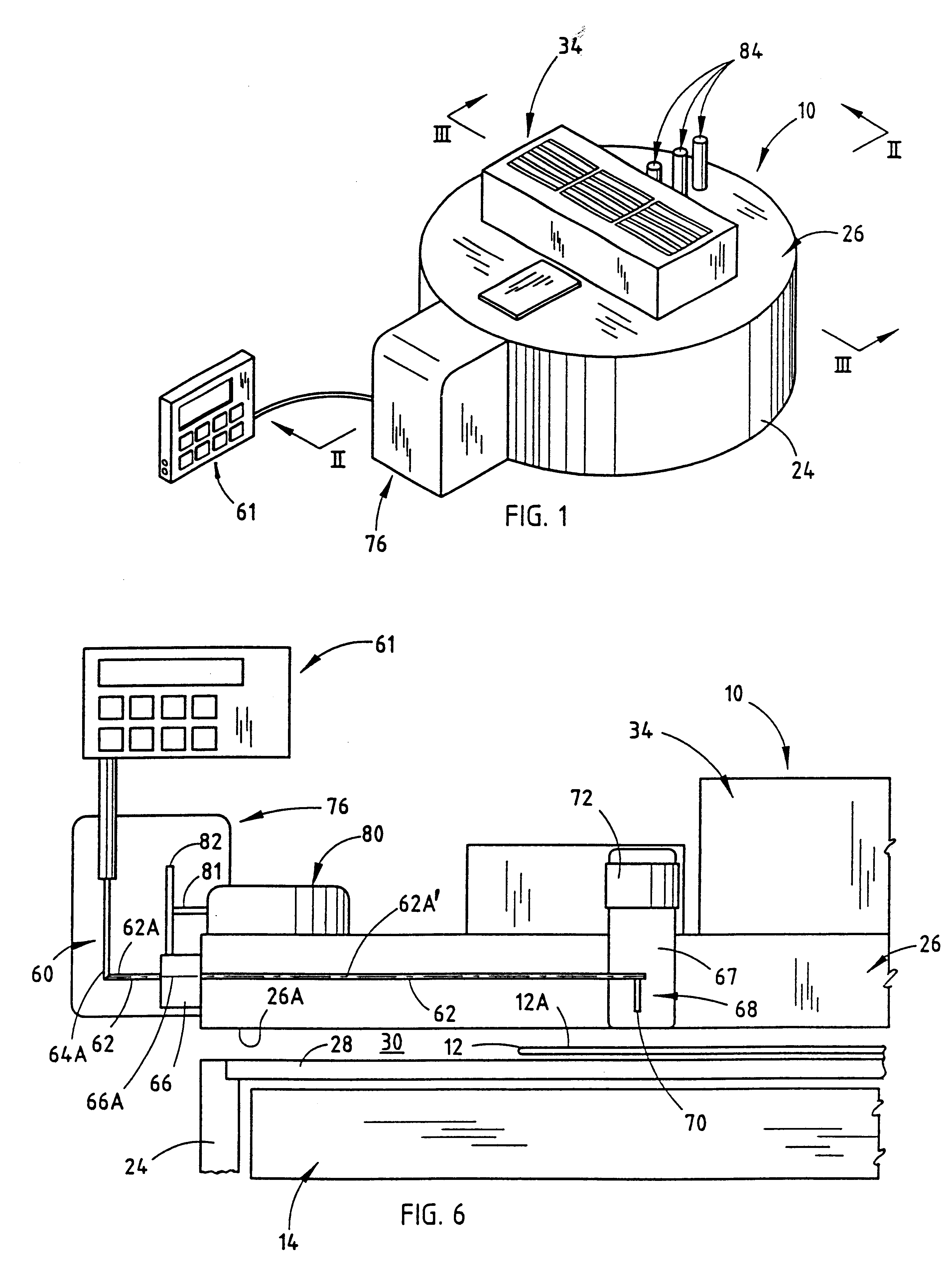

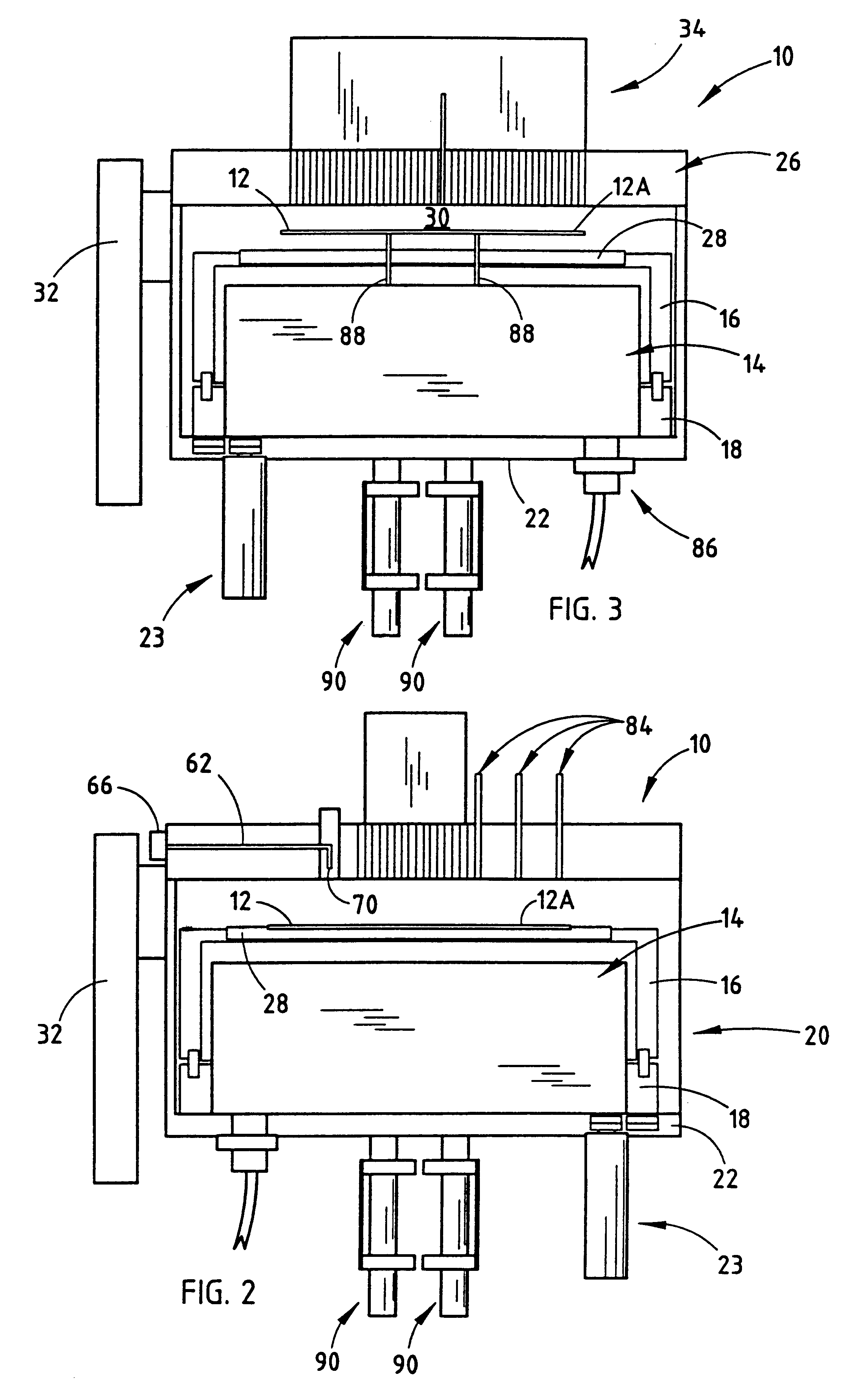

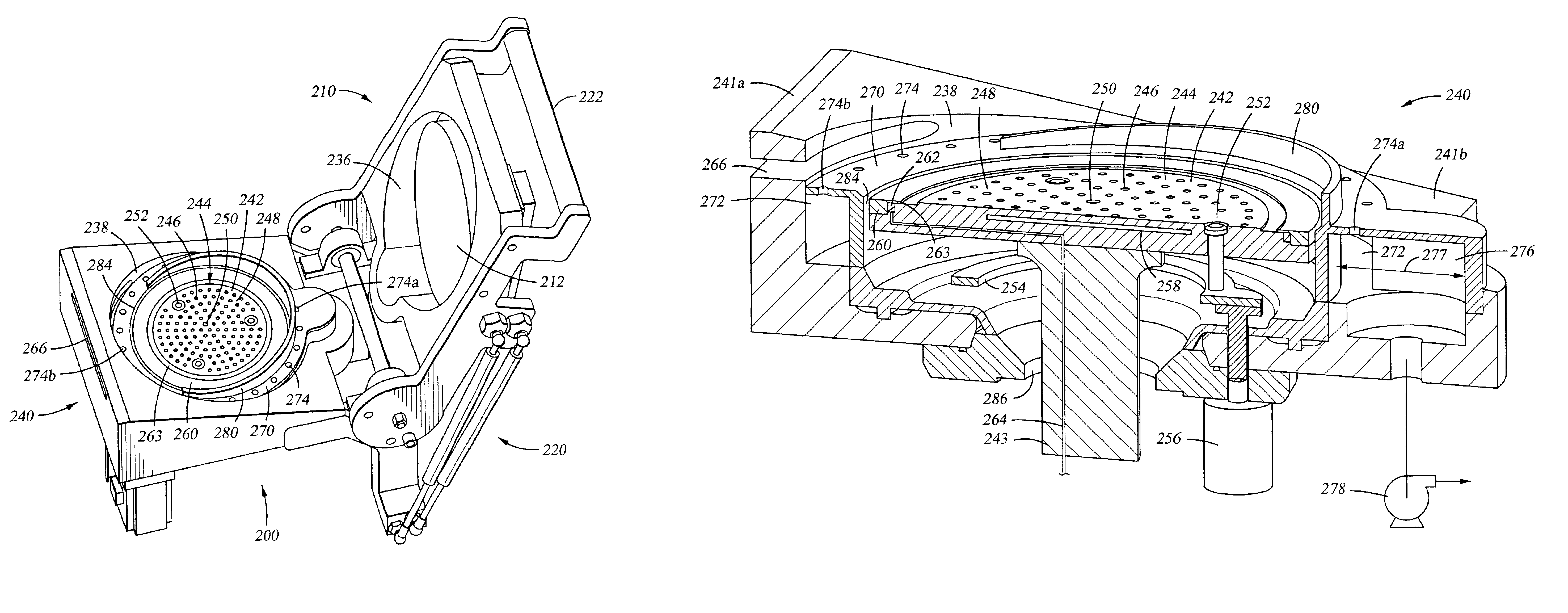

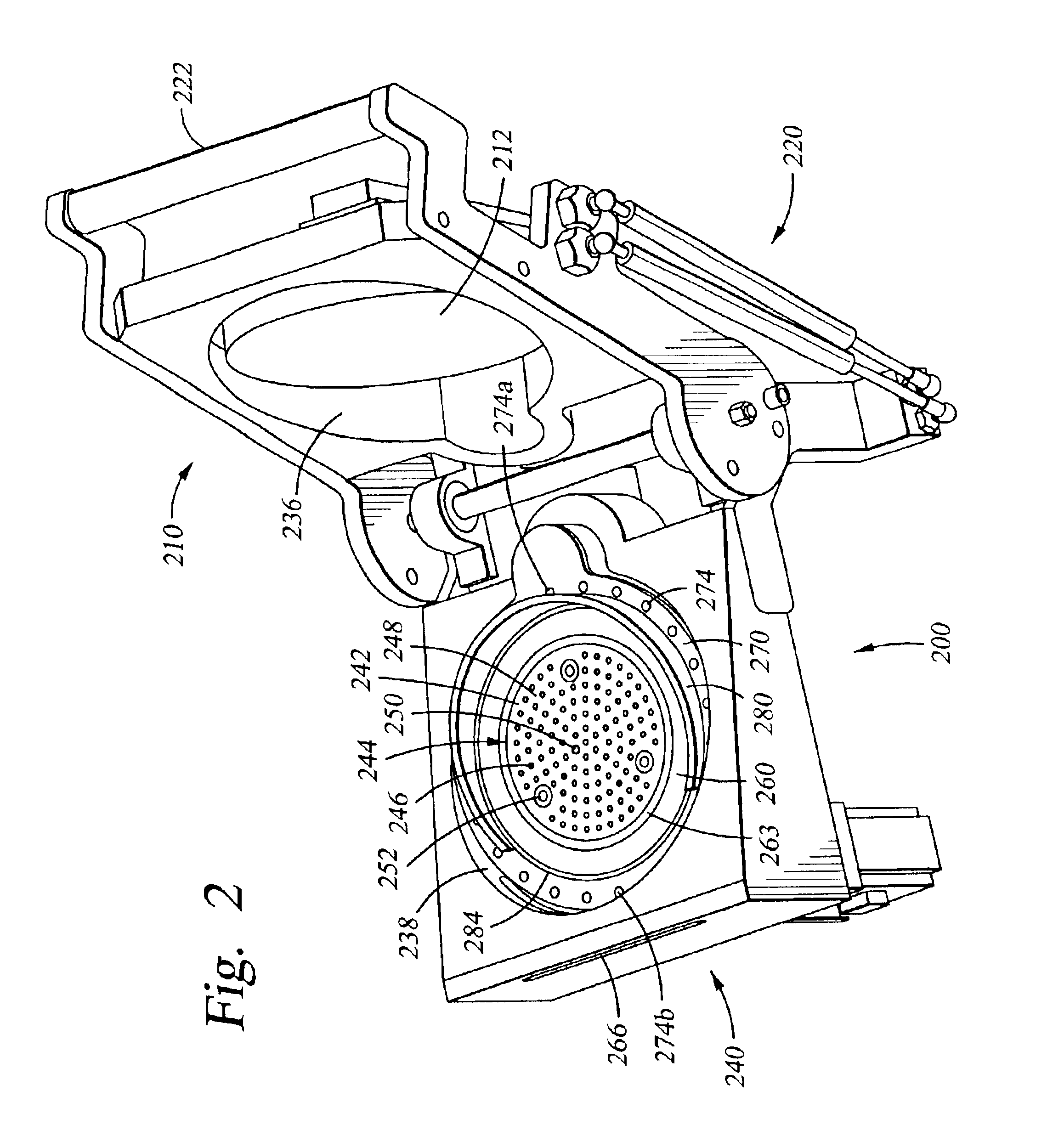

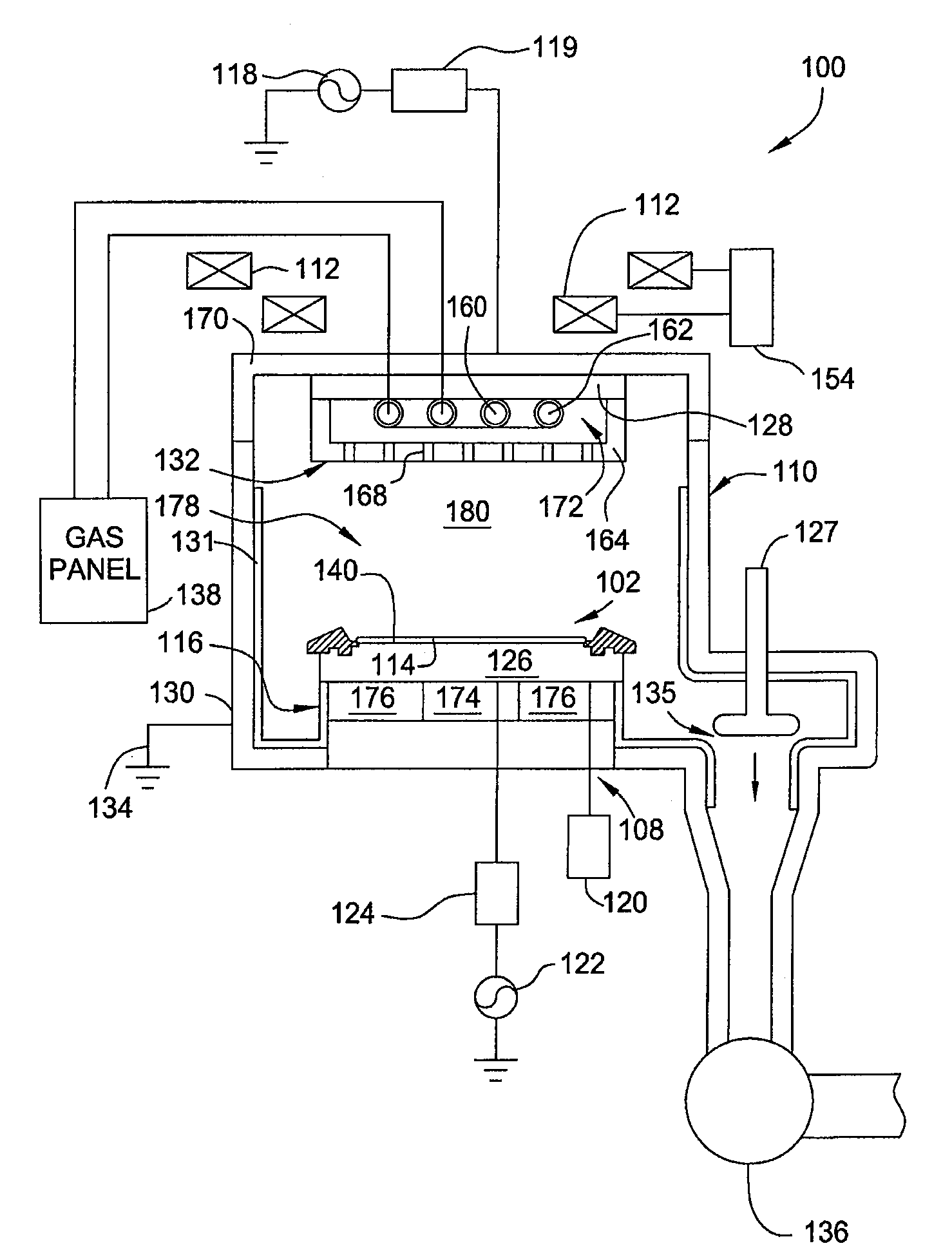

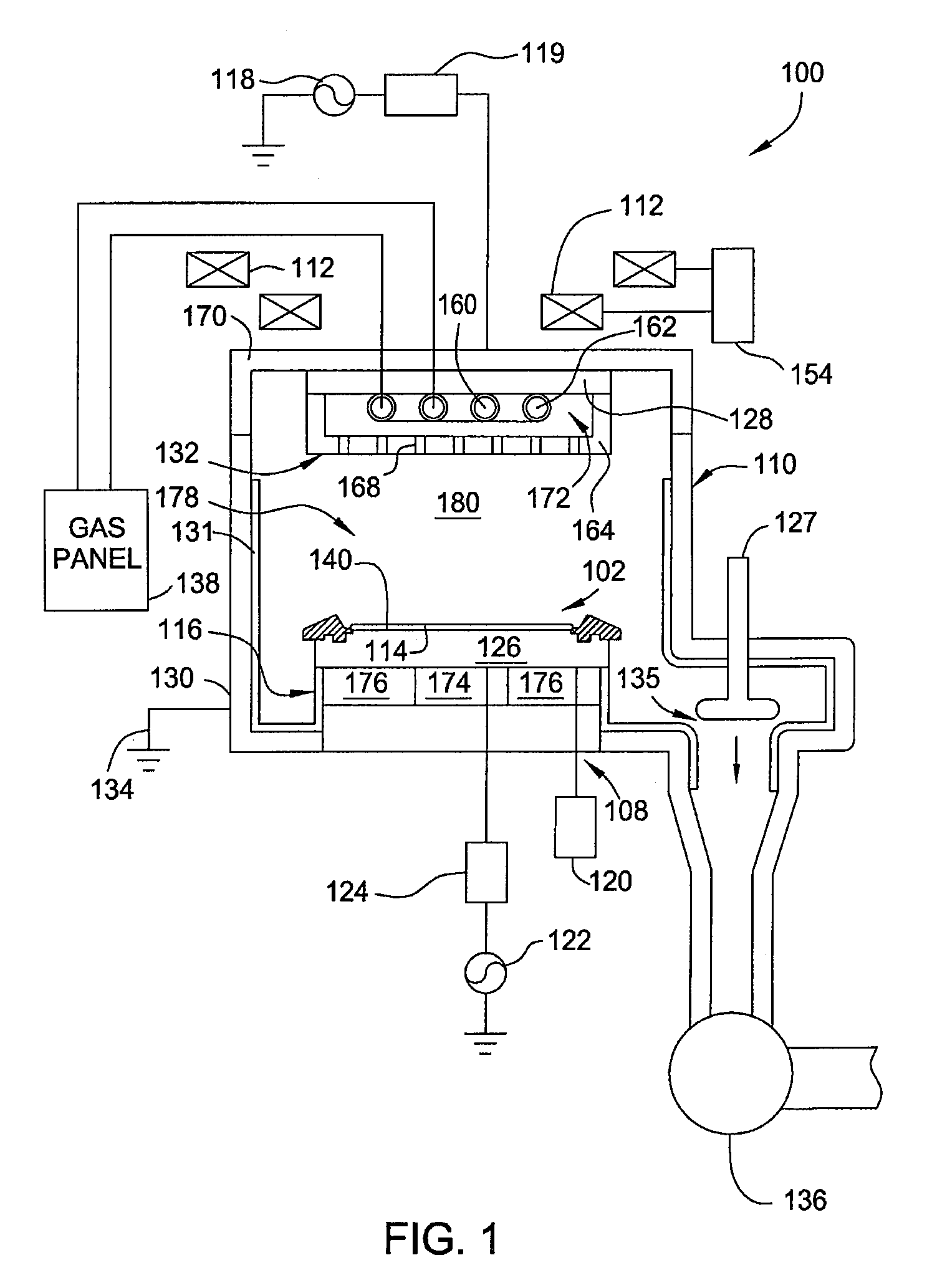

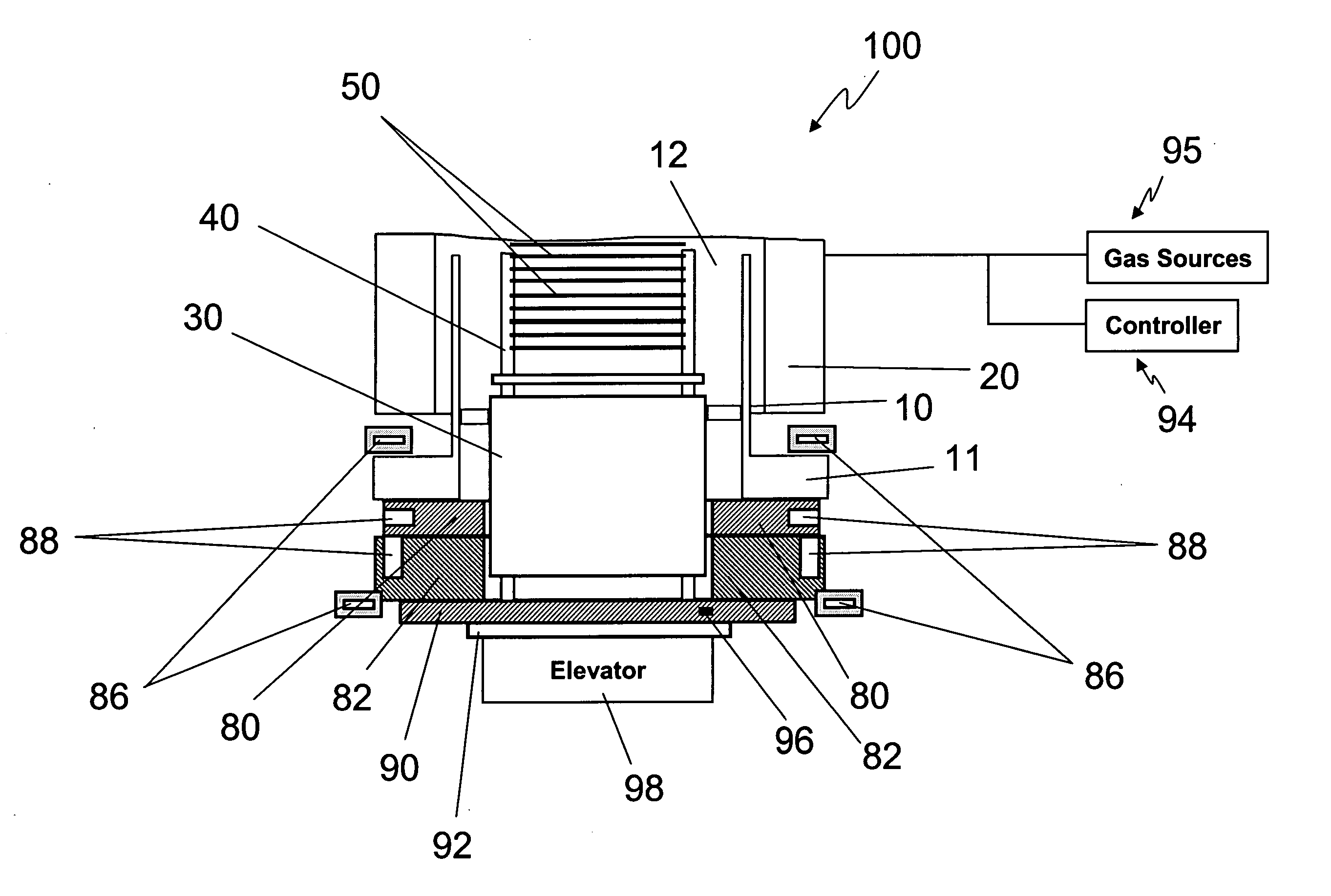

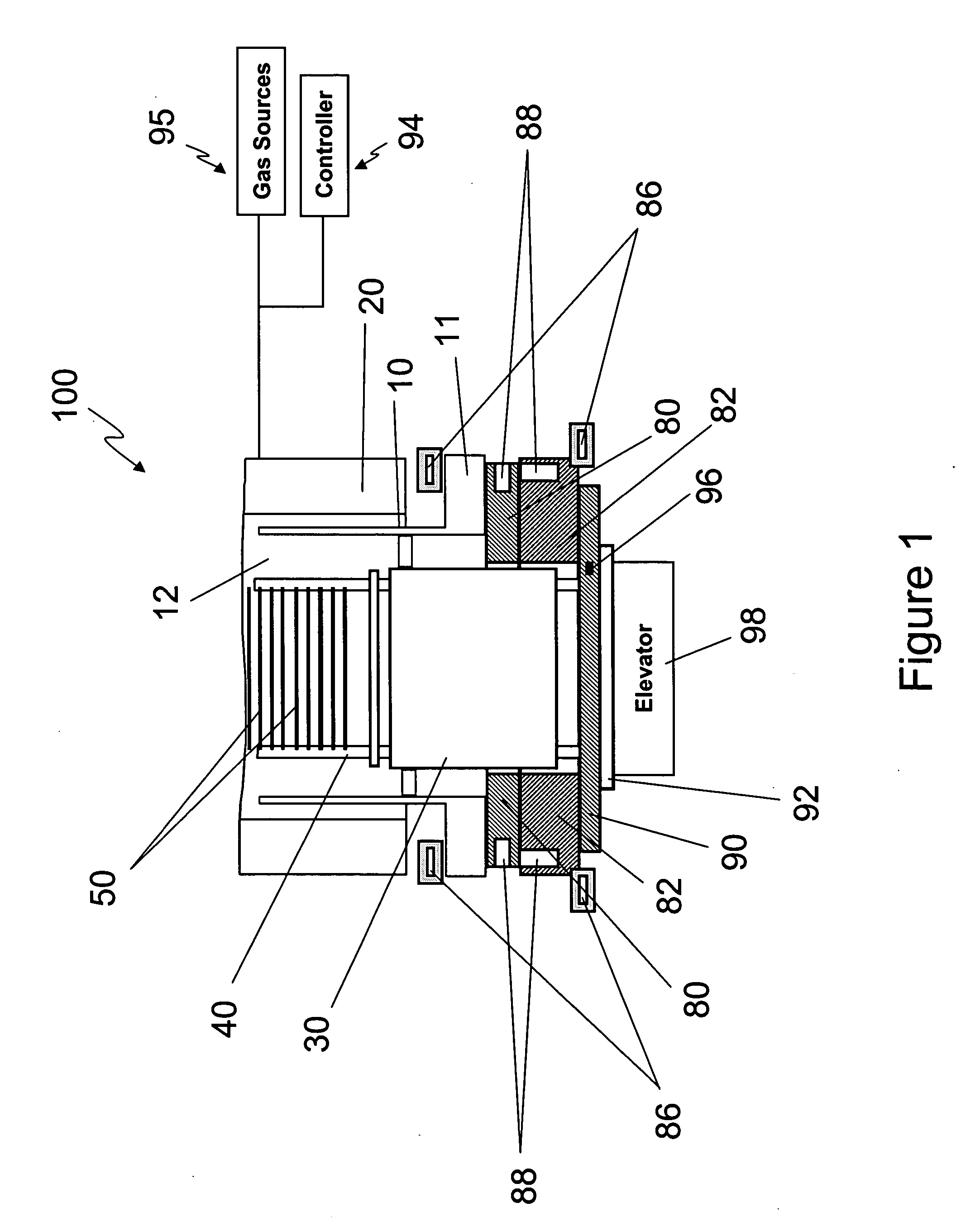

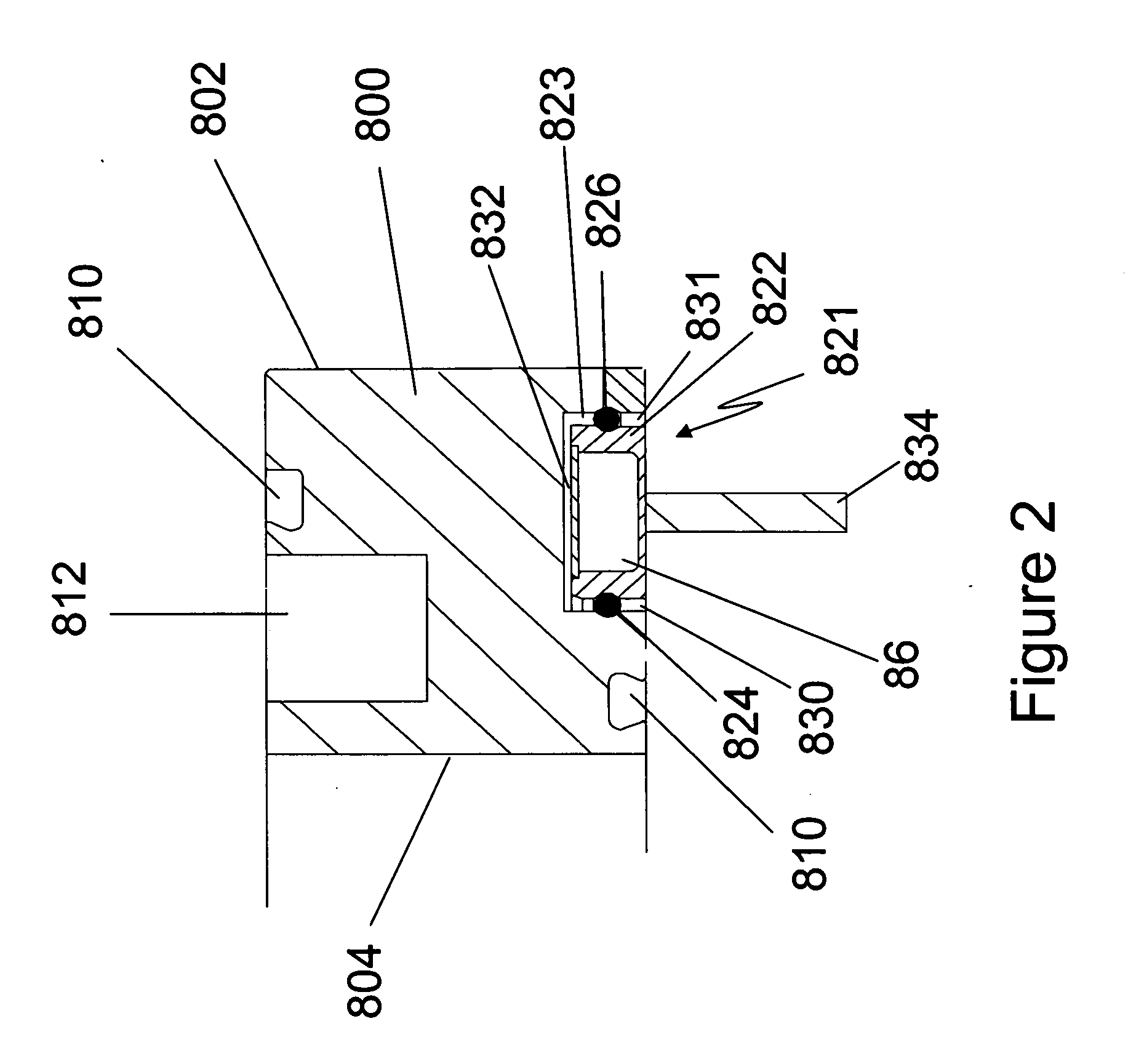

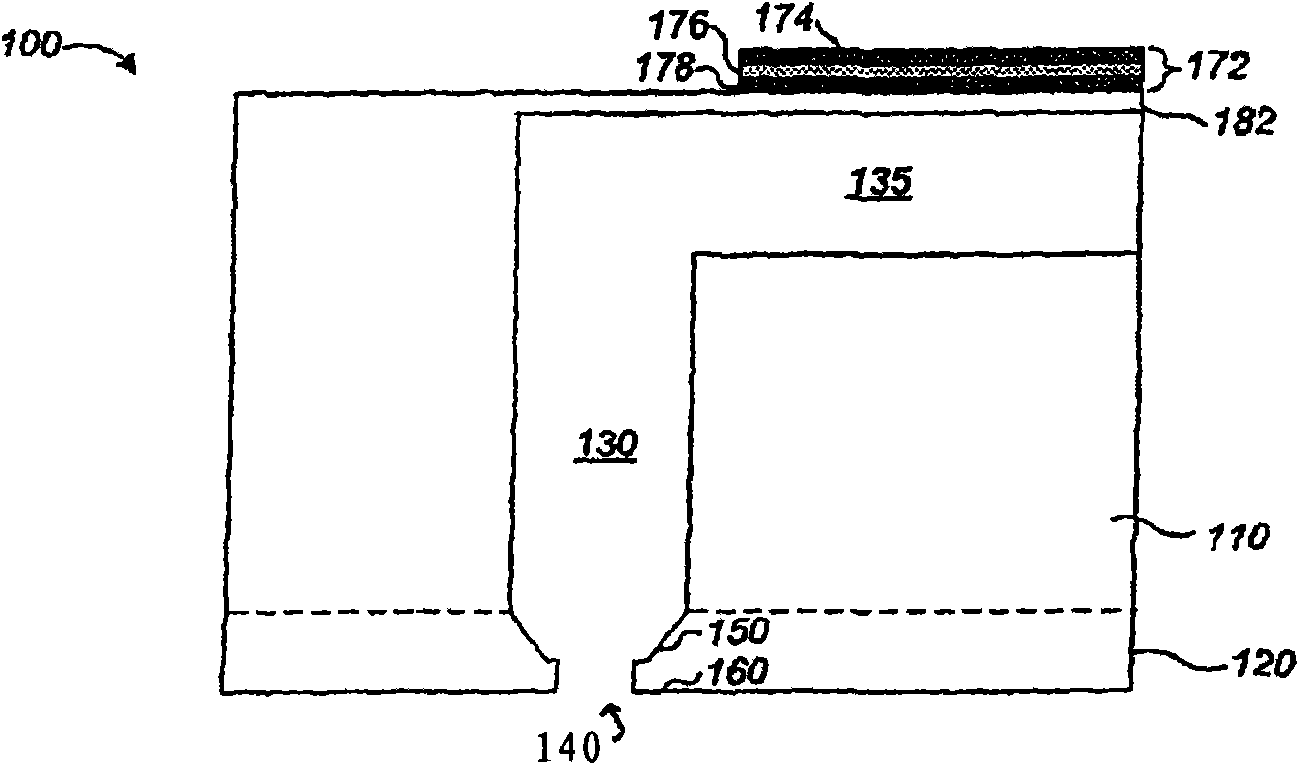

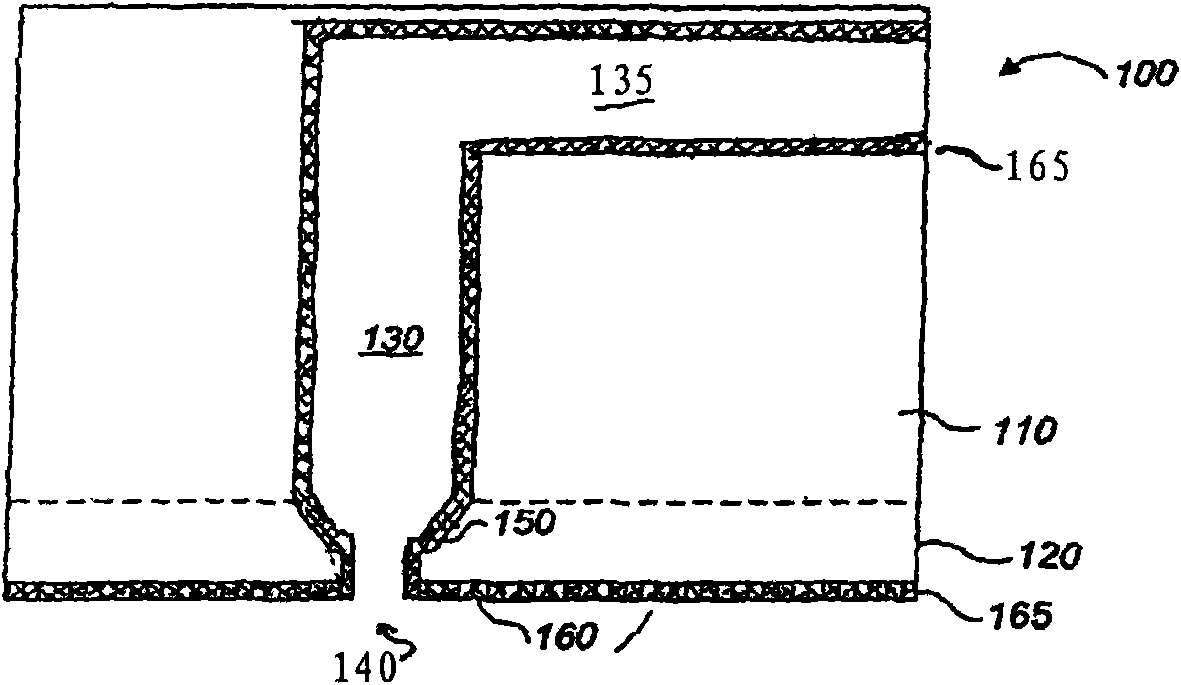

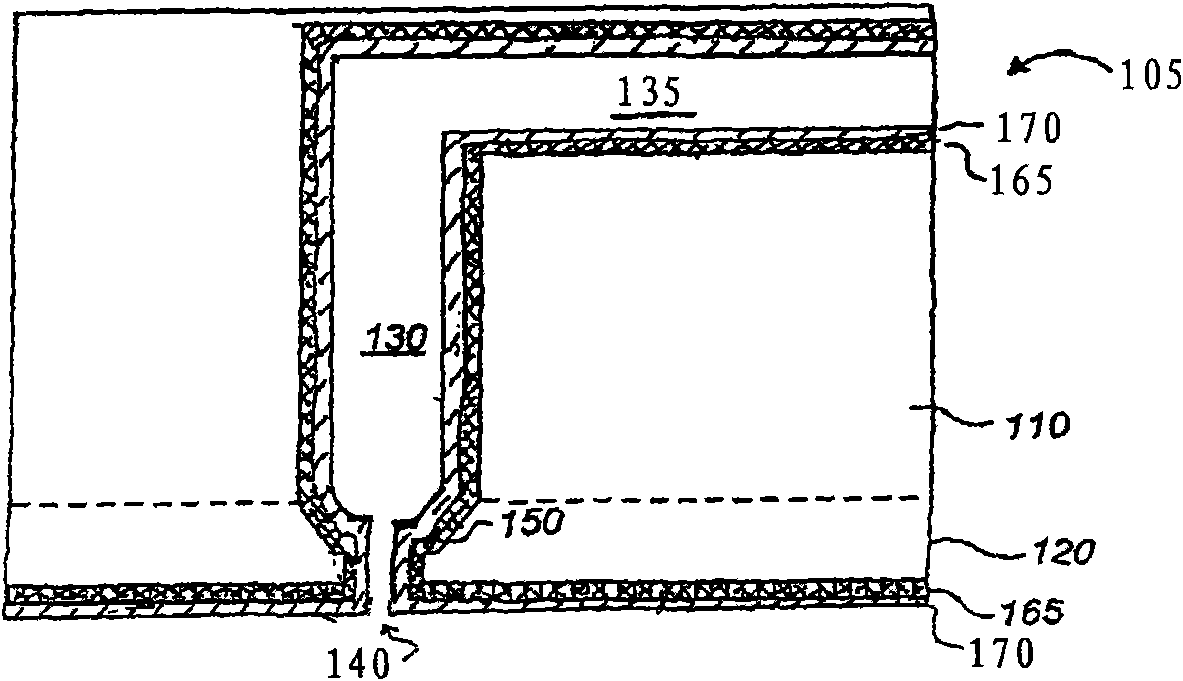

Clamshell and small volume chamber with fixed substrate support

InactiveUS6866746B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingHinge angleEngineering

Owner:APPLIED MATERIALS INC

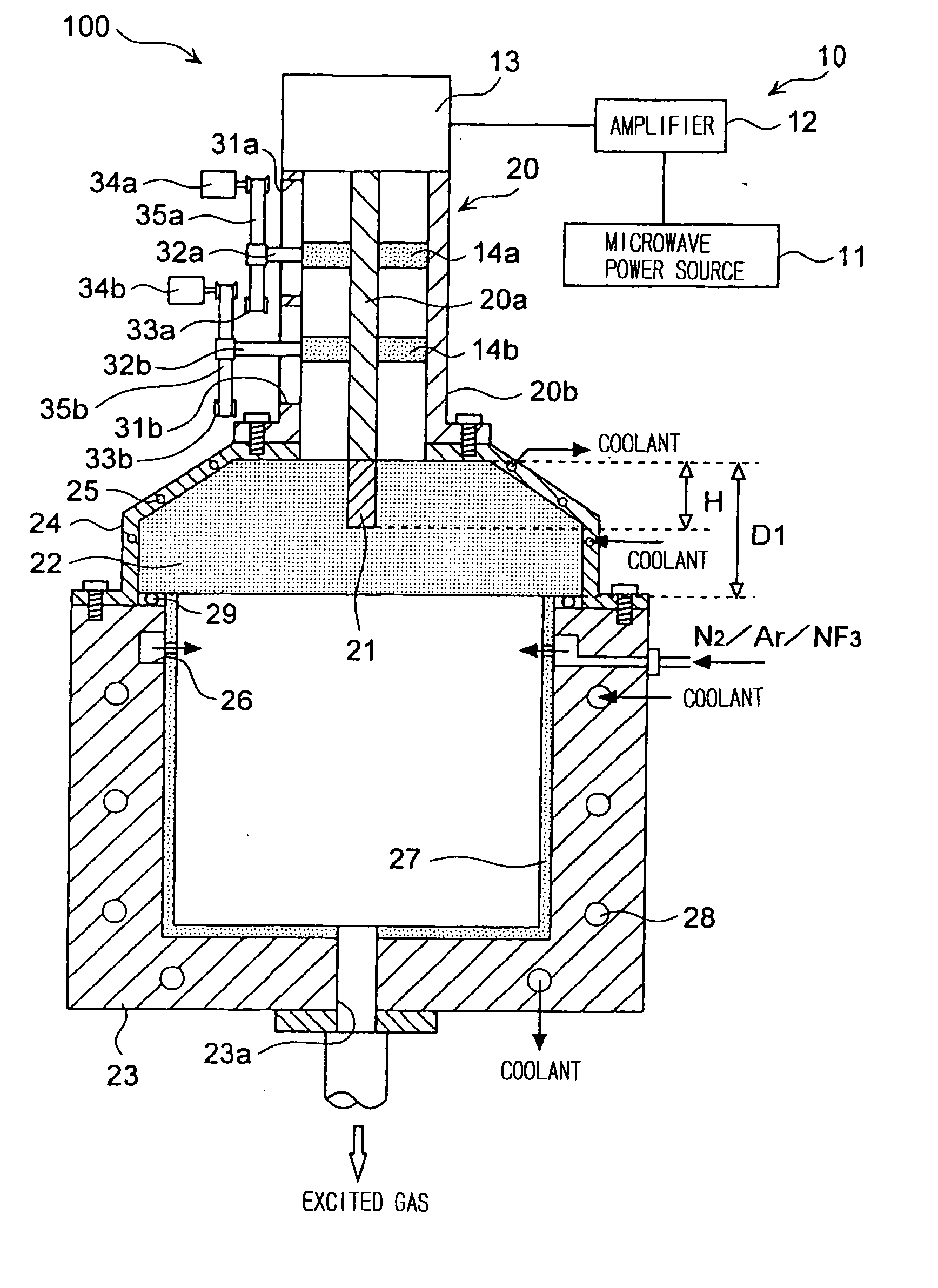

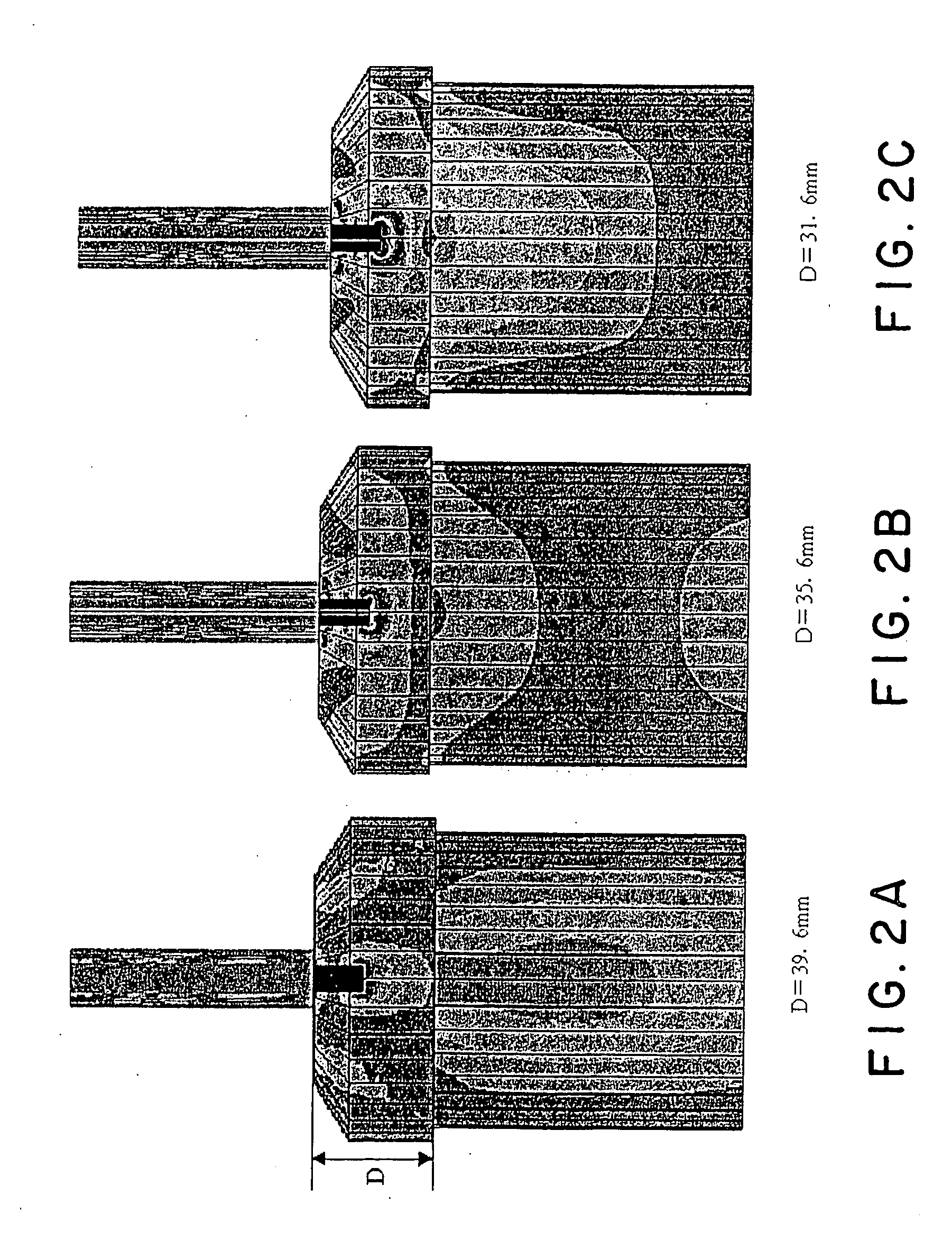

Plasma generating apparatus, plasma generating method and remote plasma processing apparatus

InactiveUS20060137613A1Improve plasma excitation efficiencySmall sizeElectric discharge tubesChemical vapor deposition coatingRemote plasmaCoaxial waveguides

Owner:TOKYO ELECTRON LTD

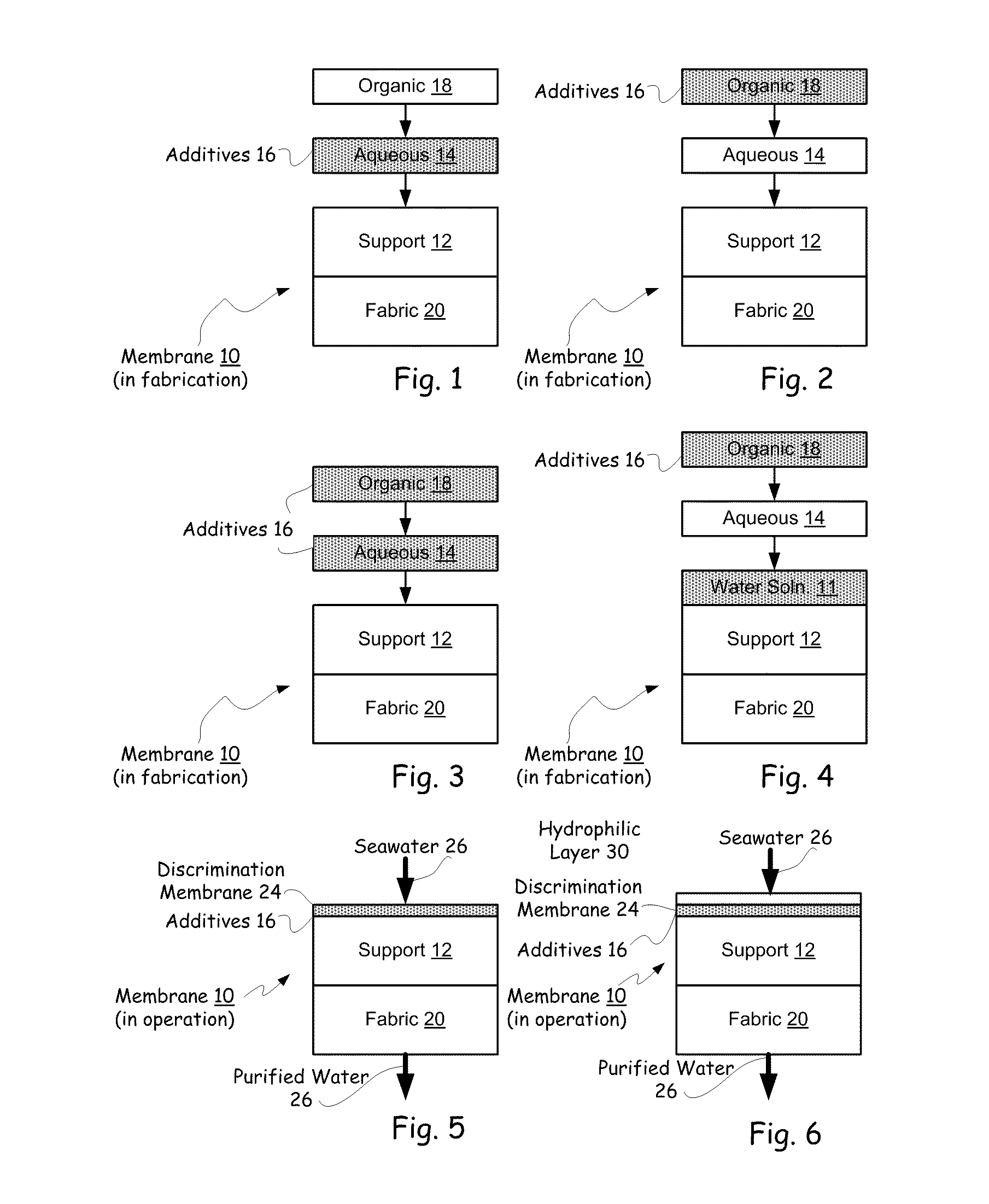

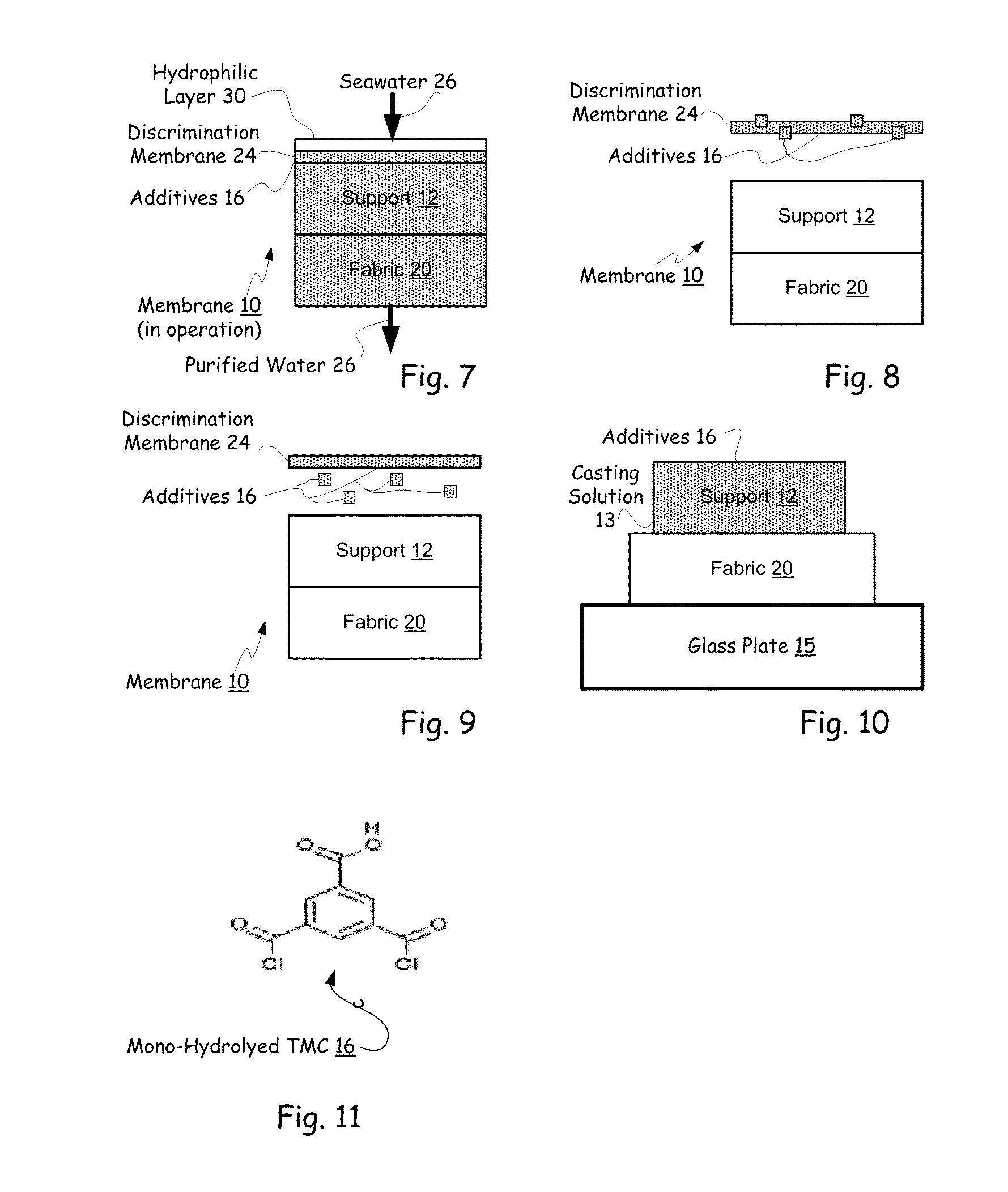

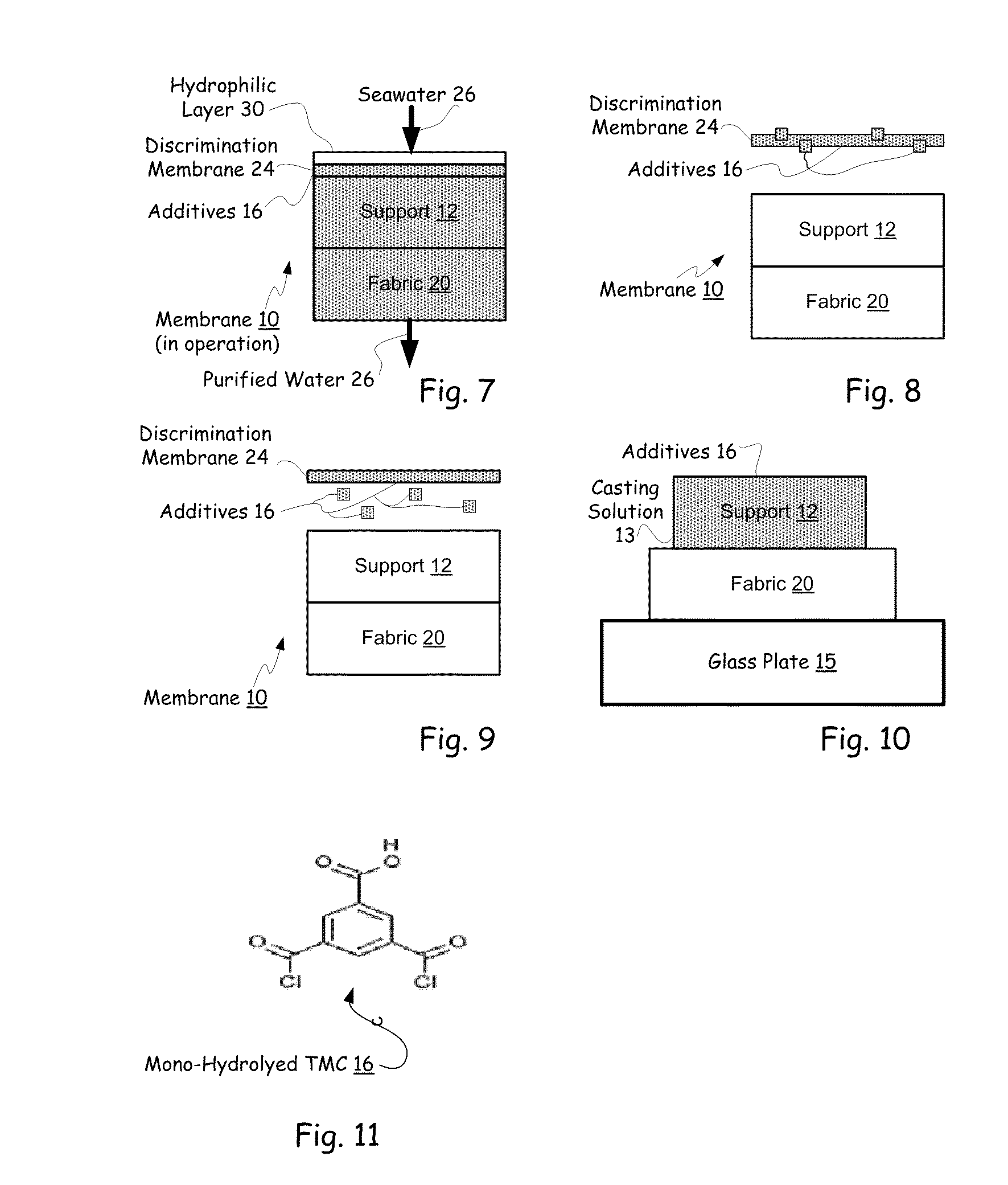

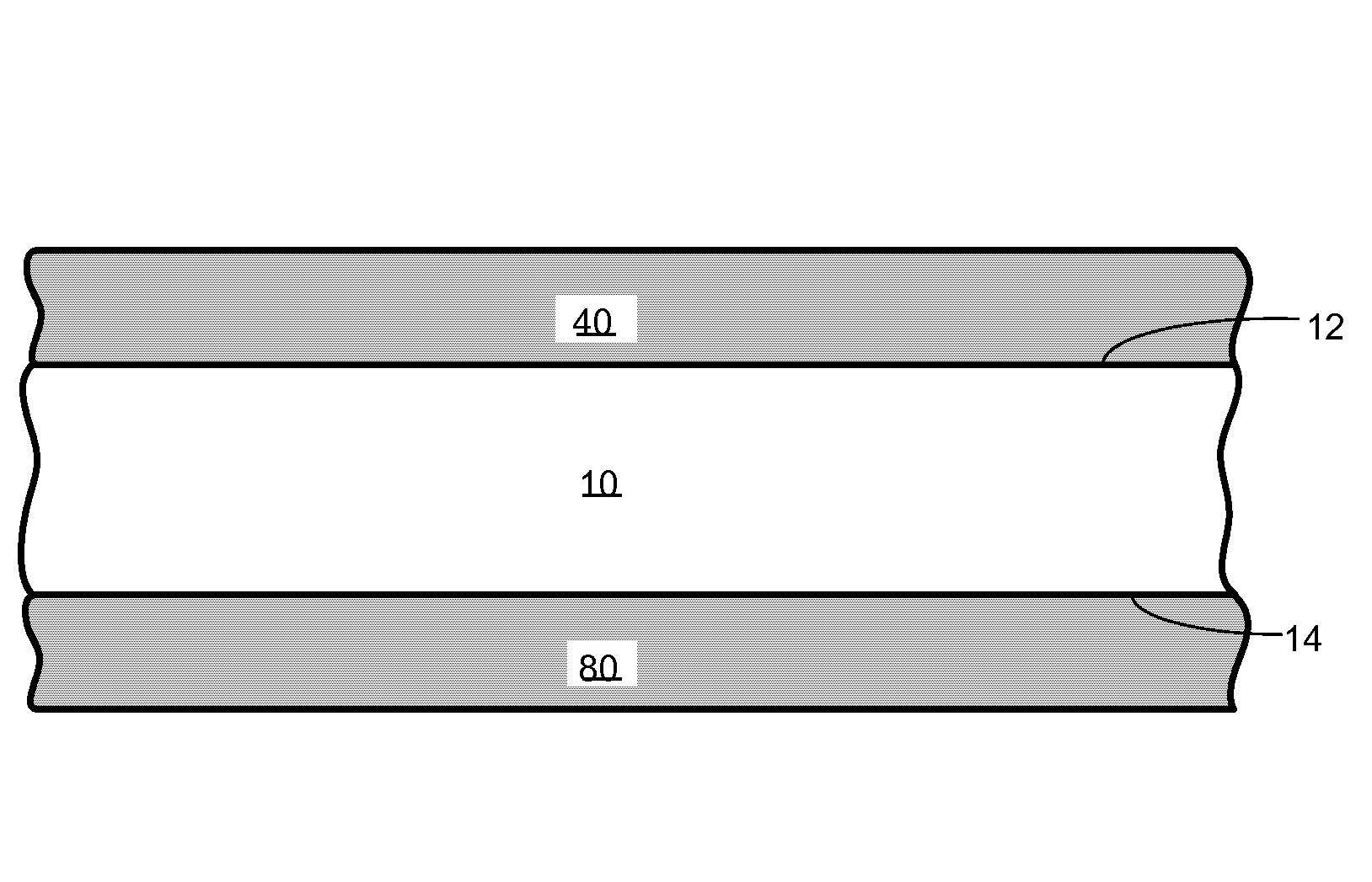

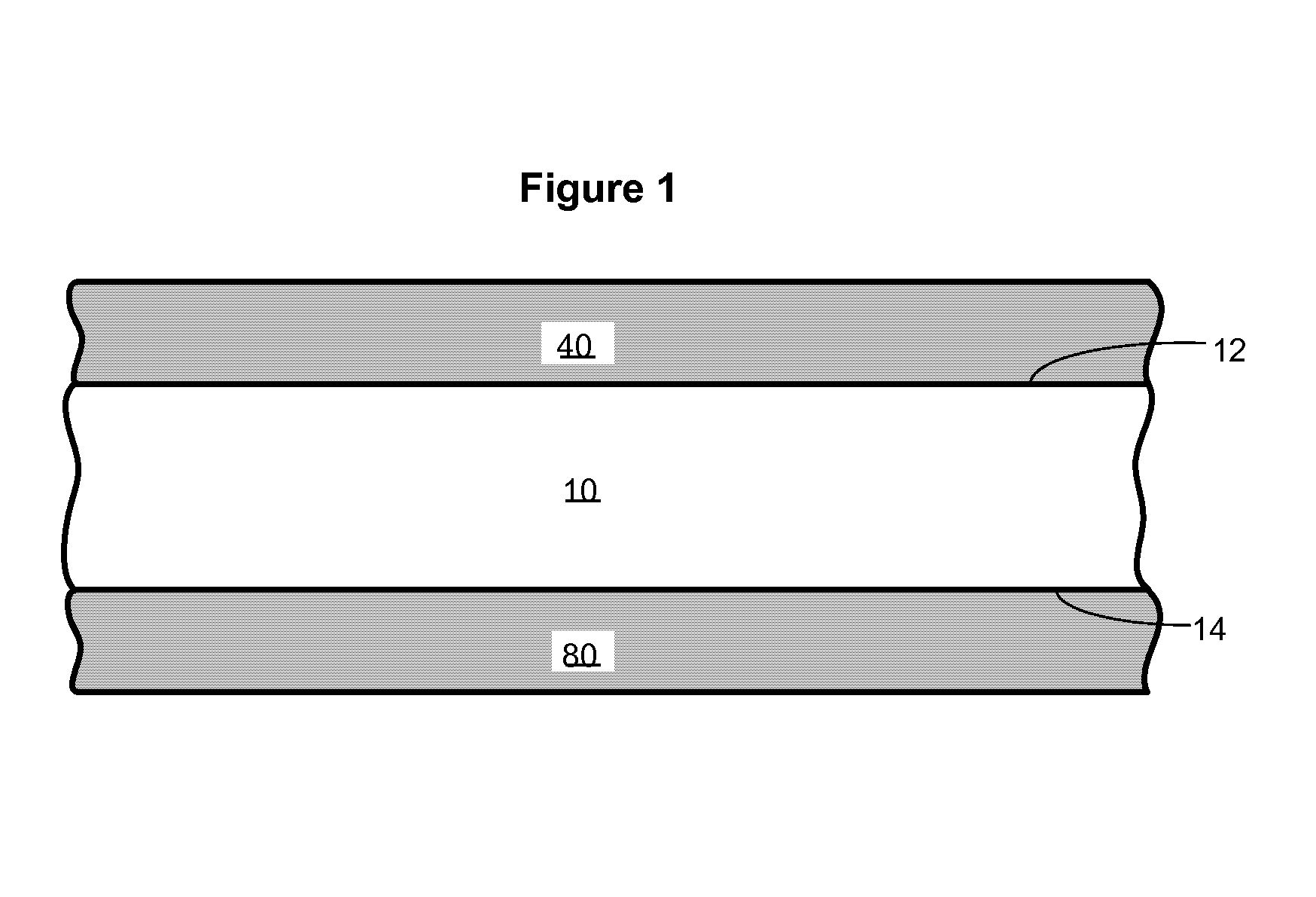

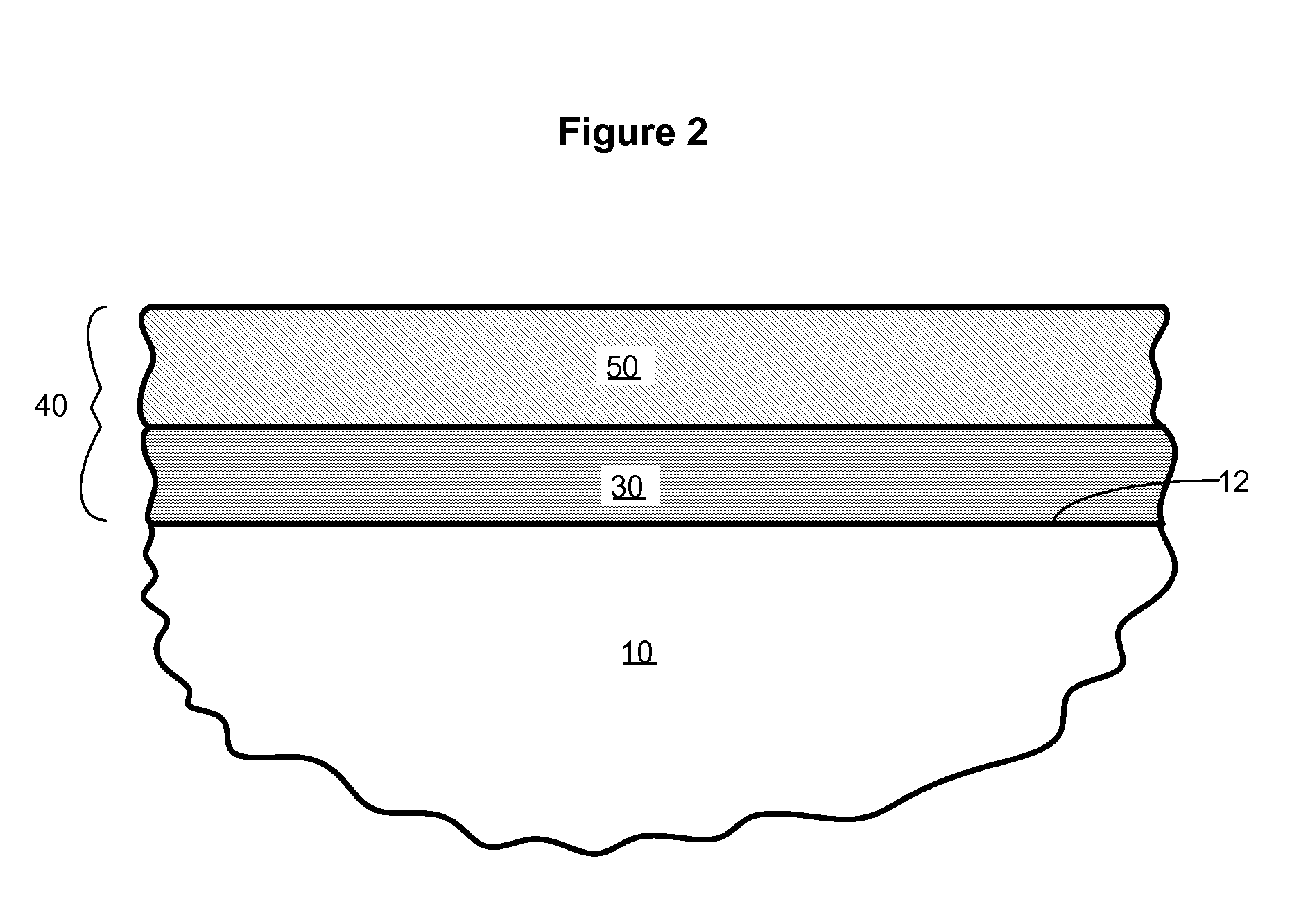

Hybrid tfc ro membranes with nitrogen additives

ActiveUS20110005997A1Increase fluxIncreased rejectionMembranesPretreated surfacesChloramine BAlkaline earth metal

Owner:NANOH2O

Method for treating a solid material to make it hydrophobic, material obtained and uses

InactiveUS6342268B1Simple and rapid and methodWater-repelling agents additionOther chemical processesChemical structureProduct gas

A solid material is treated, the chemical structure of which defines reactive protogenic hydrophillic functions accessible to gases, by applying at least one gas stream (3) onto at least one microdispersion (5) of at least one grafting reagent RX produced on the solid material, R being a hydrophobic group, X being chosen so that HX is volatile under normal conditions, R and X being chosen so that the reaction of RX on the hydrophillic functions produces covalent grafting of the hydrophobic group R with formation of the compound HX, it being possible for the reaction to be carried out in a solid / gas heterogeneous medium on all the reactive hydrophillic functions accessible to gases and only on these. The invention extends to the hydrophobic solid material obtained, and is applicable to the obtaining of natural or artificial fibrous or inorganic structures impermeable to water and to aqueous solutions and / or absorbing fats.

Owner:BT3 TECH

Opposed functional coatings having comparable single surface reflectances

ActiveUS20070248756A1Low-emissivity coatingLiquid surface applicatorsDoors/windowsLow emissivityMetallurgy

Owner:CARDINAL CG

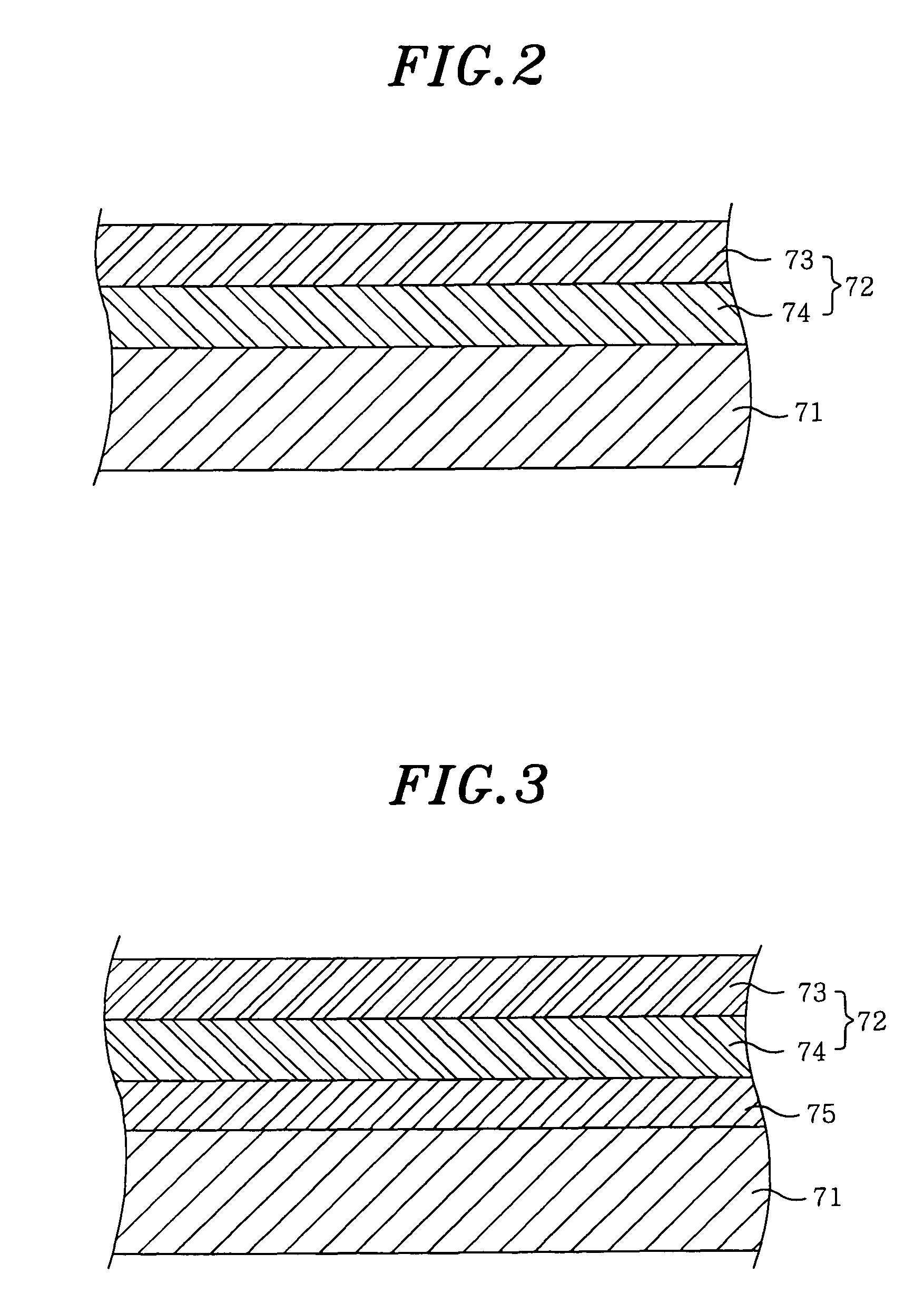

Internal member of a plasma processing vessel

ActiveUS7780786B2Prevent peelingLiquid surface applicatorsMolten spray coatingThermal sprayingMetallurgy

Owner:TOKYO ELECTRON LTD

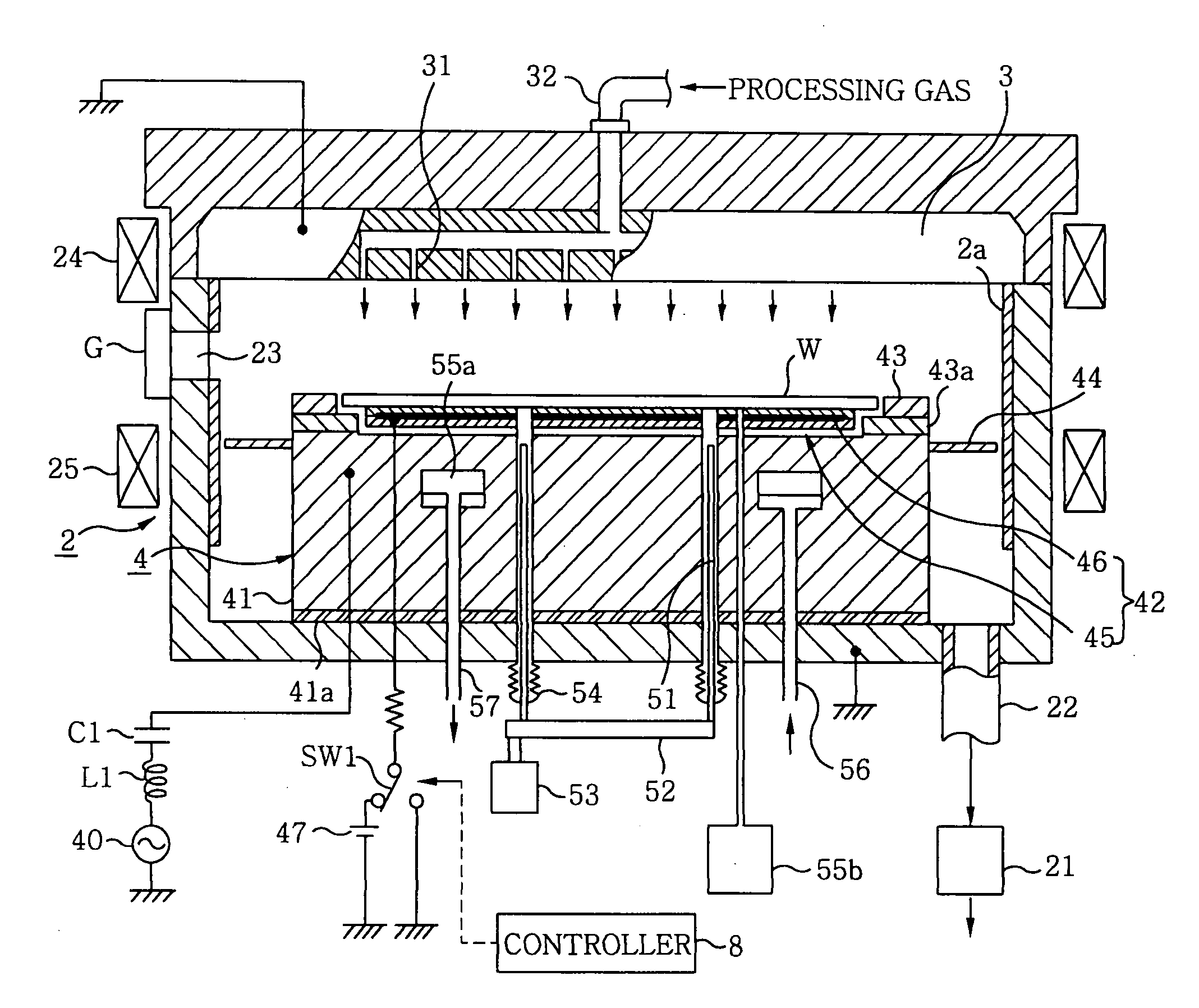

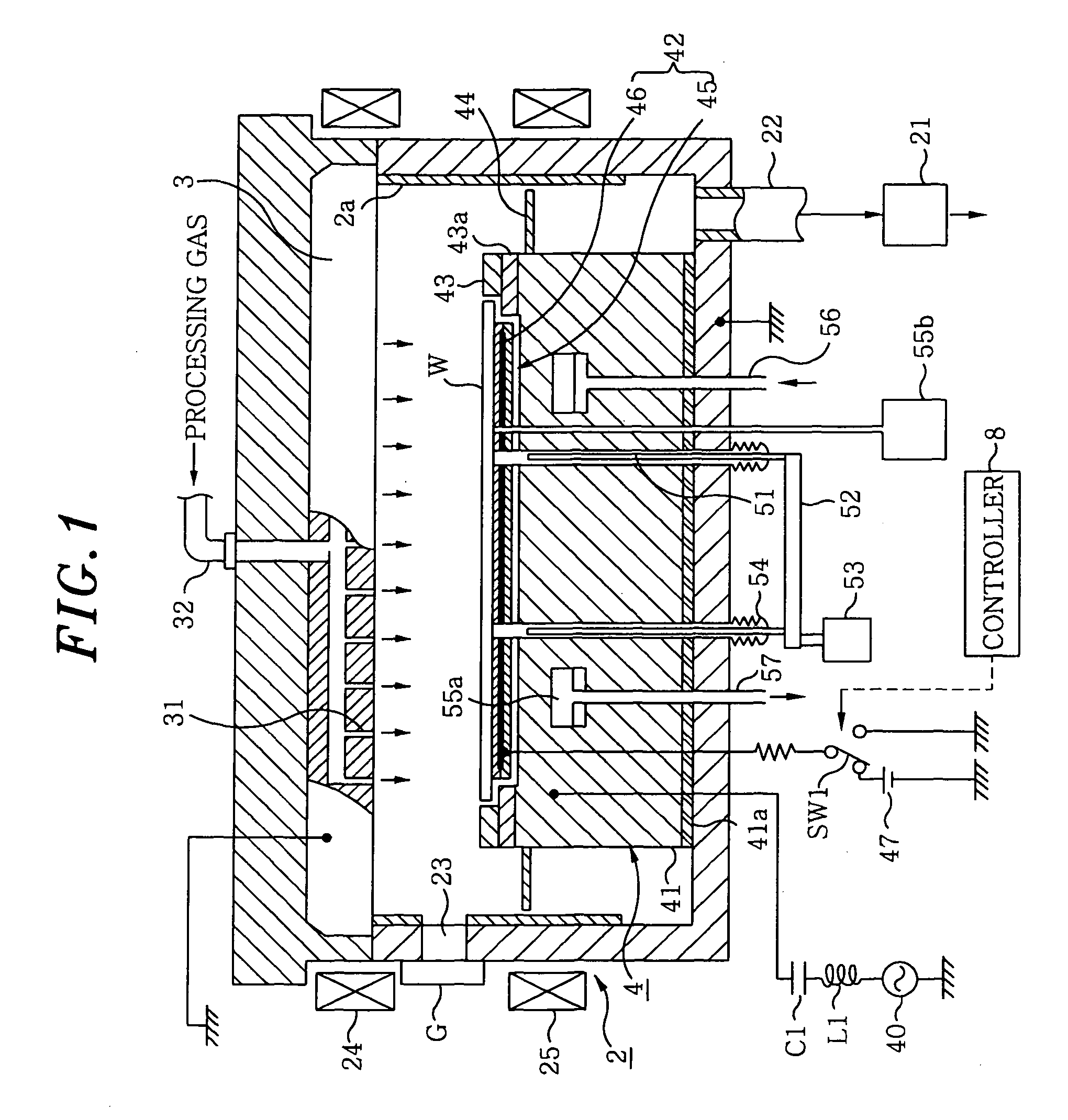

Plasma processing apparatus

InactiveUS20050217798A1Plasma discharge can be stabilizedLow running costElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringMaterials science

Owner:SHARP KK

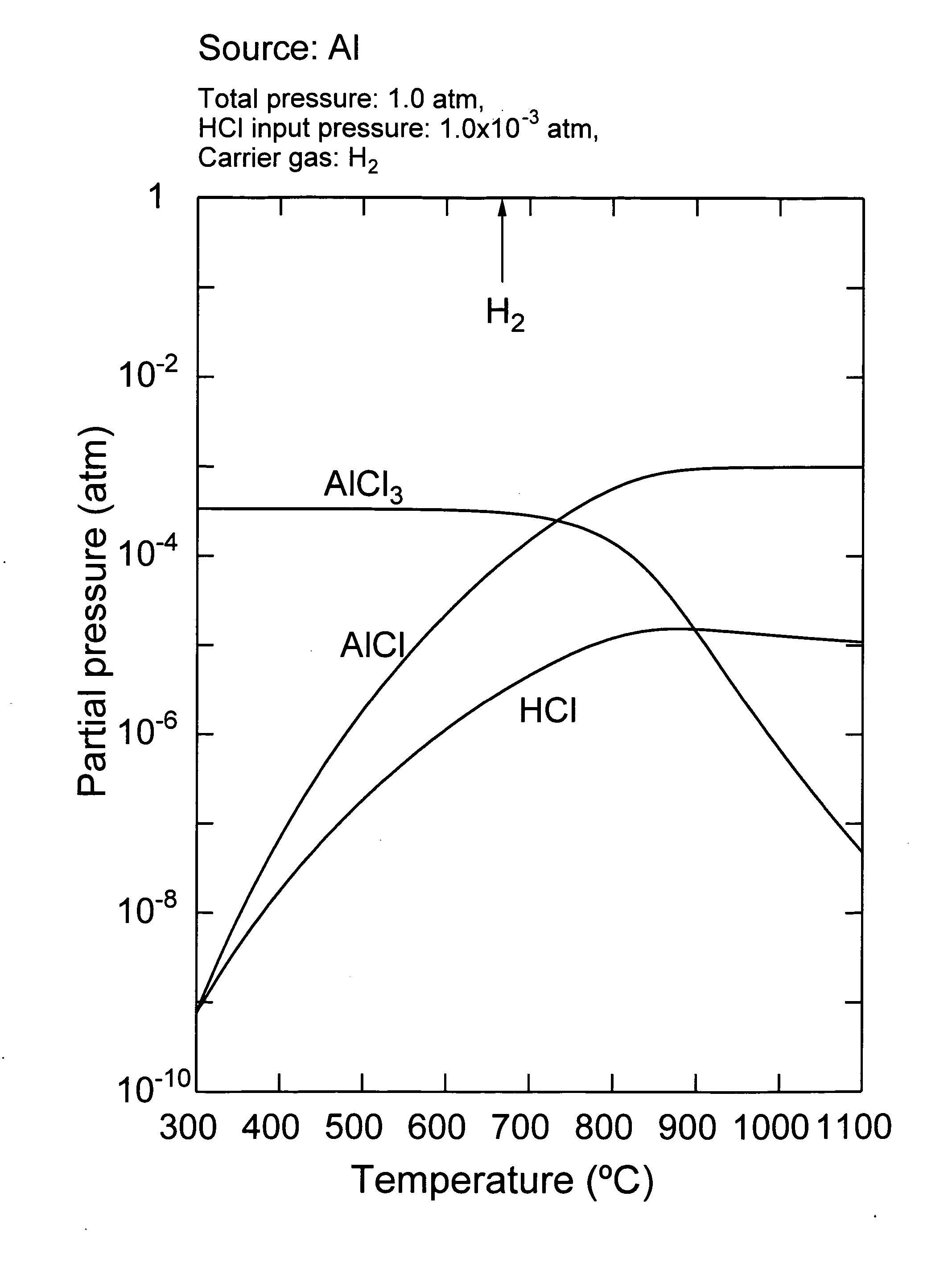

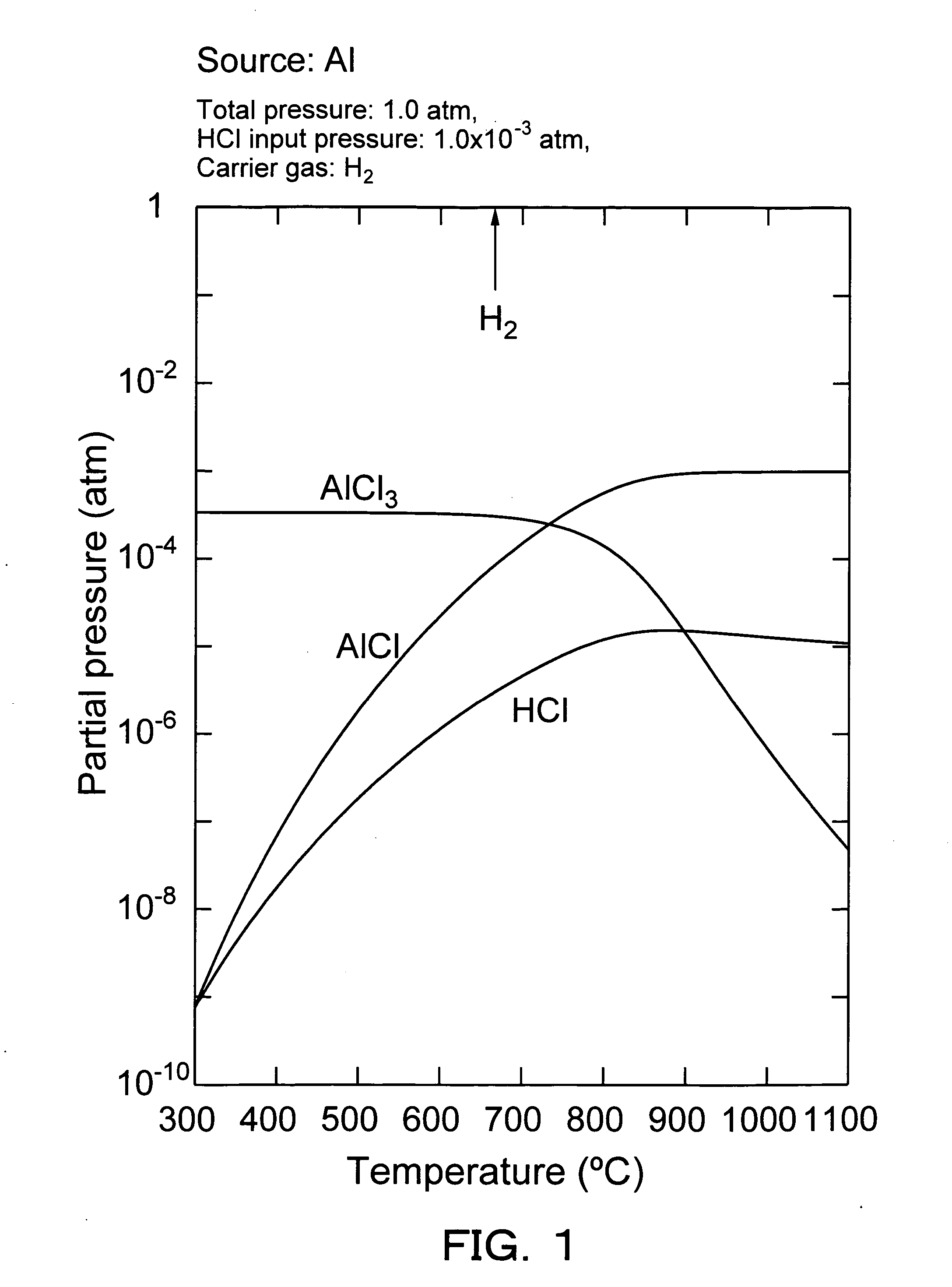

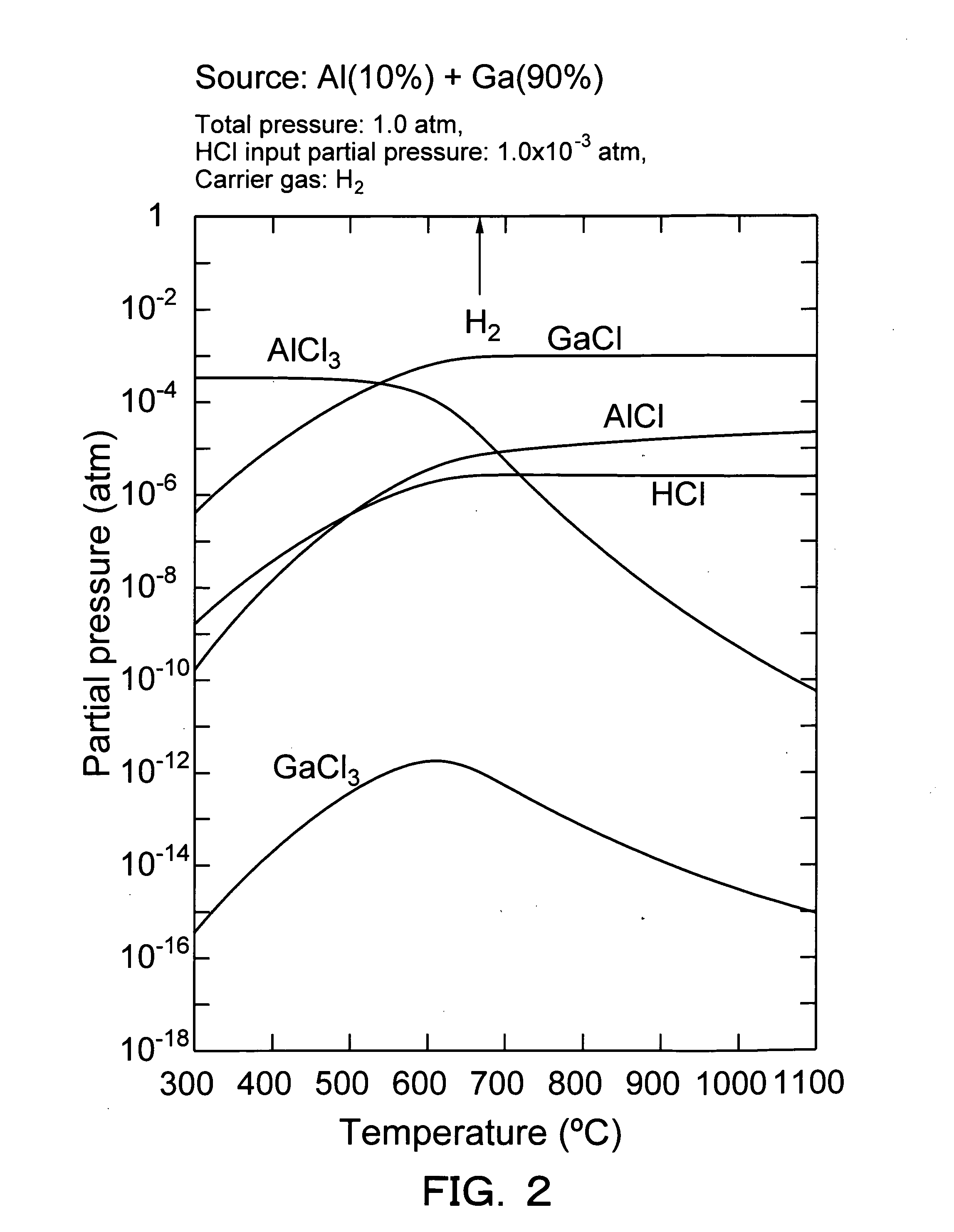

Vapor phase growth method for al-containing III-V group compound semiconductor, and method and device for producing al-containing IIl-V group compound semiconductor

InactiveUS20050166835A1Inhibits the formation of cracksAfter-treatment apparatusPolycrystalline material growthHydrogen halideGas phase

Owner:NOKODAI TLO KK

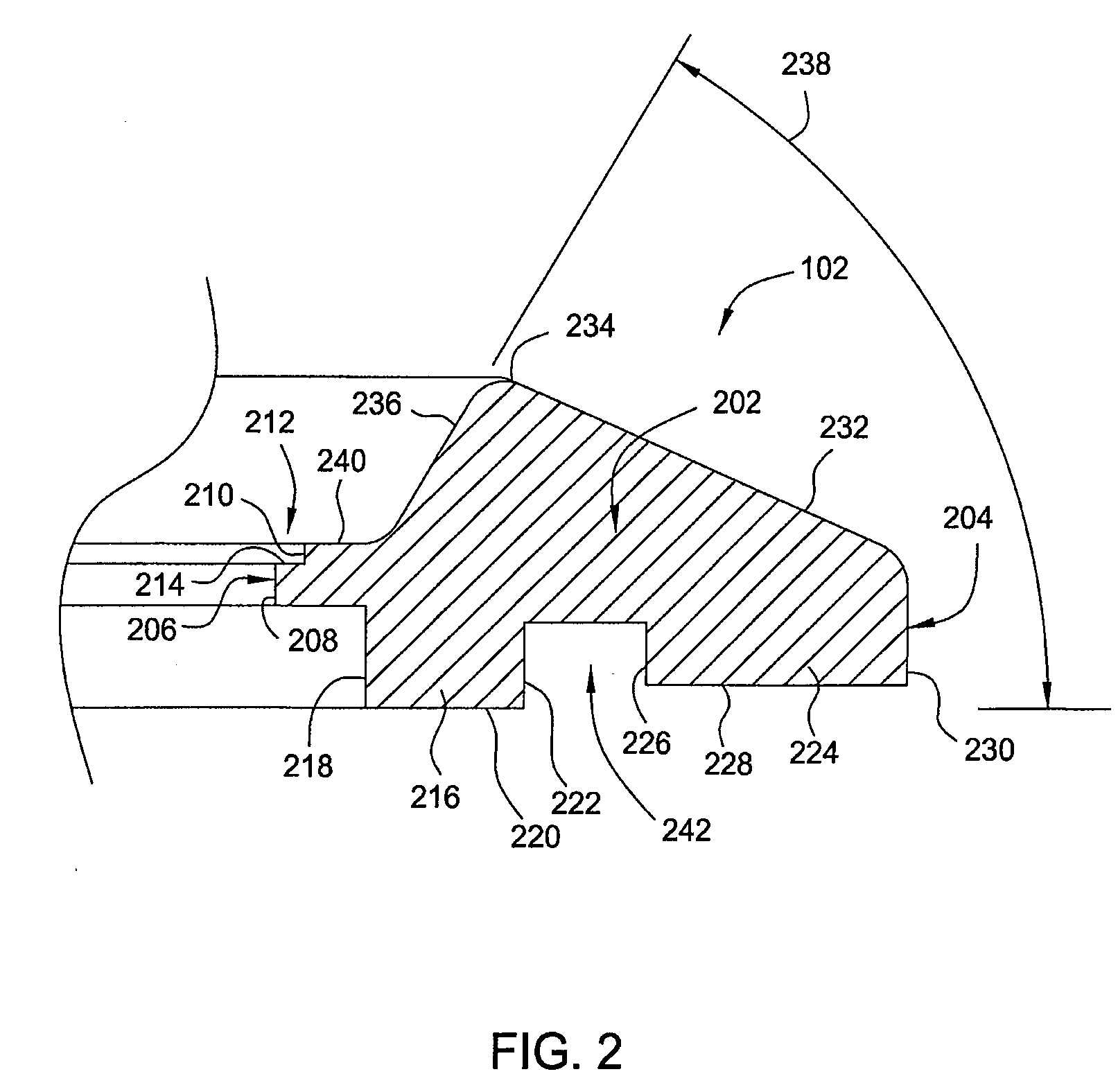

Low sloped edge ring for plasma processing chamber

ActiveUS20100059181A1Electric discharge tubesSemiconductor/solid-state device manufacturingEngineeringYttrium

Owner:APPLIED MATERIALS INC

Reactor design for reduced particulate generation

ActiveUS20060105107A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingReactor designSemiconductor

Owner:ASM INTERNATIONAL

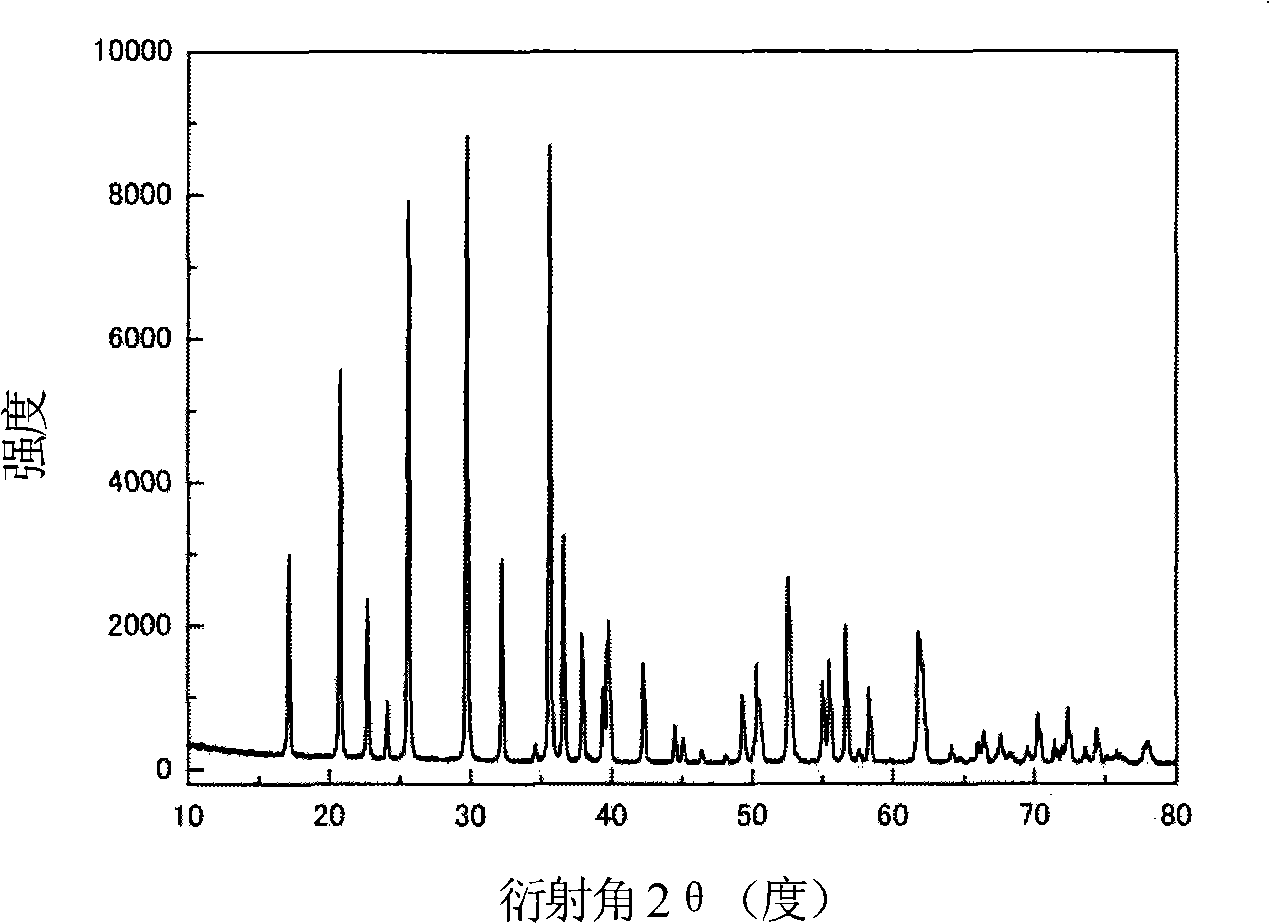

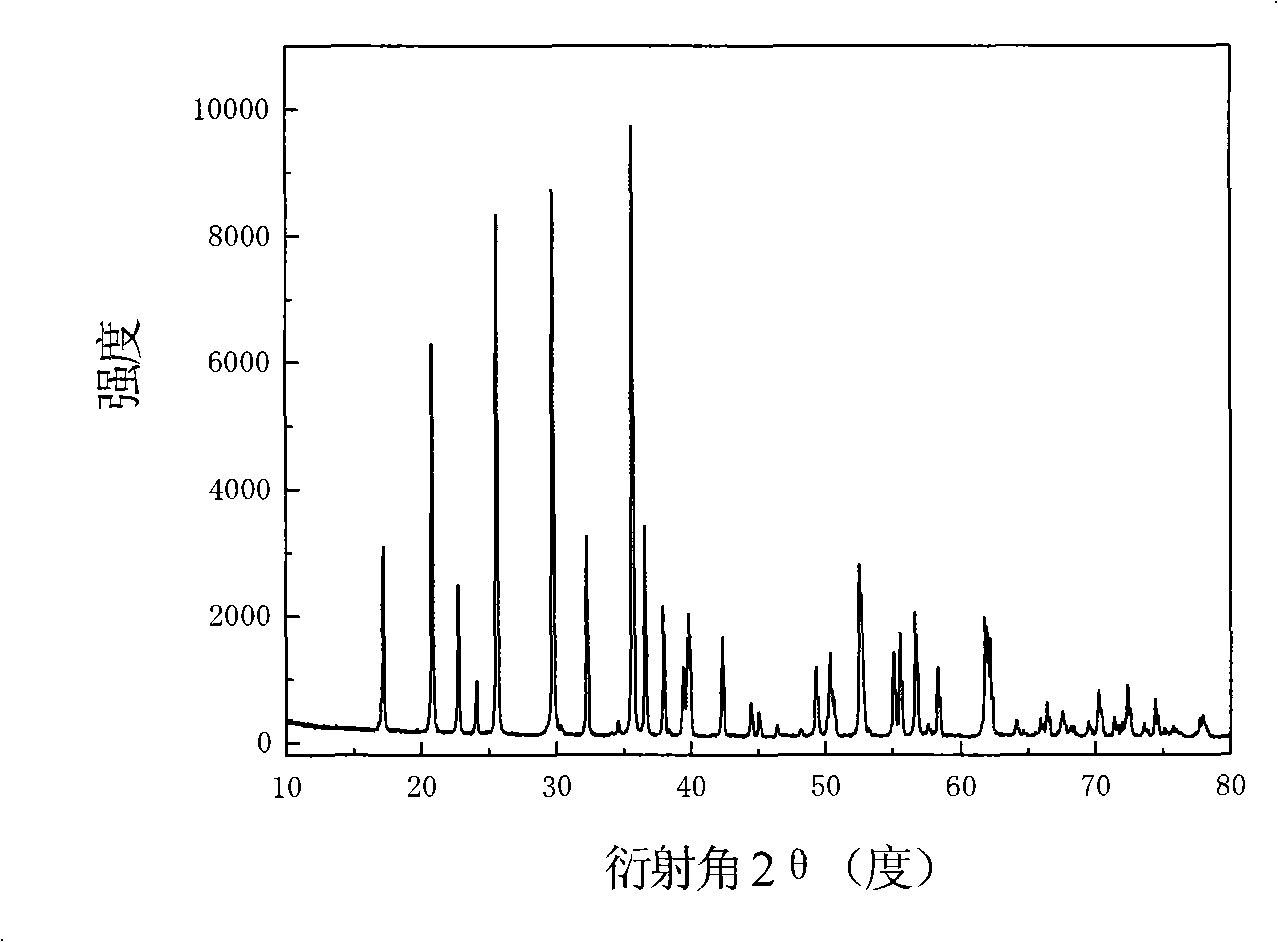

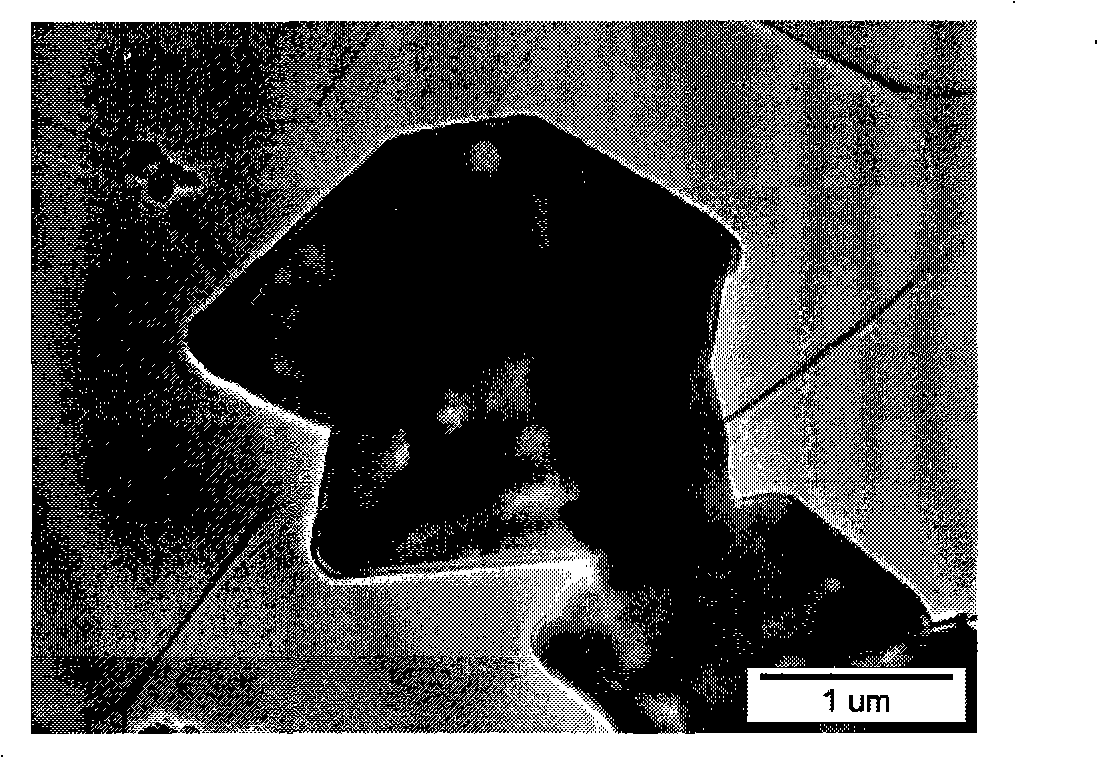

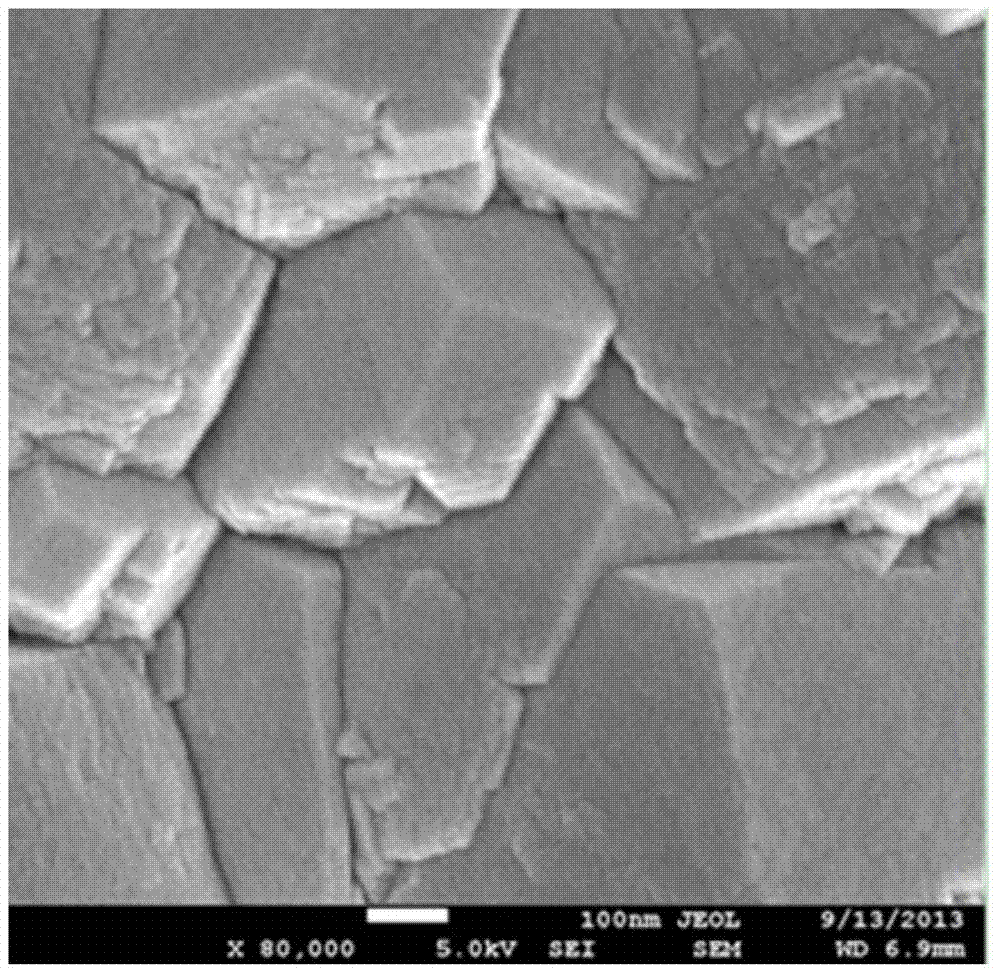

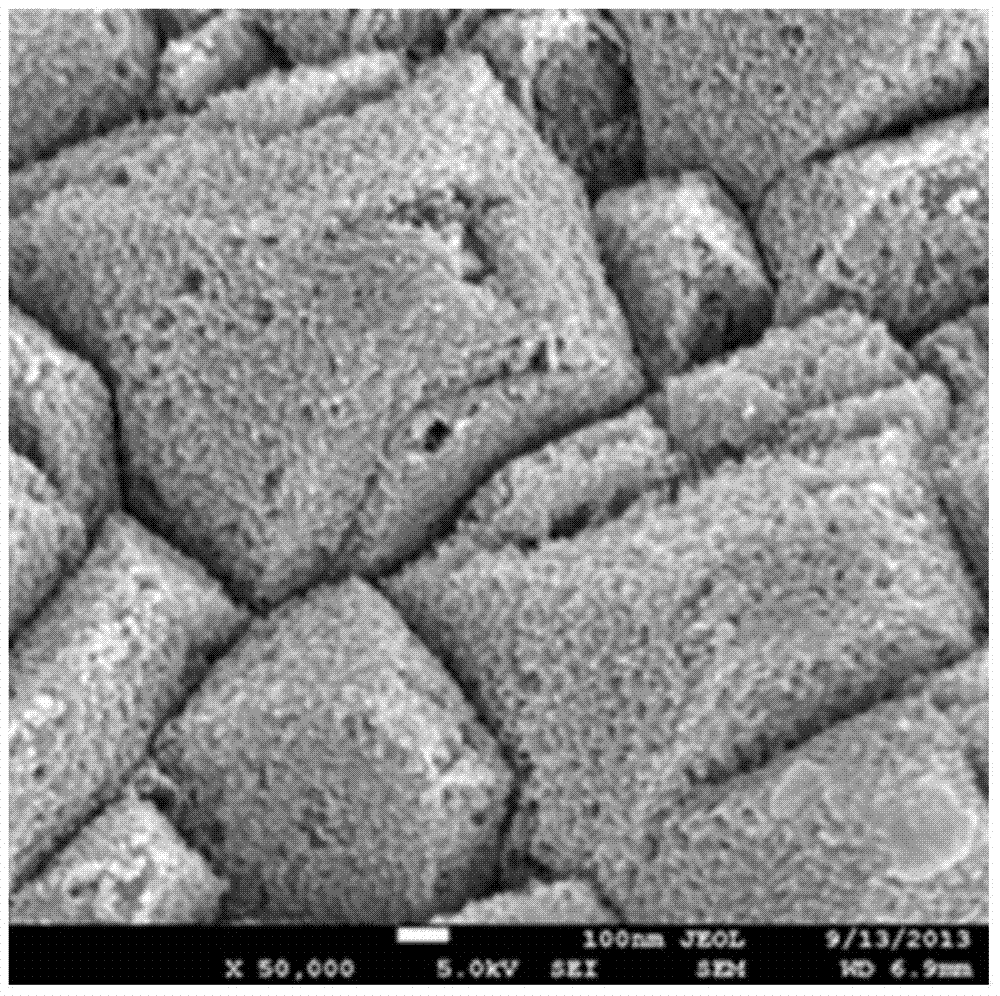

Method for uniformly and controllably coating conducting carbon layer at surface of LiFePO4 granule surface

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

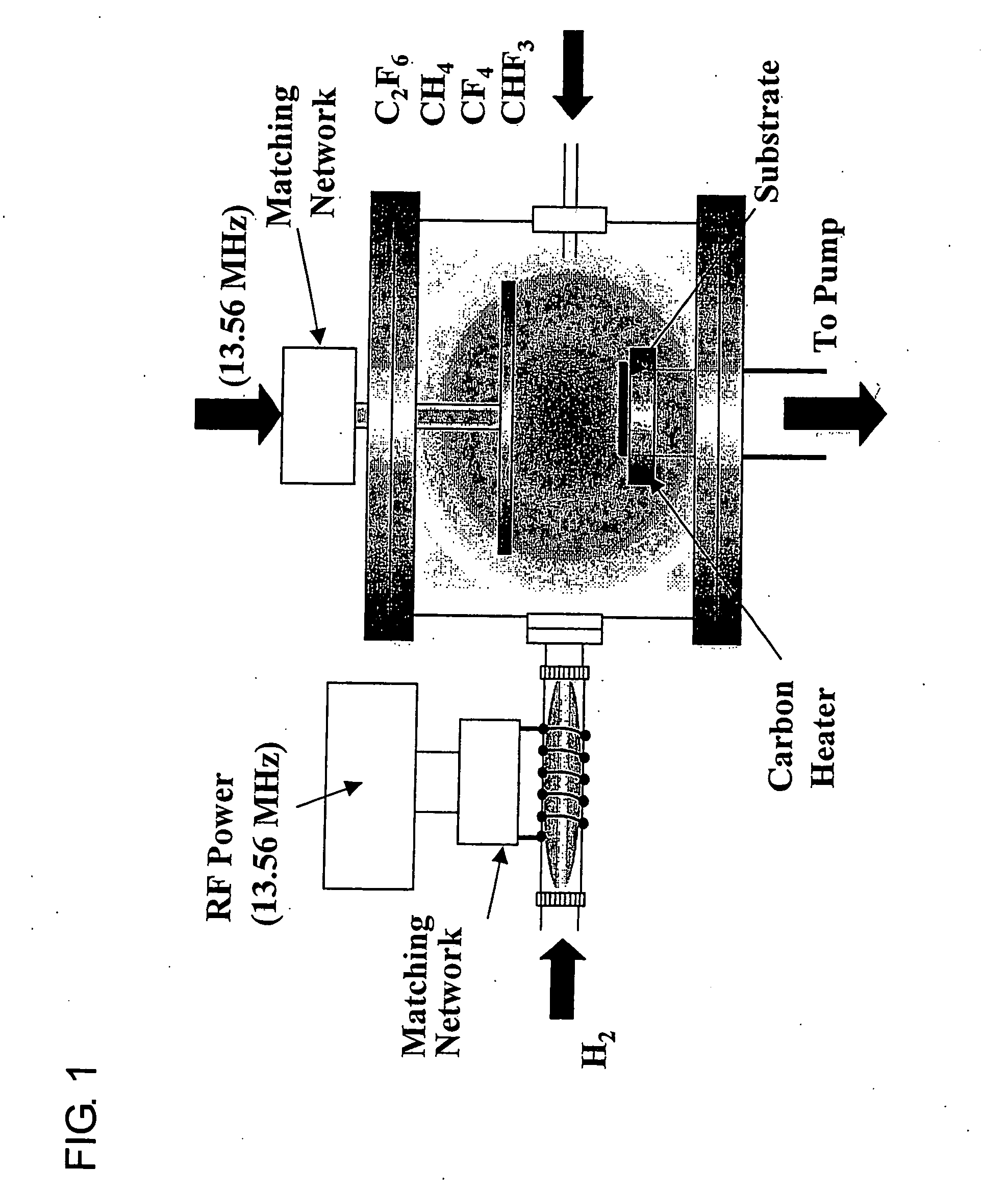

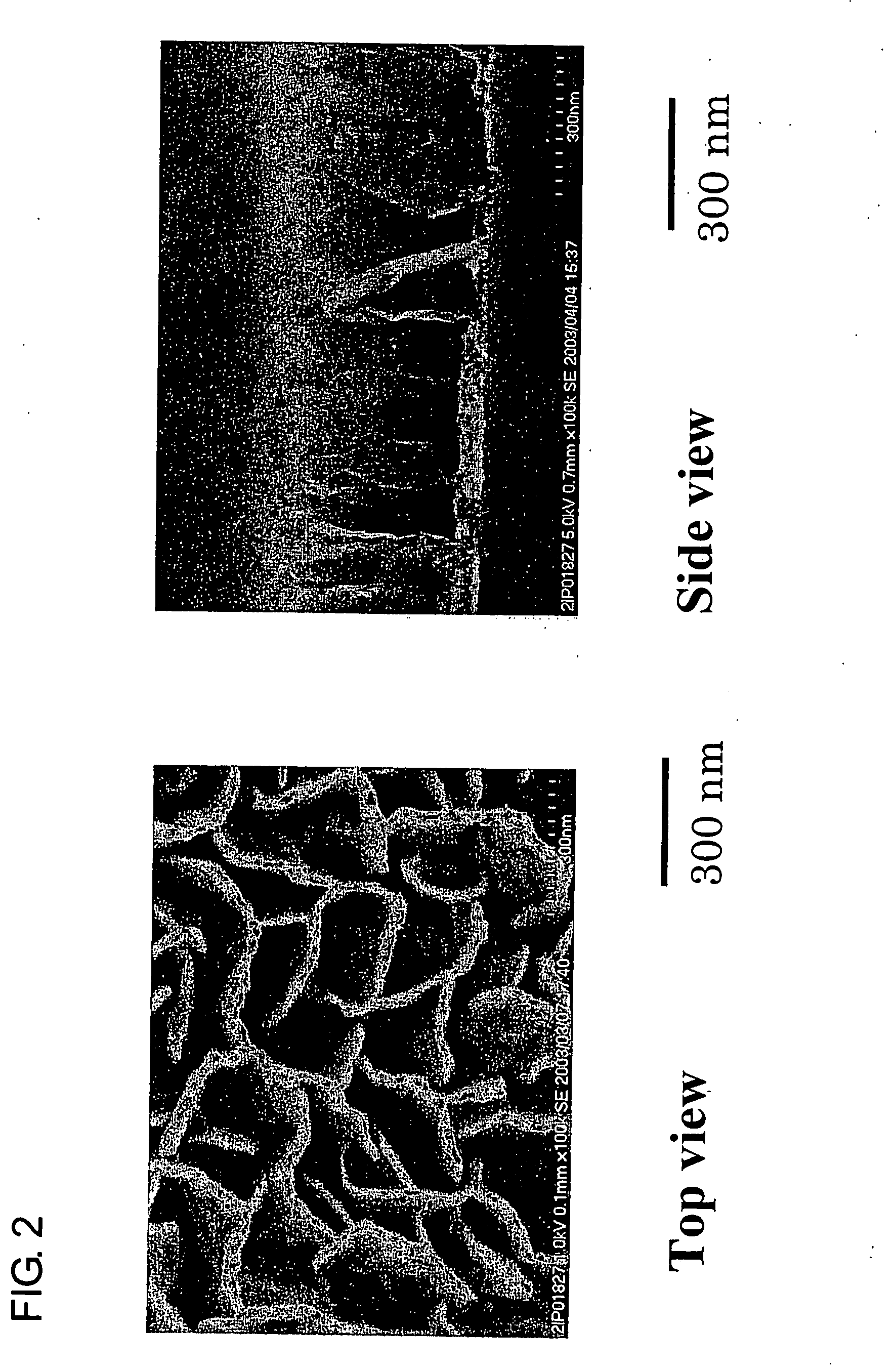

Preparation method of porous diamond film

ActiveCN104498894AImprove hydrophilicityIncrease contentChemical vapor deposition coatingAir atmosphereMicrowave

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

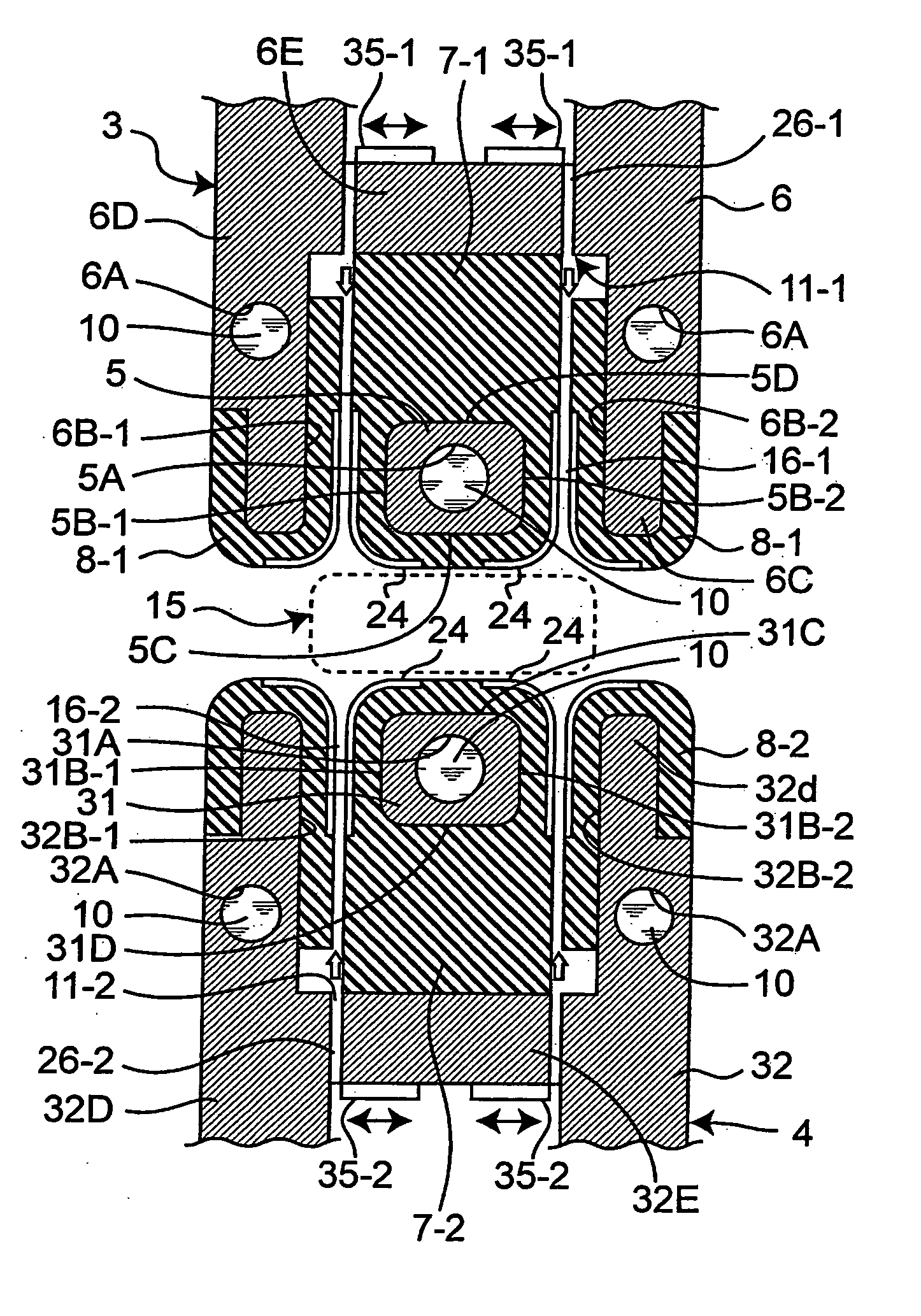

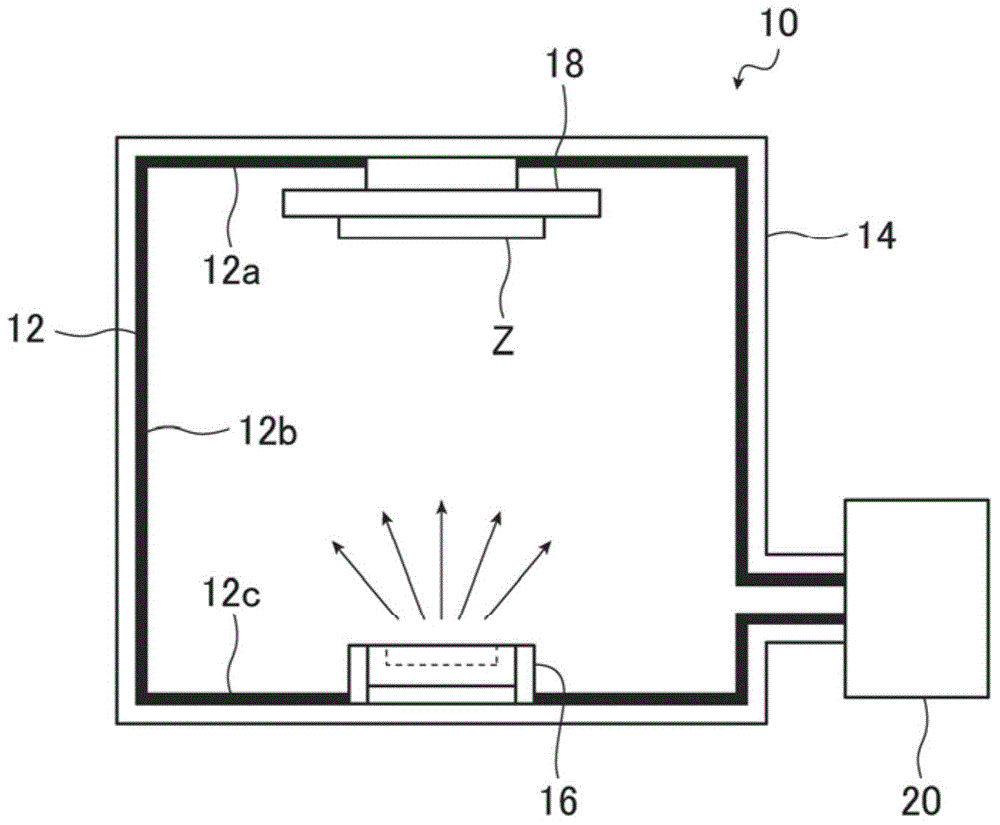

Thin film forming device for forming silicon thin film having crystallinity

InactiveUS6192828B1Electric discharge tubesSemiconductor/solid-state device manufacturingElectric dischargeSilicon thin film

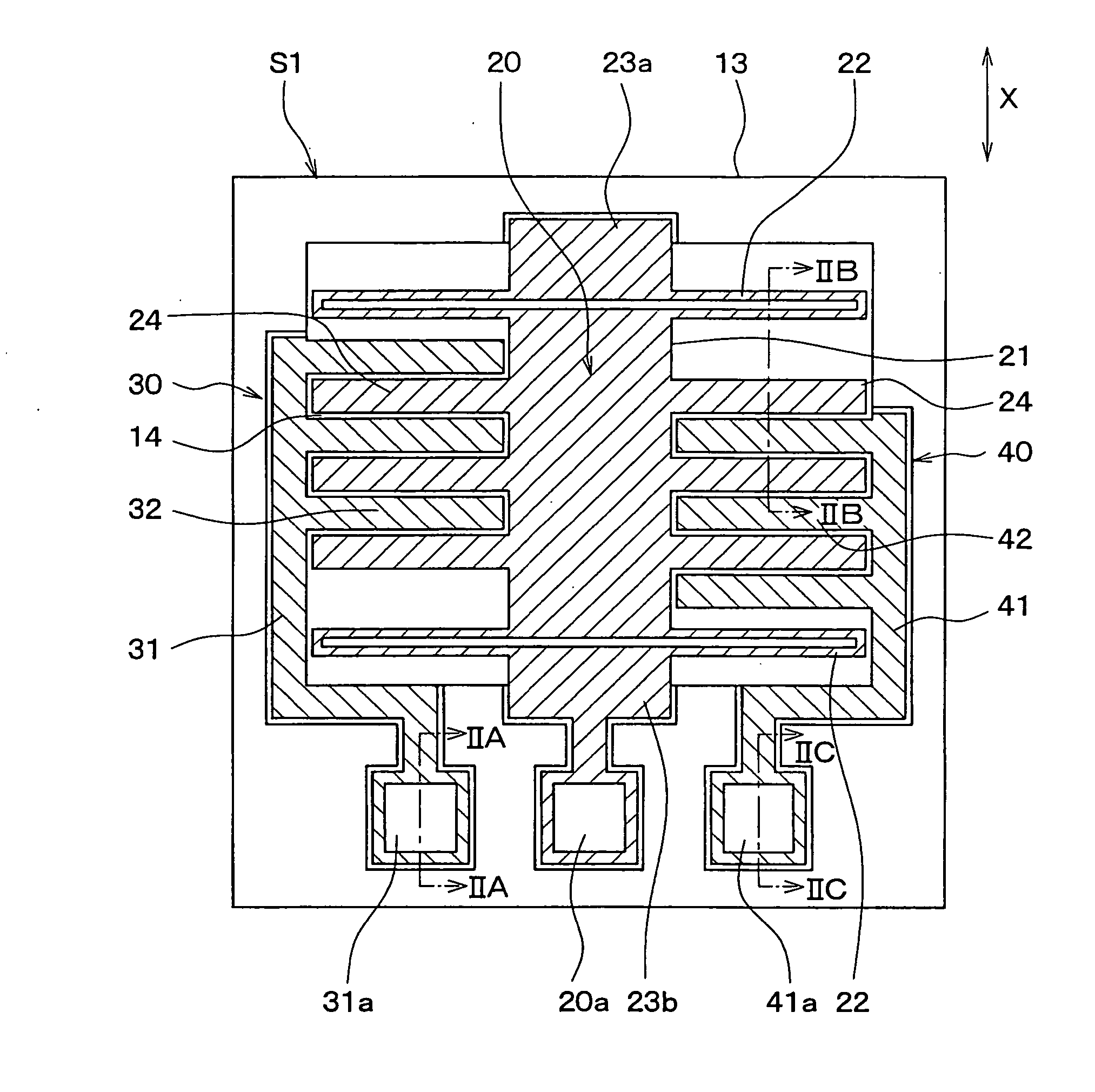

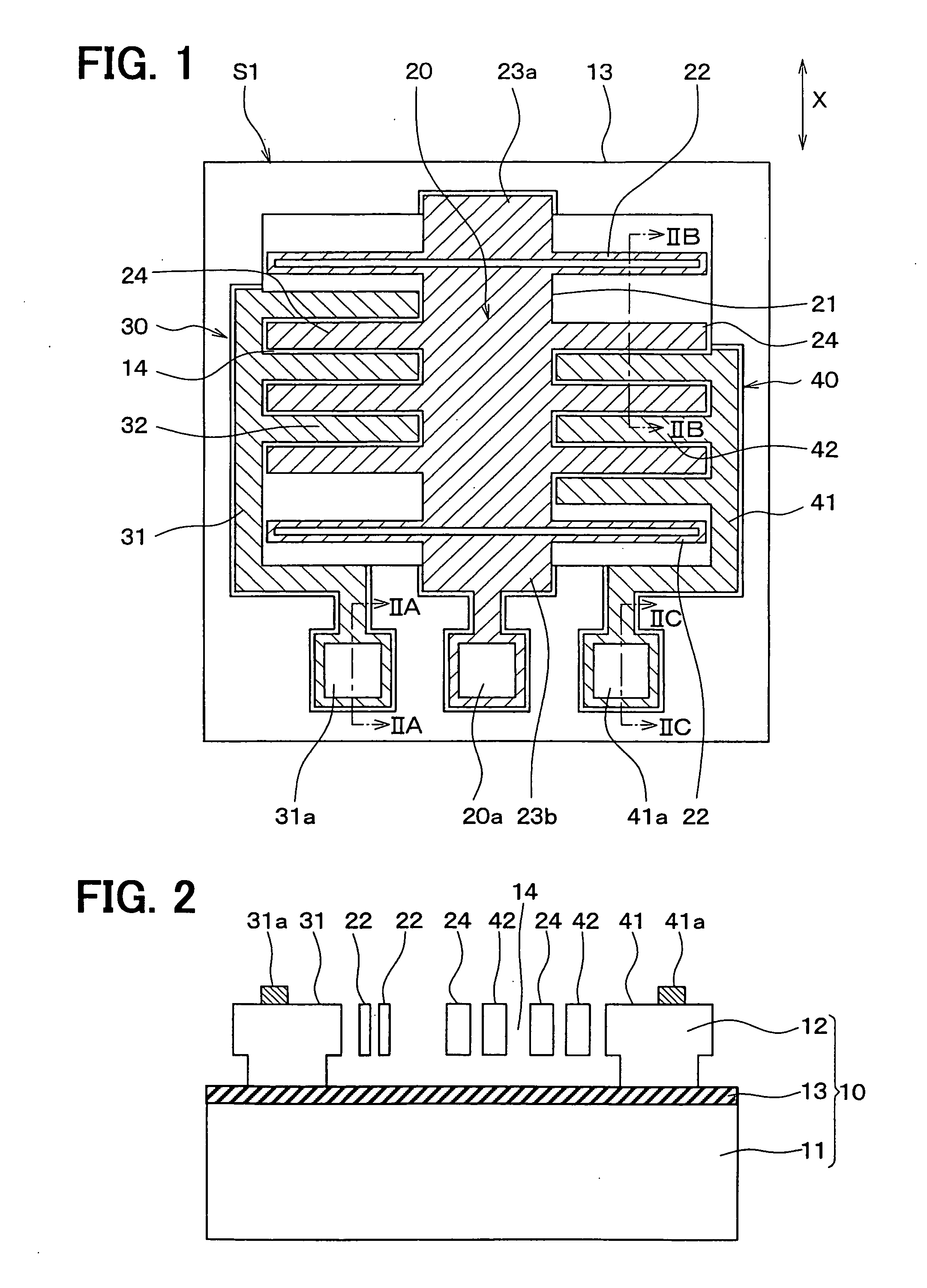

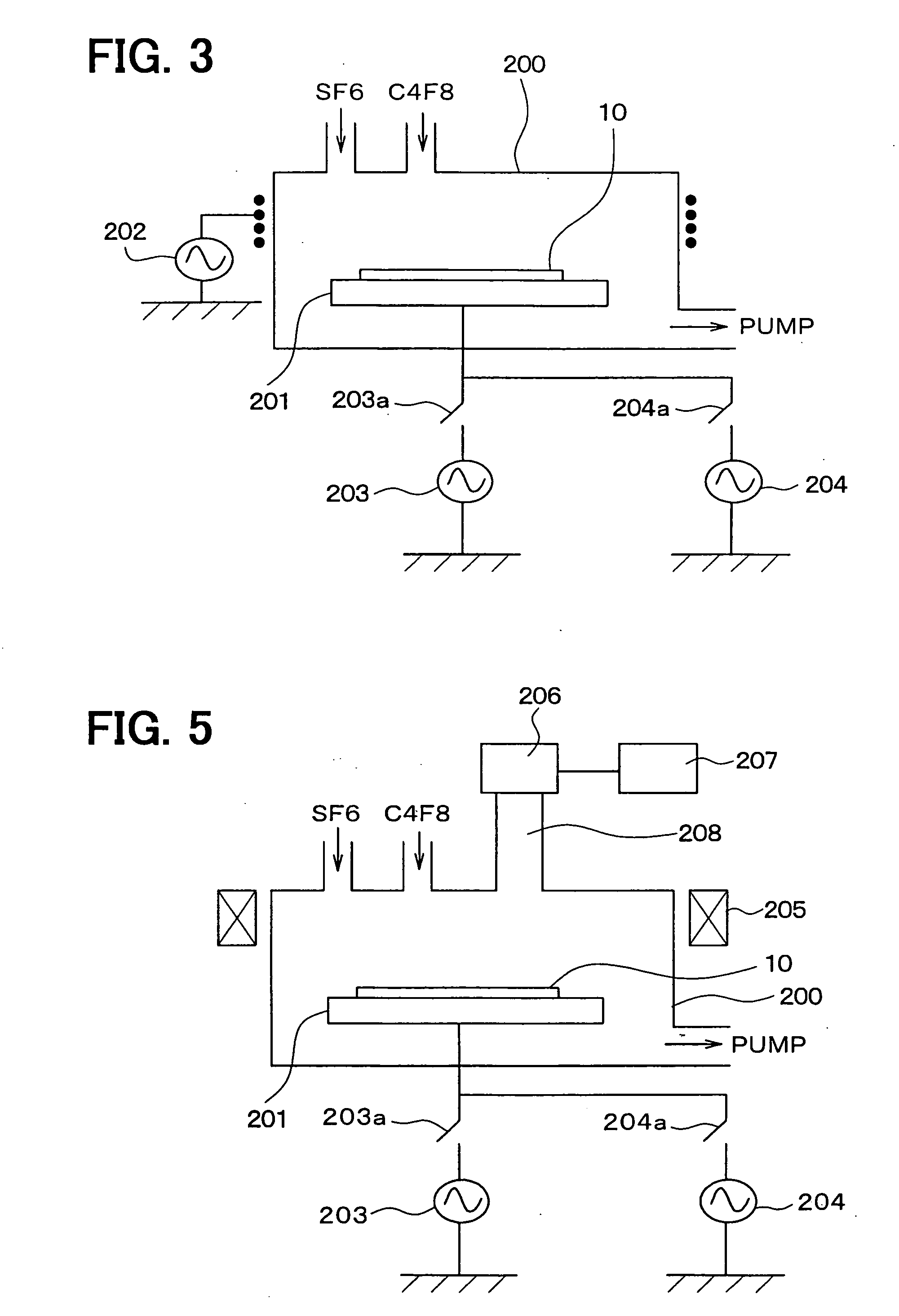

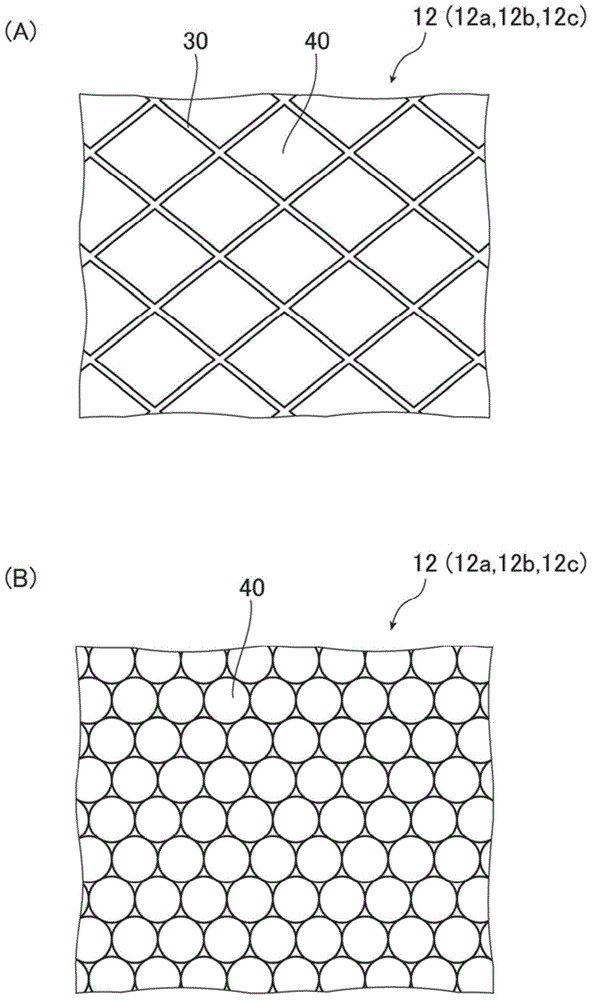

An insulating member is interposed between a film formation chamber container and a plasma chamber container. Both containers are adjacent to and communicated with each other. In the film formation chamber container, a base material holder is provided for holding the base material. Raw material gas is introduced into the plasma chamber container and ionized by high frequency electric discharge, to generate plasma. A high frequency electrode and a high frequency electric power source are provided as a plasma generating unit. There is provided a porous electrode 30, the electric potential of which is the same as that of the plasma chamber container 24, between both chambers 22, 24 to partition both chambers. A pulse electric powder source for impressing bipolar pulse voltage, in which a positive polarity portion and a negative polarity portion are alternately repeated, is provided between the base material holder and both of the plasma chamber container and the porous electrode 30, the electric potential of which is the same as that of the plasma chamber container 24.

Owner:NISSIN ELECTRIC CO LTD

Method for manufacturing movable portion of semiconductor device

ActiveUS20050054153A1Short processing timeEasy to disassembleTransistorDecorative surface effectsInsulation layerDevice material

Owner:DENSO CORP

Method of Fabricating Thin Film by Microplasma Processing and Apparatus for Same

InactiveUS20120021132A1Reduce necessityLiquid surface applicatorsMolten spray coatingIonRaw material

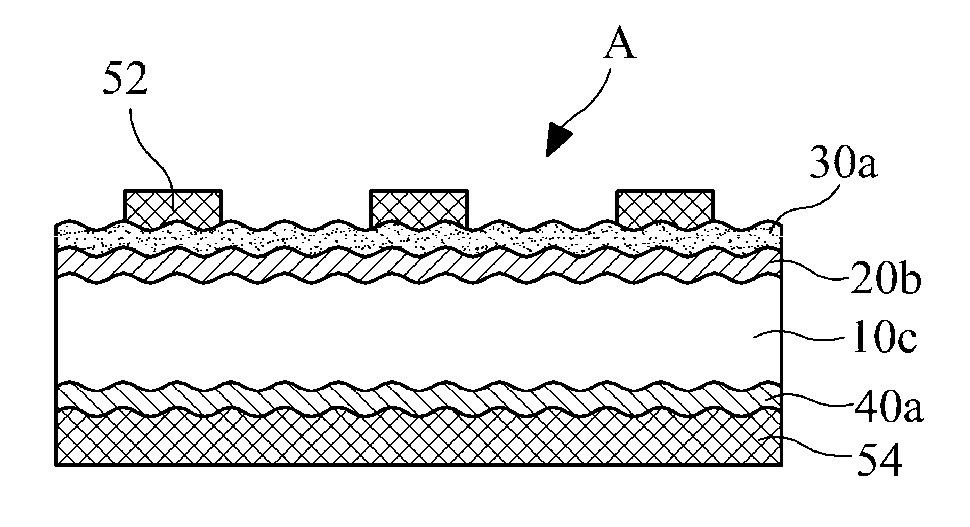

Provided is a method of fabricating, with satisfactory adhesion, a thin film of a metal or a metallic-compound, such as a metal oxide or nitride, on a substrate made of a high-melting-point material such as silicon or ceramics by using a metal or metallic-compound target as the primary raw material so as to eliminate the necessity of using harmful gases such as organometallic gas, and by using an atmospheric-pressure plasma generated under atmospheric pressure as a reaction field and also as a heat source. Additionally provided is an apparatus for fabricating the thin film. The thin-film fabrication method by microplasma processing includes the steps of disposing a raw material for thin-film fabrication in one or more tubes (A) having a uniform inner diameter throughout, introducing an inert gas and applying a high-frequency voltage to the narrow tubes (A) to generate high-frequency plasma in the narrow tubes (A), heating / evaporating the raw material while maintaining the flow rate of the plasma gas in the narrow tubes (A) and maintaining the plasma gas temperature high, ejecting the evaporated material from the narrow tubes (A) to spray it onto the substrate, heating the substrate with the plasma, and depositing the sprayed material on the substrate under atmospheric pressure.

Owner:NAT INST OF ADVANCED IND SCI & TECH

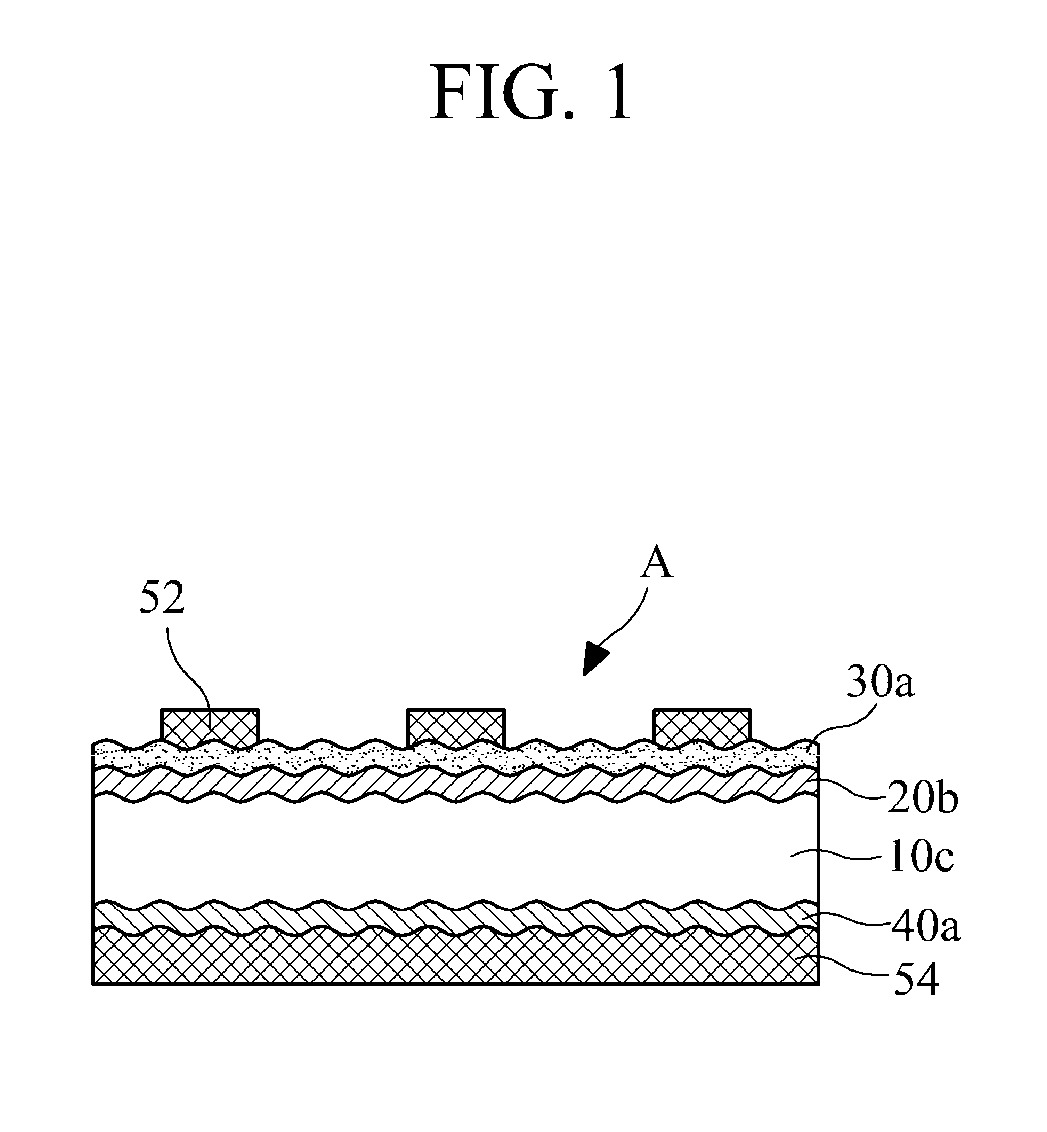

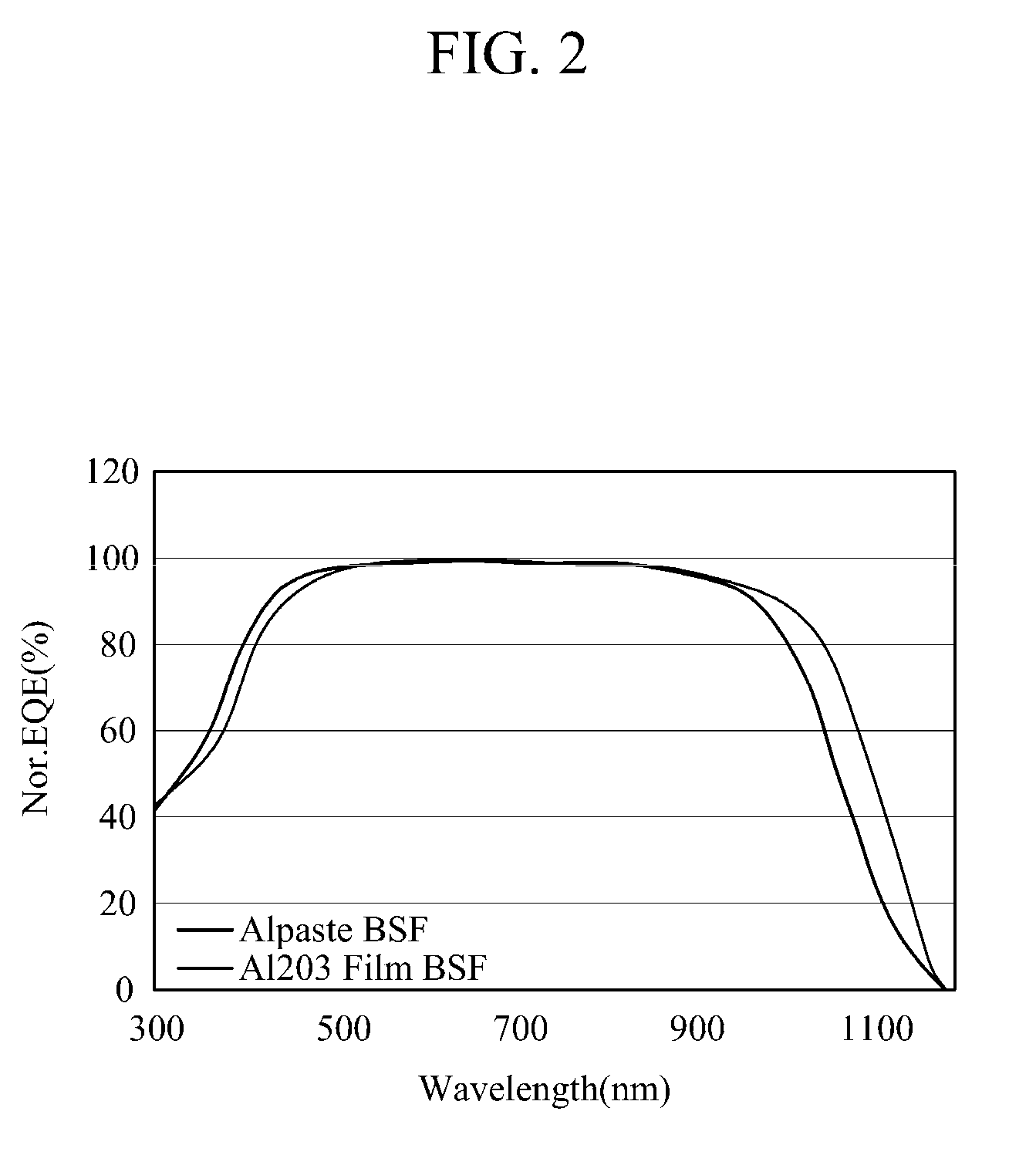

Solar cell and method of fabricating the same

InactiveUS20110083735A1High opto-electric conversion efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingBack surface fieldEngineering

Owner:WONIK IPS CO LTD

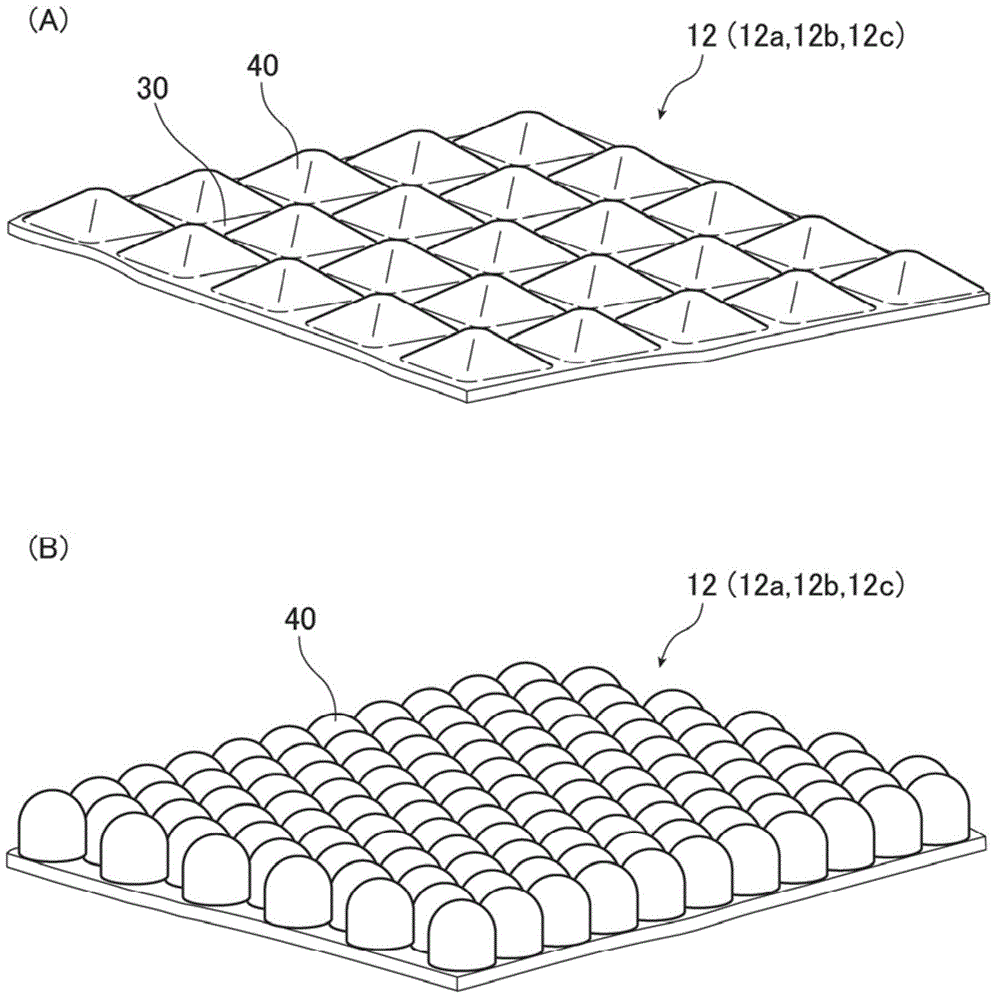

Adhesion-prevention Plate Used For Vacuum Film-forming Device And Applications Thereof

InactiveCN104032259AExcellent anti-peeling effectAnodisationVacuum evaporation coatingConvex structureEvaporation

Owner:FUJIFILM CORP

Systems and methods for enhancing mobility of atomic or molecular species on a substrate at reduced bulk temperature using acoustic waves, and structures formed using same

ActiveUS20140199550A1Improve mobilityReduce the temperatureRadiation applicationsVacuum evaporation coatingChemical physicsAcoustic wave

Under one aspect of the present invention, a method for enhancing mobility of an atomic or molecular species on a substrate may include exposing a first region of a substrate to an atomic or molecular species that forms a molecular bond with the substrate in the first region; directing a laser pulse to a second region of the substrate so as to generate an acoustic wave in the second region, the acoustic wave having spatial and temporal characteristics selected to alter the molecular bond; and transmitting the acoustic wave from the second region to the first region, the acoustic wave altering the molecular bond between the substrate and the atomic or molecular species to enhance mobility of the atomic or molecular species on the substrate in the first region.

Owner:THE AEROSPACE CORPORATION

Non-wetting coating on a fluid ejector

Owner:FUJIFILM DIMATIX

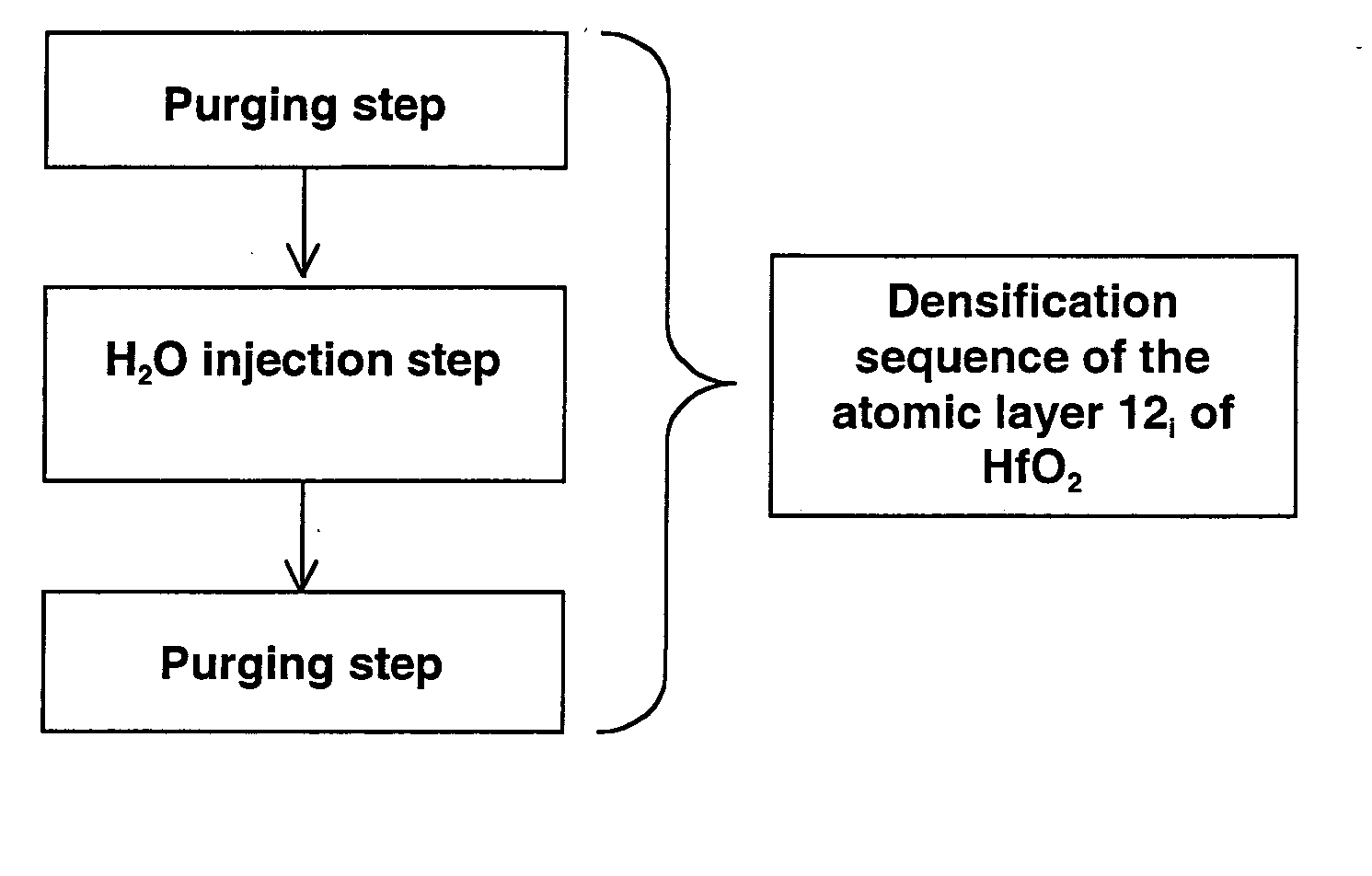

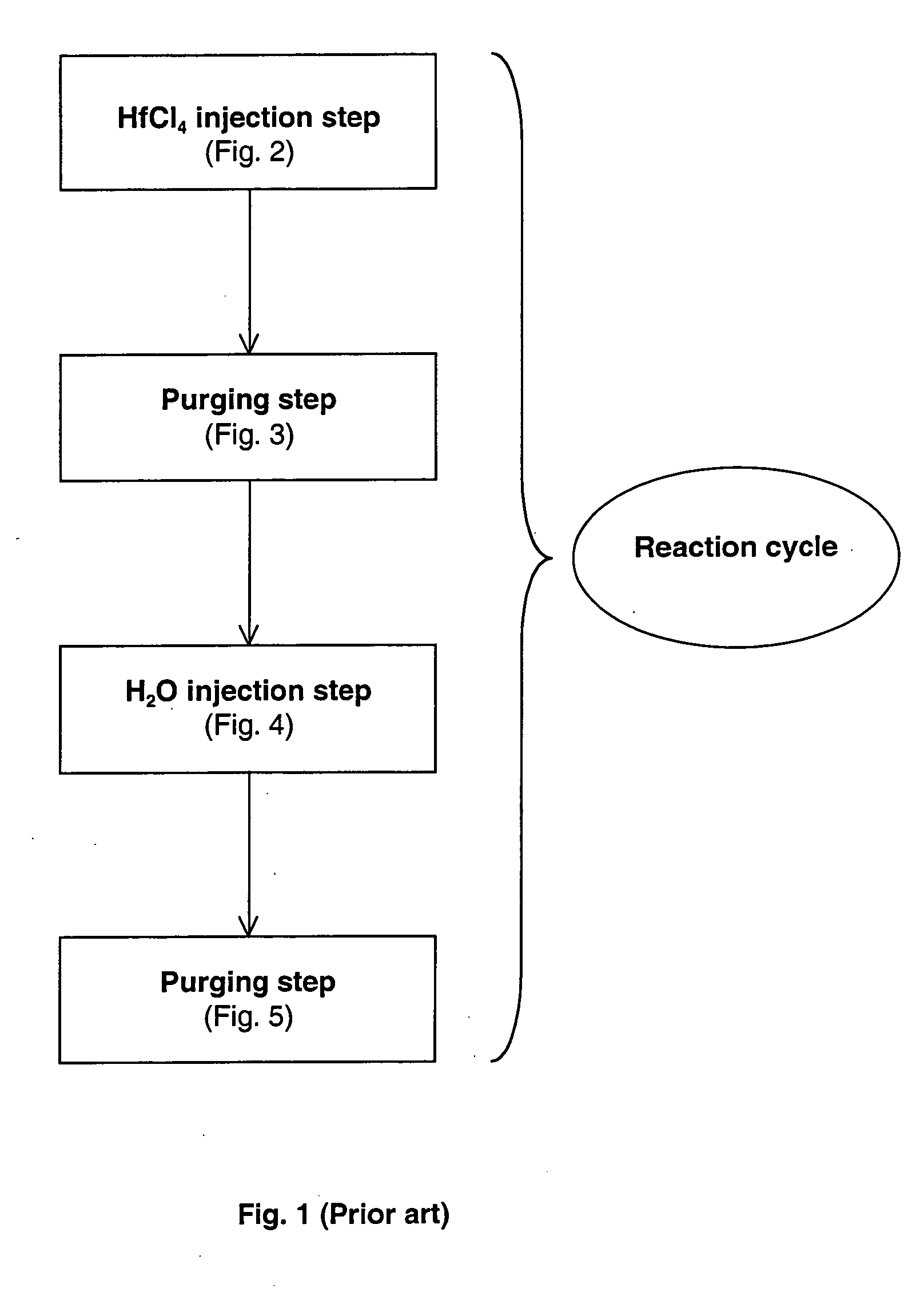

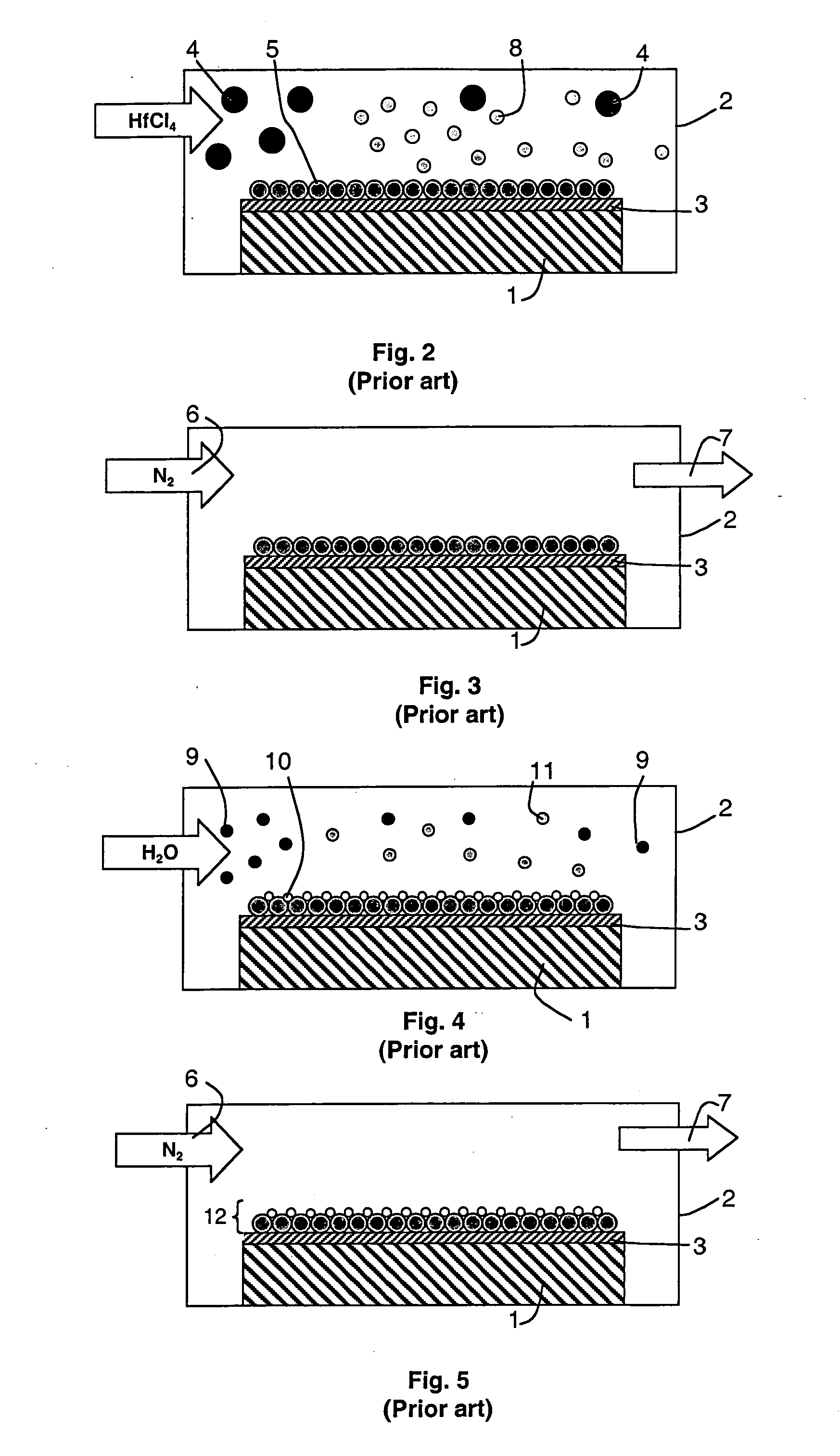

Process for deposition of a thin layer on an oxidized layer of a substrate

ActiveUS20050239298A1Effective controlSemiconductor/solid-state device manufacturingSpecial surfacesThin layerMaterials science

Owner:STMICROELECTRONICS (CROLLES 2) SAS

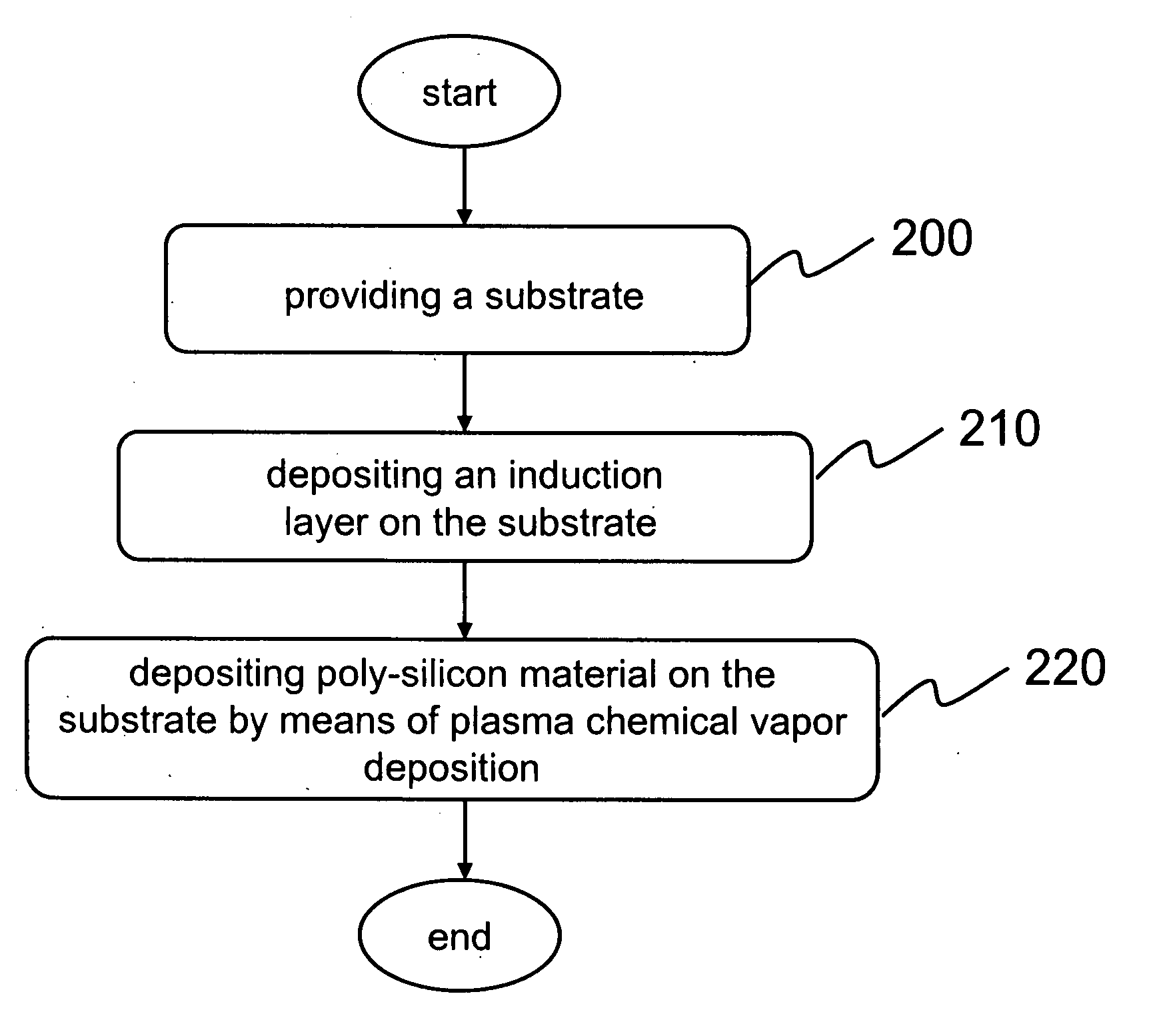

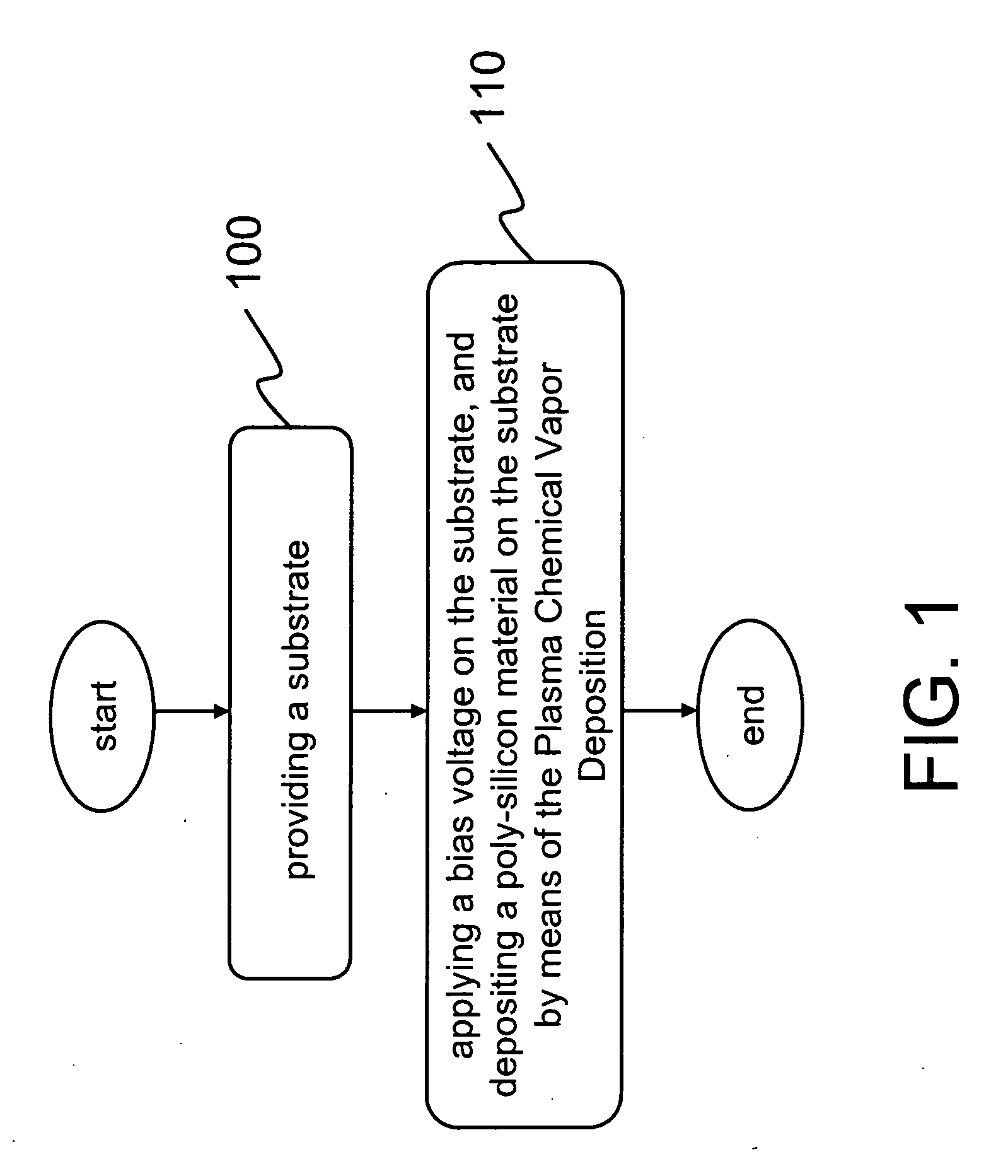

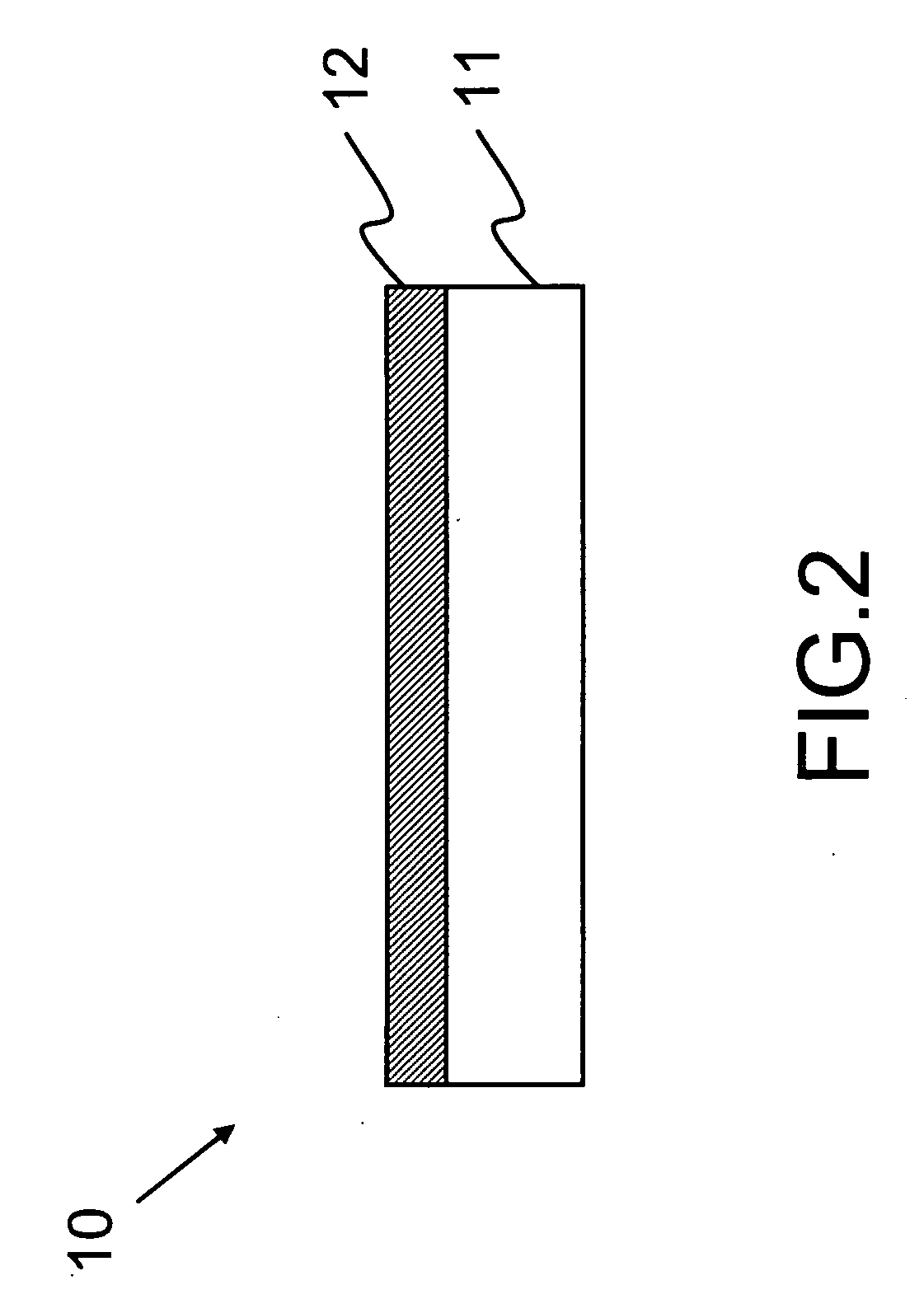

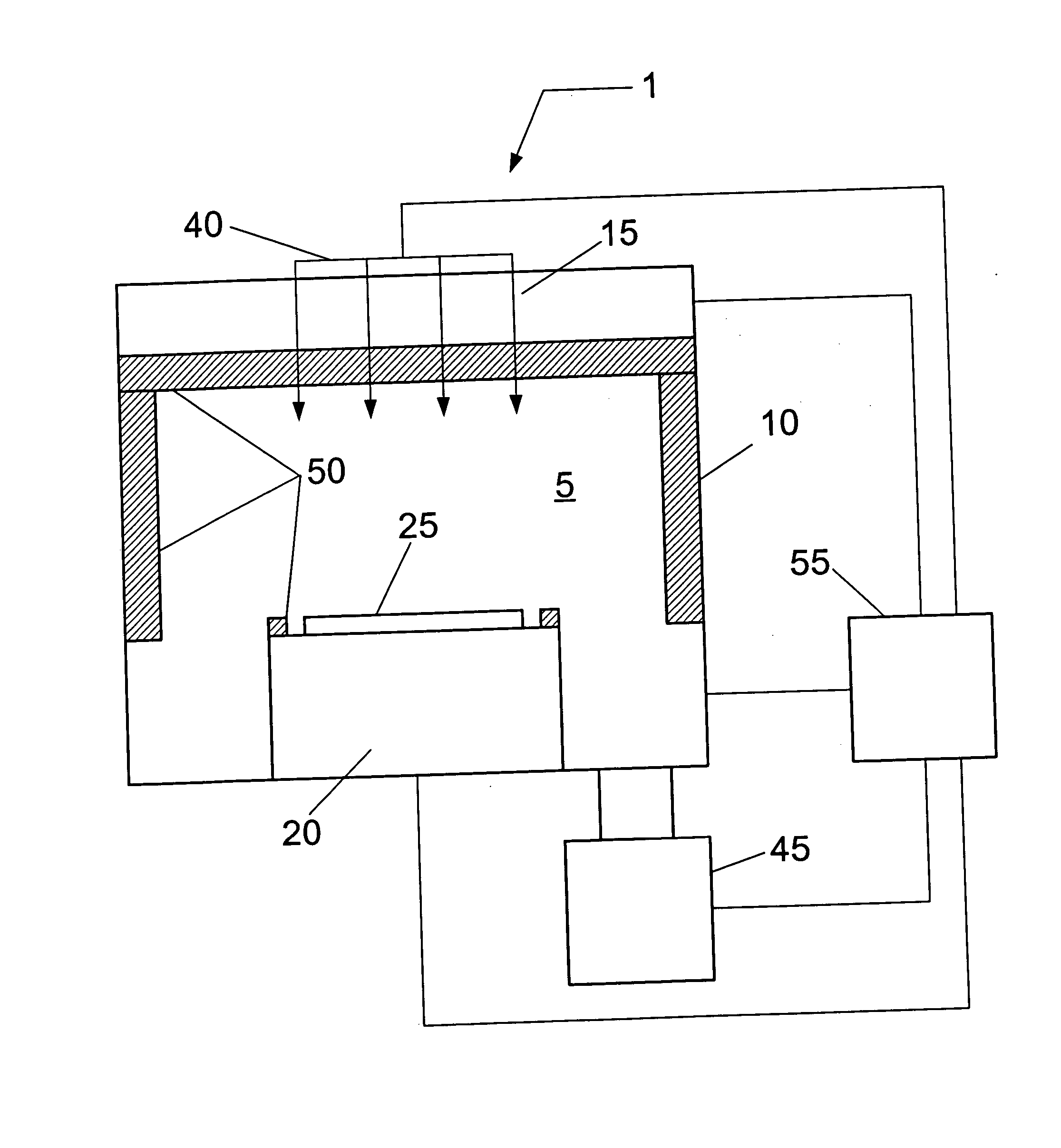

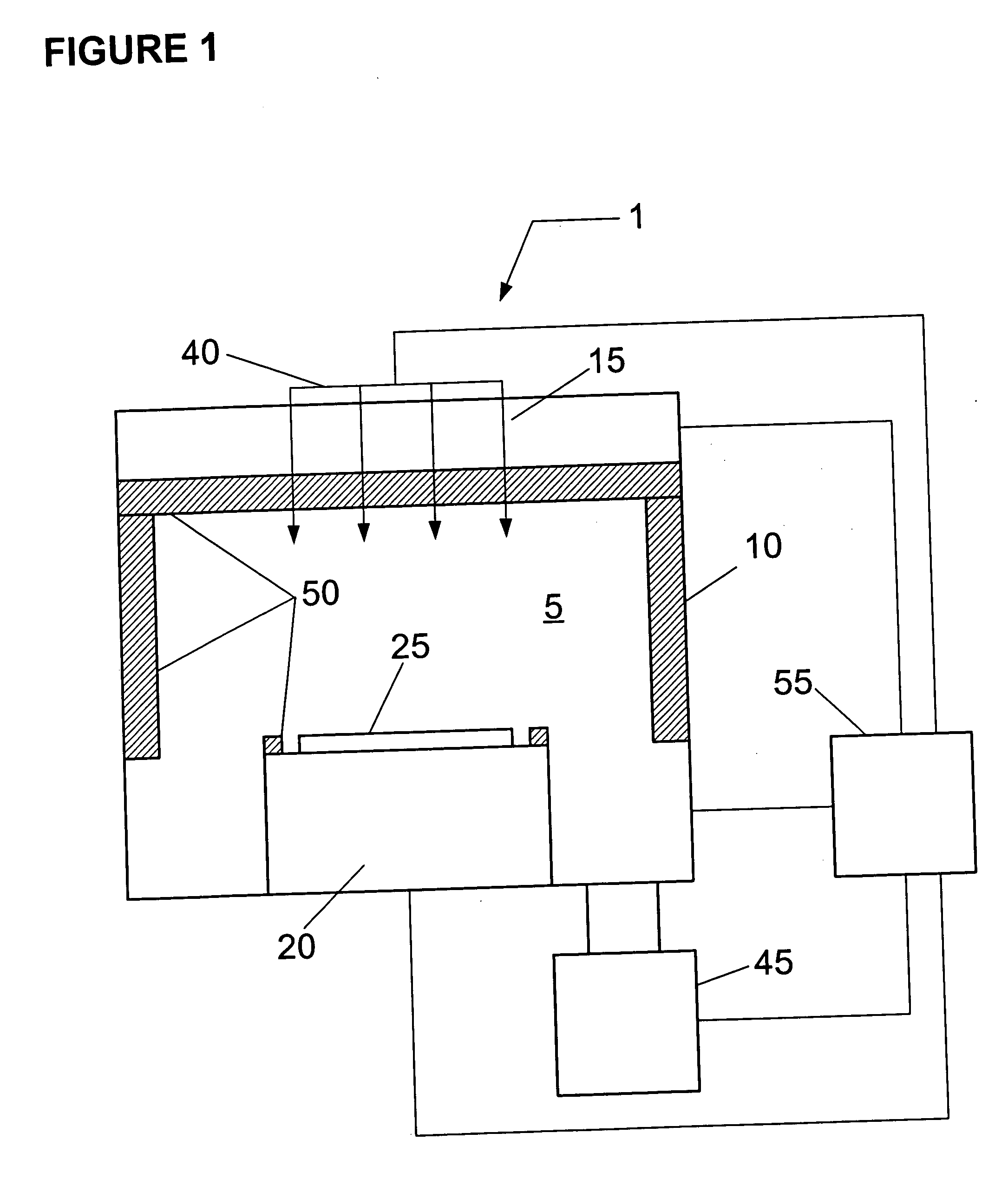

Element of low temperature poly-silicon thin film and method of making poly-silicon thin film by direct deposition at low temperature and inductively-coupled plasma chemical vapor deposition equipment therefor

InactiveUS20070077735A1Quality improvementReduce thicknessPolycrystalline material growthSolid-state devicesInductively coupled plasmaSilicon thin film

Owner:IND TECH RES INST

Method and system for introduction of an active material to a chemical process

InactiveUS20050067098A1Easy to processElectric discharge tubesSemiconductor/solid-state device manufacturingActive componentProcess engineering

Owner:TOKYO ELECTRON LTD

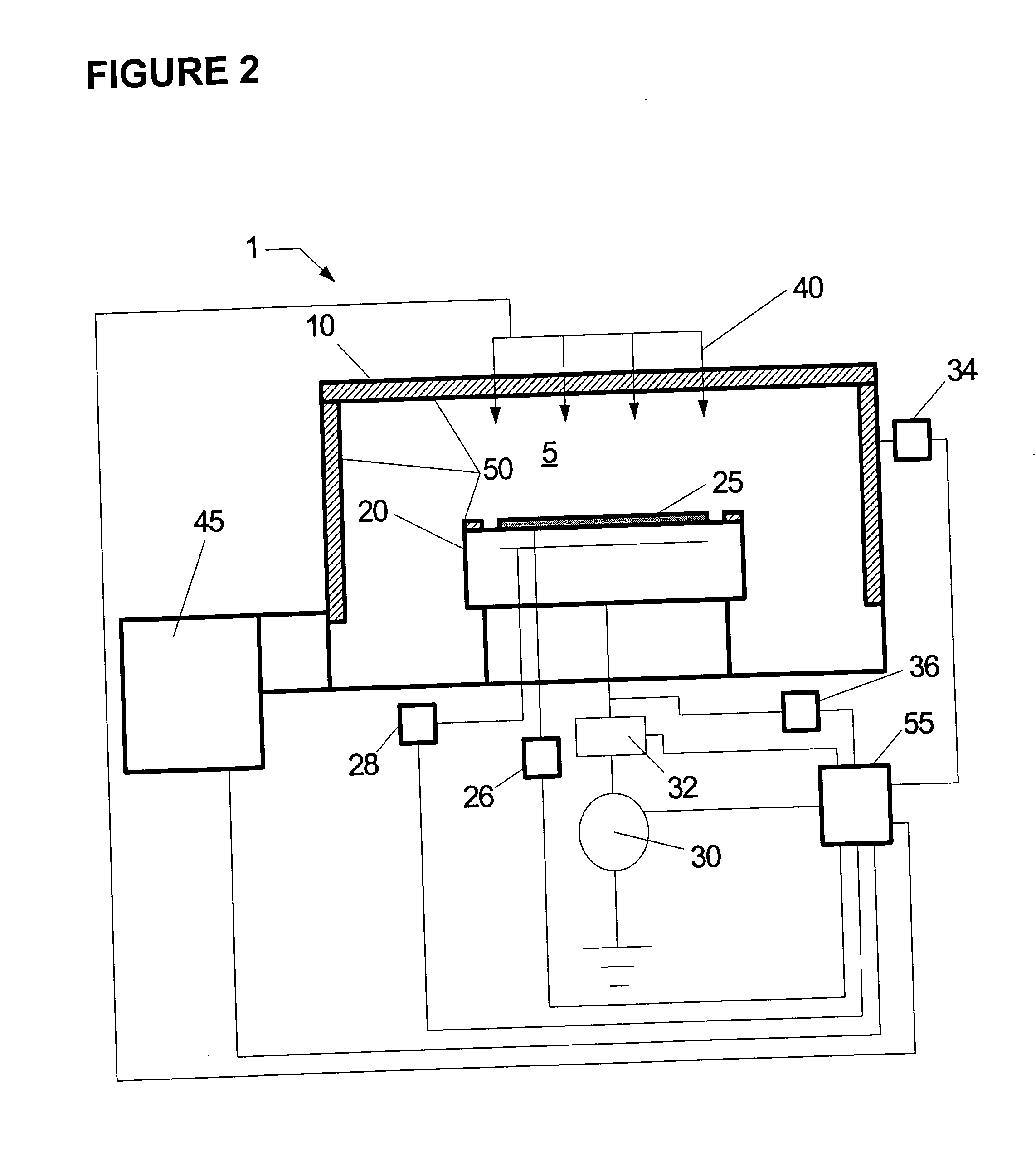

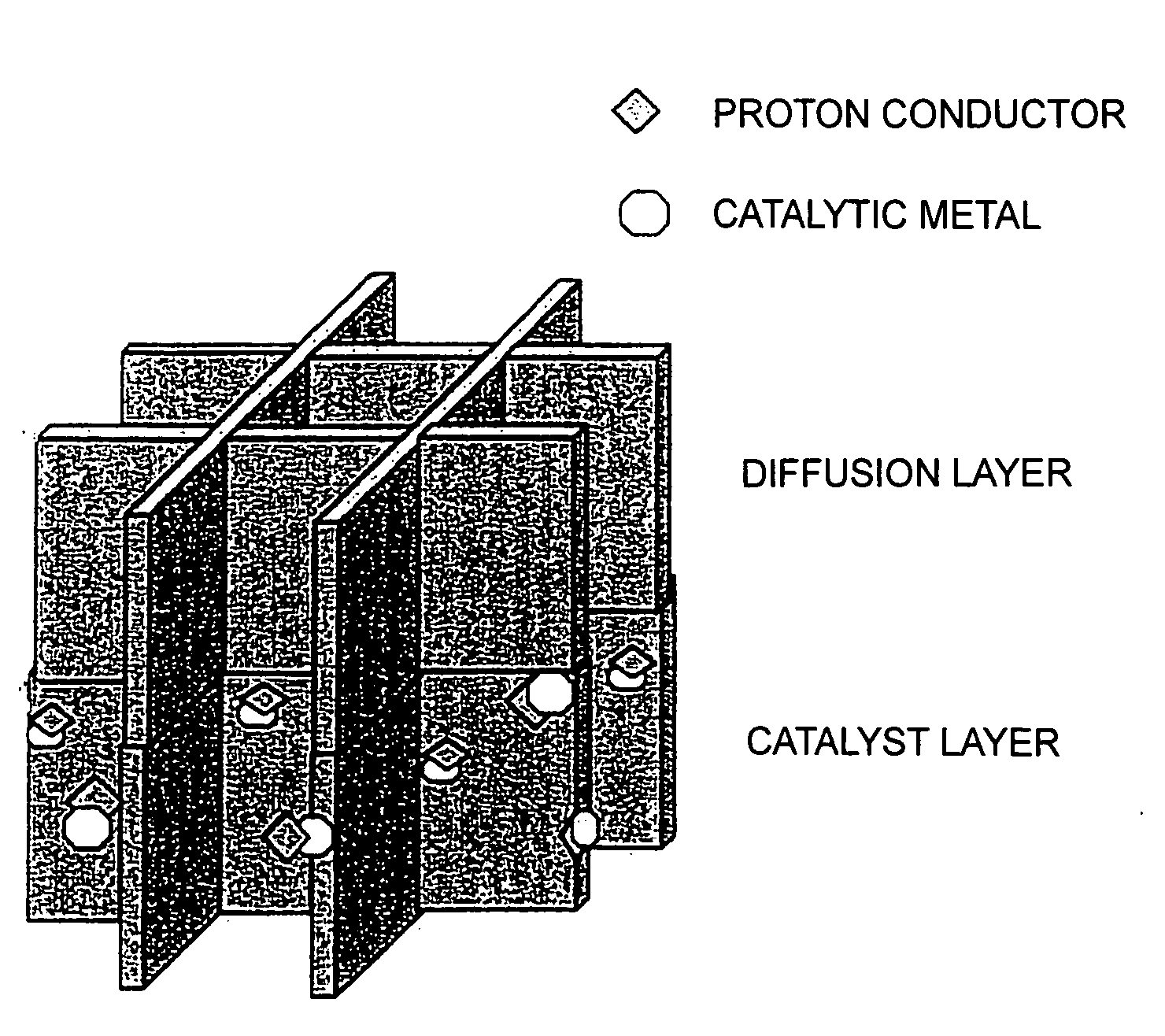

Fuel Cell Structure and Method of Manufacturing Same

InactiveUS20080187814A1Simplified cell structureReduce manufacturing costFinal product manufactureElectrode carriers/collectorsCarbon nanowallsNano size

Owner:HORI MASARU +2

Method for controlling appearance and defects of molybdenum disulfide by temperature

Owner:EAST CHINA NORMAL UNIVERSITY

Method for manufacturing miniature spring mechanical sensor for film performance test

InactiveCN101343033AReduce tensionHigh resolutionDecorative surface effectsChemical vapor deposition coatingEngineeringLinearity

Disclosed is a manufacturing method of a micro spring mechanics sensor used for the film performance test in the testing technology field; the method includes the steps that: the metal Ti layer is sputtered on the glass sheet and processed with oxidation treatment; the whirl coating of negative photoresist, front drying and development are processed on the glass sheet after the sputtering and oxidation treatment; the graphical display of the photoresist structure is realized according to the shape of the micro spring mechanics sensor designed by the mask plate; the Ni spring layer is electroformed on the processed titanium oxides layer; the micro spring mechanics sensor is processed with flatness machining; the sedimentation of the aligning marking and the displacement marking is processed on the Ni electroplated coating through the electrodeposition technology; the micro spring mechanics sensor is finally obtained after negative photoresist, the residual glass and the Ti sputtering layer are removed. The micro spring mechanics sensor prepared by the manufacturing method in the invention has the advantages of good linearity, simple process, high resolution, low cost and being easy to be integrated with the film mechanics performance test system.

Owner:SHANGHAI JIAOTONG UNIV

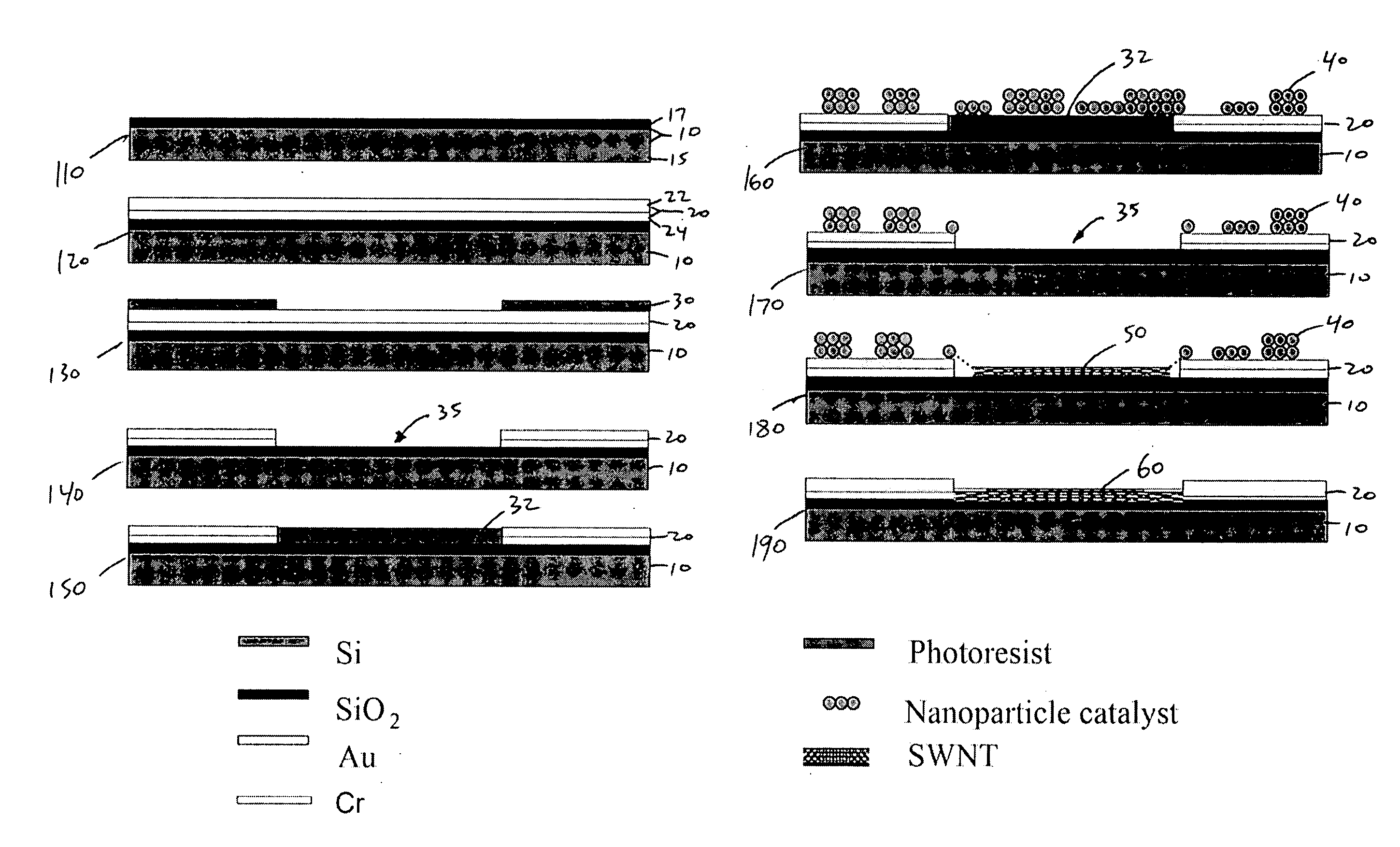

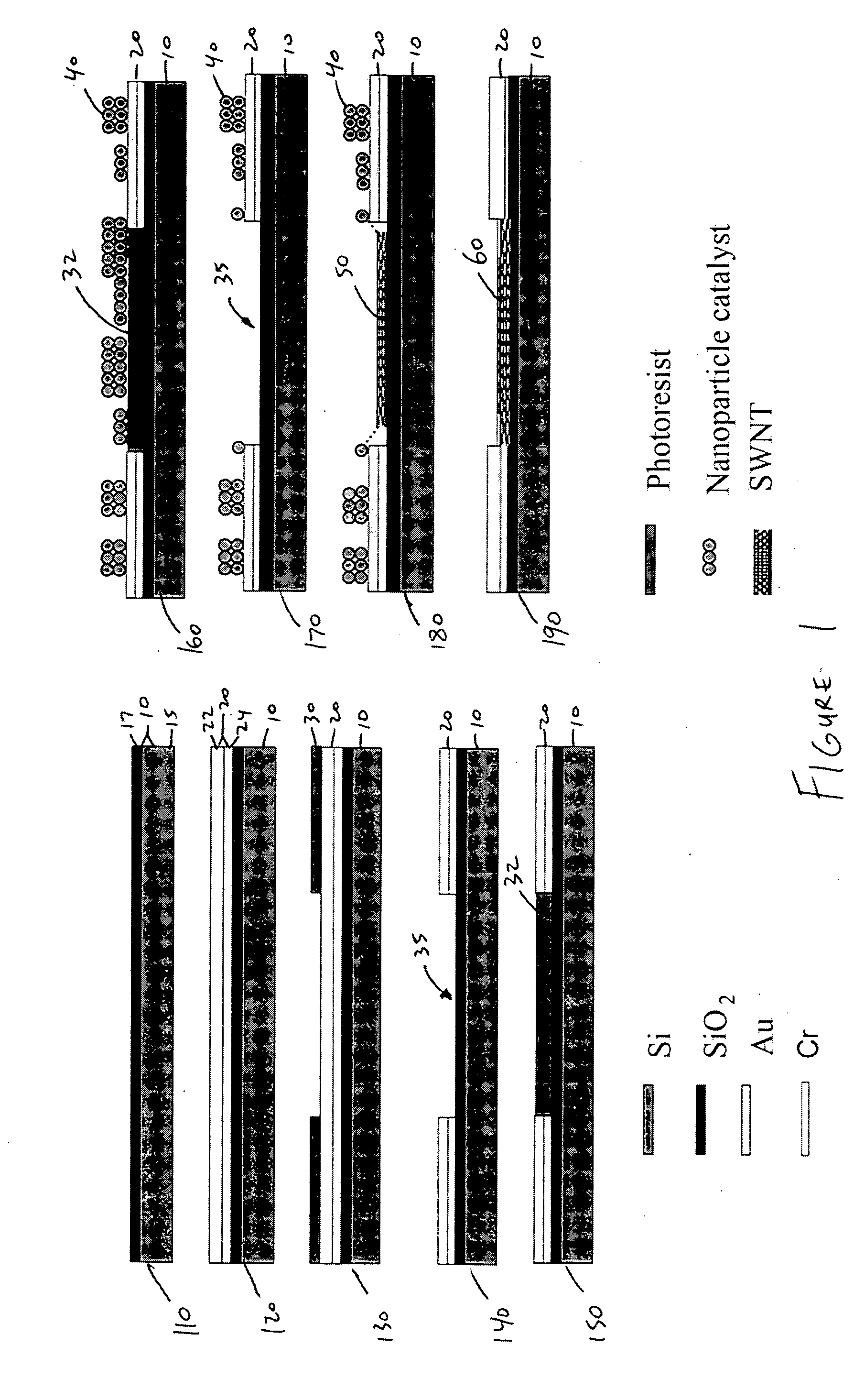

Method to make and use long single-walled carbon nanotubes as electrical conductors

ActiveUS20080020130A1Reduce turbulenceImprove the environmentMaterial nanotechnologyCatalyst activation/preparationElectrical conductorMaterials science

Owner:RGT UNIV OF CALIFORNIA

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap