Method to make and use long single-walled carbon nanotubes as electrical conductors

a single-walled carbon nanotube, long-diameter technology, applied in the direction of catalyst activation/preparation, metal/metal-oxide/metal-hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problem of less efficient process, achieve enhanced environment for ultra-long nanotube formation, reduce turbulence, and reduce turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

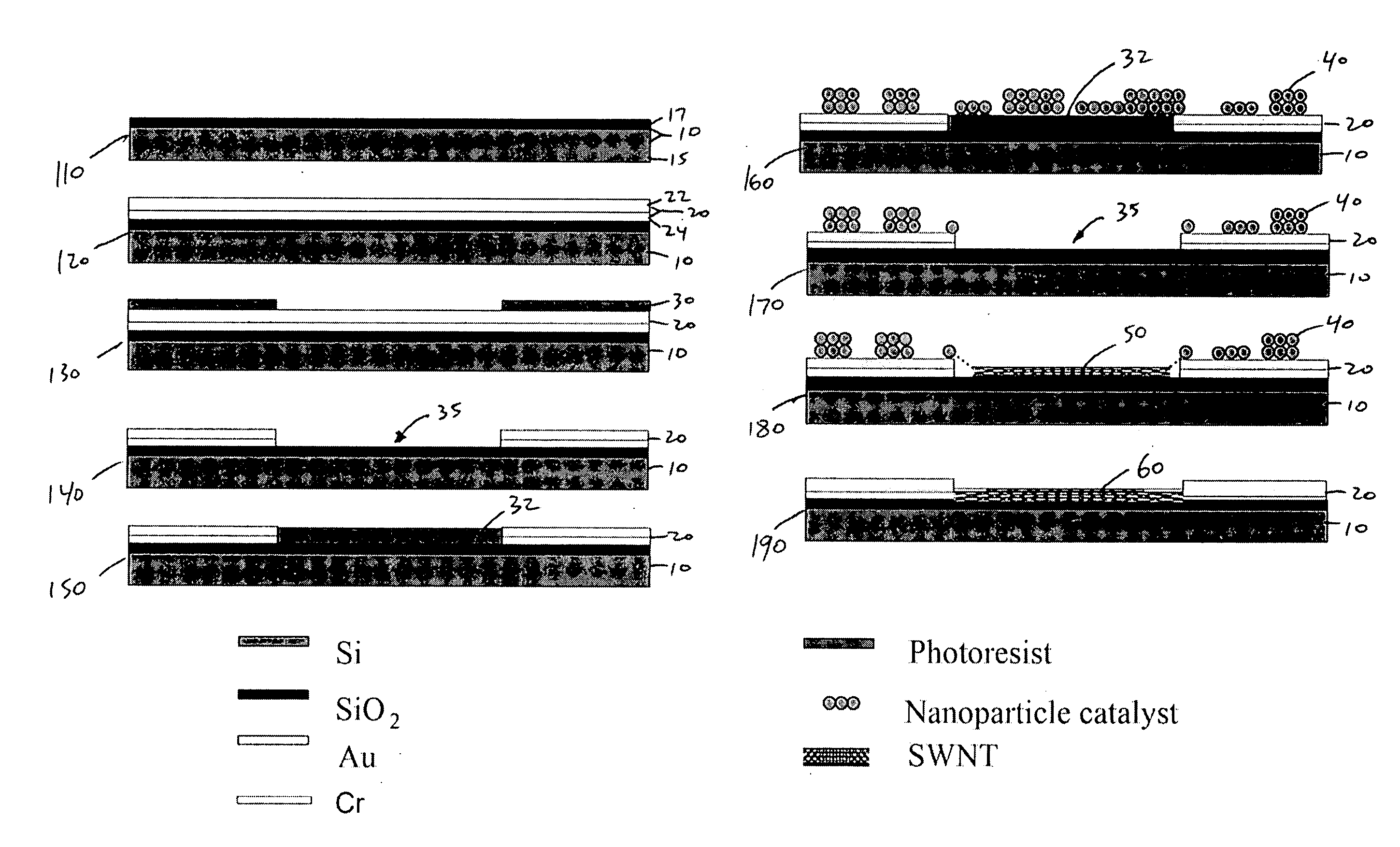

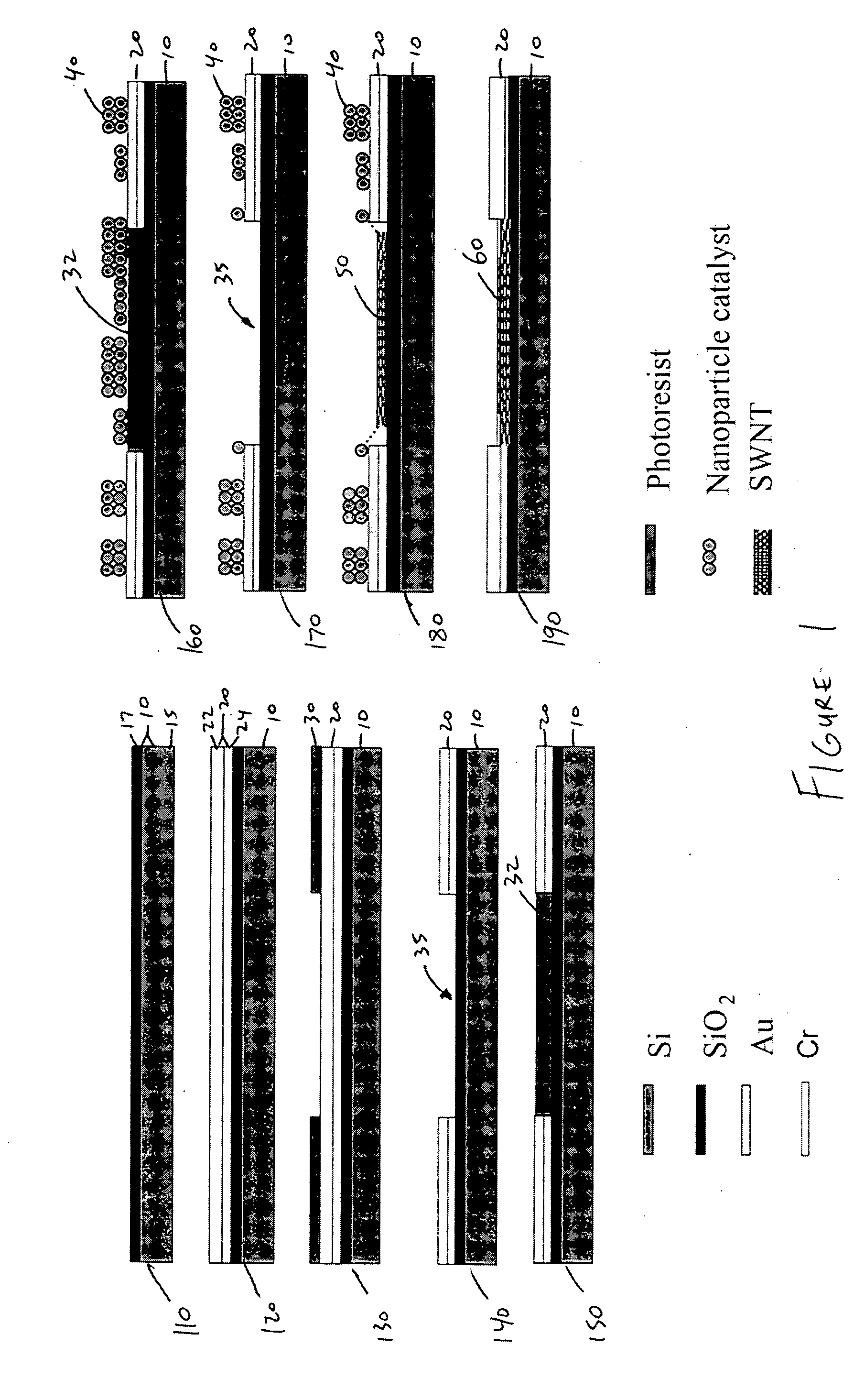

[0027]FIG. 1 depicts an exemplary method of synthesizing single-walled carbon nanotubes. The methods disclosed herein can also be modified to form multi-walled carbon nanotubes. In step 110, a substrate 10 is prepared according to cleanroom standards. The substrate 10 can comprise a lower, primary layer 15 and an upper, insulating layer 17. The primary layer 15 of the substrate 10 preferably includes silicon (Si). The insulating layer 17 can comprise a material such as silicon dioxide (SiO2), silicon nitride (Si3N4), or the like. In one exemplary embodiment, the substrate is a four inch silicon wafer with a 500 nm thick silicon dioxide (SiO2) film. The silicon wafer can be of any form known in the art. In one exemplary embodiment, the silicon wafer is a 100, p-type with a resistivity of about 12-16 kΩ-cm. The substrate 10 can also be comprised of other suitable materials such as a glass, a ceramic, a sapphire, a metal, a semiconductor material, or other materials known in the art.

[002

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap