Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

111results about "Metal/metal-oxides/metal-hydroxide catalysts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

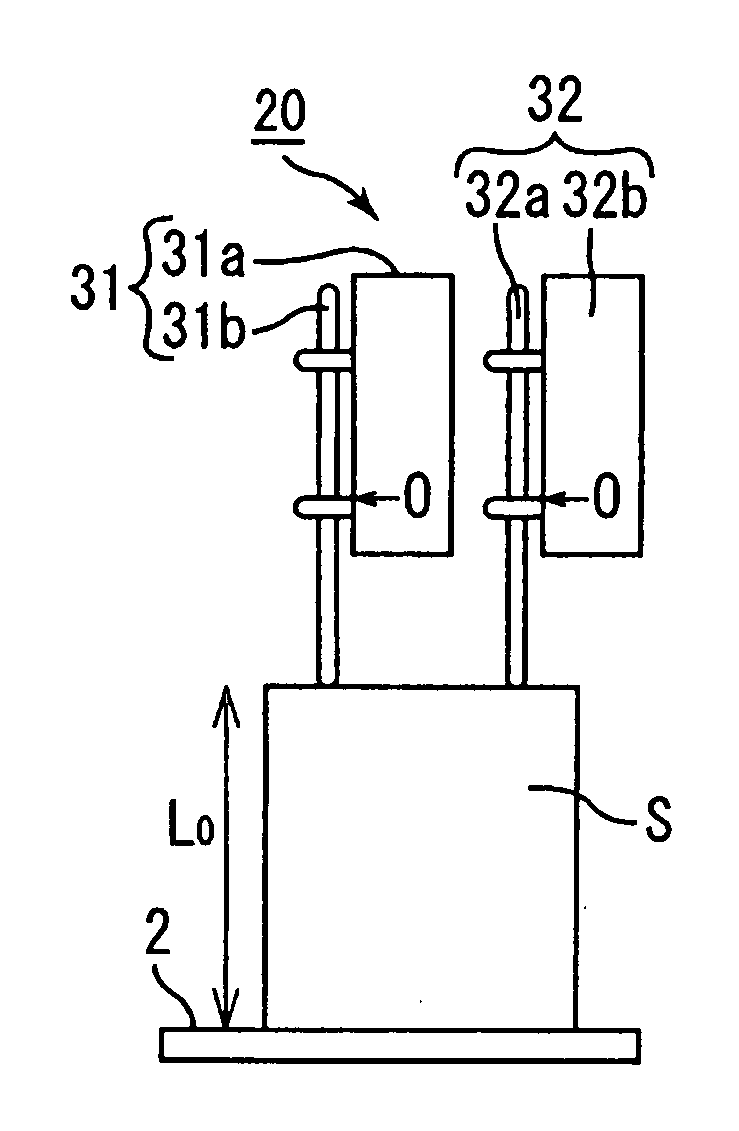

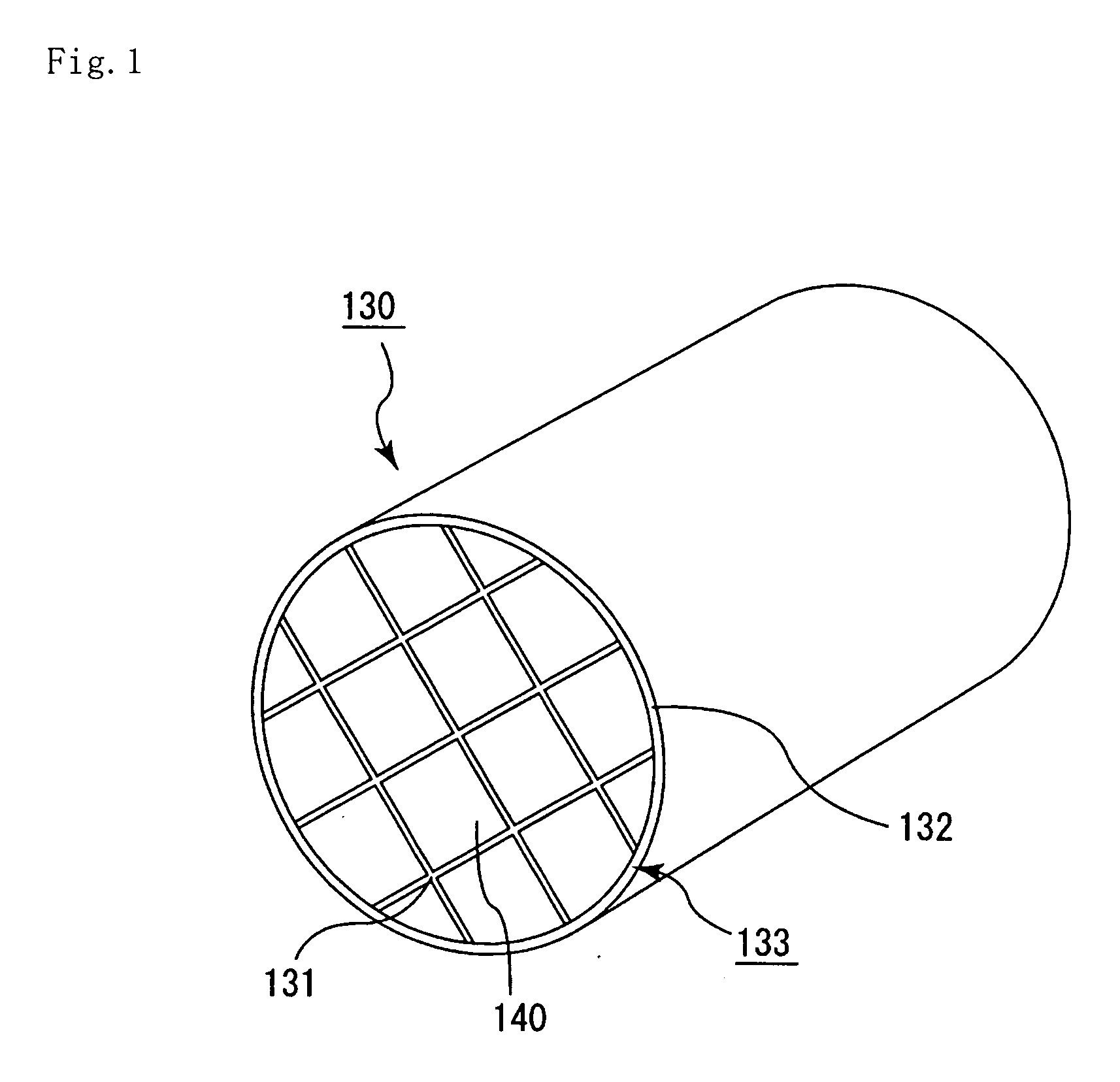

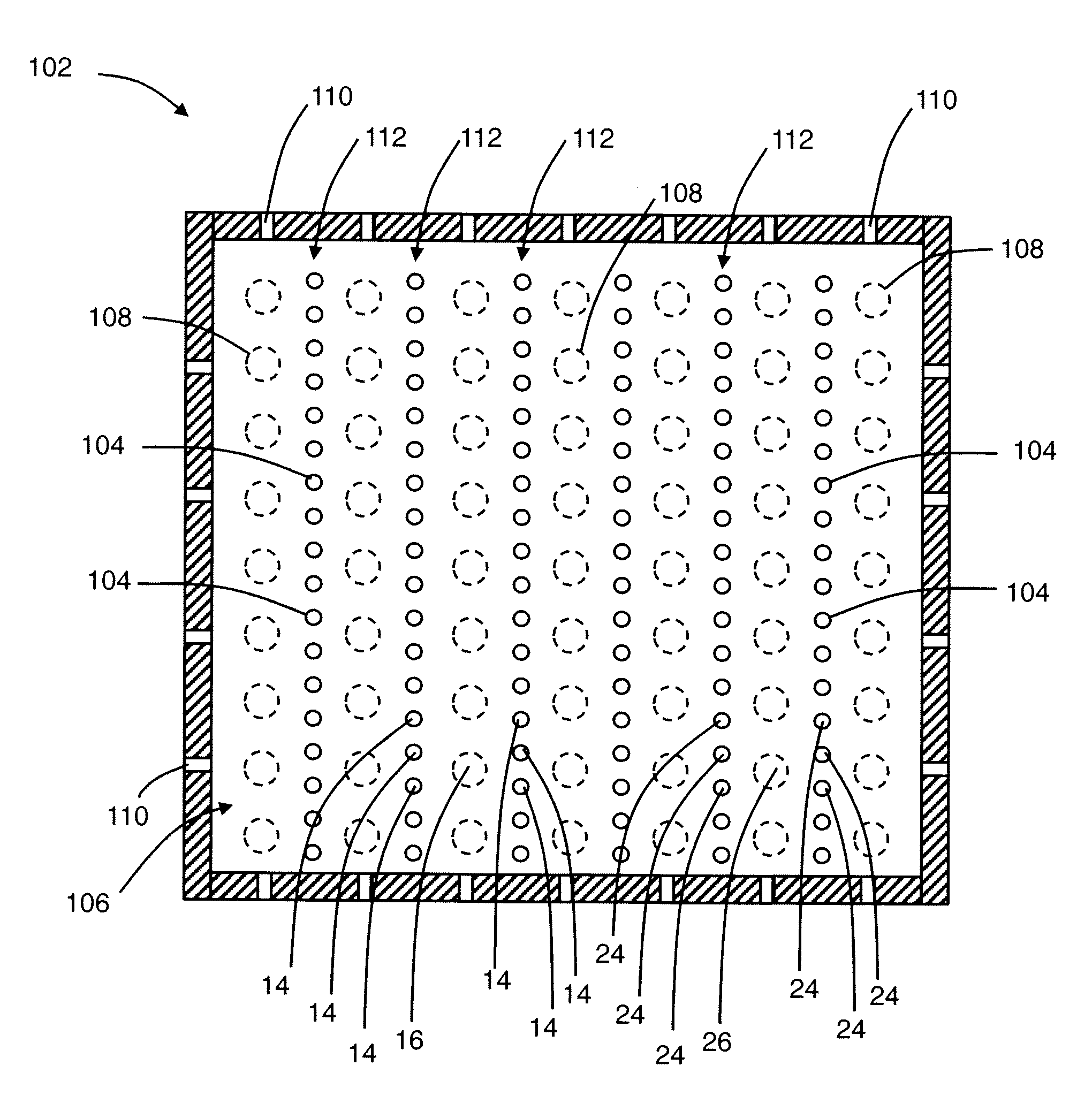

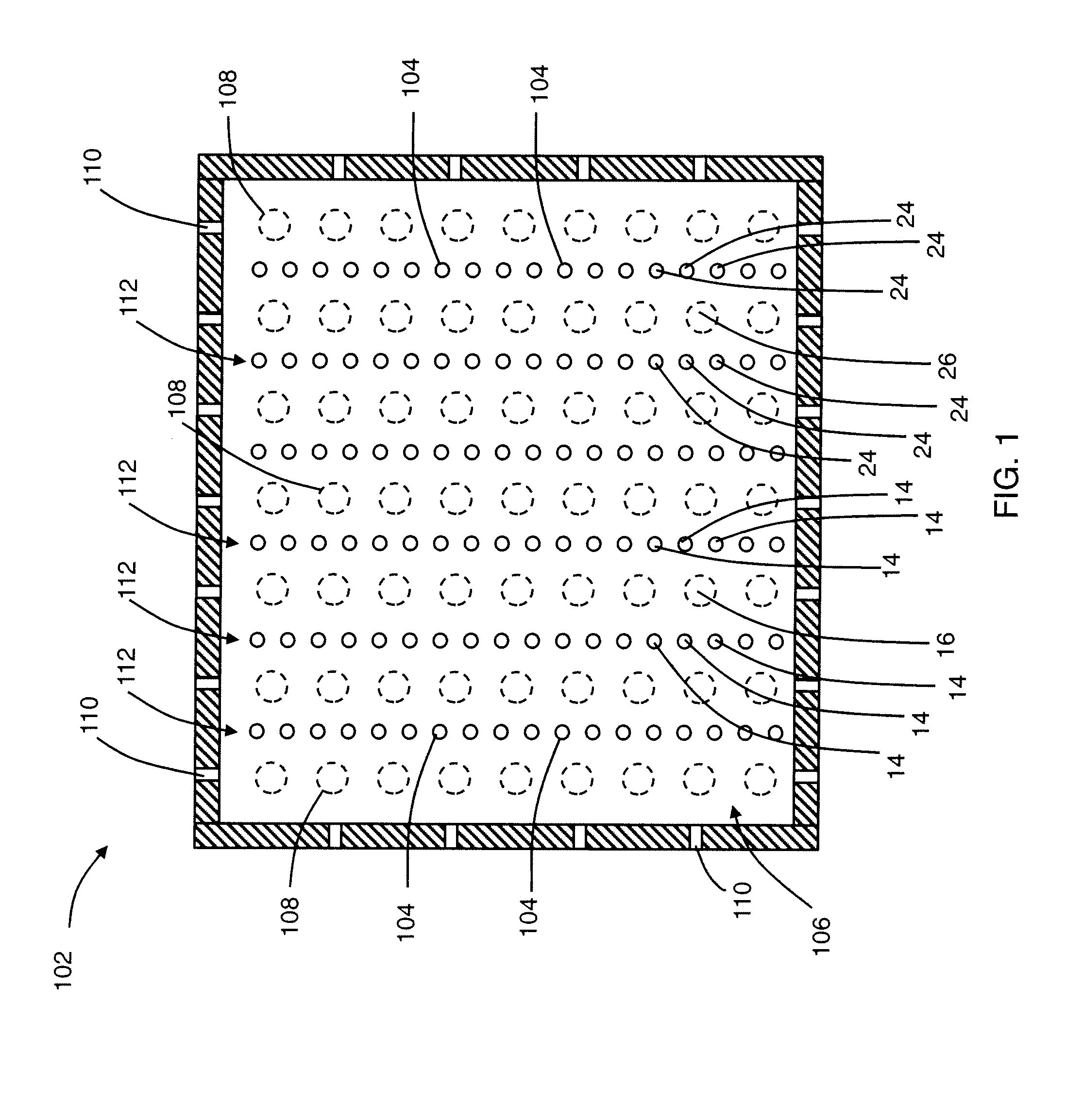

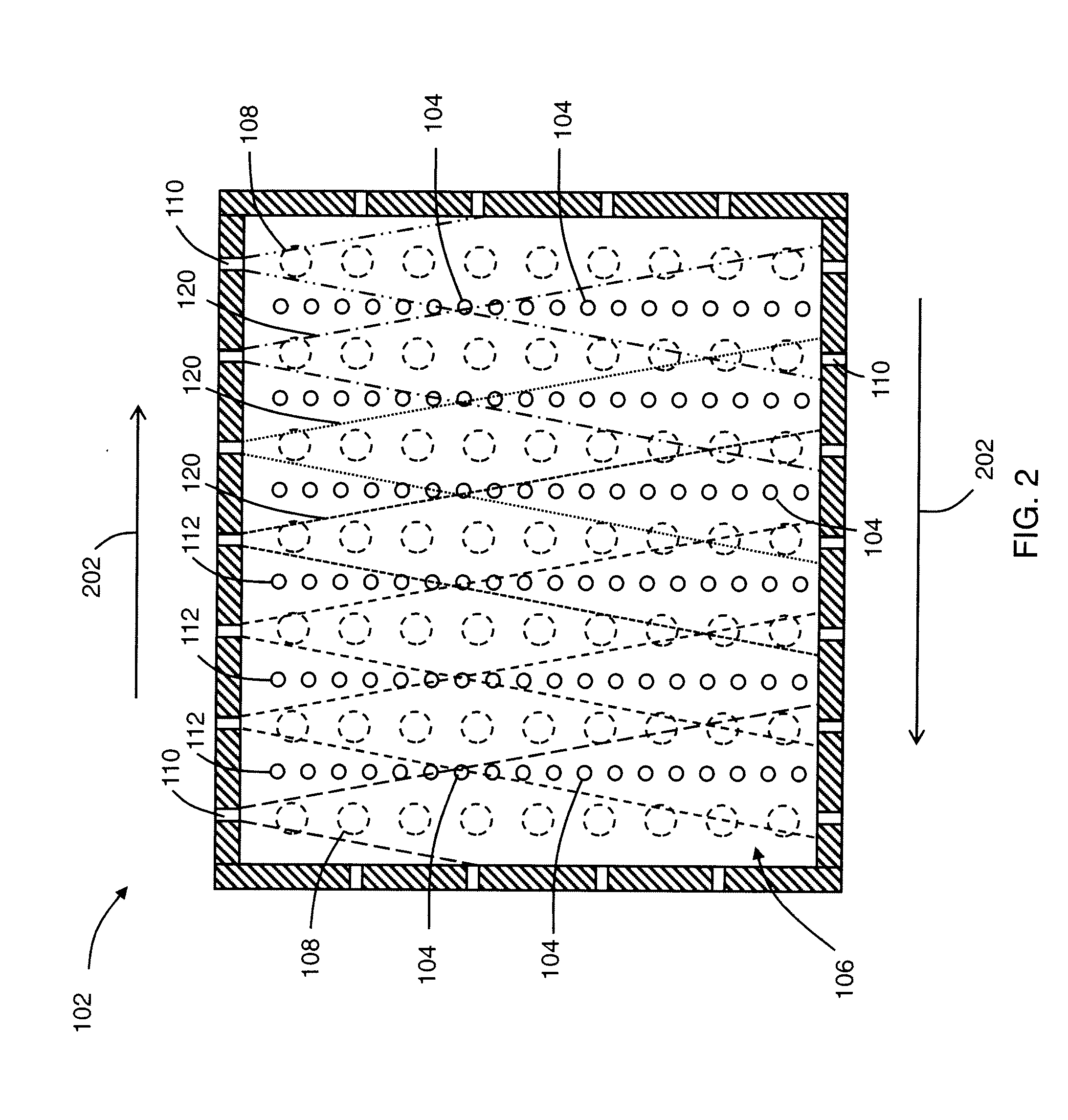

Method for inspecting honeycomb structured body and method for manufacturing honeycomb structured body

InactiveUS20070175060A1Good informationShort timeWalking sticksInternal combustion piston enginesEngineeringCell wall

Owner:IBIDEN CO LTD

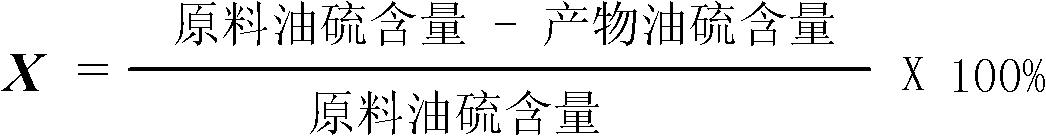

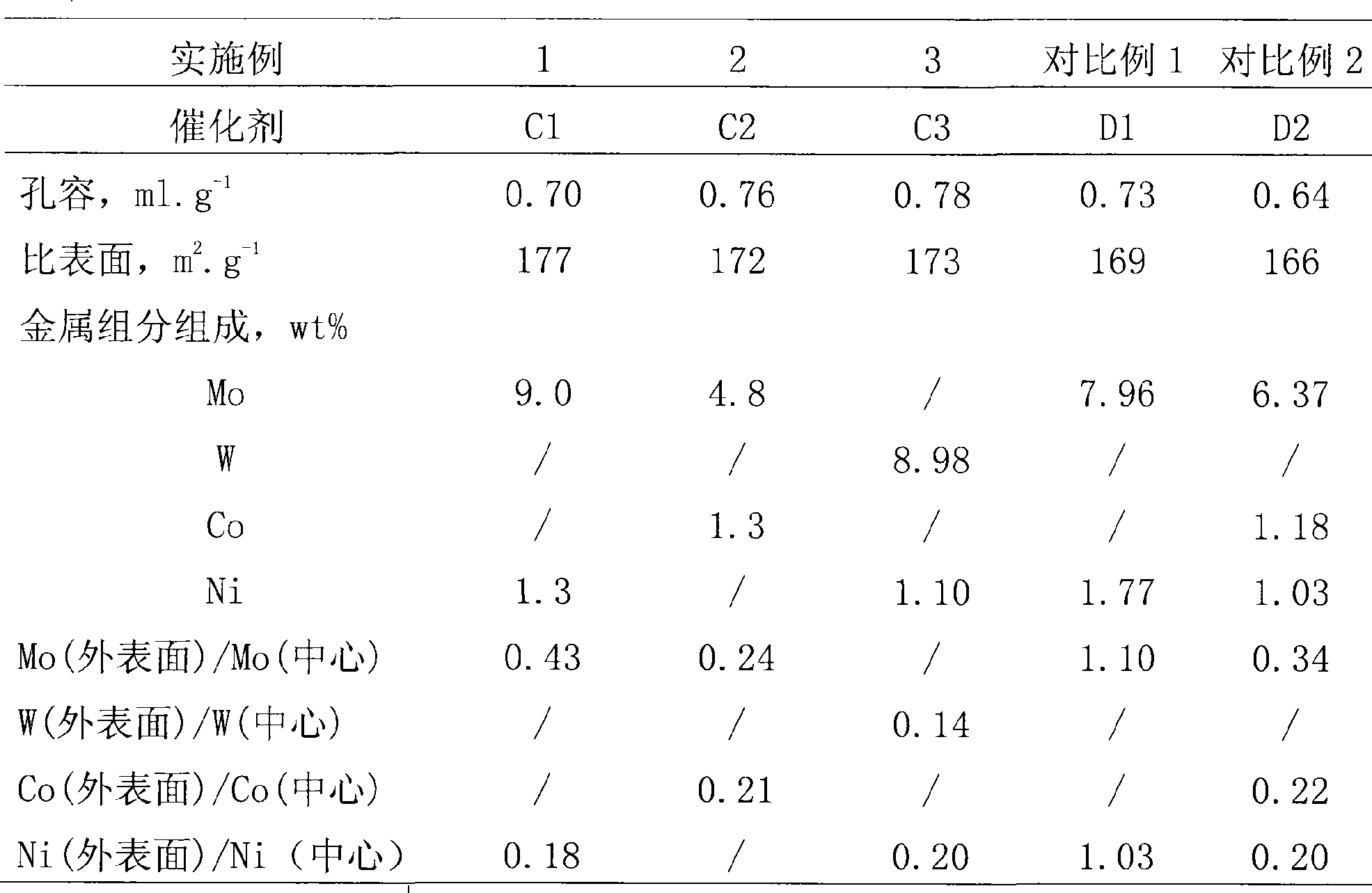

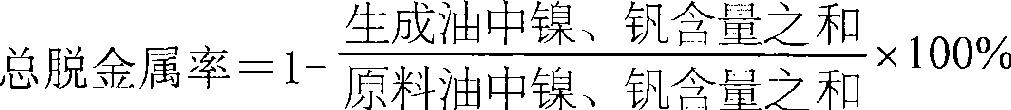

Hydrogenation catalyst and preparation method thereof

ActiveCN103143365AMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsQuaternary ammonium surfactantOrganic inorganic

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for preparing catalyst with non-uniform distribution of active metal component

InactiveCN101462080ACatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPhosphoric acidOXALIC ACID DIHYDRATE

Owner:CHINA PETROLEUM & CHEM CORP +1

Membrane-Supported Catalysts and the Process of Oxidative Dehydrogenation of Ethane Using the Same

ActiveUS20130072737A1Heterogenous catalyst chemical elementsHydrocarbon preparation catalystsParaffin waxMixed oxide

The present invention provides a continuous process for the oxidative dehydrogenation of ethane to ethylene using a mixed oxide catalyst supported onto a ceramic membrane by supplying an oxygen containing gas (air or pure oxygen) and pure ethane to the opposite sides of the membrane, so that the paraffin and the oxygen do not directly mix in the reactor.

Owner:NOVA CHEM (INT) SA

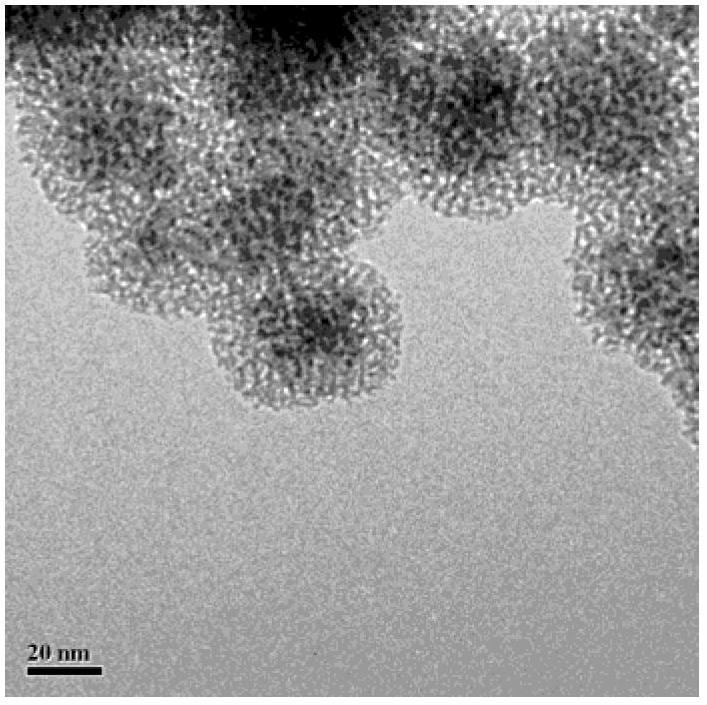

Fe3O4/CuO/pSiO2 catalyst and preparation method thereof

InactiveCN102688760AEfficient separation and recoveryReduce churnOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsChemistryActive agent

The invention relates to a Fe3O4 / CuO / pSiO2 (porous silica) catalyst, a preparation method thereof and application thereof in olefin epoxidation reaction. The preparation method comprises the following processes of: obtaining Fe3O4 microspheres serving as magnetic cores by adopting a co-precipitation method, and modifying the surfaces of the Fe3O4 microspheres by using polyvinyl pyrrolidone (PVP) in order to improve the adsorption effect of the surfaces of the Fe3O4 microspheres on metal cations; coating a CuO nano shell layer on the surfaces of the Fe3O4 microspheres by using copper acetate as a copper source through hydrothermal synthesis; and finally, coating the porous silicon dioxide shell layer by using cetyl trimethyl ammonium bromide (CTAB) as a surfactant and using ethyl orthosilicate as a silicon source, and thus obtaining a composite catalytic material with a magnetic Fe3O4 / CuO / pSiO2 core-shell structure. The catalytic performance of the composite material is researched by respectively using epoxidation reaction of styrene and cyclooctene as probe reaction, and the results prove that the catalytic material has high reaction activity and selectivity, and the catalytic material is easy to separate and recover by introducing the magnetic ores; and the catalytic material has a good circulating effect, still can keep excellent catalytic performance by dozens of times of circulation, and has a great application prospect.

Owner:UNIV OF SCI & TECH BEIJING

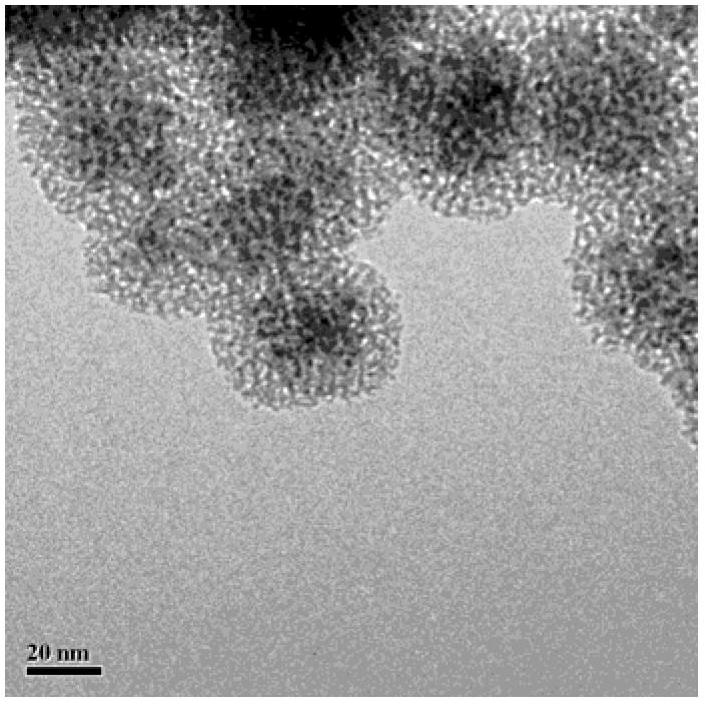

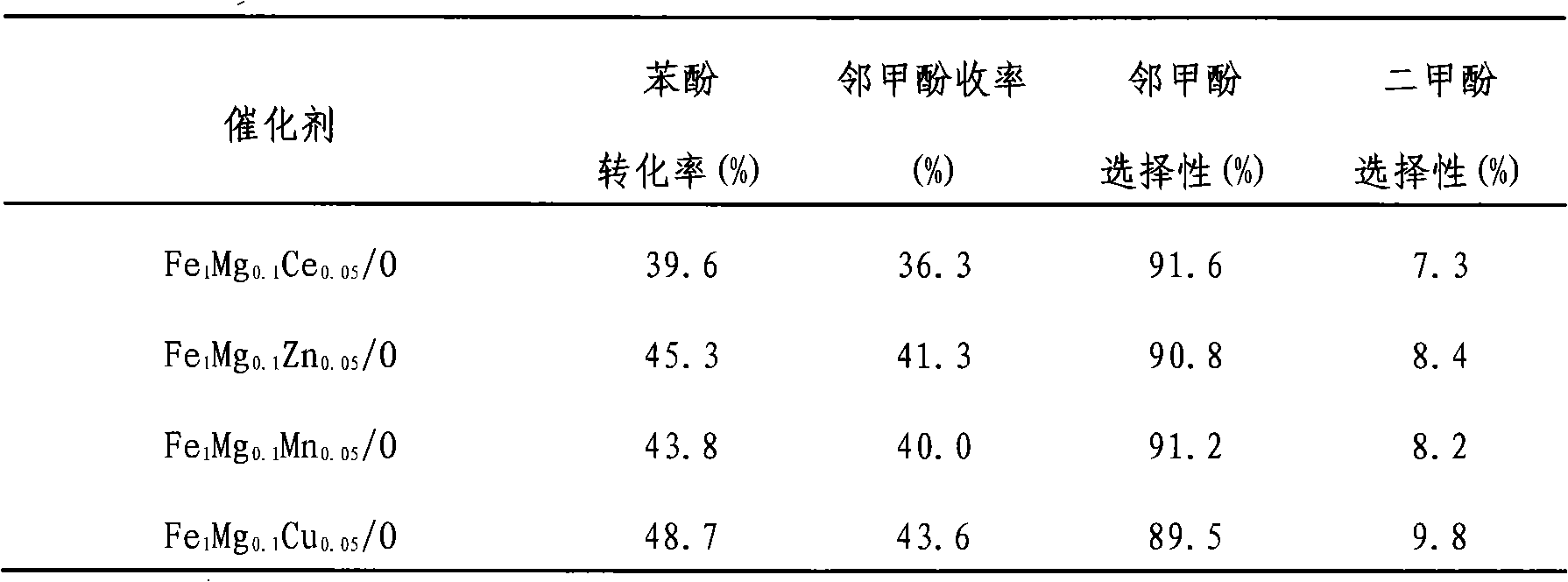

Phenol ortho-methylation catalyst and preparation method thereof

ActiveCN101513614AEasy to makeLow reaction temperatureOrganic chemistryOrganic compound preparationMagnesium saltOrtho position

Owner:HUNAN XINLING CHEM CO LTD

Catalyst for selective hydrogenation and olefin removal of reformed generated oil as well as preparation method and application

ActiveCN104014337AReduce dosageIncrease profitMetal/metal-oxides/metal-hydroxide catalystsRefining by selective hydrogenationActive componentHigh activity

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Method for preparing ZnWO4 nanorod photocatalysis material

InactiveCN102935360APhotocatalyticWith photocatalytic effectMetal/metal-oxides/metal-hydroxide catalystsTungsten compoundsHeat treatedNanorod

Owner:SHAANXI UNIV OF SCI & TECH

Biomass pyrolysis gasification multifunctional iron-based catalyst and preparation method thereof

ActiveCN103394356AGas purification with selectively adsorptive solidsMetal/metal-oxides/metal-hydroxide catalystsMuffle furnacePyrolysis

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

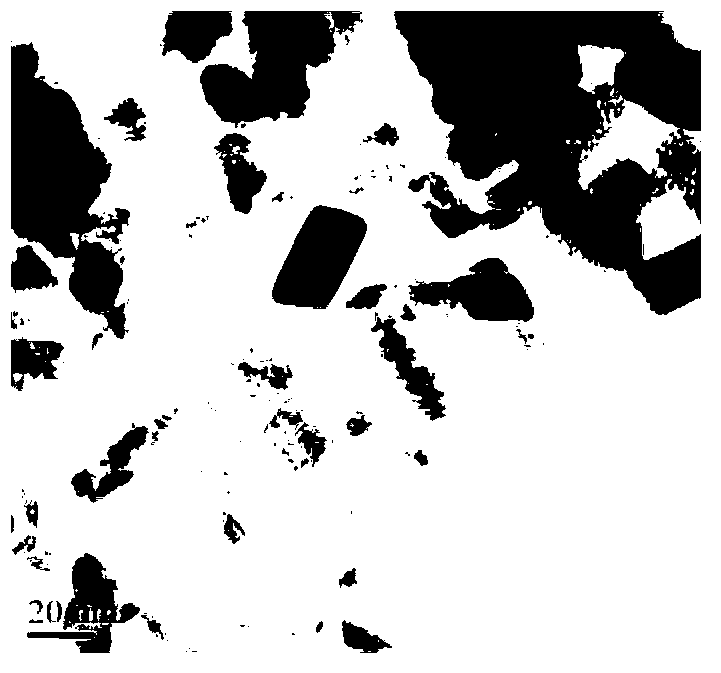

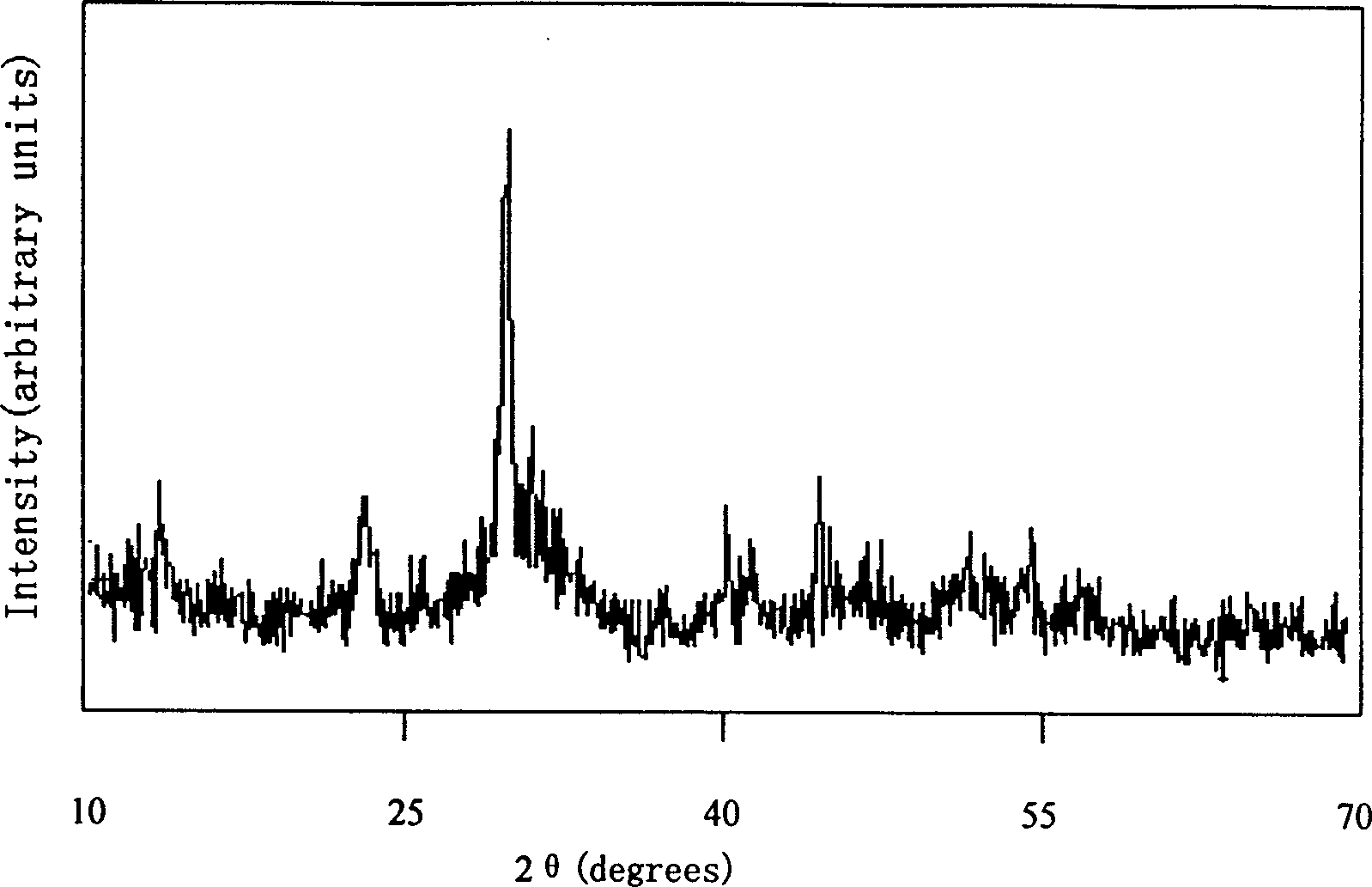

Carbon nanotube powder, carbon nanotubes, and processes for their production

InactiveUS8398949B2High purityImprove liquidityMaterial nanotechnologyBiocideCarbon nanotubeMaterials science

Owner:COVESTRO DEUTSCHLAND AG

Preparation method of manganese-based composite metal oxide ozonolysis catalyst

InactiveCN109833868AHigh activityImprove stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystOzonolysis

The invention provides a preparation method of a manganese-based composite metal oxide ozonolysis catalyst, and belongs to the fields of catalysis and environmental protection. The method uses a redoxprecipitation process to synthesize the nano-fibrous manganese-based composite transition metal oxide catalyst. The preparation method of the catalyst has the advantages of simple process, mild conditions, and realization of high stability of catalytic ozonolysis. The catalyst prepared by the method disclosed in the invention has a high ozone removal catalysis activity, and can realize complete removal of ozone at normal temperature.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

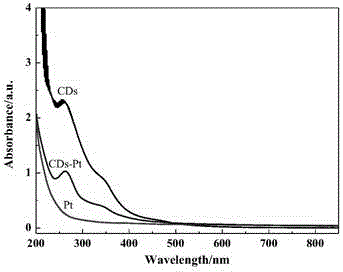

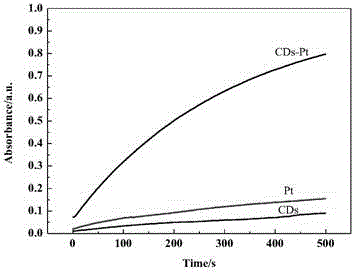

CDs-Pt nanomaterial with catalase catalytic properties

InactiveCN104549234AThe synthesis method is simpleNo pollution in the processMaterial nanotechnologyMetal/metal-oxides/metal-hydroxide catalystsPlatinumGlucose detection

Owner:JIANGNAN UNIV

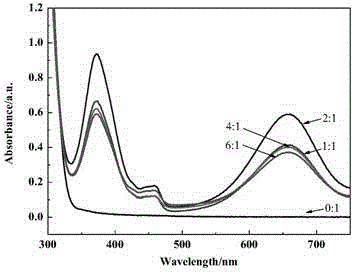

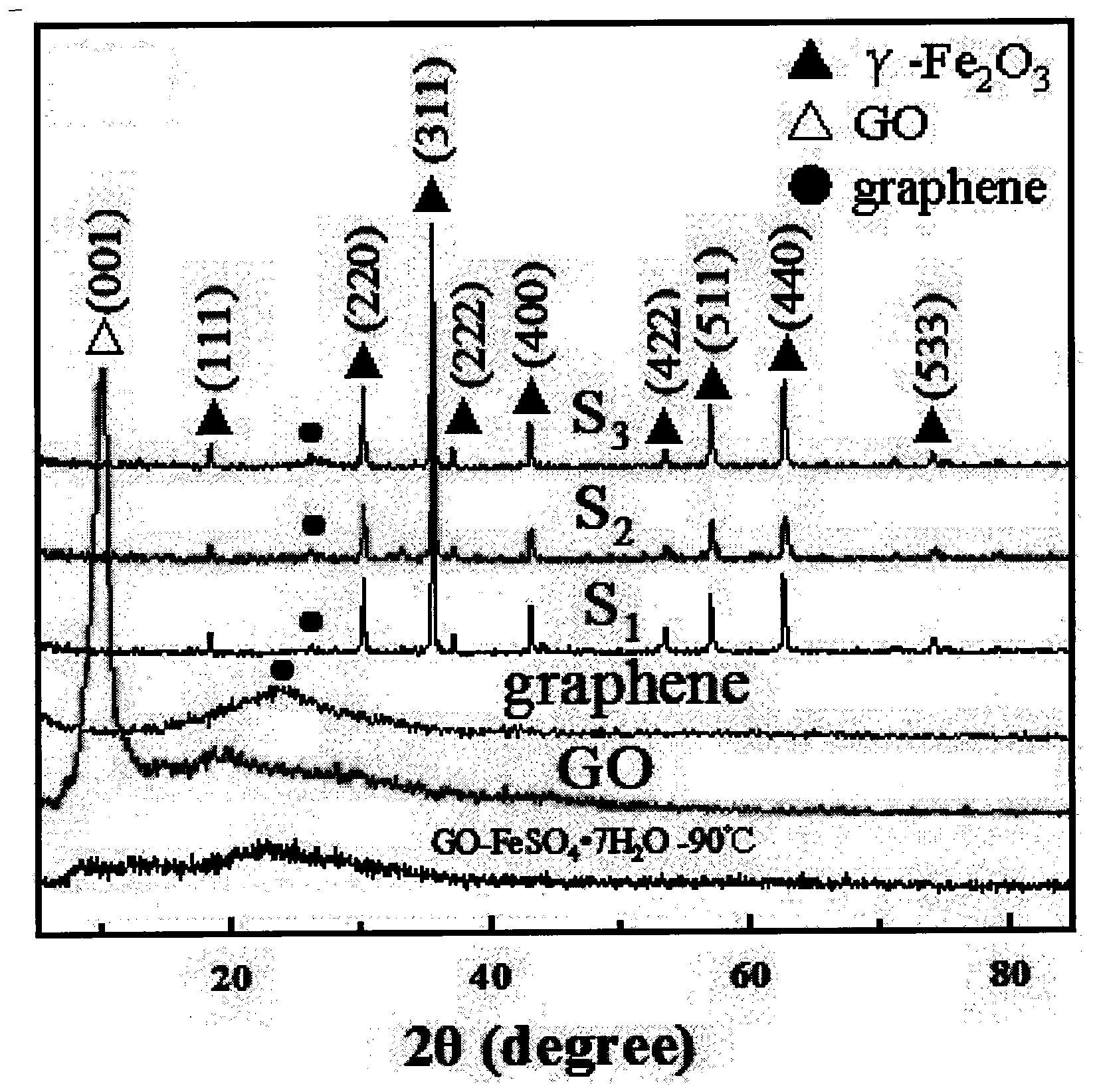

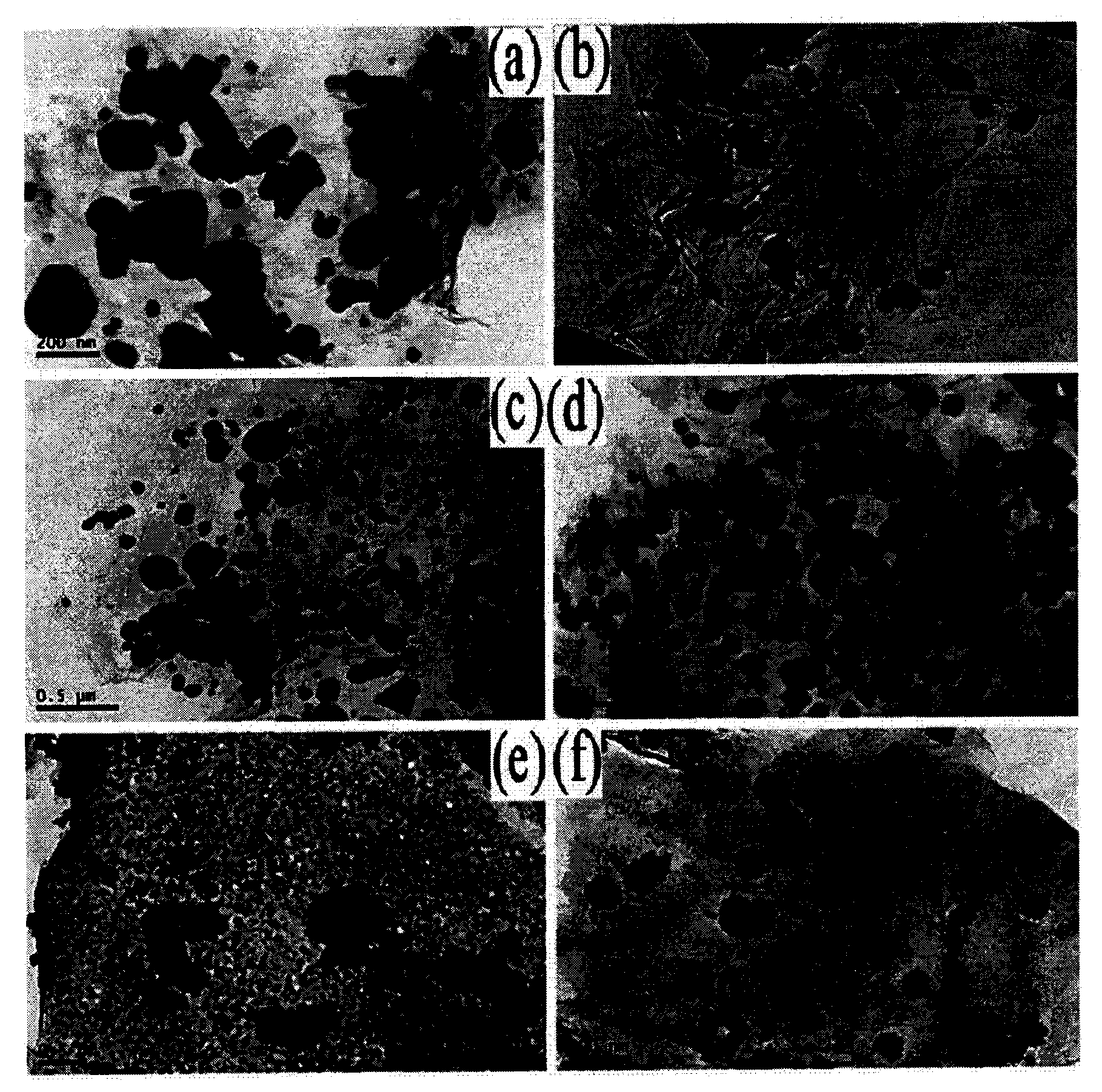

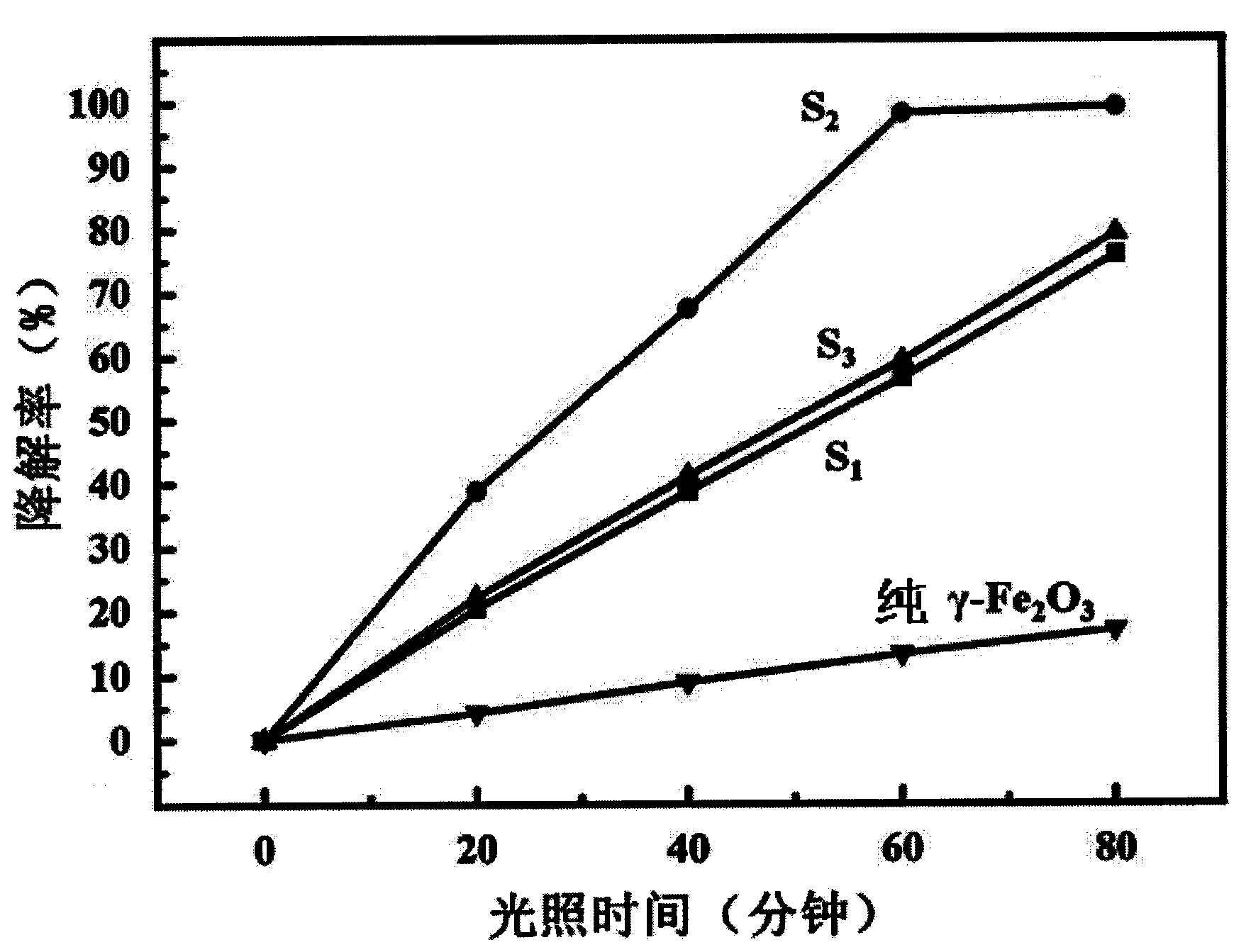

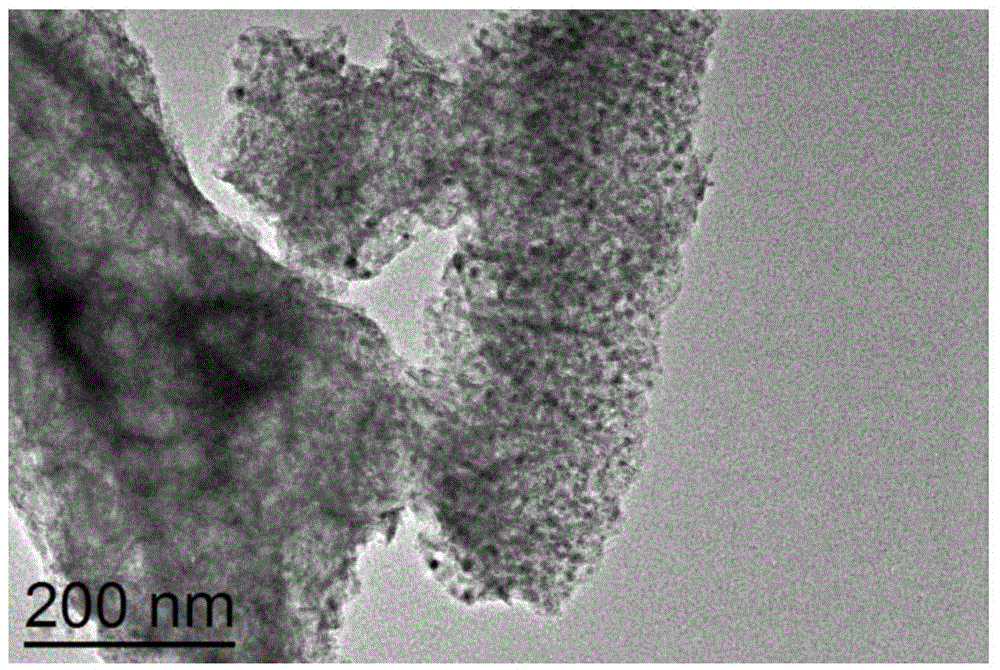

Graphene-based gamma-FeO2O3 composite material photocatalyst, and preparation method and use thereof

InactiveCN103706364AReduced band gapLarge specific surface areaMetal/metal-oxides/metal-hydroxide catalystsIron sulfateOrganic matter

Owner:魏颖

Catalyst for oxidative dehydrogenation of raw materials containing CO (carbon monoxide) gas

InactiveCN102649055ACarbon monoxideMetal/metal-oxides/metal-hydroxide catalystsLoss rateAdditive ingredient

The invention relates to a catalyst for oxidative dehydrogenation of raw materials containing CO (carbon monoxide) gas, which mainly solves the technical problems in the prior art that the hydrogen removal rate is low, and the loss rate of CO is high. The catalyst comprises a carrier, an active component and an accessory ingredient in percentage by weight: (a) the active component which is selected from at least one of platinum metals, and has the dosage being 0.003-2 percent of the weight of the catalyst in a metering manner of a simple substance; (b) the accessory ingredient which is selected from at least one of Pr, Nd, Cs and Ba, and has the dosage being 0.005-15 percent of the weight of the catalyst in a metering manner of a simple substance; and (c) 84-99.5 percent of carrier, wherein the carrier is selected from a compound type carrier of aluminum oxide and silicon oxide, and the weight ratio of the aluminum oxide to the silicon oxide is 0.01-100:1. According to the technical scheme, the problems are better solved, and the catalyst can be applied in industrial production of oxidative dehydrogenation of raw materials containing the CO gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

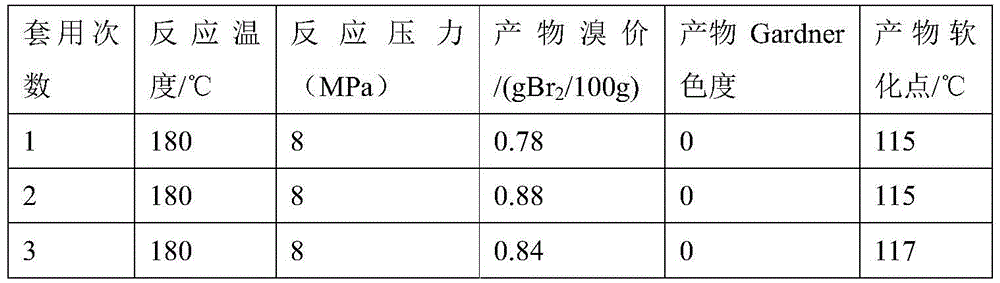

Catalyst for catalyzing hydrogenation of petroleum resin as well as preparation method and application thereof

Owner:DALIAN UNIV OF TECH

Method of Operating a Furnace

Owner:AIR PROD & CHEM INC

Method for preparing solid base catalyst with high specific surface by hybrid composite precursors

InactiveCN101554596APore Structure RegulationControl areaCarboxylic acid nitrile preparationOrganic compound preparationAcetic acidBenzaldehyde

Owner:BEIJING UNIV OF CHEM TECH

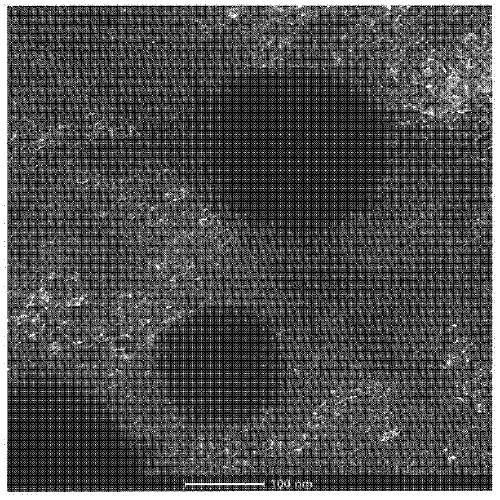

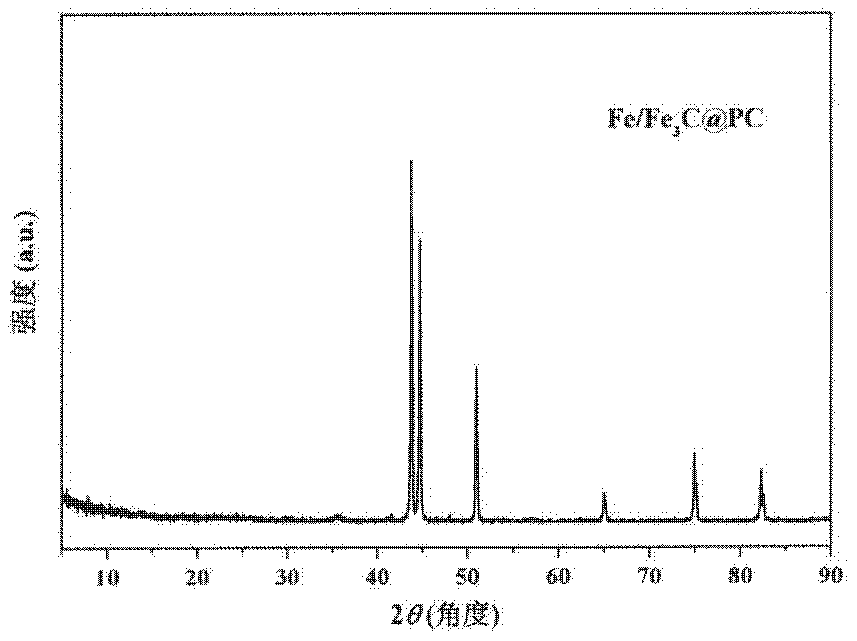

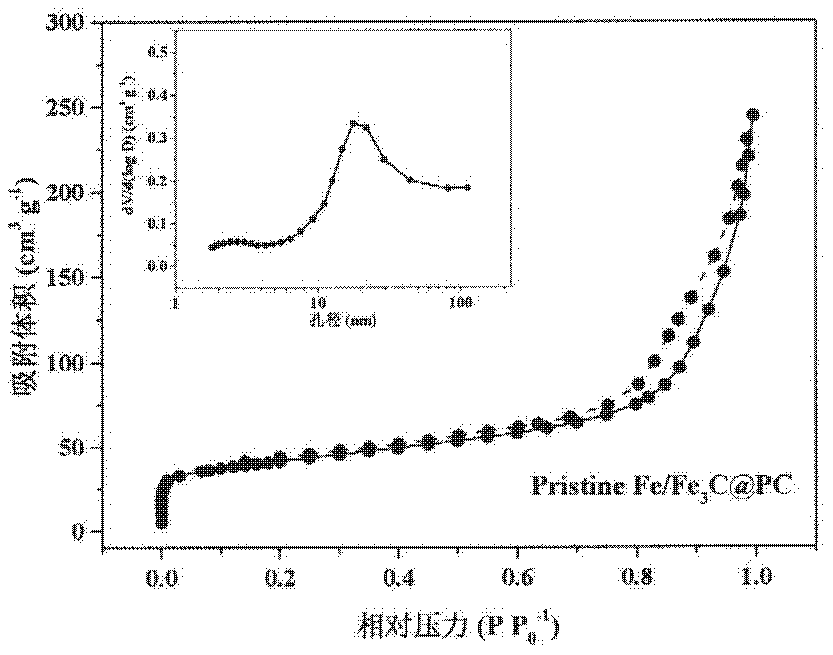

Metal organic framework derived iron-carbon catalyst suitable for heterogeneous electro-Fenton process and preparation method thereof

PendingCN111111661ASimple and fast operationLow equipment requirementsWater treatment compoundsWater contaminantsPtru catalystPorous carbon

Owner:NANKAI UNIV

Nano-grade lanthanum titanium compound oxide, its preparation method and application

InactiveCN1394680AReduce viscosityReduce the temperatureCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsOligomerLactide

Owner:CHONGQING UNIV

Ethylene oligomerization catalyst and use thereof

InactiveUS20110124938A1Easy to synthesizeLittle catalyst deteriorationHydrocarbons from unsaturated hydrocarbon additionCatalyst regeneration/reactivationOligomerPtru catalyst

Ethylene is oligomerized with a catalyst in which nickel is supported on a support containing silica and alumina. The catalyst has little deterioration over long periods and affords oligomers with high productivity.The ethylene oligomerization catalyst includes a support and a nickel compound supported on the support, the support including silica and alumina, and the amount of nickel supported is in the range of 0.0001 to 1 wt % based on the weight of the support, and the molar ratio of silica to alumina in the support (SiO2 / Al2O3) is in the range of 100 to 2000. In a process of the invention, ethylene is oligomerized with use of the catalyst.

Owner:MITSUI CHEM INC

Cobalt-aluminum composite oxide catalyst and preparation method and application thereof

PendingCN110433806ALarge specific surface areaLarge transport channelIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsCatalytic transformationPtru catalyst

The invention relates to the technical field of catalyst preparation, and discloses a cobalt-aluminum composite oxide catalyst and a preparation method and application thereof. The preparation methodcomprises the steps that metal salt solutions of cobalt and aluminum are taken as precursors correspondingly, polymer microspheres are taken as a template agent, templates are soaked in the precursorsolutions, then impregnation and roasting are conducted, and thus the cobalt-aluminum composite oxide catalyst is obtained. A three-dimensional ordered hierarchical pore structure with a mesoporous and macroporous structure is created through the polymer microspheres, thus the specific surface area of the catalyst is increased, the prepared catalyst has a large transmission pore channel, reactantmodules enter the pore channel from all directions advantageously, the diffusion resistance is lowered, thus the convective mass transfer efficiency between gases is improved, and the catalytic activity of the cobalt-aluminum composite oxide catalyst is facilitated; and meanwhile, through the large transmission channel, the situation that the modules are blocked when reacting on the pore wall or the pore channel of the transmission channel, and consequently, the reaction progress is influenced can further be effectively avoided, and the catalytic conversion efficiency of the catalyst is improved.

Owner:FUZHOU UNIV

Nickel catalyst, process for the preparation thereof, process for hydrogenation of m-dinitro benzene to m-phenylene diamine

InactiveUS20050070740A1Speed up the processLong catalyst lifeMolecular sieve catalystsOrganic compound preparationSolventSilicon dioxide

Owner:COUNCIL OF SCI & IND RES

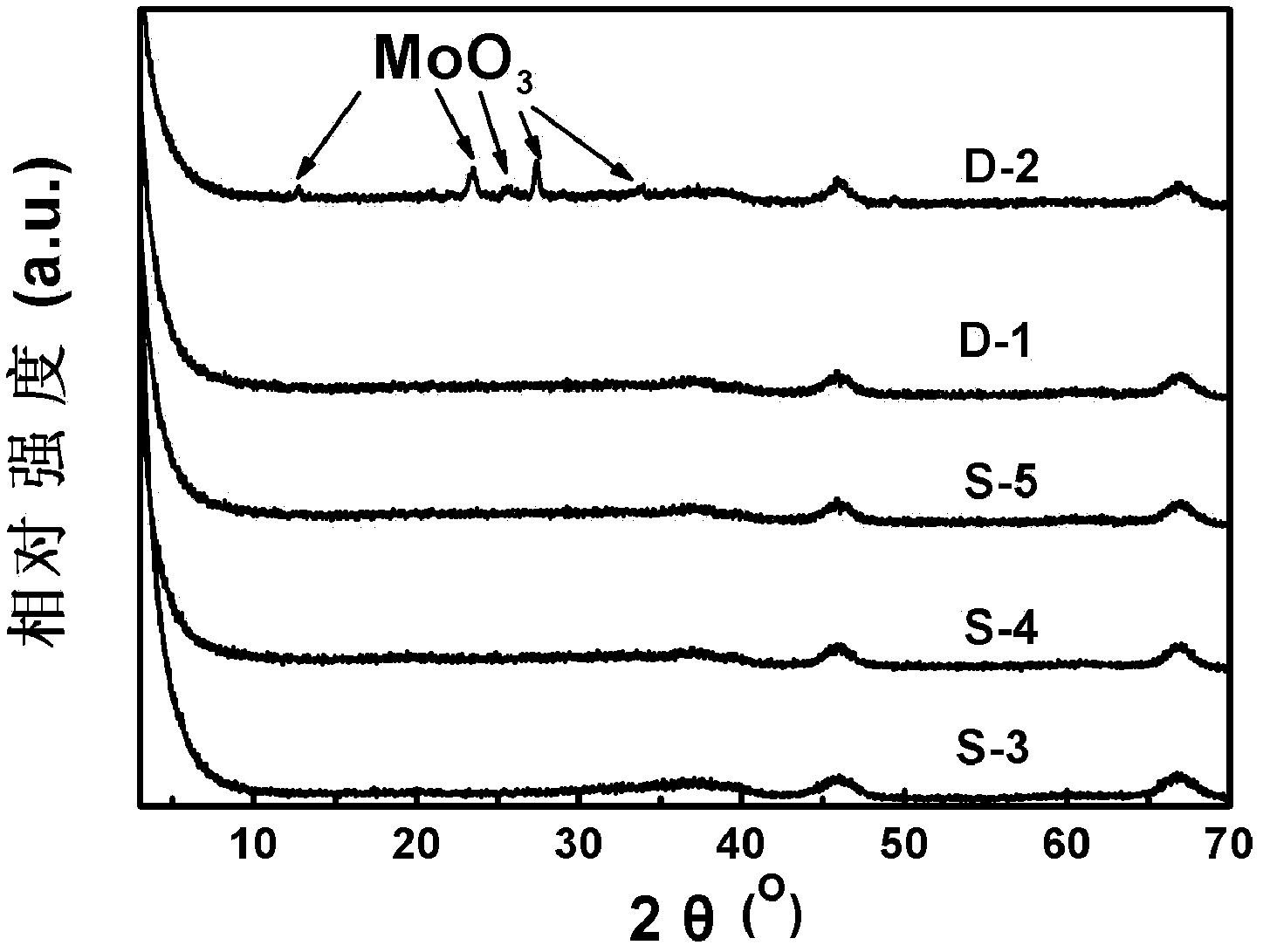

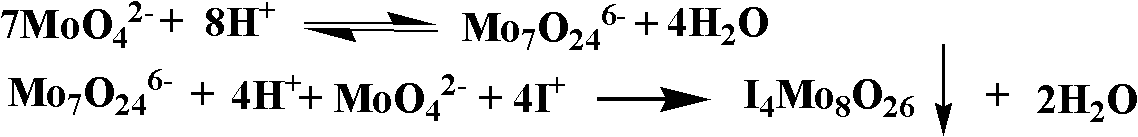

Zirconium-molybdenum oxide catalyst for methane oxidation to synthesize formaldehyde and its preparation method

InactiveCN1394681AEasy to prepareHigh mechanical strengthMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureOxygen

The molecular formula of zirconium-molybdenum oxide catalyst for synthesizing formaldehyde by means of methane oxidation is (ZrO2)x(Zr(MoO4)2)y (MoO3)z, and its preparalcon method includes the following steps: using zirconium dioxide powder ammonium molbdate powder as raw material, metering and weighing ammonium molybdate powder according to the above-mentioned molecular formula, using deionized water to prepare ammonium modybdate aqueous solution with a certain concentration, adding said aqueous solution into zirconium dioxide powder, drying the mixture, high-temp. roasting, mechanical grinding, press-forming, screening granules so as to obtain the catalyst.

Owner:TSINGHUA UNIV

Method for preparing platinum-carbon catalyst

InactiveCN104801298AImprove stabilityGood repeatabilityMetal/metal-oxides/metal-hydroxide catalystsFiltrationSolvent

The invention belongs to the technical field of catalysis and relates to a method for preparing a platinum-carbon catalyst which is high in activity and stability. The method comprises the following steps: 1, preparing a chloroplatinic acid alcohol solution : diluting the chloroplatinic acid with an alcohol solvent I so as to obtain the chloroplatinic acid alcohol solution; 2, preparing a sodium hydroxide solution : dissolving sodium hydroxide into an alcohol solvent II so as to obtain the sodium hydroxide solution; 3, preparing an activated-carbon-loaded platinum-carbon catalyst: adding the chloroplatinic acid alcohol solution prepared in advance in an activated carbon carrier, then adding the sodium hydroxide solution and carrying out microwave reduction; 4, cooling and drying, after completion of microwave reduction in the step 3, cooling the mixture to room temperature, adding deionized water, the volume of which is the same as that of the mixture, carrying out extraction filtration and washing, and carrying out vacuum drying on the catalyst. According to the invention, the operation is quick and simple, process stability and repeatability are good, active component particles are distributed uniformly, the particle size range is narrow and the fact that the particle size is controllable is realized according to the quantity of sodium hydroxide and the solvents; the catalyst prepared through the preparation method is high in activity and good in stability.

Owner:QINGDAO UNIV OF SCI & TECH

Preparation method for supported Mo-based oxidation and desulfurization catalyst

InactiveCN102294236AHigh activityRealize deep desulfurizationMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsOrganic acidPetrochemical

Owner:DALIAN UNIV OF TECH

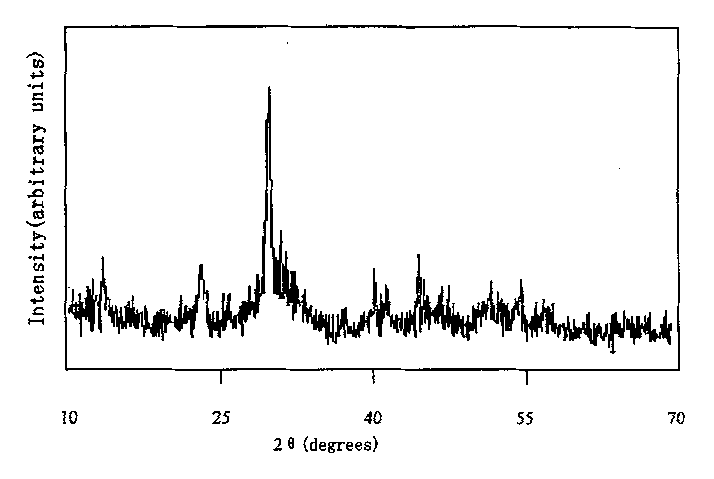

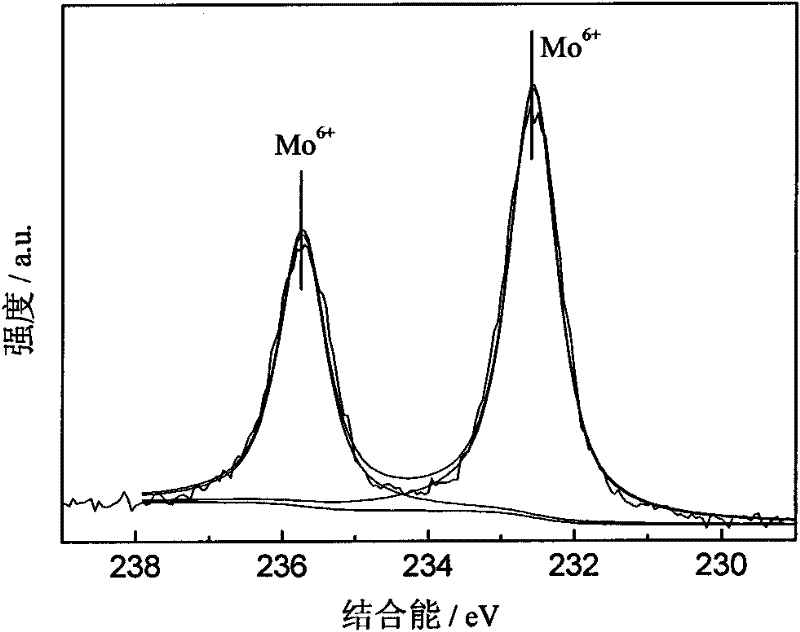

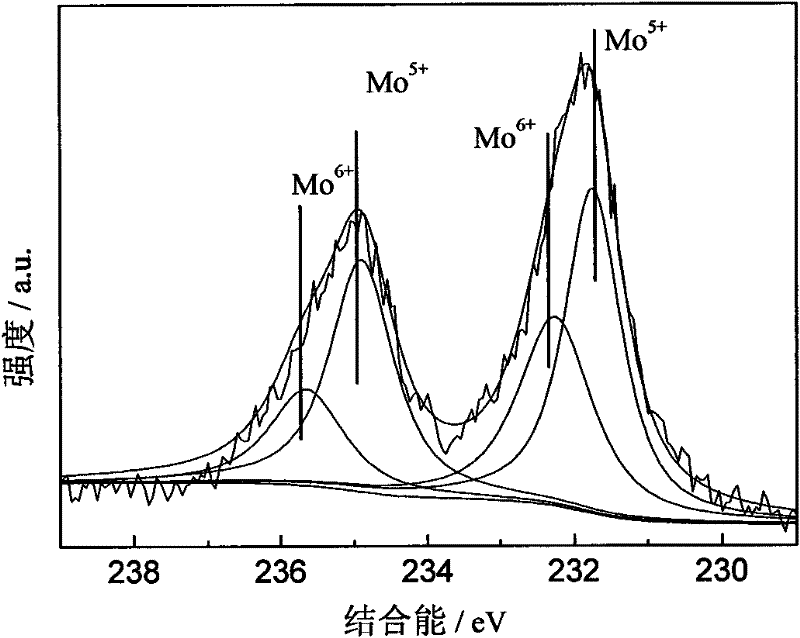

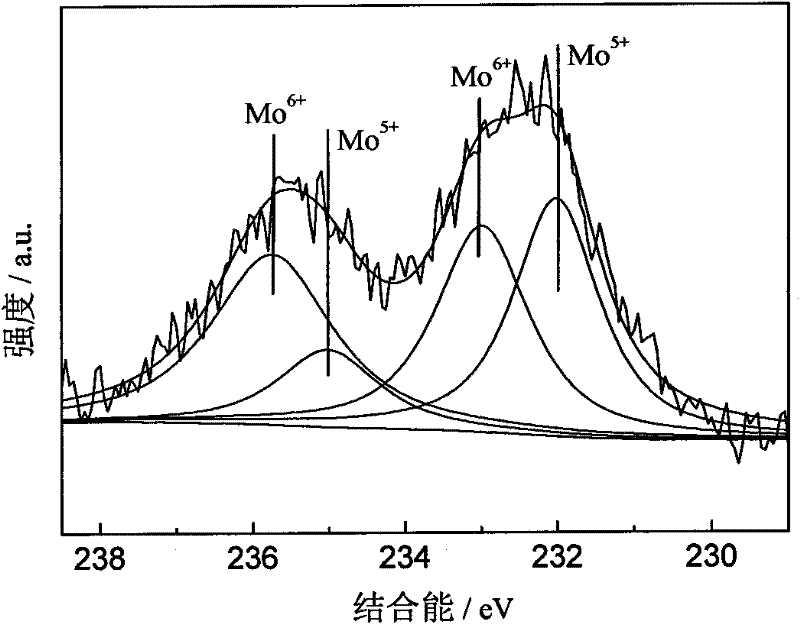

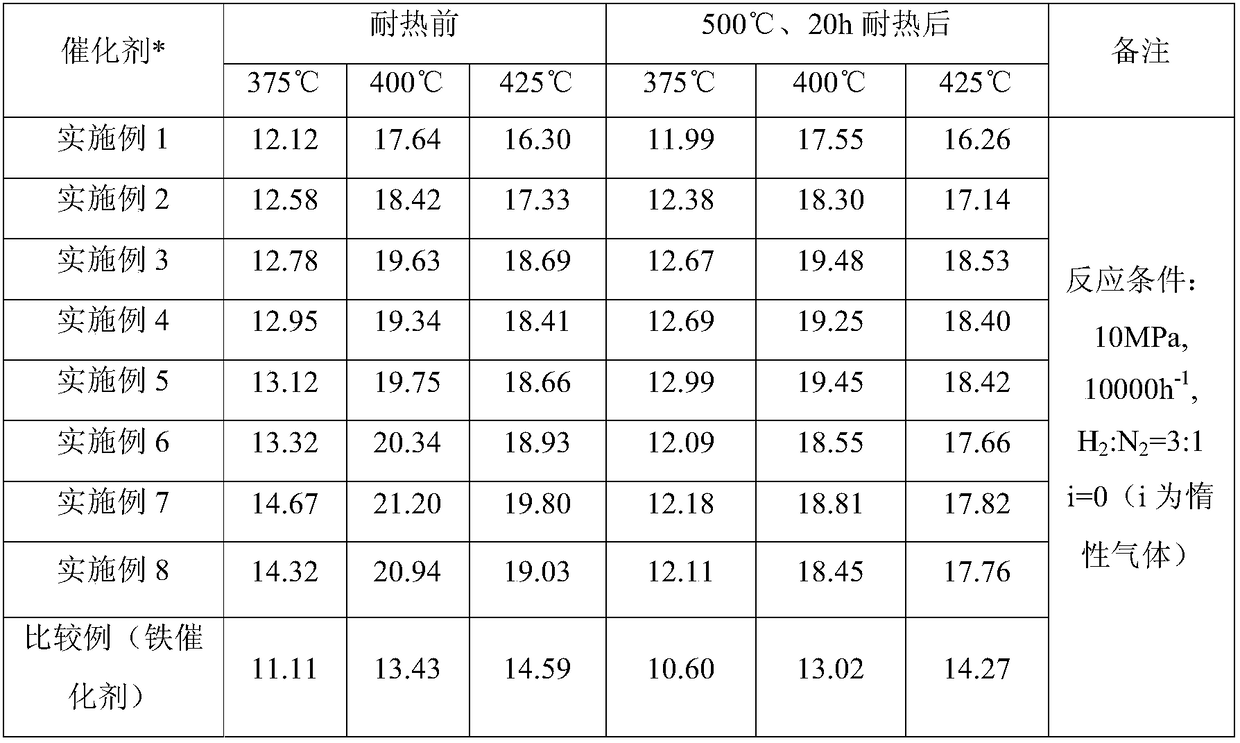

Activated carbon-supported ruthenium-based ammonia synthetic catalyst and preparation method thereof

ActiveCN108525663AGood chemical stabilityHigh activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalPotassium

Owner:福建省福大百阳化工科技有限公司

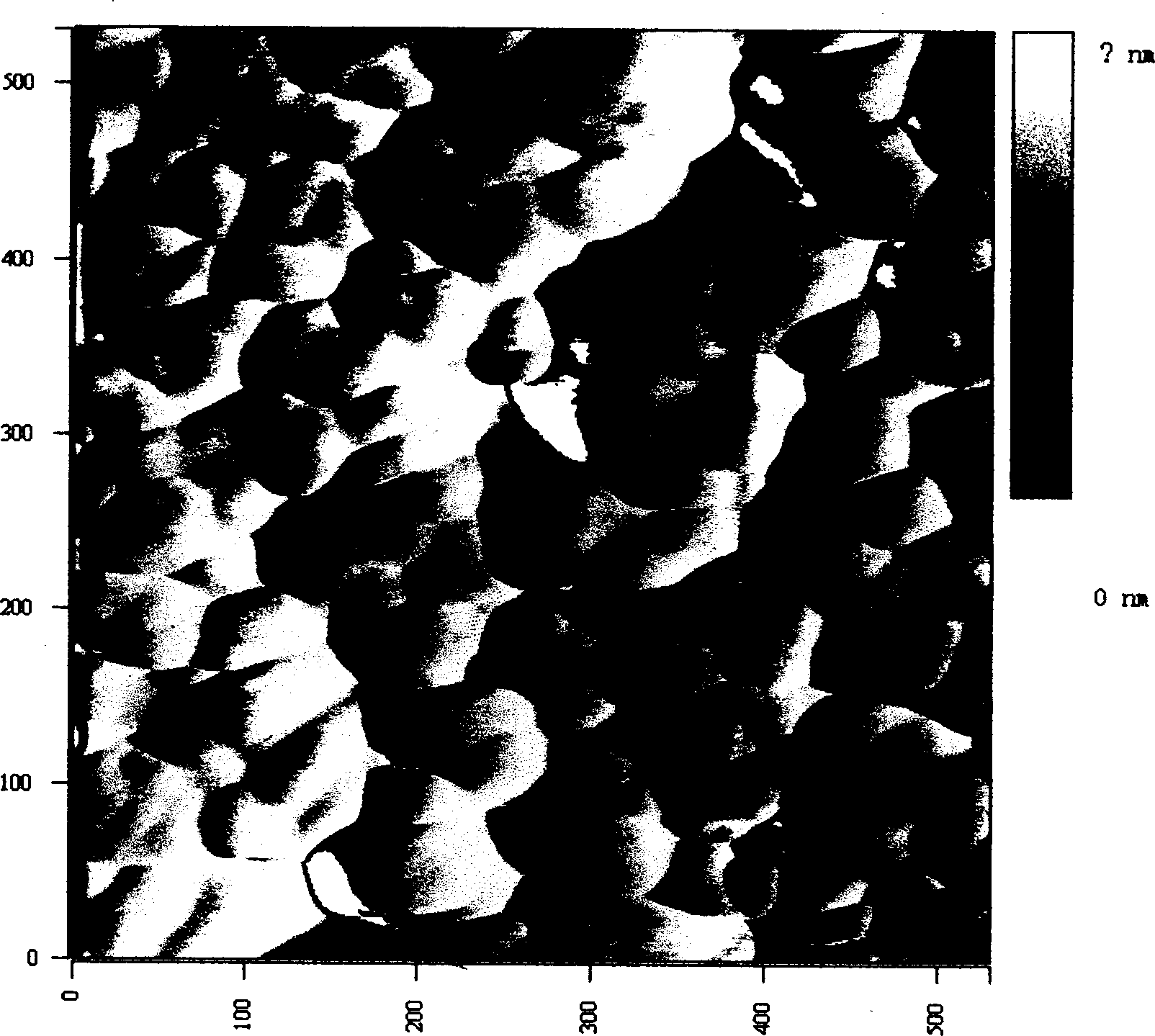

Double-faced zinc oxide nanoarray photocatalytic material and preparation method thereof

InactiveCN104549209AEasy to recycleIncrease profitMetal/metal-oxides/metal-hydroxide catalystsControllabilityZinc

The invention provides a double-faced zinc oxide nanoarray photocatalytic material and a preparation method thereof. The double-faced zinc oxide nanoarray photocatalytic material comprises ZnO nanoarrays and a quartz substrate, wherein the ZnO nanoarrays grow on two surfaces of the whole quartz substrate. The preparation method comprises the following steps: preparing a layer of a ZnO film on each of the two surfaces of the cleaned quartz substrate as a crystal seed layer respectively; simultaneously growing the ZnO nanoarrays on the two surfaces of the quartz substrate by utilizing a hydrothermal method. The double-faced ZnO nanoarrays are prepared on the quartz substrate through the hydrothermal method, so that the utilization rate of sunlight can be effectively increased and the photocatalytic performance can be remarkably improved. The preparation method has the advantages of simplicity of operation, strong controllability, low cost and the like, is suitable for large-area growth, and has a very high application value and a good application prospect; a catalyst is convenient to recover and reusable.

Owner:HARBIN INST OF TECH

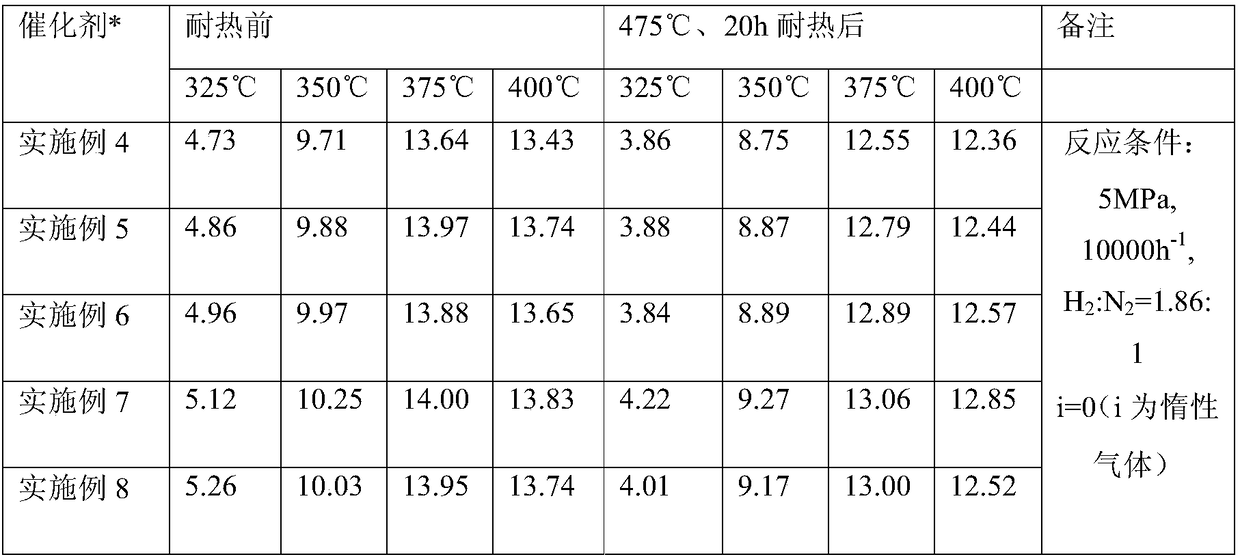

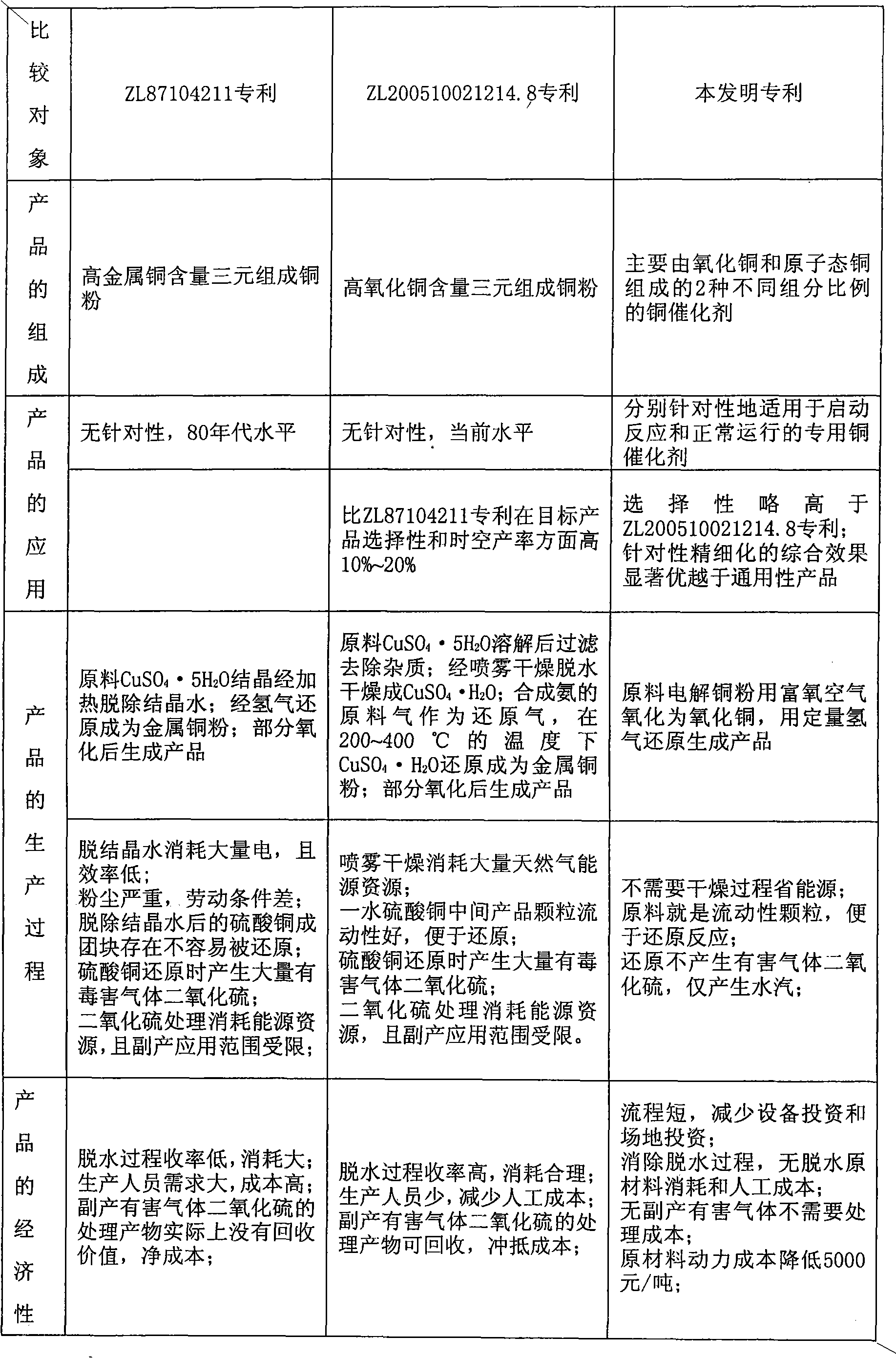

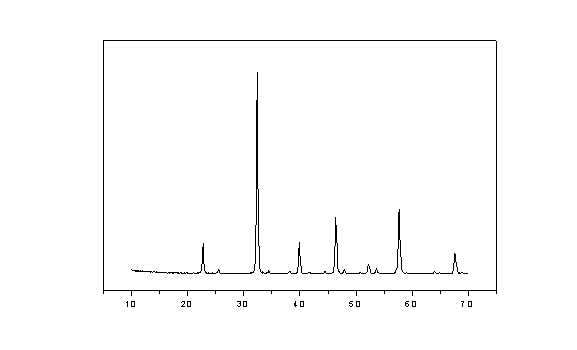

Two types of catalysts for synthesizing methyl chlorosilane and preparation method thereof

ActiveCN102059117AReduce solubilityReduce energy consumptionGroup 4/14 element organic compoundsMetal/metal-oxides/metal-hydroxide catalystsCopper oxideImpurity

Owner:成都隆盛新材料股份有限公司

Application of oxygen carrier with perovskite structure in chemical looping hydrogen production and preparation thereof

ActiveCN102862956AHydrogen productionMetal/metal-oxides/metal-hydroxide catalystsCOBALTOUS NITRATEChemistry

Owner:CHINA PETROLEUM & CHEM CORP +1

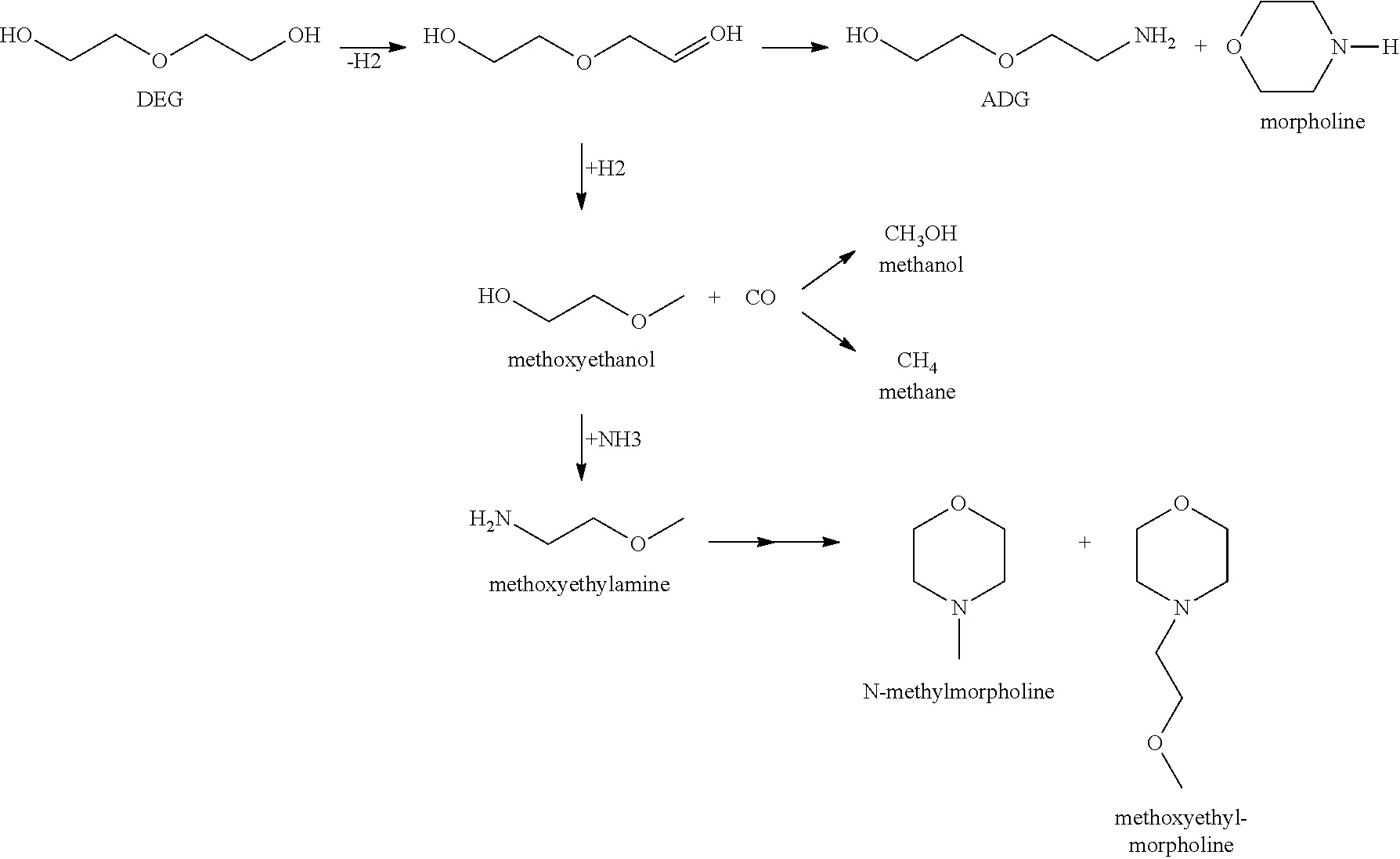

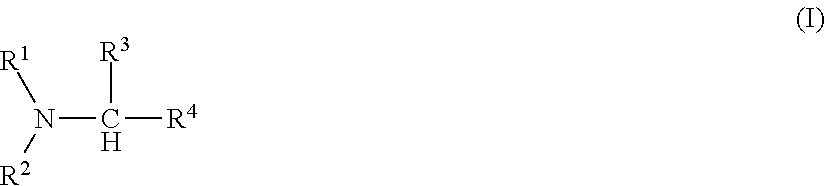

Catalyst and process for preparing an amine

ActiveUS8318982B2Enhances their economic viabilitySpeed up the conversion processOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCeriumKetone

Owner:BASF AG

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap