Metal organic framework derived iron-carbon catalyst suitable for heterogeneous electro-Fenton process and preparation method thereof

A metal-organic framework, carbon catalyst technology, applied in the fields of environment and materials, to achieve the effect of accelerating electron transfer, low equipment requirements, and improved catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] (1) Preparation of precursor MIL-101(Fe): Ferric trichloride hexahydrate, terephthalic acid and N, N dimethylformamide are mixed uniformly according to the molar ratio of 2:1:150 and placed in In a polytetrafluoroethylene reactor, react at 120°C for 24 hours, cool to room temperature and centrifuge to obtain a light yellow solid, which is washed three times with methanol.

[0022] (2) Put the MIL-101(Fe) prepared in step (1) into a vacuum drying oven, and dry at 200° C. for 12 hours.

[0023] (3) Transfer the MIL-101(Fe) prepared in step (2) to a tube furnace, and calcinate at 800°C for 6 hours under an argon atmosphere to obtain Fe / Fe 3 C@PC catalyst. Wherein, the argon flow rate is 80ml / min, and the heating rate is 5°C / min.

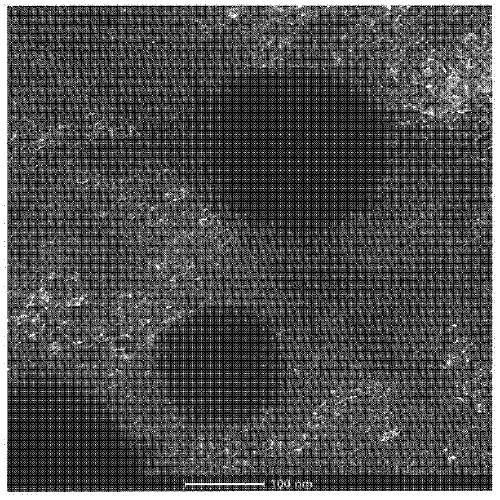

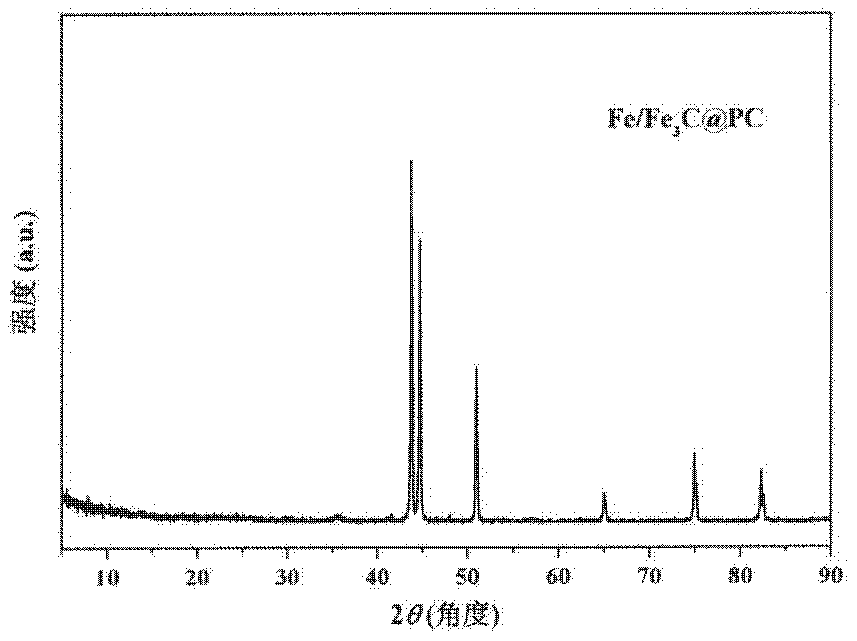

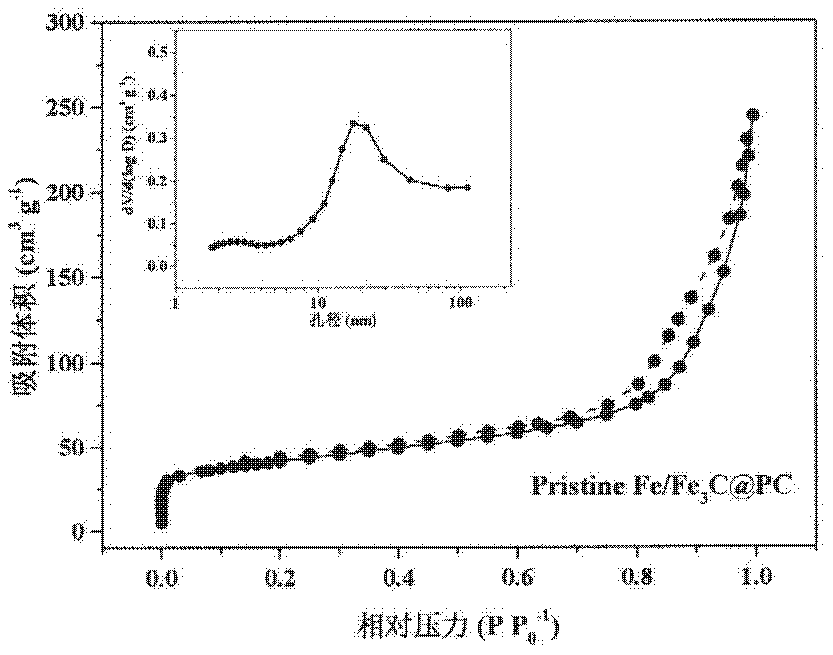

[0024] The morphology of the catalyst was characterized by transmission electron microscopy (JEM-2800), the results are shown in figure 1 , nano-iron particles are encapsulated by porous carbon. X-ray diffractometer (Ulitma IV) characteriz

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap