Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1544 results about "Materials science" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The interdisciplinary field of materials science, also commonly termed materials science and engineering, is the design and discovery of new materials, particularly solids. The intellectual origins of materials science stem from the Enlightenment, when researchers began to use analytical thinking from chemistry, physics, and engineering to understand ancient, phenomenological observations in metallurgy and mineralogy. Materials science still incorporates elements of physics, chemistry, and engineering. As such, the field was long considered by academic institutions as a sub-field of these related fields. Beginning in the 1940s, materials science began to be more widely recognized as a specific and distinct field of science and engineering, and major technical universities around the world created dedicated schools of the study, within either the Science or Engineering schools, hence the naming.

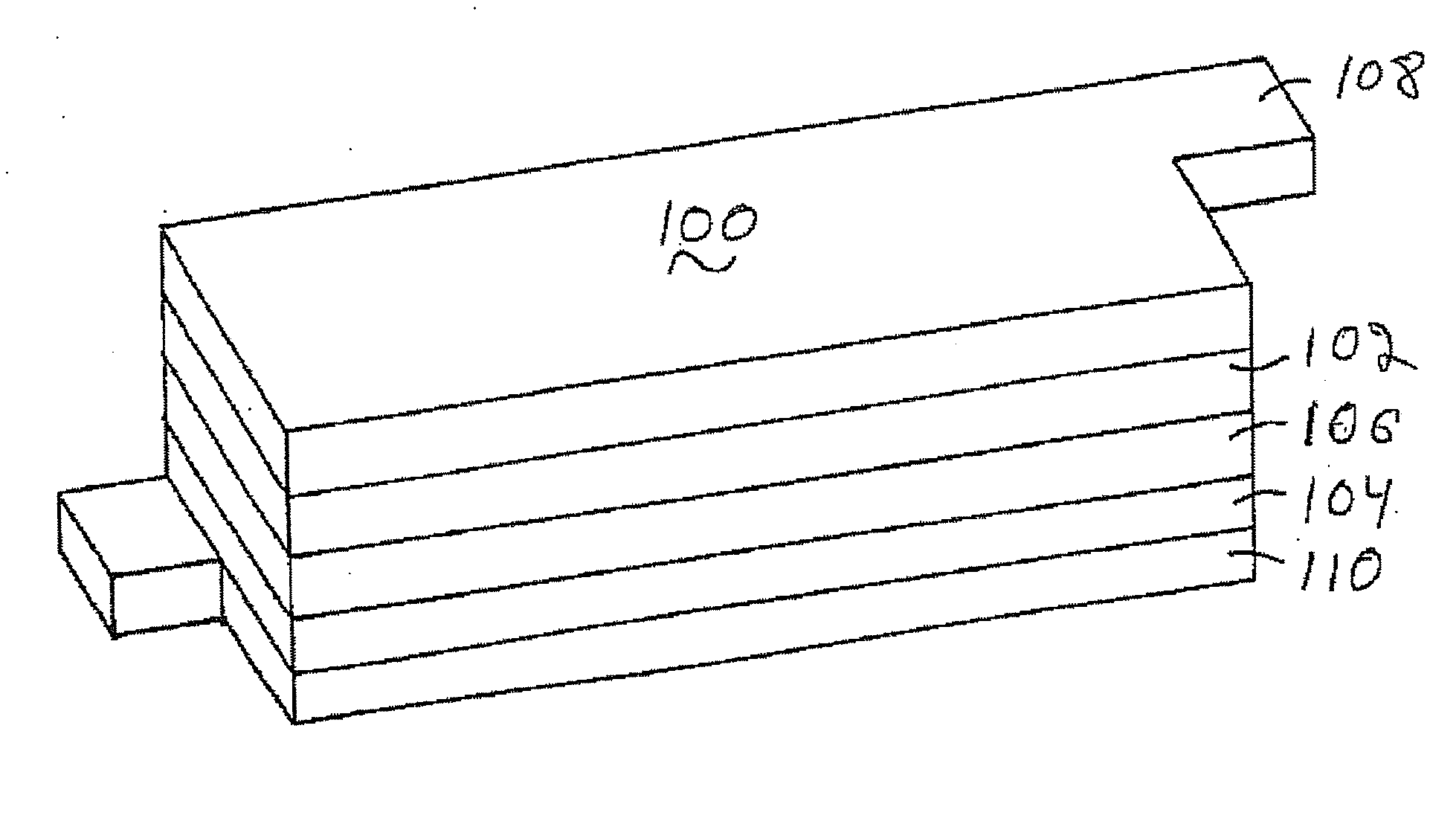

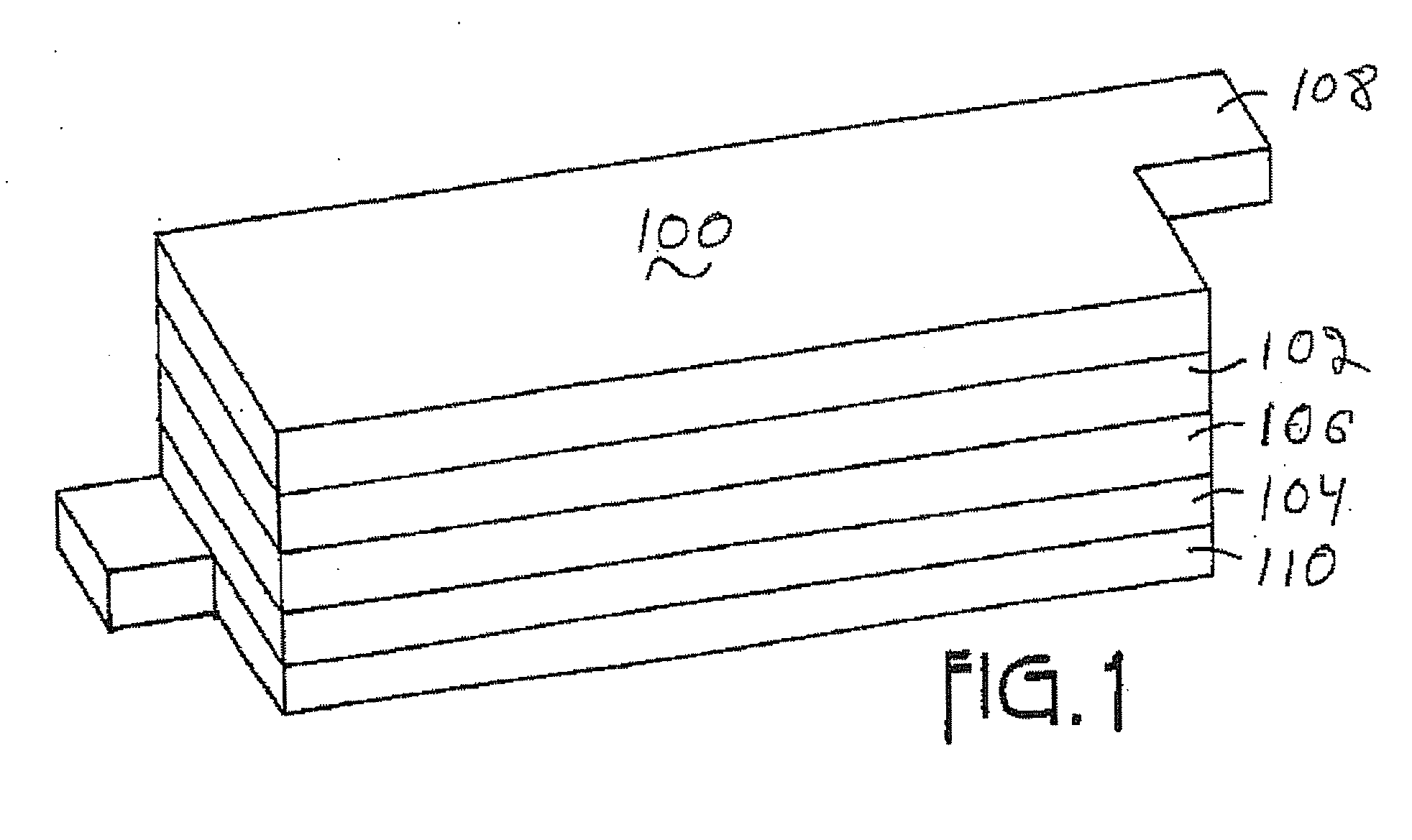

Positive electrode materials for lithium ion batteries having a high specific discharge capacity and processes for the synthesis of these materials

ActiveUS20100086853A1Electrode manufacturing processesAlkali metal oxidesDischarge rateLithium-ion battery

Owner:IONBLOX INC

Eluting, implantable medical device

Owner:COOK INC

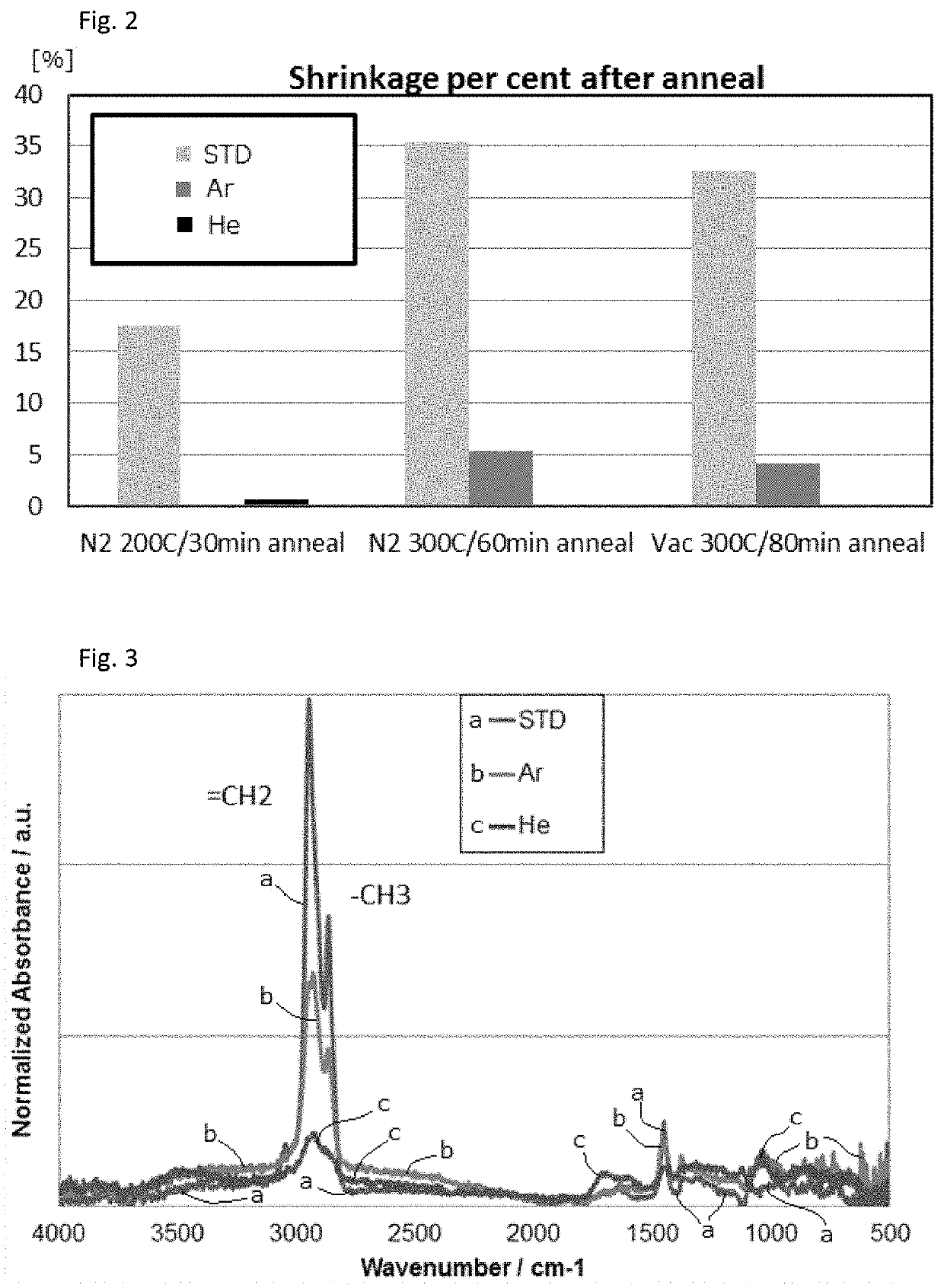

Method for reforming amorphous carbon polymer film

ActiveUS20210043444A1Improve thermal stabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingCarbon filmThin membrane

Owner:ASM IP HLDG BV

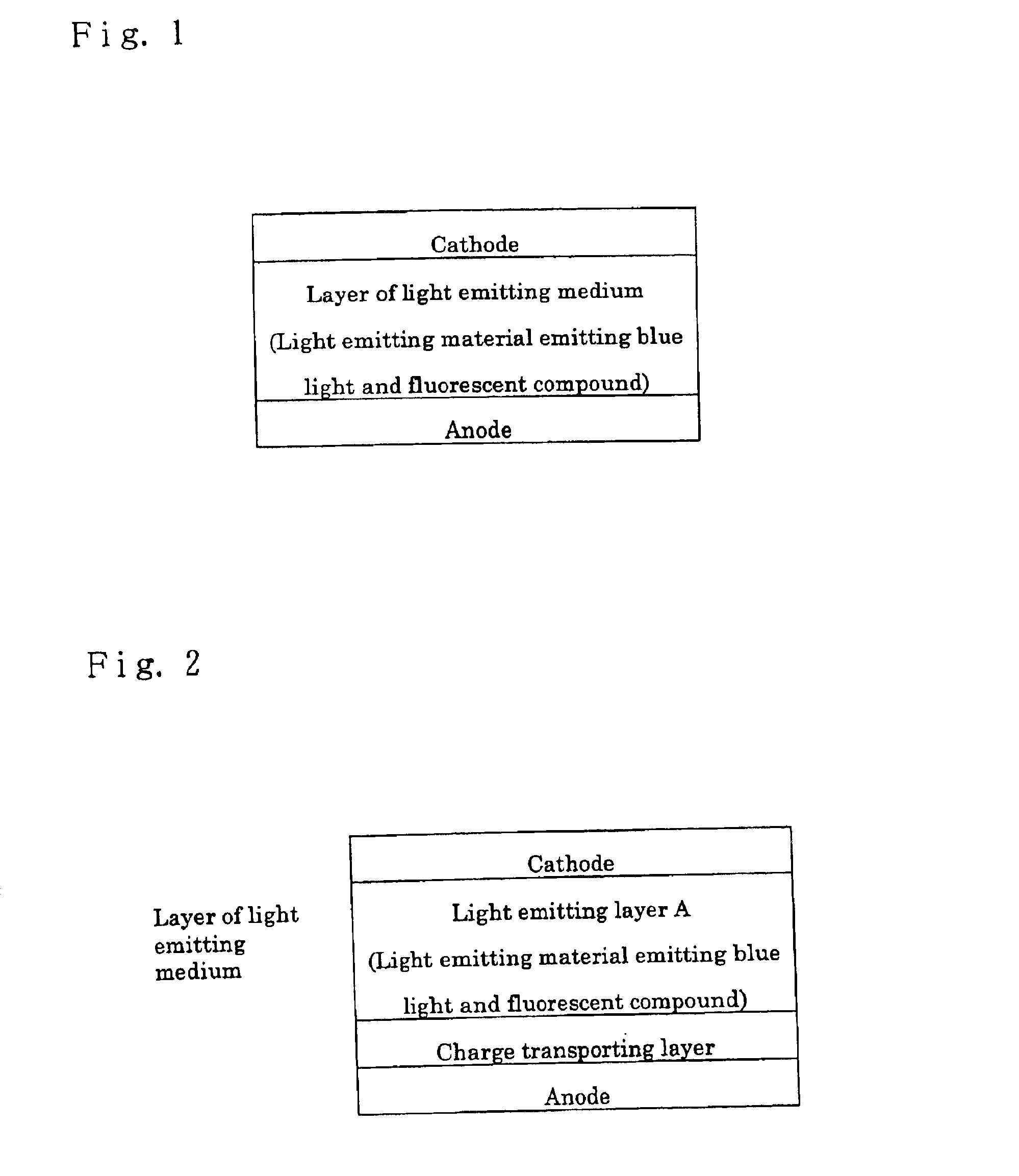

Organic electroluminescence device emitting white light

InactiveUS6866947B1Improve efficiencyDischarge tube luminescnet screensLamp detailsFluorescenceOrganic electroluminescence

An organic electroluminescence device emitting white light which emits white light and exhibits properties sufficient for practical applications, i.e., a high efficiency of light emission and a long life, is provided. The organic electroluminescence device emitting white light comprises a pair of electrodes and a layer of a light emitting medium disposed between the pair of electrodes, wherein the layer of a light emitting medium comprises a light emitting material emitting blue light and a fluorescent compound having at least one structure selected from a fluoranthene skeleton structure, a pentacene skeleton structure and a perylene skeleton structure.

Owner:IDEMITSU KOSAN CO LTD

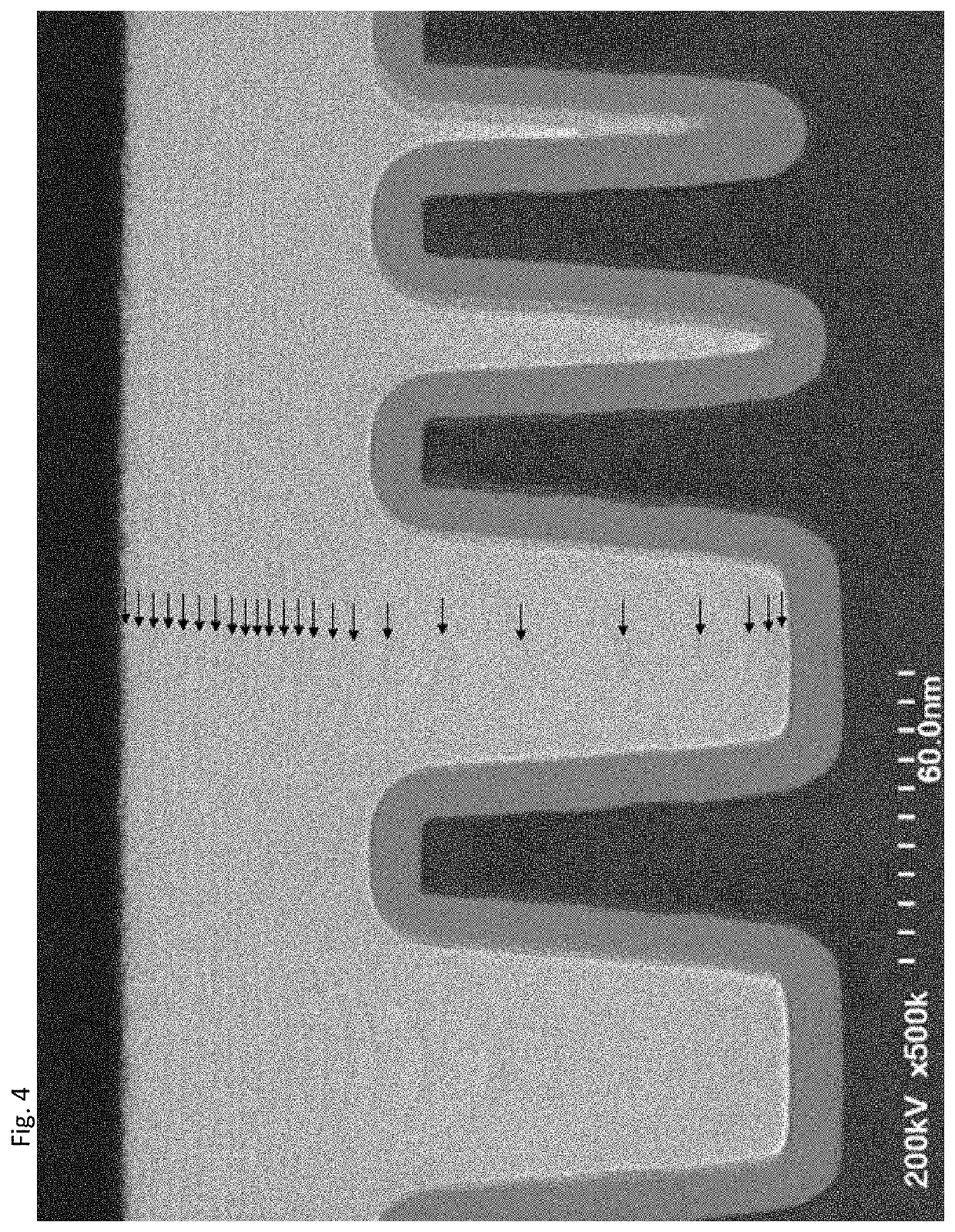

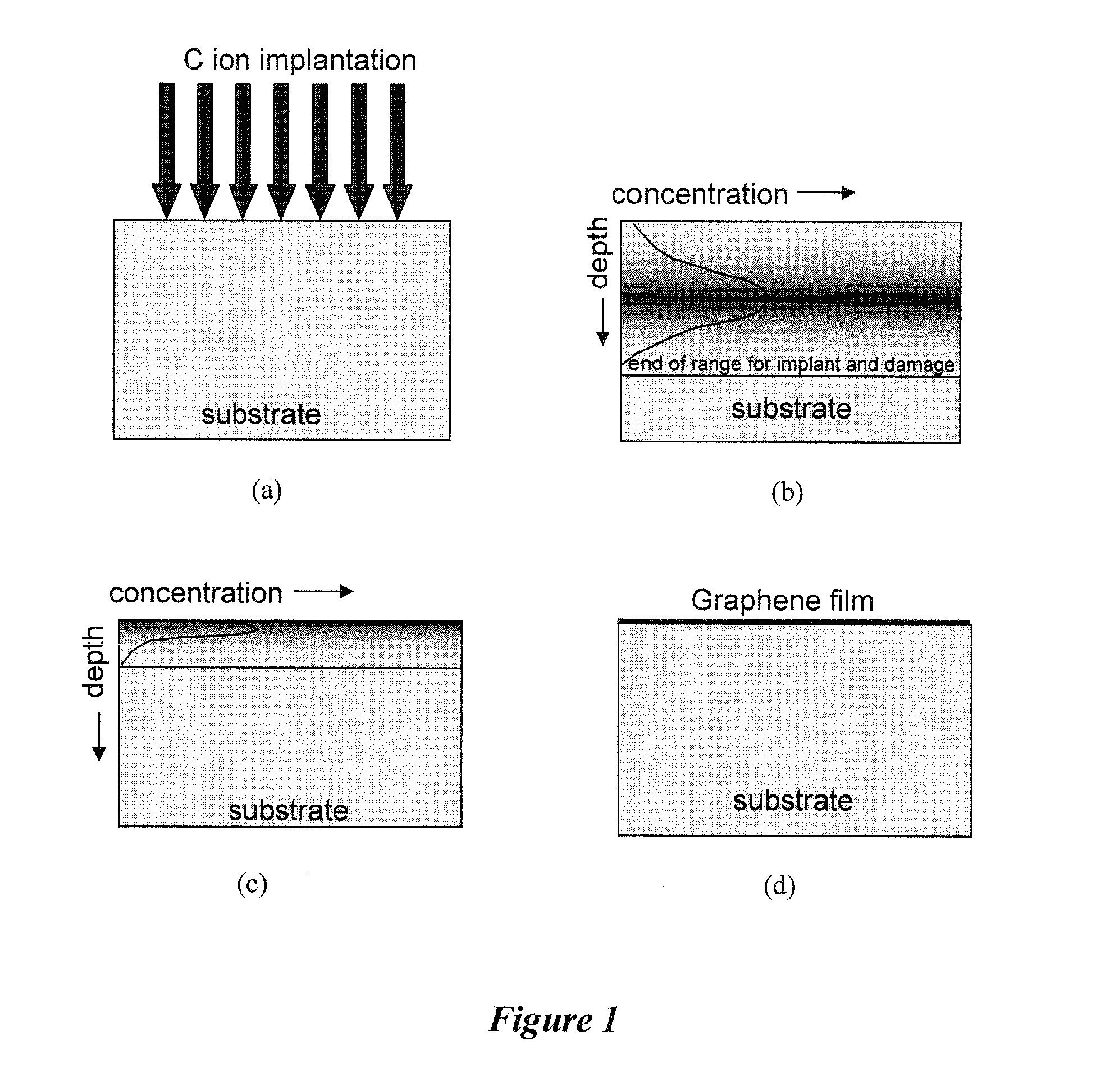

Fabrication of graphene nanoelectronic devices on SOI structures

ActiveUS20110114918A1Eliminates thermal budget limitationGood substrateSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureGraphene

A semiconductor-on-insulator structure and a method of forming the silicon-on-insulator structure including an integrated graphene layer are disclosed. In an embodiment, the method comprises processing a silicon material to form a buried oxide layer within the silicon material, a silicon substrate below the buried oxide, and a silicon-on-insulator layer on the buried oxide. A graphene layer is transferred onto the silicon-on-insulator layer. Source and drain regions are formed in the silicon-on-insulator layer, and a gate is formed above the graphene. In one embodiment, the processing includes growing a respective oxide layer on each of first and second silicon sections, and joining these silicon sections together via the oxide layers to form the silicon material. The processing, in an embodiment, further includes removing a portion of the first silicon section, leaving a residual silicon layer on the bonded oxide, and the graphene layer is positioned on this residual silicon layer.

Owner:GLOBALFOUNDRIES U S INC

Ultra-high temperature high pressure dyeing method for aramid fiber textile

InactiveCN101235598AHigh color fastnessBright colorPhysical treatmentDyeing processColour fastnessAtmospheric pressure

The invention discloses a method for dying kevlar fabrics under ultrahigh temperature and high pressure, which comprises: a preprocessing procedure under the ultrahigh temperature and the high pressure and a dying procedure under the ultrahigh temperature and the high pressure, wherein in the preprocessing procedure under the ultrahigh temperature and the high pressure, atmospheric pressure plasmas are used to process the kevlar fabrics for 1-5min, the processing temperature is 100-150DEG C, while in the dying procedure under the ultrahigh temperature and the high pressure, the temperature is 160DEG C-190DEG C, and the pressure intensity is 0.8-0.9MPa, wherein the plasma preprocessing procedure is an important procedure before the dying procedure under the ultrahigh temperature and the high pressure, since the processing for the plasma produces a plurality of active groups on the kevlar fabrics, which enables carriers to be better absorbed on the kevlar baric and thereby is beneficial for dying dye on the kevlar fabrics, simultaneously, the kevlar fabrics after dying under the ultrahigh temperature and the high pressure has high fastness, fresh color and soft hand feeling, and the washing color fastness and the abrasion color fastness of the kevlar fabrics are improved better.

Owner:ZHEJIANG SCI-TECH UNIV

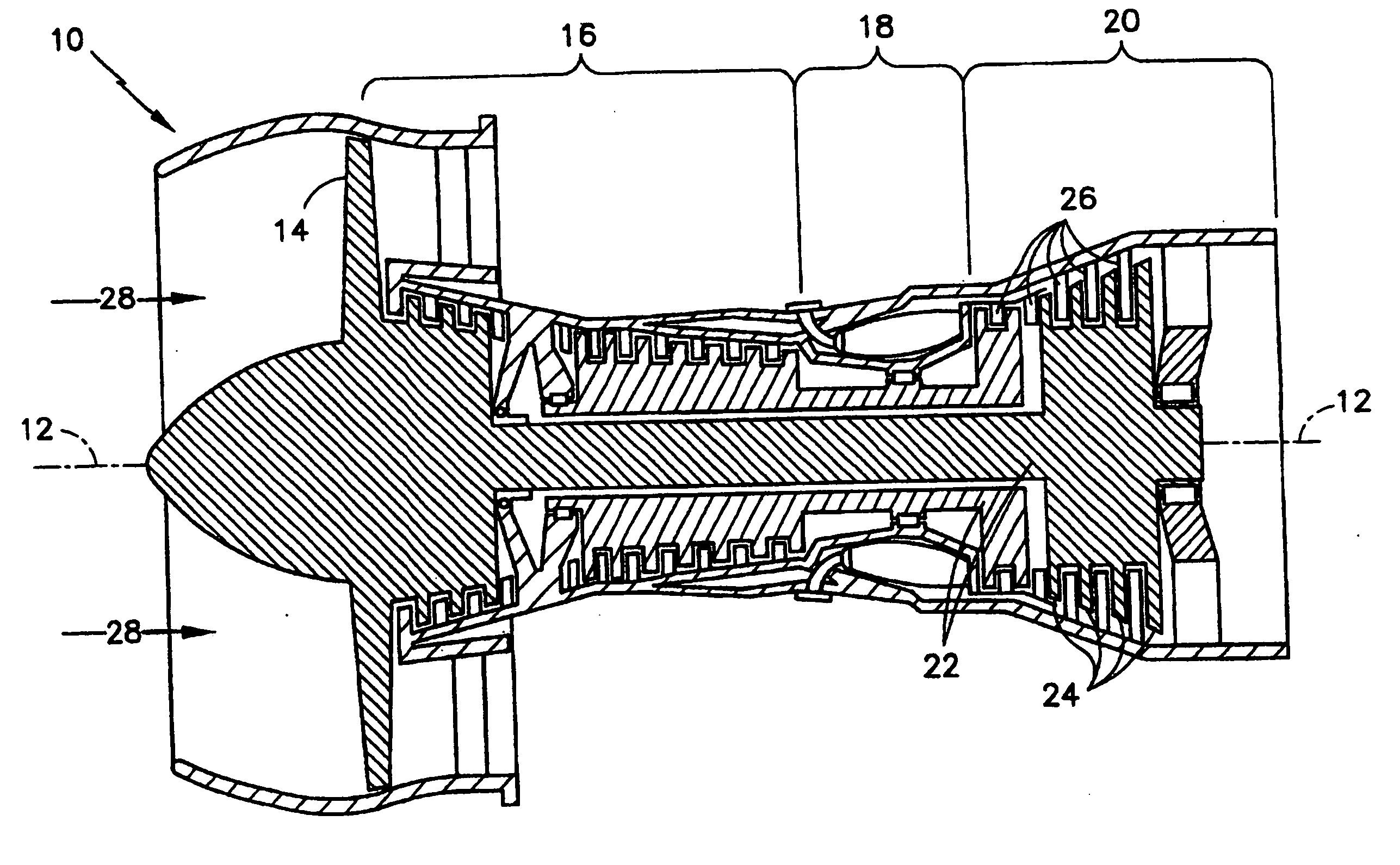

Method of producing a castable high temperature aluminum alloy by controlled solidification

ActiveUS20070062669A1Increase the speed of solidificationFoundry mouldsAerodynamics improvementRare-earth elementInvestment casting

Owner:RAYTHEON TECH CORP

Semiconductor device and method of manufacturing the same, circuit board and electronic instrument

InactiveUS6841849B2Not easily oxidizedSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

A depression is formed from a first surface of a semiconductor substrate on which is formed an integrated circuit. An insulating layer is provided on the inner surface of the depression. A first conductive portion is provided on the inside of the insulating layer. A second conductive portion is formed on the inside of the insulating layer and over the first conductive portion, of a different material from the first conductive portion. The first conductive portion is exposed from a second surface of the semiconductor substrate opposite to the first surface.

Owner:ADVANCED INTERCONNECT SYST LTD

Graphene processing for device and sensor applications

Owner:UNIV OF FLORIDA RES FOUNDATION INC

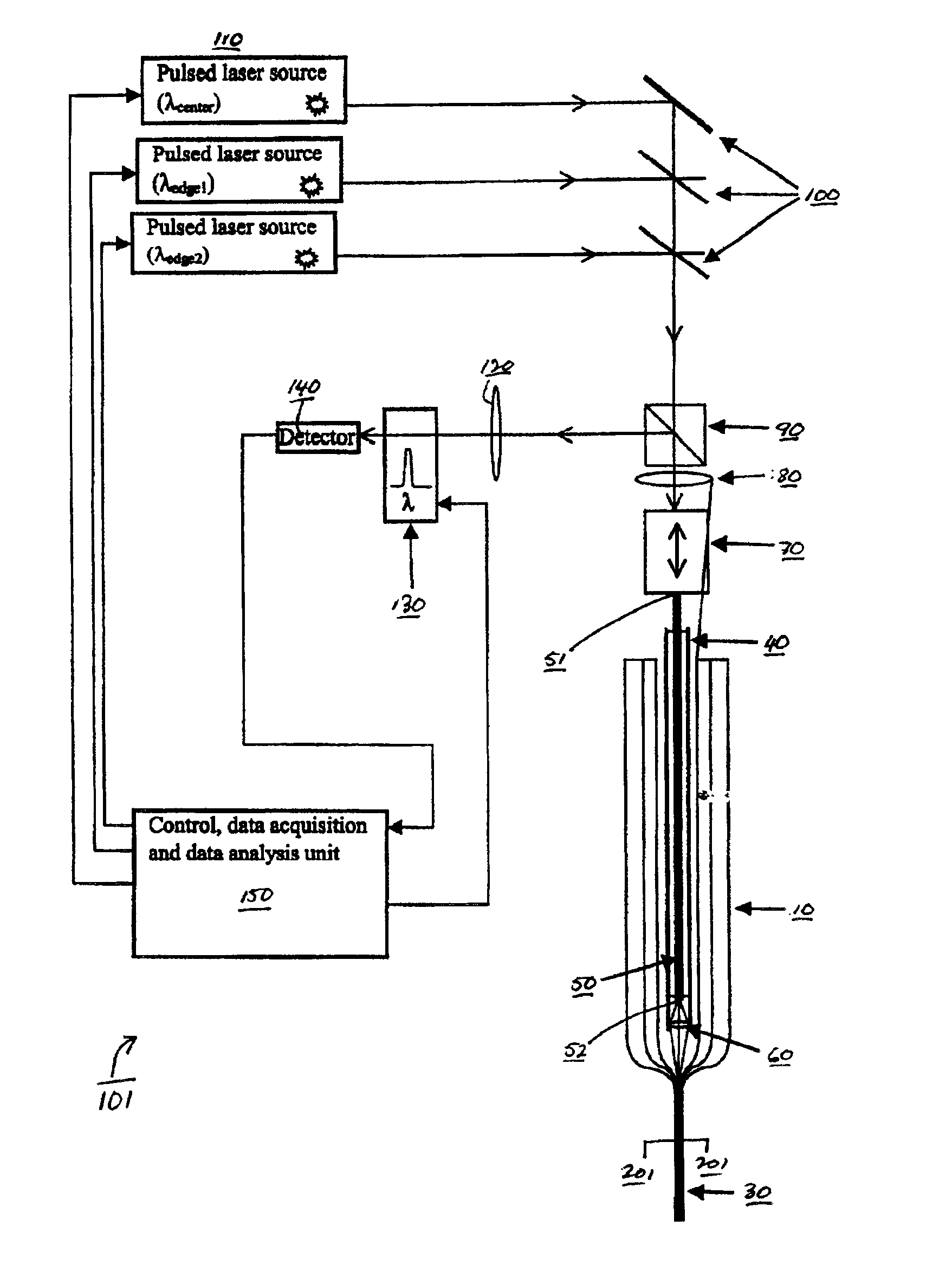

Optical waveguide monitoring

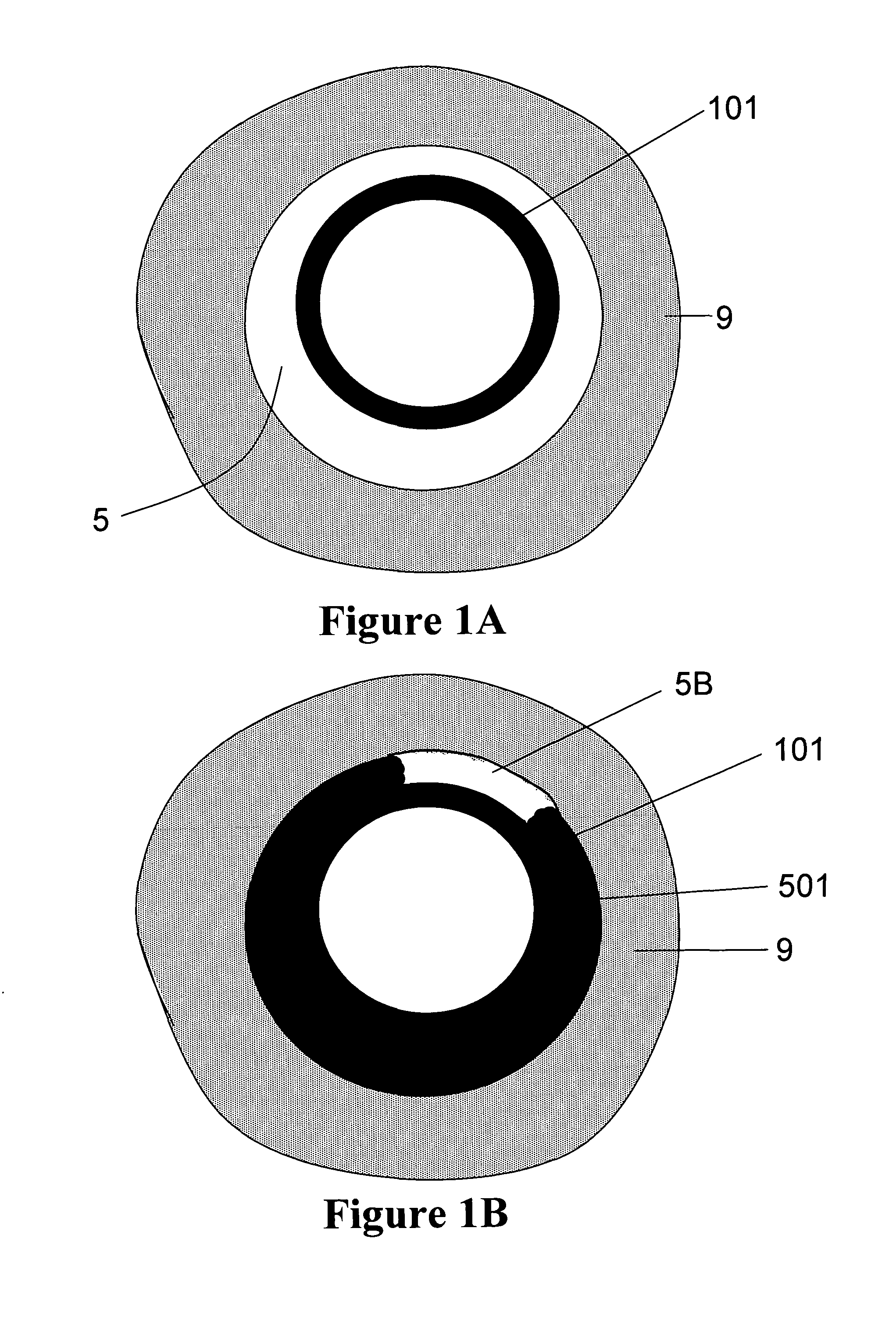

InactiveUS6879386B2Cladded optical fibreMaterial analysis by optical meansPhotonic crystalEngineering

Owner:OMNIGUIDE

Method and composition for zonal isolation of a well

ActiveUS20100163252A1Easy to bendRelieve pressureFluid removalDrilling compositionMaterials scienceCoating

Owner:SCHLUMBERGER TECH CORP

High strength organic / inorganic nano composite transparent film layer materials and method for preparing same

InactiveCN1699488AHigh refractive indexHigh transparencyCoatingsOptical elementsComposite filmRefractive index

Owner:JILIN UNIV

Preparation method of superfine fiber high-imitation grain synthetic leather

ActiveCN102304858AImprove protectionImprove breathabilityLamination ancillary operationsSynthetic resin layered productsLow-density polyethylenePolymer science

The invention discloses a preparation method of superfine fiber high-imitation grain synthetic leather. The preparation method comprises the following steps of: spinning sea-island composite fibers by utilizing nylon 6 and low-density polythene as raw materials, manufacturing non-woven fabric by utilizing the sea-island composite fibers, coating one surface of the non-woven fabric by utilizing high-solid-concentration polyurethane slurry, infiltrating the non-woven fabric by utilizing low-solid-concentration polyurethane slurry, enabling the non-woven fabric to pass through an aqueous solution of dimethylformamide after infiltrating, solidifying polyurethane and forming a cellular structure to obtain synthetic leather semi-finished products, enabling the synthetic leather semi-finished products to pass through methylbenzene to separate sea-component low-density polythene out of the sea-island fibers, peeling off the sea-island composite fibers to be superfine fibers, washing away methylbenzene through boiling water, and drying to obtain the superfine fiber high-imitation grain synthetic leather. The product manufactured by the method disclosed by the invention has the advantages of strong gradient, abundant hand feeling, fine and smooth surface wrinkles and strong toughness after being bent, and has the beneficial effects on aspects of pollution reduction, animal protection, ecological protection and the like.

Owner:SHANDONG TONGDA ISLAND NEW MATERIALS

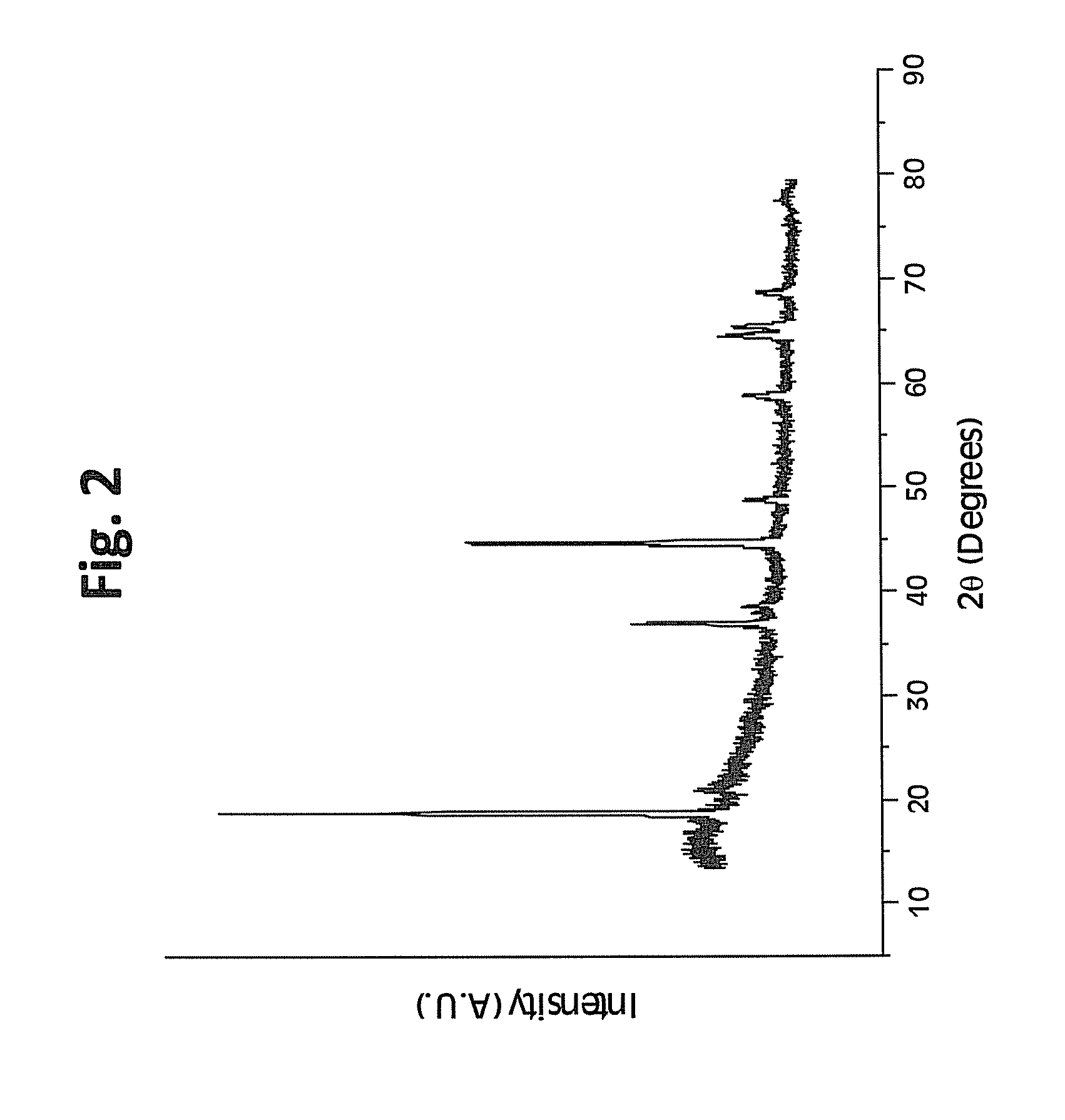

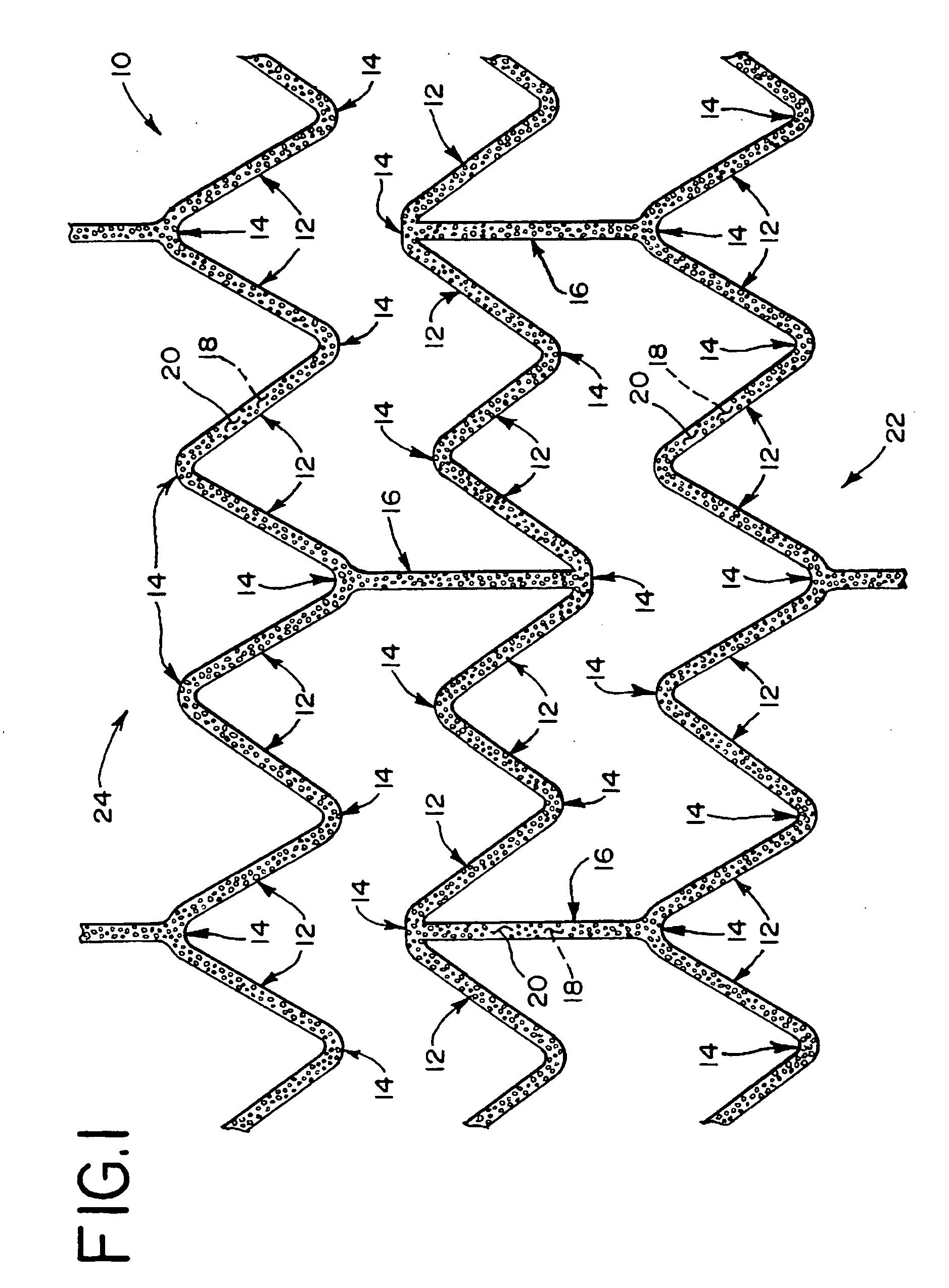

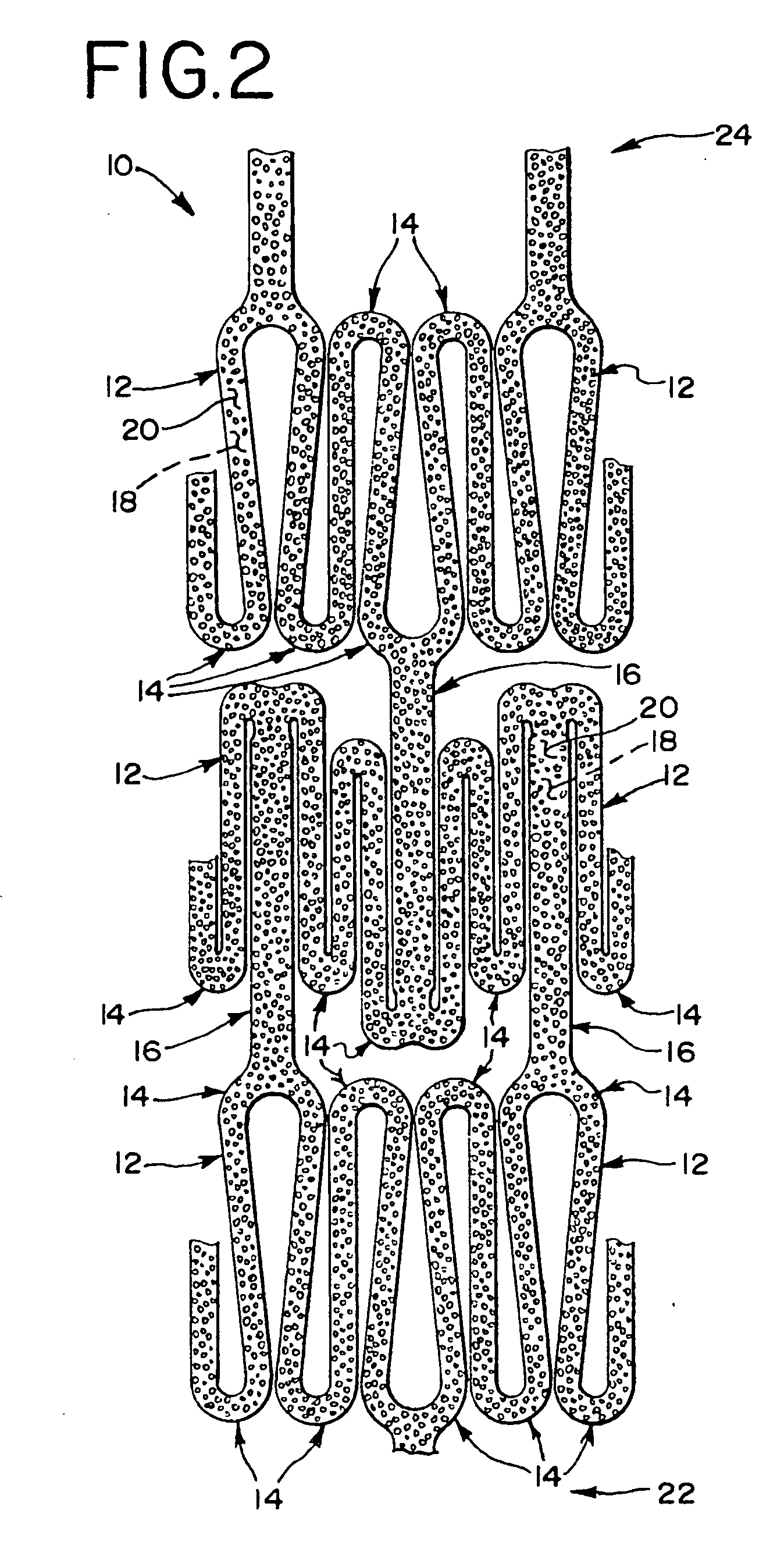

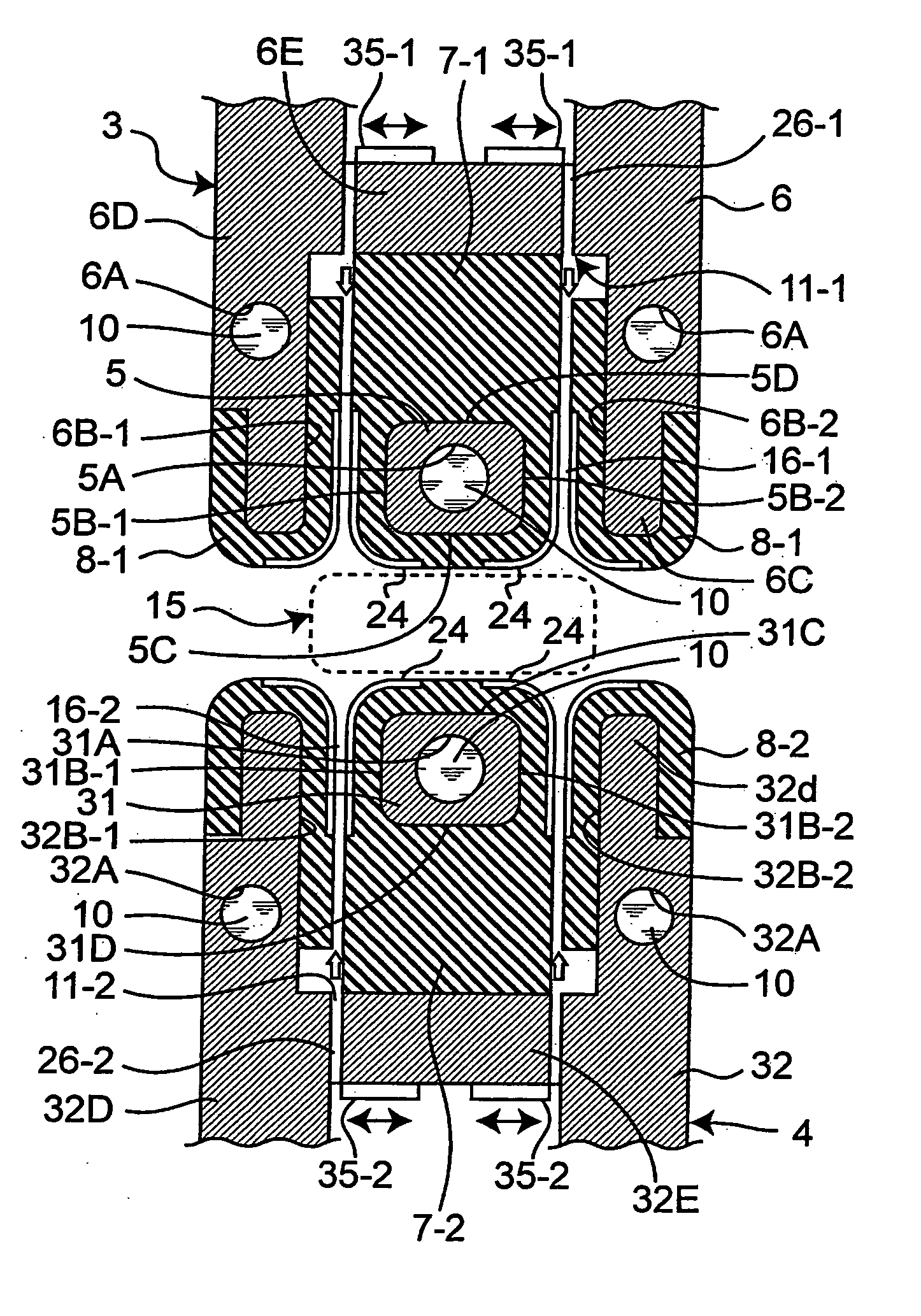

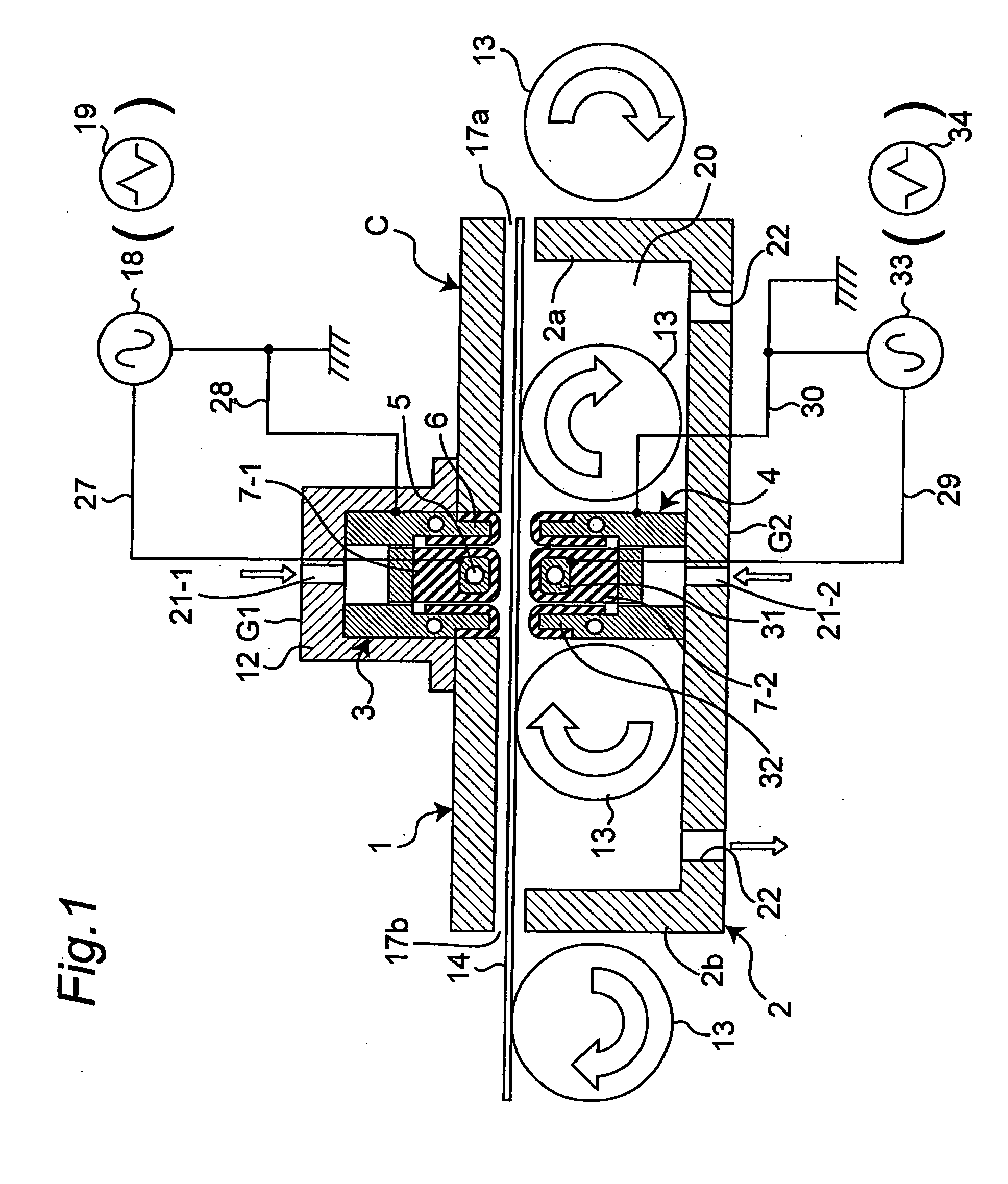

Porous electrodes, devices including the porous electrodes, and methods for their production

InactiveUS20060021649A1Improve efficiencyIncrease flexibilityElectrolytic capacitorsHybrid capacitor electrodesPore diameterConductive materials

Owner:SUMITOMO CHEM CO LTD

Wavelike steel plate and concrete combined shear wall

InactiveCN101922187AEffective energy dissipationHigh resistance to lateral forceConstruction materialWallsSheet steelWave shape

The invention discloses a wavelike steel plate and concrete combined shear wall, which belongs to the technical field of structural engineering. The wavelike steel plate and concrete combined shear wall is characterized by consisting of a wavelike steel plate, concrete, a reinforcing fabric, shear-resistant studs and connecting plates, wherein the shear wall is embedded into an edge frame; the connection modes of the wavelike steel plate and the edge frame are divided into two modes that: if the edge frame is a steel frame, the wavelike steel plate is welded with the edge steel frame at the periphery; and if the edge frame is a concrete frame, the wavelike steel plate is first welded with the four connecting plates at the periphery and then connected with the edge frame through the shear-resistant studs on the connecting plates. The outer surface of the wavelike steel plate on the side with concrete is provided with the shear-resistant studs, and the concrete is poured after the reinforcing fabric is arranged, so that the wavelike steel plate and concrete combined shear wall can be obtained.

Owner:TSINGHUA UNIV

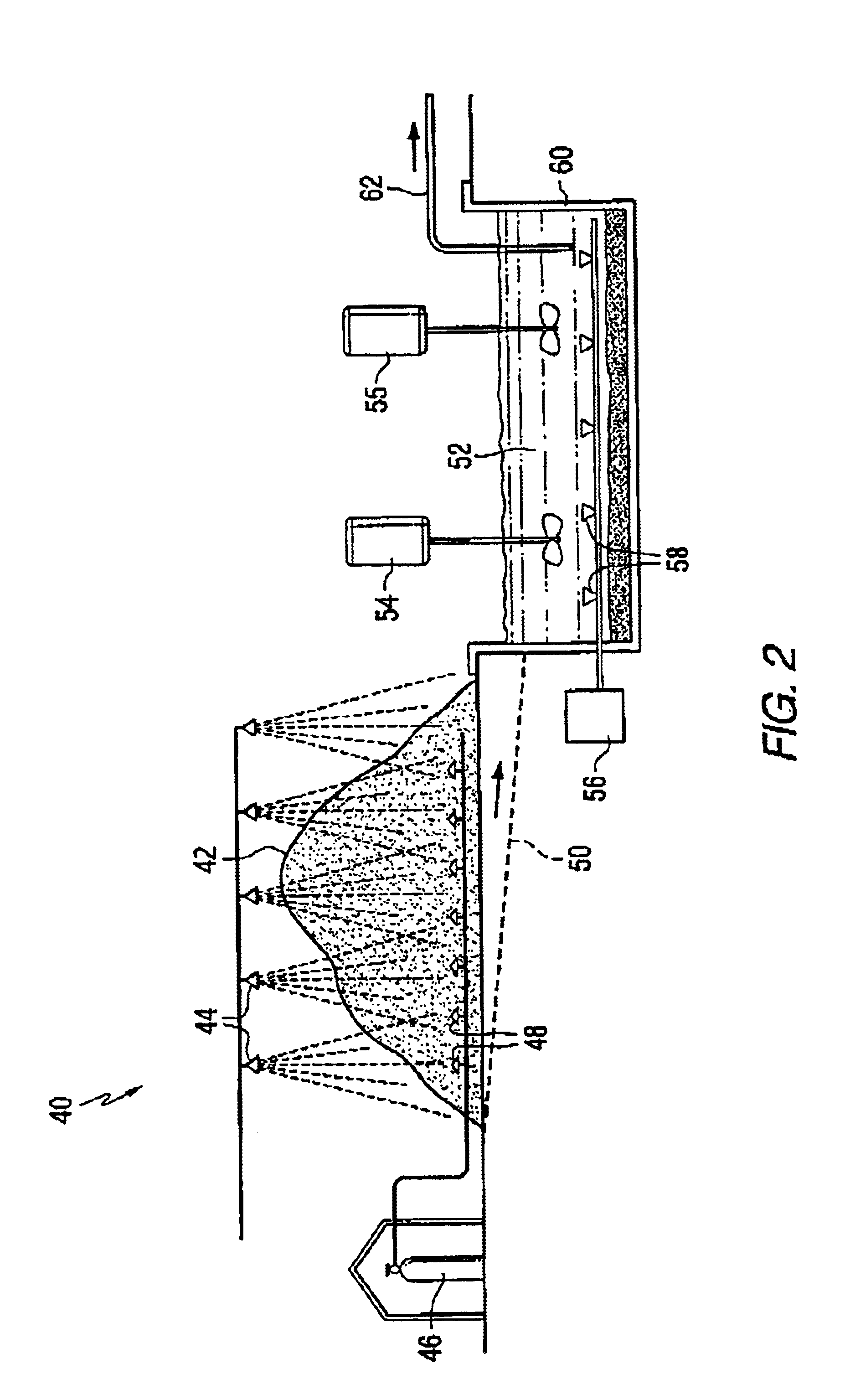

Method and apparatus for recovery of metals with hydrocarbon-utilizing bacteria

InactiveUS6875356B2Treatment using aerobic processesTreatment with aerobic and anaerobic processesSprinkler systemBioleaching

Owner:GLOBAL BIOSCI

Copper or copper alloy target/copper alloy backing plate assembly

Owner:JX NIPPON MINING& METALS CORP

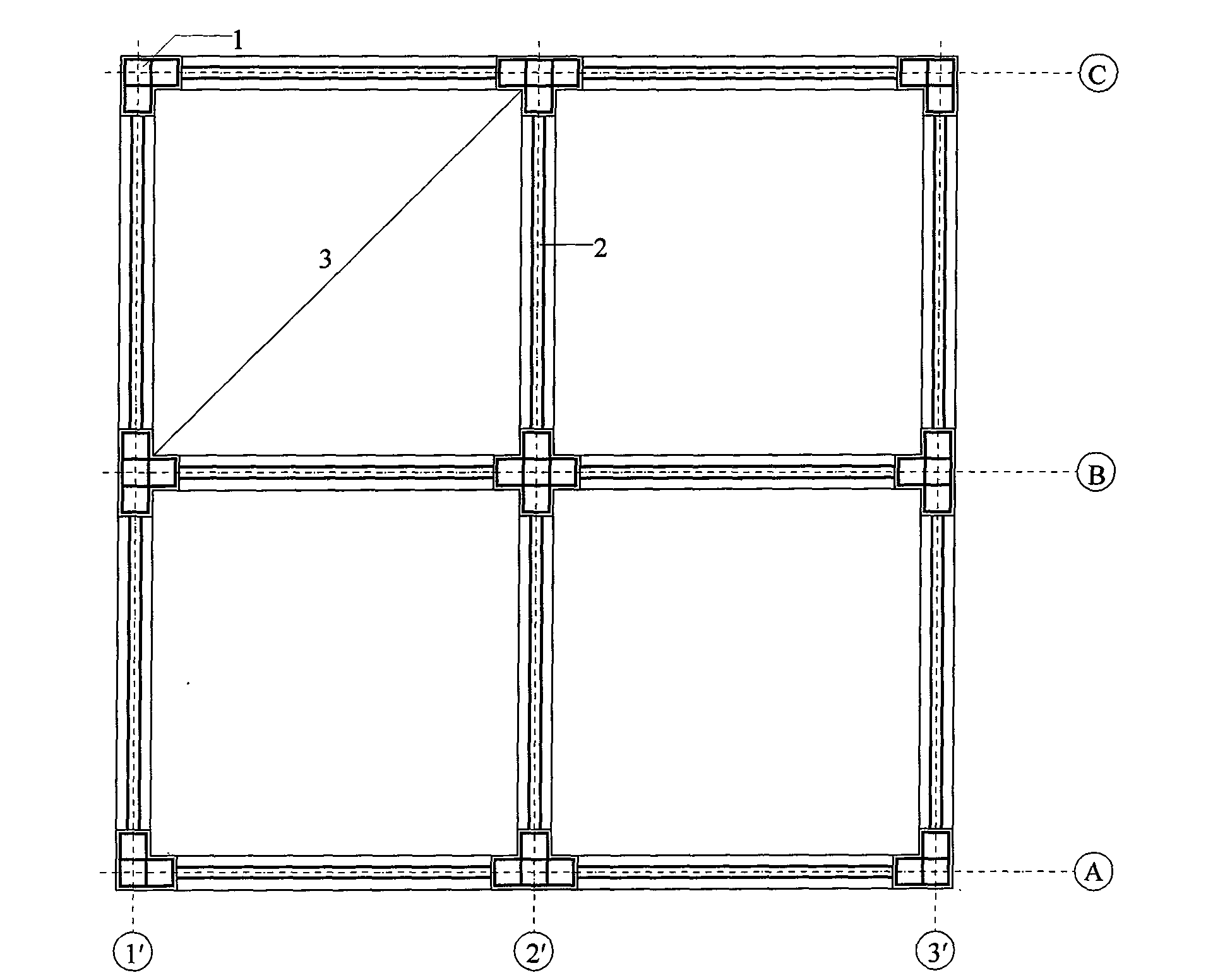

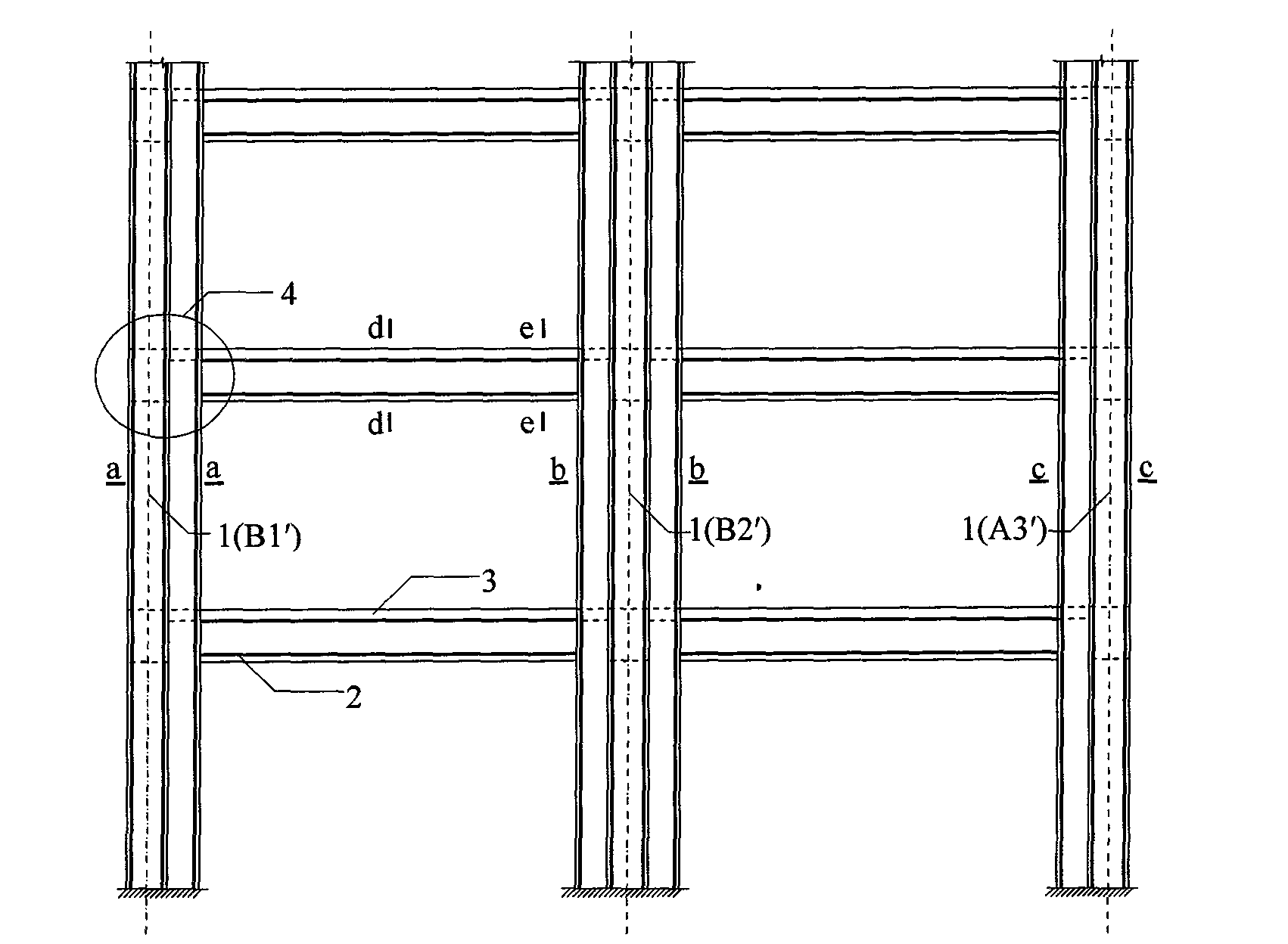

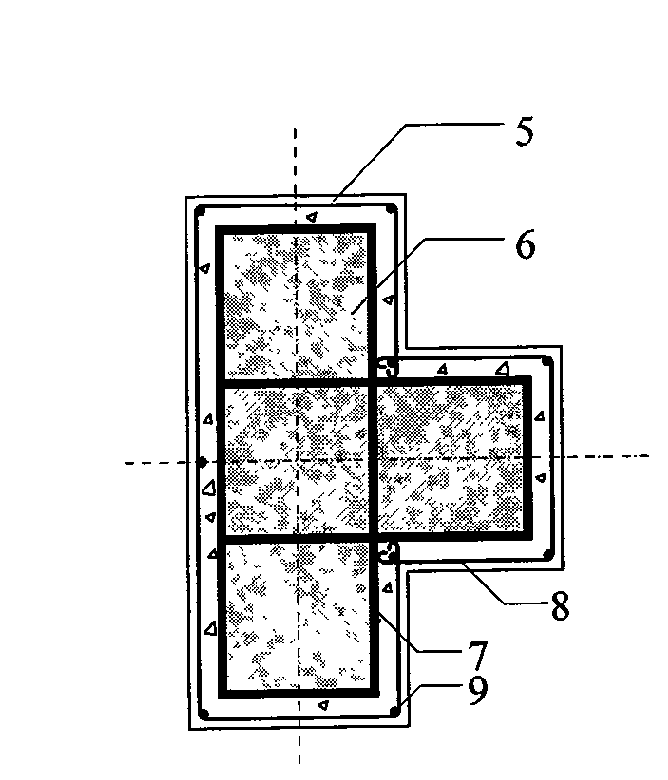

Mixed steel-concrete composite frame structure

ActiveCN101581115AEfficient use ofImprove structural fire resistanceBuilding constructionsFloor slabReinforced concrete

Owner:TSINGHUA UNIV

Vegetable fiber liquefied matter, and preparing method and use thereof

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Carbon nanofibers and procedure for obtaining said nanofibers

ActiveUS20090035569A1Quality improvementGuaranteed specific surface areaMaterial nanotechnologyCarbon compoundsFiberChemical composition

The object of the present invention is carbon nanofibers mainly characterized by their high specific volume of mesopores, their high gas adsorption capacity and presenting a graphitic hollow structure. A second object of this invention is a procedure for obtaining such carbon nanofibers, which makes use of a metallic nickel catalyst and specific process furnace parameters that combined with the chemical composition of the furnace atmosphere and the fluidodynamic conditions of the gas stream inside the furnace, result in a faster growth of the carbon nanofibers and also in a higher quality of the carbon nanofibers obtained.

Owner:GRP ANTOLIN ING SA

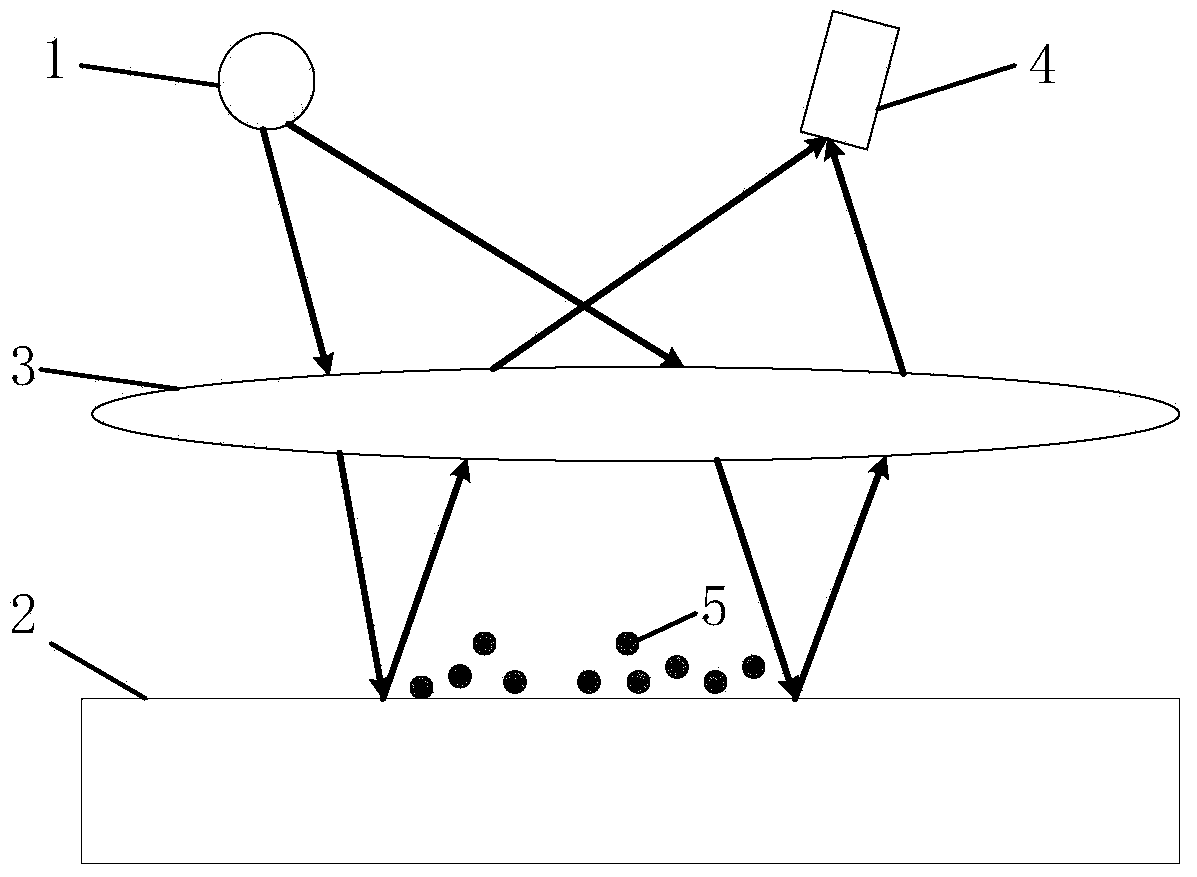

Infrared spectrum enhancement and detection method and infrared spectrum enhancement and detection device based on graphene nano antenna

ActiveCN103776790AEnhanced Absorption EnhancementReduce usageNanoopticsColor/spectral properties measurementsGratingBroadband

Owner:CHONGQING UNIV

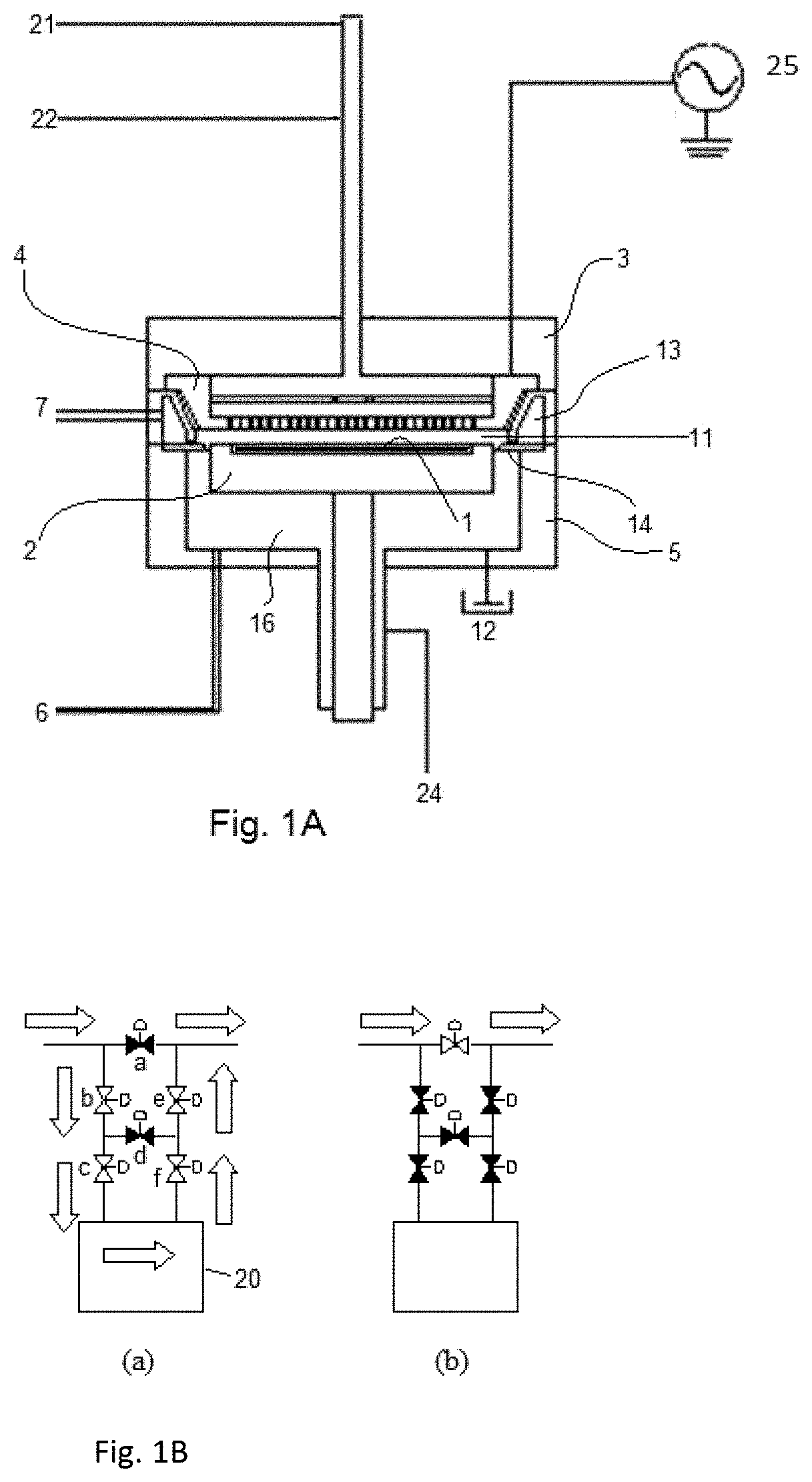

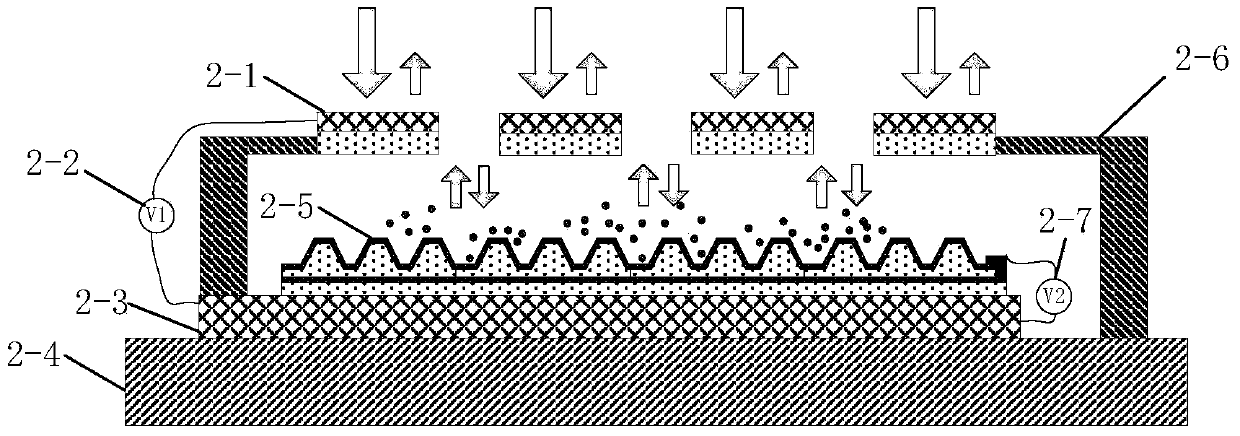

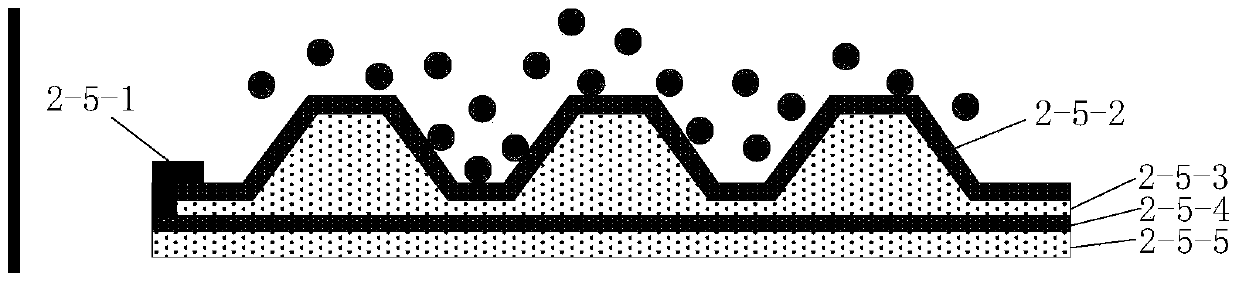

Plasma processing apparatus

InactiveUS20050217798A1Plasma discharge can be stabilizedLow running costElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringMaterials science

Owner:SHARP KK

Non-aqueous solution aluminum ion secondary battery and preparation method thereof

InactiveCN104993130AGood chemical stabilityImprove thermal stabilityCell electrodesFinal product manufactureAluminum IonElectrical battery

Belonging to the technical field of batteries, the invention relates to a non-aqueous solution aluminum ion secondary battery and a preparation method thereof. The secondary battery can be widely applied in electronics, communication, electric vehicle and other fields. The aluminum ion battery provided by the invention contains a battery anode, a battery cathode, a diaphragm and an aluminum-containing non-aqueous solution electrolyte. Specifically, the cathode active material can be carbon, graphite, carbon nanotube, graphene, super carbon, WS2 and MoS2, V2O5, TiO2 and other materials having nano-layered, tubular, linear and other structures, and the anode is aluminum-containing metal or alloy. The non-aqueous solution aluminum ion secondary battery provided by the invention has the characteristics of high specific capacity, high coulomb efficiency, long service life and environmental protection, safety and reliability, stable cycle performance, and quick charging, etc.

Owner:BEIJING ALUMINUM ENERGY S&T

Chemical Mechanical Polishing Slurry Composition for Polishing Phase-Change Memory Device and Method for Polishing Phase-Change Memory Device Using the Same

InactiveUS20090001339A1Increase chanceMinimize occurrenceOther chemical processesSolid-state devicesHigh ratePhase-change memory

Owner:CHEIL IND INC

Cement composition

InactiveUS20050016421A1High strengthImprove abilitiesOrganic fertilisersSoil conditioning compositionsPhosphateSilicic acid

To provide a novel cement which is alkalescent, capable of solidifying a wide range of soil and applicable to biological environment. That is, a cement composition comprising 100 parts by weight of magnesium oxide comprising 5 to 25% by weight of at least any one of silicic acid, alumina and iron oxide, 3 to 35 parts by weight of a phosphate, 2 to 30 parts by weight of gypsum and 0.005 to 7 parts by weight of an oxycarboxylic acid or a ketocarboxylic acid.

Owner:NAT AGRI & FOOD RES ORG +1

A production method for copper-coated aluminum material

InactiveCN101123129AAvoid high temperature oxidationAvoid lubricationCable/conductor manufactureCelsius DegreeMaterials science

Owner:丹阳市中信化工电器设备有限公司

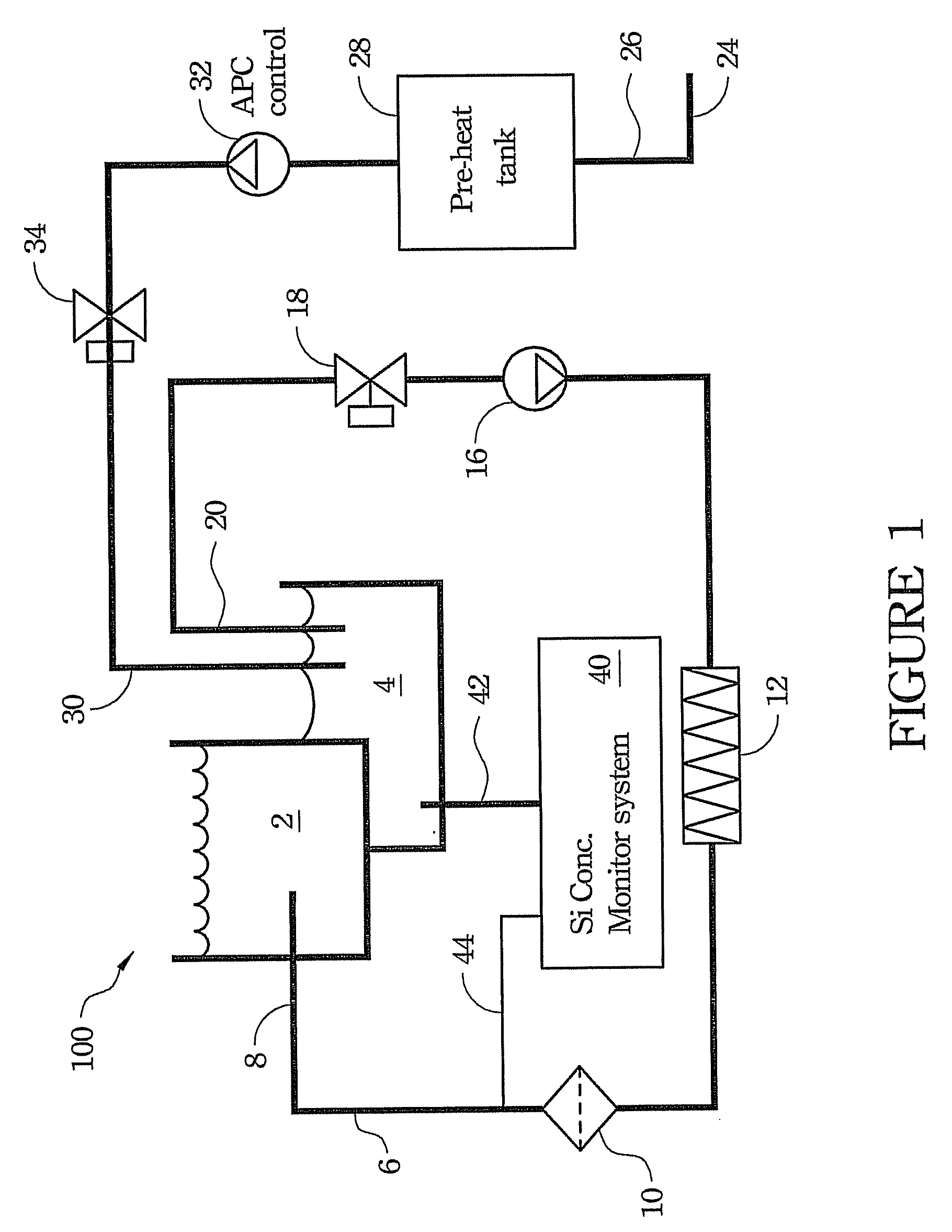

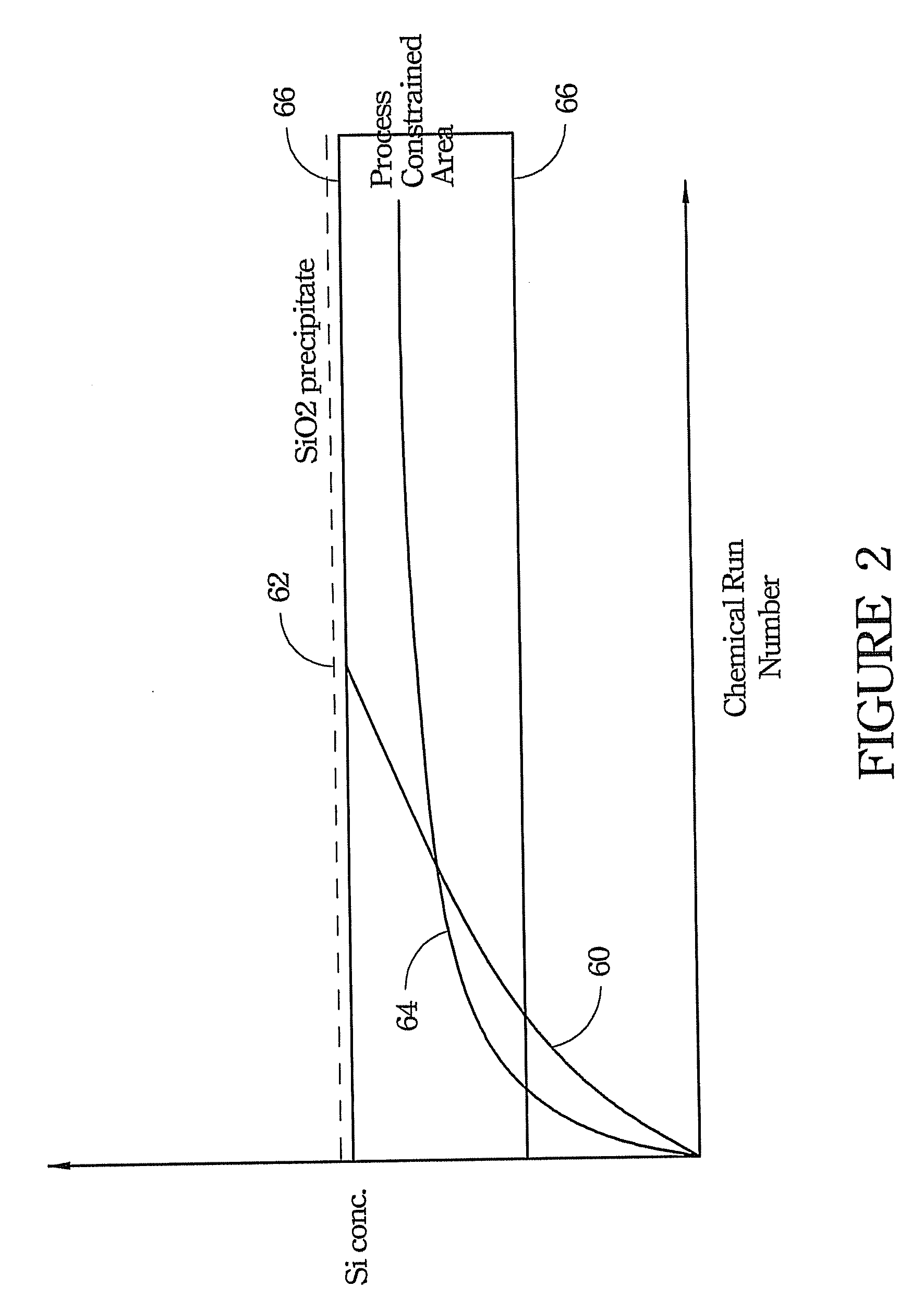

Apparatus and method for controlling silicon nitride etching tank

ActiveUS20080179293A1Semiconductor/solid-state device testing/measurementDecorative surface effectsO-Phosphoric AcidSteady state temperature

Owner:TAIWAN SEMICON MFG CO LTD

Technical method and schedule for preparation of foam carbon material used asphalt as raw material

Owner:DALIAN UNIV OF TECH

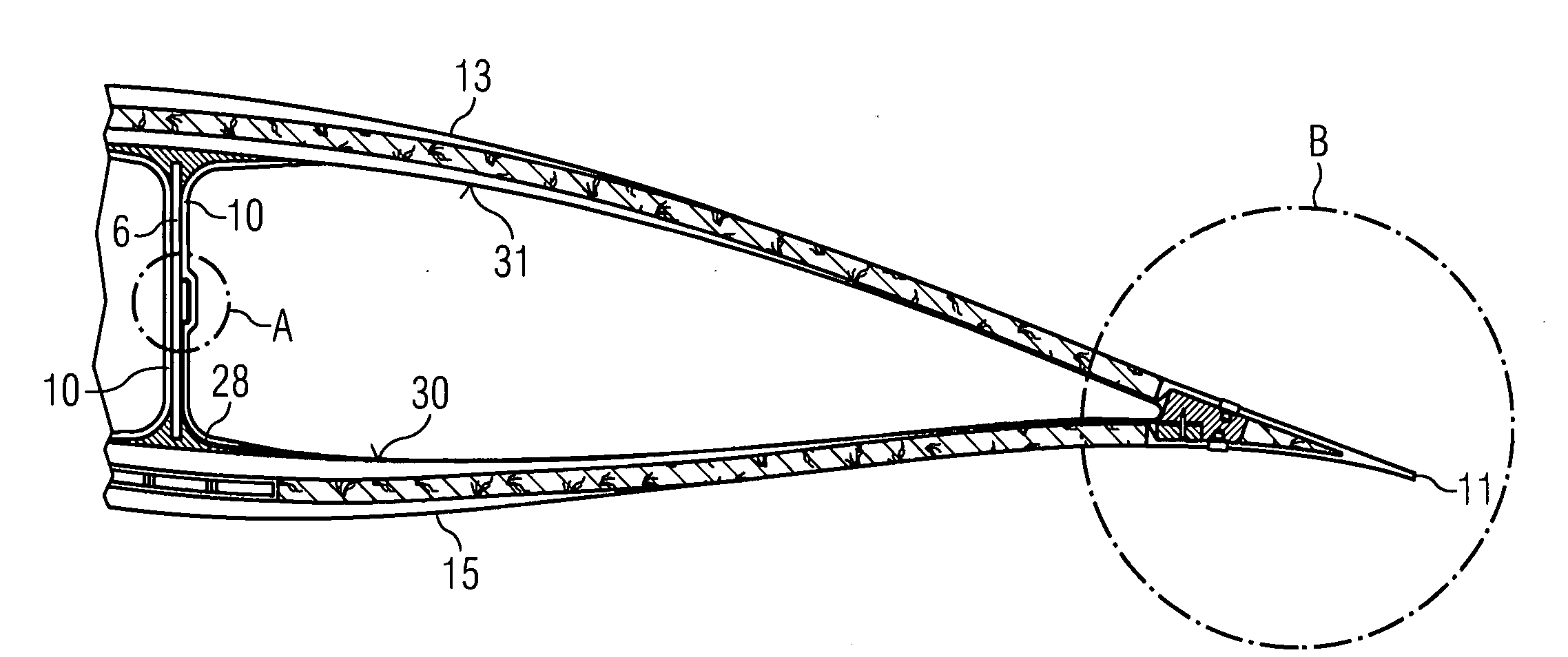

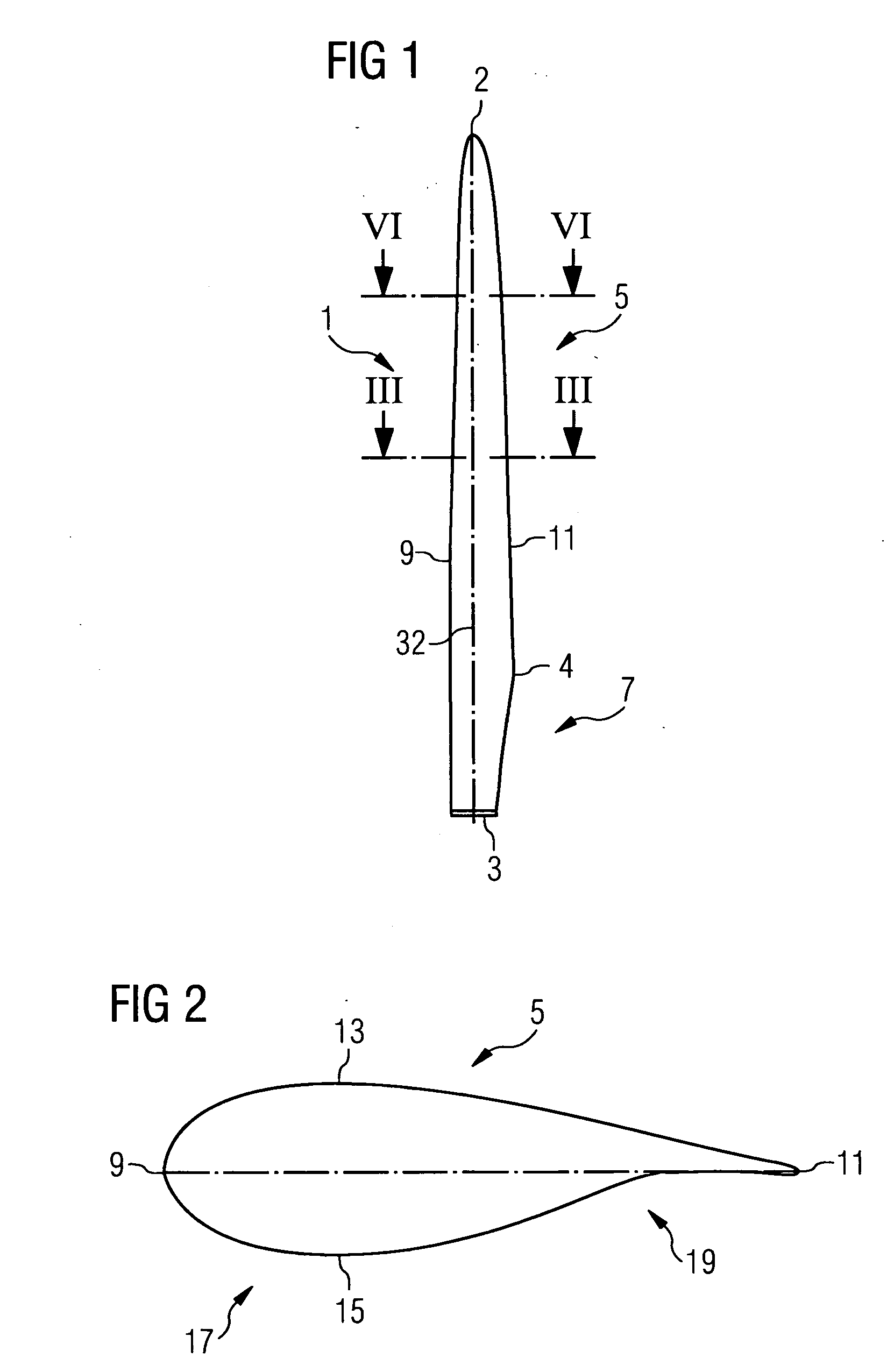

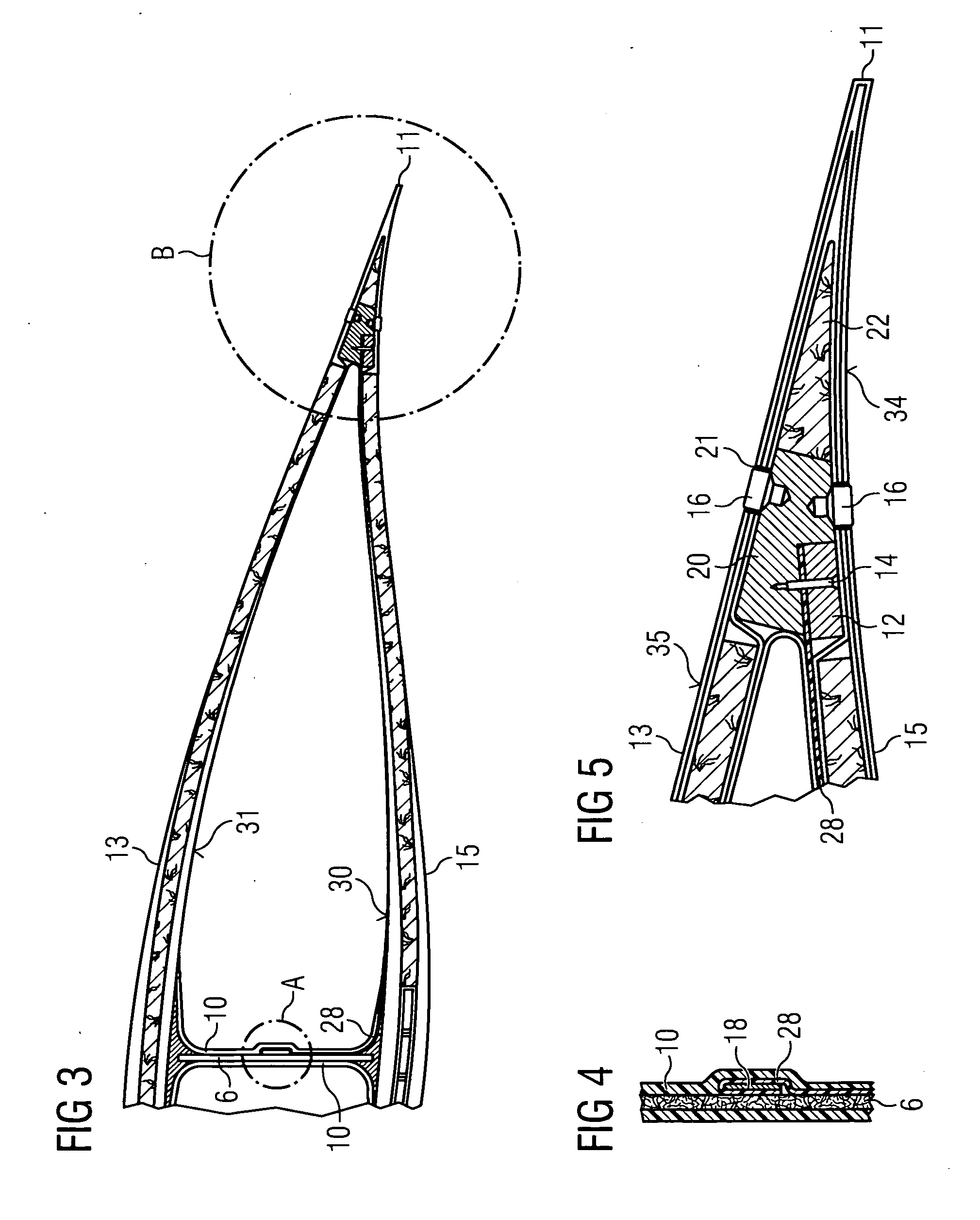

Wind Turbine Blade with an Integrated Lightning Conductor and Method for Manufacturing the Same

ActiveUS20090257881A1Reduce mechanical stressEasy to mergeFinal product manufactureLaminationElectrical conductorTurbine blade

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

Conductive composite fiber and preparation method thereof

The invention relates to a conductive composite fiber and a preparation method thereof. The conductive composite fiber comprises a skin core structure including conductive particles and organic fibers, wherein the mass percentage composition of the conductive particles is 0.5-10%, and the mass percentage composition of the organic fibers is 90-99.5%. The preparation method comprises the following steps: (1) pre-treating the organic fibers in pretreatment liquid, and blowing; (2) soaking the fibers into water dispersion liquid of the conductive particles, ultrasonically assisting the conductive particles to outer layers of the fibers in ice water bath, soaking, drying, and soaking, cleaning and drying through hydrochloric acid solution to obtain the conductive composite fiber. According to the invention, the conductive composite fiber has the advantages of no organic solvent in preparation, greenness and environmental friendliness, simple process, low cost, continuous large-scale production, high conductivity of a product, difficulty in falling conductive components, durable conductive performance, soft hand feel and capability of being knitted; and the conductive composite fiber is used as an antistatic and electromagnetic shield material and an energy storage electrode material.

Owner:DONGHUA UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap