Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60 results about "Atmospheric pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Atmospheric pressure, sometimes also called barometric pressure (after the sensor), is the pressure within the atmosphere of Earth. The standard atmosphere (symbol: atm) is a unit of pressure defined as 1,013.25 mbar (101,325 Pa; 1,013.25 hPa), equivalent to 760 mm Hg, 29.9212 inches Hg, or 14.696 psi. The atm unit is roughly equivalent to the mean sea-level atmospheric pressure on Earth, that is, the Earth's atmospheric pressure at sea level is approximately 1 atm.

Brake System for Motor Vehicles and Method for Operating a Brake System

InactiveUS20140203626A1Reduce travel requirementsFluid braking transmissionBrake action initiationsElectricityAtmospheric pressure

A brake system includes a hydraulic actuating unit, which can be actuated by way of a brake pedal, a travel simulator interacting with the hydraulic actuating unit, a pressure medium reservoir under atmospheric pressure assigned to the hydraulic actuating unit, a first electrically controllable pressure supply device, a second electrically controllable pressure supply device, an electronic control unit and an electronically controllable pressure modulation device for setting wheel-specific brake pressures. The brake system preferably operates in a “brake-by-wire” mode but can also operate in a fallback mode. The second electrically controllable pressure supply device can provide boost volume during braking in a fallback mode.

Owner:CONTINENTAL TEVES AG & CO OHG

Ultra-high temperature high pressure dyeing method for aramid fiber textile

InactiveCN101235598AHigh color fastnessBright colorPhysical treatmentDyeing processColour fastnessAtmospheric pressure

The invention discloses a method for dying kevlar fabrics under ultrahigh temperature and high pressure, which comprises: a preprocessing procedure under the ultrahigh temperature and the high pressure and a dying procedure under the ultrahigh temperature and the high pressure, wherein in the preprocessing procedure under the ultrahigh temperature and the high pressure, atmospheric pressure plasmas are used to process the kevlar fabrics for 1-5min, the processing temperature is 100-150DEG C, while in the dying procedure under the ultrahigh temperature and the high pressure, the temperature is 160DEG C-190DEG C, and the pressure intensity is 0.8-0.9MPa, wherein the plasma preprocessing procedure is an important procedure before the dying procedure under the ultrahigh temperature and the high pressure, since the processing for the plasma produces a plurality of active groups on the kevlar fabrics, which enables carriers to be better absorbed on the kevlar baric and thereby is beneficial for dying dye on the kevlar fabrics, simultaneously, the kevlar fabrics after dying under the ultrahigh temperature and the high pressure has high fastness, fresh color and soft hand feeling, and the washing color fastness and the abrasion color fastness of the kevlar fabrics are improved better.

Owner:ZHEJIANG SCI-TECH UNIV

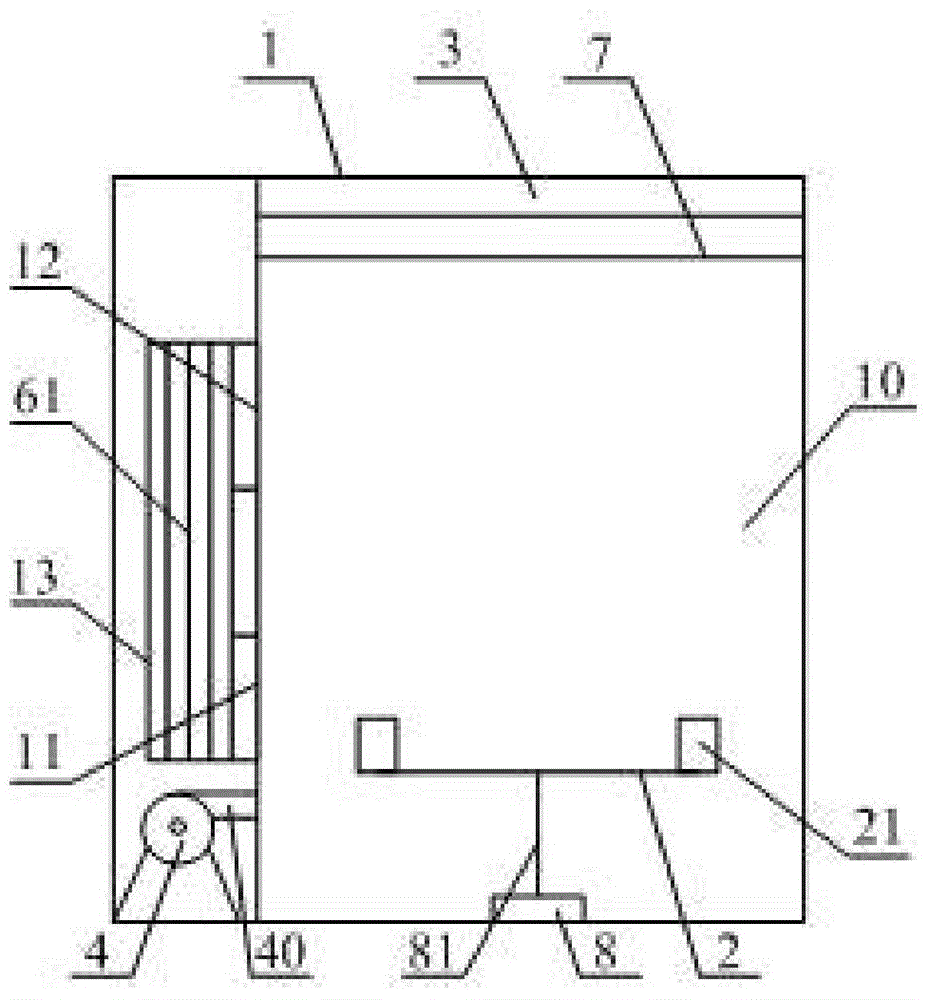

Test device for simulating ecological rock mechanical slope protection under rainfall precipitation condition

InactiveCN101216479ASimple structureAdjustable rainfall intensityFoundation testingEarth material testingFixed bearingSoil science

The invention relates to a device for testing ecological slope protection of ecologic rock and soil mechanics under simulated rainfall condition, which is mainly used for studying scouring (or erosion) characteristics test of rock and soil slope by artificial rainfall and belongs to the field of geotechnical engineering and environmental engineering. The test device comprises an automatic variable slope test rack, a test soil bin and a rainfall simulator with adjustable rain intensity, wherein a rotary support is composed of a guide rail, a crank, a crank brake, an upper shaft and a device for preventing backward sliding; a fixed bearing support is composed of a lower shaft, a bearing seat, a bending guide groove, a capstan and a lower shaft caging device; the rainfall simulator with adjustable rain intensity is disposed on the variable slope test race through a support and includes a rainfall simulator, a pressure sensor, a vibrator, a barometer, a relief valve, etc. The inventive test device has the advantages of simple structure, adjustable rain intensity, uniform rainfall, automatic online collection of air pressure, water pressure and rainfall amount of the rainfall simulator and reduced time and labor force for loading the test soil bin.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

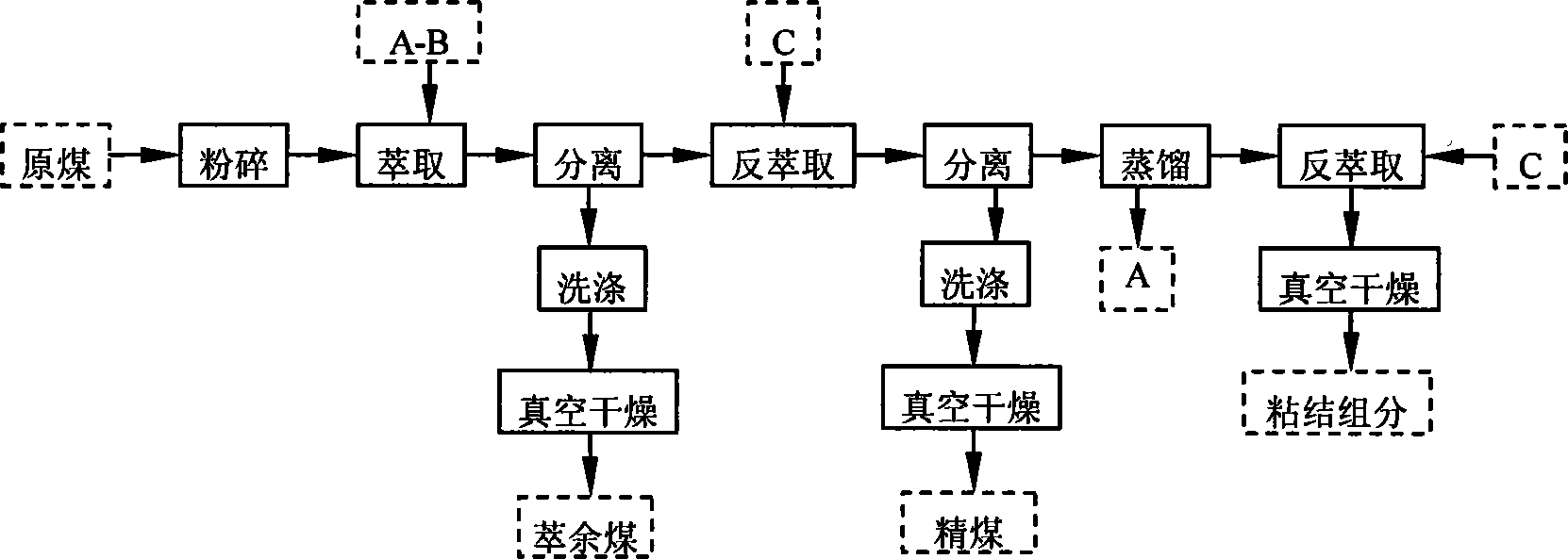

Mild coal-family component separation method based on extraction and back extraction

InactiveCN101070495AEasy to useImprove environmental benefitsSolid fuelsSolid solvent extractionWater useDistillation

Owner:CHINA UNIV OF MINING & TECH

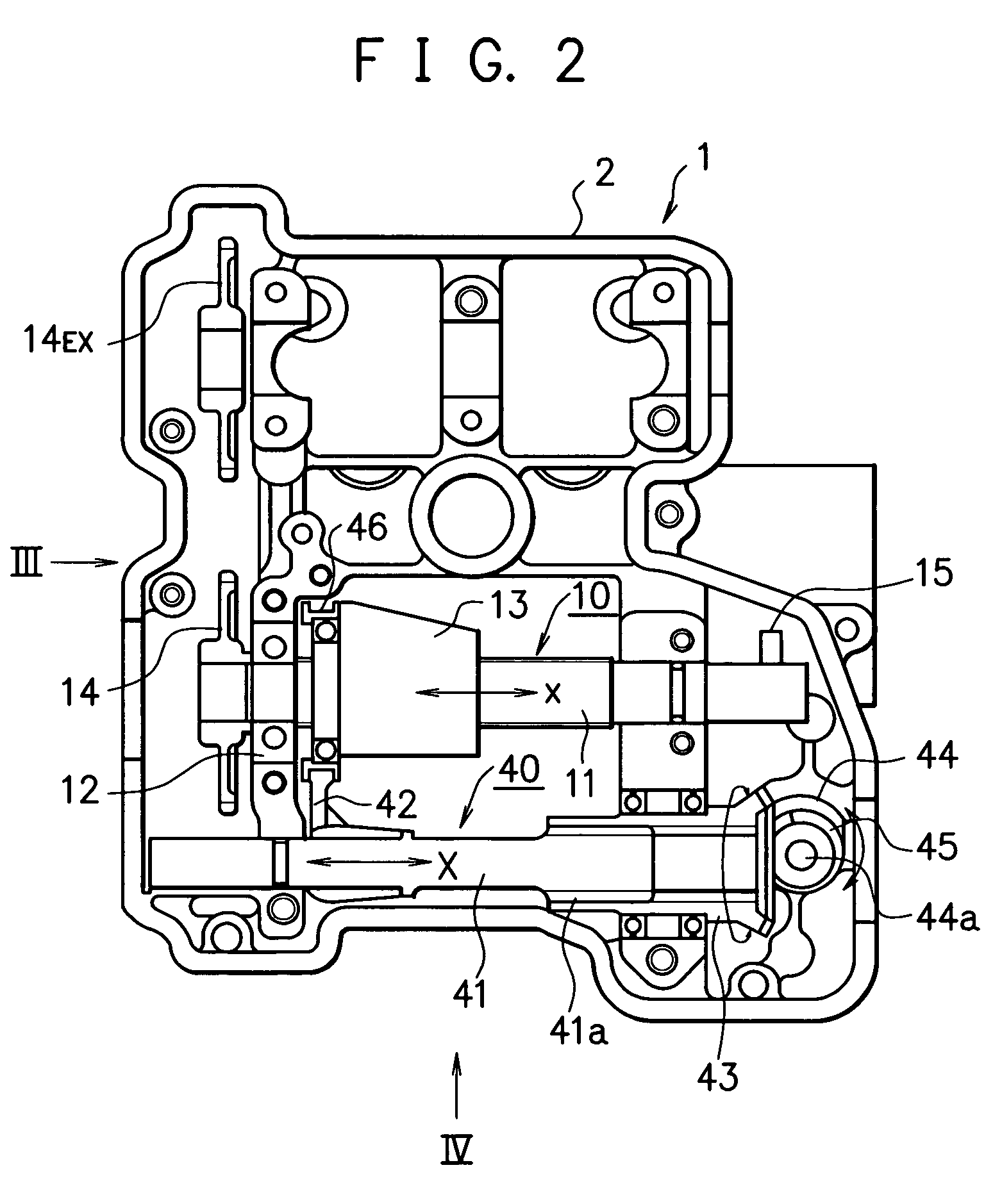

Device for controlling engine rotation stop by estimating kinetic energy and stop position

InactiveCN1912370AEasy dischargeElectrical controlInternal combustion piston enginesAtmospheric pressureSmall range

A control apparatus for an engine increases an intake air quantity just before engine stop to increase a compression pressure in a compression stroke. As the compression pressure is increased, a negative torque in the compression stroke increases and obstructs engine rotation, and brakes the engine rotation. Thus, a range of crank angle, in which torque is below engine friction, that is, in which engine rotation can be stopped, is reduced. As a result, variation in engine rotation stop position is reduced to be within a small range of crank angle. Information of engine rotation stop position is stored, and the stored information of engine rotation stop position is used at the start of an engine to accurately determine an initial injection cylinder and an initial ignition cylinder to start the engine.

Owner:DENSO CORP

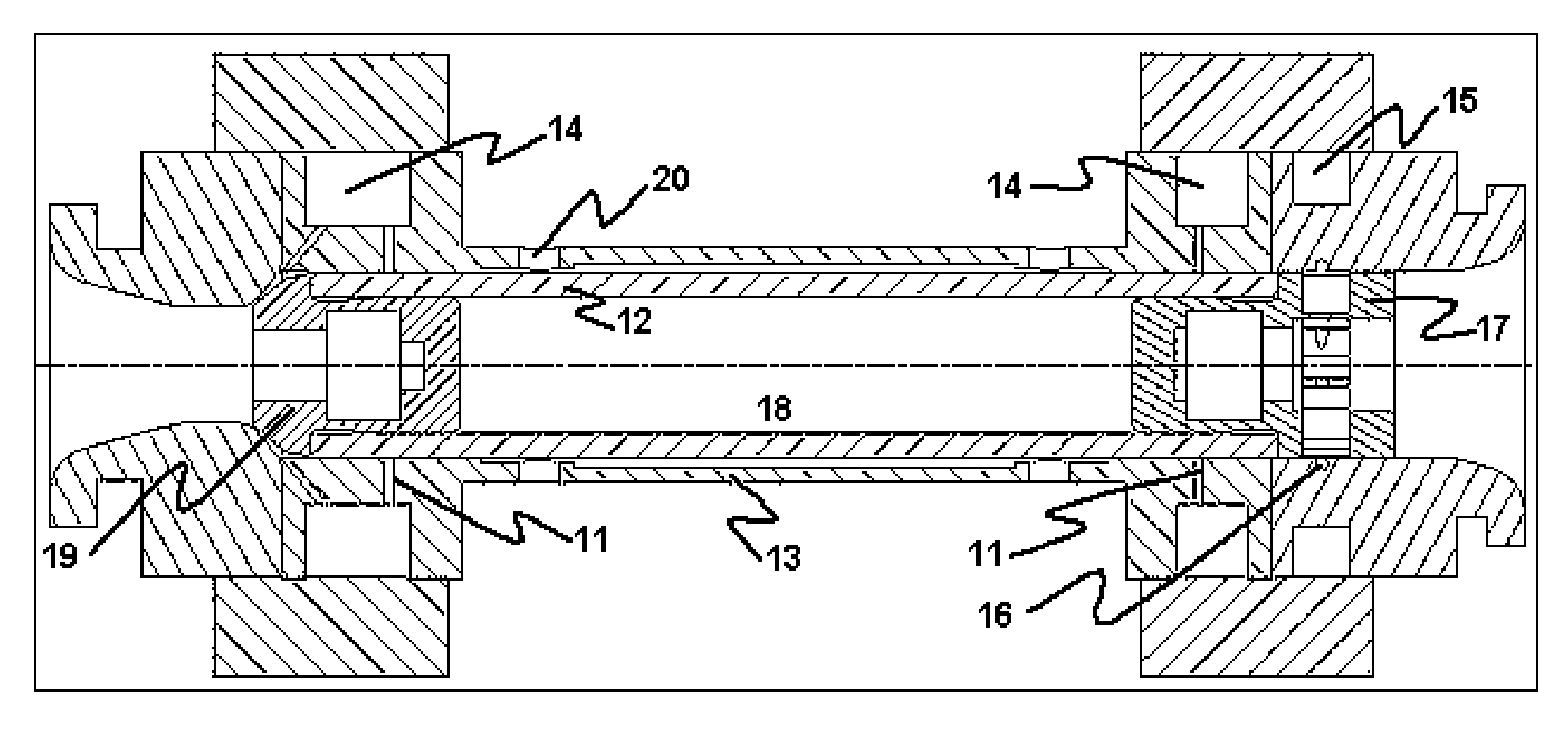

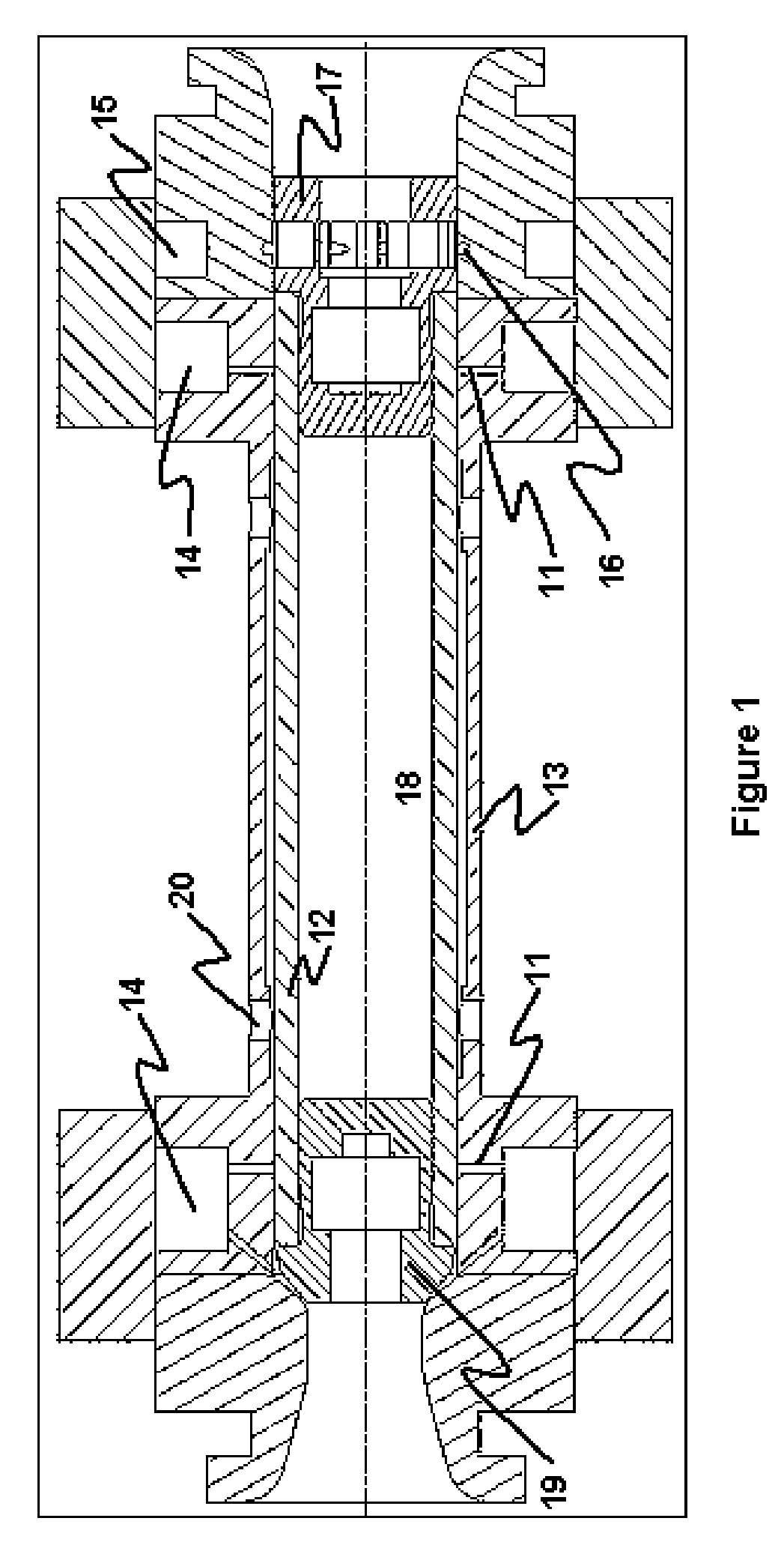

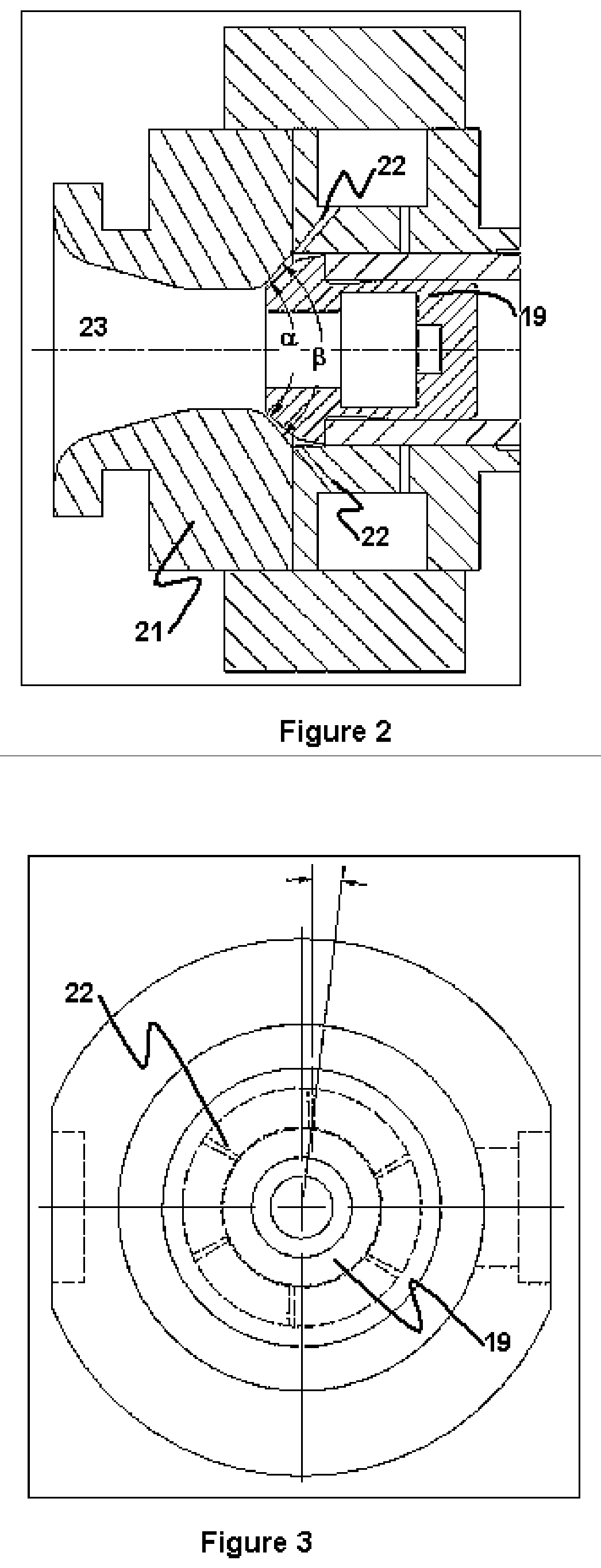

NMR MAS inflow bernoulli bearing

ActiveUS20060082371A1Improve stabilityIncrease stiffnessMagnetic circuit rotating partsMagnetic measurementsAxial pressureSurface velocity

Owner:DOTY SCI

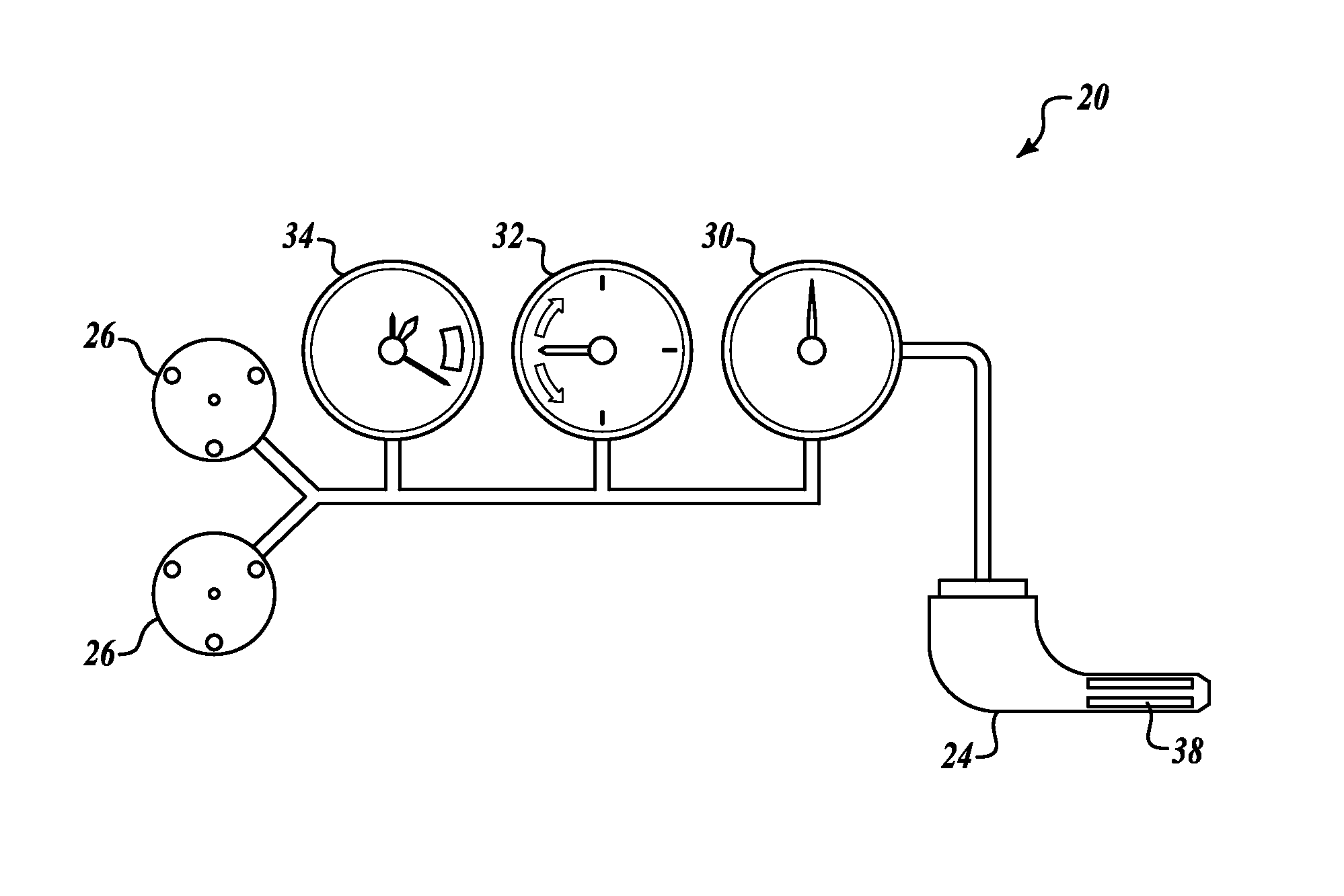

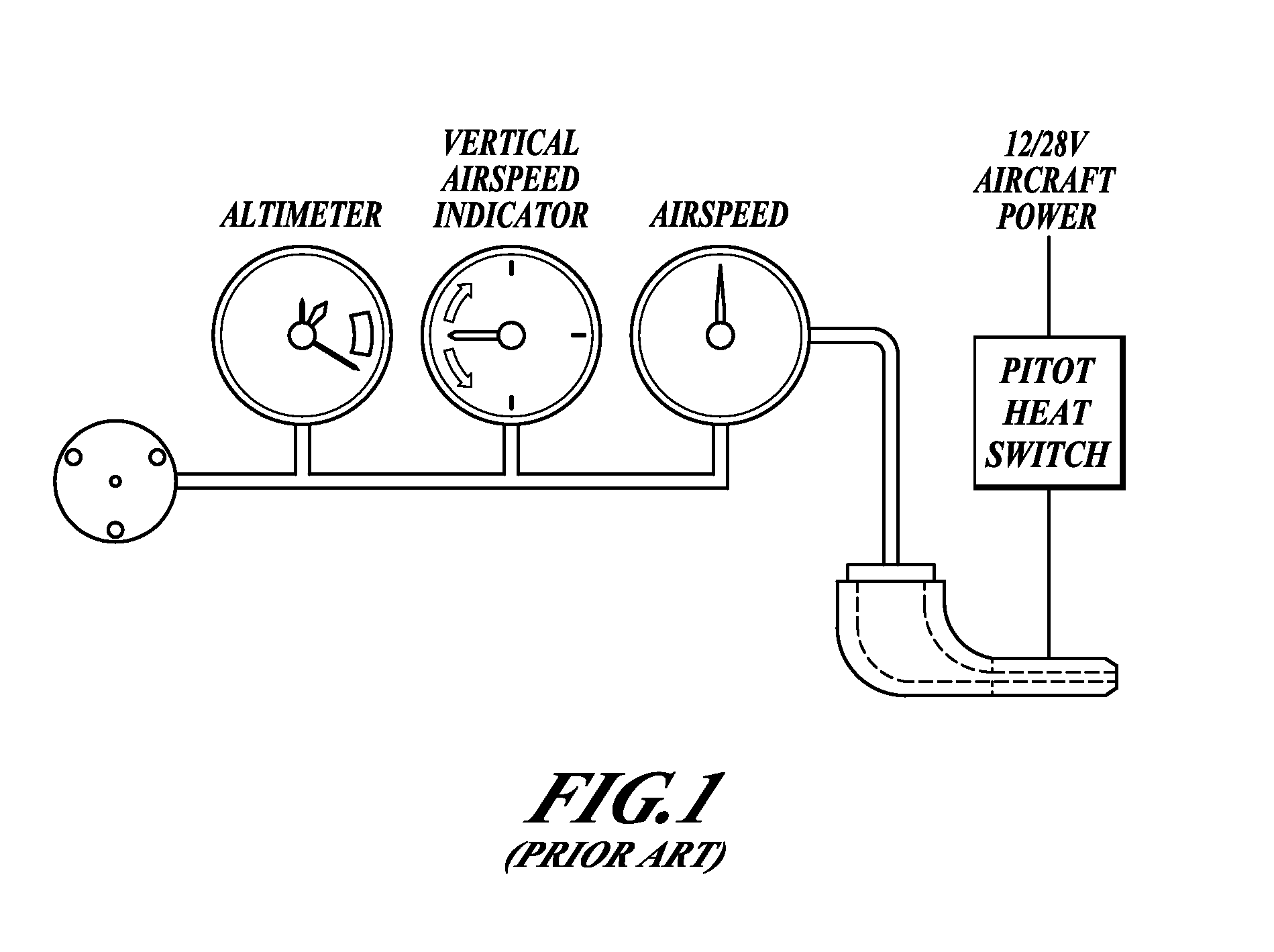

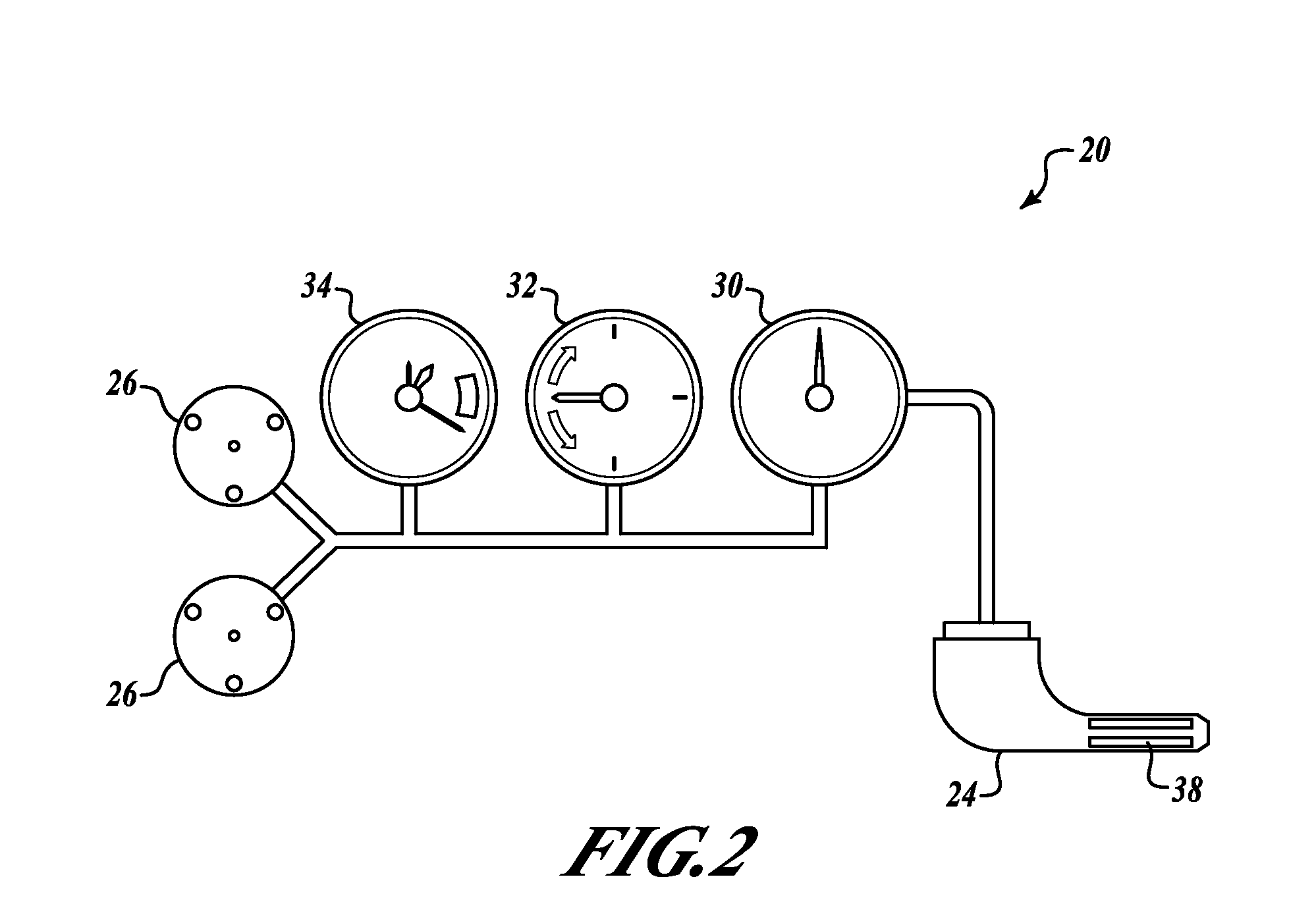

Automated heating system for ports susceptible to icing

InactiveUS20100116806A1Consumes less currentReduce power consumptionDe-icing equipmentsFluid speed measurementElectrical resistance and conductanceHeat sensitive

Owner:HONEYWELL INT INC

Method of Fabricating Thin Film by Microplasma Processing and Apparatus for Same

InactiveUS20120021132A1Reduce necessityLiquid surface applicatorsMolten spray coatingIonRaw material

Provided is a method of fabricating, with satisfactory adhesion, a thin film of a metal or a metallic-compound, such as a metal oxide or nitride, on a substrate made of a high-melting-point material such as silicon or ceramics by using a metal or metallic-compound target as the primary raw material so as to eliminate the necessity of using harmful gases such as organometallic gas, and by using an atmospheric-pressure plasma generated under atmospheric pressure as a reaction field and also as a heat source. Additionally provided is an apparatus for fabricating the thin film. The thin-film fabrication method by microplasma processing includes the steps of disposing a raw material for thin-film fabrication in one or more tubes (A) having a uniform inner diameter throughout, introducing an inert gas and applying a high-frequency voltage to the narrow tubes (A) to generate high-frequency plasma in the narrow tubes (A), heating / evaporating the raw material while maintaining the flow rate of the plasma gas in the narrow tubes (A) and maintaining the plasma gas temperature high, ejecting the evaporated material from the narrow tubes (A) to spray it onto the substrate, heating the substrate with the plasma, and depositing the sprayed material on the substrate under atmospheric pressure.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Method for fracturing coal seam by employing high-pressure gas

ActiveCN104405358ASolve the problem of air leakageGuaranteed gas pressureFluid removalSealing/packingParticulatesProduct gas

Owner:TAIYUAN UNIV OF TECH

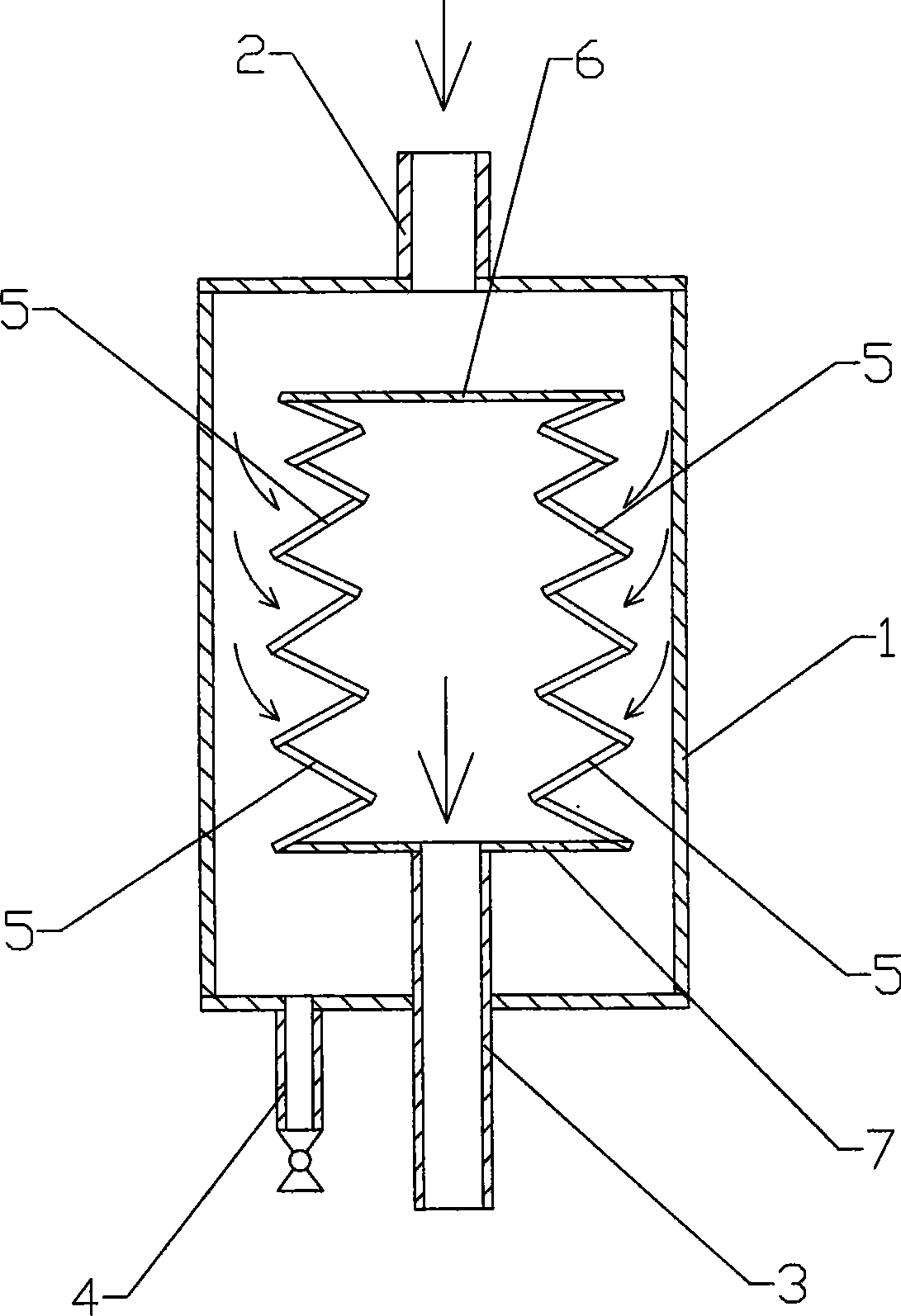

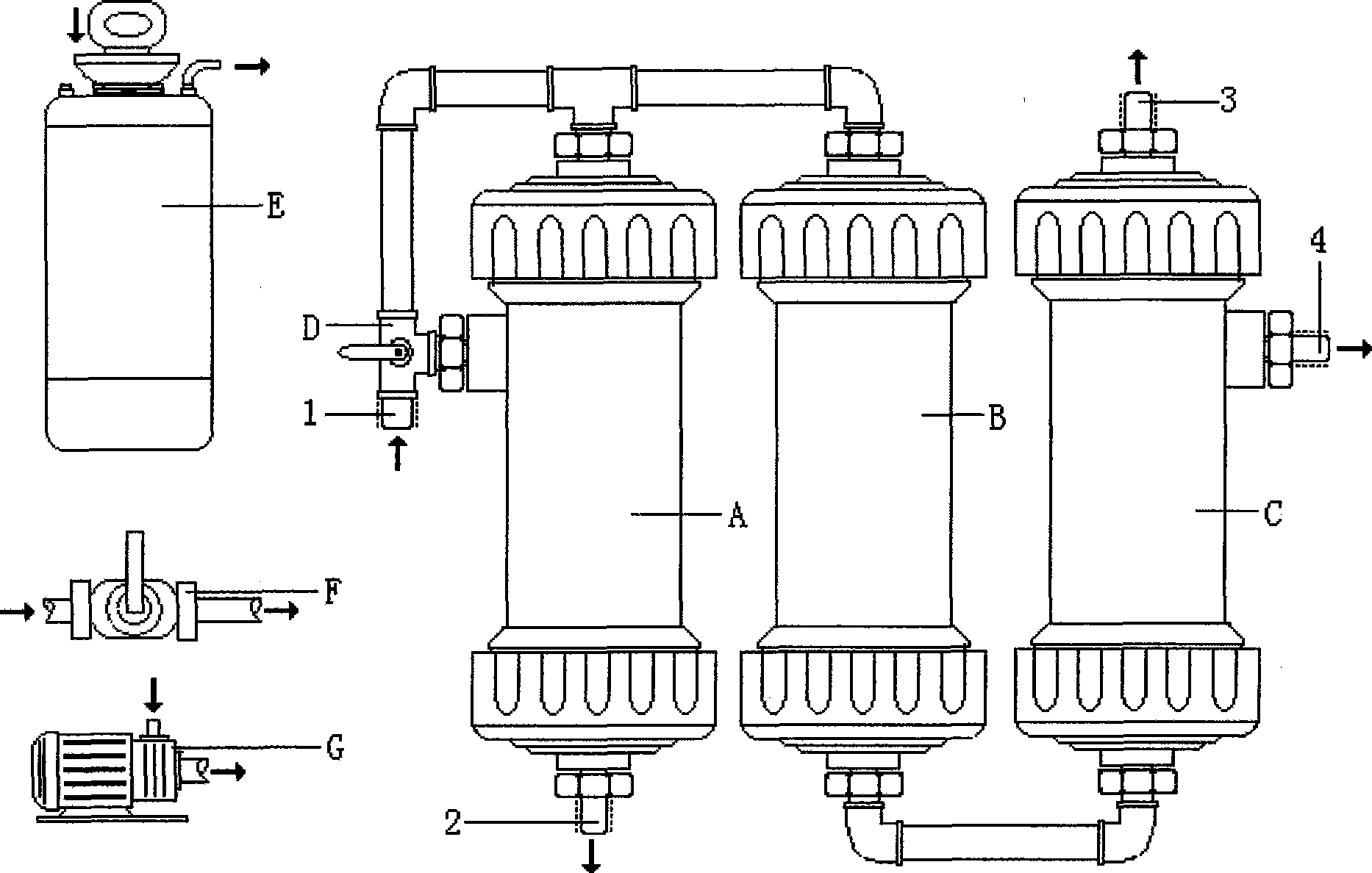

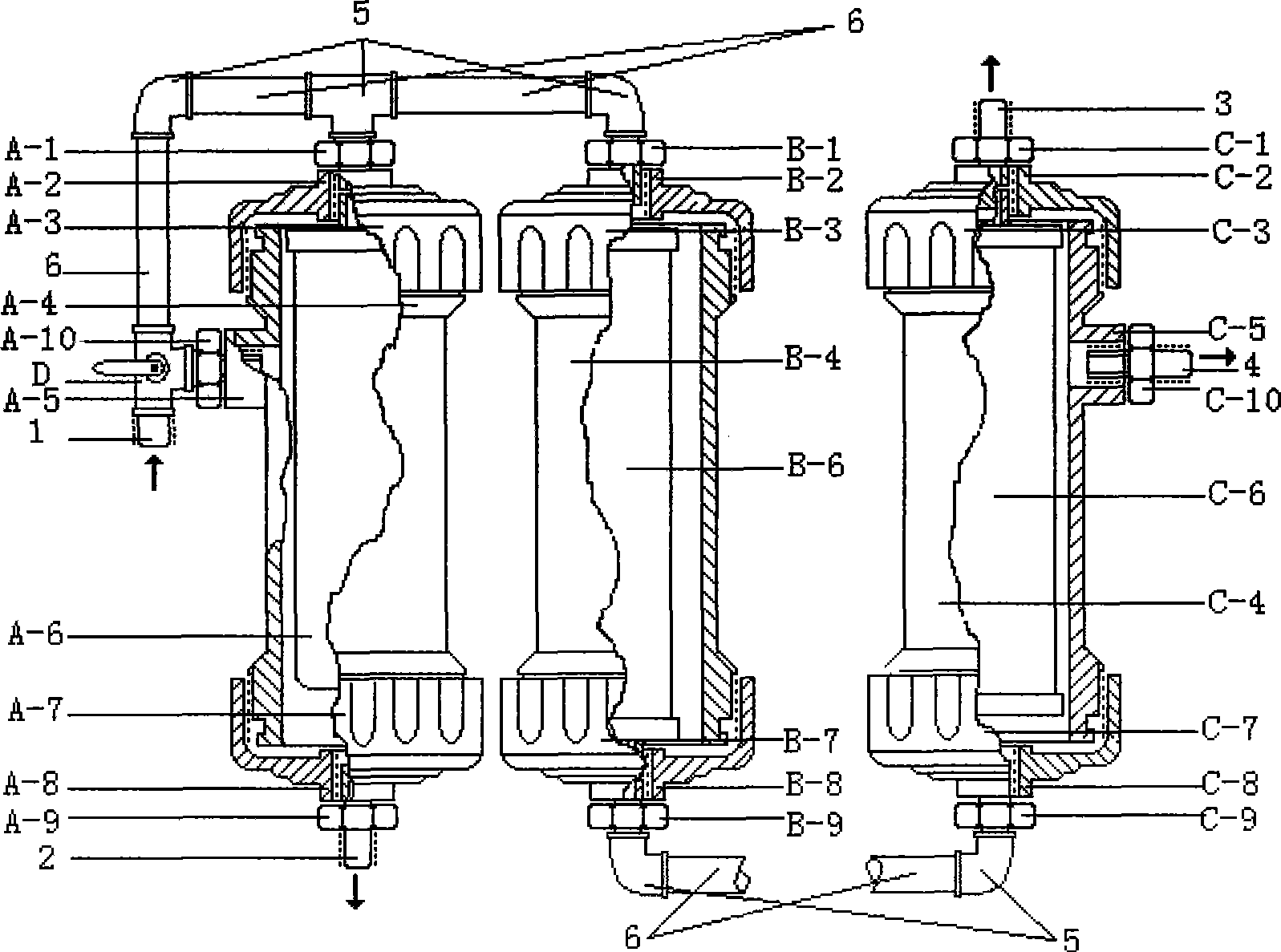

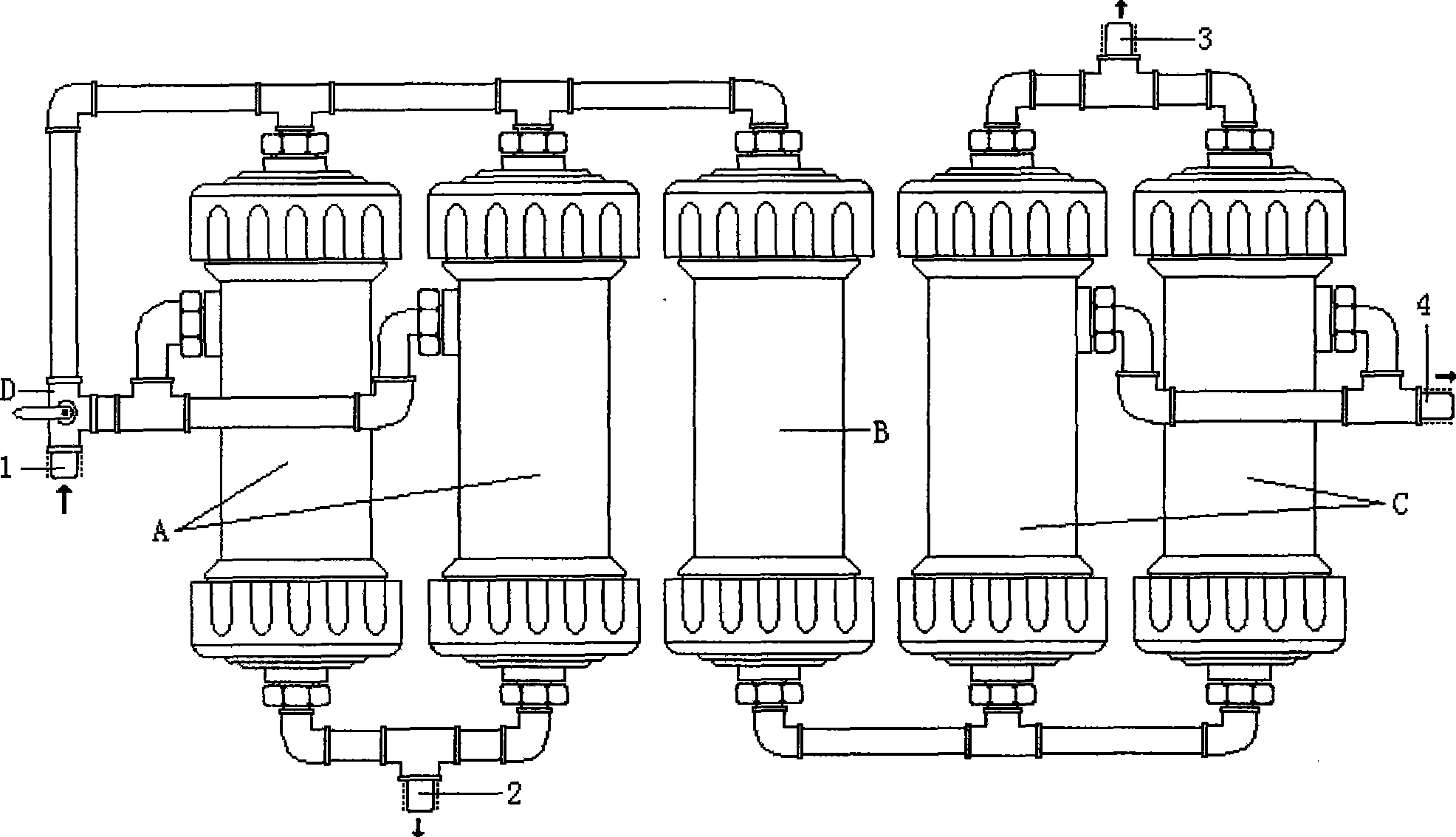

Filter

InactiveCN101462019ASmall apertureHigh densityDispersed particle filtrationBiochemical engineeringFiltration

Owner:薛文伟

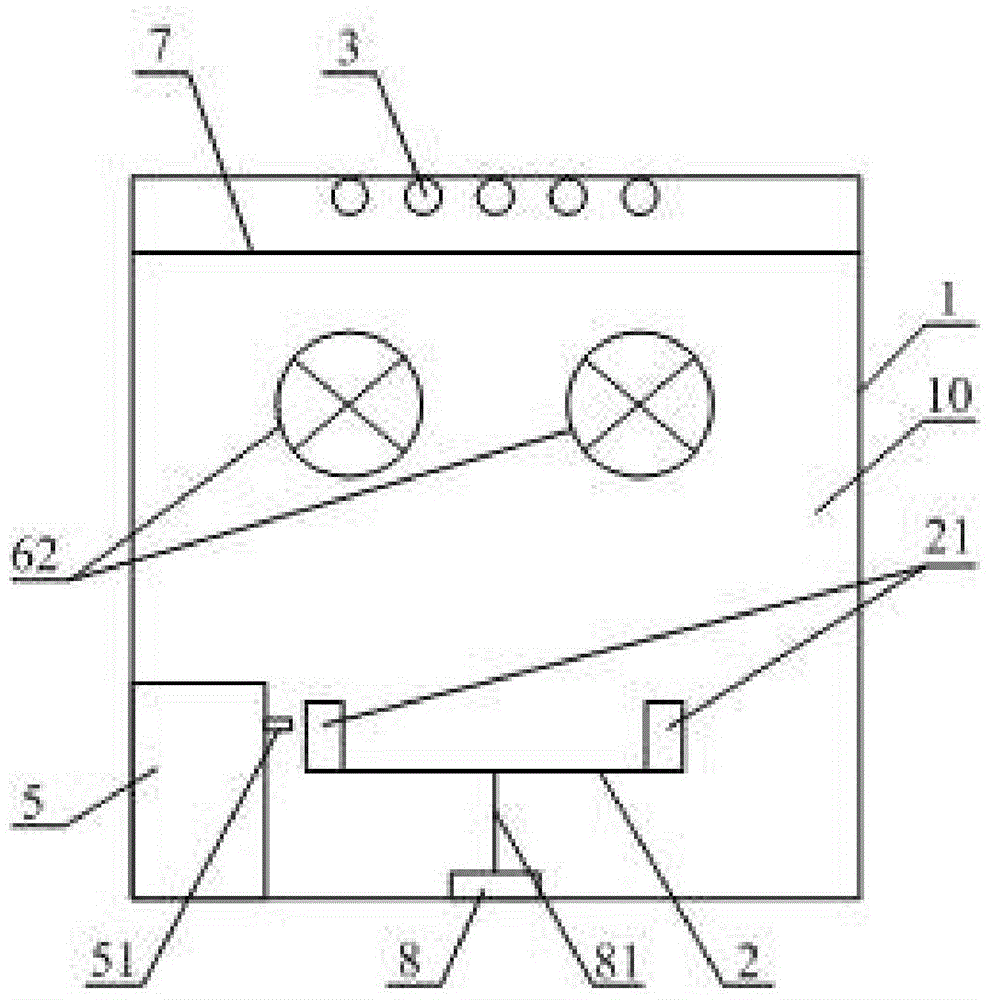

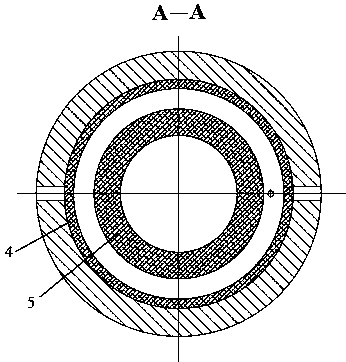

Multiple spiral dust collector

InactiveCN1548245AReduce interactionReduce resistanceSuction filtersVortex flow apparatusEngineeringAtmospheric pressure

The present invention is multiple vortex dust collector in duster. The multiple vortex dust collector includes cylindrical vortex body with partitioning wall to separate it two parts including the lower or first part and the upper or the second part. The first vortex part is provided with sucking pipe, pollutant exhaust hole, the first dust collecting chamber with exhaust port in the center of the partitioning wall, and leading pipe to the second vortex part. The second vortex part has central exhaust pipe with filtering part and sucking force generator, pollutant exhaust hole, and the second dust collecting chamber. The present invention has basically the same pollutant and air sucking direction and vortex and exhaust direction, reduced conflict between the ascending airflow and vortex, reduced friction resistance, less pressure loss, less noise and less pollutant jamming in filtering part.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

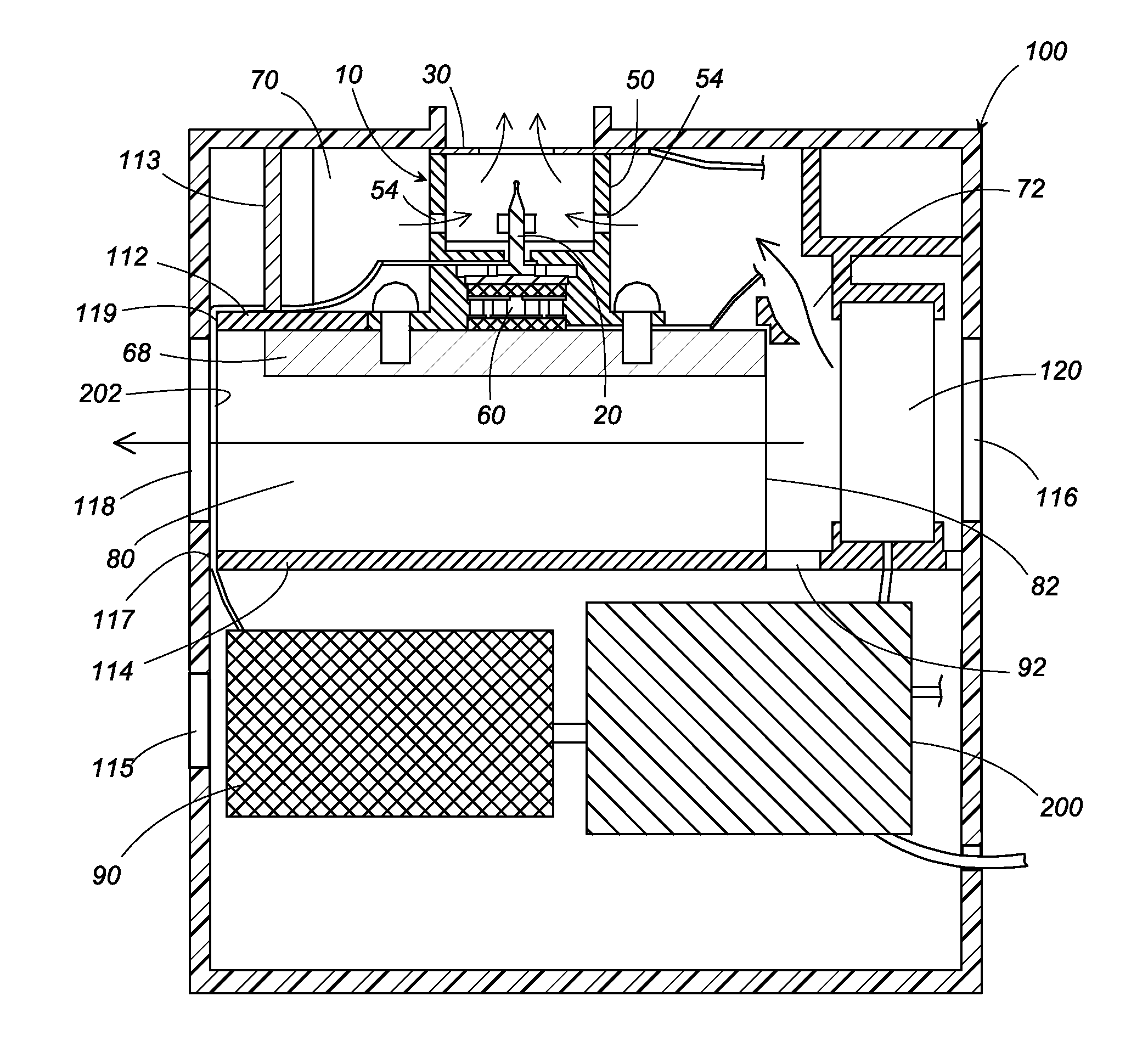

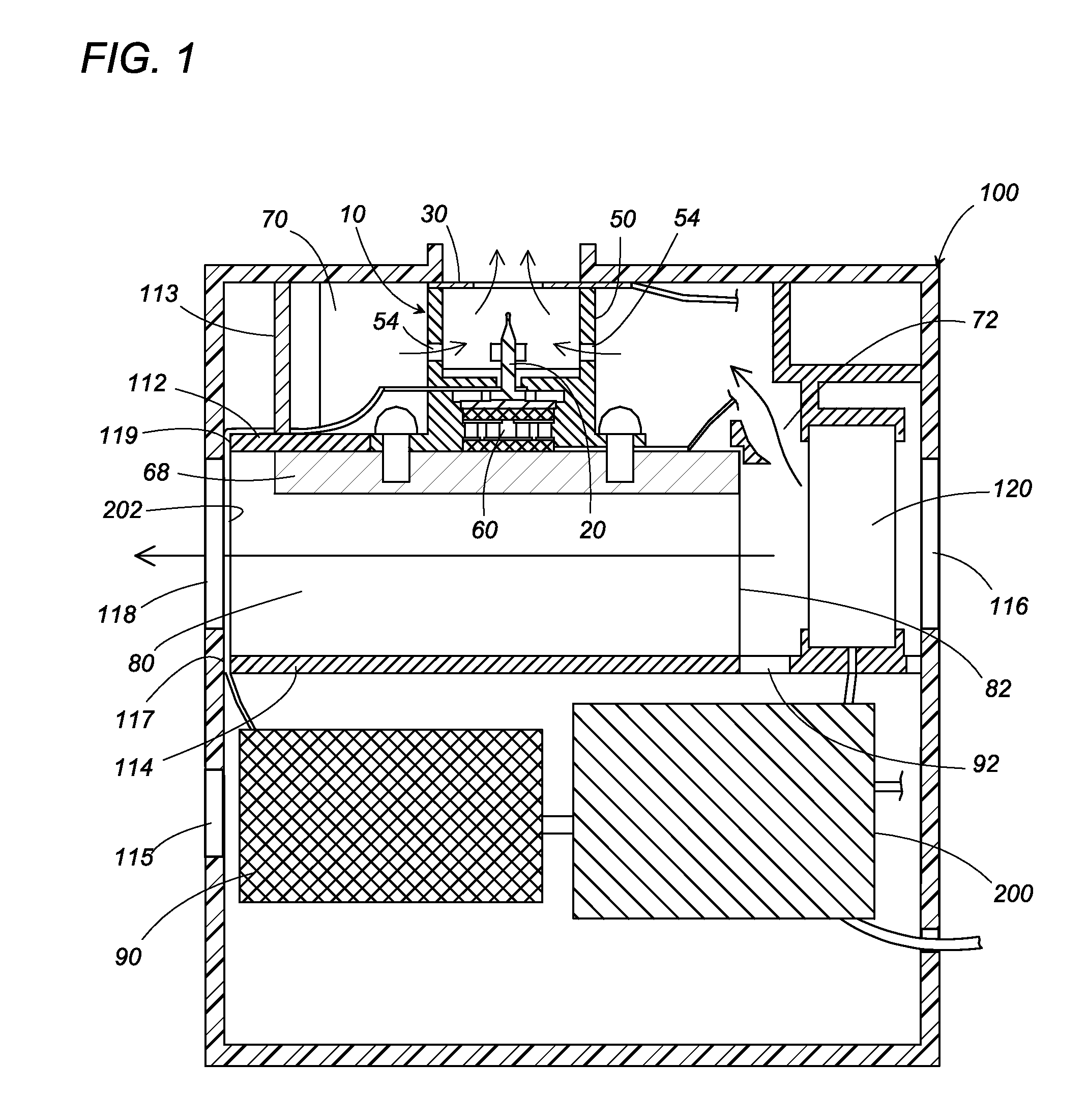

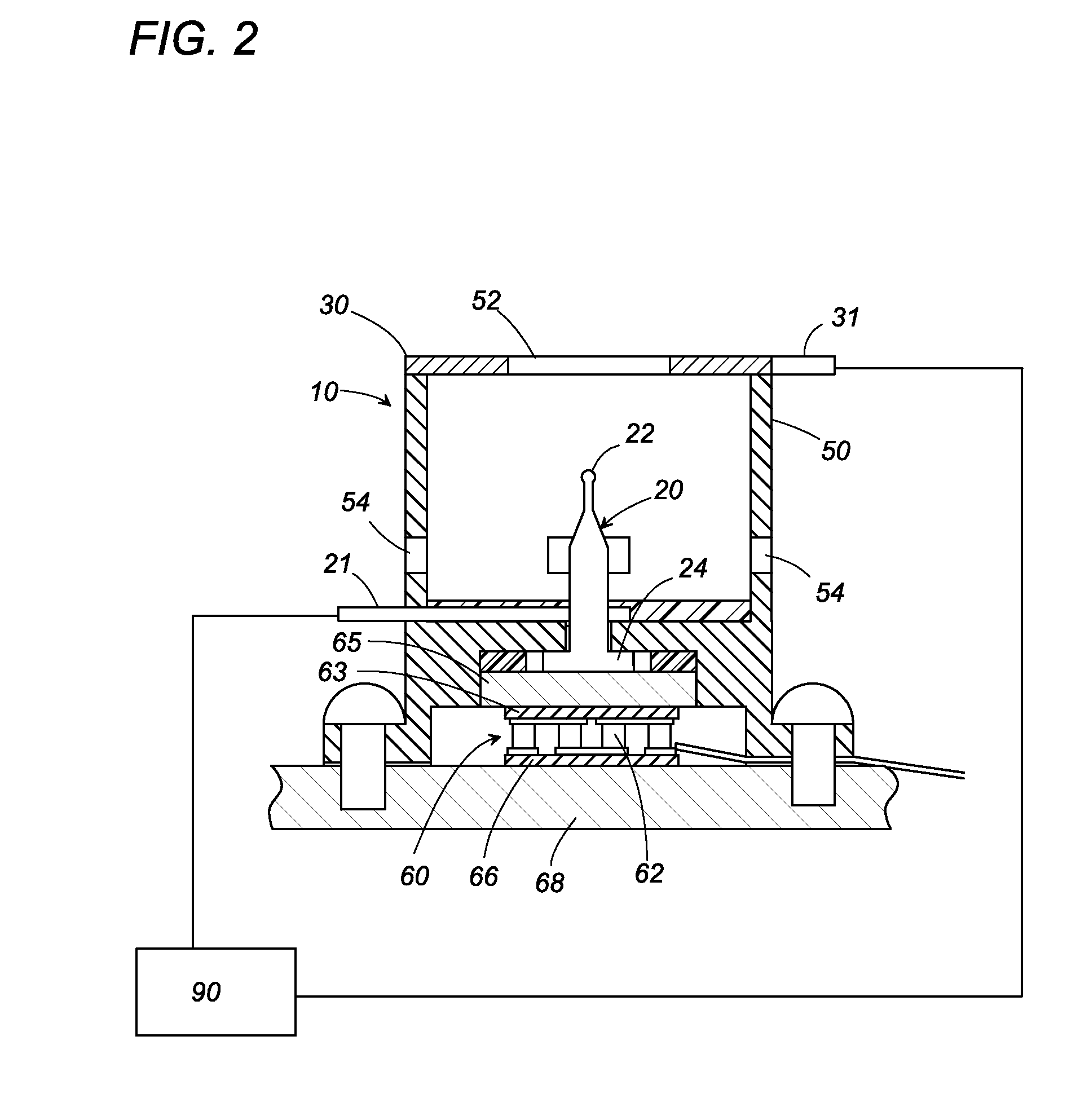

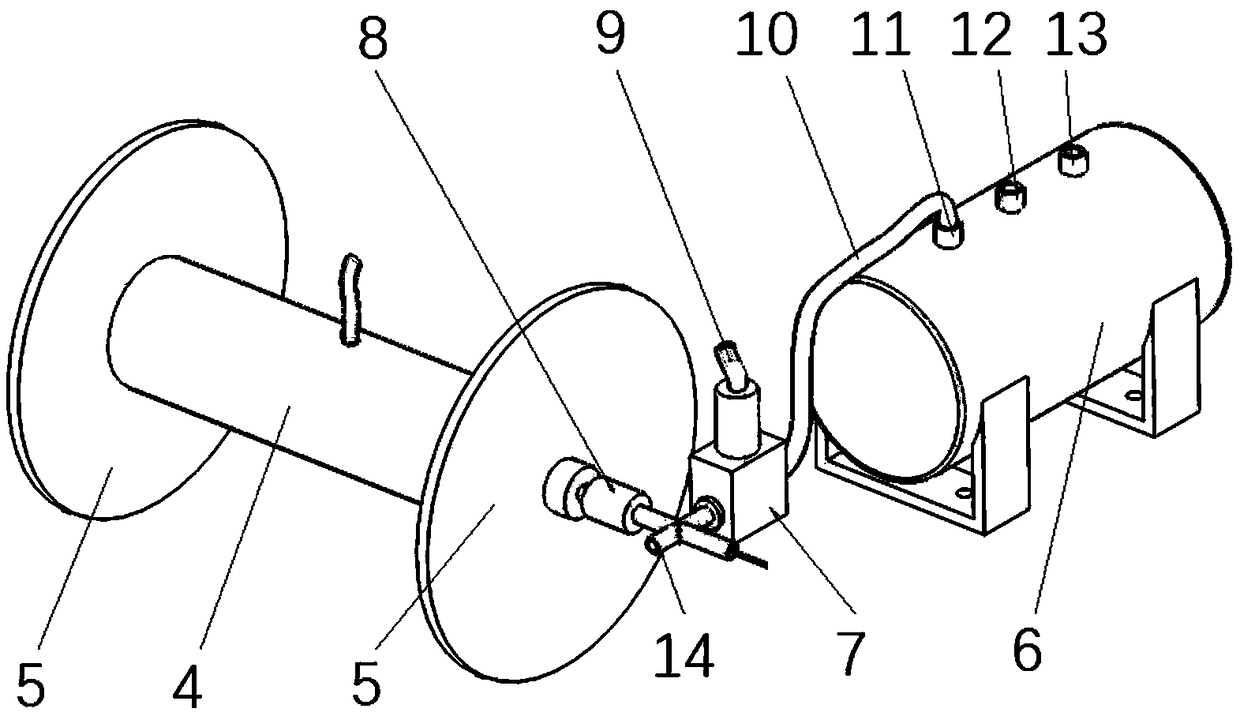

Continuous vacuum carburizing furnace

ActiveUS7029625B2Inhibit productionConvenient and efficient controlFurnace typesSolid state diffusion coatingCooling chamberAtmospheric pressure

A continuous vacuum carburizing furnace of the invention includes: a heating chamber for heating a workpiece under a atmospheric pressure; a first conditioning chamber in which the pressure is reduced from the atmospheric pressure after the receipt of the workpiece from the heating chamber; a carburizing / diffusing chamber receiving plural workpieces from the first conditioning chamber and conducting plural cycles of carburizing and diffusing processes under the reduced pressure; a second conditioning chamber in which the reduced pressure is returned to the atmospheric pressure after the receipt of the workpiece treated in the carburizing / diffusing chamber; and a cooling chamber for cooling the workpiece introduced from the second conditioning chamber under the atmospheric pressure, the furnace further comprising a door member disposed between a respective adjoining pair of the above chambers, the door member opened / closed only when the workpiece is transported from one chamber to another.

Owner:CHUGAI RO CO LTD

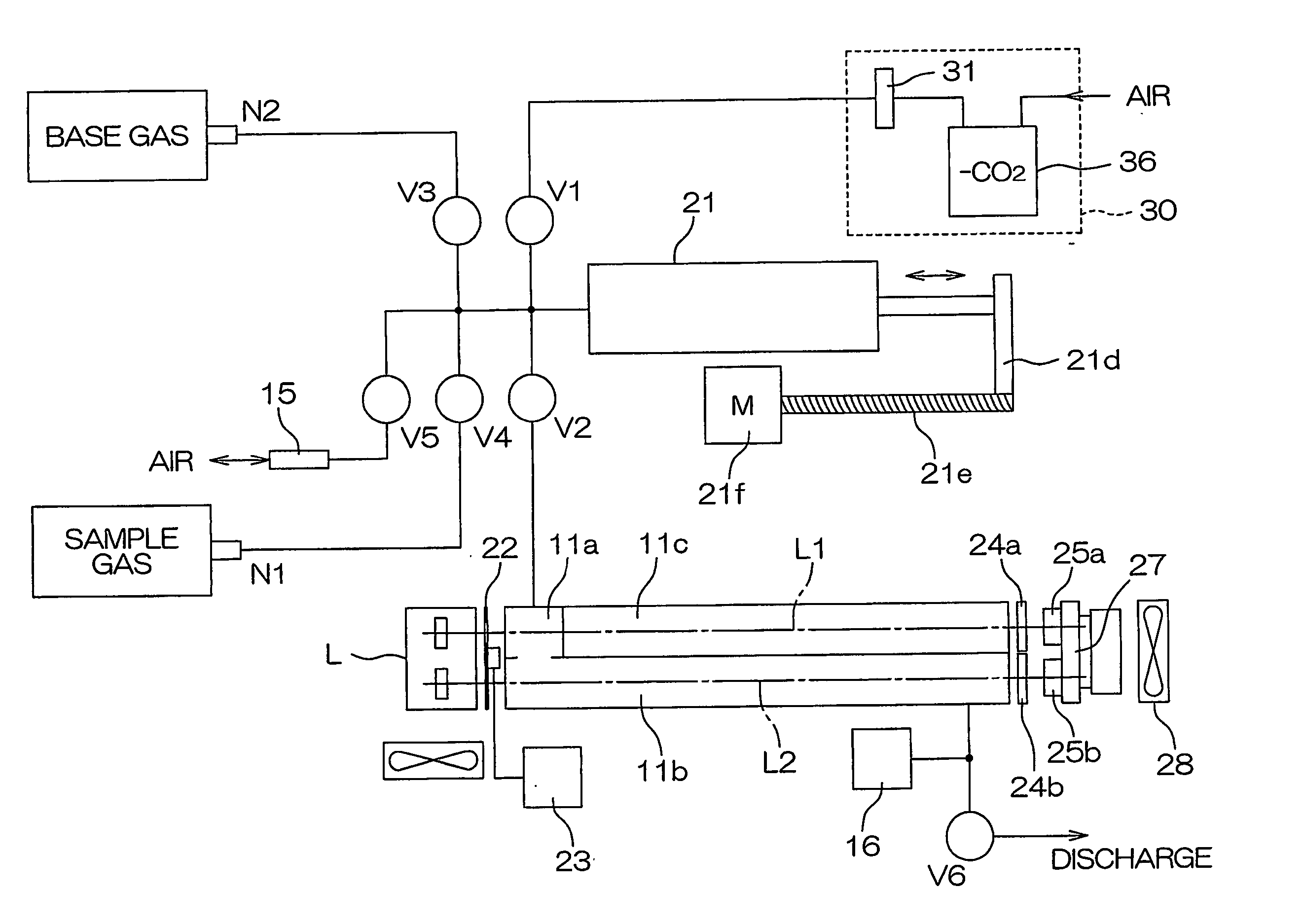

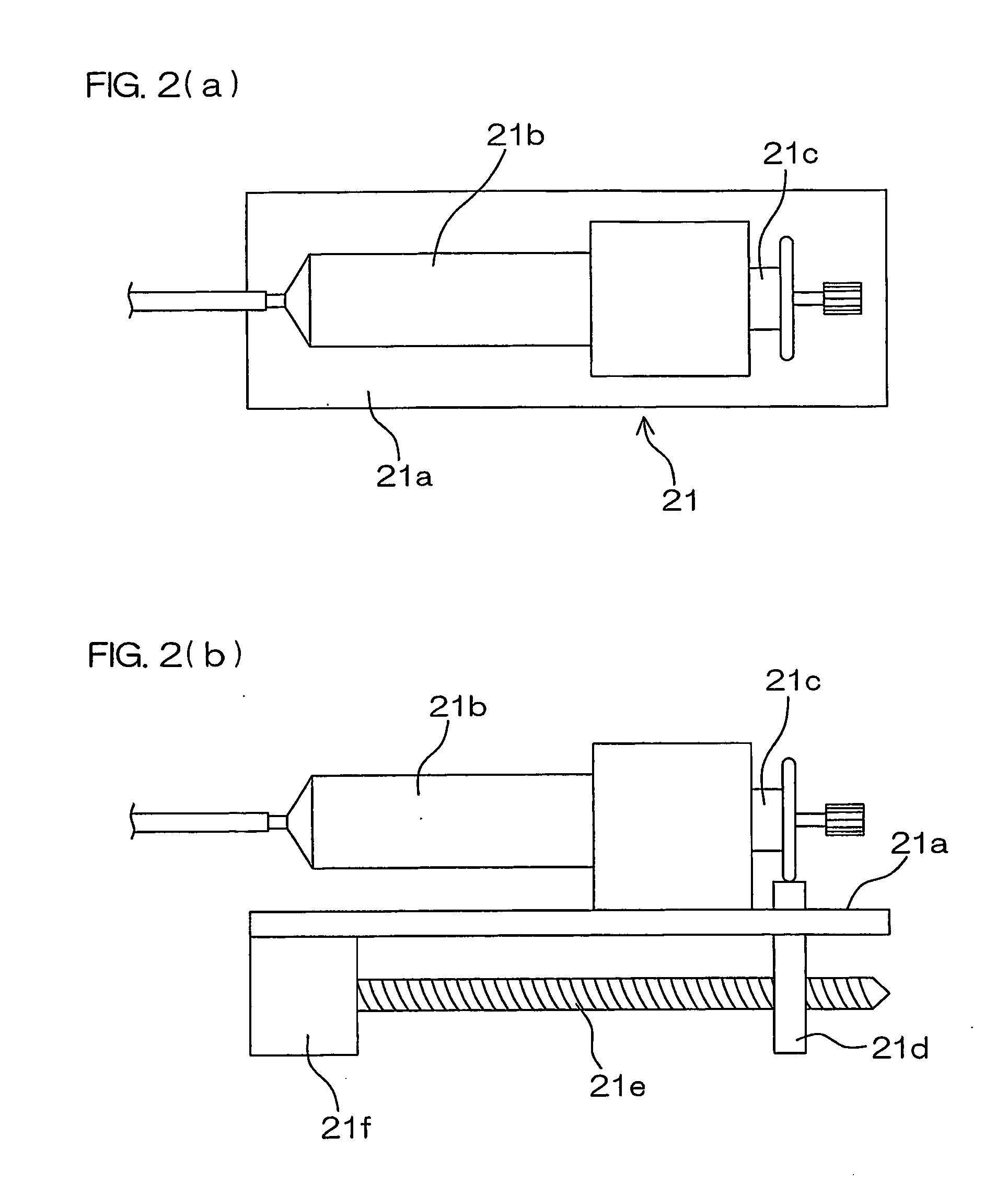

Gas injection amount determining method method in isotope gas analysis, and, isotype gas analyzing and measuring method and apparatus

ActiveUS20070077167A1Improve precisionGood reproducibilityWeather/light/corrosion resistanceWithdrawing sample devicesGas analysisExhaust valve

Owner:OTSUKA PHARM CO LTD

Method for preparing positive pole material for ferrous phosphate lithium battery from low-valence oxygen-containing acid of phosphorus

InactiveCN101332984ALow costWide variety of sourcesCell electrodesPhosphorus compoundsPhosphateFerrous salts

Owner:FUJIAN NORMAL UNIV

Environment simulation test case and environment simulation method

PendingCN106553775AReduce air pressureIncrease UV intensityCosmonautic condition simulationsEngineeringAtmospheric pressure

Owner:SHENZHEN KUANG CHI SPACE TECH CO LTD

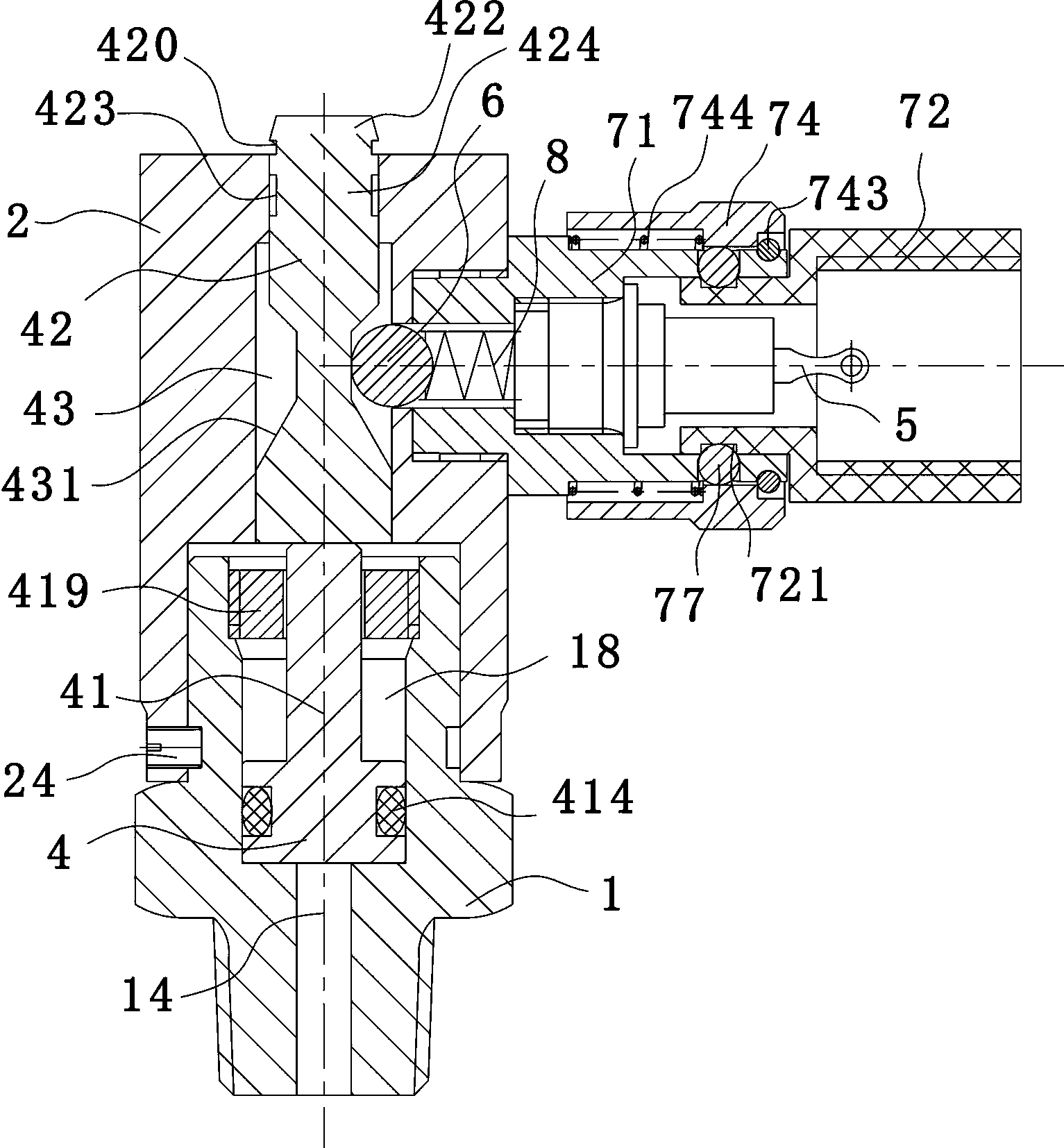

Self-locking pressure signal feedback device

Owner:浙江信达可恩消防实业有限责任公司

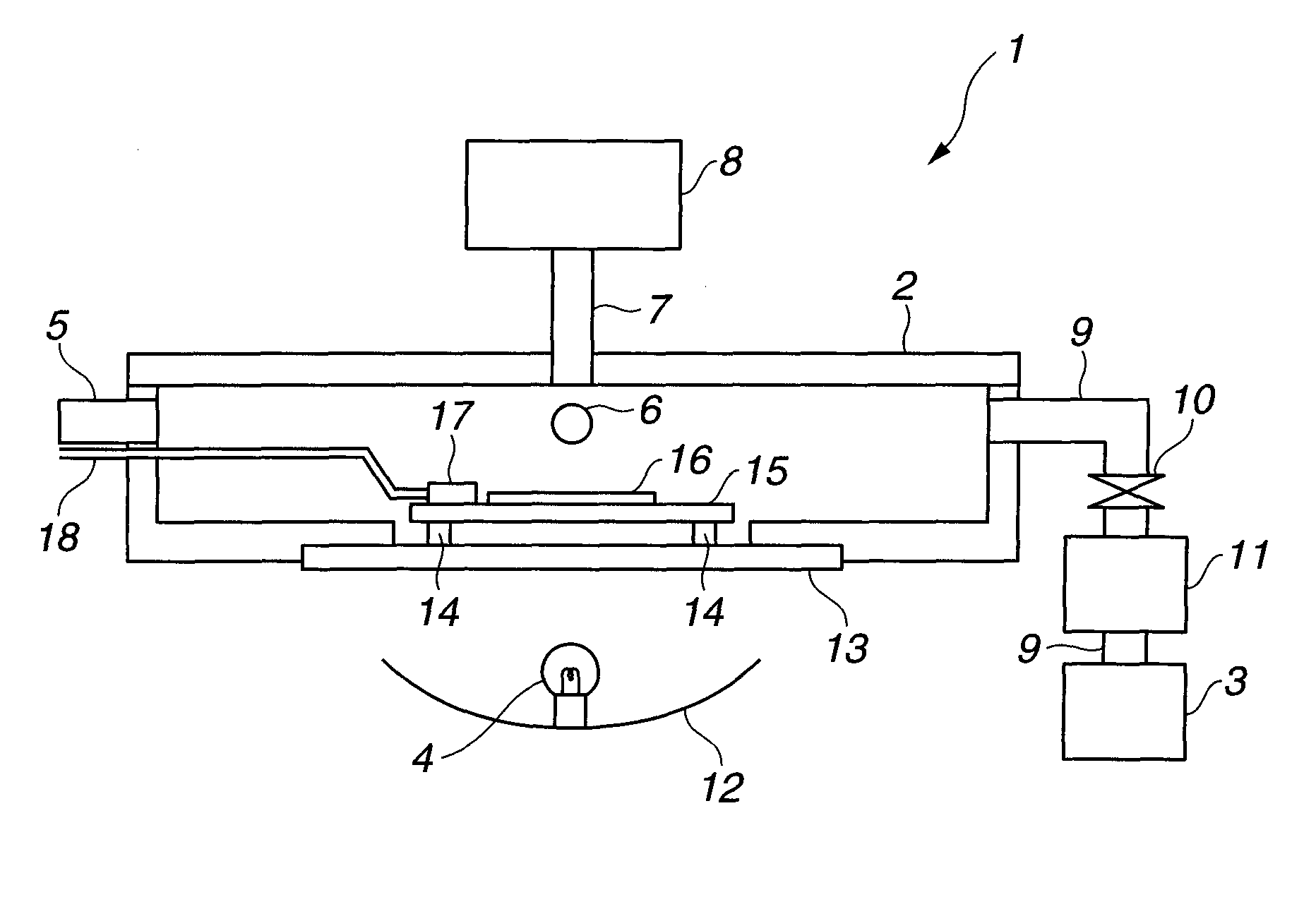

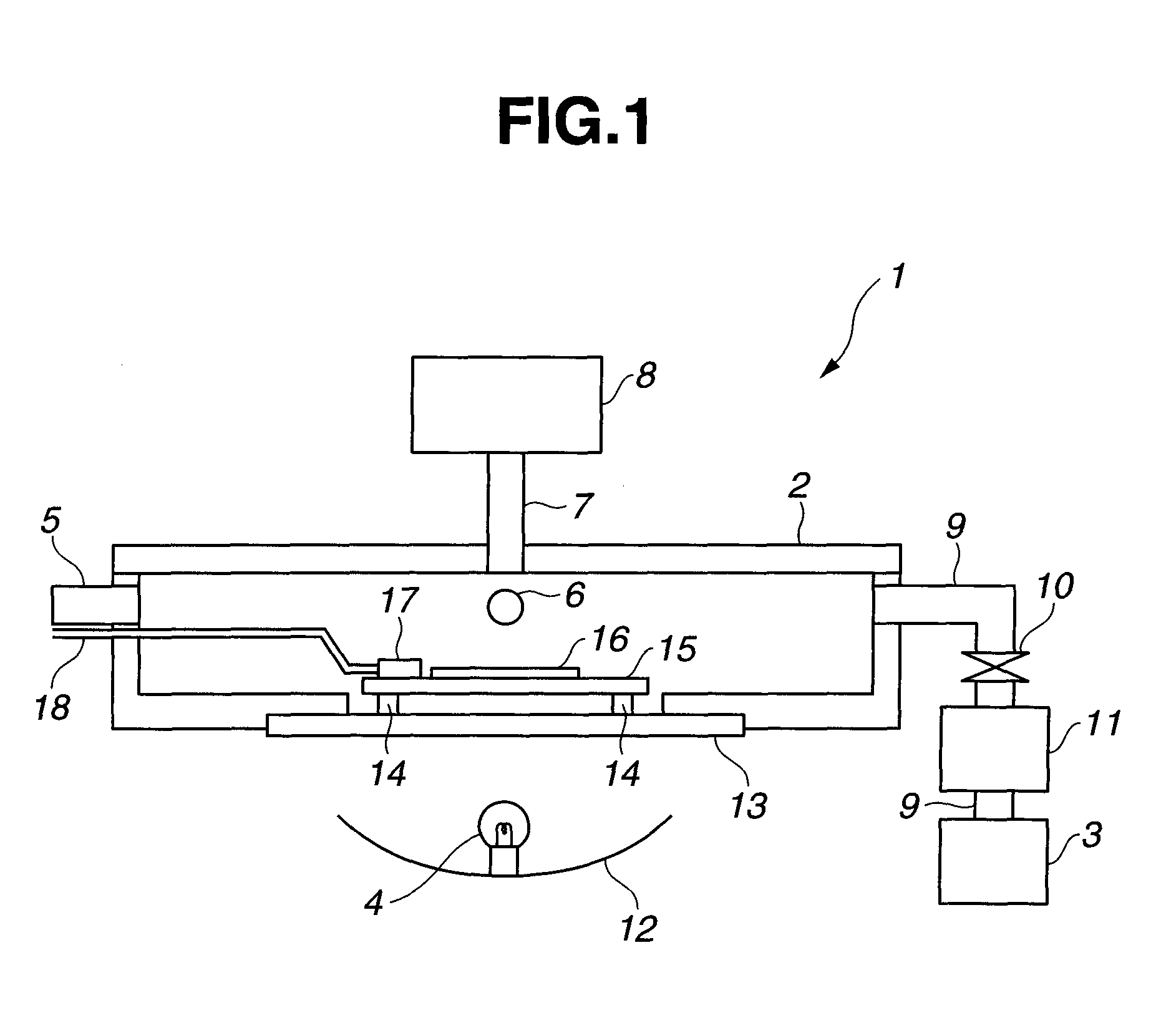

Method of removing resist and apparatus therefor

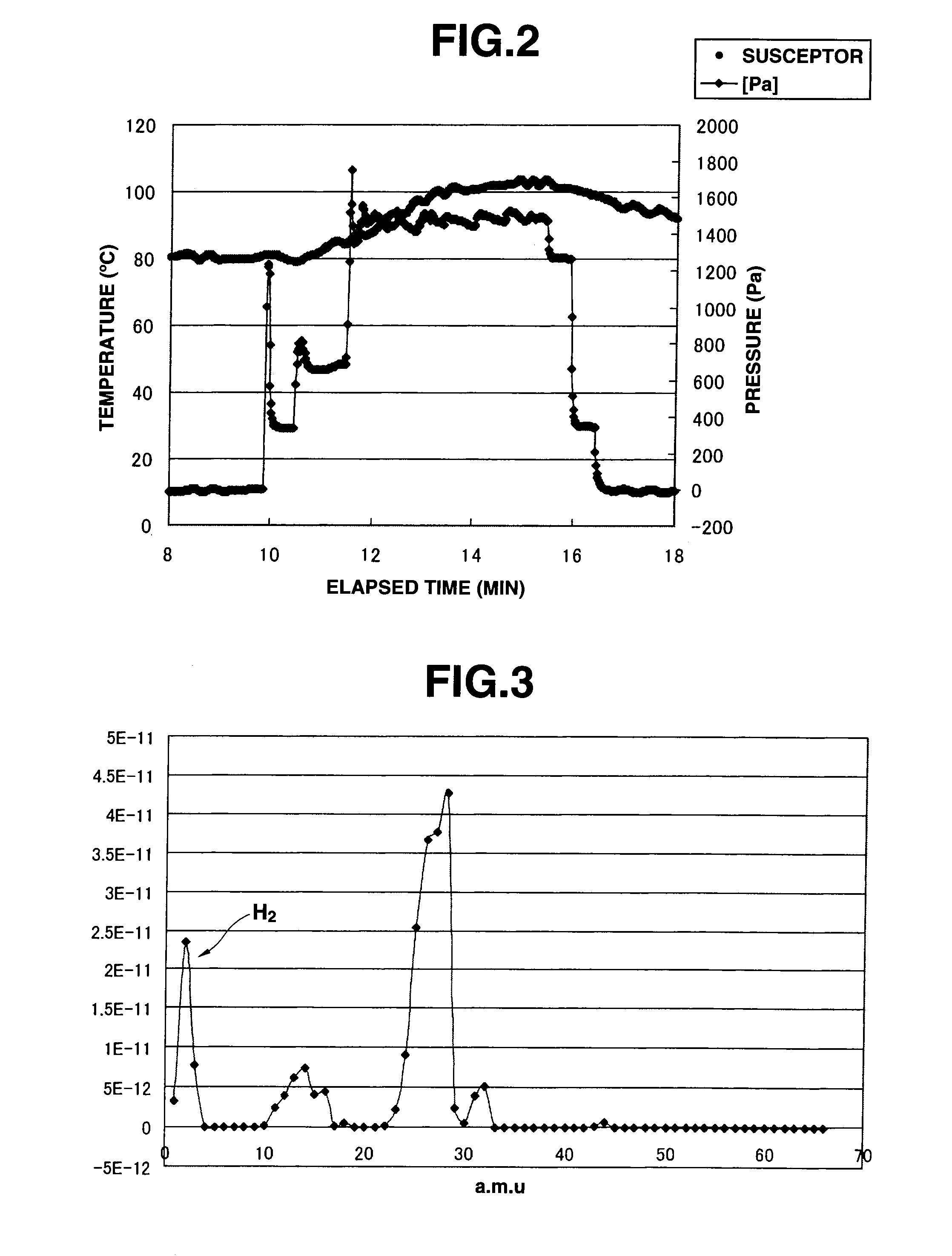

ActiveUS20100139708A1Easy to moveLow vapor pressureDecorative surface effectsHollow article cleaningResistSusceptor

Owner:MEIDENSHA ELECTRIC MFG CO LTD

Method for predicting height of urban atmospheric mixed layer

InactiveCN102175216AReduce research costsImprove research efficiencyHeight/levelling measurementAtmospheric pressureAtmospheric sciences

The invention discloses a method for predicting the height of an urban atmospheric mixed layer, and is characterized by acquiring current meteorological data of a certain city, wherein the meteorological data is an air temperature T, an atmospheric pressure P, a solar radiation value SR, an air humidity RH, a wind speed WS and a dew point temperature DT; and calculating a predicted value of the height of the atmospheric mixed layer of the city according to a formula that MLH=a1T+a2T+a3SR+a4RH+a5WS+a6DT, wherein the MLH in the formula is the height of the atmospheric mixed layer; and the a1 to a6 in the formula are regression coefficients which are derived from historical meteorological data and historical atmospheric mixed layer height through a statistical multiple linear regression method. By the method for predicting the height of the urban atmospheric mixed layer, a height value of the urban atmospheric mixed layer can be simply, quickly and accurately predicted.

Owner:CENT SOUTH UNIV

Multipurpose purifying water filtration apparatus

InactiveCN101475271ASimple structural designLow costWater/sewage treatment by ion-exchangeWater/sewage treatment bu osmosis/dialysisFiltrationAtmospheric pressure

Owner:庞剑

Characterization method for ionic liquid dissolvability

InactiveCN101470063AImprove solubilityReliable dataWeighing by absorbing componentSolubilityDissolution

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Working defrosting method of variable-frequency air-conditioner

InactiveCN110094832APrecise defrostingEasy accessMechanical apparatusSpace heating and ventilation safety systemsFour-way valveFrequency reduction

The invention discloses a working defrosting method of a variable-frequency air-conditioner. The working defrosting method provides two defrosting modes of defrosting during heating start-up and defrosting during normal working; the function of defrosting during heating start-up of the method comprises the following steps that the outdoor temperature and the coil temperature are judged before start-up is carried out, so that the situation that the heating effect is reduced due to the thickening of a frost layer caused by the fact that a heating mode is directly started is avoided, and meanwhile, an indoor evaporator is preheated, so that the air conditioner can enter a heating state faster, and the heating effect is better; and according to the method, the defrosting process during normalworking comprises the following steps that a compressor is subjected to frequency reduction treatment, after working stably, the compressor stops working, the opening degree of an electronic expansionvalve is maximum, enough time is given to balance the air pressure difference brought by airflow impact, and then a four-way valve is reversely rotated, so that the noise is reduced, and the better experience effect is given to the user.

Owner:CHUZHOU XINGLIAN ELECTRONICS CO LTD

Method for improving performance of superplastic formed component material

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Electrostatically atomizing device

InactiveUS20100133367A1Efficient dischargeBlock wellBurnersFree-cooling systemsEngineeringAtmospheric pressure

Owner:PANASONIC CORP

Pressure pulse testing machine

InactiveCN103499415AFast loadingQuick uninstallFluid pressure measurementNatural productPulse test

The invention provides a pressure pulse testing machine, and aims to solve the problem of inaccurate control of measuring parameters and waveforms due to pressure difference existing among each pressurizing point in the conventional pressure pulse technology although air pressure serving as a constantly-existing natural product can be used for effectively detecting a pressure sensor. Technical key points of the invention are that an air storing cabinet comprises a primary pressure cavity and a secondary pressure cavity; the primary pressure cavity is connected with an air pump; the upper part of the secondary pressure cavity is provided with an elastic connector, an air inlet servo valve and a standard pressure cavity in sequence; the side wall of the standard pressure cavity is provided with an exhaust electromagnetic valve group and an adjusting electromagnetic valve; pressurizing holes are uniformly distributed in the upper surface of the standard pressure cavity; a pressure sensor of a standard sensor with a waveform feedback measuring function is arranged in at least one of the pressurizing holes. The pressure pulse testing machine has the positive effects that fatigue test can be performed on a tested object under the condition that the tested object is not damaged. The pressure pulse testing machine further has the characteristics of high control degree, low cost, stability, reliability, high practicability and the like.

Owner:SHENYANG ACAD OF INSTR SCI

SiALONC ceramic with hydrogen silicone oil and Al powder and production thereof

Owner:HARBIN INST OF TECH

Applicator and method for transferring dispersion liquid

ActiveUS20080210160A1Bubble generating areReduce solubilityLiquid degasificationPressure pumpsBuffer tankDissolution

The present invention provides applicators reducing generating bubble. Dispersion liquid is supplied while the pressure of a circulation tank on the delivery side is lower than the atmospheric pressure but higher than the pressure of the space in buffer tanks. The dispersion liquid in the discharge chambers is recovered while the pressure in a circulation tank serving as recovery destination is lower than the atmospheric pressure. Gas dissolution can be reduced because the dispersion liquid does not come into contact with gases at pressures higher than the atmospheric pressure and engulffing gas or deformation of solid microparticles can be avoided because no pump is used.

Owner:ULVAC INC

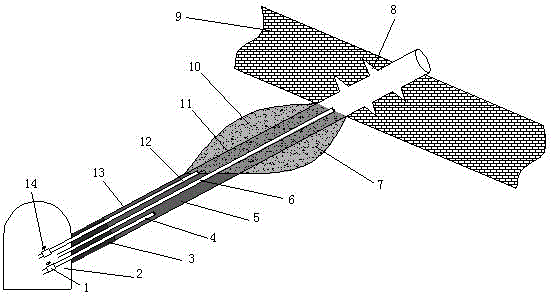

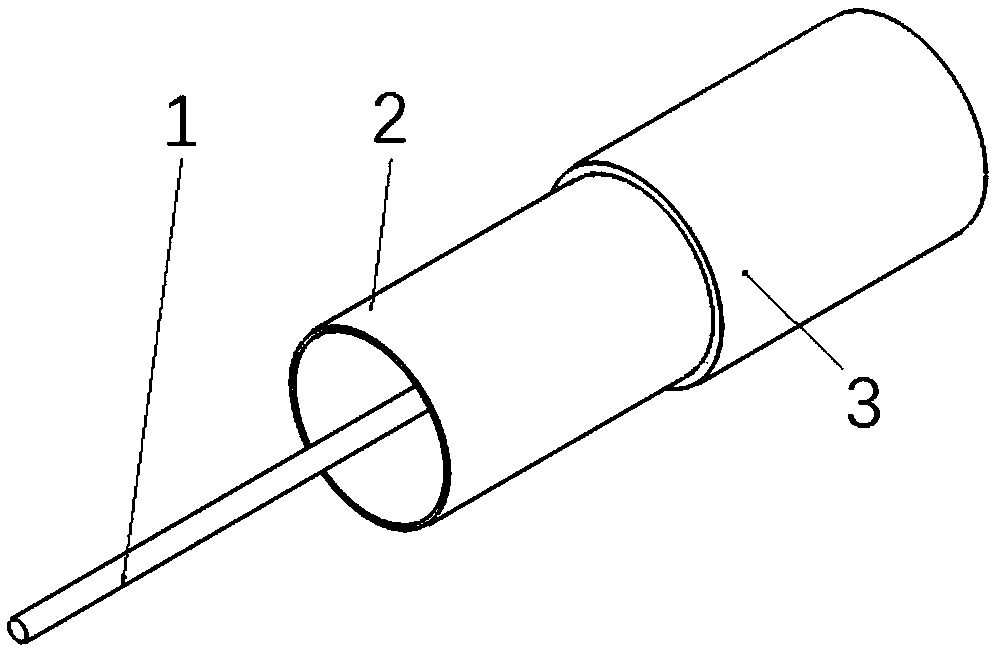

Spacecraft deorbiting electrodynamic tether

ActiveCN109264036AImprove stabilitySimple state controlCosmonautic vehiclesCosmonautic partsEffective lengthEngineering

Owner:BEIHANG UNIV

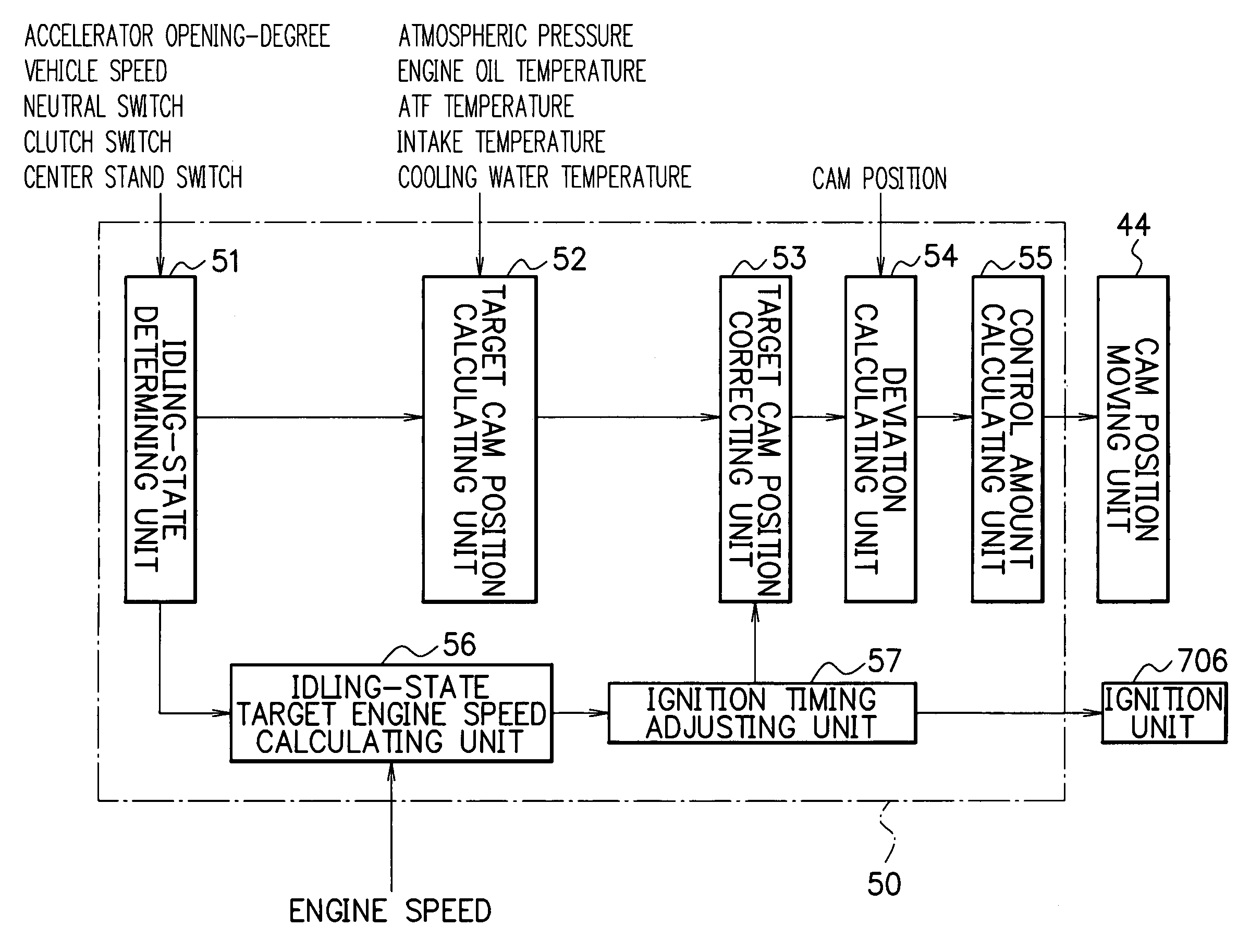

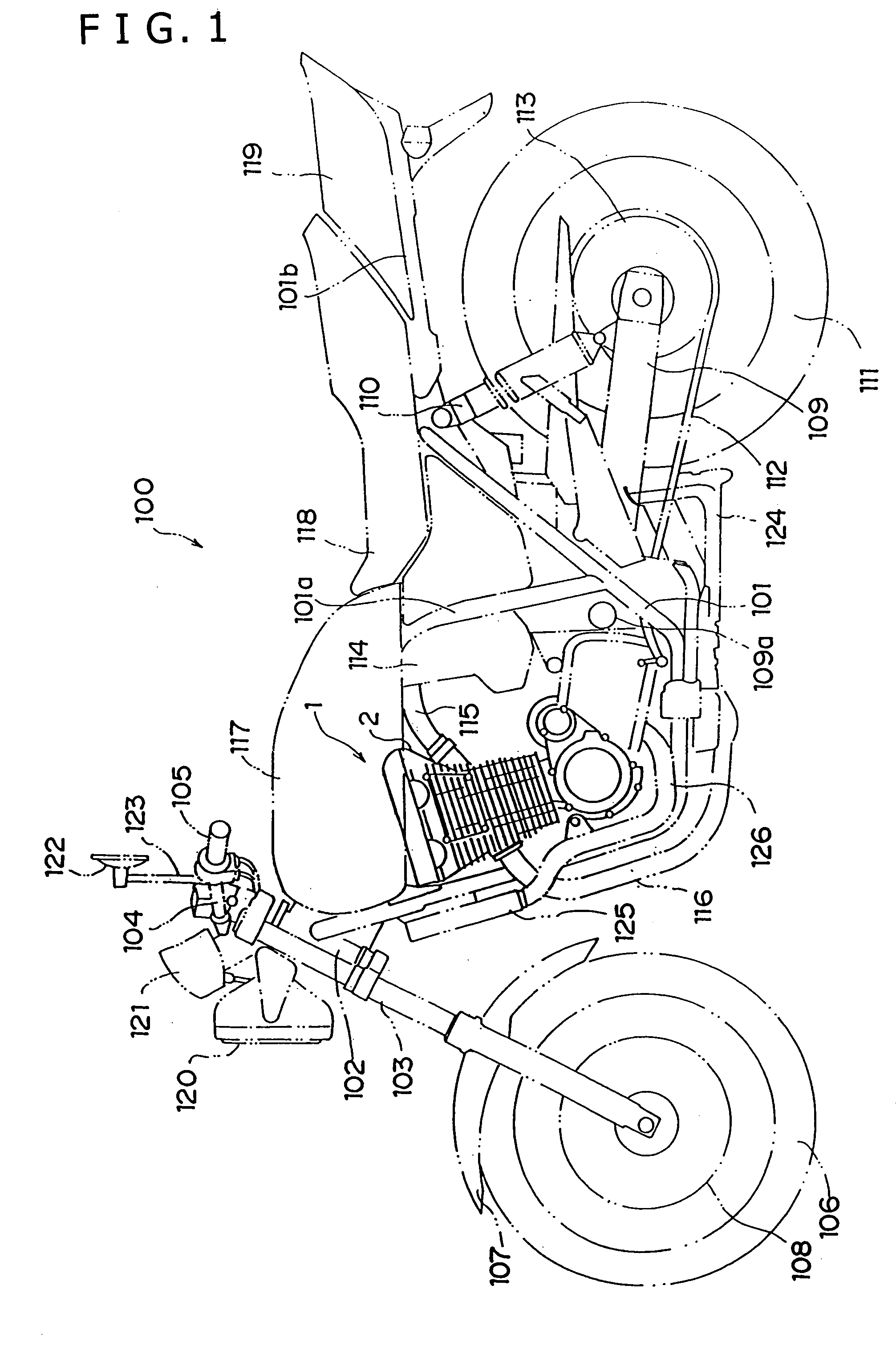

Control device and control program product for engine

Owner:SUZUKI MOTOR CORP

Gas producing agent for fire extinguisher

The invention discloses a gas producing agent for a fire extinguisher. The gas producing agent comprises, by weight, 40-80 parts of a strontium salt oxidant, 10-20 parts of a combustible agent, 2-10 parts of an additive which is a mixture of one or more of carbon powder, magnesium carbonate, calcium carbonate and potassium feldspar. The strontium salt oxidant is continuously reacted with the combustible agent, wherein the carbon in the additive also participates in the reaction to provide continuous pushing force for a fire extinguishing agent, thereby improving fire extinguishing effect. One part of the fire extinguishing agent in the fire extinguisher, under the effect of air pressure, is pushed out by pressure, and the other one part is siphoned and is entrained out by air flow under the effect of subsequent air flow, thereby reducing residue of the fire extinguishing agent and improving the fire extinguishing effect.

Owner:YANGZHOU KAILUNDA TECH CO LTD

Wiring harness automatic gluing UV curing device and production process

ActiveCN110560333AHigh degree of automationImprove work efficiencyPretreated surfacesCoatingsUV curingSwitch box

The invention discloses a wiring harness automatic gluing UV curing device and a production process in the technical field of UV curing. The device comprises a frame; a box body is arranged at the bottom of the frame; double doors are hinged to the front surface of the box body; an exhaust port is formed in the back end of the bottom of the right side surface of the box body in a penetrating mode;an external air pressure two-connected piece is arranged at the bottom of the right side surface of the box body through a groove; a three-color alarm lamp is welded on the upper surface of the framethrough a support rod; a switch box is screwed in the center of the front surface of the frame; and two sets of gantry frame stand columns are symmetrically arranged at the top of the box body through a worktable left and right. Firstly, products are placed in a left overturning table; through descending of a Z-axle module, a glue dispensing valve is controlled to finish coating of UV glue through discharge of the glue from a needle head of a glue dispensing needle; products are dried through UV rays irradiated by an UV lamp; a Y-axle module workstation on the left side is used for coating, and a Y-axle module workstation on the right side is used for changing products, so that the automation degree is high; and the change is finished through left and right sets of overturning tables, sothat the gluing and curing speed is accelerated, the time is saved, and the working efficiency is high.

Owner:SUZHOU GREAT ELECTRONIC TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap