Electrostatically atomizing device

a technology of atomizing device and atomizing chamber, which is applied in the direction of air humidification system, lighting and heating apparatus, heating types, etc., can solve the problems of inefficiency in discharging the mist generated in the atomizing barrel outward, and difficulty in efficiently discharging the mist out of the outlet port, so as to reduce the turbulent flow, efficiently discharging the mist out of the housing, and reducing the effect of turbulent flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

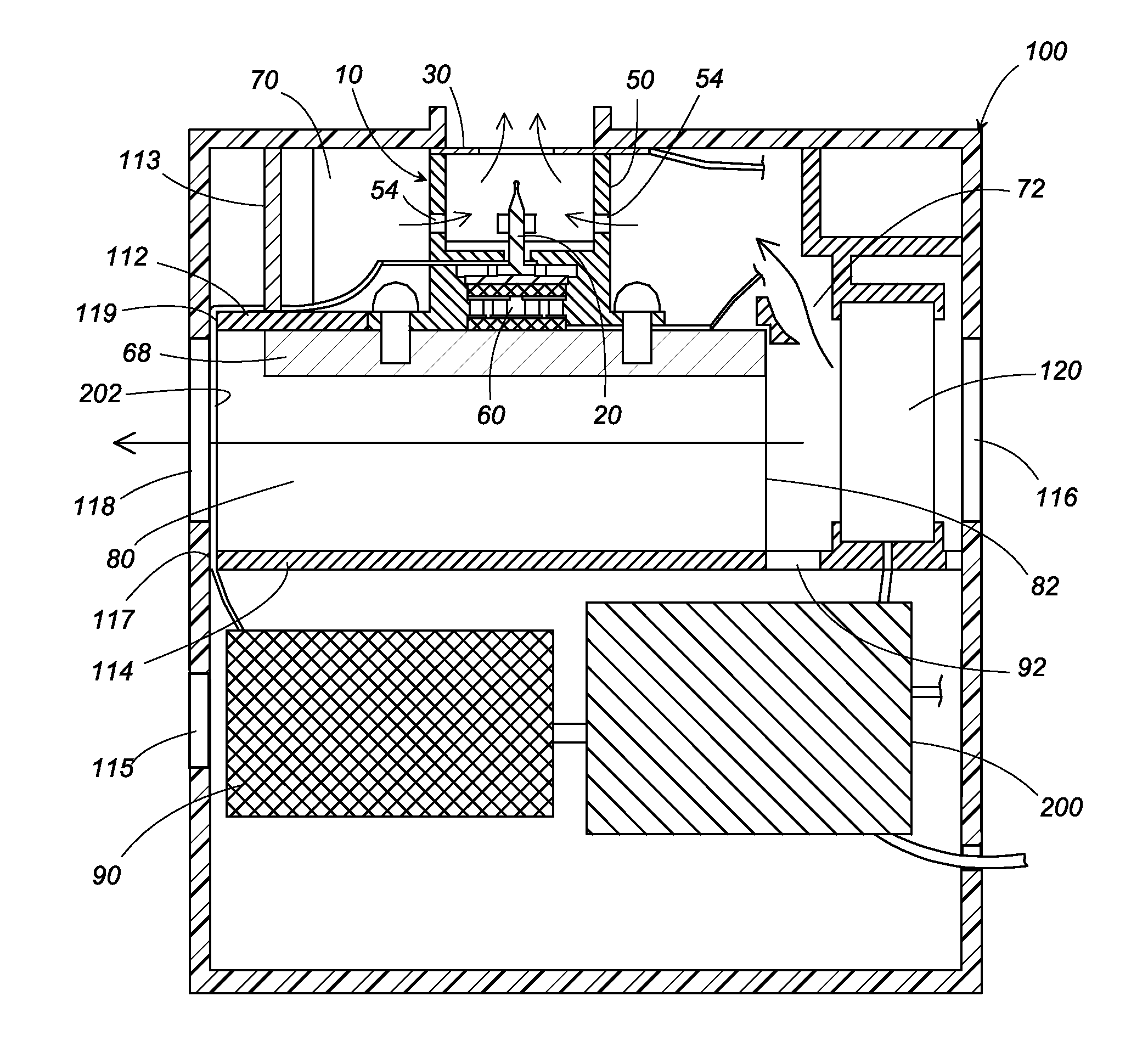

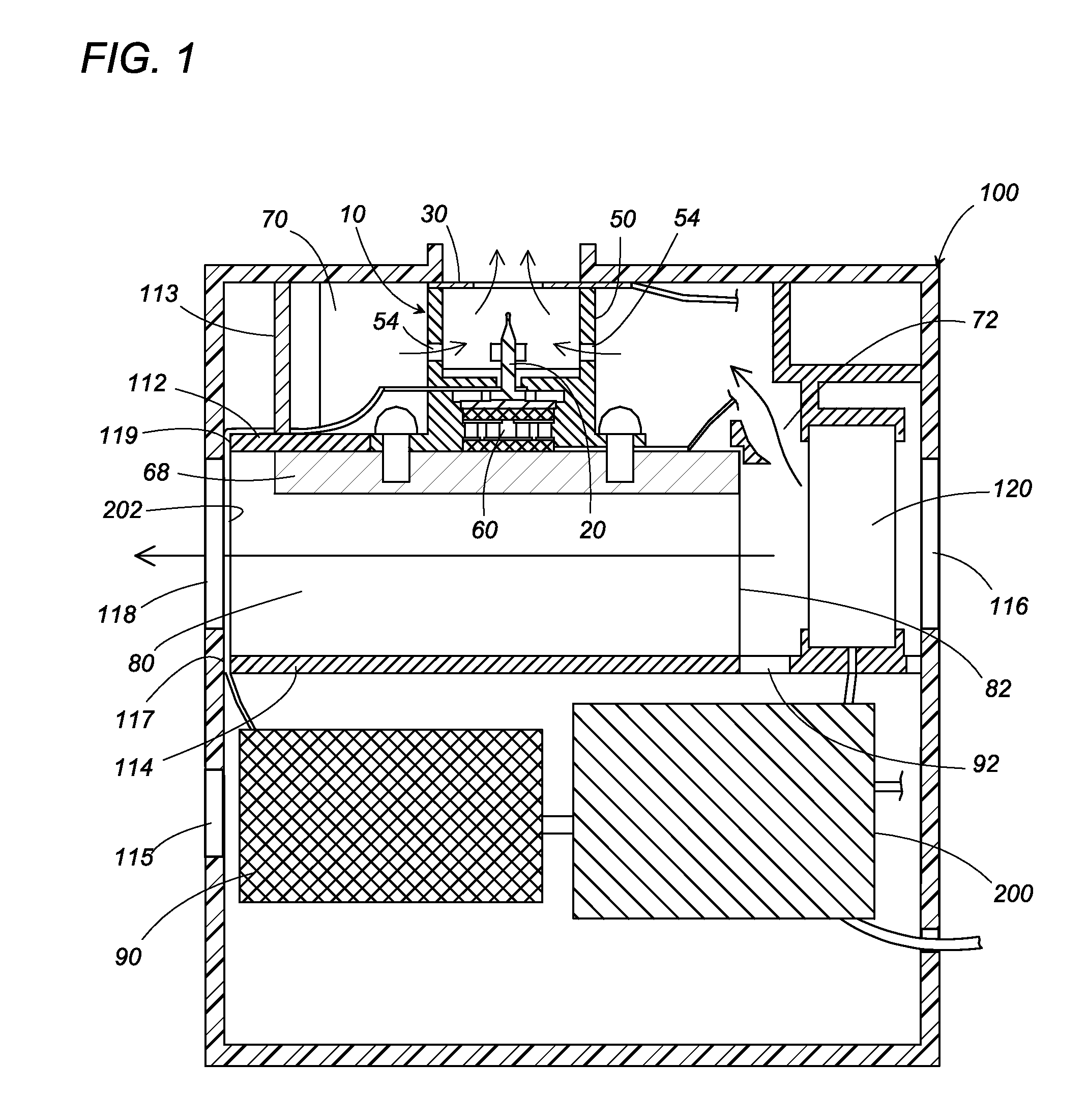

[0018]An electrostatically atomizing device in accordance with a first embodiment of the present invention is explained with reference to the attached drawings. As shown in FIG. 1, the electrostatically atomizing device includes an electrostatically atomizing unit 10 and a housing 100 which accommodates the unit. The housing 100 has, as shown in FIG. 4, a casing body 101 and a casing cap 102 which covers one side of the casing body 101.

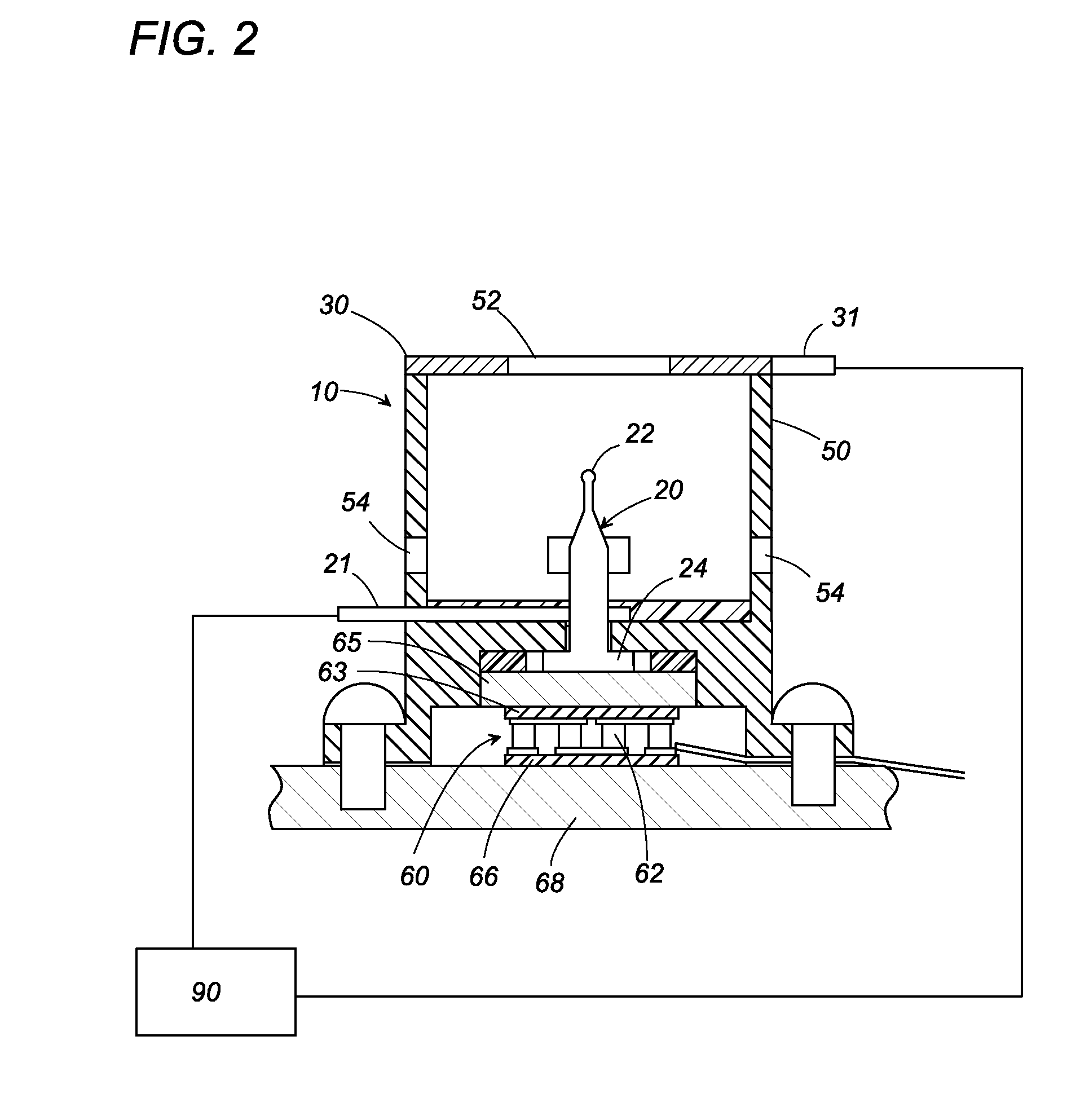

[0019]As best shown in FIG. 2, the electrostatically atomizing unit 10 includes an emitter electrode 20, an opposed electrode 30, and an atomizing barrel 50 which carries a heat exchanger 40. The emitter electrode 20 is disposed on a central axis of the atomizing barrel 50, and has its rear end fixed to a bottom face 51 of the atomizing barrel 50 so as to project its tip within the atomizing barrel 50. The opposed electrode 30 is configured into a ring shape having a circular window in its center, and is fixed to the front end of the atomizing barrel 50

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap