Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

145 results about "Hydraulic pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Brake System for Motor Vehicles and Method for Operating a Brake System

InactiveUS20140203626A1Reduce travel requirementsFluid braking transmissionBrake action initiationsElectricityAtmospheric pressure

A brake system includes a hydraulic actuating unit, which can be actuated by way of a brake pedal, a travel simulator interacting with the hydraulic actuating unit, a pressure medium reservoir under atmospheric pressure assigned to the hydraulic actuating unit, a first electrically controllable pressure supply device, a second electrically controllable pressure supply device, an electronic control unit and an electronically controllable pressure modulation device for setting wheel-specific brake pressures. The brake system preferably operates in a “brake-by-wire” mode but can also operate in a fallback mode. The second electrically controllable pressure supply device can provide boost volume during braking in a fallback mode.

Owner:CONTINENTAL TEVES AG & CO OHG

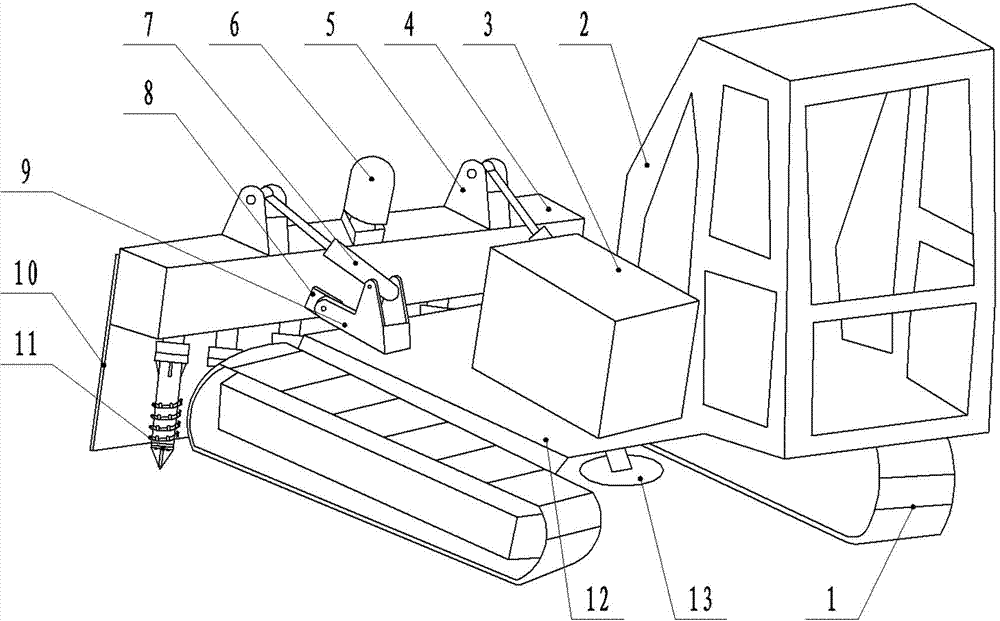

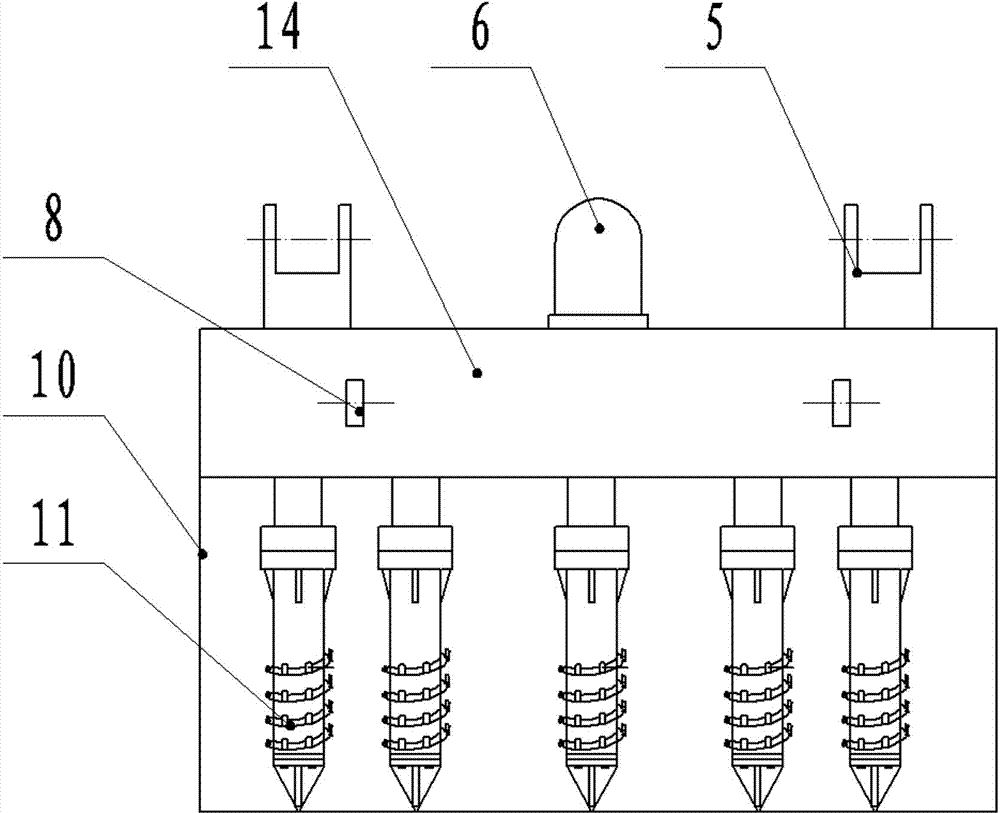

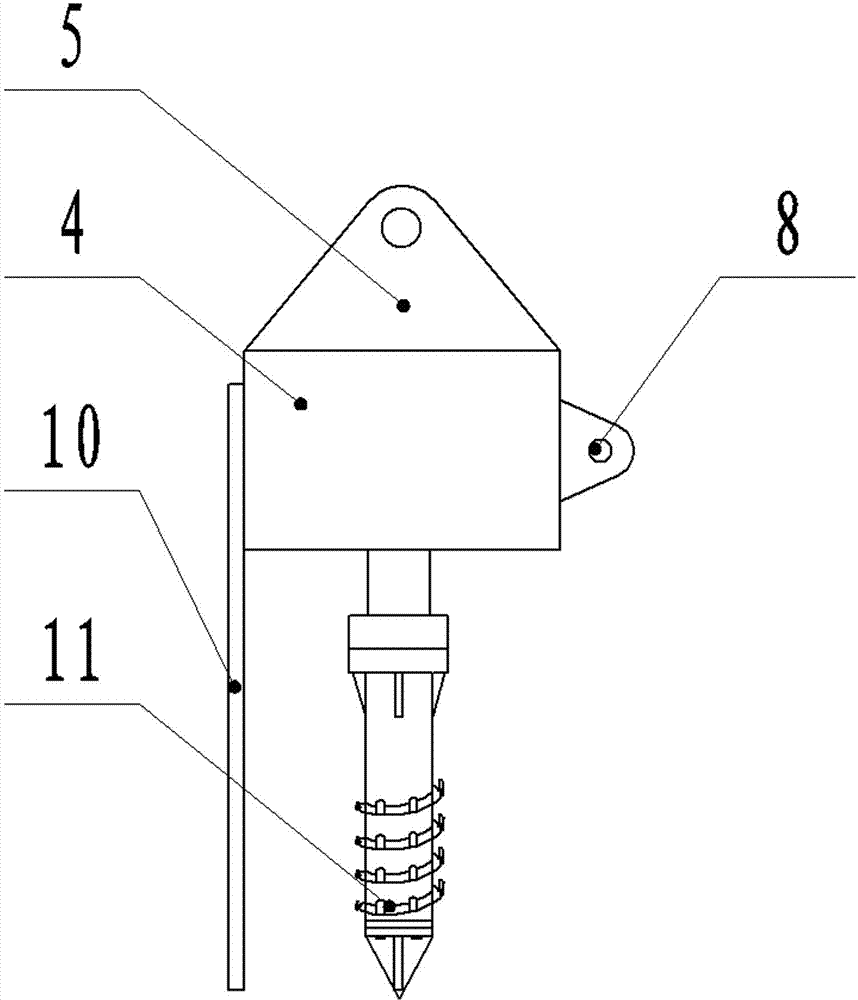

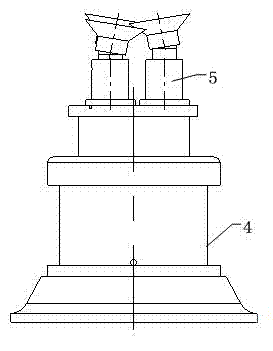

Hydraulic deep and rotary cultivation powdery ridge machine

ActiveCN104255090AIncrease productionIncrease oxygen contentSpadesTilling equipmentsHydraulic motorHydraulic cylinder

Owner:GUANGXI WUFENG MACHINERY CO LTD

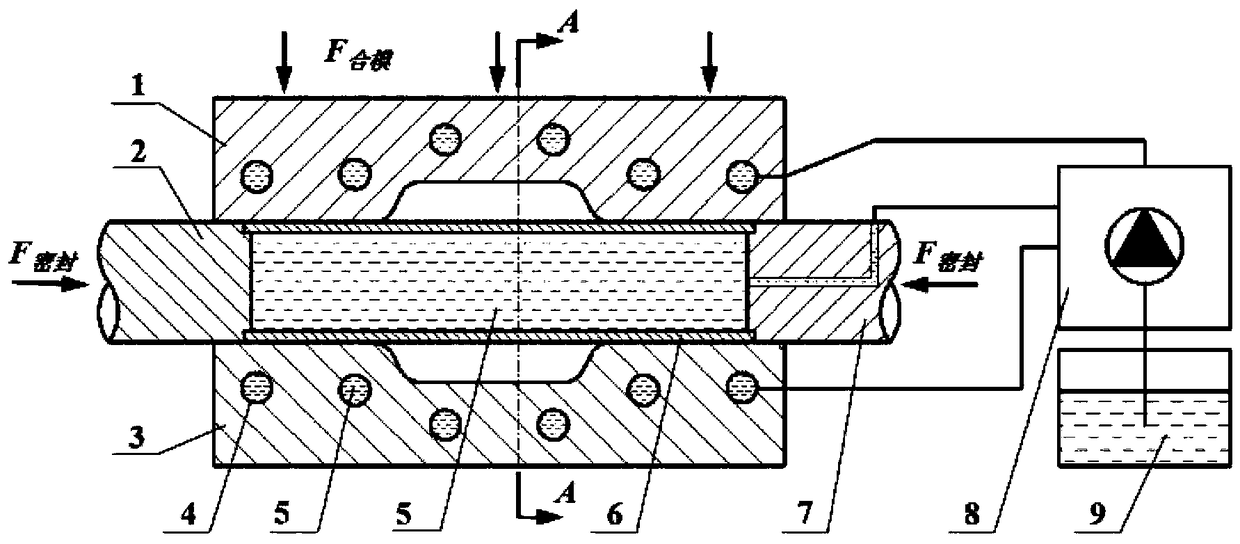

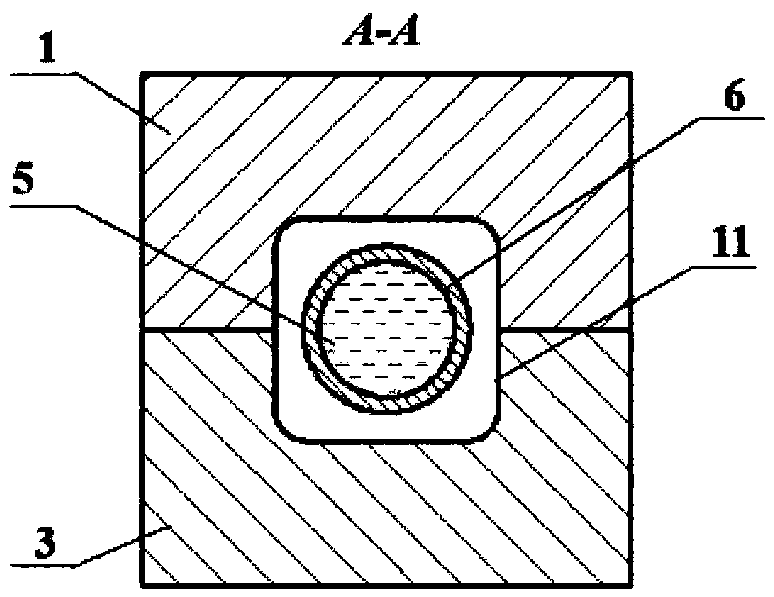

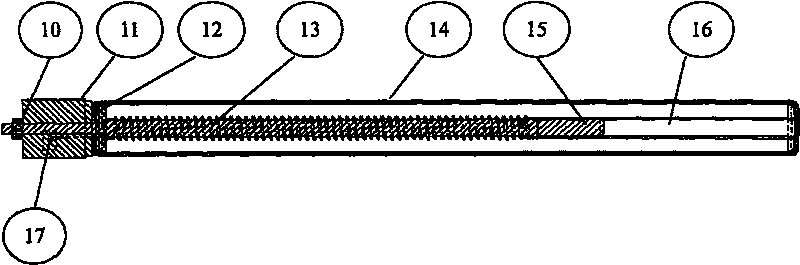

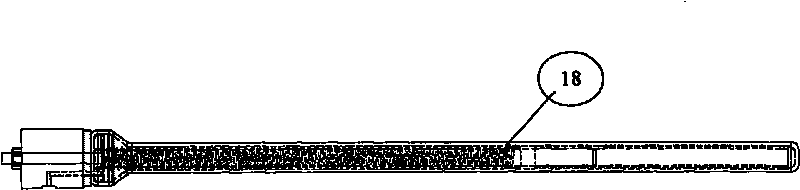

Method for performing expansion test of combined loads on solid expansion pipe

InactiveCN102023118AMeasure displacement in real timeMeasure speed in real timeMaterial strength using tensile/compressive forcesMechanical stretchingData acquisition

The invention relates to a method for performing an expansion test of combined loads on a solid expansion pipe, which comprises the following steps of: 1) preparing a sample and an expansion cone; 2) expanding an end part; 3) preparing an expansion test; 4) performing the expansion test, wherein the expansion test can be any one of the following tests: a, a mechanical stretching expansion test; b, a hydraulic expansion test; and c, a mechanical hydraulic combined expansion test; and 5) performing data acquisition and data analysis. In the method, the mechanical stretching expansion test or the hydraulic expansion test or the combined expansion test of mechanical stretching and hydraulic pressure is realized, and the displacement, speed, stretching loads and hydraulic pressure of the expansion cone and the radial deformation data of the solid expansion pipe in the process of the expansion test can be measured in real time by using axial controlled mechanical stretching loads and the hydraulic pressure and matching the corresponding expansion conical head. The invention provides a method for the expansion test for simulating actual working conditions in laboratories effectively for the detection of expansion performance and study evaluation of the solid expansion pipe and the study and improvement of a connecting structure of the expansion pipe.

Owner:XIAN SANHUAN TECH DEV GENERAL

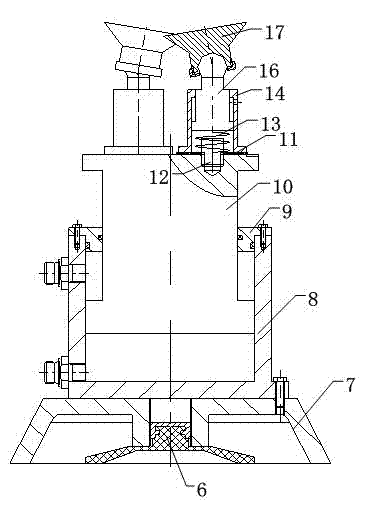

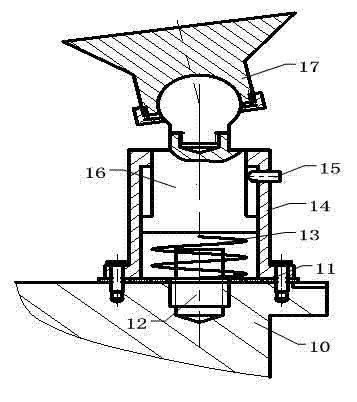

Hydraulic well packer

InactiveUS20100038073A1Big confidenceFacilitated releaseFluid removalSealing/packingEngineeringWater well

A hydraulic packing device for wellbores, known in the art as “packer”, which is a retrievable device and is used in downhole operations, that is also part of the tools used in wellbore operations, such as oil, water or gas wells, or wells of similar fluids is provided. More specifically, the main object of the invention is a double-latch packer with hydraulic fastening and packing pressure function, double retreat integrated assembly, with elements of rubber packing, which has the advantage of being able to work selectively on facilities with one packer or multiple packers, with the advantage of fastening or releasing the packer selectively in oil, water or gas wells, or wells of similar fluids.

Owner:CARRO GUSTAVO IGNACIO

Supporting device and supporting method for machining propeller blade

InactiveCN102886699AIncrease stiffnessStable supportPositioning apparatusMetal-working holdersHydraulic cylinderPropeller

Owner:JIANGSU UNIV OF SCI & TECH

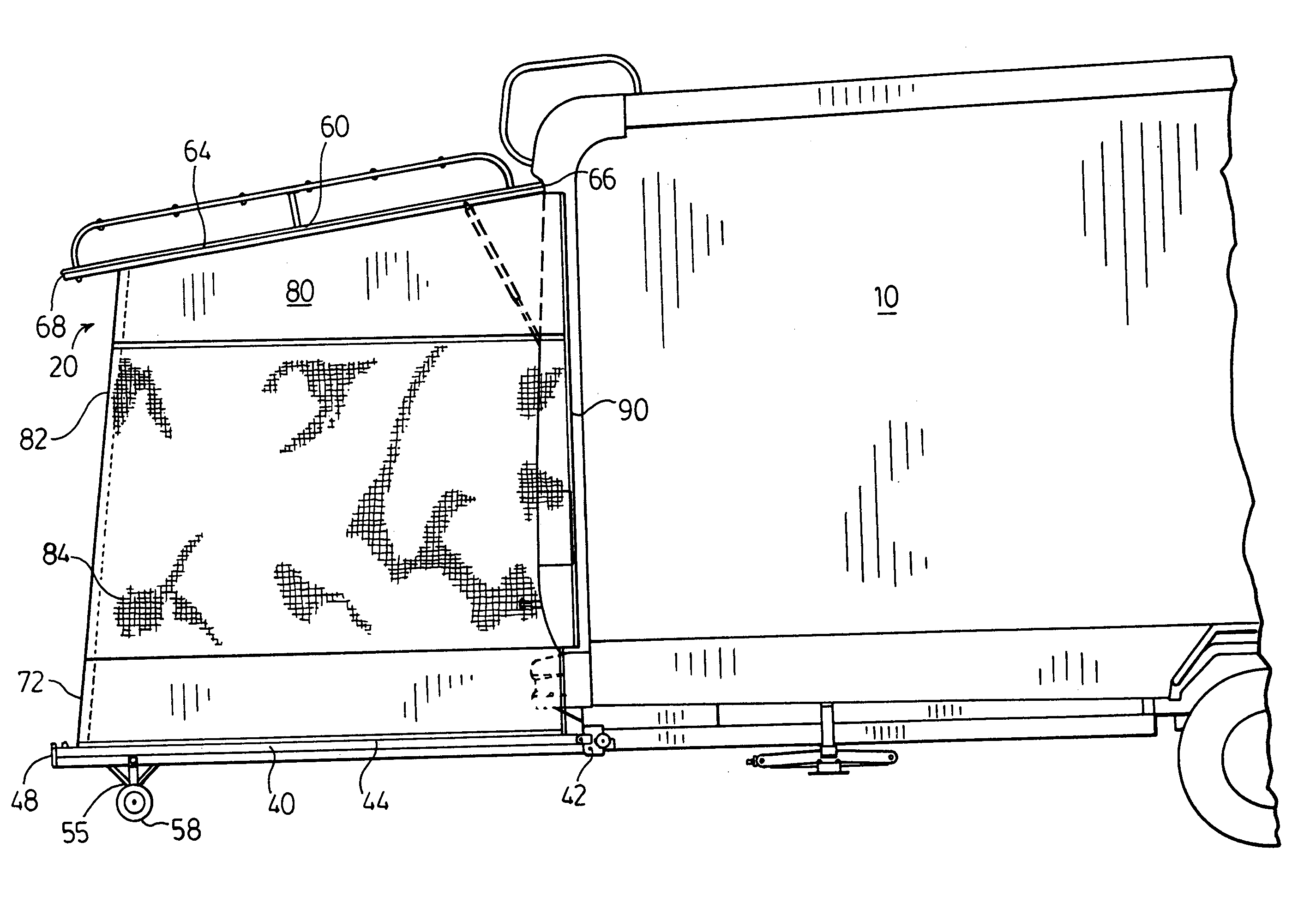

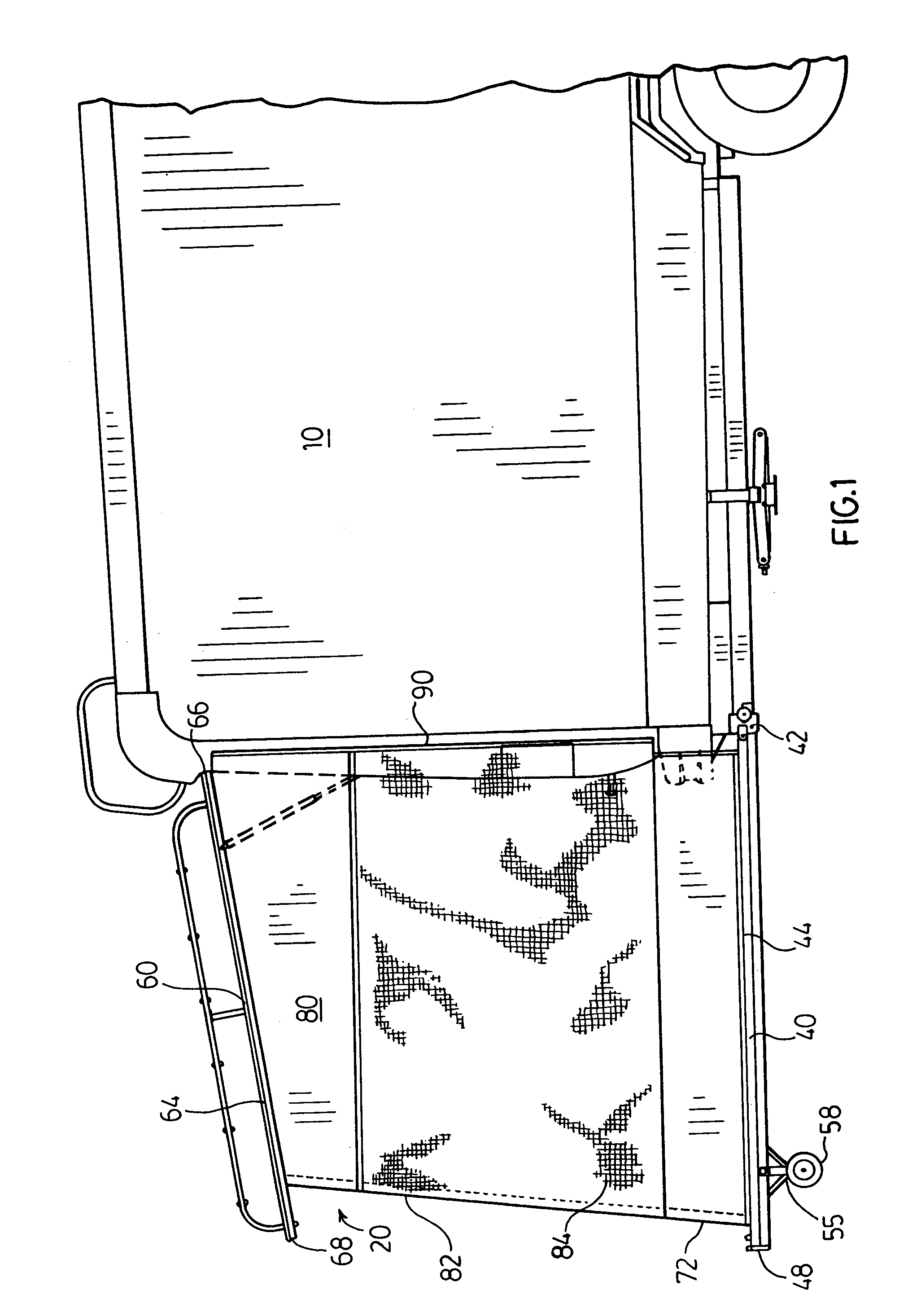

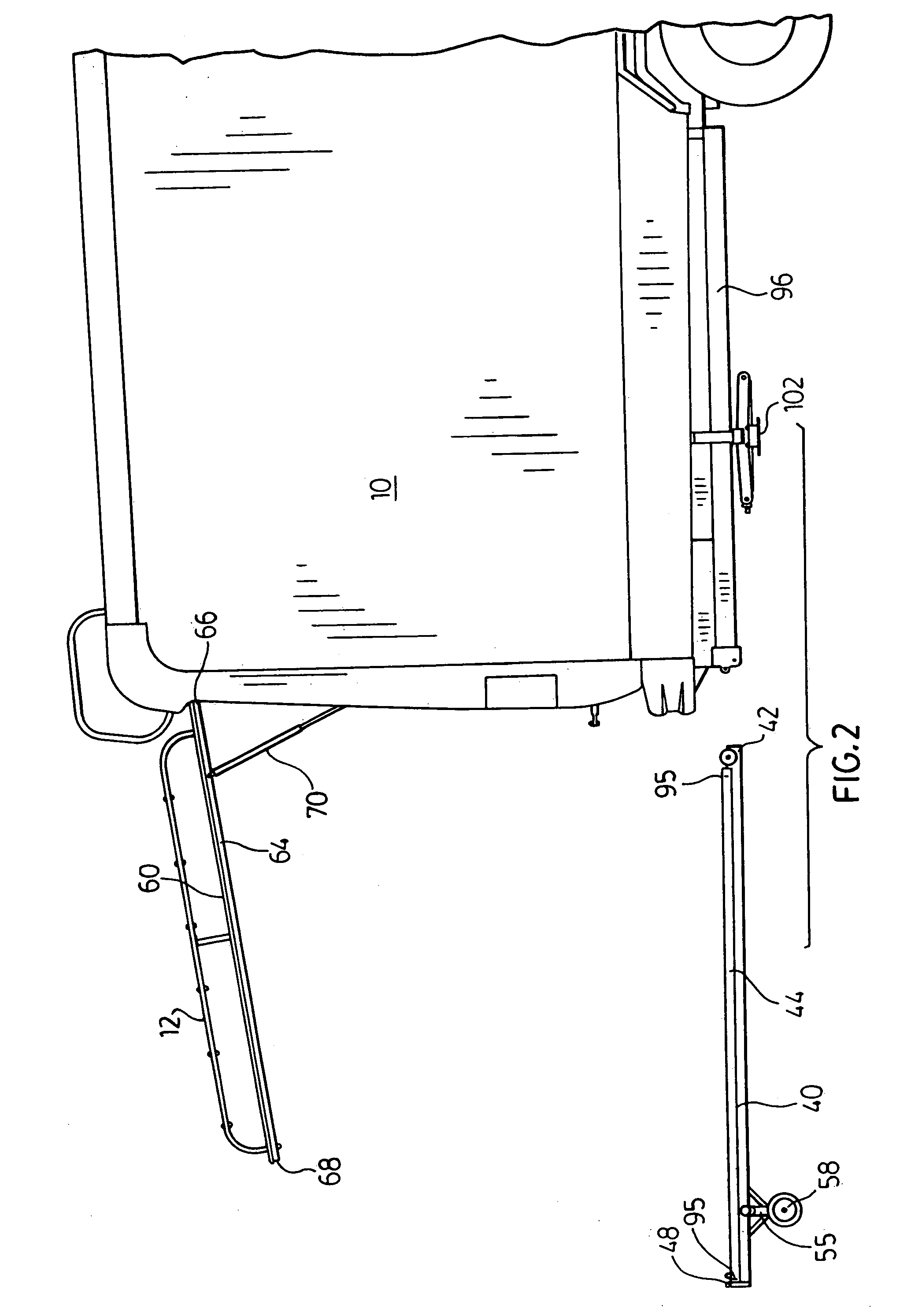

Extendable trailer patio room

InactiveUS6971707B1Vehicle with living accommodationItem transportation vehiclesEngineeringHydraulic pressure

Owner:HEARTLAND RECREATIONAL VEHICLES LLC +1

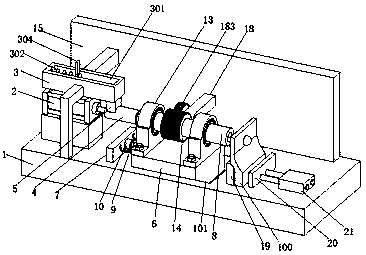

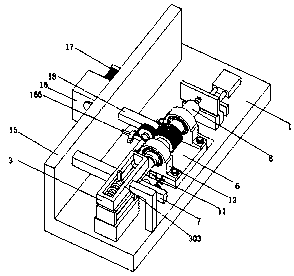

Cylinder liner combined machining machine tool

ActiveCN104801977AMeet the needs of basic functionsSimple structureTailstocks/centresOther manufacturing equipments/toolsHigh volume manufacturingEngineering

The invention relates to a cylinder liner combined machining machine tool. The machine tool comprises a machine tool body, wherein a motor device, an apron driving device, a tailstock driving device and three sets of guide rails are installed on the machine tool body, an upper apron is installed on the upper set of guide rails, an external turning tool is installed on the upper apron, a down-cutting device is installed on the lower set of guide rails, a facing tool set is installed on the down-cutting device, a headstock and a double-station complex programming tailstock are installed on the main guide rails in the middle, a headstock spindle is driven by the motor device to rotate, a boring tool and an expansion combination device are installed at the front end of the headstock spindle, a material pushing device is installed on the top of the headstock, and the double-station complex programming tailstock is a tailstock device which is provided with a telescopic hydraulic chuck mechanism and a hydraulic center mechanism at the same time. According to the cylinder liner combined machining machine tool, the machining efficiency and the accuracy of cylinder liners can be greatly improved; a production unit can formed when an automatic feeding and discharging device is further arranged so that automatic production can be achieved, the production cost can be greatly reduced, the productivity of enterprises can be improved, and the cylinder liner combined machining machine tool is particularly applicable to mass production of cylinder liners.

Owner:NING XIA XIN RUI CHANG CHENG JI CHUANG YOU XIAN GONG SI

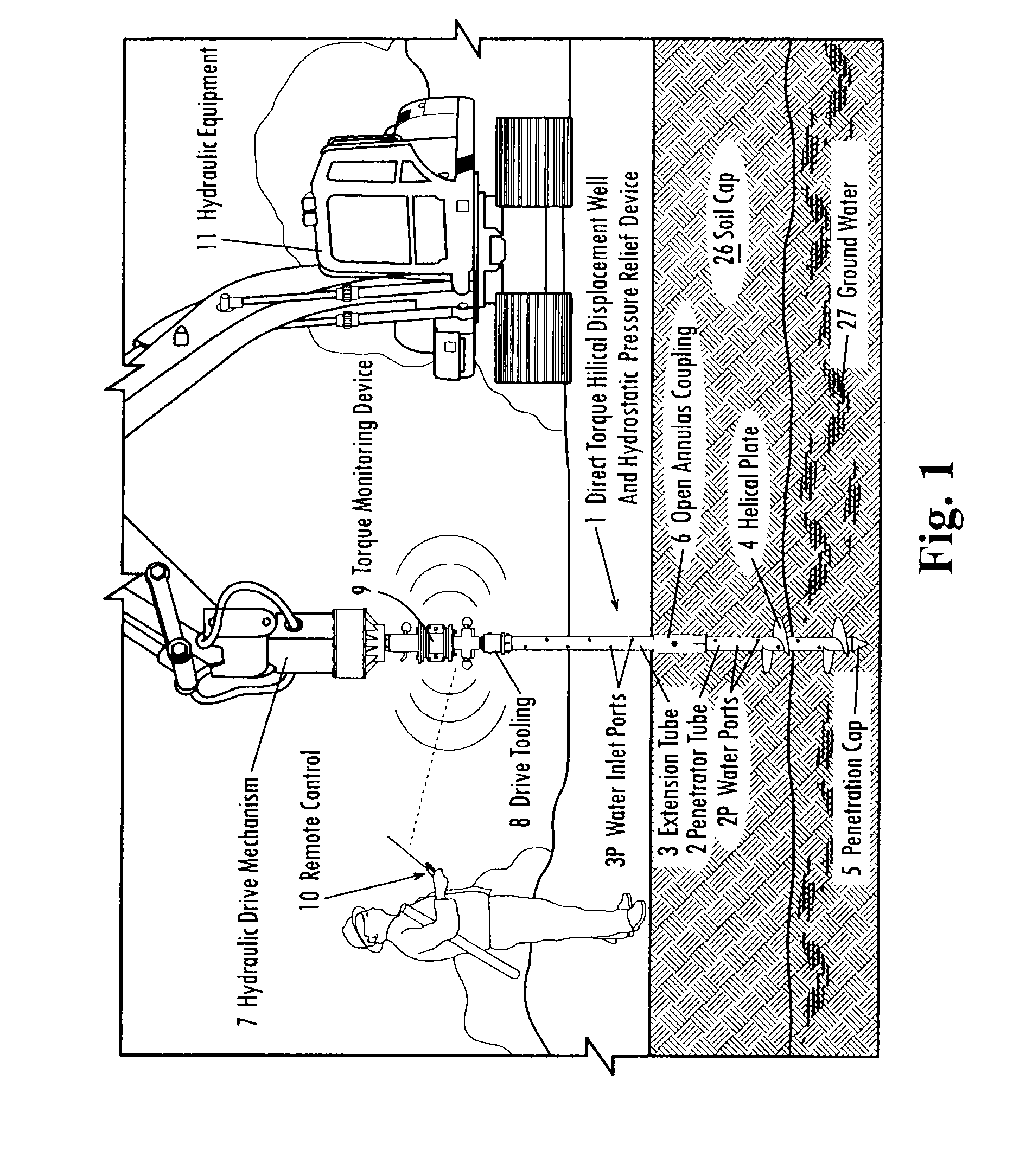

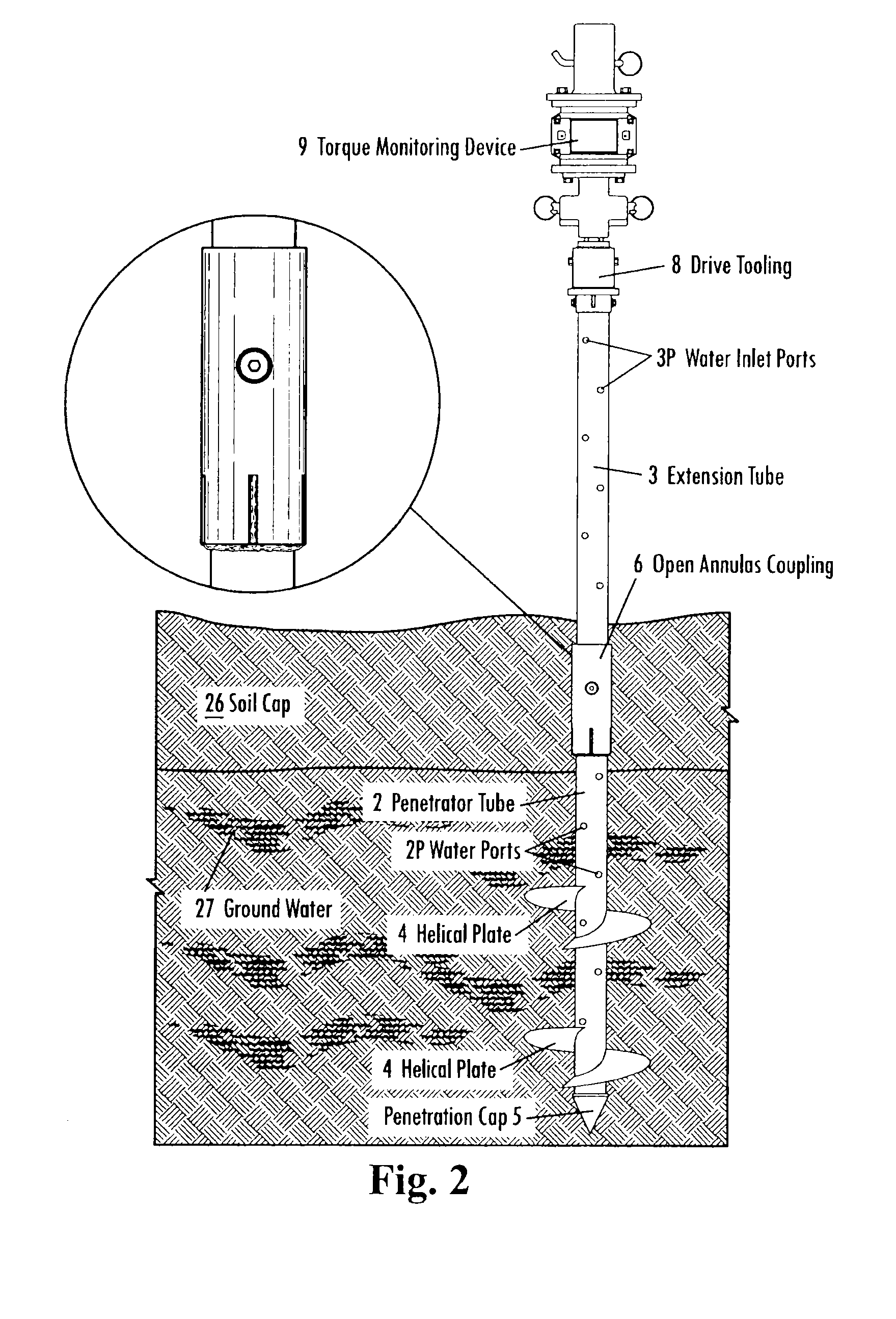

Direct Torque Helical Displacement Well and Hydrostatic Liquid Pressure Relief Device

Owner:QUEEN FRIE A R

Aluminum alloy special-shaped pipe ultralow temperature medium pressure forming method

ActiveCN109500195AAvoid cracking problemsAchieving flexible loadingShaping toolsWeld seamAbnormal shaped

Owner:DALIAN UNIV OF TECH

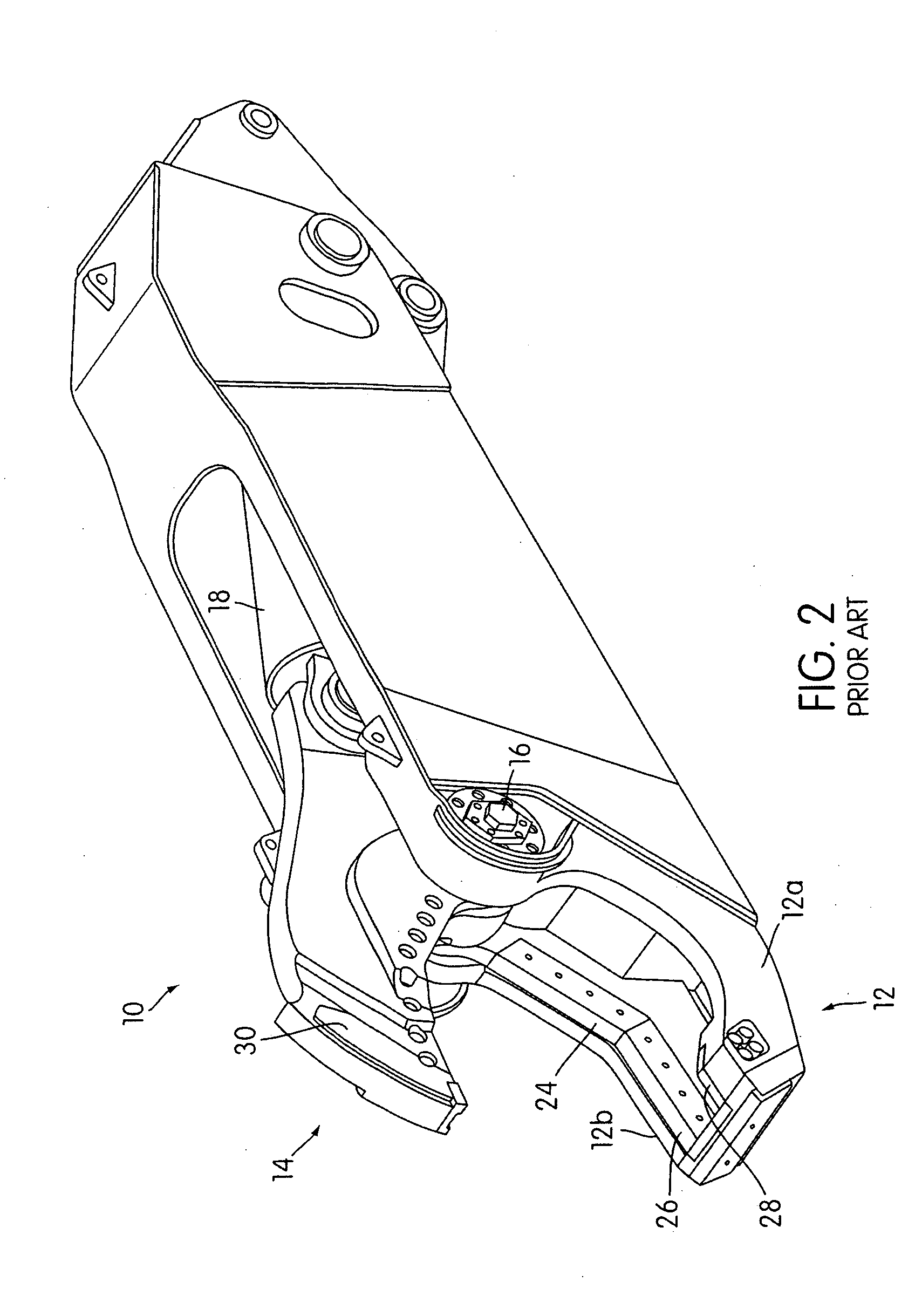

Lubricating system for material-processing shears

Owner:STANLEY WORKS THE

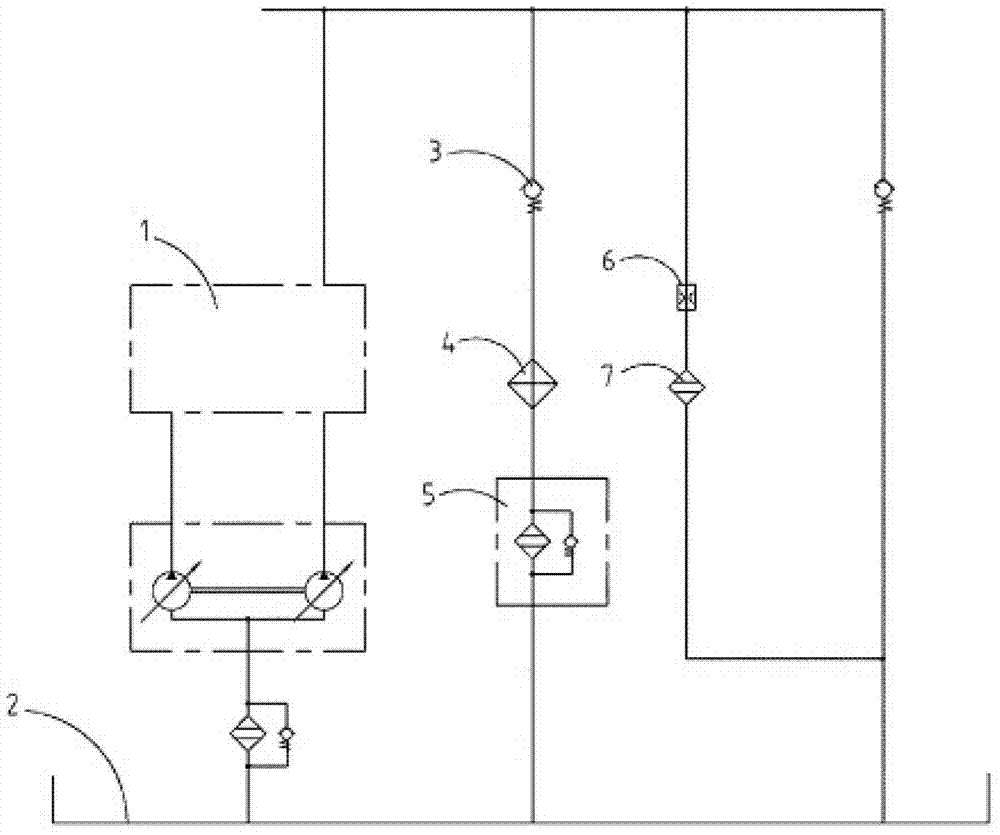

Shuttle valve, shuttle valve driving type device, winding drum brake cylinder control loop and crane

ActiveCN102889398AImprove buffer positioning functionWith buffer positioning functionMultiple way valvesHoisting equipmentsEngineeringShuttle valve

The invention relates to a shuttle valve which comprises a valve rod type valve core (11), when the output end of the shuttle valve is communicated with one of a first input end and a second input end; and one end face of the valve core and an inner wall surface, which is corresponding to one end of a valve cavity form an end face seal, and the periphery surface of the valve core (11) and an inner periphery surface of the valve cavity corresponding to one section form a cylindrical surface sealing, and an output end and the other one of the first input end and the second input end are mutually closed through the end face seal and the cylindrical surface seal. In addition, the invention also provides a shuttle valve driving type device comprising the shuttle valve, a winding drum brake cylinder control loop and a crane. The shuttle valve provided by the invention adopts a unique valve rod type valve core, the double seal is formed in a shuttle valve working process through an end face seal and the cylindrical surface seal, and the shuttle valve is capable of effectively working in a hydraulic system with relatively higher oil pressure; and the shuttle valve can effectively receive impaction and is not easy to transform, the service performance is reliable, the sealing property is relatively better, and the service life of the products is observably prolonged.

Owner:CHANGDE ZHONGLIAN ZHONGKE HYDRAULIC

Continuous nut feeding device for automobile part processing

InactiveCN110788607AQuick assemblyRealize continuous assemblyMetal working apparatusIndustrial engineeringHydraulic pressure

Owner:含山县祥瑞运输有限公司

Oil pumping unit dynamic balance timely automatic regulating device and control method thereof

InactiveCN102817588AImprove adaptabilityImprove convenienceFluid removalAuto regulationDynamic balance

The invention provides an oil pumping unit dynamic balance timely automatic regulating device and a method for improving an existing oil pumping unit with a crank and a fixed balance weight by utilizing the device. According to the oil pumping unit dynamic balance timely automatic regulating device, an adjustable balance weight part of the oil pumping unit dynamic balance timely automatic regulating device is arranged on the side surface of the crank, the adjustable balance weight part timely moves on the side surface of the crank so as to excellently regulate the dynamic balance of an oil pumping unit, further, the adjustable balance weight part comprises a carrier and one or a plurality of balance weights, the carrier can move along the crank side surface, the one or the plurality of balance weights is / are detachably arranged on the carrier, a hydraulic mechanism drives the carrier, a control device with a central processing unit (CPU) microprocessor detects the dynamic balance of the oil pumping unit and timely controls the hydraulic mechanism, then the timely dynamic balance control of the oil pumping unit is achieved, thereby the control capacity of the oil pumping unit dynamic balance is improved, simultaneously the electrical energy is saved, and the production cost is reduced.

Owner:孙显清

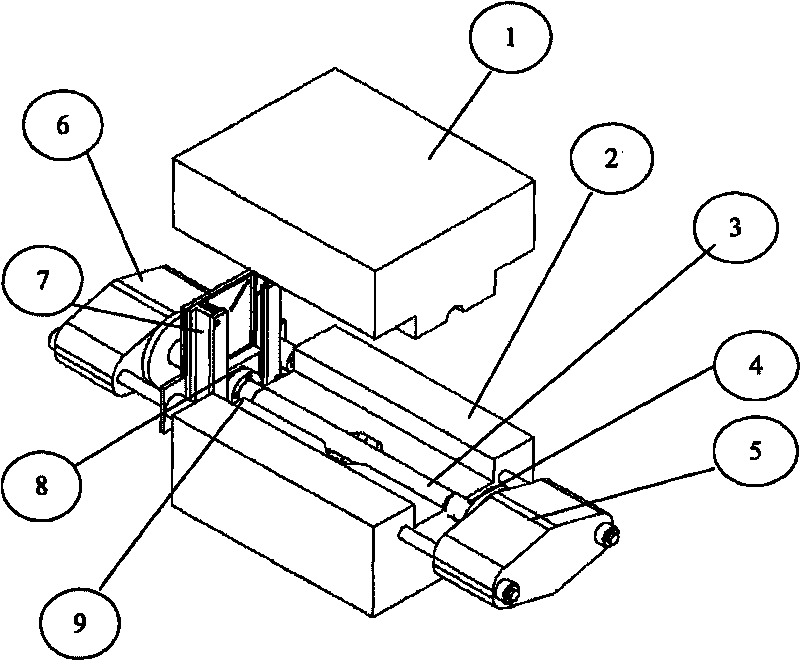

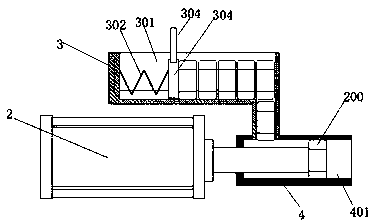

Hydraulic pressure generation unit with pneumatic actuation

InactiveUS20160230786A1Servomotor componentsAccumulator installationsEngineeringMechanical engineering

A “HYDRAULIC PRESSURE GENERATION UNIT WITH PNEUMATIC ACTUATION” in particular a multifunction unit activated by low pressure air, consisting of at least one pump (1), preferably two pumps (1 and 2), which are pneumatically automated, comprising a pneumatic cylinder (5) with a medial plunger (7), in addition to two symmetrical and opposite hydraulic plungers (8 and 9) limiting an upper hydraulic chamber (1 A and 2 A) and another lower hydraulic chamber (1 B and 2 B) having different volumes, wherein since they work in parallel and out-of-phase a reduced oil volume is required and the pulsating movement thereof is removed.

Owner:NEMA ERCIO MIGUEL

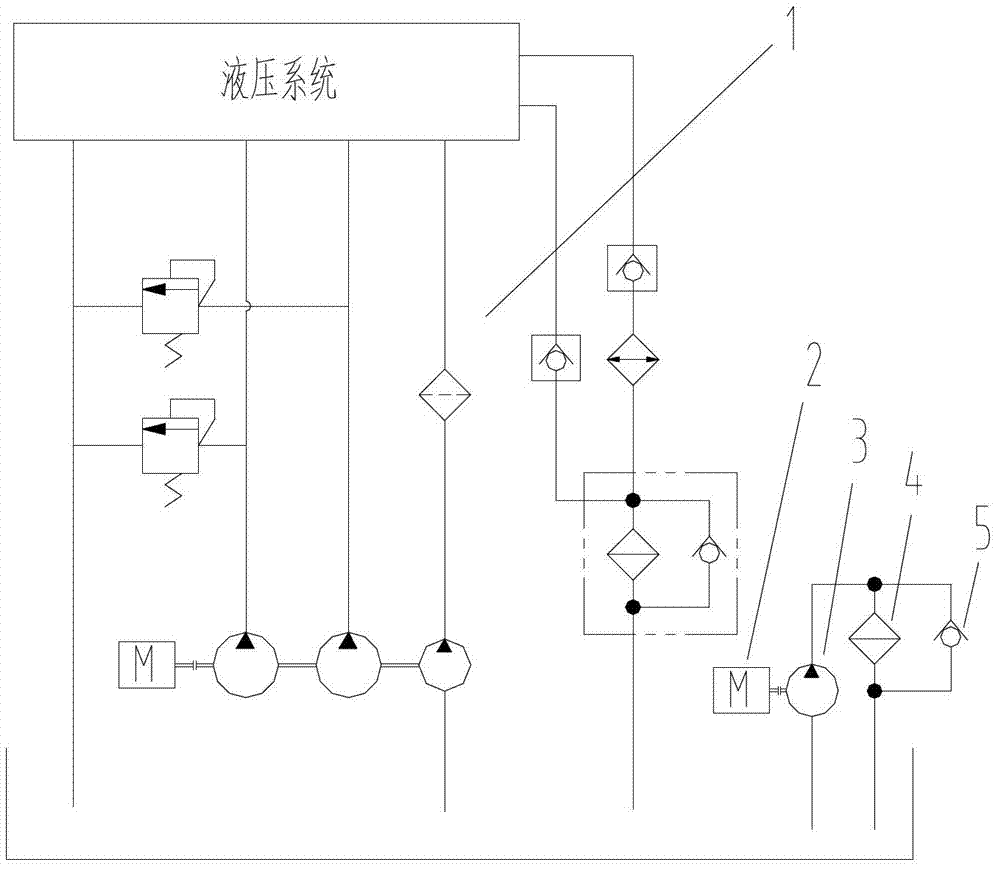

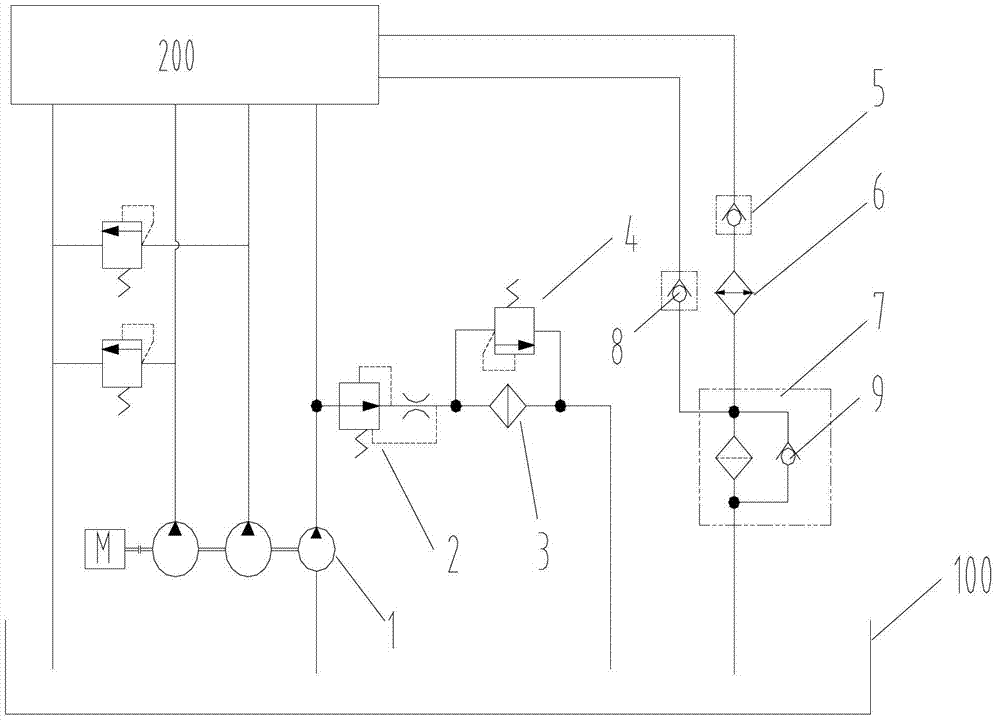

Anti-roll adjustable hydro-pneumatic suspension hydraulic system

ActiveCN112009193AGuaranteed stabilityReduce vibrationInterconnection systemsResilient suspensionsHydraulic control unitHydropneumatic suspension

The invention discloses an anti-roll adjustable hydro-pneumatic suspension hydraulic system which comprises a suspension hydraulic control unit and an oil pipeline which are arranged on each axle, each suspension hydraulic control unit comprises two groups of suspension control mechanisms on the left side and the right side respectively, and each suspension control mechanism comprises an oil cylinder, a valve piece, a pipeline and an energy accumulator; a rod cavity of an oil cylinder on one side of each suspension hydraulic control unit is communicated with a rodless cavity oil way on the other side of the same unit through a valve piece and a pipeline, and a rodless cavity of each oil cylinder is connected with an energy accumulator of the suspension control mechanism in the same set through a valve piece. The stability of speed control when the suspension oil cylinder bears large load and descends is achieved; meanwhile, the suspension oil cylinder can bear the load borne by a suspension system when a hydraulic system does not act, the hydraulic system is prevented from being overloaded, so that the safety of the hydraulic system and the whole vehicle is protected; vehicle posture adjustment and speed adjustment such as vehicle body lifting, front-back pitching, left-right inclining and vehicle body leveling can be achieved.

Owner:TAIAN AEROSPACE SPECIAL VEHICLE CO LTD

Basketball cleaning device for sports

Owner:义乌市裕晨科技有限公司

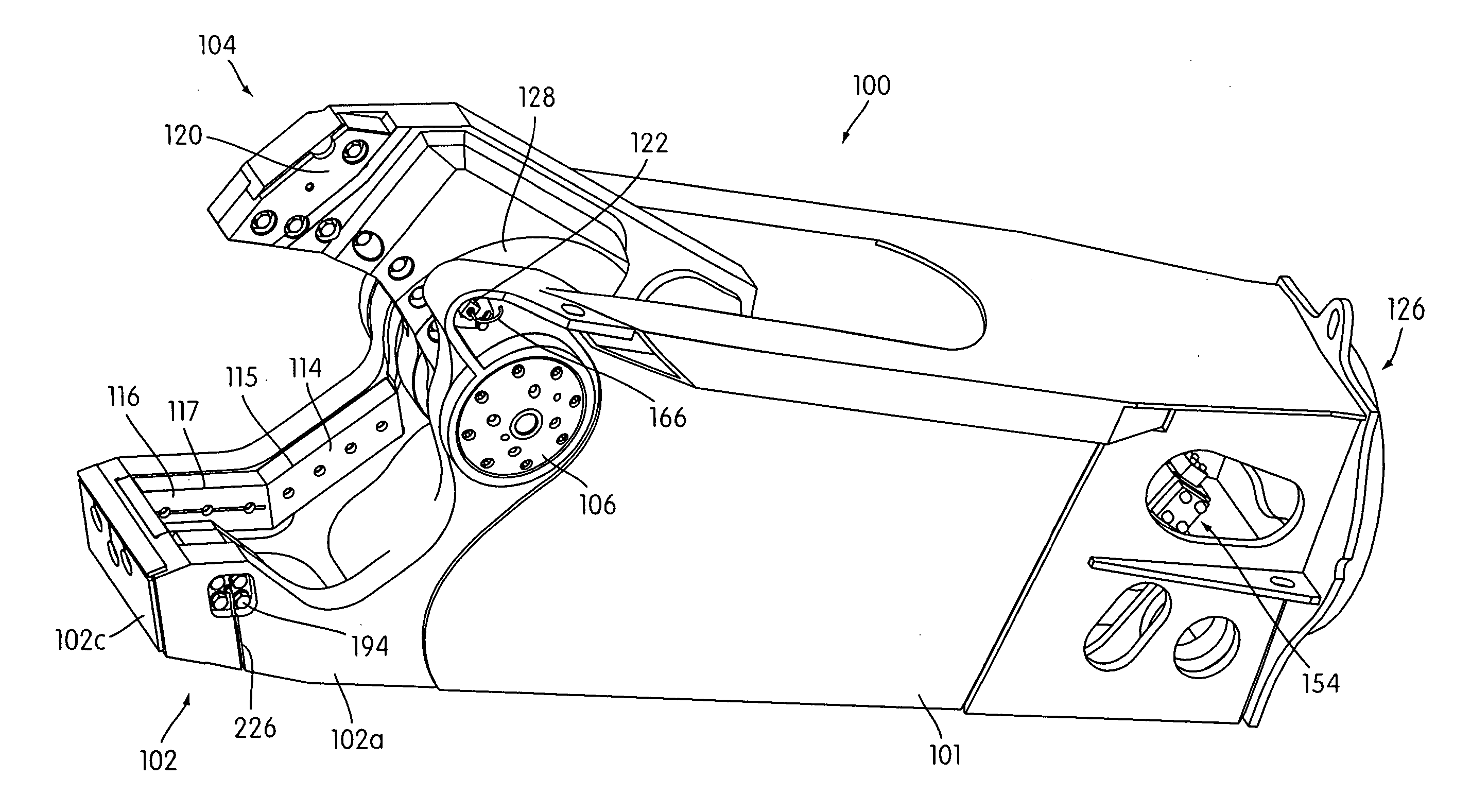

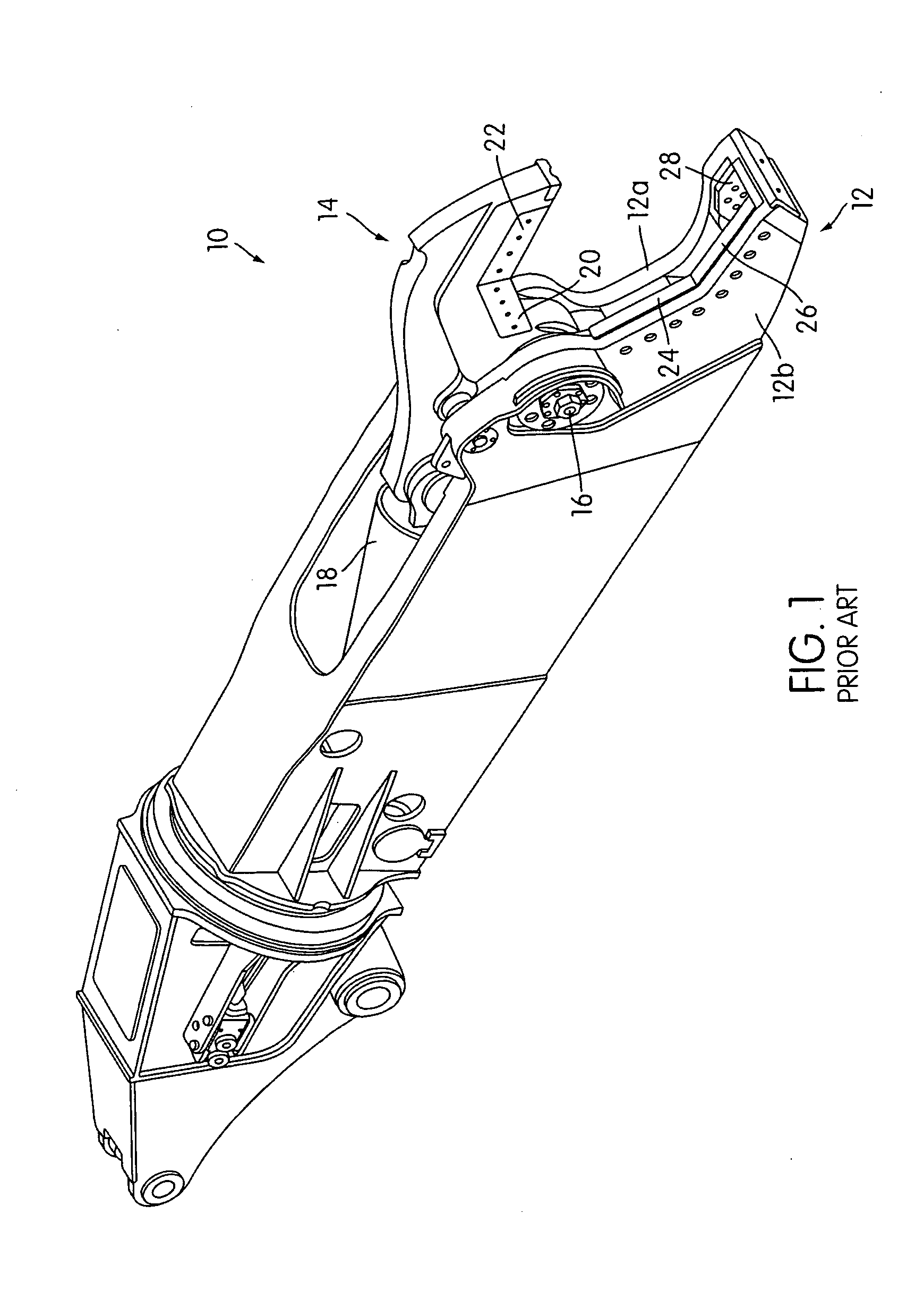

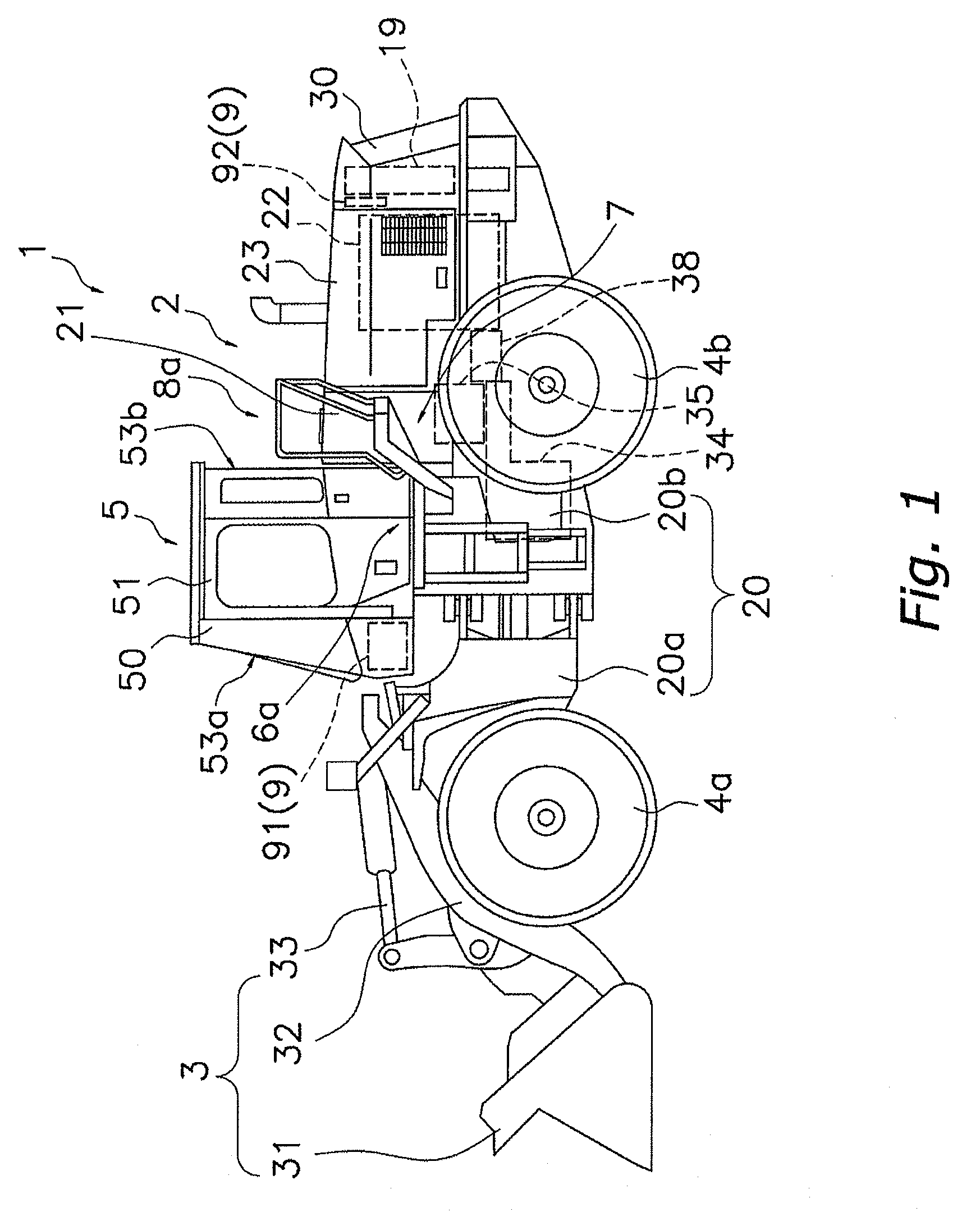

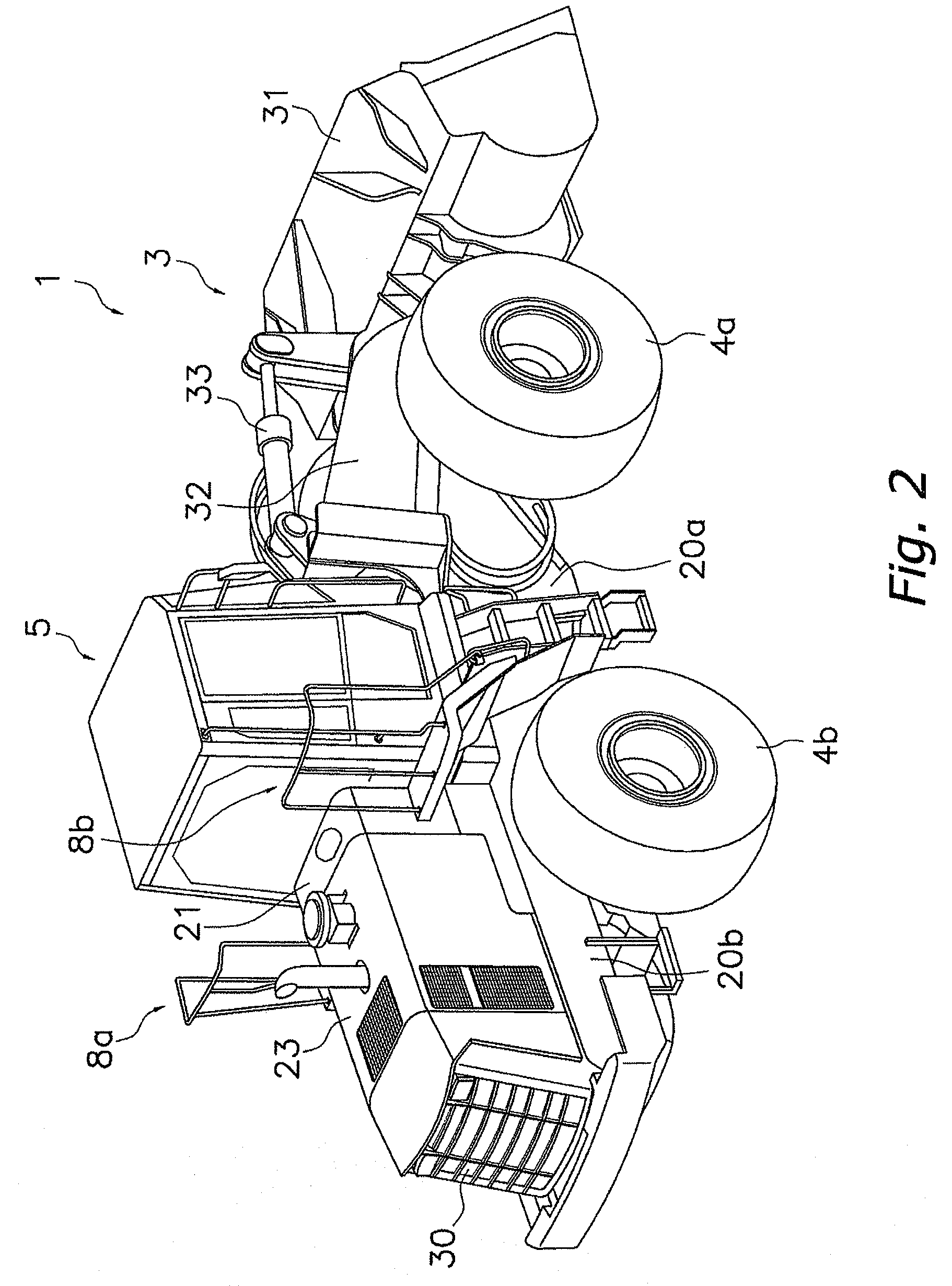

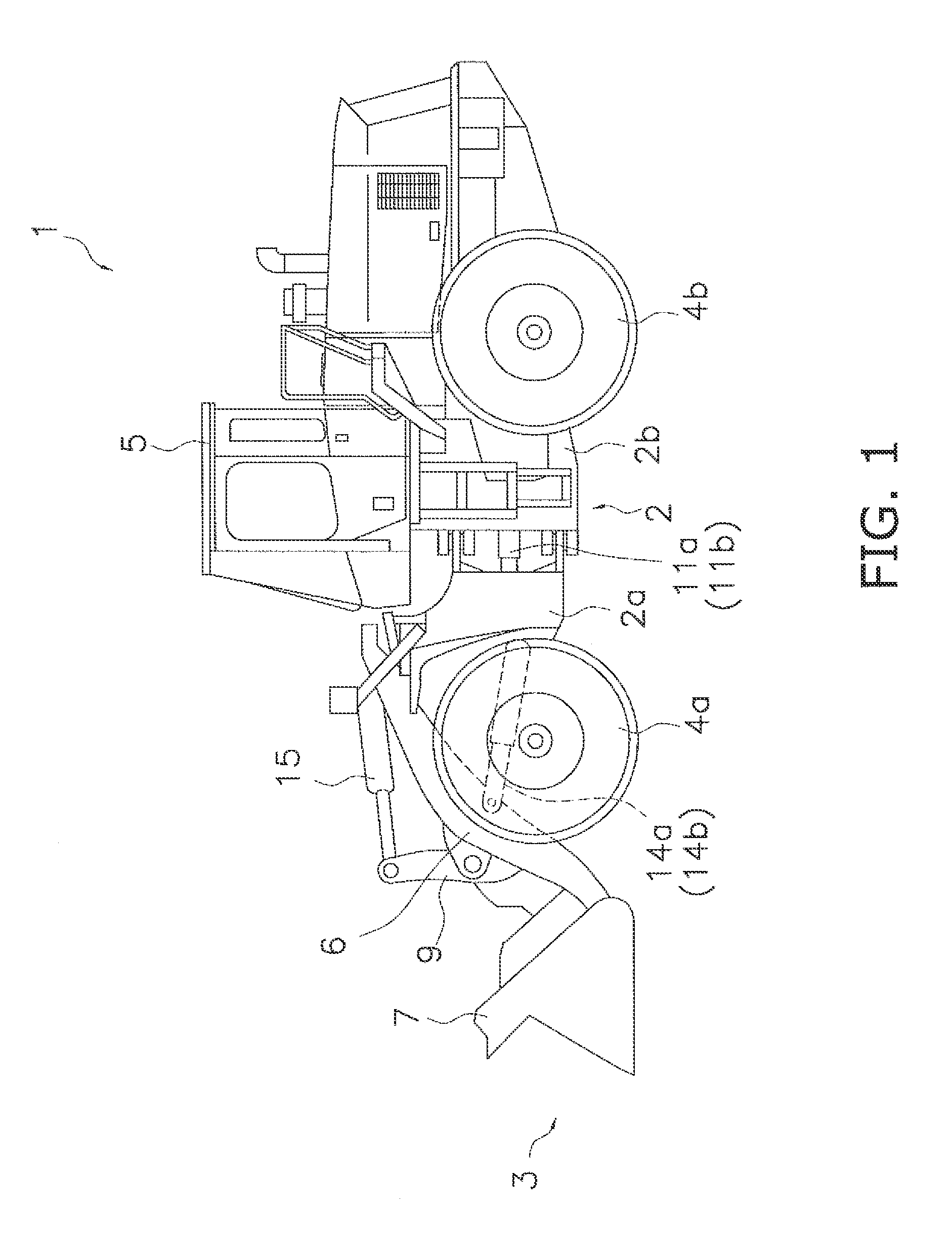

Construction vehicle

InactiveUS20090095441A1Small sizeAir-treating devicesSoil-shifting machines/dredgersVehicle frameFuel tank

Owner:KOMATSU LTD

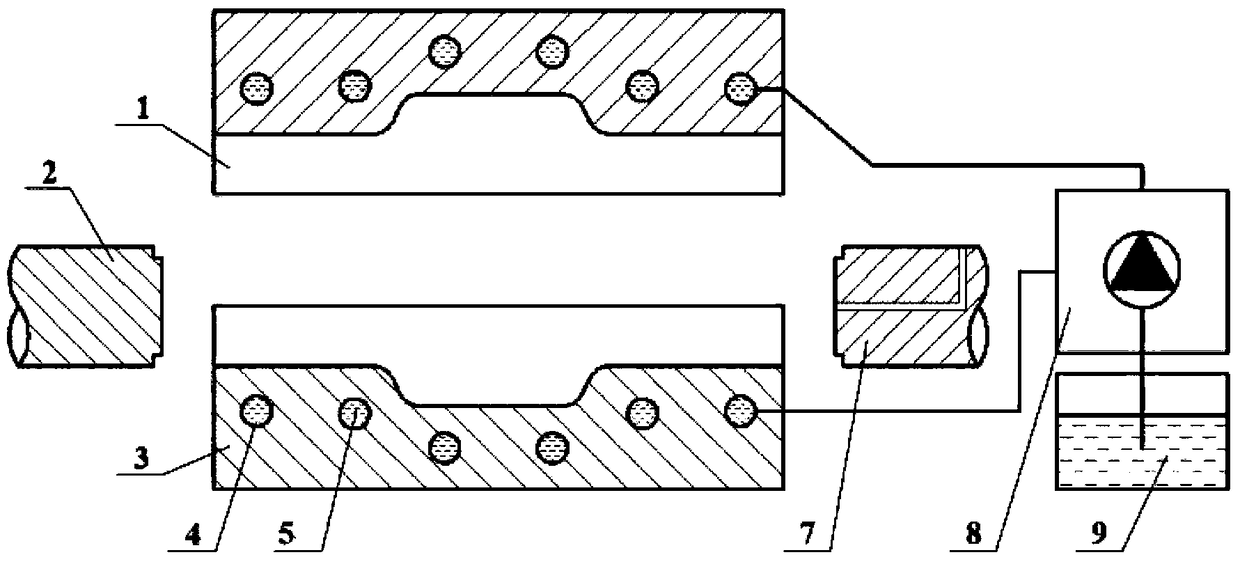

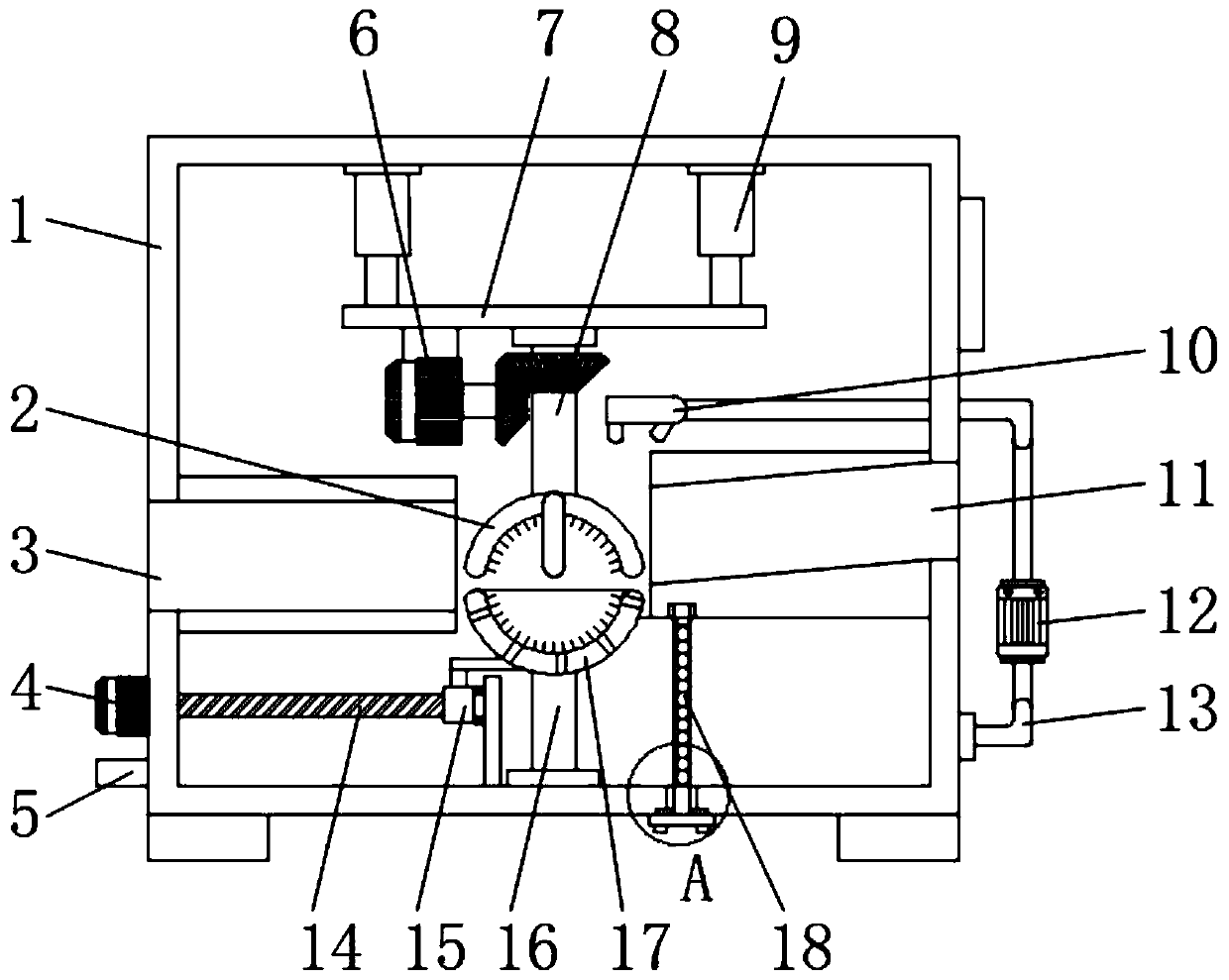

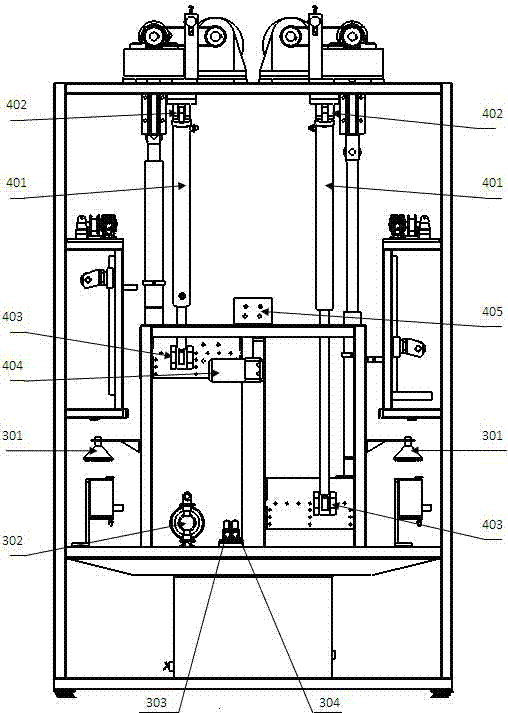

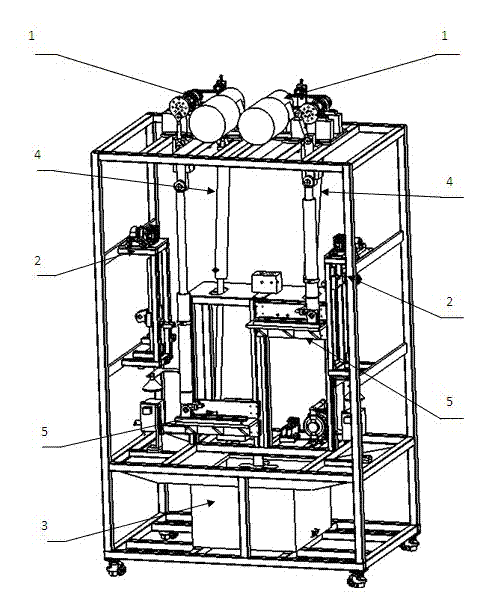

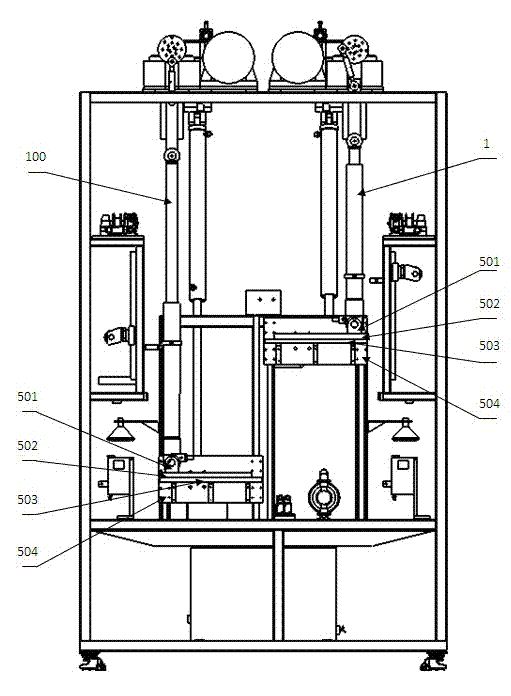

Experimental equipment for testing durability of hydraulic cylinders

ActiveCN104500502AEasy to adjustSolve the waterproof problemFluid-pressure actuator testingHydraulic cylinderEngineering

Owner:吉林大学重庆研究院

High-pressure plunger pump with energy recycling function

InactiveCN105526051AReduce deliveryImprove recycling efficiencyPositive displacement pump componentsPositive-displacement liquid enginesHigh concentrationReverse osmosis

The invention discloses a high-pressure plunger pump with an energy recycling function and relates to the technical field of hydraulic energy recycling. The problem that many energy transmission links exist in the energy recycling process is solved. The high-pressure plunger pump with the energy recycling function comprises an outer shell and a cylinder body, wherein the outer shell comprises two end covers and a shell body with a through hole; the cylinder body is arranged in the through hole of the shell body; a swash plate is arranged between the cylinder body and one of the end covers; cylinder holes are formed in the cylinder body in a circumferential array; a plunger and sliding shoe assembly is arranged in each cylinder hole; the outer shell is provided with a fluid inlet and a fluid outlet which communicate with the cylinder holes; a fluid channel is arranged on the cylinder body; a hydraulic cavity is formed between each plunger and sliding shoe assembly and the inner wall of the corresponding cylinder hole and communicates with the fluid channel; the outer shell is provided with a recycling inlet and a recycling outlet which communicate with the fluid channel. The high-pressure plunger pump with the energy recycling function is mainly applied to high-pressure fluid equipment for industrial production to achieve the functions like recycling energy of waste high-concentration sea water in reverse-osmosis seawater.

Owner:WOER TECH

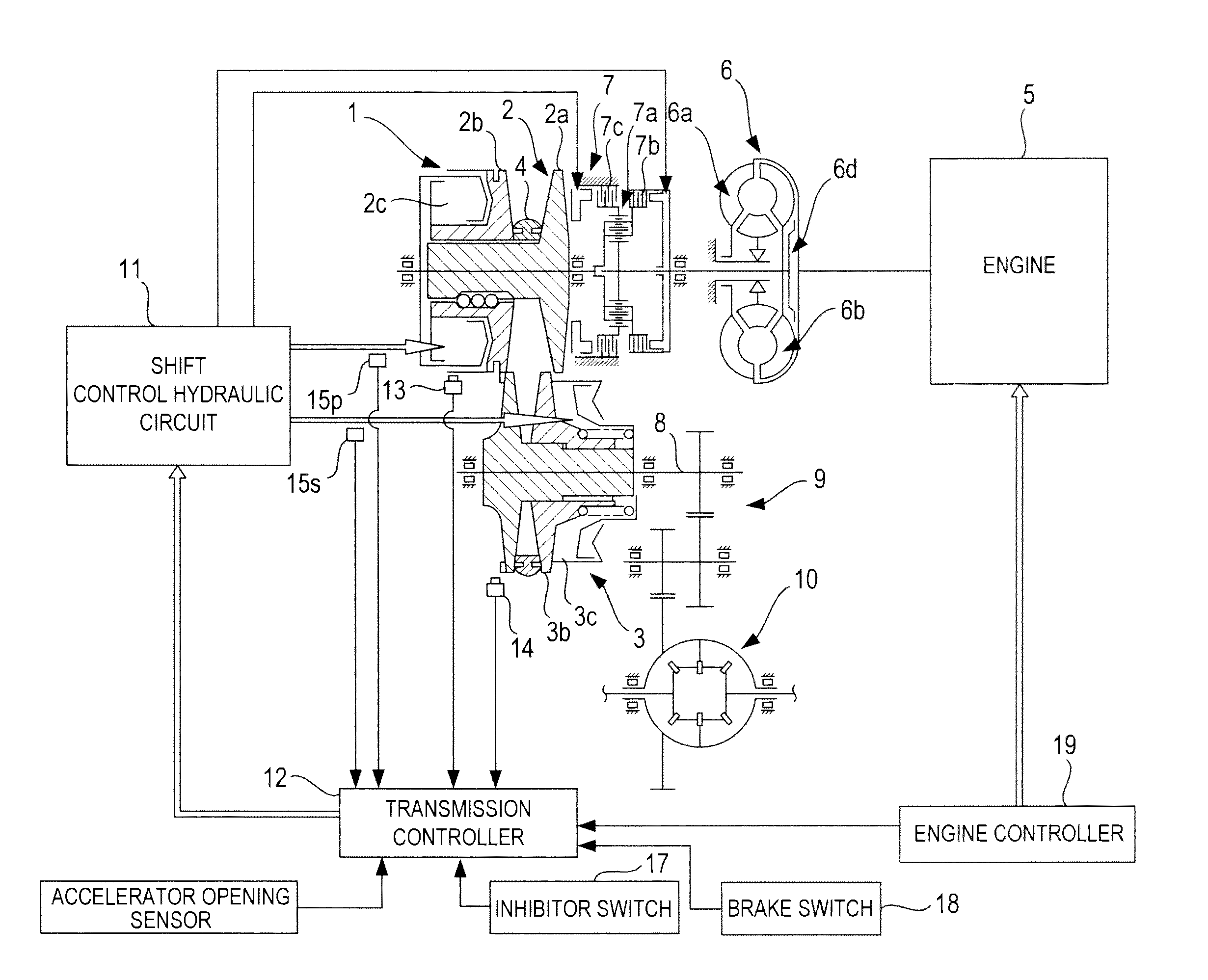

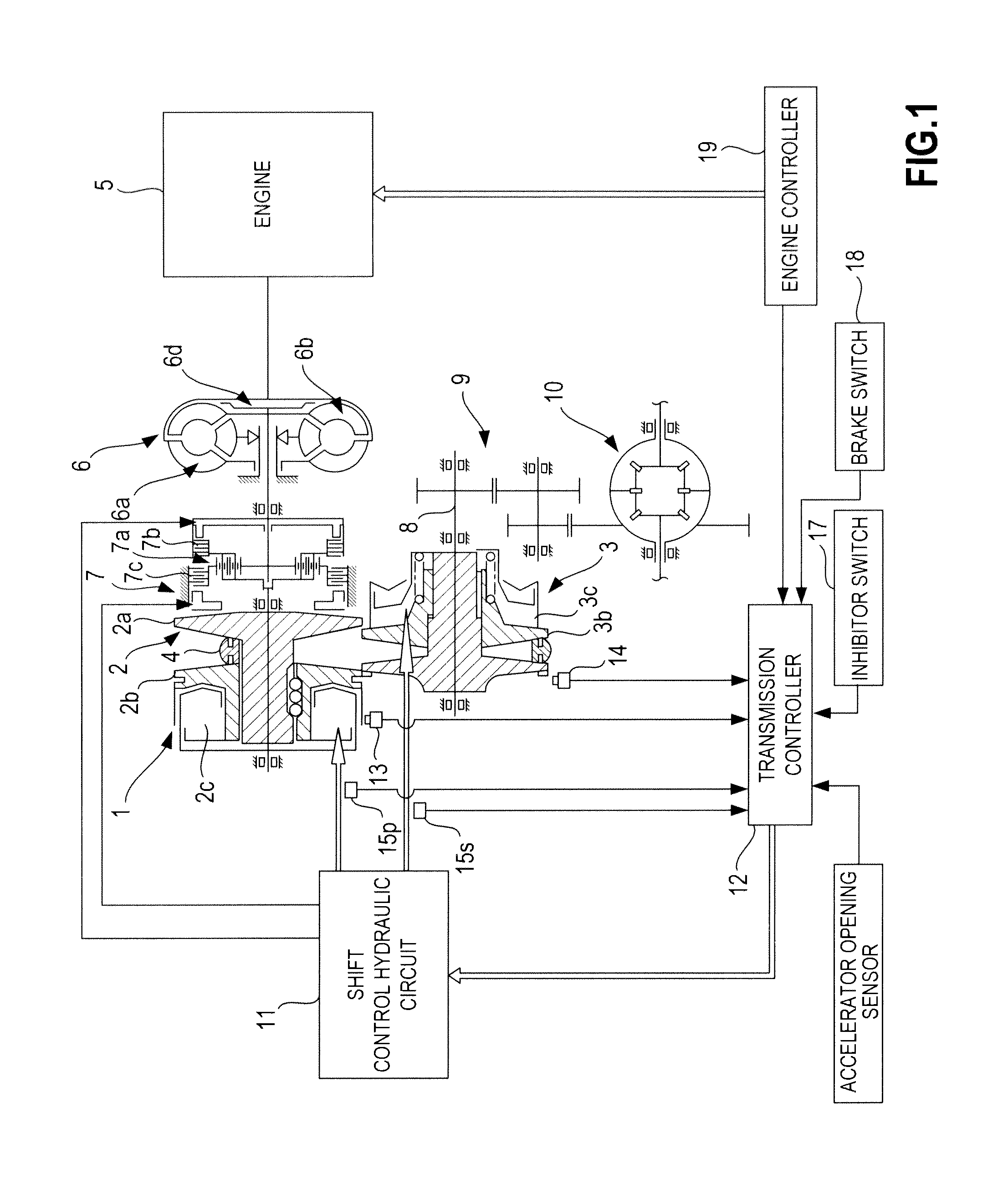

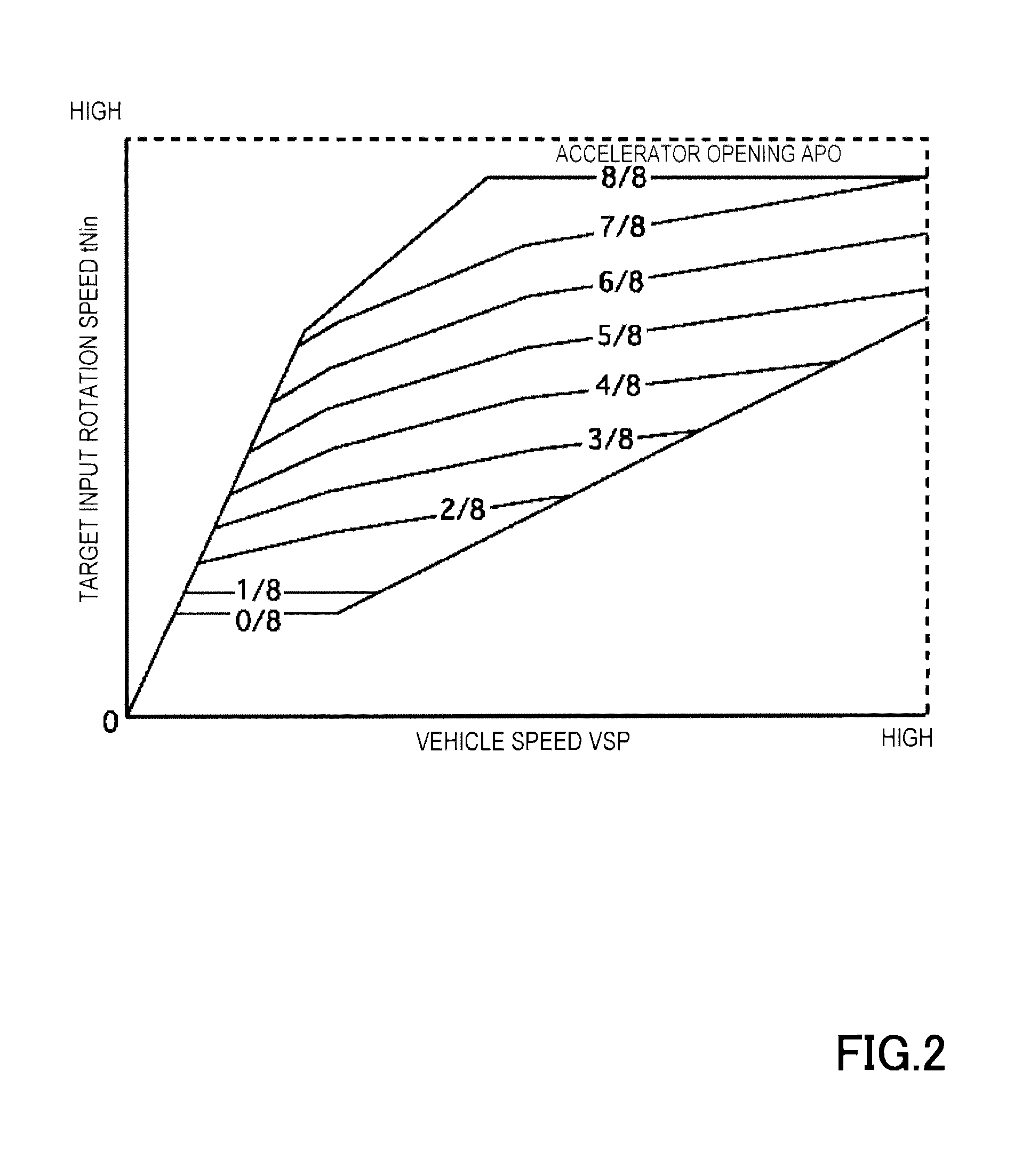

Continuously variable transmission and its hydraulic pressure control method

ActiveUS20150081181A1Improve fuel efficiencyReduced engine powerDigital data processing detailsGearing controlLower limitControl theory

Owner:JATCO LTD +1

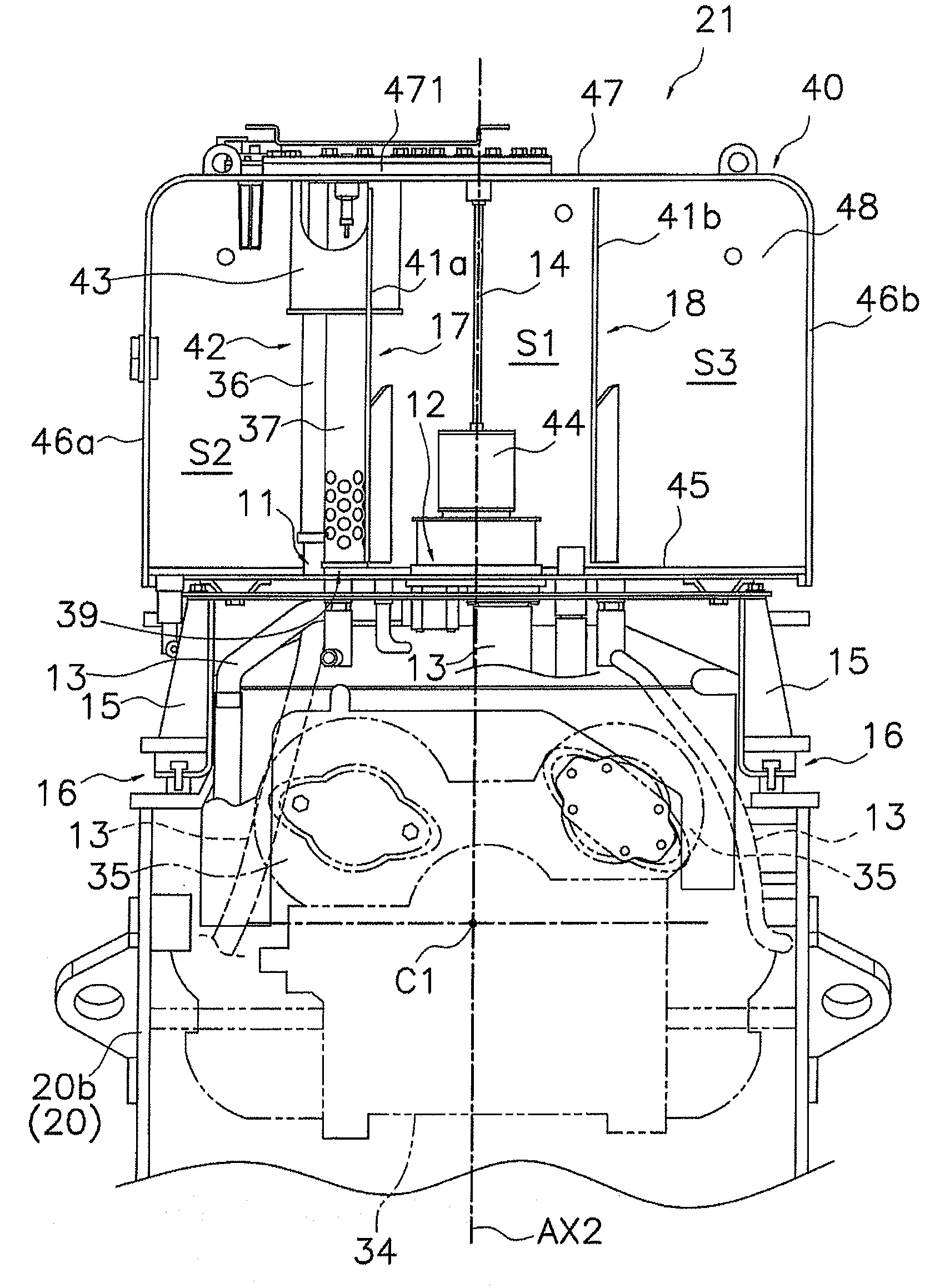

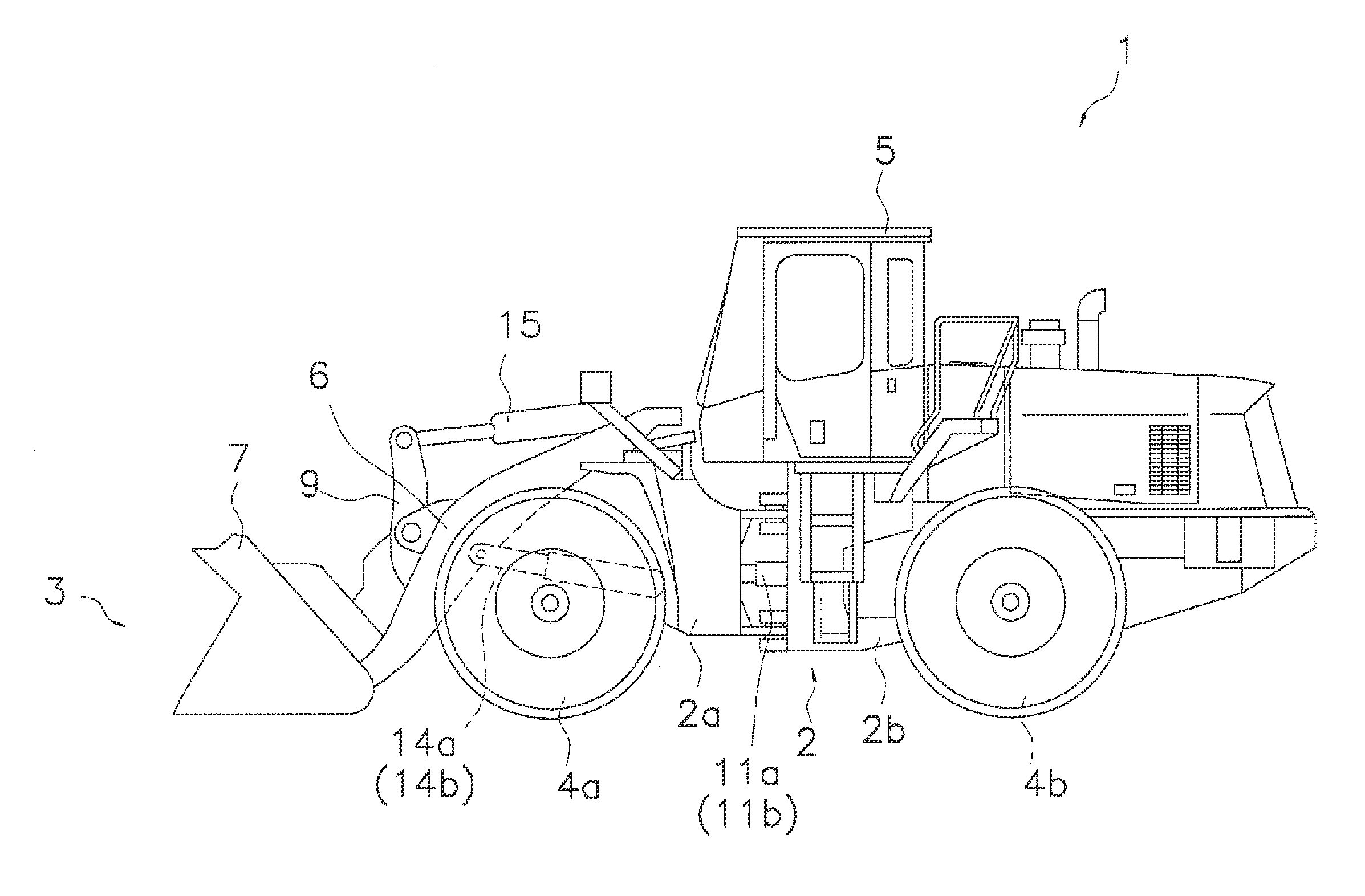

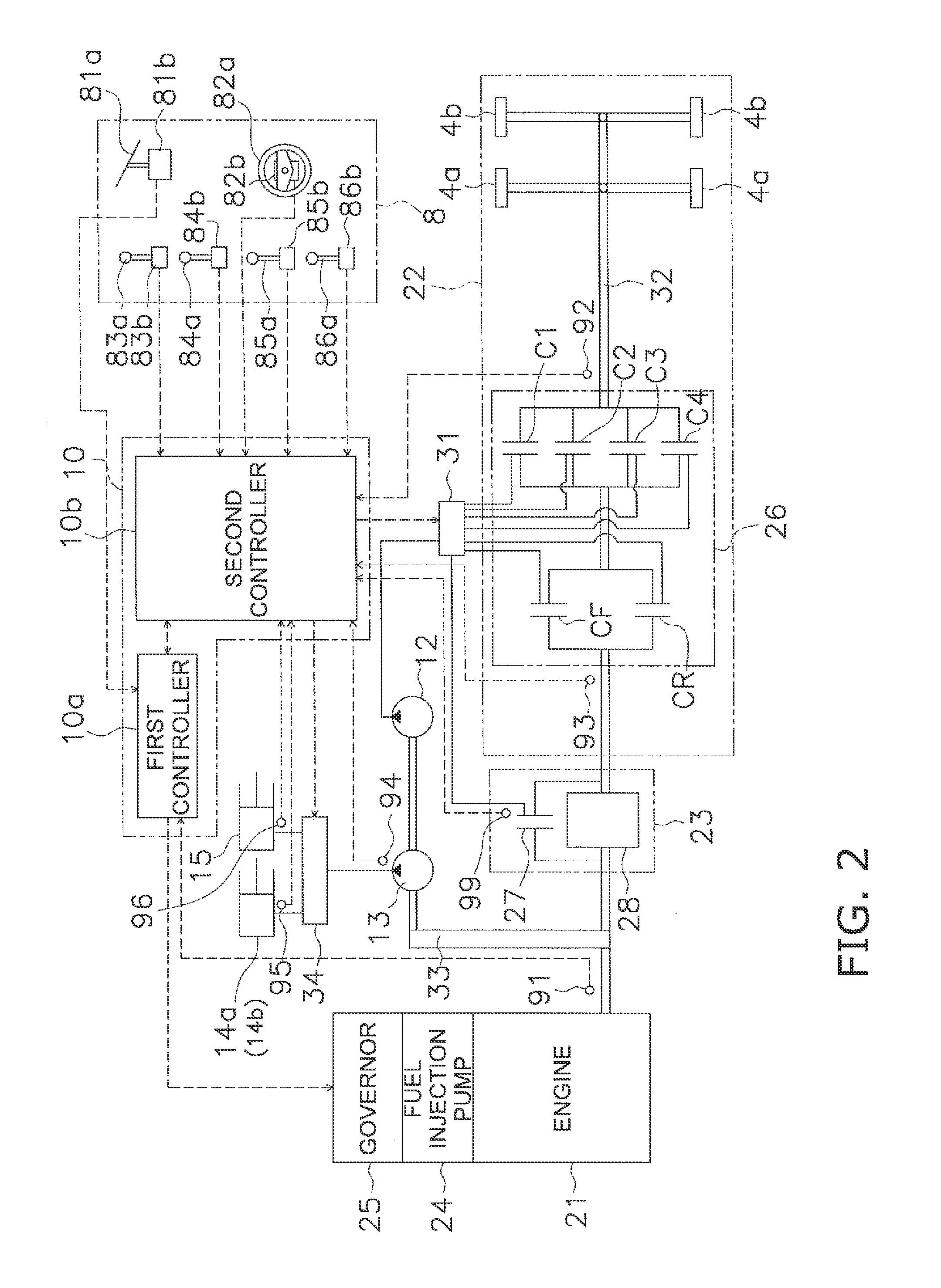

Work vehicle and method of controlling the same

ActiveUS20120245805A1Inhibit reduction in life durationImprove transmission efficiencyAnalogue computers for trafficSoil-shifting machines/dredgersInstrumentationClutch

Owner:KOMATSU LTD

Hydraulic oil filtration system and hydraulic shovel

ActiveCN103174704ASoil-shifting machines/dredgersFluid-pressure actuator componentsControl systemFiltration

Owner:ZOOMLION HEAVY IND CO LTD

Composite connection type hydraulic knife handle

ActiveCN108907776AHigh strengthPrevent extravasationPositioning apparatusMetal-working holdersConnection typeInterference fit

The invention relates to a composite connection type hydraulic knife handle. The composite connection type hydraulic knife handle comprises a main knife handle body and an elastic thin-wall inner ringarranged in the main knife handle body, wherein a hydraulic oil cavity is arranged between the main knife handle body and the elastic thin-wall inner ring; the elastic thin-wall inner ring is arranged as a barrel thin-wall structure with two thick ends and a thin middle part; and the side outer rings of the two ends of the elastic thin-wall inner ring make contact with the support surfaces of inner holes of the main knife handle body. The main knife handle body and the elastic thin-wall inner ring are fixed in a manner of combining brazed connection and interference fit connection, the effectof stress on the connection performance of the main knife handle body and the elastic thin-wall inner ring is reduced, the joint of the main knife handle body and the elastic thin-wall inner ring isprevented from tear under the high pressure state, and therefore the service life of the hydraulic knife handle is prolonged. Meanwhile, by improving the structure of a piston rod and the structure ofa piston sleeve, the piston sleeve is quickly maintained, the overall sealing performance of a hydraulic access is improved, and the overall strength of the hydraulic knife handle is improved.

Owner:CHENGDU CHENGLIN CNC TOOL CO LTD

Turnover transport vehicle with limiting mechanism

InactiveCN111661120AShorten the timeImprove turnover efficiencyHand carts with multiple axesHand cart accessoriesPush and pullElectric machine

Owner:何红侠

Steel bending equipment for steel machining

InactiveCN112139303AAvoid scratchesAvoid damageShaping toolsMetal-working feeding devicesStructural engineeringContact position

The invention discloses steel bending equipment for steel machining, and belongs to the technical field of steel machining. The steel bending equipment comprises a machine body, lubricating oil tanks,a base, roll shafts, an oil storage box, a positioning mechanism and a mounting seat, wherein the machine body is fixedly installed on the base through a side connecting plate, hydraulic machines arefixedly installed at the top of the machine body, and one ends of hydraulic rods installed at the output ends of the hydraulic machines penetrate through and extend to the outer side of the machine body to be fixedly provided with a bending plate. According to the steel bending equipment, the roller shafts are installed on the equipment, when steel is bent and pressure is applied to the bent position of the steel, the roll shafts replace a bent face to make contact with the steel, and when pressure is applied for bending, the steel can be bent along the smooth surfaces of the roll shafts, compared with traditional bending treatment, the situation that the surface of the steel is scratched and damaged is avoided, and meanwhile, the lubricating oil tanks are installed on the outer side of the equipment in a matched mode, the contact positions between the roll shafts and the steel can be effectively lubricated, and the bending smoothness is further improved.

Owner:赵桂荣

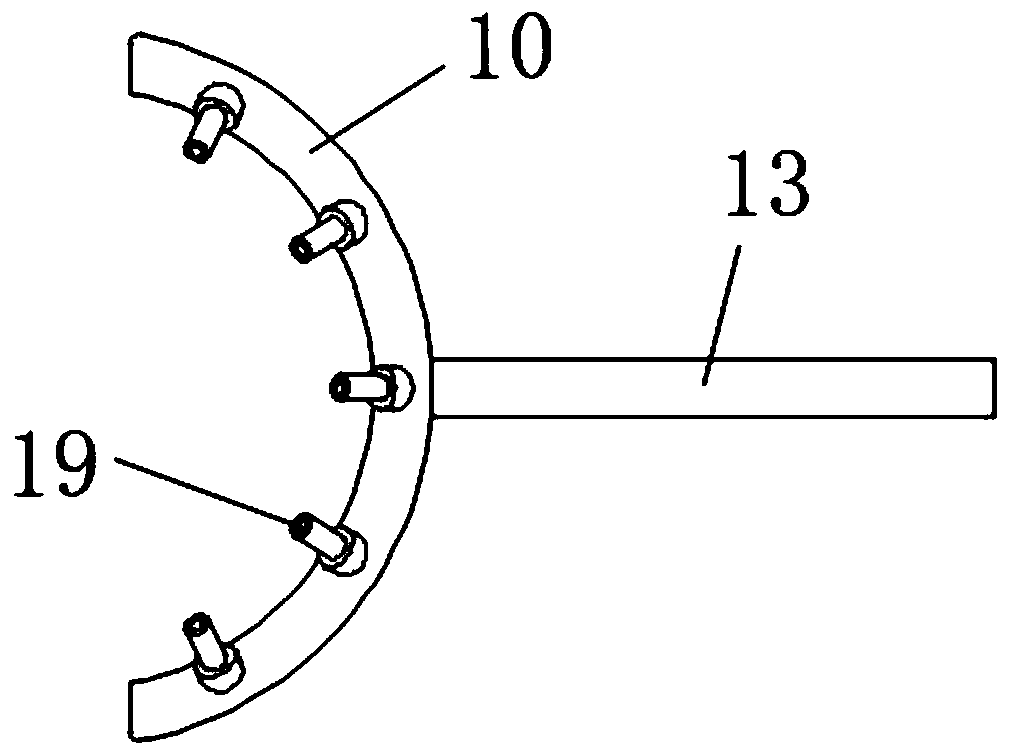

Hydraulic external line-up clamp for steel gas pipeline

InactiveCN111112935AGood adjustment functionEasy alignmentWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderStructural engineering

The invention relates to the technical field of welding auxiliary tools, in particular to a hydraulic external line-up clamp for a steel gas pipeline. The hydraulic external line-up clamp comprises apositioning plate, a central positioning element, lateral positioning elements and a synchronous feeding mechanism, wherein the central positioning element comprises two symmetric middle half rings and a first hydraulic cylinder; the two middle half rings are hinged; the articulated shafts of the two middle half rings are arranged on the upper surface of the positioning plate; the first hydrauliccylinder can drive the two middle half rings to be tightly abutted; the two lateral positioning elements are symmetrically arranged on two sides of an axial line direction of each middle half ring; the positioning plate is fixedly provided with spacing rods; the two spacing rods are independently positioned on two sides of the central positioning element and are positioned on lateral sides of theaxial line direction of lateral half rings; and the synchronous feeding mechanism can drive the two lateral positioning elements to synchronously move to a direction near or far away from the centralpositioning element relative to the positioning plate. According to the hydraulic external line-up clamp, a function that a worker can conveniently regulate a welding line between two pipelines is realized.

Owner:SHANGHAI ANHONG CONSTR ENG CO LTD

Cutting device with deformation protective structure and for hydraulic power oil tank processing

ActiveCN111702250ASolve the problem of untidyImprove stabilityMetal sawing devicesMetal sawing accessoriesStructural engineeringProcess engineering

The invention discloses a cutting device with a deformation protective structure and for hydraulic power oil tank processing. The cutting device comprises a device main body, the device main body comprises a supporting column, a supporting plate is fixedly connected to the top end of the supporting column, side plates are correspondingly connected to the left and right sides of the supporting plate, a top plate is fixedly connected between the two groups of side plates, a hydraulic push rod is fixedly connected to the bottom end of the top plate, a cutting machine is fixedly connected to the bottom end of the hydraulic push rod, a trolley is movably connected to the right side of the supporting column, a transmission mechanism is arranged on the left side of the hydraulic push rod, a clamping mechanism is arranged on the upper part of the supporting plate, an extruding mechanism is arranged in the supporting plate, a pushing mechanism is arranged in the supporting plate, and a transport mechanism is arranged on the right side of the supporting plate. According to the cutting device, the stability during cutting and the accuracy of cutting of the device are improved, a metal plate after cutting can be directly dropped into the trolley, and convenience is provided for manual collection.

Owner:HUNAN YONGSHENG HYDRAULIC TECH CO LTD

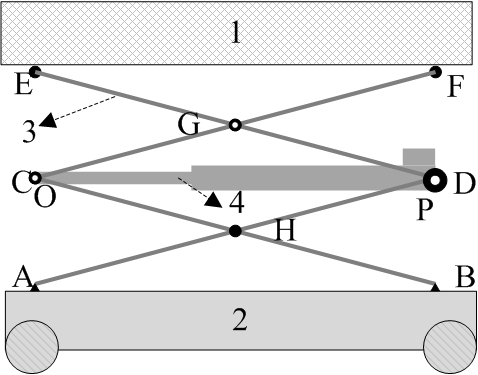

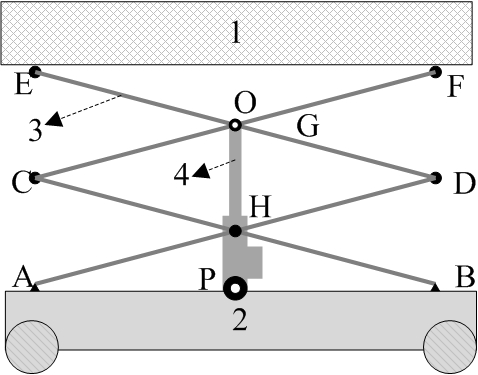

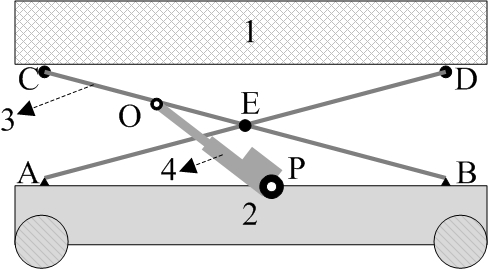

Full-electric scissor type aerial work platform

InactiveCN112850595ASolve UtilizationAddress riskSafety devices for lifting equipmentsSteering angleElectrical battery

Owner:JIANGSU ADVANCED CONSTR MASCH INNOVATION CENT LTD

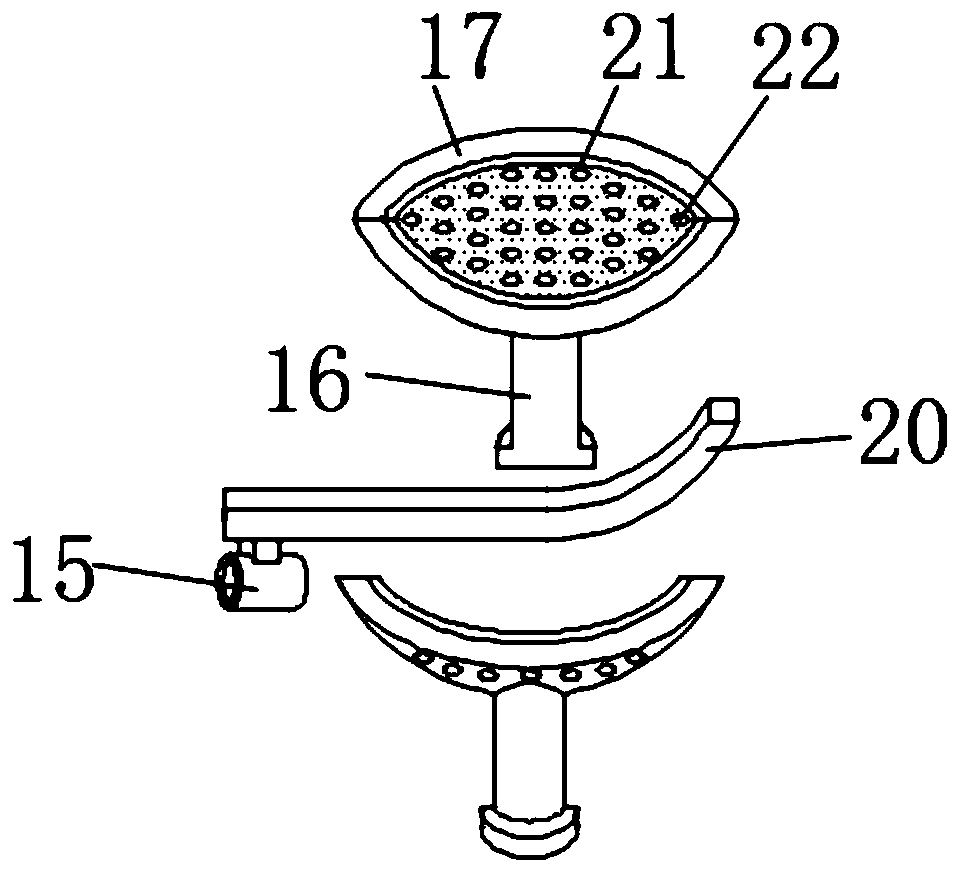

Deicing device and method for blade of wind turbine generator

InactiveCN111828265ASimple structureLow costWind motor controlFinal product manufactureMarine engineeringControl system

The invention discloses a deicing device and method for a blade of a wind turbine generator. The device comprises a plurality of spray pipes arranged on a tower drum at intervals up and down, whereinhorizontal length of each spray pipe is smaller than distance between the blade and the tower drum, all the spray pipes are connected with a hydraulic pressure station through delivery pipes, the hydraulic pressure station comprises a liquid storage tank and a hydraulic pump, an ice melting agent is stored in the liquid storage tank, the hydraulic pressure station is connected with a deicing control system, and the deicing control system is connected with a wind turbine generator control system. The deicing device has the beneficial effects of being simple in structure, low in manufacturing cost, high in deicing efficiency and low in safety risk and the deicing process is highly repeatable.

Owner:HUBEI LONGYUAN NEW ENERGY CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap