Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

27 results about "Hydraulic pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydraulic pumps are used in hydraulic drive systems and can be hydrostatic or hydrodynamic. A hydraulic pump is a mechanical source of power that converts mechanical power into hydraulic energy (hydrostatic energy i.e. flow, pressure). It generates flow with enough power to overcome pressure induced by the load at the pump outlet. When a hydraulic pump operates, it creates a vacuum at the pump inlet, which forces liquid from the reservoir into the inlet line to the pump and by mechanical action delivers this liquid to the pump outlet and forces it into the hydraulic system. Hydrostatic pumps are positive displacement pumps while hydrodynamic pumps can be fixed displacement pumps, in which the displacement (flow through the pump per rotation of the pump) cannot be adjusted, or variable displacement pumps, which have a more complicated construction that allows the displacement to be adjusted. Hydrodynamic pumps are more frequent in day-to-day life. Hydrostatic pumps of various types all work on the principle of Pascal's law.

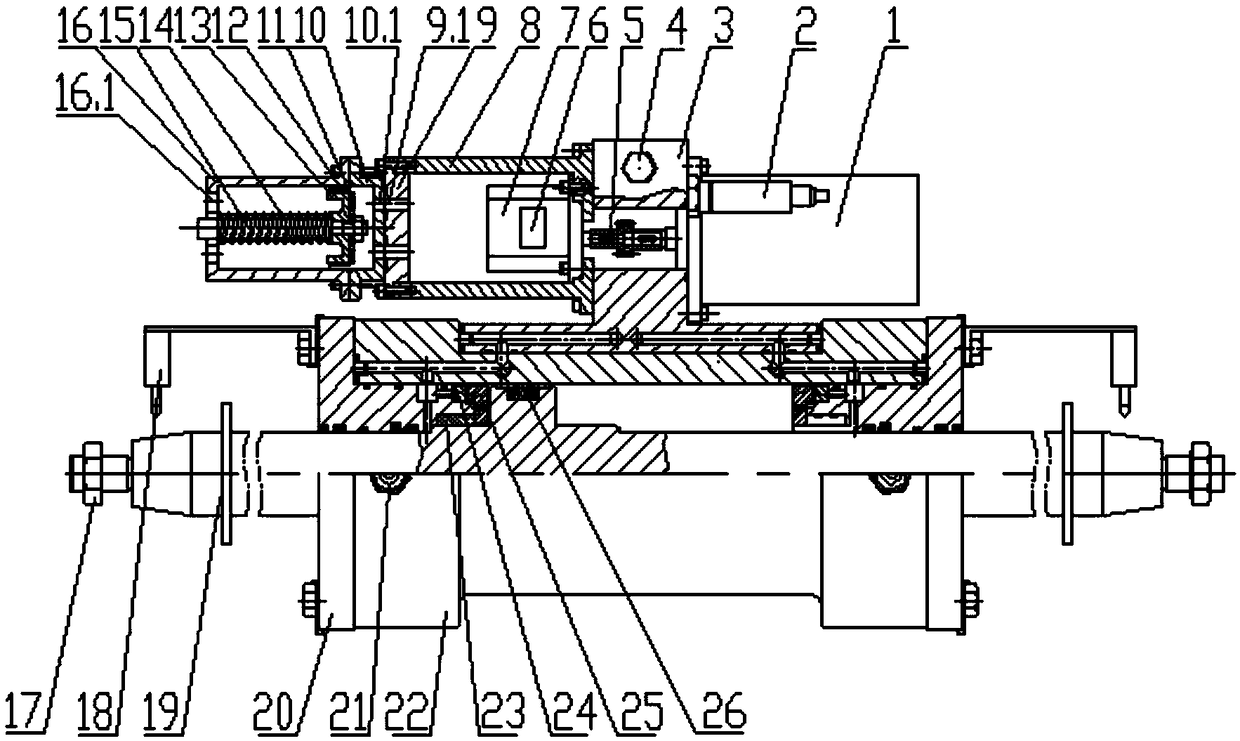

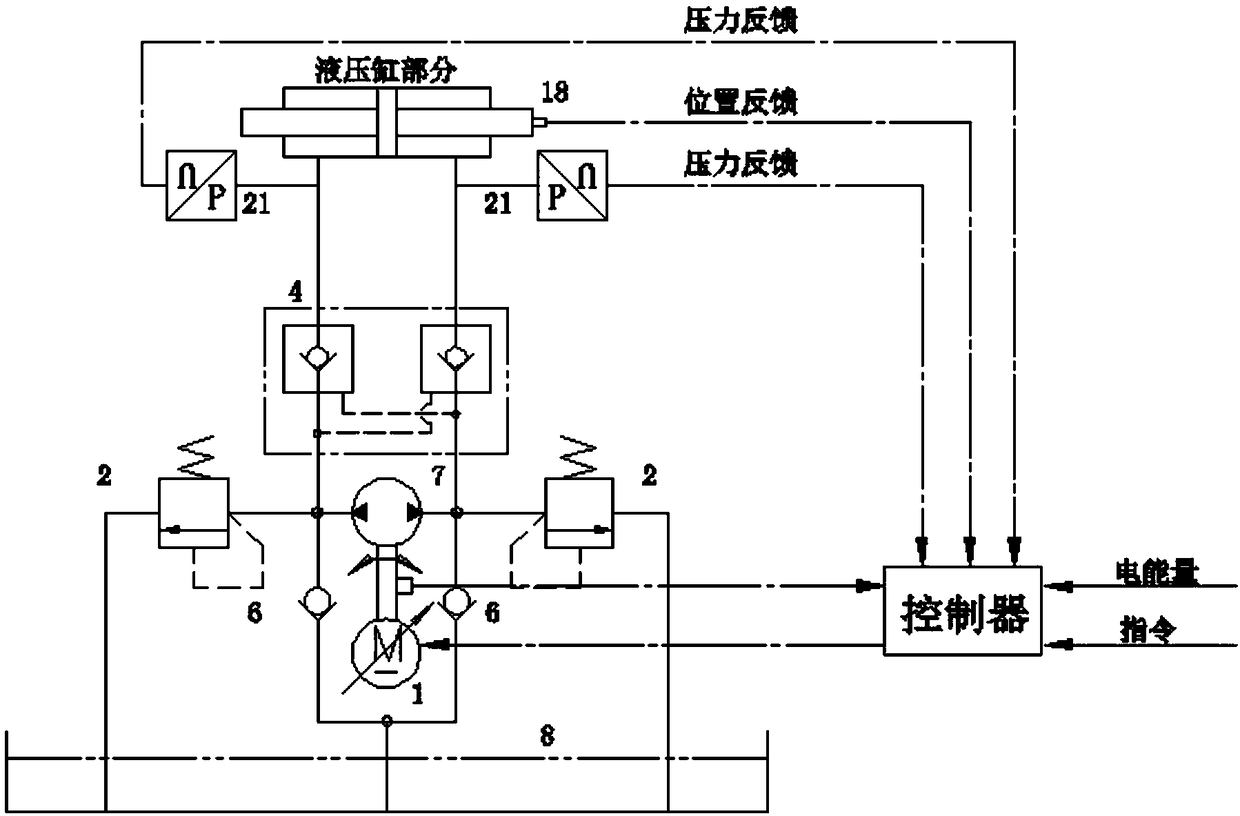

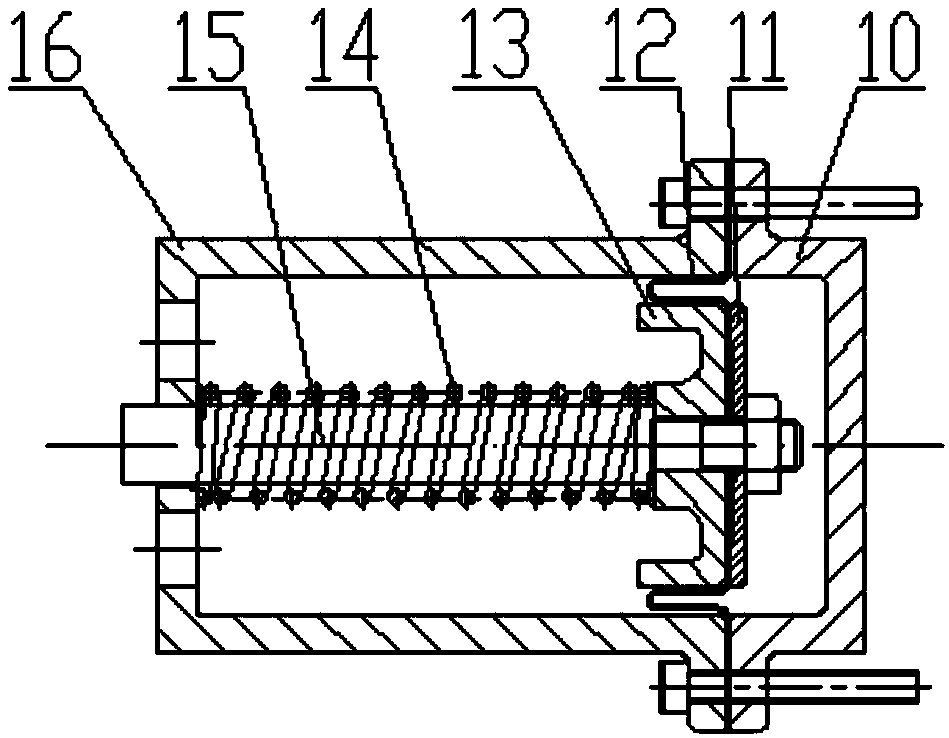

Electric static liquid actuator for deep sea

ActiveCN109340220AHigh level of integrationReduce volumeFluid-pressure actuator componentsHydraulic cylinderElectric machine

Owner:BEIJING UNIV OF TECH

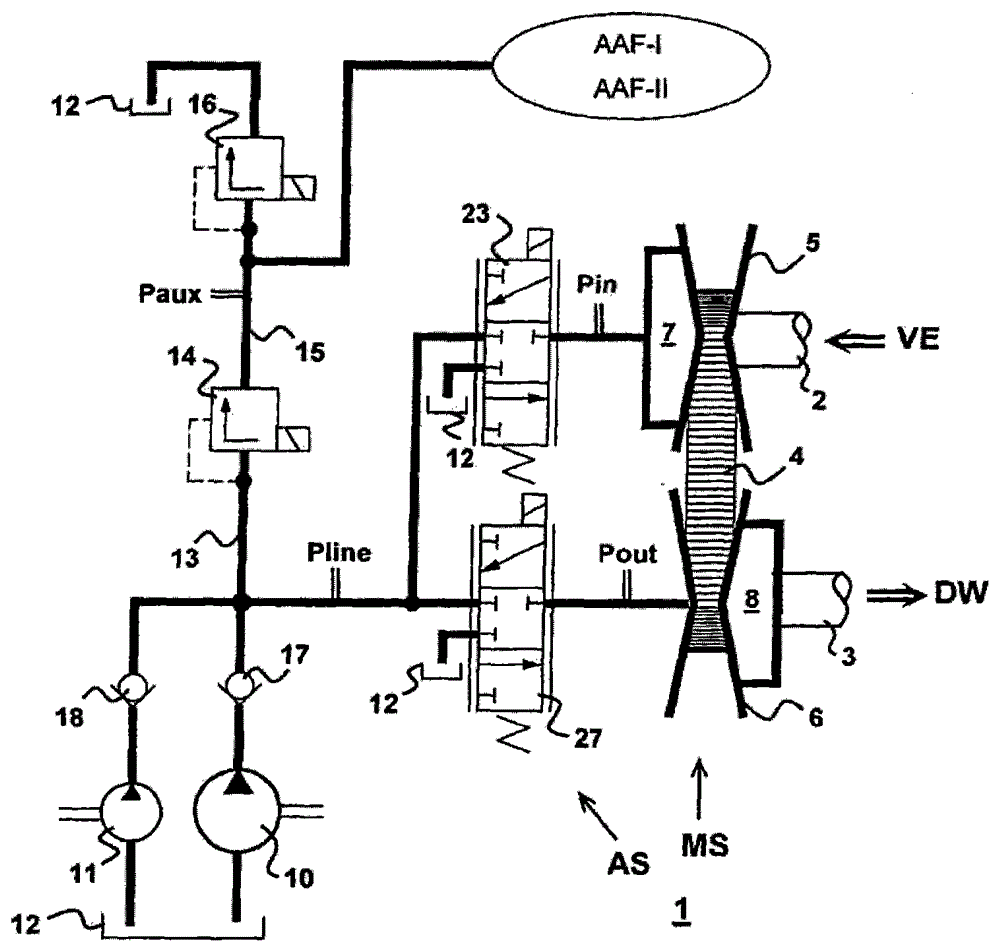

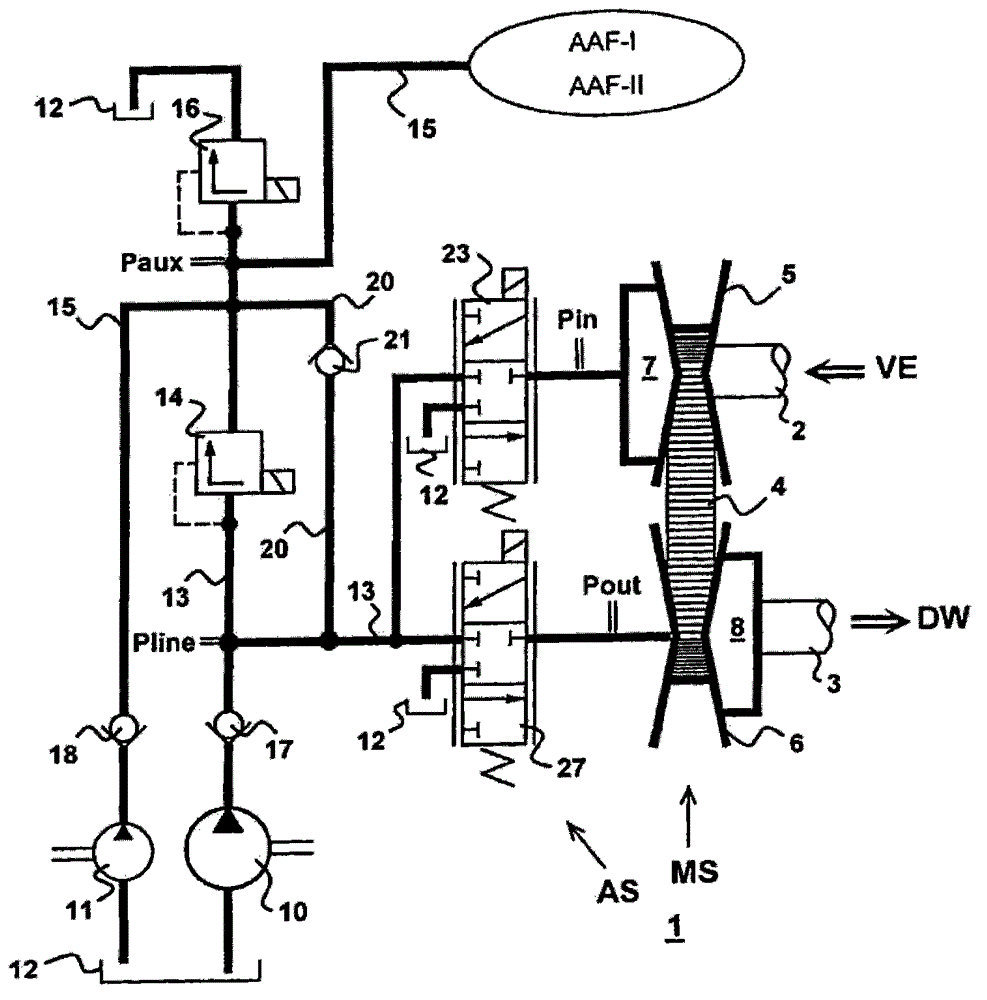

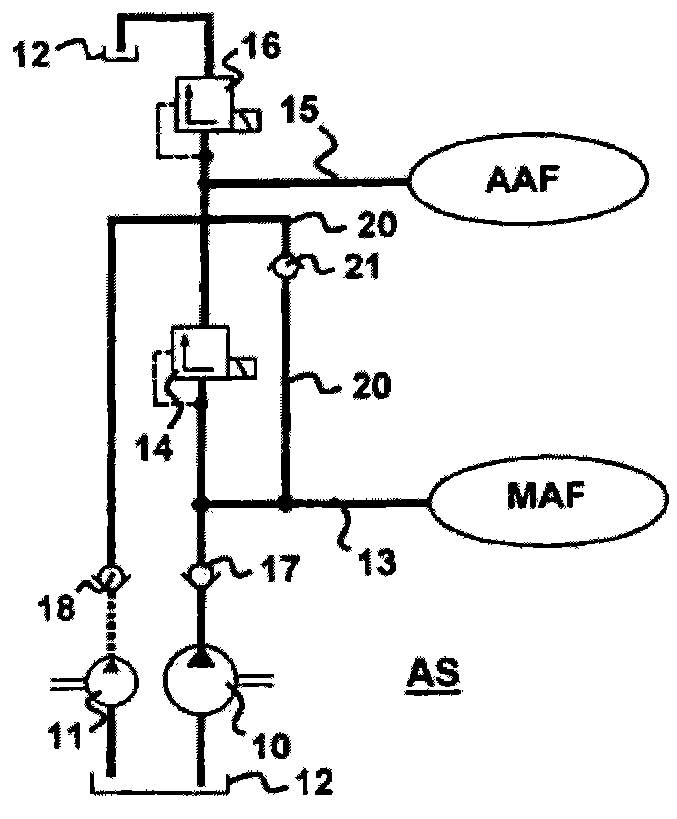

Hydraulically actuated continuously variable transmission for a vehicular drive line provided with an engine

InactiveCN104160180ASimple designImprove efficiencyGear lubrication/coolingGearing controlElectric machineHydraulic pump

Owner:ROBERT BOSCH GMBH

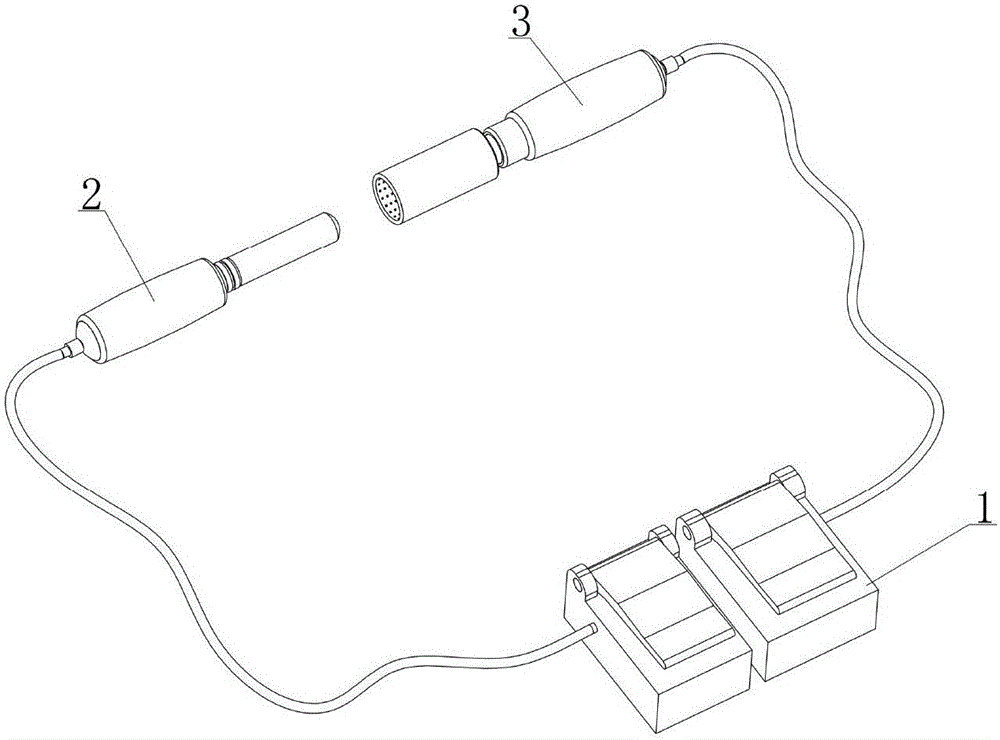

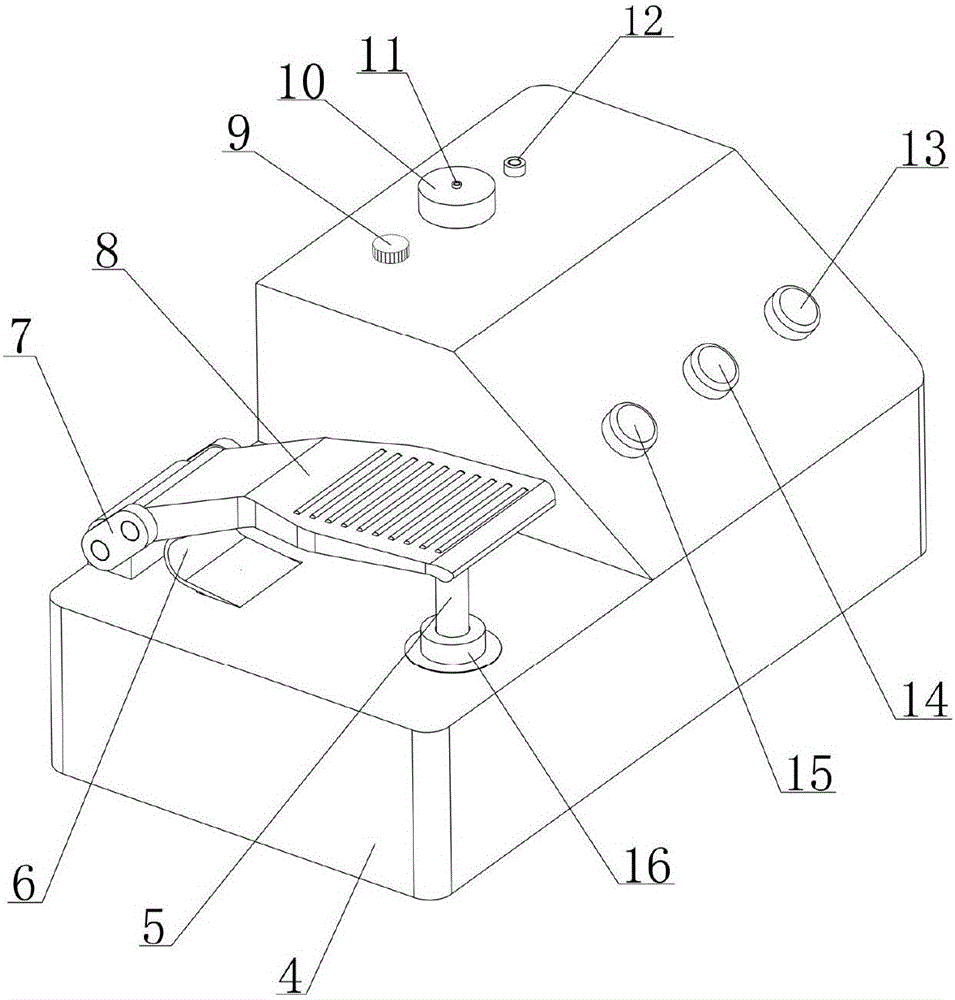

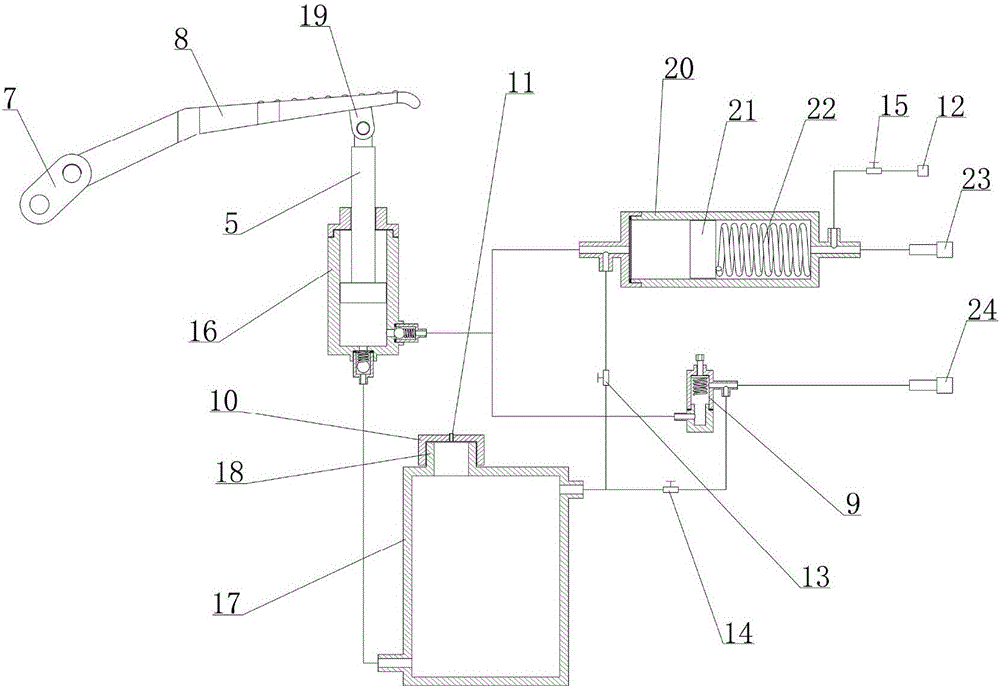

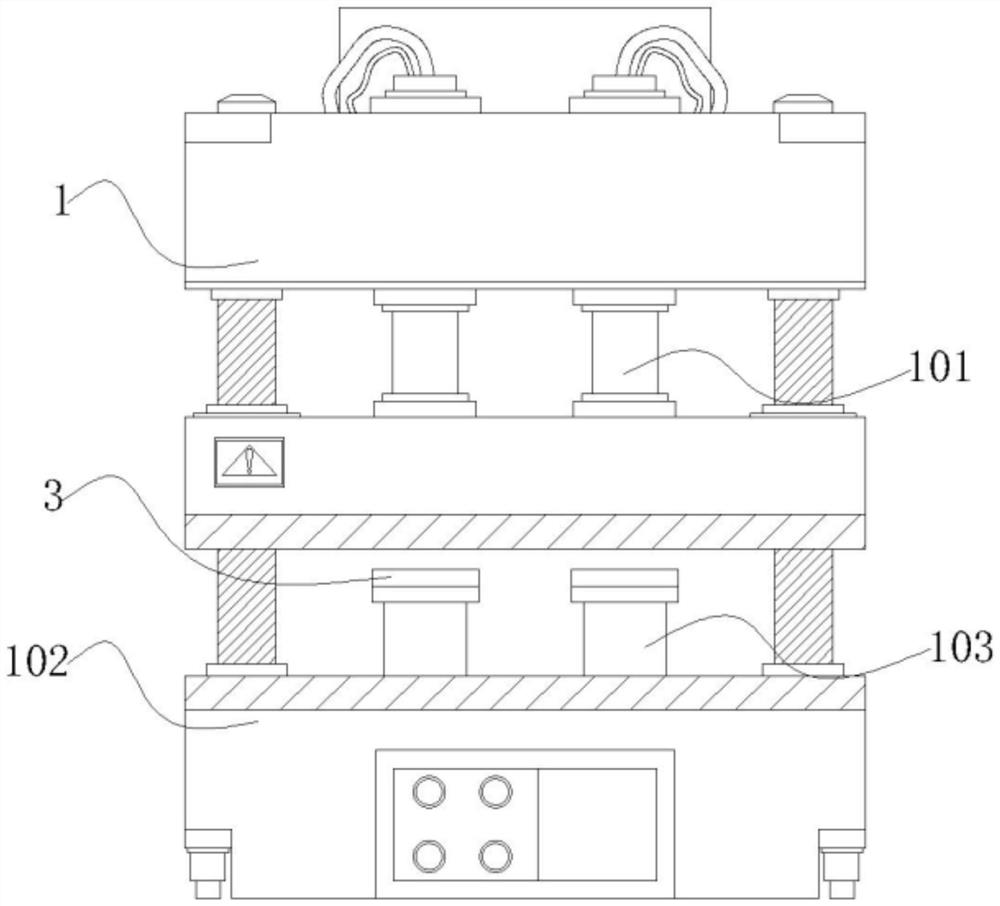

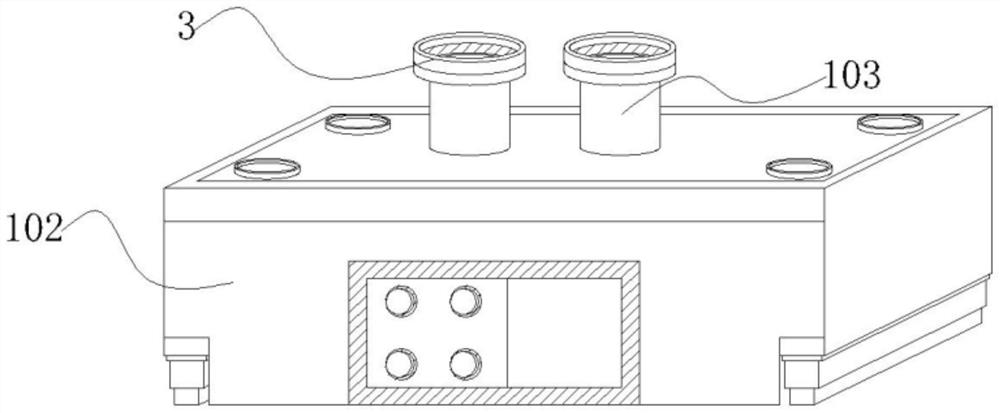

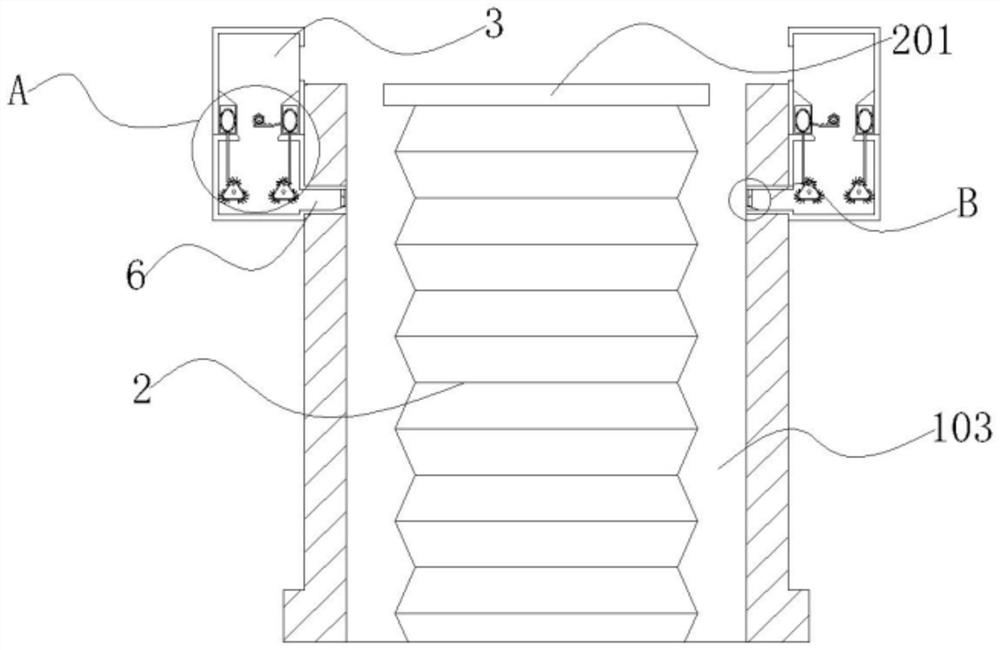

Positive-and-negative pressure driving device for mounting tool of cold shrinking cable sealing cap

ActiveCN106015148AEasy to prepareCompact structureServomotor componentsServomotorsFailure rateAdjustable pressure limiting valve

Owner:江苏智光创业投资有限公司

Device convenient for wheelchair to get-on and get-off stations

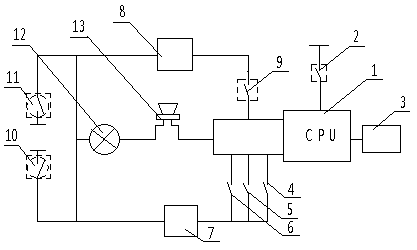

The invention relates to a device convenient for a wheelchair to get-on and get-off stations, in particular to a lifting walking device with a special structure, and belongs to the field of special devices for disabled people. The device comprises a lifting device, a walking device and a control system; and the lifting device is a hydraulic lifting platform, the walking device a stepping motor andis connected to a walking system driving wheel at the lower part of the lifting device through a chain wheel and a chain structure, the control system comprises two 51-series single-chip microcomputers, and the getting-on route and the getting-off route of the device are controlled respectively. According to the device convenient for the wheelchair to get-on and get-off the stations, a wheelchairpressure sensor arranged at the bottom of wheelchair clamping grooves can enable the device to automatically detect whether the wheelchair is driven into; a hydraulic cylinder and a hydraulic pump are installed on a lower bearing plate can control the rise and fall of an upper bearing plate; the stepping motor and a chain transmission mechanism are arranged below the lower bearing plate and can drive the wheels to move forwards and backwards; and the disabled people can take the wheelchair alone and travel can be completed, and when the disabled people drive the upper bearing plate, the device can automatically reset.

Owner:朱兰英

Water tightness test device

Owner:WUHAN MARINE MACHINERY PLANT

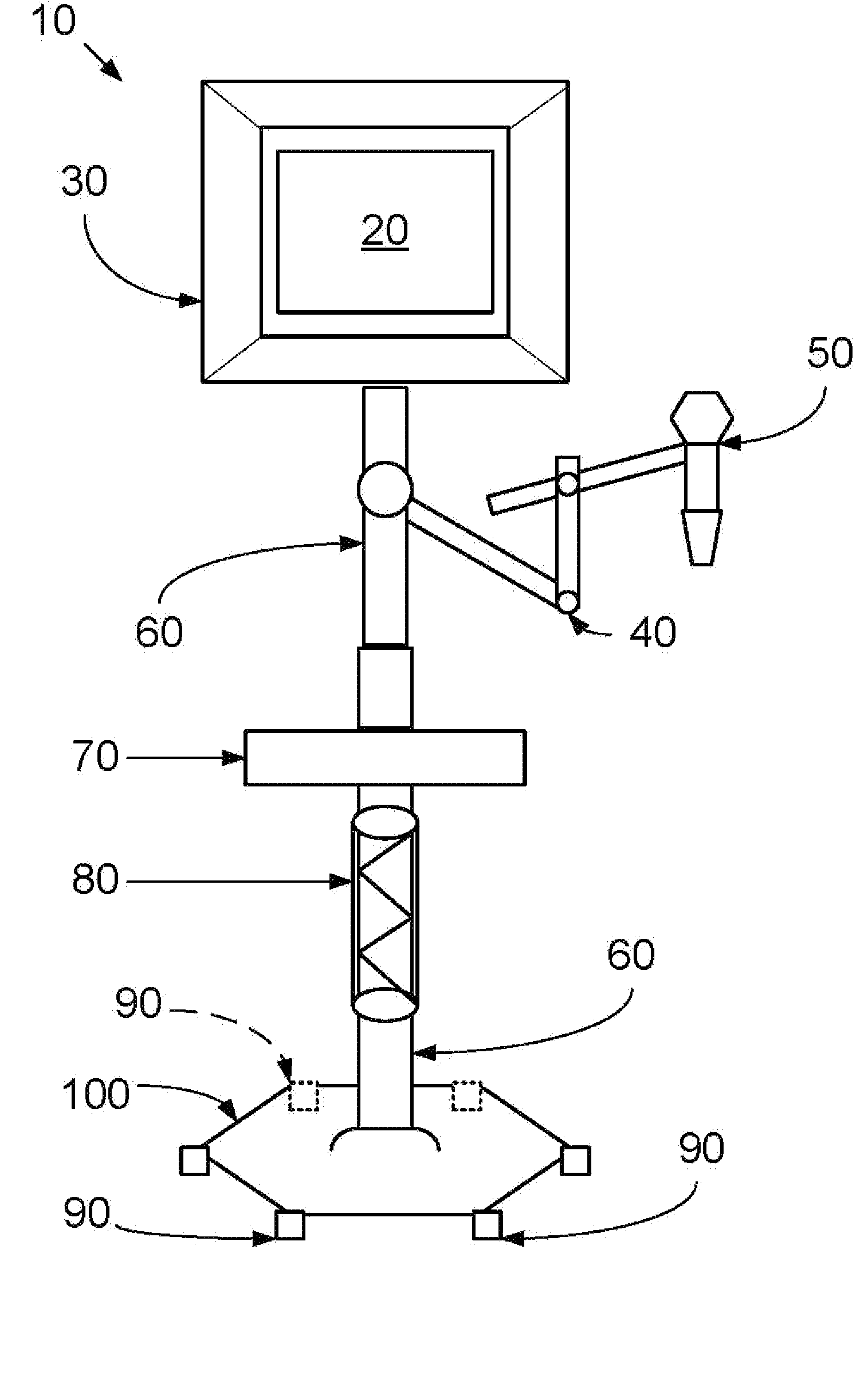

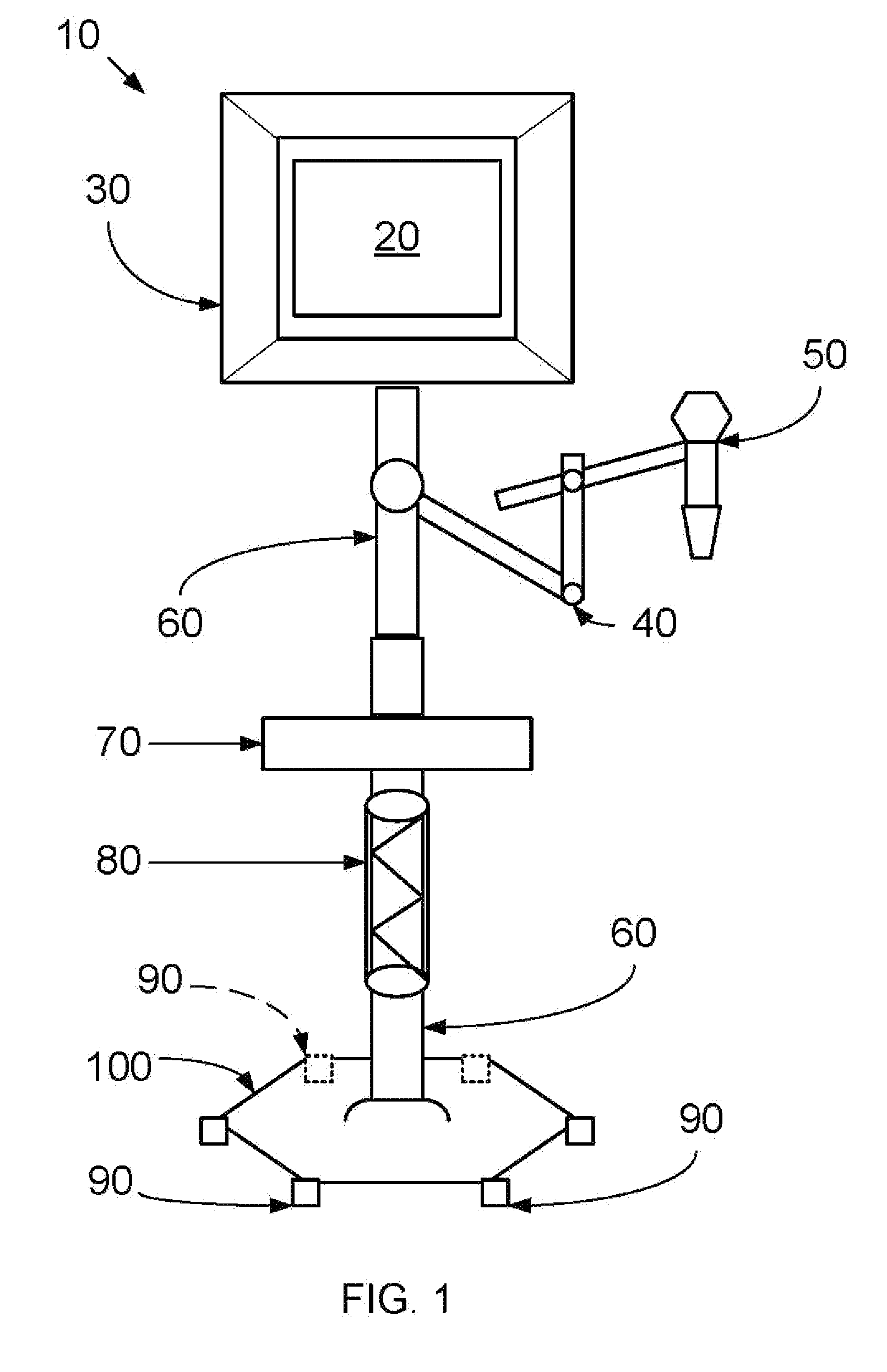

Compact Sound-Filtering Monitor and Microphone Stand

InactiveUS20110058701A1Improve sound qualityBest offset weightPiezoelectric/electrostrictive microphonesMicrophonesHydraulic pumpEngineering

Owner:FULKS ASAF

Novel hydraulic control system for combine harvester

ActiveCN103711740AIndependent of rotational speedAvoid stress stacking problemsServomotor componentsMowersControl systemHydraulic pump

Owner:ZHEJIANG AFANTE PRECISION EQUIP MFGCO

Deicing device and method for blade of wind turbine generator

InactiveCN111828265ASimple structureLow costWind motor controlFinal product manufactureMarine engineeringControl system

The invention discloses a deicing device and method for a blade of a wind turbine generator. The device comprises a plurality of spray pipes arranged on a tower drum at intervals up and down, whereinhorizontal length of each spray pipe is smaller than distance between the blade and the tower drum, all the spray pipes are connected with a hydraulic pressure station through delivery pipes, the hydraulic pressure station comprises a liquid storage tank and a hydraulic pump, an ice melting agent is stored in the liquid storage tank, the hydraulic pressure station is connected with a deicing control system, and the deicing control system is connected with a wind turbine generator control system. The deicing device has the beneficial effects of being simple in structure, low in manufacturing cost, high in deicing efficiency and low in safety risk and the deicing process is highly repeatable.

Owner:HUBEI LONGYUAN NEW ENERGY CO LTD

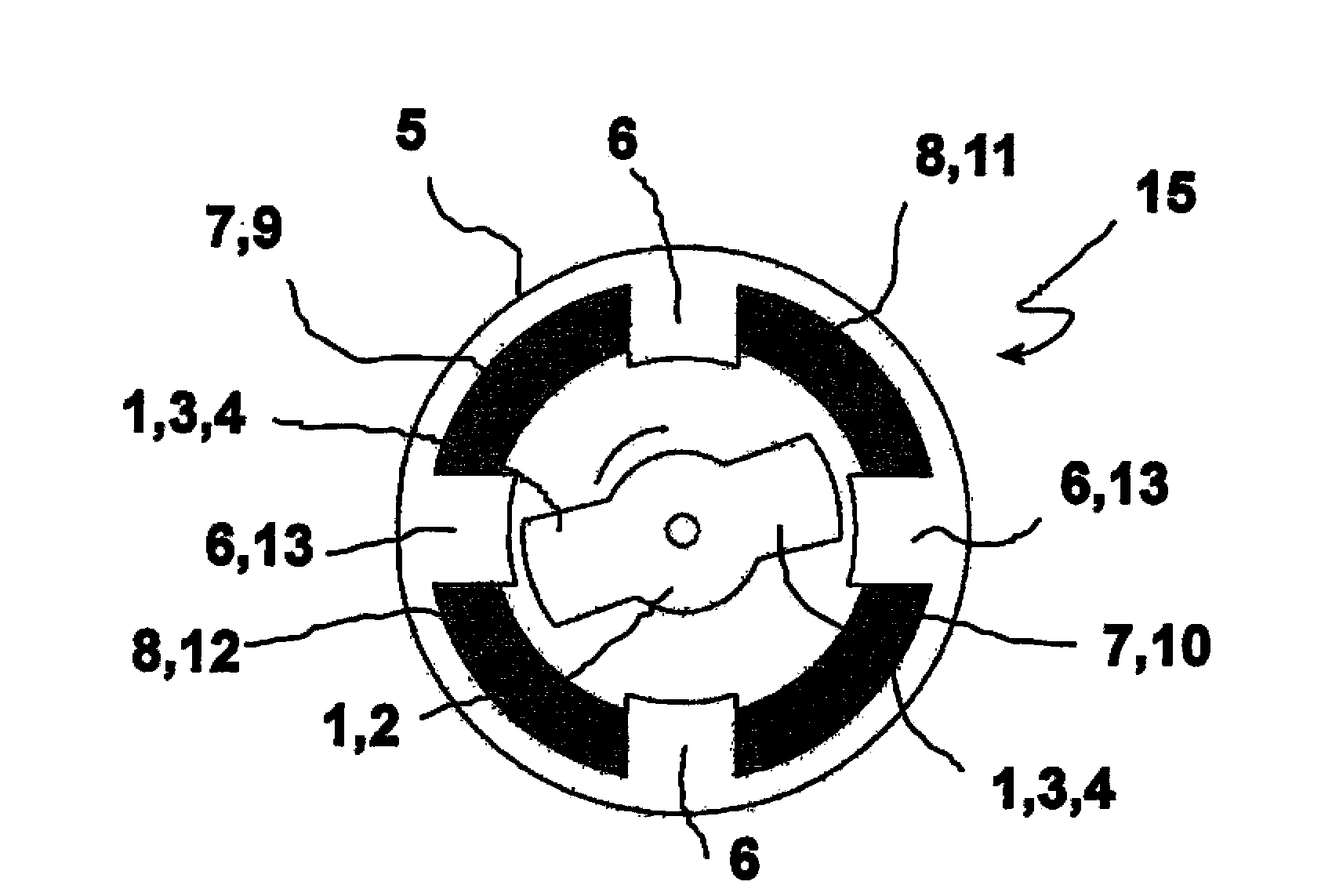

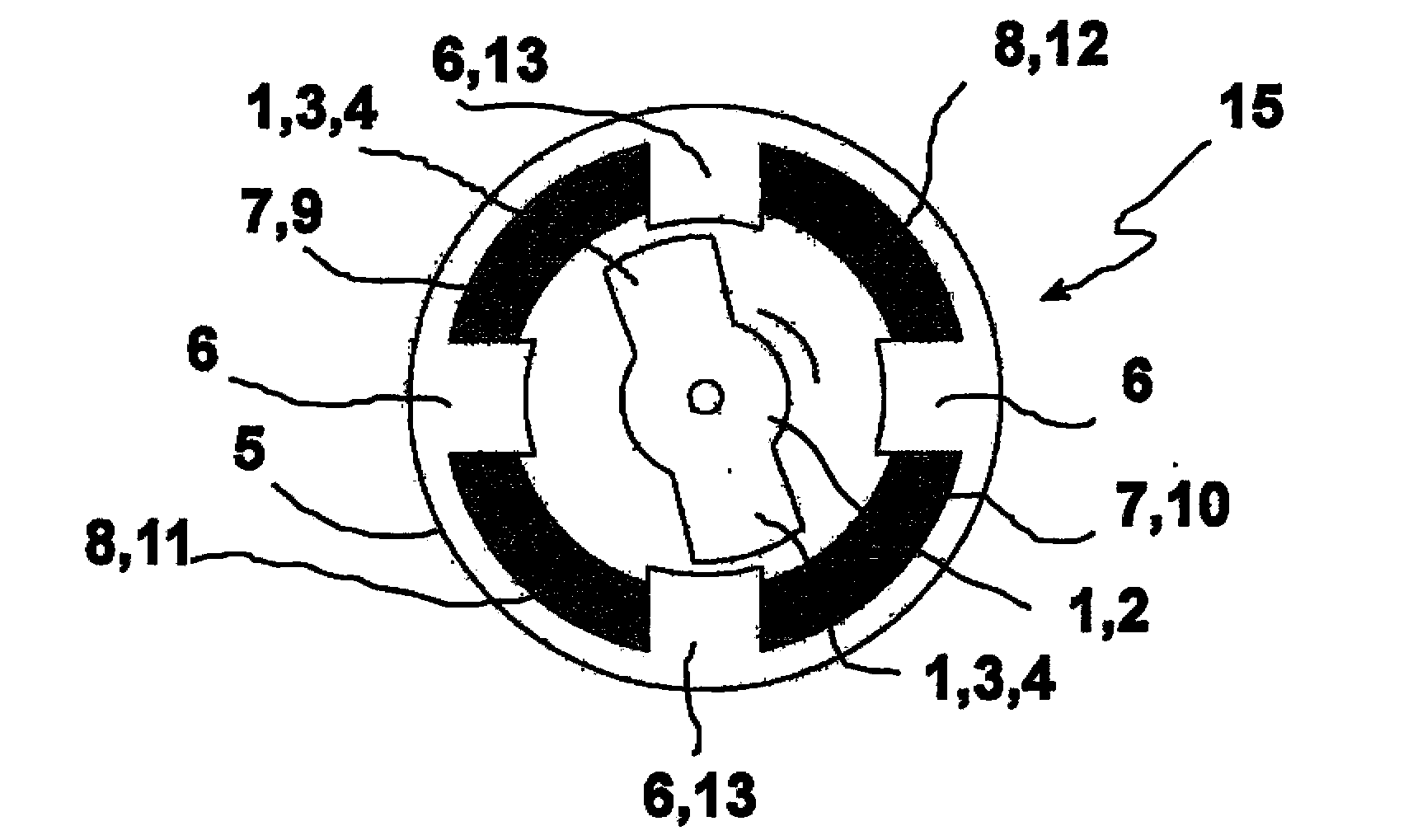

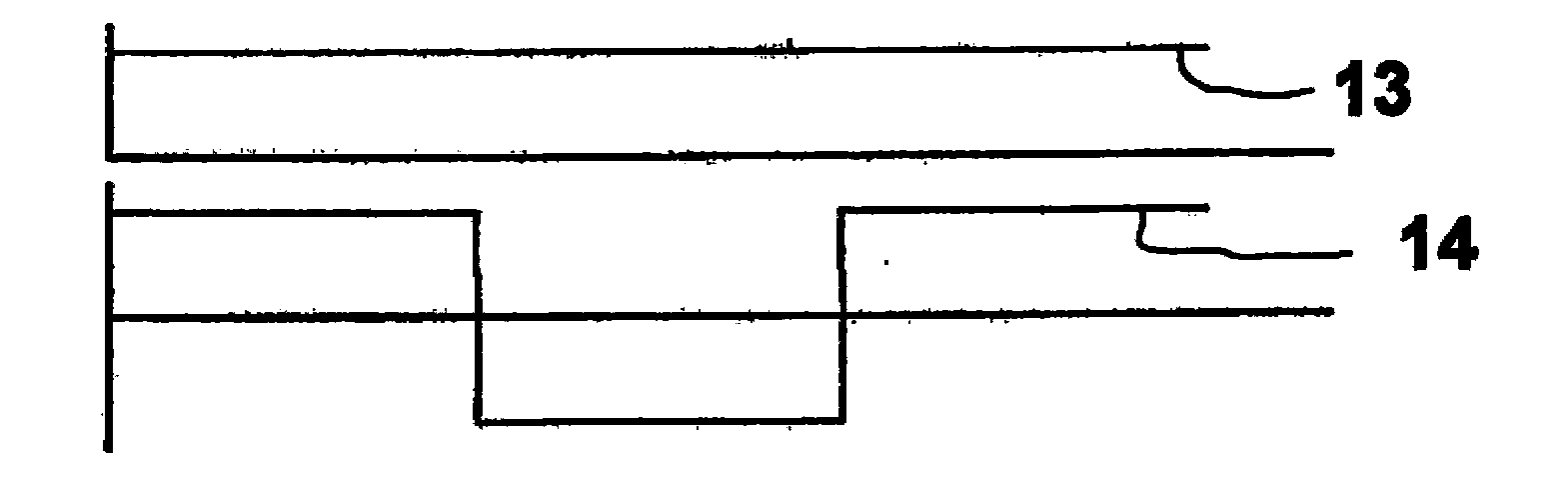

Permanent-magnet separator for separating harmful heavy metal in soil

InactiveCN104043643AImprove protectionSimple structureContaminated soil reclamationMagnetic separationHydraulic pumpEnvironmental engineering

Owner:柏连阳

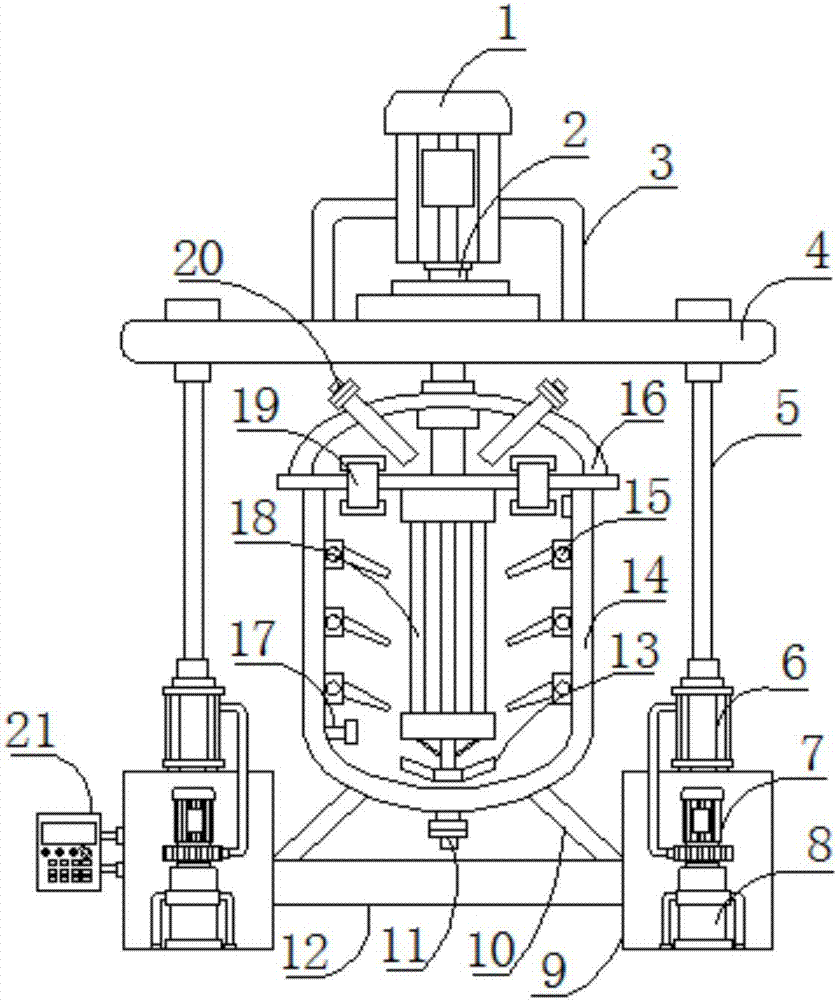

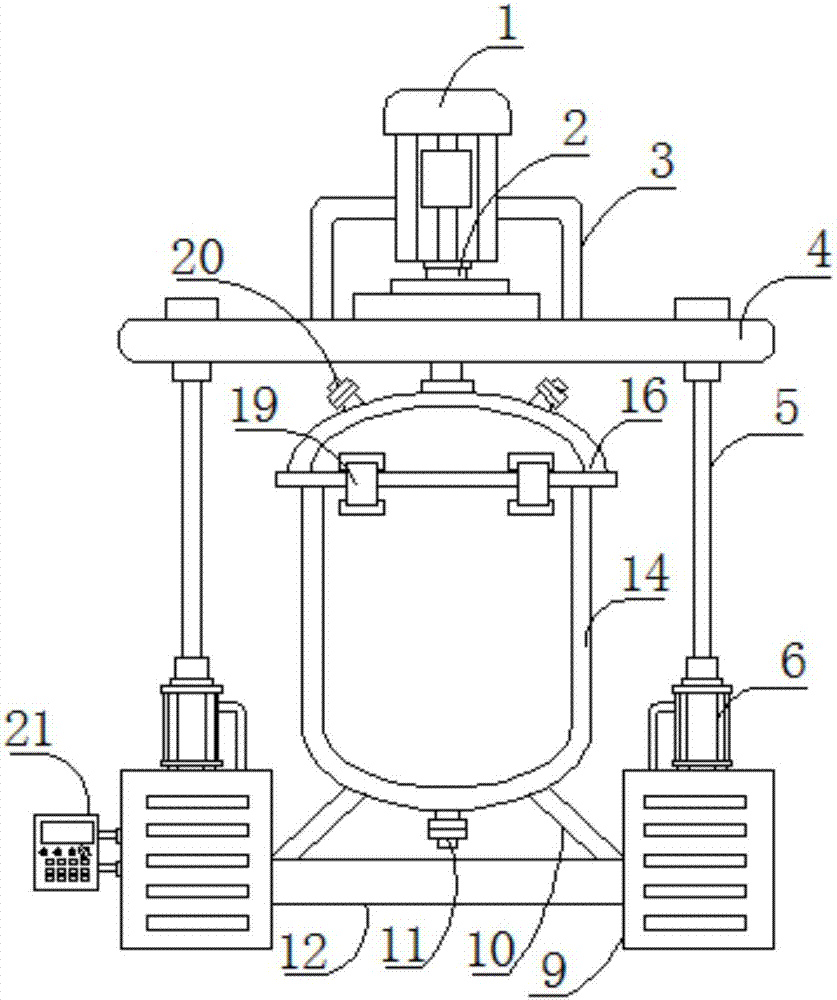

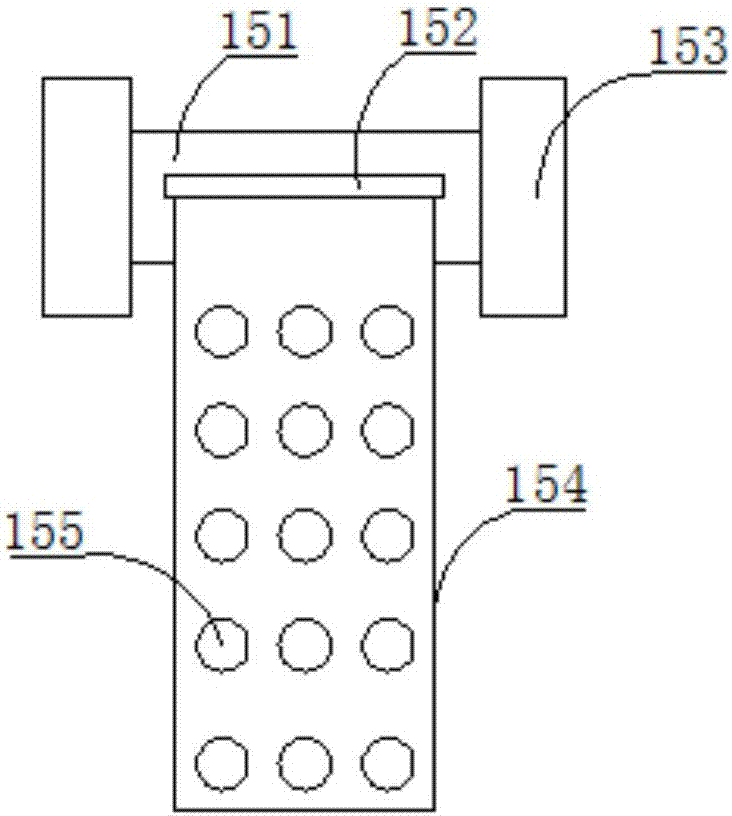

Stirring and emulsifying equipment for preparing energy-saving color paste

InactiveCN107469656AImprove centrifugal extrusionIncreased force between impactsRotary stirring mixersMixing methodsHydraulic cylinderLiquid layer

Owner:长兴利其科技有限公司

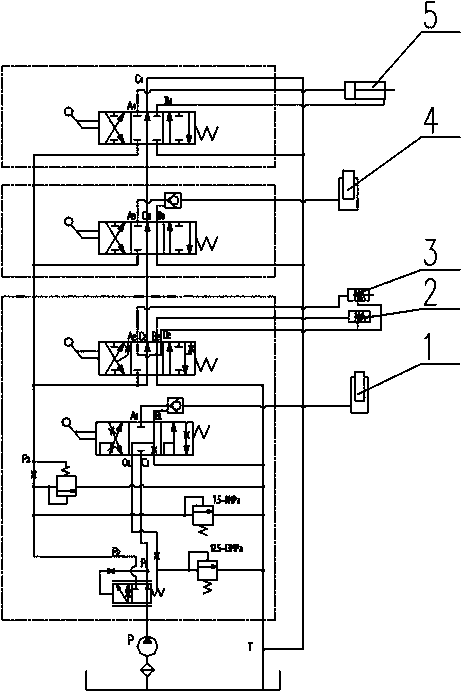

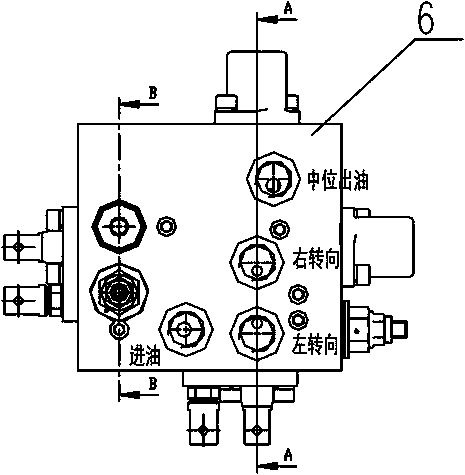

Hydraulic control system for scooptram

ActiveCN102535574AUse less componentsSimple structureSoil-shifting machines/dredgersGear pumpControl system

The invention discloses a hydraulic control system for a scooptram. The hydraulic control system comprises a braking loop which is subjected to oil supply through a right pump of a duplex gear pump and a steering loop which is subjected to oil supply through a left pump of the duplex gear pump, wherein the braking loop or the steering loop is also connected with a backup oil supply branch circuit; the backup oil supply branch circuit is controlled by an electromagnetic reversing valve to alternatively supply oil to the braking loop and the steering loop; the input end of the electromagnetic reversing valve is connected to a part behind a gathering point between the backup oil supply branch circuit and the braking loop or connected to a part behind a gathering point between the backup oil supply branch circuit and the steering loop; and one of two output ports of the electromagnetic reversing valve is connected with the input port of a steering control valve of the steering valve, and the other output port of the electromagnetic reversing valve is connected with the braking loop. According to the hydraulic control system, only one electric hydraulic pump is needed to supply oil to a brake and a steering oil cylinder, so that the technical shortcoming that the scooptram cannot be quickly started and steered at the same time in the prior art when the hydraulic system fails is overcome.

Owner:SINOSTEEL HENGYANG MASCH CO LTD

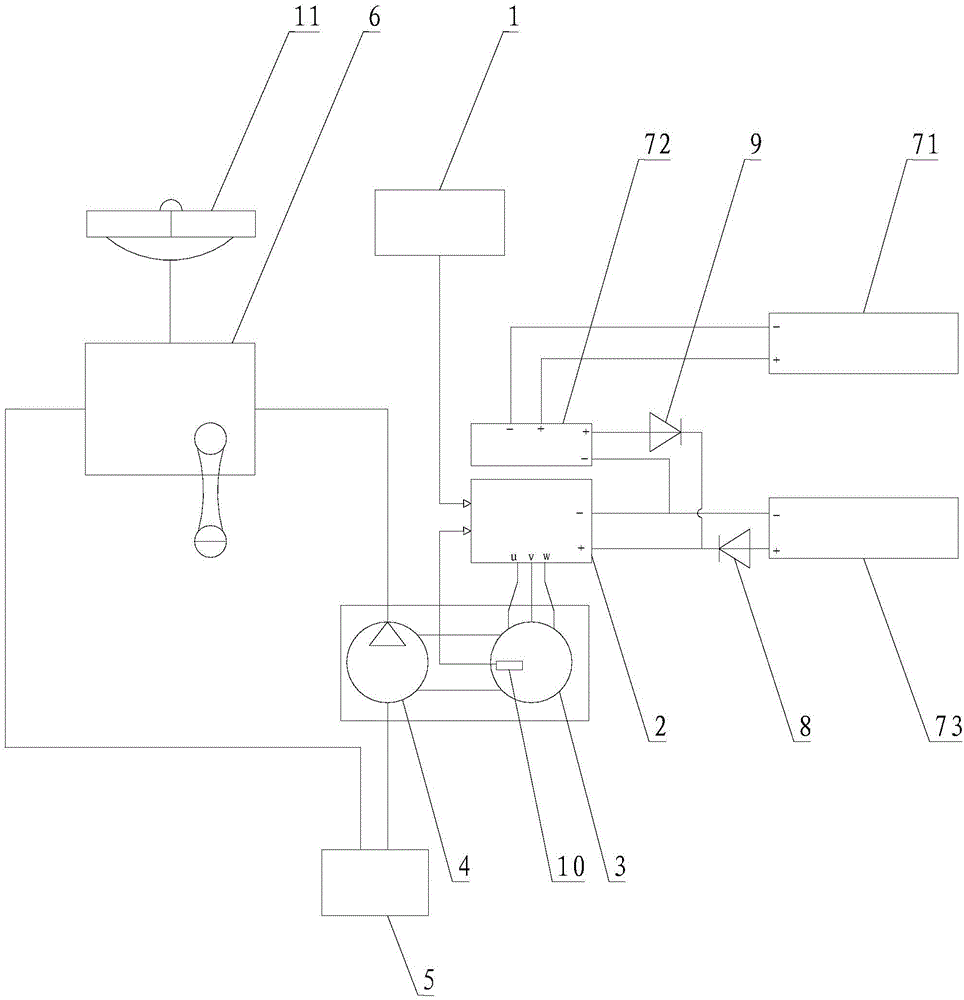

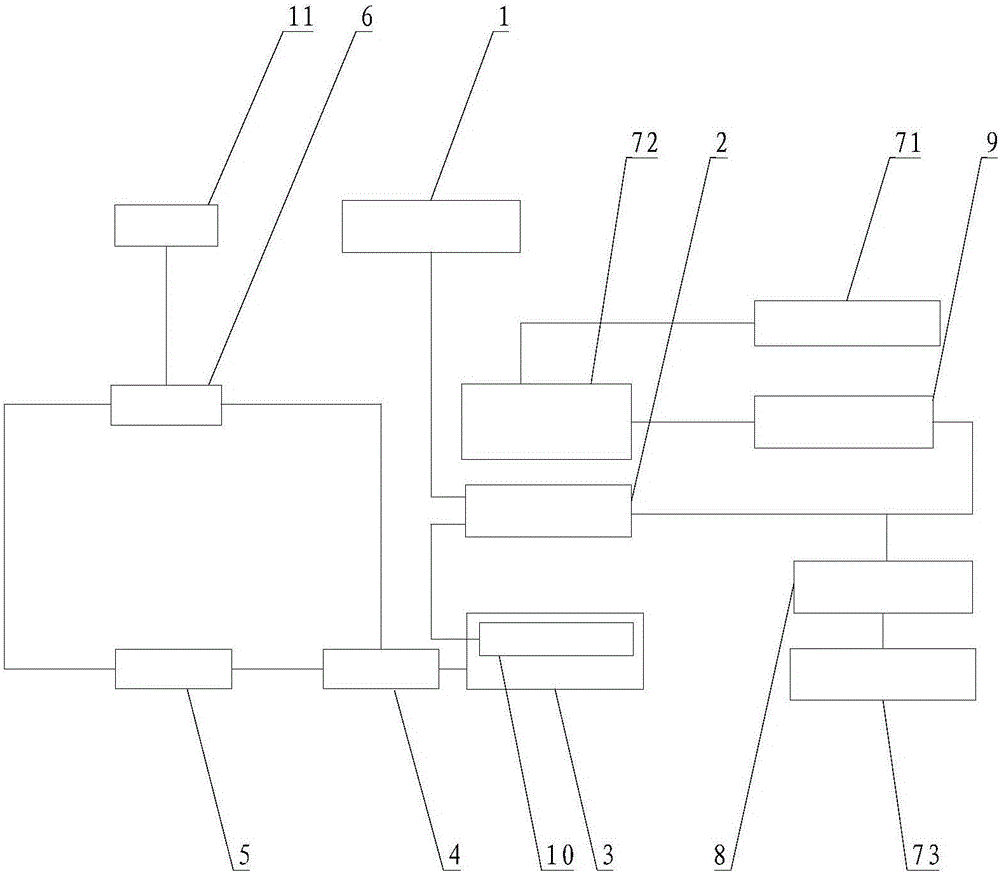

Electric hydraulic power steering system and control method thereof

InactiveCN106275063AIncrease speedStable speedSteering linkagesAutomatic steering controlElectricityLow speed

Owner:XIAMEN FUGONG POWER TECH

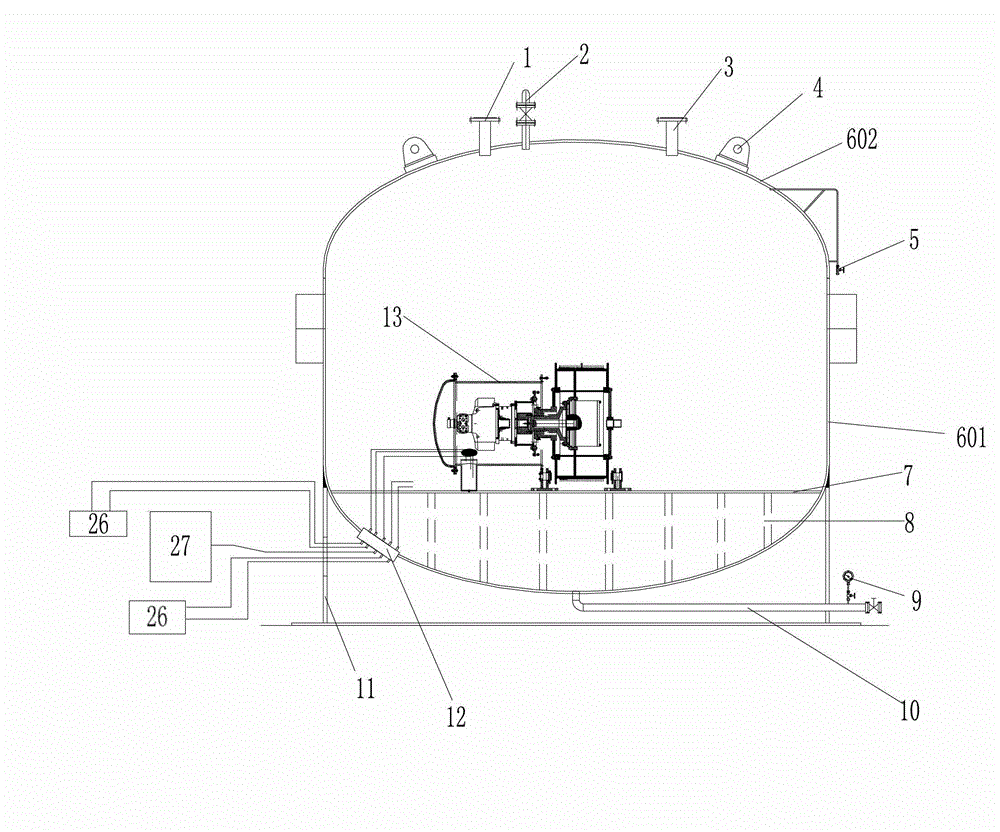

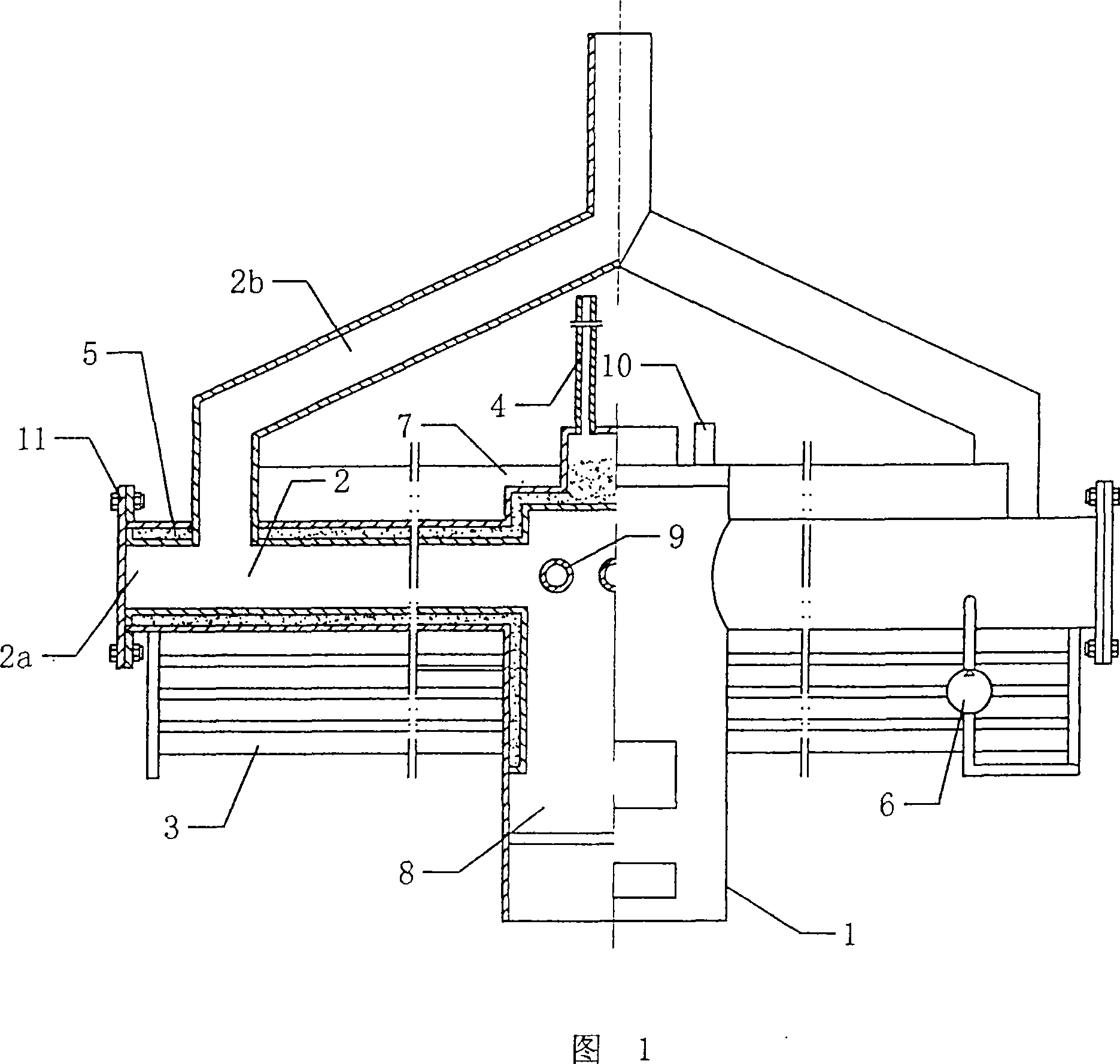

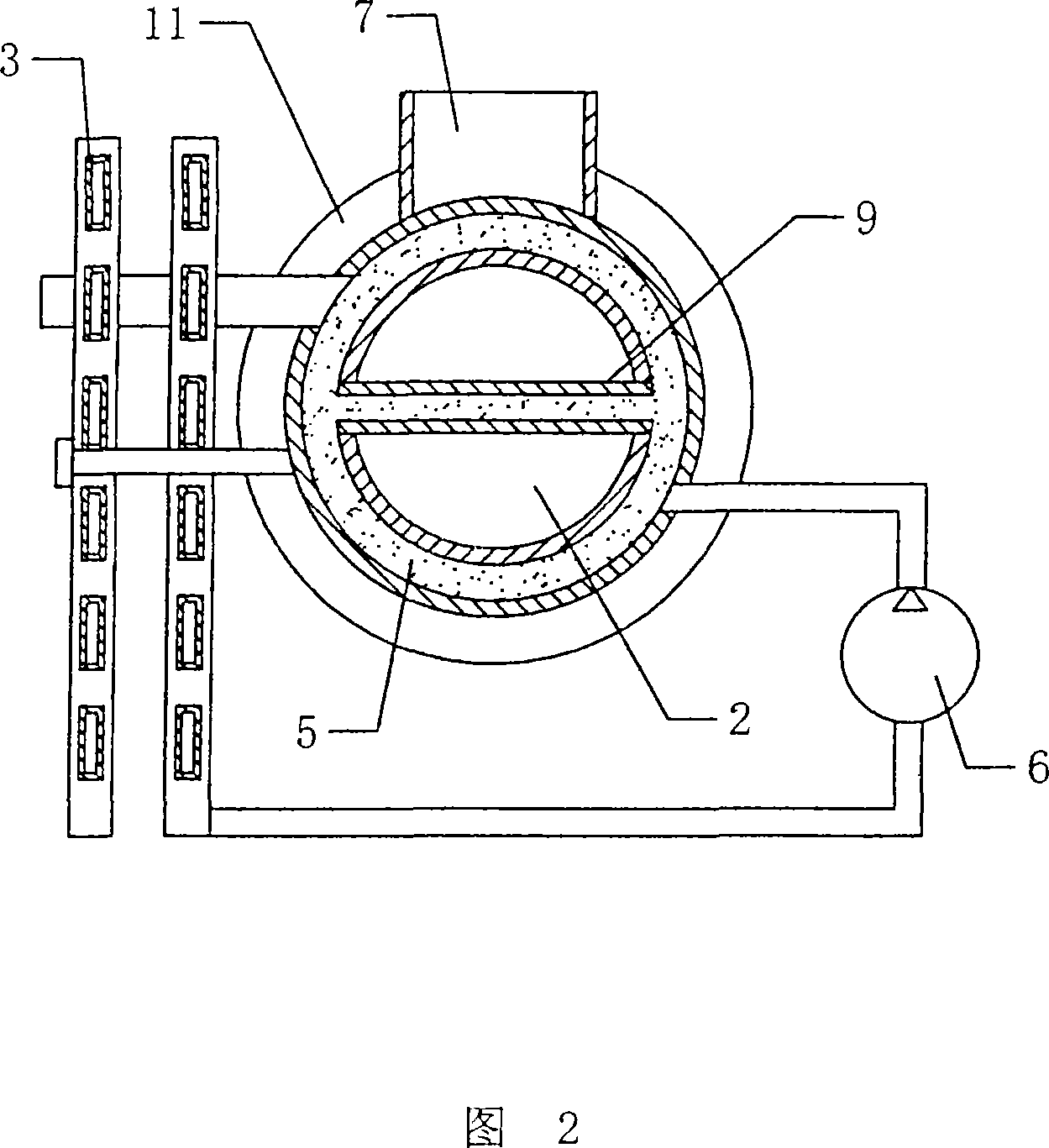

Lumber drying kiln

InactiveCN101144685AImprove thermal conductivityTemperature safetyHeating arrangementCombustion chamberHeat conducting

Owner:李祥文

Squeezing safety and automatic alarm device of diaphragm filter press

PendingCN111298490AImprove the safety requirements of automatic control operationEasy to useAlarmsElectric transmission signalling systemsText displayAutomatic control

Owner:JINGJIN ENVIRONMENTAL PROTECTION INC

Ground conveyor with electric pump motor

InactiveCN103427577AImprove cooling effectImprove reliabilityAC motor controlSynchronous motorsHydraulic pumpMagnetic reluctance

Owner:LINDE MATERIAL HANDLING

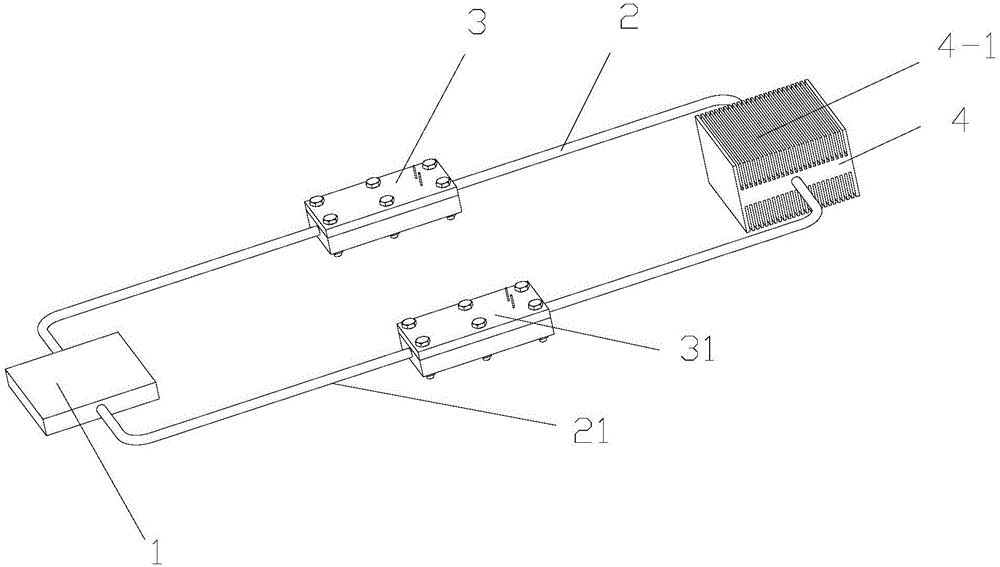

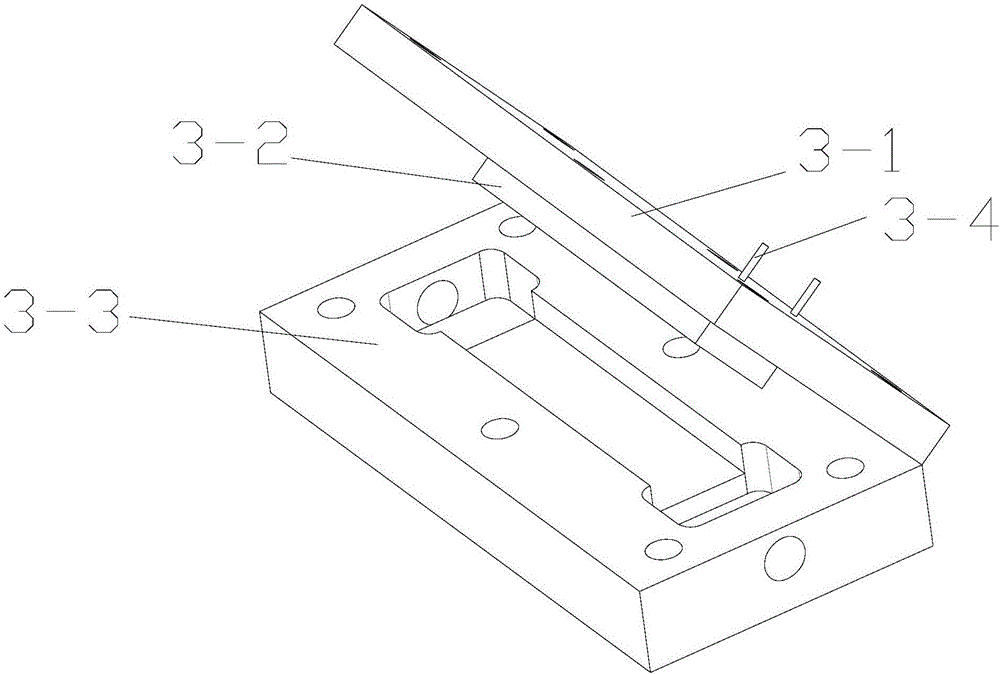

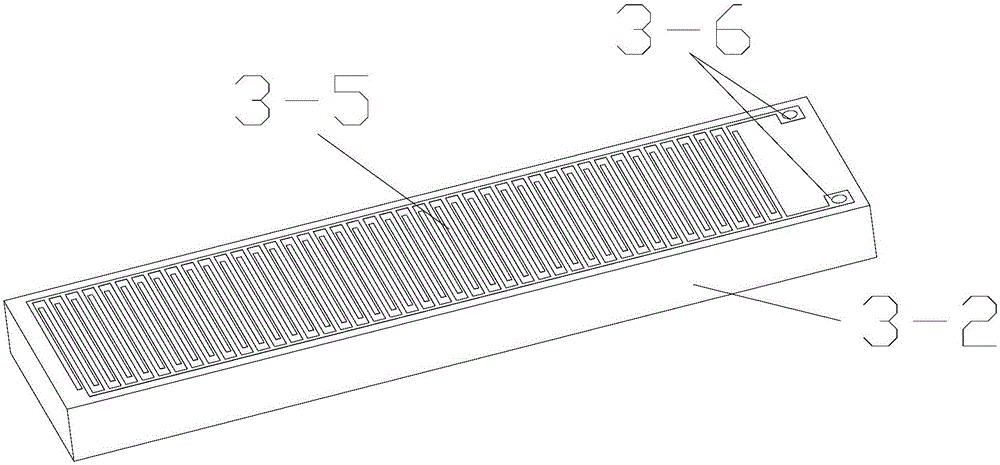

Small liquid cooling system driven by electro-hydraulic micropumps and method

InactiveCN106098657ASolution volumeReduce power consumptionSemiconductor/solid-state device detailsSolid-state devicesWorking fluidHydraulic pump

Owner:SOUTH CHINA UNIV OF TECH

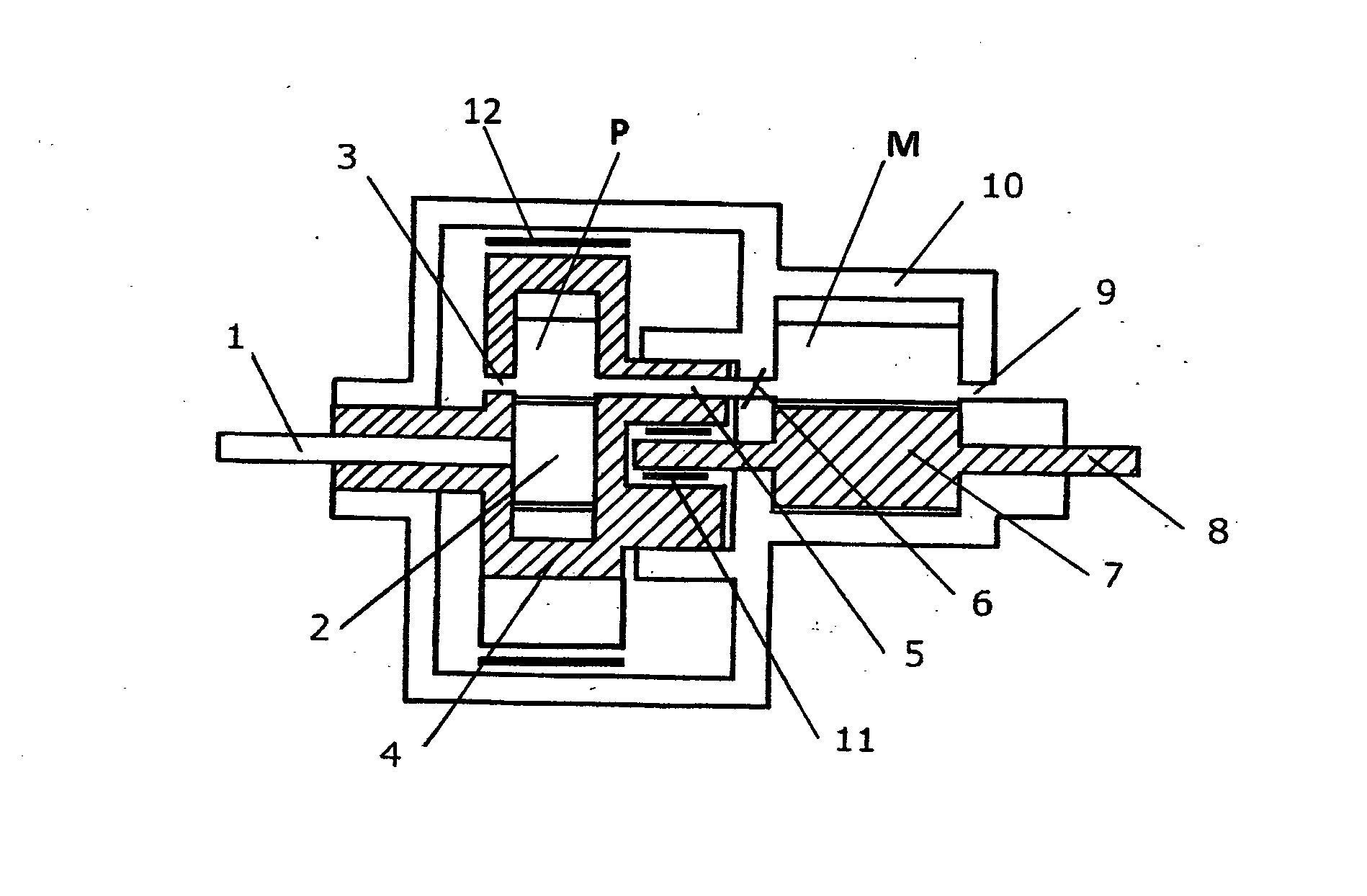

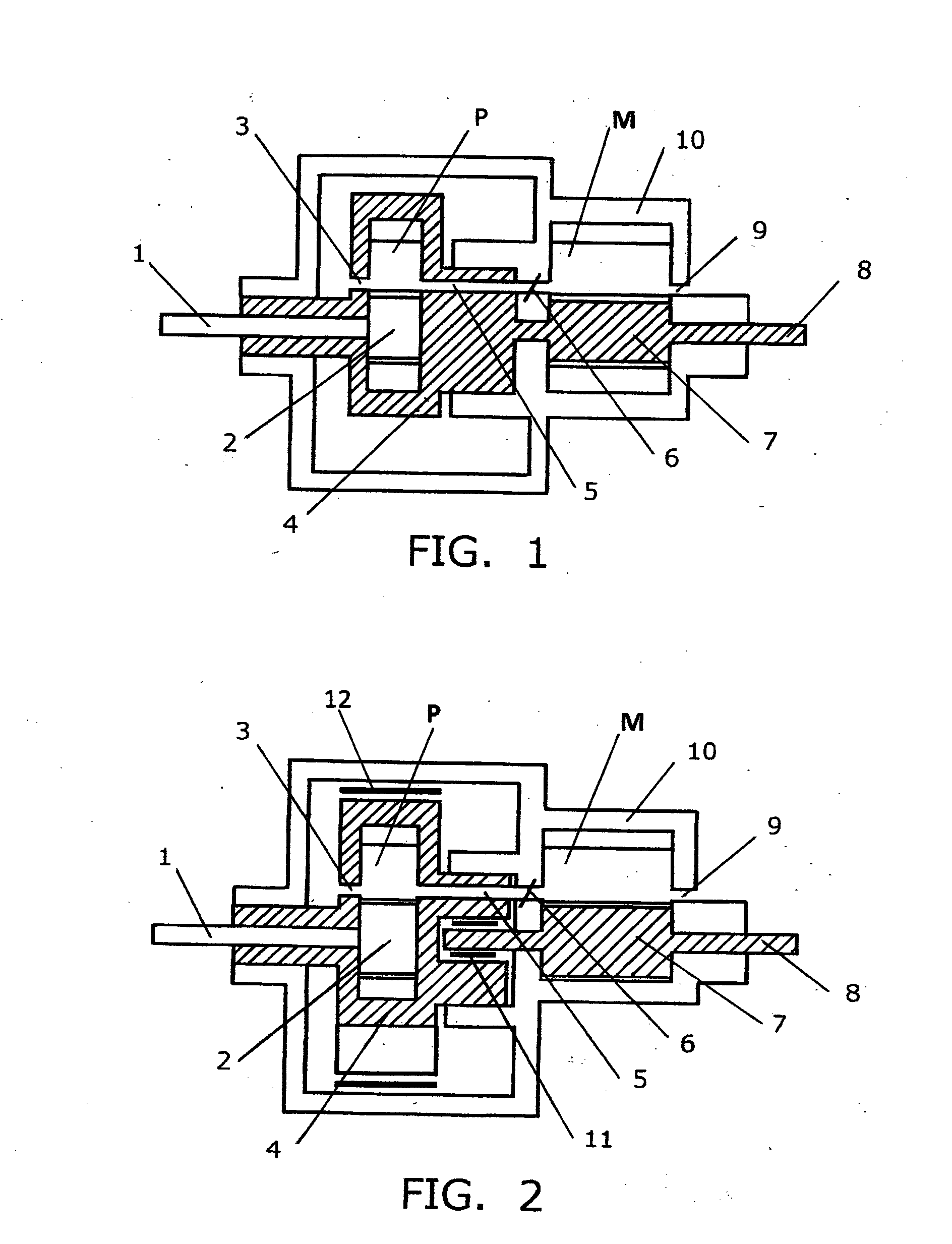

Hydraulic variable drive train

InactiveUS20150198226A1Improved gradual transmissionRotary clutchesGearing controlHydraulic motorDrive wheel

Owner:MEITIN MANUEL

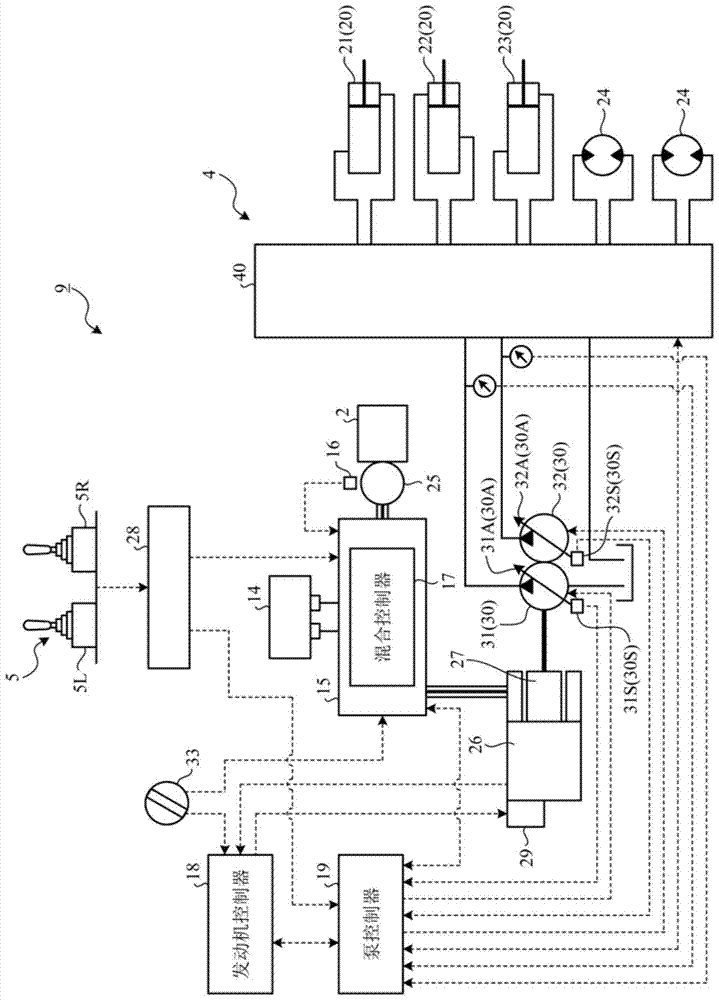

Drive device for construction equipment

ActiveCN107250560ASuppress fuel consumption deteriorationServomotor componentsMechanical machines/dredgersHydraulic pumpEngineering

Owner:KOMATSU LTD

Vehicle type continuous ironmaking water-slag separation environment-friendly device

ActiveCN111748663ATo drive the effectPowerfulRecycling and recovery technologiesProcess efficiency improvementReduction driveSlag

The invention discloses a vehicle type continuous ironmaking water-slag separation environment-friendly device. The device comprises a motor driving device, a loading trolley, a tail chain wheel, a head chain wheel, a speed reducer, a hydraulic pump station and a third connecting pipe, wherein the tail chain wheel is arranged on the left side of the head chain wheel, the head chain wheel and the tail chain wheel are located at the same height, and the tail chain wheel is connected with the head chain wheel through a running chain; a tail hydraulic tensioning device is arranged on the left sideof the tail chain wheel, the hydraulic pump station is arranged on the left side of the tail hydraulic tensioning device, the hydraulic pump station is connected with the tail hydraulic tensioning device through a first connecting pipe, and a second connecting pipe is connected to the upper portion of the right side of the first connecting pipe. A loading trolley is provided with water permeableholes, and water in water slag can be separated out in the ascending process of the loading trolley, so that the slag-water separation process is short, the energy storage effect is good, and waste heat can be conveniently recycled; in addition, a filter screen is arranged in the loading trolley, so that the water quality after slag-water separation is better.

Owner:HEBEI YIZHI ENVIRONMENTAL PROTECTION TECH CO LTD

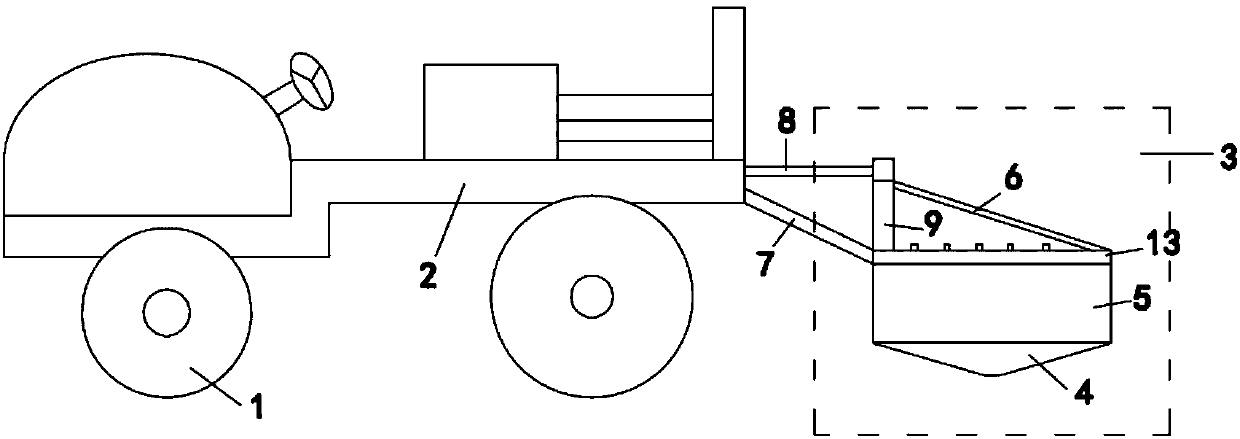

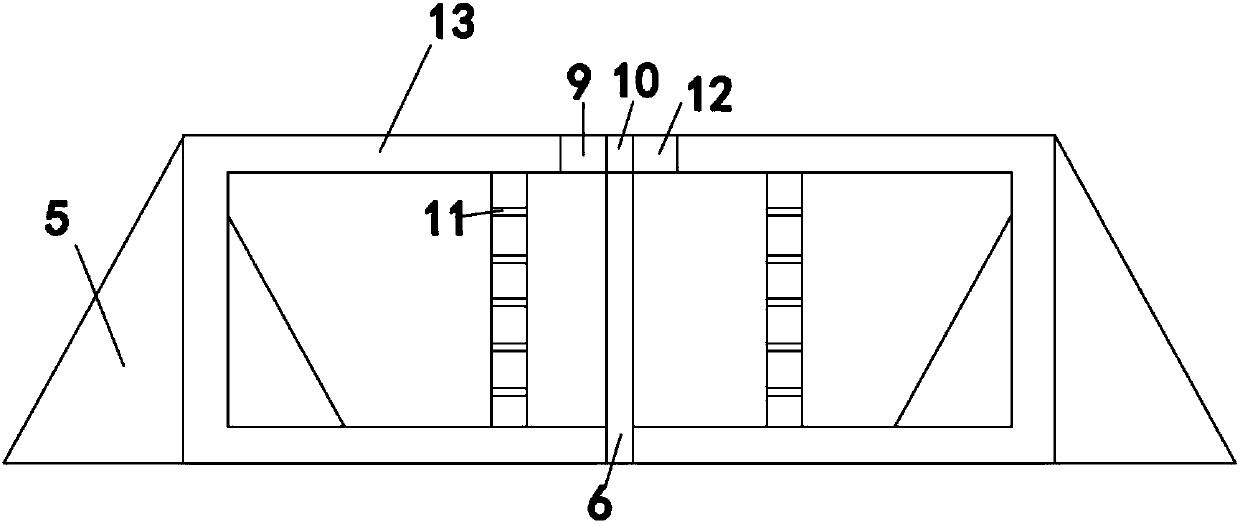

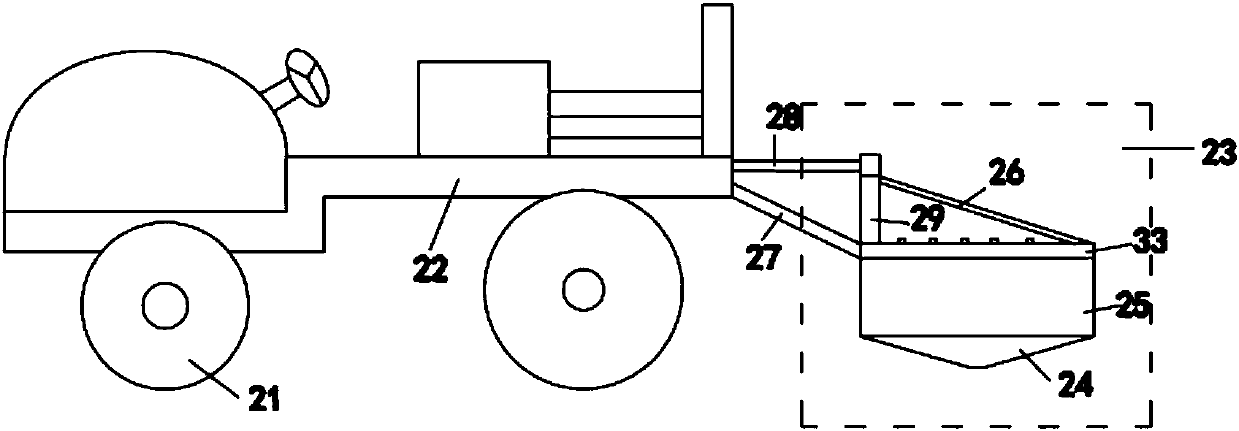

Field grooving machine

Owner:江苏红旗种业股份有限公司

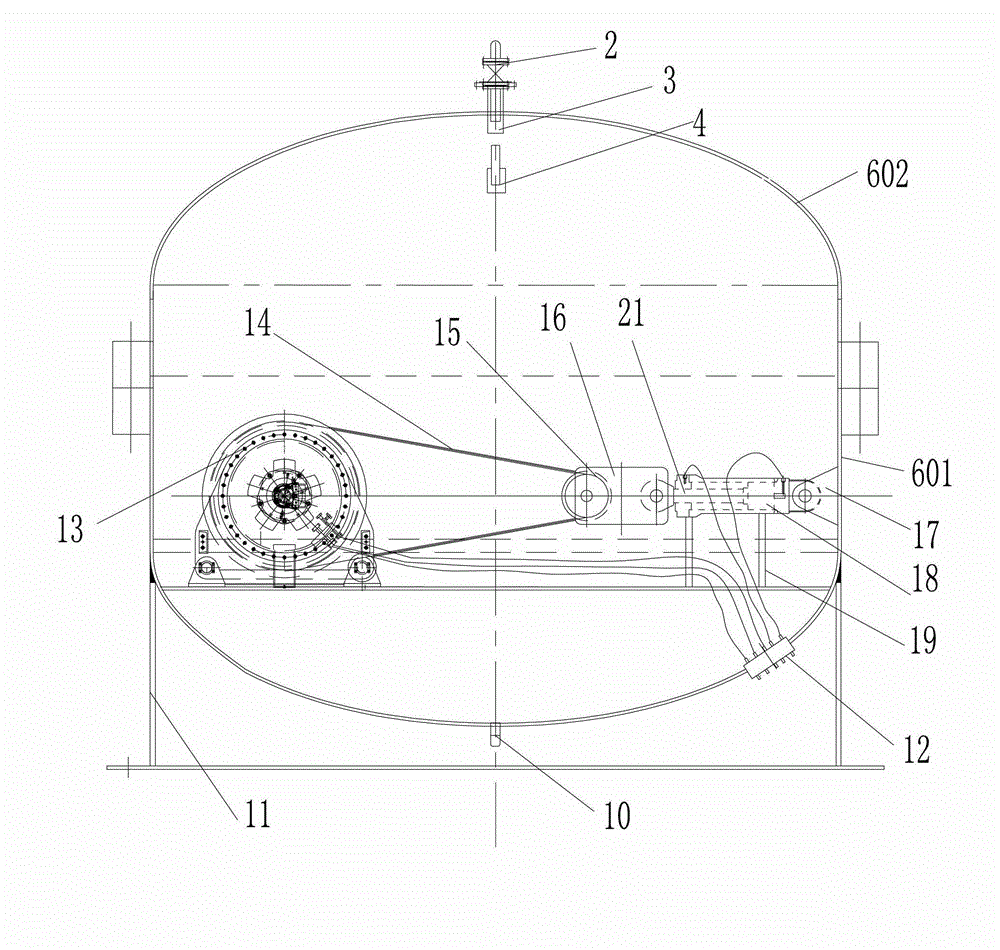

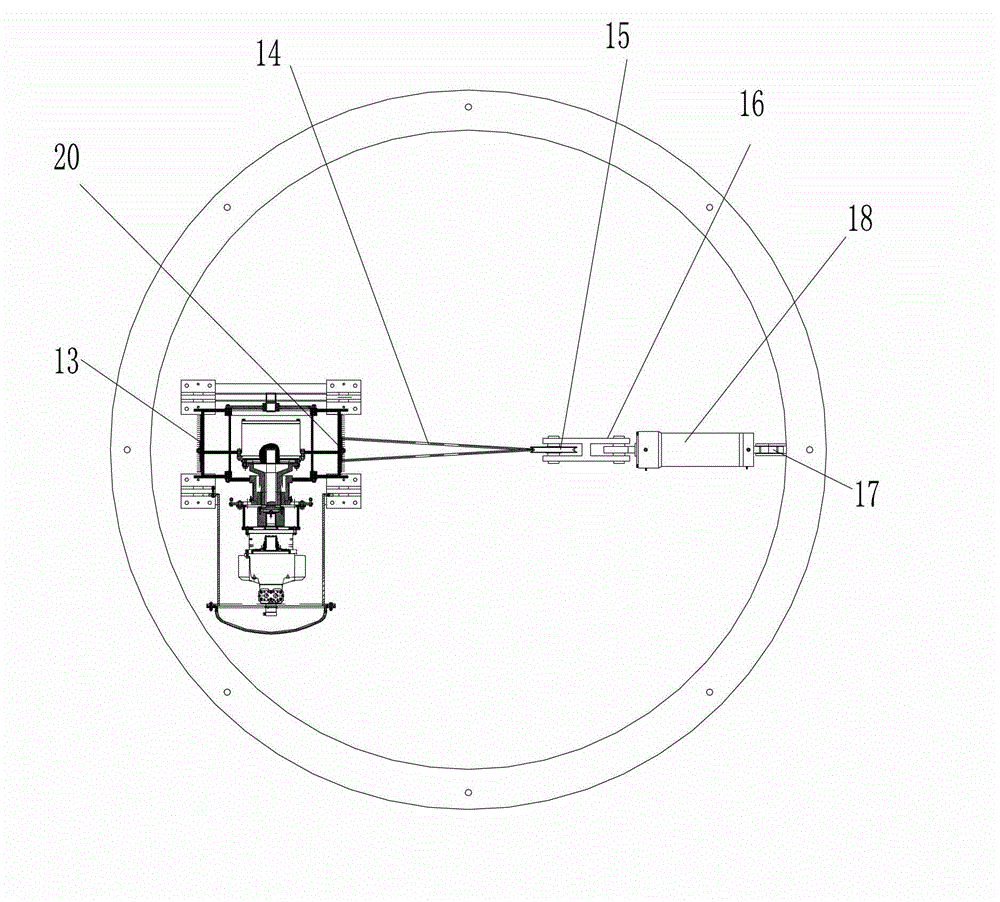

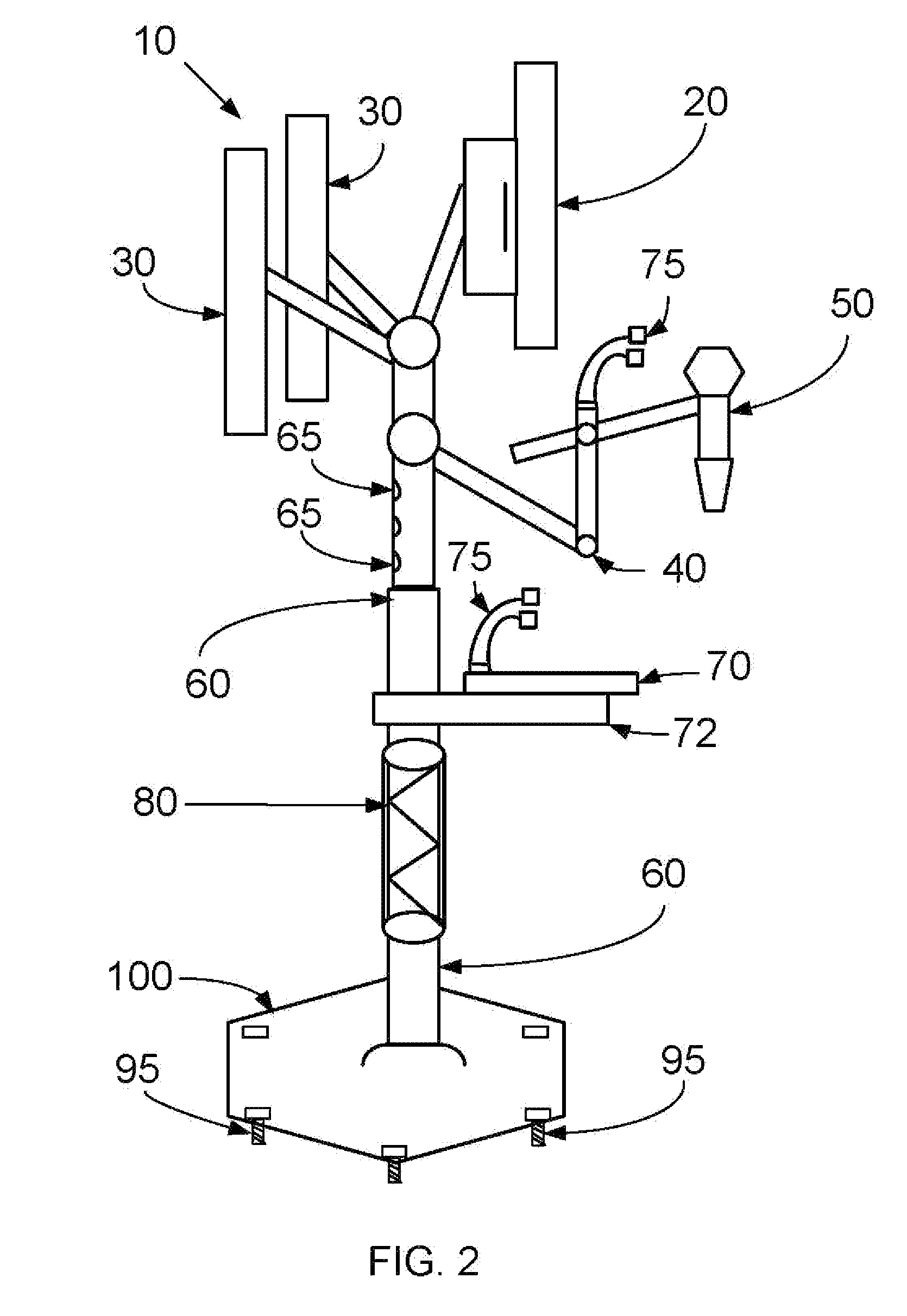

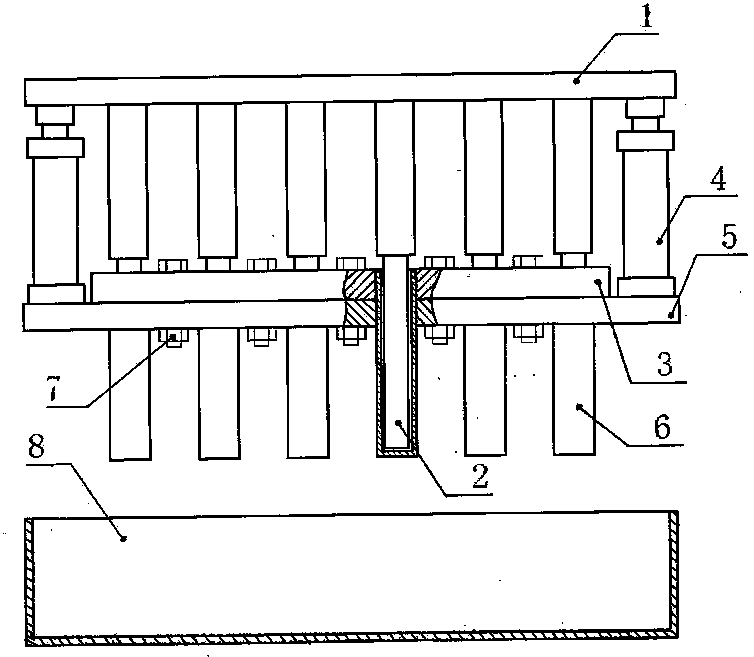

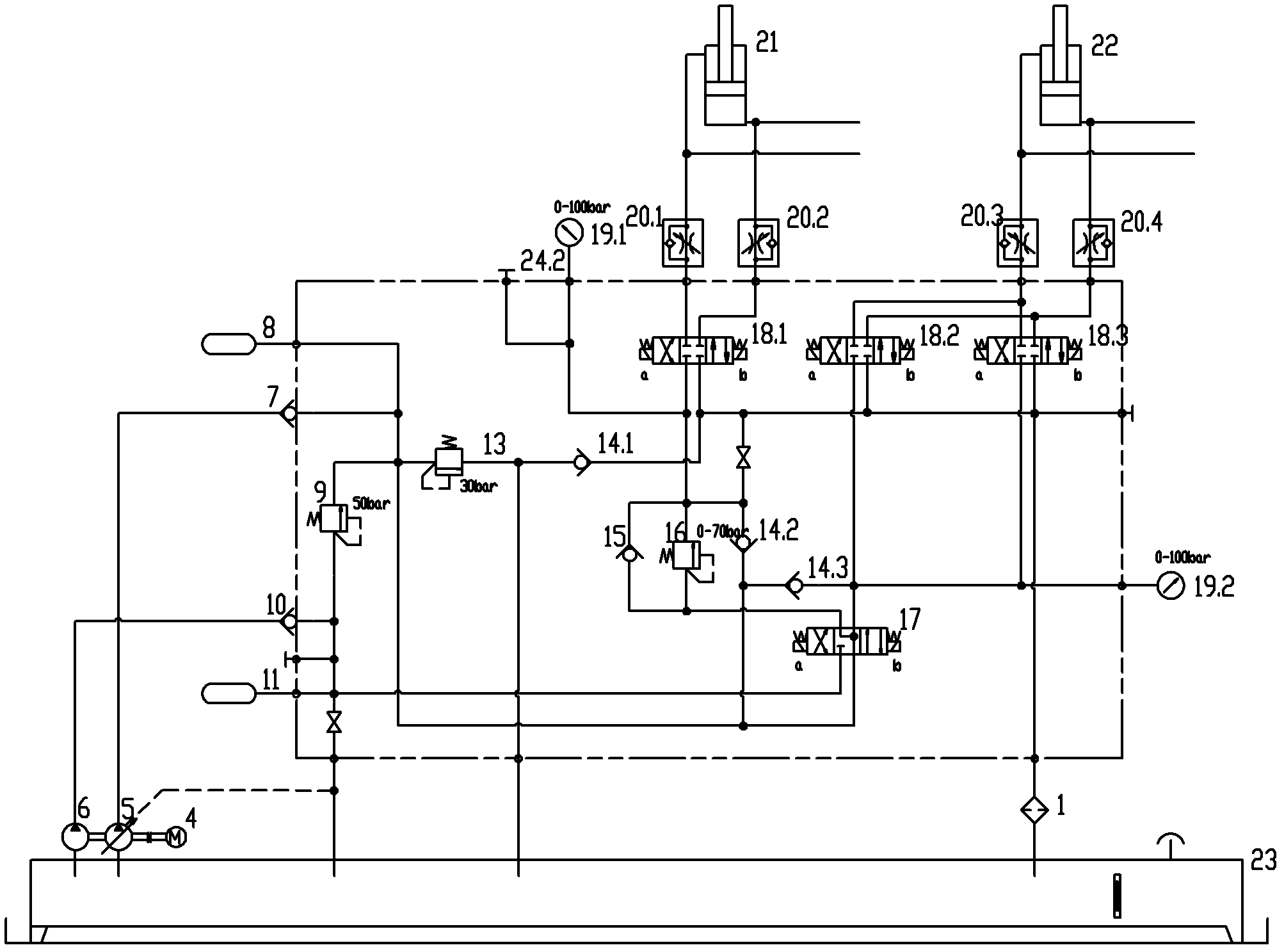

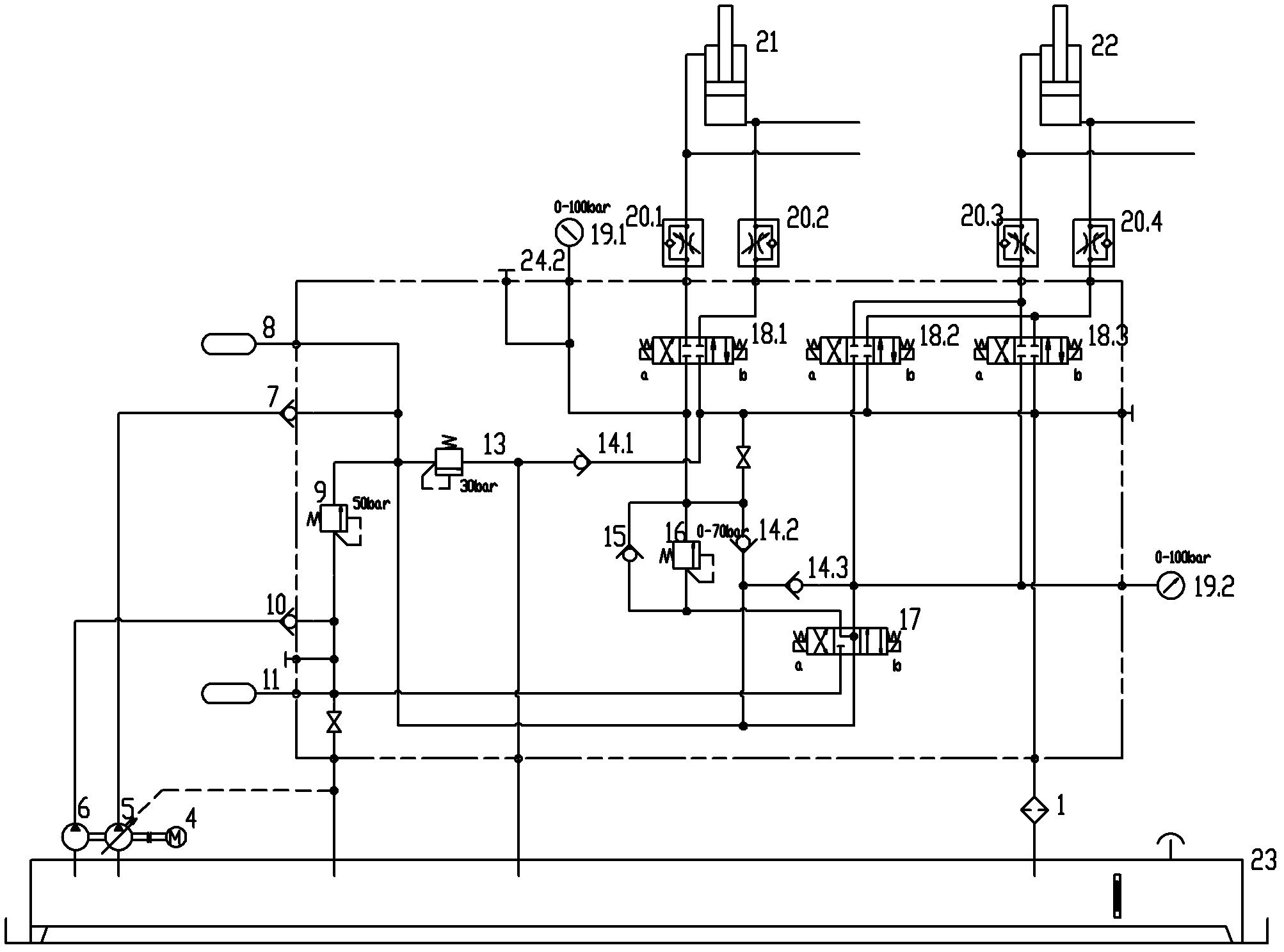

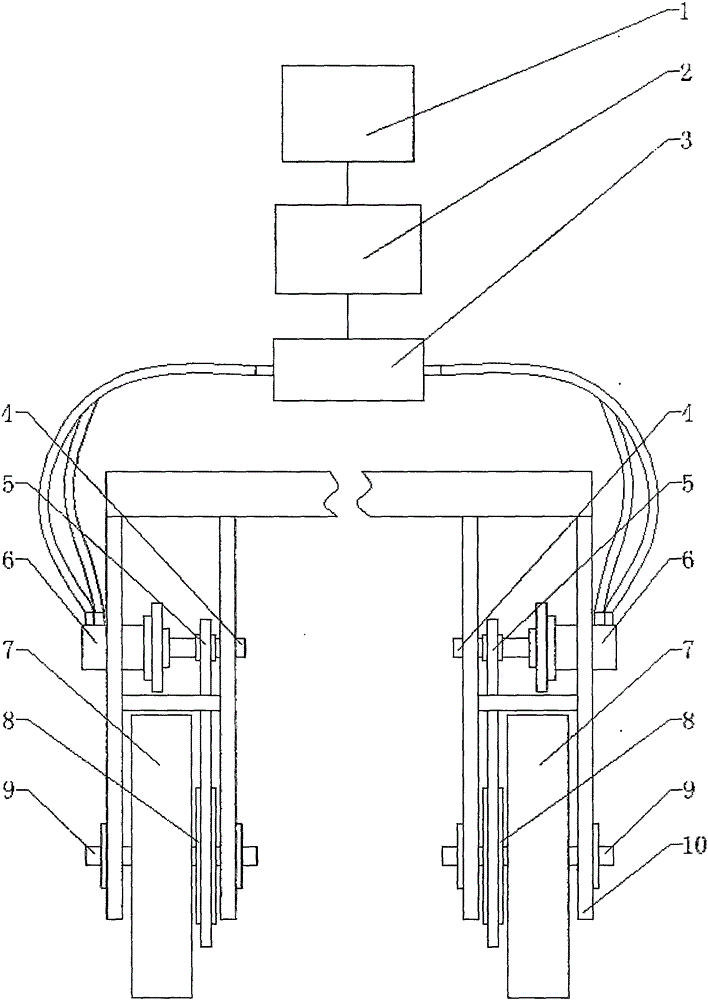

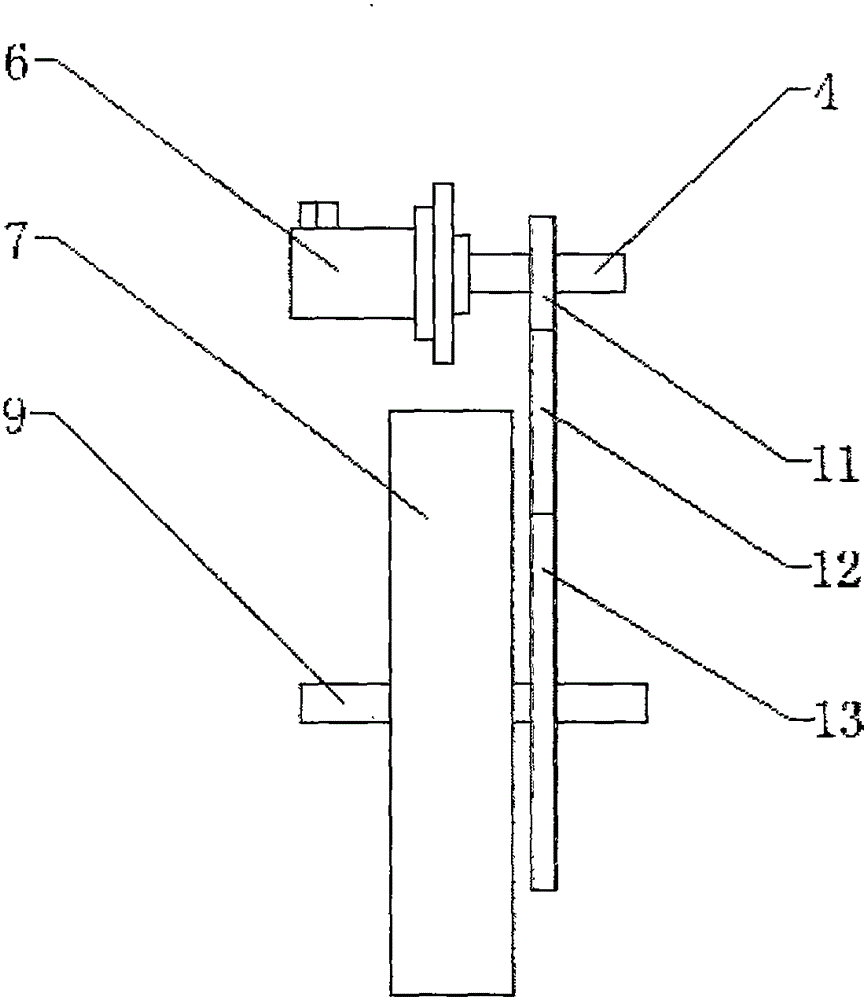

Miniature mountain track tractor rack test system

The invention belongs to the field of miniature mountain tractors, and relates to a tractor rack test system, in particular to a miniature mountain track tractor rack test system. The miniature mountain track tractor rack test system comprises a tractor steering brake oil way, a tractor transverse posture adjusting oil way, a tractor longitudinal posture adjusting oil way, a tractor three-point suspension oil way, a matched farm implement oil way, a first integrated block, a second integrated block, a second one-way valve, an engine, a hydraulic pump, a filter, a hydraulic oil tank, a two-position two-way electromagnetic overflow valve, a pressure gauge and a tractor rack electrical system. According to the miniature mountain track tractor test system, the working requirements of a mountain track tractor with an adjustable posture are met, and the reliability of the system and the part of the miniature mountain track tractor is verified.

Owner:NORTHWEST A & F UNIV

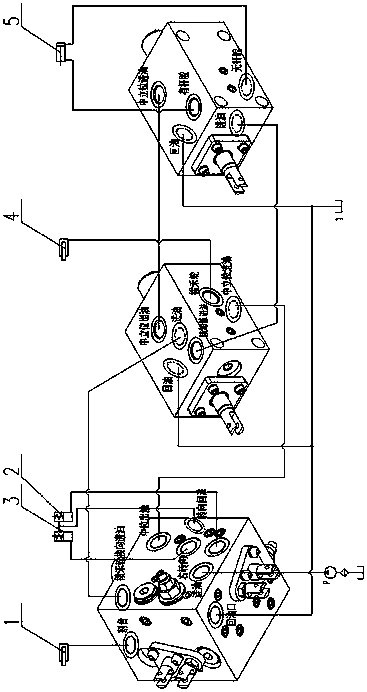

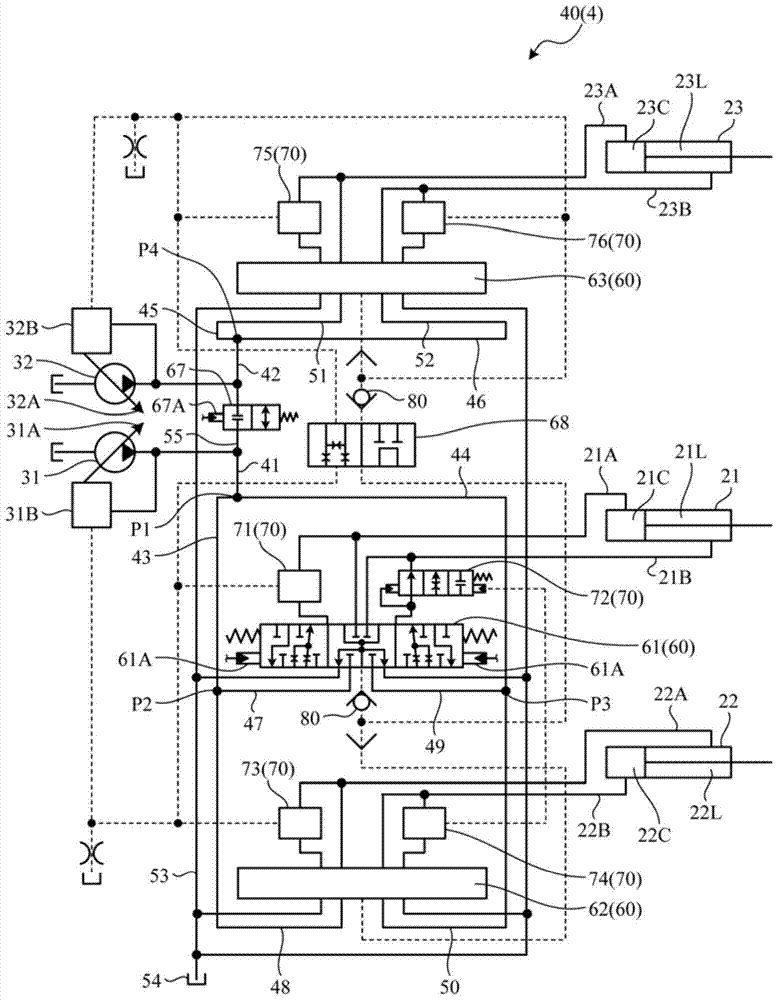

Six-mode double-oil-way oil supply system

ActiveCN105370654AReasonable layoutCompact structureServomotor componentsServomotorsElectro hydraulicEconomic benefits

The invention discloses a six-mode double-oil-way oil supply system. The system comprises a six-position five-way electro-hydraulic proportional valve, wherein the six-position five-way electro-hydraulic proportional valve is provided with a first oil inlet, a second oil inlet, an oil return port, a first oil outlet and a second oil outlet; the first oil inlet is connected with a first hydraulic pump oil source through a first oil way; the second oil inlet is connected with a second hydraulic pump oil source through a second oil way; the first hydraulic pump oil source and the second hydraulic pump oil source are both connected with an oil tank; the first oil inlet is connected with a pilot overflow valve or a direct-acting overflow valve; and the second oil inlet is connected with a pilot overflow valve or a direct-acting overflow valve. The six-mode double-oil-way oil supply system is reasonable in whole layout, compact in structure, convenient for control, flexible in control, low in power loss, high in system efficiency and high in economic benefit.

Owner:RIZHAO HAIZHUO HYDRAULIC

Hydraulic driving system for notching machine

Owner:SHANGHAI ELECTRICAL HYDRAULICS & PNEUMATICS

Rotation speed control method and device of full-hydraulic bulldozer

ActiveCN111173056AReduced working displacementMechanical machines/dredgersHydraulic motorHydraulic pump

The invention belongs to the technical field of full-hydraulic bulldozers and particularly relates to a rotation speed control method and device of a full-hydraulic bulldozer. The rotation speed control method of the full-hydraulic bulldozer includes the following steps that the current torque of an engine is obtained; the engine is controlled to run in a first rotation speed area along a set slope in a speed-down mode when the current torque of the engine is no larger than a first preset value, the working displacement of a hydraulic pump is controlled to increase, and the working displacement of a hydraulic motor is controlled to decrease; and the engine is controlled to run in a second rotation speed area in a speed-down mode when the current torque of the engine is larger than the first preset value, the working displacement of the hydraulic pump is controlled to increase, and the working displacement of the hydraulic motor is controlled to decrease. In the rotation speed control method of the full-hydraulic bulldozer, the speed-down strategy is added, the working displacement of the hydraulic pump is controlled to increase, the working displacement of the hydraulic motor is controlled to decrease, and the purposes of fast response to loads and reduction of oil consumption are achieved.

Owner:WEICHAI POWER CO LTD

Plant protection machine

Owner:王传梅

High-efficiency and high-precision quartz glass tube forming equipment

PendingCN114031270AAvoid easy displacementHigh forming precisionGlass pressing apparatusHydraulic pumpEngineering

Owner:新沂市东方石英玻璃有限公司

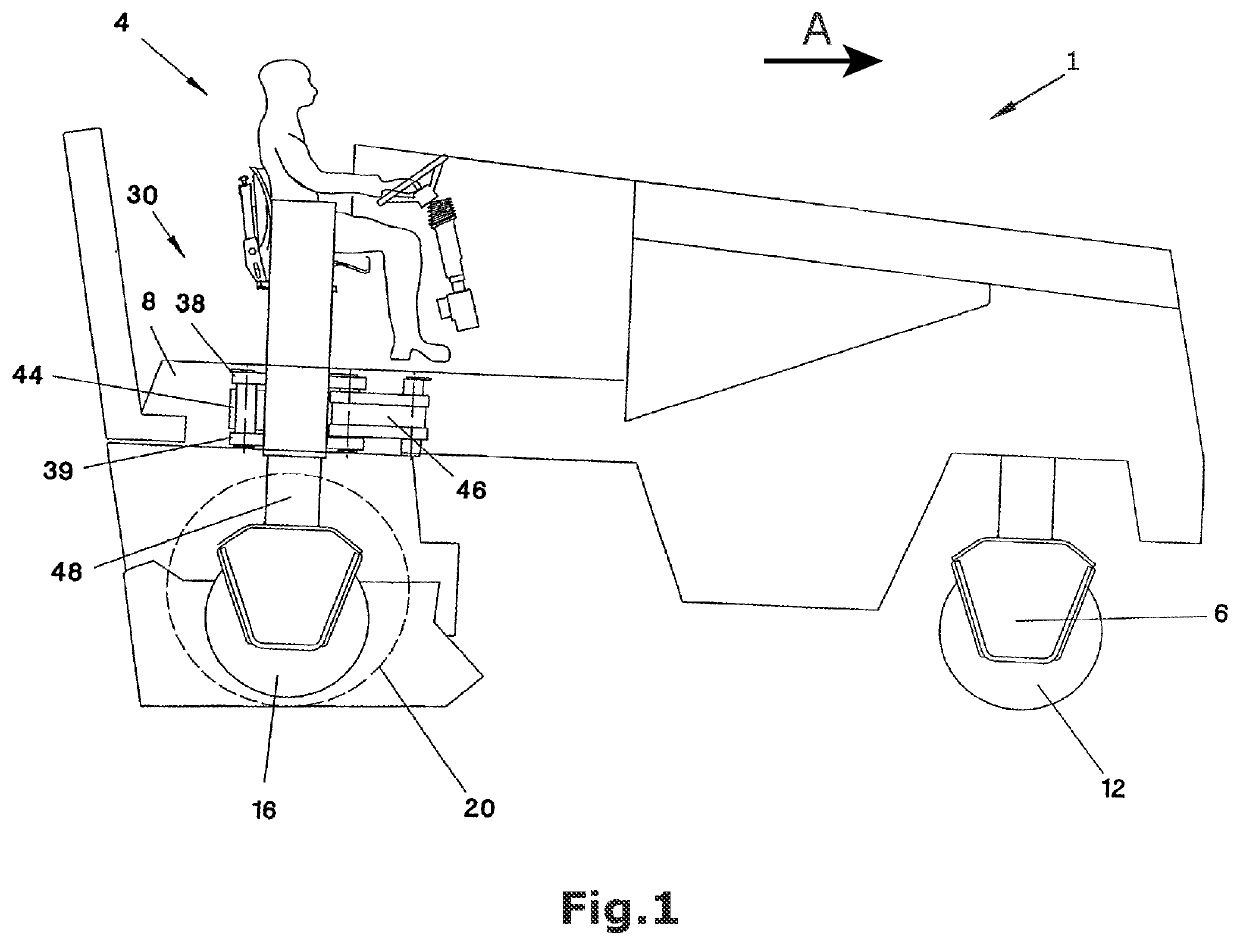

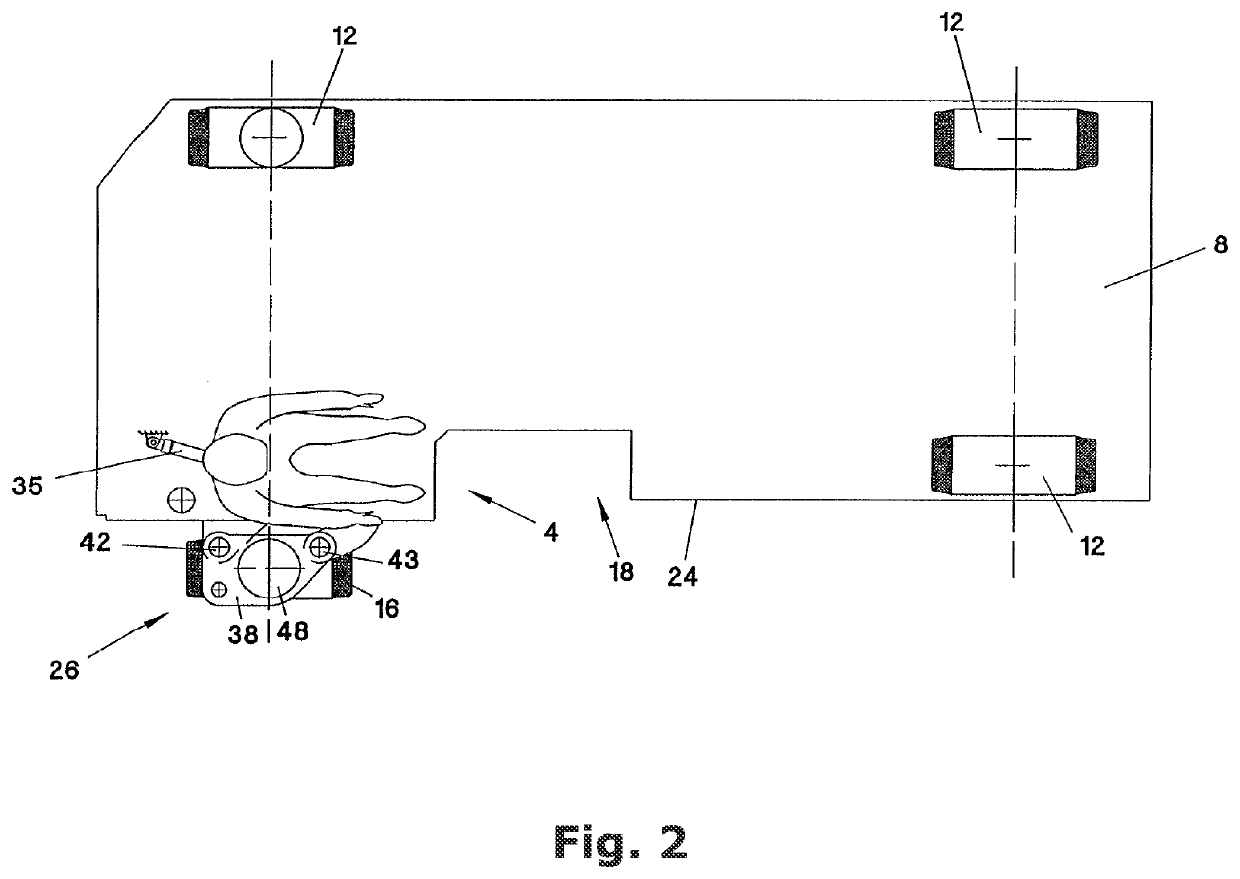

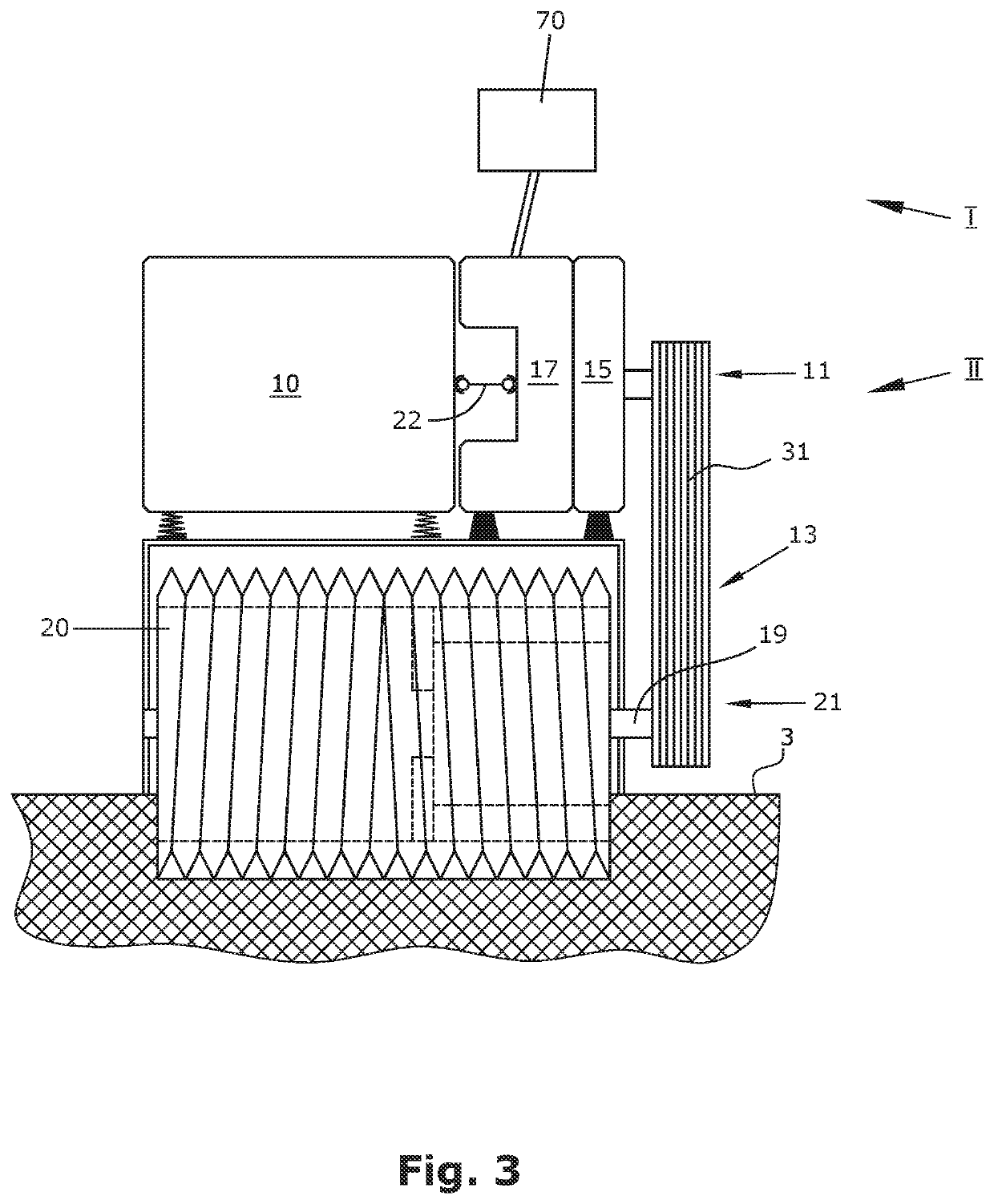

Self-propelled construction machine

ActiveUS20210189668A1Improve drive systemServomotor componentsHydraulic steering gearsHydraulic pumpMachine

Owner:WIRTGEN GMBH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap