Field grooving machine

A slotting machine and field technology, which is applied in the field of agricultural farming, can solve the problems of lower operating efficiency, high maintenance costs, and increased waste disposal, and achieve the effects of reducing farming costs, saving resources, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

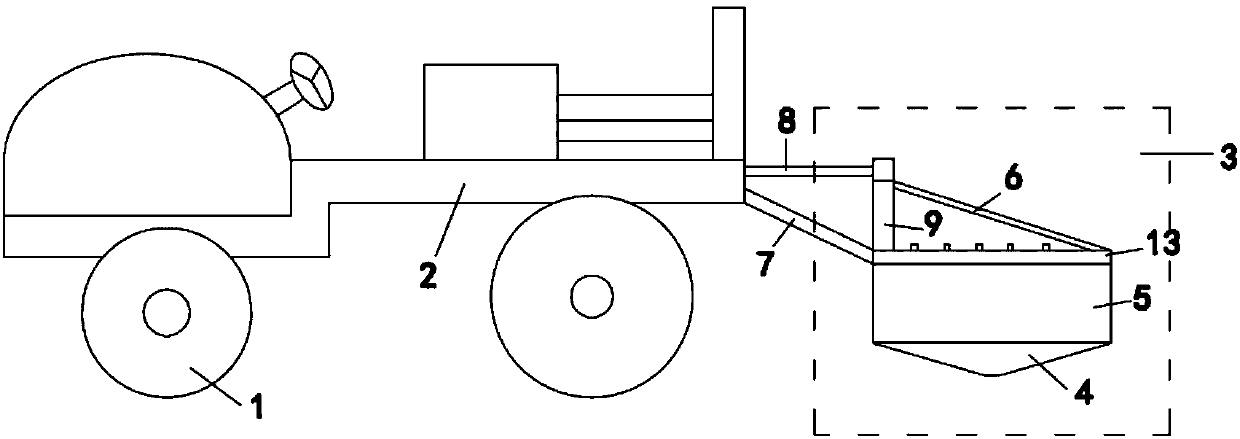

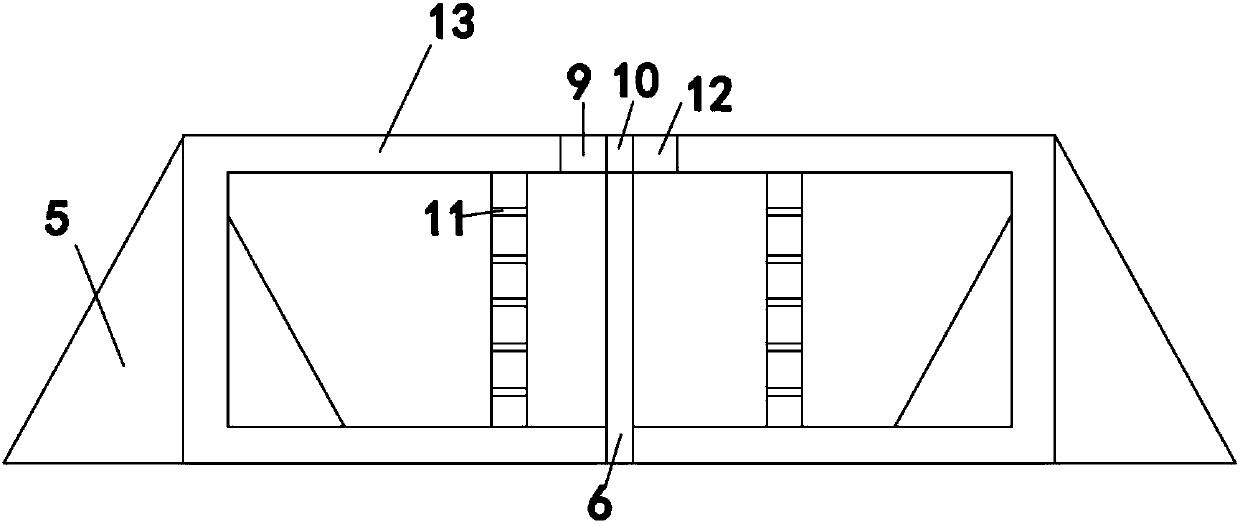

[0022] like figure 1 , figure 2 A kind of field slotting machine shown, comprises drive unit, walking frame 2, slotting device 3, 4 wheels 1, hydraulic pump, stretch rod 7, several pressing objects.

[0023] The notching device 3 includes a fixed frame 13 and two notch grinders of the same shape. The notch grinding tool includes a lower notch 4 and an upper baffle 5 . The fixed frame 13 is evenly provided with several limit stops 11, the limit stops 11 are vertically fixed on the fixed frame 13 and the limit stops 11 are matched with the pressing objects. The height of the notch grinding tool is 70cm, wherein the height of the lower notch 4 is 20cm, and the height of the upper baffle 5 is 50cm.

[0024] One top of the walking frame 2 is provided with a hydraulic pump, and the other top is provided with a driving device. The driving device is connected to the wheels 1; the four wheels 1 are evenly fixed under the walking frame 2, and the two wheels 1 on the same side are loca

Embodiment 2

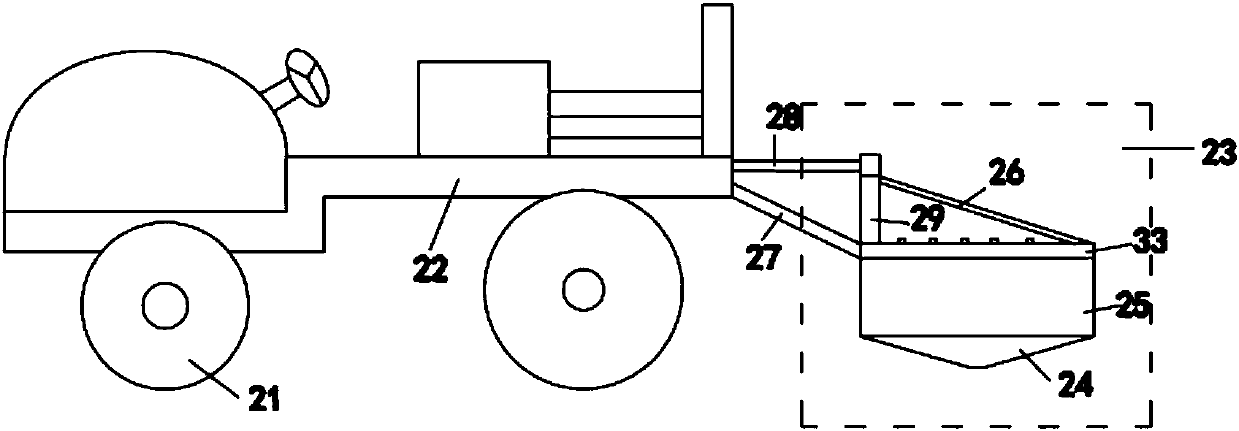

[0029] like image 3 , Figure 4 A kind of field slotting machine shown, comprises drive unit, walking frame 22, slotting device 23, 3 wheels 21, hydraulic pump, stretch rod 27, several pressing objects.

[0030] The notching device 23 includes a fixed frame 33 and three notch grinders of the same shape. The notch grinding tool includes a lower notch 24 and an upper baffle 25 . The fixed frame 33 is evenly provided with several limit stops 31 , the limit stops 31 are vertically fixed on the fixed frame 33 and the limit stops 31 are matched with the pressing objects. The height of the notch grinding tool is 70cm, wherein the height of the lower notch 24 is 20cm, and the height of the upper baffle plate 25 is 50cm

[0031] One top of the walking frame 22 is provided with a hydraulic pump, and the other top is provided with a driving device. The driving device is connected with the wheels 21; the three wheels 21 are uniformly fixed under the walking frame 22, and the shape forme

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap