Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about "Gripping heads" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

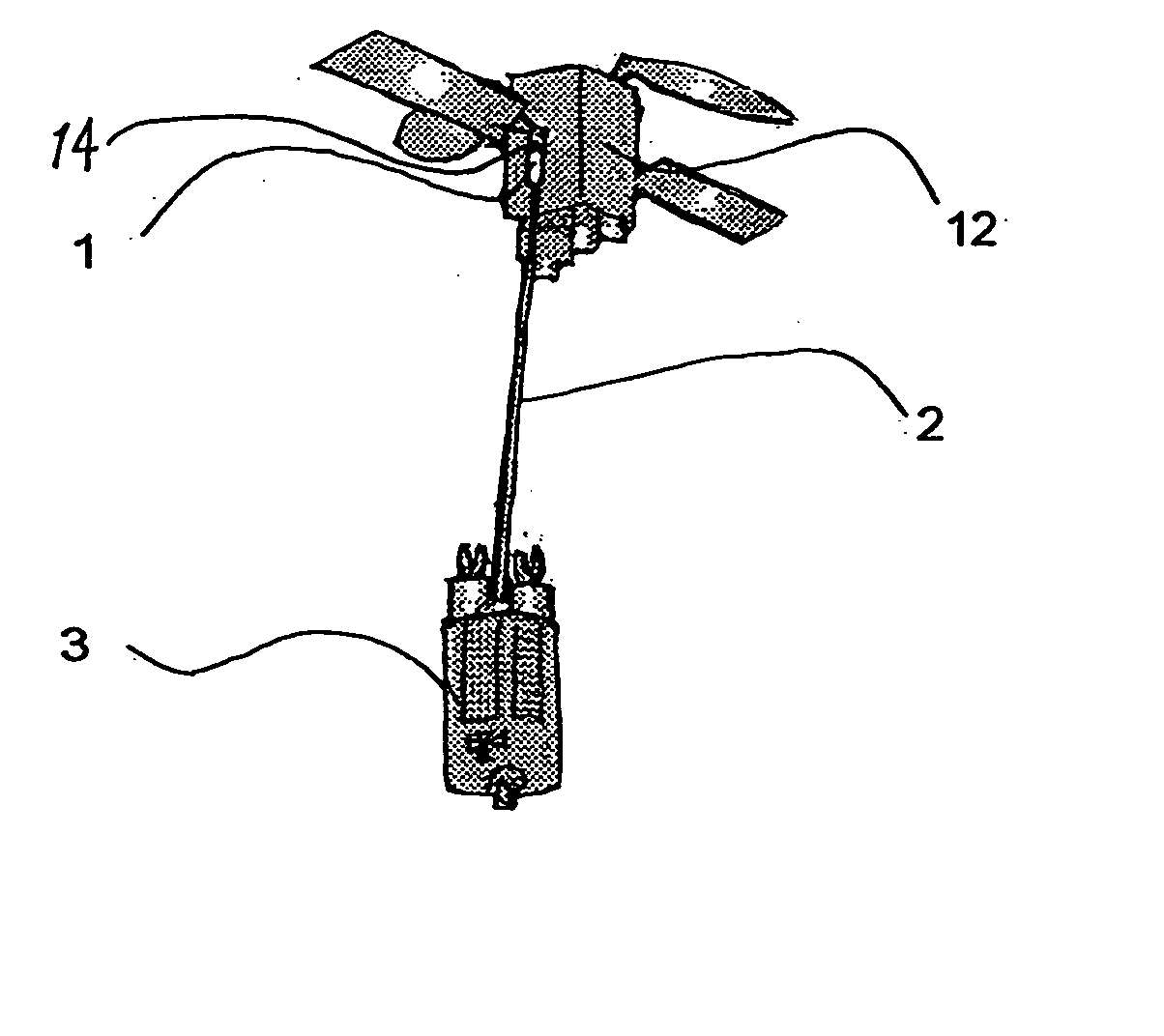

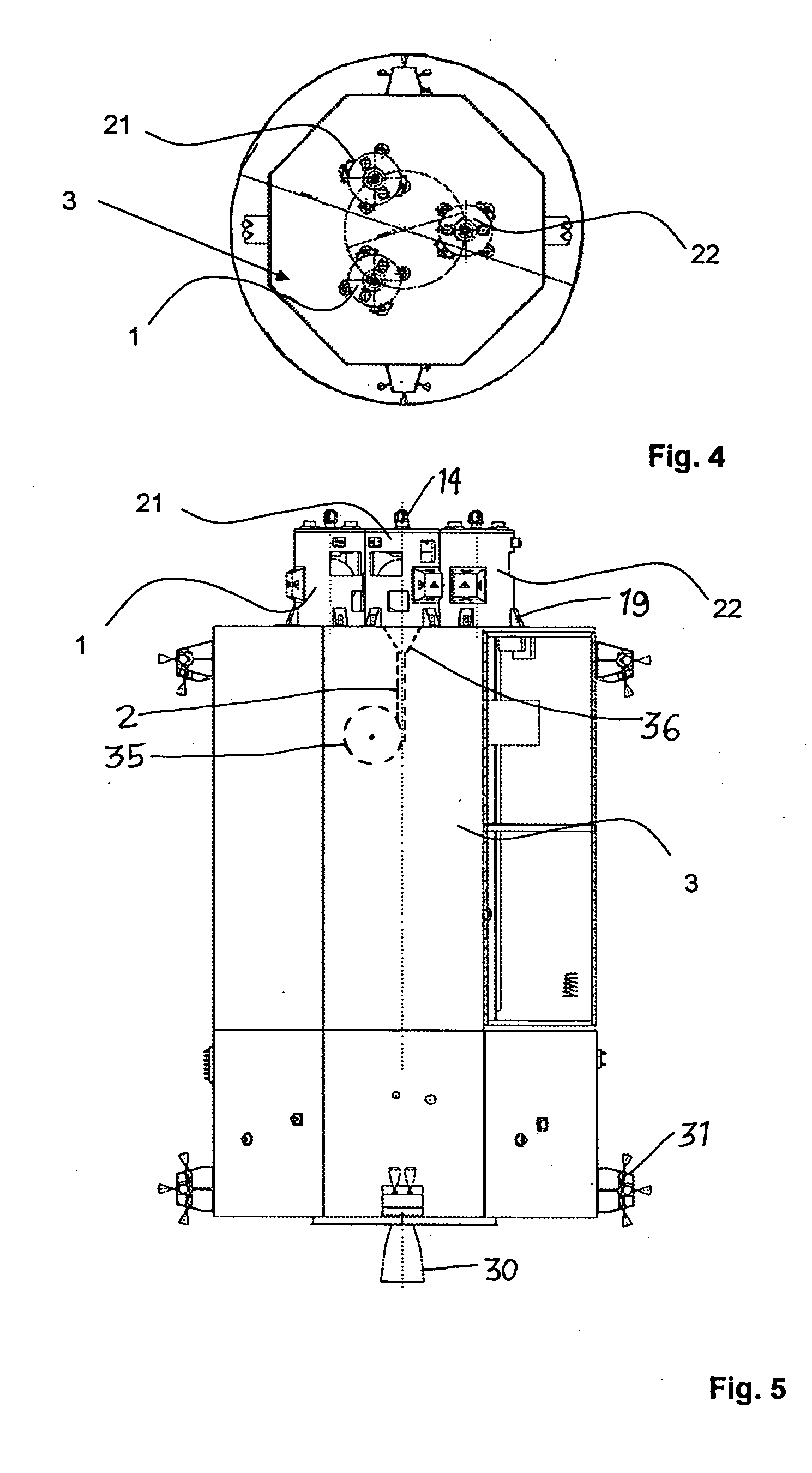

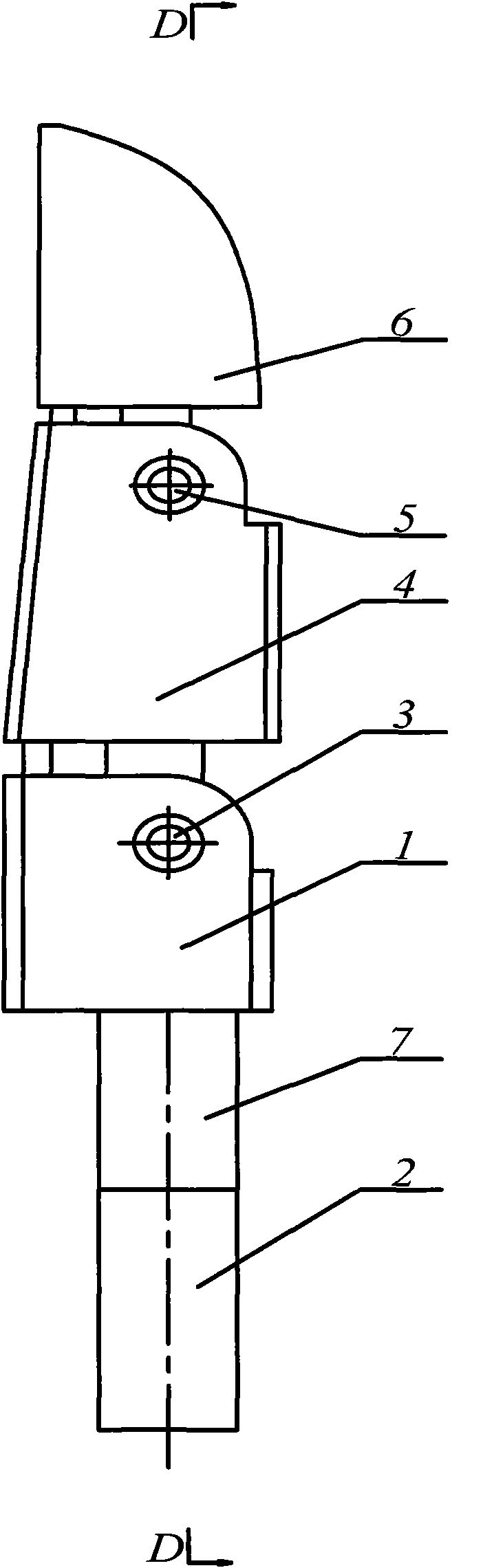

Apparatus for grasping objects in space

InactiveUS20050103940A1Secure and stable grasping configurationGripping headsSystems for re-entry to earthSatelliteEngineering

Owner:ASTRIUM GMBH

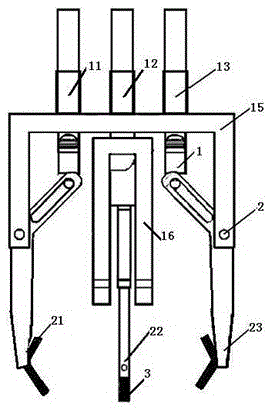

Robotic end of arm tool method and apparatus

An end of arm tool has a mounting bracket mounting the end of arm tool to the robot arm for movement therewith and has a plurality of operating mechanisms mounted to the mounting bracket, a plurality of gripping devices each operatively connected to a respective operating mechanism and movable along a path, and a plurality of individual motors each operatively connected to a respective gripping device for moving the respective gripping device along its respective path. At least one programmable controller for operating the motors is provided to adjust the positions of the gripping devices along their respective paths to one of a plurality of predetermined positions established by the controller for gripping the article and to position the end of arm tool adjacent the article so that at least one of the gripping devices grips the article.

Owner:SAS AUTOMATION

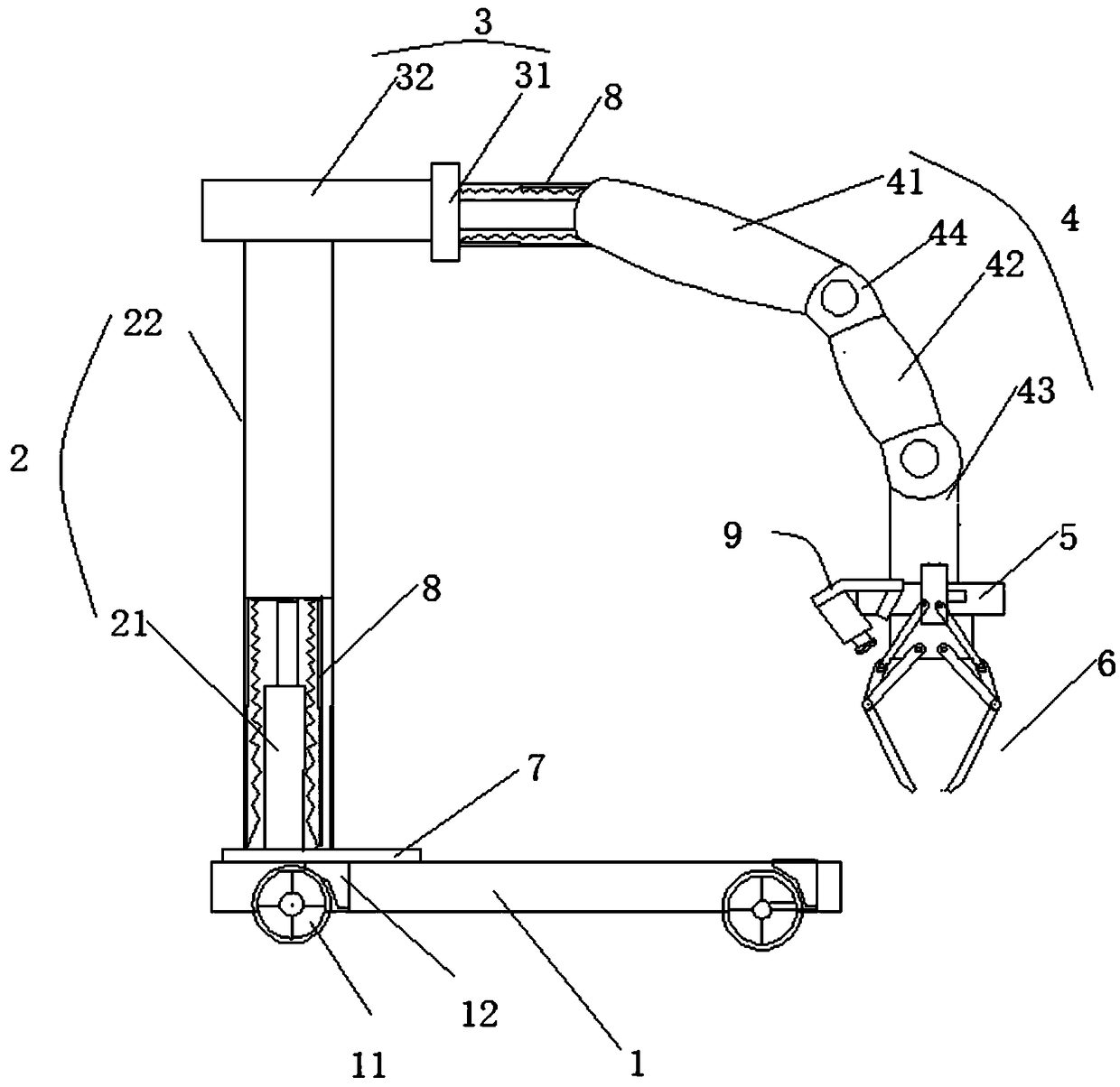

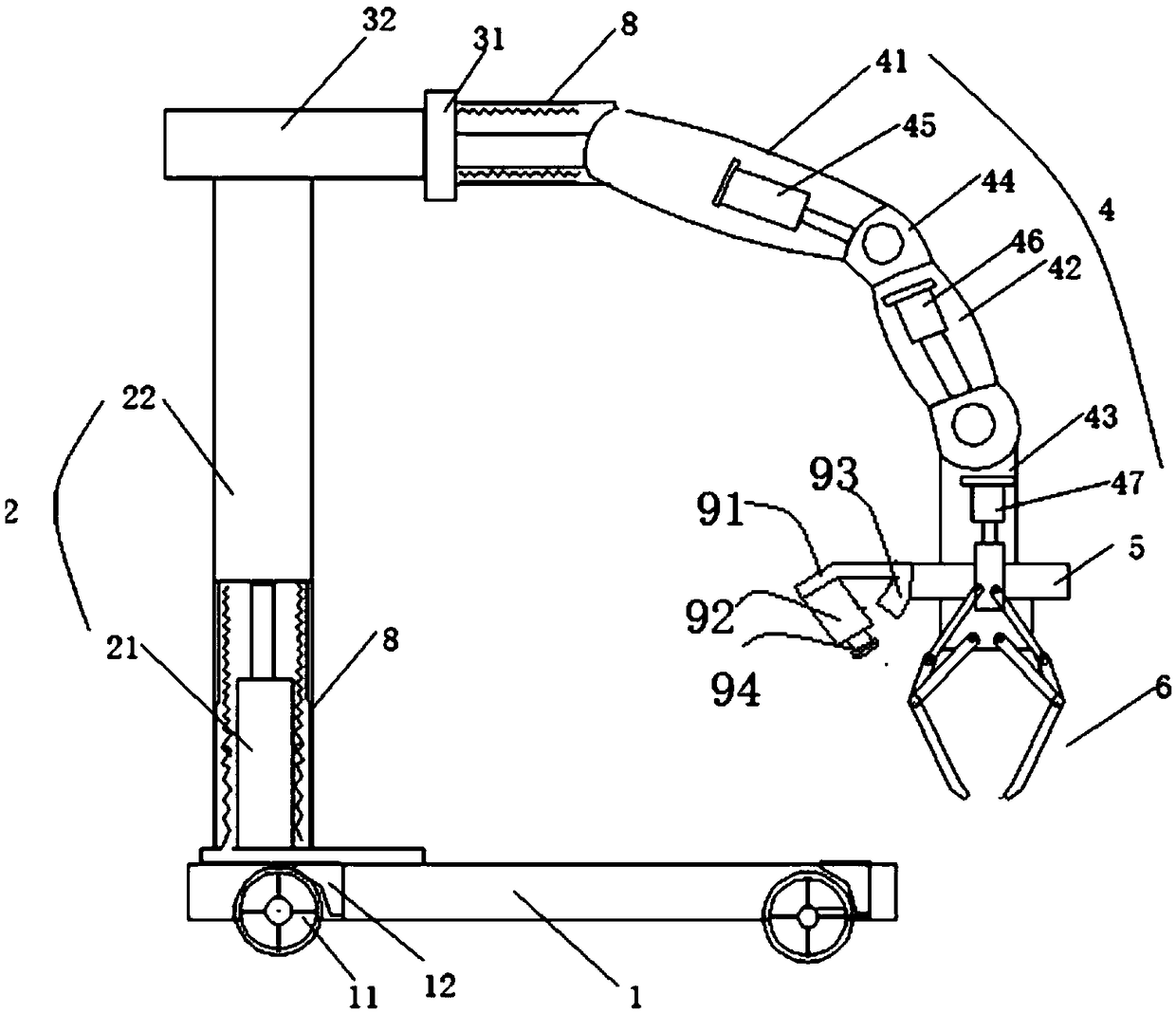

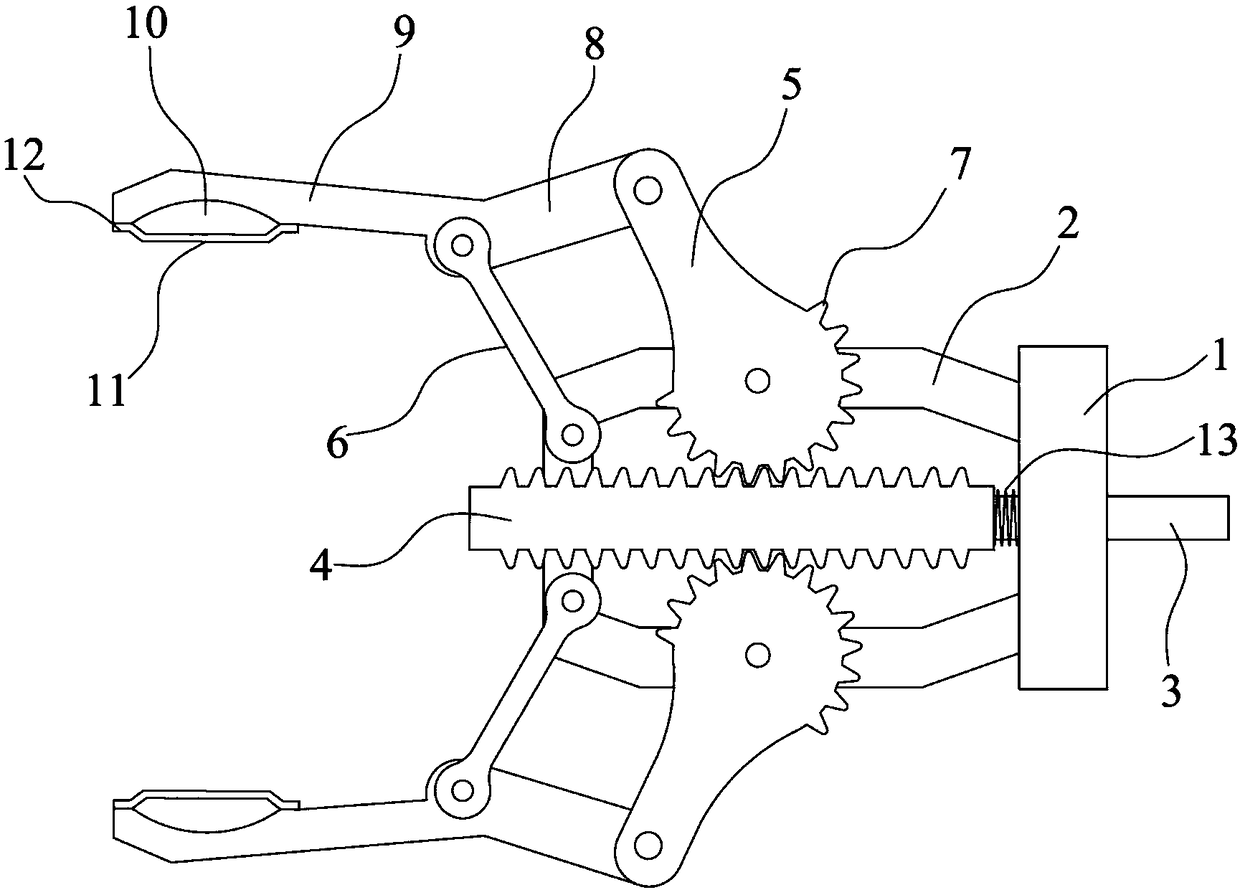

Material carrying mechanical arm capable of rotating and displacing and working method thereof

Owner:薛敏强

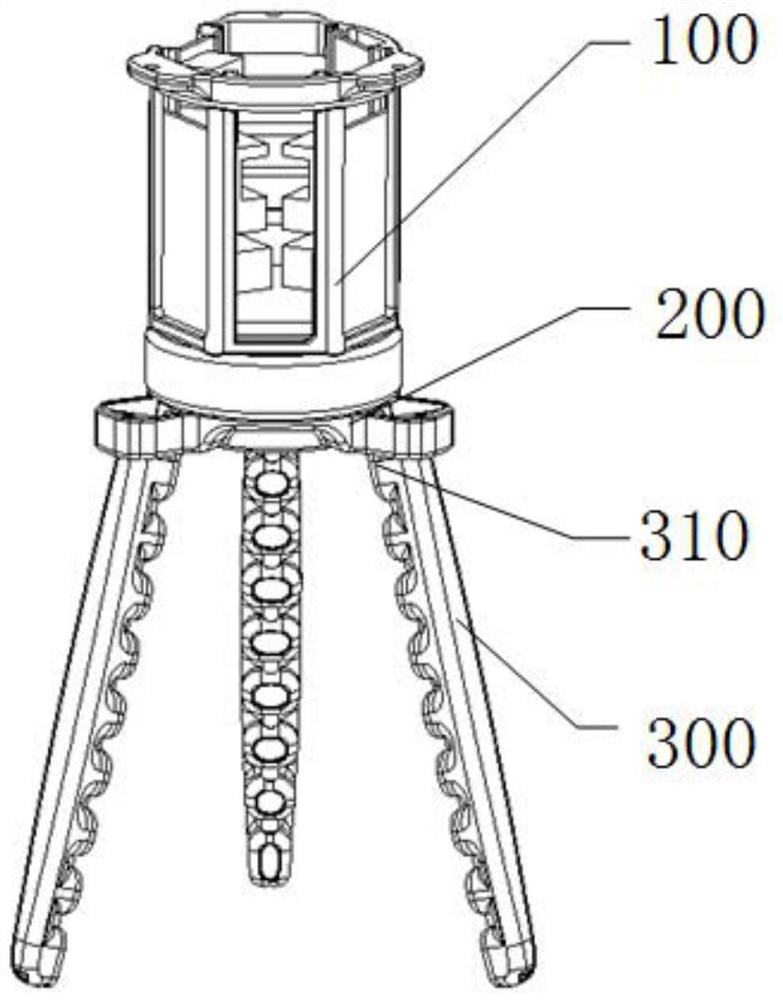

Intelligent climbing and fruit picking robot

InactiveCN106416625AReduce labor intensityCompact structureGripping headsPicking devicesSlide plateIndustrial engineering

The invention discloses an intelligent climbing and fruit picking robot which comprises eight crawler wheels, four wheel carriers, four first stepper motors, a bottom plate, a lower fixing claw, a second stepper motor, a rotary plate, a third stepper motor, a lead screw support, a lead screw, a slide plate, a fourth stepper motor, a lower rotary frame, a first electric cylinder, an upper rotary frame, a second electric cylinder, an upper fixing claw, a fifth stepper motor, a bag bracket, a fixing column, a fifth electric cylinder, a fixing plate, a sixth electric cylinder and hydraulic shears. The intelligent climbing and fruit picking robot has the advantages that the intelligent climbing and fruit picking robot is compact in structure, high in automation degree and applicable to various environments and is small, work for picking fruits from trees can be safely and efficiently carried out, the labor intensity can be relieved for workers to a great extent, and the work efficiency can be improved.

Owner:NANTONG NORTH BUND CONSTR ENG CO LTD

Flexible humanoid mechanical finger

Owner:TSINGHUA UNIV

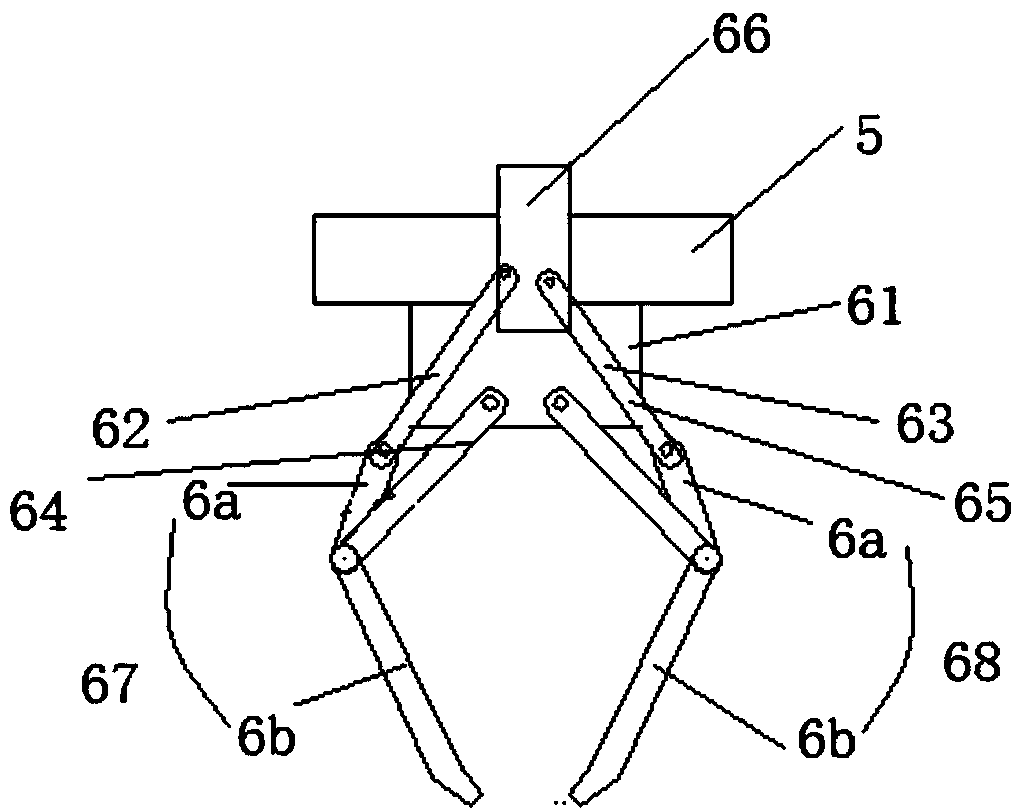

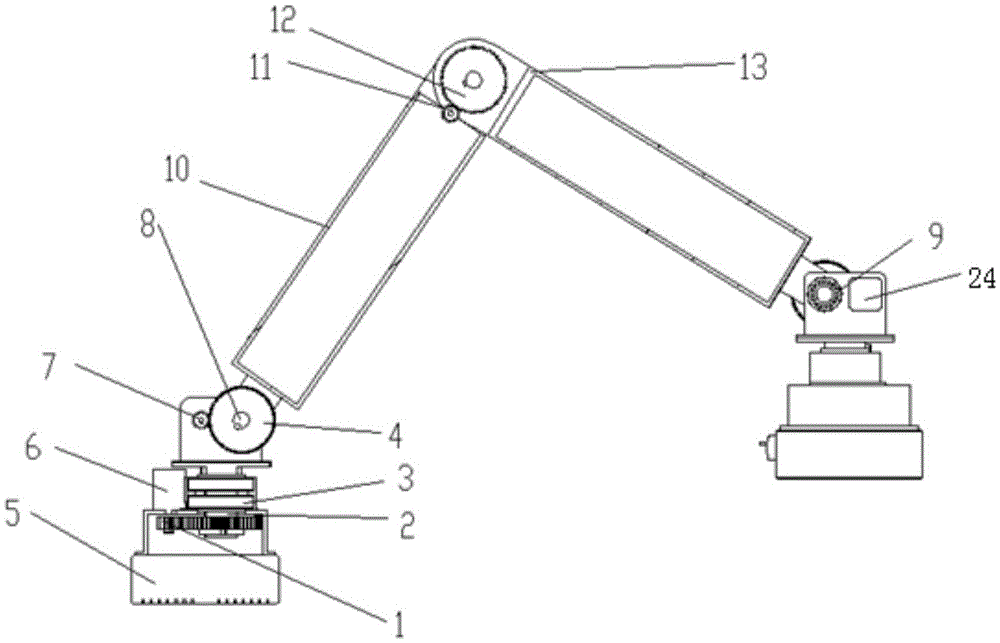

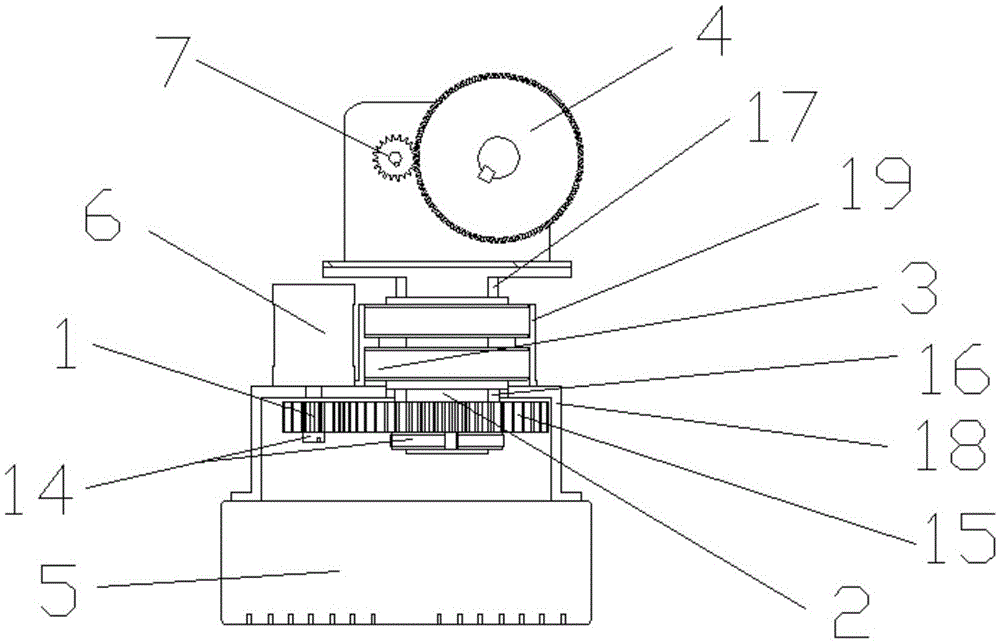

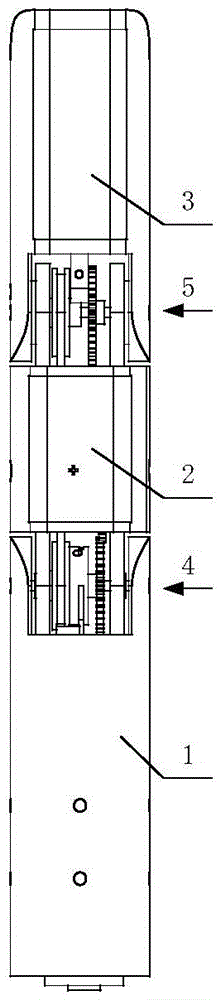

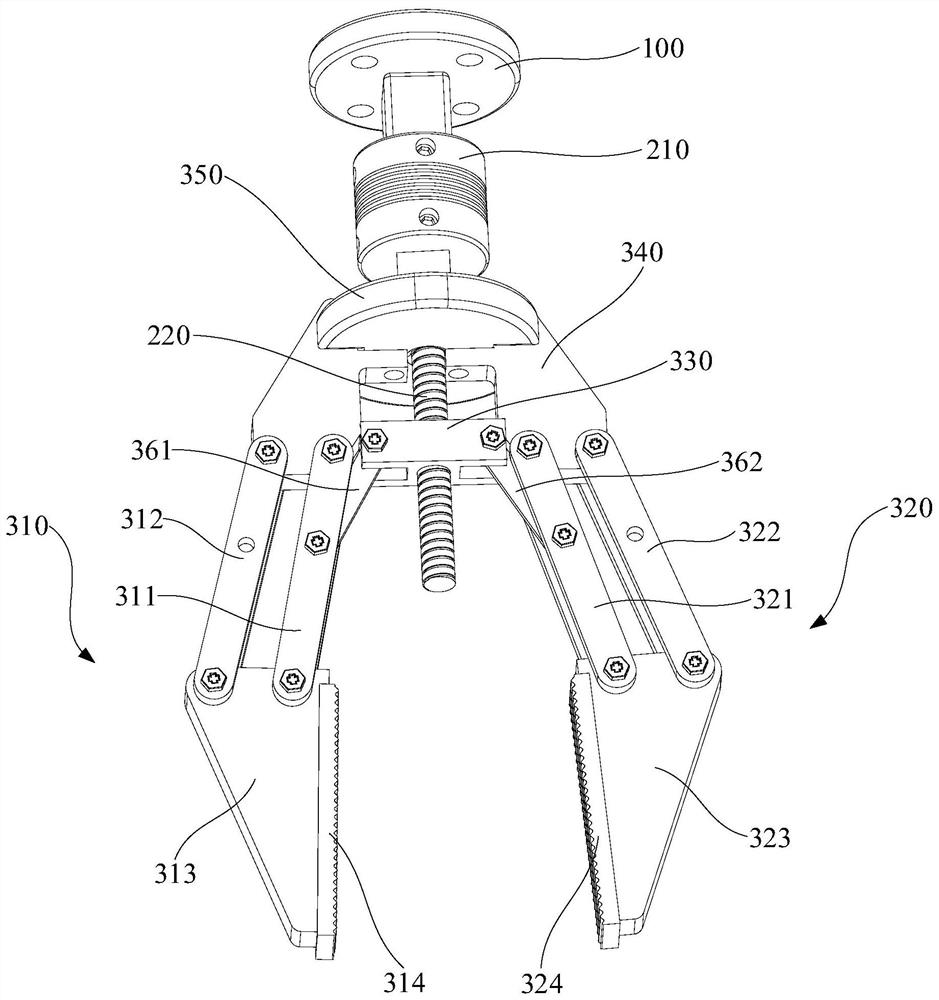

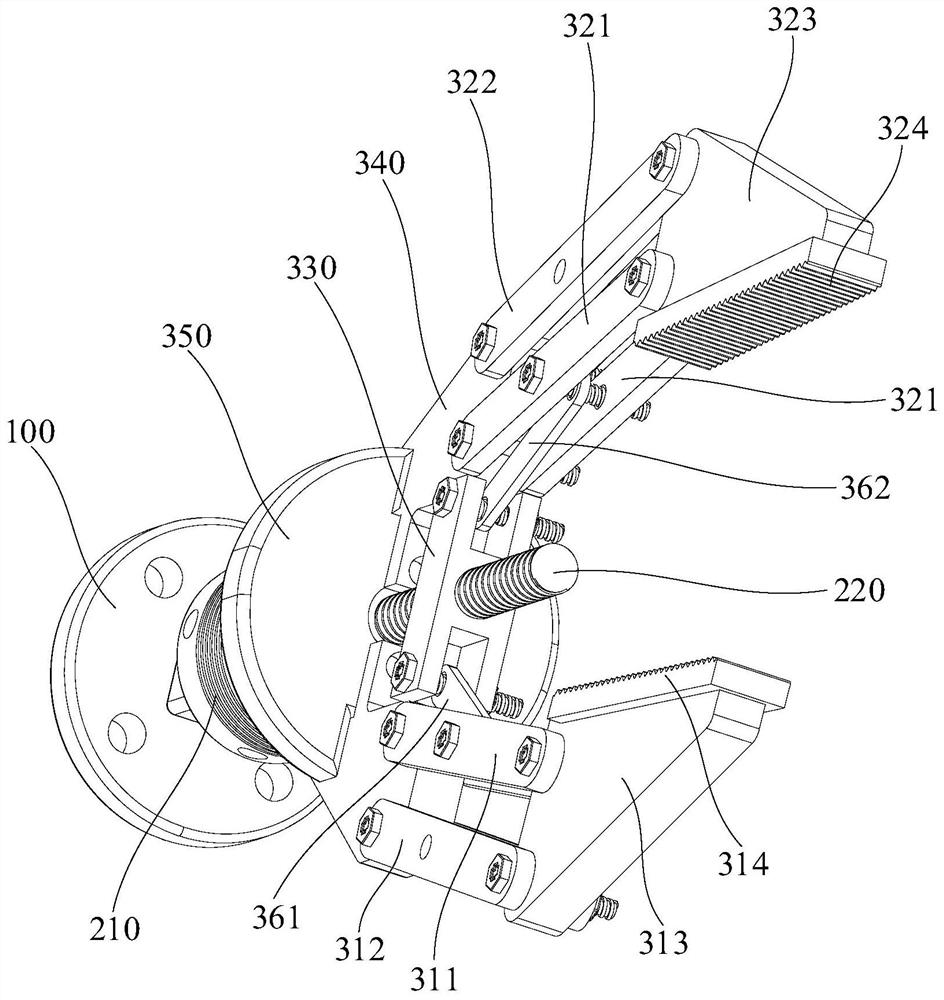

Large-opening-and-closing-angle manipulator

InactiveCN108544522ALarge opening and closing angleAvoid being scratchedGripping headsEngineeringManipulator

Owner:东阳市天齐科技有限公司

Coal mine lifter patrol robot mechanism based on electromagnetic suckers

Owner:CHINA UNIV OF MINING & TECH

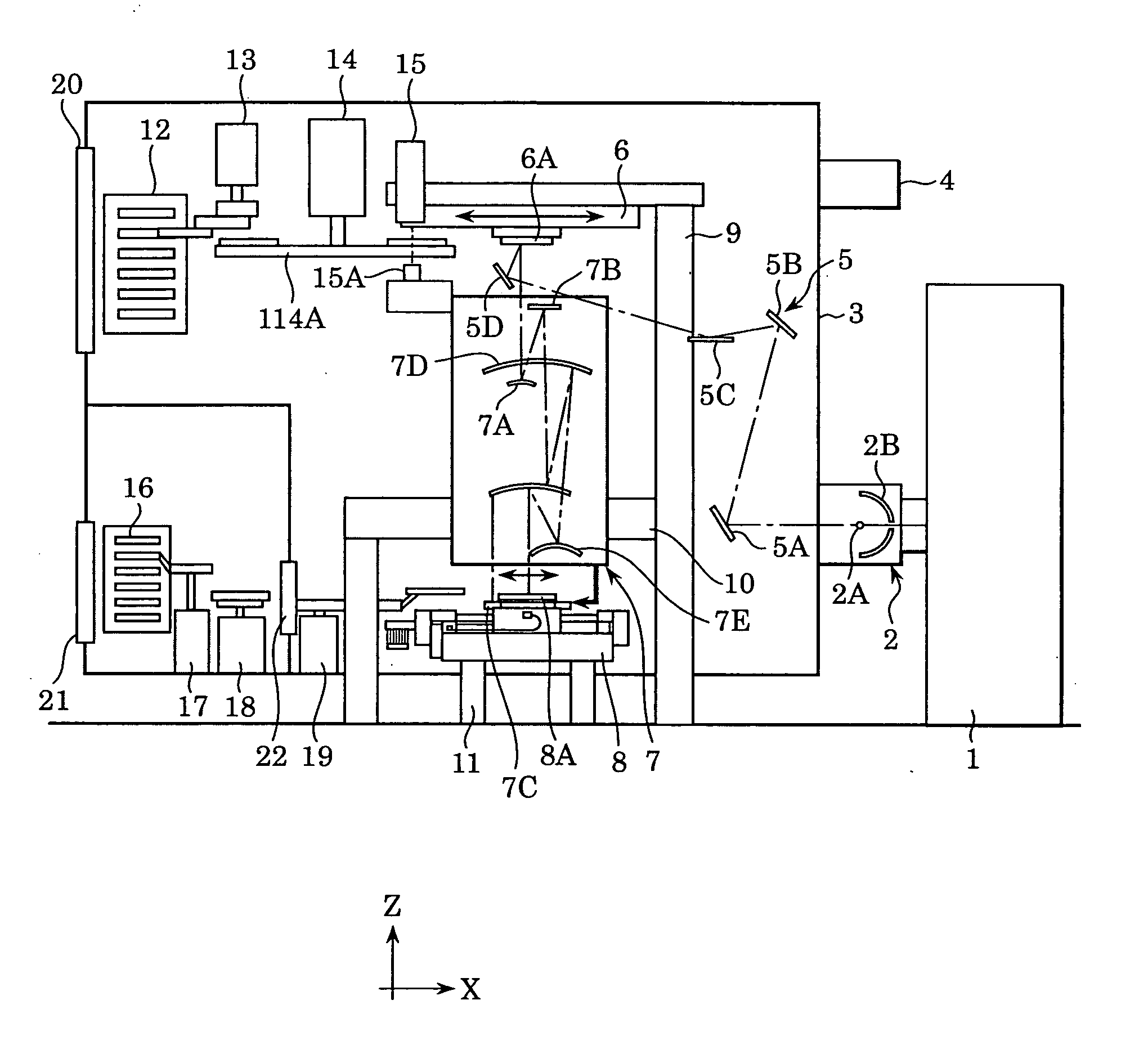

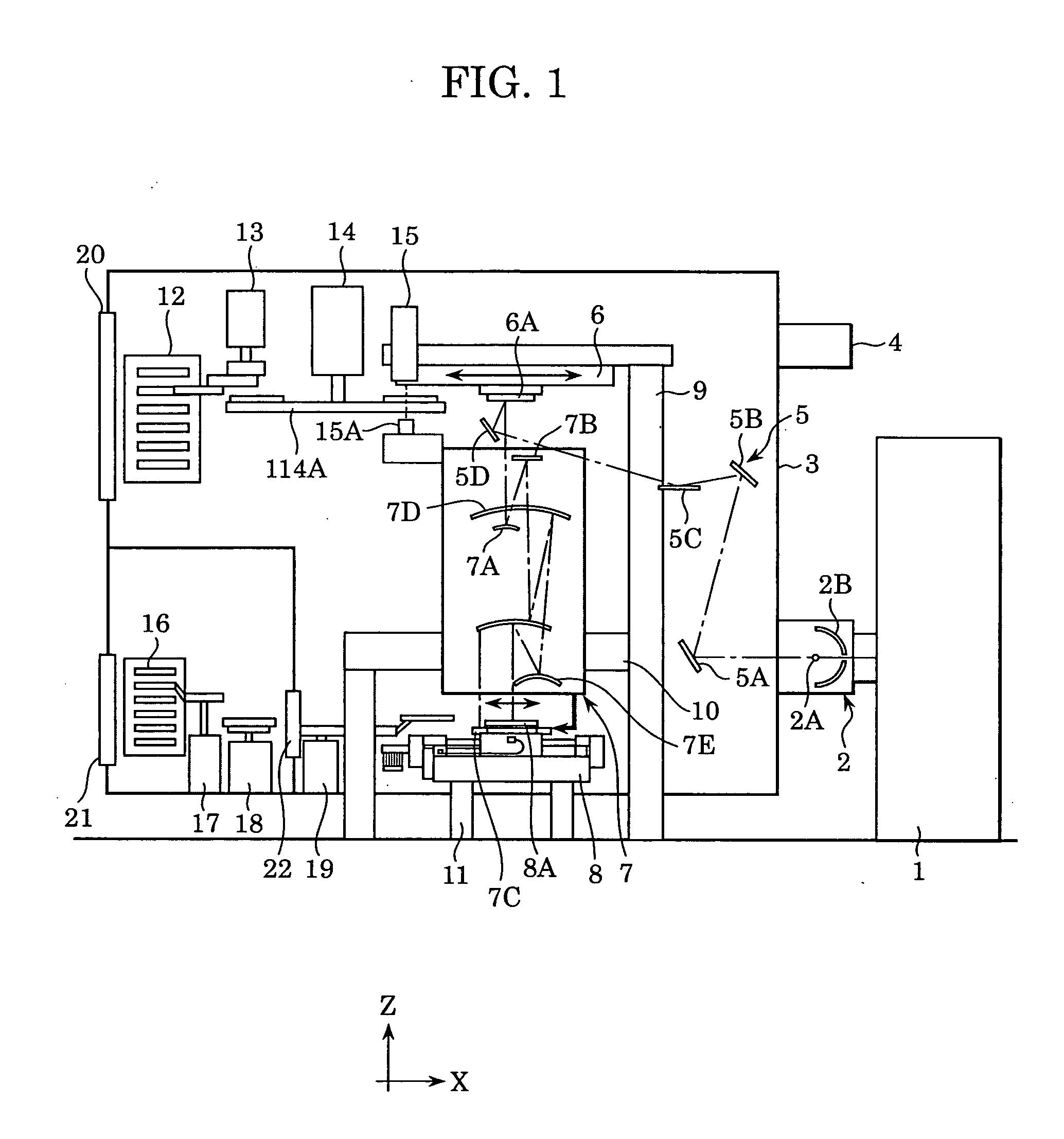

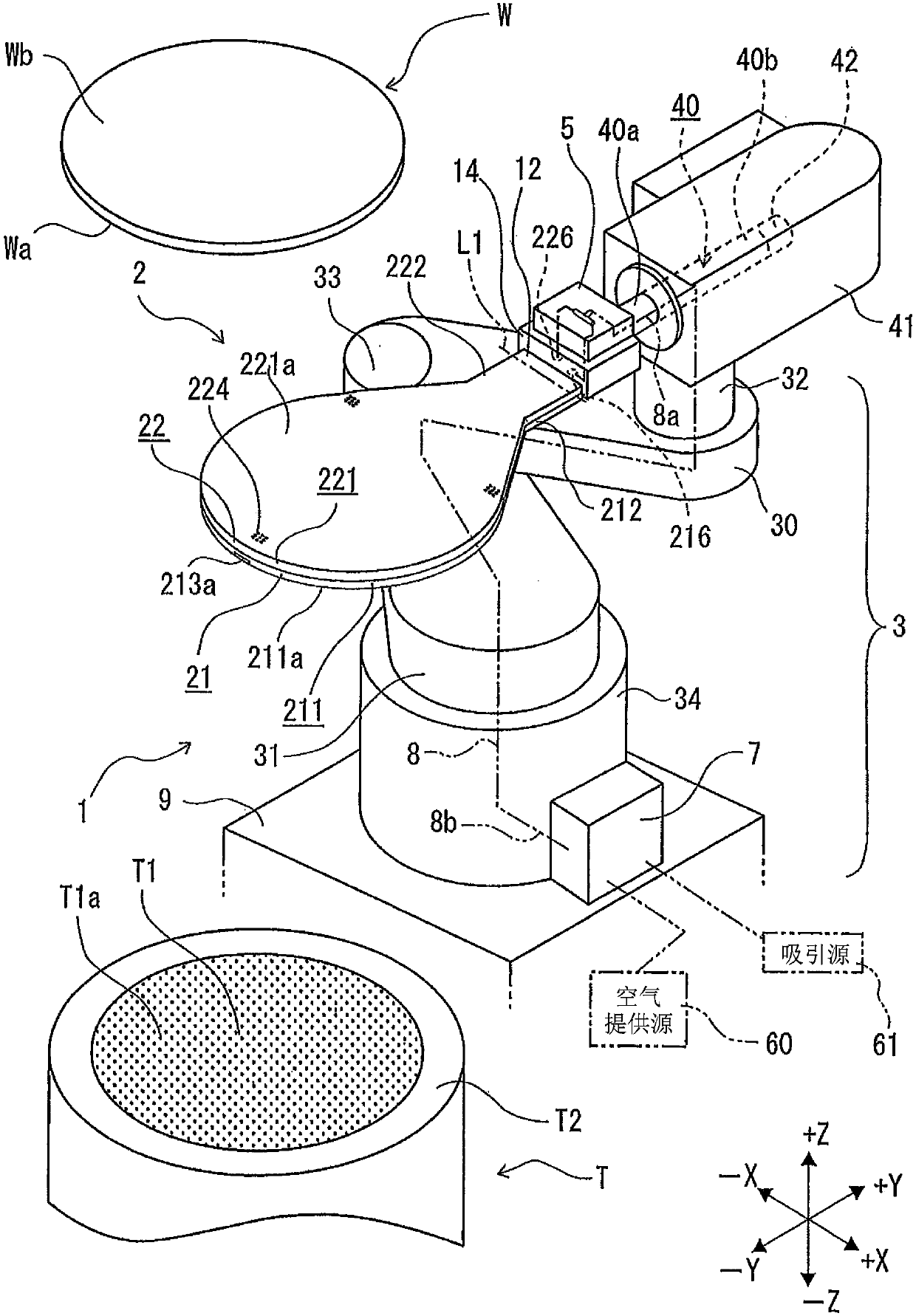

Conveying method, conveyance apparatus, exposure apparatus, and device manufacturing method

InactiveUS20050275998A1Reliable and reliableGripping headsEmergency protective arrangement detailsElectrostatic attractionEngineering

Owner:CANON KK

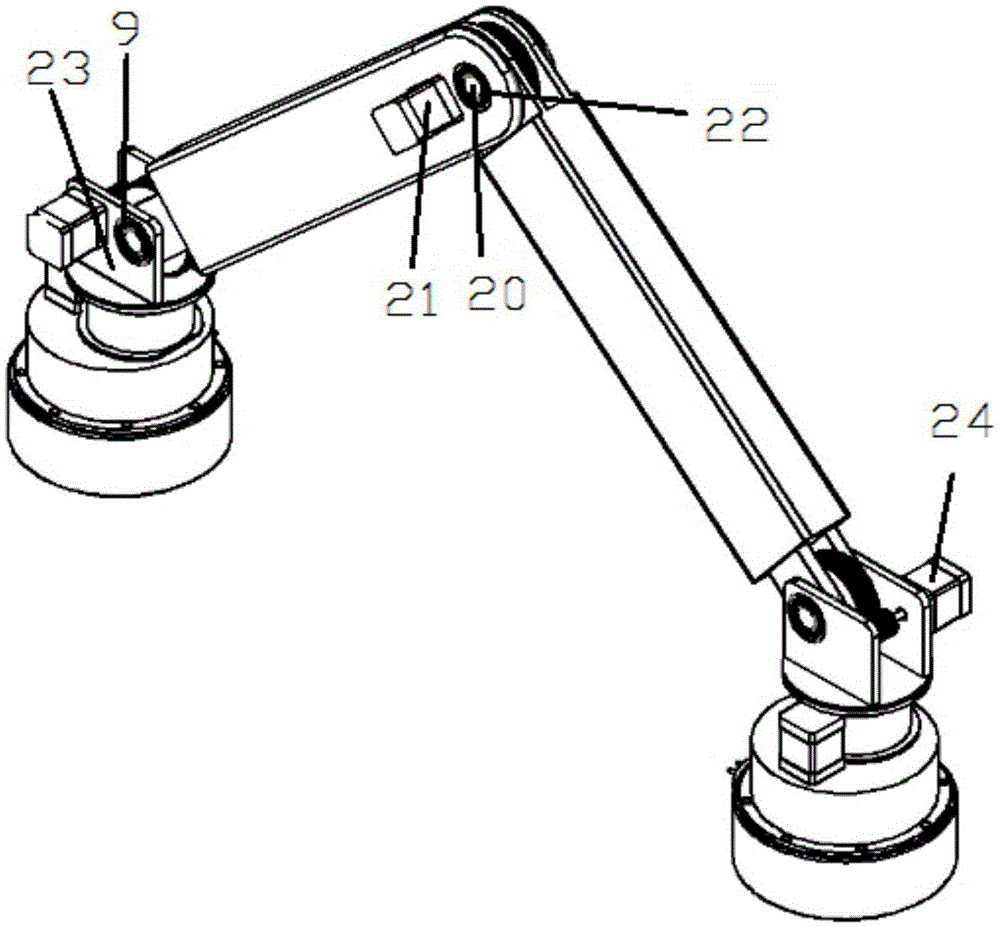

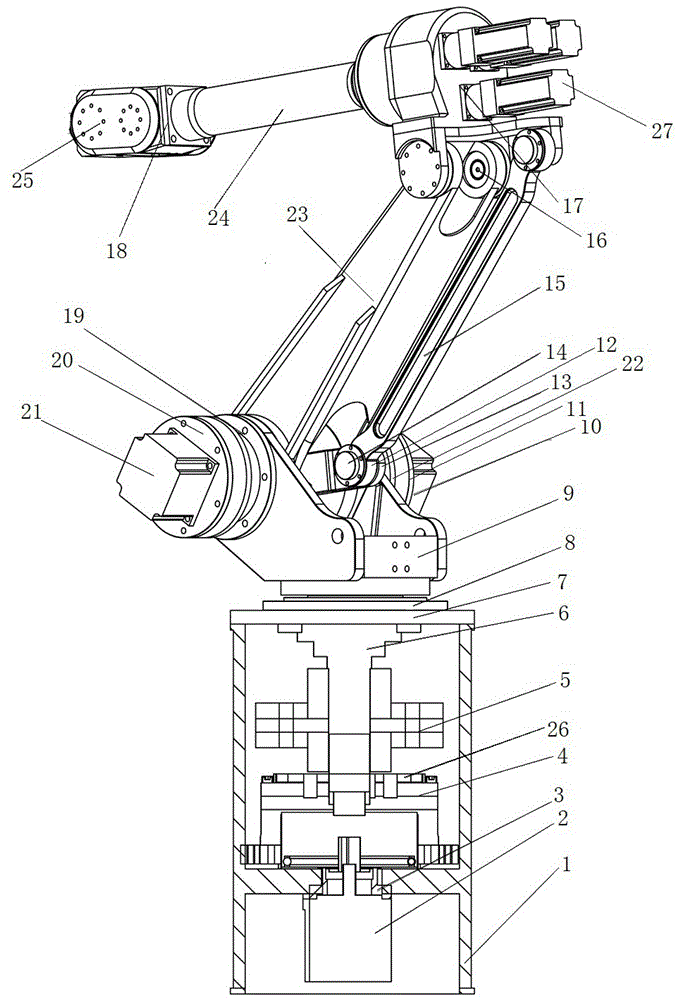

Six-degree-of-freedom mechanical arm device of block press dedicated for optical element, and picking and placing method thereof

PendingCN106607878ATroubleshoot pipeline layout issuesSmall radius of rotationProgramme-controlled manipulatorGripping headsCouplingReducer

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

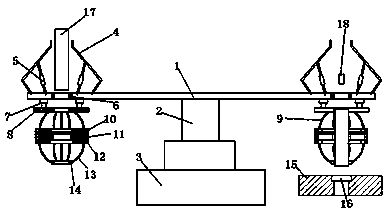

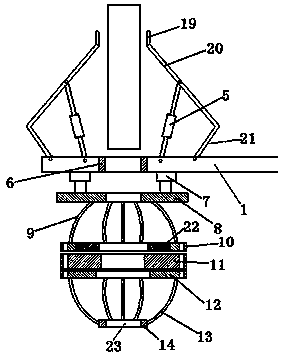

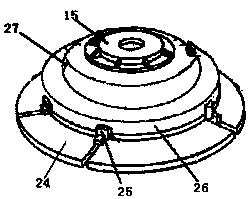

Mechanical arm capable of relatively stably and conveniently grasping spherical part

Owner:SUZHOU BEITELUO INTELLIGENT TECH CO LTD

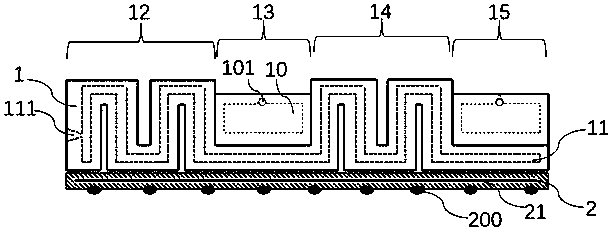

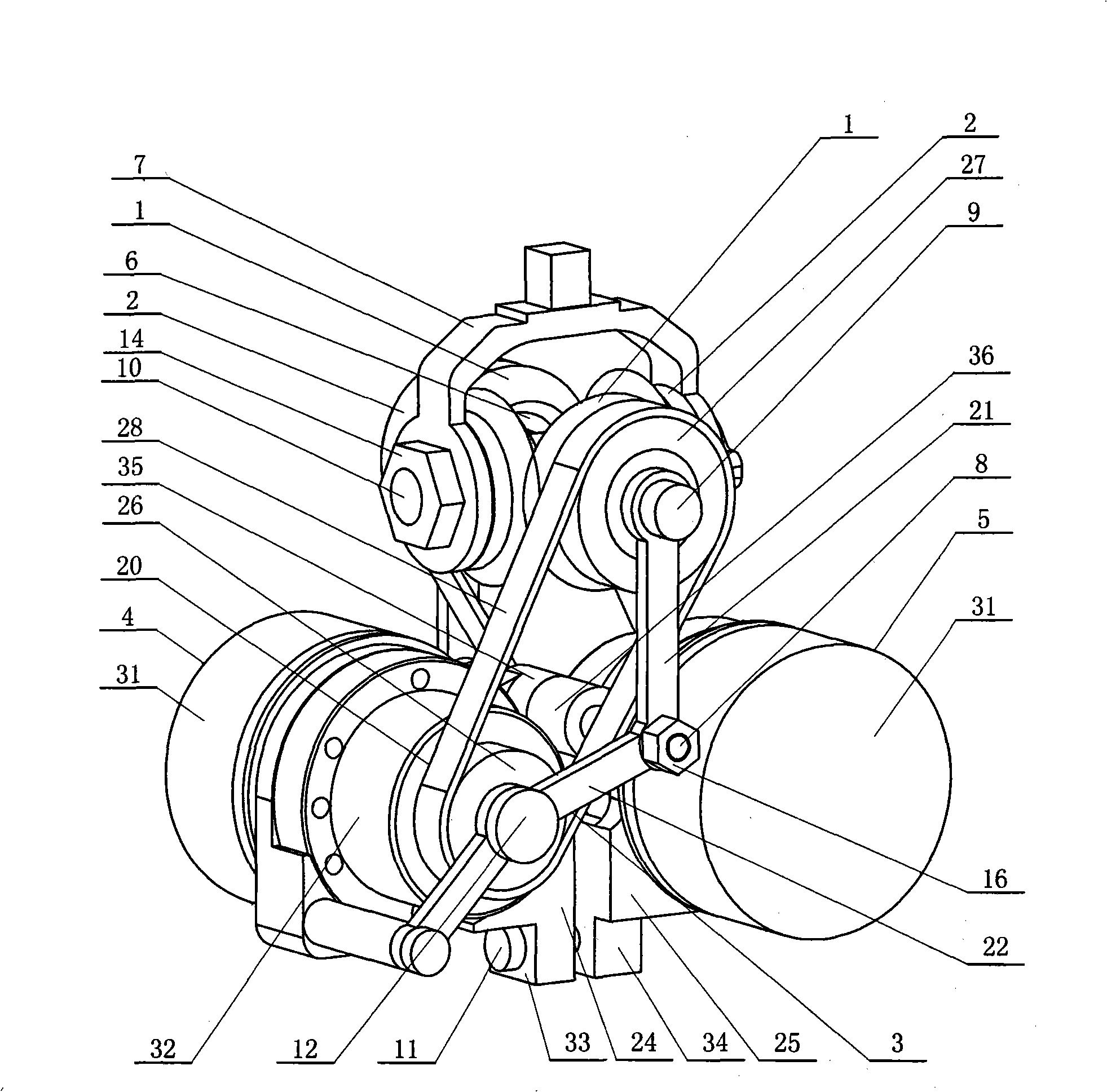

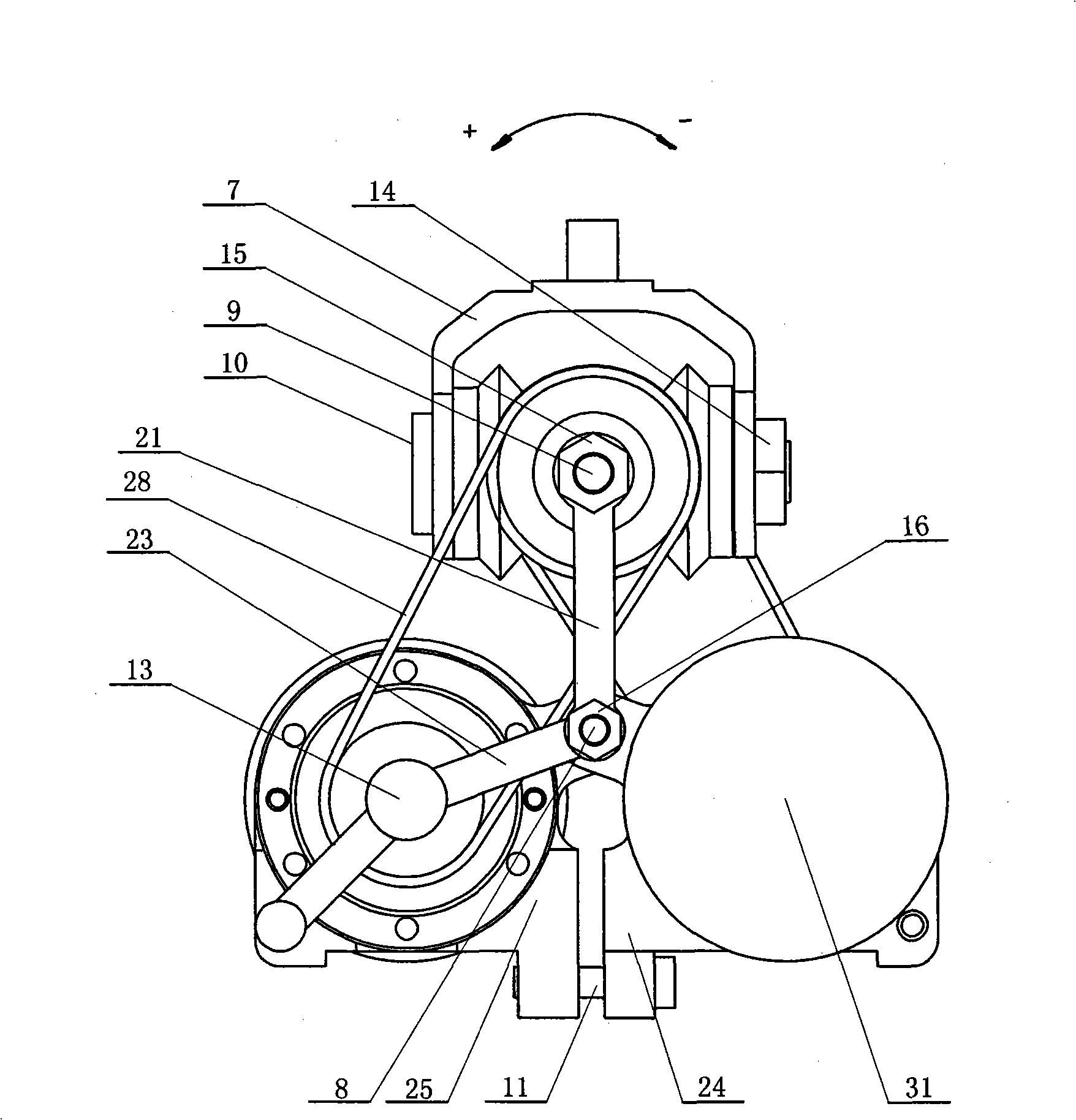

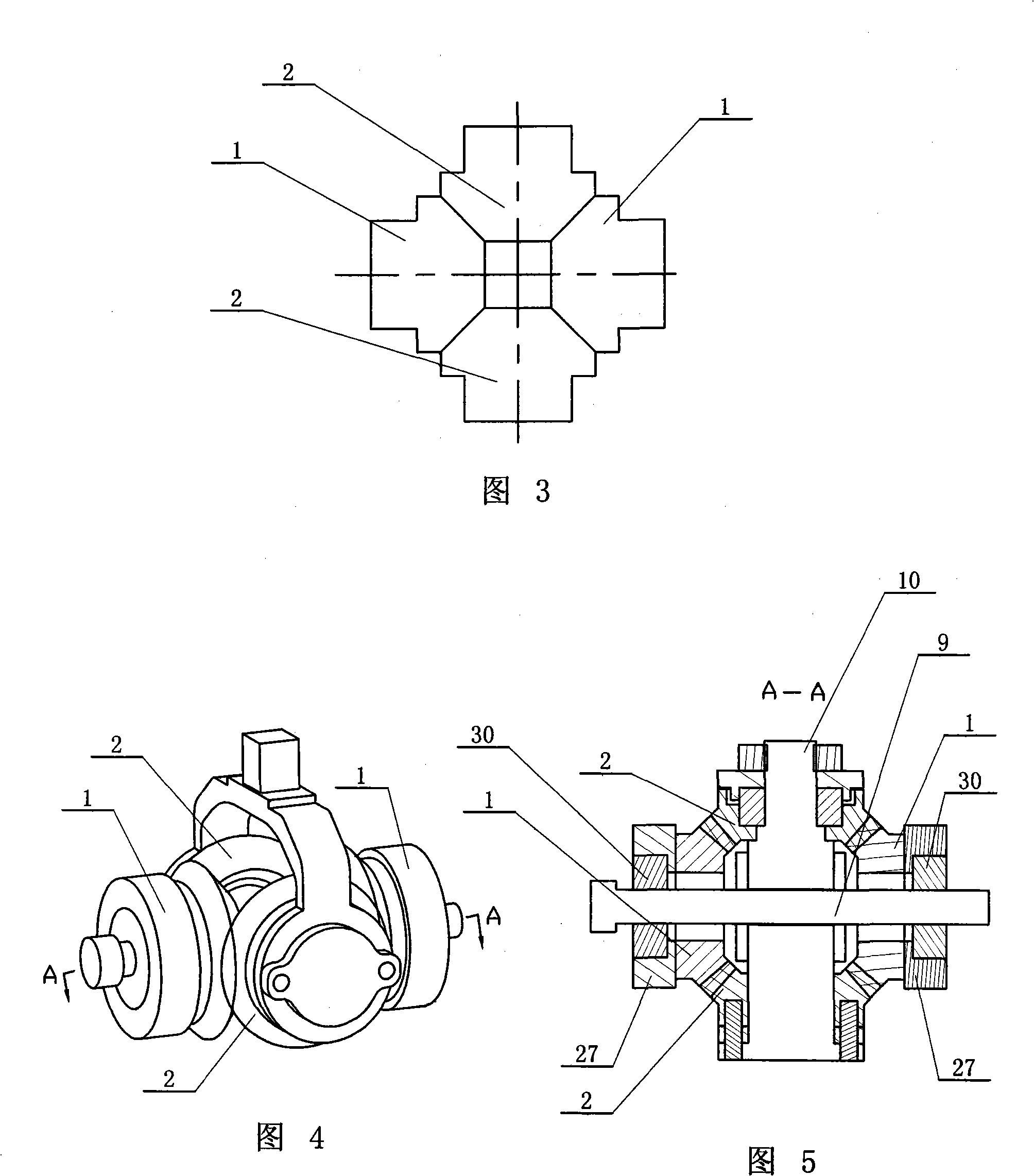

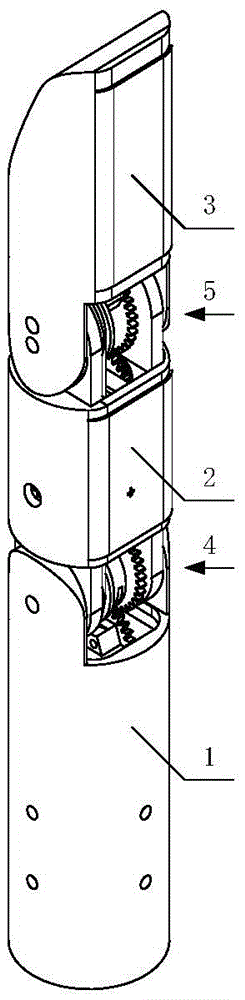

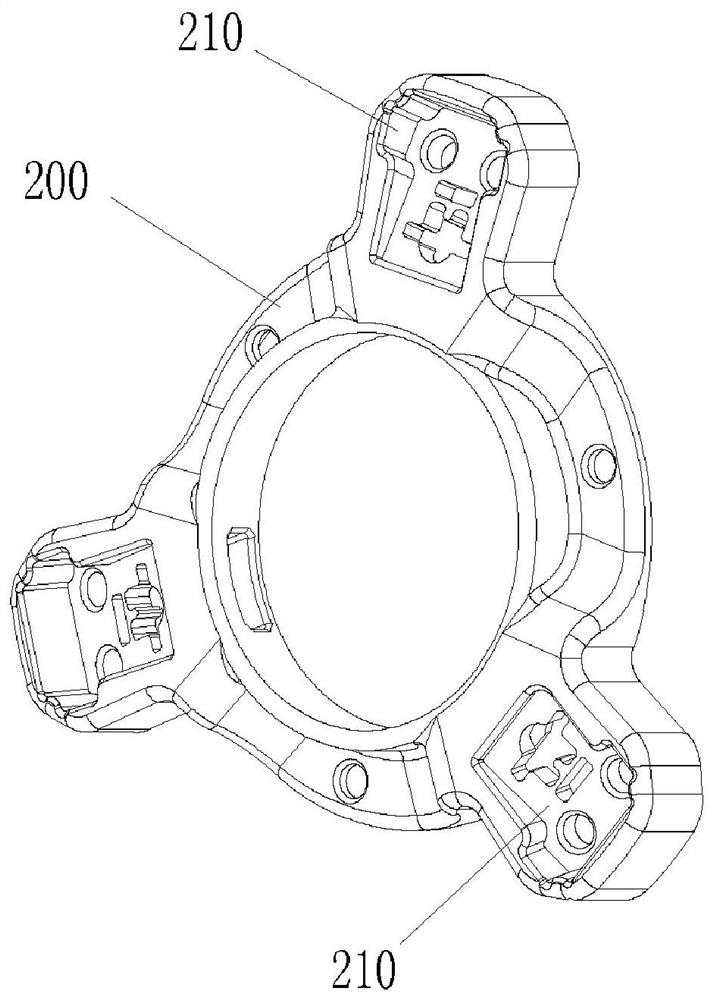

Finger base joint transmission mechanism of dexterous robot hand with adjustable pre-tightening and transmission inter space

InactiveCN101327594AReasonable force balance effectSimple structureGripping headsRobot handGear wheel

Owner:HARBIN INST OF TECH

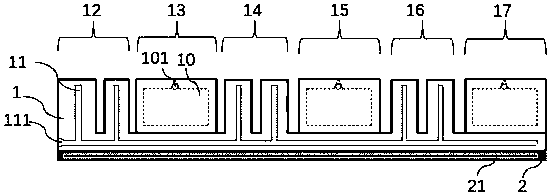

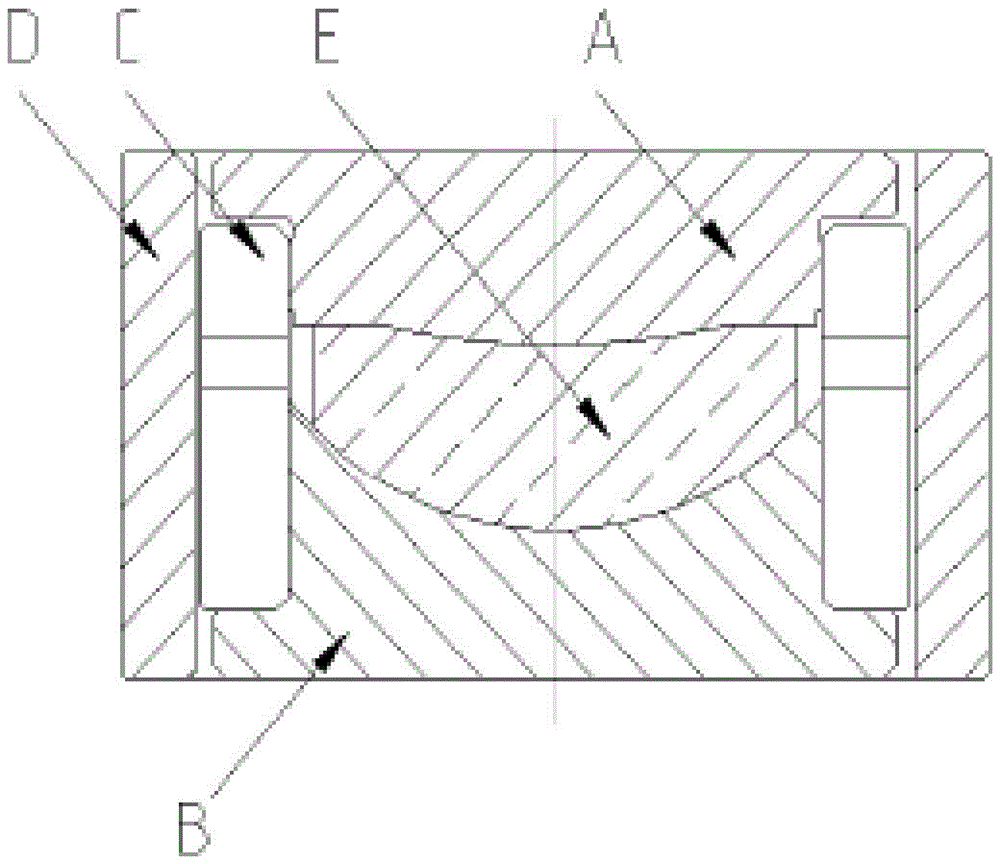

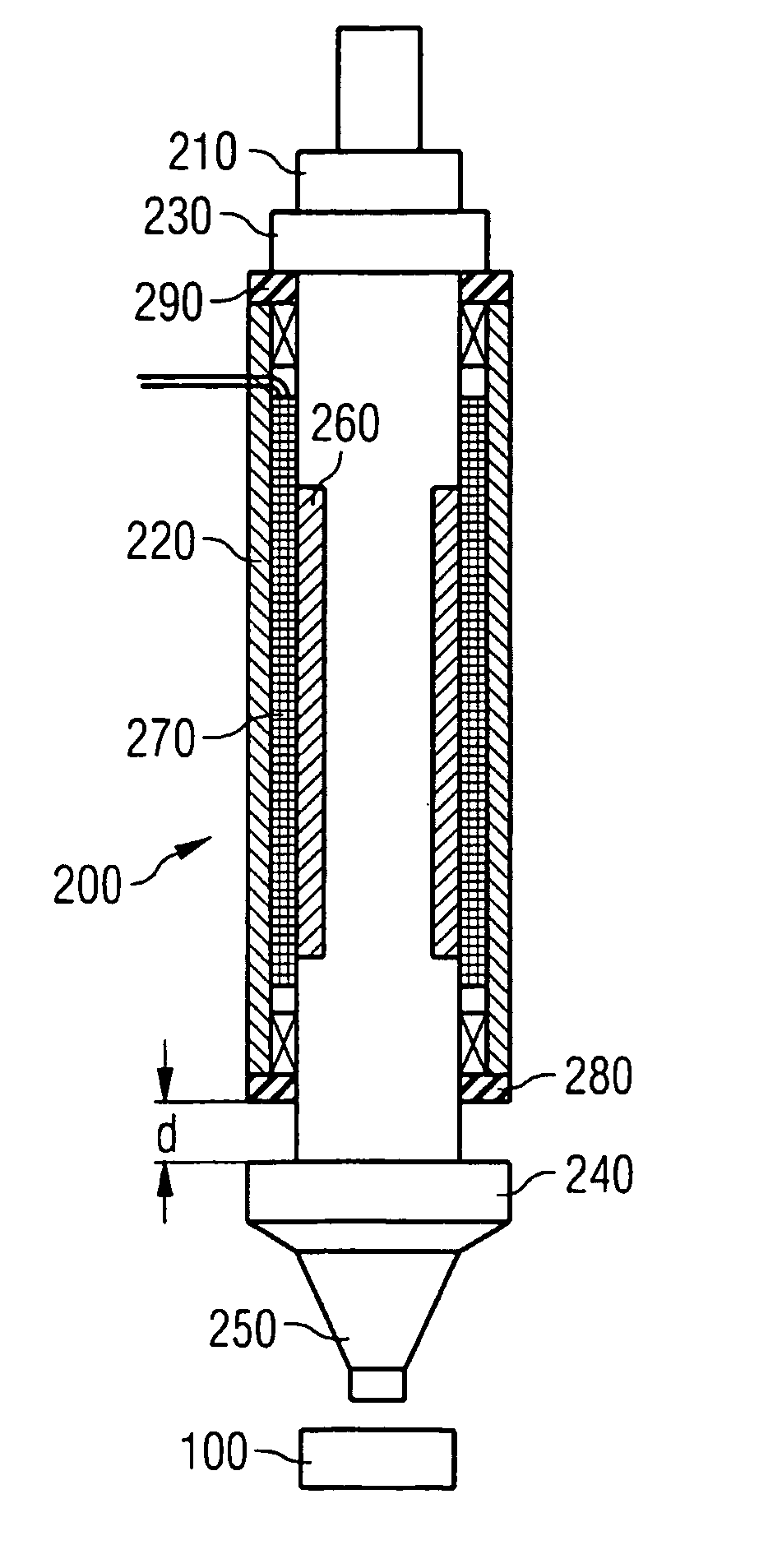

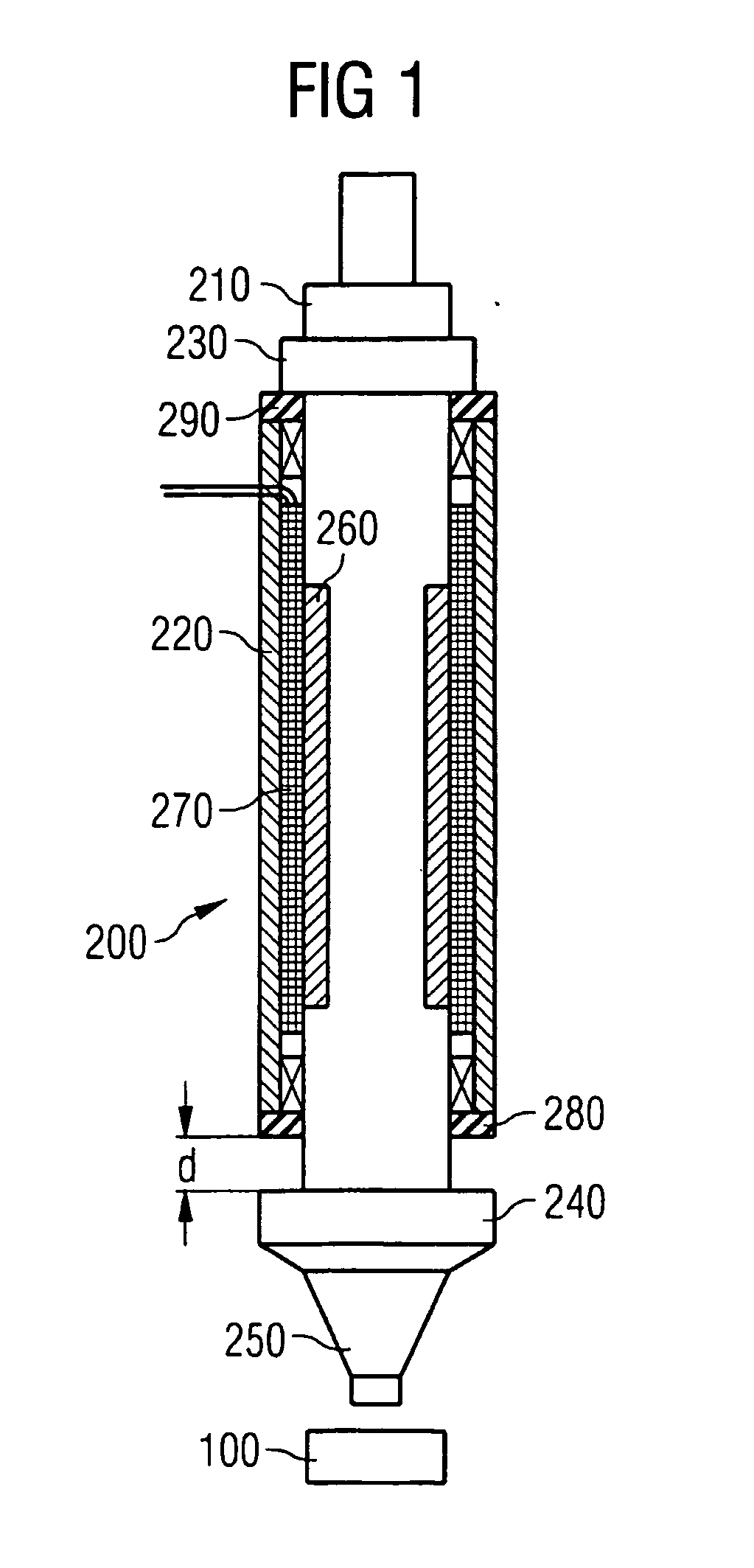

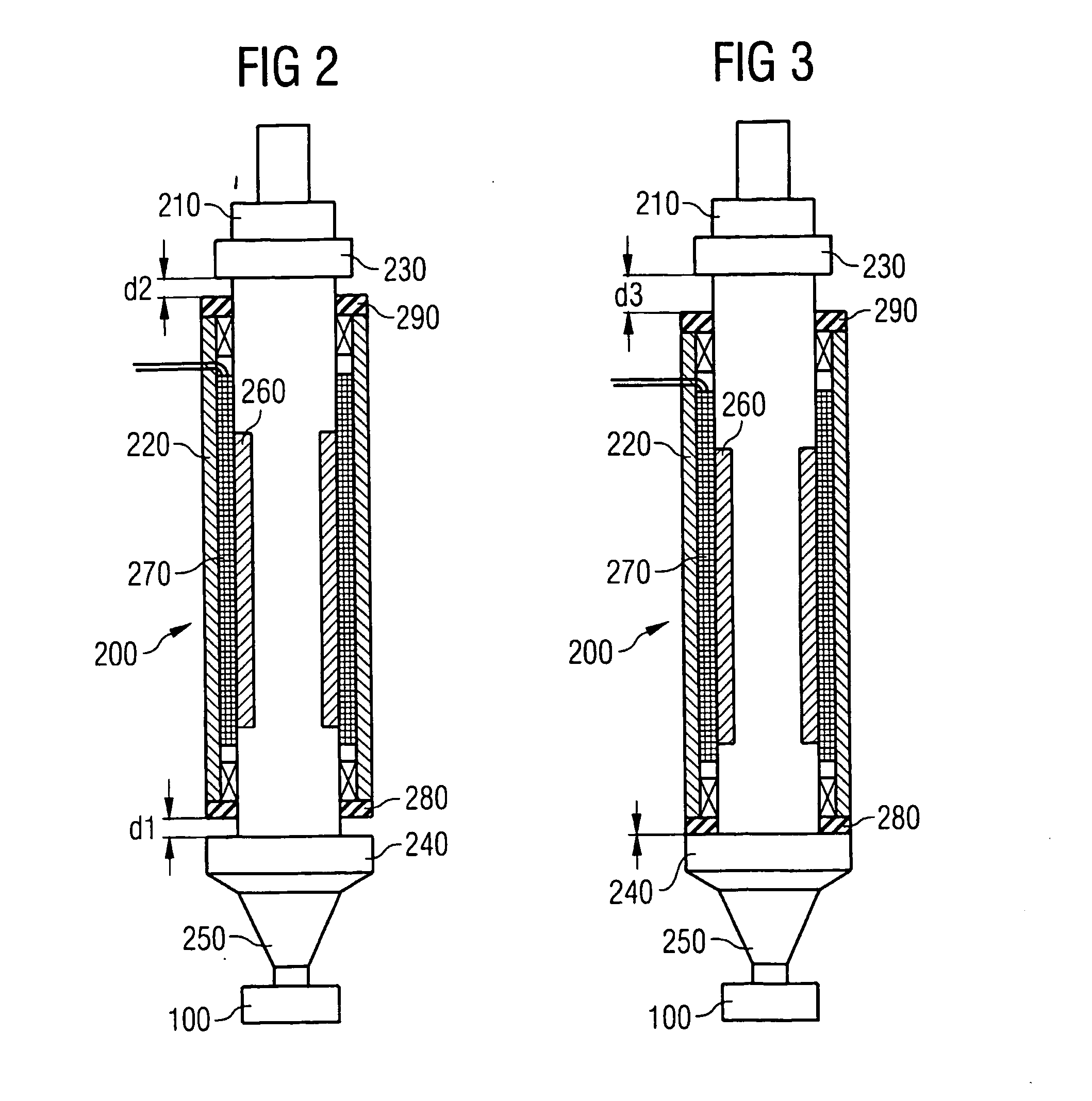

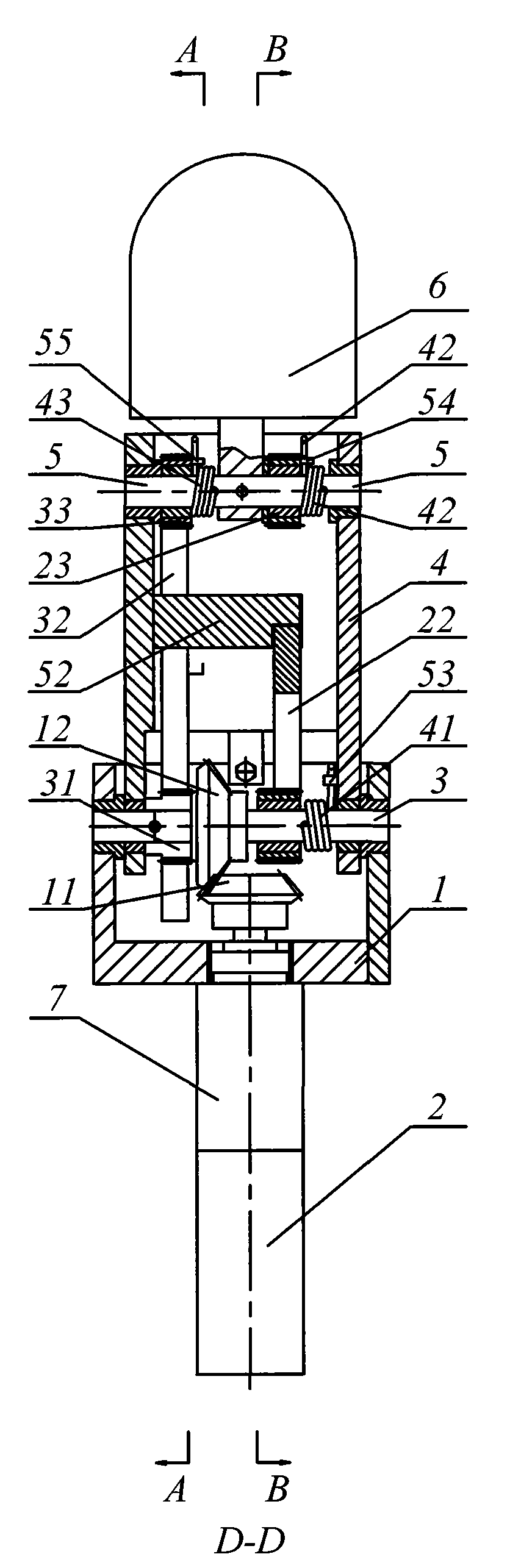

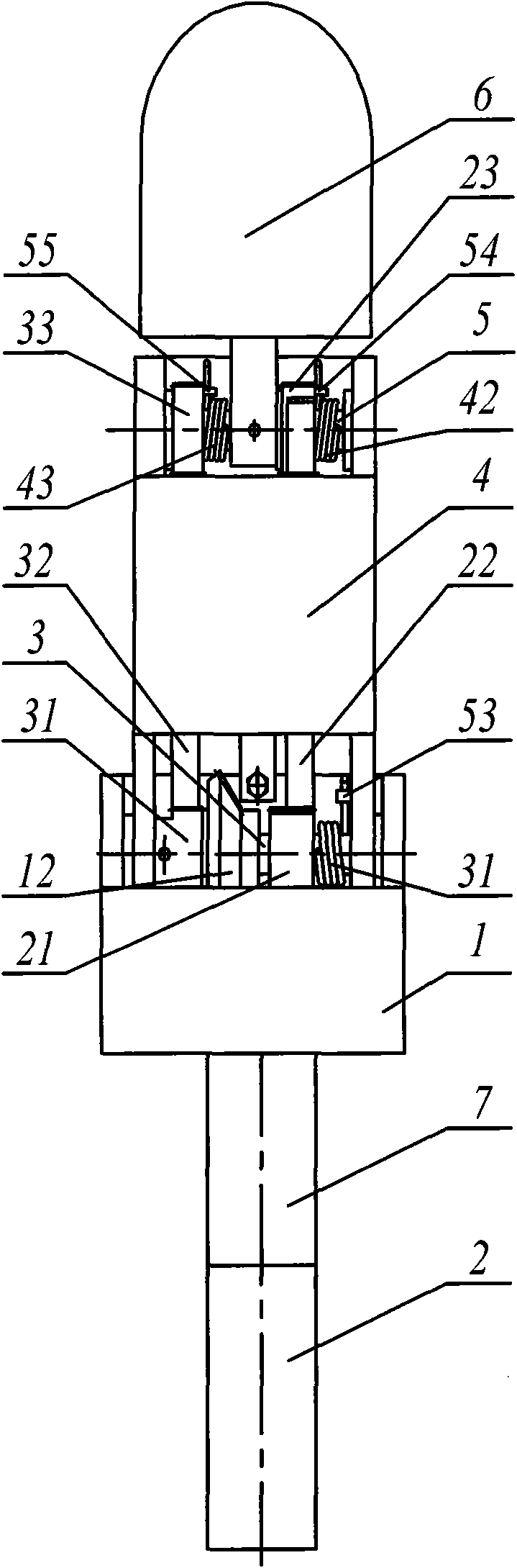

Placing device and method for placing objects onto substrates

InactiveUS20050035613A1Reduce the overall heightGripping headsSemiconductor/solid-state device manufacturingCouplingEngineering

Owner:SIEMENS AG

Method and device for implementing unmanned management of farmland

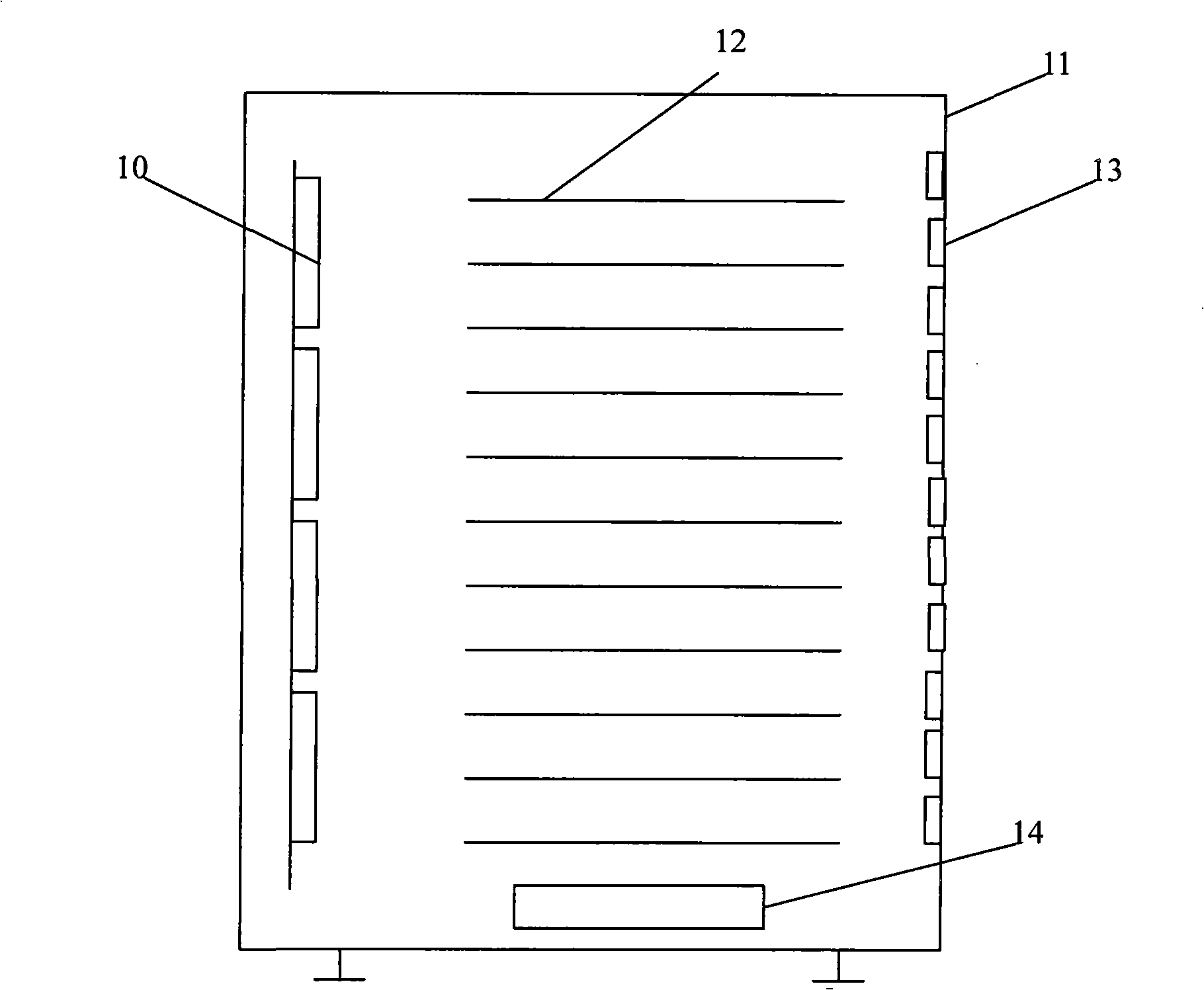

InactiveCN102934544AAvoid idle wasteEasy transferProgramme-controlled manipulatorGripping headsAgricultural scienceAgricultural engineering

Owner:贾相征

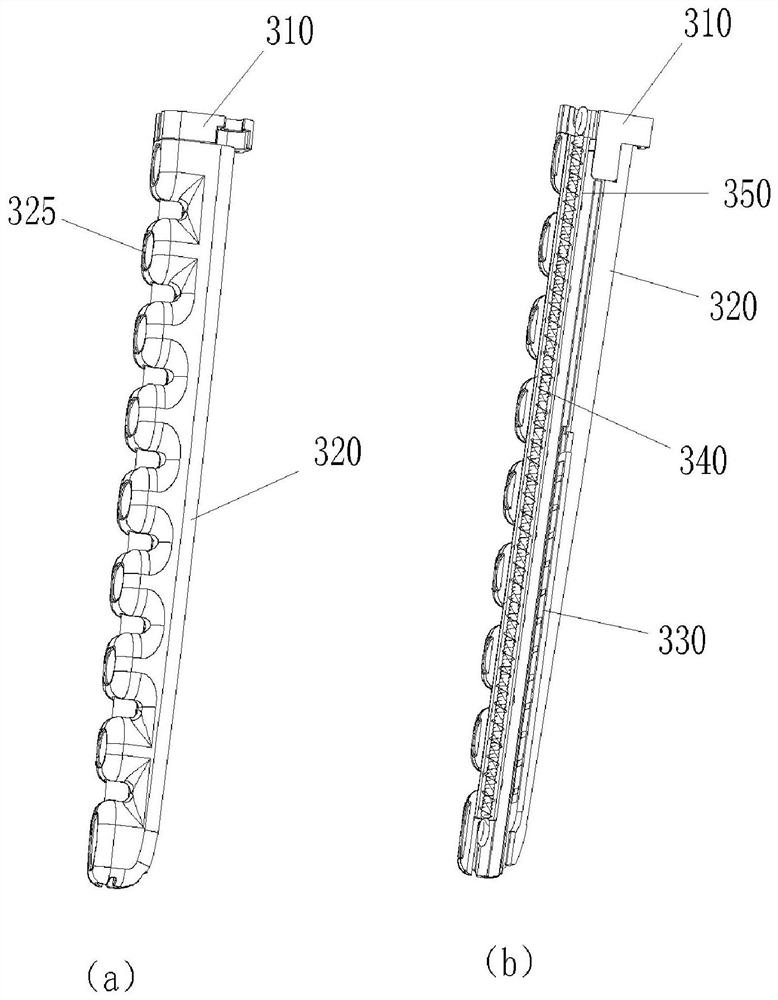

Multi-axis wheel train robot finger device for achieving parallel opening and closing and self-adaptive enveloping

Owner:TSINGHUA UNIV

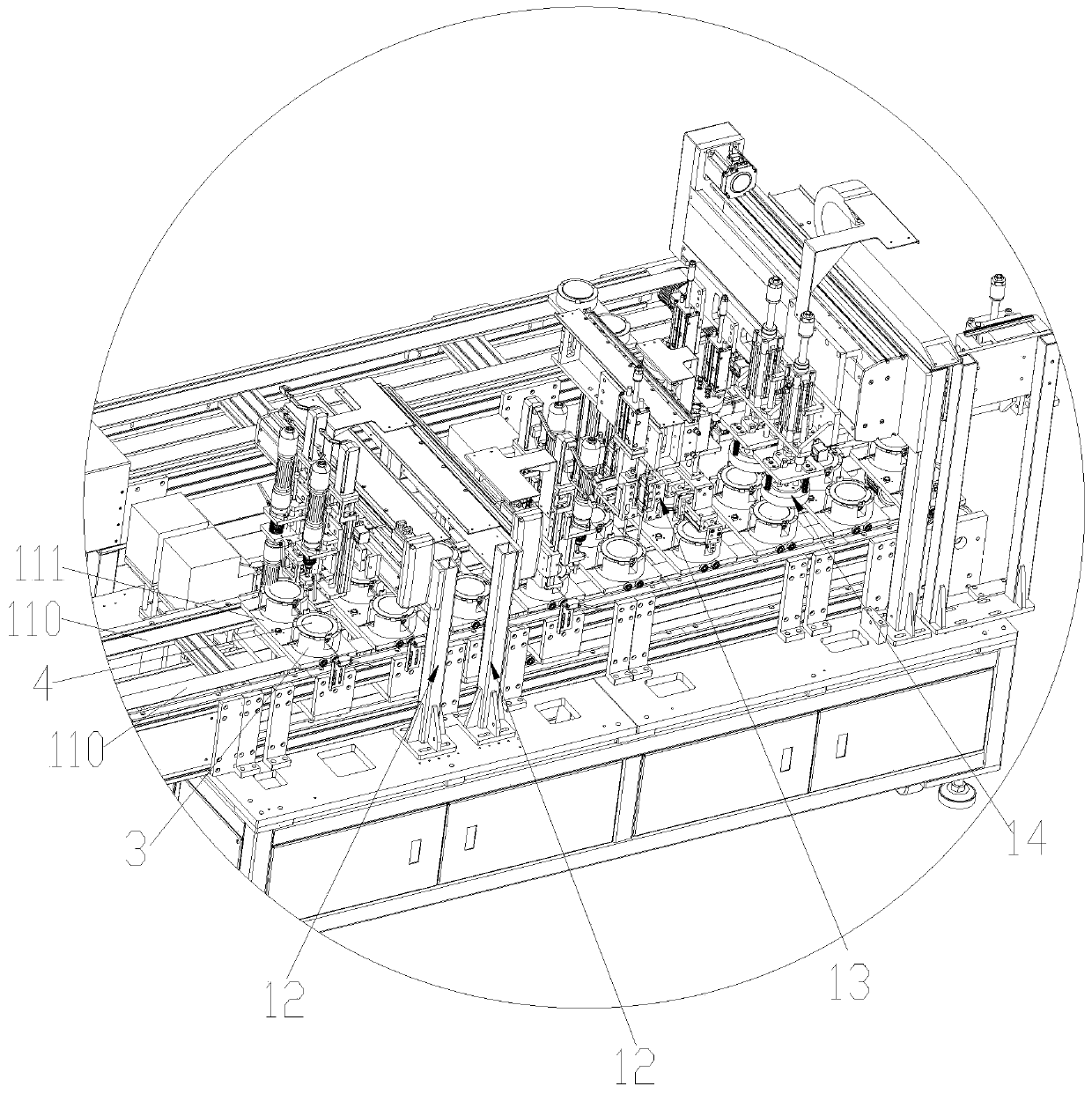

Automatic down lamp assembling equipment

PendingCN111002030AGripping headsAssembly machinesManufacturing engineeringElectrical and Electronics engineering

Owner:江苏阳铭互联智能系统有限公司

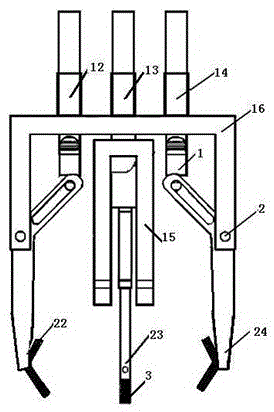

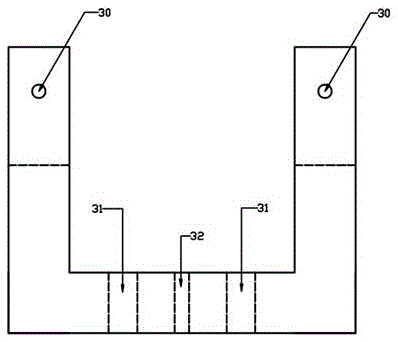

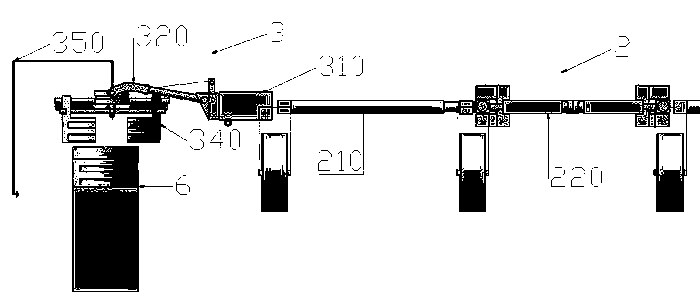

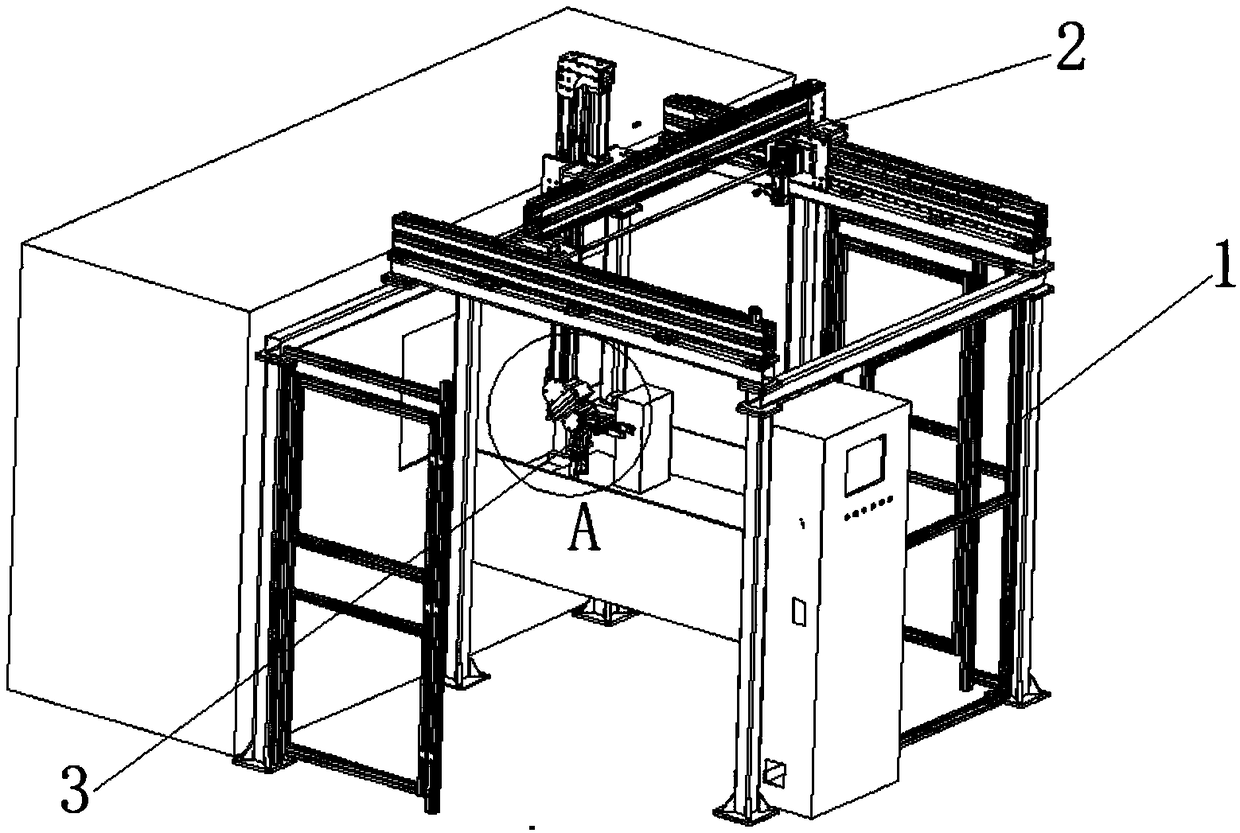

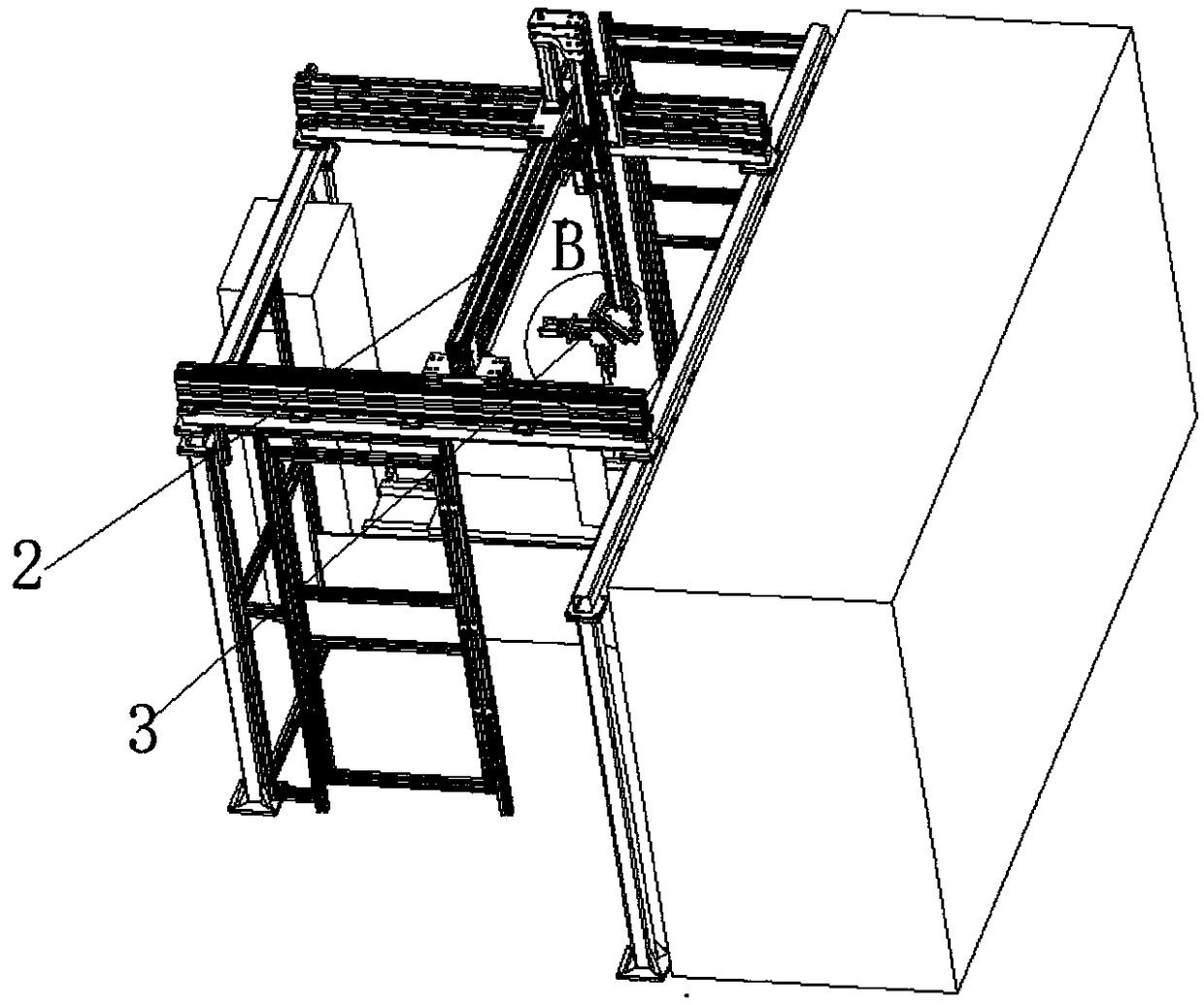

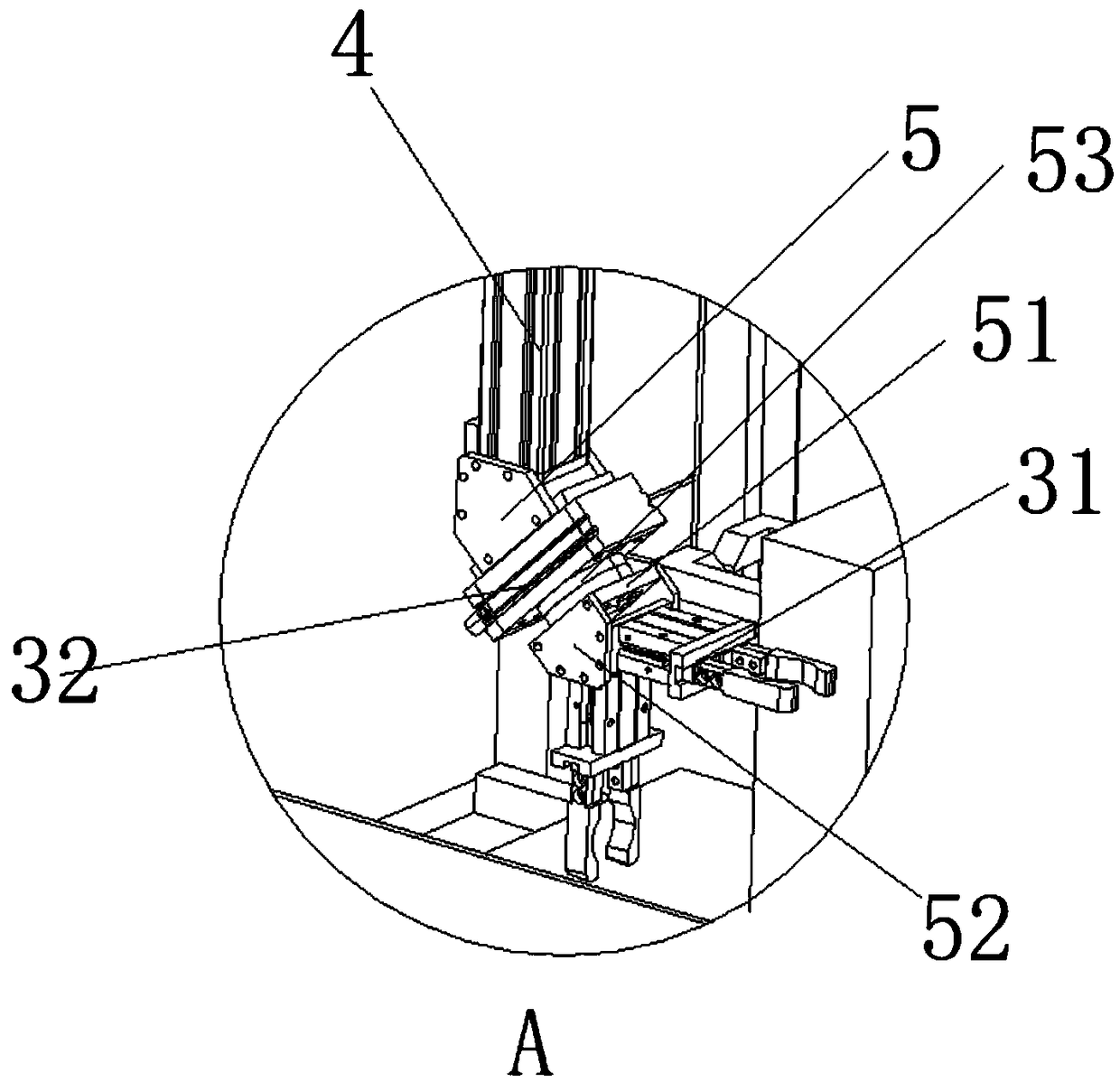

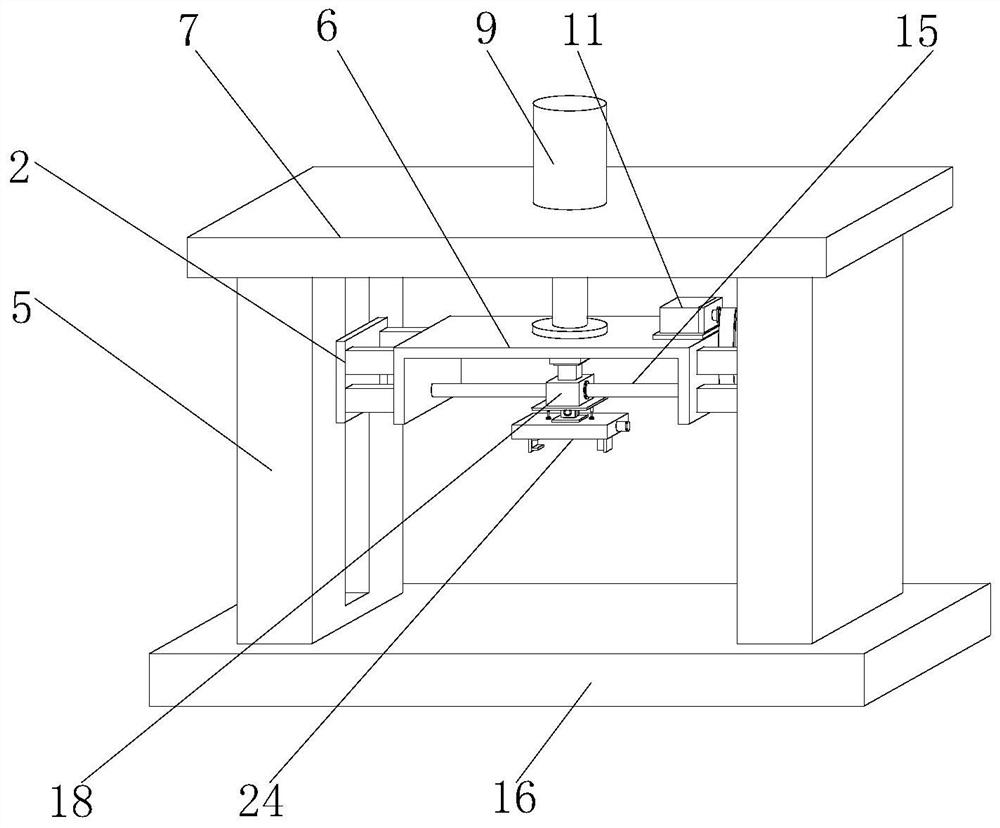

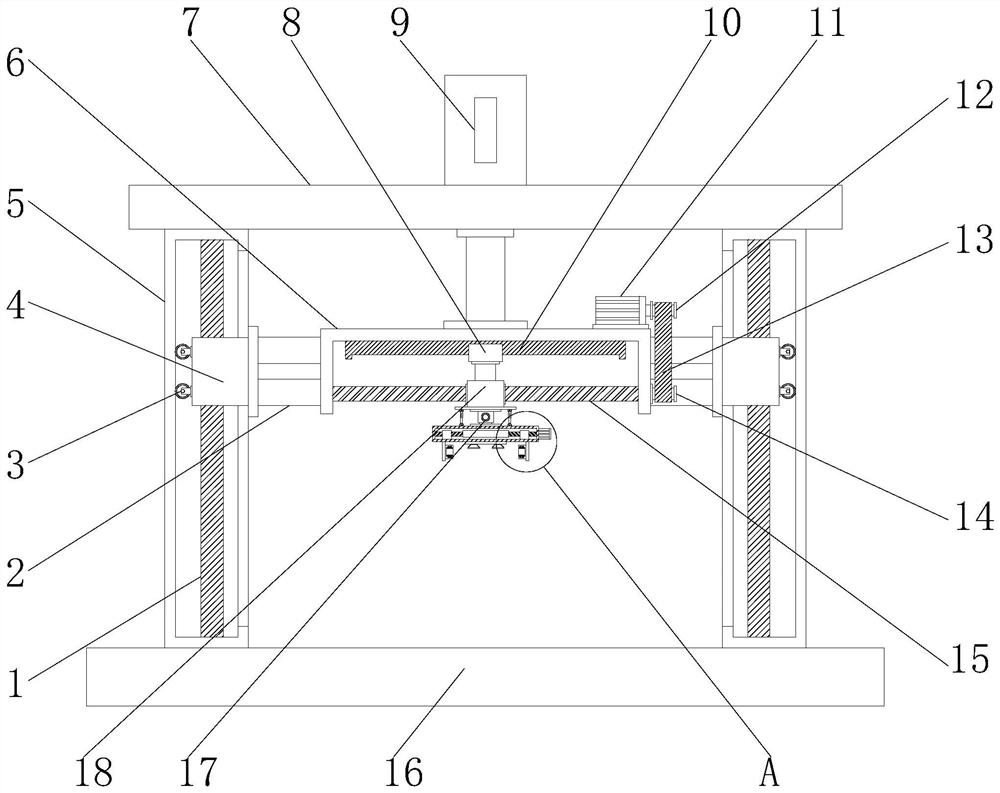

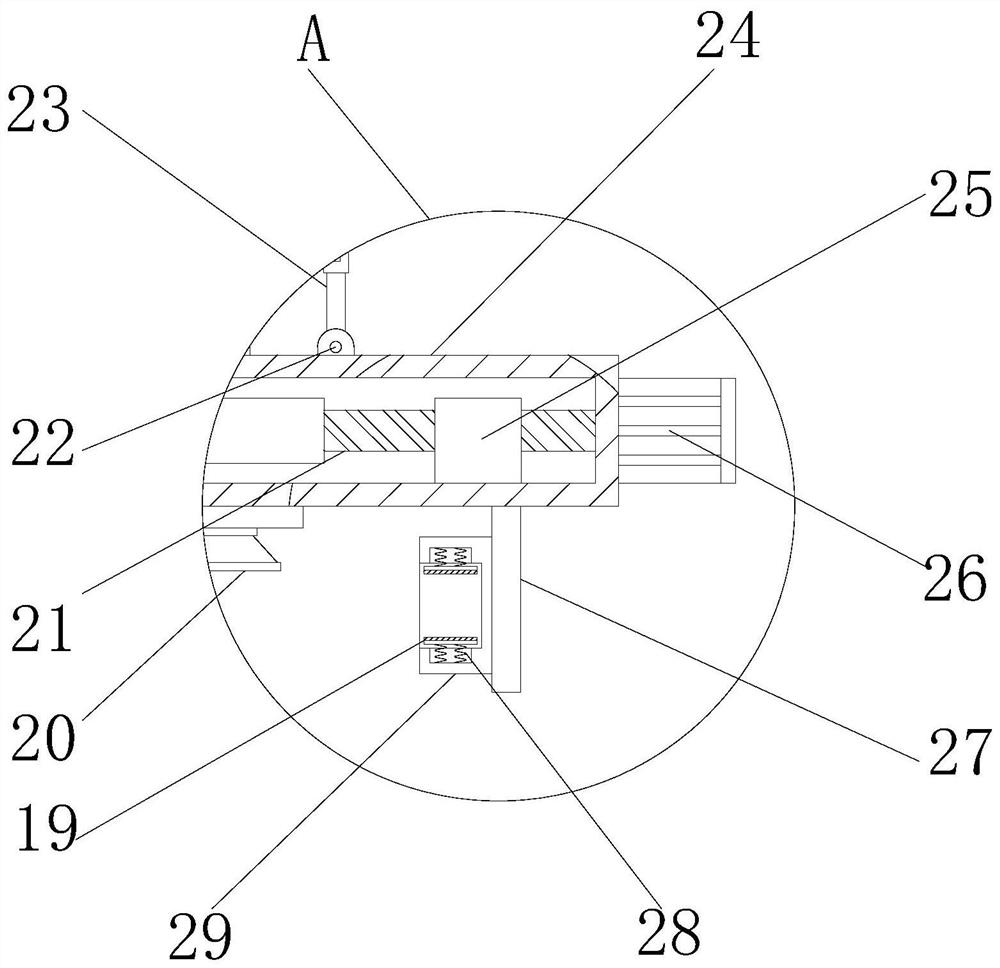

Three-axis truss gripping device and using method thereof

Owner:WUHU QUAN CHENG INTELLIGENT TECH

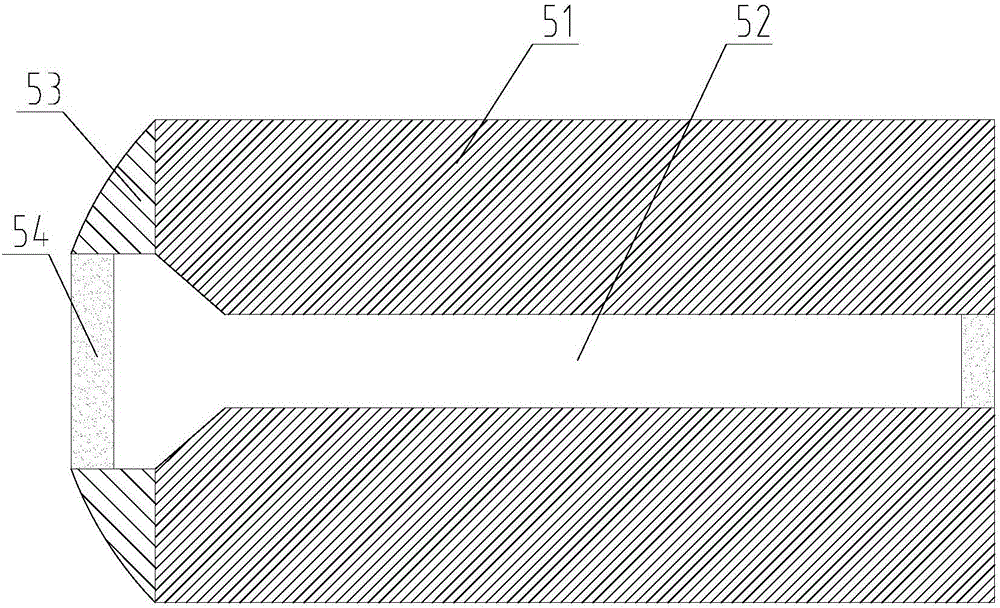

End Effector with Internal Valve

A bellows 10 is configured for connection to an end effector of a robot and includes a valve 28 supported in the interior space of the bellows. A flow of low pressure air is induced from inside the bellows into a vacuum plenum 24 for retrieving a work product by the open end 16 of the bellows. High pressure air is moved through a conduit 50 into the valve to terminate the flow of low pressure air and terminate the suction applied by the bellows to the work product.

Owner:AMF AUTOMATION TECH

Soft body grabbing device and method based on artificial muscle driving

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

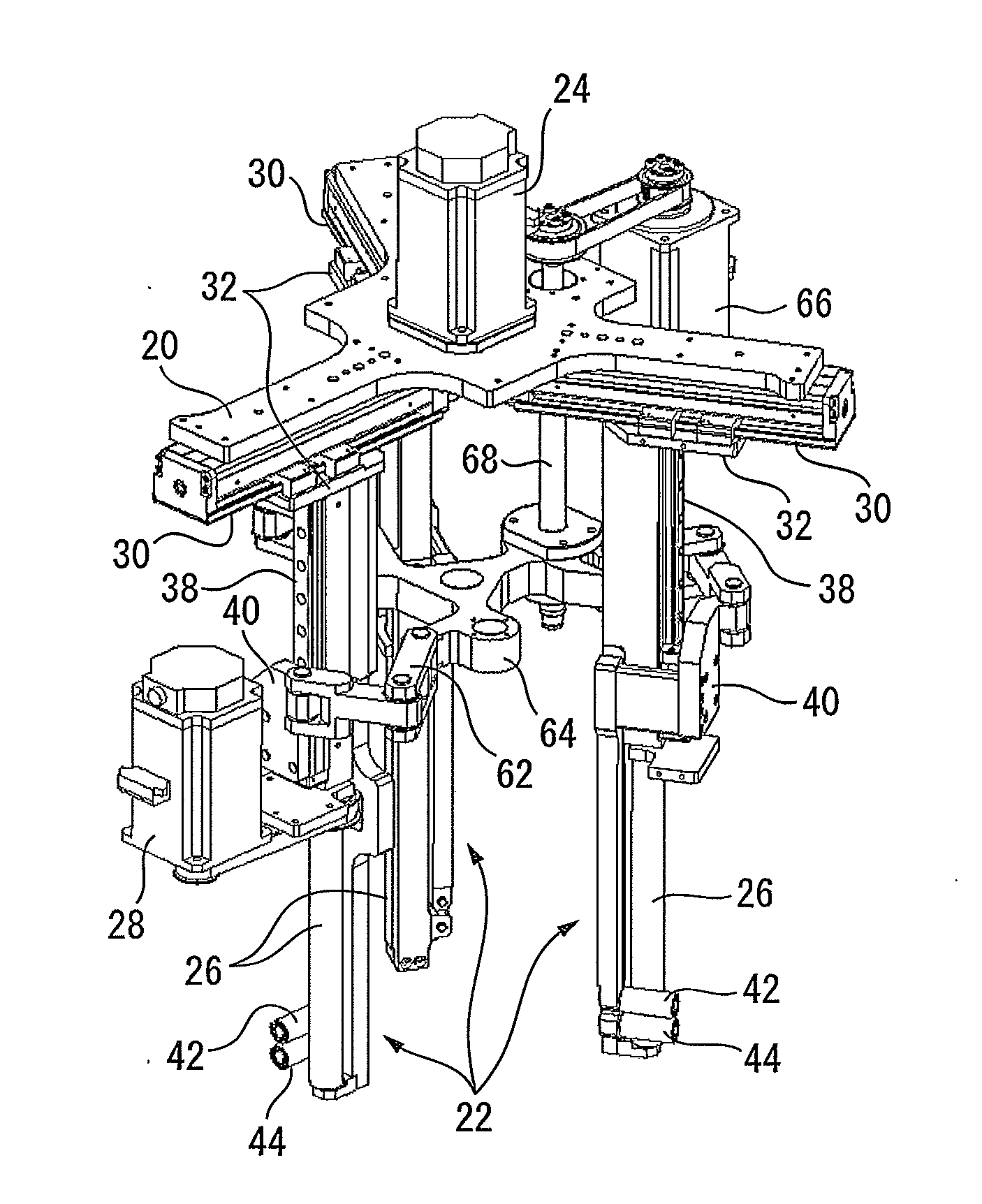

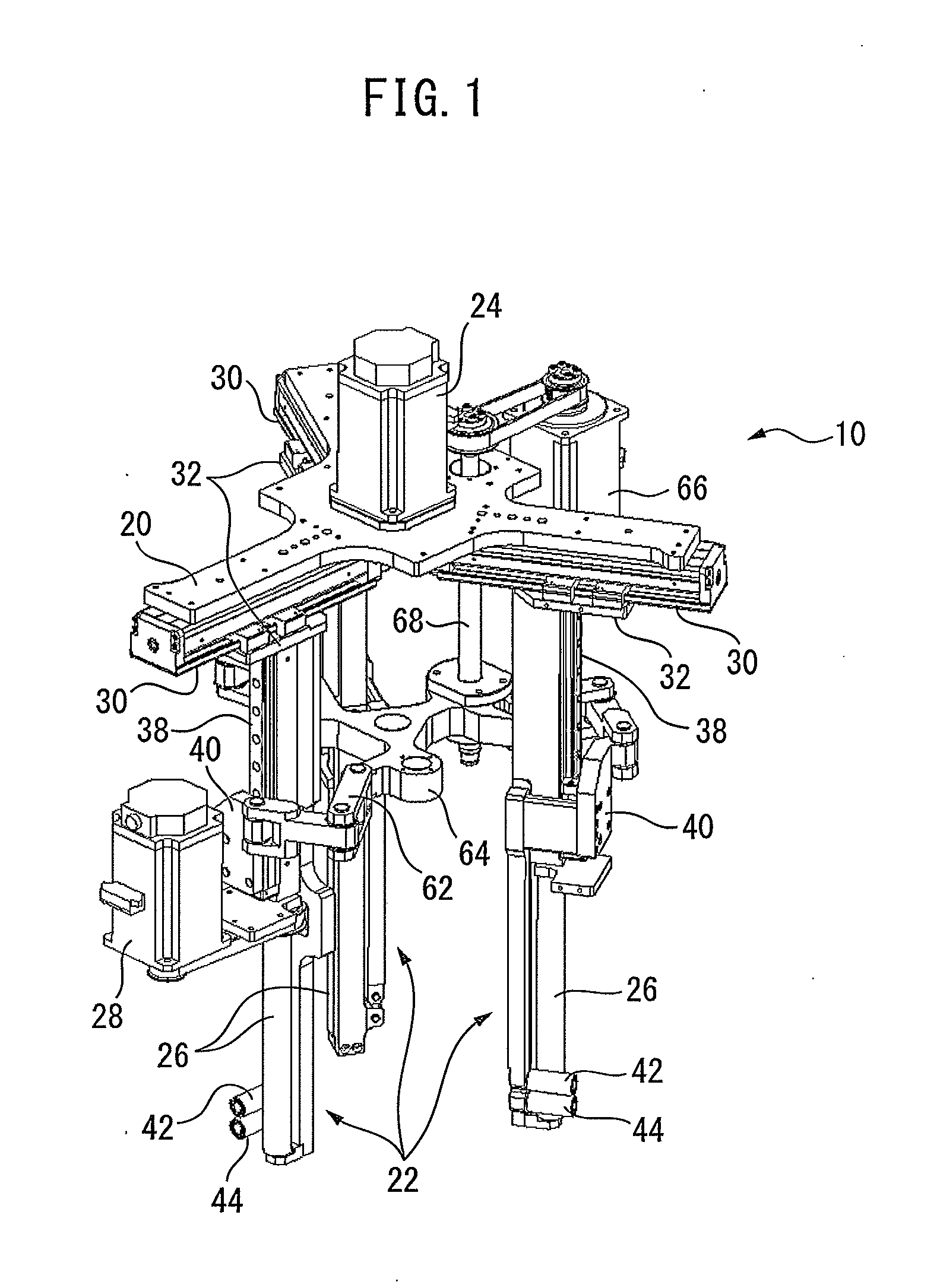

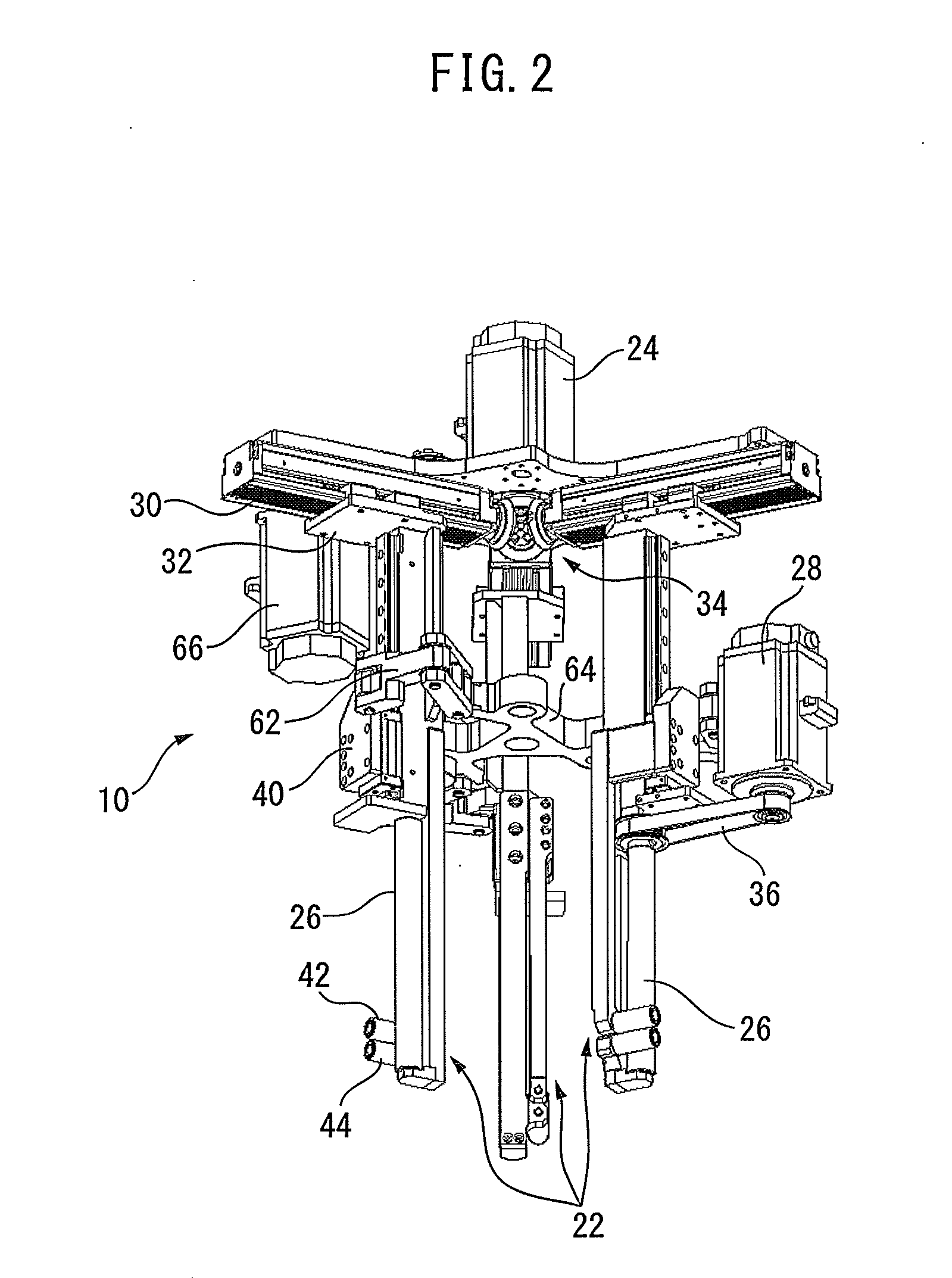

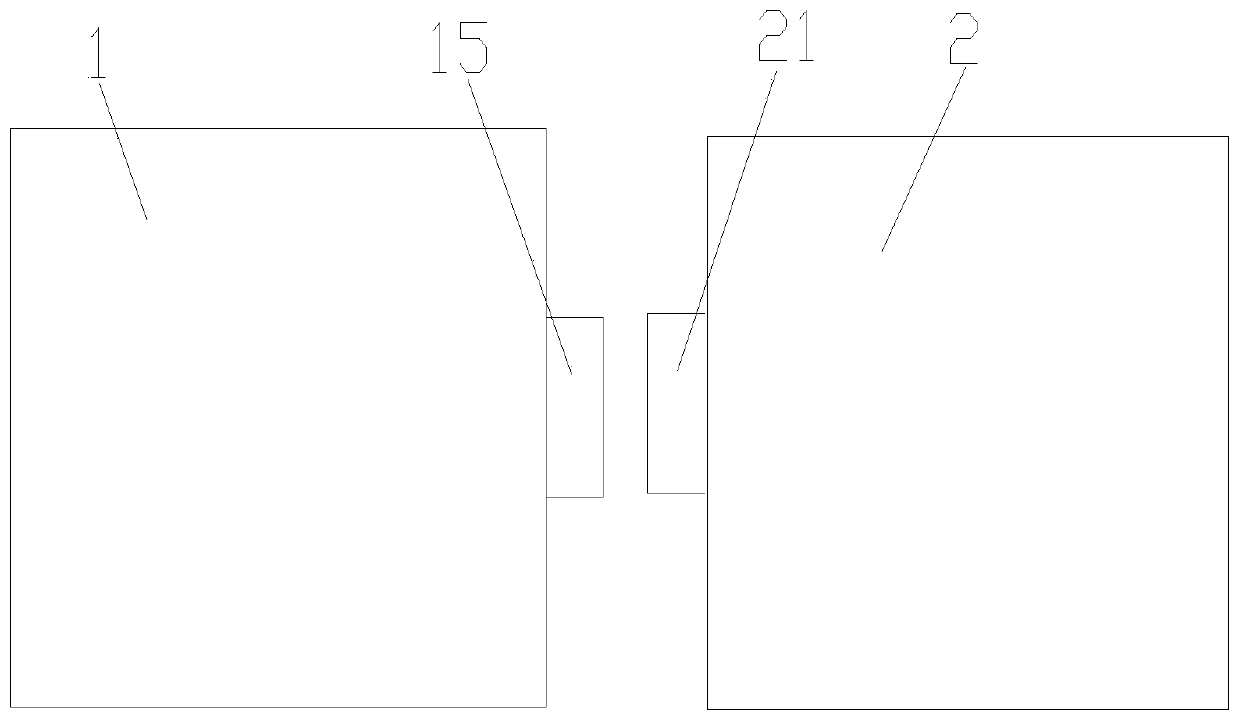

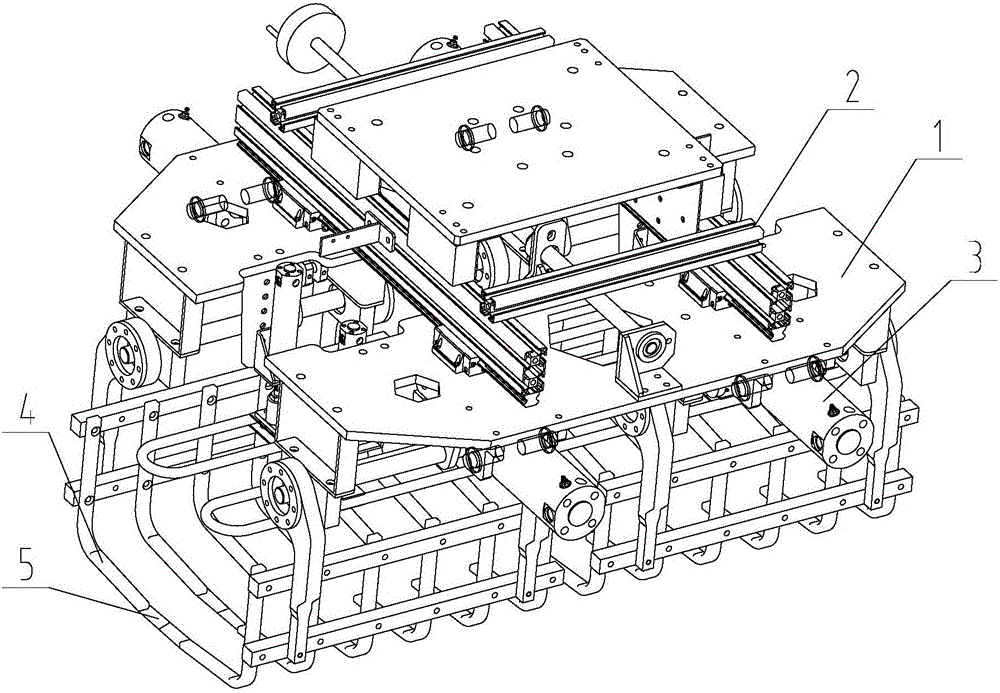

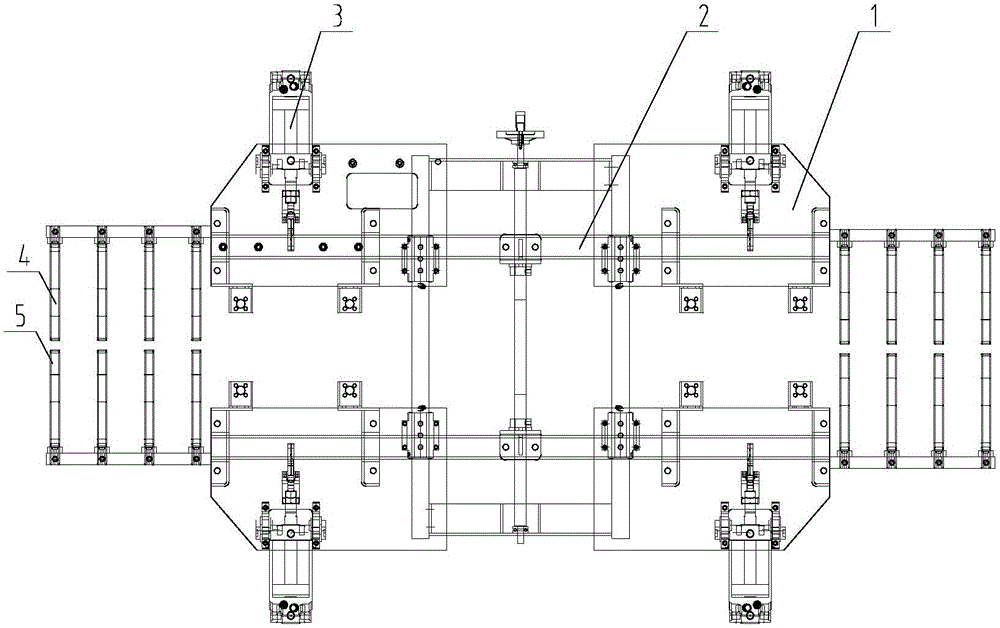

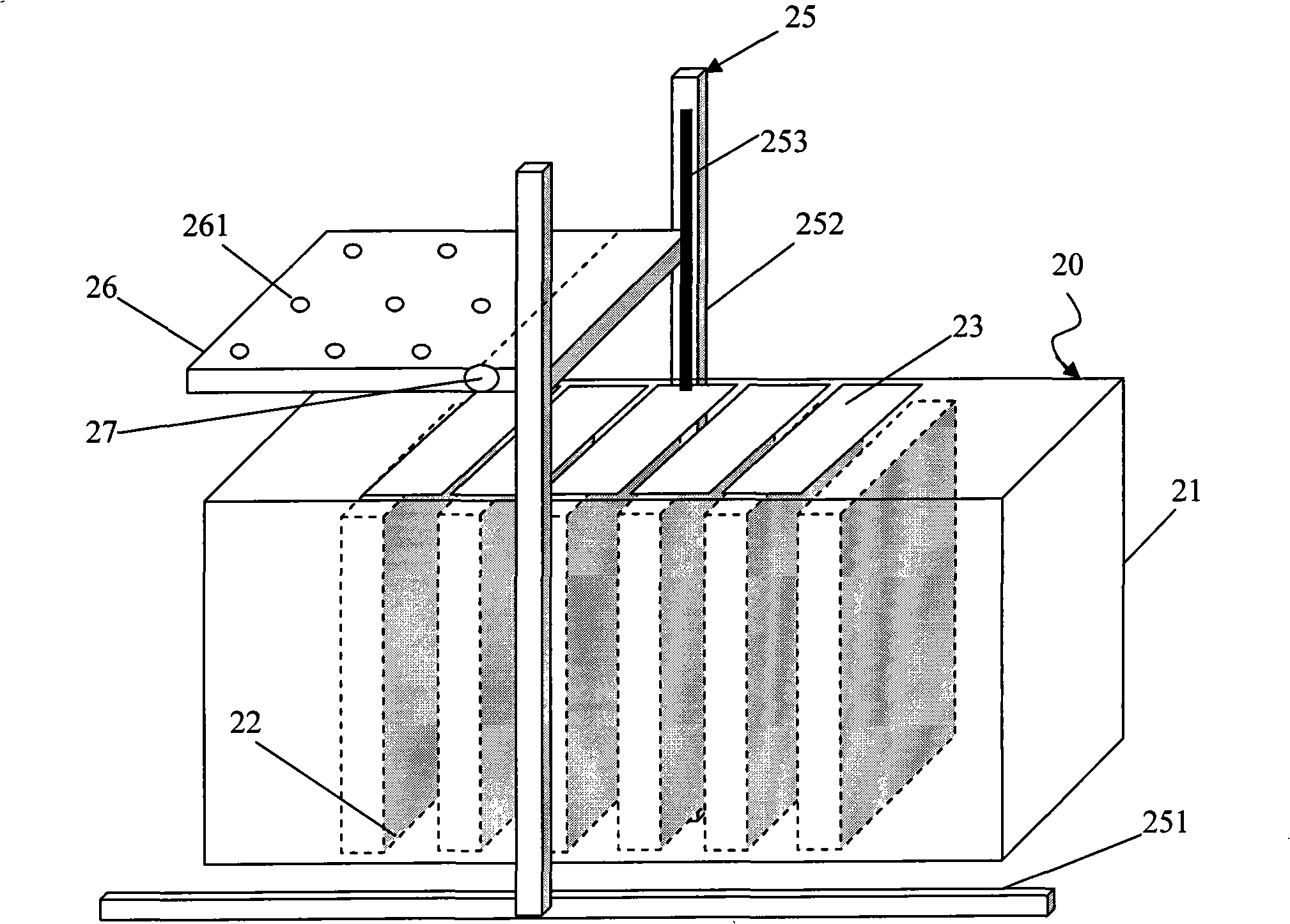

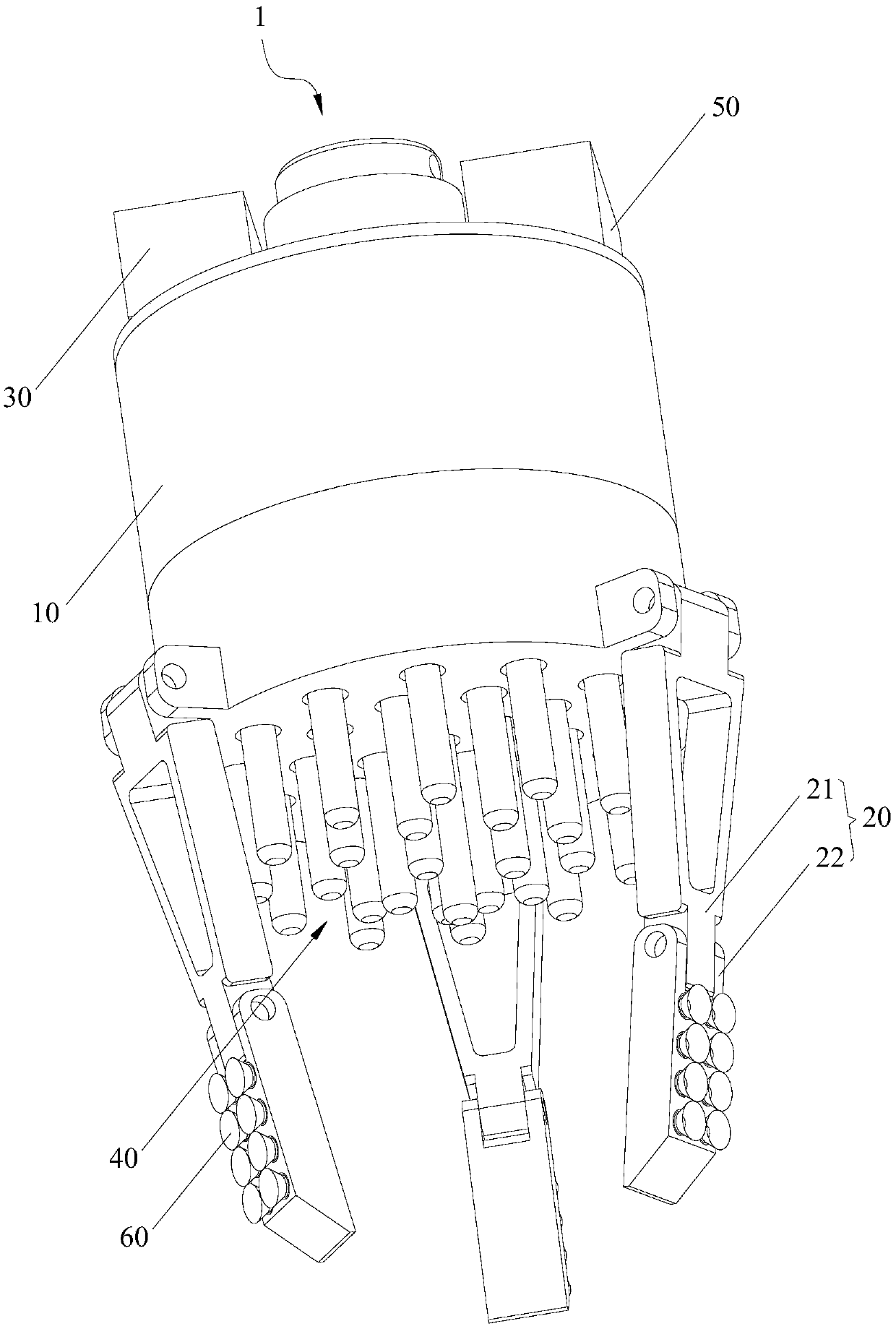

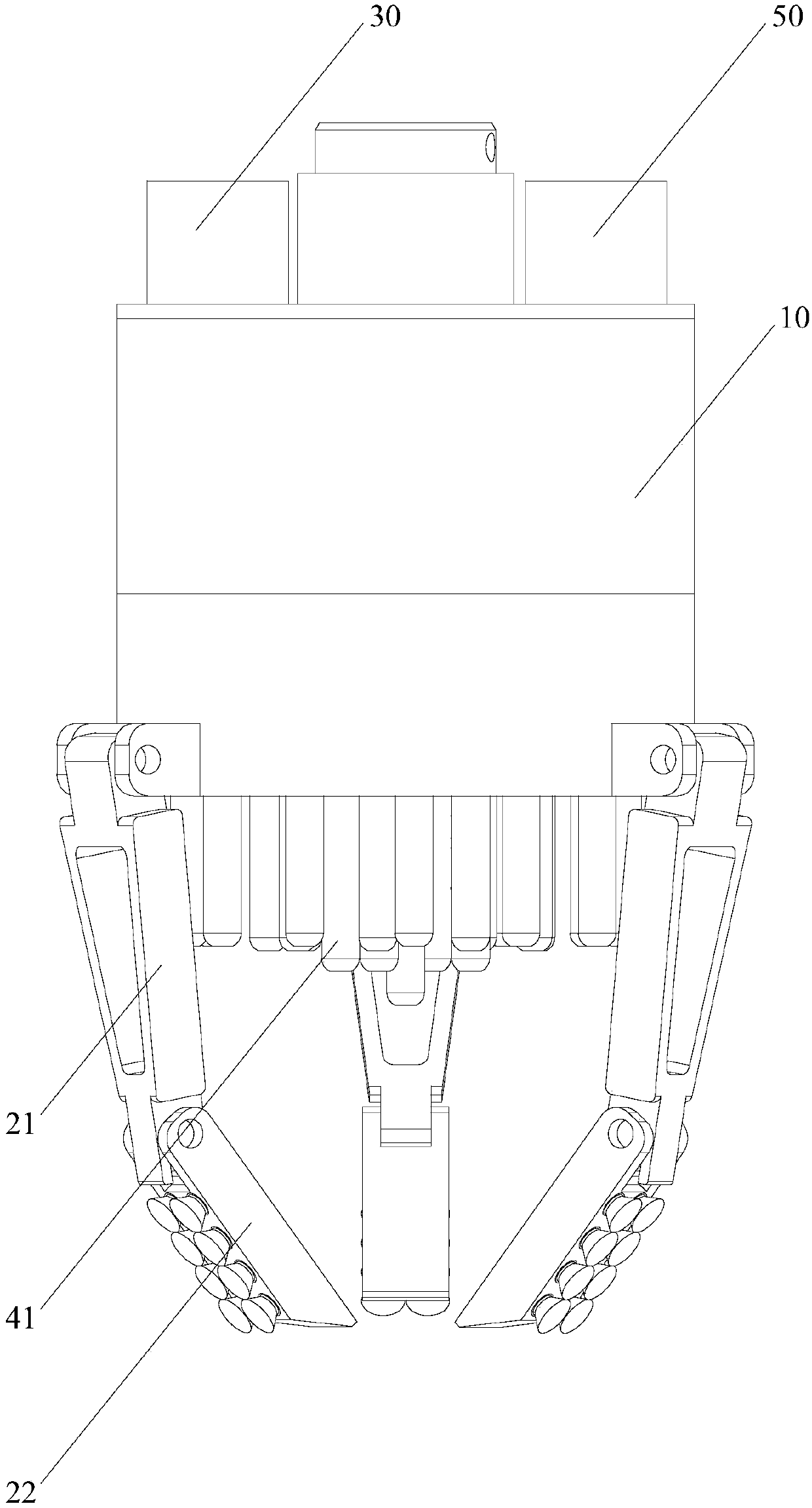

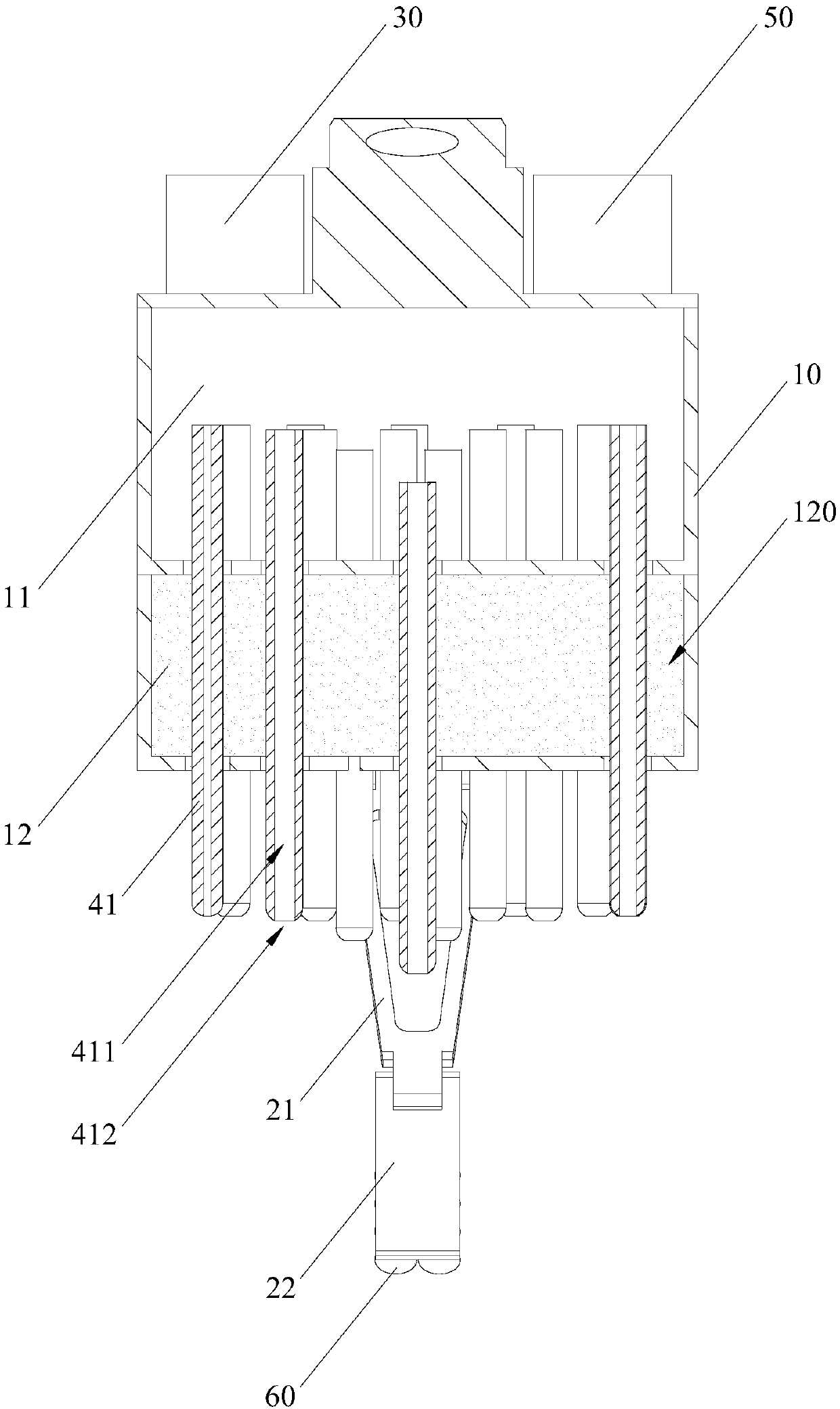

Assembling manipulator for electric locomotive wheel driving unit

The invention relates to the technical field of electric locomotives, and provides an assembling manipulator for an electric locomotive wheel driving unit. The electric locomotive wheel driving unit comprises main tracks, a cross beam, a slide carriage, a transverse walking mechanism, a lifting mechanism, and a picking mechanism, wherein the cross beam is movably arranged on the main tracks, and comprises cross beam tracks; the extending directions of the main tracks are perpendicular to the extending directions of the cross beam tracks; the slide carriage is arranged on the cross beam tracks;the transverse walking mechanism is connected with the slide carriage and is movably arranged relative to the cross beam tracks to drive the slide carriage to move along the cross beam tracks; the lifting mechanism is connected with the slide carriage and comprises a ram; the ram is movably arranged relative to the slide carriage in the vertical direction; the picking mechanism is connected withthe ram and comprises a clamping jaw part used for clamping a workpiece; the clamping jaw part is arranged adjustably relative to the position of the ram.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

Intelligent robot gripper for stacking system

ActiveCN105084021AFree crawlingAchieve fixationProgramme-controlled manipulatorGripping headsRubber ringGlass fiber

Owner:东莞智动力电子科技有限公司

Liquid metal type robot dexterous hand

The invention discloses a liquid metal type robot dexterous hand. Refrigeration and heating liquid metal driving joint working cylinders and liquid metal self-generating electricity devices are assembled inside close knuckles; far knuckles are connected to one ends of the close knuckles to form single fingers; the other ends of the close knuckles are connected with a palm; and the fingers are connected to the palm and together with an intelligent controller to form the liquid metal robot dexterous hand. Magnetic poles of the liquid metal self-generating electricity devices are assembled on theouter sides of the middle portions of the refrigeration and heating liquid metal driving joint working cylinders, the liquid metal cutting magnetic poles generates magnetic induction lines to generate cutting current, and upper electrode layers and lower electrode layers of the refrigeration and heating liquid metal driving joint working cylinders transmit the current to a battery through rectifiers of the liquid metal self-generating electricity devices. The liquid metal type robot dexterous hand has the property of self-adaptively matching the shape of a grasped object, and has a liquid metal moving self-generating electricity function.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Seal heat treatment apparatus, manipulator apparatus and rigidification substrate method thereof

InactiveCN101349504ASimple structureDoes not affect the placementGripping headsCharge supportsHigh intensityEngineering

Owner:INESA DISPLAY MATERIALS

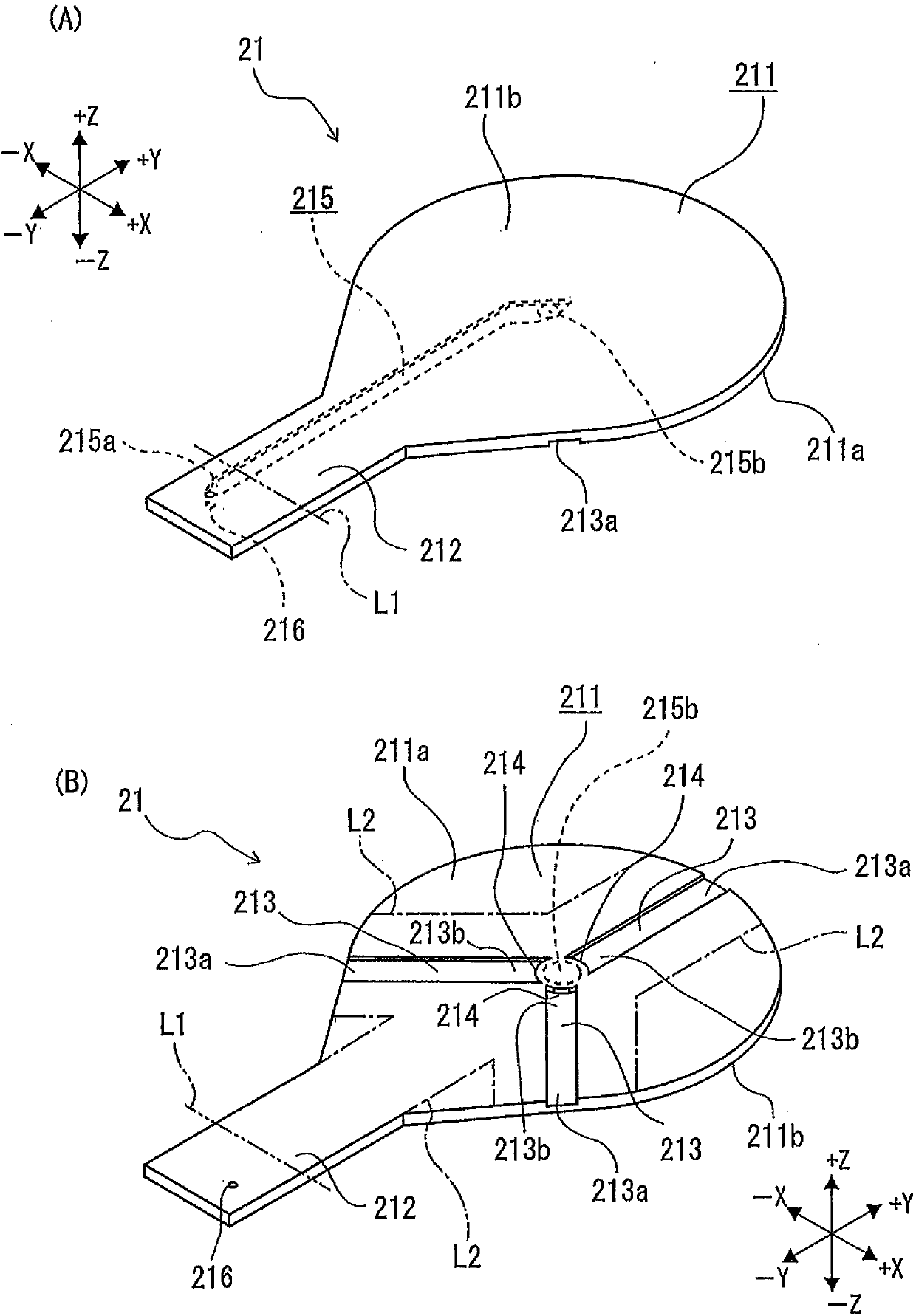

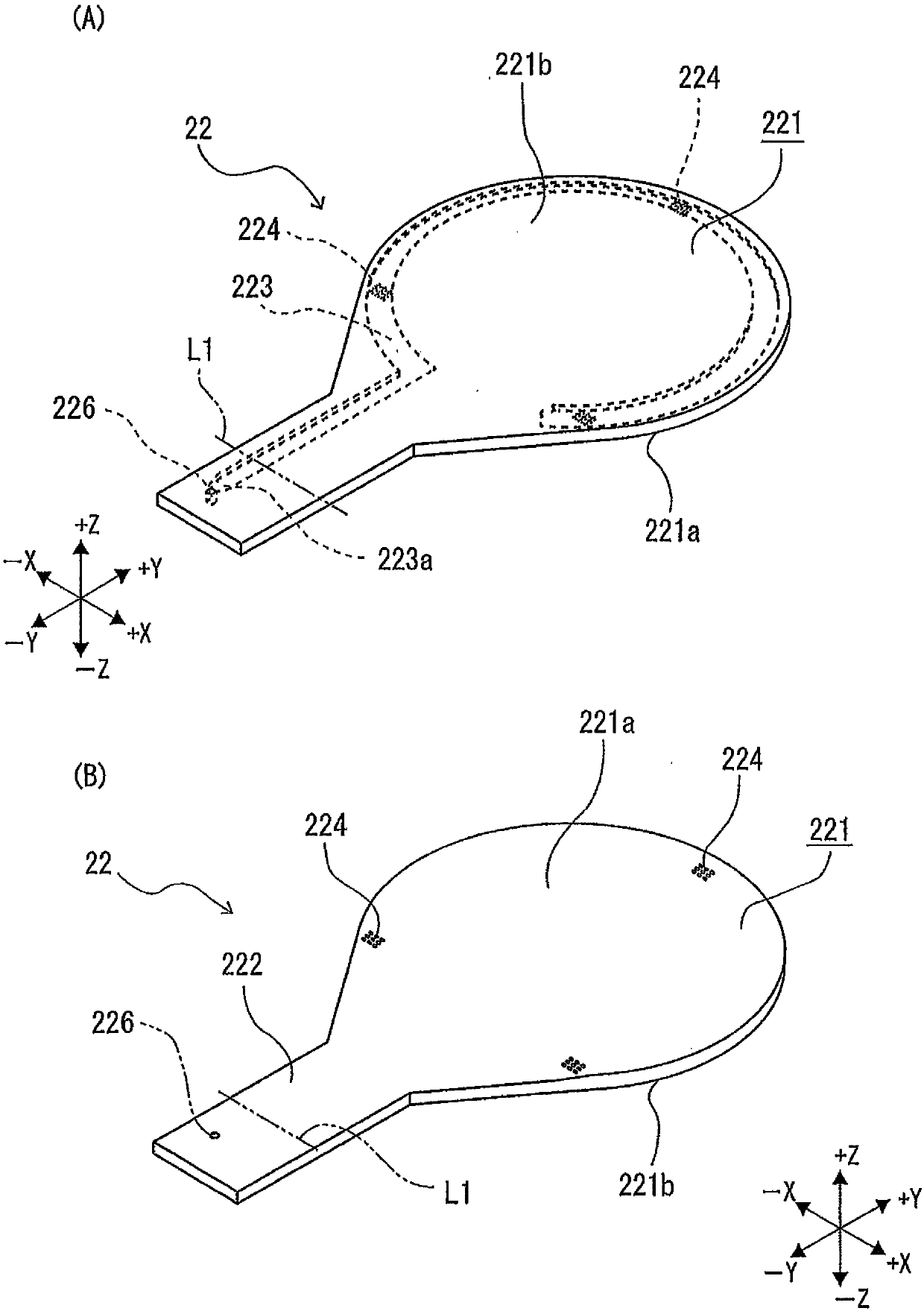

Robot hand and transporting robot

ActiveCN107891427AGripping headsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:DISCO CORP

Rack type parallel coupling underactuated robot finger device

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV +1

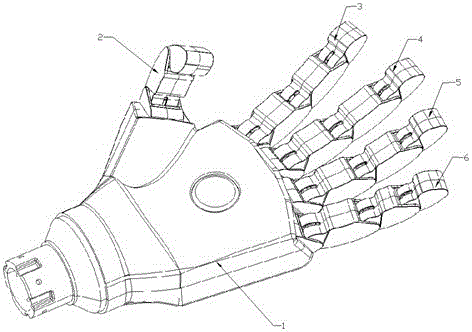

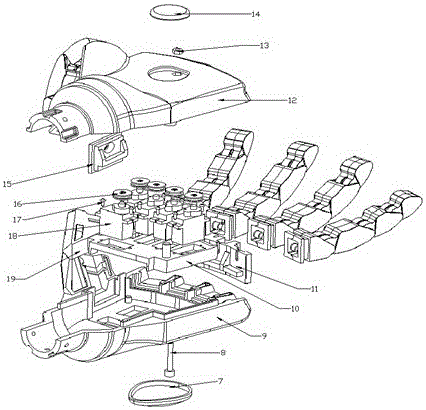

Multifunctional robot hand

PendingCN110640770ASolve the technical problem of not being able to adapt to special-shaped objectsImprove smoothnessGripping headsRobot handEngineering

Owner:SHENZHEN CANSINGA TECH CO LTD

Mechanical gripper and robot

Owner:GUANGDONG BAIYUN UNIV

Manipulator with motion controlled by torsion spring and steering engines

Owner:SHENZHEN SANBOT INNOVATION INTELLIGENT CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap