Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76results about "Gearing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluid dampening chain tensioning device

In one embodiment, a chain tensioning system is provided which maintains tension on a chain and permits slow changes in chain tension while dampening sudden changes. An exemplary embodiment may permit slow changes in chain tension while dampening sudden changes through the use of a fluid dampening device. Additionally, some embodiments may permit slow changes in chain tension while dampening sudden changes in only one direction of chain tension change.

Owner:BLACKGLASS

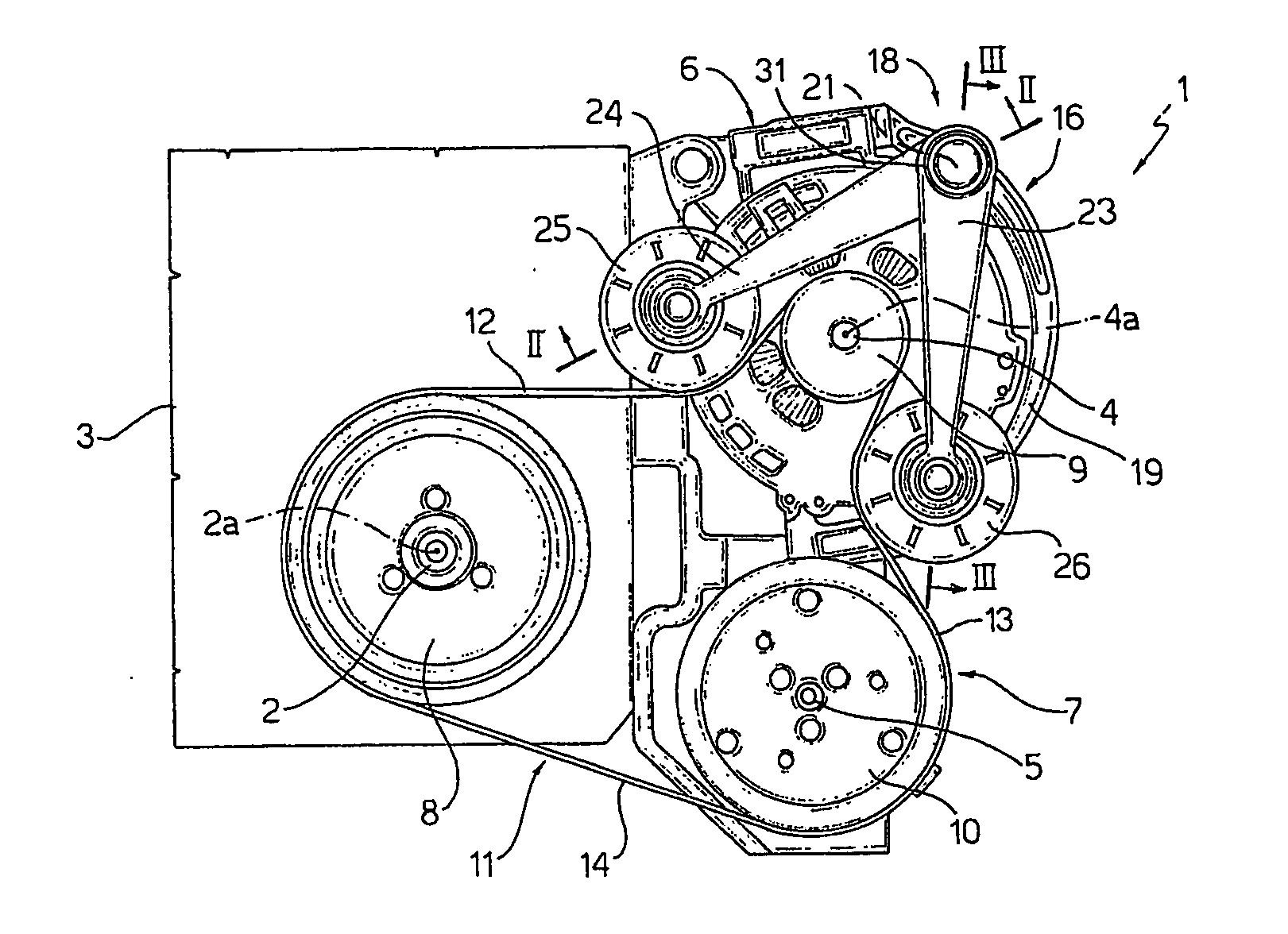

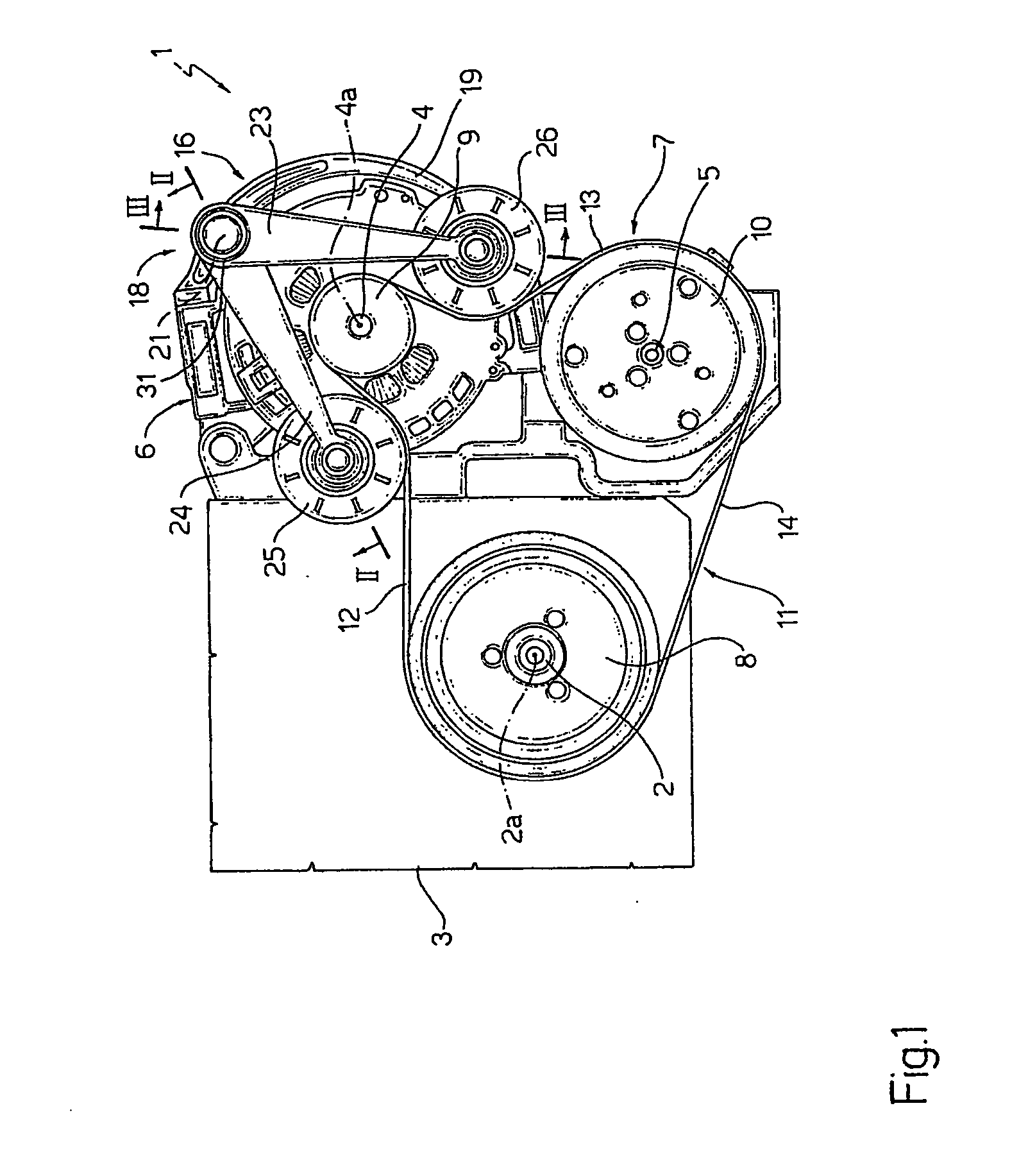

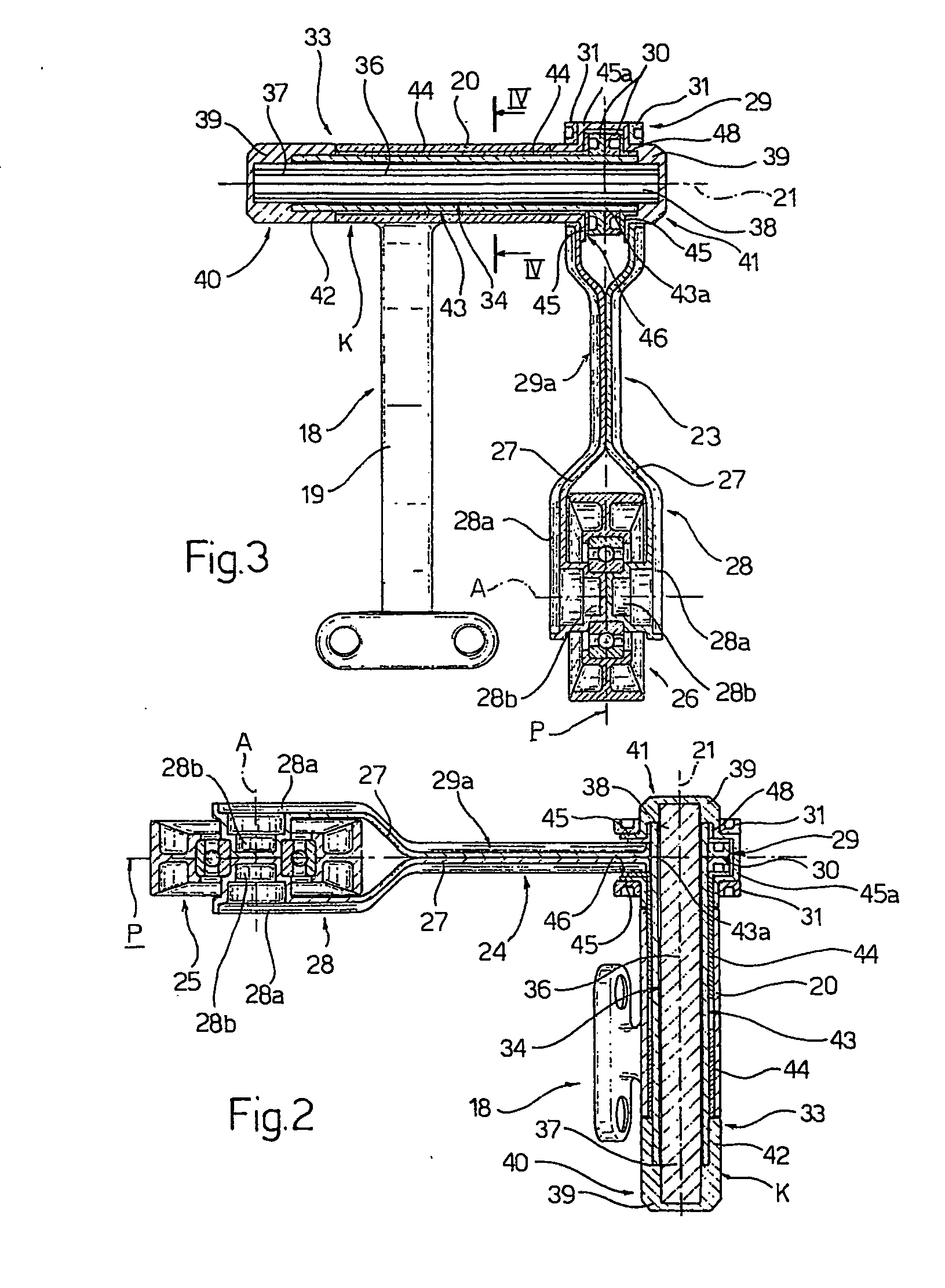

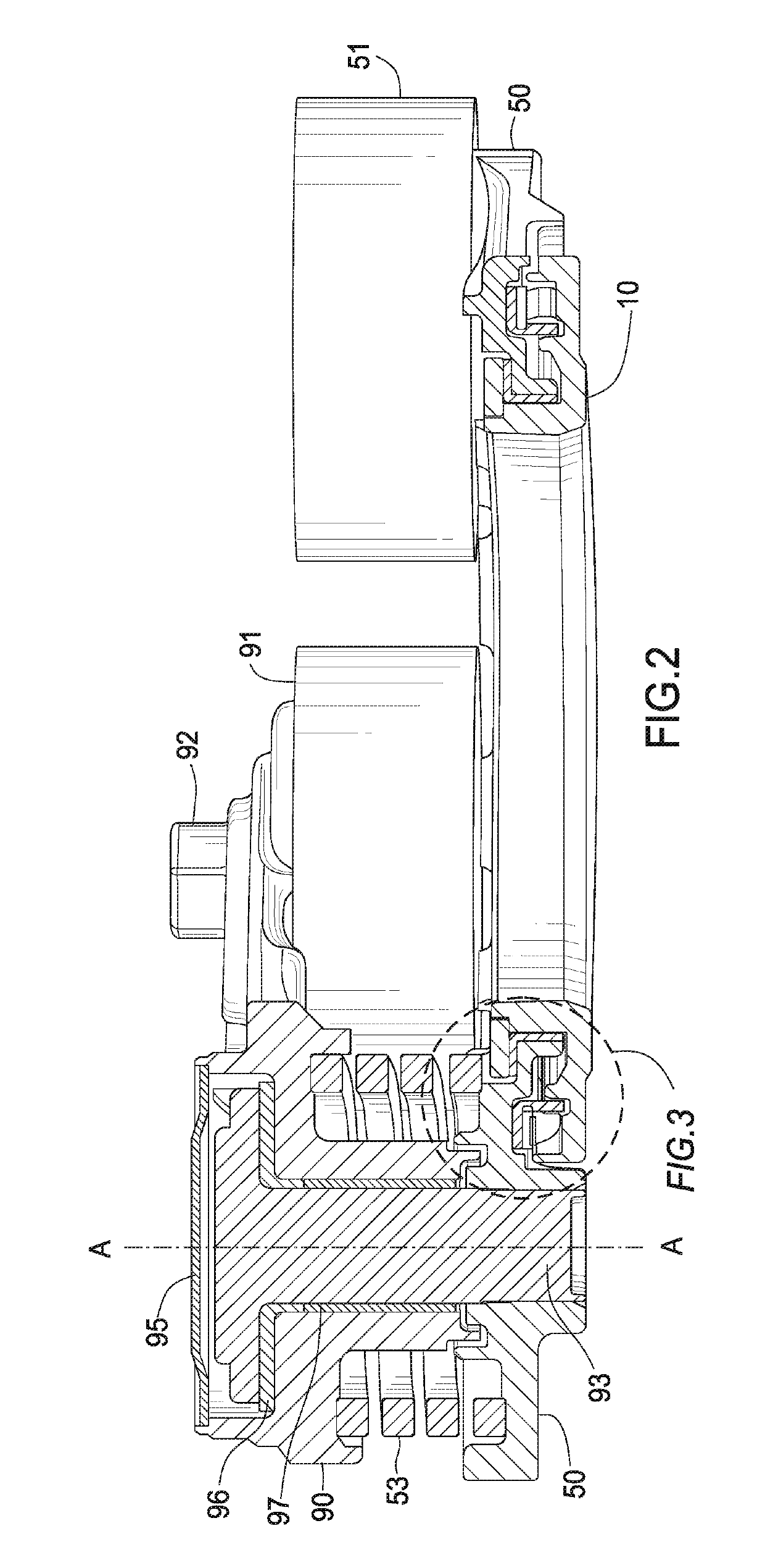

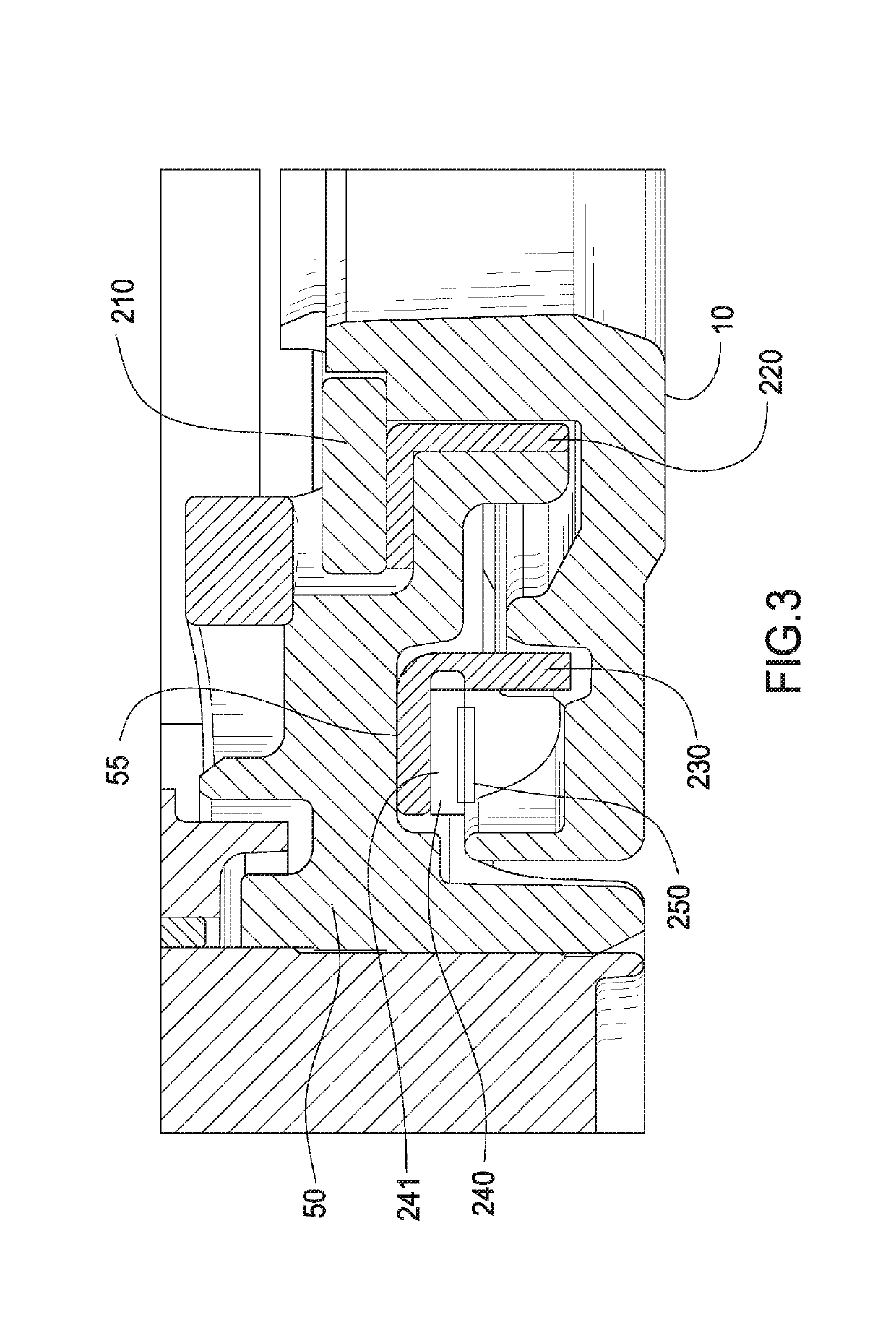

Two-arm belt tensioner

ActiveUS20070037648A1Easy and cheap to produceGearingMachines/enginesInternal combustion engineIdler-wheel

Owner:DAYCO EURO +1

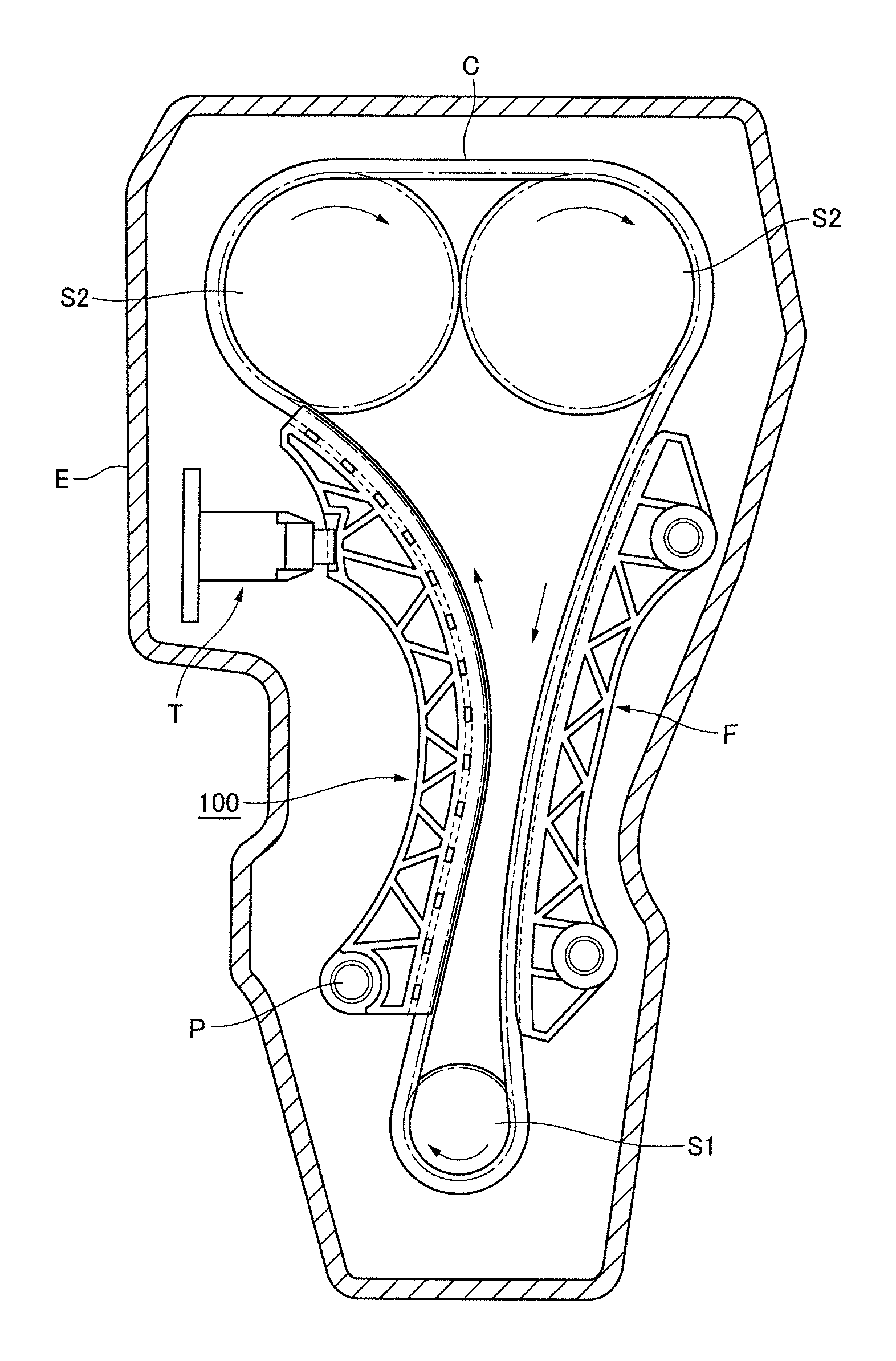

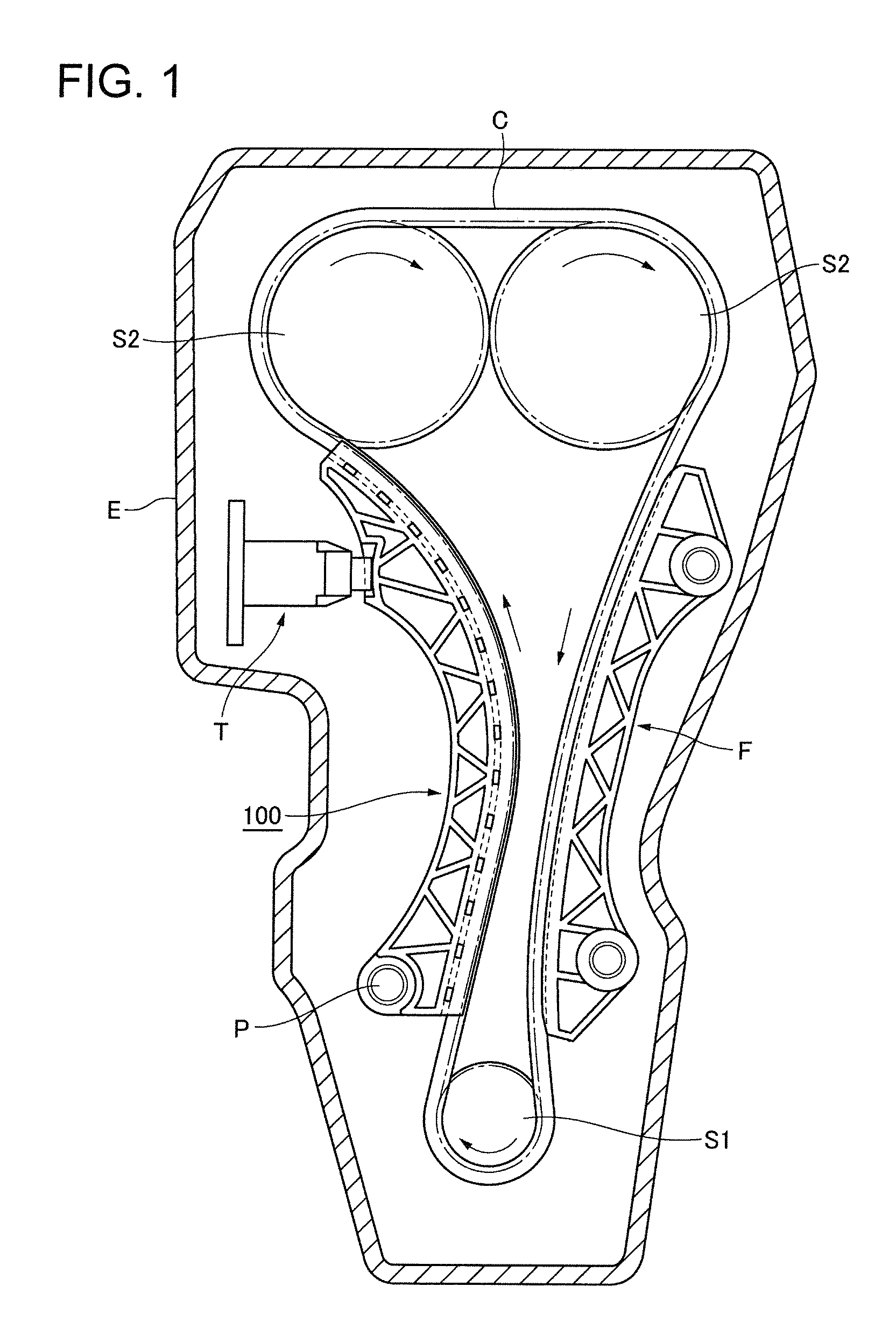

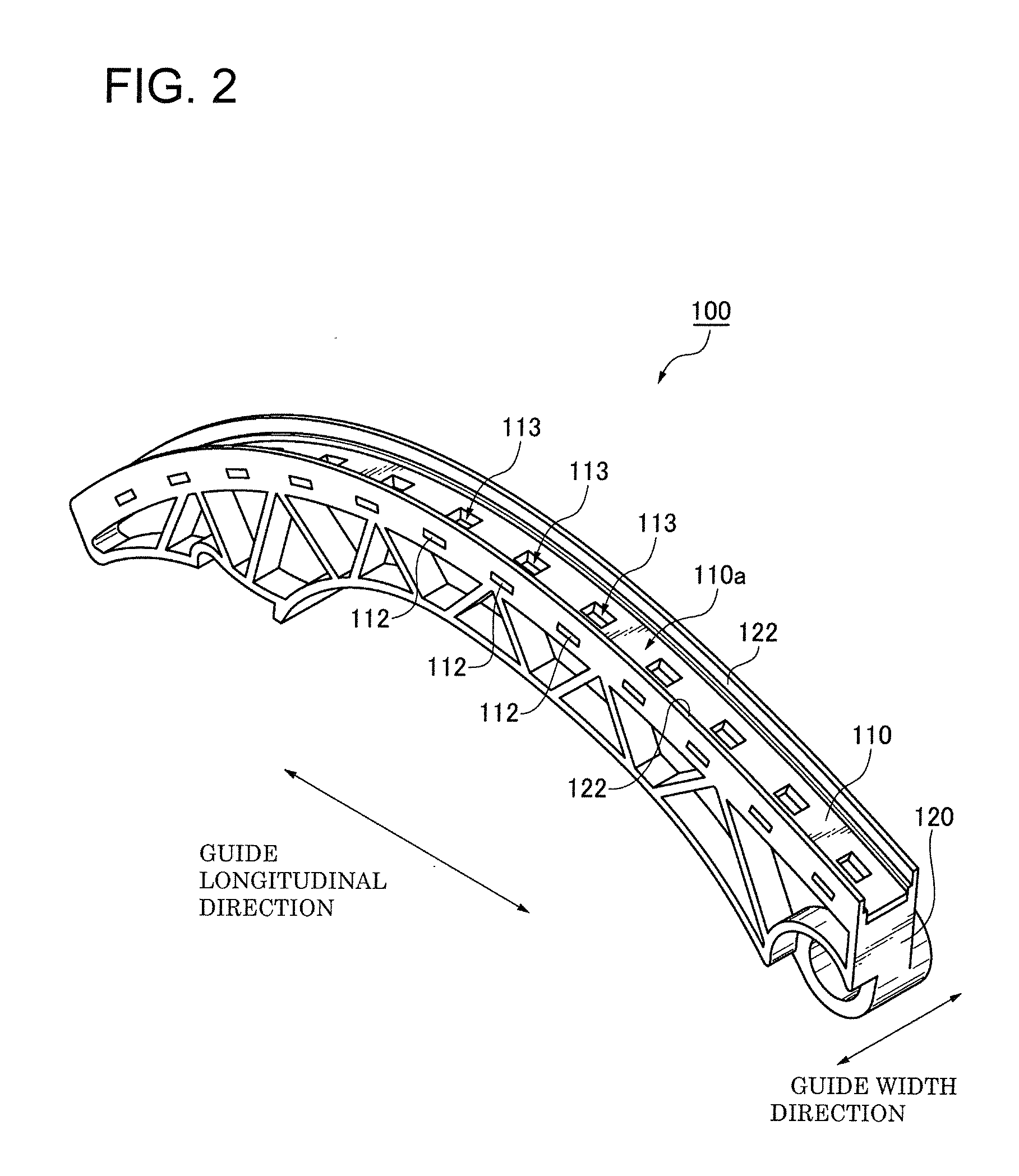

Transmission guide

Owner:TSUBAKIMOTO CHAIN CO

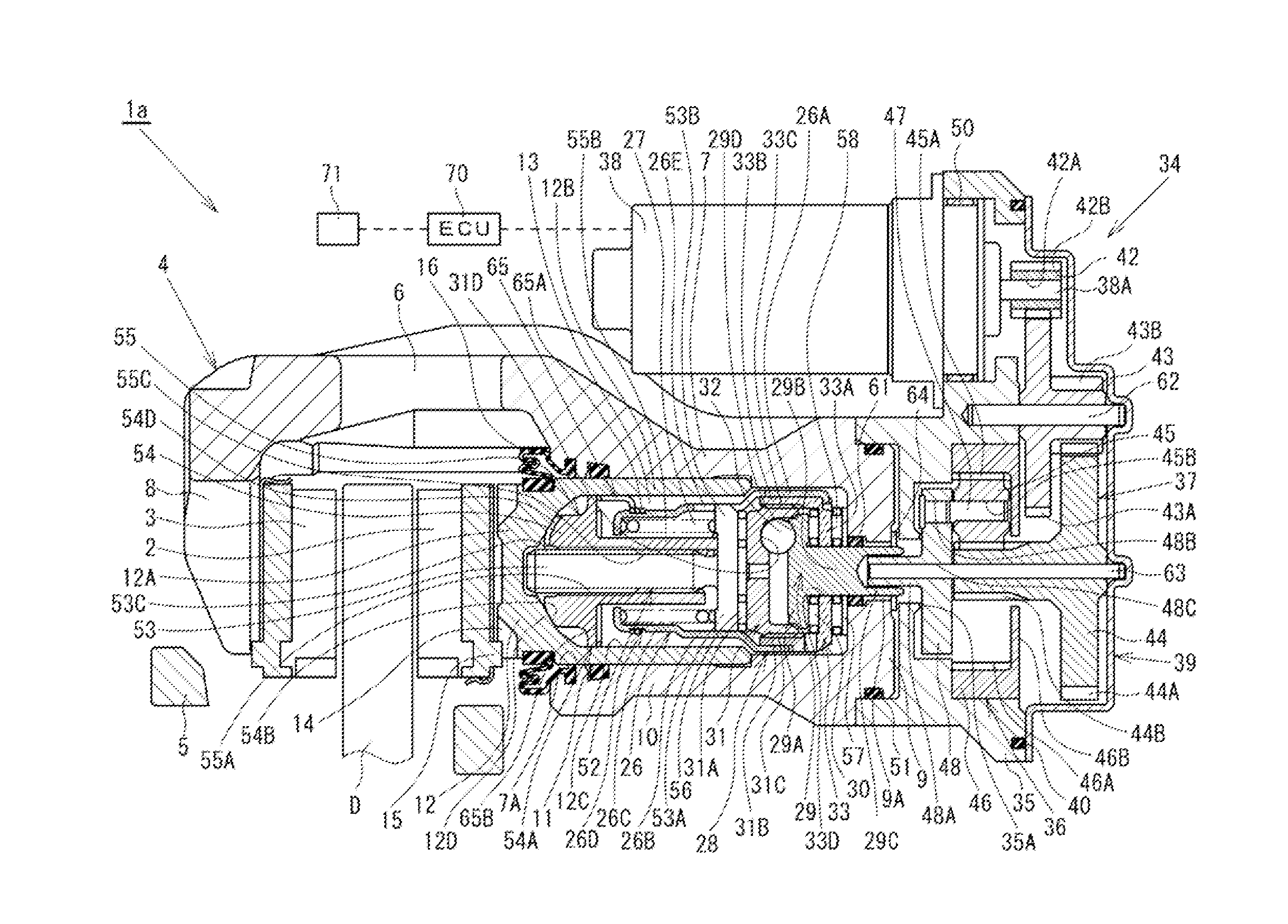

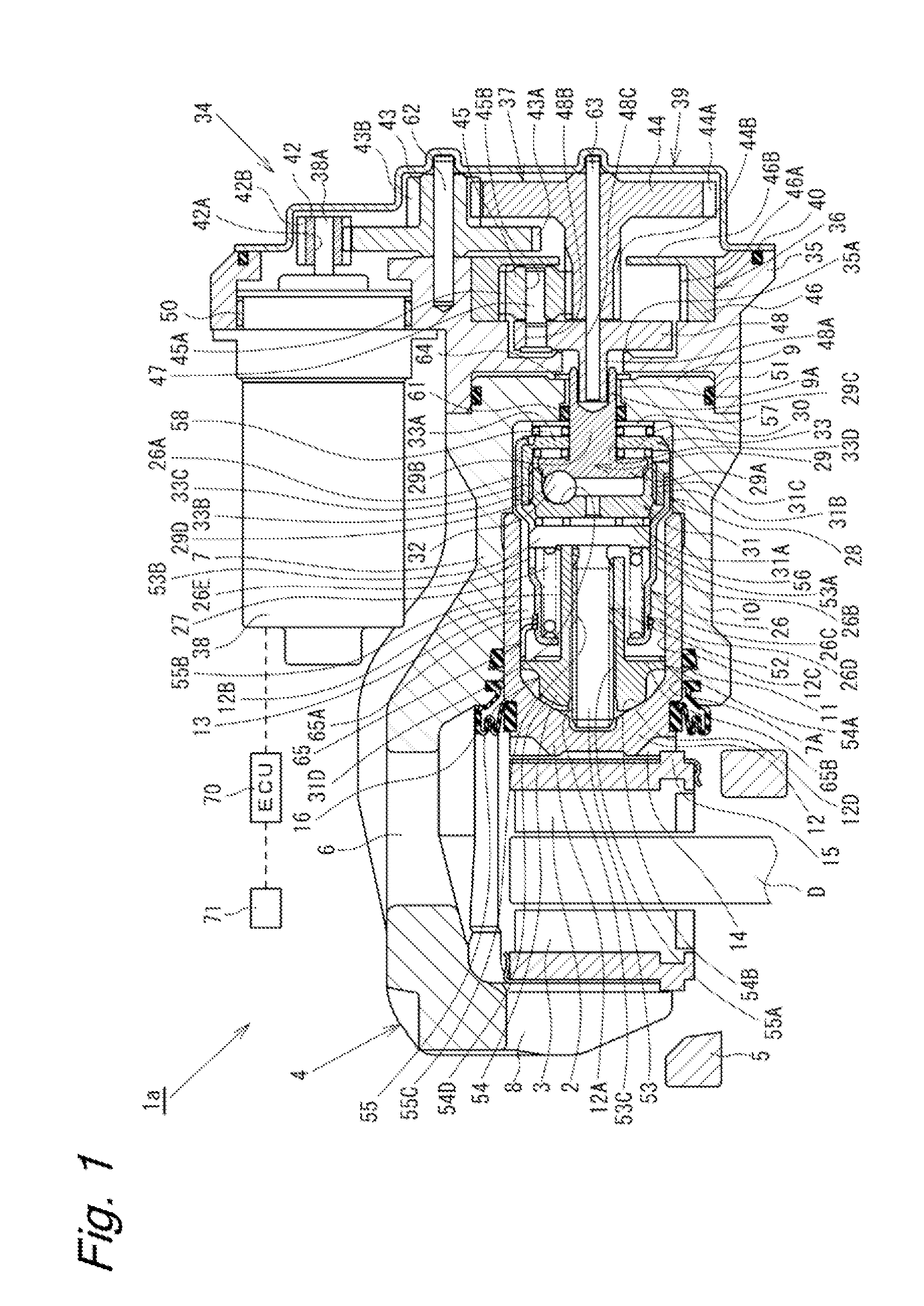

Disk brake

ActiveUS20120261220A1Increase productivityBraking element arrangementsAxially engaging brakesCalipersParking brake

Owner:HITACHI ASTEMO LTD

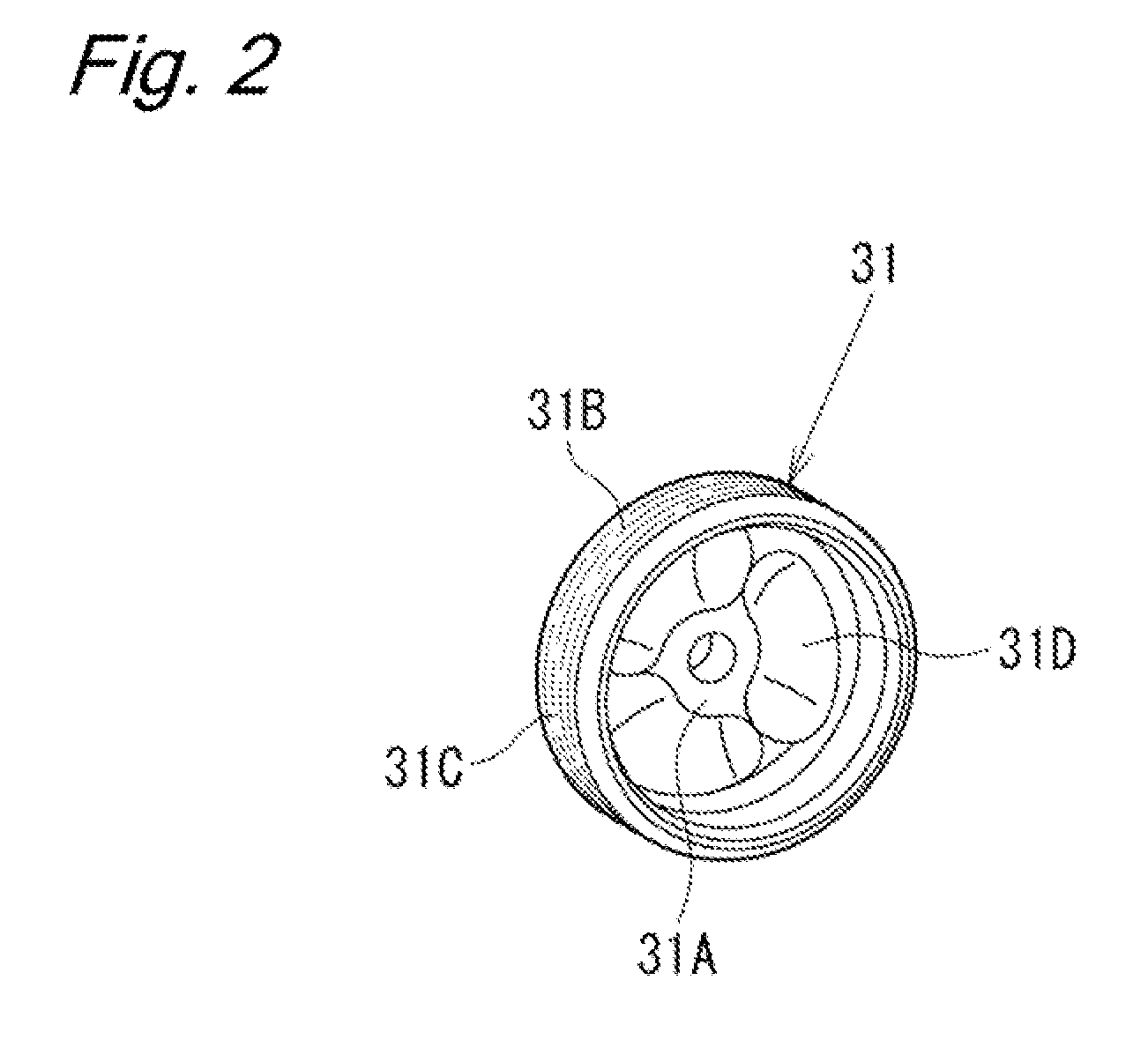

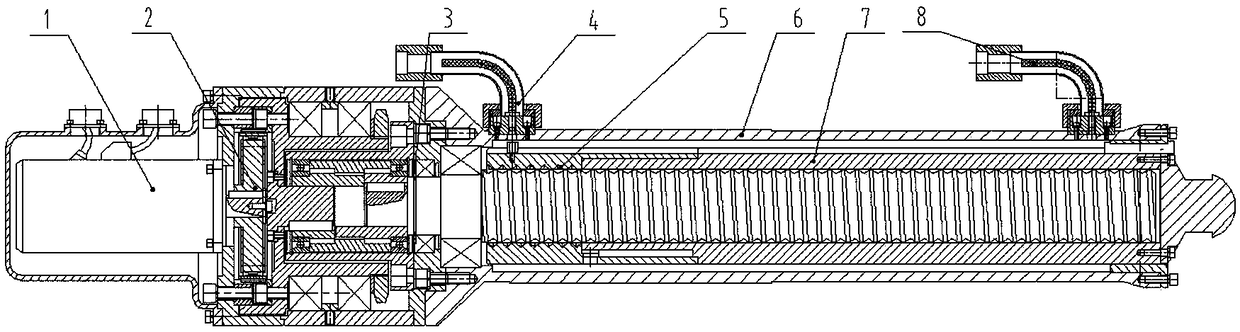

In-wheel actuator and in-wheel assembly comprising the same

An in-wheel assembly is provided, and the in-wheel assembly includes an in-wheel actuator and a wheel. The in-wheel actuator includes a driving motor; a decelerator which is disposed inside the driving motor and configured to reduce a rotational speed of the driving motor; and a hollow shaft which is disposed inside the driving motor and configured to transfer a rotational force of the driving motor to the decelerator, which is accommodated in a hollow of the hollow shaft, and circulates fluid inside of the driving motor with respect to a surface of the decelerator when driven to rotate by the driving motor. The wheel accommodates the in-wheel actuator and receives a rotational speed reduced by the decelerator to rotate.

Owner:SAMSUNG ELECTRONICS CO LTD

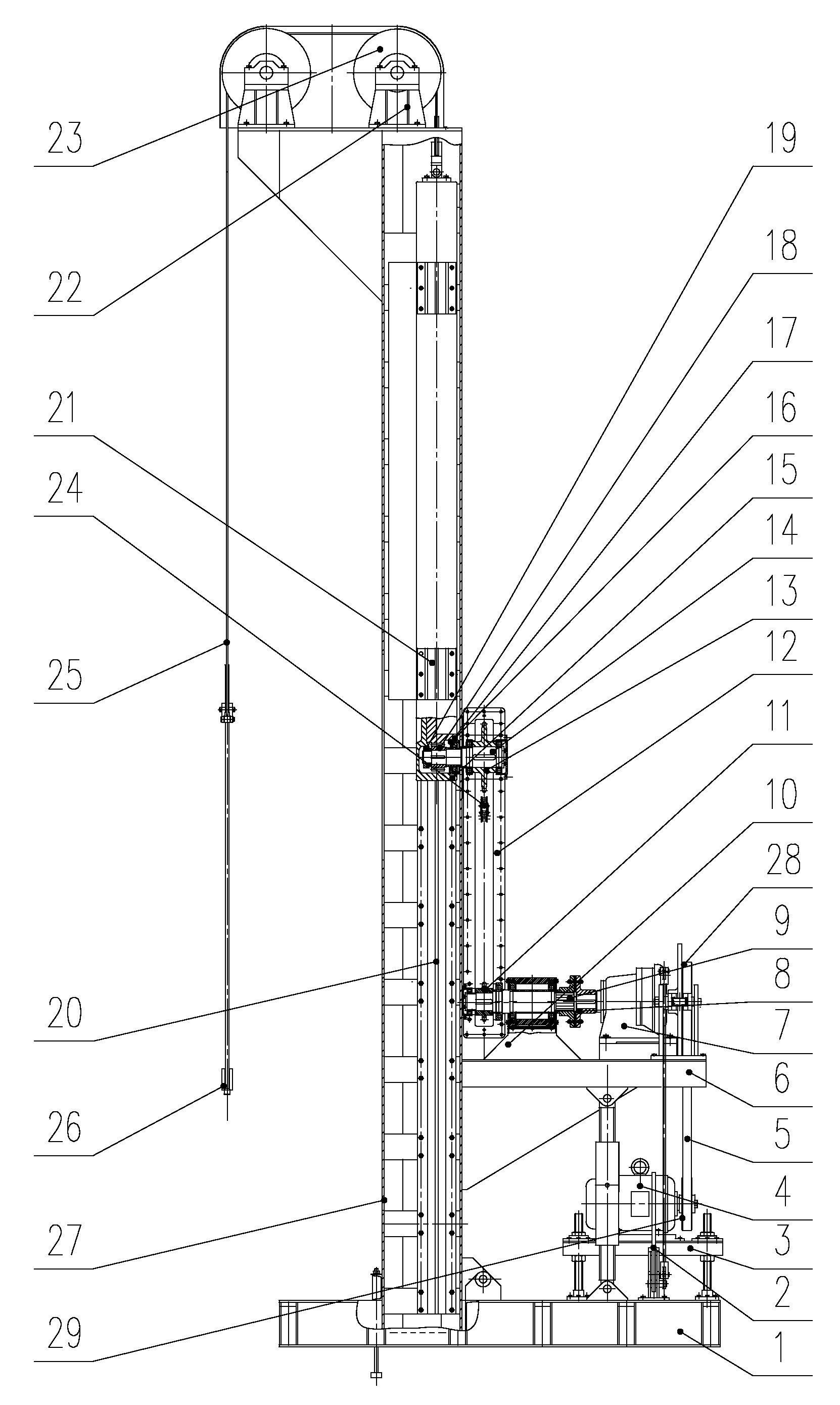

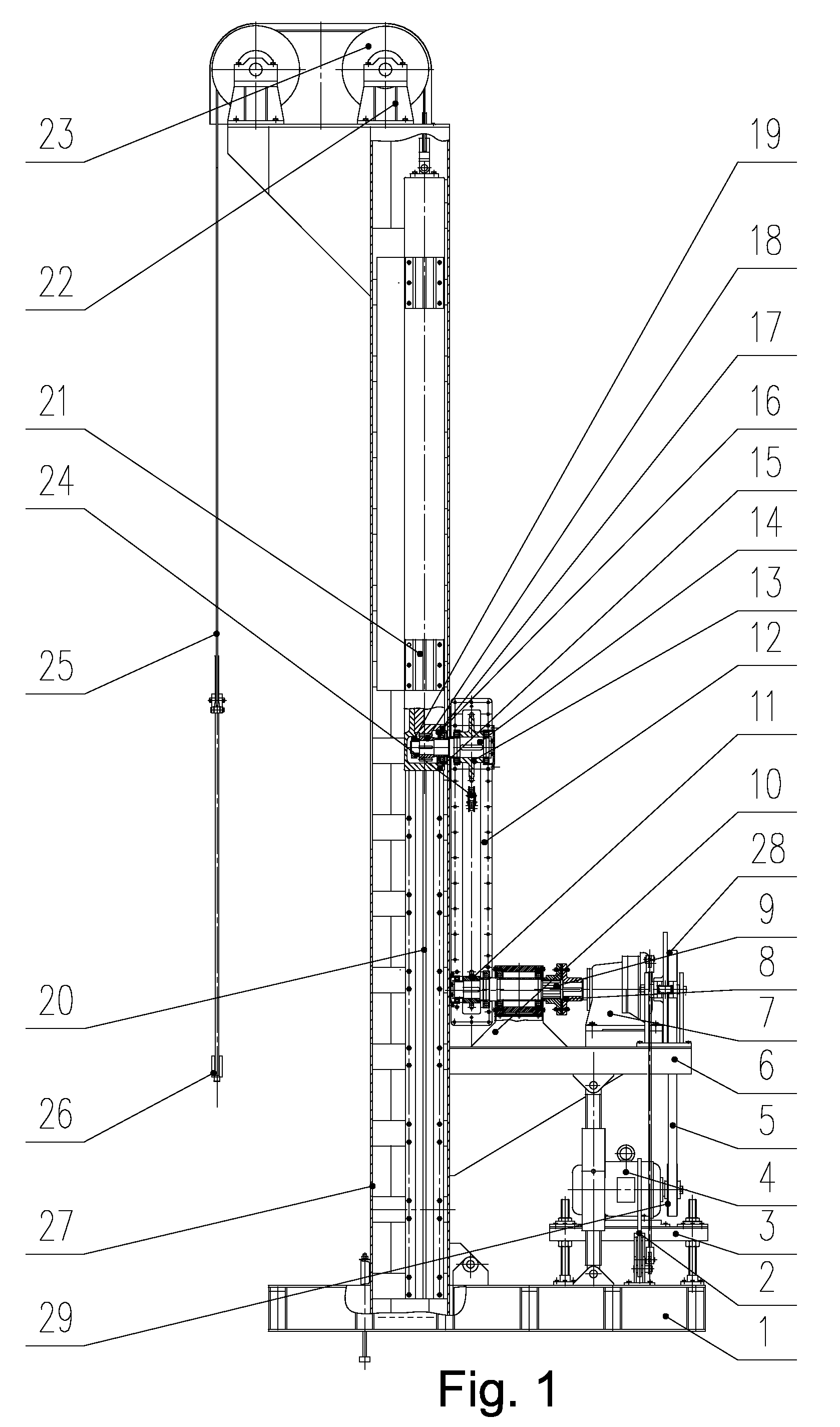

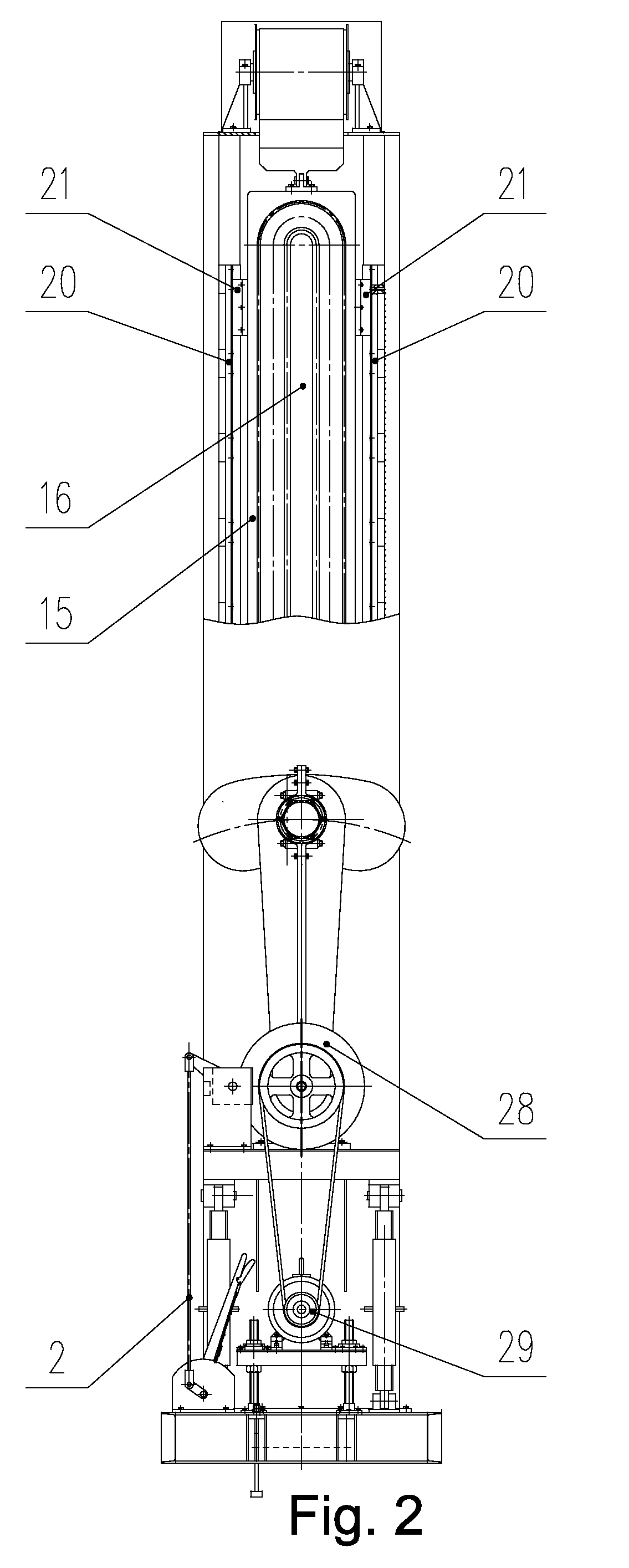

Ring Rack Oil Pumping Machine

Owner:SINOPEC GROUP SHENGLI GASOLINEEUM ADMINISTRATION TRANSPORT CORP

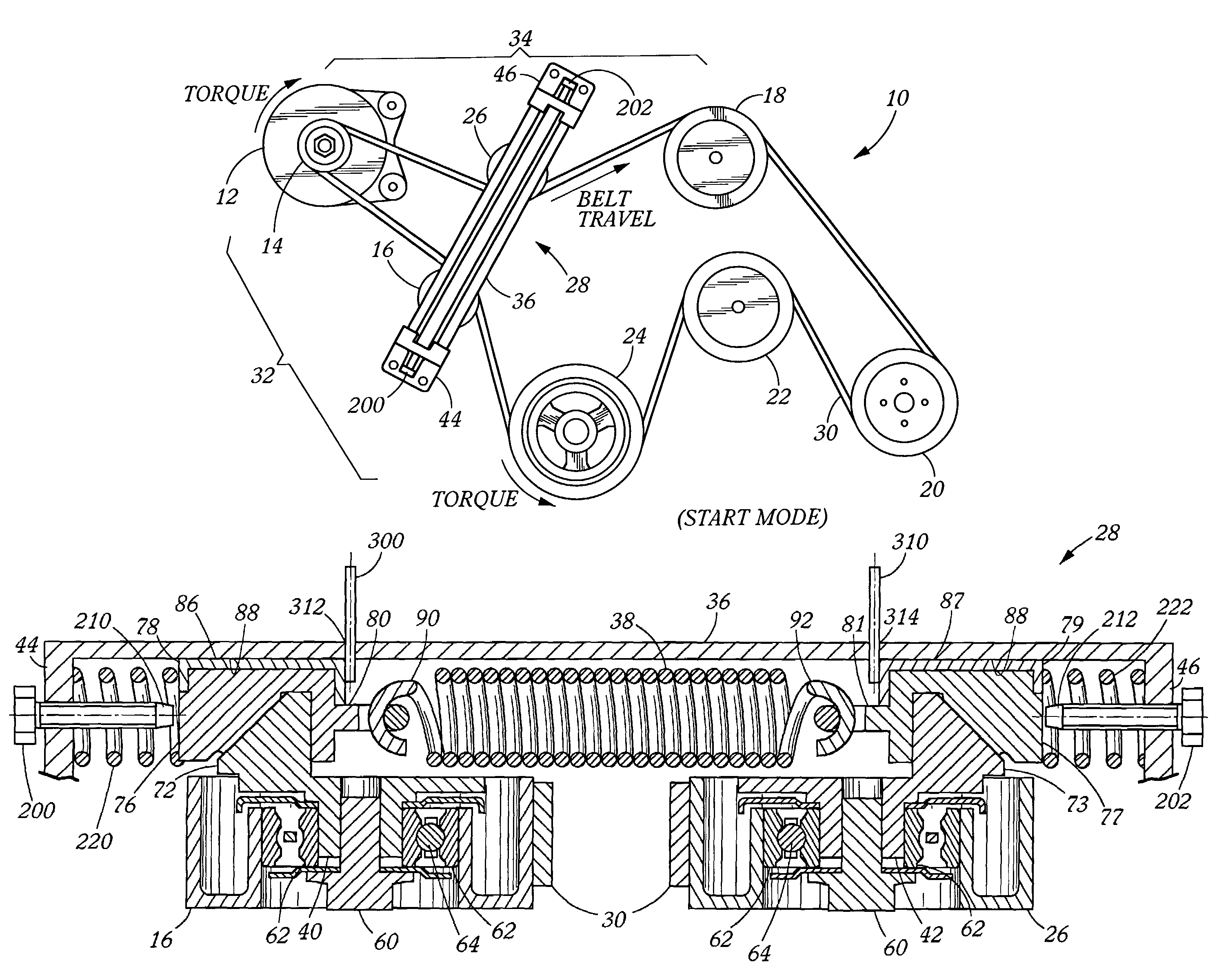

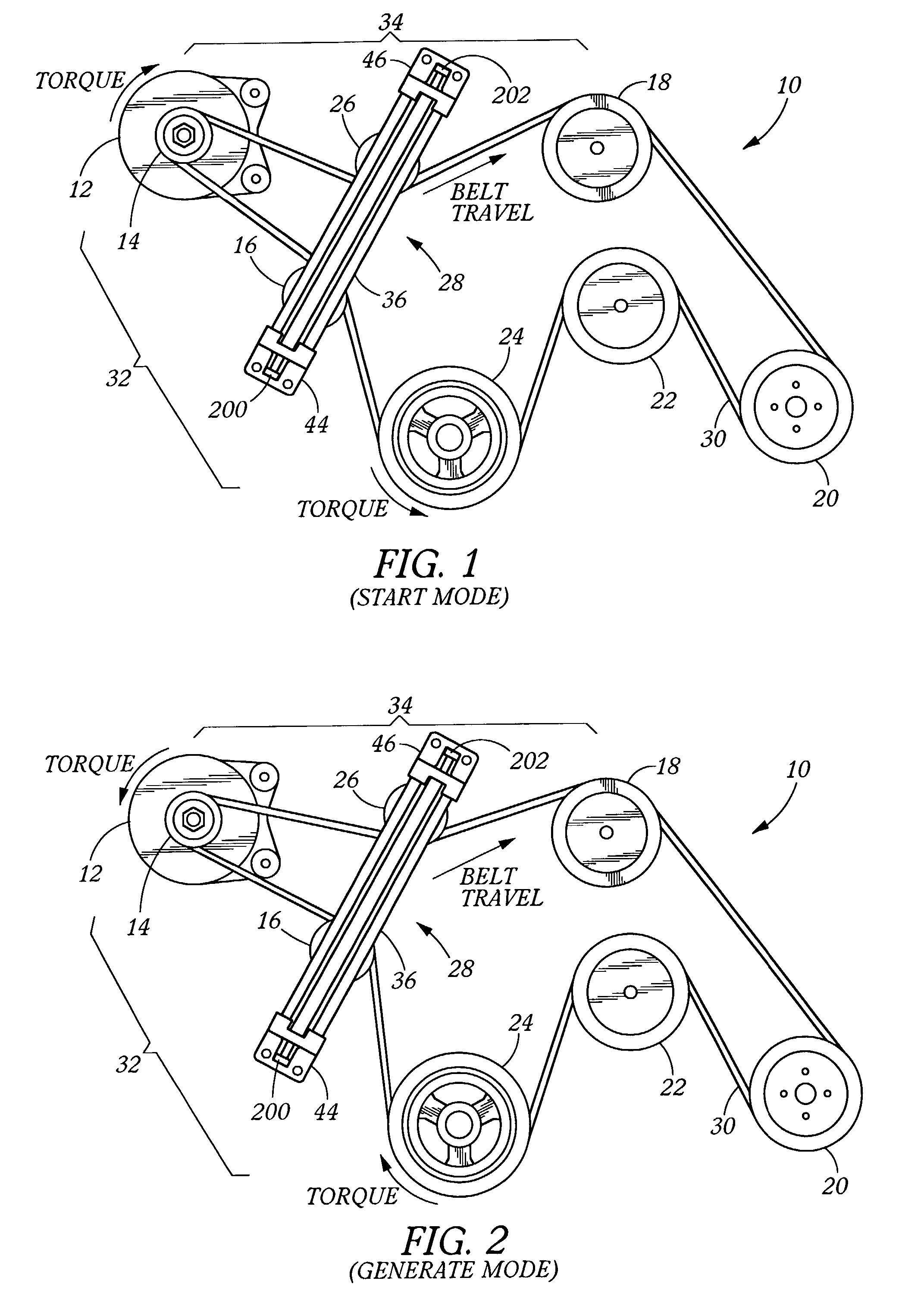

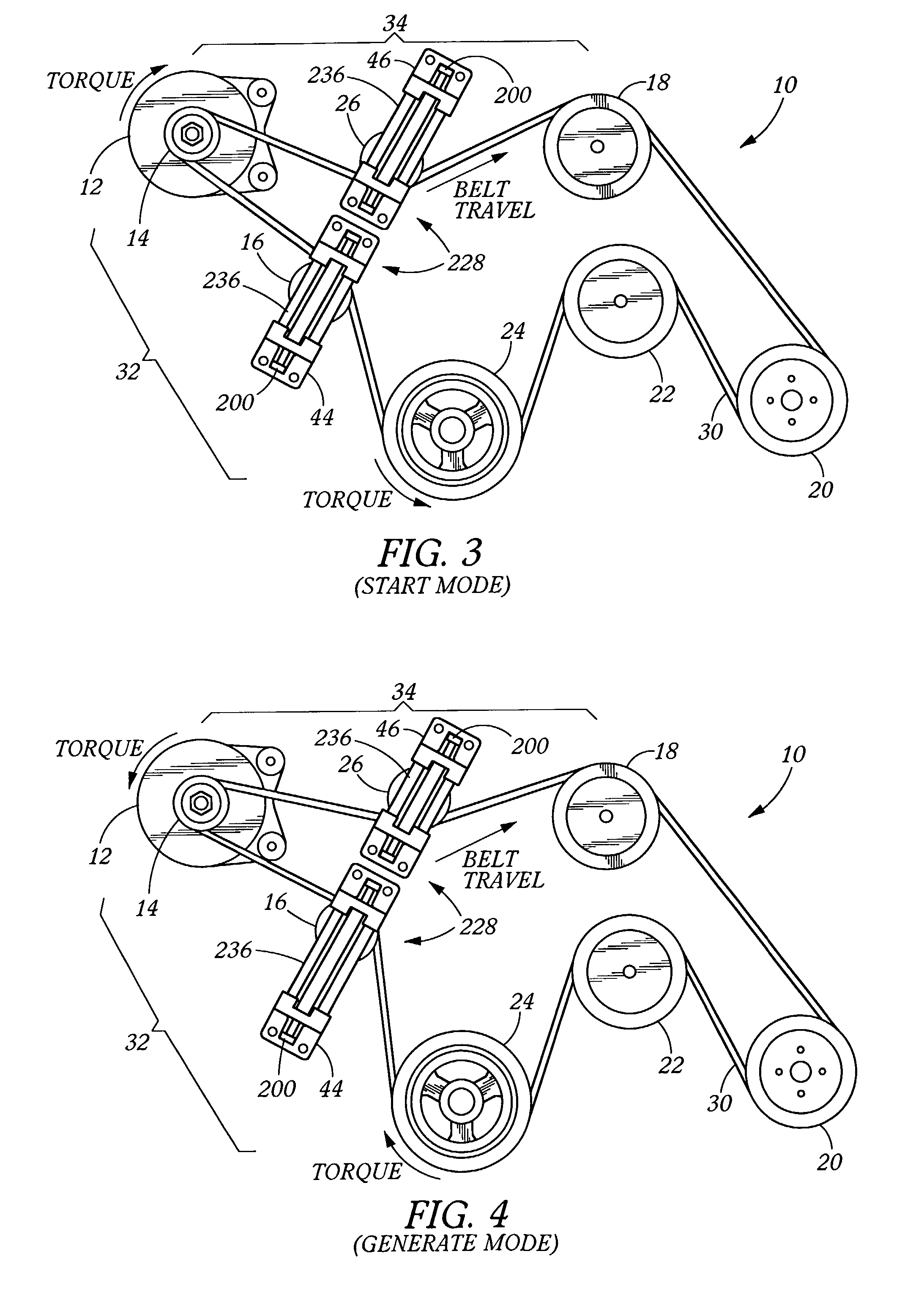

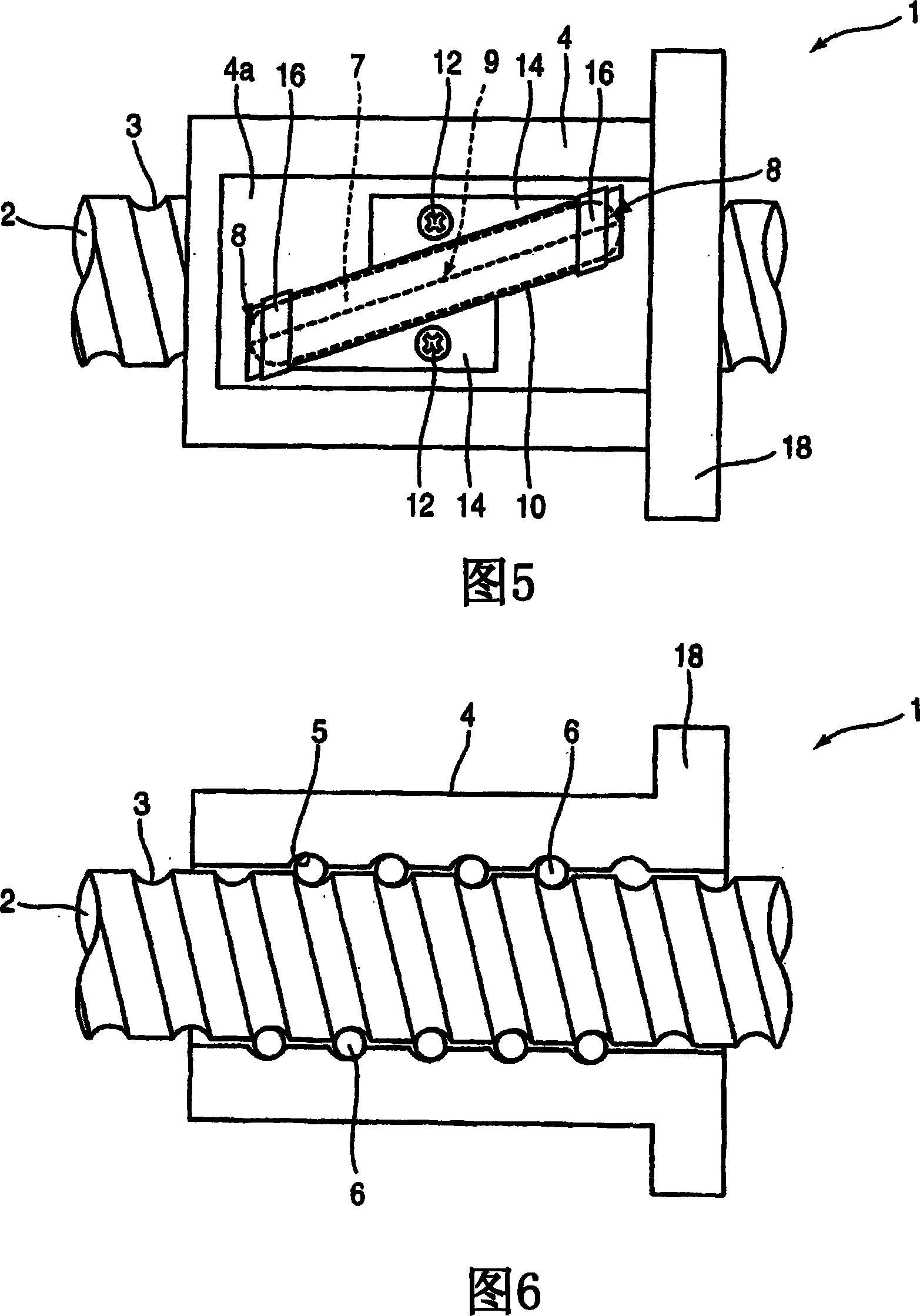

Travel limited linear belt tensioner

A belt tensioner for a belt drive system as a belt tensioner, a first belt tensioner pulley, a crankshaft pulley, an accessory pulley, and a power transmission belt trained about the first belt tensioner, crankshaft, and accessory pulleys. The belt tensioner is of the type that includes an attachment point adapted to be affixed to a stationary point relative to a cylinder block of an engine, a track, and a first carrier mounted in sliding relation with the track with two degrees freedom of movement. The first belt tensioner pulley is rotatably mounted upon the first carrier for engaging the power transmission belt. A resilient member biases the first carrier in longitudinal relation to the track. The tensioner further includes a travel limiting mechanism.

Owner:BONUTTI 2003 TRUST A THE

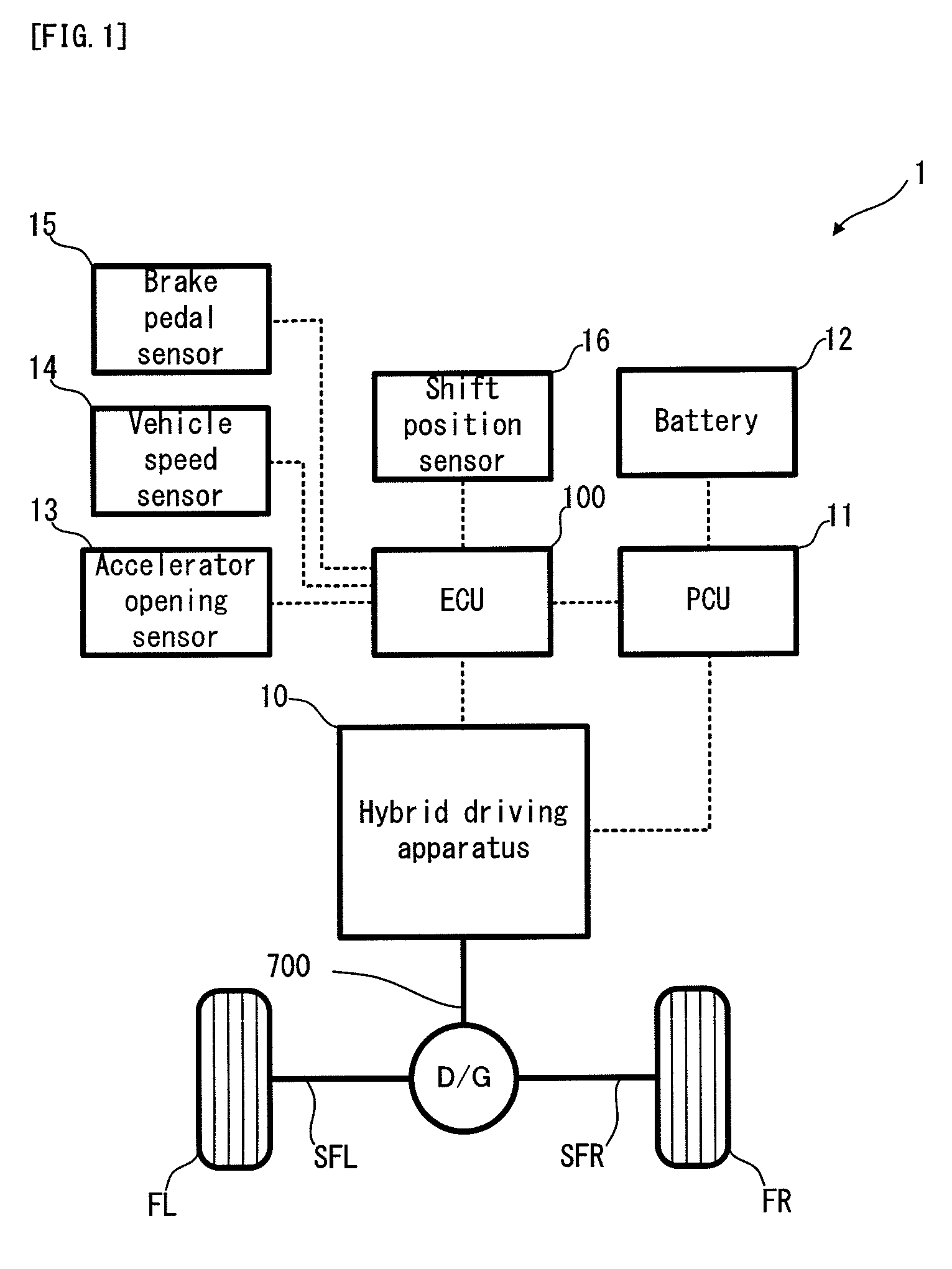

Vehicle control apparatus

ActiveUS20120053769A1Suppress sudden changesMitigate torque shockHybrid vehiclesDigital data processing detailsElectric machineryControl theory

Owner:TOYOTA JIDOSHA KK

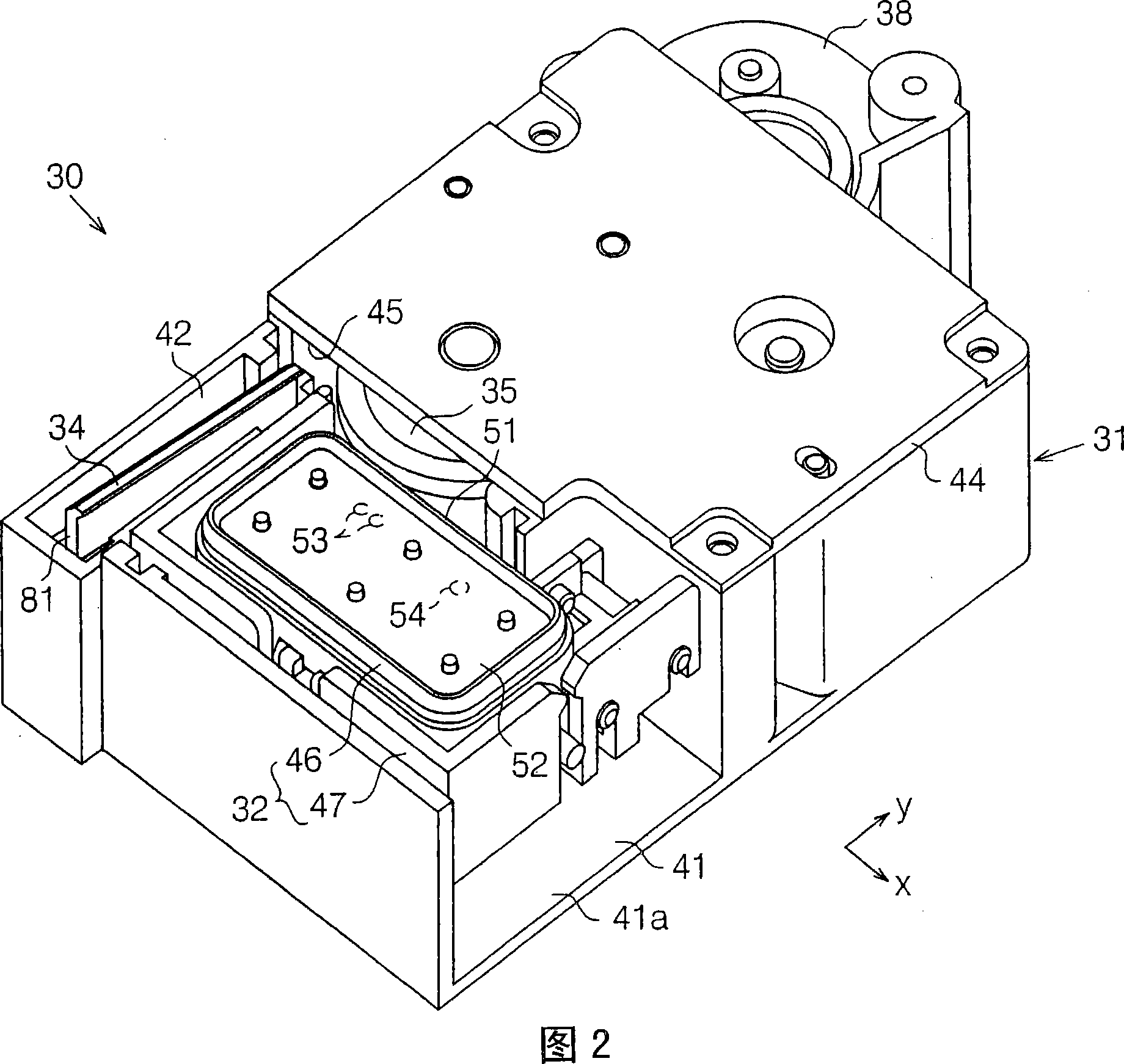

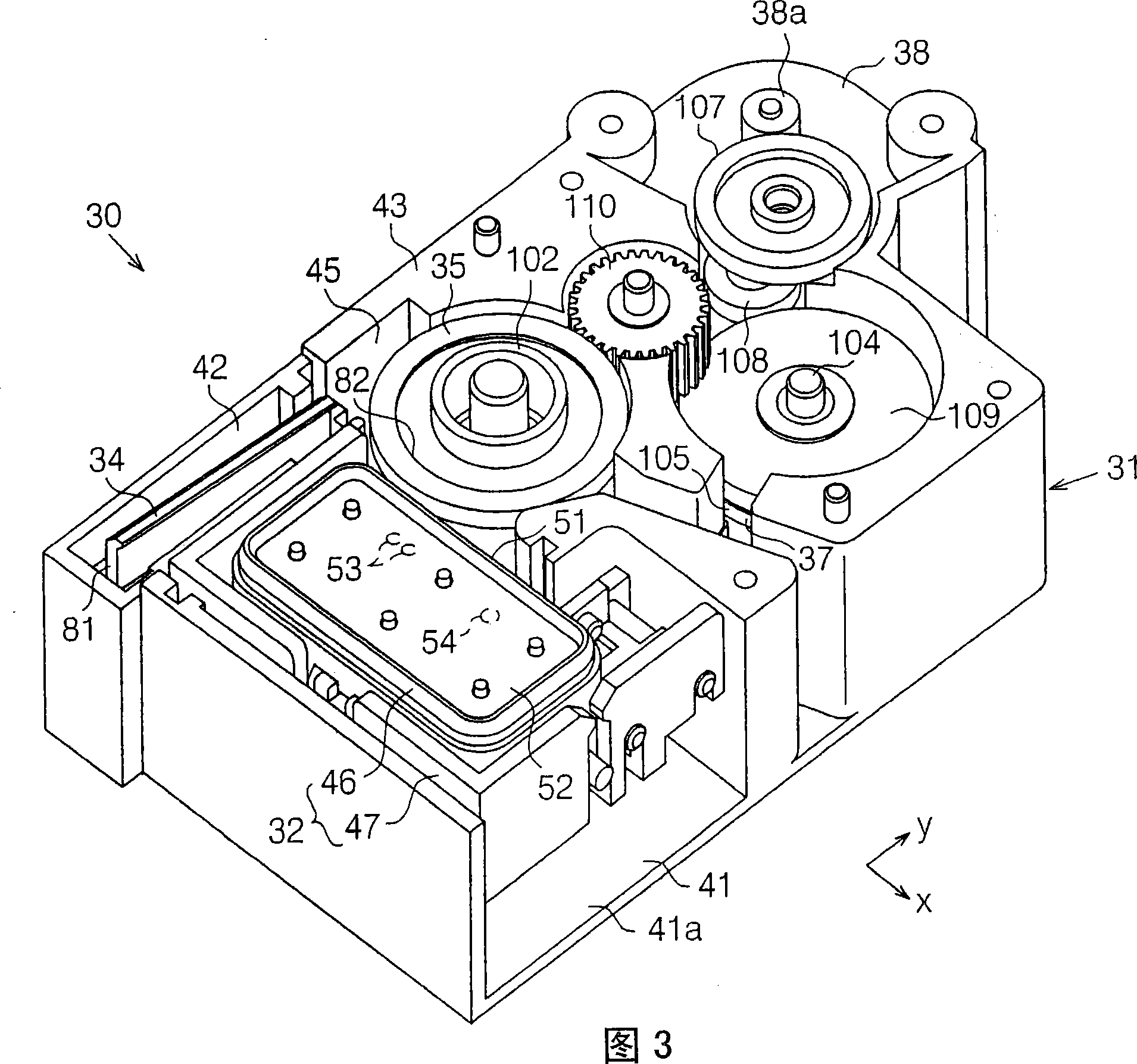

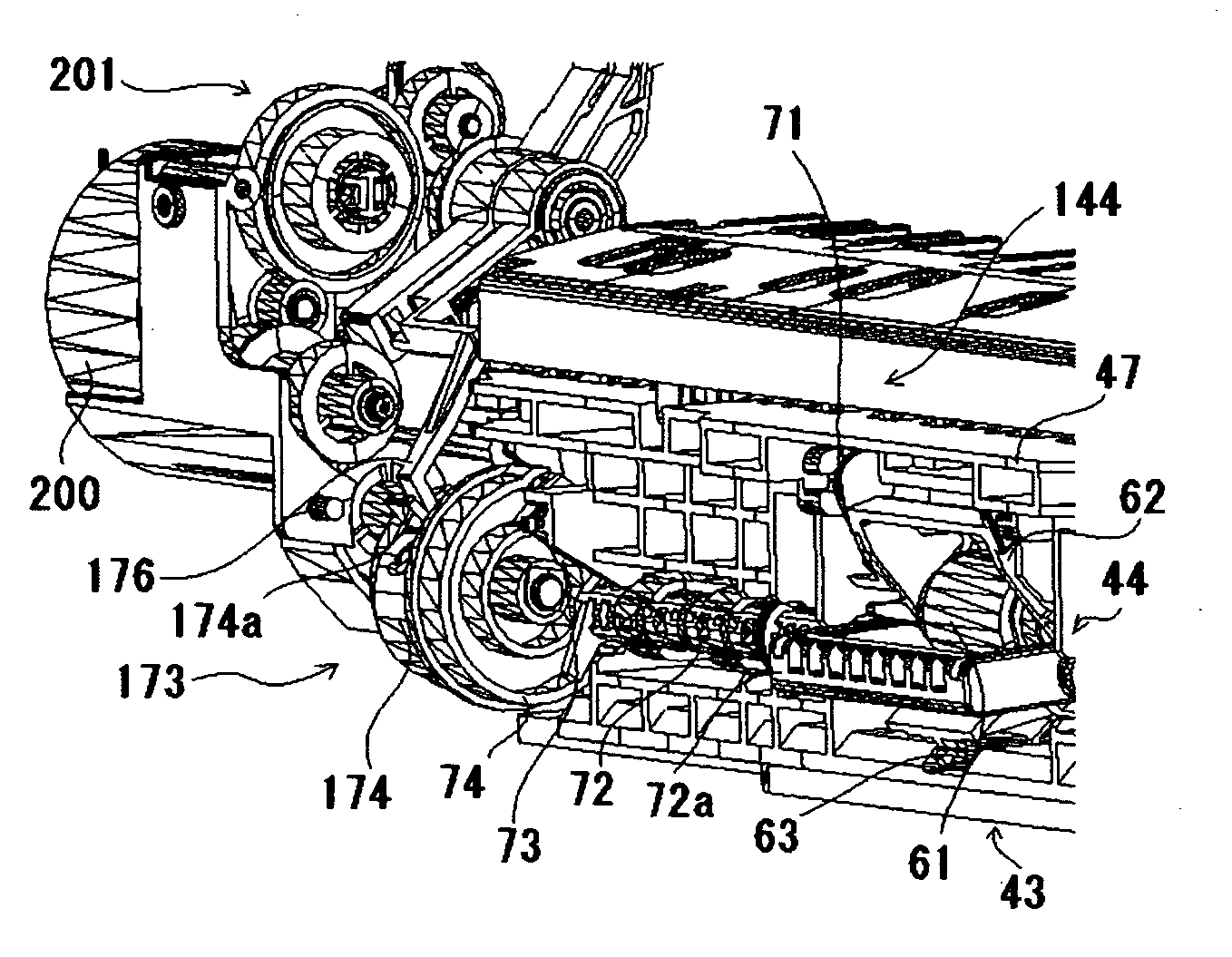

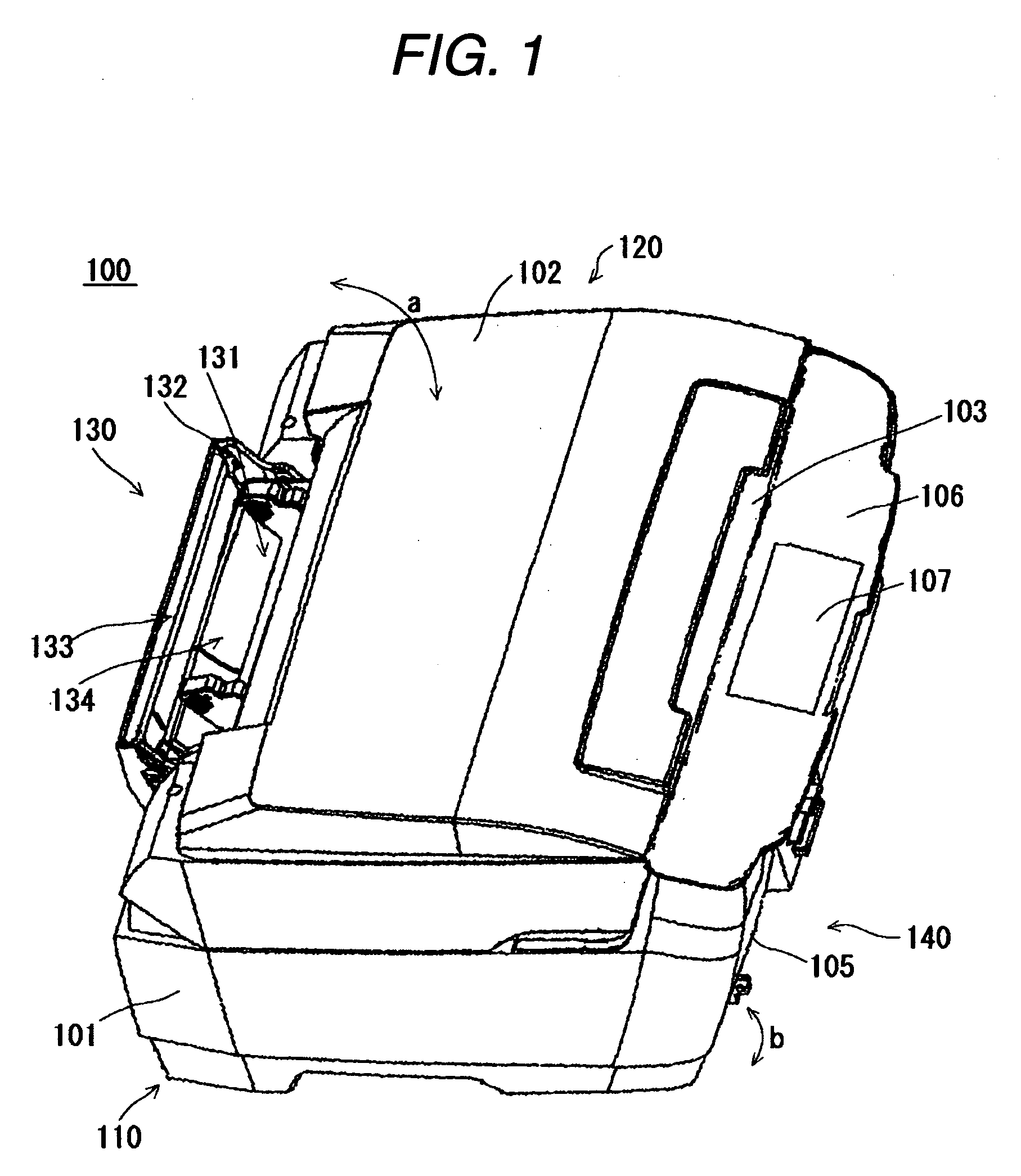

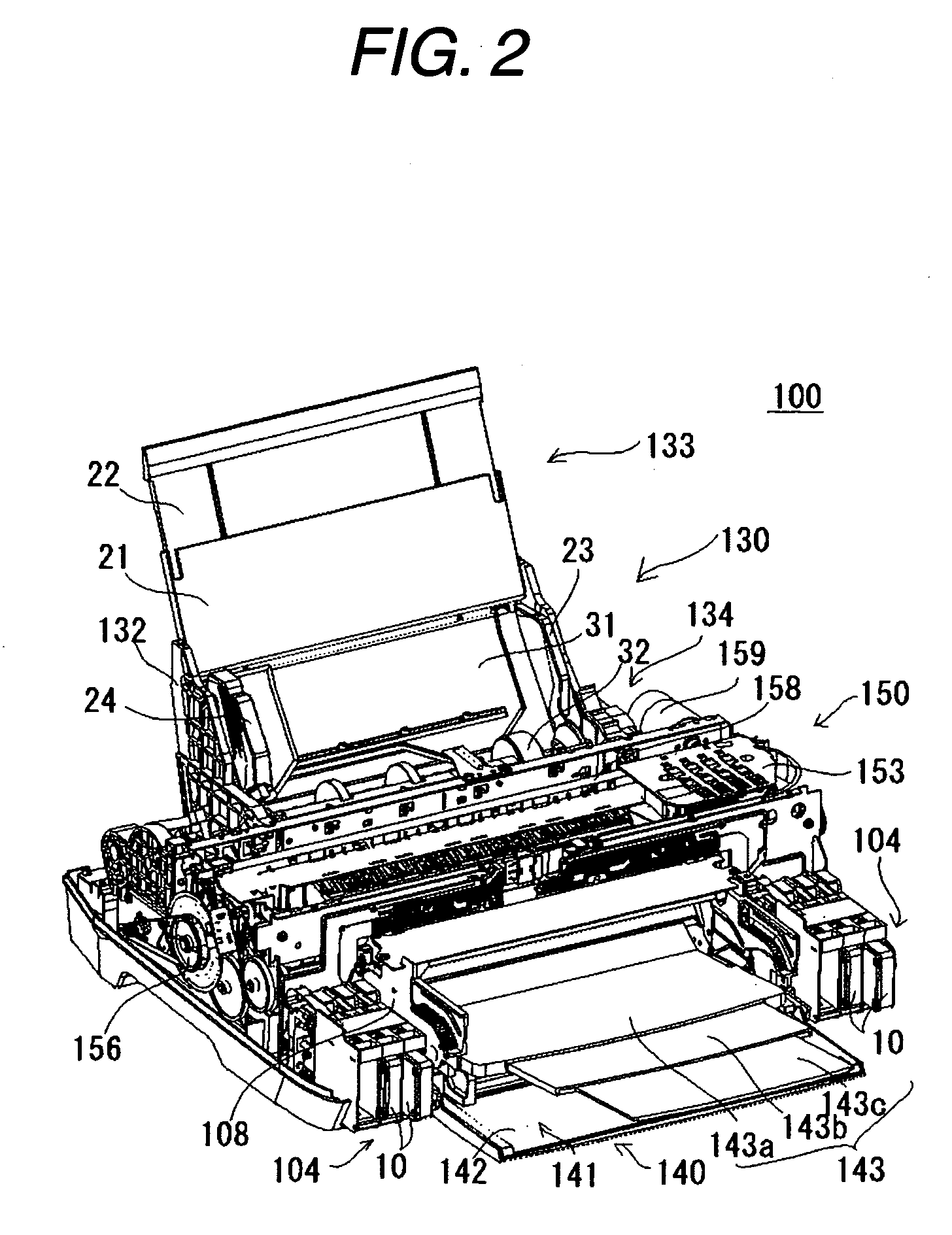

Rotor, drive converting apparatus, cleaning apparatus, wiping apparatus, and liquid ejection apparatus

A nozzle protecting device 30 of an ink jet type recording apparatus has a cap 46 which covers nozzles of a recording head and a cap support member 47 which is connected to the cap 45 via a spring member 80. The distance between the cap 46 and the cap support member 47 can be changed by elastic deformation of the spring member 80. A vent hole 54 is formed in the cap 46. A valve seat 56 which covers the terminal portion of the vent hole 54 is provided. A valve body 58 is rotatably attached to the lower portion of the cap 46. The valve body 58 selectively abuts on and parts from the valve seat 56 in accordance with the distance between the cap 46 and the cap support member 47. As a result, the inside of the cap 46 is opened and closed to air via the vent hole 54.

Owner:SEIKO EPSON CORP

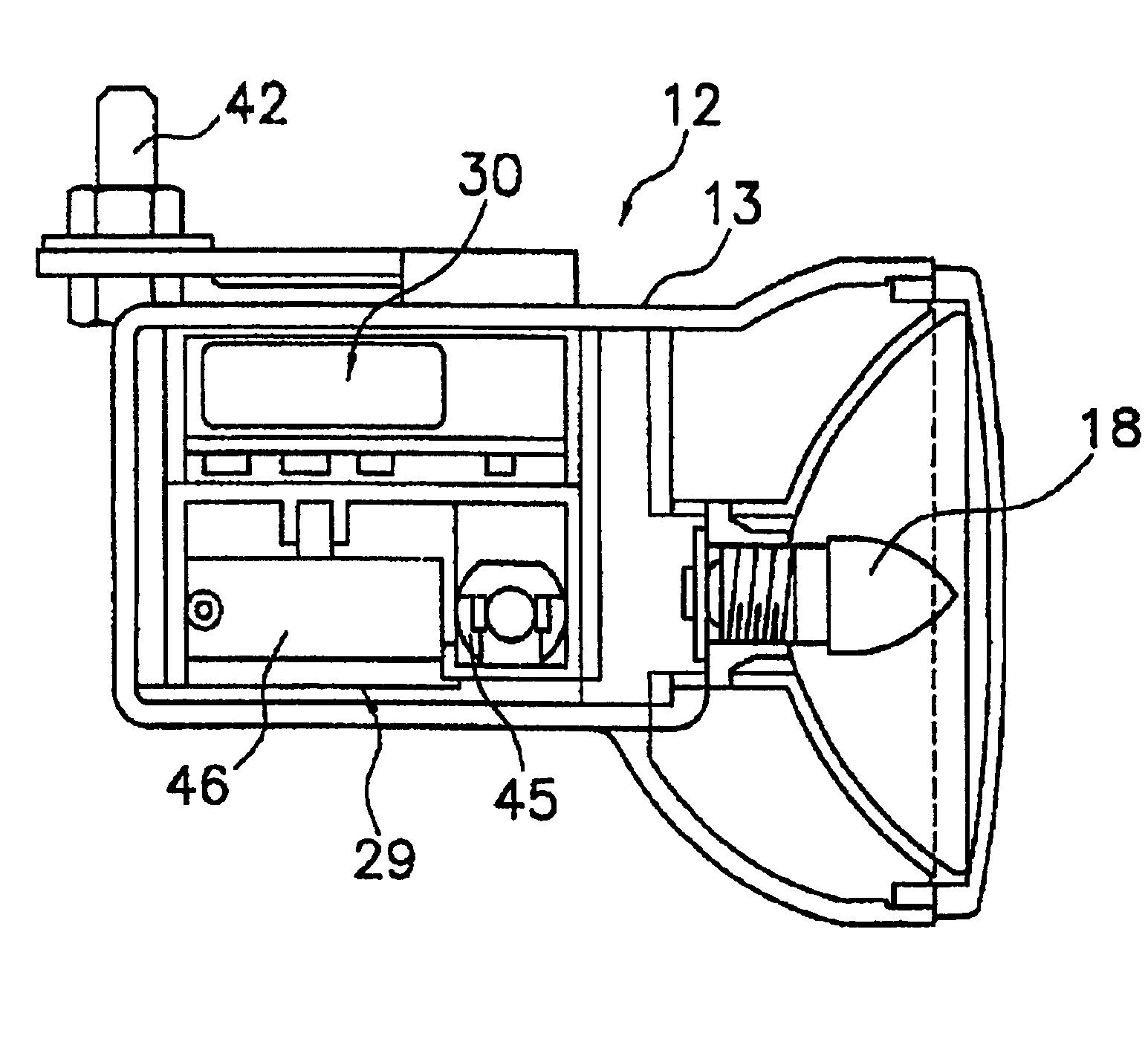

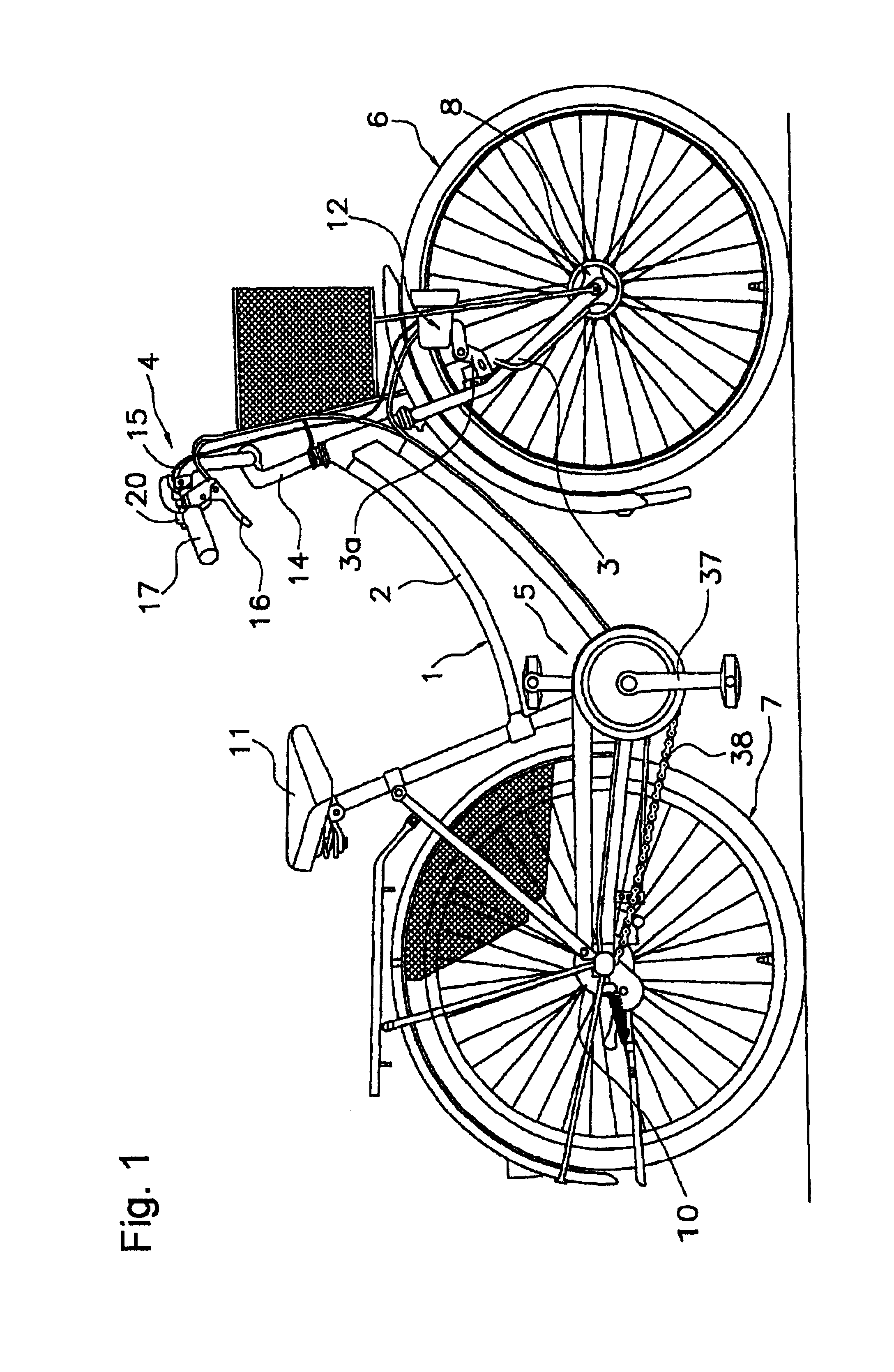

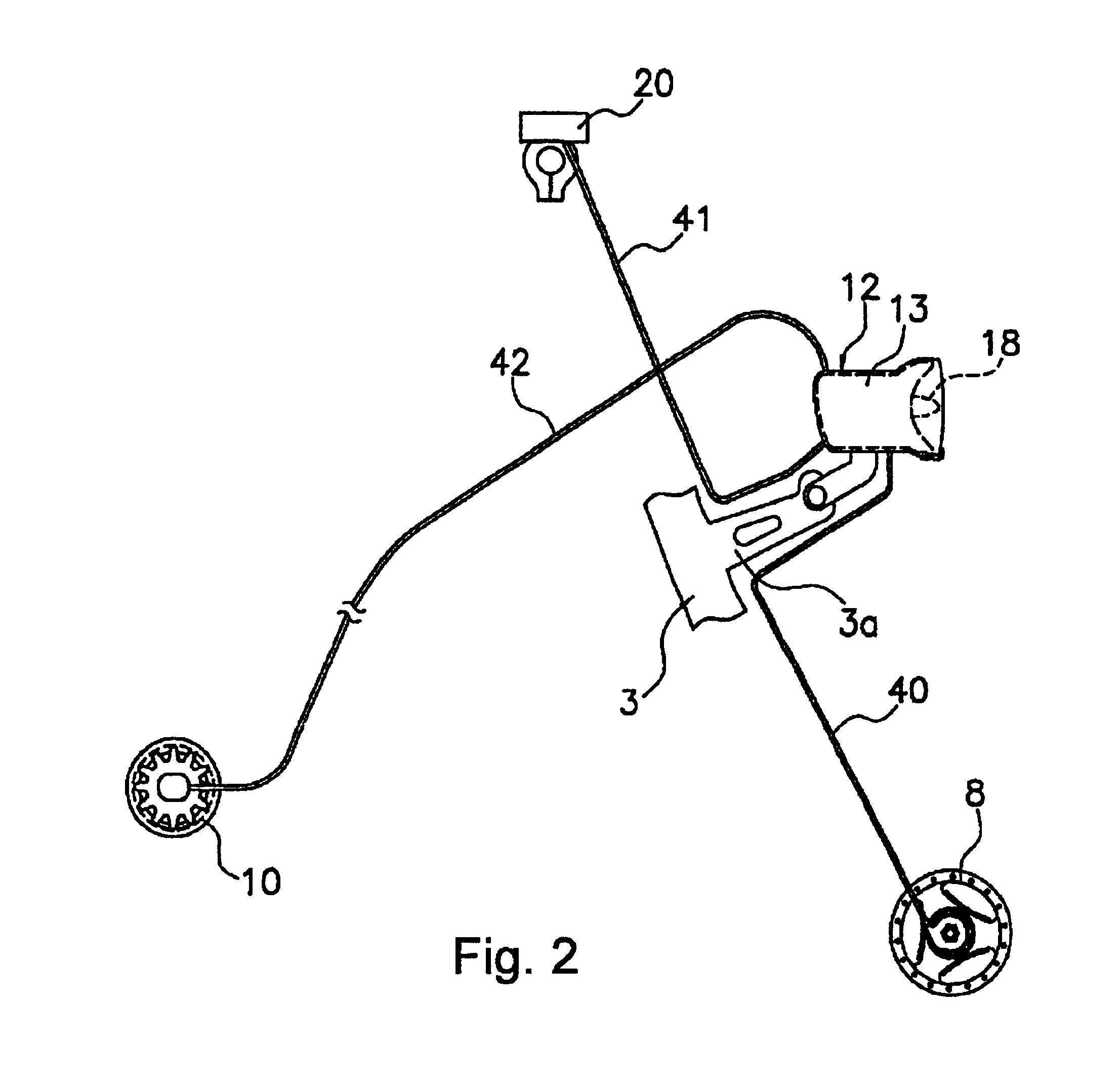

Electronic bicycle shift control device

Owner:SHIMANO INC

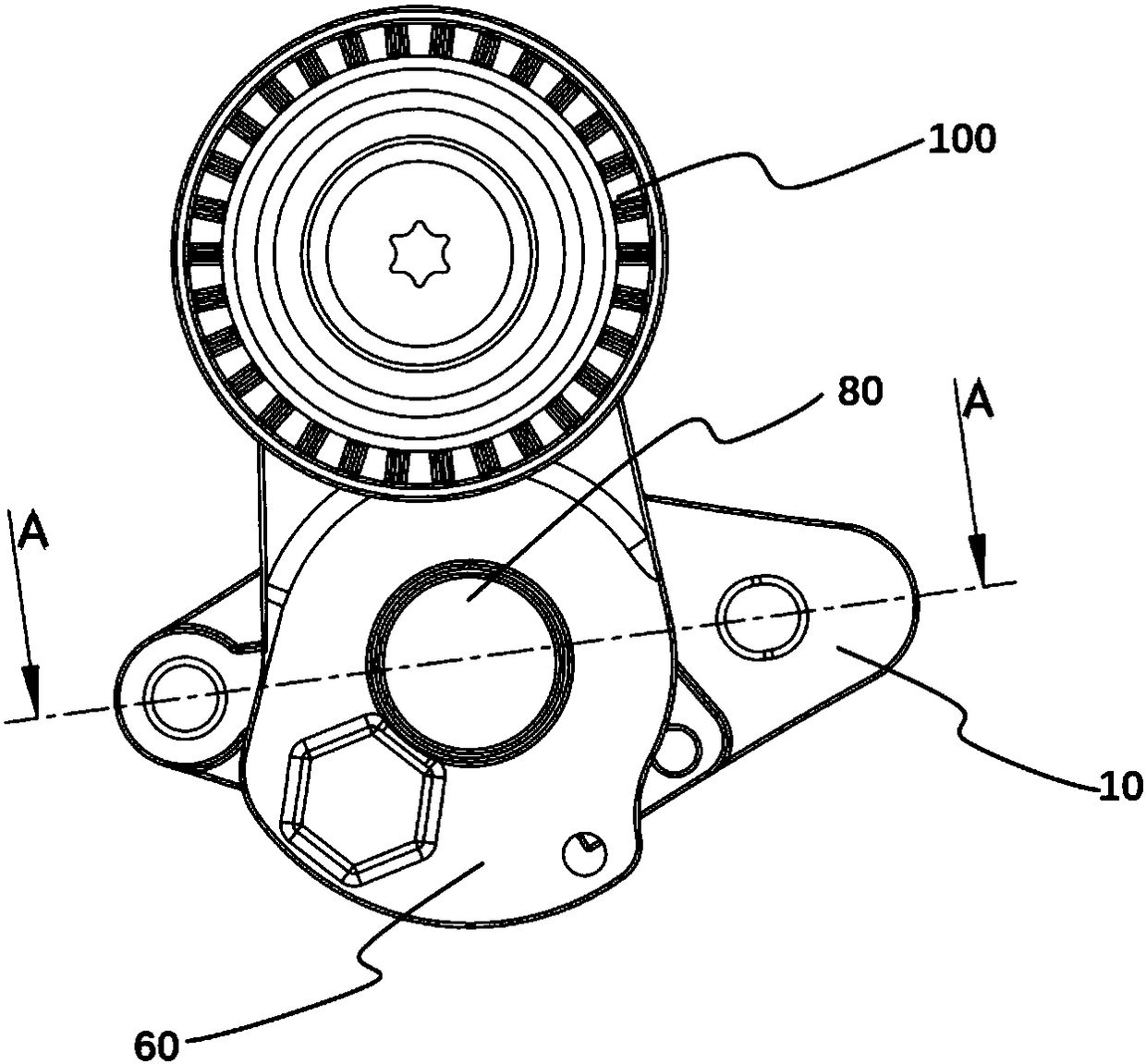

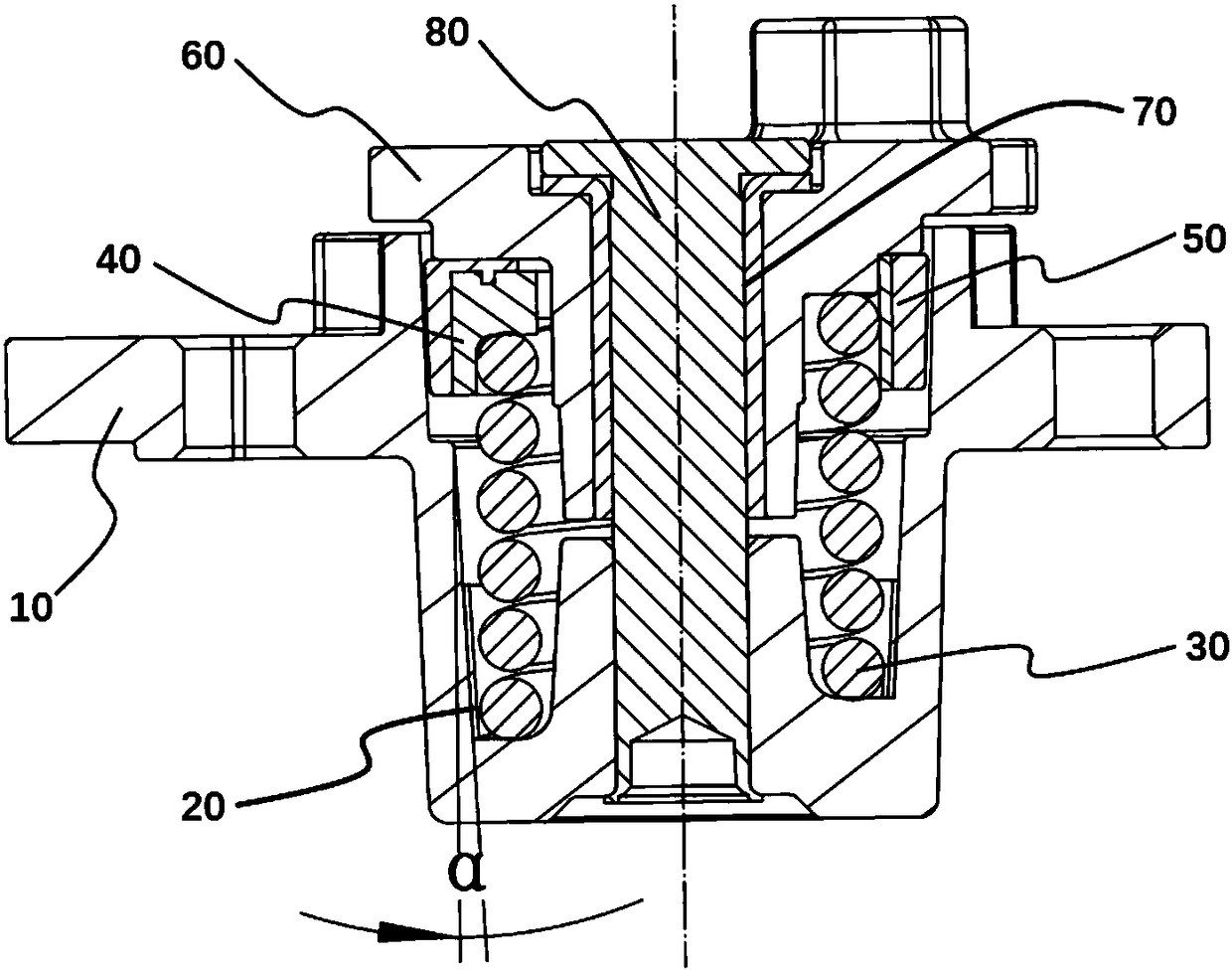

Orbital Tensioner

Owner:THE GATES CORP

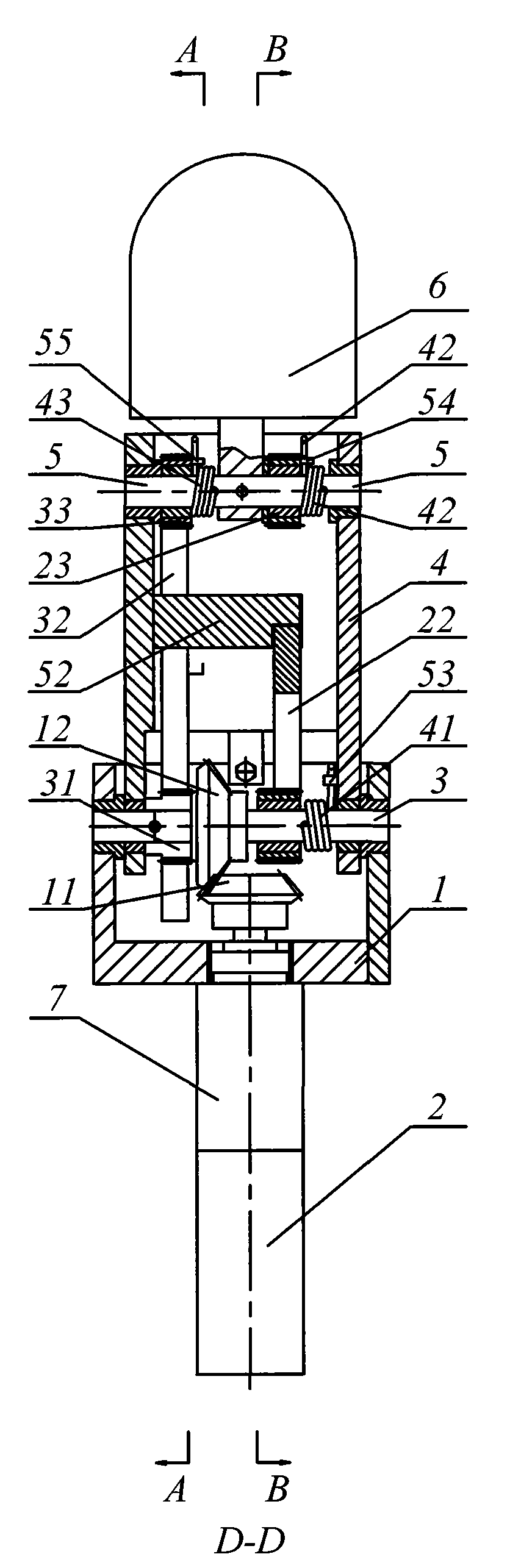

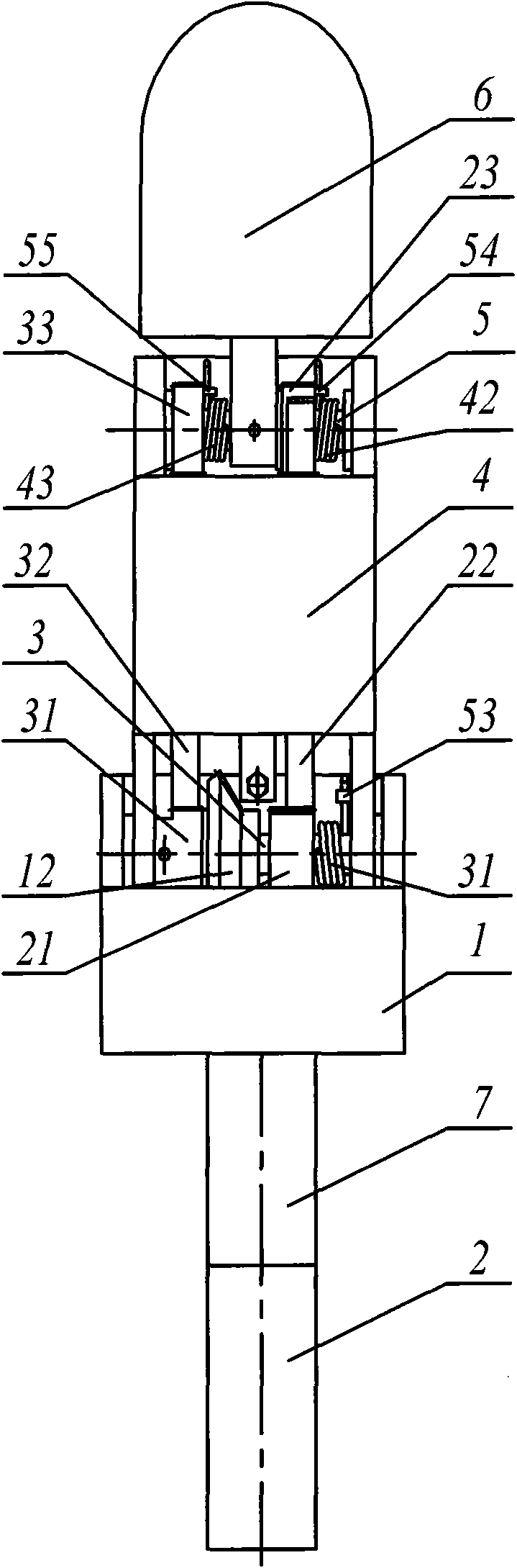

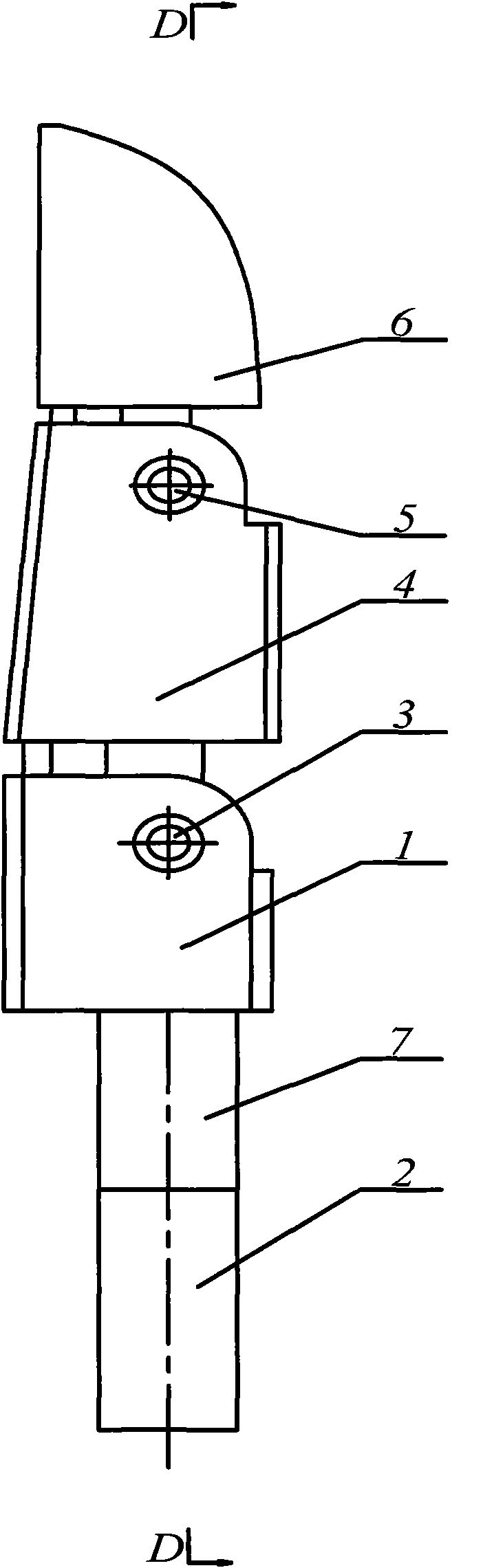

Variable-rigidity and high-damping type automatic tensioning device

Owner:SOUTH CHINA UNIV OF TECH

Power connection/disconnection mechanism and medium feeding apparatus, recording apparatus and liquid ejecting apparatus

Owner:SEIKO EPSON CORP

Energy Generation Method and Apparatus by the Harnessing of Centrifugal Force

An energy generation apparatus uses centrifugal force to generate energy in a controlled manner. The apparatus includes a dual function input shaft and output shaft rotatably attached to opposite sides of a housing defining an axis of orbit, an output gear fixed upon the output shaft, an input sprocket rotatably mounted on the output shaft, and at least two frame gear assemblies, each having a frame gear and at least two weight gears. The frame gears rotate about their centres and also orbit around the output gear in response to an input from the input sprocket.

Owner:LEVINY GEOFFREY WILLIAM GOOD

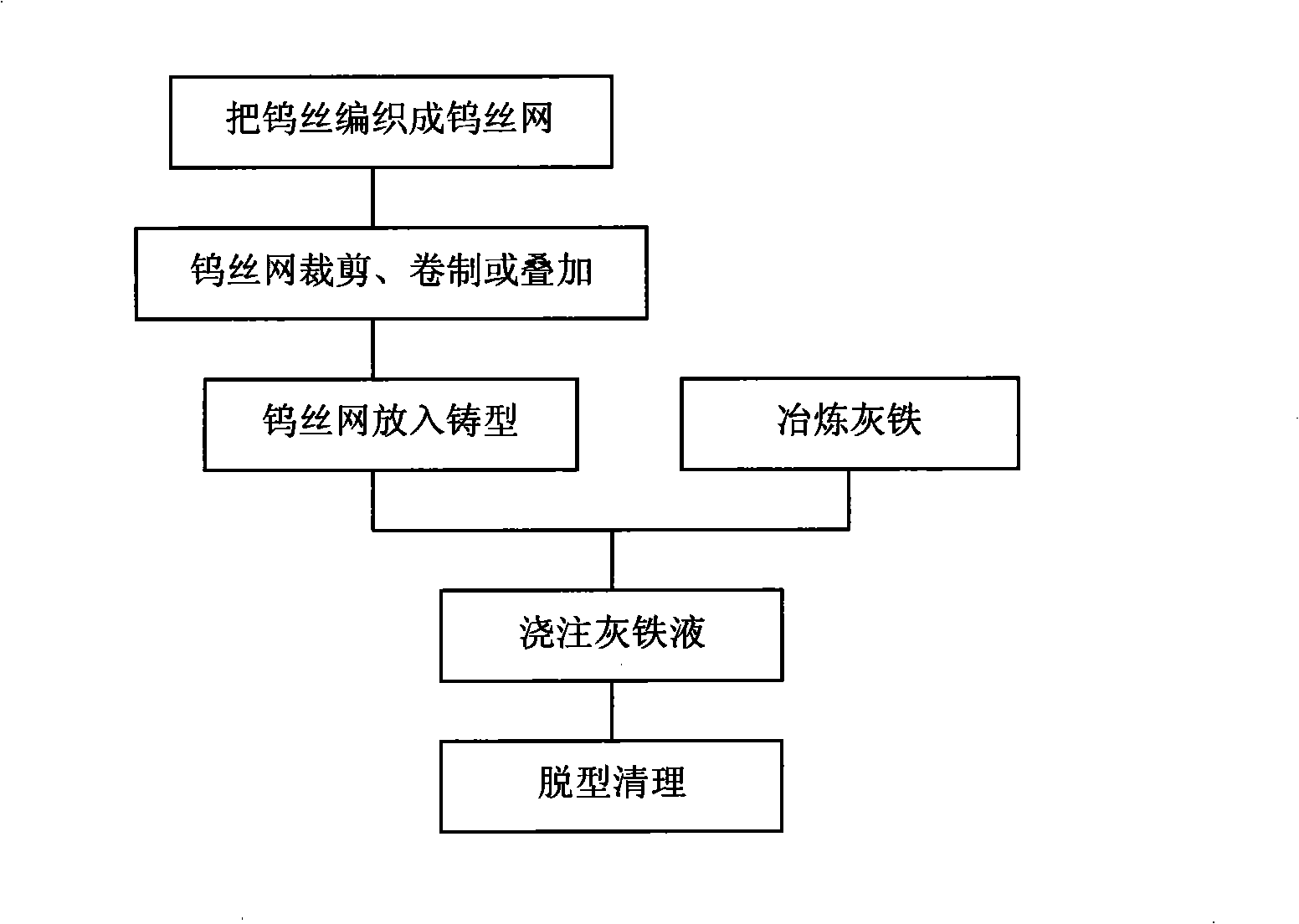

Method for preparing gray iron-base composite material for in situ production of tungsten carbide

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

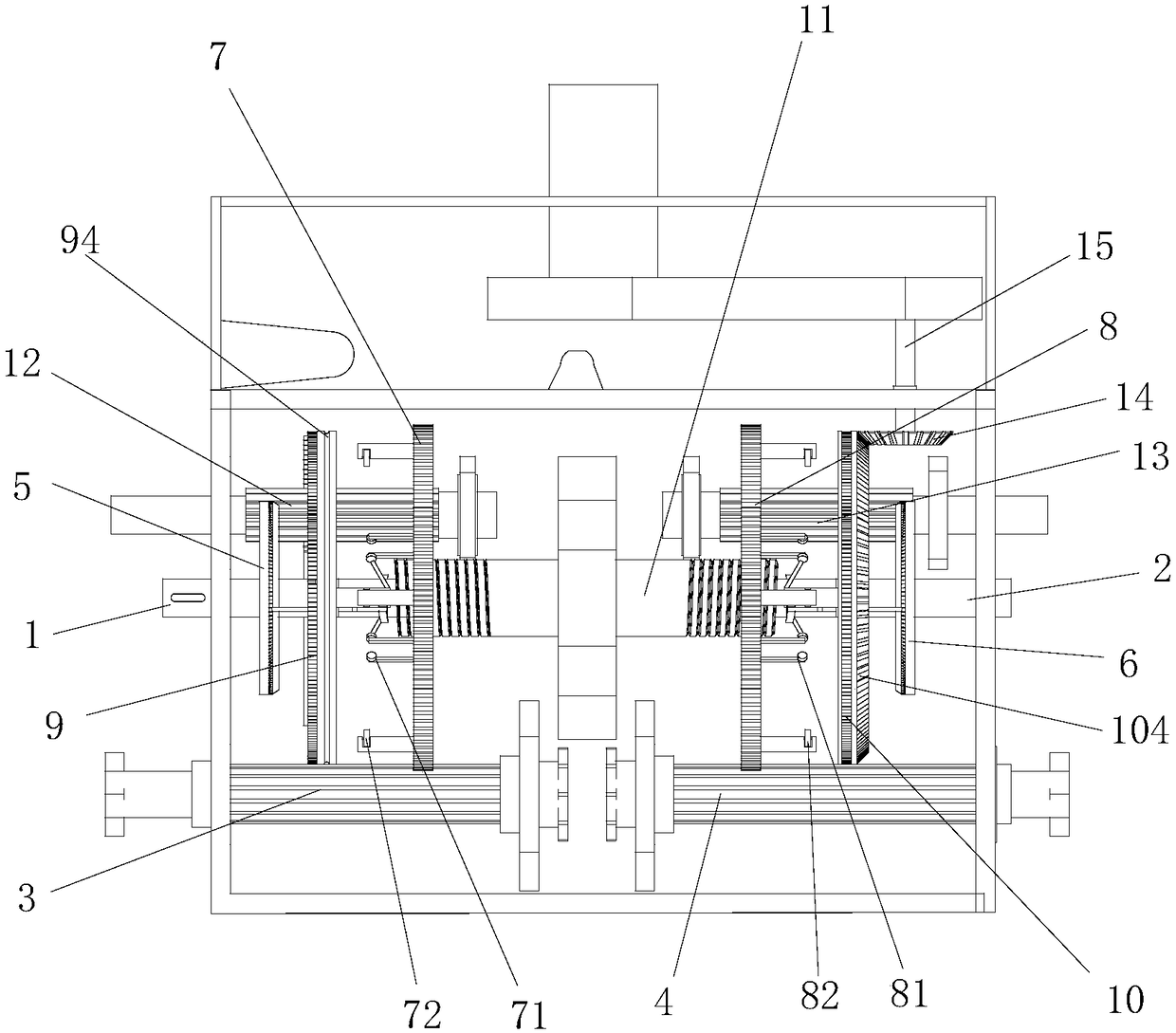

Speed regulation device of low-abrasion belt type general-purpose engine

The invention discloses a speed regulation device of a low-abrasion belt type general-purpose engine, and solves the problems of low abrasion and adjustable stepless speed change which are both considered by an output shaft of the general-purpose engine in the prior art. The speed regulation device comprises a frame, a regulating rod, a transmission belt, a rim shaft and the output shaft of the general-purpose engine, wherein a drive cone and a driven cone are respectively arranged on the rim shaft and the output shaft of the general-purpose engine which are parallel, adjacent side boundaries in a common longitudinal section of the drive cone and the driven cone are parallel, the drive cone and the driven cone are respectively sleeved with a drive belt and a driven belt, the transmission belt is tightly sleeved on the outer surfaces of the drive belt and the driven belt, the regulating rod which is parallel to the output shaft of the general-purpose engine is connected to the frame in a sliding manner and has an axial movement degree of freedom, a push block used for pushing a narrow side of the transmission belt is arranged on the free end of the regulating rod, a groove matched with the cross section of the transmission belt is arranged on the outer surfaces of the drive belt and the driven belt, and the transmission belt is embedded into the groove. According to the speed regulation device, different line speed ratios of the drive side and the driven side are realized so as to achieve the stepless speed change of the output shaft of the general-purpose engine.

Owner:CHONGQING DAJIU SCI & TECH DEV

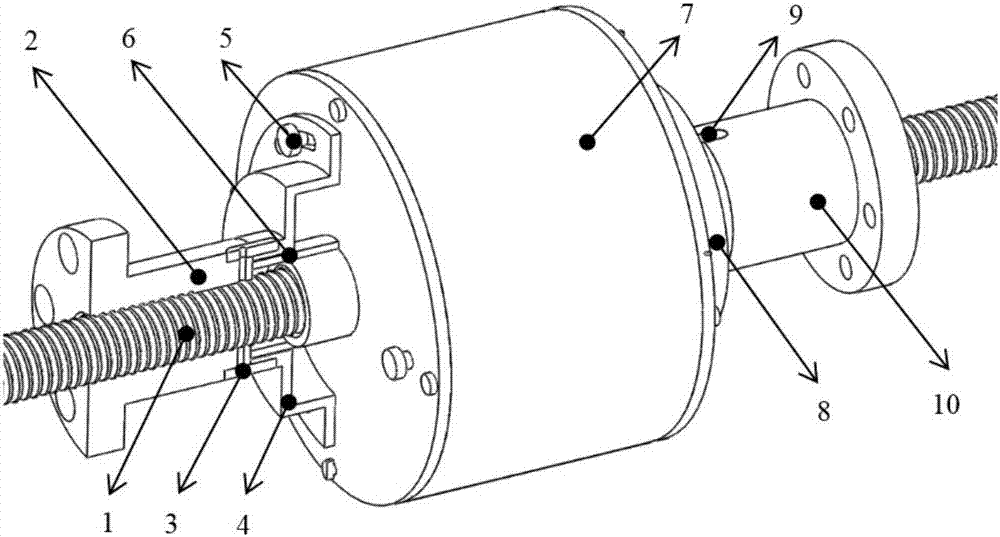

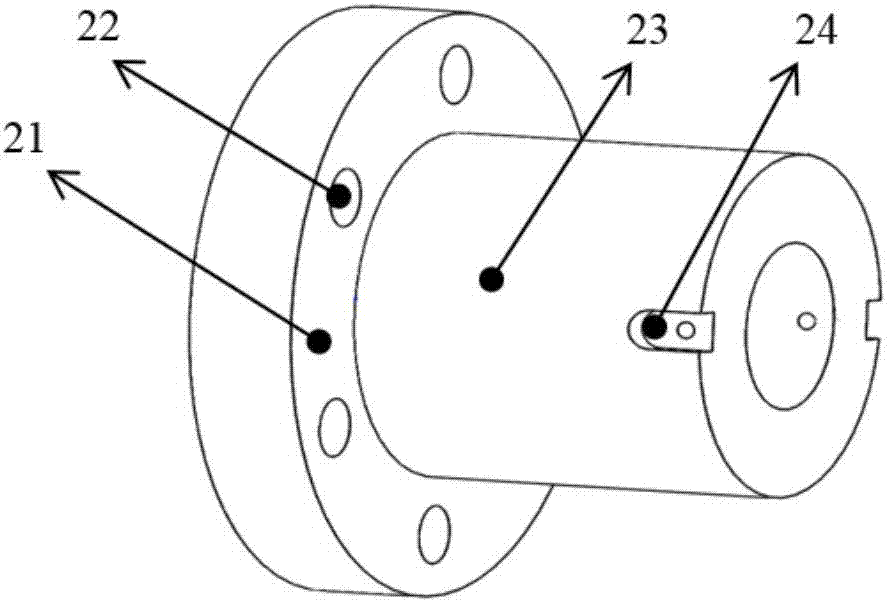

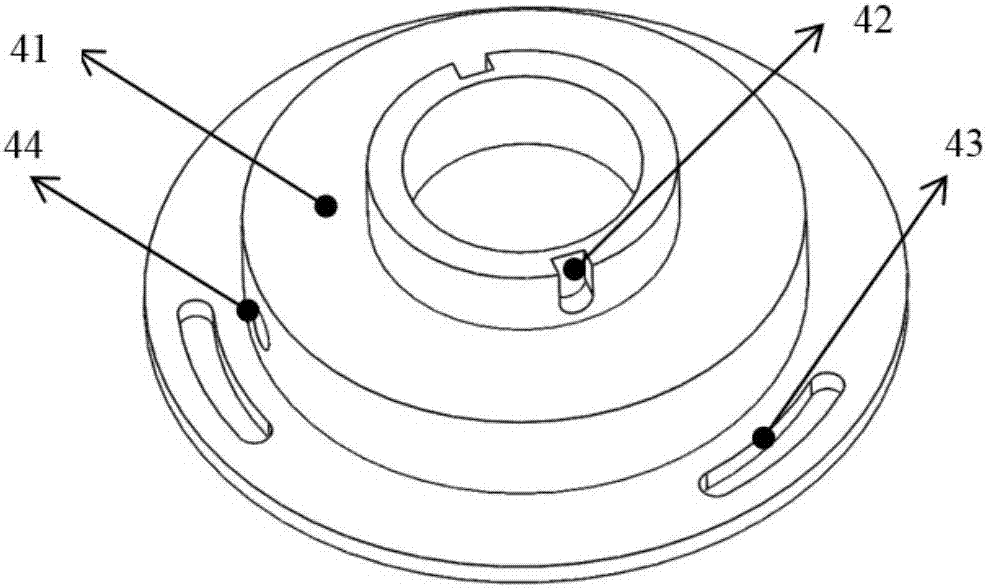

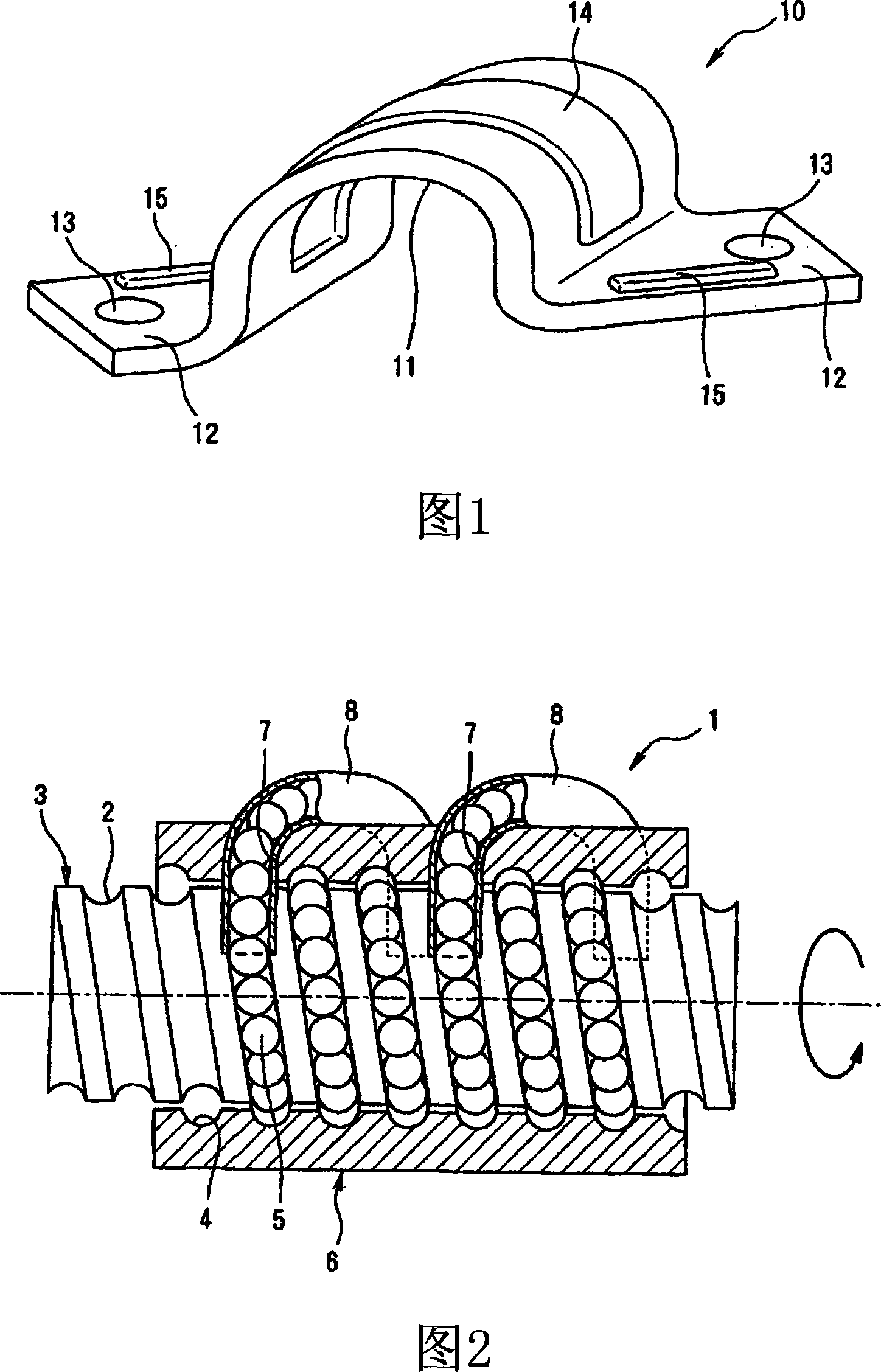

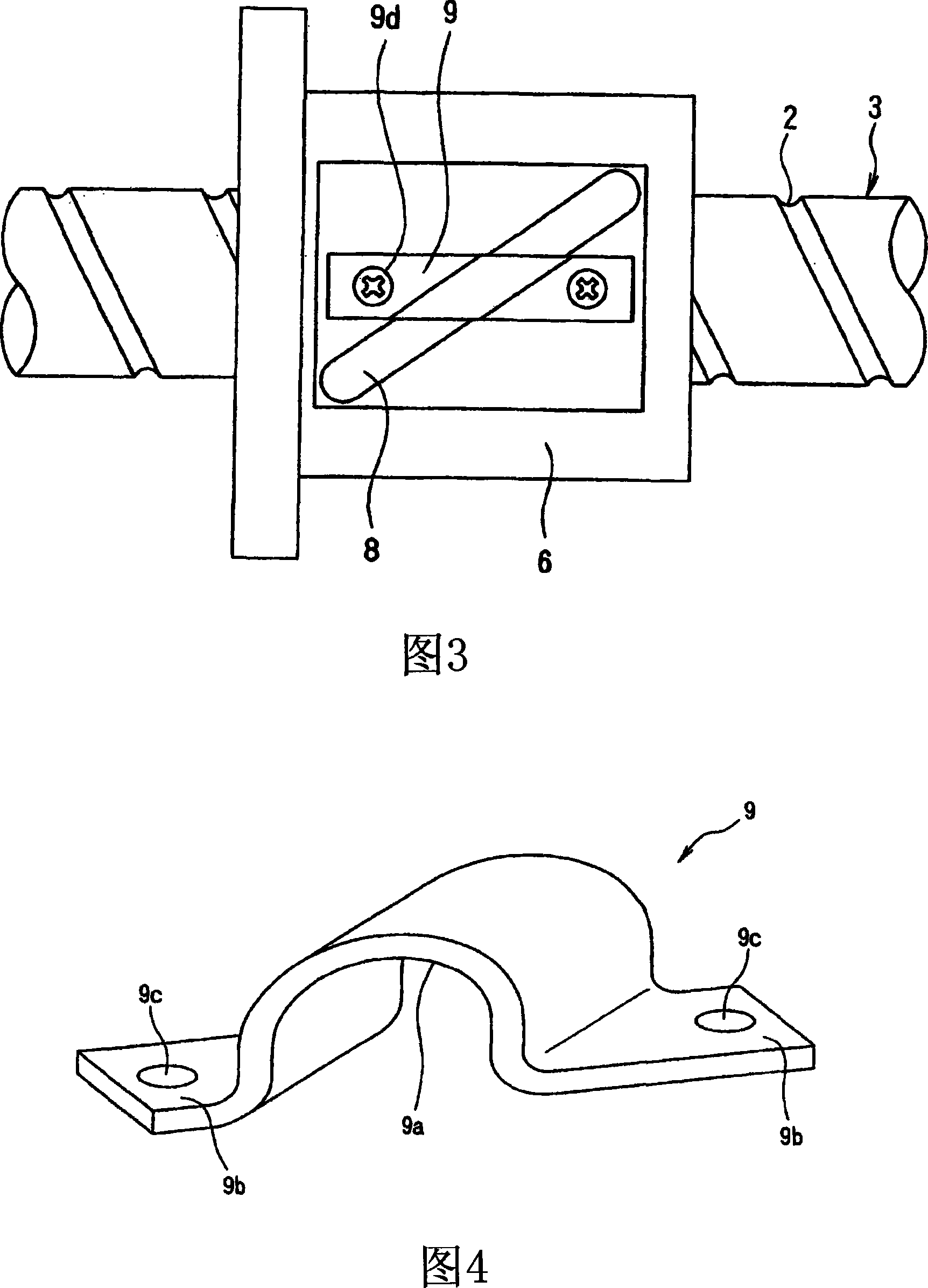

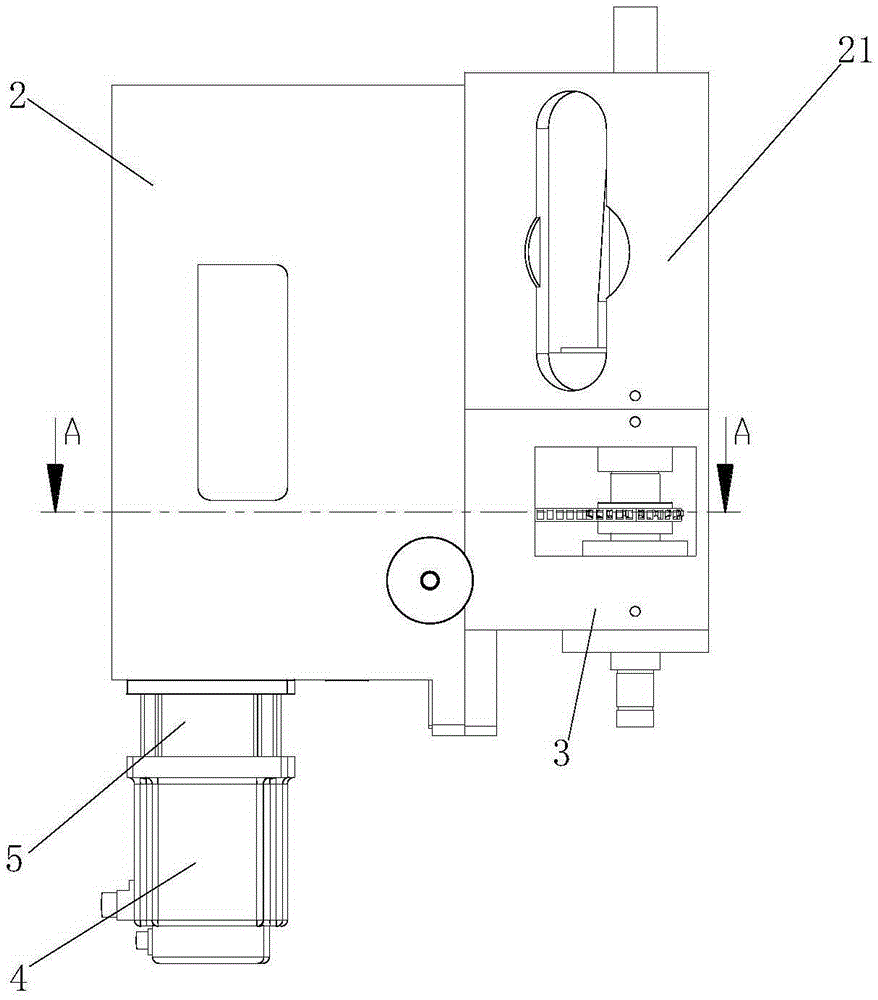

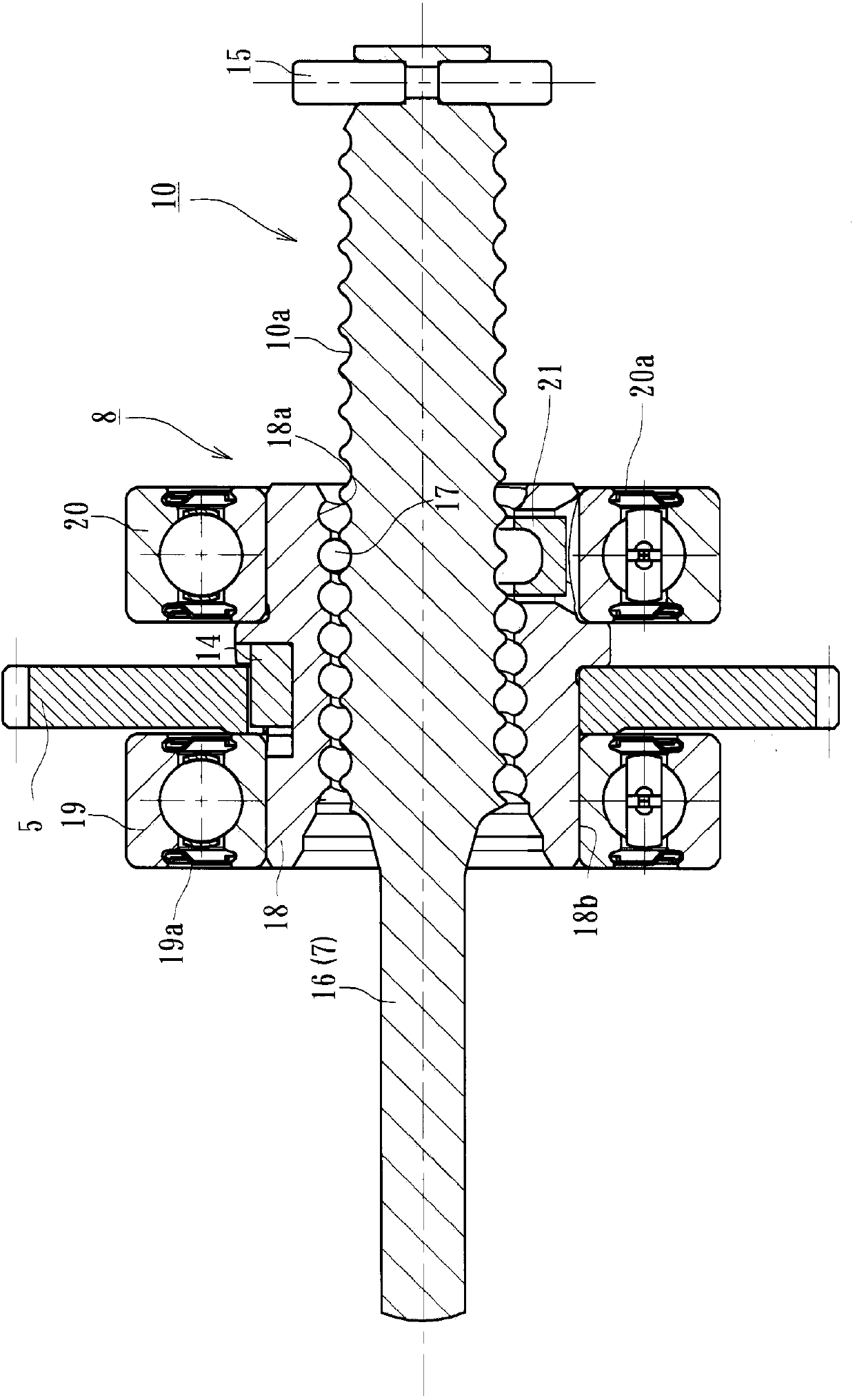

Combined type double nut ball screw pair with adjustable pre-tightening force and installation method

Owner:SHANDONG UNIV

Articulated chain with low-friction link plate back

Owner:IWIS MOTORSYSTEME GMBH & CO KG

Die-casting method of thin-wall oil pipe embedding part oil pan

The invention discloses a die-casting method of a thin-wall oil pipe embedding part oil pan. The method comprises the steps of preheating oil pipes through an oven; moving a wood board at the bottom of a machine stand to reach the middle of a die to prepare for mounting the oil pipe; moving out the heated oil pipes from the oven; keeping the surfaces of the oil pipes free of oil stain; aligning the middle of the oil pipes to two end heads; mounting the #1 oil pipe above and mounting the #2 oil pipe below, wherein the #1 oil pipe and the #2 oil pipe are respectively mounted on corresponding fixing points of the oil pan; examining whether the #1 oil pipe and the #2 oil pipe are clung to a U-shaped clamping slot; connecting the #1 oil pipe and the #2 oil pipe through a plurality of aluminum embedding part blocks which are fixed on the U-shaped clamping slot in the die before closing the die and pouring of a die-casting machine; moving out the oil pan after production; examining whether the oil pipes expose, oil pipe feeders and each pin hole are damaged by buckling, and an interlayer and each corner are burnt and adhered with aluminum. The method has the advantages that the oil pipes can be accurately positioned, aluminum cannot overflow from oil pipe positioning holes, and the oil pipes cannot be flattened and deformed due to non-uniform stressing.

Owner:GUANGDONG HONGTUNANTONGDIE CASTING +1

Supporting leg control device

Owner:WUHAN BINHU ELECTRONICS

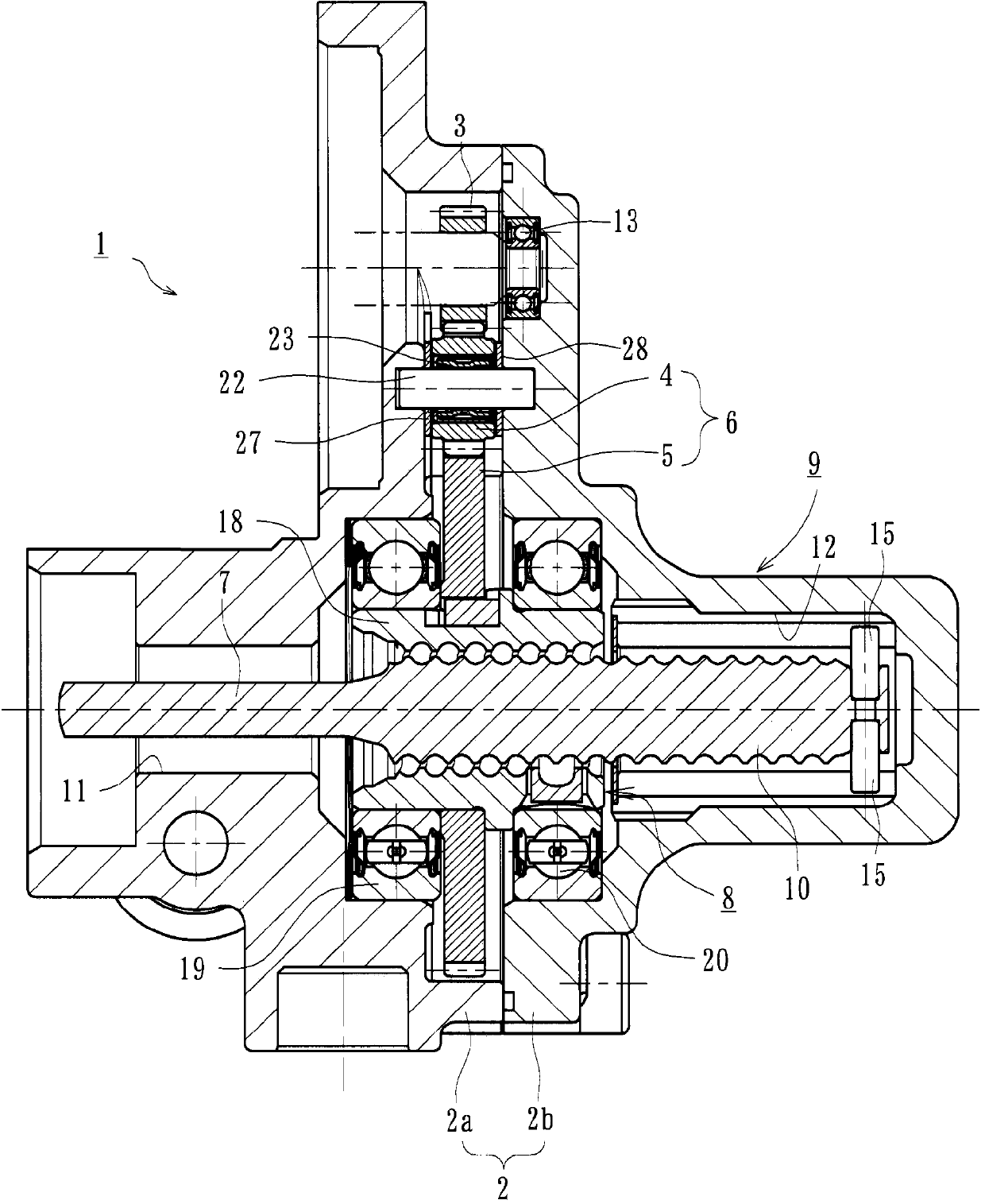

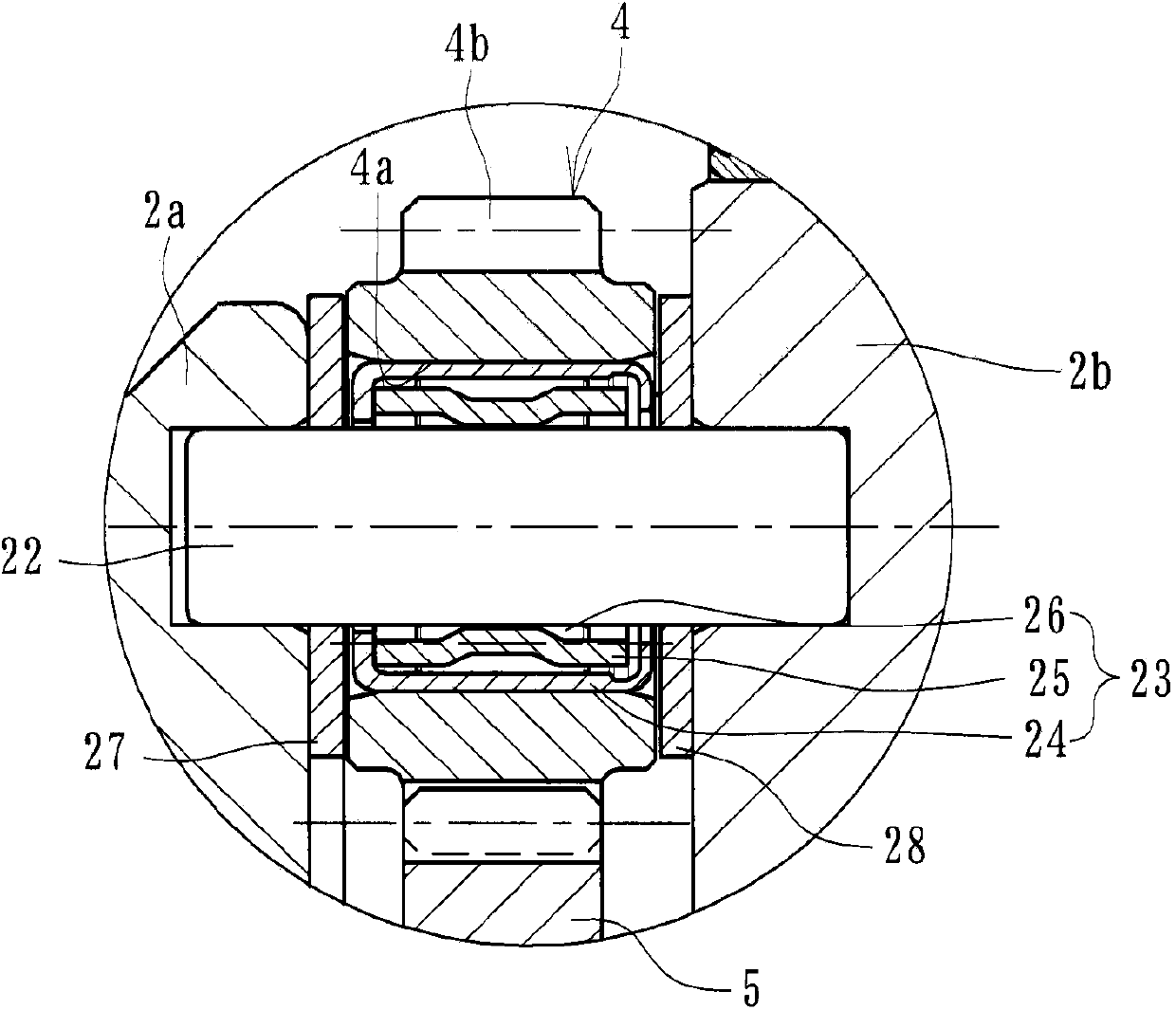

Ball screw device

Owner:NSK LTD

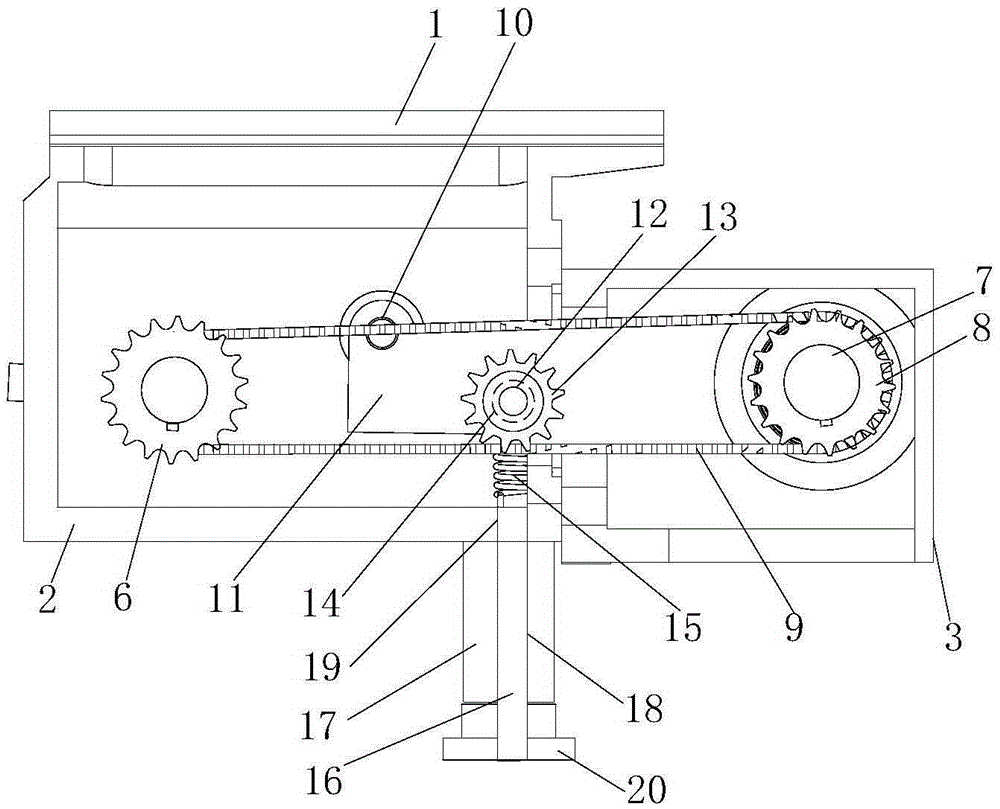

Chain transmission mechanism for grinding machine

Owner:芜湖中驰机器人科技有限公司

Electric linear actuator

Owner:NTN CORP

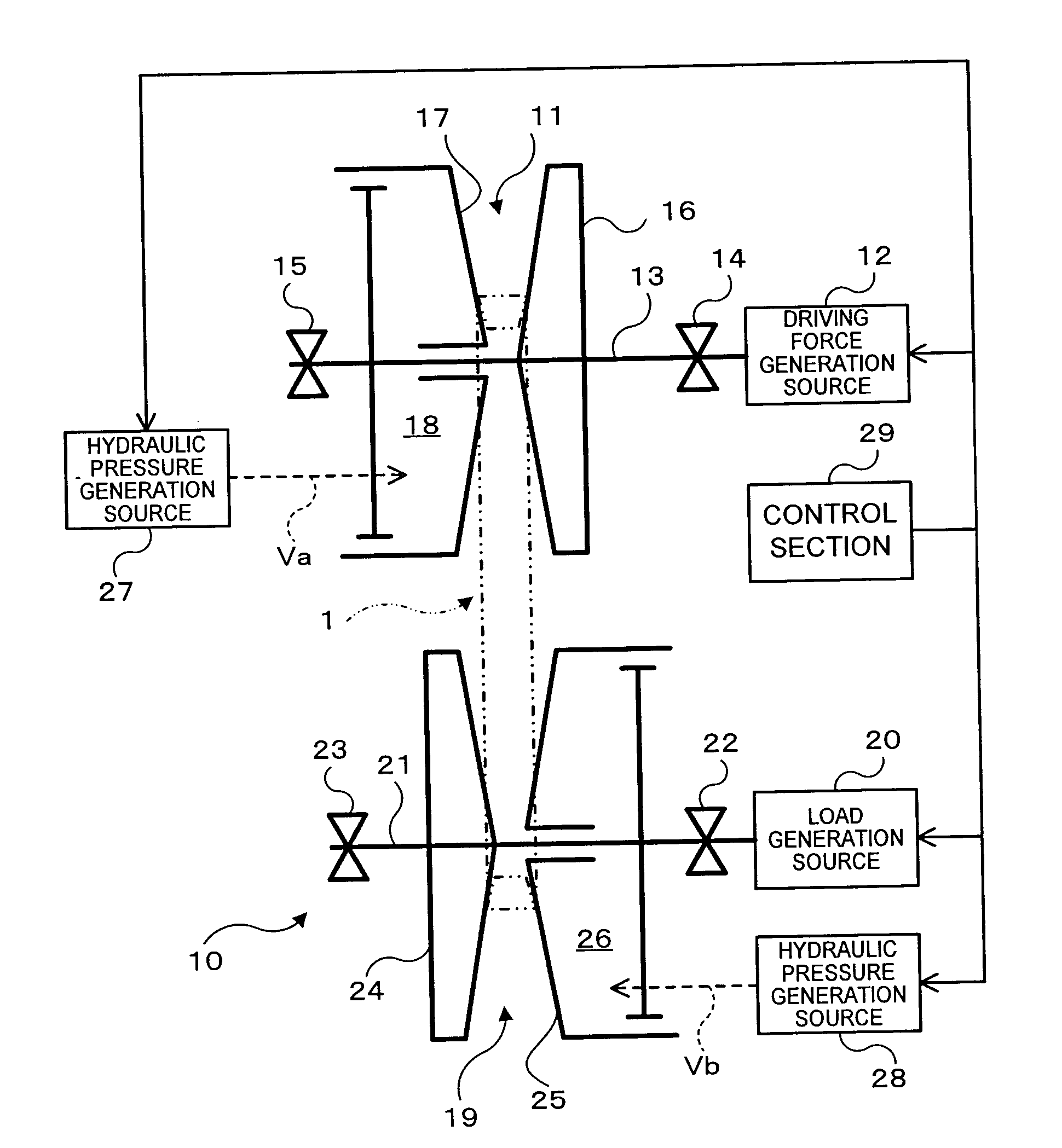

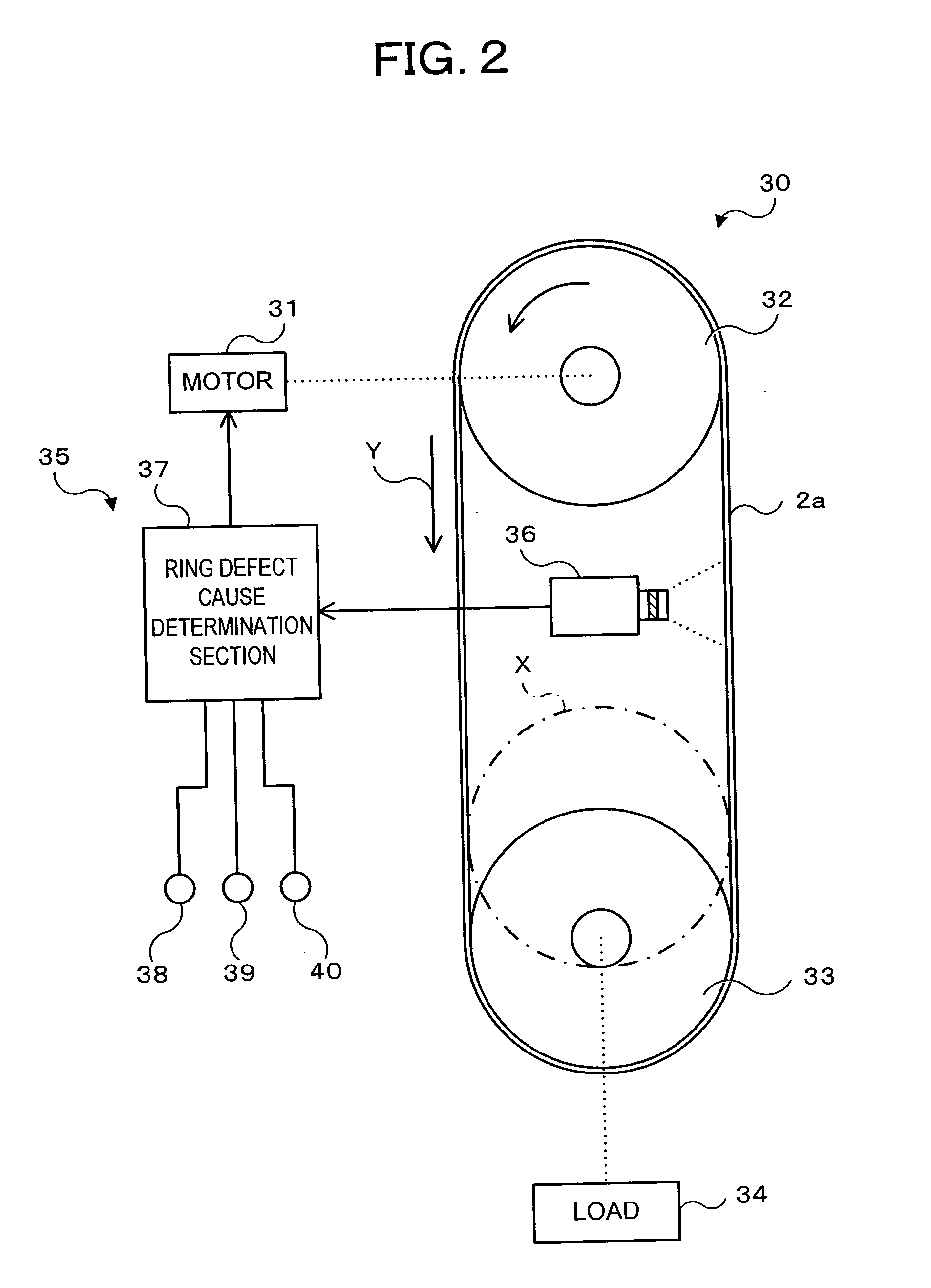

Continuously variable transmission belt inspection method and inspection device thereof

InactiveUS20060037415A1Unnecessary part can be avoidedLow costV-beltsMachine gearing/transmission testingEngineeringMetal powder

Owner:JATCO LTD

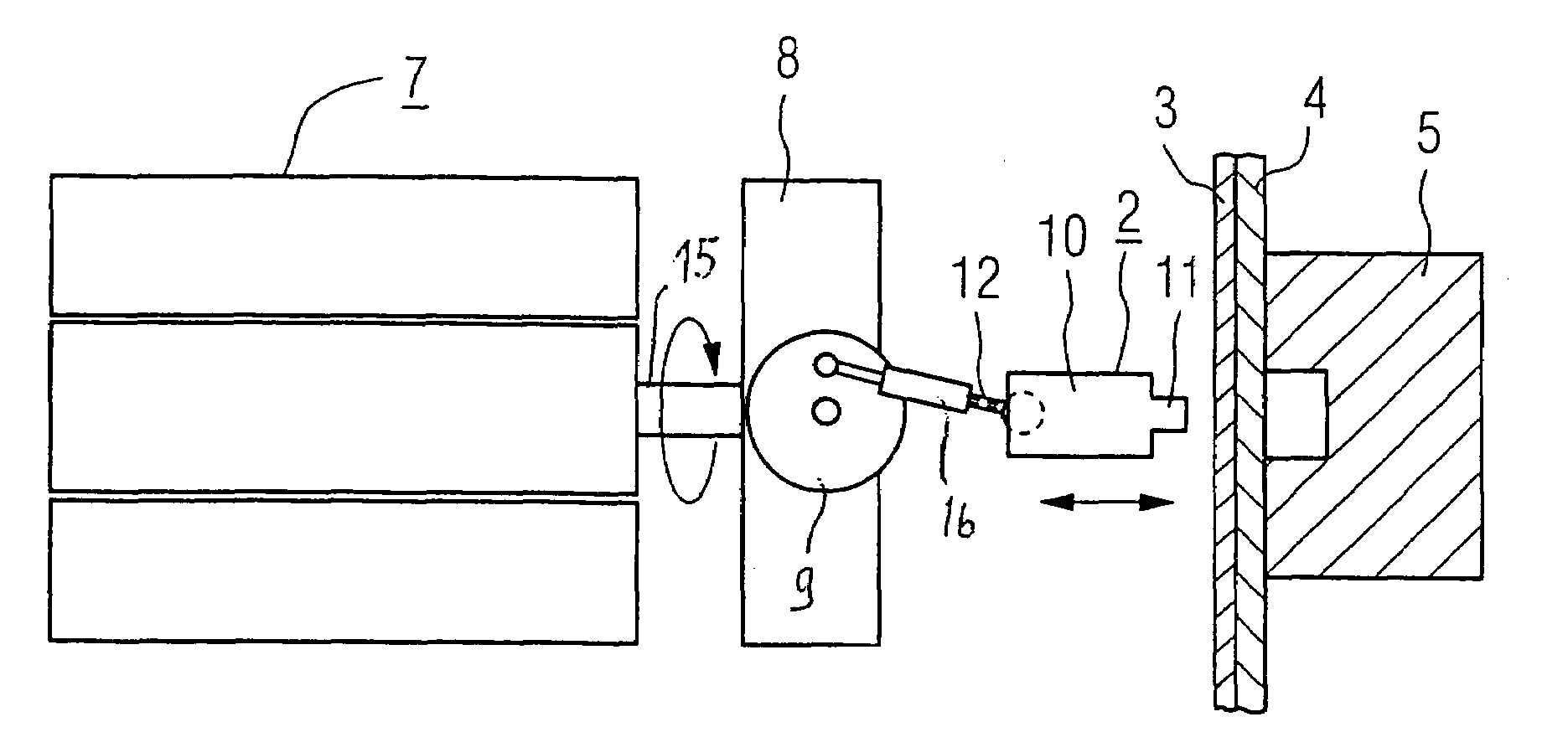

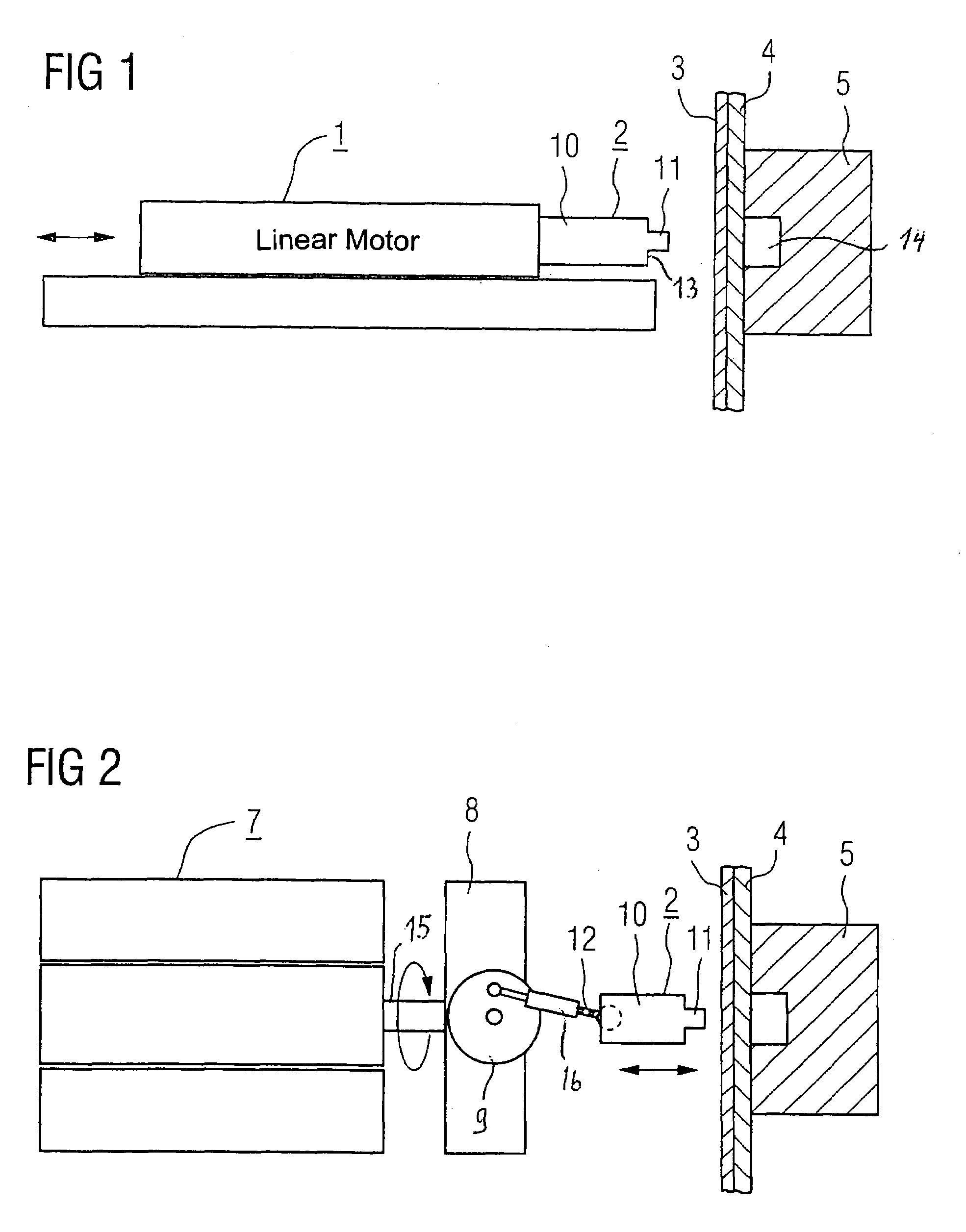

Electric drive for a shaping die

InactiveUS7313861B2Controlling profileReduce noiseGearingLarge fixed membersElectricityElectric drive

Owner:SIEMENS AG

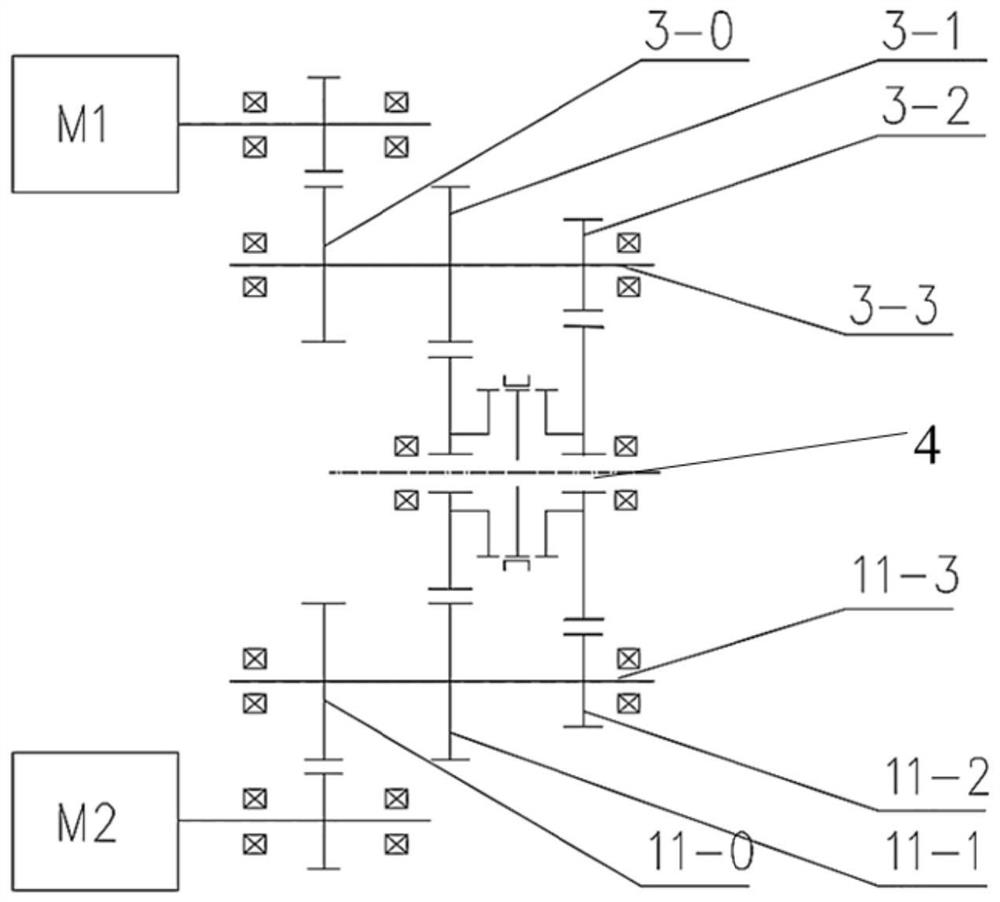

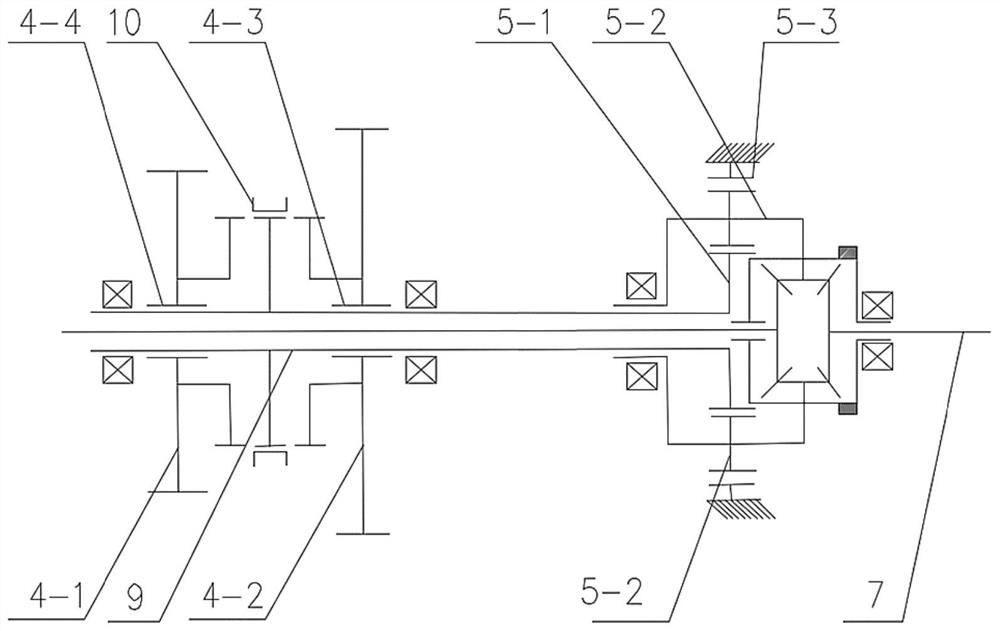

Vehicle with dual motor electric drive axle

Owner:SINO TRUK JINAN POWER

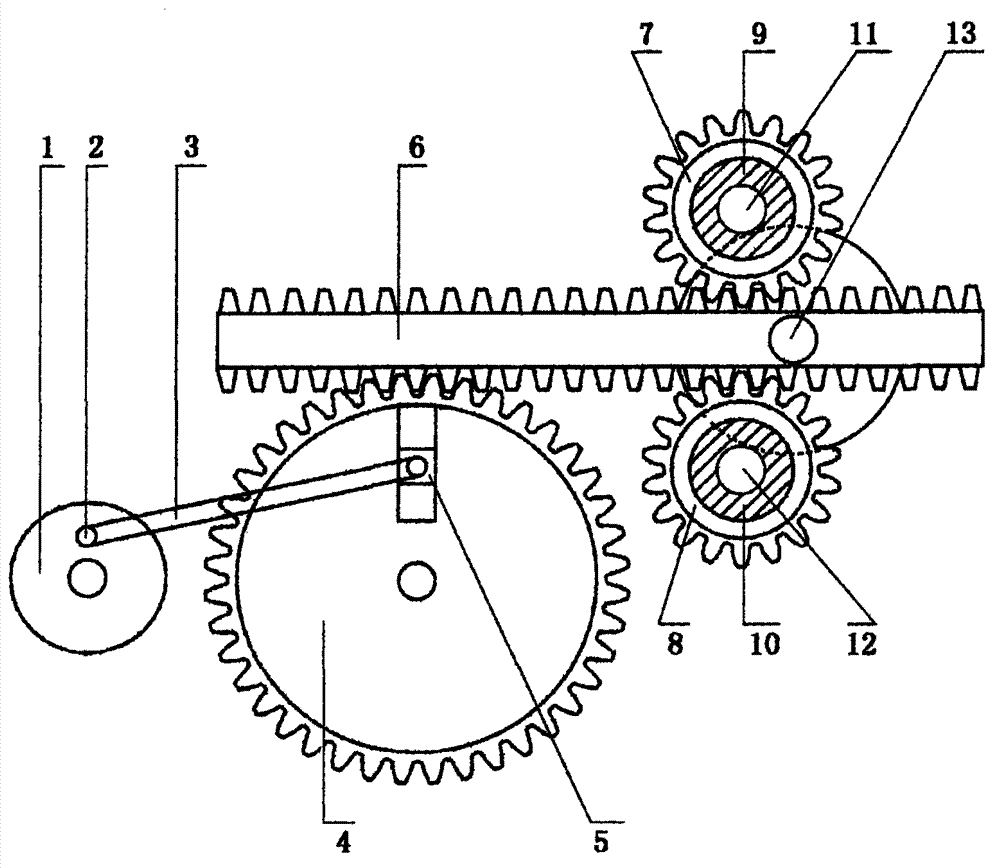

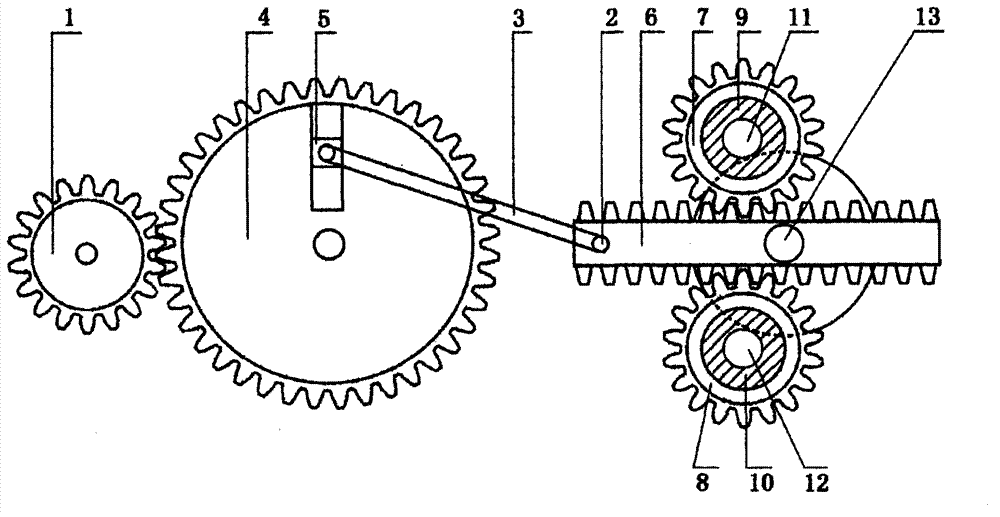

Rack type parallel coupling underactuated robot finger device

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV +1

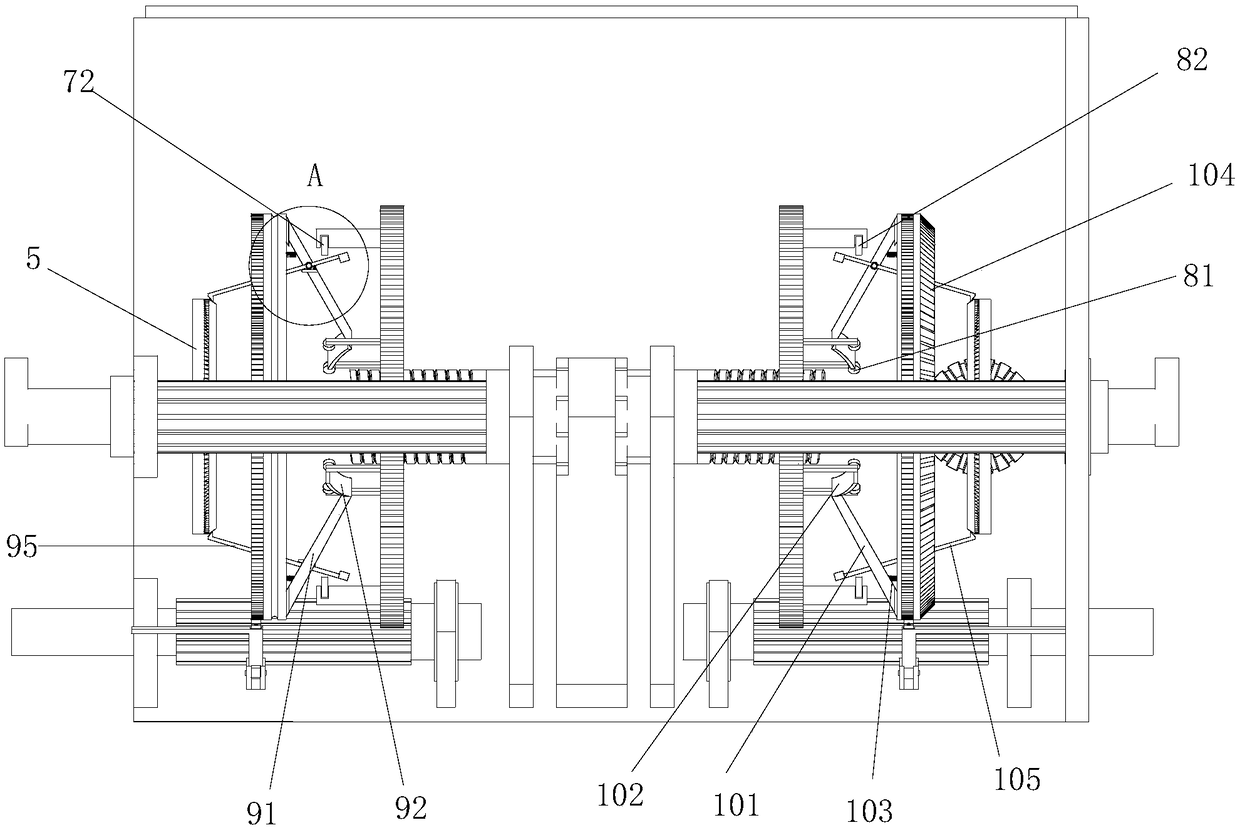

Mechanical device capable of realizing remote classification transmission control

ActiveCN108458081AReduce manufacturing costLow running costGearingGearing detailsDrive shaftGear wheel

Owner:SHANDONG UNIV OF SCI & TECH

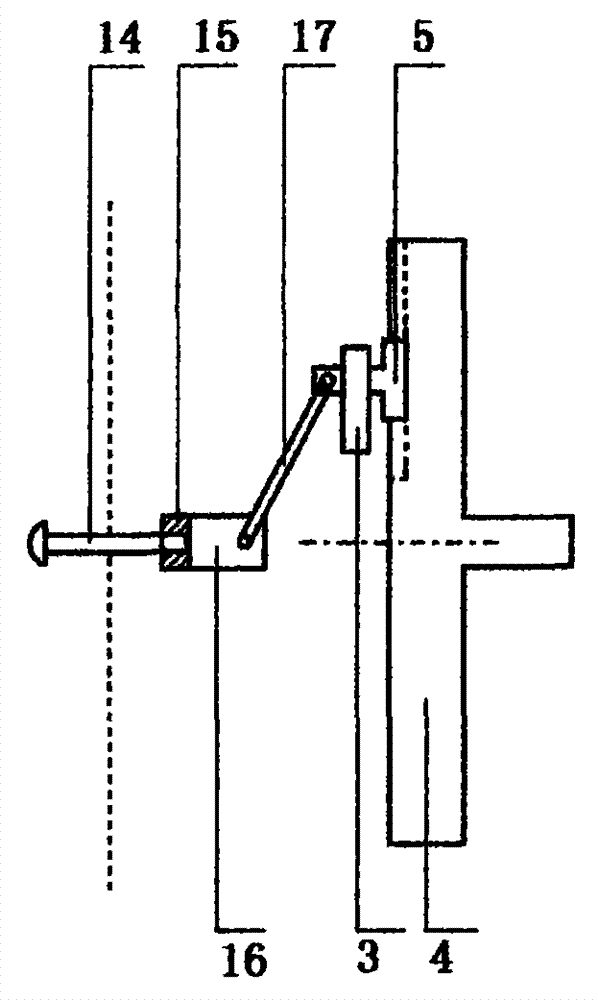

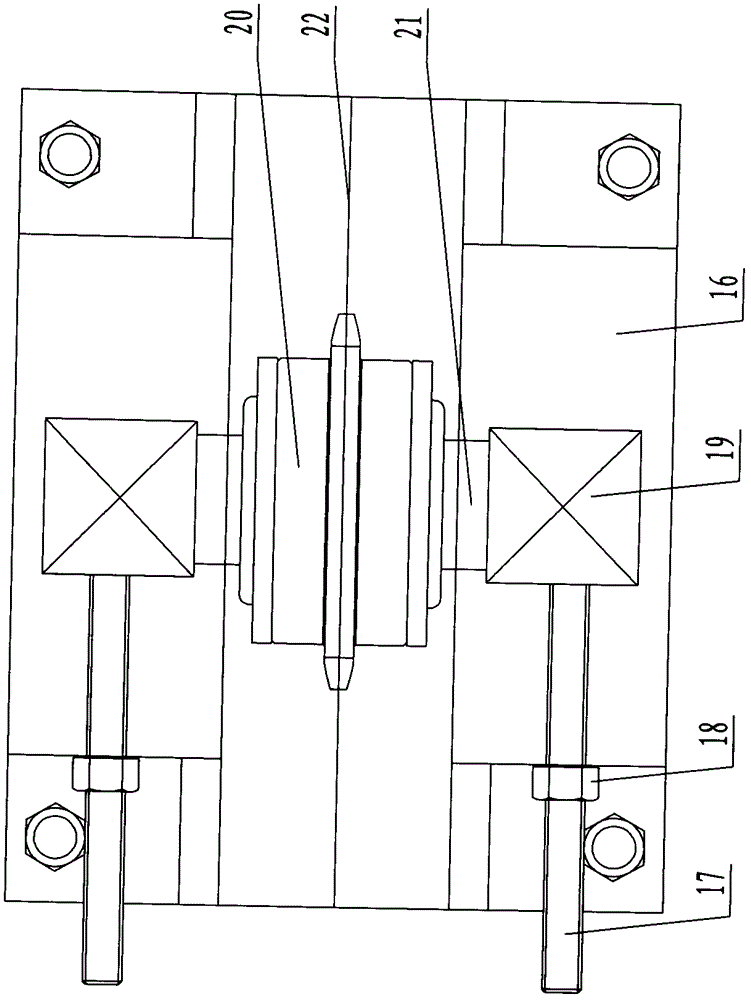

Linkage platform screen door of subway

InactiveCN105756463ARealize linkage controlAdjustable tightnessGearingRailway componentsEngineeringPulley

Owner:江苏浔丰轨道交通科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap