Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60 results about "Building material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Building material is any material which is used for construction purposes. Many naturally occurring substances, such as clay, rocks, sand, and wood, even twigs and leaves, have been used to construct buildings. Apart from naturally occurring materials, many man-made products are in use, some more and some less synthetic. The manufacturing of building materials is an established industry in many countries and the use of these materials is typically segmented into specific specialty trades, such as carpentry, insulation, plumbing, and roofing work. They provide the make-up of habitats and structures including homes.

Industrially-applicable method for preparing polymer foamed material by using supercritical fluid technology

Owner:CHANGZHOU TIANSHENG NEW MATERIALS RES INST CO LTD

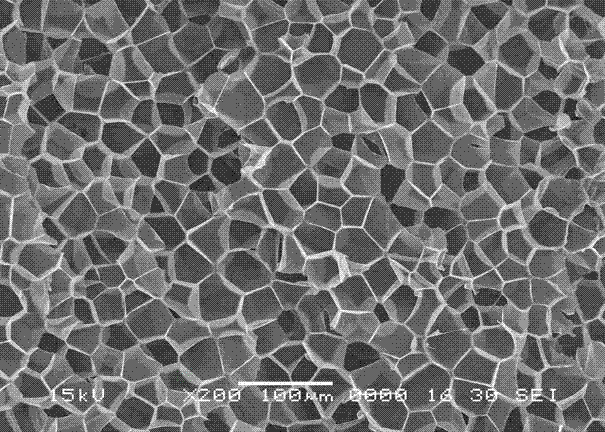

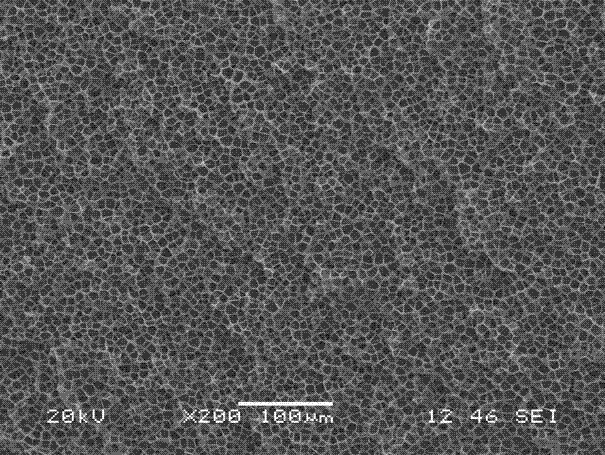

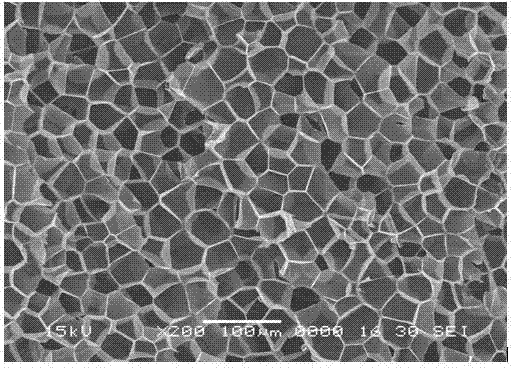

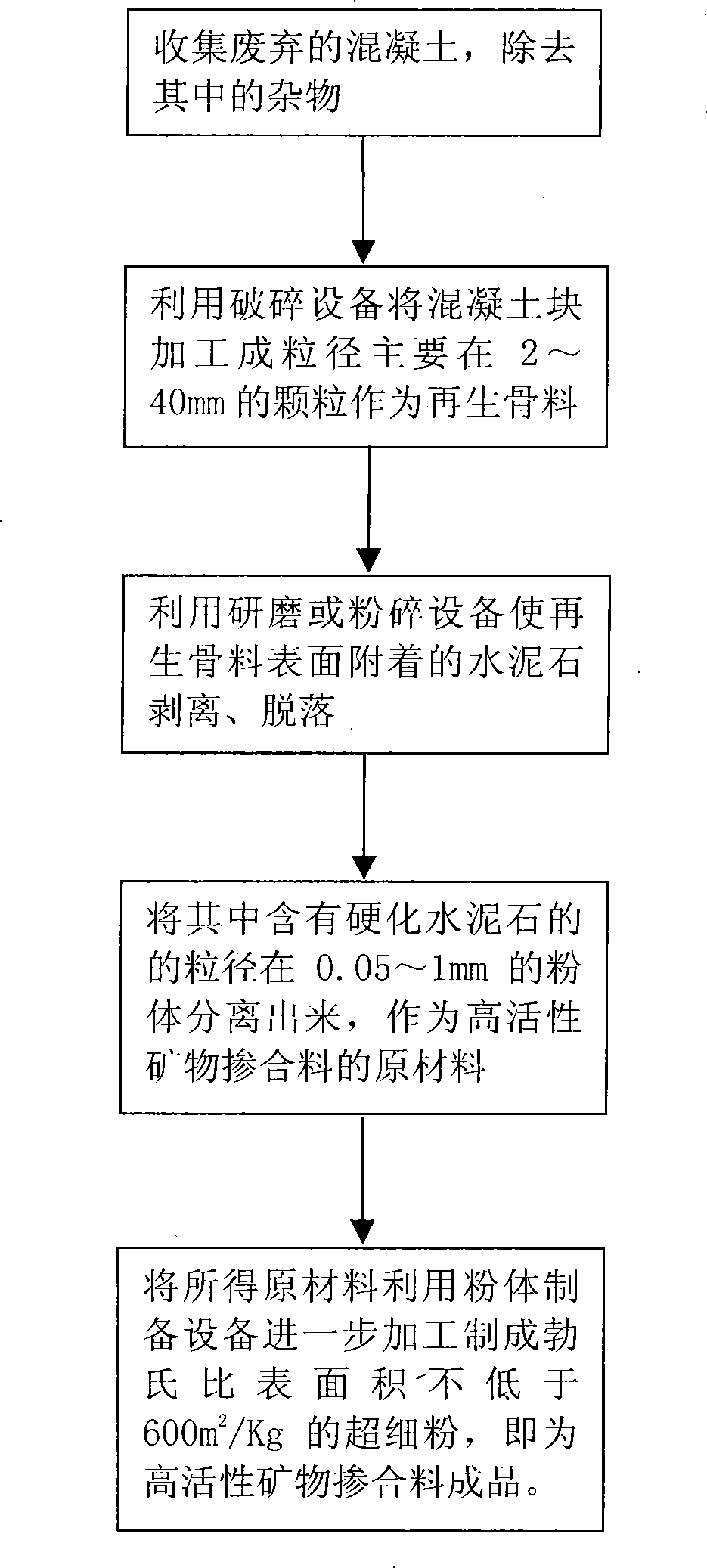

Method for manufacturing high-activity mineral blending material and application thereof

InactiveCN101244906AIncrease 3d intensityReduce water consumptionSolid waste managementPrice ratioCement paste

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

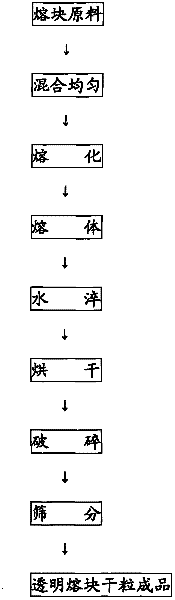

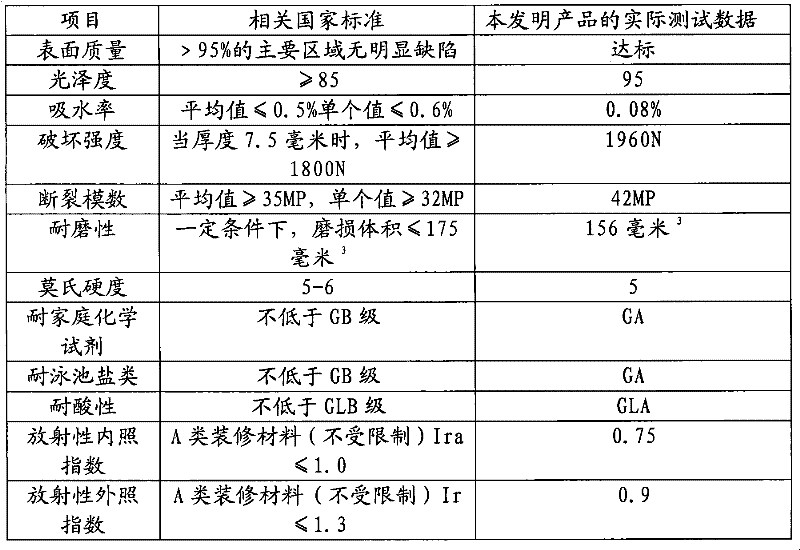

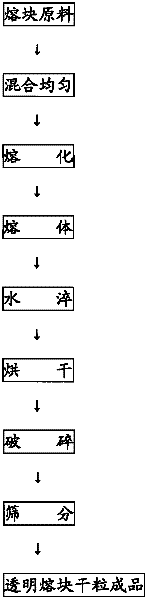

Method for producing transparent clinker capable of being compounded with colored glaze ceramic blank

Owner:GUANGDONG BODE FINE IND CONSTR MATERIAL

Openable skirt type steel reinforcement cage of reamed pile

The invention discloses an openable skirt type steel reinforcement cage of a reamed pile and belongs to piling building materials. According to the openable skirt type steel reinforcement cage, a reaming section of a pedestal pile has a horizontal expansion function, the reinforced concrete structure forms of the existing rotary expanding piles are changed, and the load capacity of the rotary expanding piles is increased; the steel reinforcement cage is unfolded at the bottom of a hole through a plurality of link mechanisms, the appearance of the unfolded steel reinforcement cage is basically similar to the contour of the reamed hole, the link mechanisms are simultaneously opened and are connected with an existing steel reinforcement cage through steel stranded wires, then, concrete is cast, the link mechanisms serve as steel reinforcement members, and thus, the strength of concrete members of rotary expanding pile bodies is enhanced.

Owner:XUZHOU LEHMAN MASCH TECH CO LTD

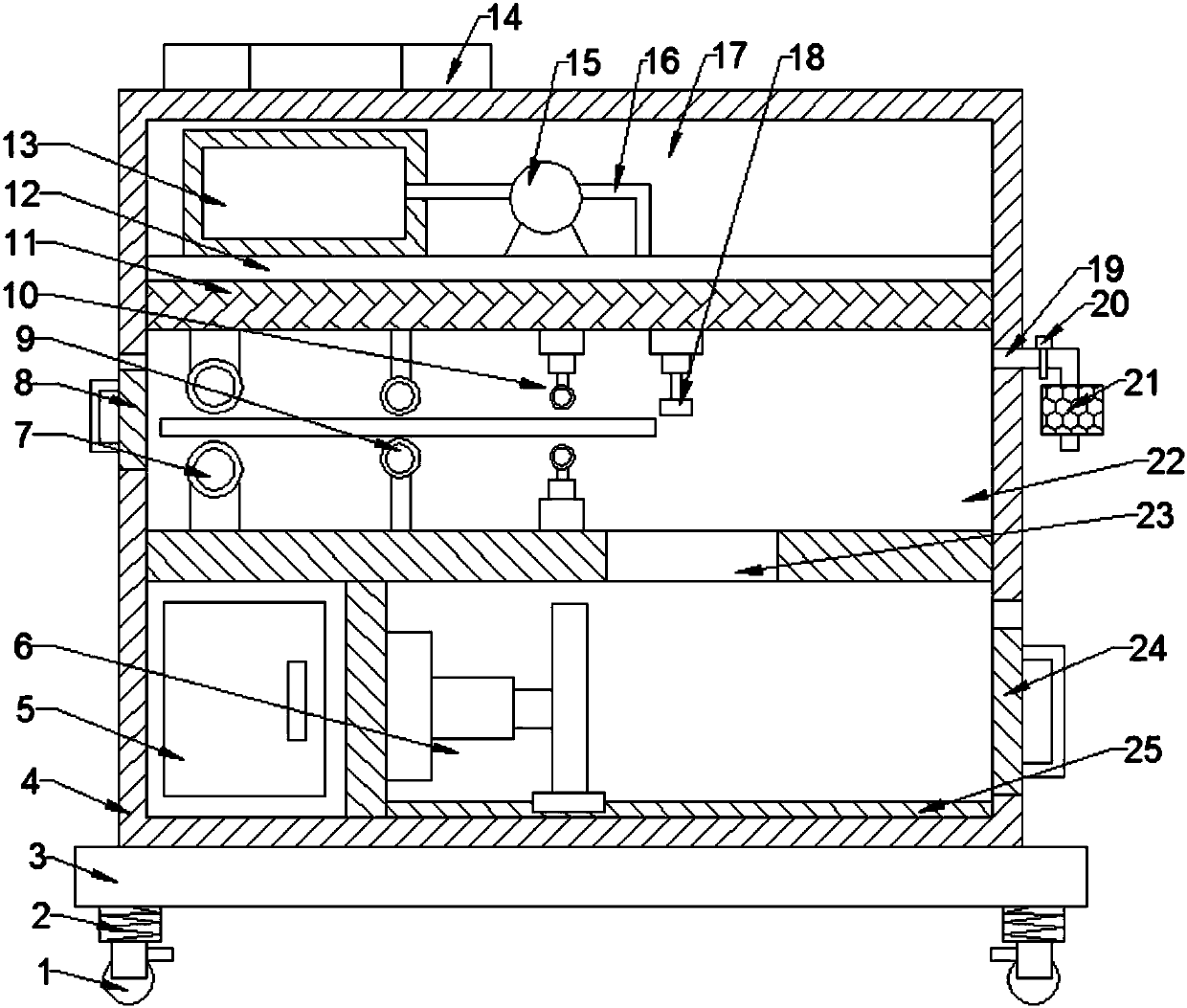

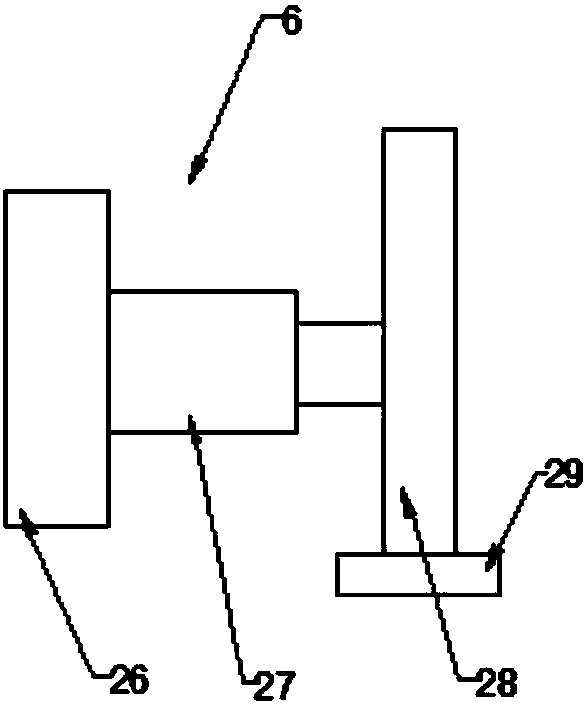

Dust-free type building material cutting and polishing device

InactiveCN107649882AOther manufacturing equipments/toolsMaintainance and safety accessoriesBuilding materialEngineering

Owner:QUANZHOU HUIAN MINTOU TRADING CO LTD

Far infrared Nixing pottery product and preparation method thereof

The invention discloses a far infrared Nixing pottery product and a preparation method thereof. The far infrared Nixing pottery finished product, far infrared Nixing pottery powder and far infrared Nixing pottery slurry is prepared by adding the metal oxides Cr2O3, MgO, MnO2 and ZrO2 and other compounds serving as auxiliary raw materials into Nixing pottery which is made in Qinzhou, Guangxi, and has the advantages of more cheap chemical components, high content and high quality and serves as a main raw material and roasting the mixture at the temperature of between 1,000 and 1,200 DEG C in a high-temperature electric furnace or a high-temperature roasting furnace or a high-temperature burning kiln according to the pottery. The far infrared Nixing pottery product transmits a far infrared ray with the wavelength of 6 to 23 mu m at the normal temperature and can be applied to the industry, medical care and living goods in the fields such as medical care, energy conservation and environment protection, building materials, heat insulating materials, water quality improvement, paper making plastic, fiber weaving, food preservation, food roasting, wine making industry, pharmaceutical industry and the like. The preparation method has the advantages of simple process, low energy consumption, low cost, high benefit and good product quality.

Owner:李建洪

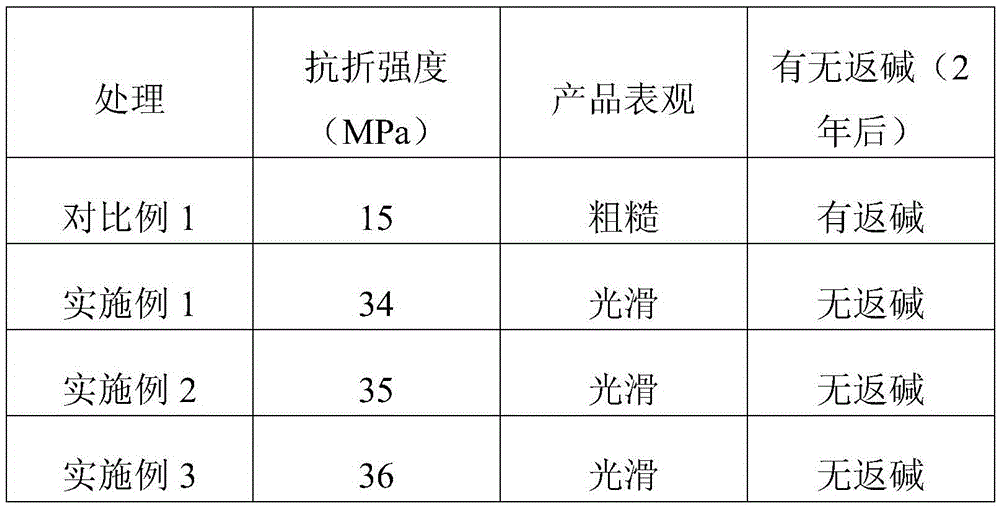

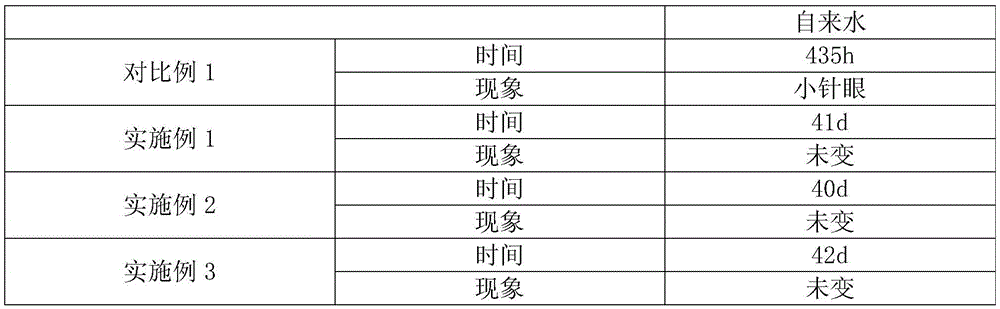

Saltpetering-prevention sulphoaluminate cement product and preparation method thereof

Owner:ZHUODA NEW MATERIALS TECH GRP WEIHAI CO LTD

Shale-sintered hollow ganged brick

Owner:陈振杰

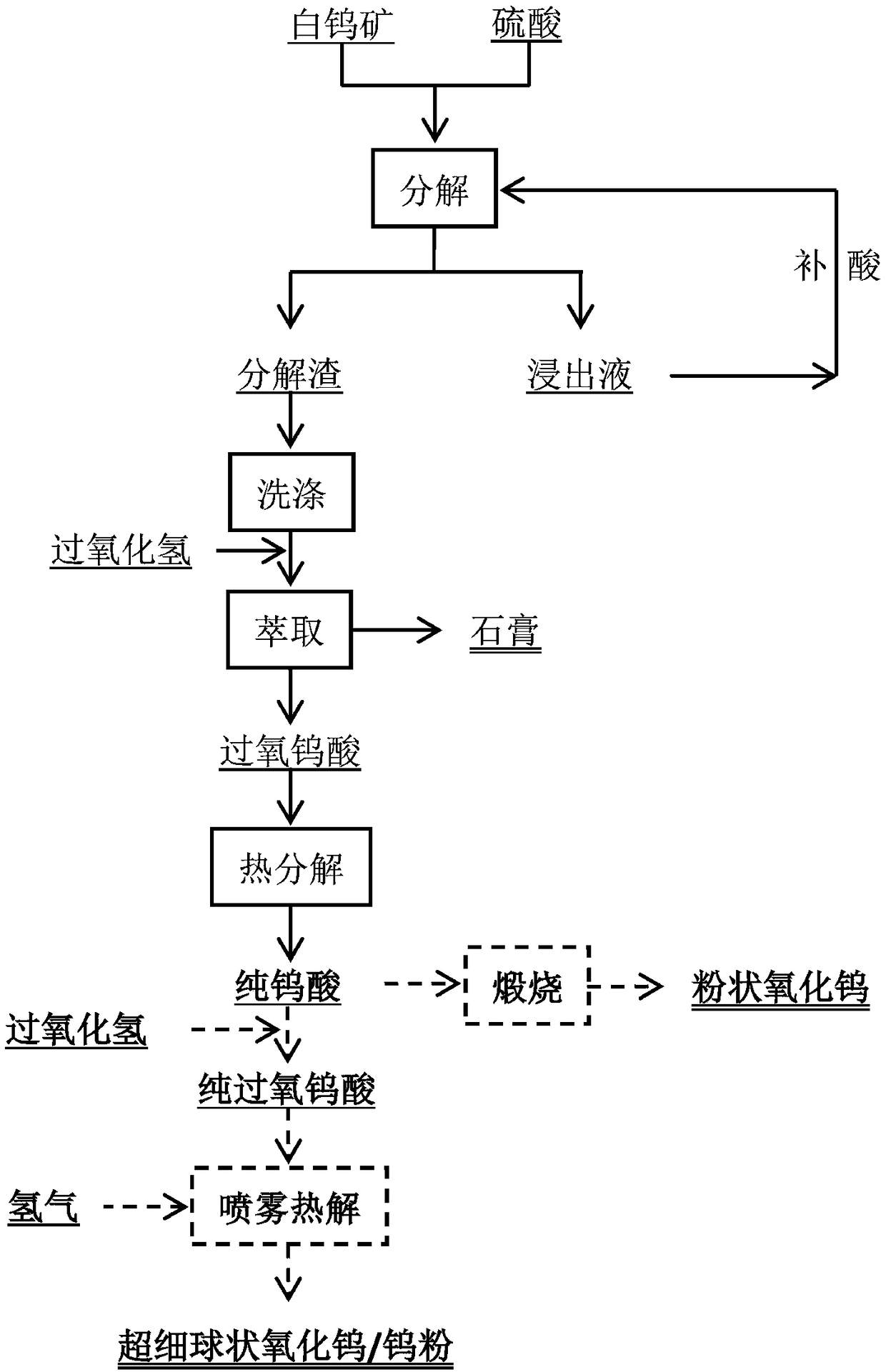

Method for preparing tungsten oxide and tungsten powder from scheelite

ActiveCN108640156AReduce break down costReduce manufacturing costTungsten oxides/hydroxidesProcess efficiency improvementDecompositionCalcination

Owner:CENT SOUTH UNIV

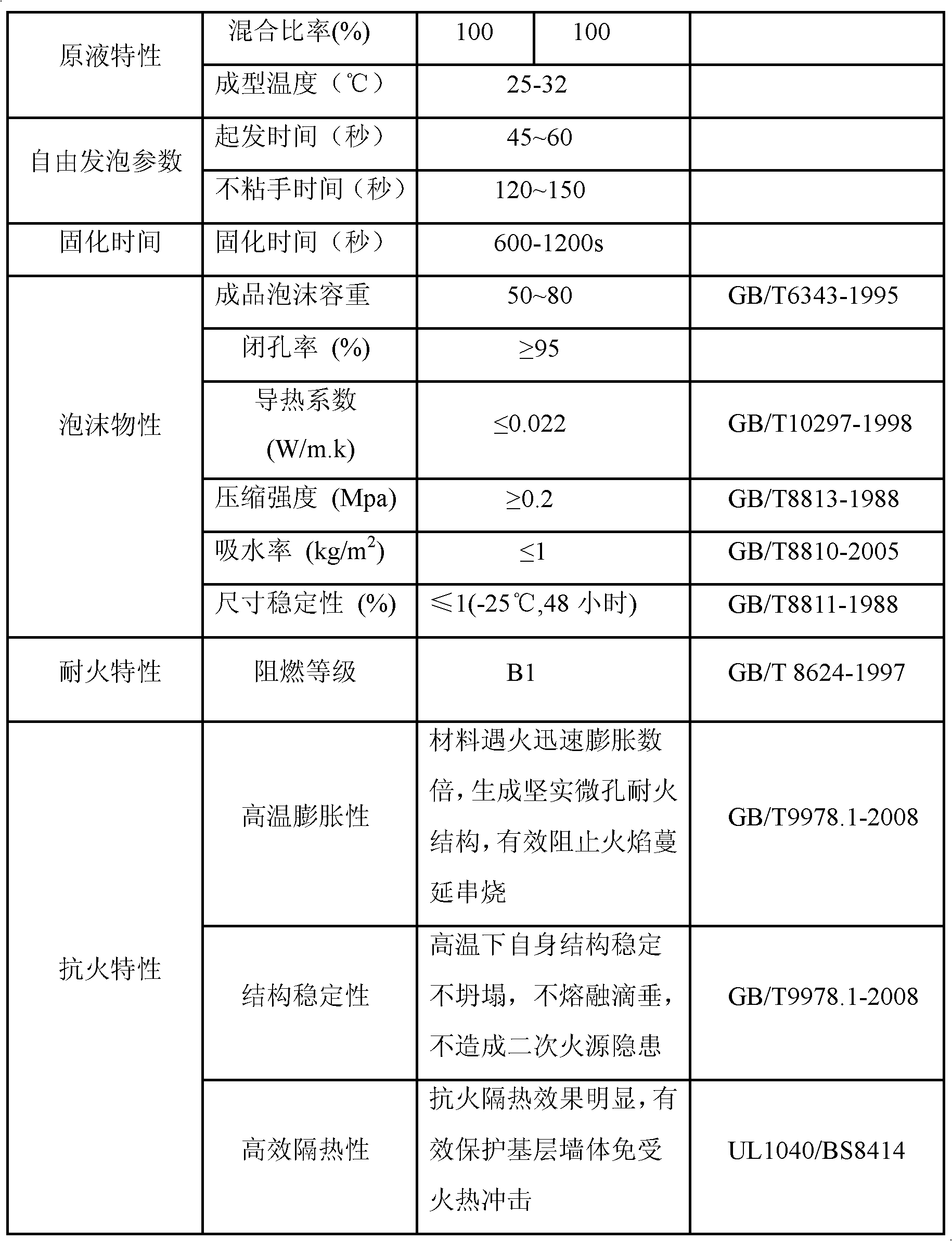

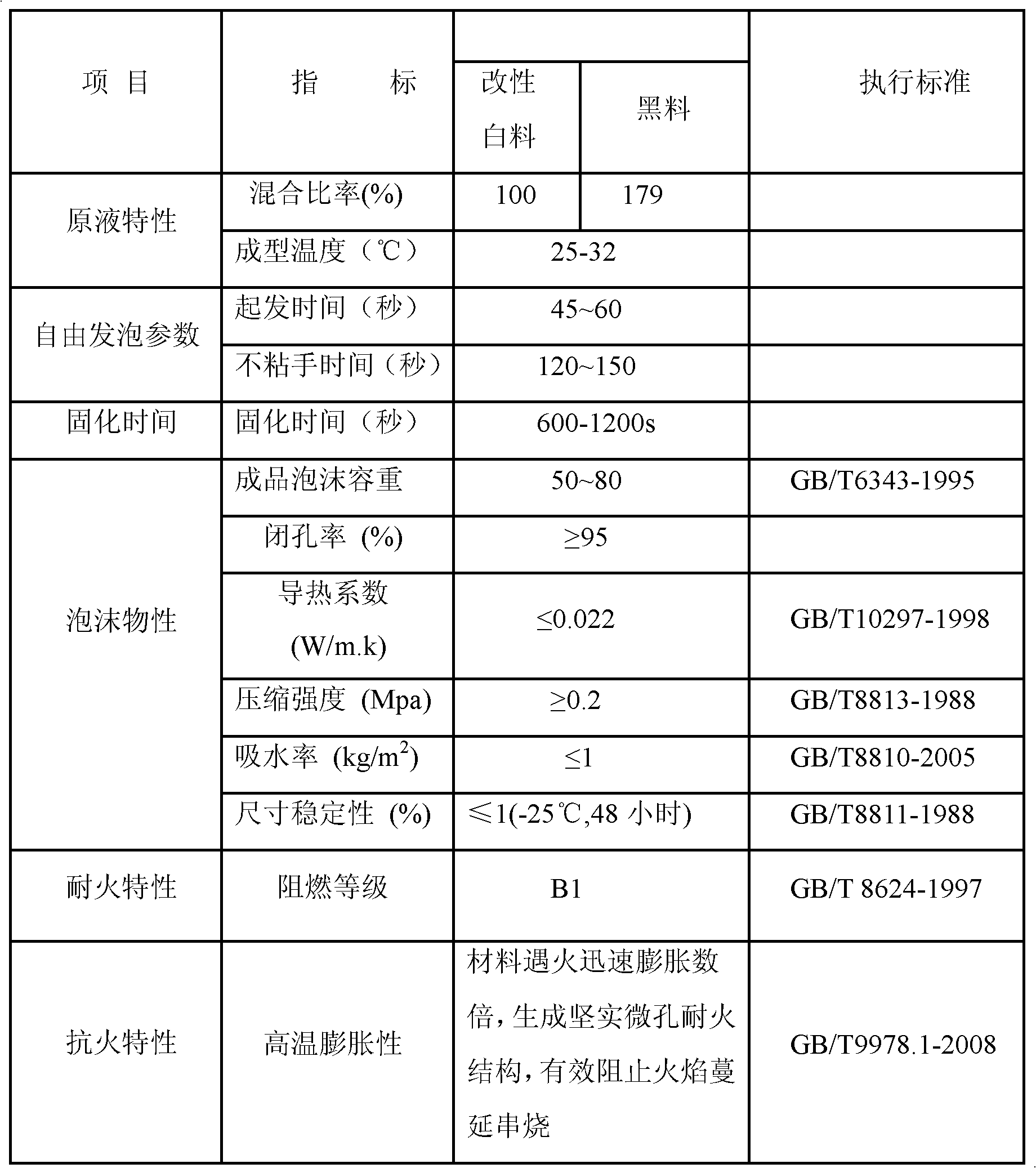

High flame-retardant rigid polyurethane foam and its preparation method

Owner:山东华德隆建材科技有限公司

Self-repairing ecological cement road material and preparation method

Owner:CHENDU NEW KELI CHEM SCI CO LTD

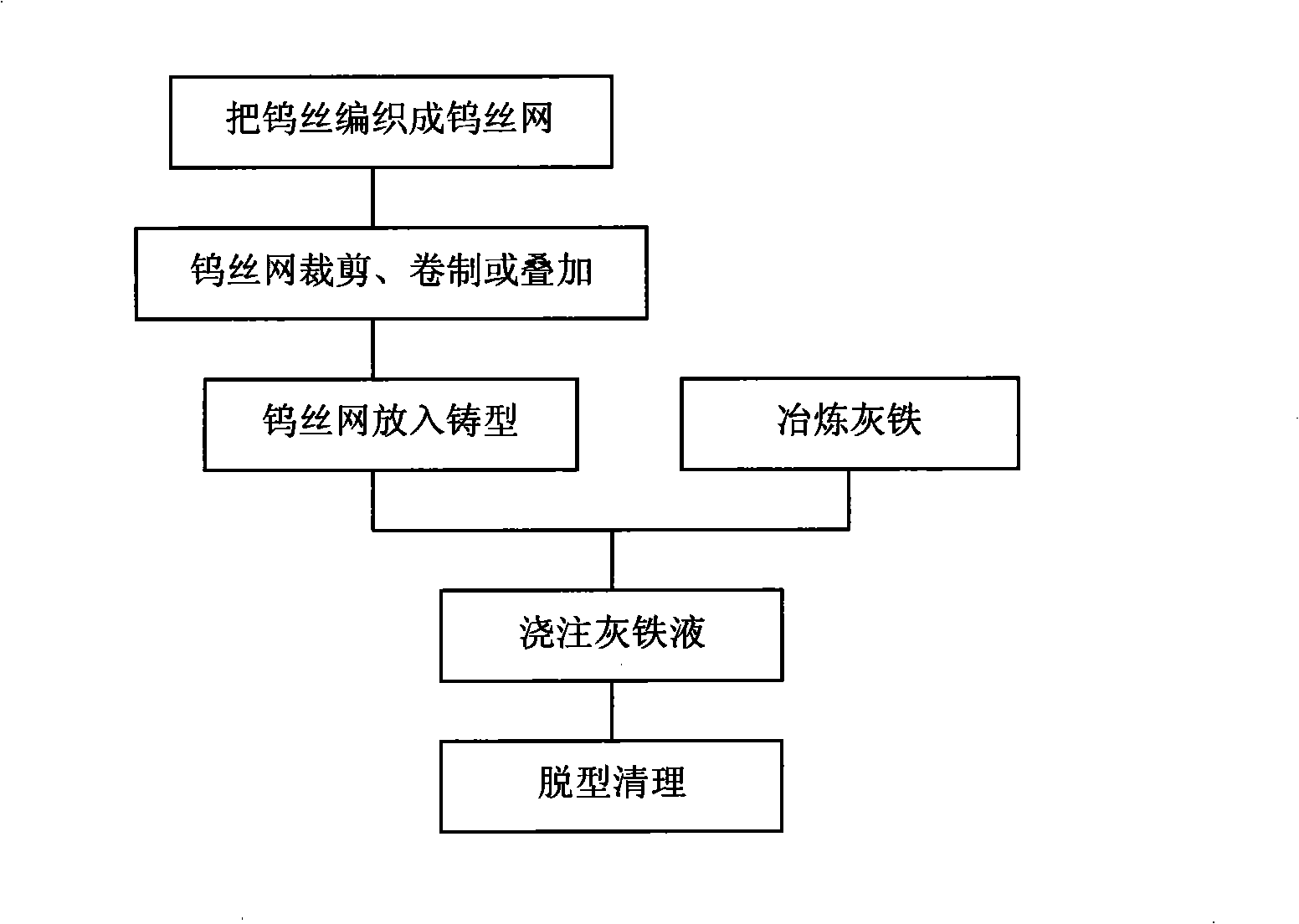

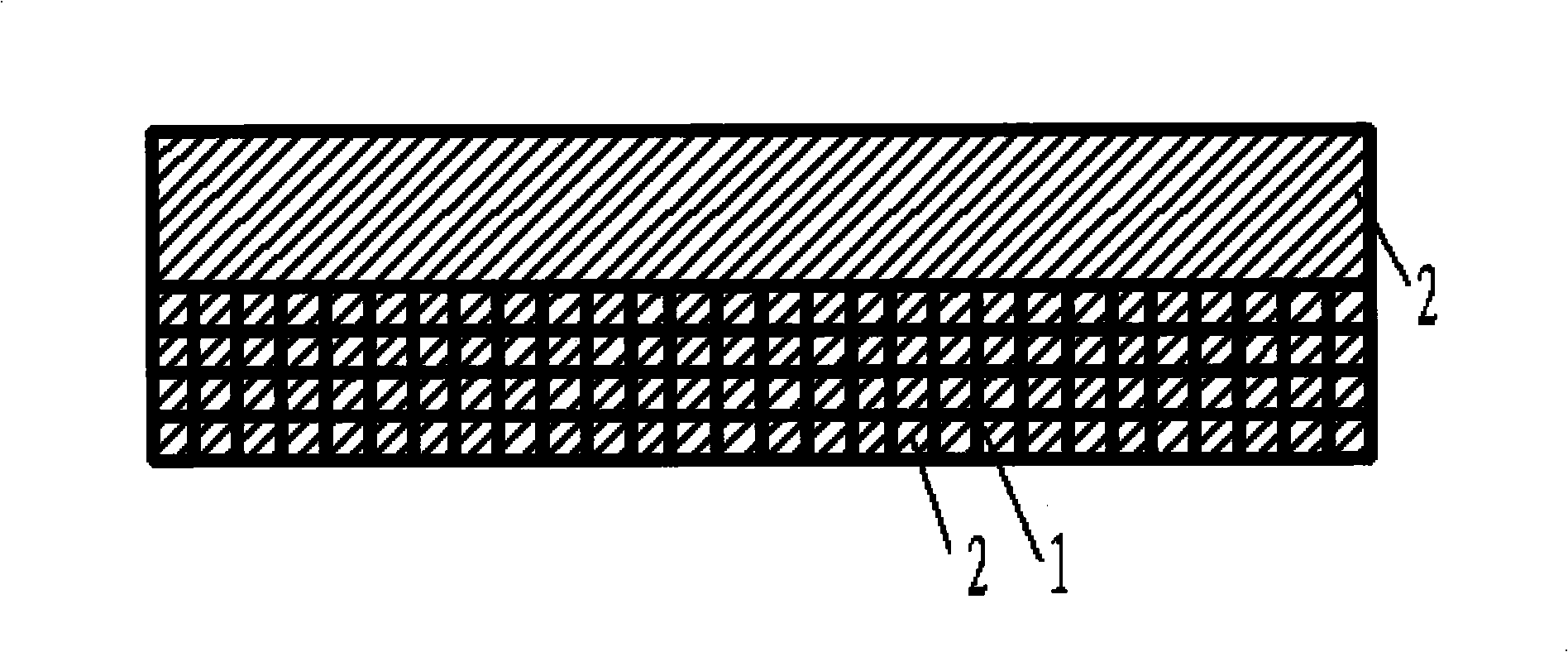

Method for preparing gray iron-base composite material for in situ production of tungsten carbide

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Cement-based fire door core

Owner:GEORGIA PACIFIC GYPSUM LLC

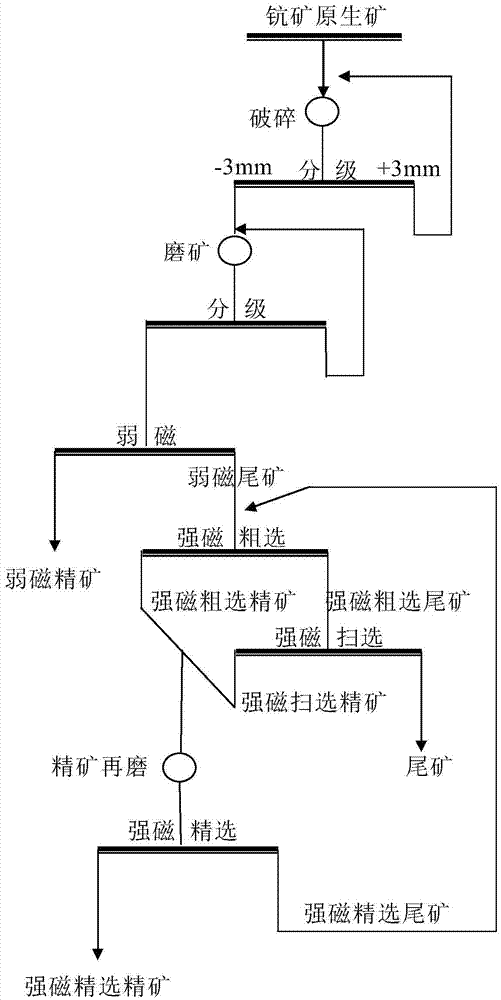

Mineral separation and enrichment method for primary scandium ore

ActiveCN105435958ASimple processEconomically reasonableMagnetic separationWet separationChemical industryEnrichment methods

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

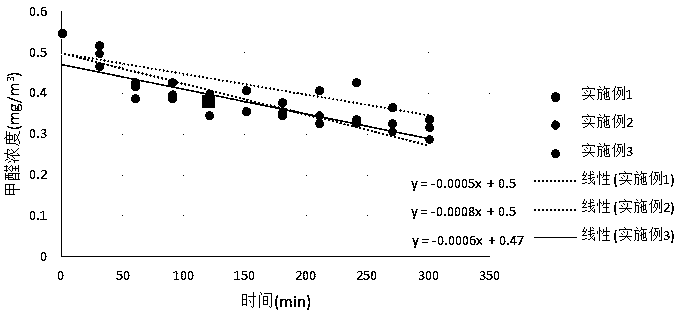

Photocatalytic concrete prepared with phosphogypsum-based hydraulic composite binding material and preparation method of photocatalytic concrete

Owner:TONGJI UNIV

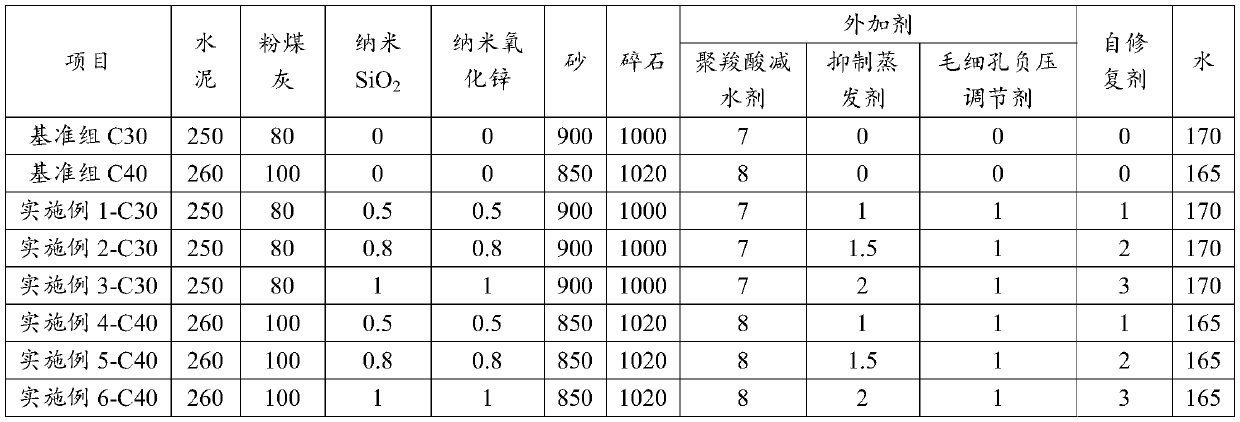

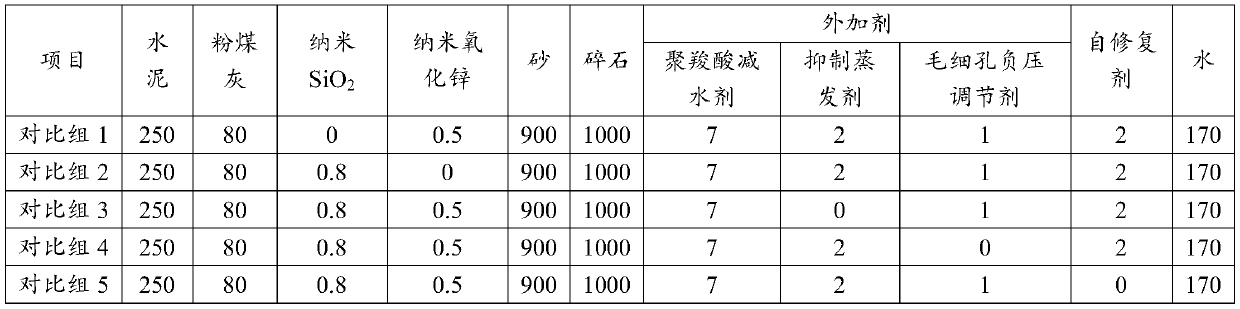

Anti-cracking impervious concrete

Owner:中建西部建设西南有限公司 +1

Preparation method of far infrared antibacterial ceramic

InactiveCN106866115AReduce manufacturing costTake advantage ofCeramic materials productionClaywaresSpray GranulationEmissivity

Owner:SICHUAN UNIV

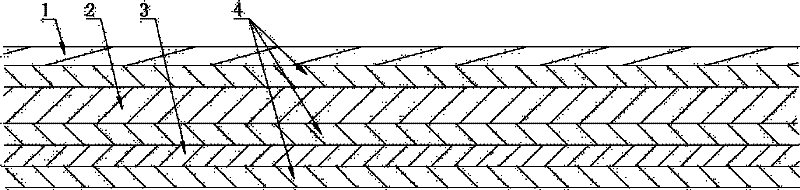

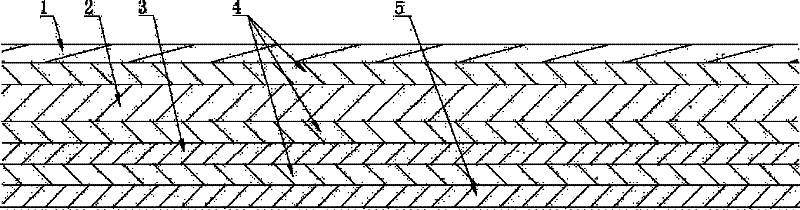

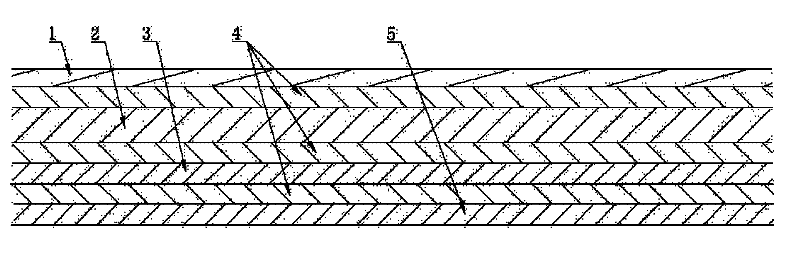

Enhanced reflective EPE thermal insulating building material

ActiveCN102444214AHigh tensile strengthHigh tear strengthHeat proofingMetal layered productsLow-density polyethylenePolymer science

Owner:ZHEJIANG PENGYUAN NEW MATERIAL TECH GRP CO LTD

Fungicidal and Parasiticidal Fire-Retardant Powder

InactiveUS20130274347A1Improve air qualityMinimizes fume emissionBiocideSolid waste managementNatural fiberFire retardant

Owner:SOLVAY SA

Municipal waste harmless recycling method with sewage cyclic utilization

InactiveCN109500049AHarmlessRealize resource processingGeneral water supply conservationSolid waste disposalRefuse-derived fuelChemical reaction

The invention relates to a municipal waste harmless recycling method with sewage cyclic utilization. Municipal waste is sorted into waste raw materials and preparation raw materials of waste derived fuel in manual sorting, magnetic sorting and mechanical sorting modes, then the preparation raw materials of the waste derived fuel obtained in the previous process are prepared into the waste derivedfuel, additionally, the raw materials are mixed with clay, limestone and iron powder and are crushed so as to be calcined in a rotary kiln to prepare raw materials for building materials, fly ash andsmoke which are generated by calcination of the rotary kiln are treated in dedusting and chemical reaction modes, and finally, denitrification, nitrification, ultrafiltration and reverse osmosis treatment are performed on sewage, so that the waste cleaning water is purified. The municipal waste is converted into the raw materials for the building materials, the municipal waste can be recycled, sothat the use rate of the municipal waste is greatly increased, and the sewage generated in a waste treatment process can be purified and reused, so that water resources are saved.

Owner:DONGGUAN UNIV OF TECH

Autoclaved aerated concrete block and preparation method thereof

Owner:HUNAN UNIV OF SCI & TECH

Thermal-insulation coating

Owner:SHANGHAI JUNXIONG INVESTMENT

Bamboo plywood and preparing method thereof

ActiveCN107310001AEasy to spreadImprove permeabilityWood treatment detailsReed/straw treatmentPolyvinyl alcoholDiluent

Owner:SHENZHEN ART DECORATION ENG CO LTD

Machining method for steel members

ActiveCN106695253AImprove production efficiencyReduce processing stepsStrutsPillarsEconomic benefitsMachining

The invention belongs to the technical field of building materials and provides a machining method for steel members. According to the method, firstly, the number of target steel members needing to be machined and required parameters are determined; then, the shapes and sizes of combined steel members are determined, and corresponding bed-jigs are prepared; main part assembling of the combined steel members and part assembling and welding are completed on the bed-jigs; and finally, according to the number of the target steel members and the required parameters, the combined steel members are cut, and then a preset number of target steel members with preset length are obtained. According to the machining method for the steel members, after a steel raw material is assembled and welded into one combined steel member, cutting is carried out, and at least two steel members with the same cross section form and the same length or different lengths are obtained. Compared with an existing machining method for independent one-by-one assembling and welding of the single steel raw material, the machining method has the beneficial effects that the machining procedures are reduced, the manufacturing efficiency of the steel members is greatly improved, the cost is reduced easily, and the considerable economic benefits are created.

Owner:CHINA CONSTR STEEL STRUCTURE GUANGDONG CO LTD +1

Micro-nano bubble water, preparation method thereof and mortar composition

ActiveCN114538816AExtended retention timeImprove stabilitySustainable biological treatmentMicro nanoEnvironmental engineering

The invention relates to the technical field of building materials, and particularly discloses micro-nano bubble water, a preparation method of the micro-nano bubble water and a mortar composition.The particle size of micro-nano bubbles in the micro-nano bubble water ranges from 100 nm to 1000 nm, and D10 of the micro-nano bubbles in the micro-nano bubble water ranges from 150 nm to 200 nm, D50 of the micro-nano bubbles in the micro-nano bubble water ranges from 250 nm to 400 nm, and D90 of the micro-nano bubbles in the micro-nano bubble water ranges from 700 nm to 800 nm; the preparation method of the micro-nano bubble water comprises the steps that when aeration gas is introduced into water for circulation, the amount of the aeration gas is 8-15 L / min, and the aeration time is 5-15 min. The invention further discloses a mortar composition which comprises the micro-nano bubble water, and the mortar composition has the advantages that the retention time of micro-nano bubbles is prolonged, and then the stability of the micro-nano bubble water is improved.

Owner:CHINA CONSTR WESTERN CONSTR NORTH CO LTD

Waterproof, sun-proof and heat-insulating building material protection brick and preparation method thereof

InactiveCN111072338ACeramic shaping apparatusRoof covering insulationsBuilding materialHeat conservation

Owner:深圳市汇海鑫科技有限公司

Soil modifier, and preparation and application method thereof

Owner:安徽红太阳新材料有限公司

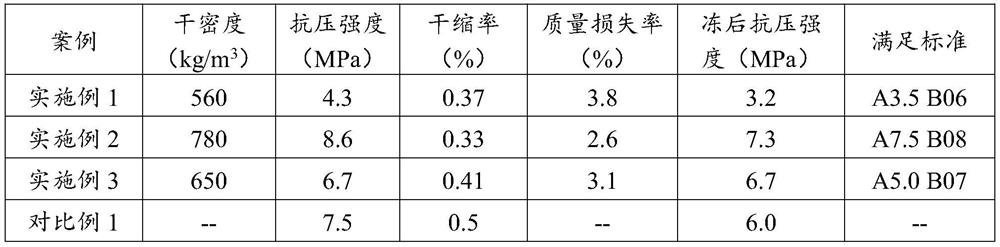

Ultra-fine fly ash light self-insulation wall plate and manufacturing method thereof

InactiveCN107780590ALow refractorinessReduce weightCeramic shaping plantsBuilding componentsAir separationUltra fine

Owner:SHANXI HUATONG LANTIAN ENVIRONMENTAL PROTECTION

Preparation method of modified pitchstone-based thermal insulation mortar

InactiveCN110282929AImprove insulation effectImprove crack resistanceCrack resistanceThermal insulation

Owner:含山县领创新材料科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap