Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35 results about "Silica fume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silica fume, also known as microsilica, (CAS number 69012-64-2, EINECS number 273-761-1) is an amorphous (non-crystalline) polymorph of silicon dioxide, silica. It is an ultrafine powder collected as a by-product of the silicon and ferrosilicon alloy production and consists of spherical particles with an average particle diameter of 150 nm. The main field of application is as pozzolanic material for high performance concrete.

Castable for blast-furnace tapping channel and preparation method thereof

Owner:JIANGSU REFUTA NEW MATERIALS CO LTD

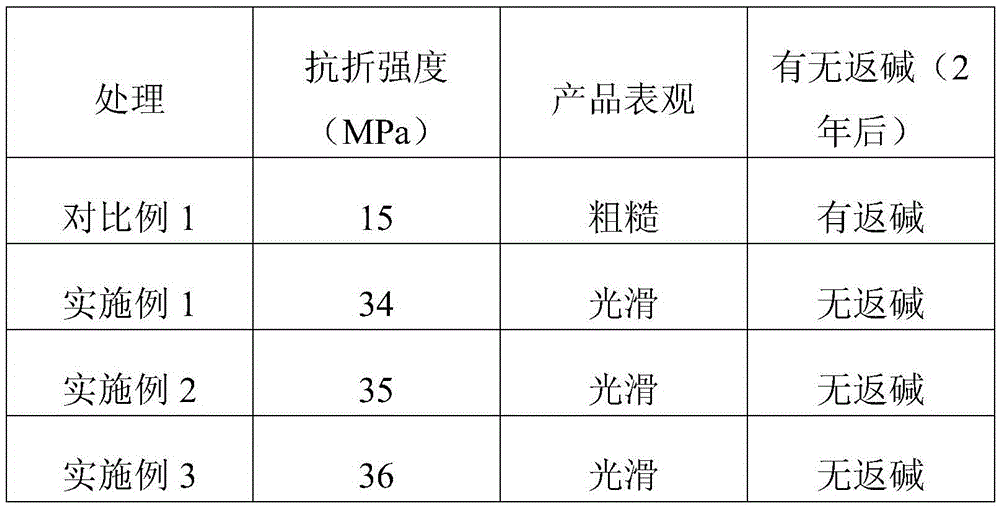

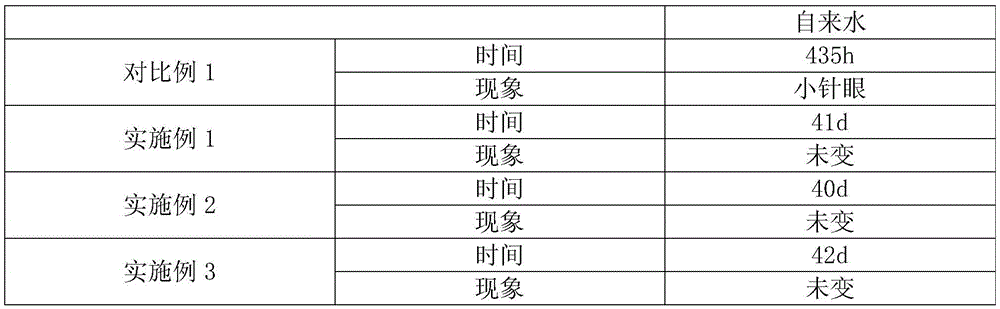

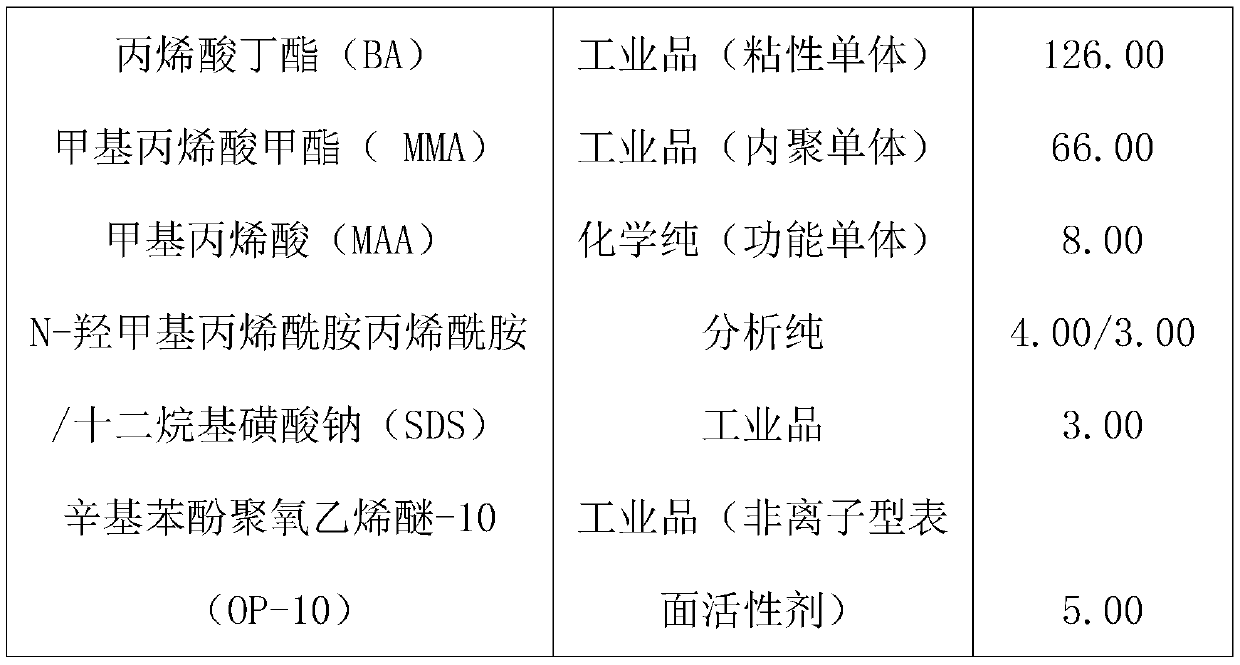

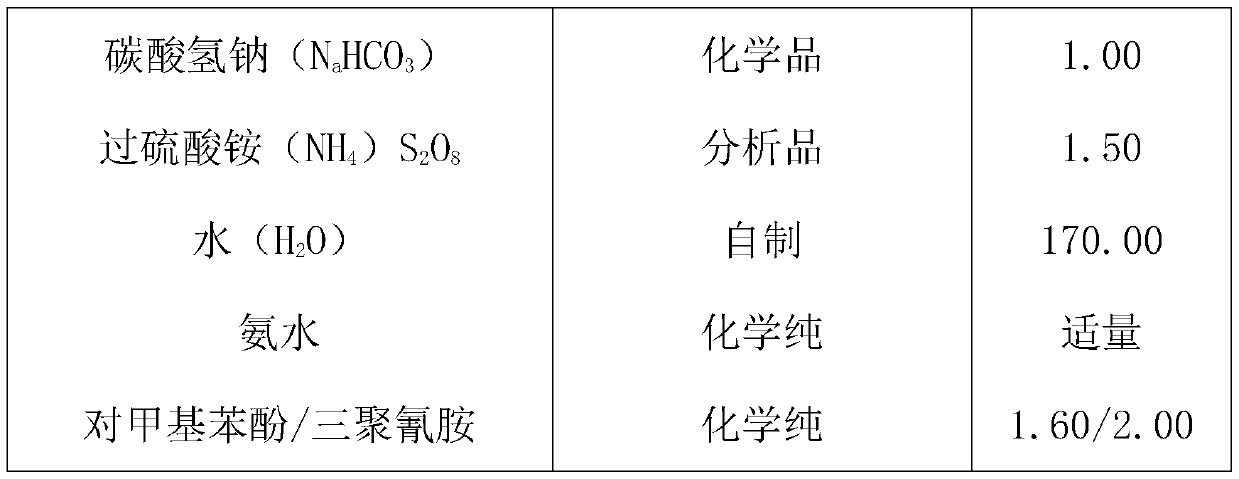

Saltpetering-prevention sulphoaluminate cement product and preparation method thereof

Owner:ZHUODA NEW MATERIALS TECH GRP WEIHAI CO LTD

Refractory composition for pure hydrogen atmosphere high temperature furnace

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

Foaming-ceramic heat insulating board and preparing method thereof

InactiveCN105503238ALow thermal conductivityHigh compressive and flexural strengthCeramicwarePorosityPotassium

Owner:韩功篑

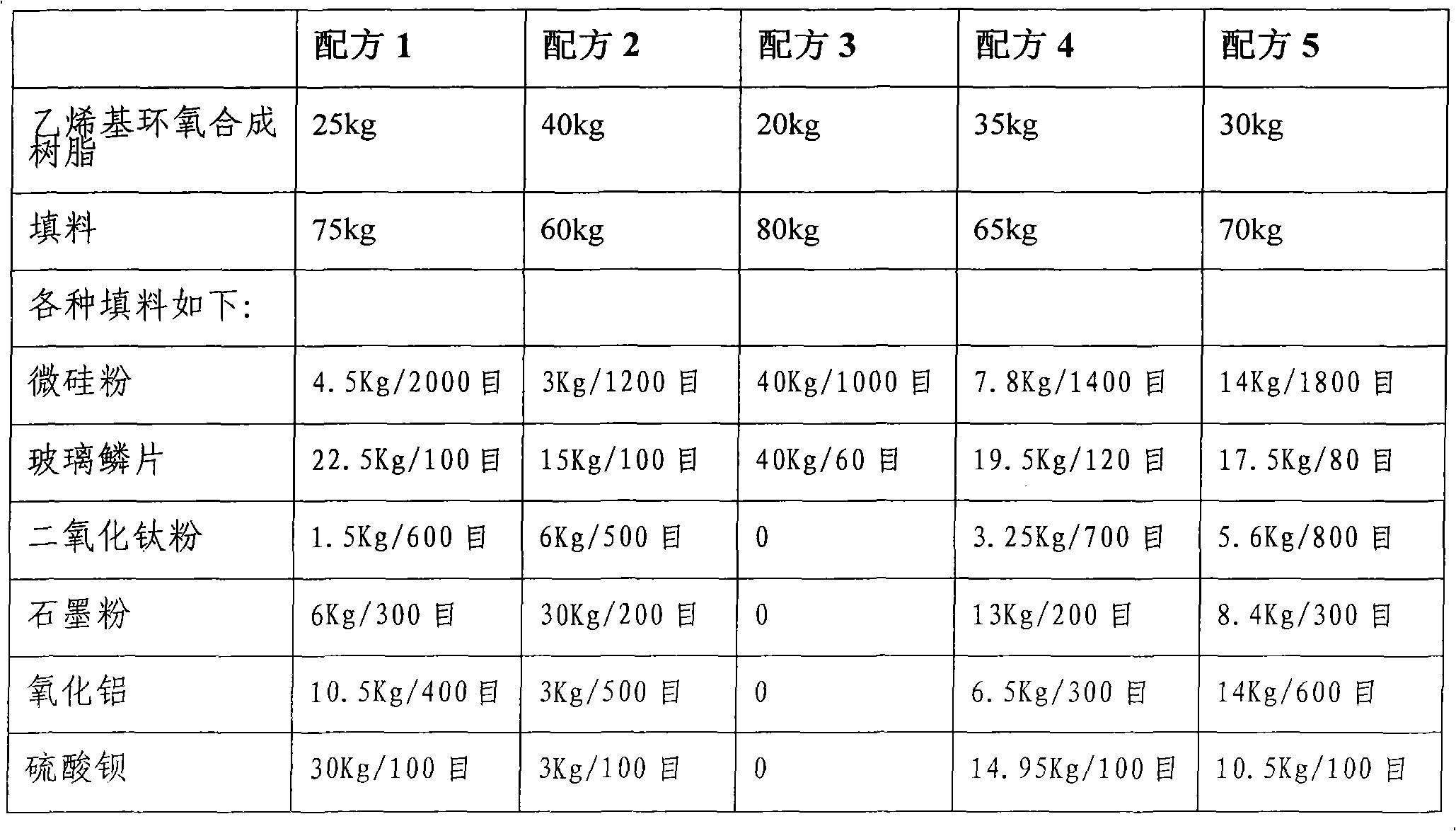

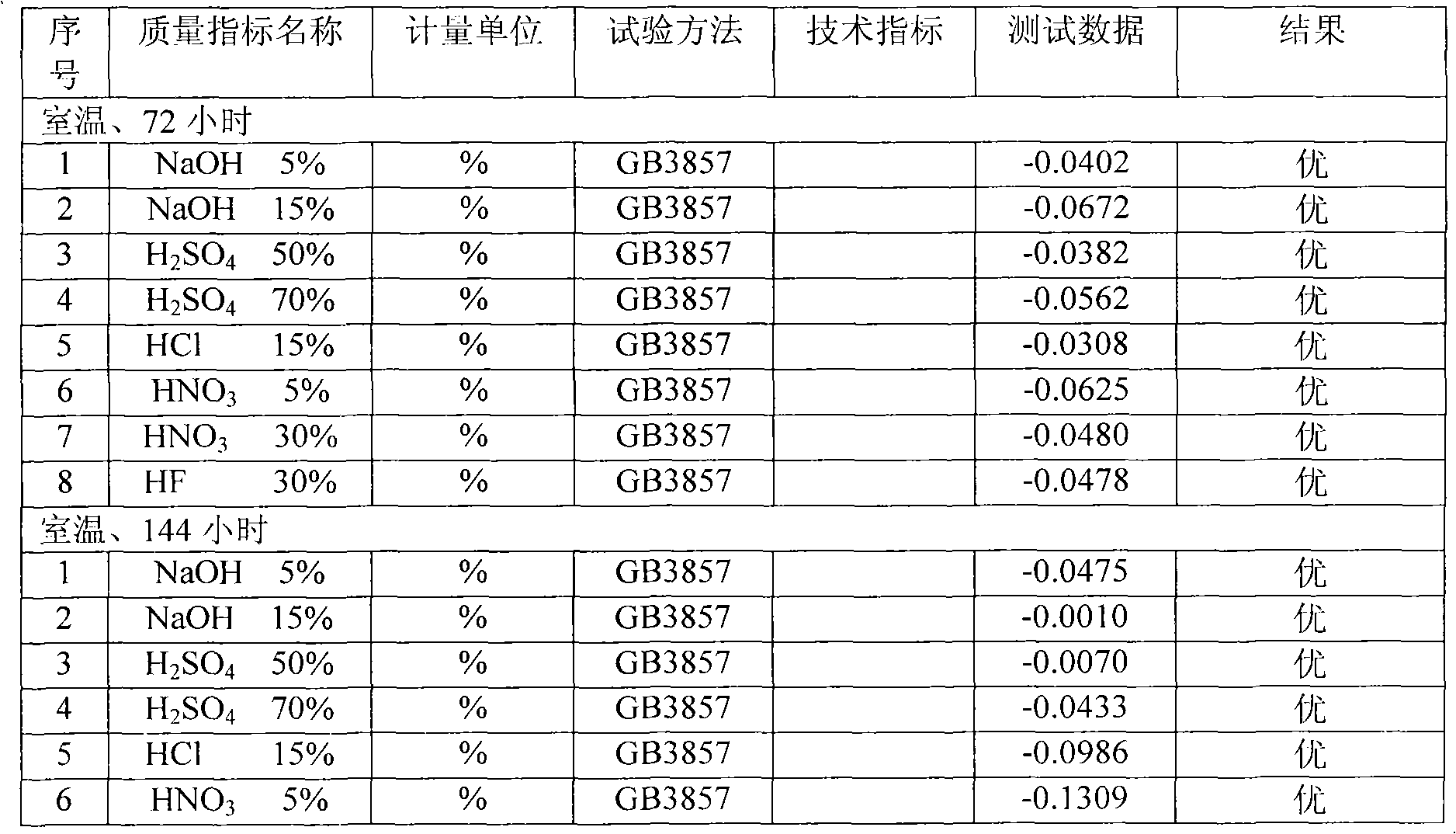

Coating material for sealing coal wall of gob-side coal roadway

Owner:SHANDONG UNIV OF SCI & TECH

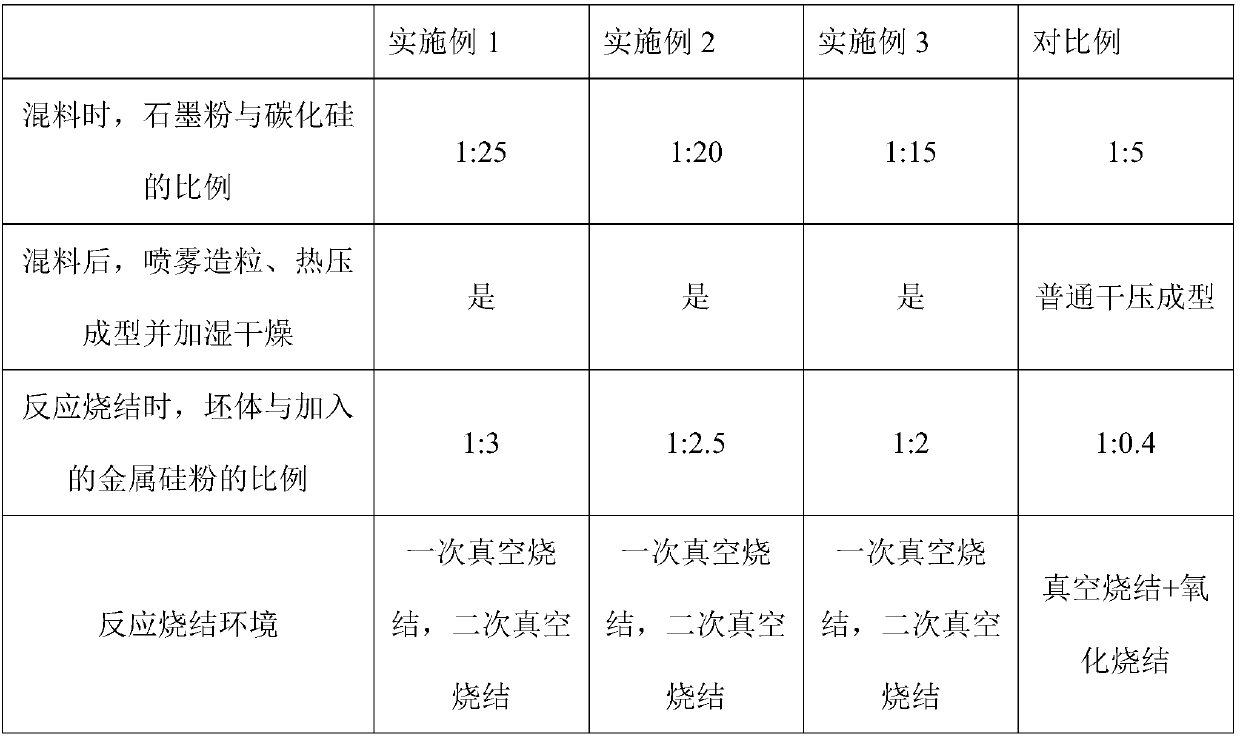

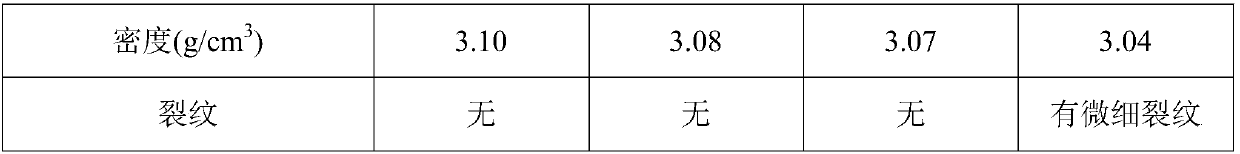

Preparation method of large-sized compact silicon carbide ceramic plate

Owner:WEIFANG HUAMEI FINE TECHN CERAMICS

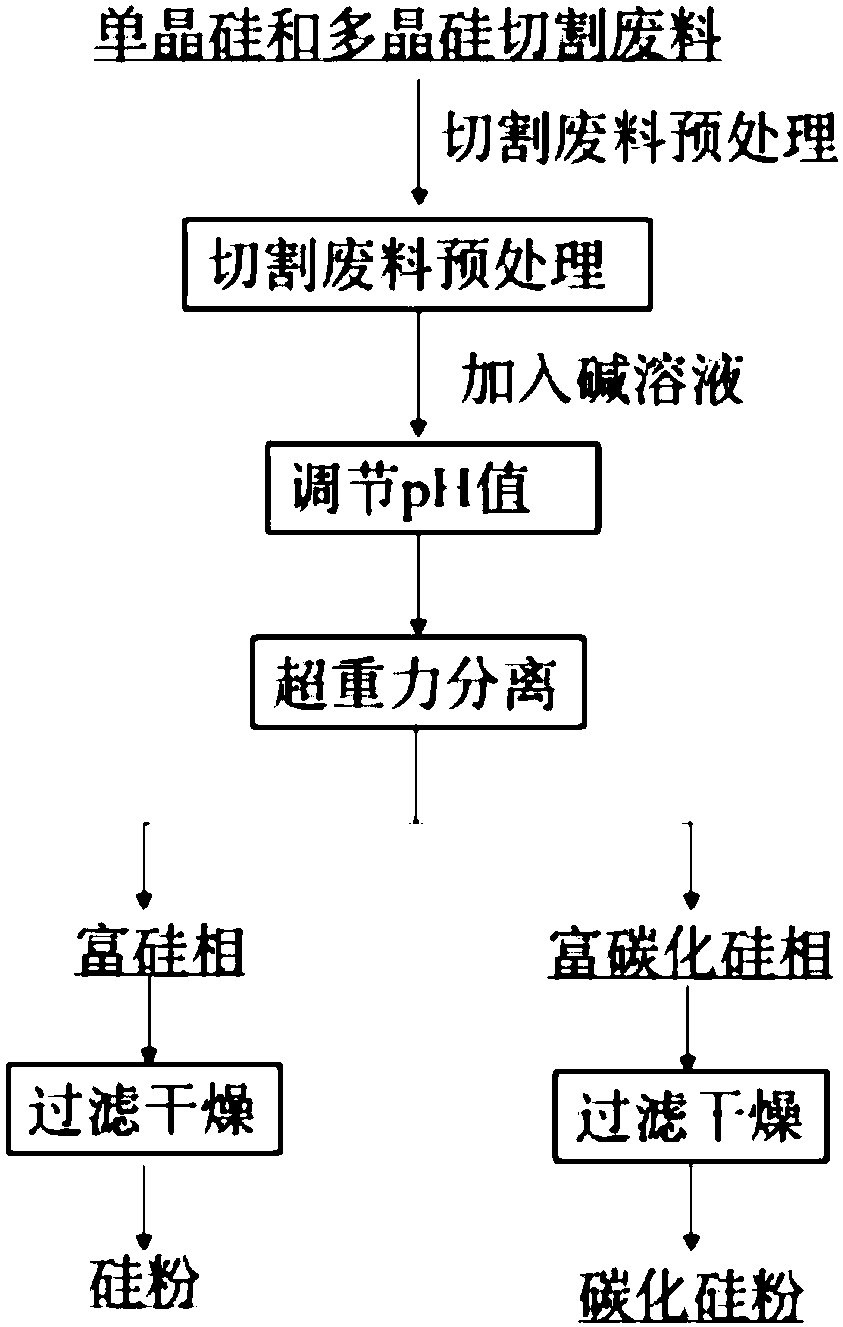

Method for recycling silicon powder from crystalline silicon cutting waste

Owner:CHINA ENFI ENGINEERING CORPORATION

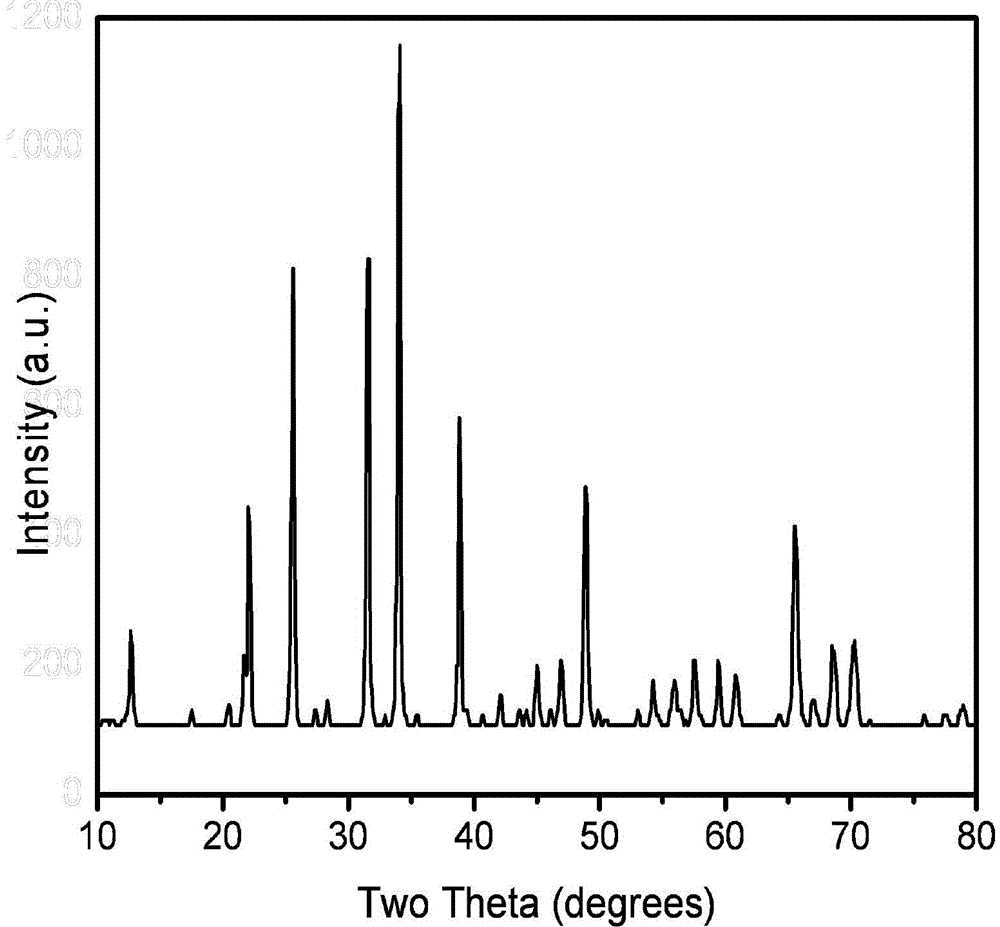

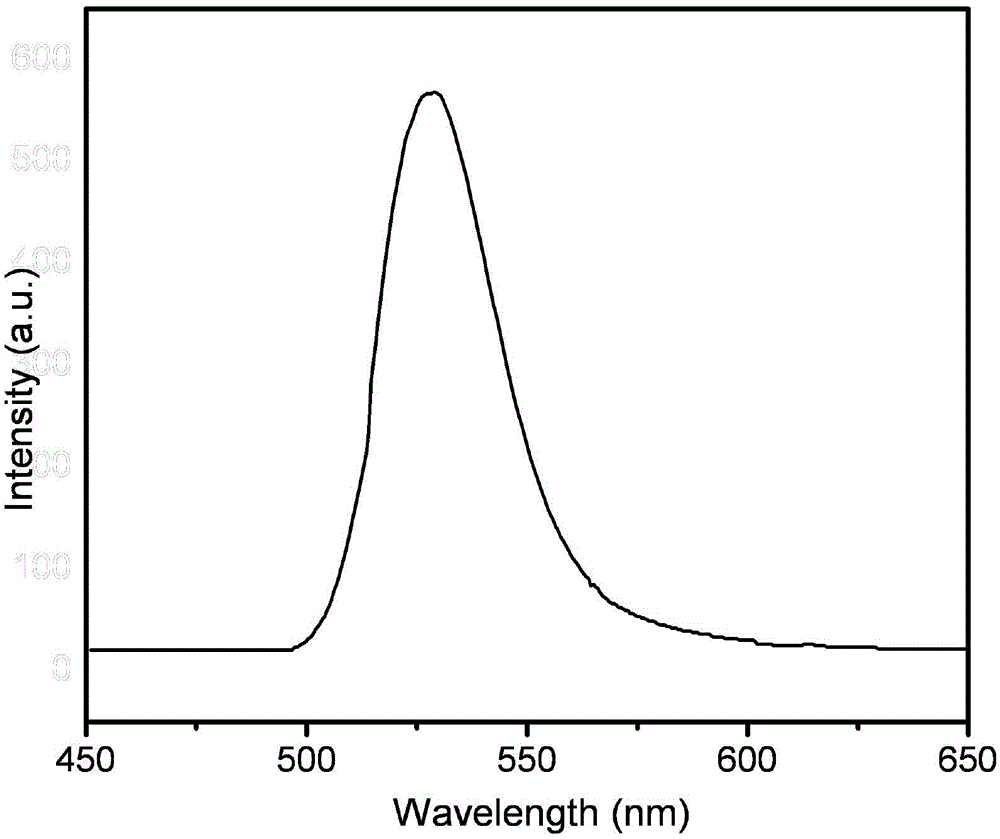

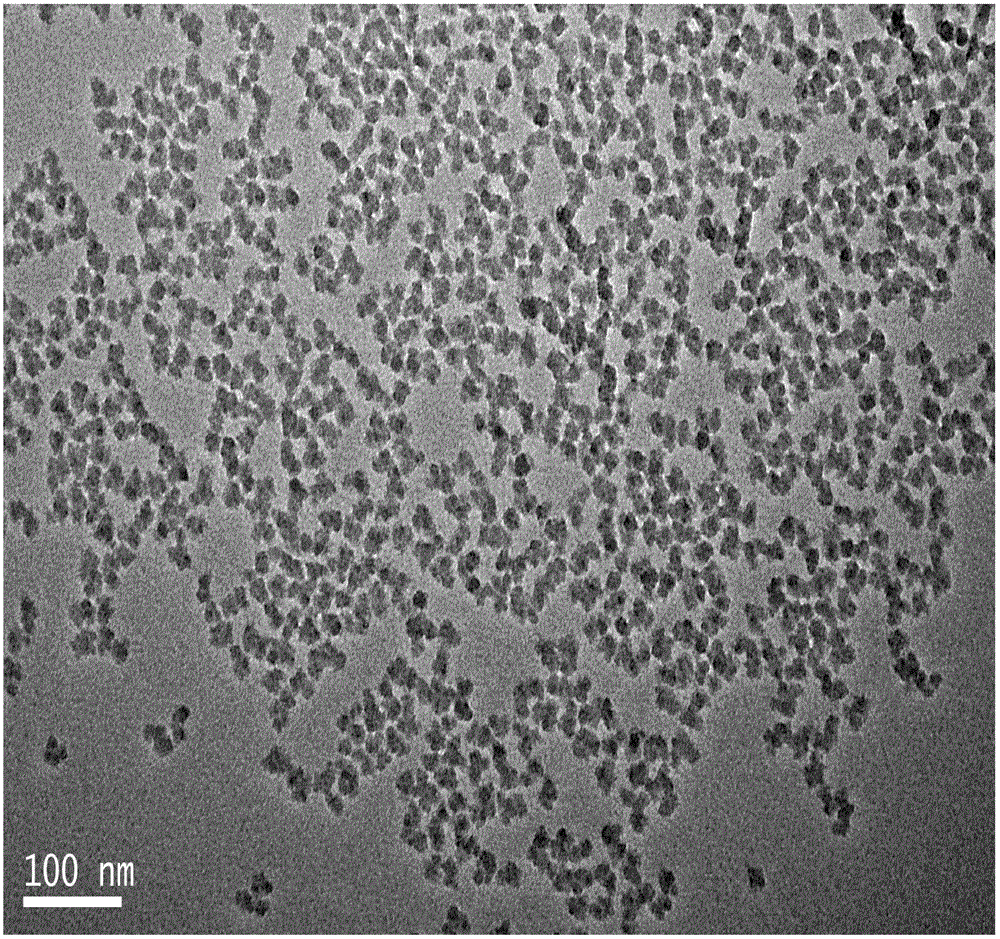

Method of synthesizing nano zinc silicate light emitting material by using waste silicon powder by hydrothermal method

InactiveCN104087289ATo achieve the purpose of resource recyclingSimple methodLuminescent compositionsPolytetrafluoroethyleneMaterials science

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

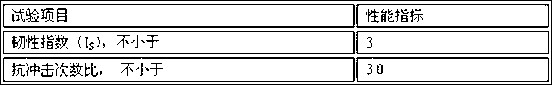

Concrete anti-seismic impact-resistant anti-cracking agent

Owner:上海武冠新材料有限公司

Multiwall carbon nanotube cement-based composite material and preparation method thereof

The invention relates to a multiwall carbon nanotube cement-based composite material and a preparation method thereof. The composite material is prepared from the following raw materials in parts by weight: 0.4 to 0.7 part of surfactant, 10 to 20 parts of ethanol, 0.05 to 0.15 part of multiwall carbon nanotubes, 1.5 to 1.8 parts of nano silicon dioxide, 100 parts of cement gelling material, 10 to20 parts of silica fume, 300 to 400 parts of standard sand, and 40 to 60 parts of water. The multiwall carbon nanotube is added into the cement-based composite material, so that the composite materialis low in porosity, small in average aperture, and compact in structure, thereby improving the mechanical performance of the material. By virtue of determination, the pressure resistant strength is increased by 11.6 to 20.99 percent, so that the service life of a building is effectively prolonged. The method disclosed by the invention is simple and easy in operation, controllable in cost, capableof solving the agglomeration problem of the multiwall carbon nanotube, and capable of preventing the secondary agglomeration of the multiwall carbon nanotube in the cement-based composite material. In the current construction process of smart cities and green cities, the multiwall carbon nanotube cement-based composite material have wide market prospect and application value.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

Solid waste-based baking-free environment-friendly hollow brick and preparation method thereof

Owner:SHANDONG UNIV +1

Composite material for ceramic sealing ring and preparation method thereof

Owner:HARBIN XINHUI SPECIAL CERAMIC

Baking-free pavior brick and preparation method thereof

Owner:合肥聪亨新型建材科技有限公司

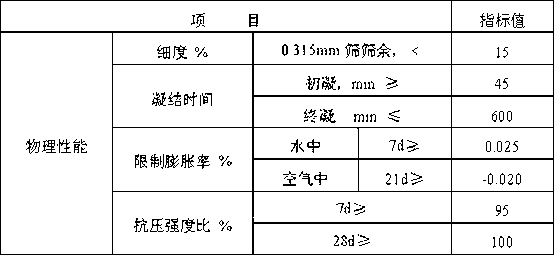

Shield grouting material and preparation method thereof

Owner:北京华阳众信建材有限公司

System for recycling silicon powder in polycrystalline silicon reduction tail gas and method thereof

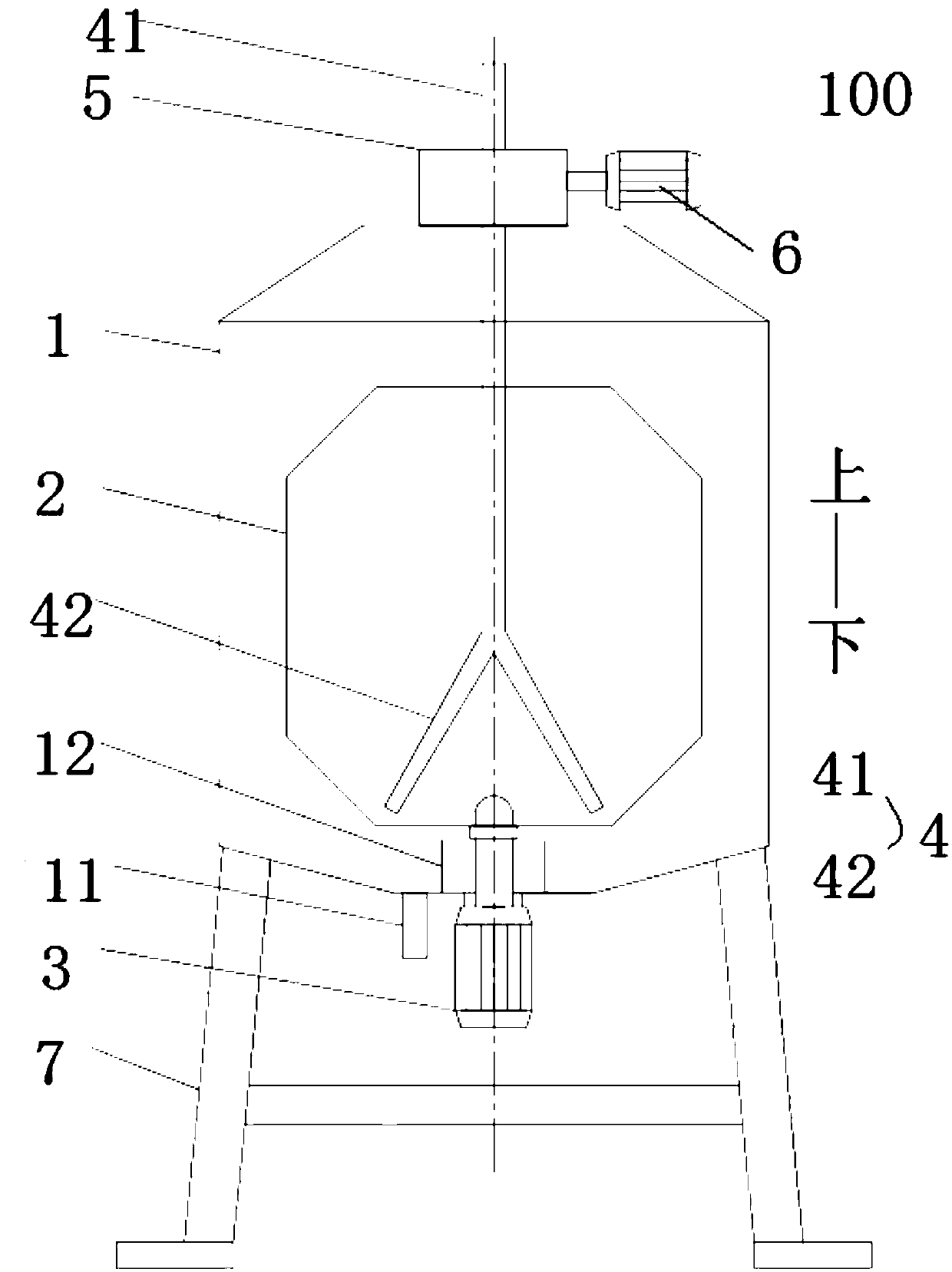

InactiveCN111661827AHigh activityReduced activityNitrogen compoundsHalogenated silanesSlagSolid content

The invention discloses a system for recycling silicon powder in polycrystalline silicon reduction tail gas and a method thereof, the recycling system comprises a main filter and a residual liquid filter which are connected in sequence, a silicon powder outlet of the residual liquid filter is connected with a nitriding furnace, and an outlet of the nitriding furnace is connected with a grinder. Through cooperative filtering of the main filter and the residual liquid filter, the solid content of drying liquid in the residual liquid filter is increased, drying energy consumption can be reduced,and the drying effect can be enhanced. Compared with an existing silicon slag recovery method, the method has the advantages that the separated silicon powder basically has no silane residue on the surface, is high in activity, can be directly fed into a nitriding furnace to be used for manufacturing silicon nitride powder, and is high in recycling value. The method is low in energy consumption and good in drying effect, the silicon powder discharged out of the filter is high in activity and can be directly recycled, meanwhile, the silicon powder with low value is changed into a silicon nitride product with higher additional value, and the economic value of polycrystalline silicon reduction reaction byproducts is increased.

Owner:SICHUAN YONGXIANG POLY SILICON

Method for preparing silicon alloy with waste silicon sludge

Owner:常州赛蓝微粉科技有限公司

Preparation method of silicon tube sputtering target material

ActiveCN112410737ASelf-strength is goodHigh hardnessSiliconVacuum evaporation coatingSputteringUltrasound device

Owner:光洋新材料科技(昆山)有限公司

Low-volume-weight iron tailing powder reactive powder concrete and preparation method thereof

Owner:SHENYANG POLYTECHNIC UNIV +1

Fiber-reinforced high-strength foam concrete as well as preparation method and application thereof

Owner:SICHUAN CHINA STRUCTURE RESIDENTIAL IND

Manufacturing method of high-performance marine concrete

Owner:NANTONG ZHONGRUN CONCRETE

Non-crystallization concrete accelerator

A non-crystalline concrete quick-setting agent, the main component is clinker made by mixing bauxite, soda ash and quicklime, and adding 55‑60 parts of acrylic acid copolymer, 5‑15 parts of nitric acid, and 15 parts of silicon powder 20 parts, polyethyleneimine 5-10 parts, malonic acid 1-5 parts. Described acrylic acid copolymer is preferably 57 parts. Compared with the prior art, the present invention has the beneficial effects that: the present invention makes the quick-setting agent have a good effect by adding acrylic acid copolymer, nitric acid, silicon powder and polyethyleneimine.

Owner:SHENYANG CHUANGDA TECH TRADE MARKET

Ultra-high performance concrete containing metakaolin and preparation method of ultra-high performance concrete

Owner:TONGJI UNIV

Concrete

Owner:HUIZHOU HAIHONG CEMENT PROD CO LTD

Acidic lithium slag-Portland cement-silica fume composite cementing material and preparation method thereof

ActiveCN110877970AImprove flexural performanceAccurate control of densityCeramicwareFoaming agentSludge

The invention discloses an acidic lithium slag-Portland cement-silica fume composite cementing material. The composite cementing material comprises Portland cement, acidic lithium slag, silica fume, agraphene material, iron tailings and a light filler. The invention further discloses a preparation method of the composite cementing material. The preparation method comprises the following steps: taking and uniformly mixing fly ash, 15-25 parts by weight of sludge, oyster shell powder, clay, water and fusible foaming particles, granulating the obtained mixture, and firing the granulated mixtureto obtain the light filler; mixing the Portland cement with silica fume, and grinding the obtained mixture to obtain a first ground product; respectively grinding the acidic lithium slag, the graphenematerial and the iron tailings; mixing the first ground product, the acidic lithium slag powder, the graphene powder and the iron tailing powder to obtain a second ground product; and uniformly mixing the second ground product with the light filler to obtain the finished cementing material product. A foaming agent is not used, the density of the material is controlled by utilizing the light filler, and the material density can be accurately controlled, so that the quality of the finished product is improved.

Owner:HUNAN LVSHENG TECH DEV CO LTD

Light-weight middle-high pressure mold and preparation method thereof

ActiveCN112142408AAffect productionAvoid deformationCeramic shaping apparatusPortland cementWater reducer

Owner:JOMOO KITCHEN & BATHROOM

Ceramic steel material

Owner:HUZHOU ZHIWEI TECHNICAL SERVICE CO LTD

Fireproof door core plate and production method thereof

InactiveCN106517989AImprove compatibilityImprove fire resistanceCeramicwarePhosphoric acidFire retardant

Owner:雅安市晶强板业有限公司

Non-flowable quick-setting phosphate cement repair material with strong cohesive forces and preparation method thereof

ActiveUS11339092B2Quick SetupImprove crack resistanceSolid waste managementCarboxylic acidP phosphate

The present invention belongs to the field of composite materials, and particularly to a non-flowable quick-setting phosphate cement repair material with strong cohesive forces and the preparation method thereof. The material comprises the following raw materials in percentage by weight: 20% to 40% of sand, 5% to 12% of ammonium dihydrogen phosphate, 10% to 25% of magnesium oxide, 2% to 8% of fly ash, 30% to 60% of rubber powder, 6% to 10% of silica fume, 0.35% to 0.6% of a polycarboxylate high efficiency water-reducing agent, 1% to 5% of sodium silicate, 1.5% to 2% of a polypropylene fiber, 0.5% to 2% of a retarder, and 8% to 10% of water. The material is used as the repair material for the special positions of bottom boards of bridges or facades of buildings which are damaged, and the repair effect thereof is remarkable.

Owner:YU JIAHUAN +1

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap