Concrete

A technology of concrete and metakaolin, which is applied in the field of concrete, can solve the problems of high cost and complex processing technology, and achieve the effects of reasonable formula, improved economic benefits, and reduced overall construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

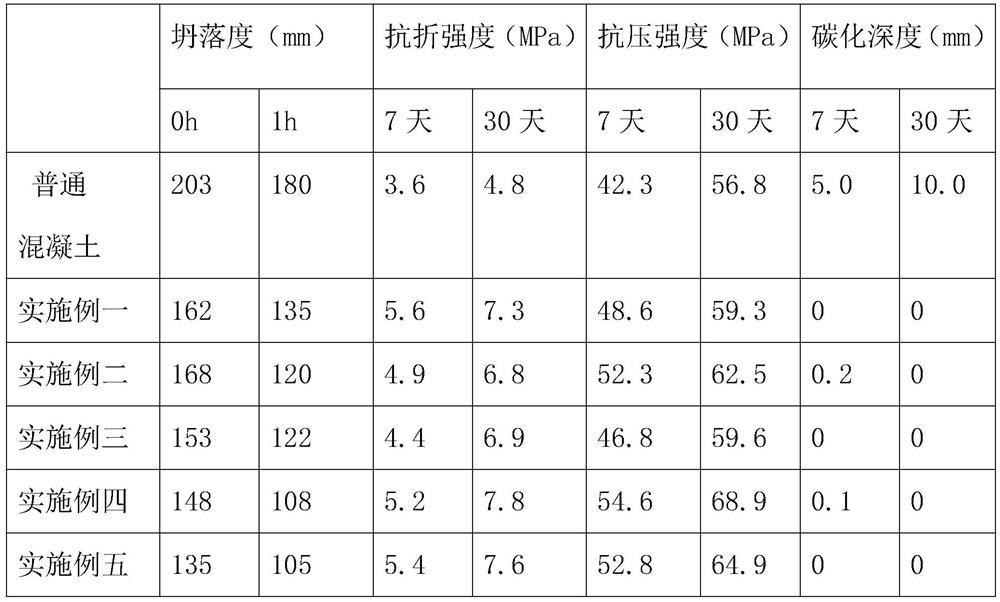

Examples

Embodiment 1

[0021] A concrete, comprising the following raw materials by weight: 30 parts of geopolymers, 10 parts of activation solution, 30 parts of artificial bones, 30 parts of eggshells, 5 parts of sea sand, 5 parts of silicon powder, 3 parts of graphene powder, and pulverized coal 10 parts of ash, 10 parts of concrete strengthener and water. The processing method is S1. First, raw materials are prepared, and geopolymer is preheated; S2, artificial bone and eggshell are ground into granules for use; S3, geopolymer, artificial bone and eggshell mixture, sea sand , silicon powder, graphene powder, fly ash and concrete additives are sequentially added into the mixing tank for mixing and stirring; the particle size of the artificial bone and eggshell mixture in S2 is 3 mm. The stirring time in S3 was 1 hour. The concrete additive in S3 is a mixture of water reducer, retarder, air-entraining agent and thickener S4, finally adding activation liquid and water for uniform stirring.

Embodiment 2

[0023] A concrete, comprising the following raw materials by weight: 35 parts of geopolymers, 15 parts of activation solution, 35 parts of artificial bones, 35 parts of eggshells, 6 parts of sea sand, 6 parts of silicon powder, 4 parts of graphene powder, and pulverized coal 12 parts of ash, 13 parts of concrete strengthener and water. The processing method is S1. First, raw materials are prepared, and geopolymer is preheated; S2, artificial bone and eggshell are ground into granules for use; S3, geopolymer, artificial bone and eggshell mixture, sea sand , silicon powder, graphene powder, fly ash and concrete additives are sequentially added into the mixing tank to mix and stir evenly; the particle size of the artificial bone and eggshell mixture in S2 is 4 mm. The stirring time in S3 was 1.5 hours. The concrete additive in S3 is a mixture of water reducer, retarder, air-entraining agent and thickener S4, finally adding activation liquid and water for uniform stirring.

Embodiment 3

[0025] A concrete, comprising the following raw materials by weight: 40 parts of geopolymers, 20 parts of activation solution, 40 parts of artificial bones, 40 parts of eggshells, 8 parts of sea sand, 8 parts of silicon powder, 4 parts of graphene powder, and pulverized coal 15 parts of ash, 20 parts of concrete strengthener and water. The processing method is S1. First, raw materials are prepared, and geopolymer is preheated; S2, artificial bone and eggshell are ground into granules for use; S3, geopolymer, artificial bone and eggshell mixture, sea sand , silicon powder, graphene powder, fly ash and concrete additives are sequentially added into the mixing tank for mixing and stirring; the particle size of the artificial bone and eggshell mixture in S2 is 5 mm. The stirring time in S3 was 1.5 hours. The concrete additive in S3 is a mixture of water reducer, retarder, air-entraining agent and thickener S4, finally adding activation liquid and water for uniform stirring.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap