Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67 results about "Graphene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene (/ˈɡræfiːn/) is an allotrope of carbon in the form of a single layer of atoms in a two-dimensional hexagonal lattice in which one atom forms each vertex. It is the basic structural element of other allotropes, including graphite, charcoal, carbon nanotubes and fullerenes. It can also be considered as an indefinitely large aromatic molecule, the ultimate case of the family of flat polycyclic aromatic hydrocarbons.

Fabrication of graphene nanoelectronic devices on SOI structures

ActiveUS20110114918A1Eliminates thermal budget limitationGood substrateSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureGraphene

A semiconductor-on-insulator structure and a method of forming the silicon-on-insulator structure including an integrated graphene layer are disclosed. In an embodiment, the method comprises processing a silicon material to form a buried oxide layer within the silicon material, a silicon substrate below the buried oxide, and a silicon-on-insulator layer on the buried oxide. A graphene layer is transferred onto the silicon-on-insulator layer. Source and drain regions are formed in the silicon-on-insulator layer, and a gate is formed above the graphene. In one embodiment, the processing includes growing a respective oxide layer on each of first and second silicon sections, and joining these silicon sections together via the oxide layers to form the silicon material. The processing, in an embodiment, further includes removing a portion of the first silicon section, leaving a residual silicon layer on the bonded oxide, and the graphene layer is positioned on this residual silicon layer.

Owner:GLOBALFOUNDRIES U S INC

Graphene conductive polyester fibers and preparation method thereof

ActiveCN104164707AOvercome cohesionOvercome uniformity issuesElectroconductive/antistatic filament manufactureSpinnerette packsPolyesterFiber

Owner:湖州市中磊化纤有限公司

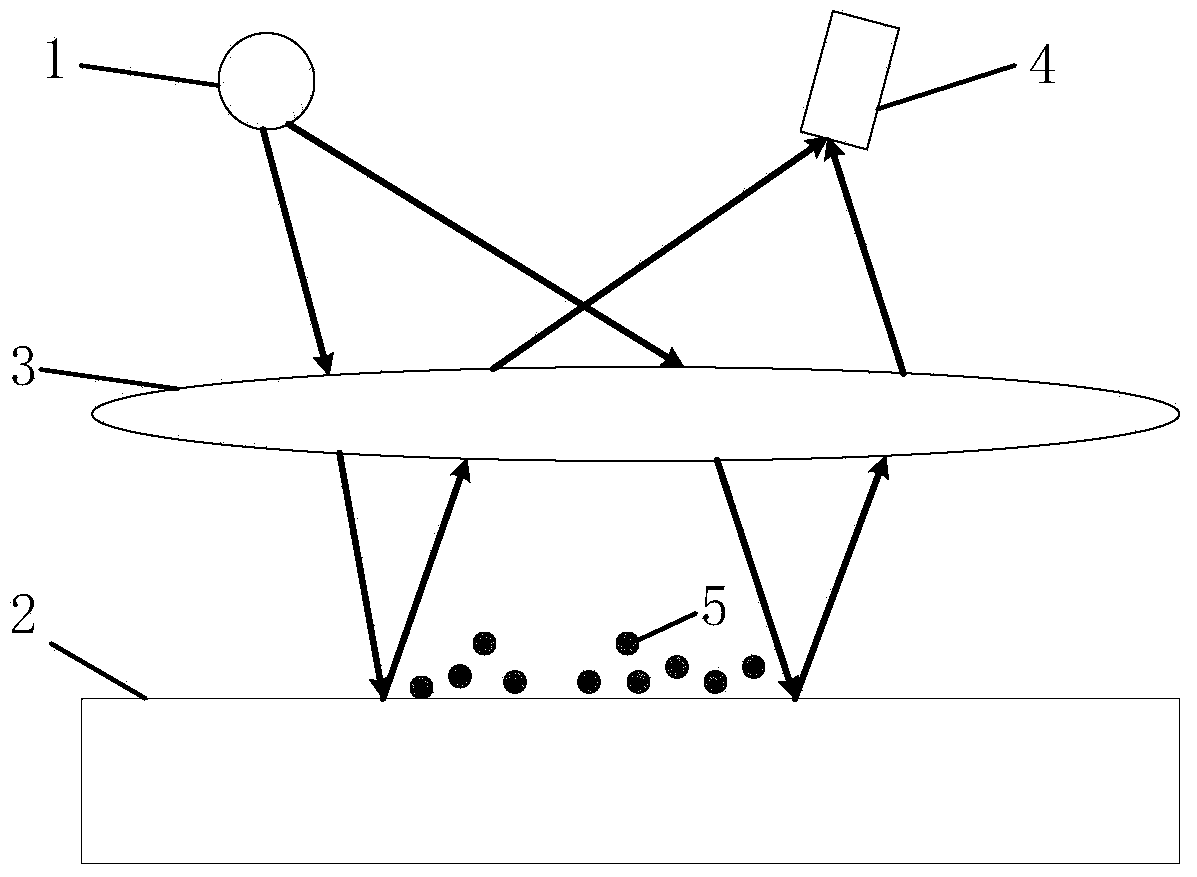

Infrared spectrum enhancement and detection method and infrared spectrum enhancement and detection device based on graphene nano antenna

ActiveCN103776790AEnhanced Absorption EnhancementReduce usageNanoopticsColor/spectral properties measurementsGratingBroadband

Owner:CHONGQING UNIV

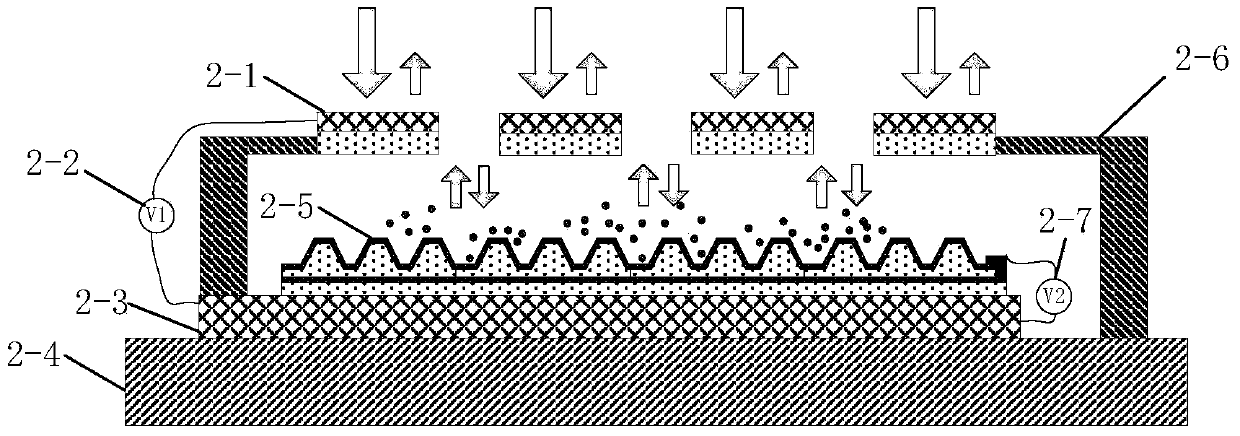

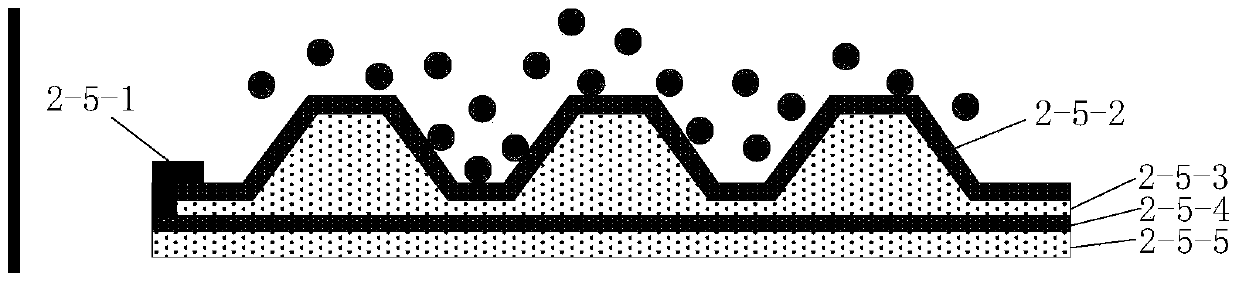

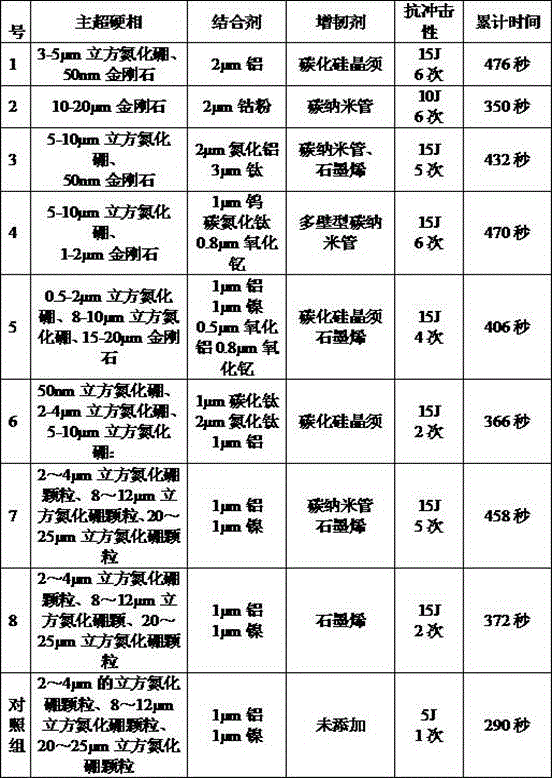

High-tenacity polycrystalline composite material, high-tenacity polycrystalline blade and preparation method of high-tenacity polycrystalline blade

InactiveCN105908041AImprove fracture toughnessImprove impact resistanceTurbinesOther manufacturing equipments/toolsCarbide siliconCarbon nanotube

Owner:FUNIK ULTRAHARD MATERIAL

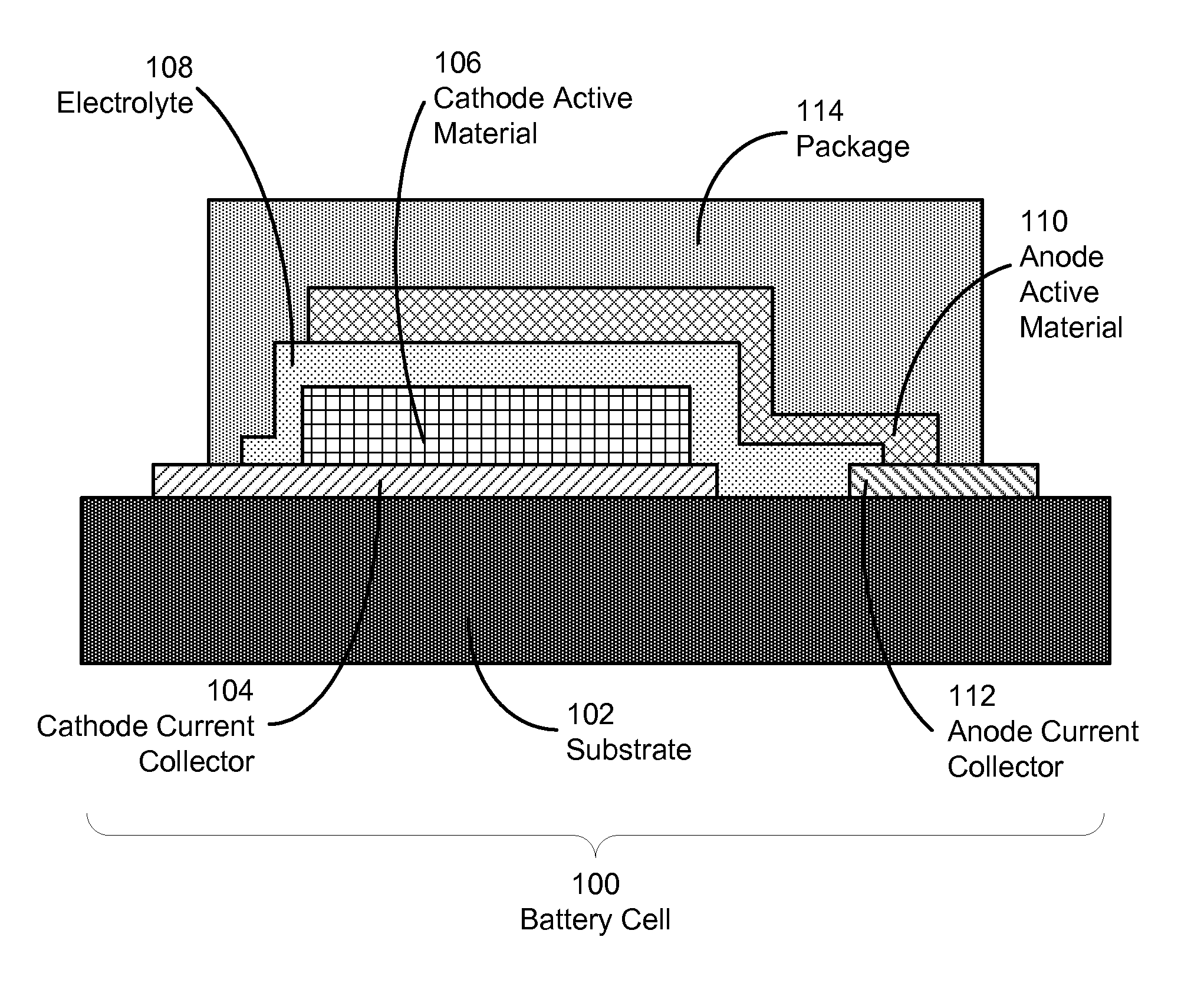

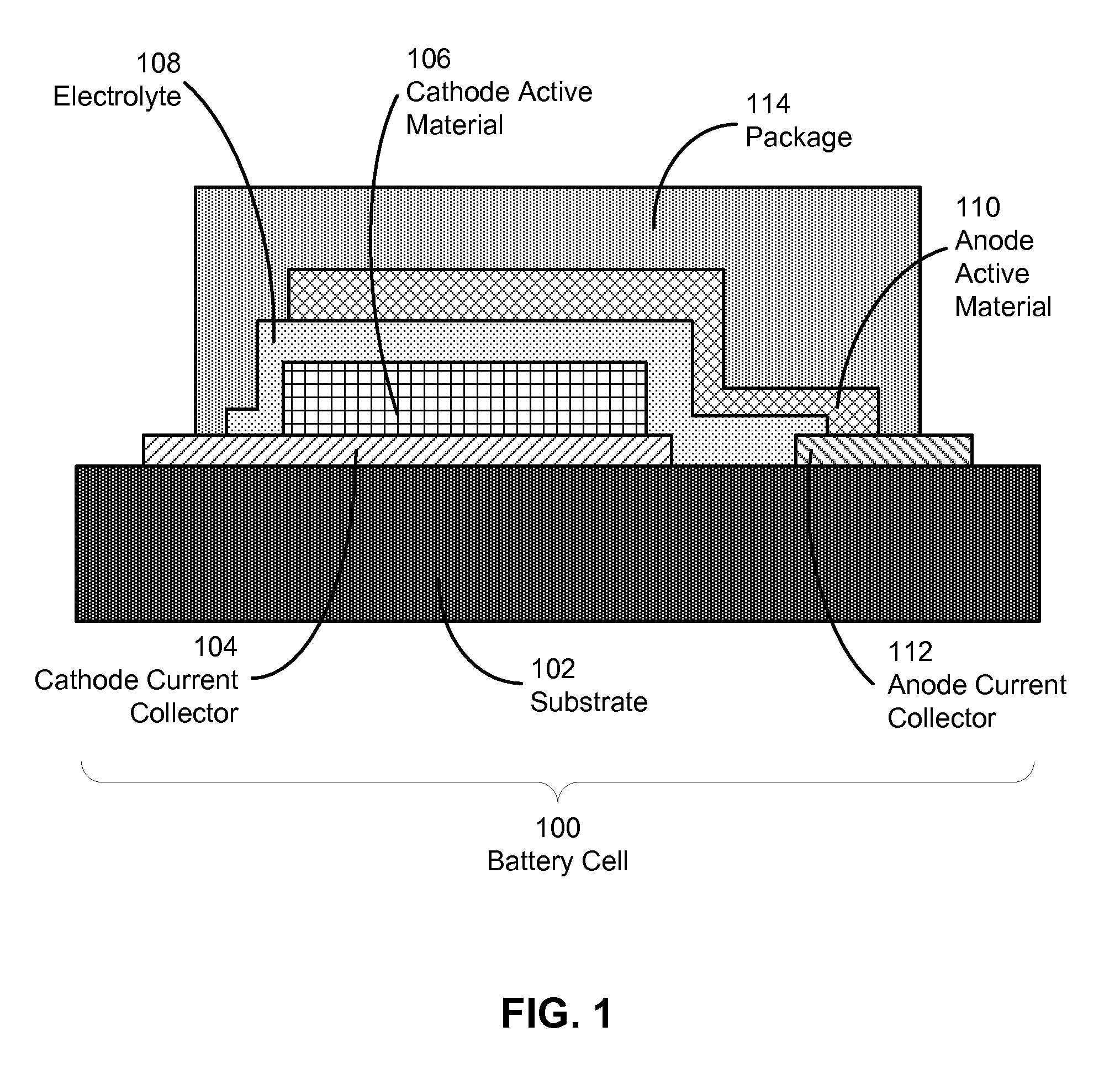

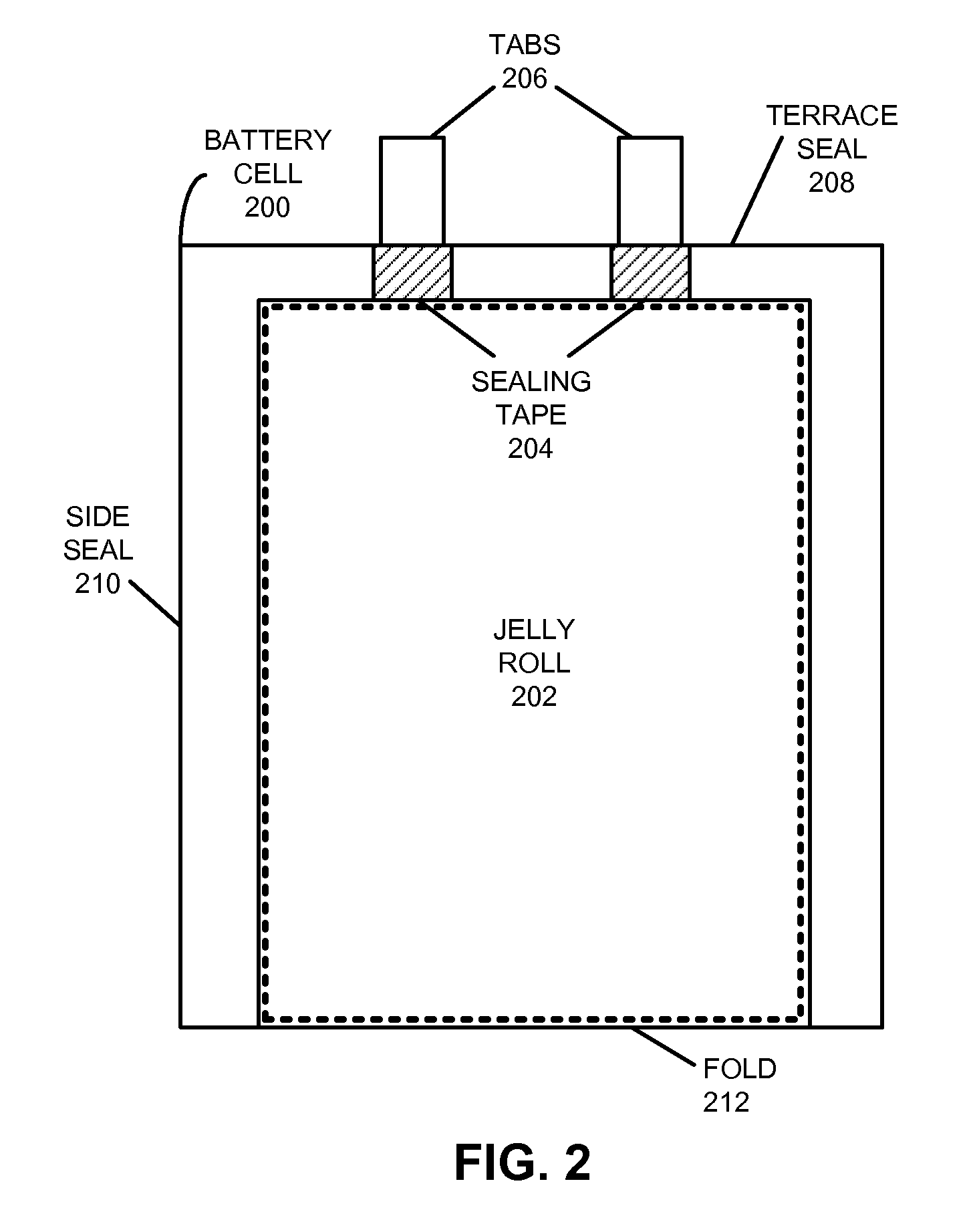

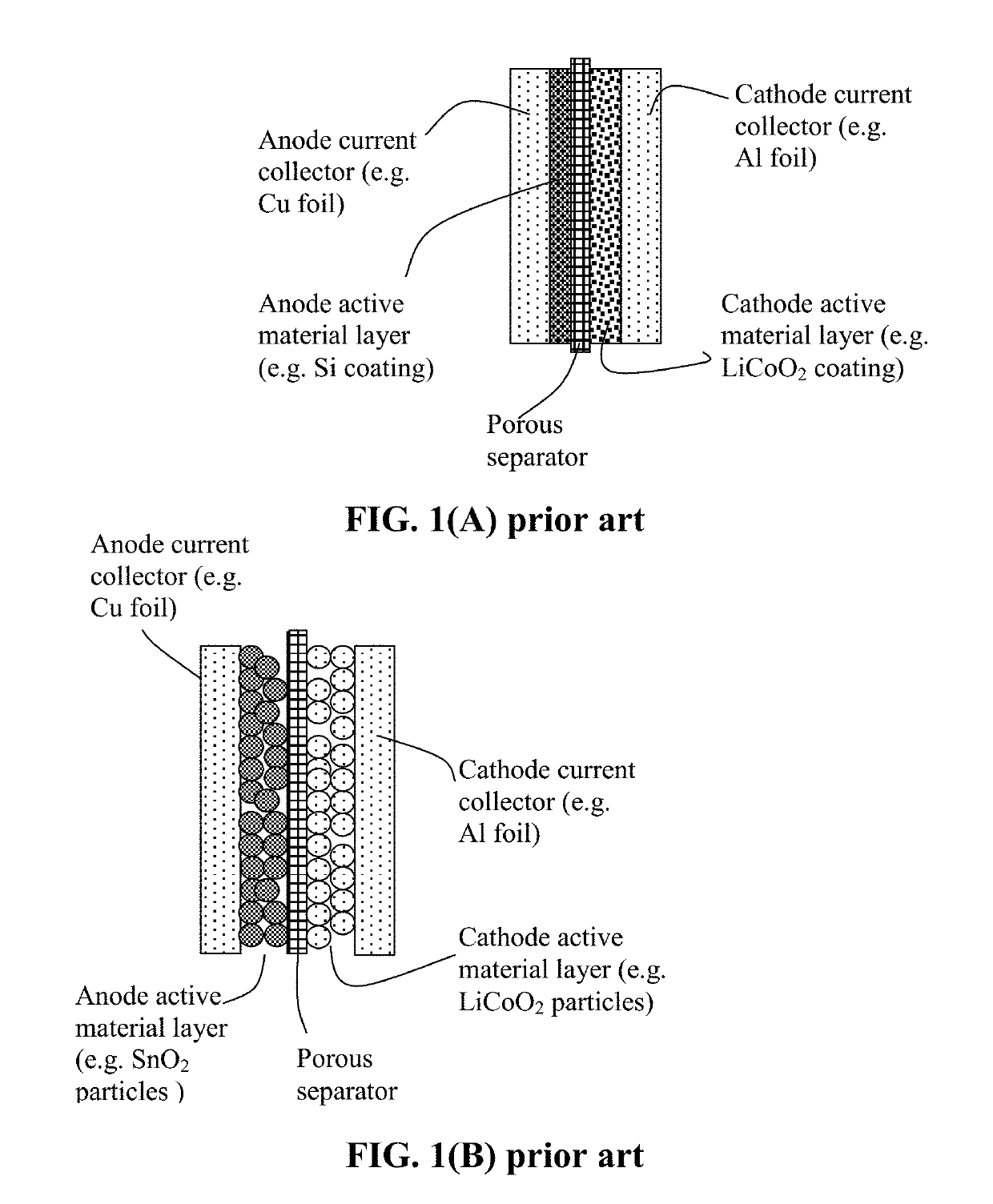

Graphene current collectors in batteries for portable electronic devices

InactiveUS20130095389A1Reduce manufacturing costIncrease energy densityElectrode carriers/collectorsSolid electrolyte cellsManufacturing cost reductionEngineering

Owner:APPLE INC

Non-aqueous solution aluminum ion secondary battery and preparation method thereof

InactiveCN104993130AGood chemical stabilityImprove thermal stabilityCell electrodesFinal product manufactureAluminum IonElectrical battery

Belonging to the technical field of batteries, the invention relates to a non-aqueous solution aluminum ion secondary battery and a preparation method thereof. The secondary battery can be widely applied in electronics, communication, electric vehicle and other fields. The aluminum ion battery provided by the invention contains a battery anode, a battery cathode, a diaphragm and an aluminum-containing non-aqueous solution electrolyte. Specifically, the cathode active material can be carbon, graphite, carbon nanotube, graphene, super carbon, WS2 and MoS2, V2O5, TiO2 and other materials having nano-layered, tubular, linear and other structures, and the anode is aluminum-containing metal or alloy. The non-aqueous solution aluminum ion secondary battery provided by the invention has the characteristics of high specific capacity, high coulomb efficiency, long service life and environmental protection, safety and reliability, stable cycle performance, and quick charging, etc.

Owner:BEIJING ALUMINUM ENERGY S&T

Graphene anti-PM2.5 mouth mask filter sheet functional layer and applications in filter sheet

Owner:QINGDAO REALEADER ADVANCED MATERIALS TECH

Three-dimensionalgraphene composite aerogel and preparation method thereof

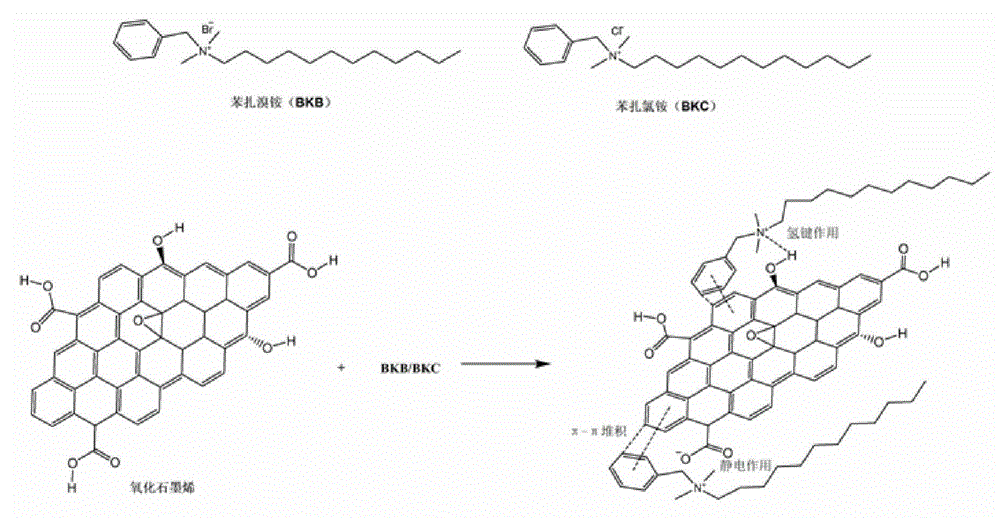

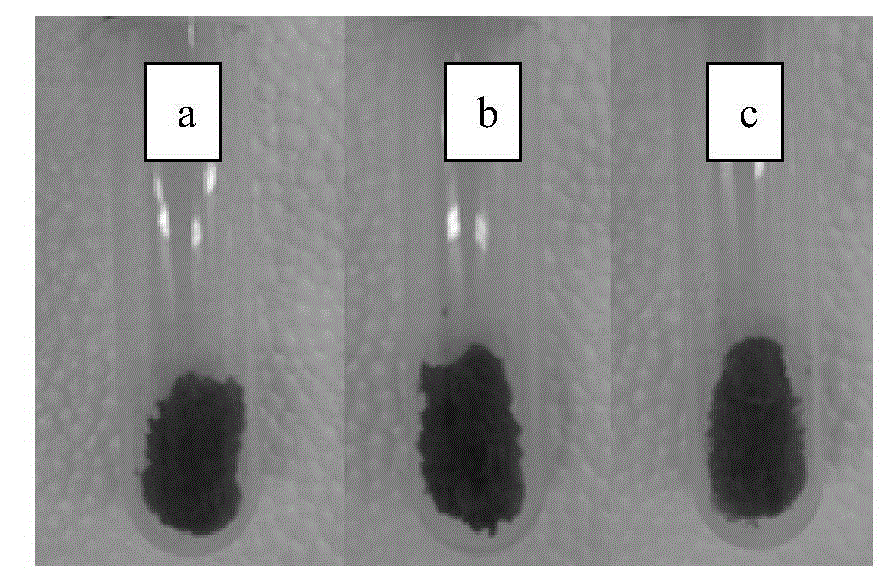

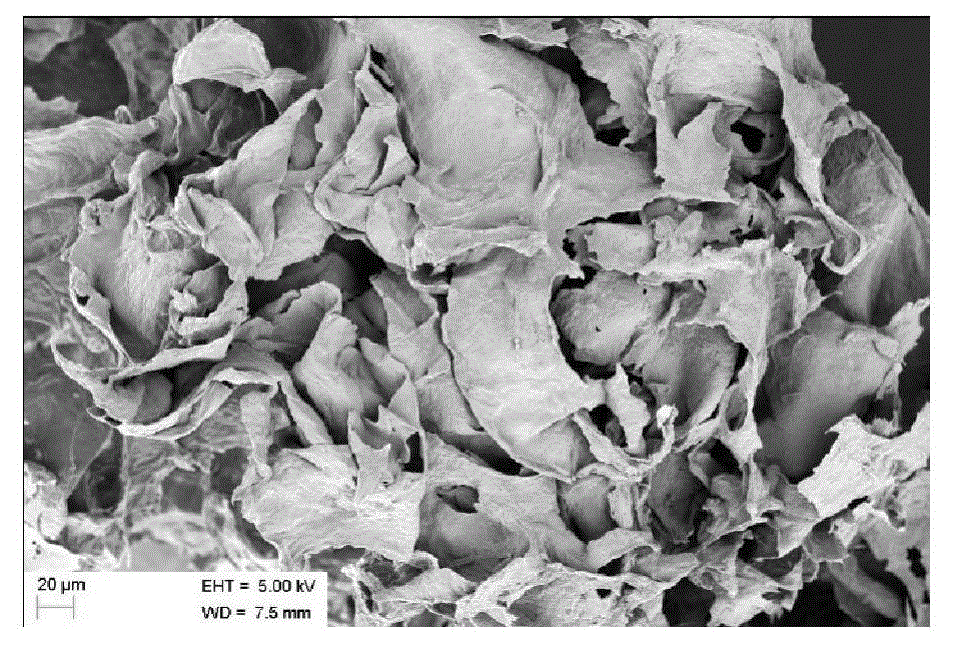

ActiveCN106890605ASimple methodGood lookingOther chemical processesWater contaminantsFiberChemical reaction

The invention discloses three-dimensionalgraphene composite aerogel. High-molecular material nano fiber with a biomass polysaccharide structure is compounded with oxidized graphene through a surface electrostatic-force effect, and then the composite aerogelis prepared by utilizing hydrazine hydrate reduction and a method for high-temperature pyrolysis in an inert atmosphere. The invention further discloses a preparation method of the three-dimensionalgraphene composite aerogel. The method for preparing the three-dimensionalgraphene composite aerogel is simple, easy to operate, large in specific surface area, uniform in pore size distribution and good in electrical conductivity, and the chemical reactivity is improved.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Transparent anti-static polyvinylidene fluoride piezoelectric material and preparation method thereof

InactiveCN103102623AImprove antistatic performanceExcellent piezoelectric propertiesCarbon nanotubePolyvinylidene difluoride

The invention relates to a transparent anti-static polyvinylidene fluoride piezoelectric material and a preparation method thereof. The filler is very difficult to uniformly disperse by adding carbon nano-tubes, graphene or zinc oxide to PVDF (Polyvinylidene Fluoride) material in the prior art; and the material is directly transmitted to be conductive from insulating, and is not attractive. The polyvinylidene fluoride piezoelectric material is a mixture of polyvinylidene fluoride and ionic liquid. The preparation method of the transparent anti-static polyvinylidene fluoride piezoelectric material comprises the following steps of: drying the polyvinylidene fluoride and the ionic liquid for 24 hours to 48 hours at 80 DEG C to 110 DEG C in a vacuum environment; adding the dried polyvinylidene fluoride and ionic liquid in a mass ratio of 100:(0.5-40) to a fusion smelting device for melting-blending at 180 DEG C to 200 DEG C to obtain a mixture; and discharging the mixture from the melting-blending device, cooling the mixture to normal temperature and crystallizing the cooled mixture to obtain the polyvinylidene fluoride piezoelectric material. The polyvinylidene fluoride piezoelectric material disclosed by the invention has good antistatic property, good piezoelectricity and excellent transparency. According to the preparation method of the polyvinylidene fluoride piezoelectric material disclosed by the invention, the normal melting-blending device is only needed to be used, and the industrial preparation is simple.

Owner:HANGZHOU NORMAL UNIVERSITY

Aqueous graphene-based electric-conducting ink and preparation method thereof

The invention relates to aqueous graphene-based electric-conducting ink, which comprises: 1-15% of an aqueous resin, 30-90% of a graphene-based composite slurry, 0.5-3% of a first auxiliary agent and5-10% of a solvent, wherein the graphene-based composite slurry comprises graphene micro-sheets, carbon nano-tubes, nano-scale superconducting carbon black, a diluent and a second auxiliary agent, anda mass ratio of the graphene to the carbon nano-tubes to the nano-scale superconducting carbon black is (3-10):(0.5-5):(0.1-4). The aqueous graphene-based electric-conducting ink of the invention isstable in performance, environmentally friendly, efficient and extremely low in resistance value, and can replace the existing solvent-based ink products on the market. The invention also relates to apreparation method of the aqueous graphene-based electric-conducting ink.

Owner:NINGBO MORSH TECH

Microelectronic temperature sensor and preparation method thereof

InactiveCN105967136AHigh sensitivityReduce the effect of fringe capacitancePrecision positioning equipmentThermometers using electric/magnetic elementsElectricityElectron temperature

Owner:HOHAI UNIV CHANGZHOU

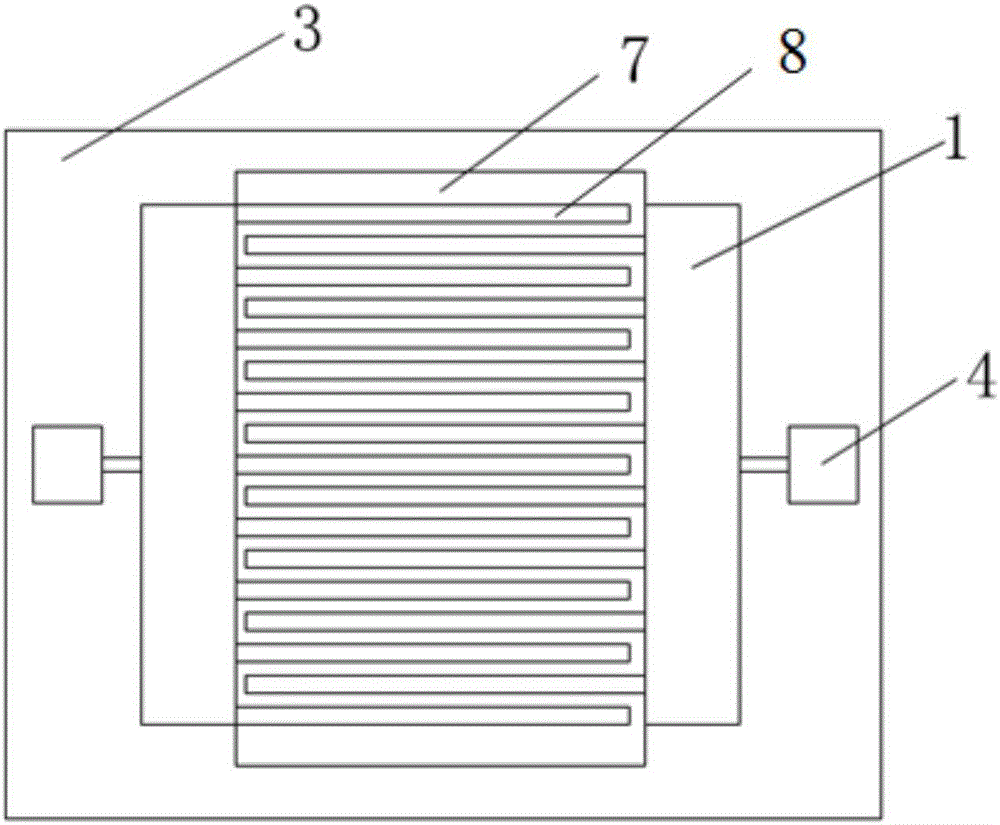

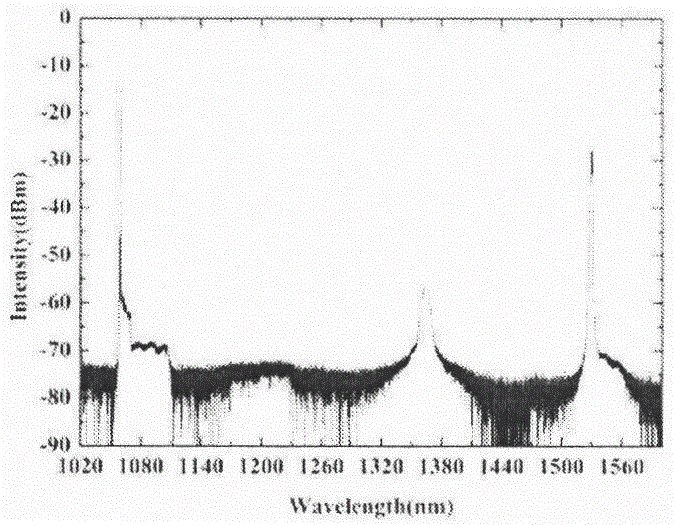

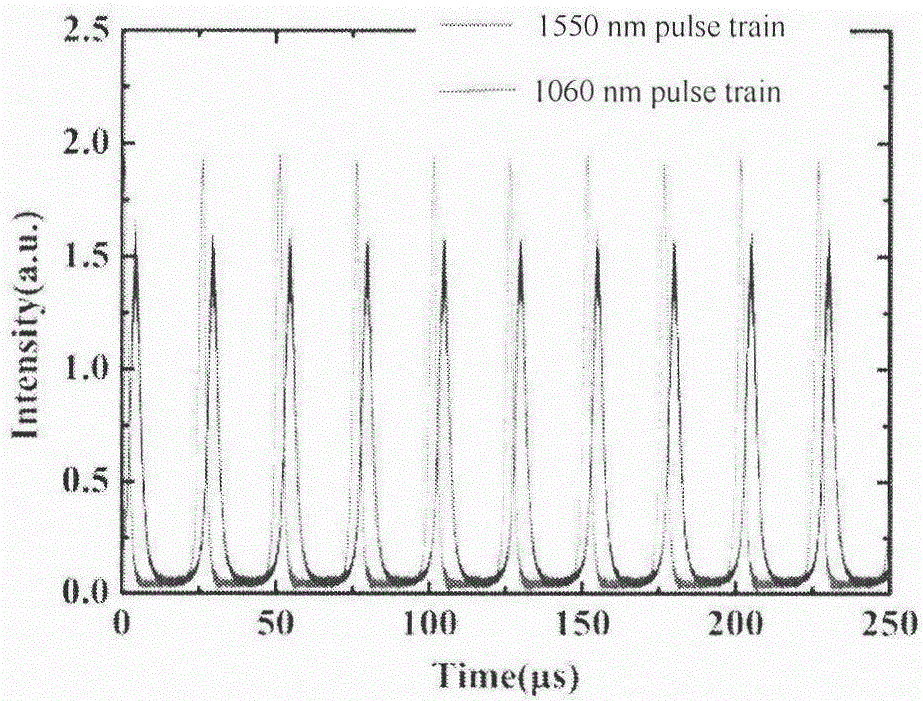

Dual-wavelength synchronous Q-switched fiber laser based on graphene

InactiveCN106654832AActive medium shape and constructionFiber disk laserRing laser

Owner:NANKAI UNIV

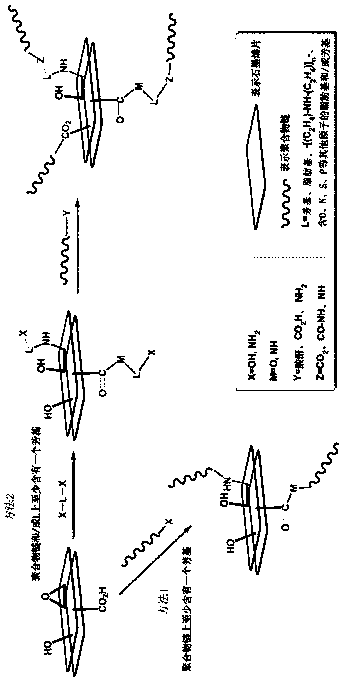

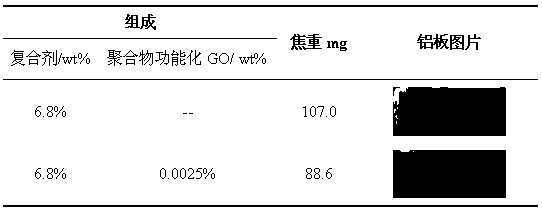

Polymer functional graphene and preparation method and application thereof

Owner:江西福安路润滑材料有限公司 +1

Preparation process of vanadium-nitrogen alloy

The invention discloses a preparation process of a vanadium-nitrogen alloy. The preparation process comprises the steps that a vanadium-containing compound is subjected to mechanical activation treatment at first, a reaction promoter, graphene and a binder are added to obtain qualified mixed materials, the mixed materials are subjected to aging treatment and fed into a calcining kiln to be calcined, a drying stage, a carbonization stage, a nitridation stage and a cooling stage are sequentially carried out, a product is discharged from the kiln, and the vanadium-nitrogen alloy finished productwith the vanadium content larger than or equal to 77.0% is obtained. According to the preparation process, quality is good, product quality is stable, the production process is stable, and the production cost is low.

Owner:涂绪洋

Novel microchip laser supporting optical fiber output

ActiveCN103050870AStable outputStable single frequency outputOptical resonator shape and constructionActive medium materialCarbon nanotubeMicrochip laser

Owner:BEIJING UNIV OF TECH

Thermal insulation material and preparation method thereof

InactiveCN107721451AEvenly dispersedEffective control of cell stabilityConstruction materialCeramicwareFoaming agentPolymer science

The invention discloses a thermal insulation material and a preparation method thereof. The thermal insulation material comprises a cement-based block skeleton and graphene modified polystyrene, wherein the cement-based block skeleton comprises multiple cavities; the multiple cavities are filled with graphene modified polystyrene; and graphene modified polystyrene is formed by performing melt extrusion on graphene and polystyrene resin according to a weight ratio of 1:(1-5) in the multiple cavities in the presence of an alkane foaming agent. According to the thermal insulation material disclosed by the invention, the strength and thermal insulation property are further improved.

Owner:ZHONGJING ECO IND CO LTD

Super-clean graphene and preparation method thereof

The invention discloses super-clean graphene and a preparation method thereof. The preparation method of the super-clean graphene comprises the following steps: putting foam copper on a copper substrate, and attaching; leading carbon source gas and hydrogen to perform chemical vapor deposition; after deposition is completed, obtaining the super-clean graphene at the contact surface of the copper substrate and the foam copper. The preparation method has the advantages that the preparation method is simple and is suitable for large-scale production, the continuous clean area reaches the sub-centimeter level, and the preparation method is suitable for the fields of electronics, optics and the like.

Owner:PEKING UNIV

Compound antibacterial gel, preparation method thereof and applications thereof

InactiveCN103598179AEasy to recycleEasy to filterBiocideDisinfectantsAntibacterial activityGram-positive bacterium

Owner:广东海尔斯激光医疗科技有限公司

High-strength high-elongation antibacterial soft graphene rubber latex

Owner:镇江华扬乳胶制品有限公司

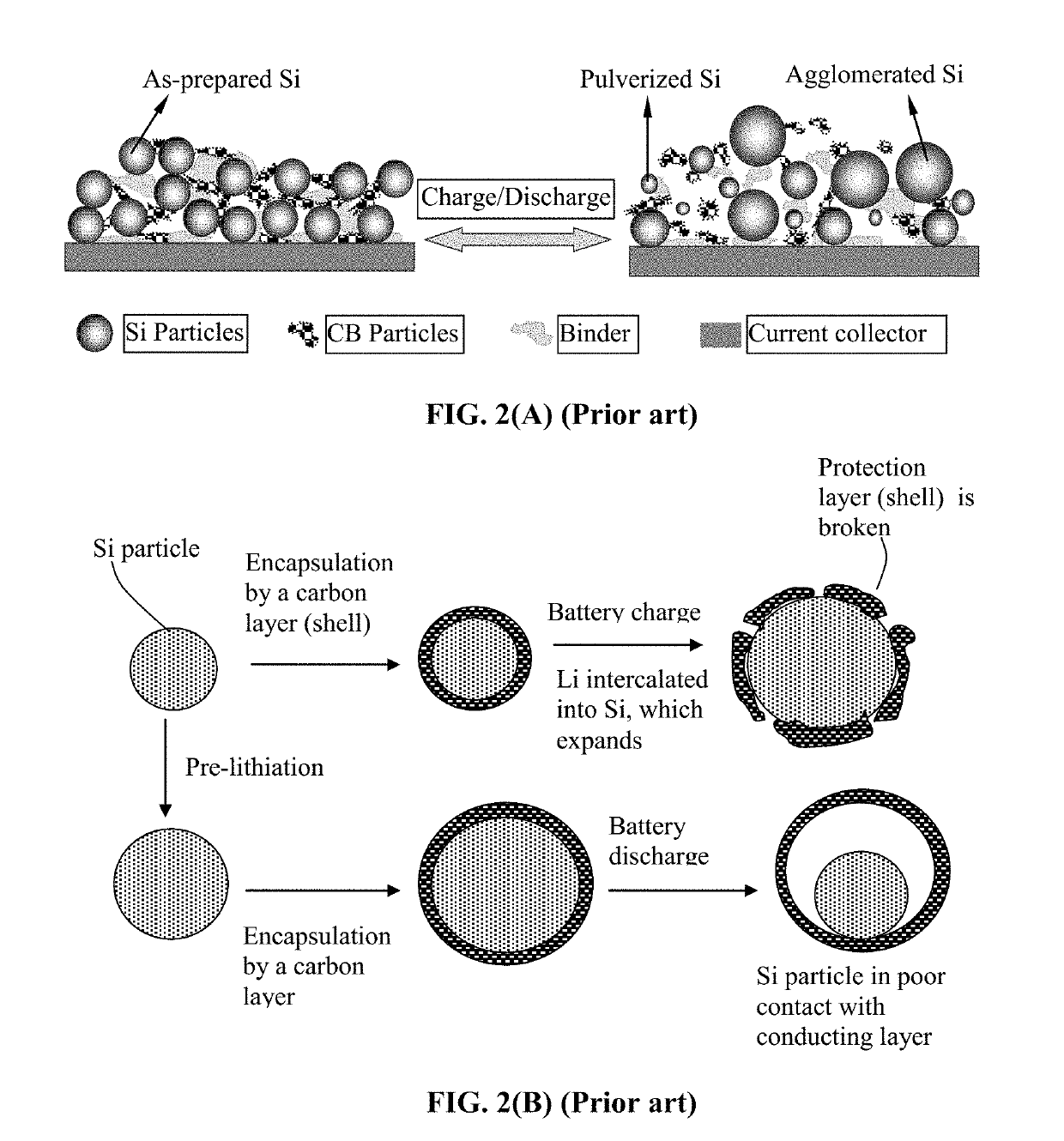

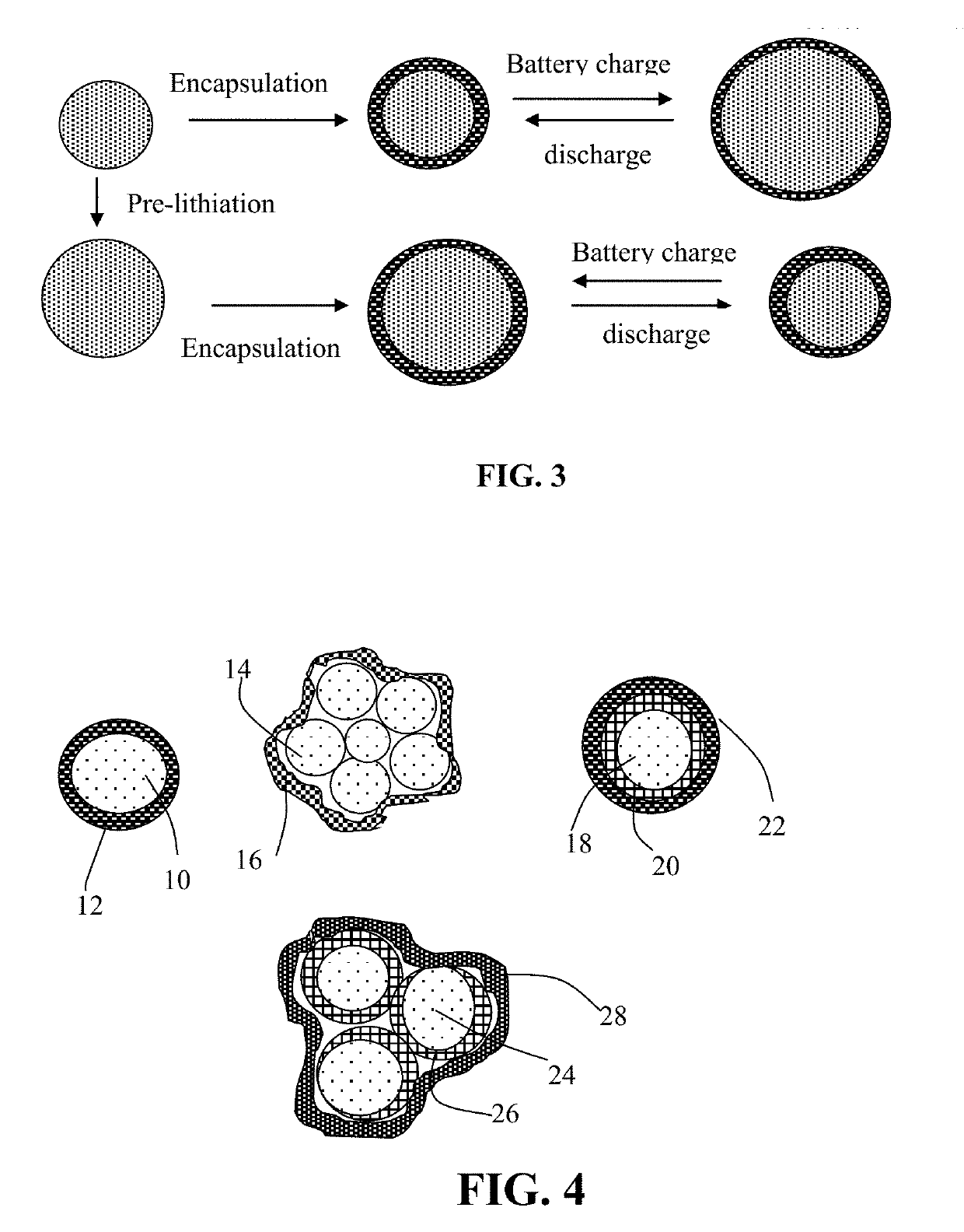

Method of Producing Elastomer Composite-Encapsulated Particles of Anode Active Materials for Lithium Batteries

PendingUS20190267663A1Easy to packFaster lithium ion transportNegative electrodesSecondary cellsParticulatesLiquid medium

Owner:GLOBAL GRAPHENE GRP INC

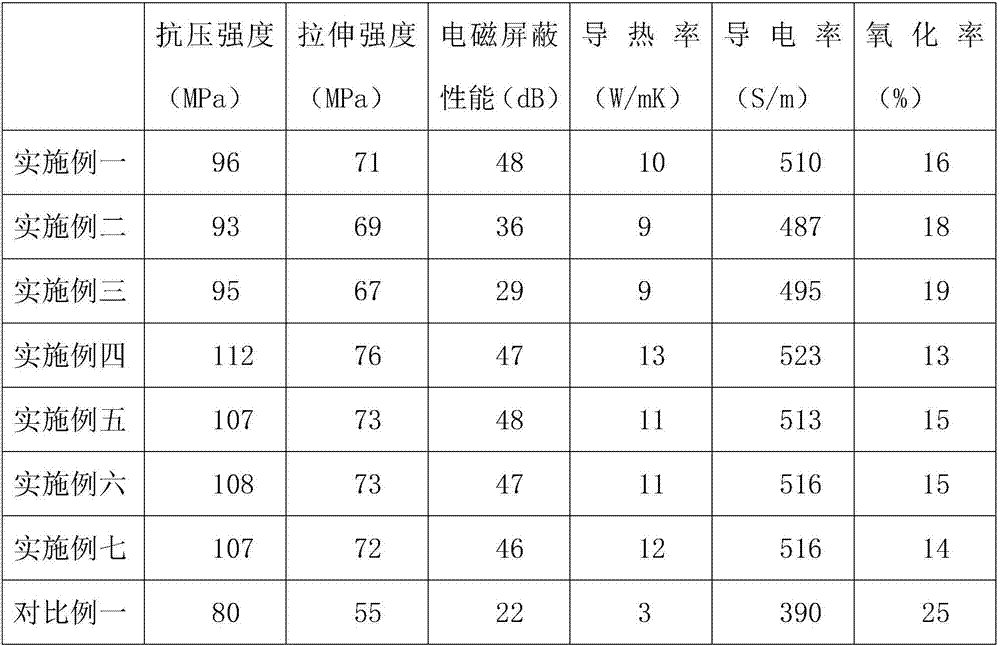

Preparation method of heat-conducting, electricity-conducting and electromagnetic-shielding multifunctional composite material

InactiveCN108003612AImprove electromagnetic shielding performanceImprove tensile propertiesHeat-exchange elementsElectricityHeat conducting

Owner:江西伟普科技有限公司

Preparation method of graphene-butadiene-acrylonitrile rubber latex matting glove

InactiveCN109457465AWith body temperature far infraredImprove antibacterialGlovesLight resistant fibresVulcanizationPolymer science

The invention relates to a preparation method of a graphene-butadiene-acrylonitrile rubber latex matting glove. The preparation method comprises, S1, arranging a glove liner on a hand mould in a covering mode; S2, impregnating the glove liner into curing agent for 20-30 s; S3, totally immersing the glove liner into graphene-butadiene-acrylonitrile composite slurry at a latex viscosity of 600-700 cp for 10-15 s; S4, performing salt spray treatment on the immersed glove liner; S5, performing primary drying inside a vulcanization crosslinking drying oven; S6, washing the dried glove; S4, performing secondary drying on the washed glove inside the oven; S8, performing cooling and demoulding to obtain the graphene-butadiene-acrylonitrile rubber latex matting glove. The prepared graphene-butadiene-acrylonitrile rubber latex matting glove is high in wearing resistance, puncture resistance, tear resistance and cutting resistance, highly antibacterial, capable of achieving far infrared radiationand the like.

Owner:NANTONG JIADELI SAFETY PROD CO LTD

Graphene modified self-lubricating wear-resistant coating

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

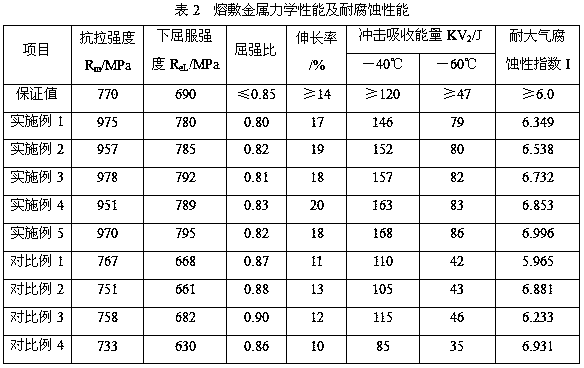

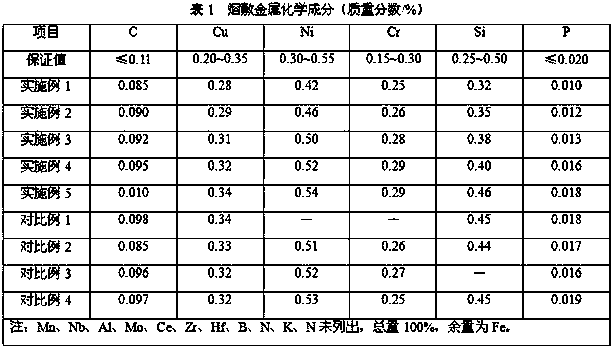

Bridge steel Q690qE matched flux-cored wire

ActiveCN109158796AImprove mechanical propertiesHigh chemical activityWelding/cutting media/materialsSoldering mediaIron powderCore component

Owner:ZHENGZHOU UNIV

Thin-film capacitor housing heat dissipation coating and preparation method thereof

A thin-film capacitor housing heat dissipation coating is prepared from, by mass, 35 parts of resol, 3 parts of gelatin, 5 parts of glycidyl methacrylate, 3 parts of sodium dodecyl benzene sulfonate, 3 parts of gloss oil, 5 parts of dimethyl dicarbonate, 3 parts of olive oil, 3 parts of colored glaze carbylic acid, 3 parts of olive oil, 3 parts of graphene, 5 parts of pigment, 50 parts of distilled water, 3 parts of benzoyl paeoniflorin, 3 parts of sodium hypochlorite, 5 parts of a modifying agent, 3 parts of calcium carbonate, 3 parts of glacial acetic acid, 3 parts of magic acid, 5 parts of polyester resin, 3 parts of potassium dihydrogen phosphate, 1 part of sodium phosphate, 3 parts of aluminum silicate, 3 parts of imidazole, 3 parts of cohesive soil, 3 parts of polyvinyl alcohol and 3 parts of sodium borohydride. The modifying agent is added in a traditional formula to perform modification processing, the coating coated on a capacitor housing can effectively guide capacitor inside temperature rising due to work to the housing and convert heat into infrared radiation waves, and the working voltage of a capacitor can be also in a stable state in addition to prolonging of the service life of the capacitor.

Owner:HUAIAN SHENGYU ELECTRONICS

Graphene-containing wear-resistant composite material and preparation method thereof

Disclosed are a graphene-containing wear-resistant composite material and a preparation method thereof. The composite material is in a sheet-layer shape, and by weight, 500 g of latex correspondinglycontains 3-5 g of calcium chloride, 10-20 g of zinc oxide, 15-25 g of analytically-pure magnesium oxide, 2-6 g of stearic acid, 1-3 g of an accelerator NA-22 and 20-30 g of large-radial-size graphenemicrochips, wherein calcium chloride, zinc oxide, analytically-pure magnesium oxide, stearic acid, the accelerator NA-22 and the large-radial-size graphene microchips are uniformly dispersed in the latex. The preparation method comprises the steps of preparation of the graphene microchips, preparation, preparation of rubber masterbatches and preparation of the sheet-layer composite material.

Owner:GUOHONG ZHONGJING GRP CO LTD

Environment-friendly ceramic coating material for water faucet

InactiveCN106189561ACorrosion resistantWear-resistantAnti-corrosive paintsCarbon fibersPolybutylene terephthalate

Owner:朱燕华

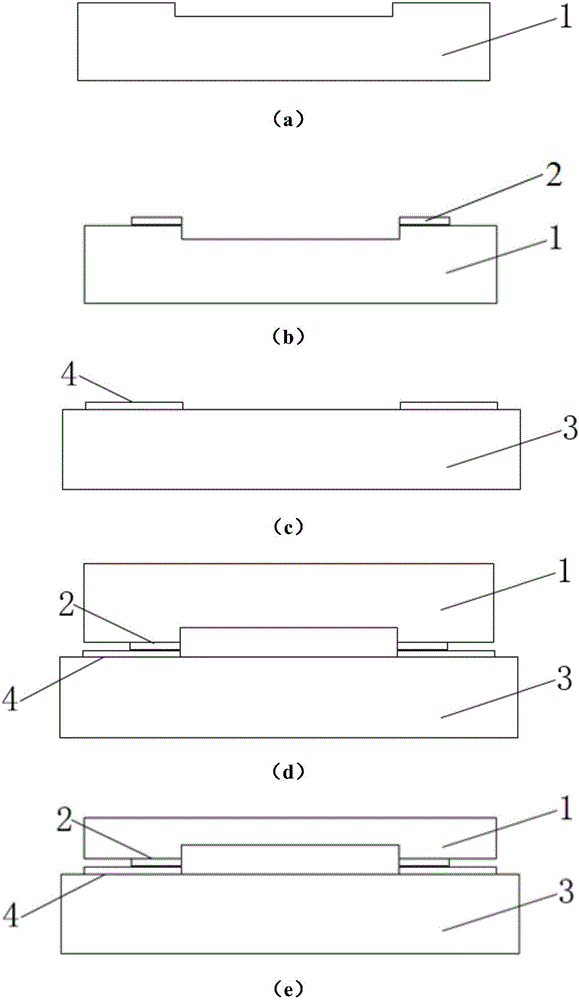

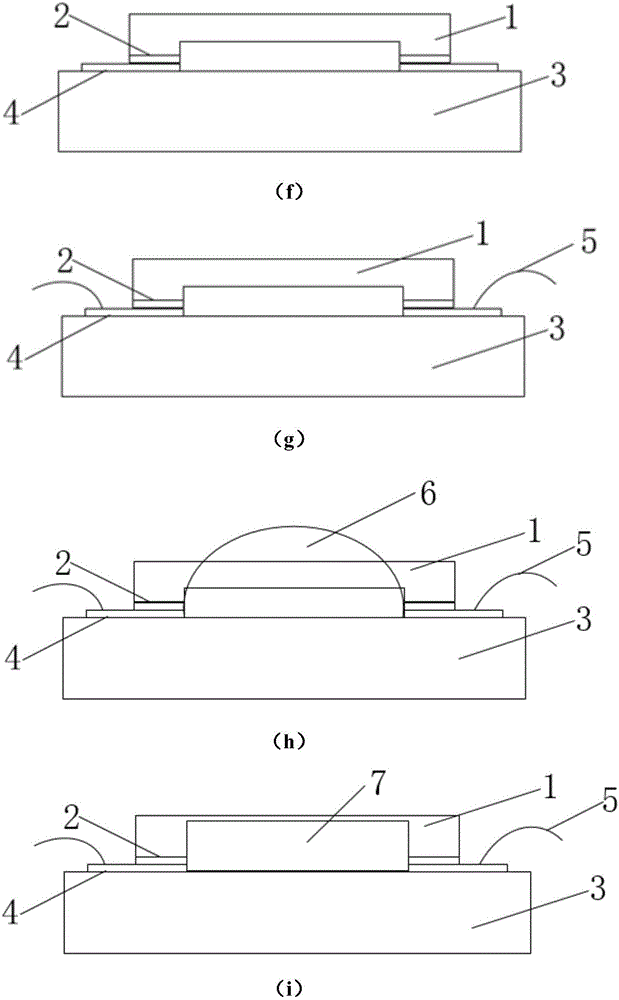

Gallium oxide-based ultraviolet detector and manufacture method therefor

ActiveCN108922931ASimple preparation processLow costFinal product manufactureSemiconductor devicesResponse sensitivityUltraviolet detectors

The present invention provides a gallium oxide-based ultraviolet detector, which comprises a gallium oxide crystal substrate, a graphene layer, a first ohmic contact electrode and a second ohmic contact electrode, wherein the first ohmic contact electrode is grown on a first plane of the gallium oxide crystal substrate; a second plane of the gallium oxide crystal substrate is formed with a needletip type structure; the graphene layer is located on the surface of the second plane of the gallium oxide crystal substrate and contacts with the needle tip type structure formed on the second plane of the gallium oxide crystal substrate; and the second ohmic contact electrode is grown on the surface of the graphene layer that is not in contact with the gallium oxide crystal substrate. The invention also provides a manufacture method for the gallium oxide-based ultraviolet detector. The gallium oxide-based ultraviolet detector and the manufacture method for the gallium oxide-based ultravioletdetector in the invention can improve the response sensitivity and the response speed of the ultraviolet detector; the process is simple; and the cost is low.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

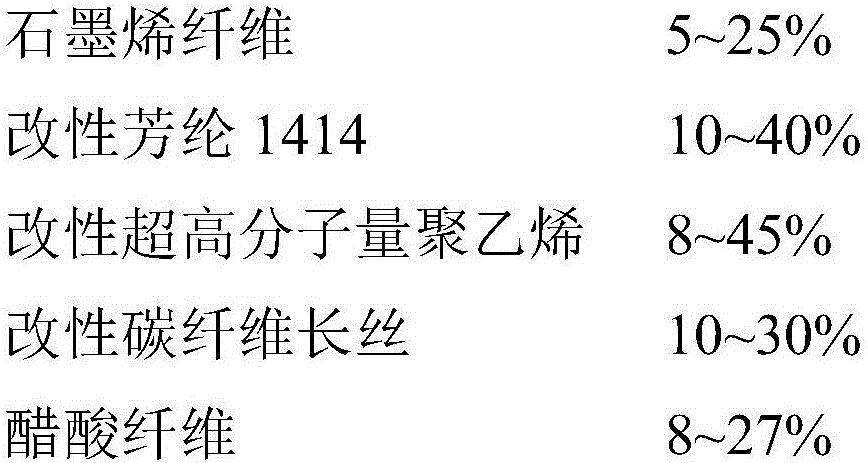

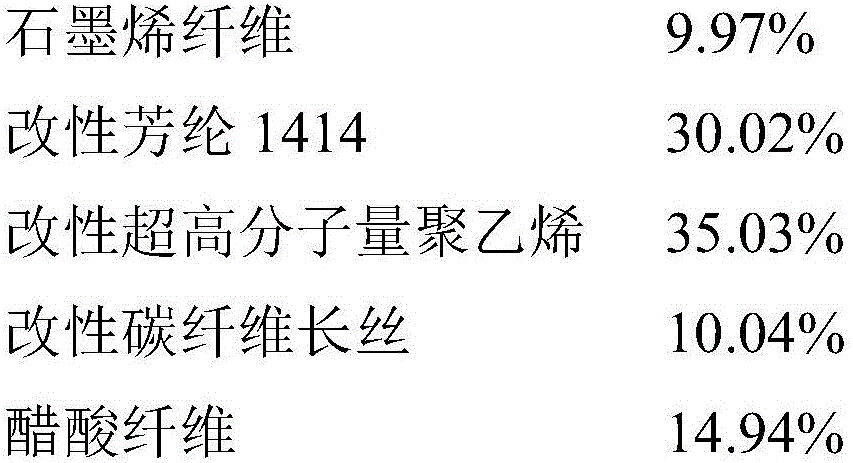

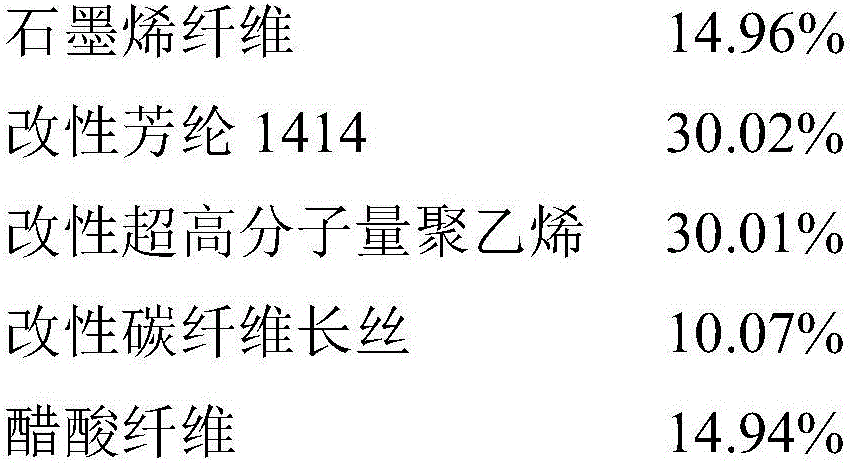

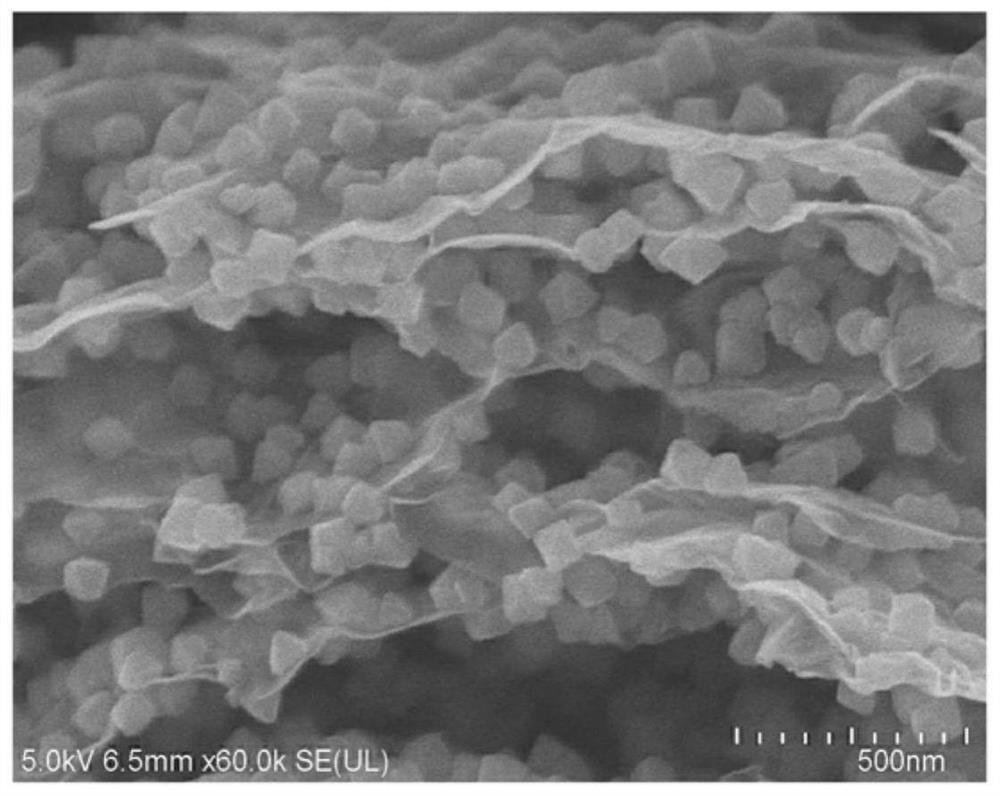

Ultralight bulletproof cloth and manufacture method thereof

Owner:广东军铠防护科技有限公司

Graphene/functionalized metal-organic framework material composite intercalation as well as preparation method and application thereof

PendingCN112421133AImprove conductivityEasy transferLi-accumulatorsCell component detailsElectrolytic agentInterface impedance

Owner:GUANGDONG UNIV OF TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap