Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about "Li-accumulators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

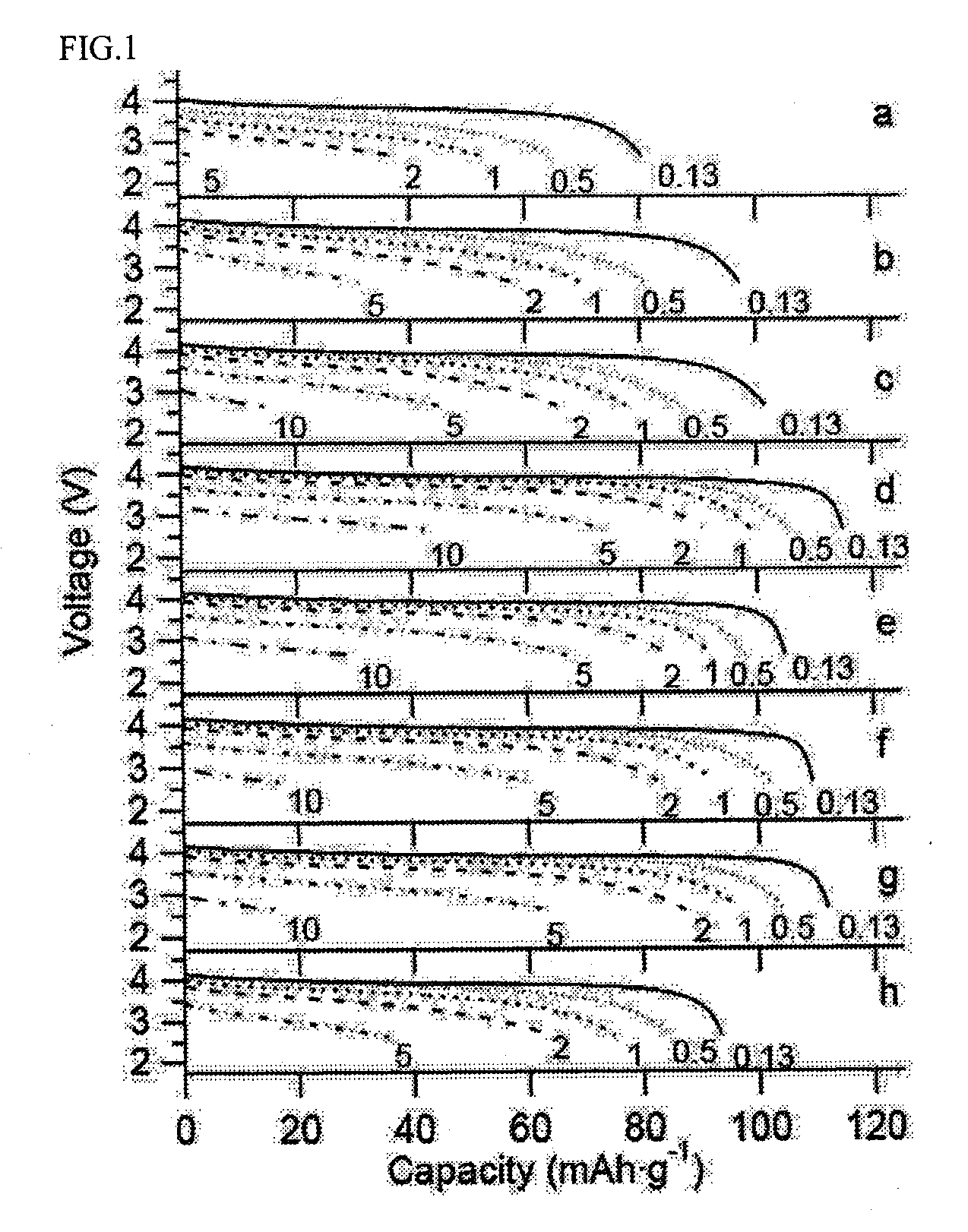

Positive electrode materials for lithium ion batteries having a high specific discharge capacity and processes for the synthesis of these materials

ActiveUS20100086853A1Electrode manufacturing processesAlkali metal oxidesDischarge rateLithium-ion battery

Owner:IONBLOX INC

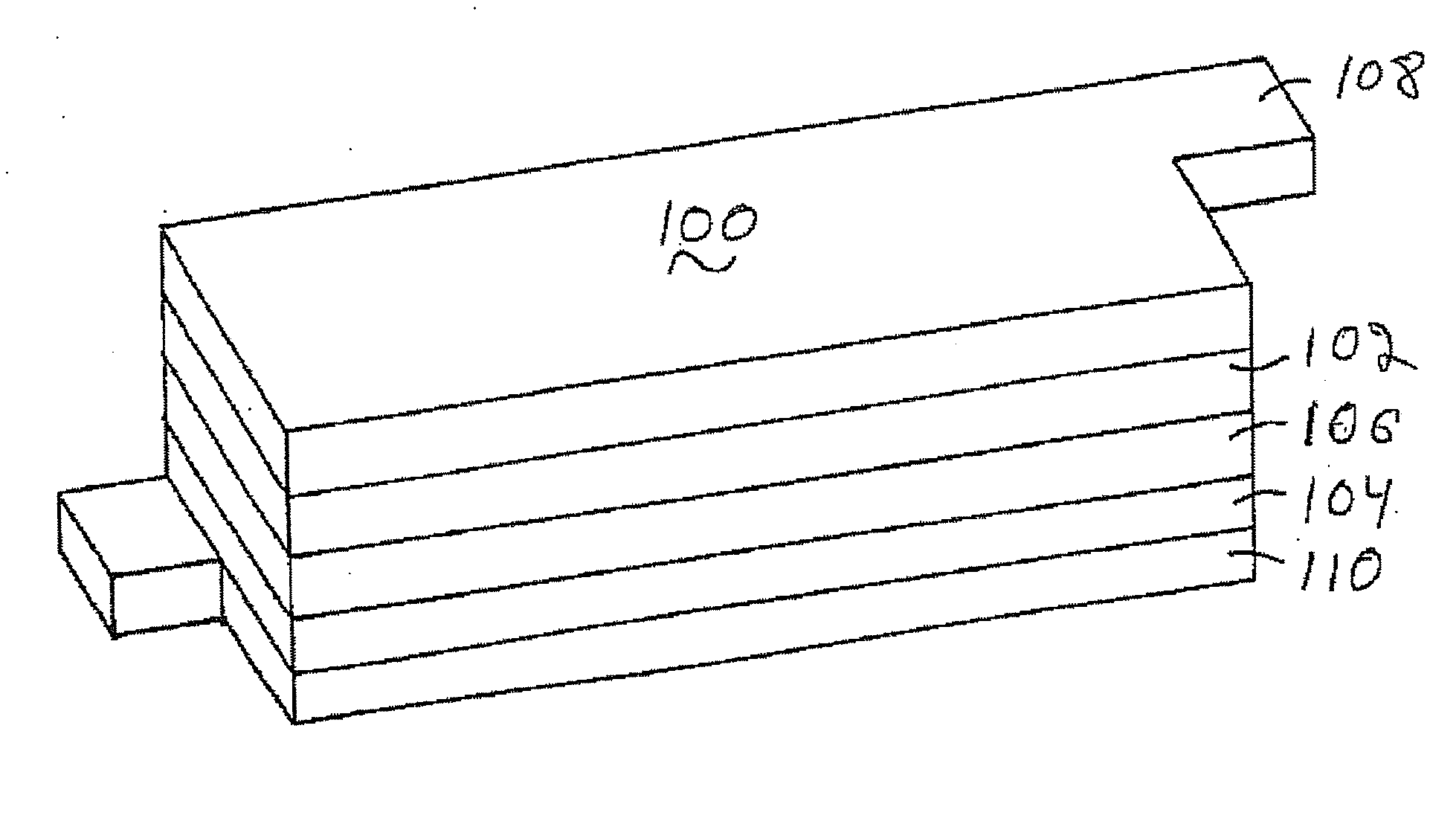

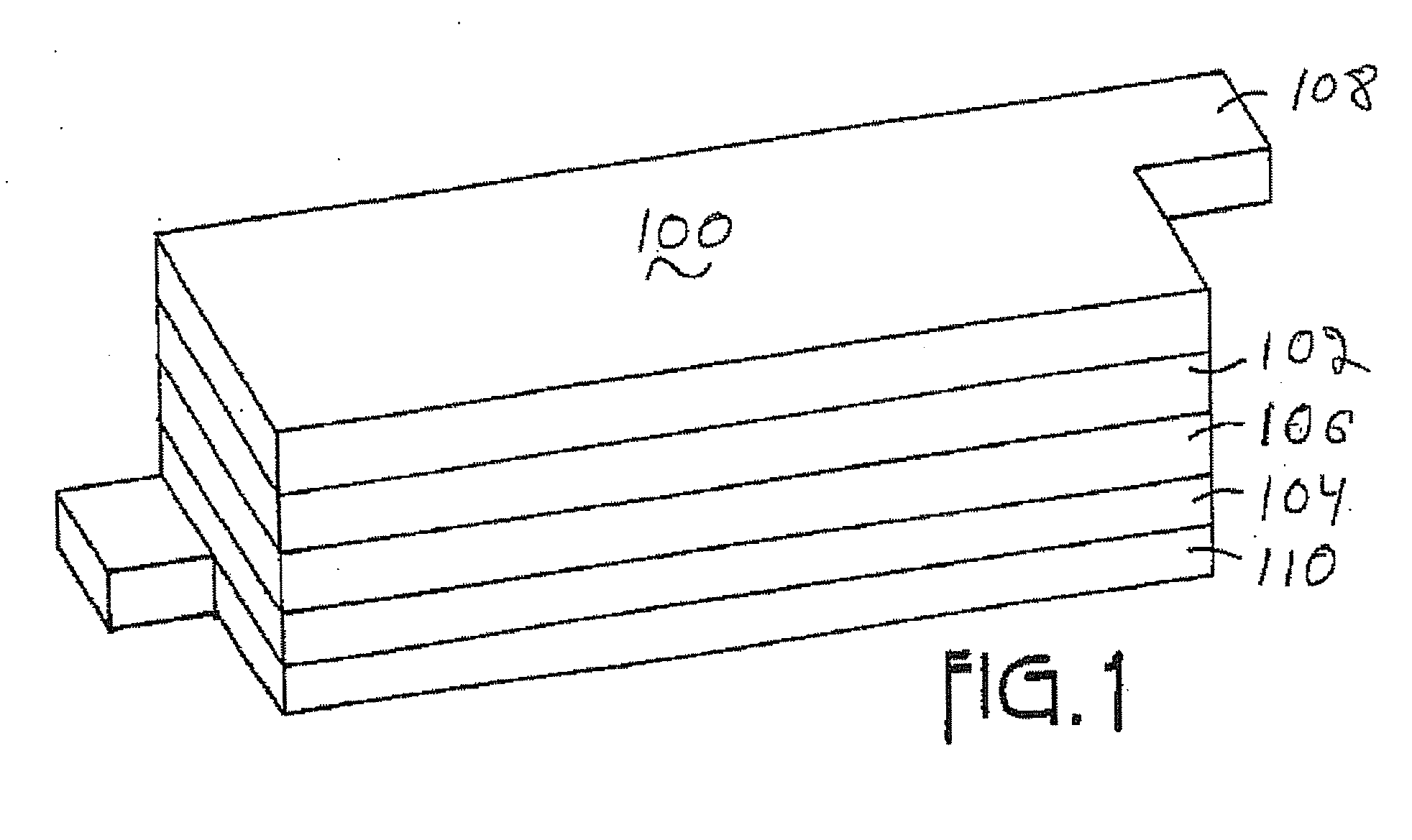

All-solid lithium battery

ActiveUS20090081554A1Improve output performanceLayer formationSolid electrolytesElectrode carriers/collectorsRedoxSulfide

Owner:NAT INST FOR MATERIALS SCI

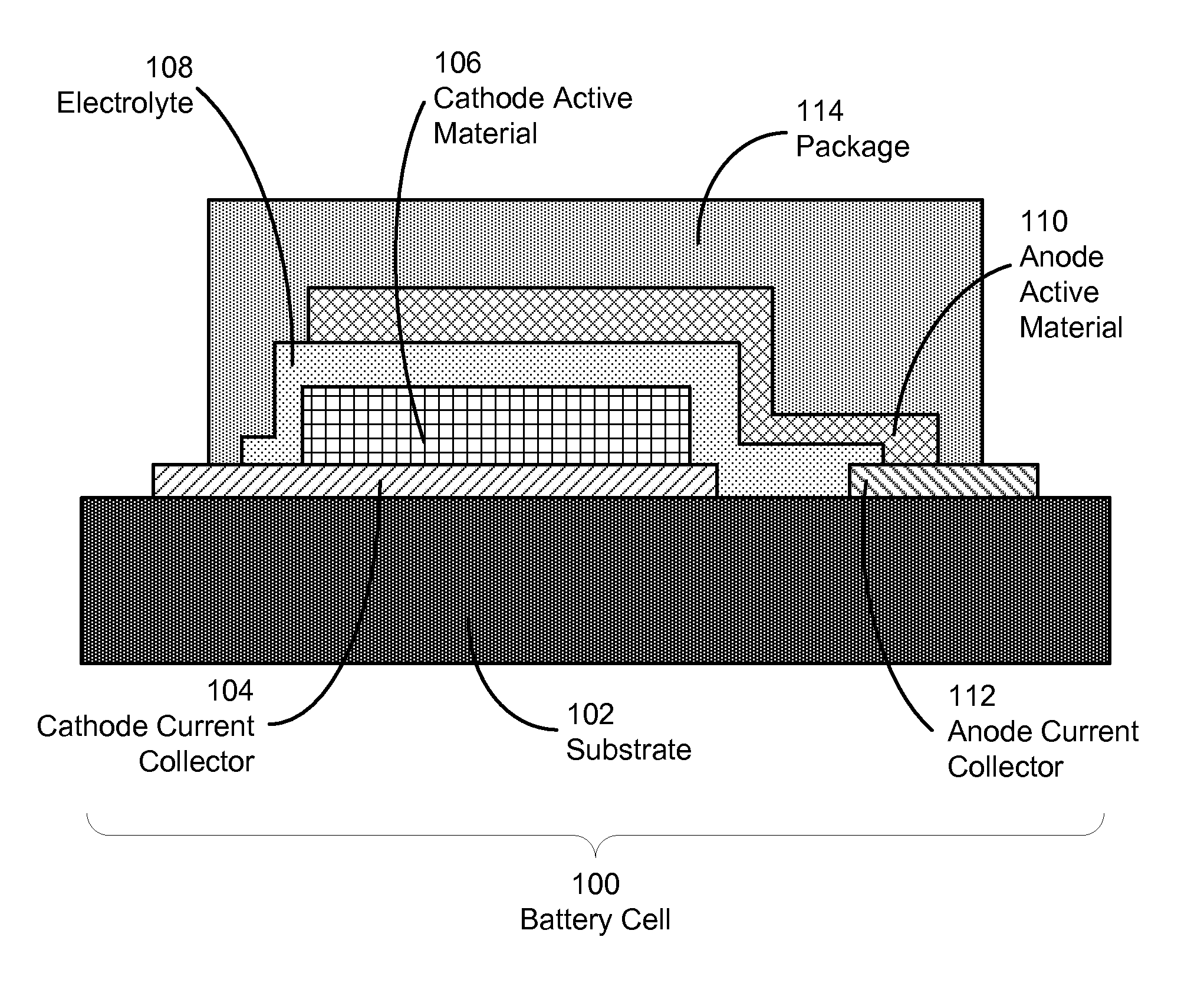

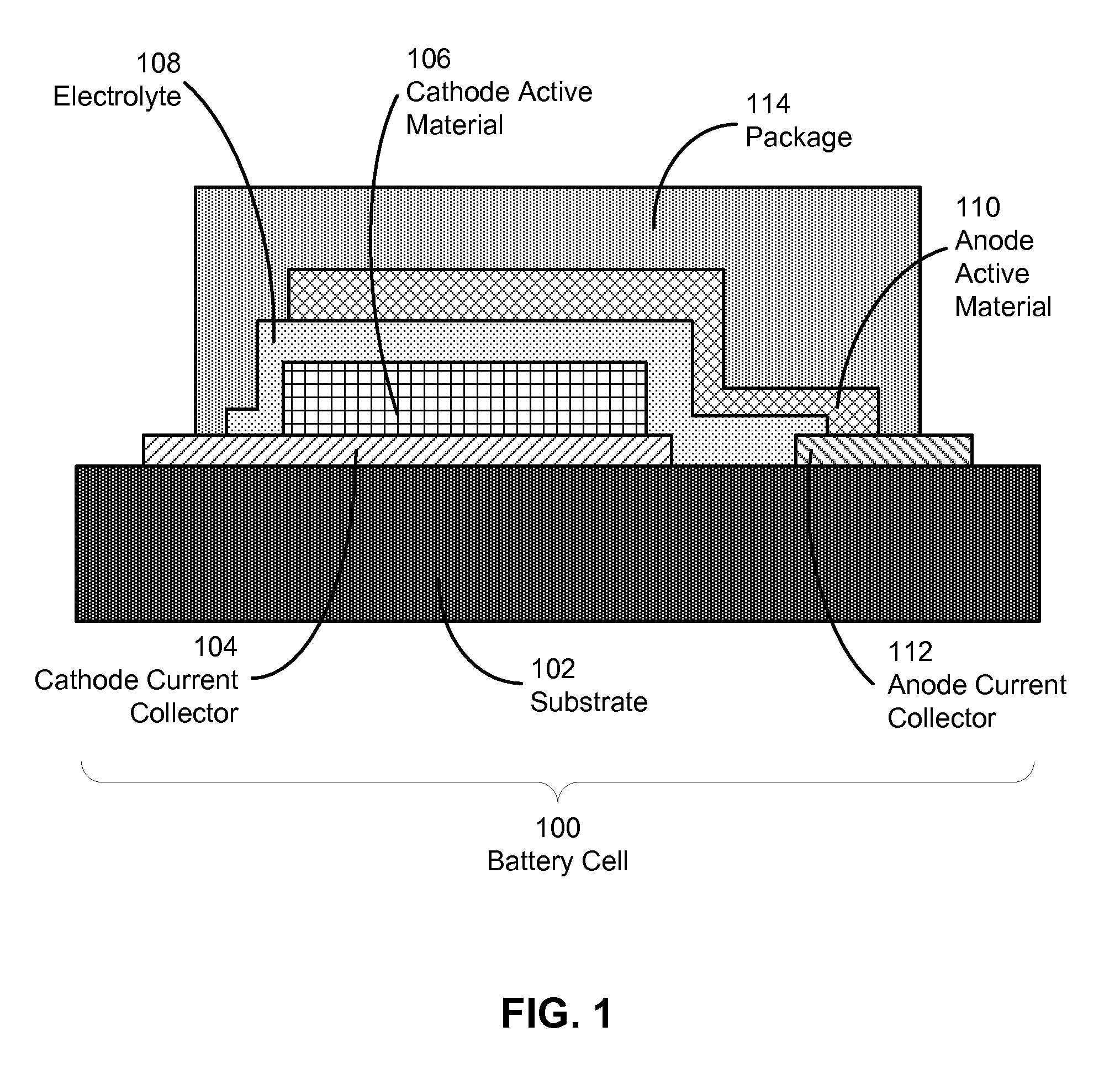

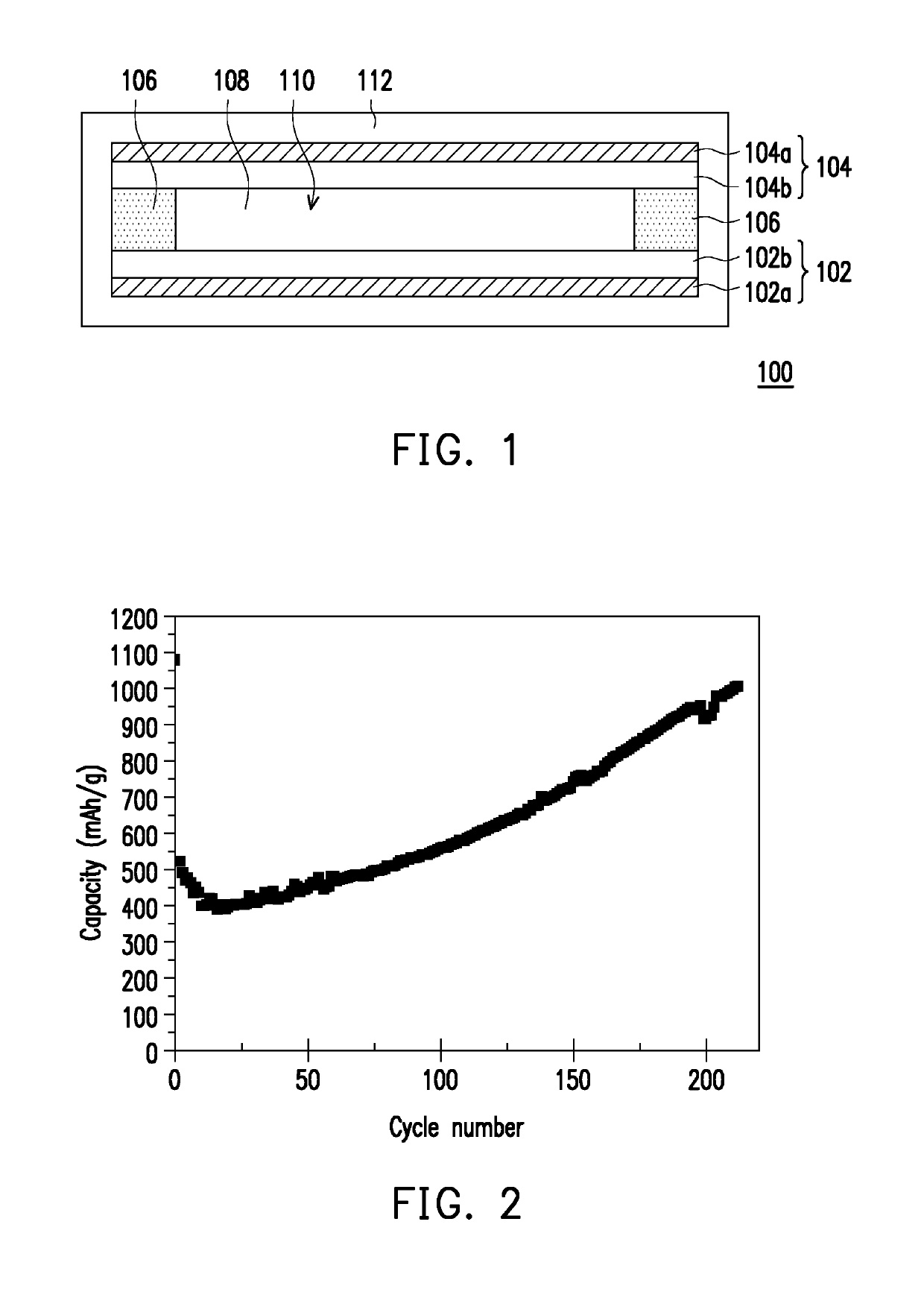

Graphene current collectors in batteries for portable electronic devices

InactiveUS20130095389A1Reduce manufacturing costIncrease energy densityElectrode carriers/collectorsSolid electrolyte cellsManufacturing cost reductionEngineering

Owner:APPLE INC

Negative electrode active material for non-aqueous electrolyte secondary batteries and non-aqueous electrolyte secondary battery using negative electrode active material

InactiveUS20150221950A1Improve efficiencyImprove propertiesNegative electrodesNon-aqueous electrolyte accumulator electrodesCharge dischargeNon aqueous electrolytes

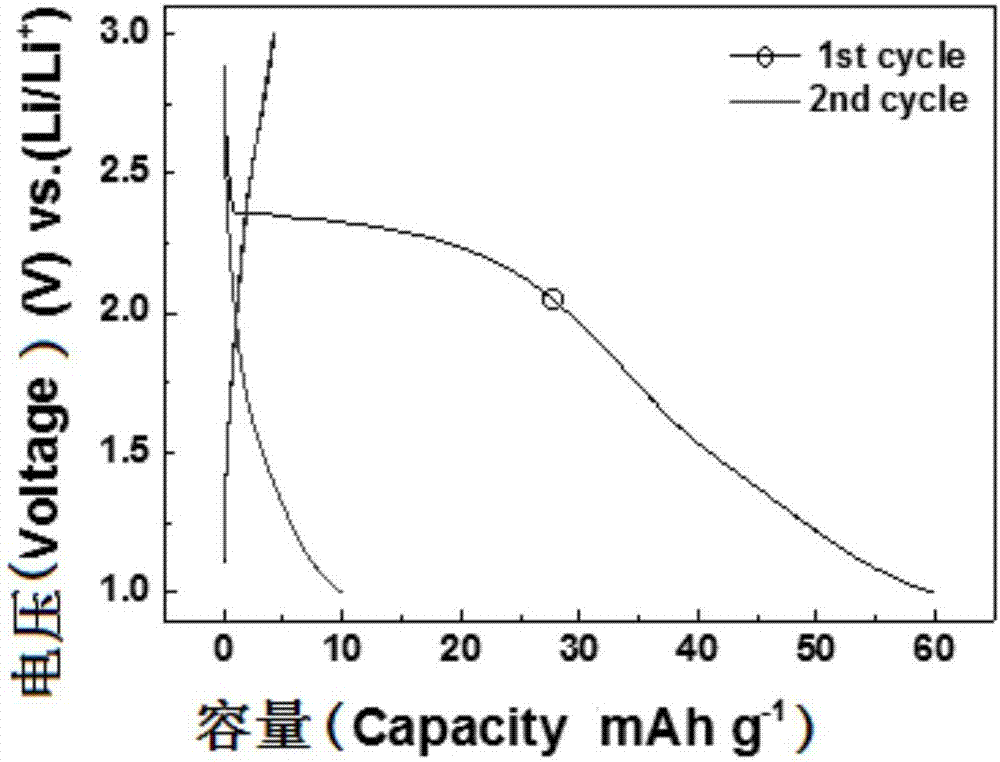

In a non-aqueous electrolyte secondary battery using SiOX as a negative electrode active material, it is an object to improve initial charge-discharge efficiency and cycle properties. Provided is a negative electrode active material containing particles made of SiOX containing a lithium silicate phase, 50% to 100% of the surface of each particle made of SiOX being covered by carbon. The proportion of the number of moles of the lithium silicate phase to the number of moles of the particles made of SiOX is 0.5 mole percent to 25 mole percent. The average primary particle size of the particles made of SiOX is 1 μm to 15 μm.

Owner:SANYO ELECTRIC CO LTD

Composite electrolyte membrane based on functional polymer and preparation method thereof, and lithium-sulfur secondary cell

Owner:NAT UNIV OF DEFENSE TECH

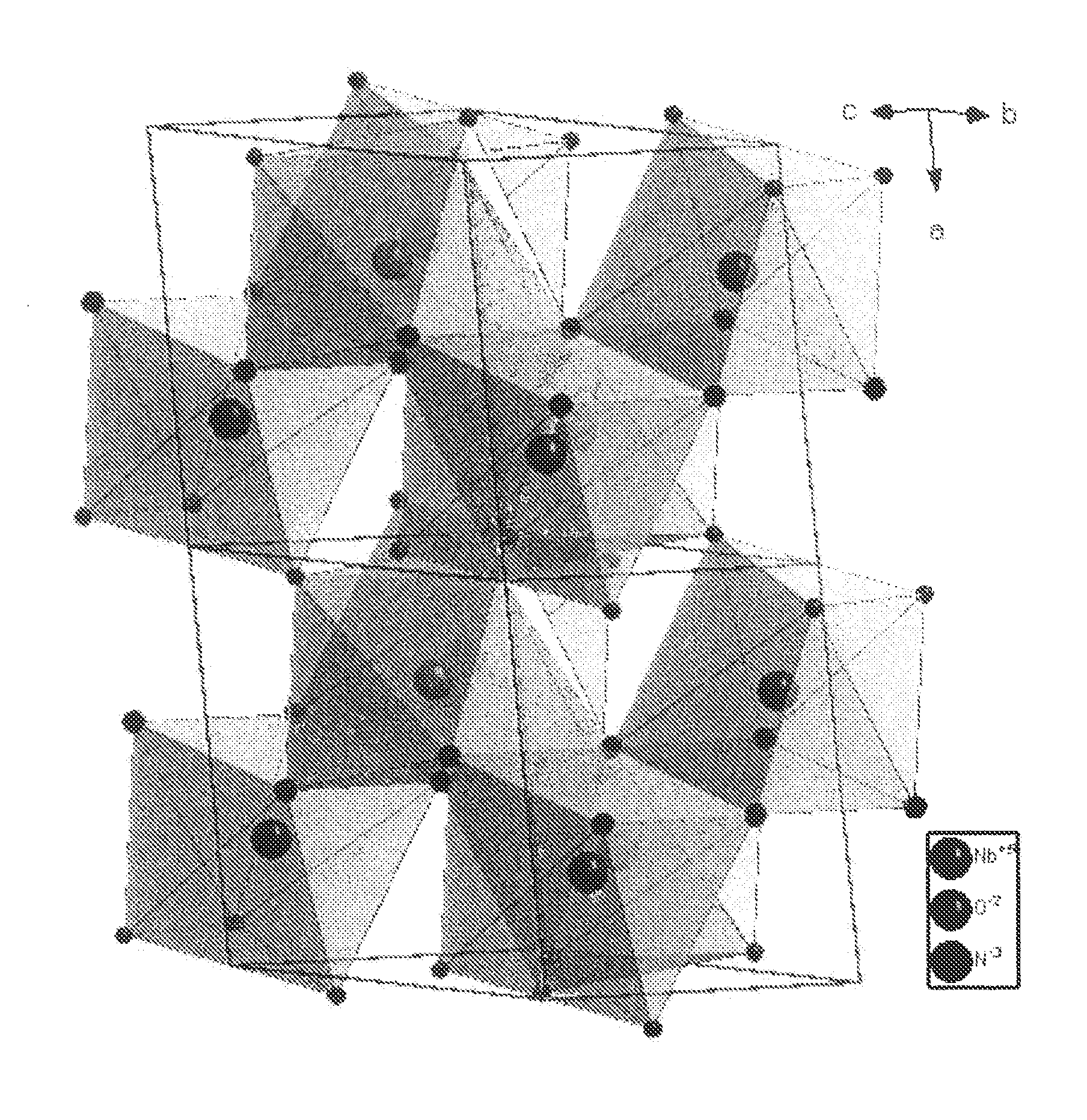

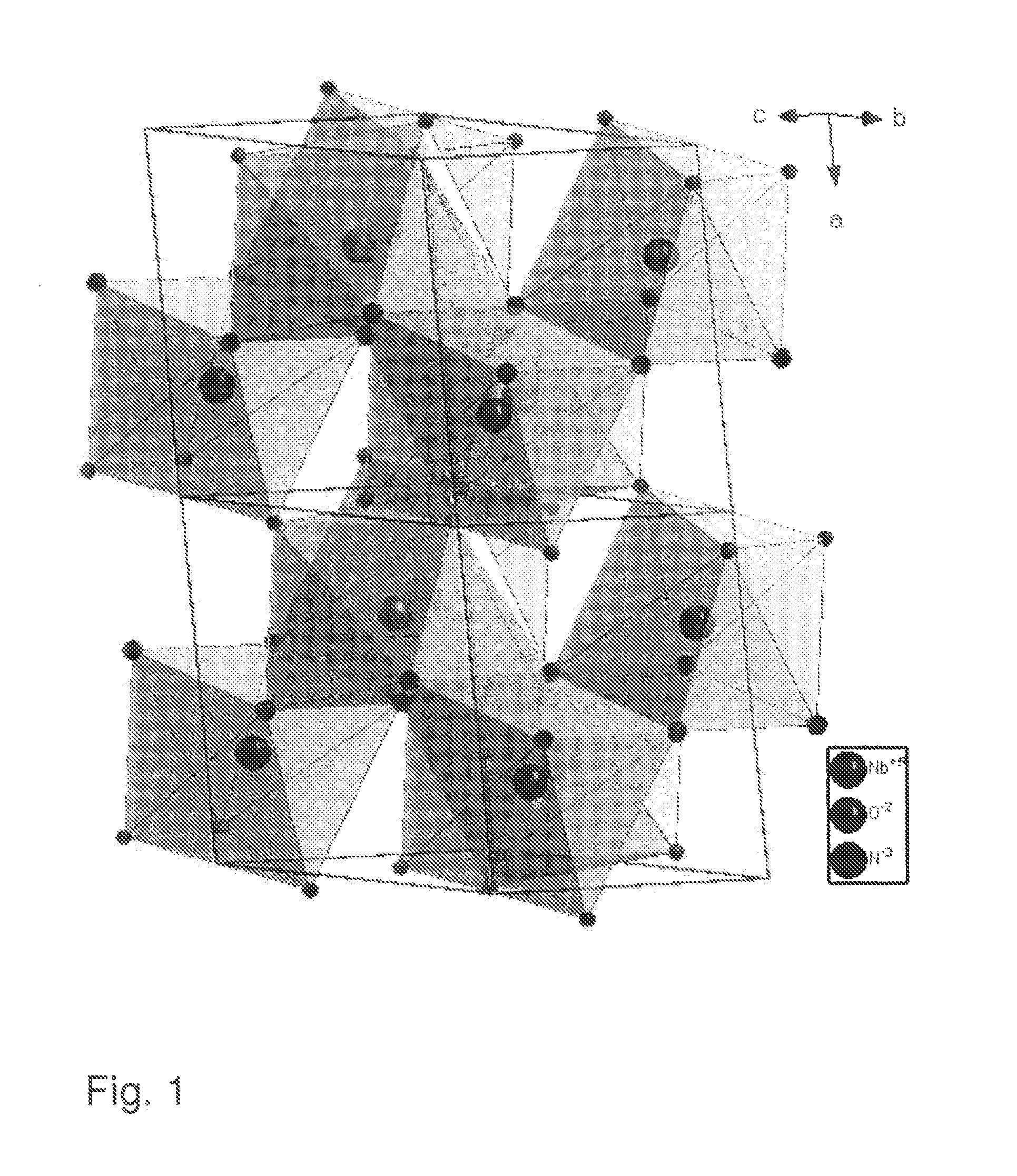

Transition metal oxidenitrides

ActiveUS20110305949A1Weight increaseImprove electrical performanceMaterial nanotechnologyNitrogen compoundsElectrical conductorNanoparticle

Owner:BELENOS CLEAN POWER HLDG

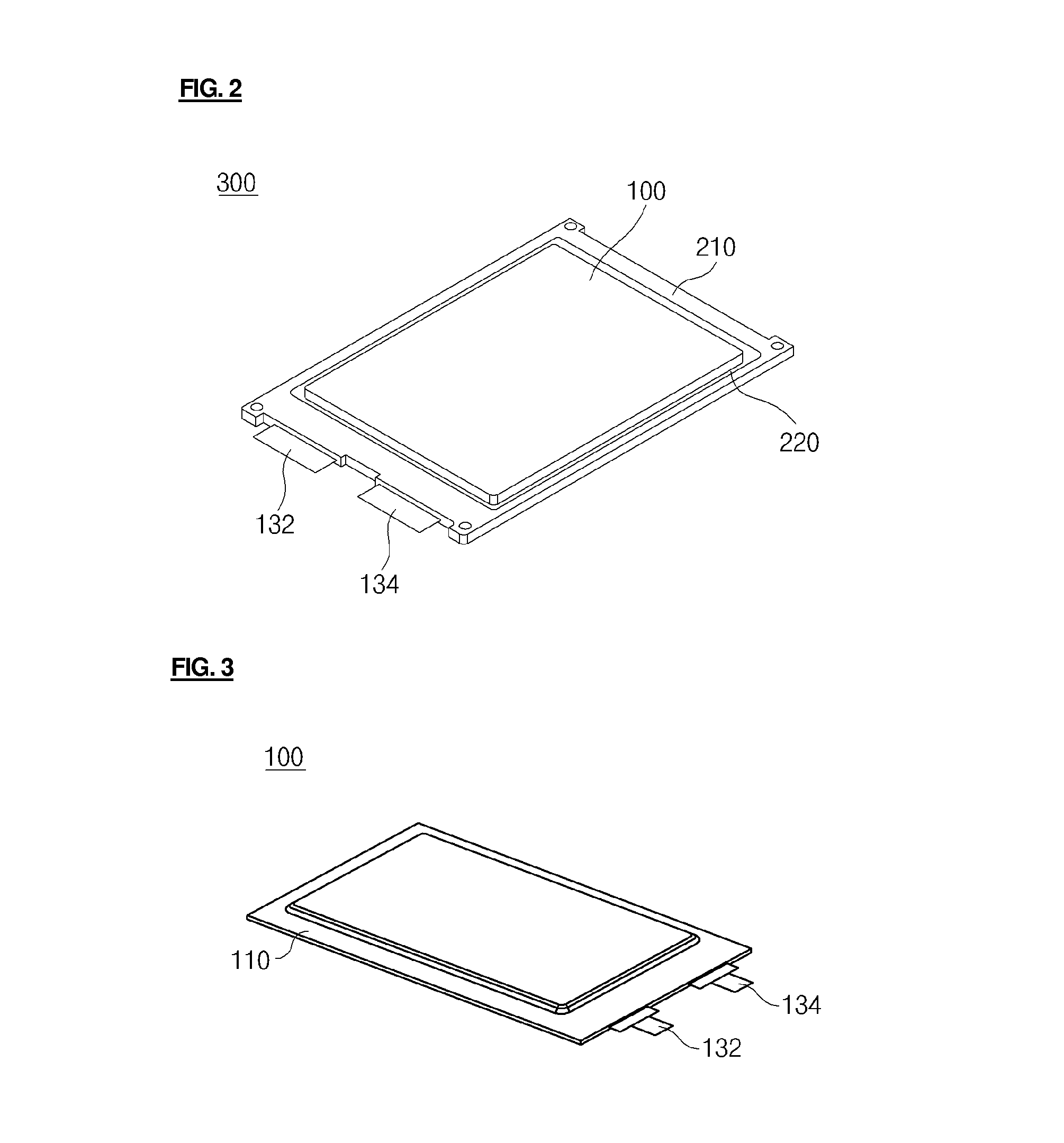

Battery module

ActiveUS20160197387A1Easy dischargeIncrease temperatureSmall-sized cells cases/jacketsFinal product manufactureDischarge efficiencyEngineering

Owner:LG ENERGY SOLUTION LTD

Method for treating lithium metal with fluoroethylene carbonate and application of lithium metal in solid-state batteries

ActiveCN108468042AEasy to prepareLow costCell electrodesMetallic material coating processesMetallic lithiumElectrical battery

The invention relates to a method for treating the surface of lithium metal with fluoroethylene carbonate and an application of the lithium metal in solid-state batteries, and belongs to the technicalfield of preparation of negative electrode materials for lithium batteries. The method comprises that a lithium negative electrode is immersed in fluoroethylene carbonate, and then taken out and subjected to drying treatment to volatilize a residual liquid on the surface. The method is simple and easy to operate and easy to control, has obvious effect on solving the problems of poor compatibilityof lithium metal / solid electrolyte interfaces and lithium dendrite growth in conventional solid-state batteries, and is suitable for large-scale commercialized production.

Owner:SHANDONG UNIV

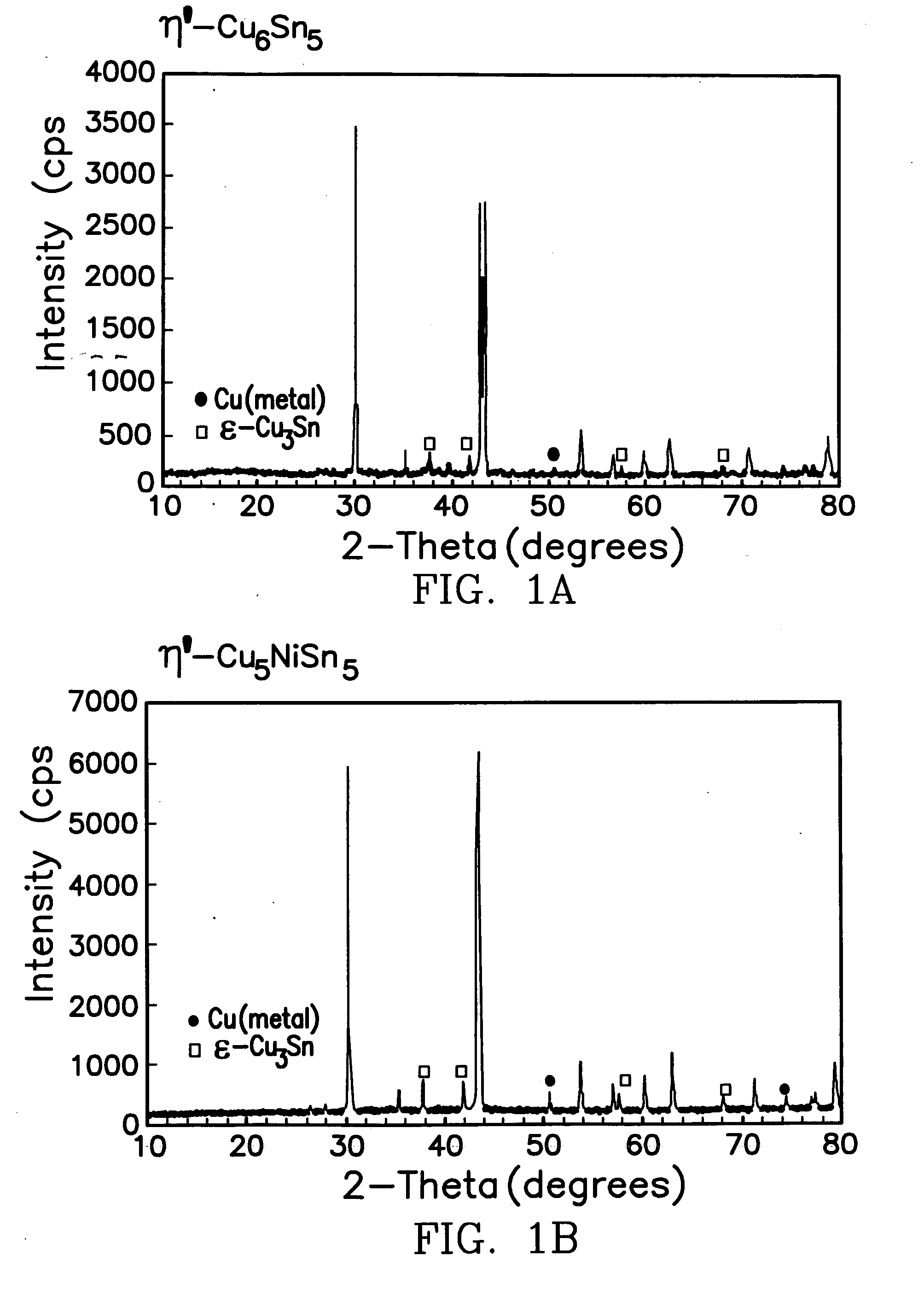

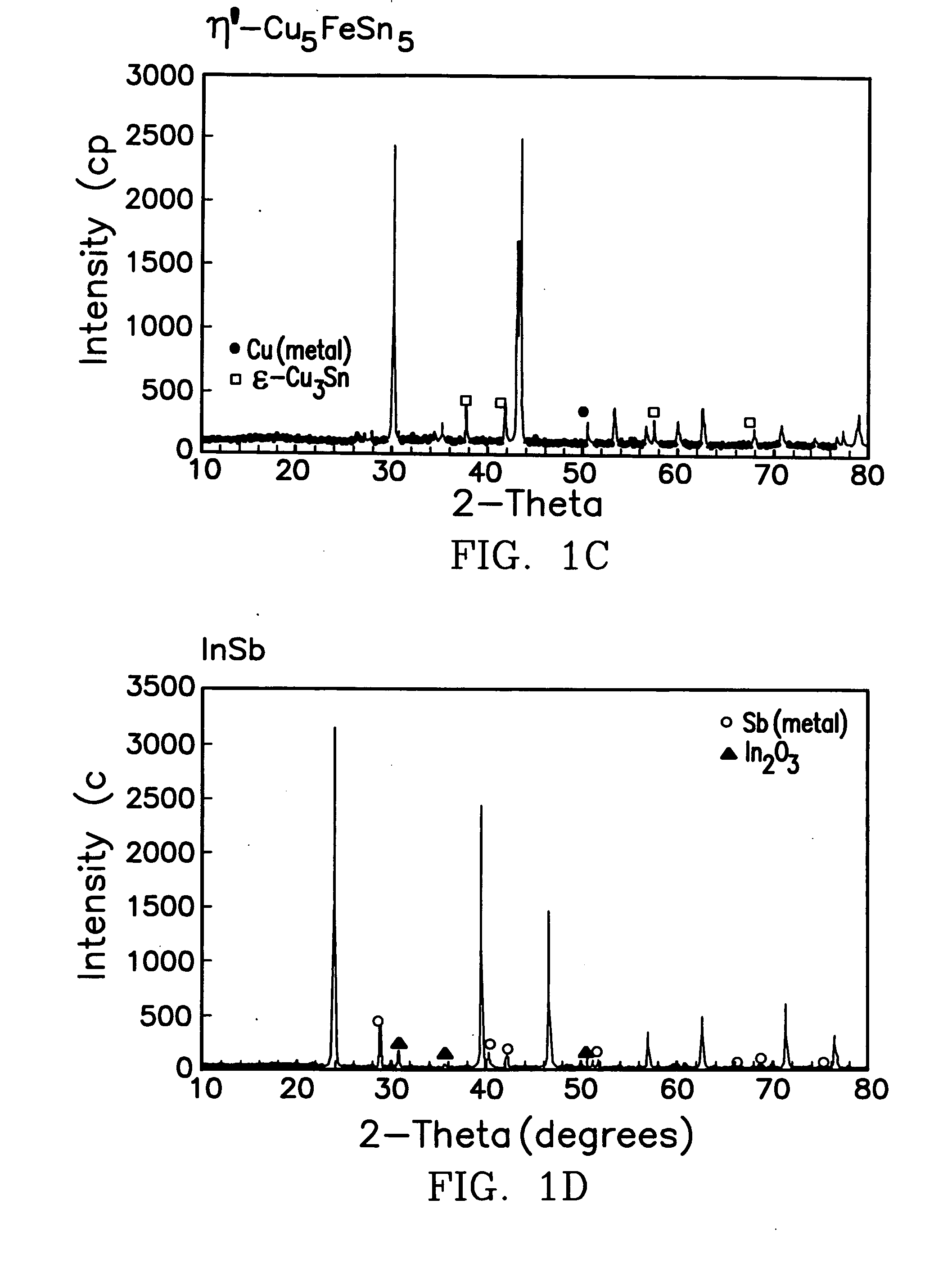

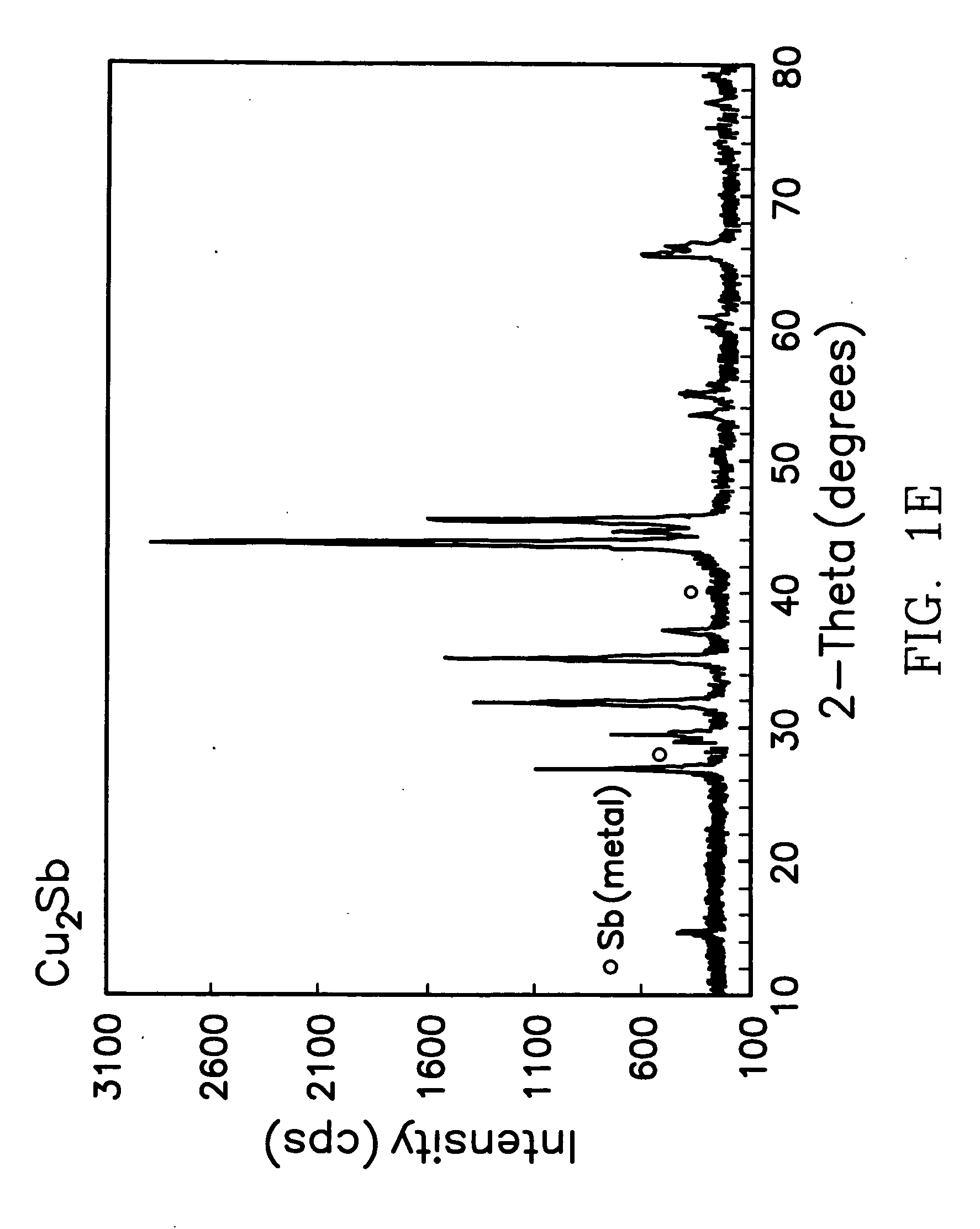

Synthesis of intermetallic negative electrodes for lithium cells and batteries

InactiveUS20070111094A1Primary cell to battery groupingLi-accumulatorsElectrochemical cellOrganic solvent

Owner:UCHICAGO ARGONNE LLC

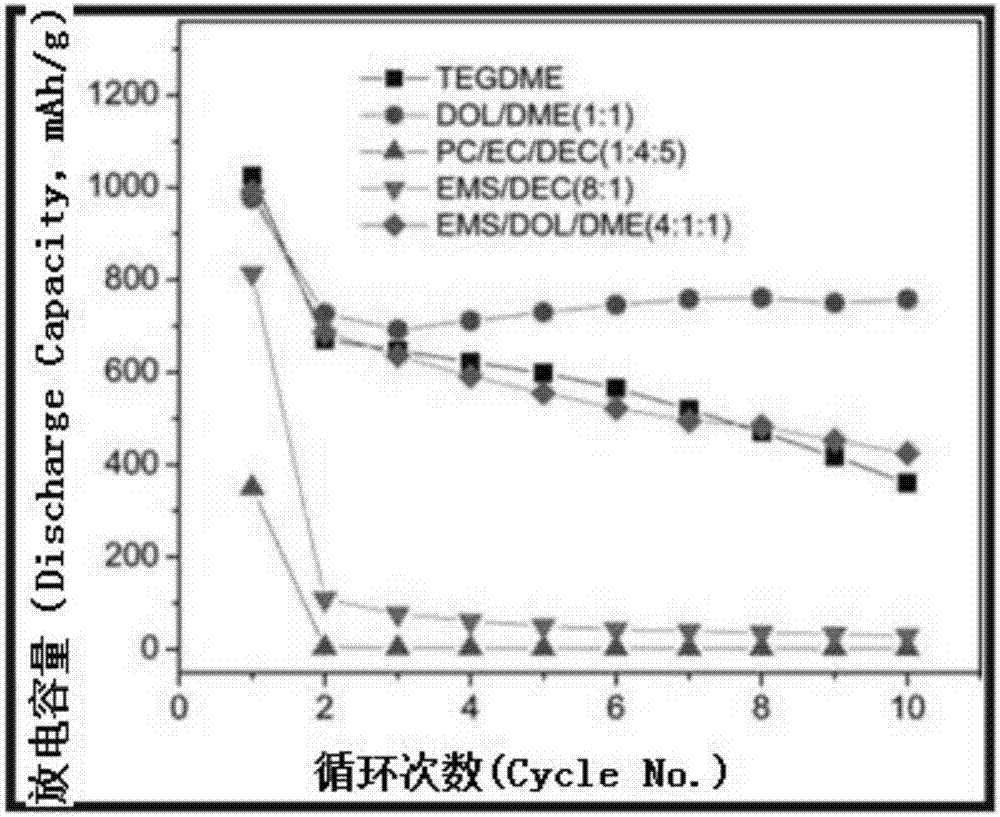

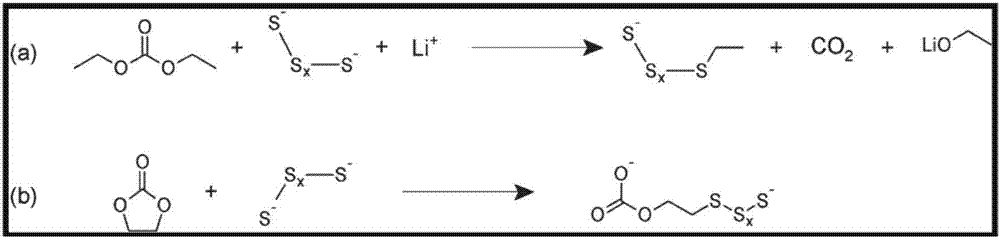

Lithium-sulfur battery electrolyte and lithium-sulfur battery adopting same

Owner:SHANDONG UNIV

Solid-state electrolyte, lithium battery cell and lithium battery

InactiveCN109935896AImprove interfacial adhesionImprove wettabilityMaterial nanotechnologyFinal product manufactureSolid state electrolyteShear modulus

The invention relates to the field of lithium batteries, in particular to a solid-state electrolyte, a lithium battery cell and a lithium battery. The solid-state electrolyte is an anti-perovskite solid-state electrolyte, and includes one or more super base clusters selected from Li3Se+, Li3S+ and Li3O+ and one or more super halogen clusters selected from BH4-, AlH4-, BF4-, FeH4-, CoH4- and NiH4-.The solid-state electrolyte exhibits a nanowire morphology. Therefore, the solid-state electrolyte has an electrochemical window above 5V and excellent interfacial adhesion, wettability and lithium ion conductivity, and the molecular skeleton of the solid-state electrolyte has good tolerance. Based on the structural characteristics of the solid-state electrolyte, the solid-state electrolyte has the advantages of high shear modulus, high Young's modulus and capability of inhibiting the growth of lithium dendrites.

Owner:CHENGDU DACHAO TECH CO LTD

Lithium ion secondary battery positive electrode active material, and production method thereof

Owner:ASAHI GLASS CO LTD

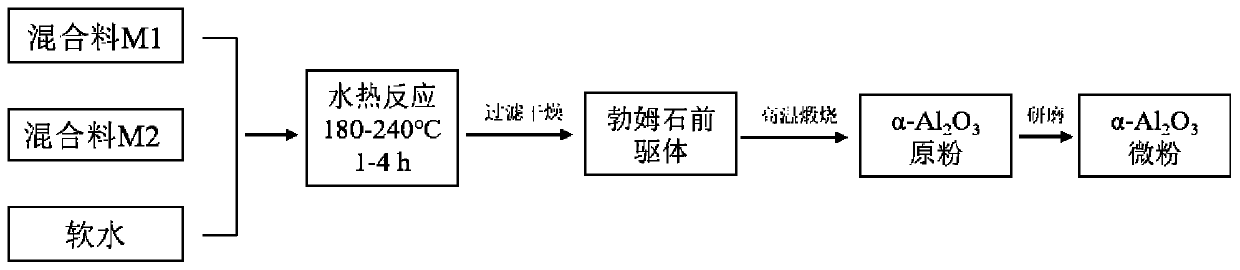

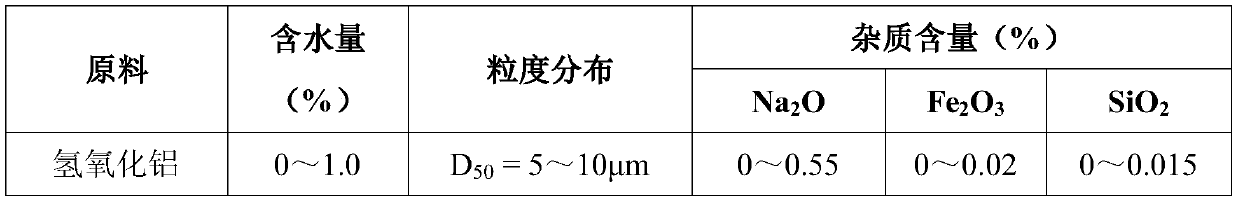

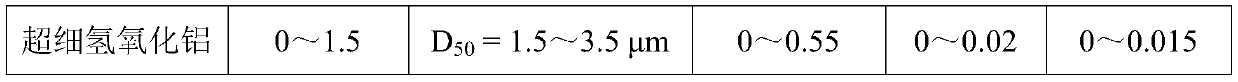

Preparation method of special alumina for high-purity lithium battery separation membranes

Owner:苏州盛曼特新材料有限公司

Positive electrode for nonaqueous electrolyte secondary battery and nonaqueous electrolyte secondary battery

ActiveUS20170187036A1InhibitionWithout deteriorating battery characteristicFinal product manufactureElectrode carriers/collectorsLithiumInorganic particle

The positive electrode as an embodiment includes a positive electrode current collector mainly composed of aluminum, a positive electrode mixture layer containing a lithium-containing transition metal oxide and disposed above the positive electrode current collector, and a protective layer disposed between the positive electrode current collector and the positive electrode mixture layer. The protective layer contains inorganic particles, an electro-conductive material, and a binding material; is mainly composed of the inorganic particles; and is disposed on the positive electrode current collector to cover the positive electrode current collector in approximately the entire area where the positive electrode mixture layer is disposed and at least a part of the exposed portion of the positive electrode current collector where the positive electrode mixture layer is not disposed on the surface of the positive electrode current collector.

Owner:PANASONIC CORP

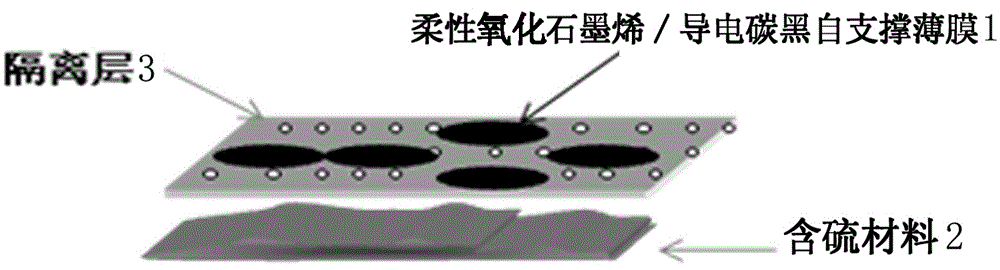

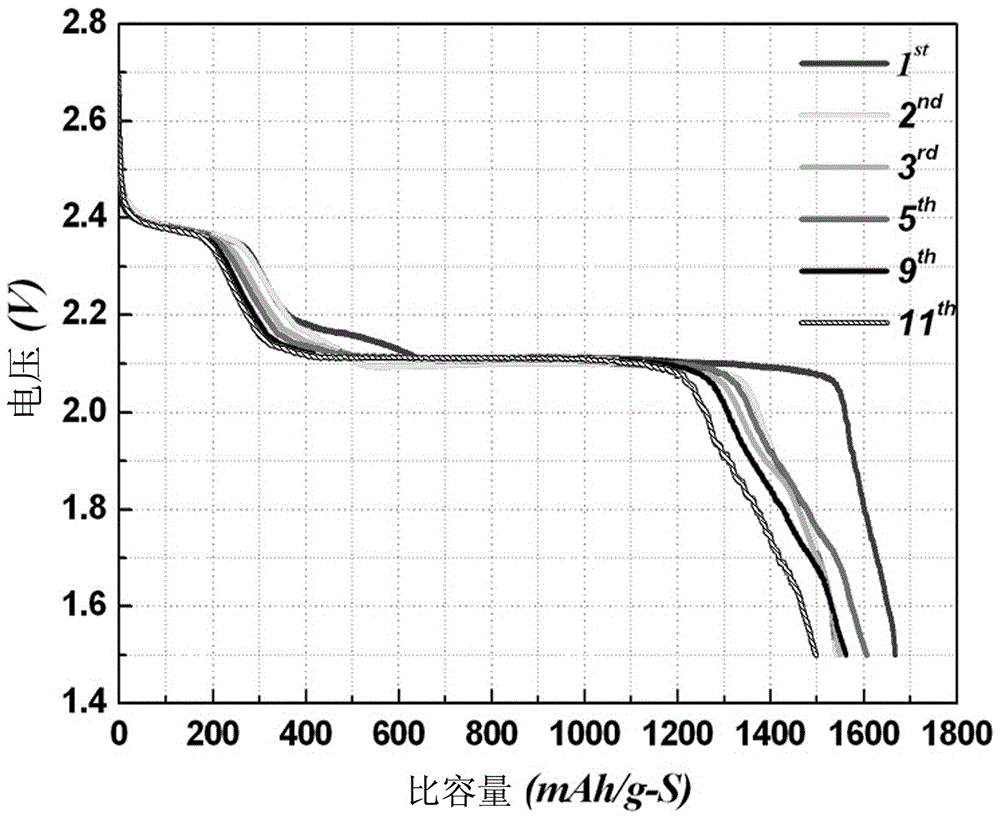

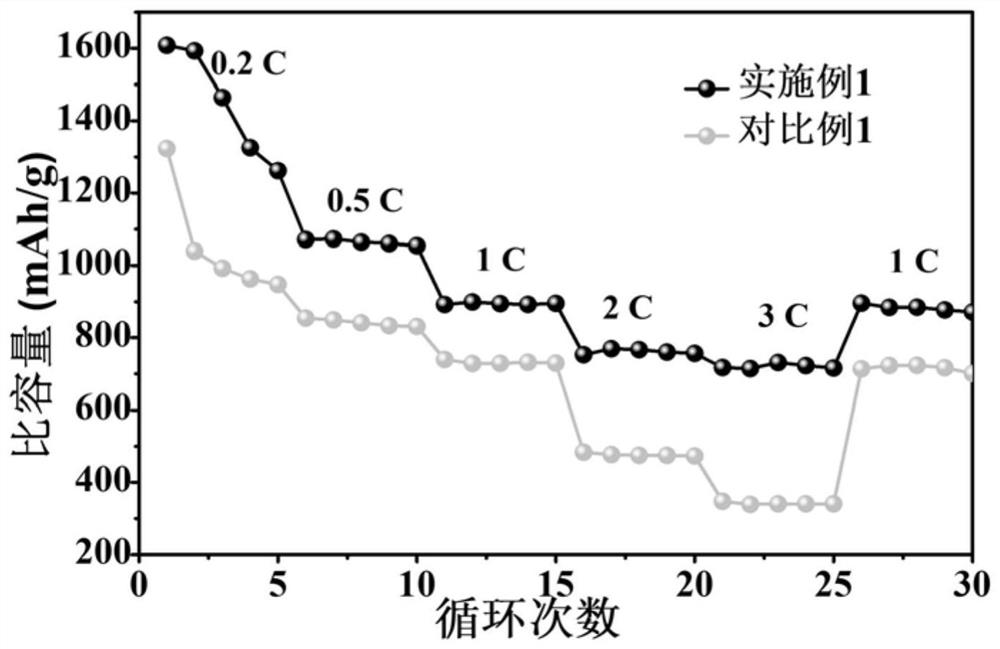

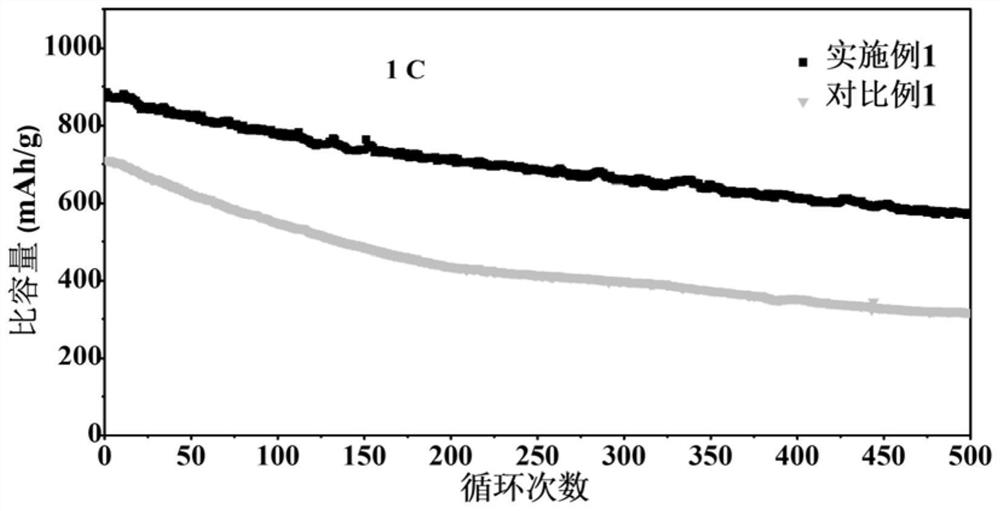

High-specific-energy flexible integrated electrode and preparation method therefor

ActiveCN106450423ASolve the problem of high specific energy characteristicsSolve the problem without degrading the high specific energy characteristics of the electrodeElectrode carriers/collectorsLi-accumulatorsCharge dischargePolysulfide

Owner:SHANGHAI INST OF SPACE POWER SOURCES

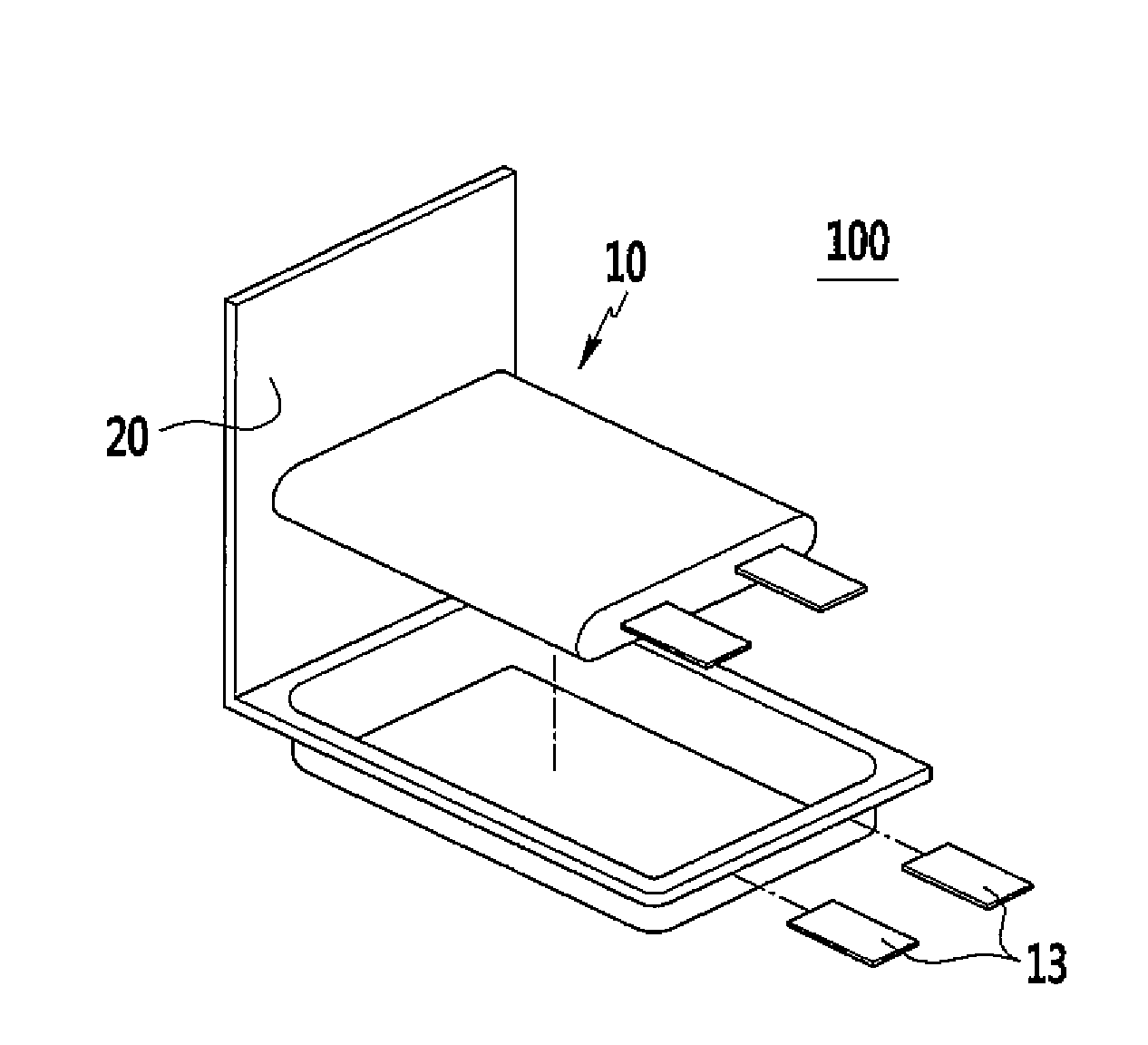

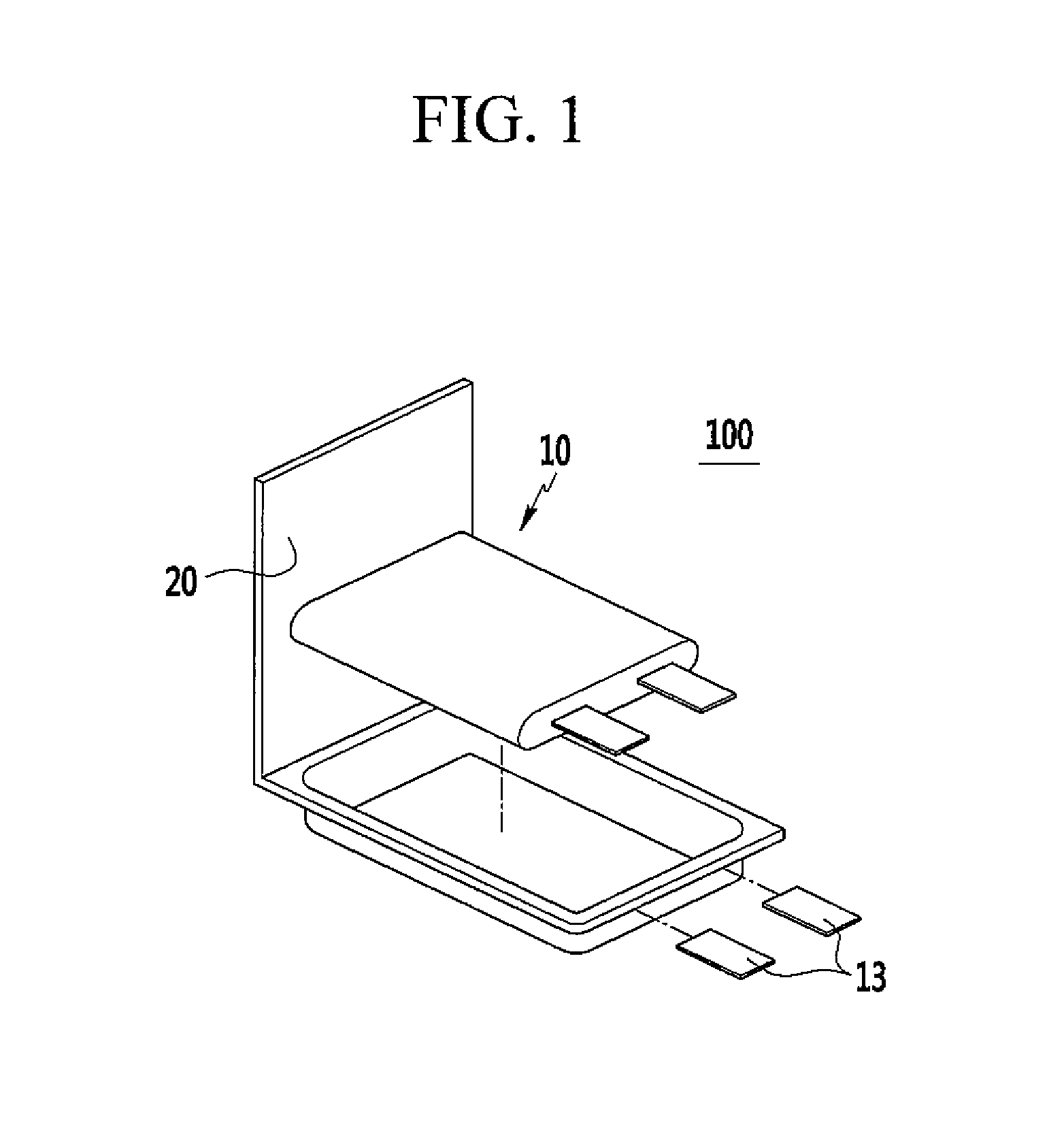

Electrode assembly, manufacture method thereof and lithium secondary battery

InactiveCN103887472AEasy to processExtend your lifeFinal product manufactureLi-accumulatorsLithiumEngineering

The invention discloses an electrode assembly which comprises a first polar plate, and two second polar plates, wherein active material layers are coated on two surfaces of the first polar plate, the first polar plate is continuously bent into a Z shape of a vertical cross-section along the length direction of the first polar plate, an active material layer is coated on one surface of the second polar plate, each second polar plate is continuously bent into a Z shape of a vertical cross-section along the length direction of the second polar plate, two surfaces of the first polar plate, coated with the active material layers, are respectively opposite to surfaces of the two second polar plates, coated with the active material layers, an isolating layer is arranged between the surfaces of the first polar plate, which are opposite to the second polar plates, and the first polar plate and the second polar plates are respectively provided with a contact region with connected leads. The electrode assembly is low in requirement of production equipment, is easy to process and manufacture, and is relatively prolonged in service life. The material utilization rate of the electrode assembly can be increased, the cost is lowered, and the energy density of a battery is improved, so that the volume of the electrode assembly is relatively reduced under the same capacity.

Owner:INST OF IND TECH GUANGZHOU & CHINESE ACADEMY OF SCI +1

Functionalized quantum dot composite solid electrolyte membrane and preparation method and application thereof

ActiveCN110504486AImprove mechanical propertiesEasy to makeSolid electrolytesLi-accumulatorsSolid state electrolytePolyethylene oxide

Owner:河南景创新能源科技有限公司

Method of static scaling of image in holographic lithography

ActiveUS20150185697A1Holographic light sources/light beam propertiesLi-accumulatorsLithographic artistLength wave

Proposed is a method of static scaling of an image in holographic lithography. The method consists of generating a final virtual digital hologram of the original pattern through a sequence of mathematical calculations with participation of a virtual coherent light source having a predetermined wavelength λ1 and producing an actual hologram on the basis of the virtual digital hologram of the original pattern. The obtained hologram can be used for forming an actual original pattern in a predetermined size. When it is necessary to produce the original pattern in another size, this can be done by static scaling by merely selecting another wavelength for the laser source with adjustable wavelength. The method allows determining the wavelength range in which scalability is possible with substantially homotetic transformation of the image.

Owner:RAKHOVSKY VADIM

Positive Electrode Active Material for Lithium Secondary Battery

Provided is a novel positive electrode active material which can effectively suppress the quantity of gas generated by the reaction with an electrolytic solution. Proposed is a positive electrode active material for a lithium secondary battery including positive electrode active material particles obtained by equipping the entire surface or a part of a surface of lithium manganese-containing composite oxide particles (also referred to as the “core particles”) operating at a charging voltage in a region exceeding 4.3 V in a metal Li reference potential with a layer A containing at least titanium (Ti), aluminum (Al), zirconium (Zr), or two or more kinds of these.

Owner:MITSUI MINING & SMELTING CO LTD

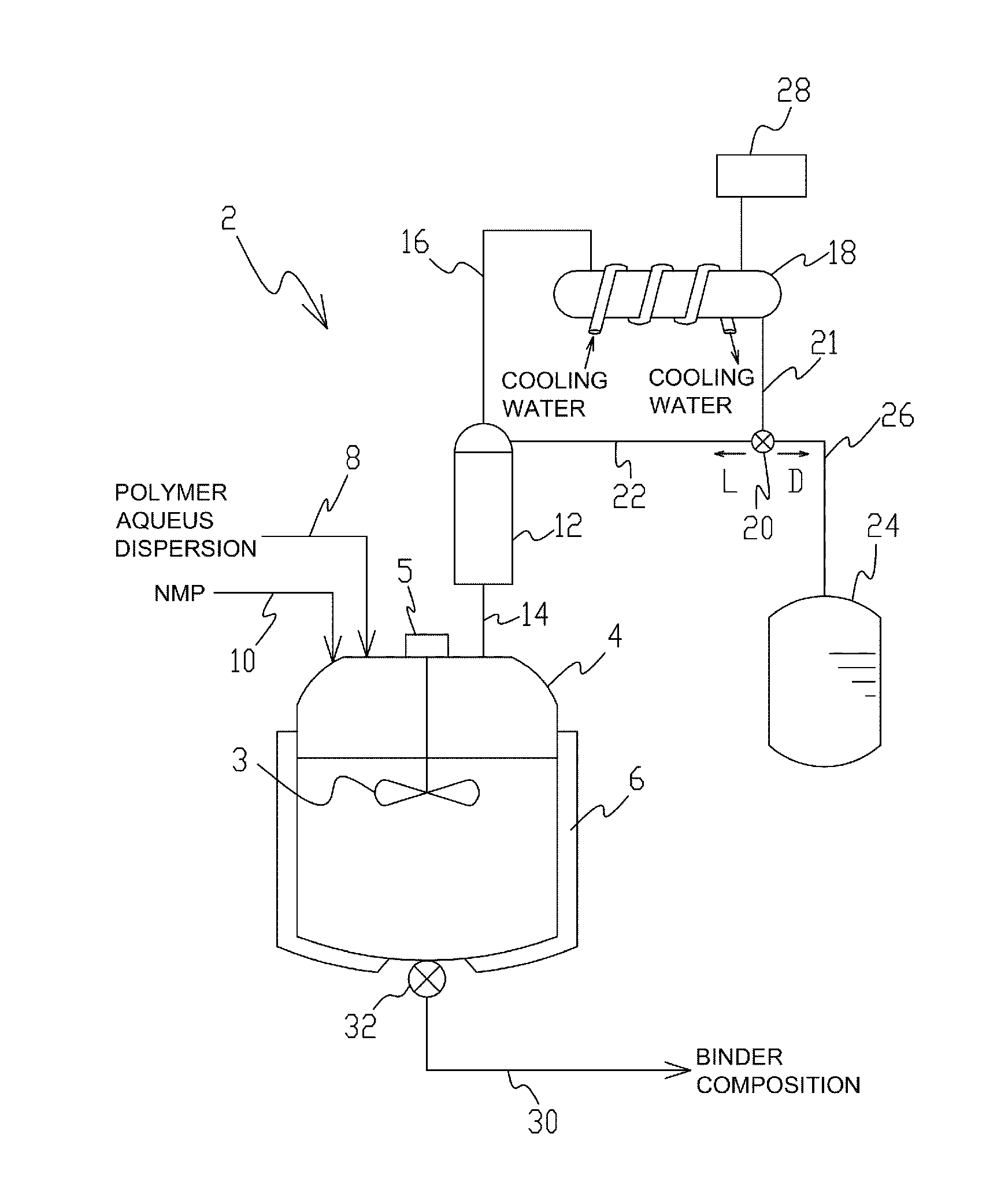

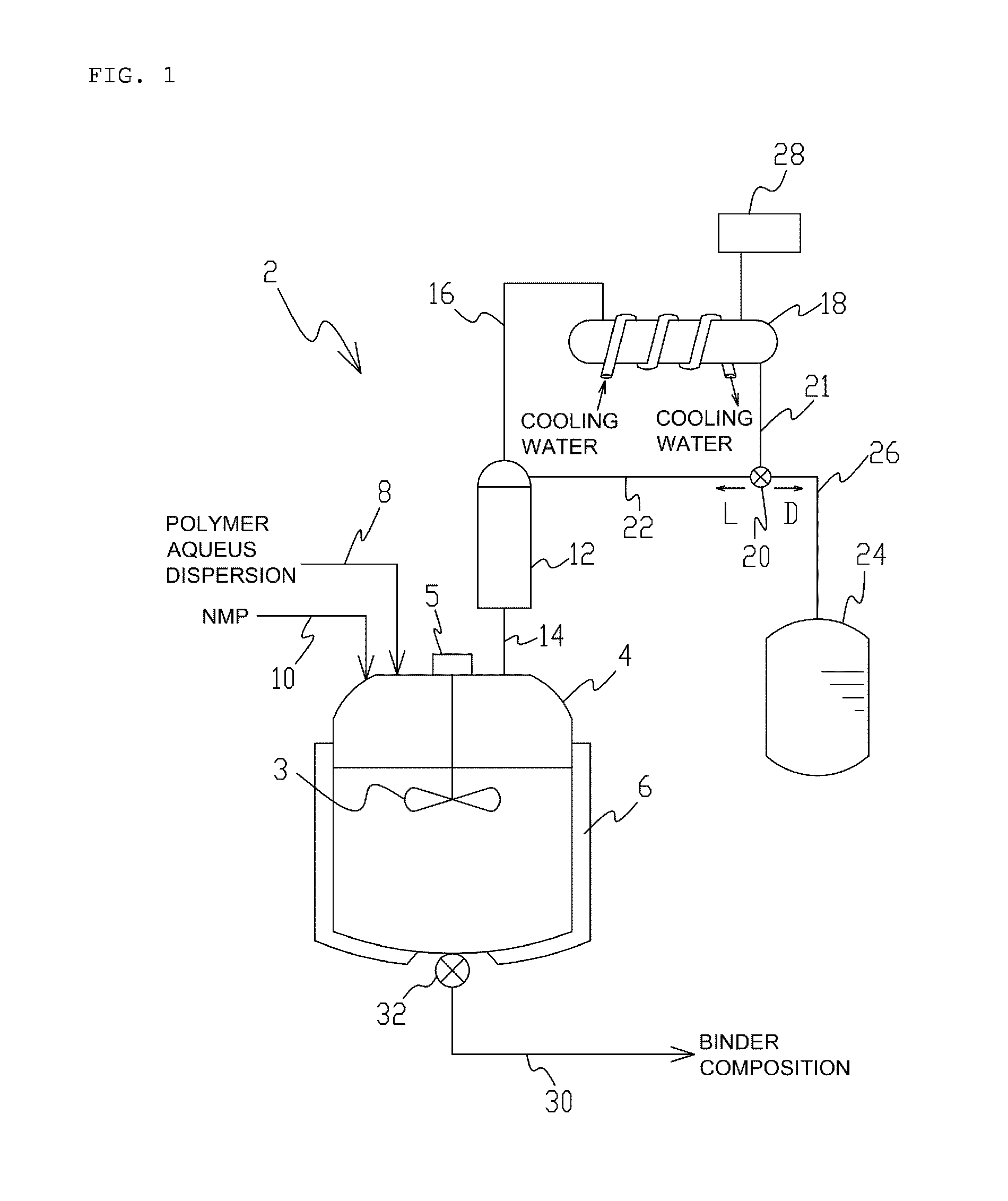

Method for producing slurry for heat-resistant layer for lithium ion secondary battery and method for producing electrode for lithium ion secondary battery

InactiveUS20140242296A1Reduce the amount of waterEfficiently obtainedElectrode manufacturing processesMixing methodsPolymer scienceDistillation

Owner:ZEON CORP

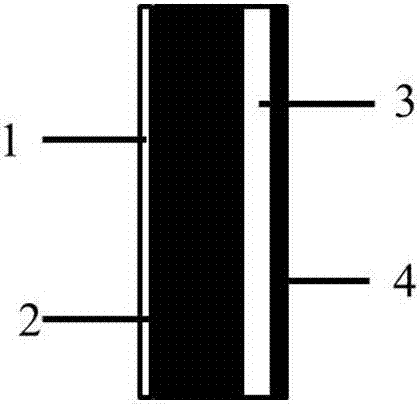

Lithium secondary battery possessing stress relaxation layer

InactiveCN102420339AImprove cycle lifeFinal product manufactureElectrode carriers/collectorsAdhesiveEngineering

The invention provides a high-capacity lithium secondary battery which relaxes the stress on the electrode to prevent the falling or loosing of the electrode. The degradation of the lithium secondary battery caused by the charging-discharging circulation is not serious. The lithium secondary battery includes a winding group which is formed by winding the anode and the cathode together, and a baffle plate is arranged between the anode and the cathode. The anode and the cathode can absorb and discharge lithium ions reversibly. The lithium secondary battery also includes an organic electrolyte solution which dissolves the electrolytes containing the lithium ions. The cathode s formed by coating an agent-mixed layer which contains an active material and an adhesive on a collector electrode. The collector electrode is formed by arranging the stress relaxation layer possessing the inner stress on at least one side of a surface or the back of a copper foil.

Owner:HITACHI LTD

Electrode, nonaqueous electrolyte battery, battery pack and vehicle

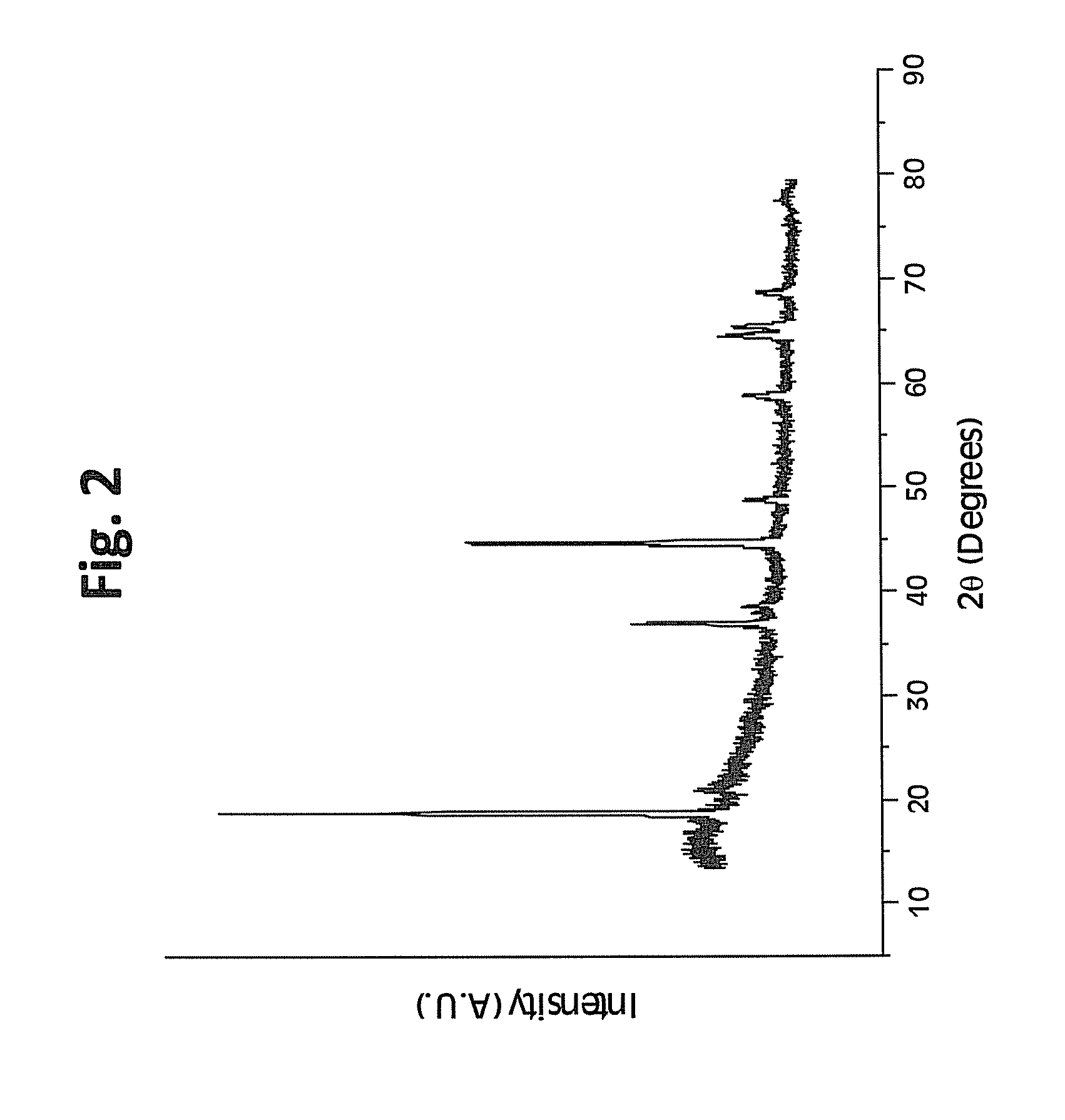

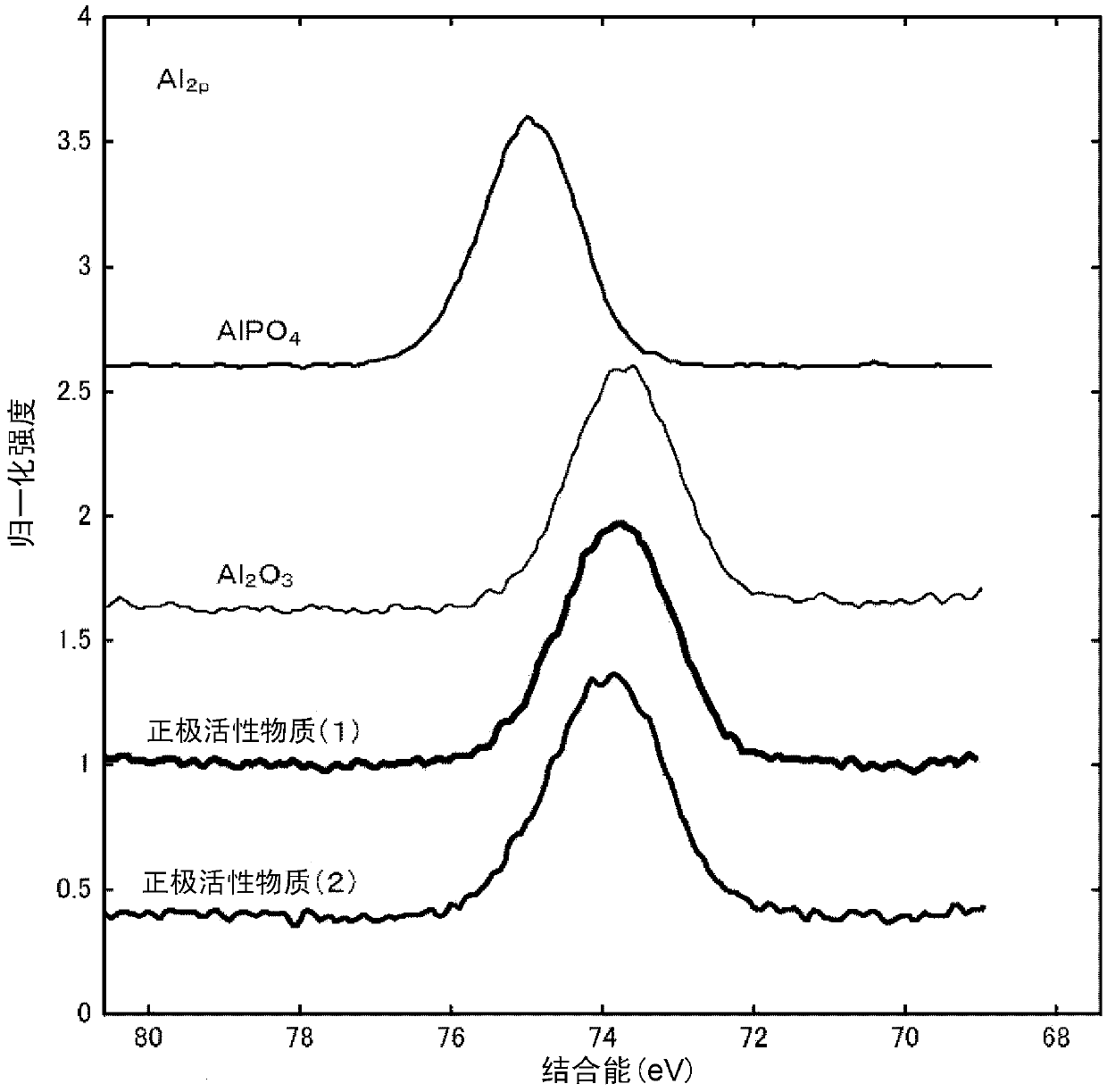

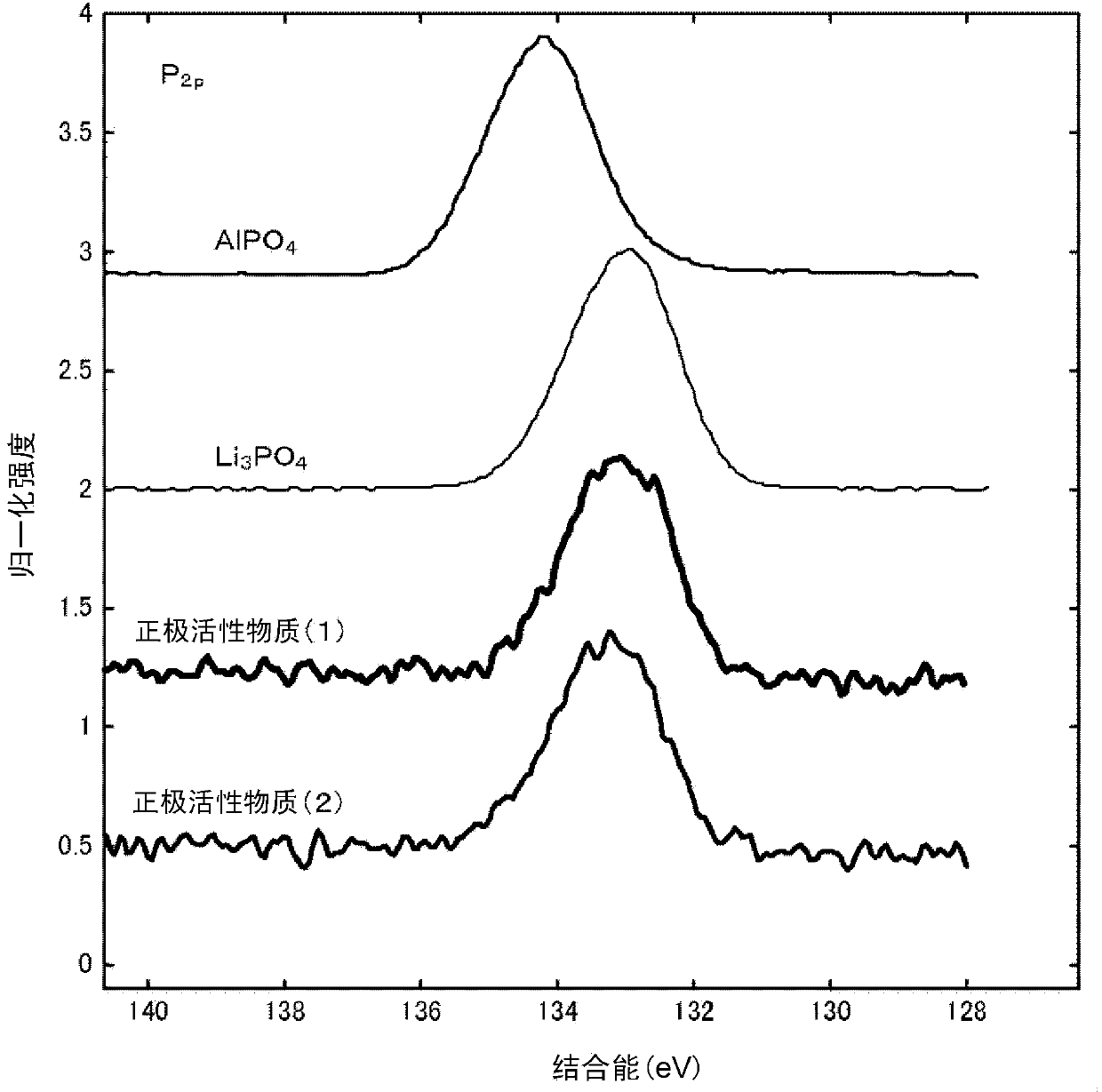

ActiveCN108630908AImprove life characteristicsAlkali titanatesNegative electrodesBinding energyX-ray

The invention relates to an electrode, a nonaqueous electrolyte battery, a battery pack and a vehicle. The invention provides an electrode excellent in service performance. According to one approach,an electrode (3) is provided. The electrode (3) includes an active material-containing layer (3b). The active material-containing layer (3b) includes a Na-containing niobium-titanium composite oxide having an orthorhombic crystal structure. The active material-containing layer (3b) satisfies I2 / I1>=1. I1 is an intensity of a peak P1 appearing in a binding energy range of 289 eV to 292 eV in an X-ray photoelectron spectroscopy spectrum of the active material-containing layer (3b). I2 is an intensity of a peak P2 appearing in a binding energy range of 283 eV to 285 eV in the X-ray photoelectronspectroscopy spectrum of the active material-containing layer (3b).

Owner:KK TOSHIBA

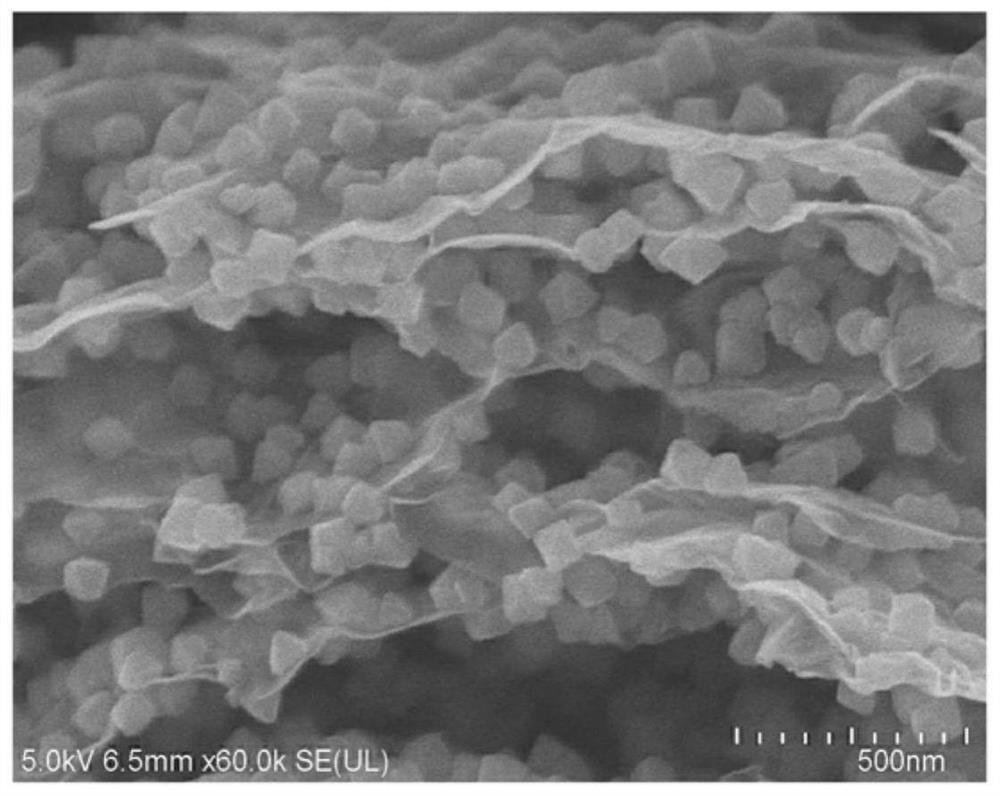

Graphene/functionalized metal-organic framework material composite intercalation as well as preparation method and application thereof

PendingCN112421133AImprove conductivityEasy transferLi-accumulatorsCell component detailsElectrolytic agentInterface impedance

Owner:GUANGDONG UNIV OF TECH

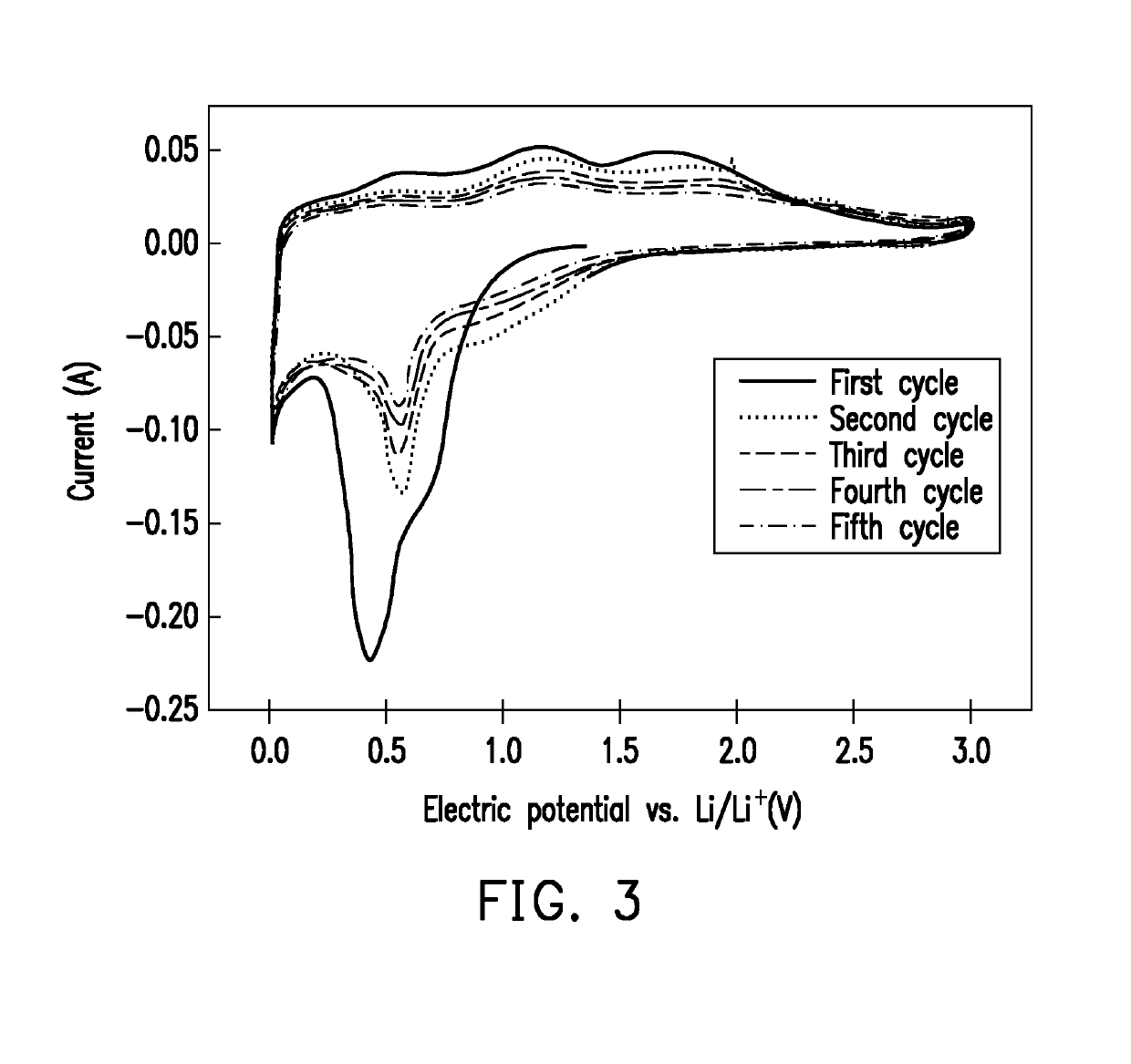

Electrode material for secondary battery and secondary battery

ActiveUS20190305357A1Improve stabilityLarge capacityCell electrodesLi-accumulatorsEngineeringElectrolyte

Owner:NATIONAL TSING HUA UNIVERSITY

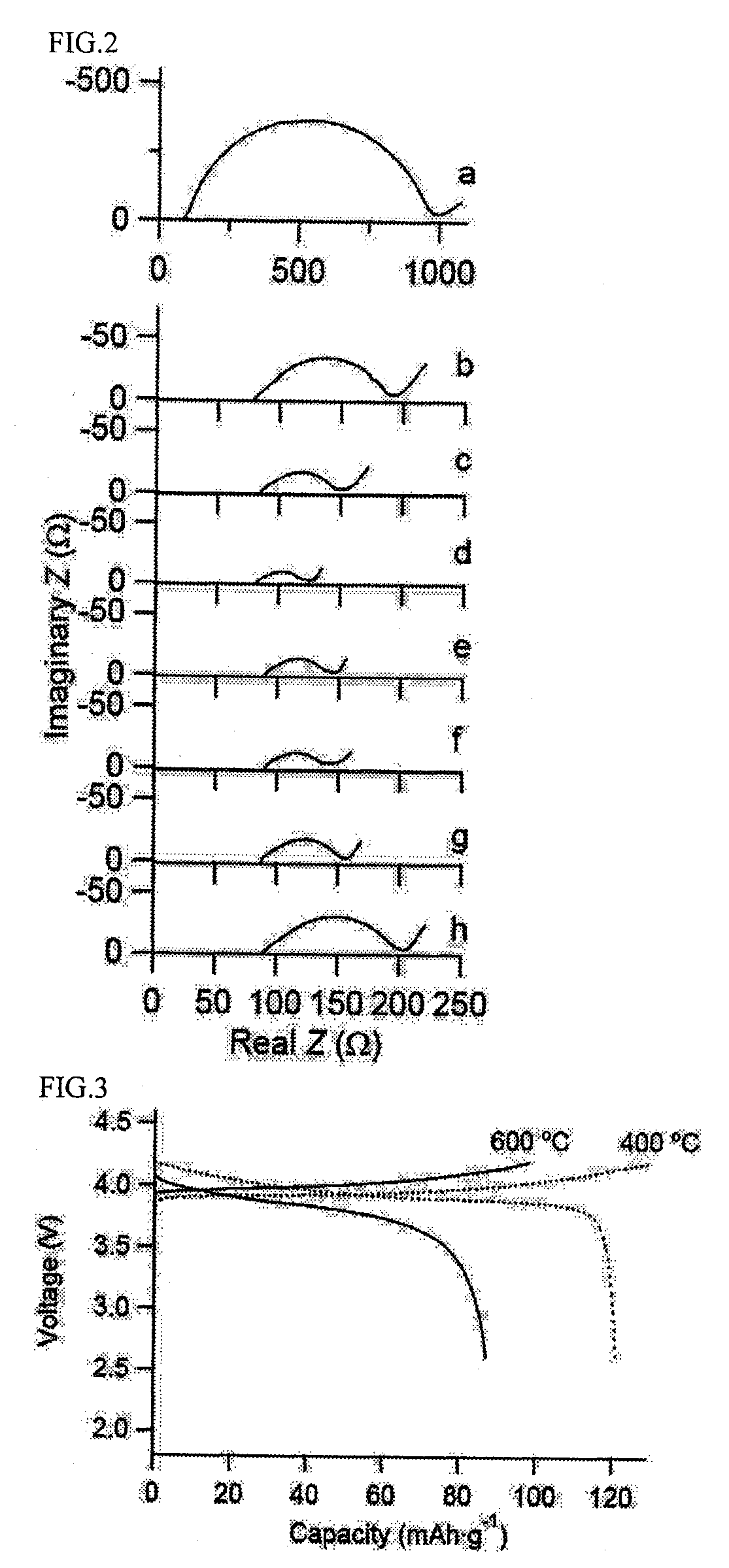

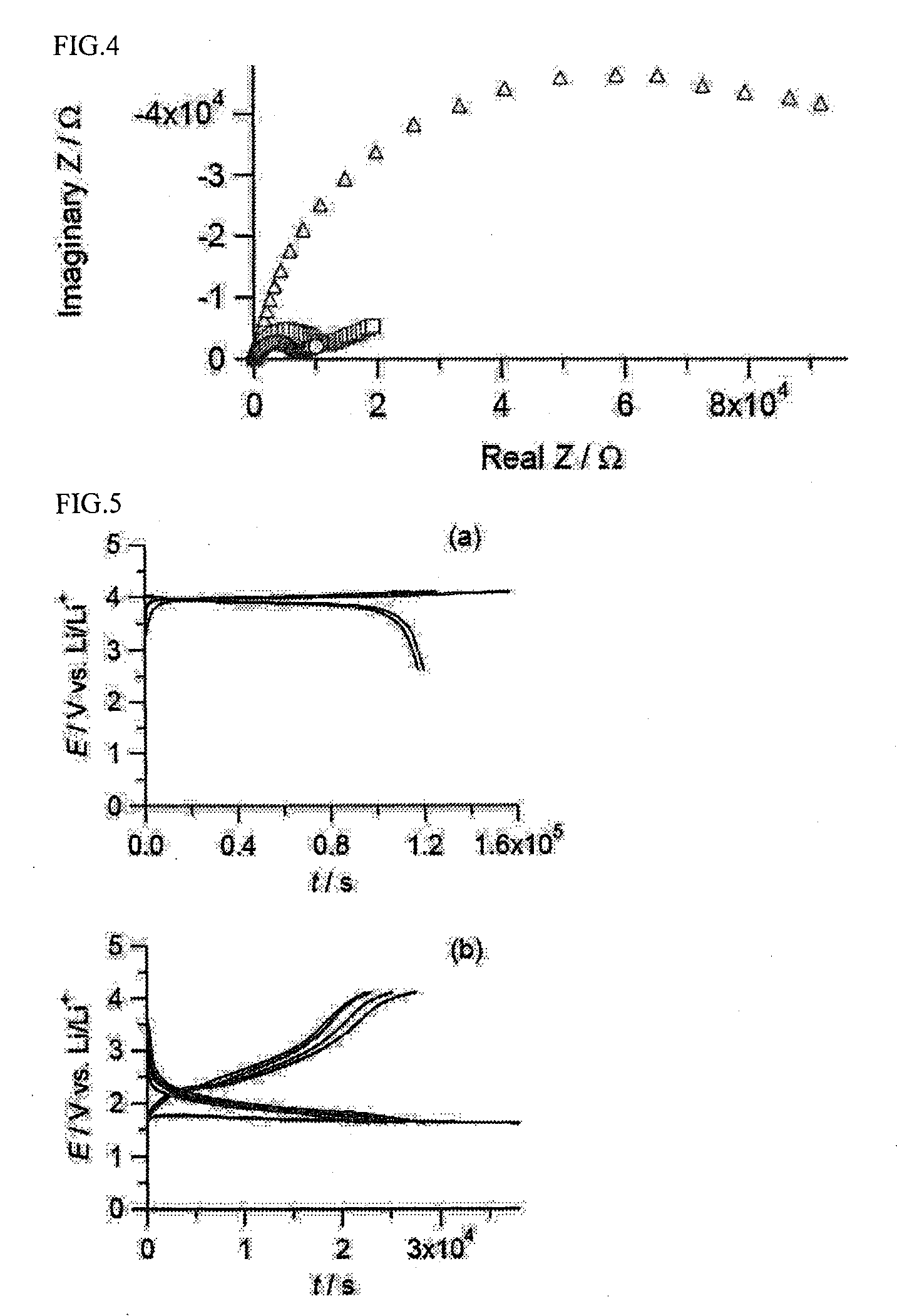

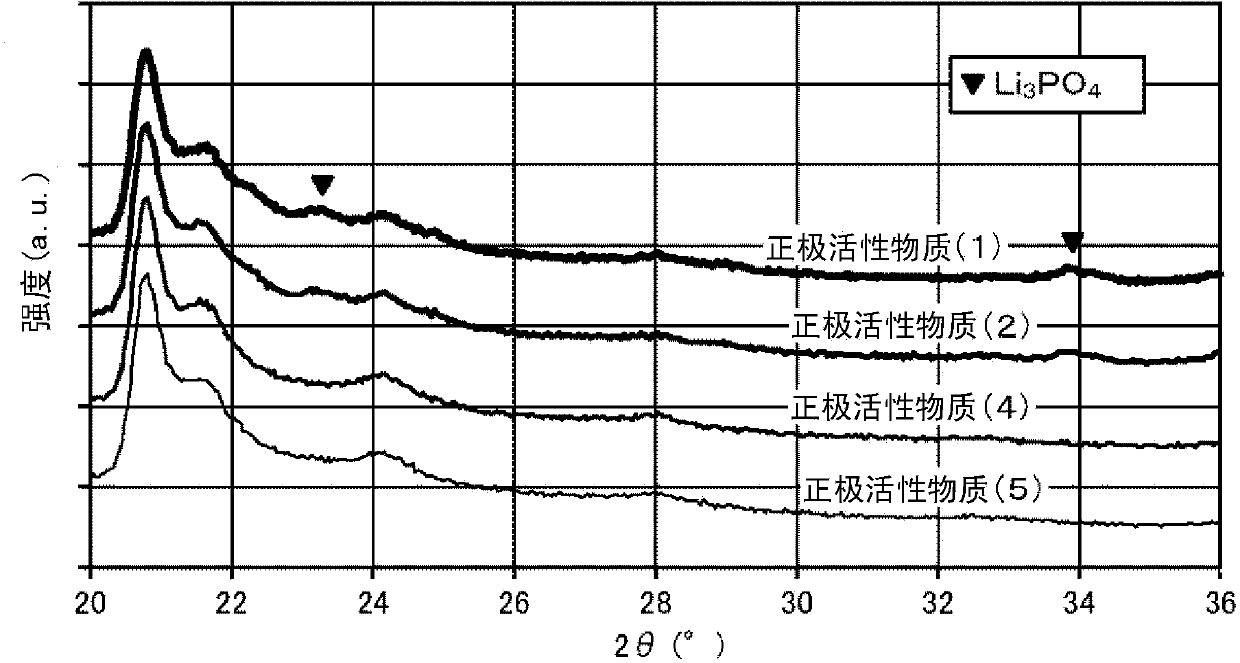

Positive electrode active material particle powder for non-aqueous electrolyte secondary battery, method for producing same, and non-aqueous electrolyte secondary battery

ActiveUS20180183039A1Excels in high-temperature propertyExcellent charge/discharge cycle property propertyElectrode thermal treatmentPositive electrodesSpinelLithium manganese oxide

Owner:TODA IND

Rechargeable lithium battery

InactiveUS20150125735A1Improved cycle life characteristicsCell electrodesLi-accumulatorsElectrolytic agentEthylene carbonate

Owner:SAMSUNG SDI CO LTD

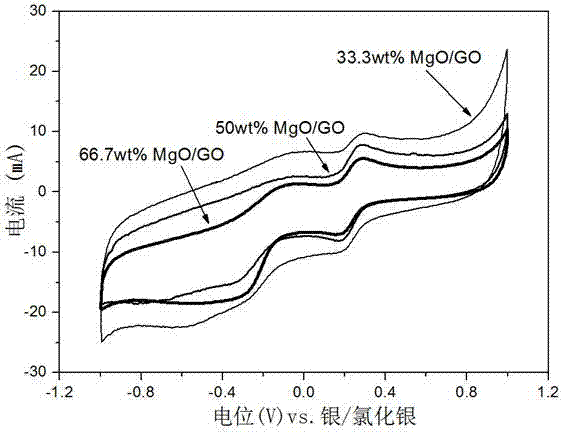

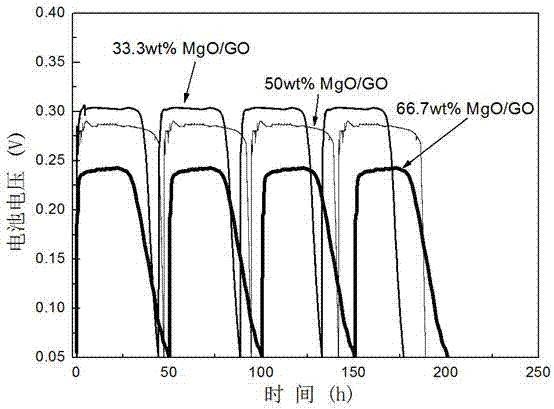

Composite cathode of microbial fuel cell and preparation method and application thereof

PendingCN107221682AWide variety of sourcesLow priceHybrid capacitor electrodesBiochemical fuel cellsOxide compositeAlloy

Owner:SOUTH CHINA UNIV OF TECH +1

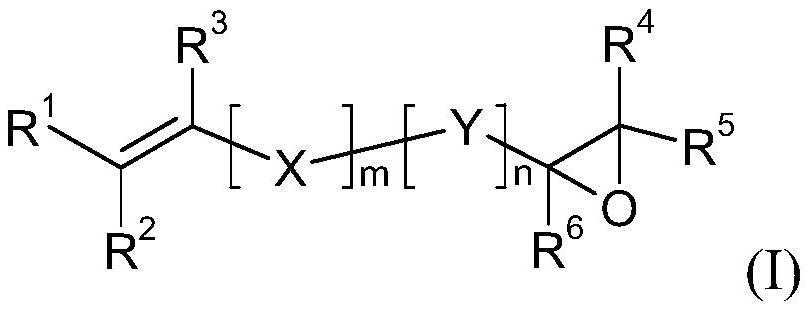

Electrode composition for a cathode of a cell of a lithium-ion battery, a cathode slurry composition, a cathode and the battery incorporating it

The present invention relates to an electrode composition for a cathode of a cell of a lithium-ion battery comprising an epoxy group-containing fluorine-free copolymer, a cathode slurry composition comprising the electrode composition, a cathode, a process for manufacturing this cathode, and a lithium-ion battery having one or more cells incorporating this cathode.

Owner:ARLANXEO DEUT GMBH

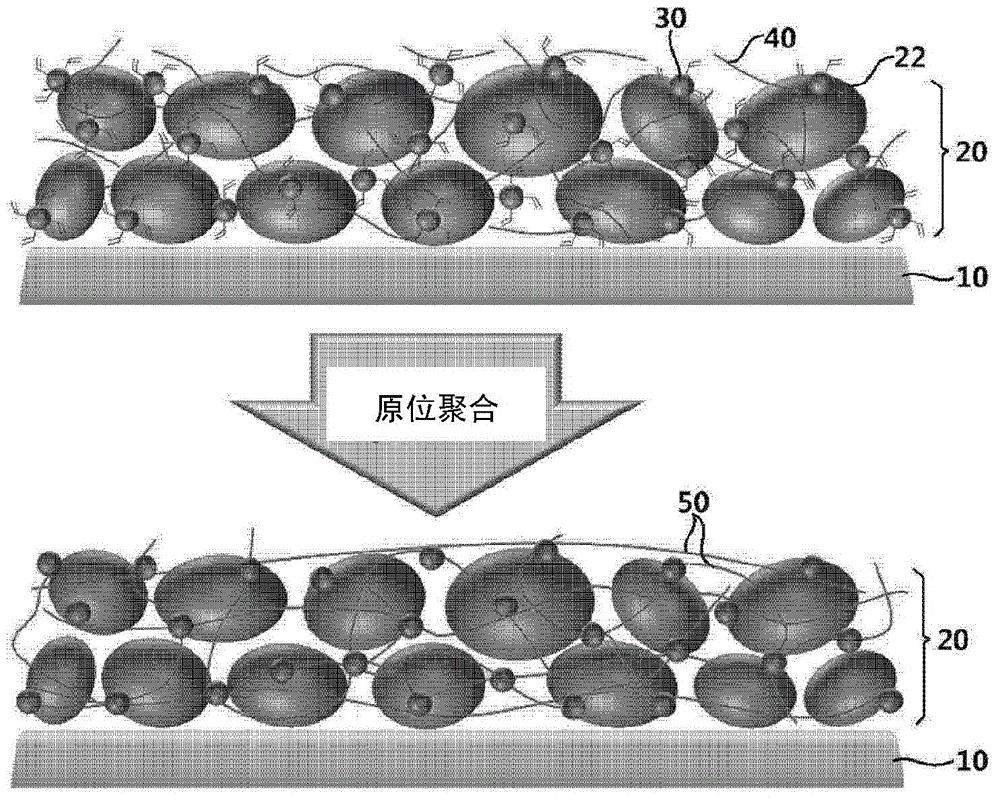

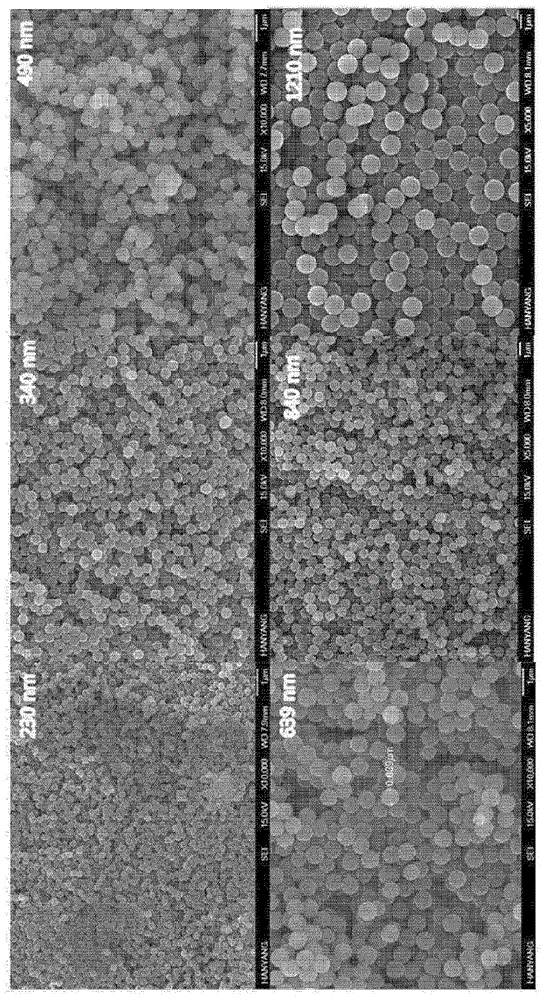

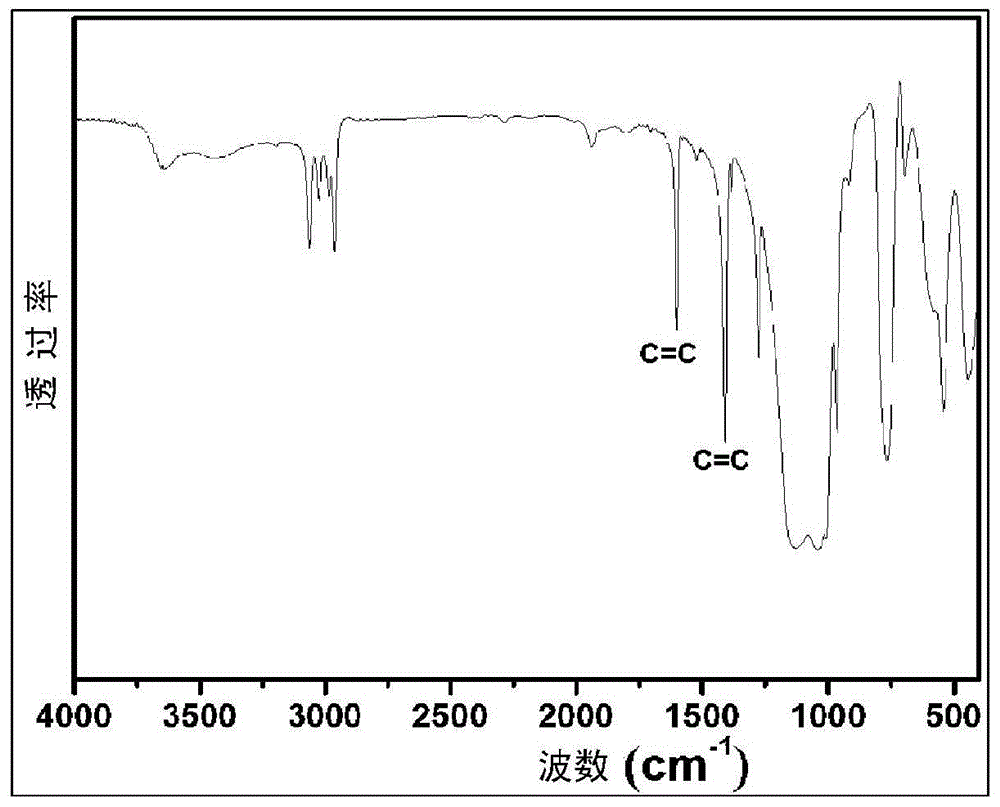

Electrode for lithium secondary battery, lithium secondary battery using same and method for manufacturing same

InactiveCN104956529ALi-accumulatorsNon-aqueous electrolyte accumulator electrodesIn situ polymerizationCurrent collector

Owner:IUCF HYU (IND UNIV COOP FOUNDATION HANYANG UNIV)

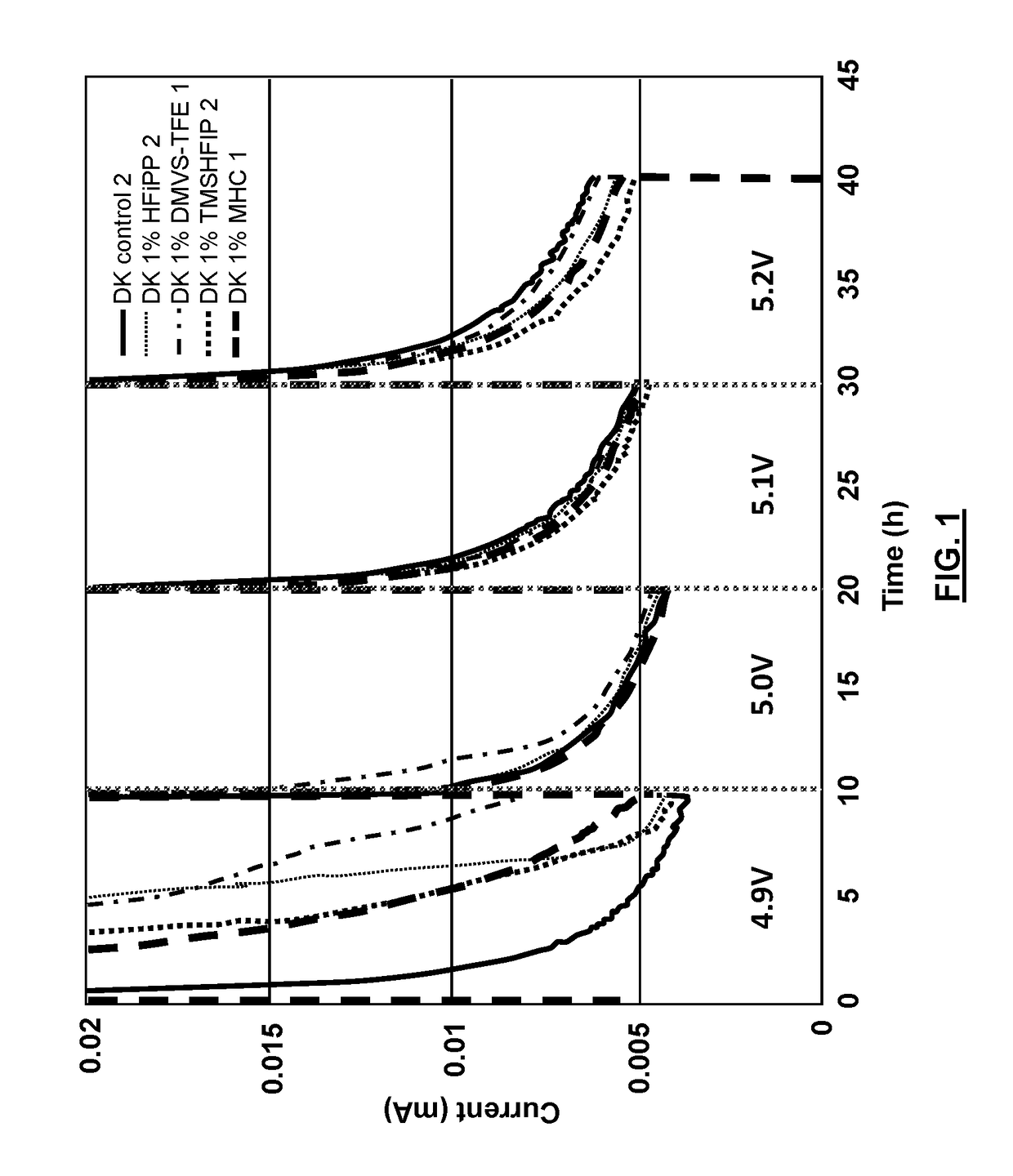

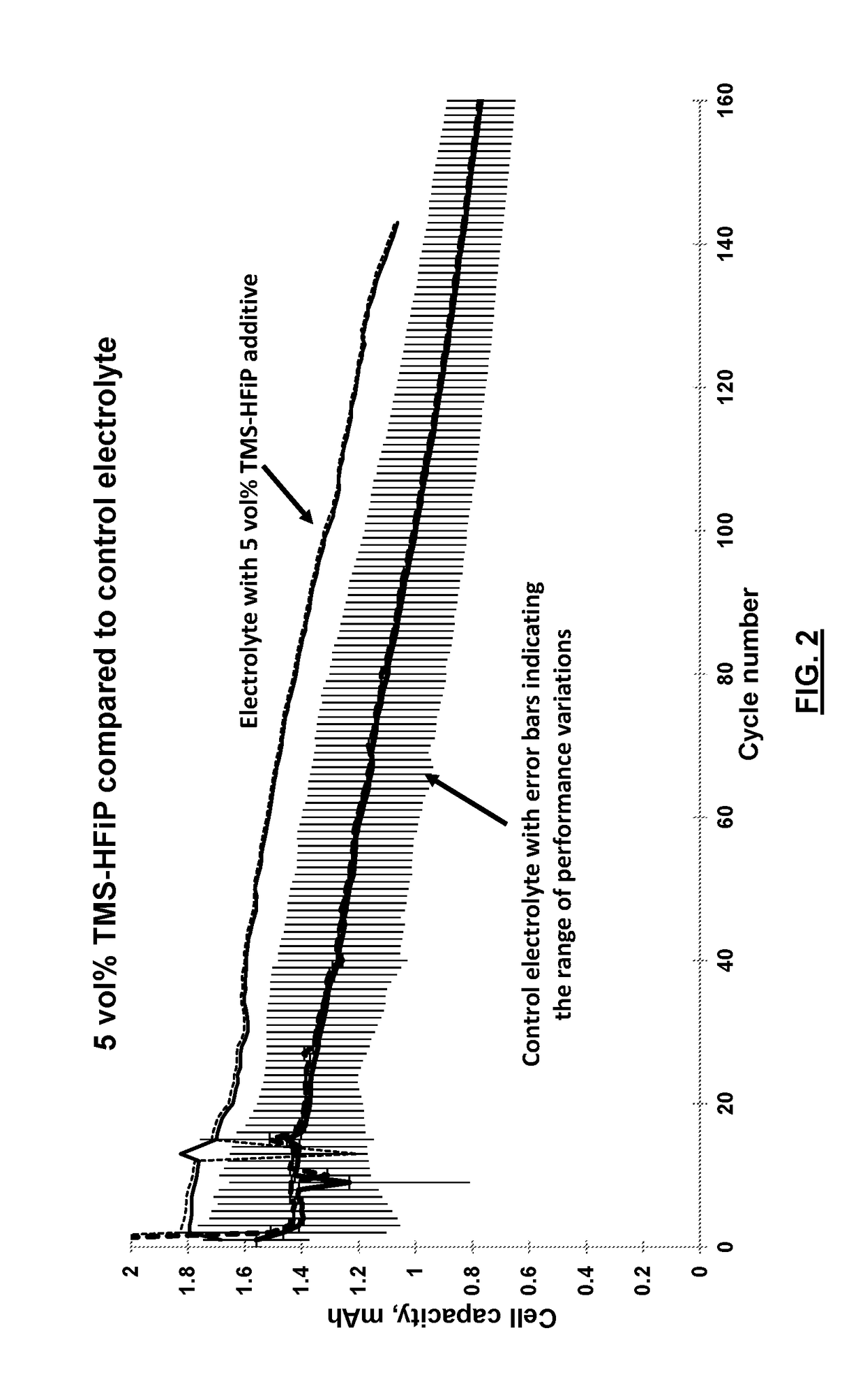

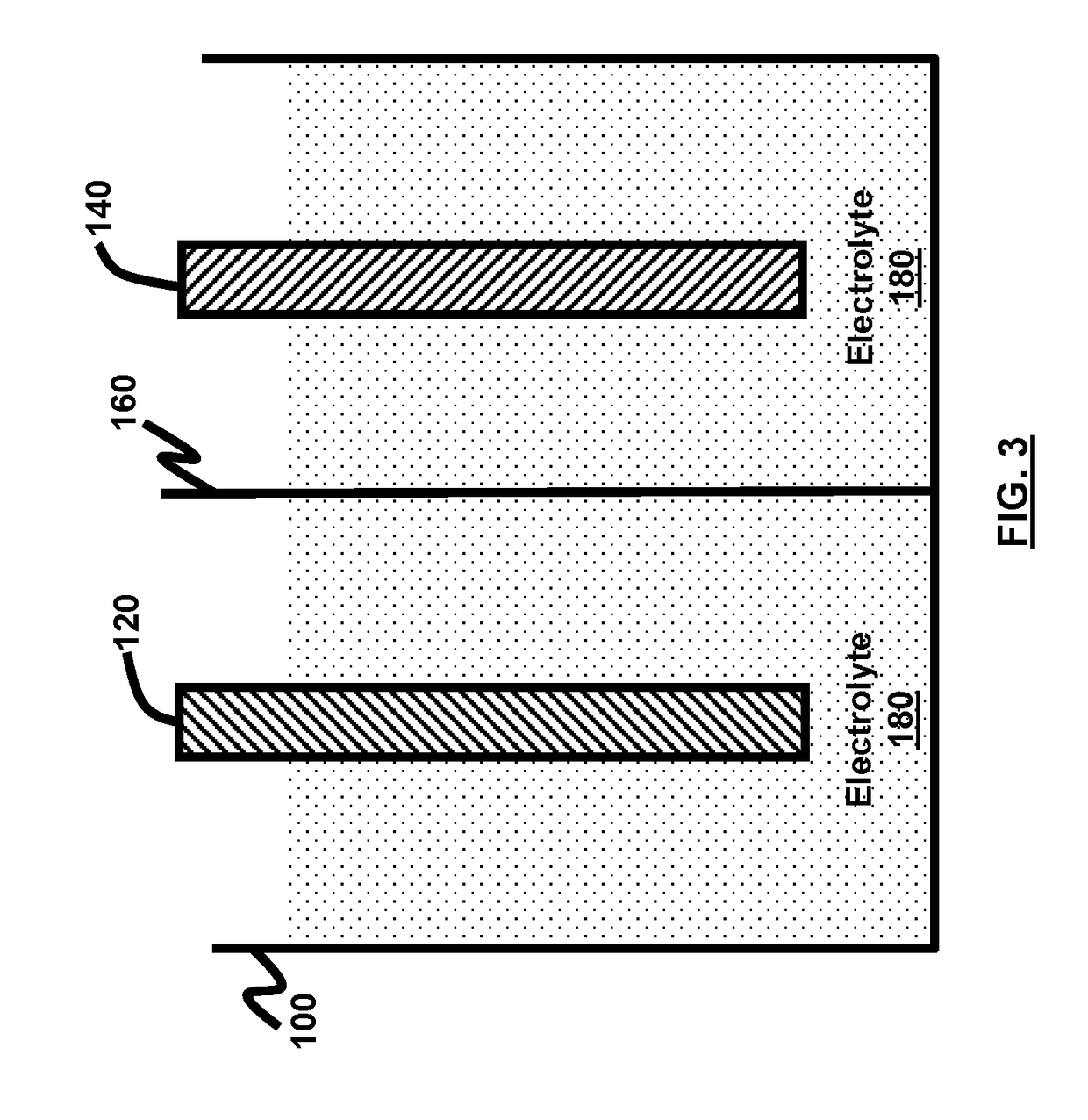

Electrolyte solvents and additives for advanced battery chemistries

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap