Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about "Negative electrodes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Negative electrode active material for non-aqueous electrolyte secondary batteries and non-aqueous electrolyte secondary battery using negative electrode active material

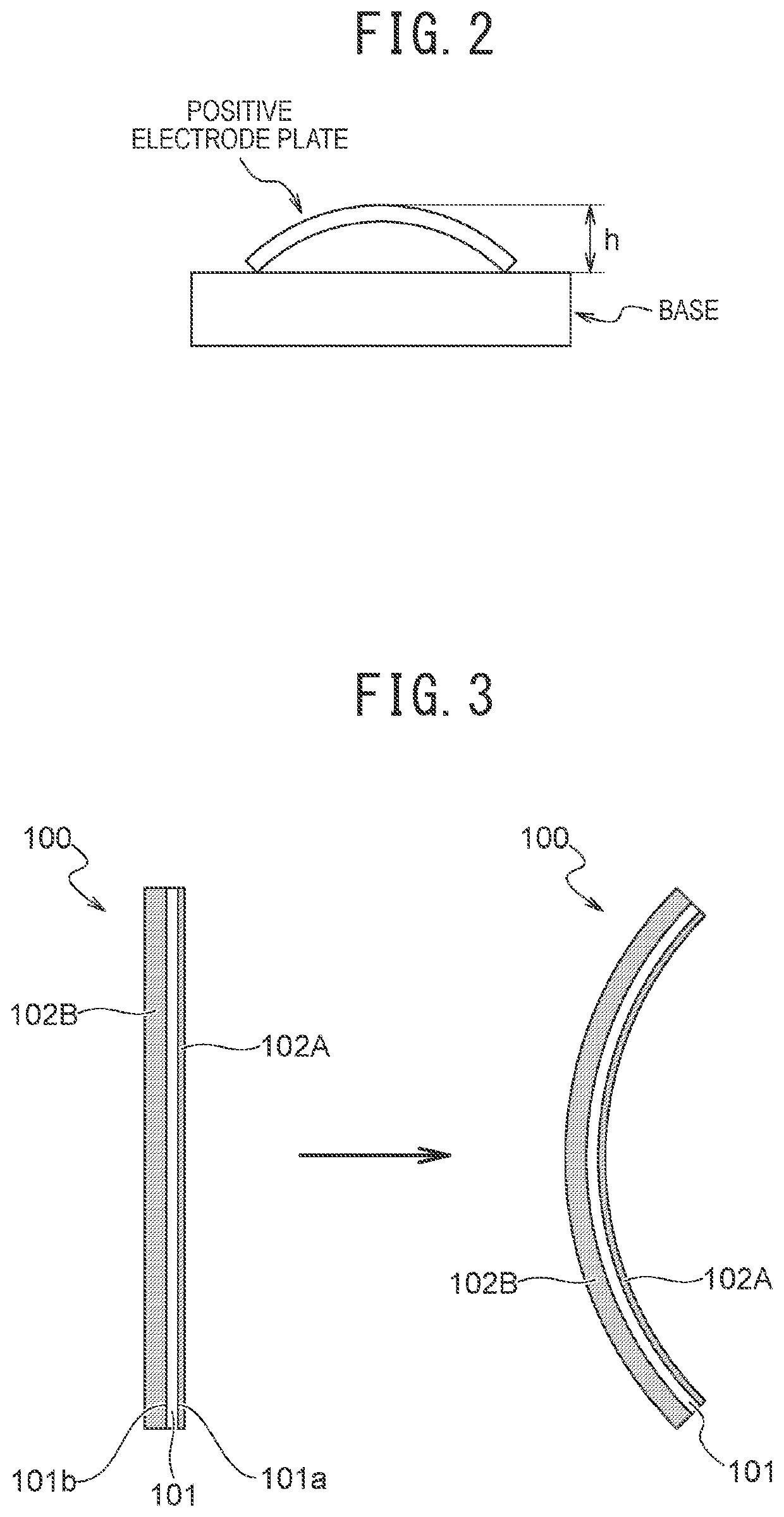

InactiveUS20150221950A1Improve efficiencyImprove propertiesNegative electrodesNon-aqueous electrolyte accumulator electrodesCharge dischargeNon aqueous electrolytes

In a non-aqueous electrolyte secondary battery using SiOX as a negative electrode active material, it is an object to improve initial charge-discharge efficiency and cycle properties. Provided is a negative electrode active material containing particles made of SiOX containing a lithium silicate phase, 50% to 100% of the surface of each particle made of SiOX being covered by carbon. The proportion of the number of moles of the lithium silicate phase to the number of moles of the particles made of SiOX is 0.5 mole percent to 25 mole percent. The average primary particle size of the particles made of SiOX is 1 μm to 15 μm.

Owner:SANYO ELECTRIC CO LTD

Negative electrodes for zinc nickel secondary batteries and their fabrication methods

InactiveUS20060172197A1Effective recombinationLow internal pressureNegative electrodesAlkaline accumulator electrodesCarbon blackAqueous solution

Owner:BYD CO LTD

Graphite negative electrode material of low-temperature lithium ion battery and preparation method thereof

Owner:CENT SOUTH UNIV

Method for preparing ferric vanadate-graphene negative electrode composite material

ActiveCN104766975AUniform textureGood dispersionNegative electrodesSecondary cellsDispersityReaction rate

Owner:SHENZHEN PANGU ENVIRONMENTAL PROTECTION TECH CO LTD

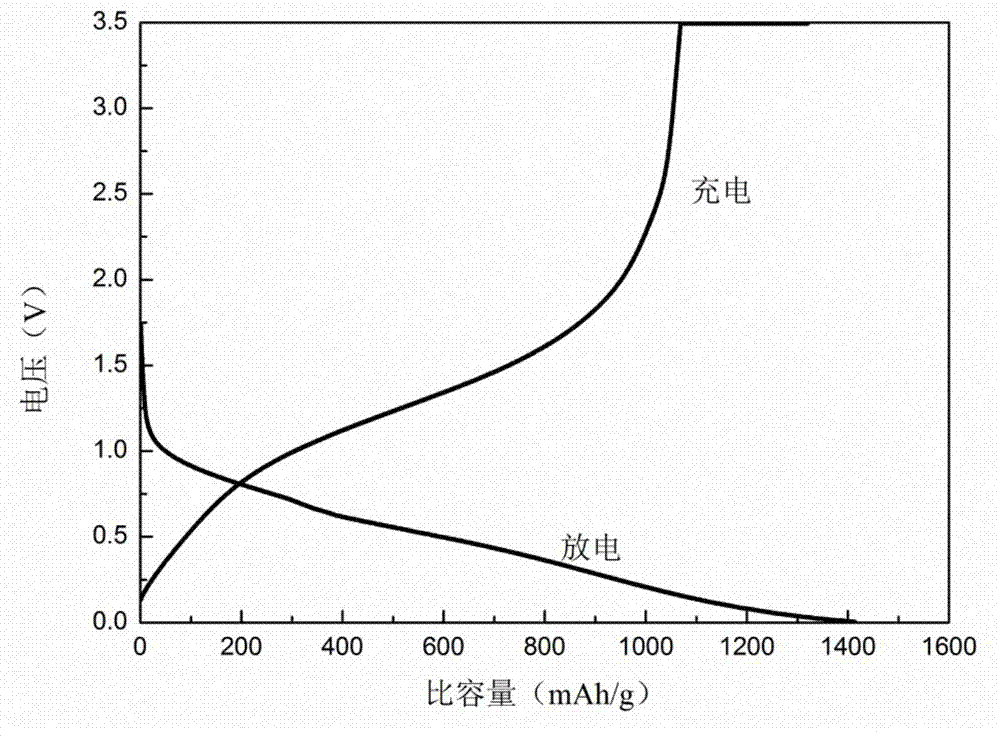

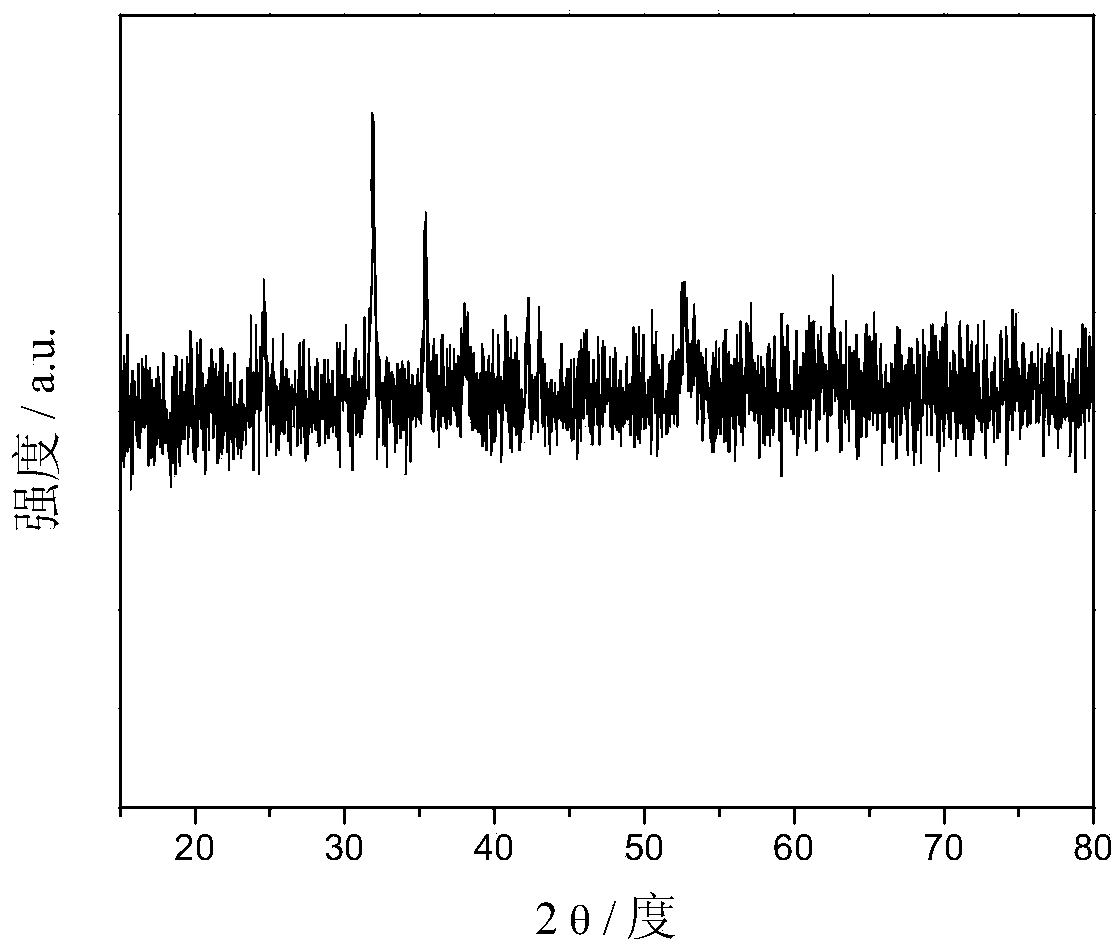

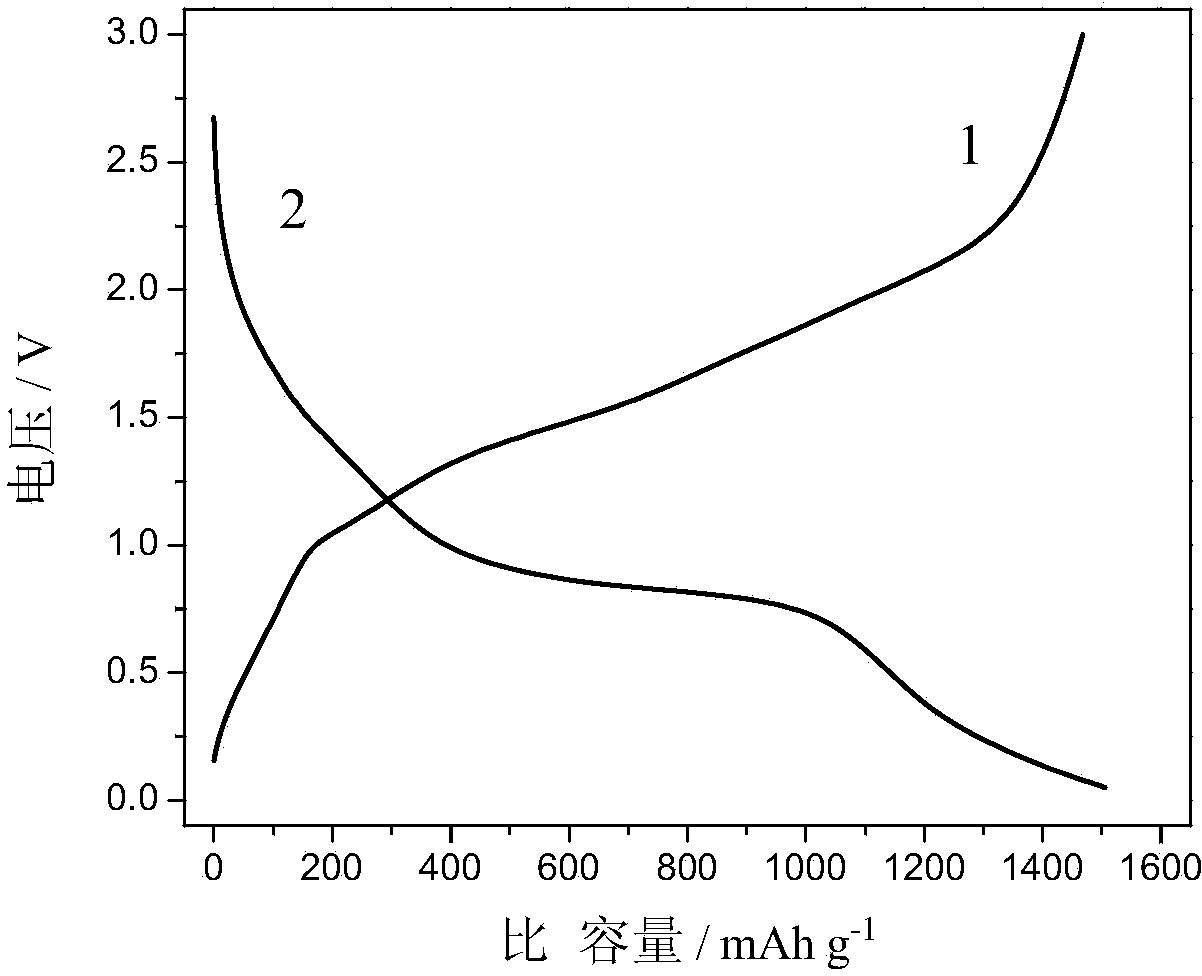

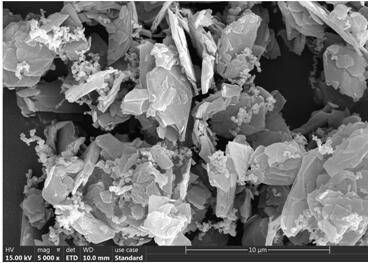

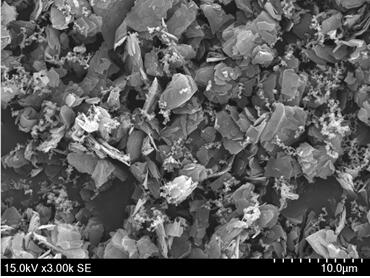

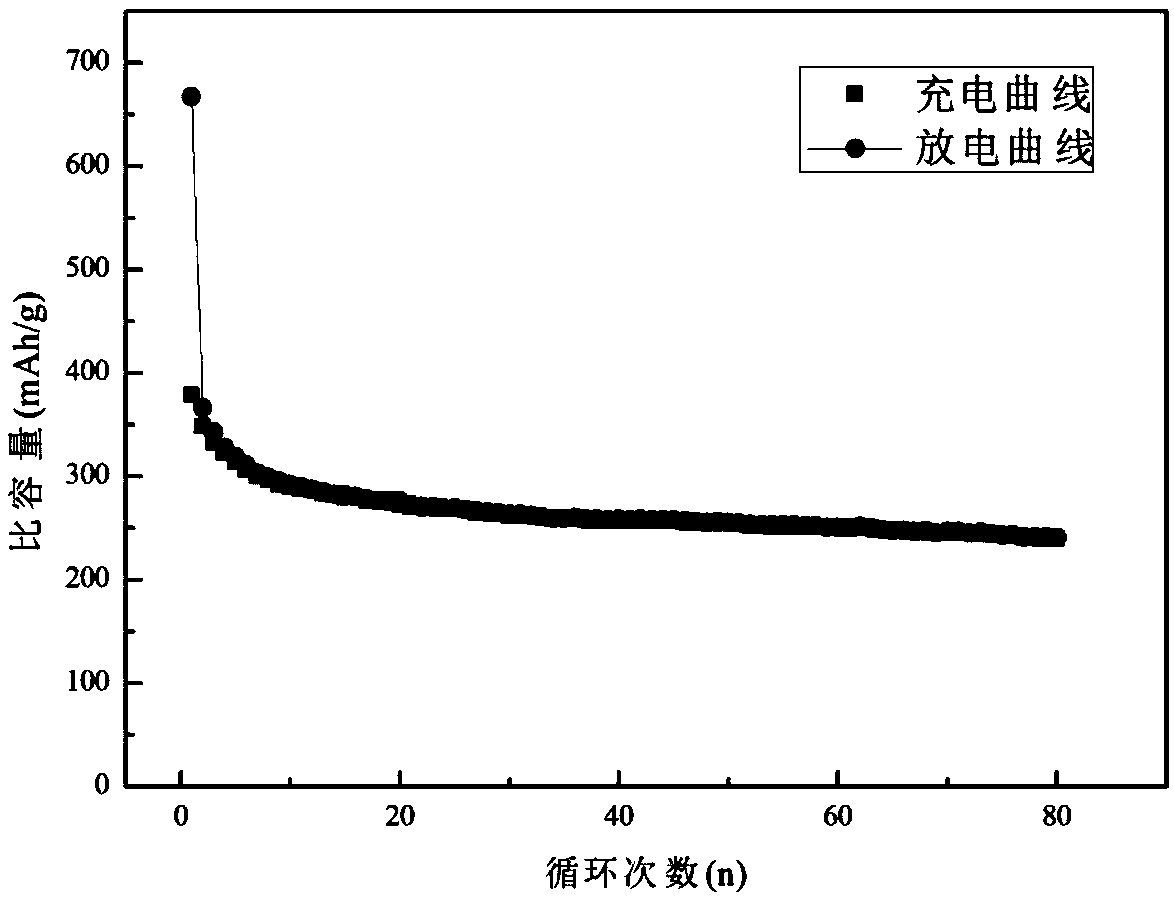

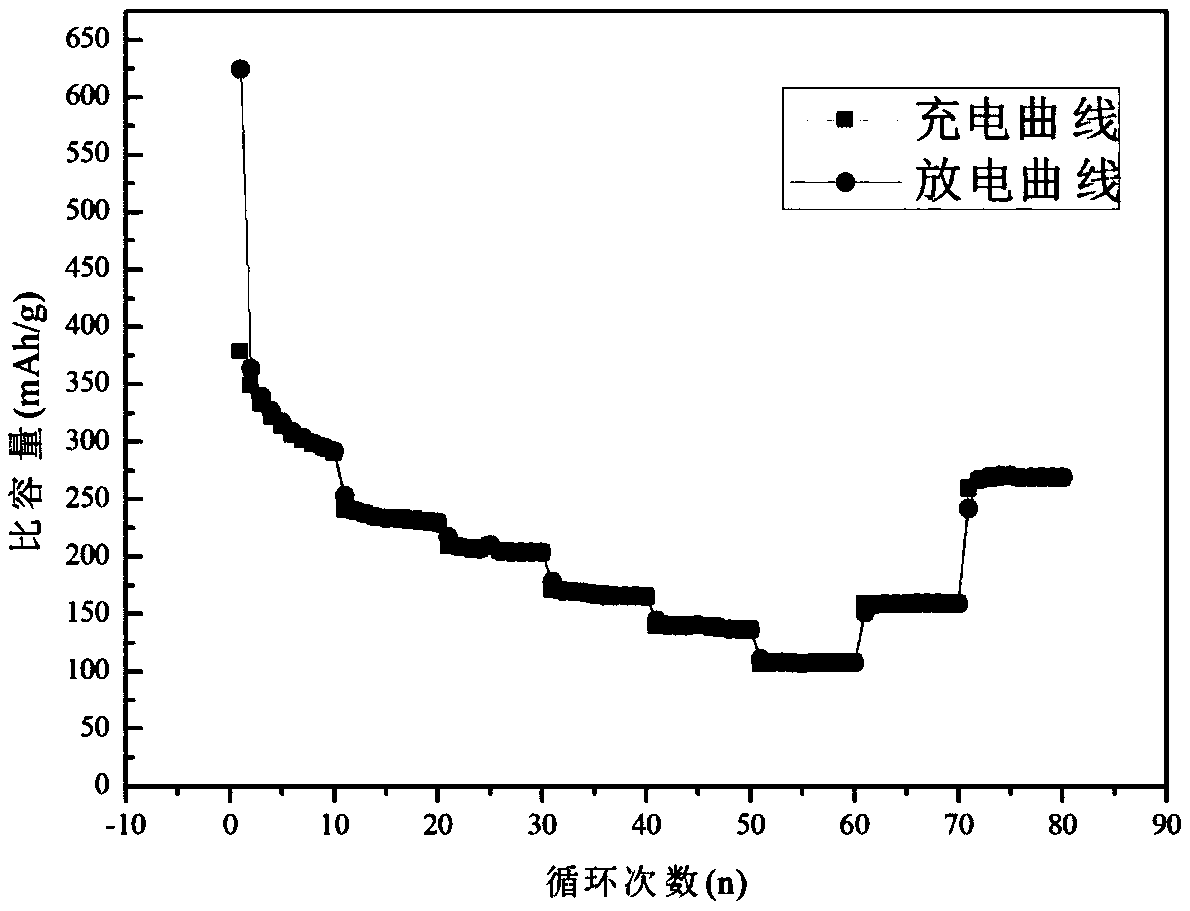

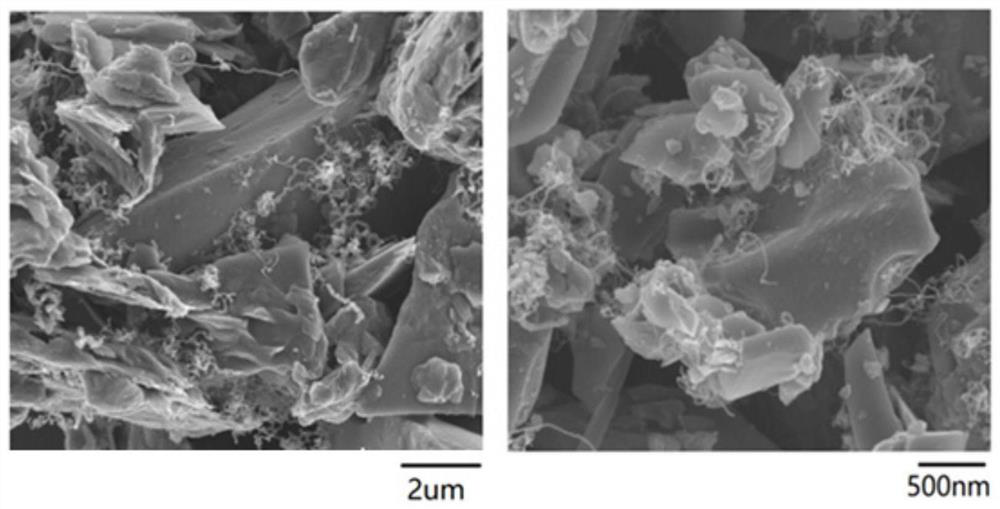

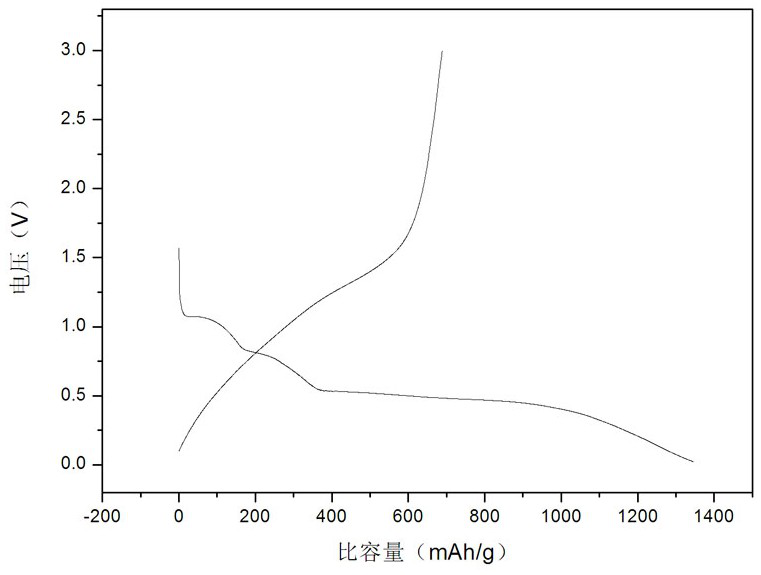

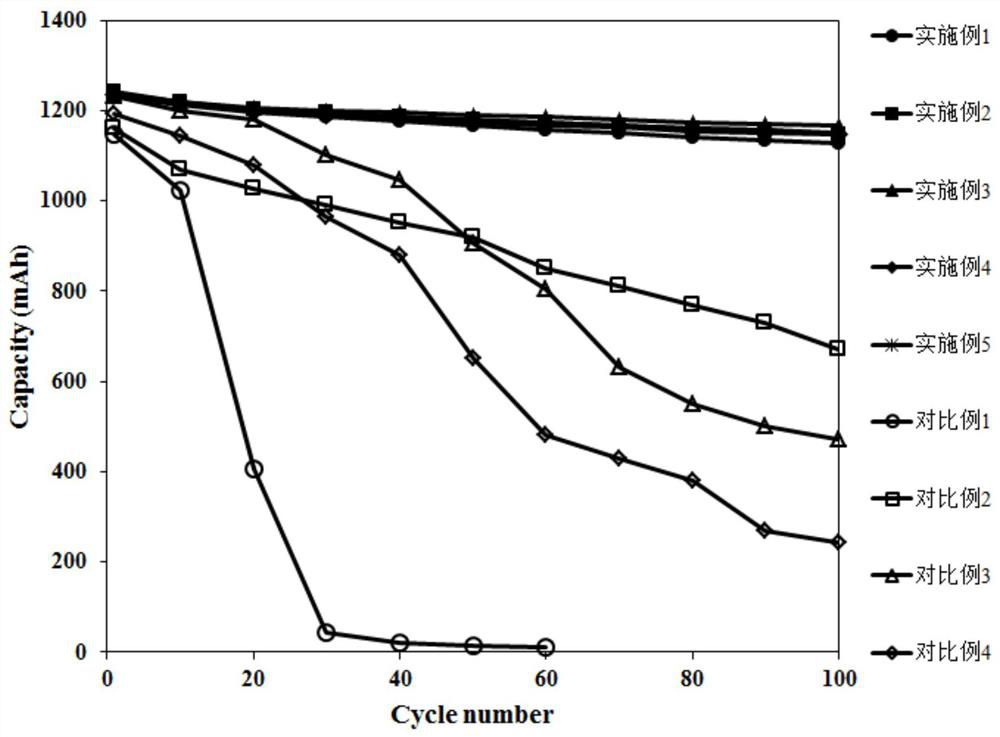

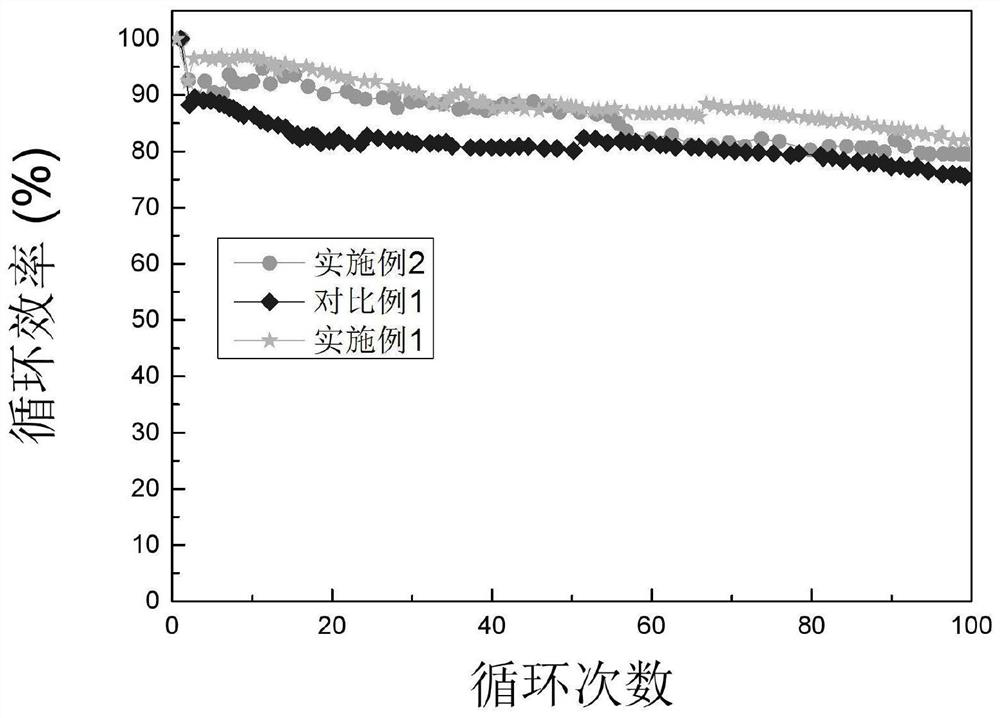

MoS2@C composite anode material for lithium ion battery and preparation method thereof

ActiveCN111900408AImproved magnification performanceLimit volume expansionNegative electrodesSecondary cellsCarbon layerBattery cell

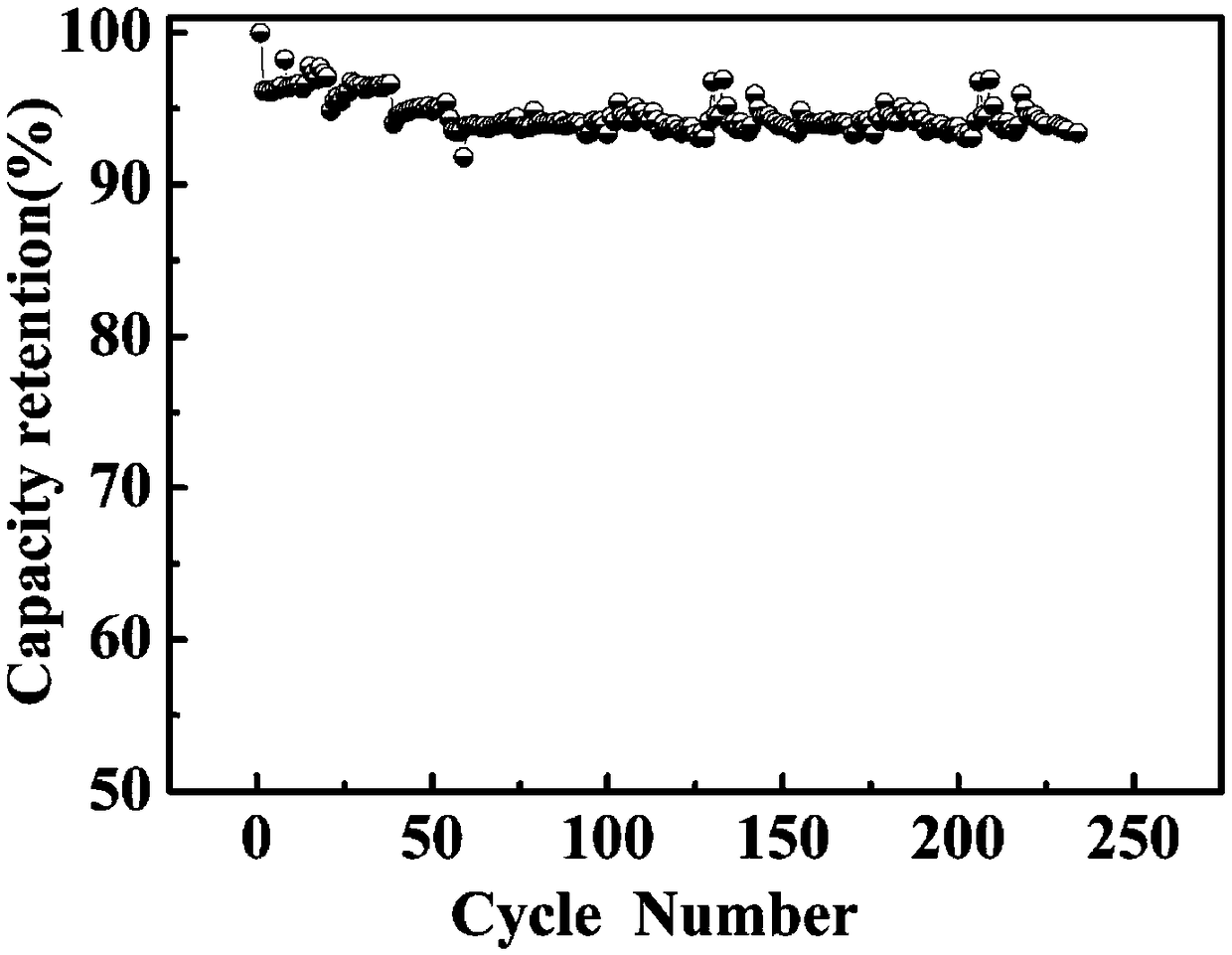

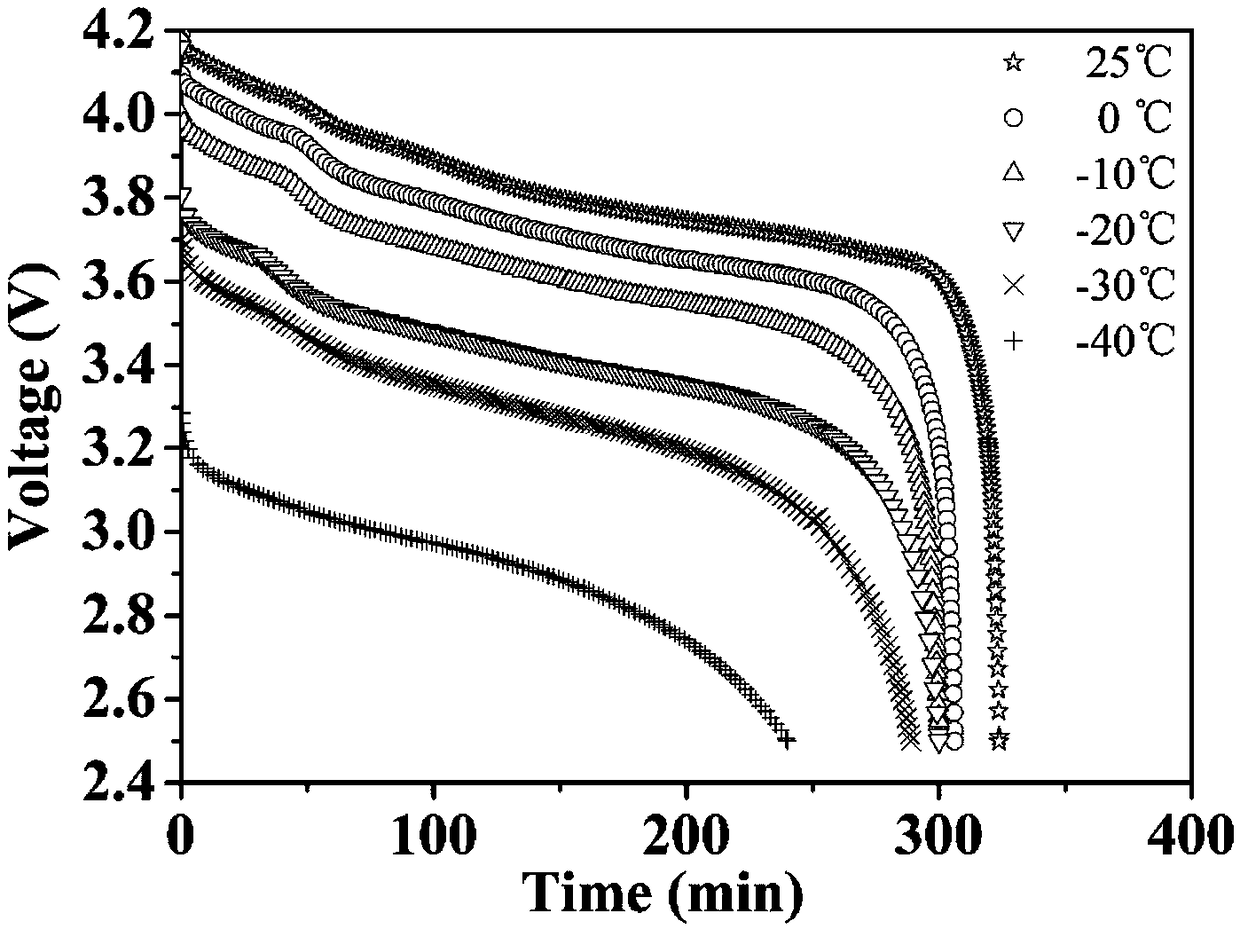

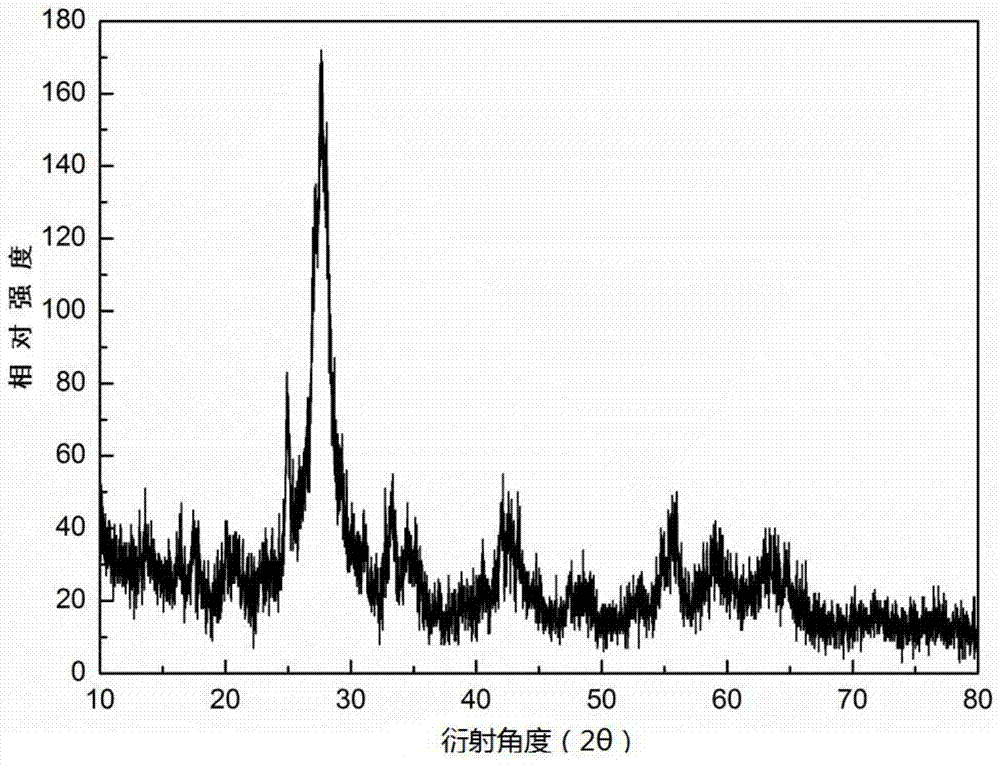

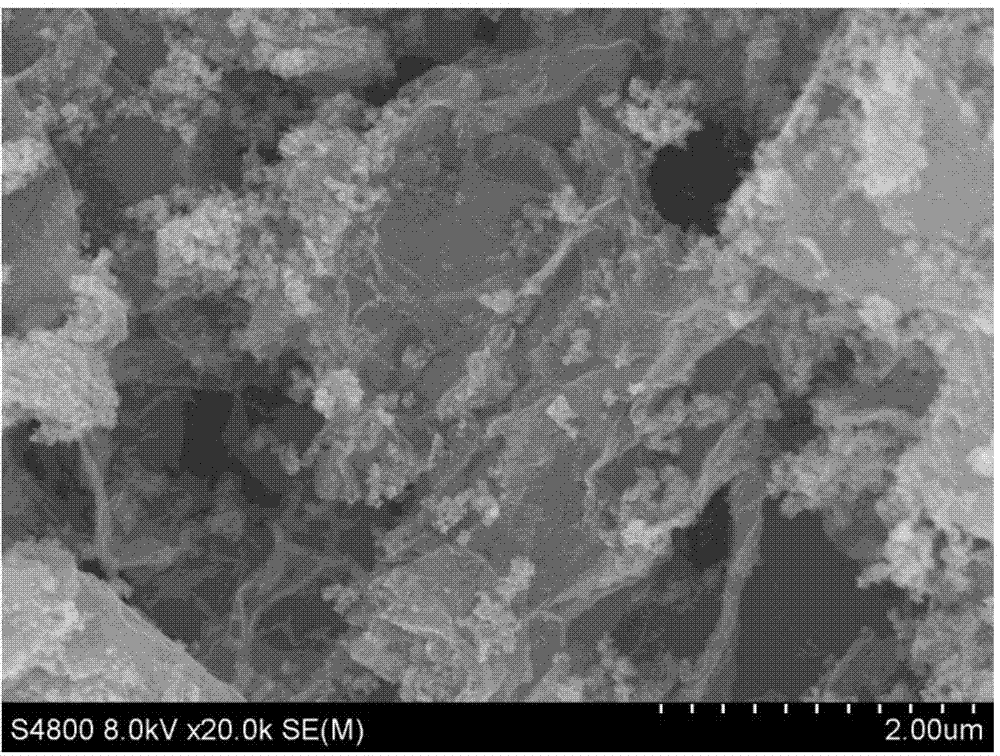

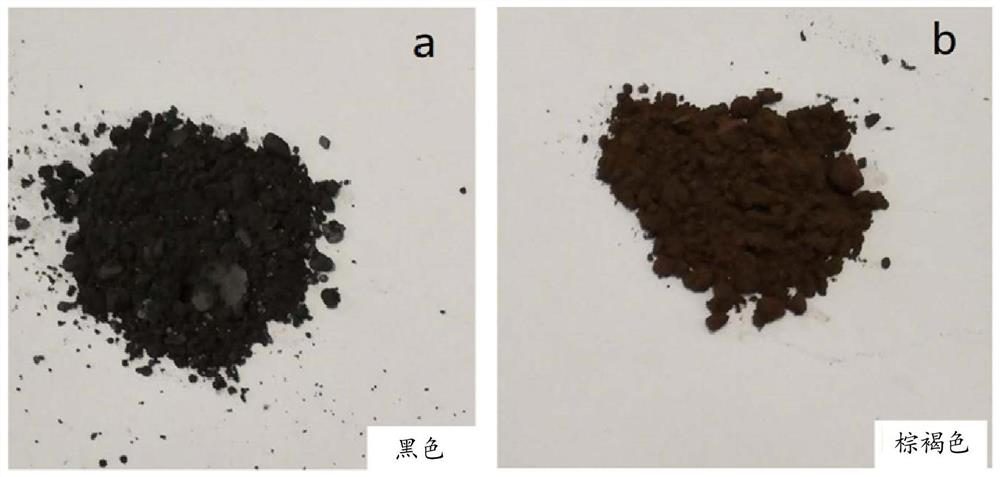

The invention discloses a MoS2@C composite anode material for a lithium ion battery and a preparation method thereof, MoS2 sheets in the composite anode material are stacked disorderly and intertwinedto form a wormlike microsphere structure, and the MoS2@C composite anode material comprises 38-43% of Mo, 47-53% of S and the balance of C. According to the invention, MoS2 and a carbon material arecompounded; the prepared anode material has a wormlike structure; the diffusion path of Li<+> can be shortened; the composite material has excellent rate capability; and the carbon layer coated on thesurface of the MoS2 sheet can limit the further growth of the MoS2 nanosheet and can inhibit the problem of easy volume expansion of the MoS2 composite material in the cycle process, thereby effectively enhancing the rate capability and cycle stability of the lithium ion battery anode material.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

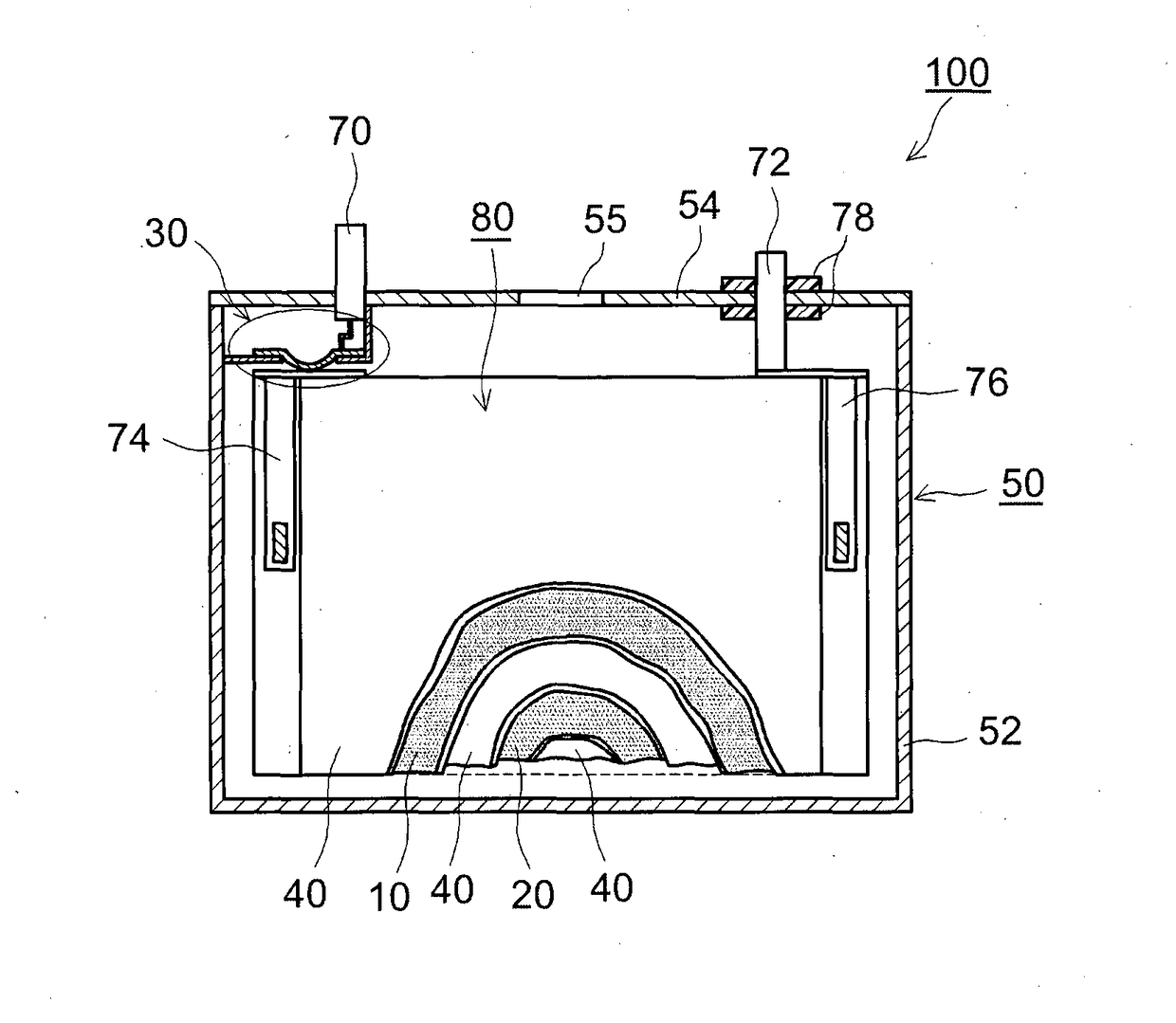

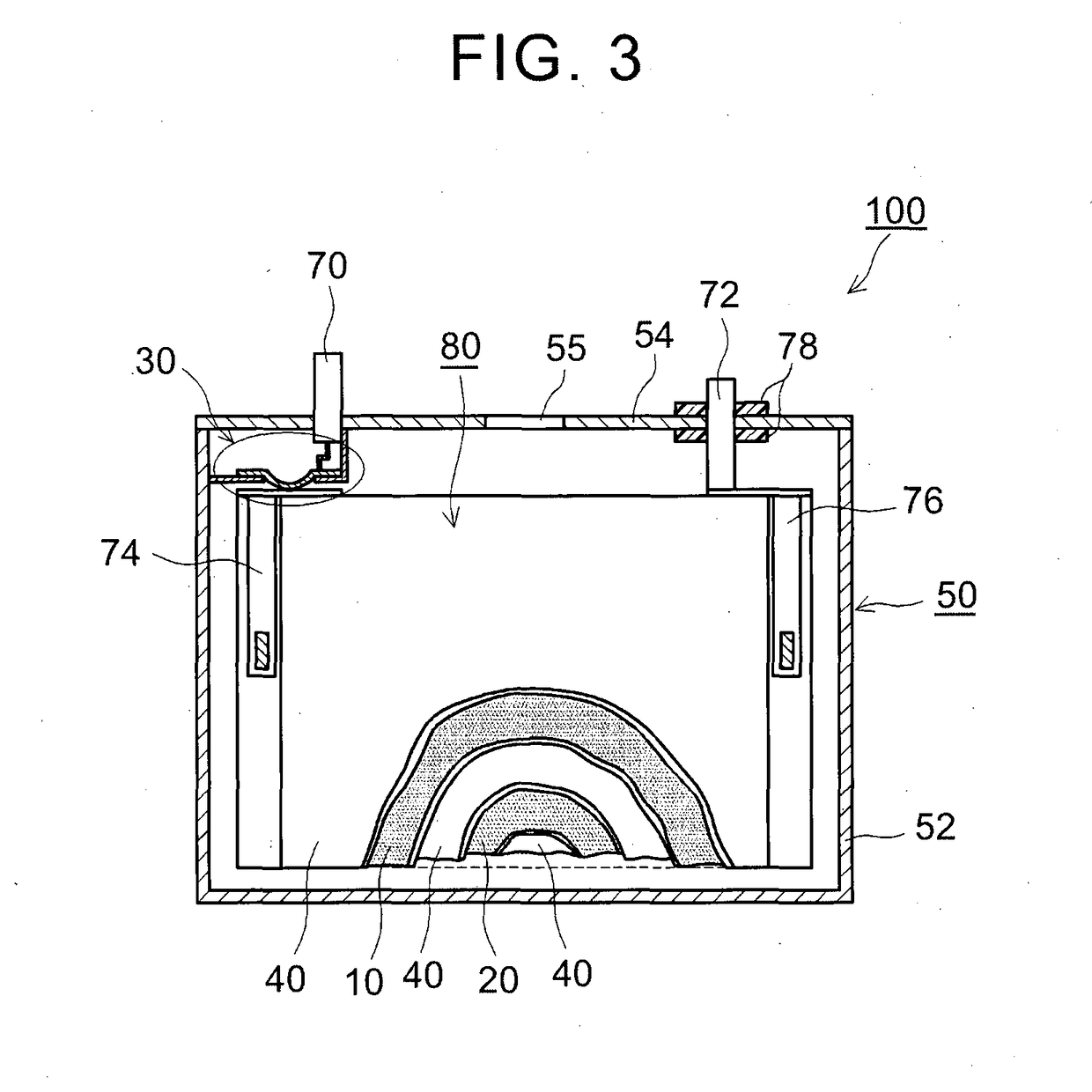

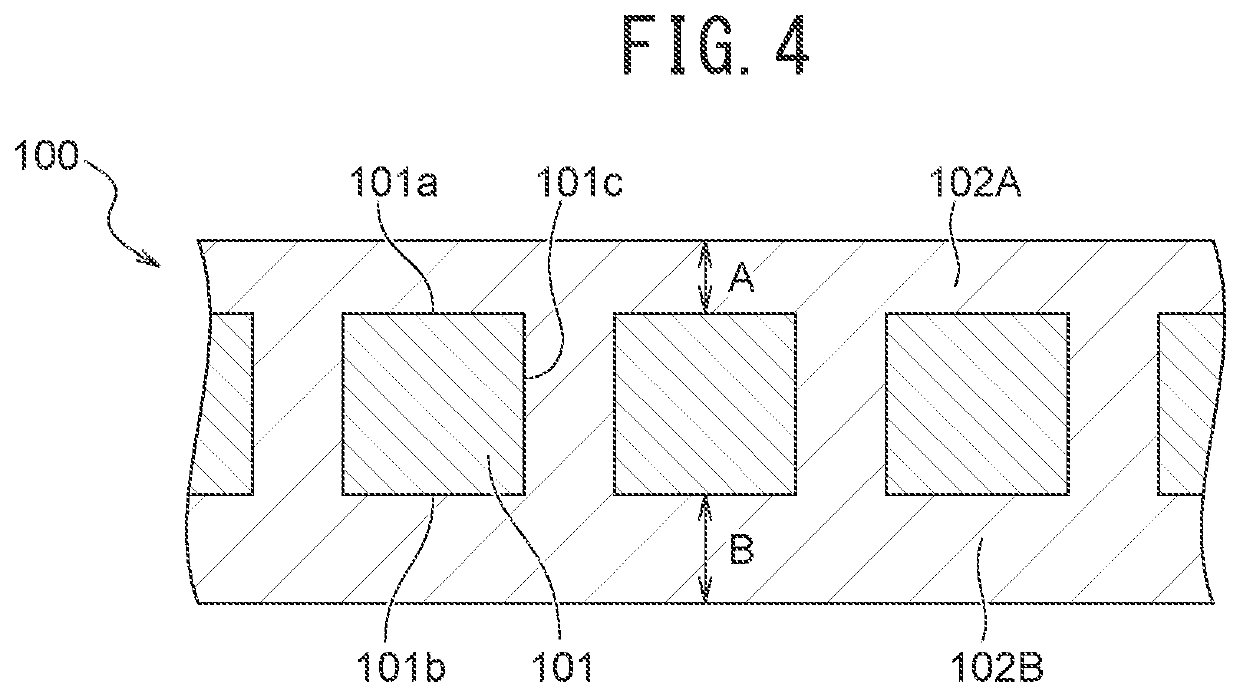

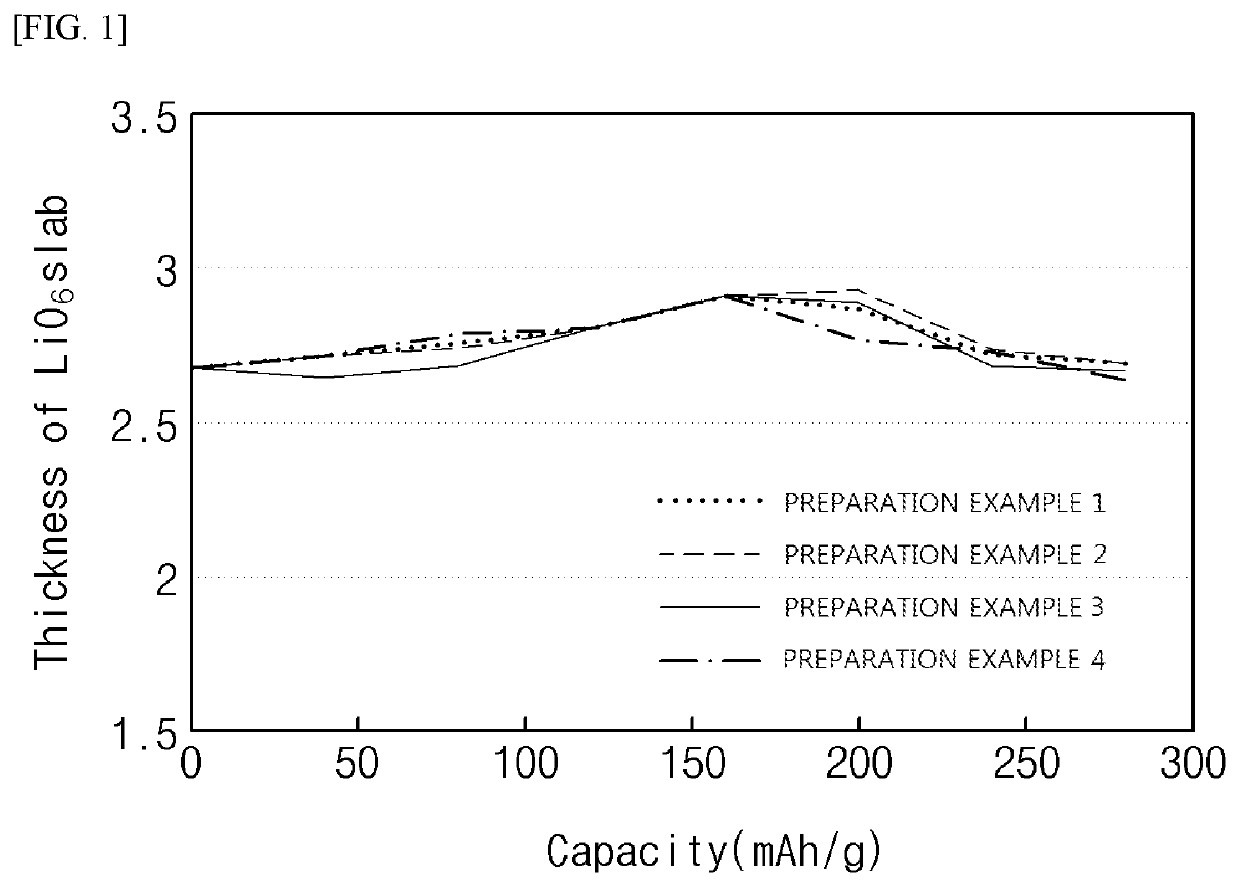

Nonaqueous secondary battery

ActiveUS20170077486A1Accurate operationStable controlFinal product manufactureNegative electrodesEngineeringElectrode

Owner:TOYOTA JIDOSHA KK

Ferrous carbonate/graphene composite material and preparation method and applications thereof

ActiveCN103840132AHigh specific capacityImprove cycle performanceNegative electrodesSecondary cellsMass ratioConcentration ratio

Owner:HUNAN YACHENG NEW MATERIAL CO LTD

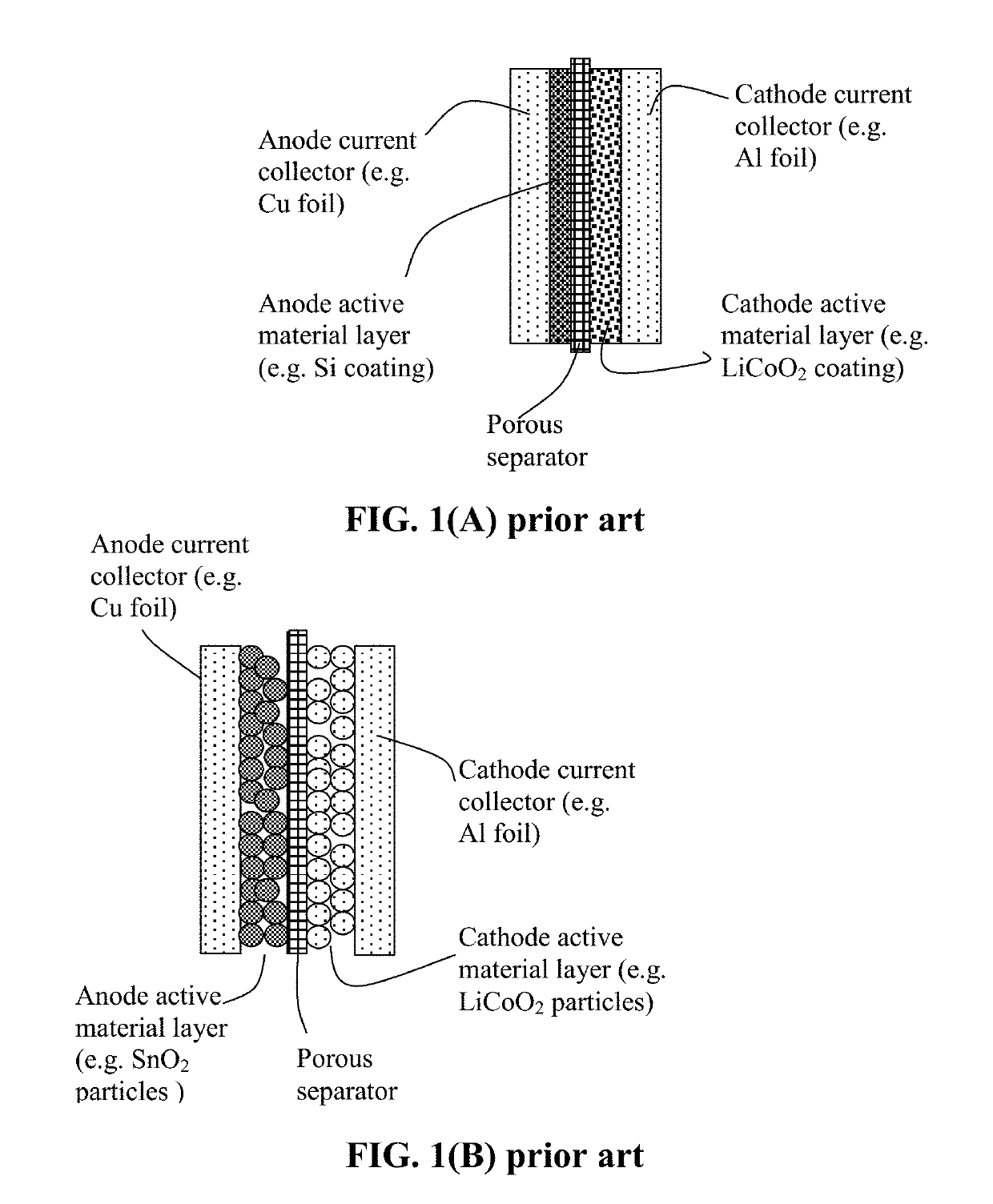

Method of Producing Elastomer Composite-Encapsulated Particles of Anode Active Materials for Lithium Batteries

PendingUS20190267663A1Easy to packFaster lithium ion transportNegative electrodesSecondary cellsParticulatesLiquid medium

Owner:GLOBAL GRAPHENE GRP INC

Negative electrode material and preparation method thereof and secondary battery

Owner:SHENZHEN DYNANONIC

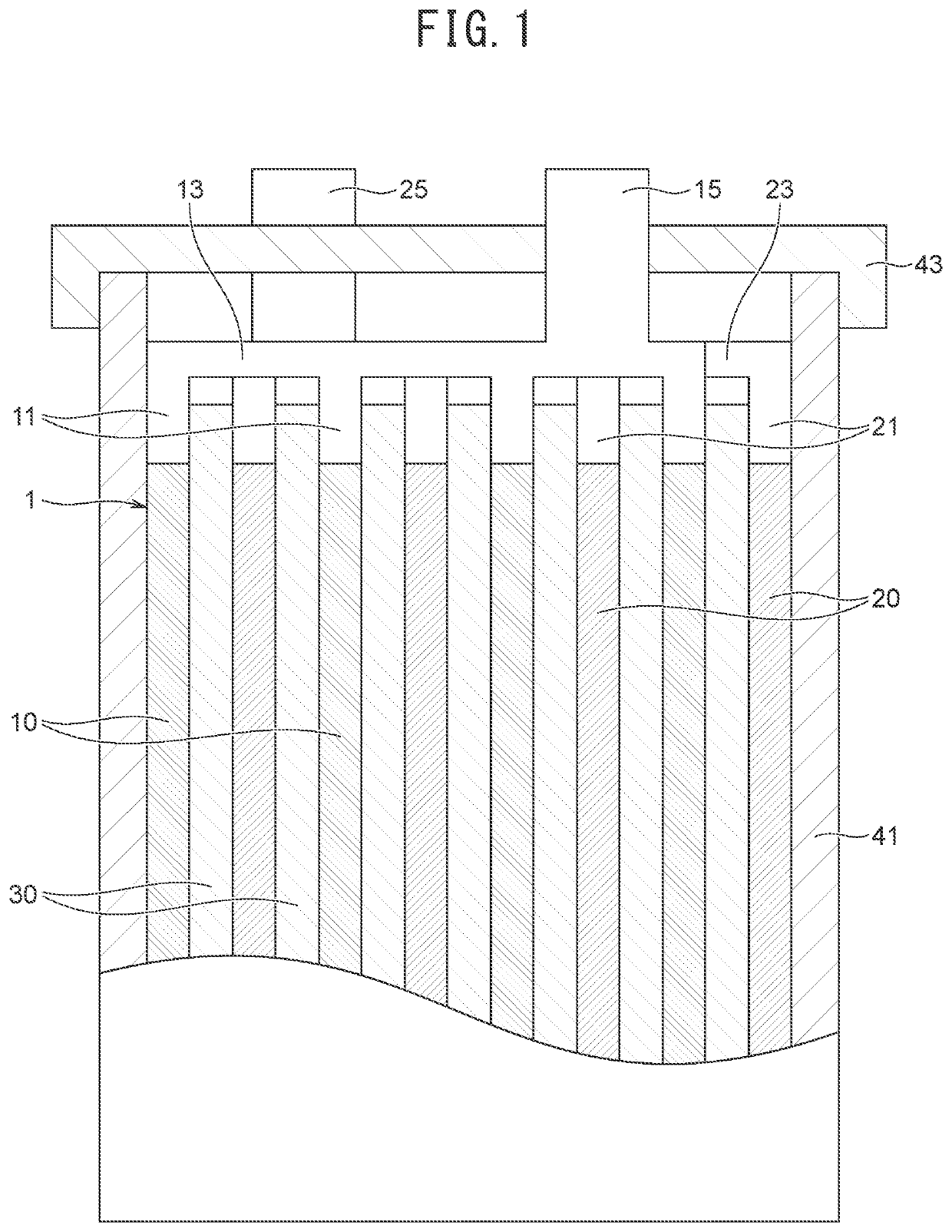

Electrode, nonaqueous electrolyte battery, battery pack and vehicle

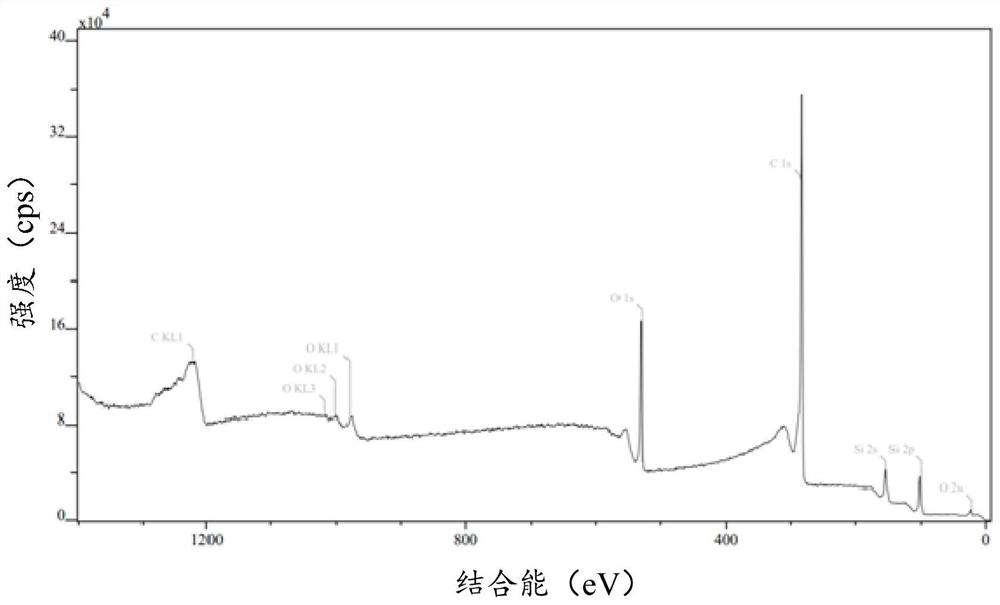

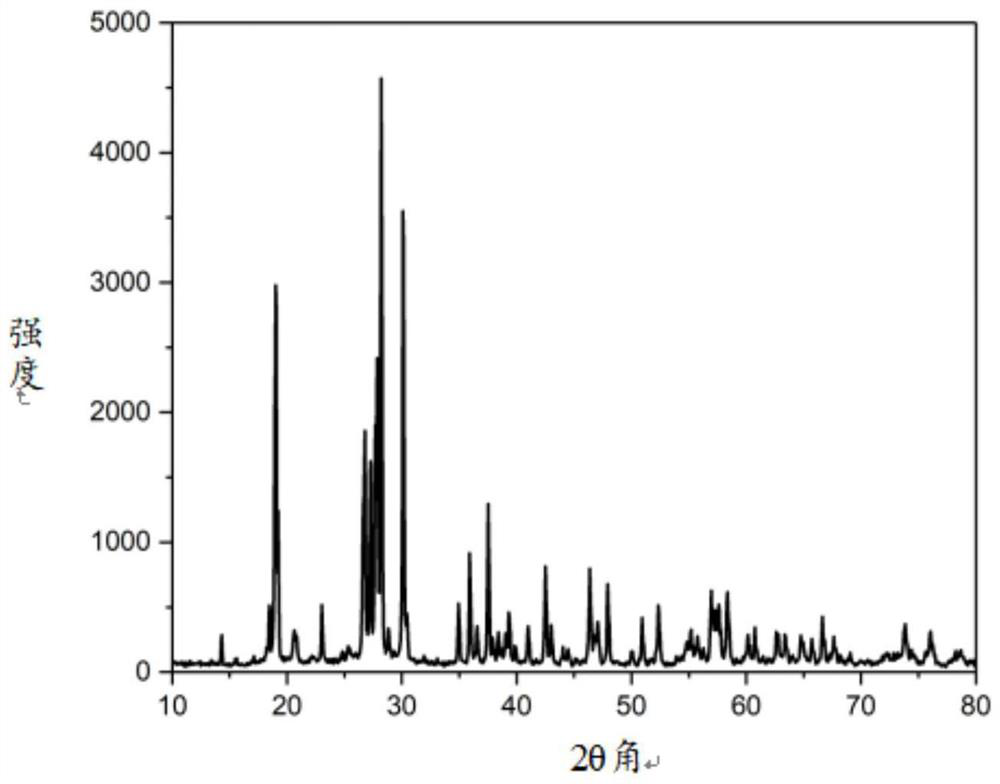

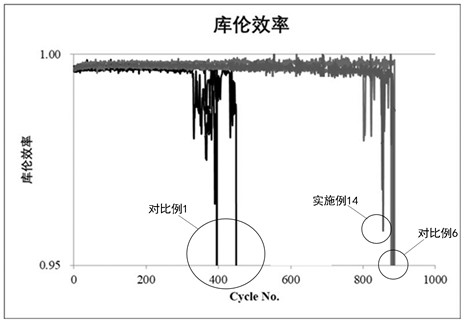

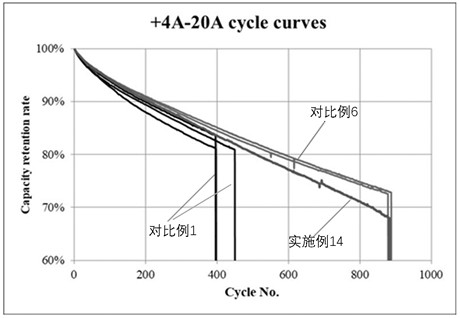

ActiveCN108630908AImprove life characteristicsAlkali titanatesNegative electrodesBinding energyX-ray

The invention relates to an electrode, a nonaqueous electrolyte battery, a battery pack and a vehicle. The invention provides an electrode excellent in service performance. According to one approach,an electrode (3) is provided. The electrode (3) includes an active material-containing layer (3b). The active material-containing layer (3b) includes a Na-containing niobium-titanium composite oxide having an orthorhombic crystal structure. The active material-containing layer (3b) satisfies I2 / I1>=1. I1 is an intensity of a peak P1 appearing in a binding energy range of 289 eV to 292 eV in an X-ray photoelectron spectroscopy spectrum of the active material-containing layer (3b). I2 is an intensity of a peak P2 appearing in a binding energy range of 283 eV to 285 eV in the X-ray photoelectronspectroscopy spectrum of the active material-containing layer (3b).

Owner:KK TOSHIBA

Silicon-based negative electrode material and preparation method thereof, lithium ion battery and electric appliance

InactiveCN112820847AImprove cycle stabilityHigh reversible capacityElectrode thermal treatmentNegative electrodesElectrical batteryCopper foil

The invention discloses a silicon-based negative electrode material and a preparation method thereof, a lithium ion battery and an electric appliance and relates to the technical field of battery electrode material preparation. The preparation method of the silicon-based negative electrode material comprises the following steps: annealing a primary negative electrode material which is obtained by cold spraying and is loaded with a Si-Cu coating on the surface in an inert gas atmosphere at the temperature of 500-800 DEG C, and preserving heat for 7-9 hours. The silicon-based negative electrode material is prepared by the preparation method. The lithium ion battery adopts the silicon-based negative electrode material as a negative electrode. The electric appliance takes the lithium ion battery as a power supply. After the primary negative electrode material of the Si-Cu coating is obtained through cold spraying on the copper foil, the Si-Cu3Si-Cu composite material obtained through annealing treatment at the proper temperature and the proper heat preservation time is used as the negative electrode material of the lithium ion battery and has good cycle stability and reversible capacity.

Owner:GUANGDONG INST OF NEW MATERIALS

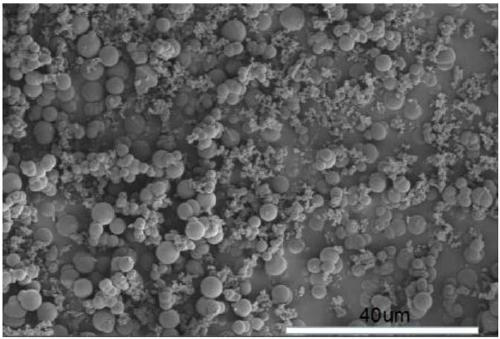

Method for preparing (V, Ti) 2AlC submicron sheets and nanoparticles

ActiveCN112010305AReduce energy consumptionSimple and time-saving operationCarbon compoundsNegative electrodesAl powderArgon atmosphere

The invention relates to a method for preparing (V, Ti) 2AlC submicron sheets and nanoparticles. The method comprises: mixing dried V powder, Ti powder, Al powder, Sn powder and C powder according toa molar ratio of (1.8-1): 1, (0.2-1): (0.2-1): (1-1.5): (0-0.35): (0.85-1.2), grinding in a ball mill, carrying out high-temperature self-propagating synthesis on the obtained powder in an argon atmosphere, so that (V, Ti) 2AlCMAX phase materials are obtained, crushing and grinding the (V, Ti) 2AlCMAX phase materials, carrying out solvent ultrasonic treatment, carrying out standing precipitation on a solution obtained after ultrasonic treatment for 2-5 days, taking an upper-layer solution, and carrying out centrifugation, wherein a lower-layer precipitate comprises (V, Ti) 2AlC submicron sheets, and the supernatant comprises a colloidal solution of (V, Ti) 2AlC nanoparticles. The method is low in energy consumption, safe, environmentally friendly, easy to operate, capable of saving time and low in cost, and the prepared (V, Ti) 2AlC submicron sheets and nanoparticles are suitable for being used as lithium ion battery negative electrode materials.

Owner:YANCHENG INST OF TECH

Negative electrode for lithium ion battery, preparation method of negative electrode and lithium ion battery comprising negative electrode

PendingCN114864942AEasy to prepareImprove performanceNegative electrodesSecondary cellsOrganic solventMethyl carbonate

The present invention relates to a negative electrode for a lithium ion battery comprising a film-forming additive contributing to the formation of an SEI film, said film-forming additive comprising lithium ions and having a solubility of less than 1 g lithium salt per 100 g organic solvent in one or more organic solvents selected from ethylene carbonate, propylene carbonate, diethyl carbonate, dimethyl carbonate or ethyl methyl carbonate.

Owner:NIO TECH ANHUI CO LTD

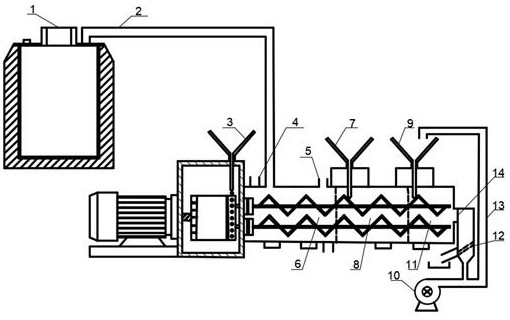

Method for preparing lithium battery negative electrode by compounding silicon, carbon and silicon dioxide in extruder

ActiveCN112151767AImprove composite effectAchieve physical wrappingNegative electrodesSecondary cellsNano siliconSilicon monoxide

Owner:梧州市同创新能源材料有限公司

Preparation method of chitosan-based spherical negative lithium ion battery carbon electrode

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH +1

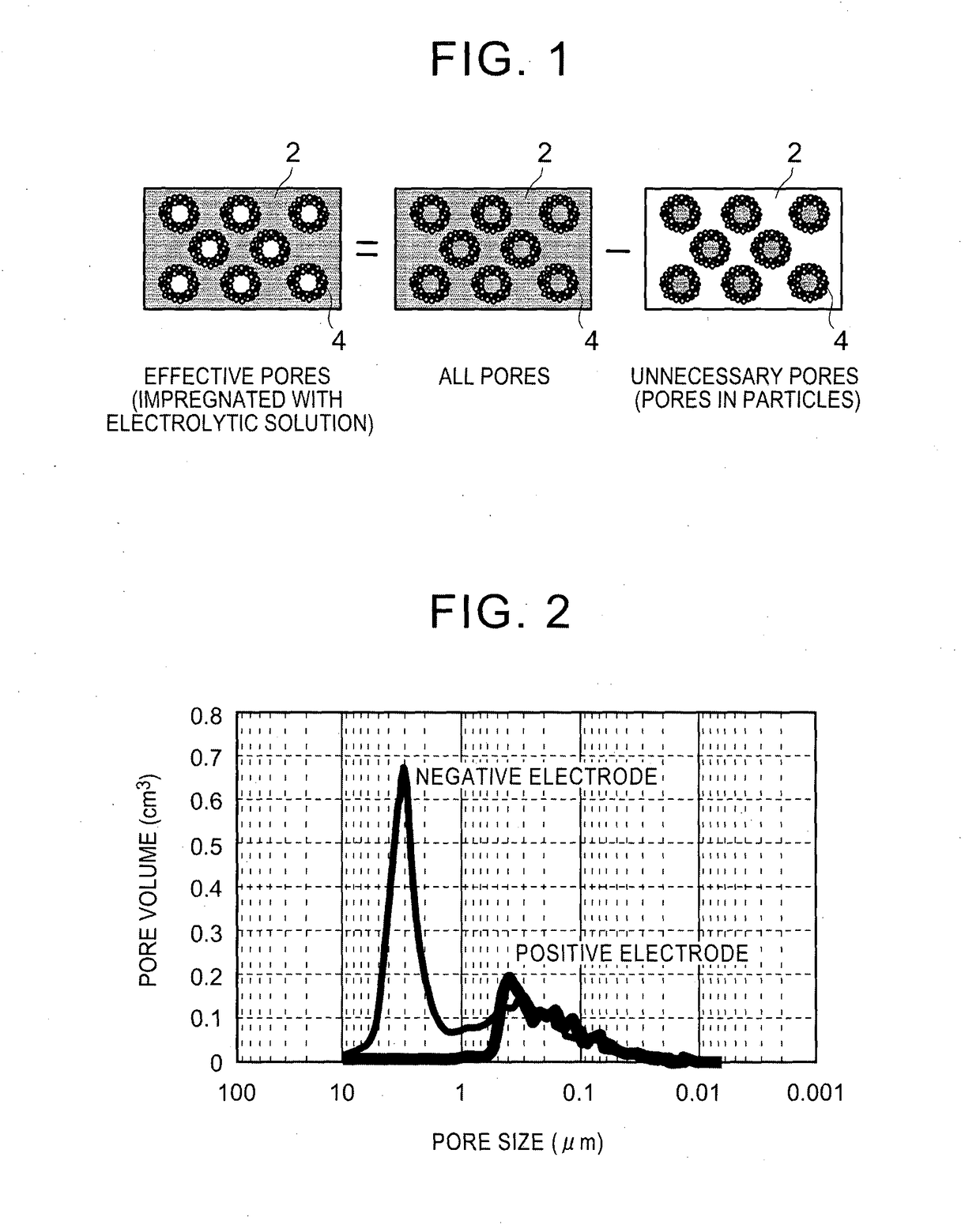

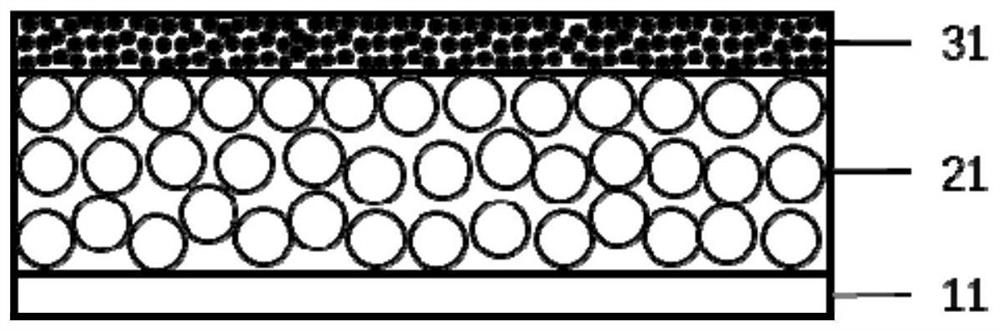

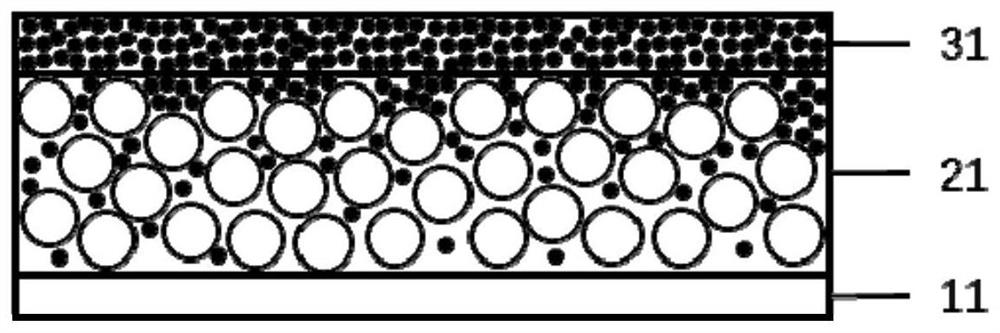

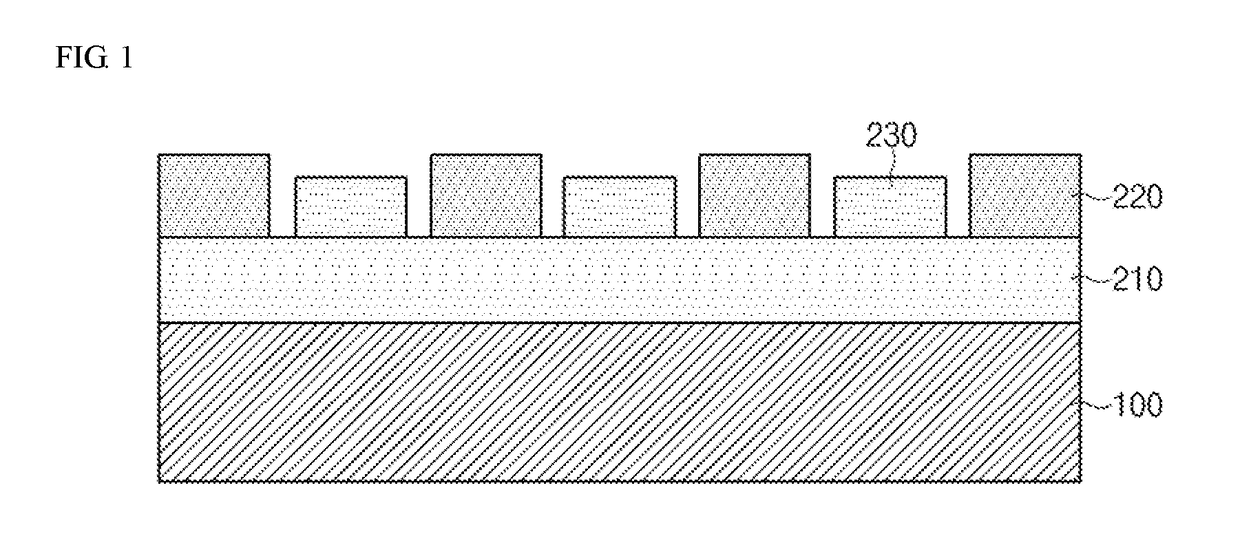

Electrode for nonaqueous electrolyte secondary battery and method of manufacturing the same

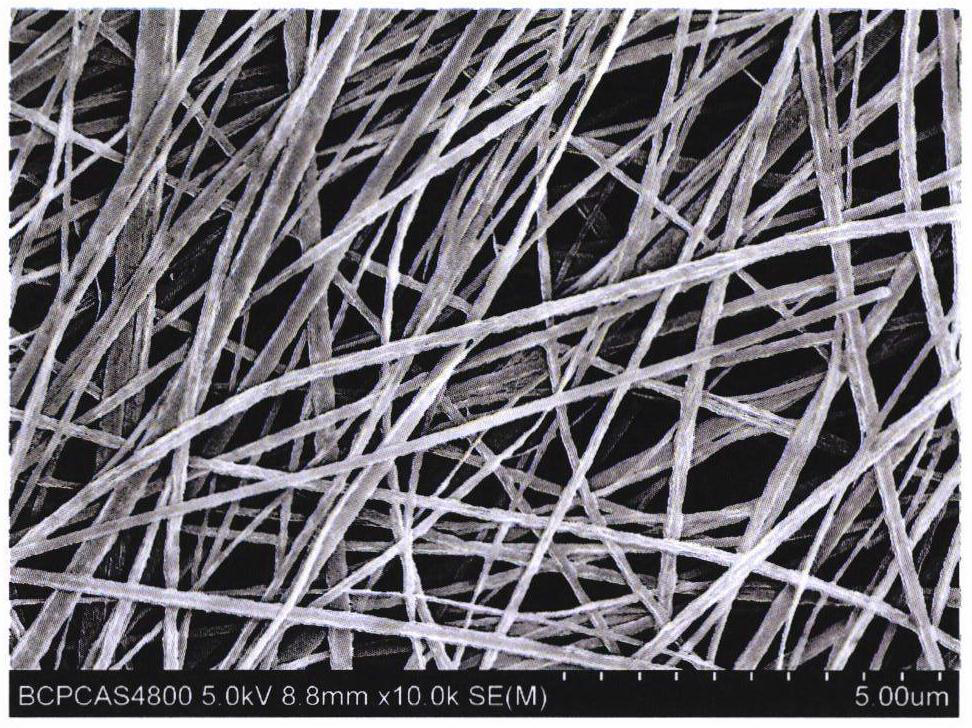

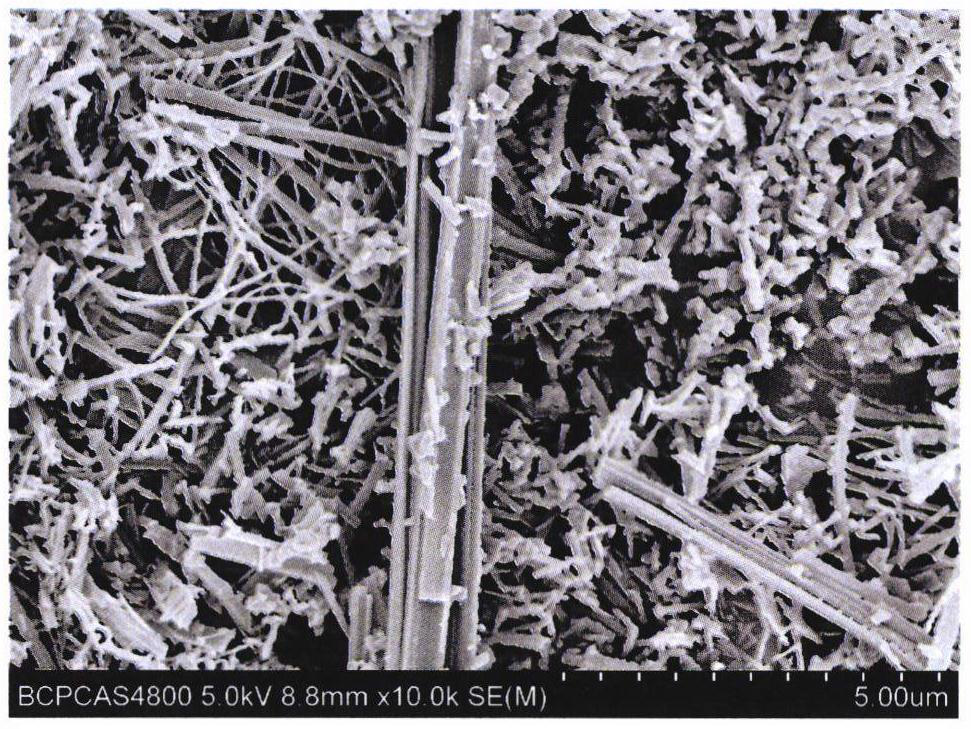

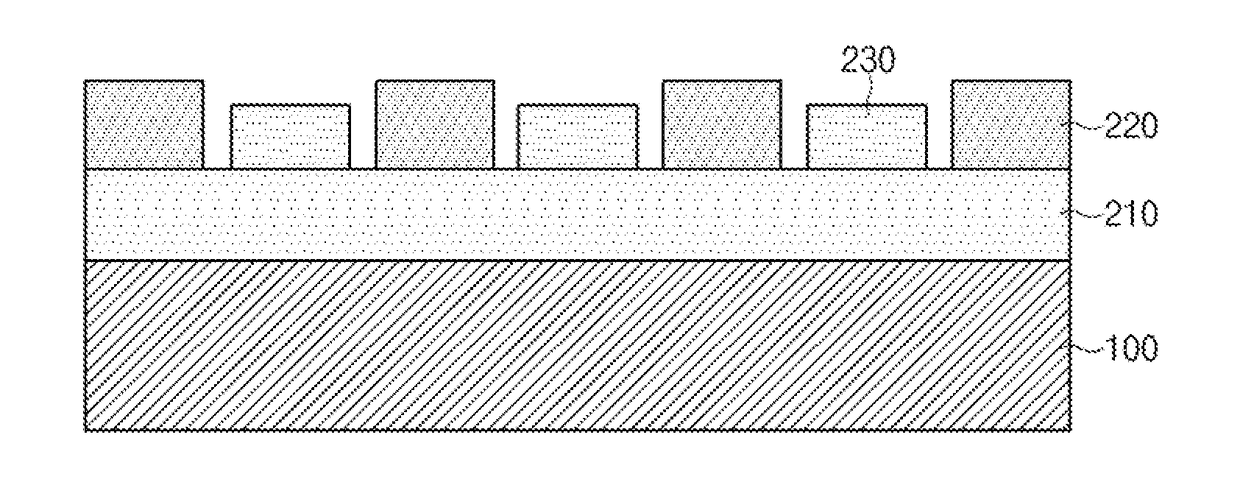

ActiveUS20160204438A1Volatilization of the solvent penetrating into the hollow active material particle is promotedReduce unevennessNegative electrodesPositive electrodesElectrolyteMaterials science

An electrode for a nonaqueous electrolyte secondary battery includes an electrode mixture layer. The electrode mixture layer contains a hollow active material particle and a needle-shaped filler having a through-hole that extends through the needle-shaped filler in a longitudinal direction. The needle-shaped filler is arranged on surfaces of the hollow active material particle.

Owner:TOYOTA JIDOSHA KK

Preparation method of double-layer zinc stannate nanosheet negative electrode material as well as product and application of double-layer zinc stannate nanosheet negative electrode material

PendingCN114229888AIncrease the areaHigh conductivityTin compoundsNegative electrodesNanoparticlePhysical chemistry

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Negative electrode active material, preparation method thereof, and negative electrode and secondary battery including same

PendingUS20220231280A1Alkaline-earth metal silicatesNegative electrodesComposite materialCrystallite

Owner:LG ENERGY SOLUTION LTD

Inorganic solid electrolyte layer of lithium battery, composite negative plate for lithium battery and preparation method and application of composite negative plate

Owner:BEIJING WELION NEW ENERGY TECH CO LTD +1

Lithium ion battery and preparation method thereof

ActiveCN114824281ANegative electrodesElectrolyte accumulators manufactureLithium electrodeEngineering

Owner:天鹏锂能技术(淮安)有限公司

Lead Storage Battery

PendingUS20210167363A1Suppress increaseAccurately determineFinal product manufactureElectrode carriers/collectorsElectrolytic agentLead dioxide

Owner:THE FURUKAWA BATTERY CO LTD

Negative Electrode for Lithium Secondary Battery and Lithium Secondary Battery Including the Same

Owner:SK ON CO LTD

Positive Electrode Active Material for Lithium Secondary Battery and Lithium Secondary Battery

PendingUS20210226206A1Excellent capacity characteristicsImprove featuresNegative electrodesPositive electrodesPhysical chemistryBattery cell

Owner:LG CHEM LTD

Lithium battery negative electrode, preparation method thereof and battery

ActiveCN113659149ASolve the technical problem of easy formation of dead lithiumImprove Coulombic efficiencyElectrode carriers/collectorsNegative electrodesMetallic lithiumPhysical chemistry

Owner:中国电子新能源(武汉)研究院有限责任公司

Lithium ion battery, battery module, battery pack, and electric device

Owner:CONTEMPORARY AMPEREX TECH CO

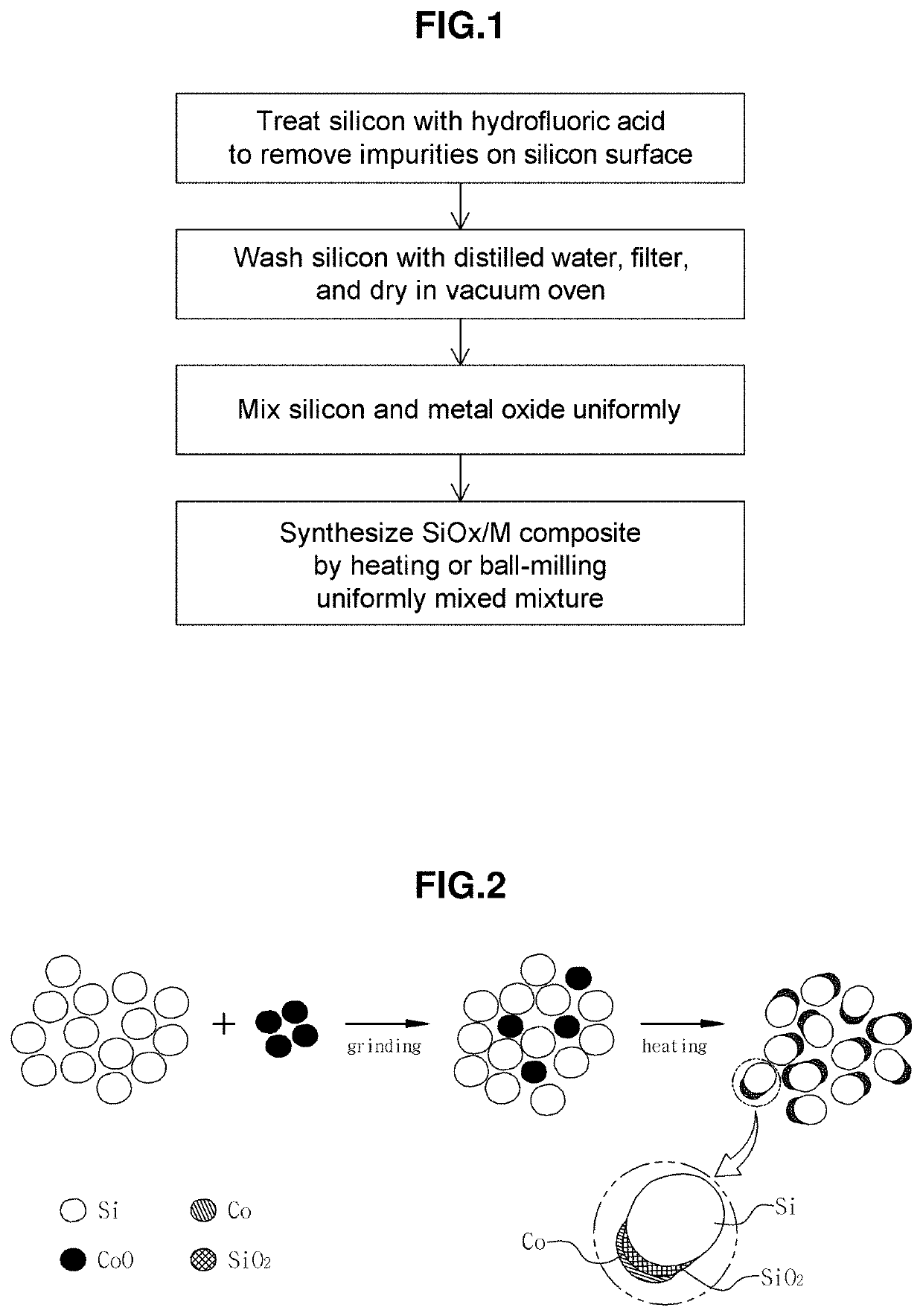

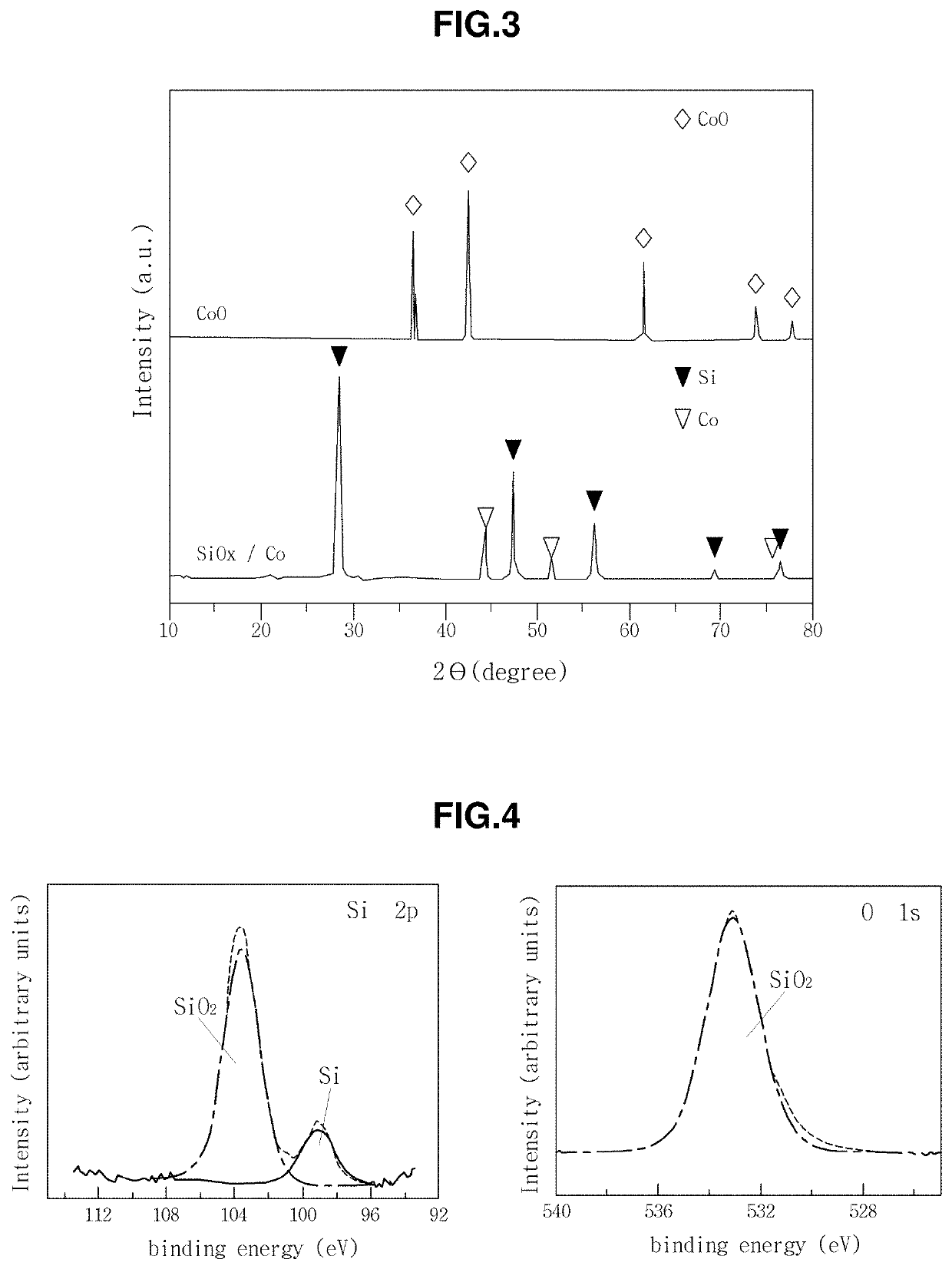

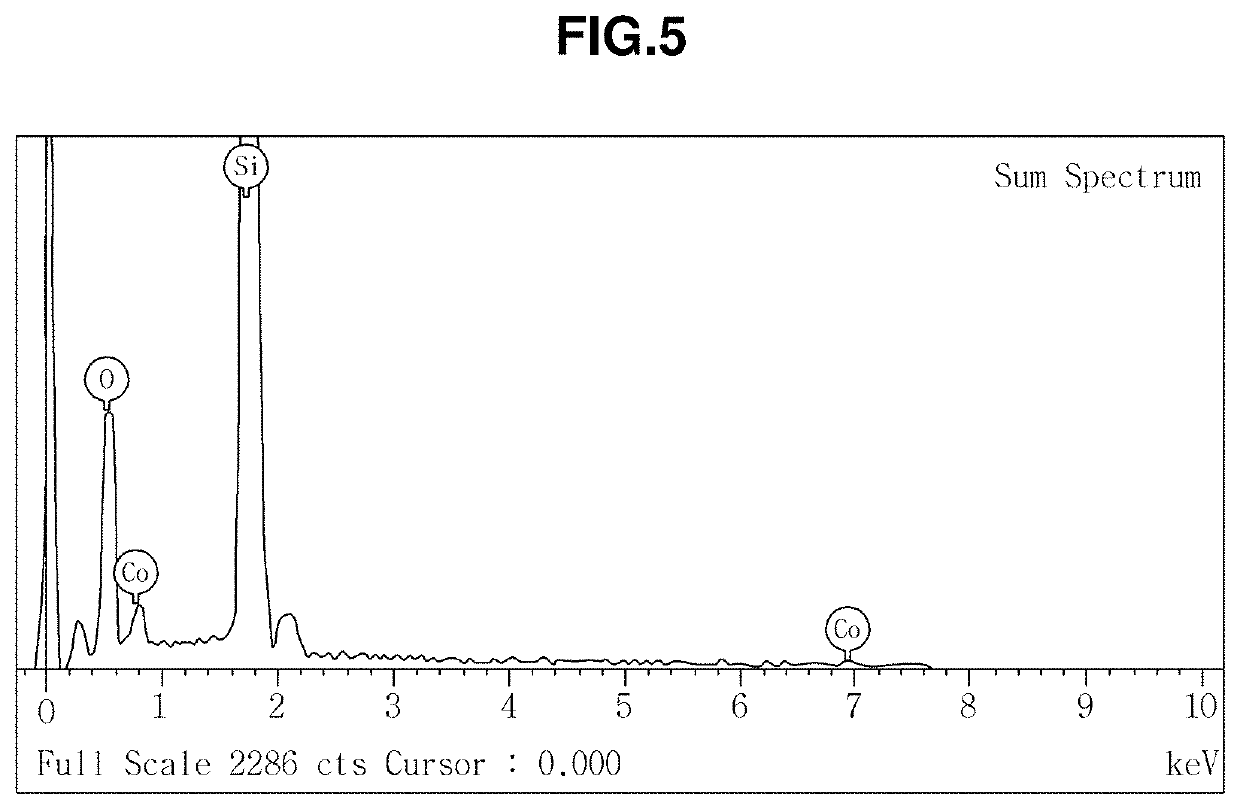

Method for preparing negative electrode active material, for lithium secondary battery, comprising silica-metal composite, and negative electrode active material prepared thereby

PendingUS20210253437A1Evenly distributedExtend your lifeSilicaElectrode thermal treatmentElectrical batterySilicon dioxide

Owner:GWANGJU INST OF SCI & TECH

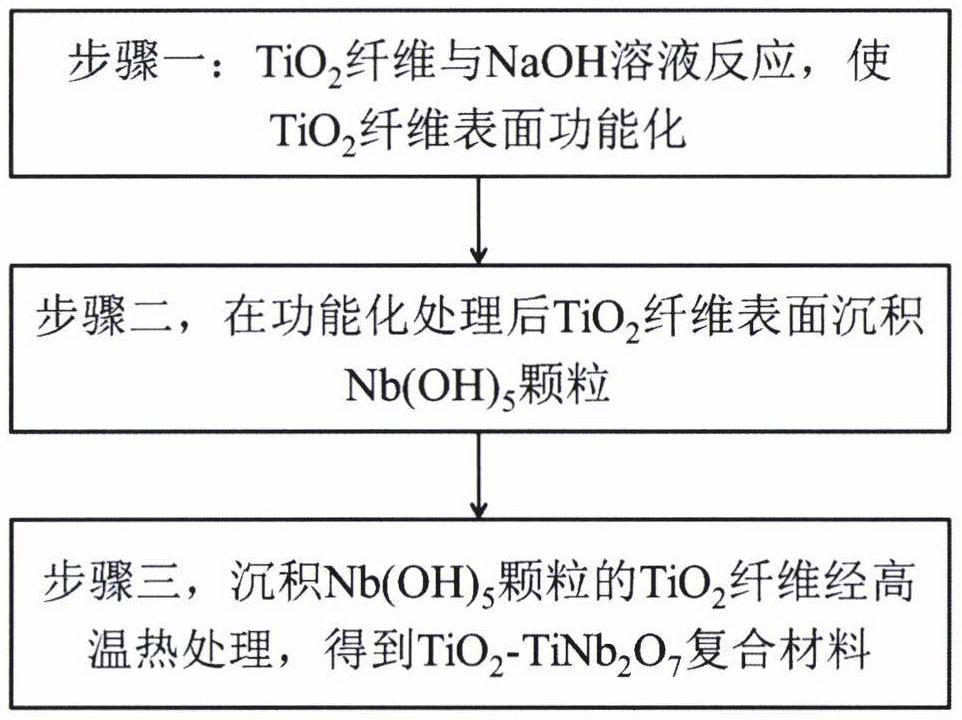

Preparation method of TiO2-TiNb2O7 composite negative electrode material for lithium ion battery

Owner:中国人民解放军军事科学院防化研究院

Negative electrode and secondary battery including the same

ActiveUS20180309162A1Capacity of electrodeFaster rateFinal product manufactureElectrode carriers/collectorsEngineeringVolume expansion

Owner:LG ENERGY SOLUTION LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap