Negative electrode material and preparation method thereof and secondary battery

A negative electrode material and composite material technology, applied in the field of battery material synthesis, can solve the problems of low specific capacity, fast capacity decay, poor cycle stability, etc., achieve high specific capacity, alleviate cycle deterioration, and guarantee cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

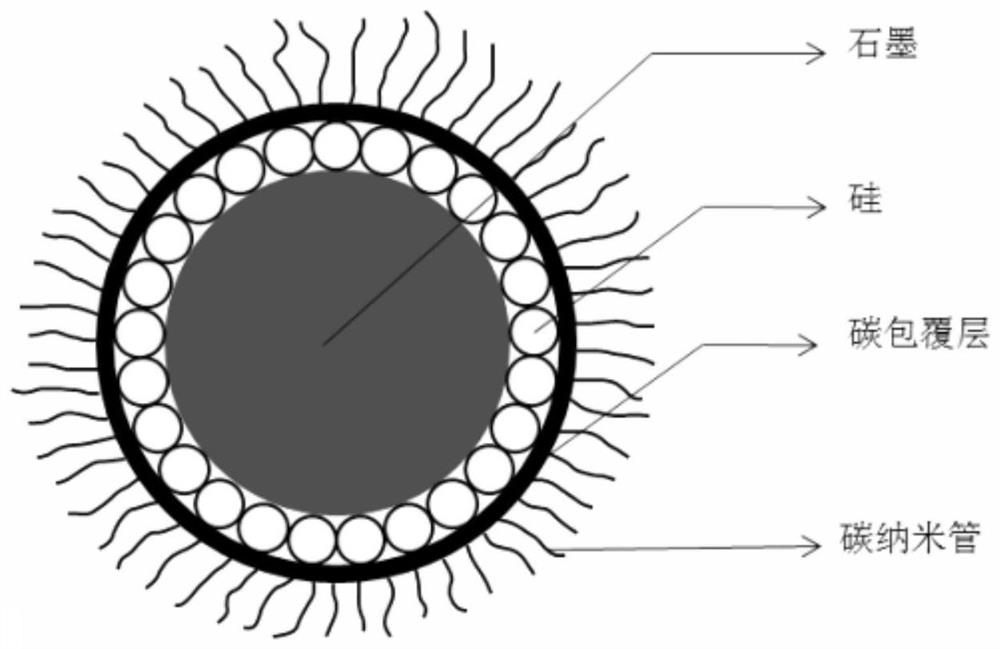

[0041] The embodiment of the present invention provides a kind of preparation method of negative electrode material, it comprises the following steps:

[0042]S1. Provide graphite and silicon powder;

[0043] S2, mixing graphite and silicon powder, coating the surface of graphite with silicon powder, to obtain a silicon / graphite composite material;

[0044] S3. Carry out carbon coating treatment on the silicon / graphite composite material, prepare a carbon coating layer on the surface of the silicon / graphite composite material, and obtain a carbon-coated silicon / graphite composite material;

[0045] S4. In situ growing carbon nanotubes with an aspect ratio greater than 3000 on the surface of the carbon-coated silicon / graphite composite material to obtain a negative electrode material.

[0046] In the preparation method of the negative electrode material provided by the embodiment of the present invention, firstly, by wrapping the silicon powder on the surface of the gra

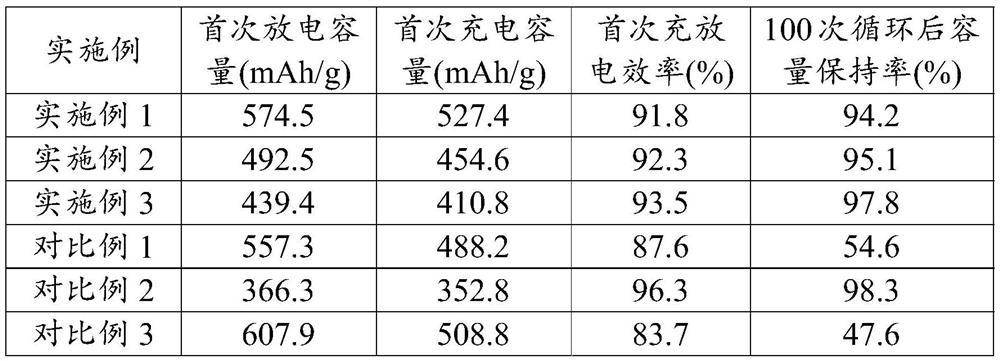

Embodiment 1

[0076] A preparation method of negative electrode material, comprising the steps of:

[0077] (11) Take 20g of polyvinylpyrrolidone and dissolve it in 2500g of absolute ethanol, add 50g of silicon powder with an average particle size of 100nm and ultrasonically disperse, then add 1000g of artificial graphite with an average particle size of 5-20 μm, stir and mix to form a solid content of 30% homogeneous slurry; then spray drying (the inlet temperature of the hot air is 200°C, and the outlet temperature is 40°C), to obtain a silicon / graphite composite material;

[0078] (12) Take 35g of high-temperature petroleum pitch, dissolve it in tetrahydrofuran, remove the filter residue by suction filtration, then add the silicon / graphite composite material to the filtrate, stir for 2 hours, remove the solvent in a vacuum oven at 70°C, and pass through 200 mesh after ball milling Sieve, the obtained powder is heated up to 1000°C at a rate of 5°C / min under a nitrogen atmosphere, kept

Embodiment 2

[0081] A preparation method of negative electrode material, comprising the steps of:

[0082] (21) Take 20g of polyvinylpyrrolidone and dissolve it in 2450g of absolute ethanol, add 30g of silicon powder with an average particle size of 100nm and ultrasonically disperse, then add 1000g of natural graphite with an average particle size of 5-20 μm, stir and mix to form a solid content of 30% homogeneous slurry; then spray drying (the inlet temperature of hot air is 250°C, and the outlet temperature is 60°C) to obtain a silicon / graphite composite material;

[0083] (22) Take 50g of phenolic resin, dissolve it in absolute ethanol, add silicon / graphite composite material, remove the solvent in a vacuum oven at 85°C after stirring for 2 hours, and pass through a 200-mesh sieve after ball milling; the resulting powder is in a nitrogen atmosphere , the temperature was raised to 900°C at a rate of 2°C / min, kept at a temperature of 5 hours, and the temperature was naturally lowered.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap