Preparation method of lithium ion battery negative electrode composite material

A lithium-ion battery and composite material technology, which is applied in the field of preparation of lithium-ion battery negative electrode composite materials, to achieve the effect of avoiding matching selectivity and reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

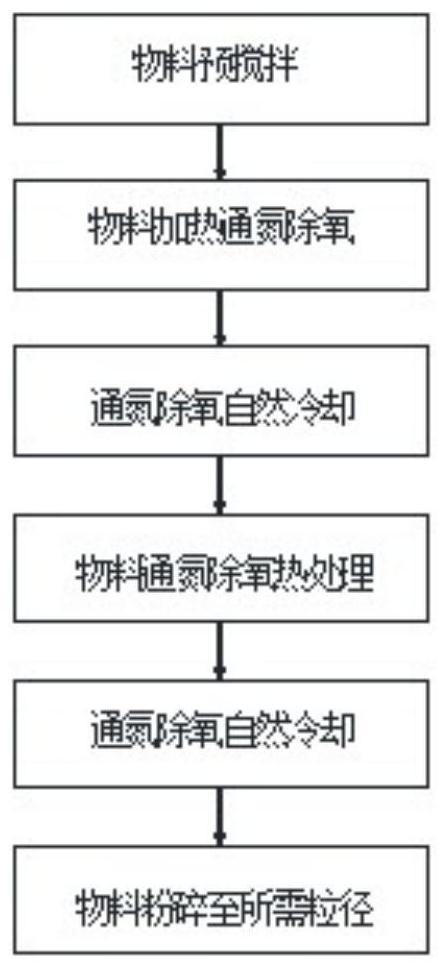

[0022] A preparation method of a lithium ion battery negative electrode composite material, comprising the steps of:

[0023] Step 1, mix the coal tar pitch powder and the negative electrode material to be coated evenly;

[0024] Step 2, under a nitrogen atmosphere, heat the coal tar pitch powder to melt, and continue stirring at the same time; make the mixture solidify after cooling;

[0025] In the third step, the solidified mixture is subjected to heating and carbonization treatment, cooled and pulverized to obtain the negative electrode material.

[0026] In one embodiment, the weight ratio of the coal tar pitch powder in the first step to the negative electrode material to be coated is in the range of 1:5 to 5:1, more preferably 1:3 to 3:1, and more preferably 1: 2~2:1.

[0027] In one embodiment, the negative electrode material to be coated in the first step is selected from silicon, silicon oxide, silicon oxide and the like.

[0028] In one embodiment, the mixing in the

Embodiment 1

[0040] (1) Put the coal tar pitch powder and the negative electrode material to be coated into the mixing bucket according to the weight ratio of 2:1, and fully stir for 1 hour at 25°C;

[0041] (2) Pass nitrogen into the material barrel to remove oxygen until the end of step (4);

[0042] (3) Heat the mixed material to 260°C while continuing to stir the mixed material;

[0043] (4) Natural cooling and solidification of the mixed material;

[0044](5) Put the solidified mixture into a tube furnace and heat it to 300°C at a heating rate of 2°C / min for 1 hour under the protection of nitrogen, and continue to heat at a heating rate of 2°C / min to 600°C for 2 hours. , continue to heat up to 900°C at a heating rate of 2°C / min to volatilize and remove the hydrocarbons and other volatile components in the coal tar pitch, and then cool naturally to room temperature;

[0045] (6) Take out the heat-treated mixed material and crush it to the particle size required for the negative el

Embodiment 2

[0047] (1) Put the coal tar pitch powder and the negative electrode material to be coated into the mixing bucket according to the weight ratio of 1:2, and fully stir for 1 hour at 25°C;

[0048] (2) Pass nitrogen into the material barrel to remove oxygen until the end of step (4);

[0049] (3) Heat the mixed material to 260°C while continuing to stir the mixed material;

[0050] (4) Natural cooling and solidification of the mixed material;

[0051] (5) Put the solidified mixture into a tube furnace and heat it to 320°C at a heating rate of 3°C / min for 2 hours under the protection of nitrogen, and continue to heat at a heating rate of 1°C / min to 550°C for 3 hours. , continue to heat at a heating rate of 3°C / min to 850°C for 1 hour to volatilize and remove the hydrocarbons and other volatile components in the coal tar pitch, and then cool naturally to room temperature;

[0052] (6) Take out the heat-treated mixed material and crush it to the particle size required for the n

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap