Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

231 results about "Composite material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A composite material (also called a composition material or shortened to composite, which is the common name) is a material made from two or more constituent materials with significantly different physical or chemical properties that, when combined, produce a material with characteristics different from the individual components. The individual components remain separate and distinct within the finished structure, differentiating composites from mixtures and solid solutions.

Copolymer, process for producing the same, and resist composition

InactiveUS6706826B1Improve adhesionImprove solubilityOriginals for photomechanical treatmentPhotosensitive materials for photomechanical apparatusSolventResist

The present invention relates to a copolymer for use in paints, resists, and the like; a method for manufacturing the same; and a resist composition using the same. The copolymer according to the present invention is obtained by means of polymerizing at least one monomer containing an alicyclic structure and one monomer containing a lactone structure, and the distribution of the copolymer composition of said monomer containing a lactone structure in said copolymer is in the range of -10 to +10 mol % of the average copolymer composition of said monomer containing a lactone structure in said entire copolymer. In addition, the copolymer according to the present invention is obtained by means of polymerizing a monomer containing an alicyclic structure, a monomer containing a lactone structure, and another vinyl monomer comprising a higher polarity than said monomer containing an alicyclic structure, but a lower polarity than said monomer containing a lactone structure. The copolymer according to the present invention exhibits superior adhesion properties to surfaces possessing a high polarity, such as metal surfaces and the like, in addition to excellent hydrophobic and thermal resistance properties, and also displays a favorable solubility in solvents used for paints, resists, and the like.

Owner:MITSUBISHI CHEM CORP

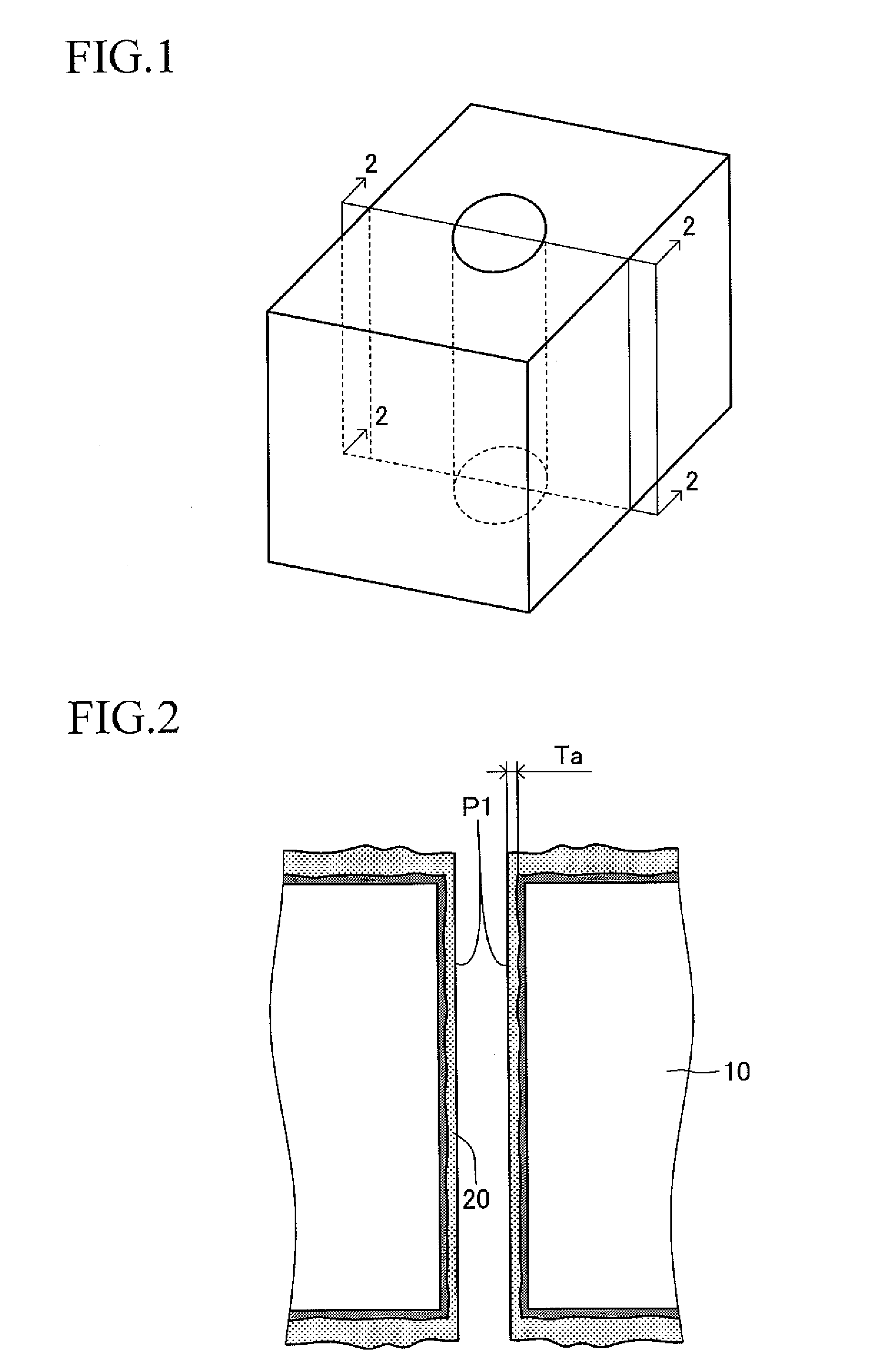

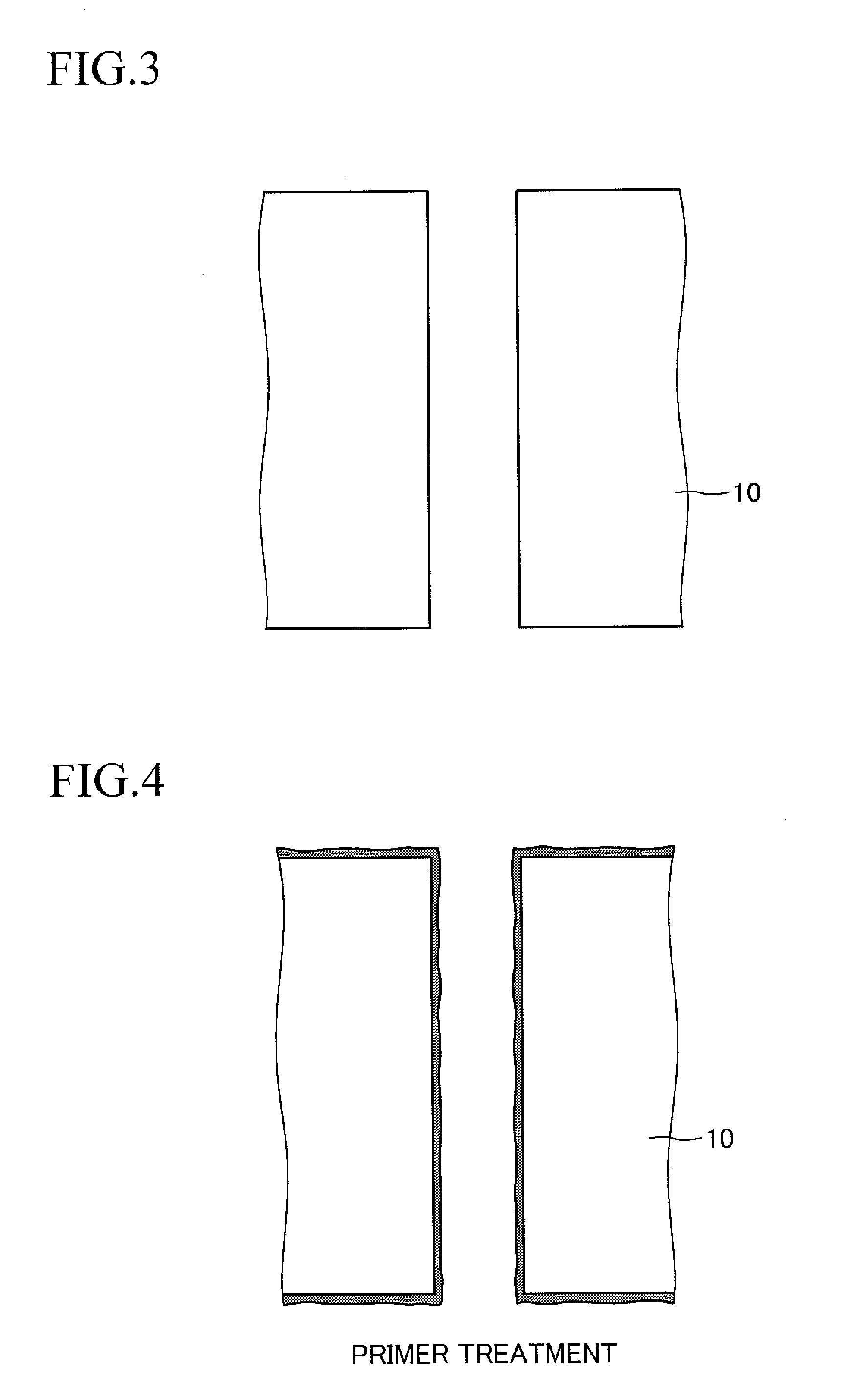

Active Energy Ray-Curable Organopolysiloxane Resin Composition, Optical Transmission Component, And Manufacturing Method Thereof

ActiveUS20080032061A1Good adhesionHigh optical transmittanceCladded optical fibreFibre mechanical structuresChemistrySilorane Resins

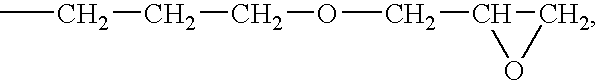

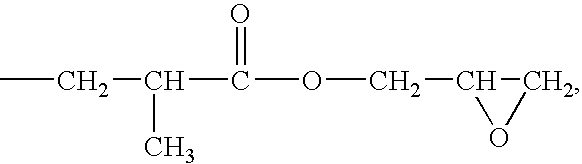

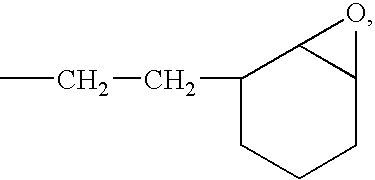

An active energy ray (e.g. UV rays)-curable organopolysiloxane resin composition comprises (A) 100 parts by weight of an organopolysiloxane resin containing epoxy groups and aromatic hydrocarbon groups, (B) 0.05 to 20 parts by weight of a photo acid generator, (C) 0.01 to 20 parts by weight of a photosensitizer or photo-radical generator, and (D) 0 to 5,000 parts by weight of an organic solvent. An optical transmission component made of the above-mentioned composition cured by irradiation with active energy rays (for example, UV rays). A method for manufacturing an optical transmission component by irradiating the above-mentioned composition with active energy rays (for example, UV rays).

Owner:DOW TORAY CO LTD +1

Chemical mechanical polishing aqueous dispersion, chemical mechanical polishing method, and kit for preparing chemical mechanical polishing aqueous dispersion

ActiveUS20090165395A1Polishing rate is loweredImprove productivity and yieldPigmenting treatmentOther chemical processesCompound (substance)Materials science

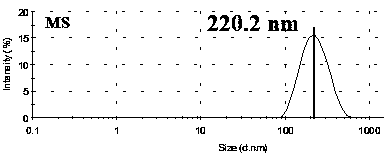

A chemical mechanical polishing aqueous dispersion includes (A) abrasive grains having a pore volume of 0.14 ml / g or more, and (B) a dispersion medium.

Owner:JSR CORPORATIOON

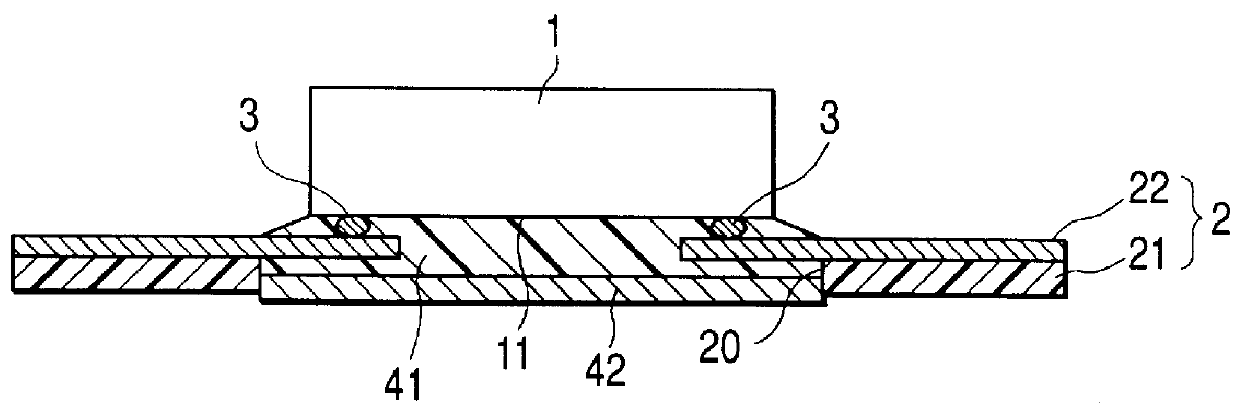

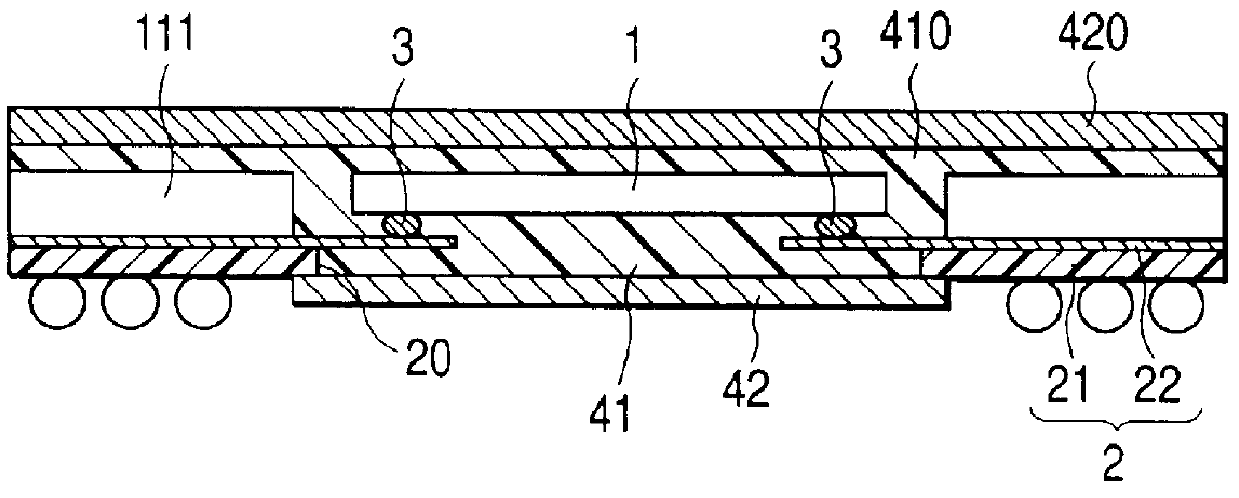

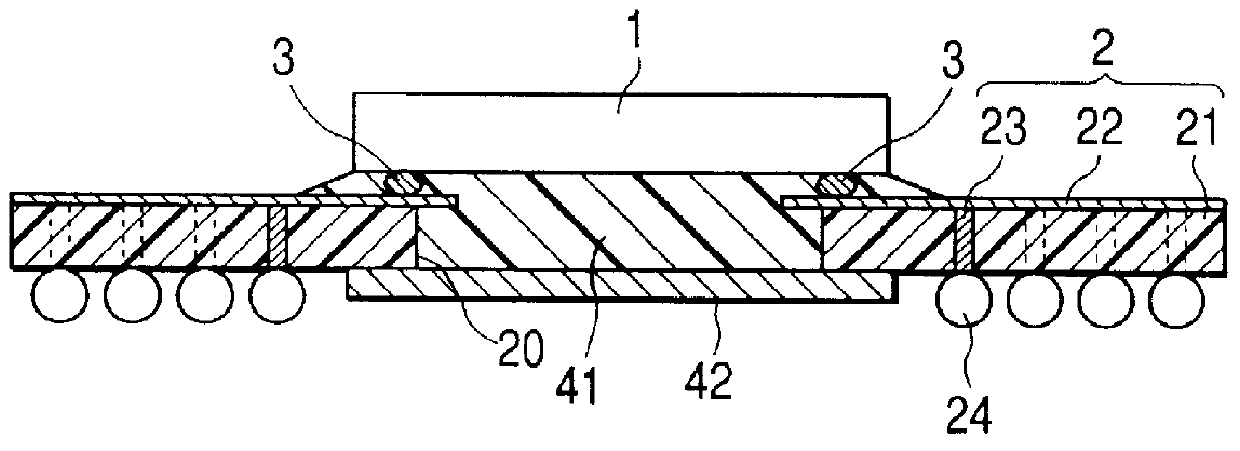

Semiconductor device having metal foil integral with sealing resin

InactiveUS6023096ASemiconductor/solid-state device detailsSolid-state devicesComposite materialMetal foil

A semiconductor device with a metal foil and a sealing resin material. Metal foil is formed integrally with the sealing resin layer.

Owner:NITTO DENKO CORP

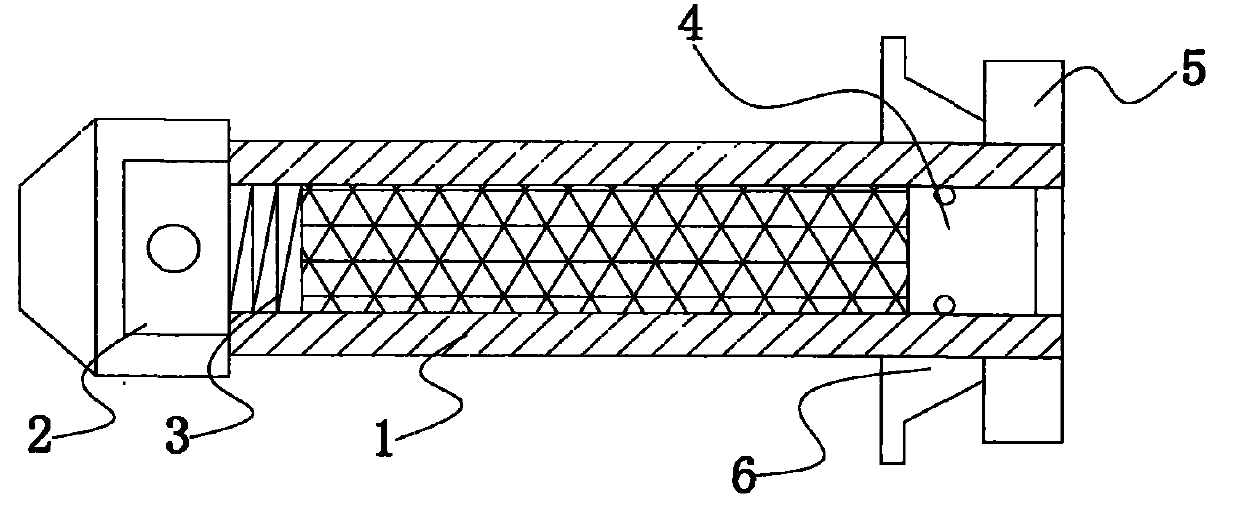

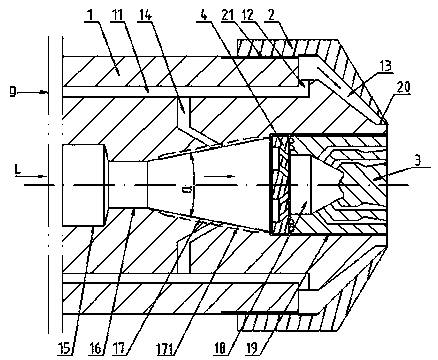

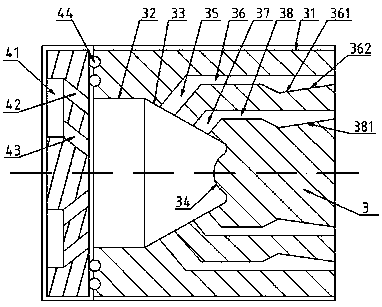

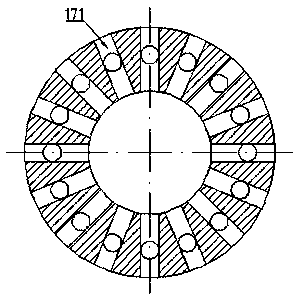

Heater for cigarette-type electronic cigarette device

ActiveUS20200046028A1Heating evenlyIncrease the heating areaMedical devicesTobacco devicesEngineeringElectronic cigarette

Provided is a heater for a cigarette-type electronic cigarette device. A heater for a cigarette-type electronic cigarette device according to an exemplary embodiments of the present invention comprises: a support body made of a ceramic material and formed to have a hollow so as to surround a cigarette; an electrode pattern formed on one surface of the support body so as to heat the cigarette inserted into the support body when power is applied; and a cover layer which has an insulation property and covers the electrode pattern.

Owner:AMOSENSE

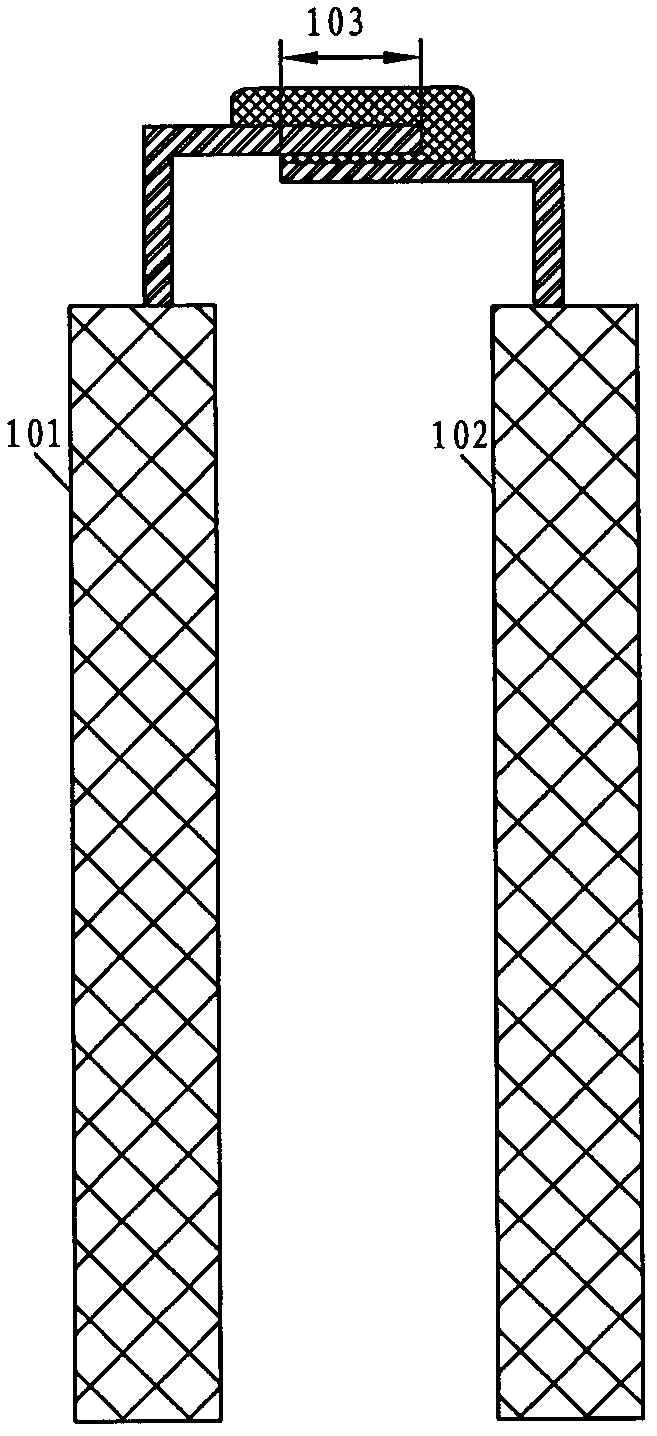

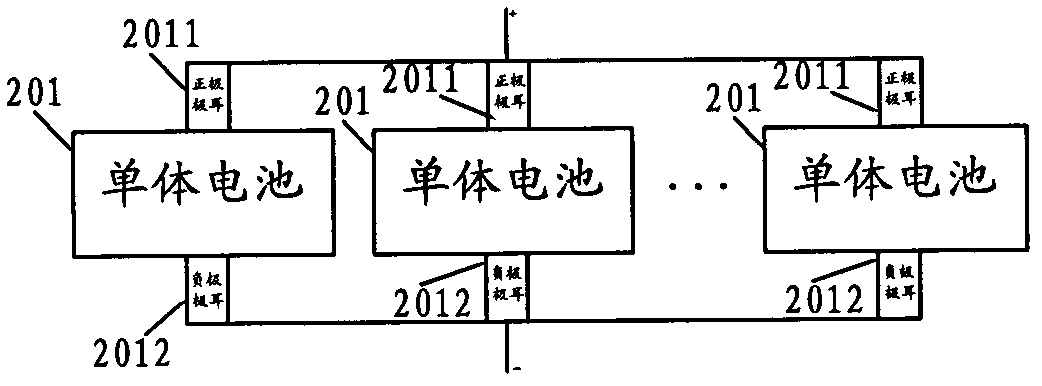

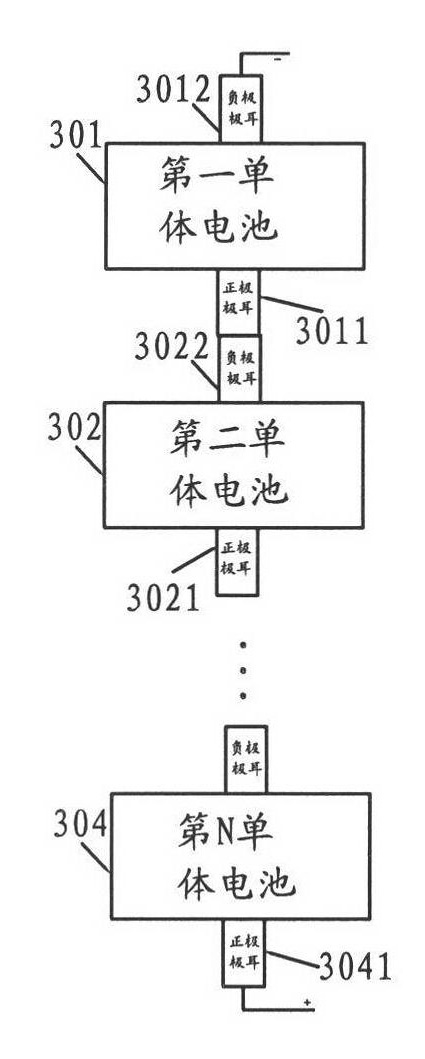

Lithium ion battery pack and soldering method for single batteries therein

ActiveCN102332611AAvoid bloatingFinal product manufactureCell component detailsBattery cellMaterials science

Owner:SHENZHEN GREPOW BATTERY CO LTD

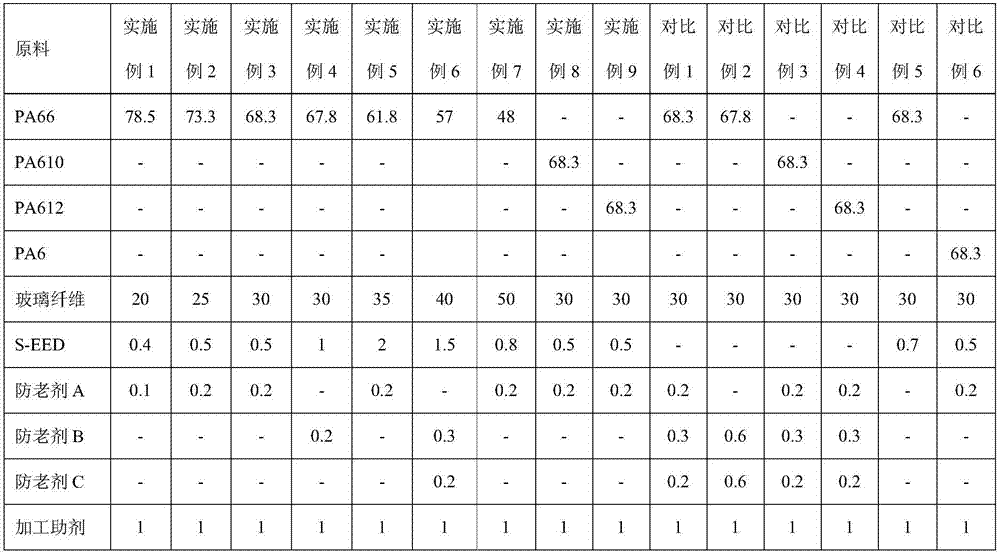

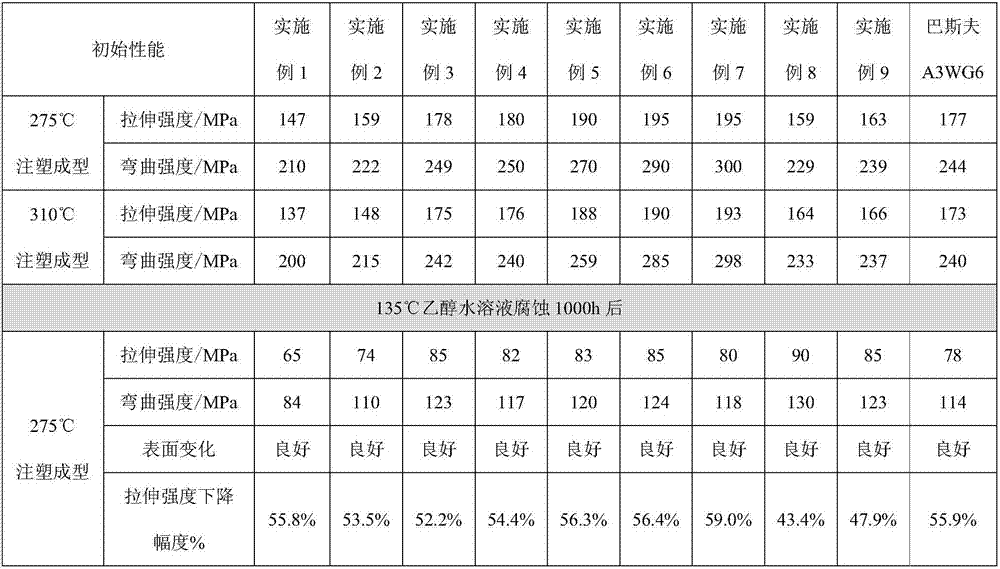

Hydrolysis and alcoholysis-resisting reinforced nylon material and preparation method thereof

ActiveCN107298855AImprove hydrolysis and alcoholysis resistanceExcellent processing temperature resistanceIntercoolerTemperature resistance

Owner:BENSONG ENG PLASTICS HANGZHOU

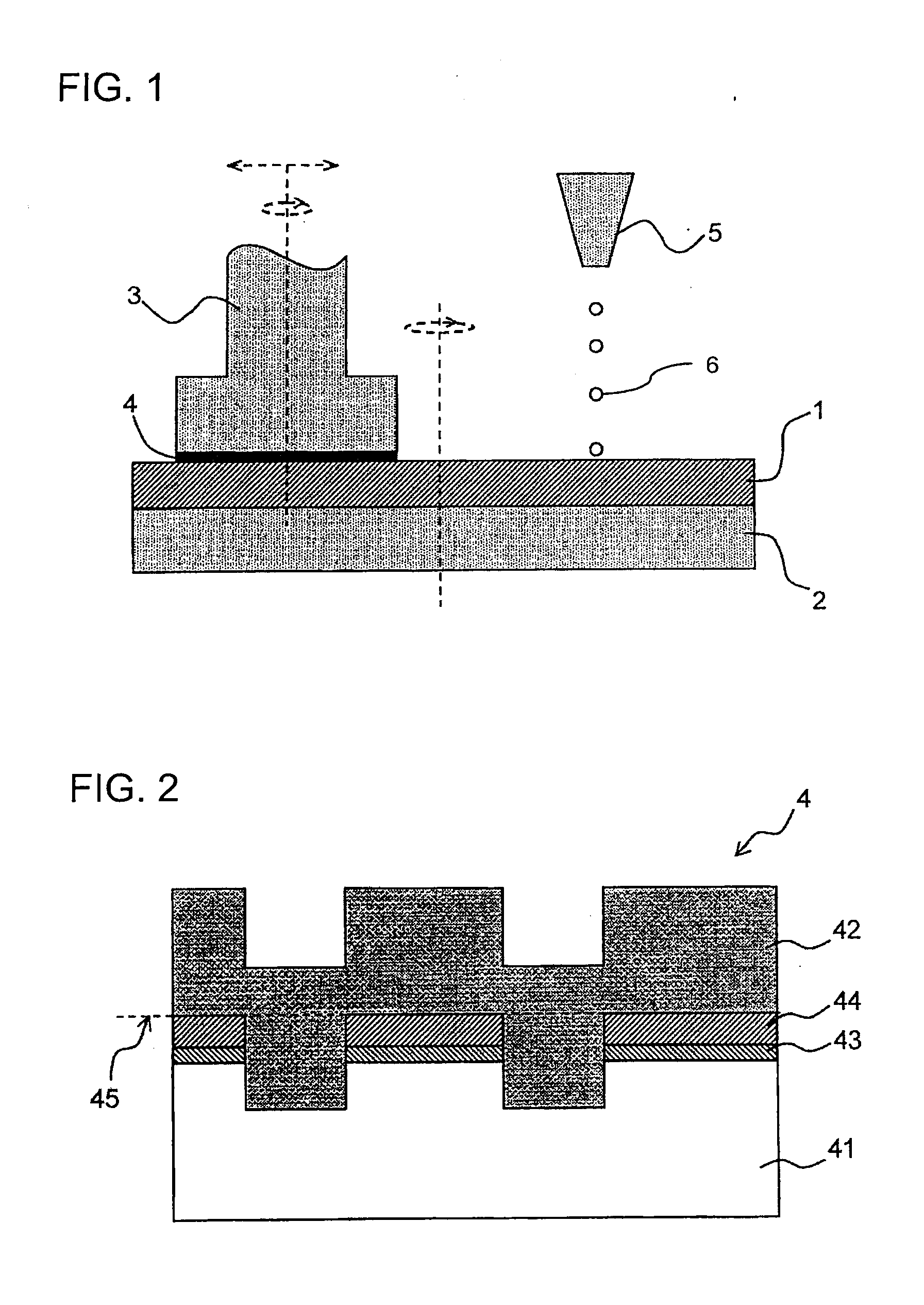

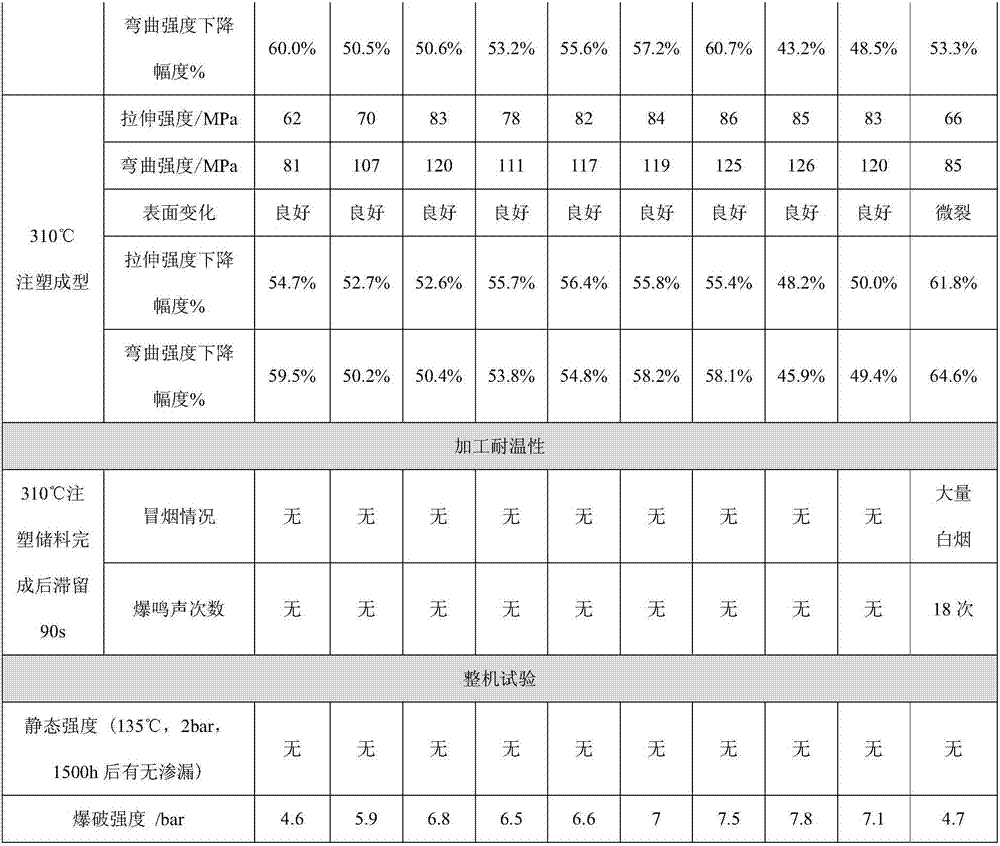

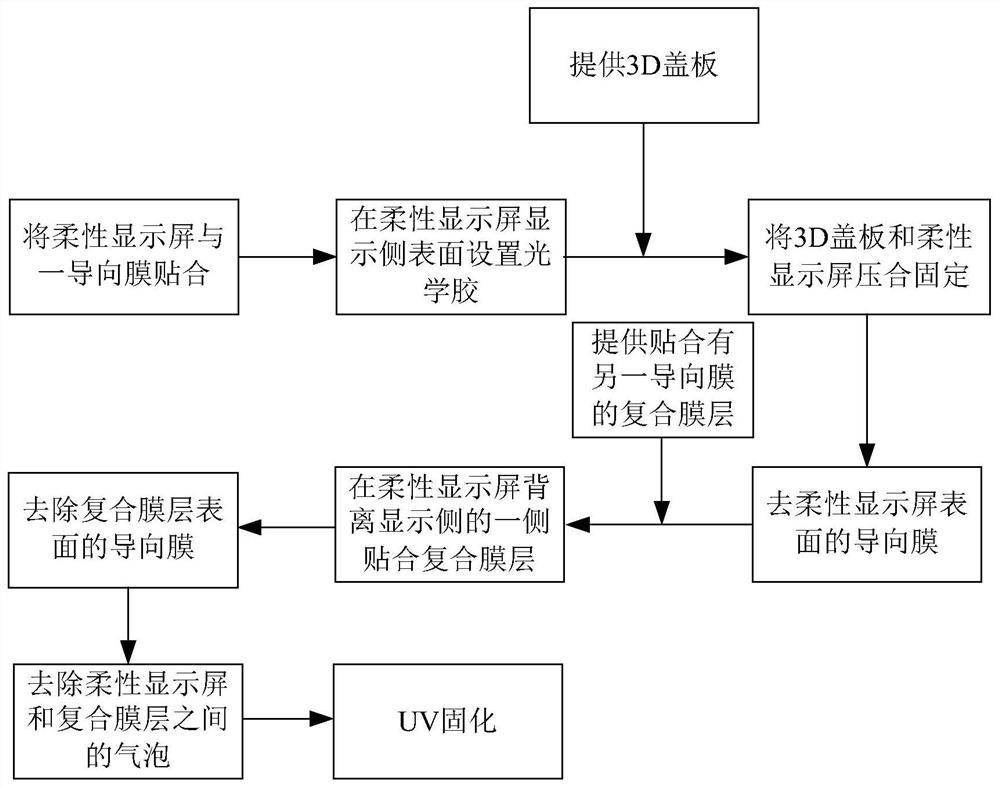

Laminating device and laminating method for curved display panel and composite film layer

ActiveCN112265281AImprove bonding yieldAvoid damageDomestic articlesIdentification meansFlexible circuitsEngineering

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

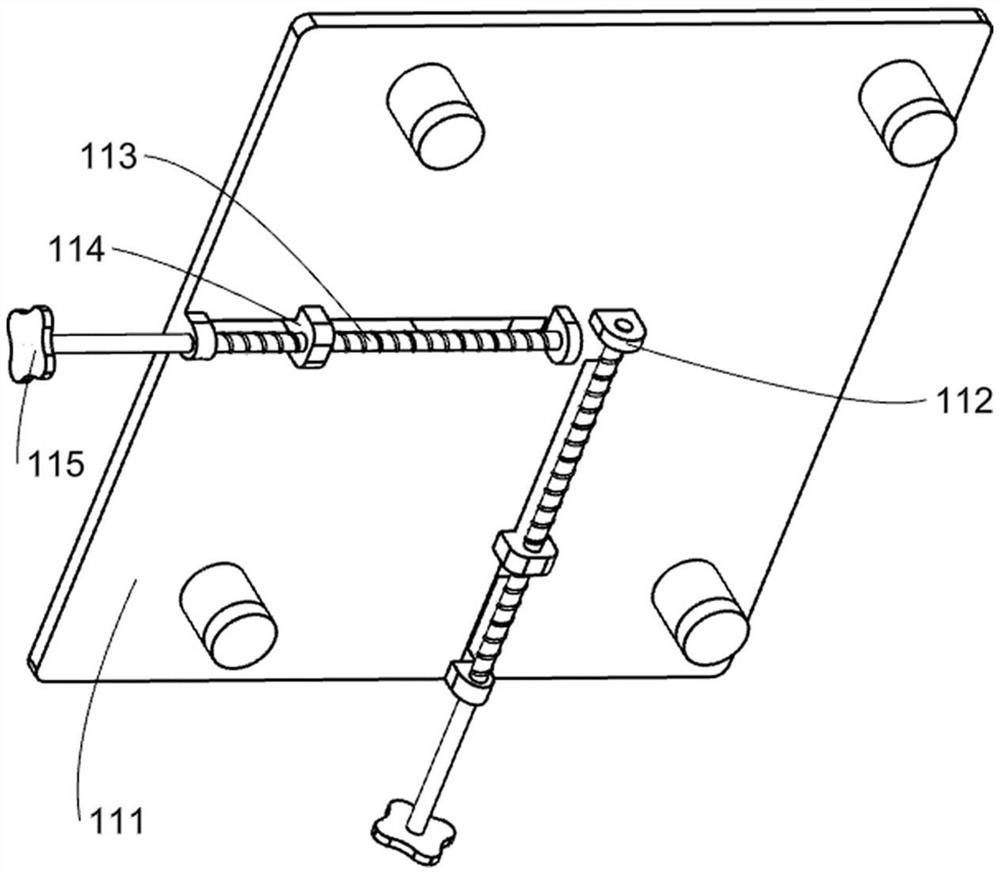

Injection type hollow resin anchor bar

InactiveCN103867220AAnchor bolts are reasonably stressedReduce maintenance workloadAnchoring boltsComposite materialEngineering

The invention discloses an injection type hollow resin anchor bar which comprises an anchor bar body, an anchor head, a mixer, a piston and a nut. An elongated external thread is arranged on the outer wall of the anchor bar body, a hollow agent cavity is formed inside the anchor bar body, the anchor head 2 is arranged at the front end of the anchor bar body, the rear end of the anchor bar body is matched with the external thread on the surface of the anchor bar body in a screwed manner through the nut, the piston fitting the inner wall of the agent cavity is arranged at one end of the agent cavity, the mixer is arranged at the other end of the agent cavity, one end of the mixer is connected with the anchor head, and a cutting edge is arranged at the other end of the mixer. By the aid of a full-length anchoring mode, the anchor bar is more reasonable in stress, maintenance workload of the mounted anchor bar can be largely decreased, resin anchoring agents enter an anchor hole and are solidified after appropriate anchoring agents prefilled in an anchor bar cavity are pressurized, and anchoring construction operation can be simplified.

Owner:高原

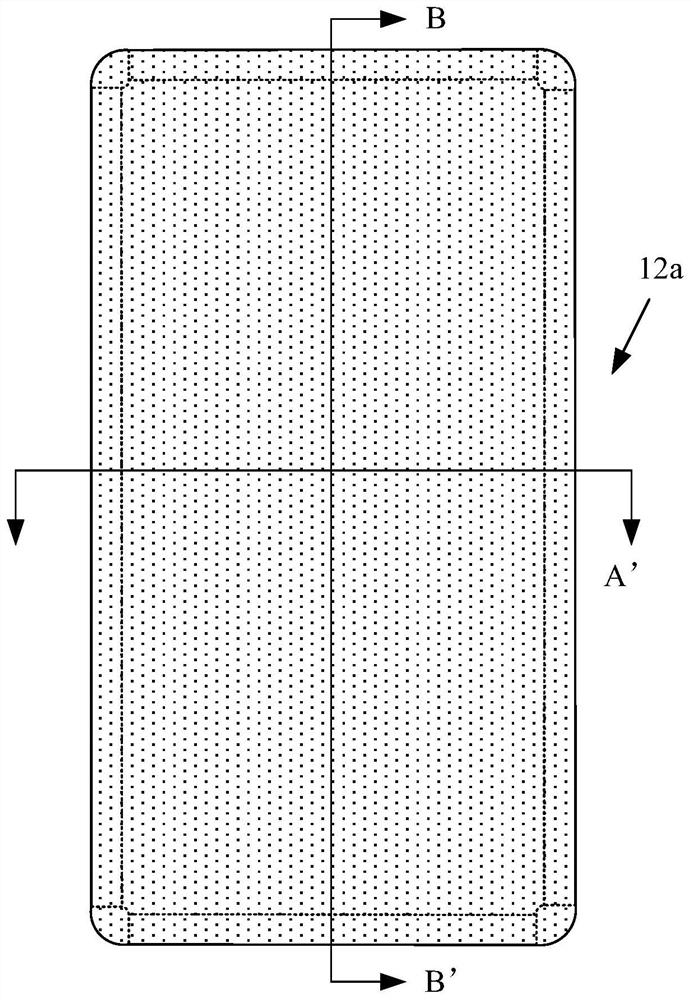

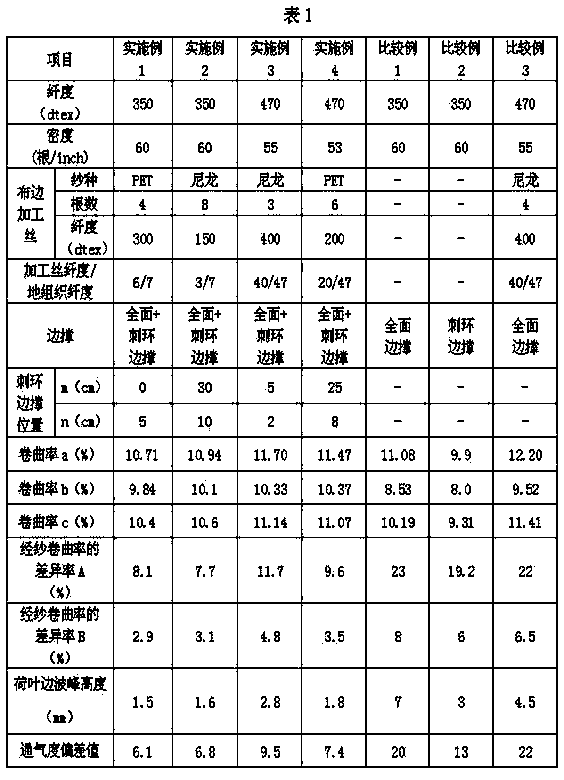

Fabric for safety air bag and production method of fabric

ActiveCN104278392ALow utilization efficiencyGood fixation effectPedestrian/occupant safety arrangementSelvedgesAirbag deploymentMechanical engineering

Owner:TORAY IND INC

MoS2@C composite anode material for lithium ion battery and preparation method thereof

ActiveCN111900408AImproved magnification performanceLimit volume expansionNegative electrodesSecondary cellsCarbon layerBattery cell

The invention discloses a MoS2@C composite anode material for a lithium ion battery and a preparation method thereof, MoS2 sheets in the composite anode material are stacked disorderly and intertwinedto form a wormlike microsphere structure, and the MoS2@C composite anode material comprises 38-43% of Mo, 47-53% of S and the balance of C. According to the invention, MoS2 and a carbon material arecompounded; the prepared anode material has a wormlike structure; the diffusion path of Li<+> can be shortened; the composite material has excellent rate capability; and the carbon layer coated on thesurface of the MoS2 sheet can limit the further growth of the MoS2 nanosheet and can inhibit the problem of easy volume expansion of the MoS2 composite material in the cycle process, thereby effectively enhancing the rate capability and cycle stability of the lithium ion battery anode material.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Preparation method of mesoporous silica in situ doped acrylic resin bone cement composite for enhancing durable release capacity of medicines

Owner:NANJING DRUM TOWER HOSPITAL

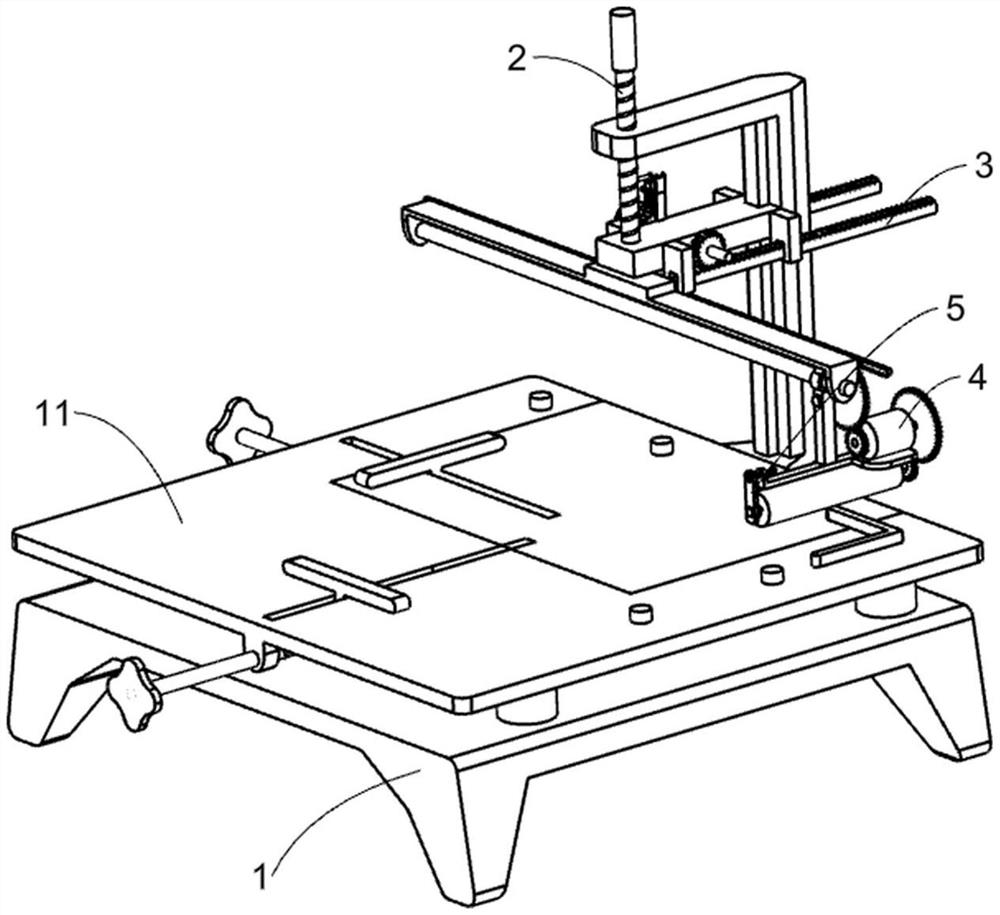

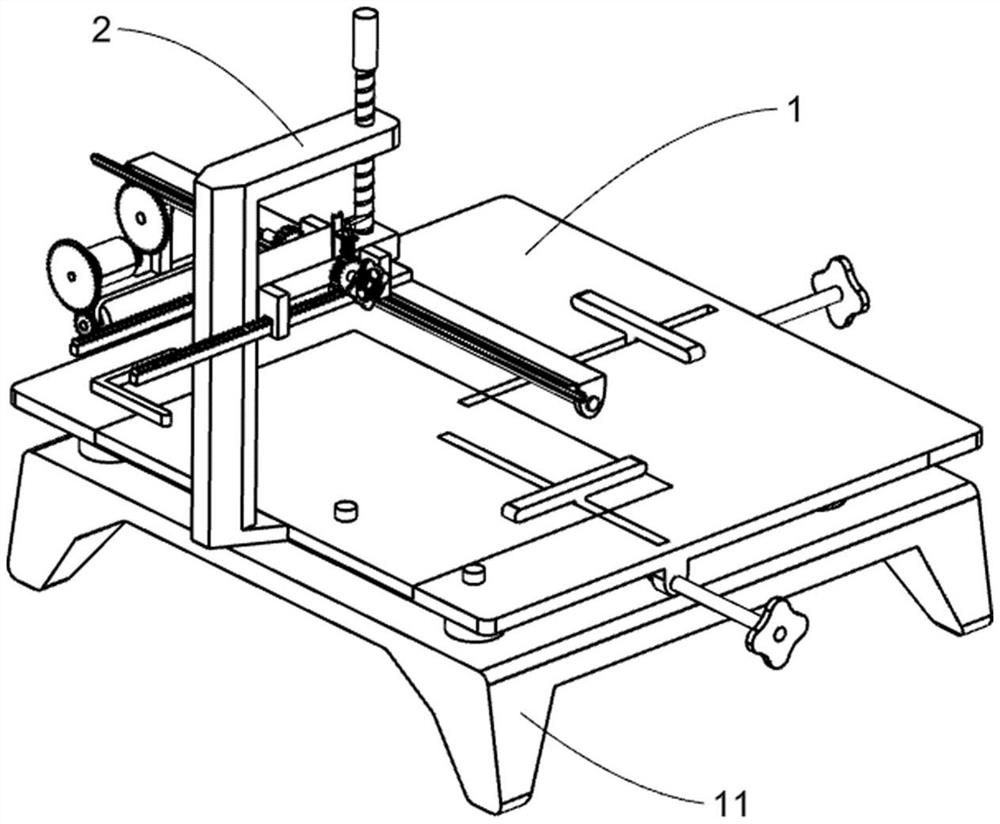

Ceramic tile surface polishing device

PendingCN112025523ATo achieve the function of high and low adjustmentTo achieve the effect of clampingGrinding wheel securing apparatusGrinding carriagesComposite materialCeramic tiles

Owner:凌亮

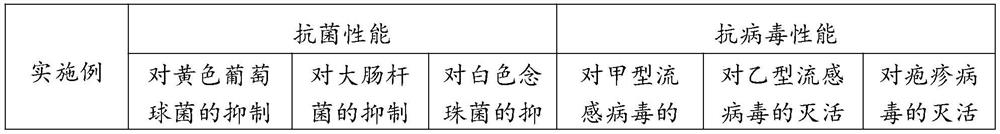

Antibacterial and antiviral cellulose fiber and preparation method and application thereof

ActiveCN112176451AGood antiviral effectDoes not affect physical propertiesPhysical treatmentBiochemical fibre treatmentRegenerating fibersCyclodextrin

Owner:青岛尼希米生物科技有限公司

Production method of forming mold

InactiveUS20120240383A1Forming accuracyHigh shape accuracyMetal rolling stand detailsCoatingsEnd millComposite material

Owner:NGK INSULATORS LTD

Pigment spraying device for ceramic product production process

Owner:景德镇一牧堂陶瓷科技有限公司

Nano multi-layer composite solid lubricating film layer with long service life under space irradiation and preparation thereof

ActiveCN112760607AAchieve self-lubricationReduce coefficient of frictionVacuum evaporation coatingSputtering coatingSputteringAlloy substrate

The invention discloses a nano multi-layer composite solid lubricating film layer with a long service life under space irradiation and preparation thereof. The nano multi-layer composite solid lubricating film layer composed of a Ti binding layer, a TiN bearing layer and an AgTiNi / MoS2Ti nano multi-layer lubricating functional layer is deposited on a titanium alloy substrate, an aluminum alloy substrate, a stainless steel substrate, a bearing steel substrate and the like by adopting a closed magnetic field unbalanced magnetron sputtering technology. The nano multi-layer composite film layer can reliably serve for a long time in strong space irradiation environments such as low-orbit high atomic oxygen density, medium-high-orbit high electron proton density and high ultraviolet irradiation dose, and is high in bearing capacity and low in friction coefficient, thus, the service life of a moving part of a spacecraft exposed in the space irradiation environments can be greatly prolonged, and the reliability of the moving part is improved. In addition, the preparation method has the characteristics that the process is environment-friendly and flexible, the film thickness is uniform, the compactness is good, the preparation process of the film layer is controlled in a programmed manner, the modulation period of the film layer is easy to regulate and control, and batch treatment can be realized, industrial production is easy to realize, and the good application prospect is achieved.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

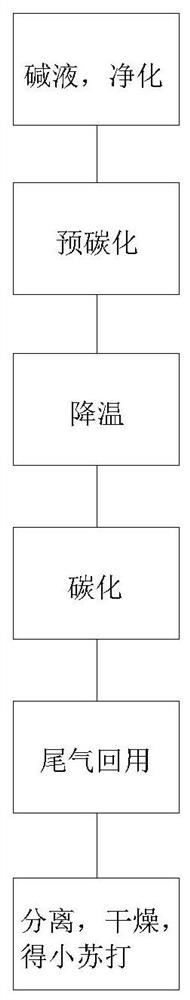

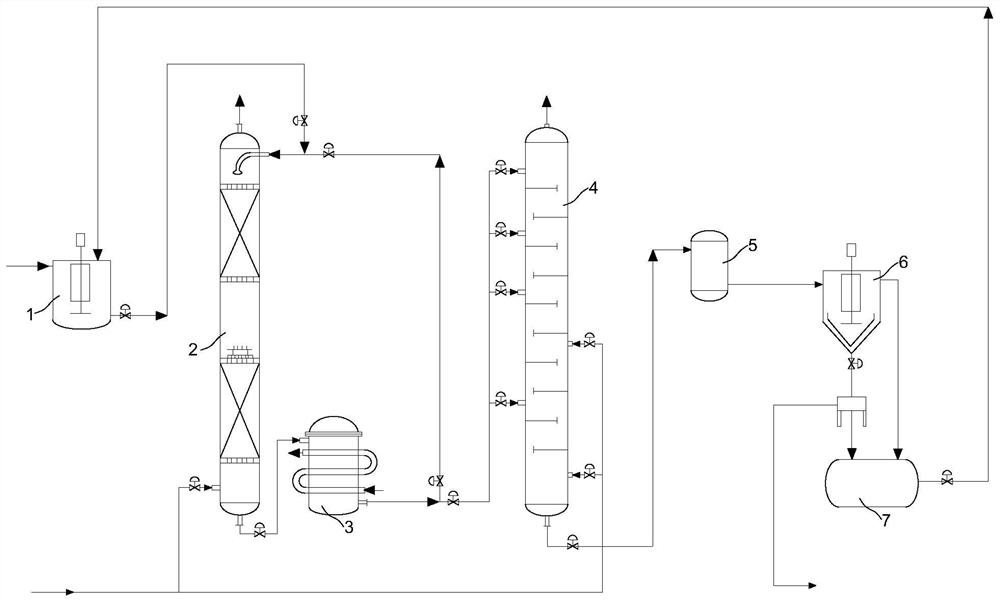

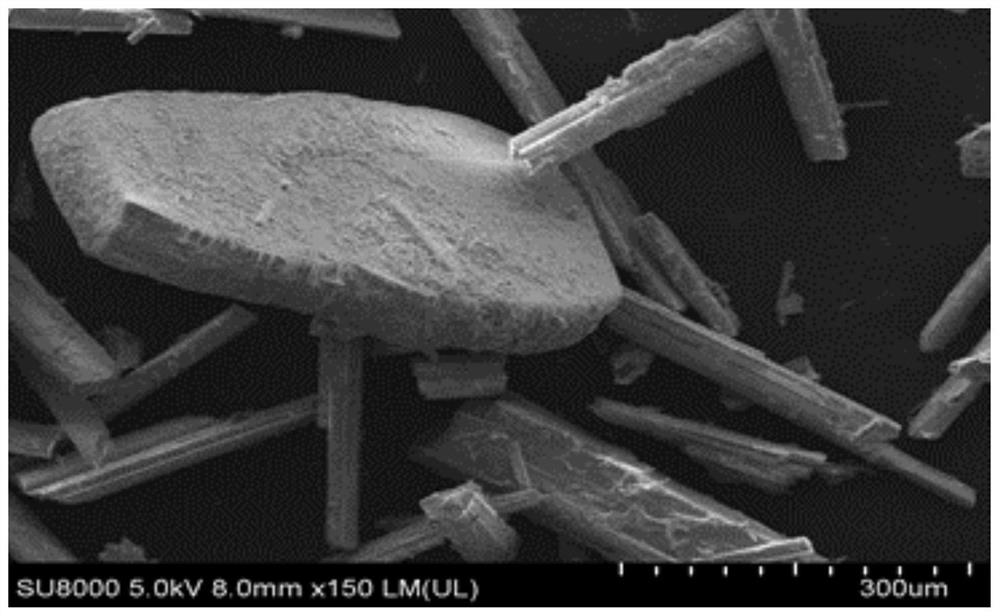

Method for preparing large-particle baking soda by secondary carbonization method and obtained baking soda

ActiveCN111634928ALarge particle sizeLower the discharge temperatureProductsBicarbonate preparationCarbonizationMaterials science

Owner:山东海天生物化工有限公司

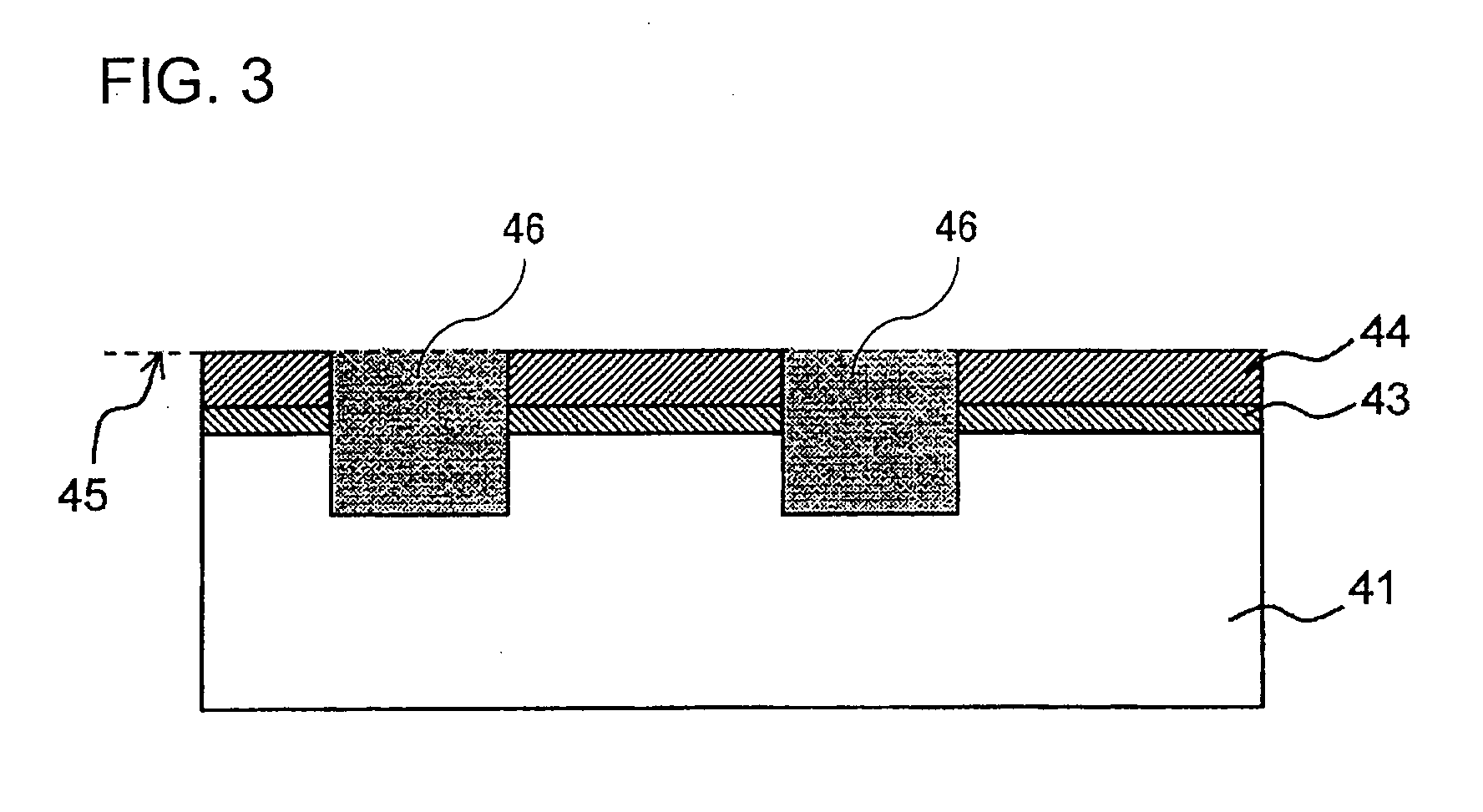

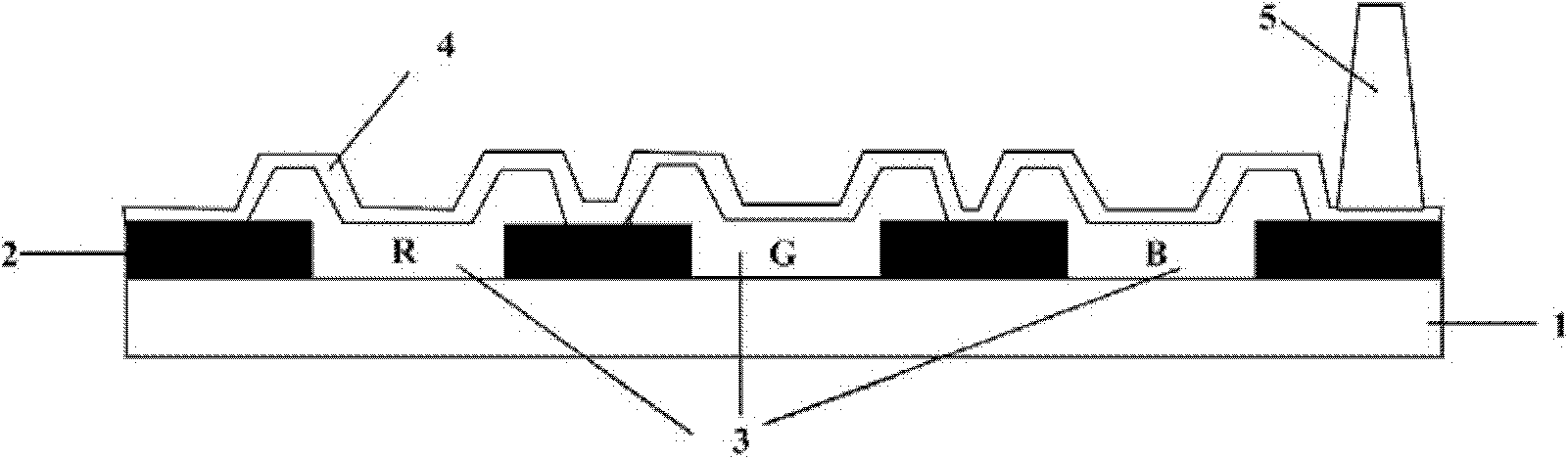

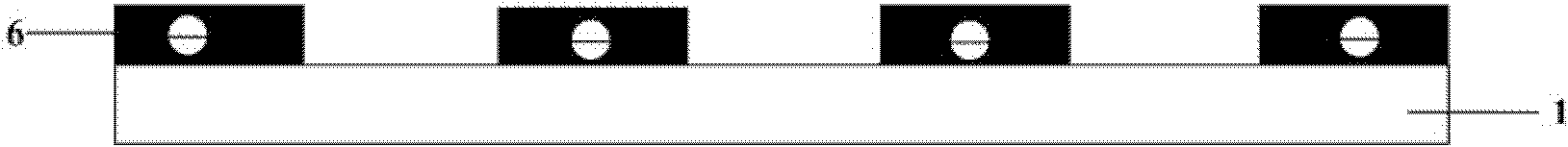

Color filter and manufacturing method thereof

InactiveCN102654592AFit tightlySimple structureOptical filtersPhotomechanical apparatusBlack matrixMaterials science

Owner:BOE TECH GRP CO LTD

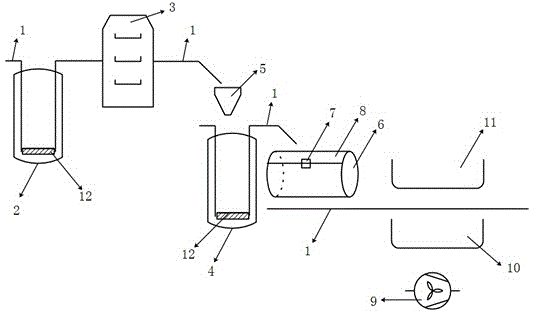

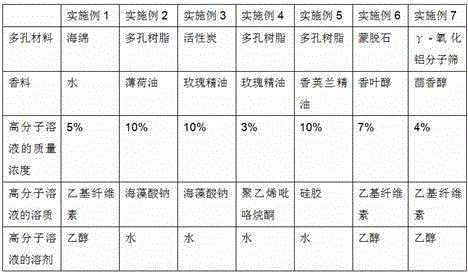

Preparation device and application method of three-layer sandwich-structure spice sustained-release filter tip additive

Owner:CHINA TOBACCO YUNNAN IND

Method of producing fuel cell separator, and fuel cell

InactiveUS20090098431A1Improve wettabilityStable electromotive forceFuel cells groupingRadiation applicationsPolymer scienceFuel cells

Owner:DAINIPPON INK & CHEM INC

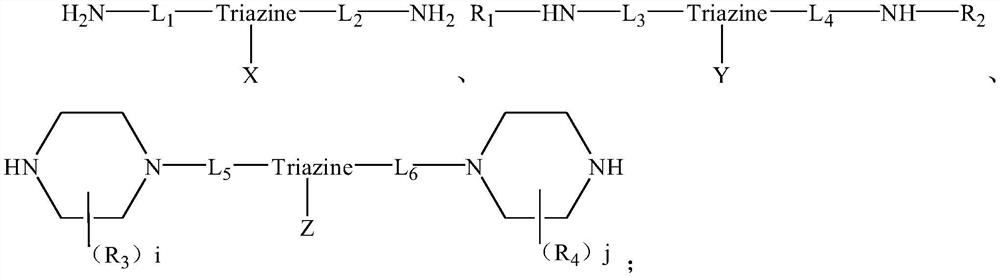

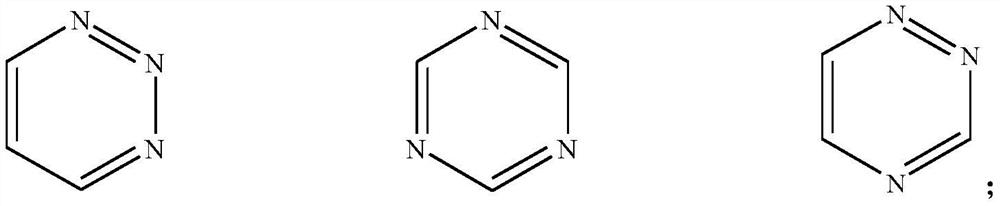

Preparation method of polytriazine alkali-resistant composite nanofiltration membrane

PendingCN114130220AImprove throughputImprove selective separation performanceMembranesReverse osmosisPolymer scienceTriazine

Owner:WANHUA CHEM GRP CO LTD

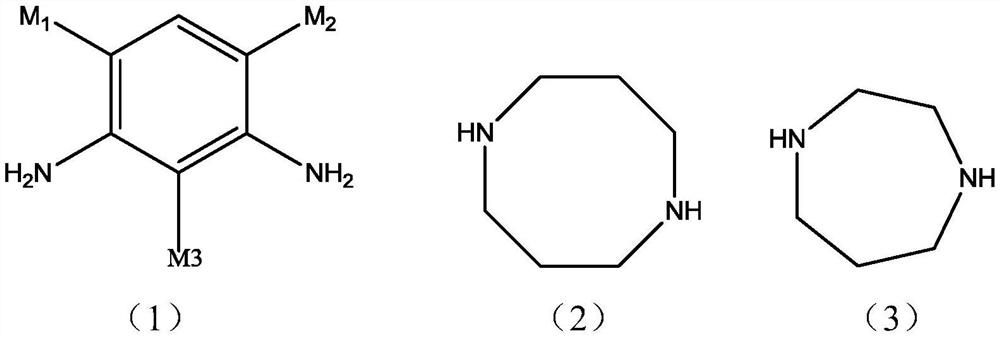

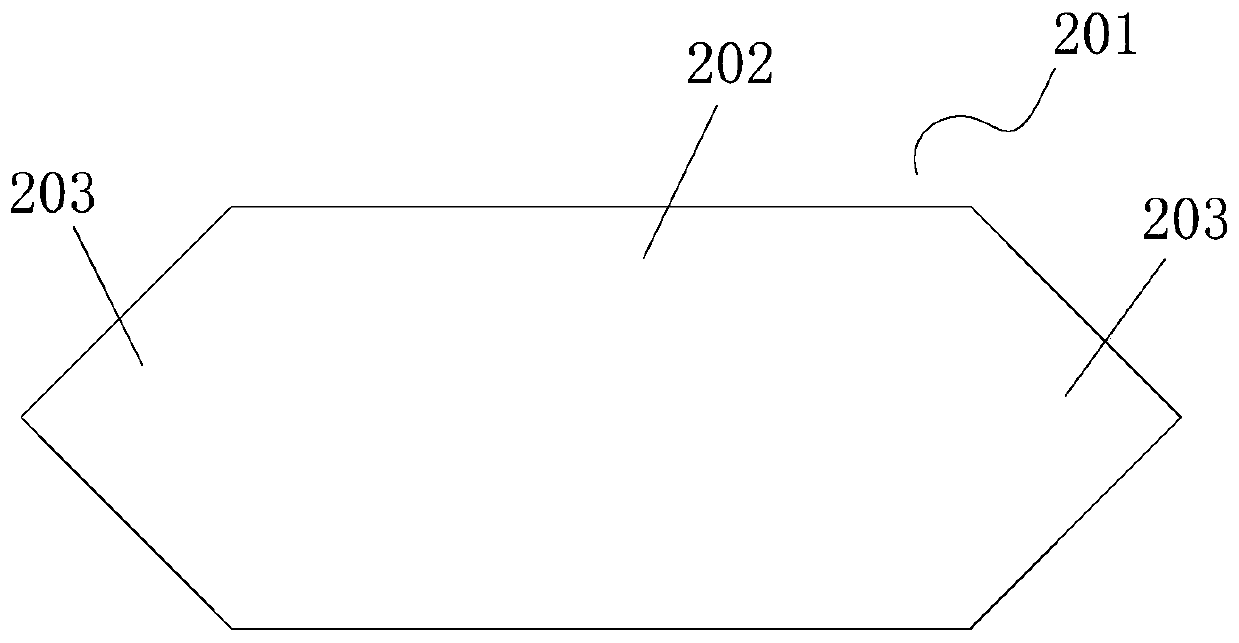

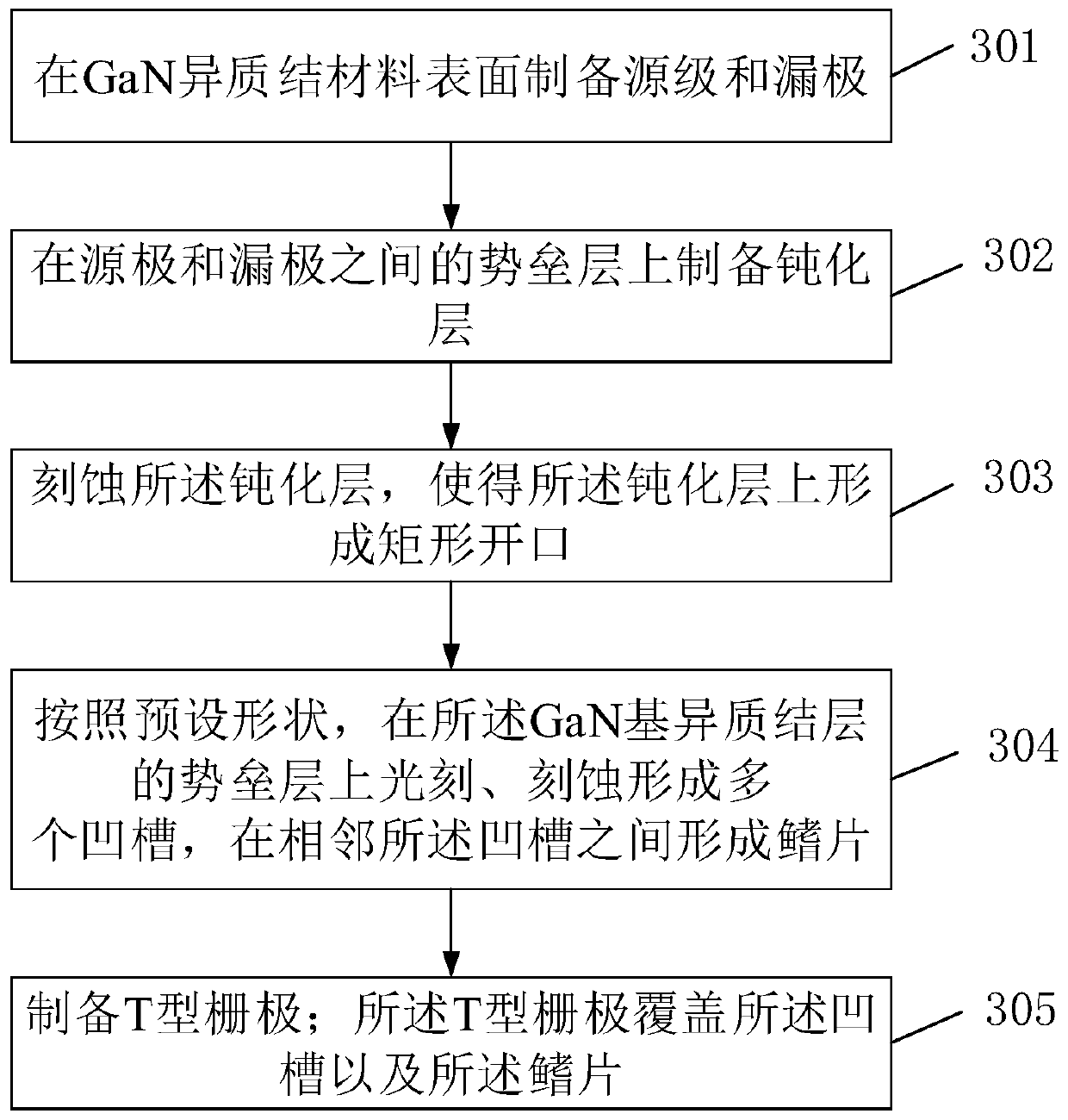

GaN-based fin field effect transistor device and manufacturing method thereof

InactiveCN110571265AUniform electric field distributionReduce electric field strengthSemiconductor/solid-state device manufacturingSemiconductor devicesPhysicsField-effect transistor

The invention provides a GaN-based fin field effect transistor device and a manufacturing method thereof. The device comprises a substrate, a buffer layer, a barrier layer and a passivation layer which are arranged in sequence, wherein a source is arranged at one end of the barrier layer, and a drain is arranged at the other end of the barrier layer; the passivation layer is arranged on the barrier layer between the source and the drain; an opening is formed in the middle of the passivation layer; a plurality of grooves are formed in the barrier layer region corresponding to the opening; finsare arranged between the adjacent grooves; a T-shaped gate is arranged on the passivation layer, and the T-shaped gate covers the groove and the fins; the length of the groove is equal to that of thebottom of the T-shaped gate; the thickness of the fin is equal to the depth of the groove; and the width of the portion, away from the passivation layer, of the groove is larger than the width of theportion, close to the passivation layer, of the groove.

Owner:XIDIAN UNIV

Painting process for clay model

ActiveCN105964509APaint adhesionFirmly attachedPretreated surfacesCoatingsMetallurgyMining engineering

The invention discloses a painting process for a clay model. The painting process comprises the steps of conducting cleaning, wherein the surface of the clay model is cleaned; forming an isolating layer through spraying, wherein the isolating layer is sprayed to the surface of the clay model; forming an adhesion layer through spraying, wherein the adhesion layer is sprayed to the isolating layer; spraying an undercoat, wherein the undercoat is sprayed on the surface of the adhesion layer; spraying colored paint, wherein the colored paint is sprayed to the undercoat; and spraying surface paint, wherein the surface paint is sprayed to the colored paint. By means of the painting process for the clay model, paint can firmly adhere to the clay model, the paint surface is high in quality, and the quality and visual effect of the paint surface of a real automobile can be achieved.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD

Process for producing polyethylene

The present invention relates to a process for producing ethylene copolymers in a multistage process comprising at least one slurry phase polymerization stage and at least one gas phase polymerization stage in the presence of Ziegler Natta catalyst comprising a solid catalyst component, a cocatalyst of a compound of group 13 metal and an external additive selected from alkoxysilanes of formula (I) R1nSi(OR2)4-n, (I) where n is an integer 0 to 3, each R1 are equal or different and are selected among H, halogen, alkyl groups of 1 to 6 10 carbon atoms optionally substituted with one or more halogen atoms, alkenyl groups of 2 to 6 carbon atoms optionally substituted with one or more halogen atoms, and aryl groups of 6 to 12 carbon atoms optionally substituted with one or more halogen atoms, or the R1 groups can form with the Si atom they are linked to a ring of 3 to 8 ring atoms, provided that all R1 are not hydrogen, R2 are equal or different and are selected among alkyl groups of 1 to 6 carbon atoms optionally substituted with one or more halogen atoms, alkenyl groups of 2 to 6 carbon atoms optionally substituted with one or more halogen atoms, and aryl groups of 6 to 12 carbon atoms optionally substituted with one or more halogen atoms, or the OR2 groups can form with the Si atom they are linked to a ring of 3 to 8 ring atoms, halogen is Br, Cl or F. The invention further relates to the catalysts and use thereof in said multistage process r for producing ethylene copolymers having melt flow rate ratio FRR21 / 5 at least 40 and / or polydispersity index PDI of at least 27.

Owner:BOREALIS AG

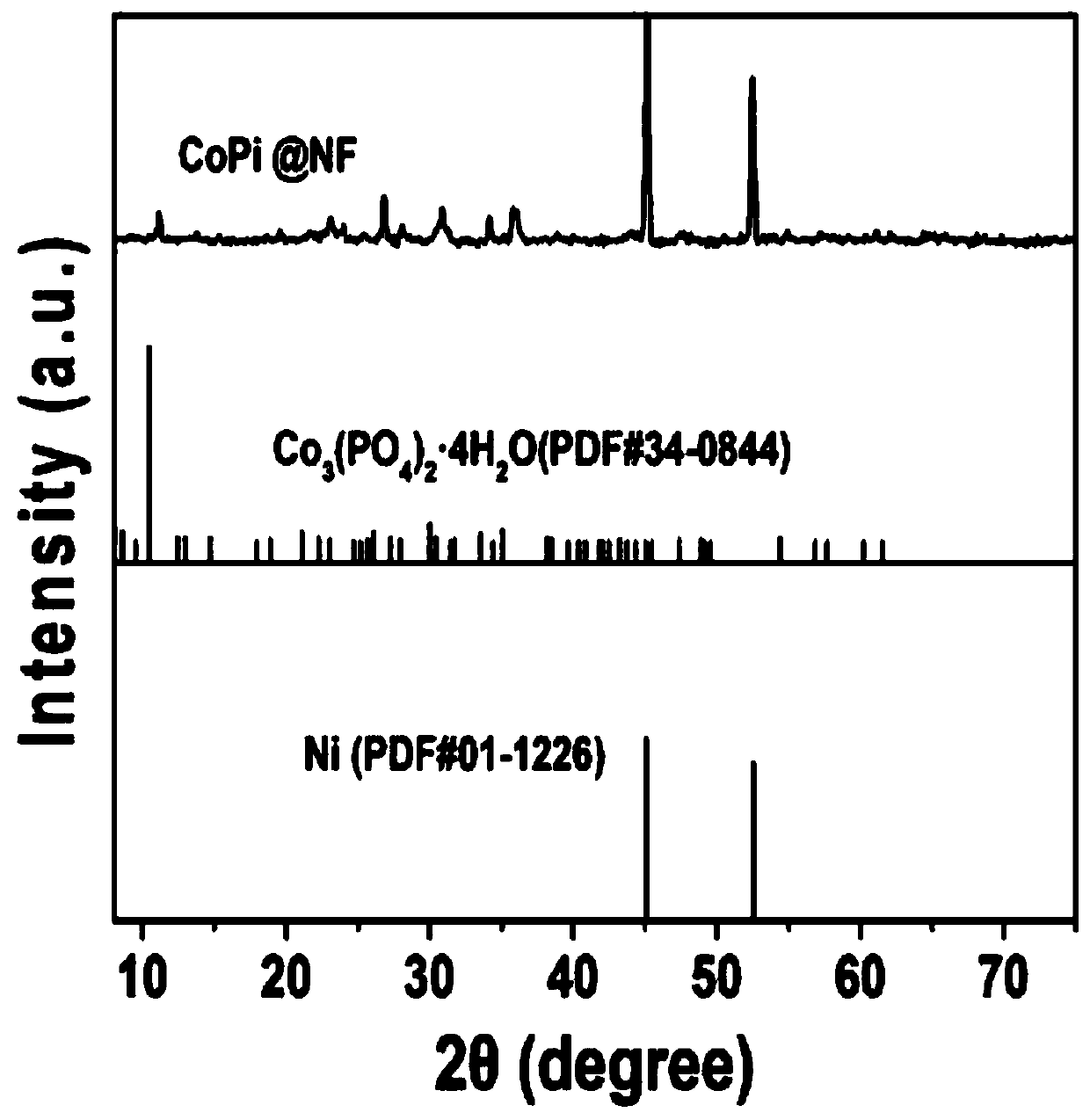

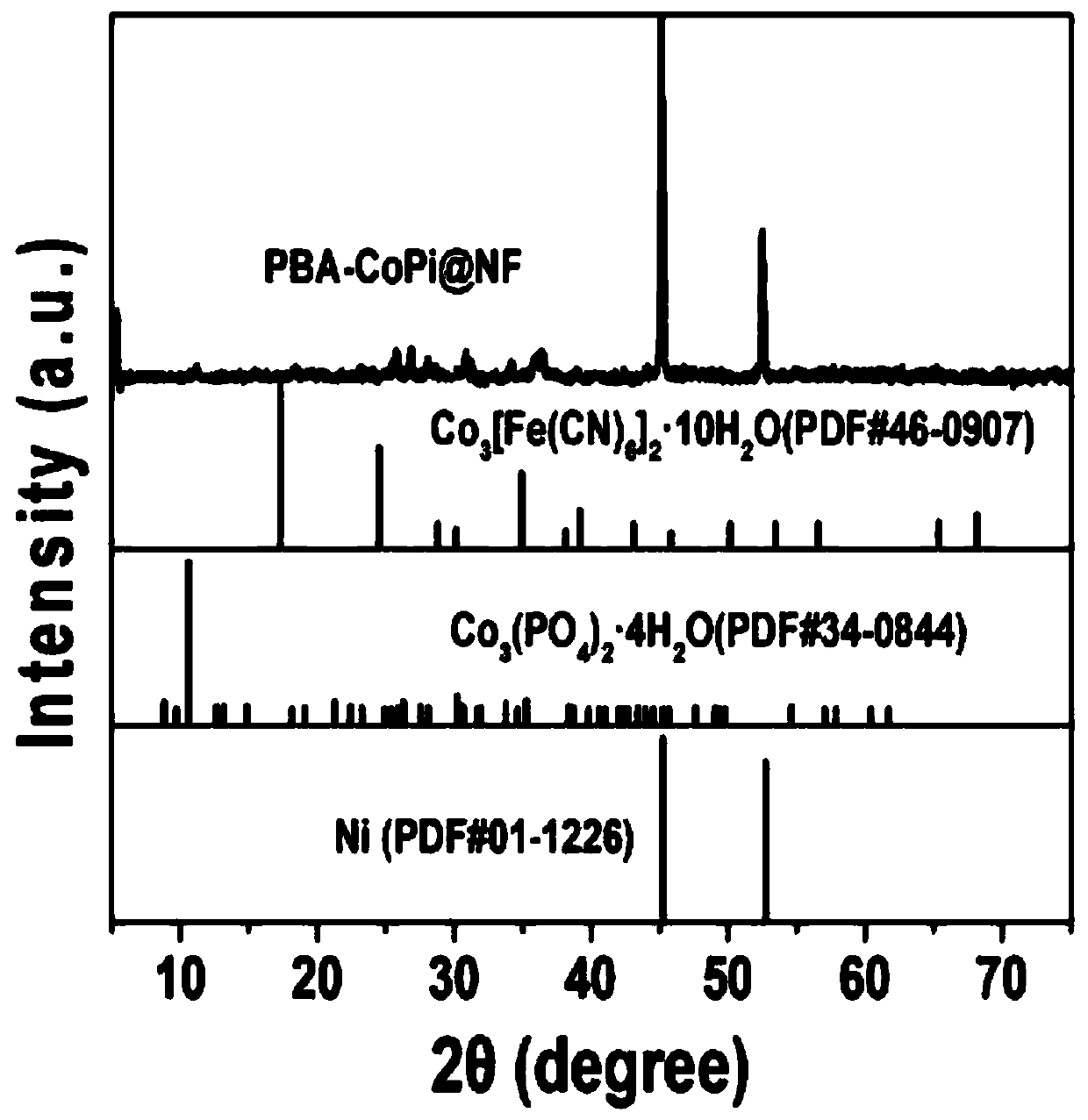

Cobalt iron oxide-cobalt phosphate electrocatalytic oxygen evolution composite material, and preparation method and application thereof

ActiveCN111036247AShape is easy to controlImprove performanceMetal/metal-oxides/metal-hydroxide catalystsElectrodesAir atmosphereMaterial synthesis

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

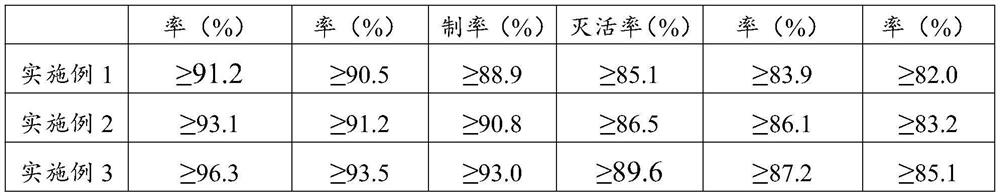

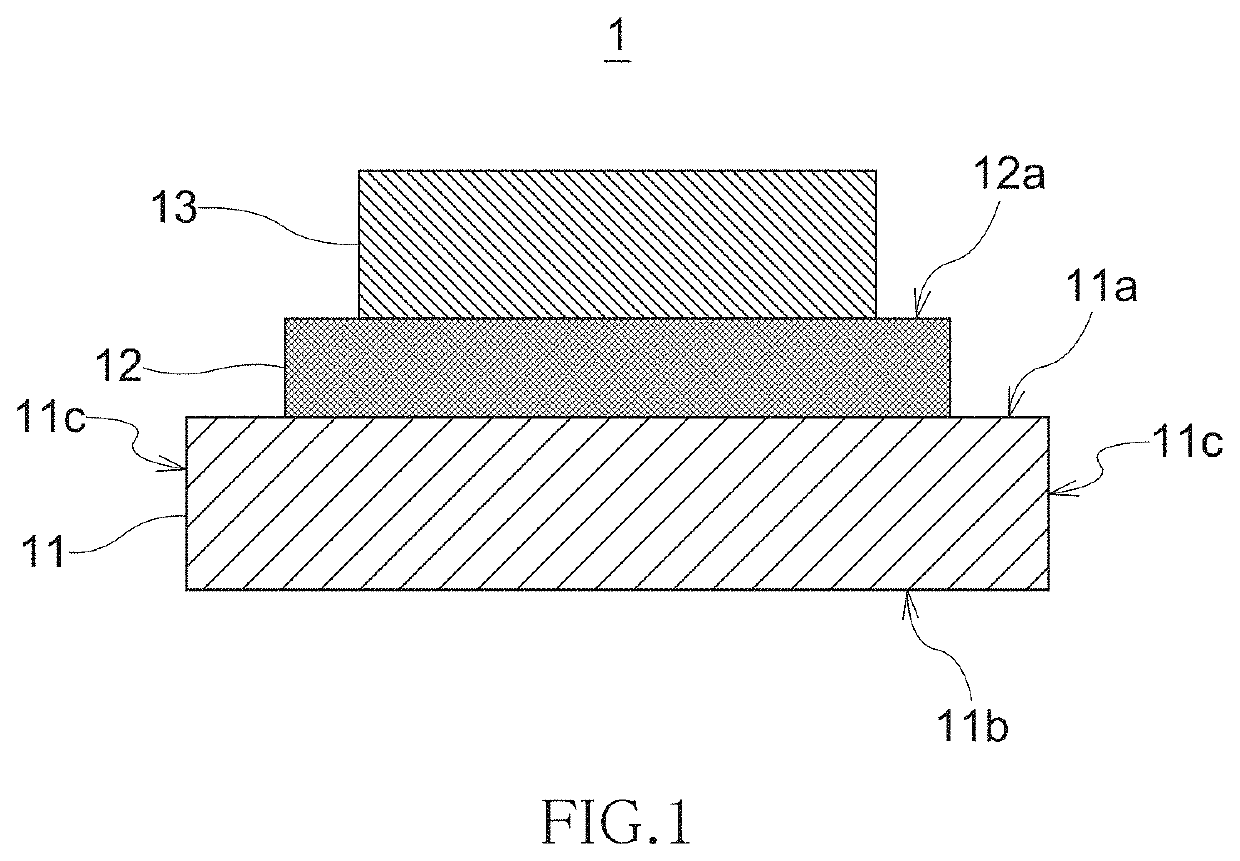

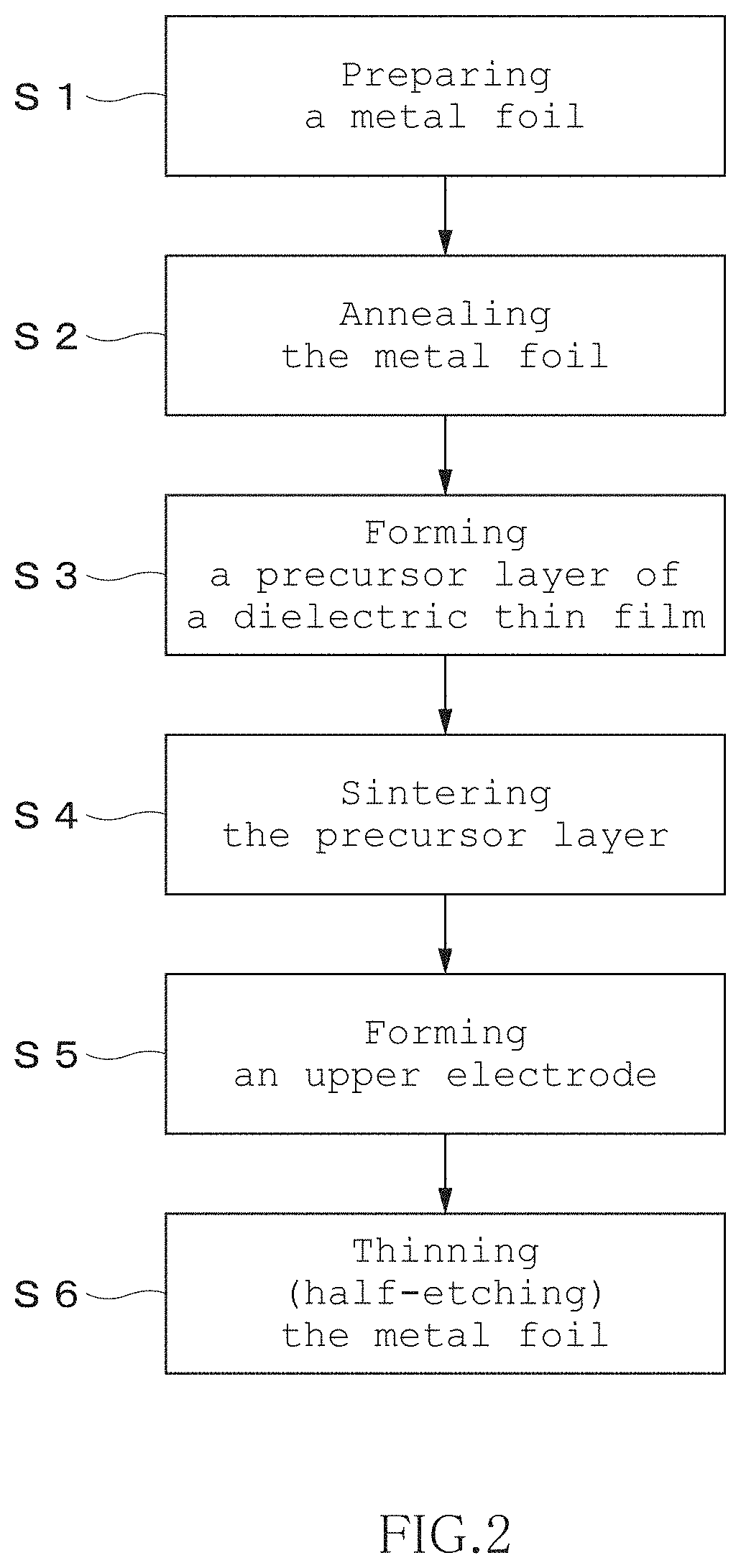

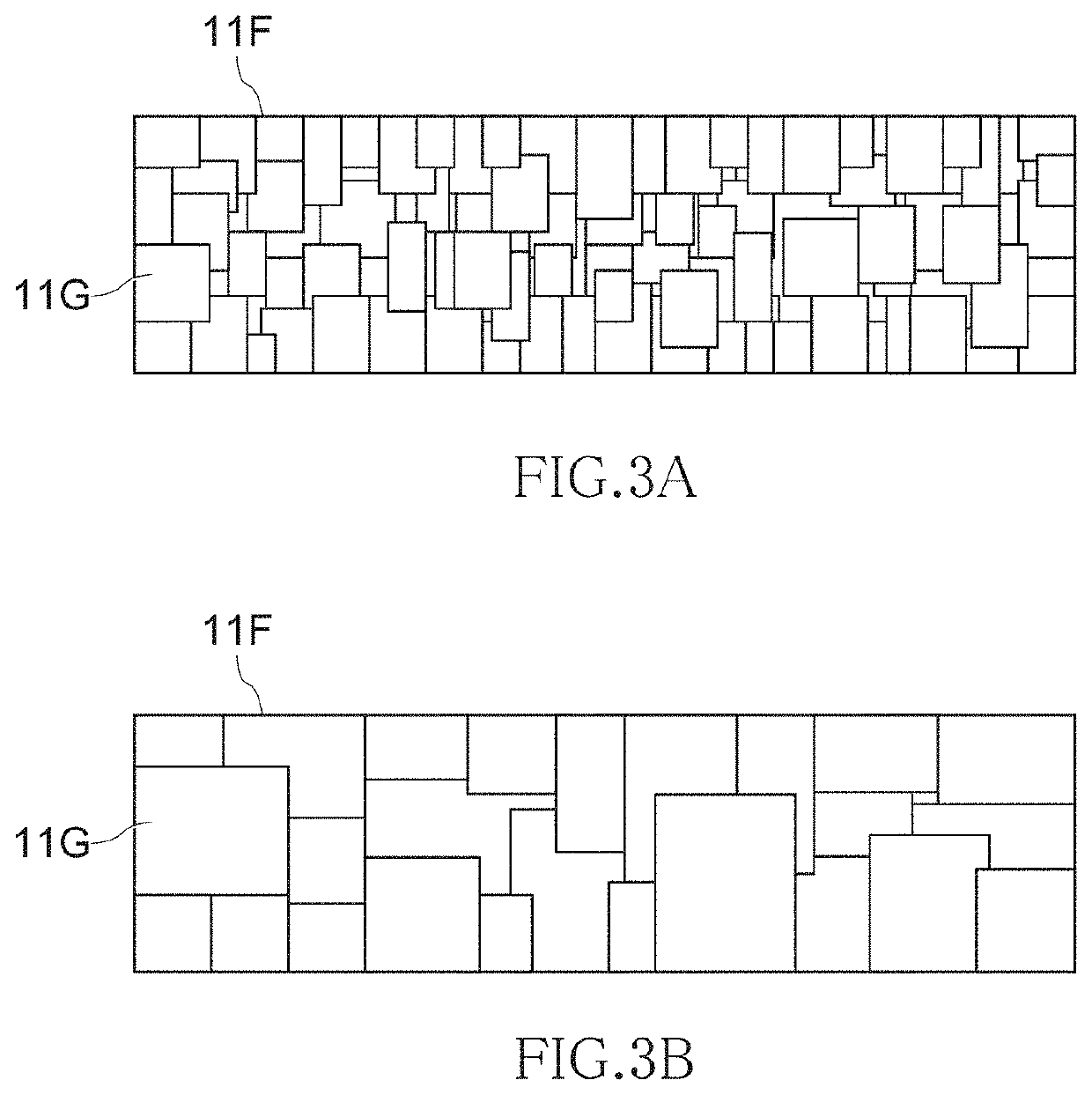

Thin film capacitor, manufacturing method therefor, and substrate with built-in electronic component

ActiveUS20200135406A1Reduce thicknessImprove cooling effectFixed capacitor electrodesThin/thick film capacitorMetal foilThin membrane

Owner:TDK CORPARATION

Auxiliary bag suitable for mold release agent to be cleaned

The invention discloses an auxiliary bag suitable for mold release agent to be cleaned, and belongs to the technical field of mold release agent cleaning. The auxiliary bag suitable for the mold release agent to be cleaned comprises a large-diameter multi-layer bag, the large-diameter multi-layer bag comprises a first waterproof layer, a second waterproof layer and a third waterproof layer, the second waterproof layer is located between the first waterproof layer and the third waterproof layer, and the end, away from the second waterproof layer, of the first waterproof layer is fixedly connected to an annular air bag. According to the auxiliary bag, an auxiliary device used for cleaning the mold release agent on the surface of a mold is provided, the cleaning agent flows between the mold and the interior of the device by the device, full contact and emulsification dissolution of the cleaning agent and the mold release agent are achieved, meanwhile, in combination with contact friction of the mold release agent cleaning device on the surface of the mold, removal of the mold release agent can be further promoted, and therefore the one-time circulating cleaning process of the mold release agent is achieved, multiple cleaning steps in the prior art are omitted, and the cleaning efficiency of the mold release agent is greatly improved.

Owner:黄婉霞

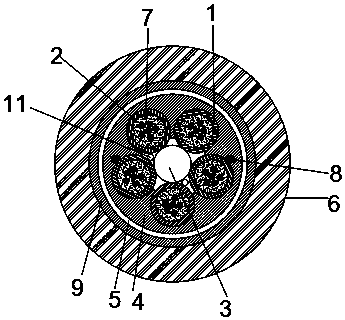

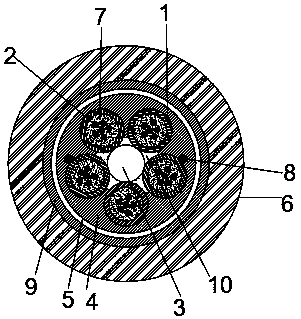

Optical cable with new structure and production method thereof

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD

Super absorbent resin and preparation method thereof

The invention provides super absorbent resin and a preparation method thereof. The preparation method comprises the steps of: mixing and heating a dispersion medium, a surfactant and a dispersing agent to obtain a substrate solution; mixing the substrate solution with a certain amount of an initiator-based mixed solution A and an acrylic acid solution A, heating, carrying out primary polymerization reaction, and evaporating out part of water; and then mixing the substrate solution with a certain amount of an initiator-based mixed solution B and an acrylic acid solution B to carry out secondary polymerization reaction, then evaporating out part of water, and carrying out post-crosslinking, distillation treatment, solid-liquid separation and drying to obtain spherical resin particles. According to the preparation method, complete interface fusion or partial interface fusion among the spherical resin particles can be avoided, the particle size of the synthesized spherical resin particles can be controlled within a certain distribution range, meanwhile, the synthesized resin does not have a special shape, and the water absorption effect of the resin is improved.

Owner:YANKUANG COAL WATER SLURRY GASIFICATION & COAL CHEM NAT ENG RES CENT CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap