Hydrolysis and alcoholysis-resisting reinforced nylon material and preparation method thereof

A reinforcing material and hydrolysis-resistant technology are applied in the field of hydrolysis-alcoholysis-resistant reinforced nylon materials and their preparation, which can solve the problems of unfavorable industrialized production, high price and high production cost, and achieve improved hydrolysis-alcoholysis resistance and excellent processing temperature resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9 and comparative example 1-6

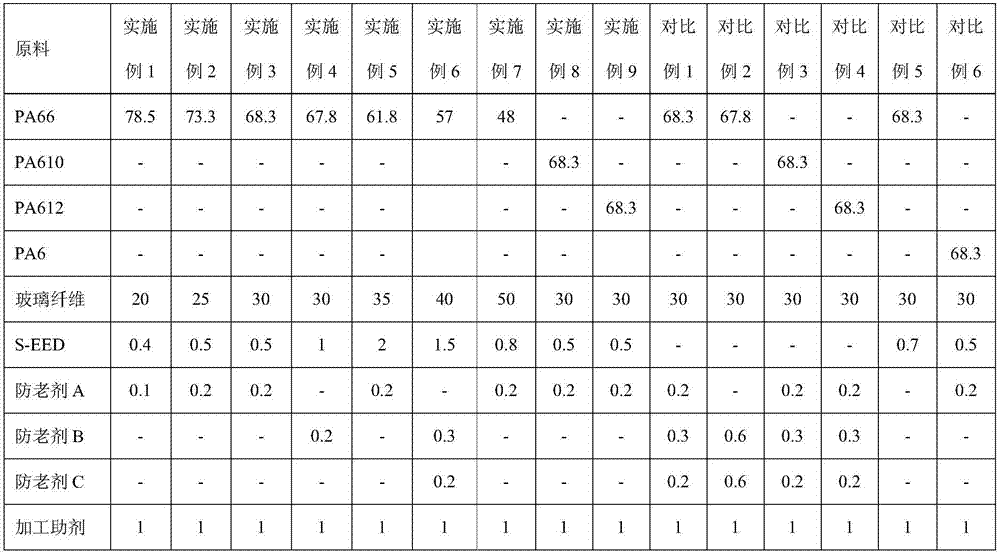

[0060] Examples 1-9 and Comparative Examples 1-6: Preparation of hydrolysis and alcoholysis-resistant reinforced nylon materials

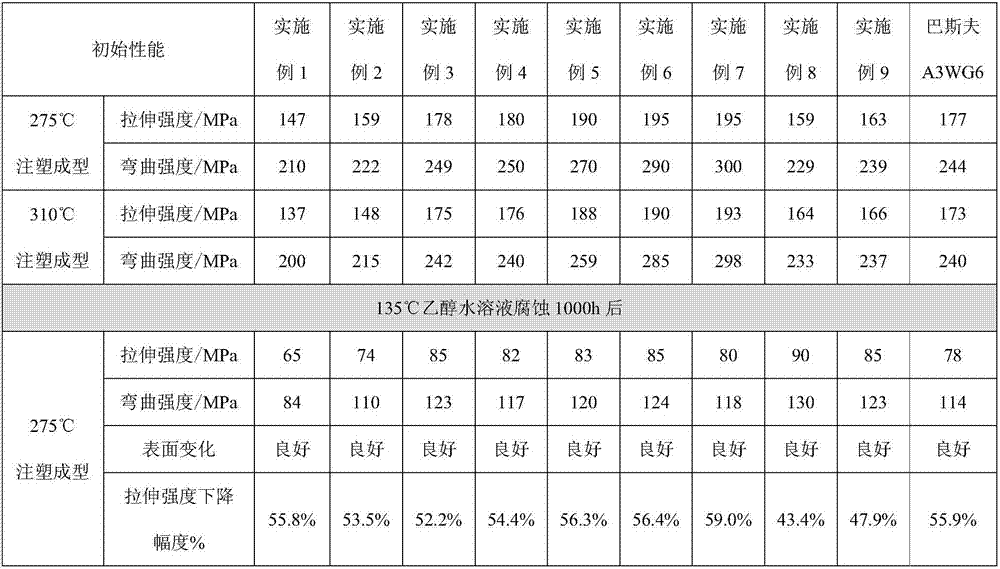

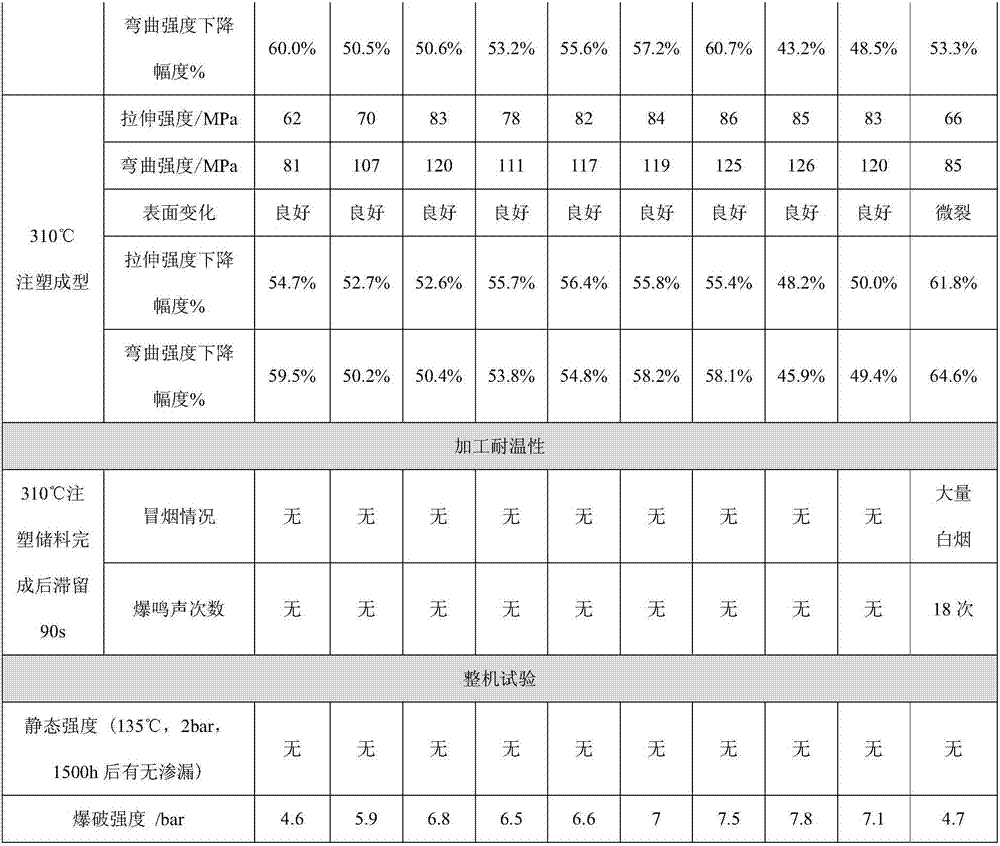

[0061] According to the material ratio in Table 1, add nylon resin, some reinforcing materials, anti-degradation agents, and processing aids to the mixer and mix them, then add them to the extruder from the main feeding port, and add the remaining reinforcing materials to the extruder from the side feeding port machine; after melt blending, cooling, air-drying and granulation, it is obtained; injection molding test samples were carried out at 275 ° C and 310 ° C injection molding temperatures, and the performance tests are shown in Table 2 and Table 3, respectively.

[0062] Table 1 embodiment 1~9 and comparative example 1~6 prepare the concrete proportioning ratio of each component of nylon material

[0063]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap