Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59 results about "Polymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In polymer chemistry, polymerization is a process of reacting monomer molecules together in a chemical reaction to form polymer chains or three-dimensional networks. There are many forms of polymerization and different systems exist to categorize them.

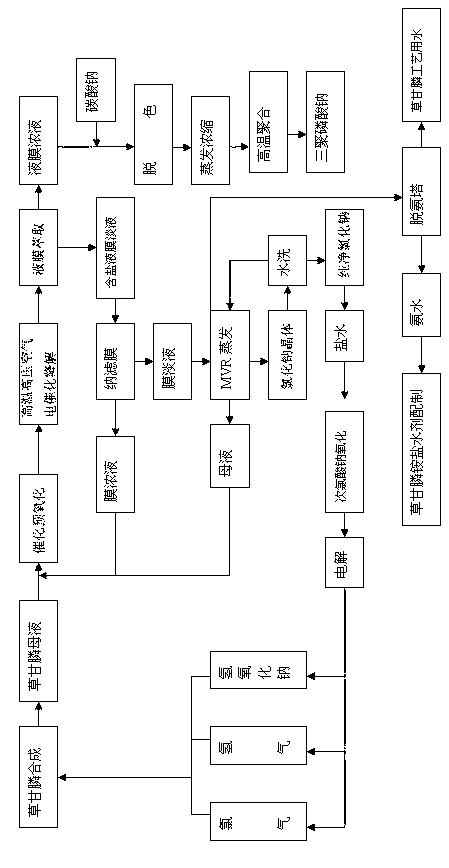

Cyclic production method of glyphosate

ActiveCN103012474AAvoid influenceReduce pollutionBiocideGroup 5/15 element organic compoundsEvaporationHigh pressure

Owner:HANGZHOU JINFADA CHEM IND

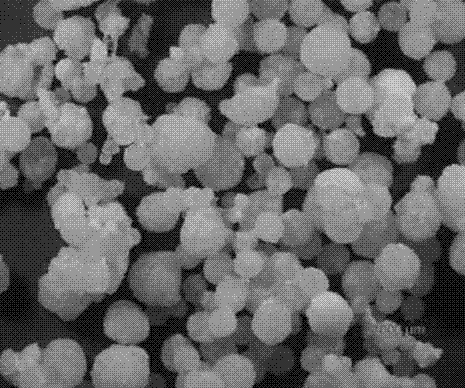

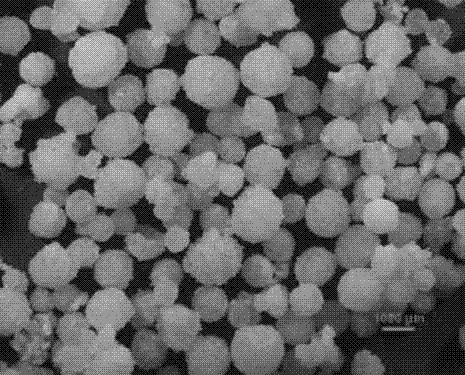

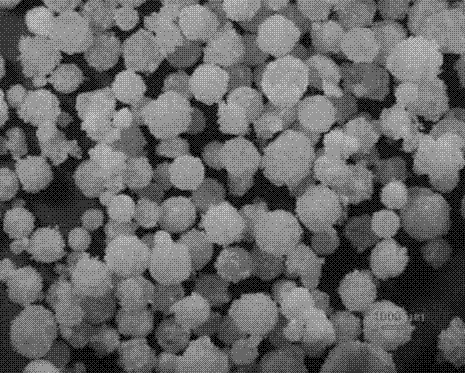

Spherical polybutylene-1 with high isotacticity and preparation method thereof

ActiveCN103288993AThe polymerization method is simpleSolve the difficulty of simultaneously controlling the isotacticity of polybuteneButenePolymer science

Owner:QINGDAO UNIV OF SCI & TECH

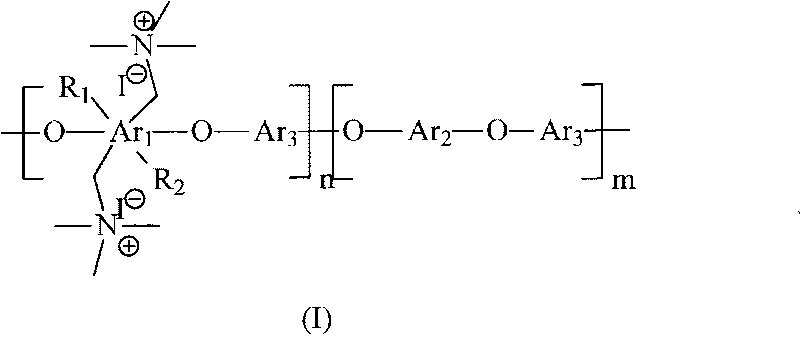

Polyarylether containing quaternary ammonium side groups and preparation method thereof

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

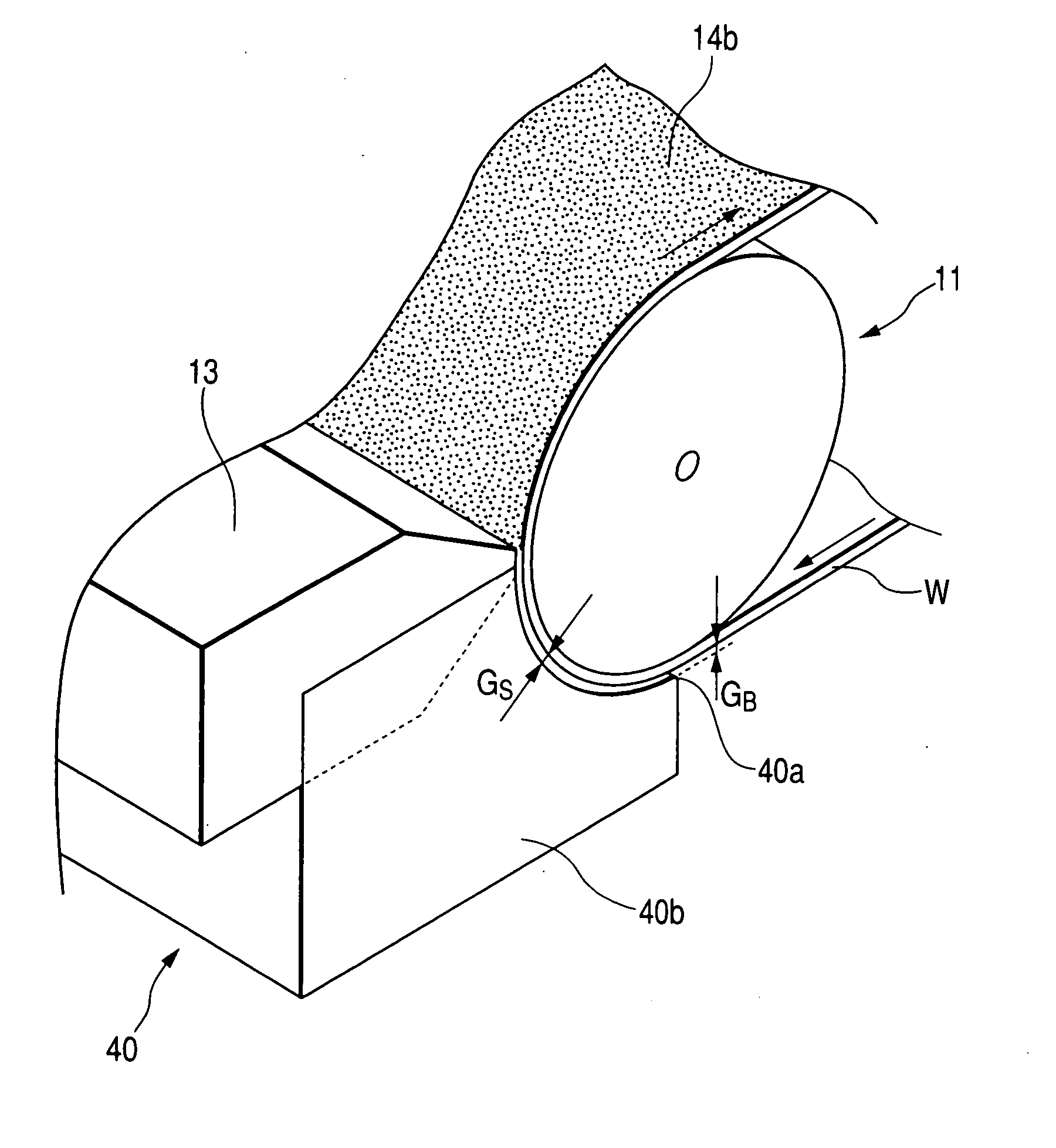

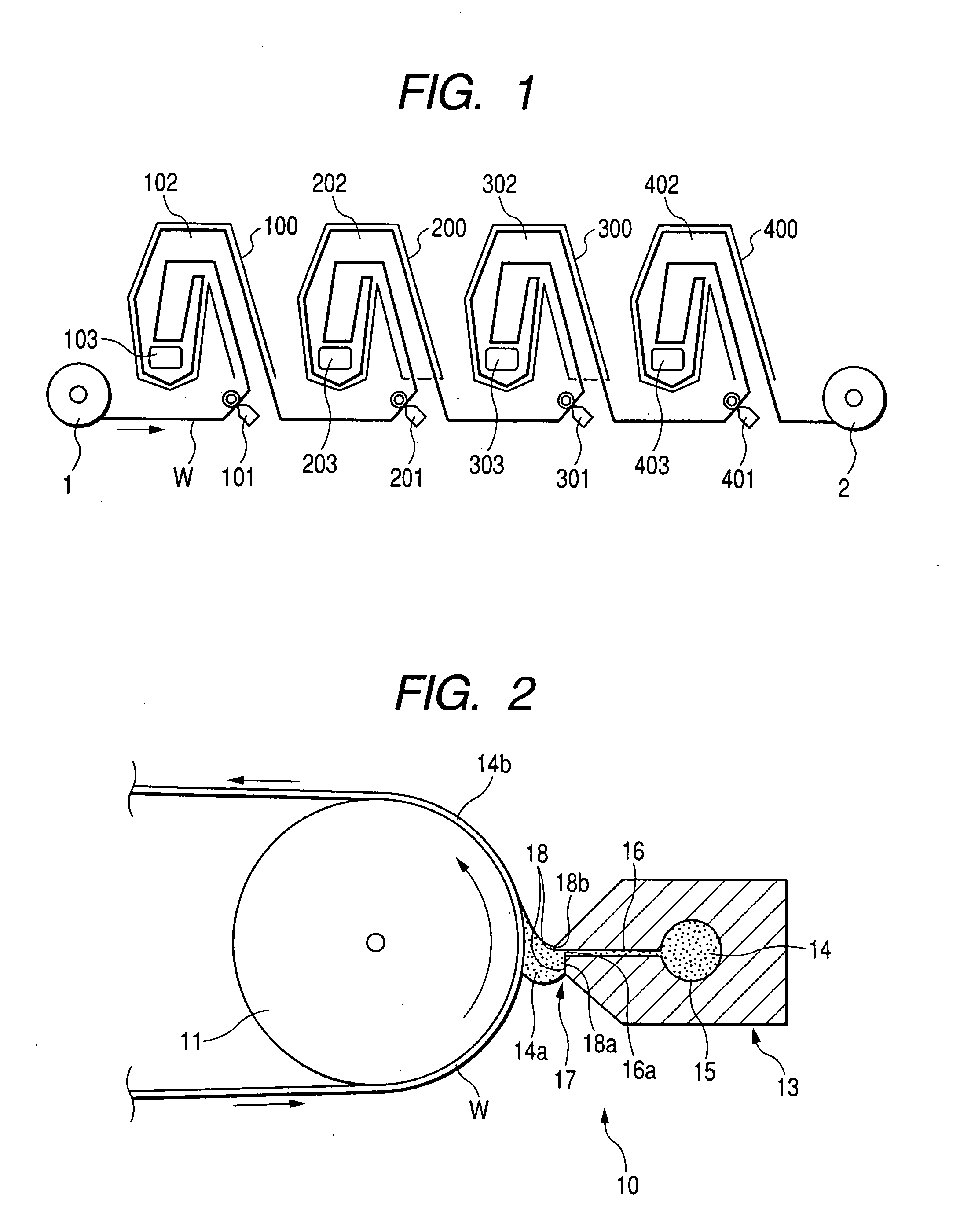

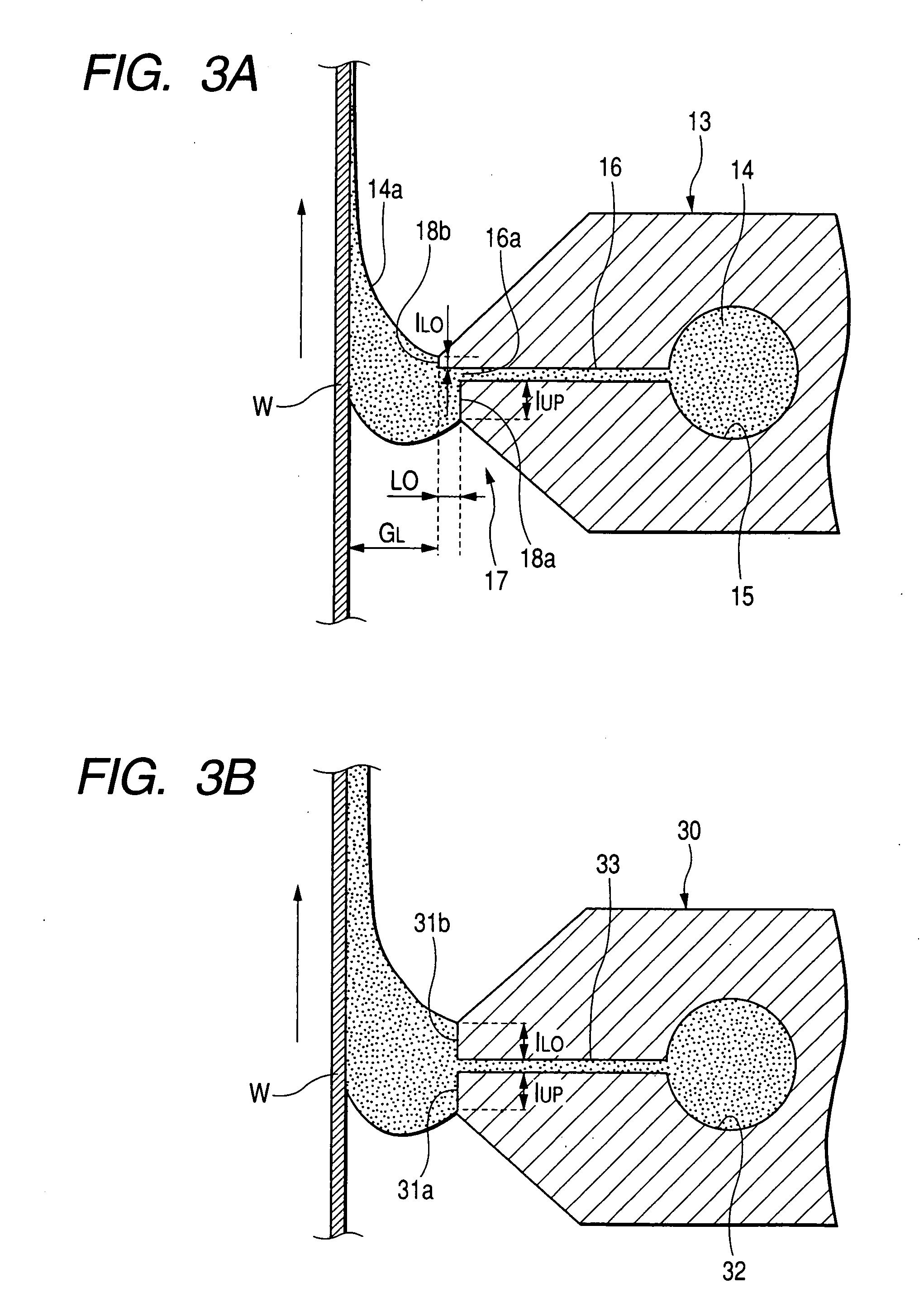

Method of Producing Optical Film and Anti-Reflection Film Optical Film, Anti-Reflection Film, Polarizing Plate and Image Display Device Comprising Same

InactiveUS20070247711A1Improve scratch resistanceSufficient anti-reflection propertyPretreated surfacesPolarising elementsLength waveWavelength range

Owner:FUJIFILM CORP

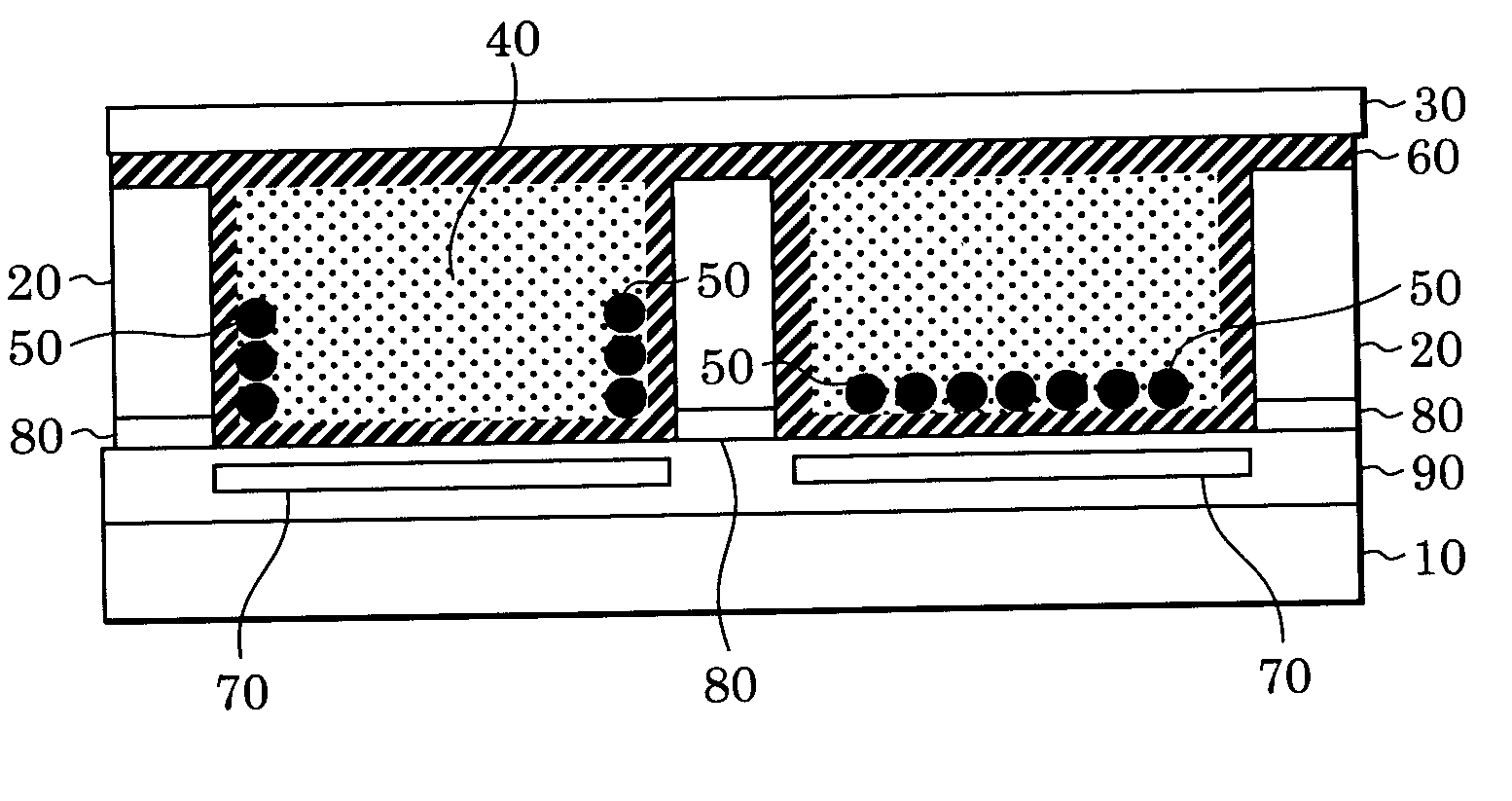

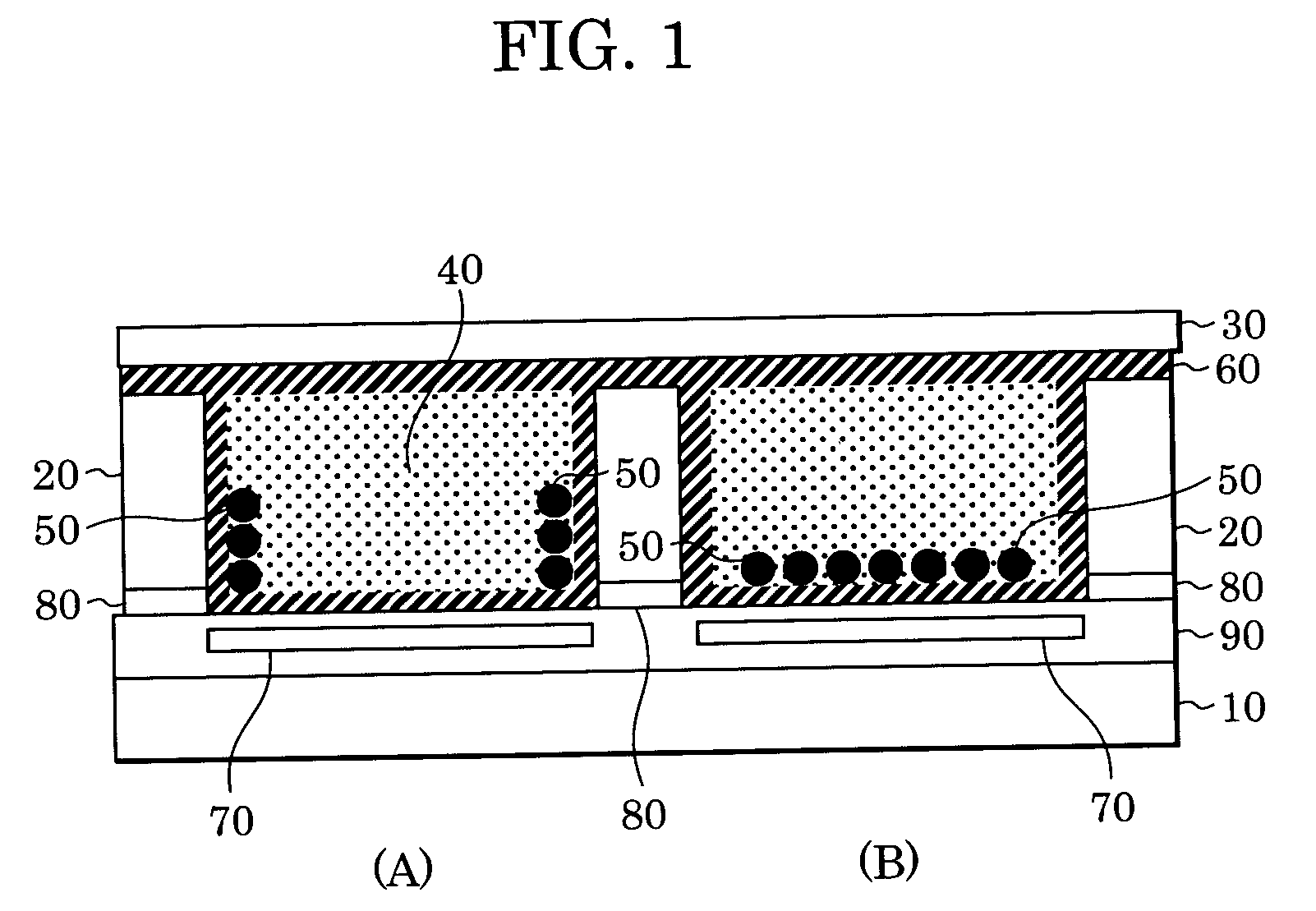

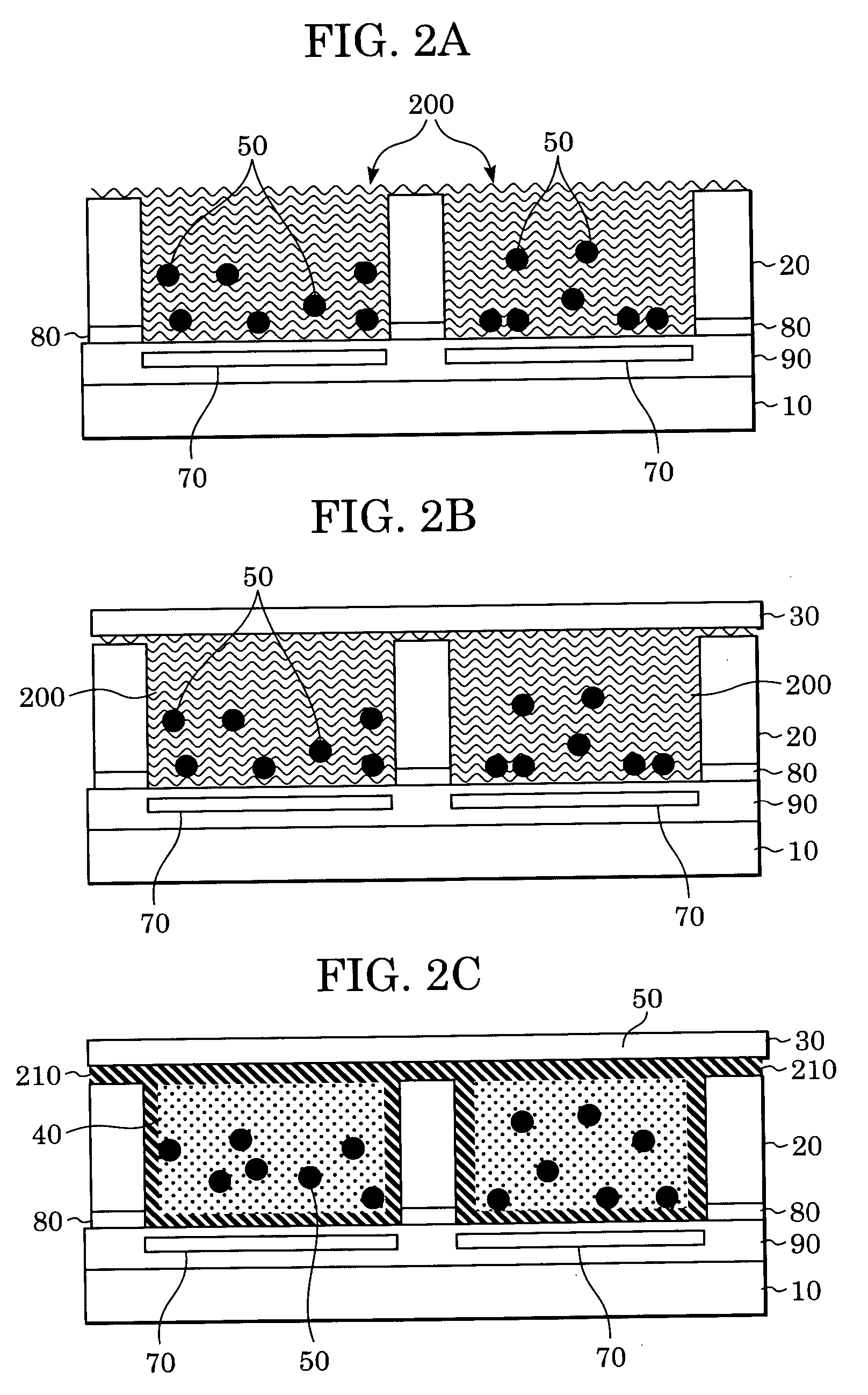

Method for manufacturing display device

Owner:CANON KK

Terpene resin and preparation method thereof

InactiveCN102633919AEliminate quality impactEliminate the effects ofFood preparationTrimethylsilyl chloridePolymer science

The invention discloses a terpene resin and a preparation method thereof. The preparation method comprises steps as follows: terpene substances are used as a raw material, AlCl3 in the presence of an aromatic solvent is used as a main catalyst, and a cocatalyst is used in the reaction; polymerization is carried out at low temperature to prepare the crude terpene resin product; and the crude terpene resin product is washed and distilled under reduced pressure to obtain the terpene resin product. The cocatalyst is trimethylchlorosilane, triethylchlorosilane, tripropylchlorosilane or tributylchlorosilane, and accounts for 1-5% of the total mass of the terpene substance raw material; the main catalyst AlCl3 accounts for 4-12% of the total mass of the terpene substance raw material; the elemental chlorine content in the prepared terpene resin product is less than 100mg / kg, and the metallic aluminum content is less than 10mg / kg; the terpene resin product does not contain metallic antimony; and the residue level of the volatile solvent is less than 25mg / kg. The product reaches to the food level.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

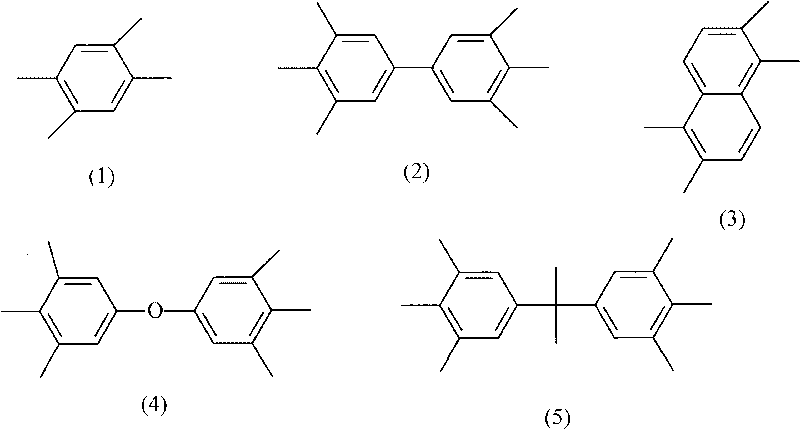

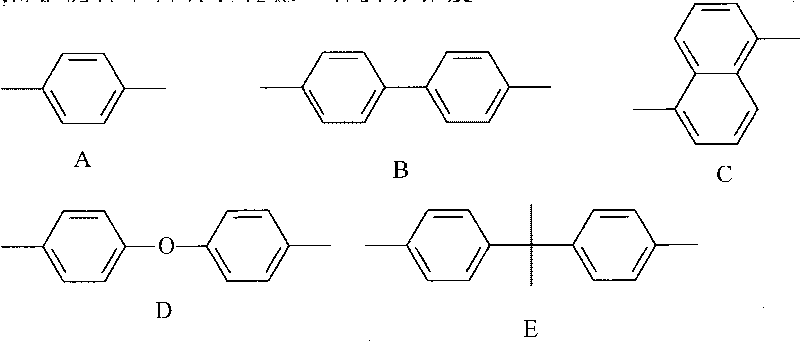

Polymerization of diisopropenylbenzene

InactiveUS20060270815A1Hydrocarbons from unsaturated hydrocarbon additionHydrocarbonsCombinatorial chemistryLinear polymer

Processes for preparing substantially linear polymers from diisopropenylbenzenes are provided. The polymers are useful in making a variety of products, including coatings, pigment dispersing agents, and stabilizers.

Owner:EI DU PONT DE NEMOURS & CO

Method for manufacturing resin for urethane-based optical material, resin composition for same, and optical material manufactured thereby

ActiveUS20130303721A1Avoid it happening againPreventing white tape residueLensMoisturePolymerization

Owner:MITSUI CHEM INC

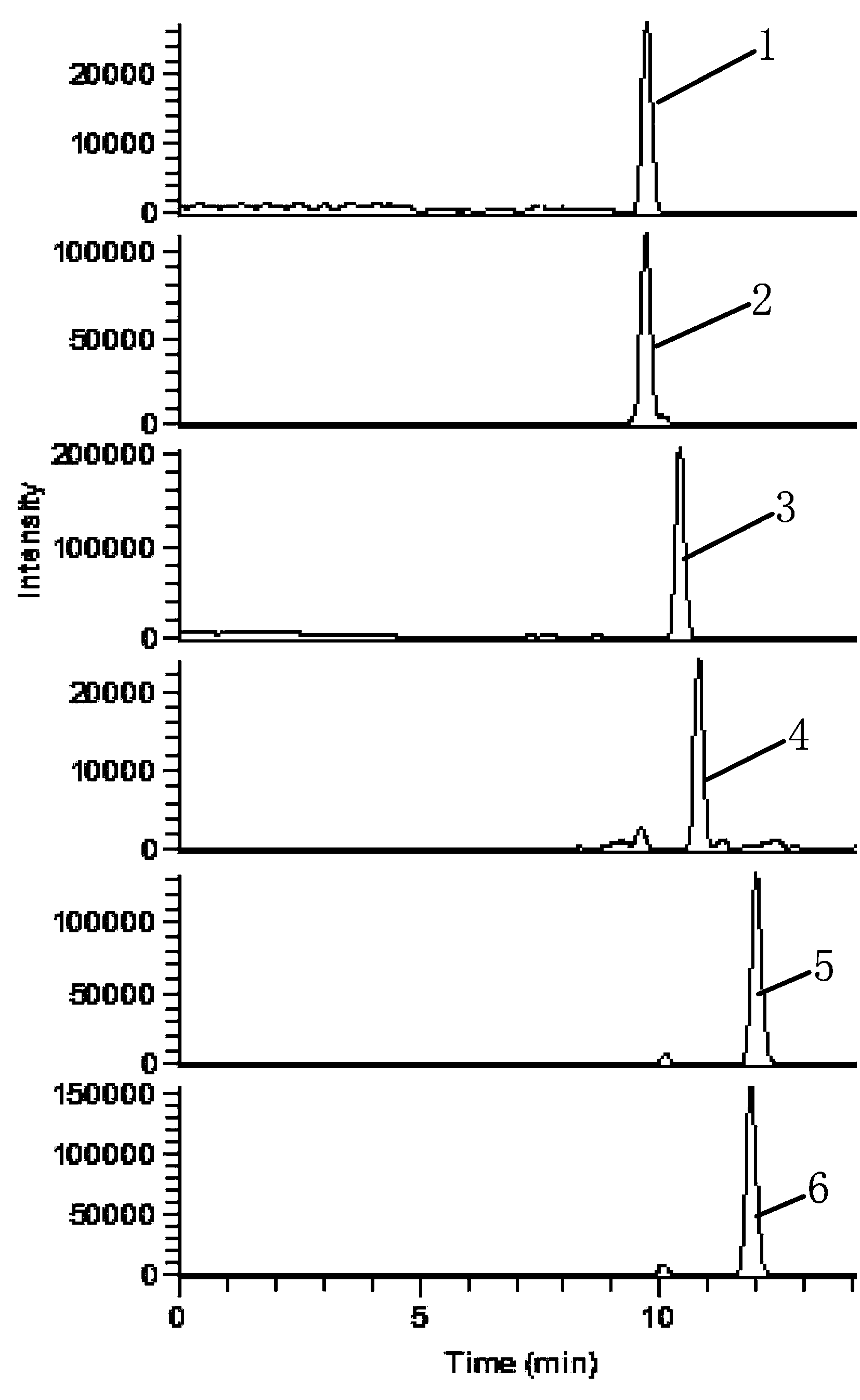

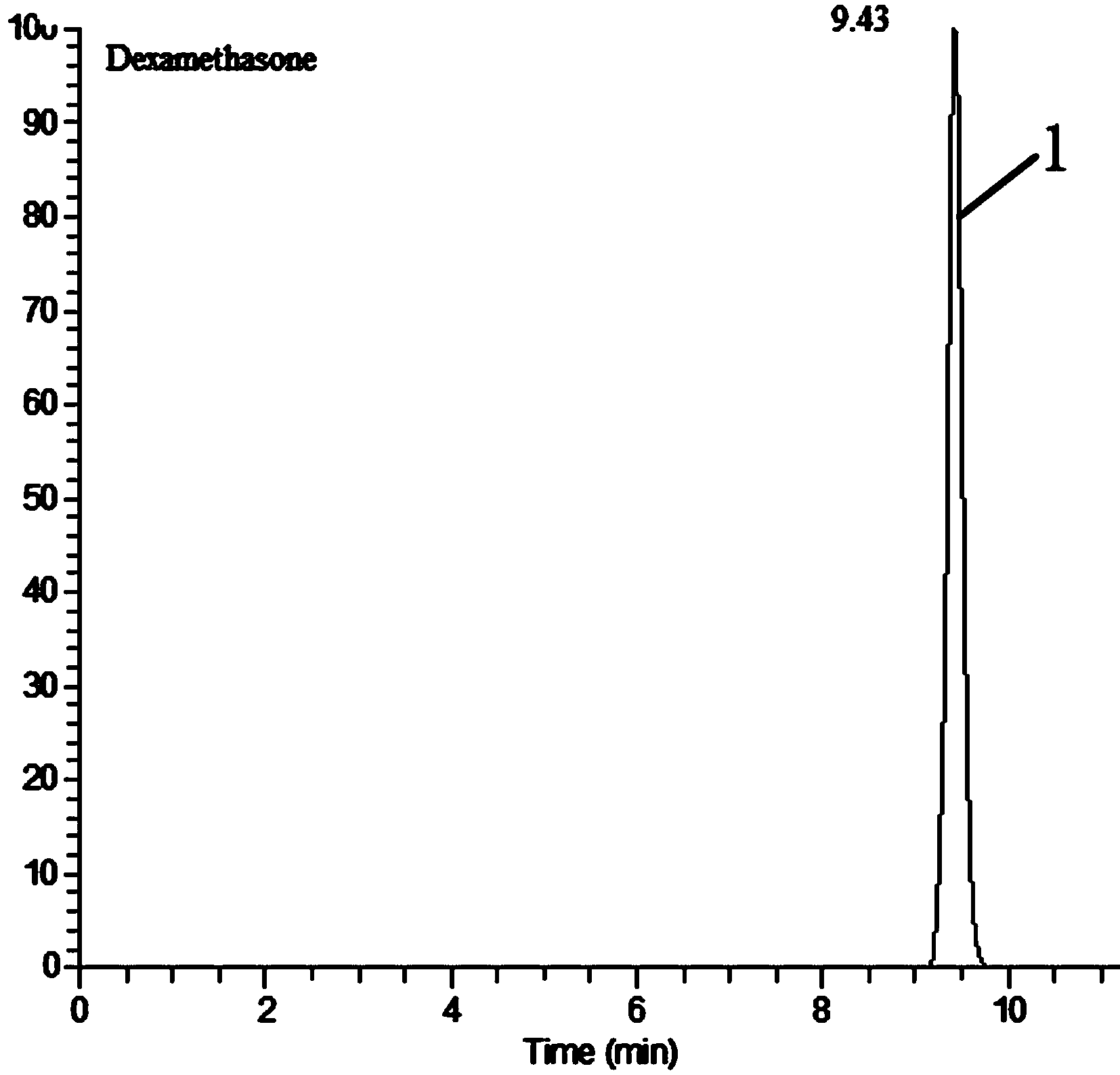

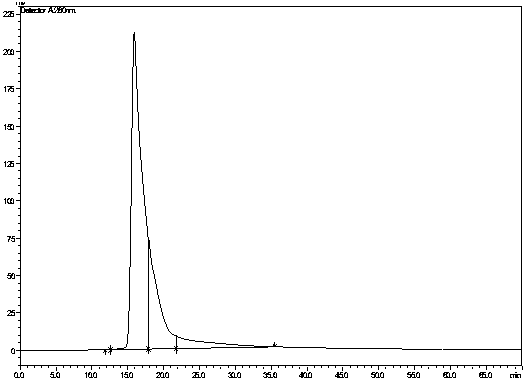

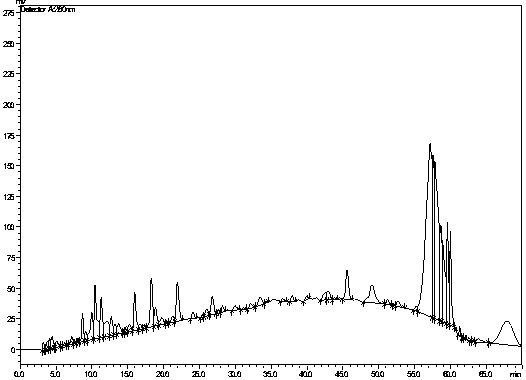

Online purification solid-phase extraction monolithic column and preparation method and purposes of monolithic column

ActiveCN103869013AAchieve purification effectTo achieve the purpose of enrichmentComponent separationHot peppersChemical compound

Owner:INSPECTION & QUARANTINE TESTING CENT OF HEBEI ENTRY EXIT INSPECTION & QUARANTINE BUREAU

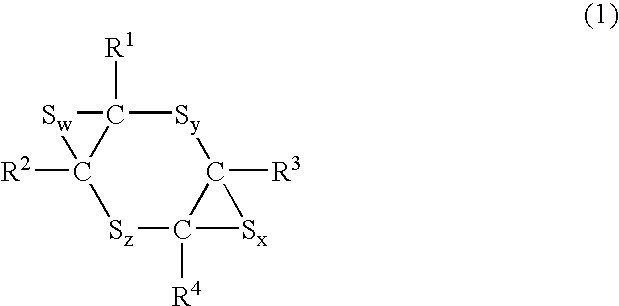

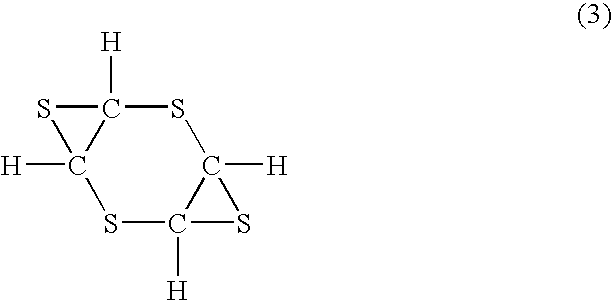

Alicyclic compound for optical material

InactiveUS20040158031A1High refractive indexOrganic chemistryDiffusing elementsSulfurRefractive index

Owner:MITSUBISHI GAS CHEM CO INC

Modified polyurethane acrylic resin and preparation method thereof

InactiveCN107353865ANot yellowingGood weather resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterAdhesive

The invention discloses a modified polyurethane acrylic resin, which is prepared by polymerization among hydroxyl acrylate, diisocyanate, alkylated 4,4'-dicyclohexanol, and polyester / polyether glycol. The invention provides a method of preparing the modified polyurethane acrylic resin at the same time. The provided modified polyurethane acrylic resin does not contain active functional group such as phenyl ring, amino group, or the like, so the modified polyurethane acrylic resin will not become yellow even if the modified polyurethane acrylic resin is irradiated by light, and the weatherability is good. The resin can be applied to an adhesive, and has a good waterproof performance, good anti-falling performance, good drug resistant property, and excellent thermal stability.

Owner:SHENZHEN BAILICHU GLUE IND CO LTD

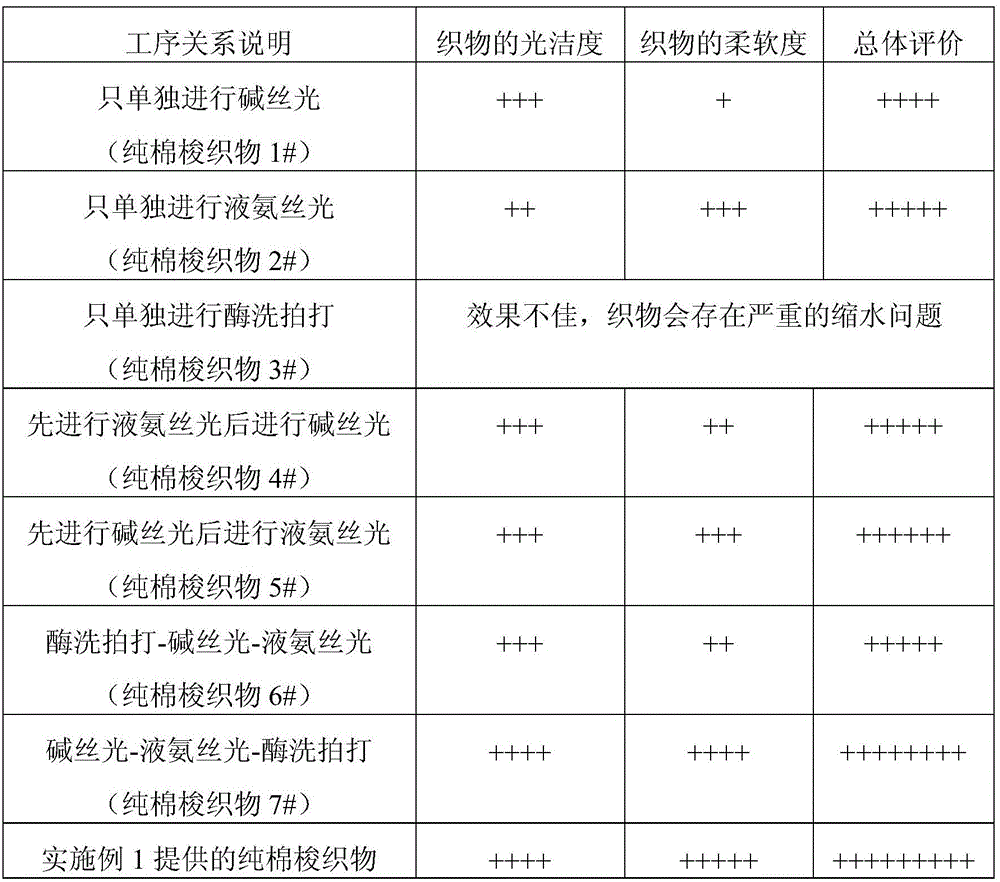

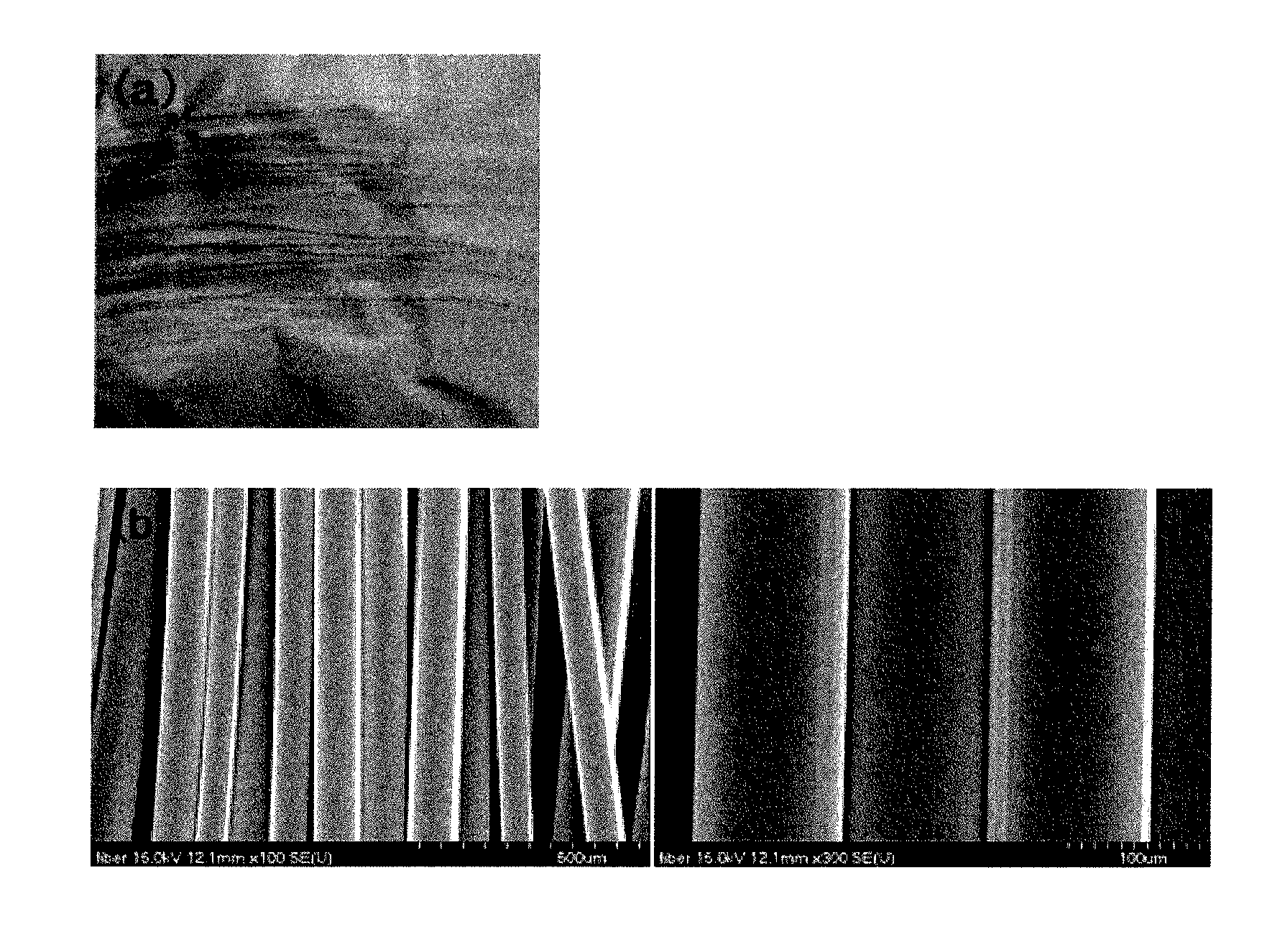

Elastic pure cotton woven fabric with smooth surface and soft handle and preparation method thereof

ActiveCN106012494AObvious bodyIncrease elasticityBiochemical treatment with enzymes/microorganismsGrip property fibresCellulaseProcess time

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Environment-friendly spackling compound and preparation method thereof

InactiveCN103804975ANot easy to layerHigh in plant polysaccharidesFilling pastesSolid componentAdhesive

Owner:WUHAN YOUBANG NEW MATERIAL CHEM

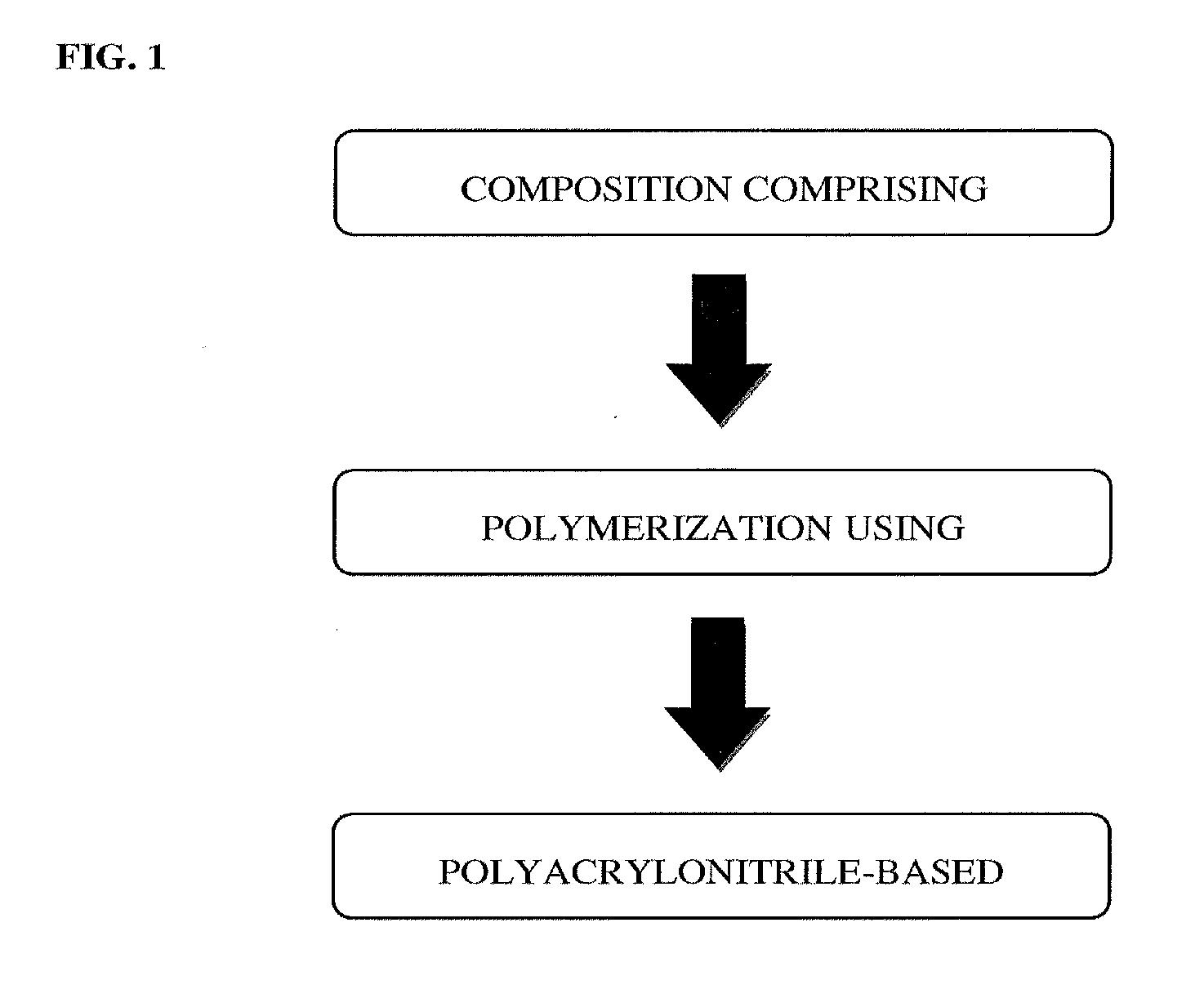

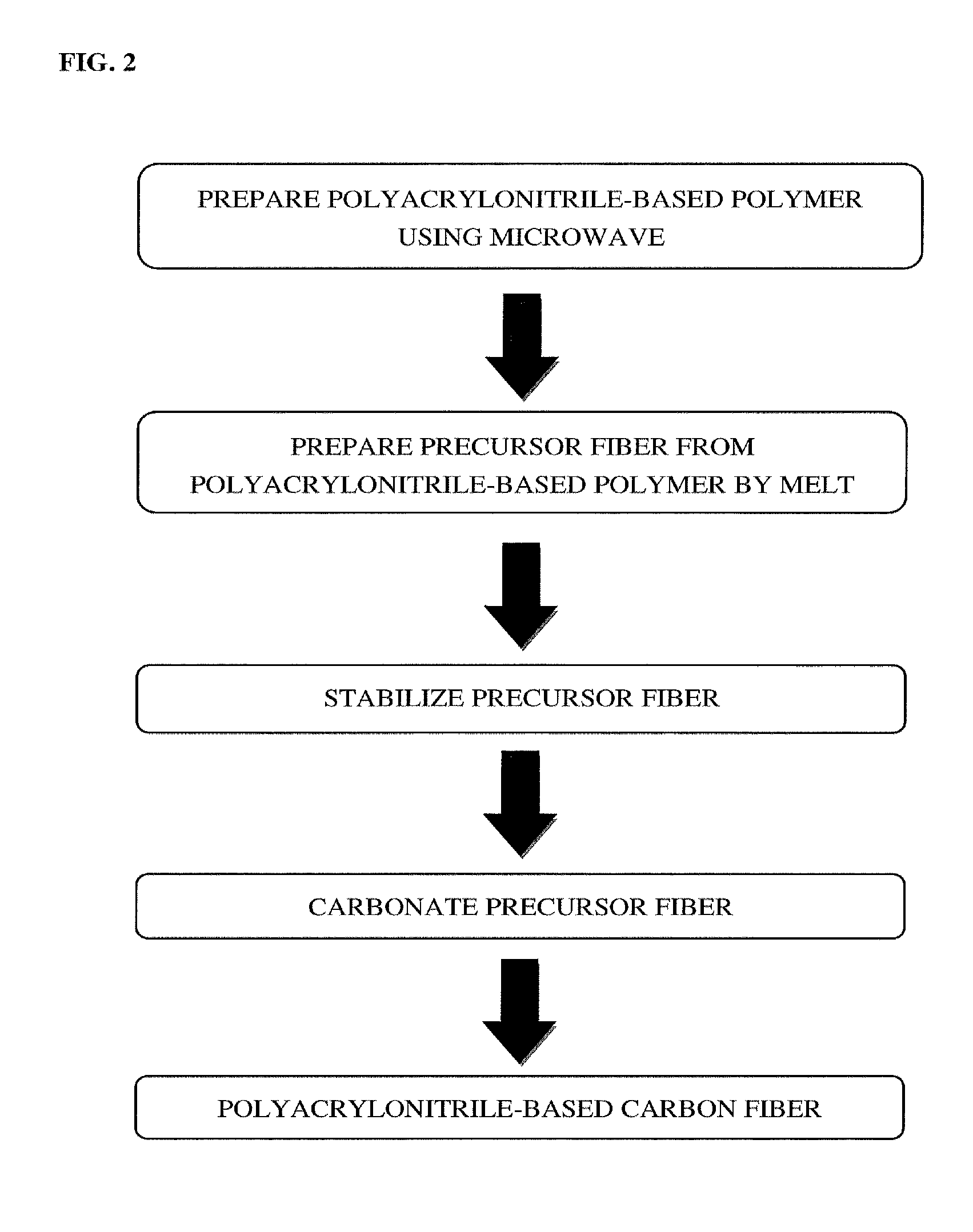

Method for preparing polyacrylonitrile-based polymer for preparation of carbon fiber using microwave and method for preparing carbon fiber using the same

ActiveUS20120288434A1Short polymerization timeLot of preparationFibre chemical featuresEnergy based chemical/physical/physico-chemical processesPolymer scienceCarbon fibers

Owner:TFJ GLOBAL INC

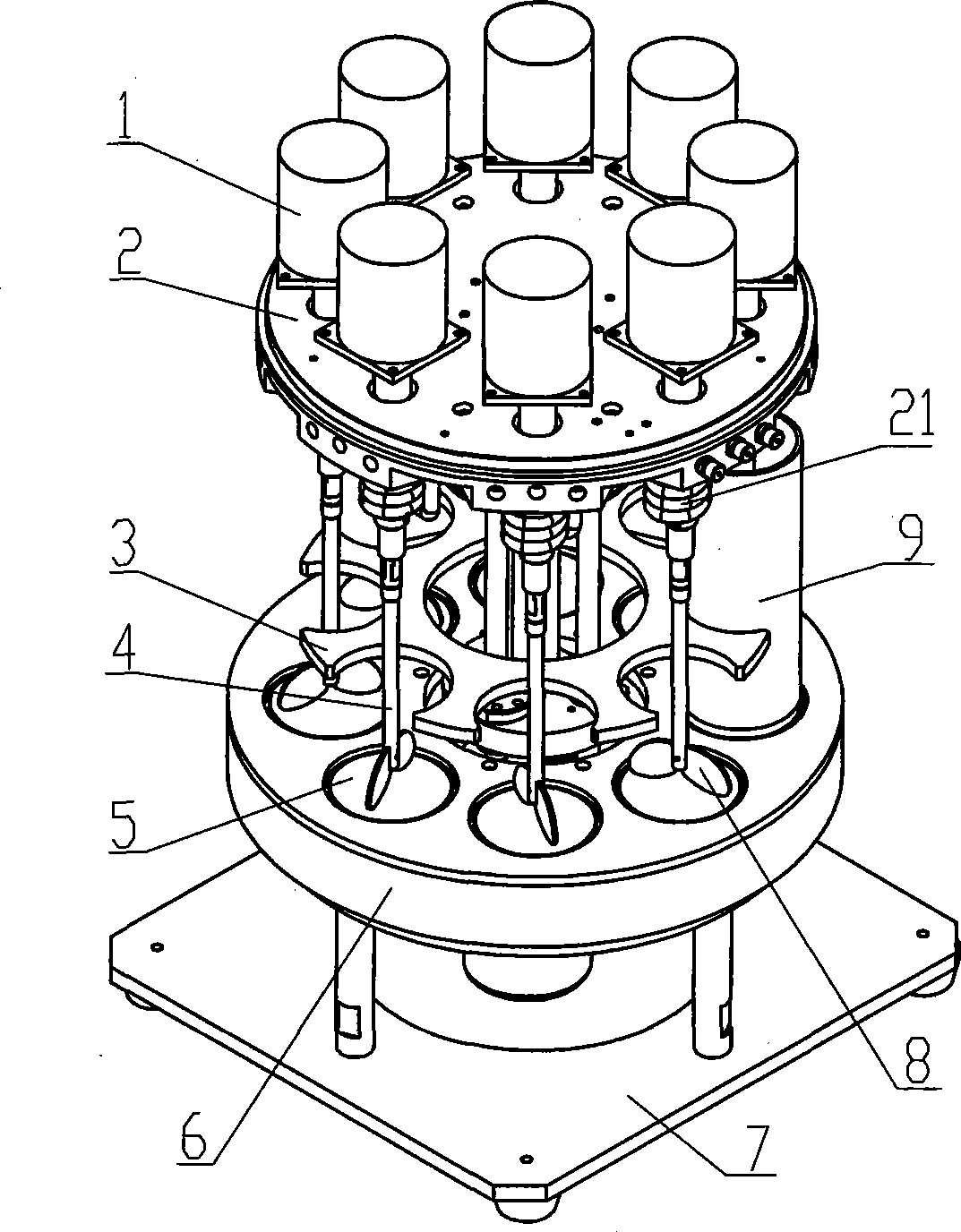

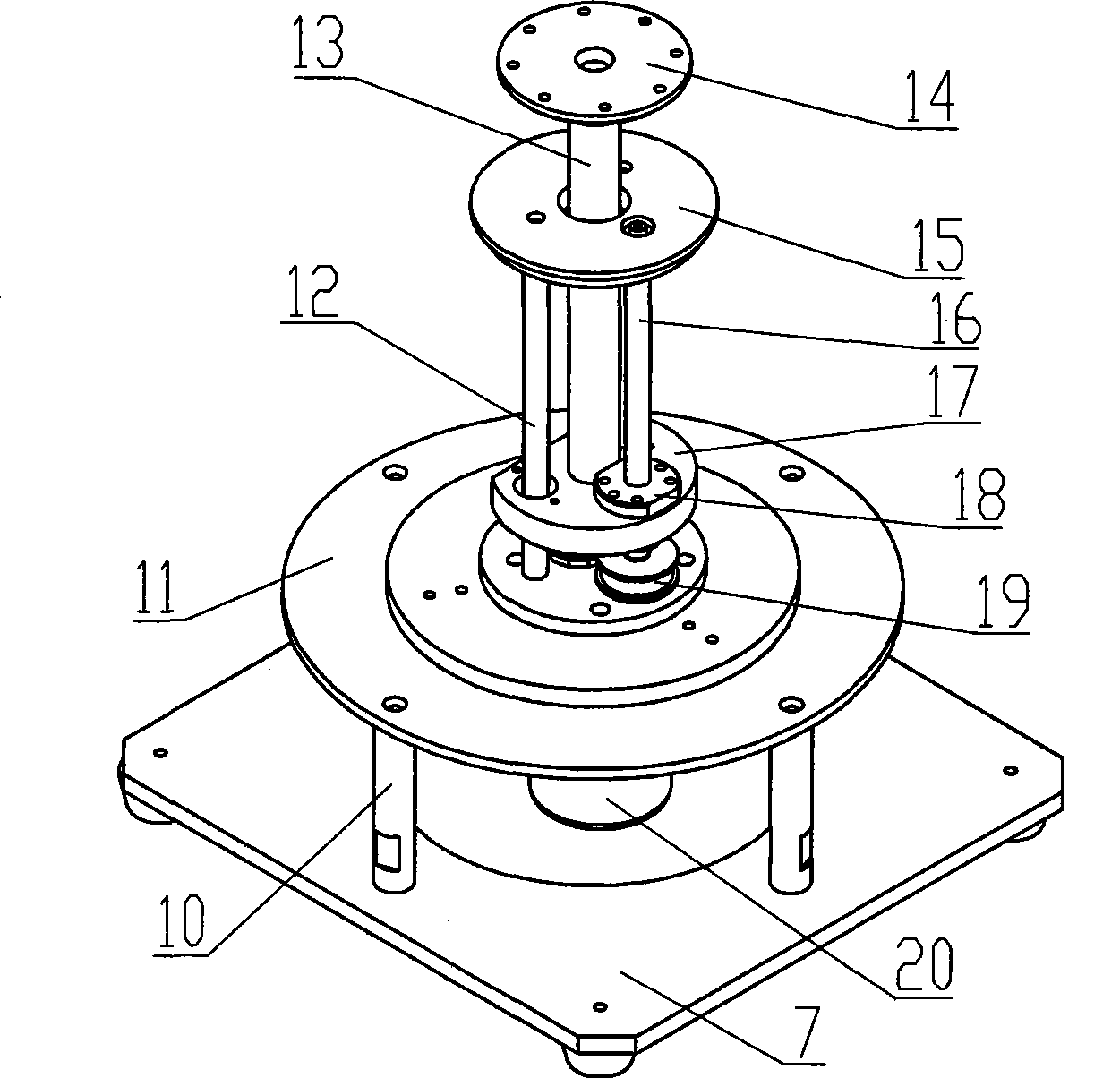

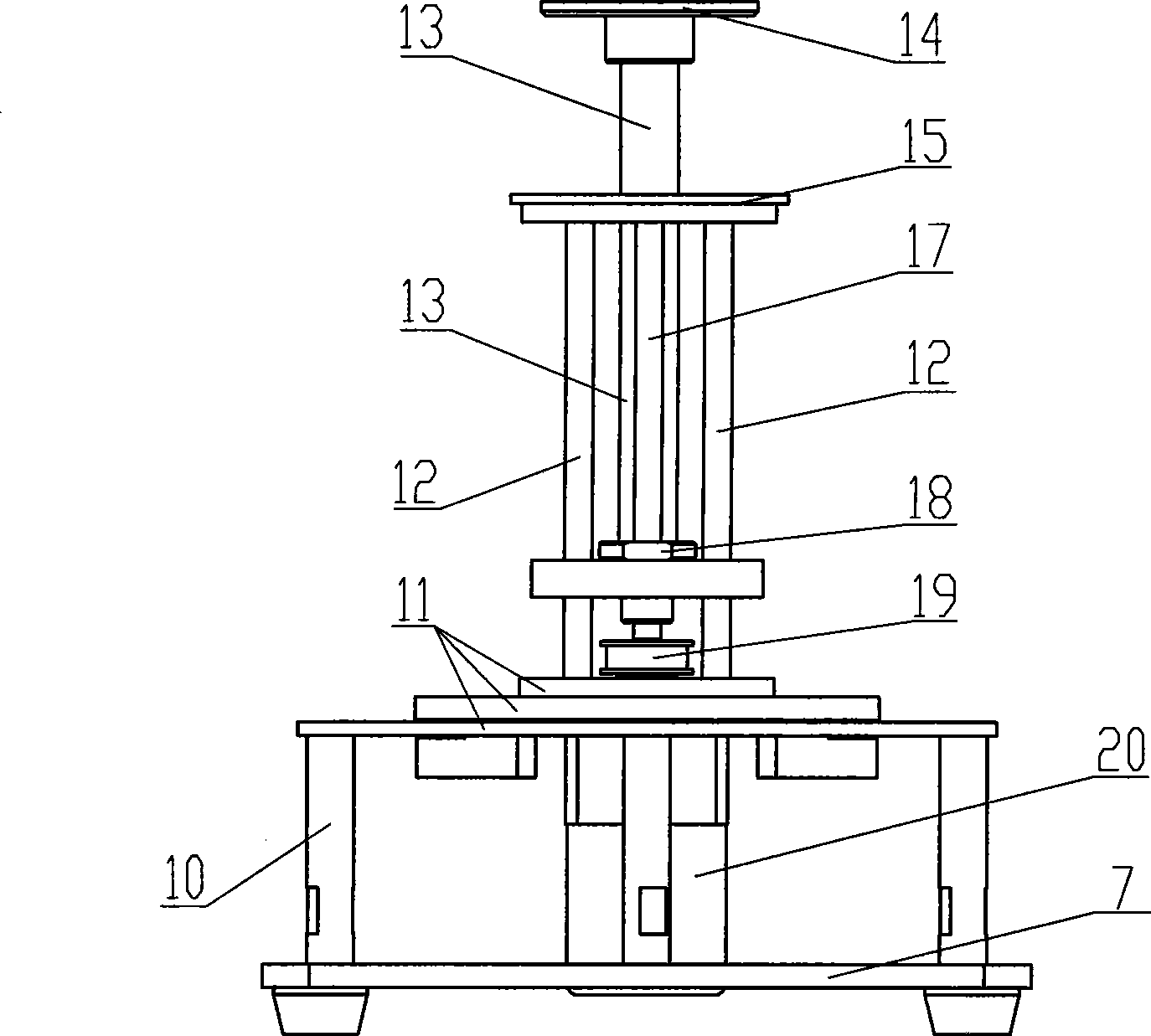

Parallel polymerization synthesis device

InactiveCN101362071AEasy to useSave research timeRotary stirring mixersMixer accessoriesResearch efficiencyReaction temperature

Owner:深圳市新和创智能科技有限公司

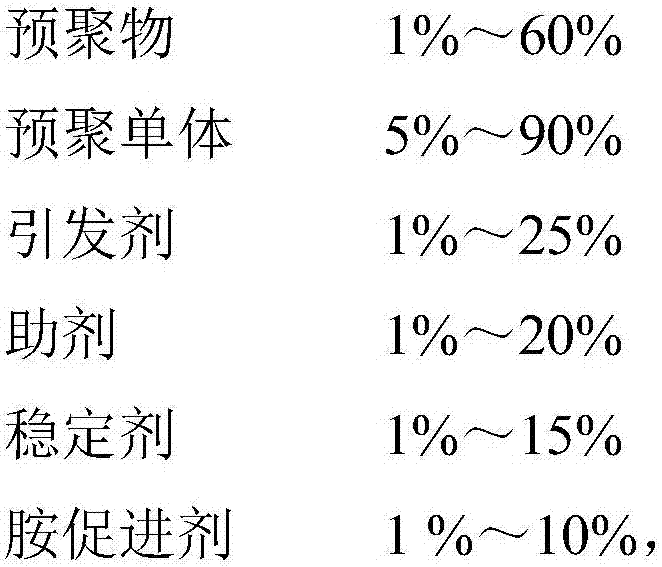

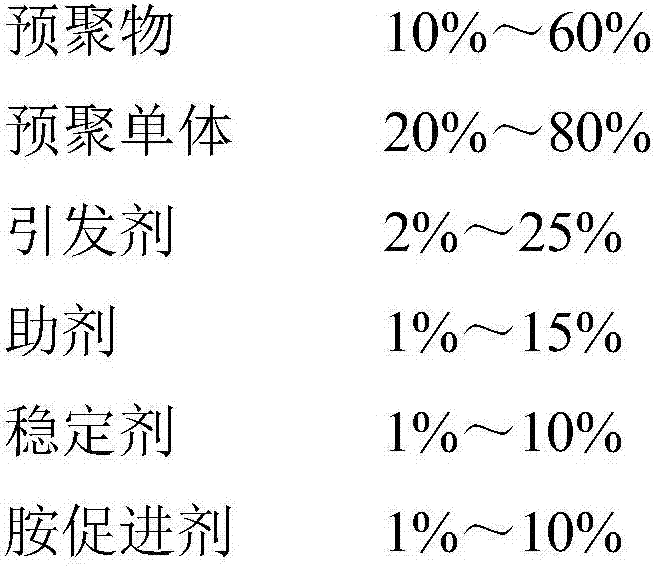

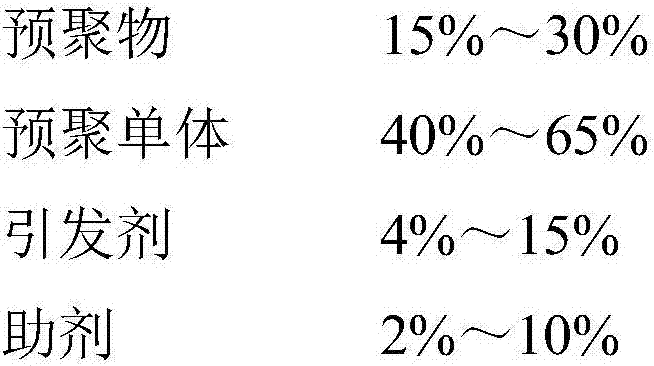

High-fidelity durable lightfast UV/UVLED curing coating for note and preparation method thereof

InactiveCN107325691ALow VOC/NOVOCWith transparentWax coatingsPaper coatingMethacrylateVinyl ether

Owner:XIAN BANKNOTE PRINTING +1

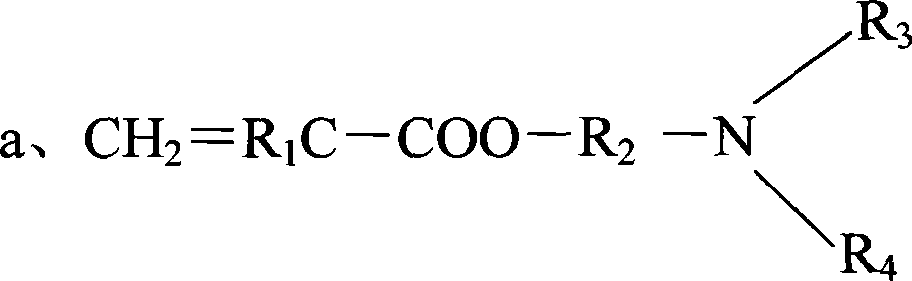

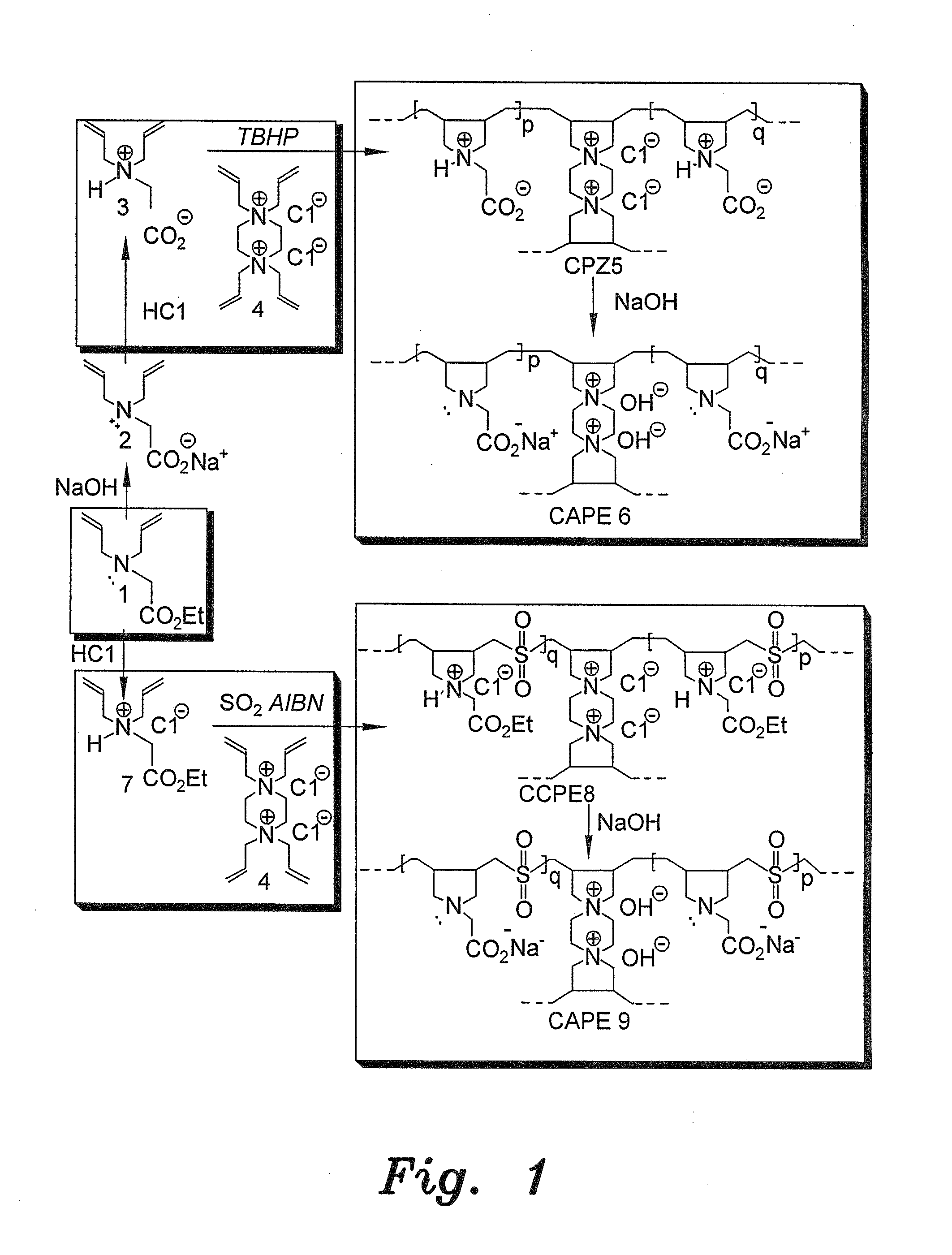

Case-hardening zwitterion type polymer for hair, preparing method and application of the same

ActiveCN101130588AFeel goodGood water solubilityCosmetic preparationsHair cosmeticsCase hardeningWater soluble

Owner:GUANGZHOU TINCI MATERIALS TECH

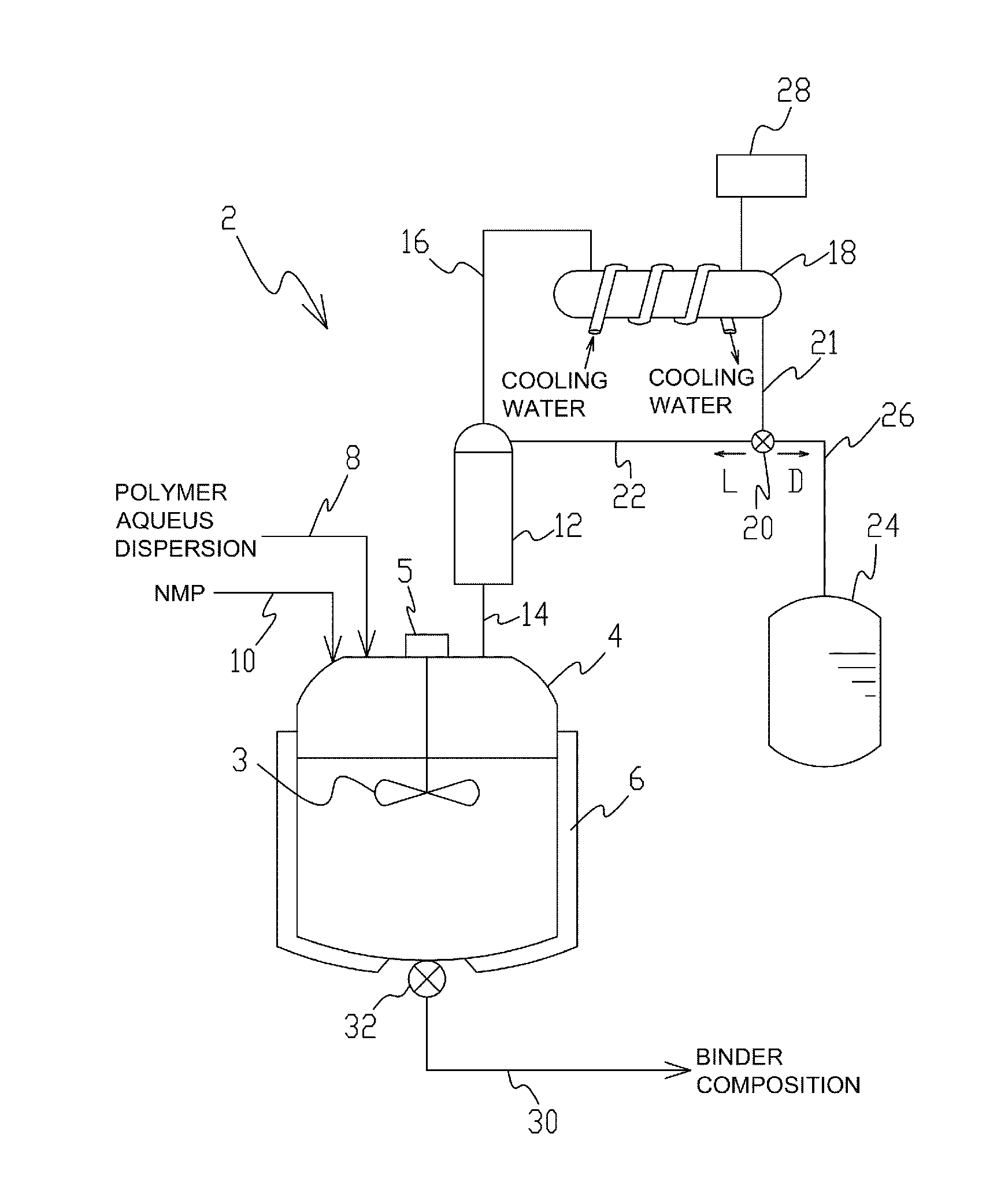

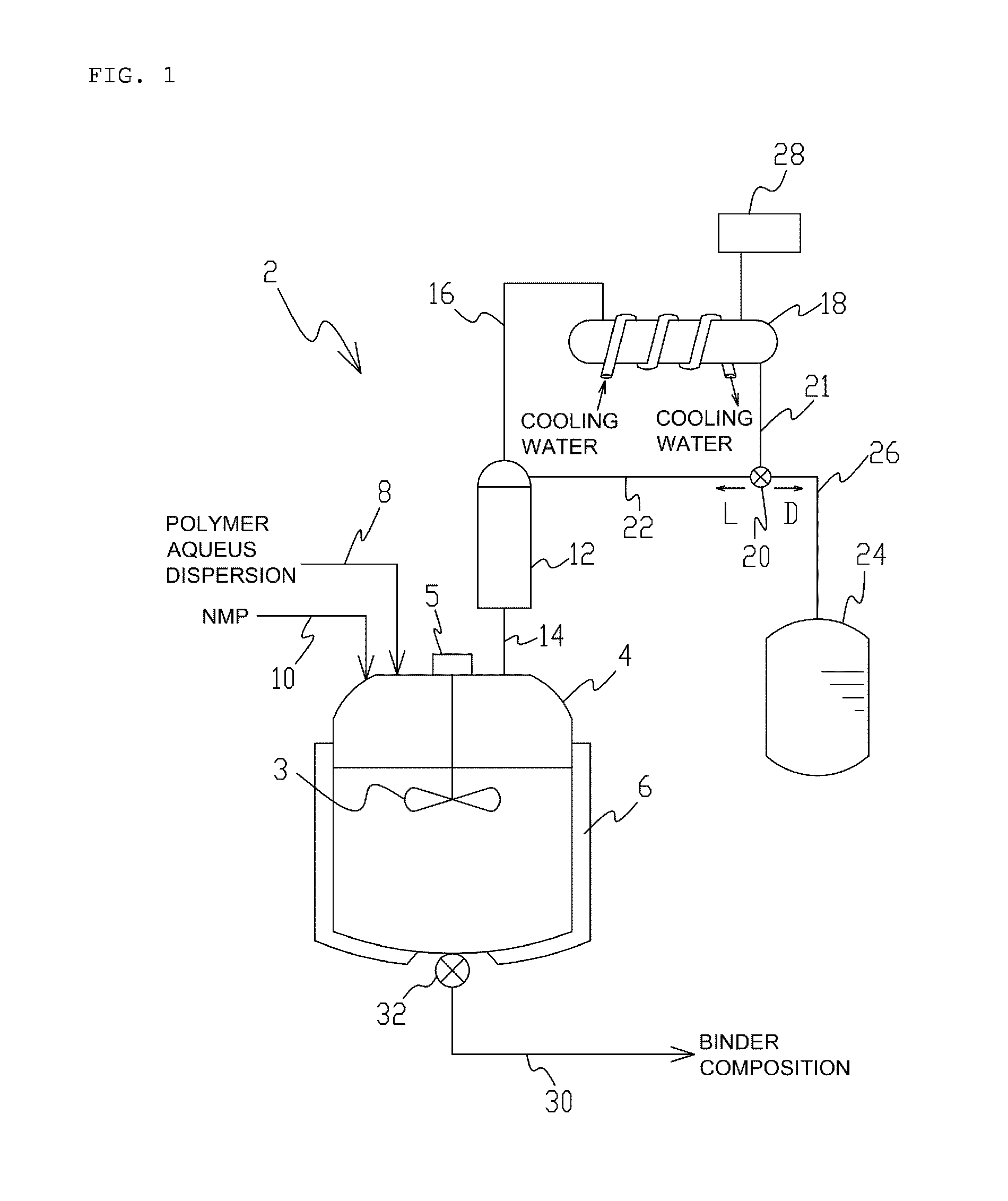

Method for producing slurry for heat-resistant layer for lithium ion secondary battery and method for producing electrode for lithium ion secondary battery

InactiveUS20140242296A1Reduce the amount of waterEfficiently obtainedElectrode manufacturing processesMixing methodsPolymer scienceDistillation

Owner:ZEON CORP

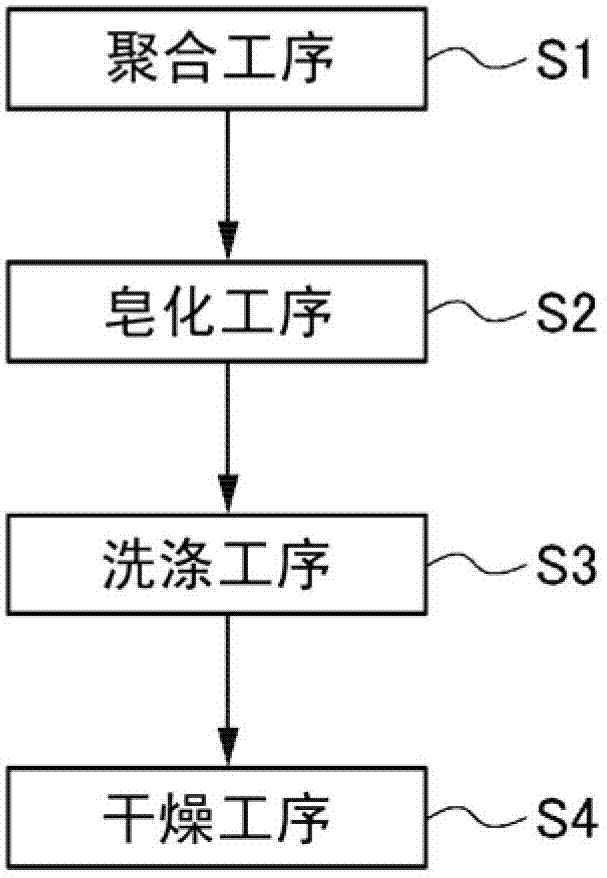

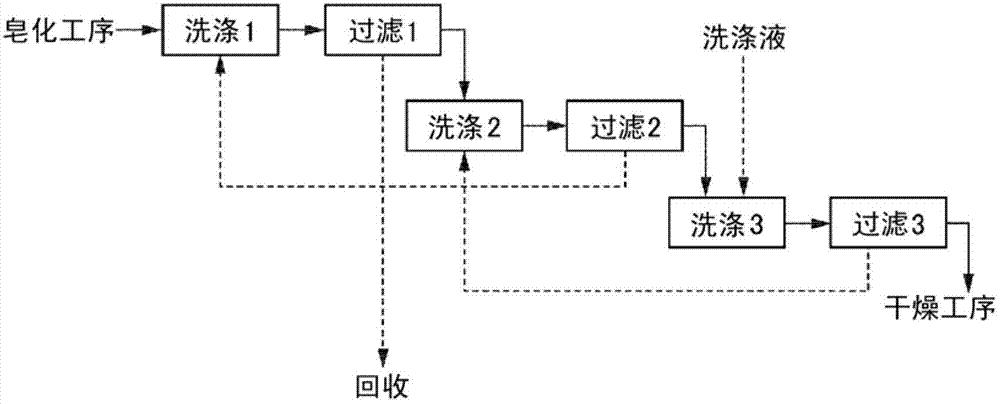

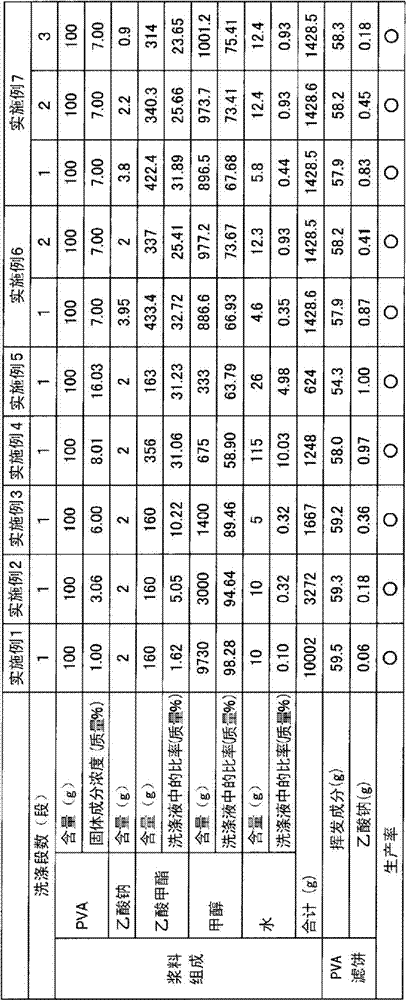

Method for producing polyvinyl alcohol resin

Owner:DENKA CO LTD

Method for chemical degradation of polymer procyanidins by using lithium hydroxide

Owner:HARBIN INST OF TECH AT WEIHAI

Cross-linked polyaminocarboxylates for the removal of metal ions from aqueous solutions

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Preparation method of organic tin-free chlorine ether resin

Owner:HANGZHOU ELECTROCHEM GROUP

Super absorbent resin and preparation method thereof

The invention provides super absorbent resin and a preparation method thereof. The preparation method comprises the steps of: mixing and heating a dispersion medium, a surfactant and a dispersing agent to obtain a substrate solution; mixing the substrate solution with a certain amount of an initiator-based mixed solution A and an acrylic acid solution A, heating, carrying out primary polymerization reaction, and evaporating out part of water; and then mixing the substrate solution with a certain amount of an initiator-based mixed solution B and an acrylic acid solution B to carry out secondary polymerization reaction, then evaporating out part of water, and carrying out post-crosslinking, distillation treatment, solid-liquid separation and drying to obtain spherical resin particles. According to the preparation method, complete interface fusion or partial interface fusion among the spherical resin particles can be avoided, the particle size of the synthesized spherical resin particles can be controlled within a certain distribution range, meanwhile, the synthesized resin does not have a special shape, and the water absorption effect of the resin is improved.

Owner:YANKUANG COAL WATER SLURRY GASIFICATION & COAL CHEM NAT ENG RES CENT CO LTD

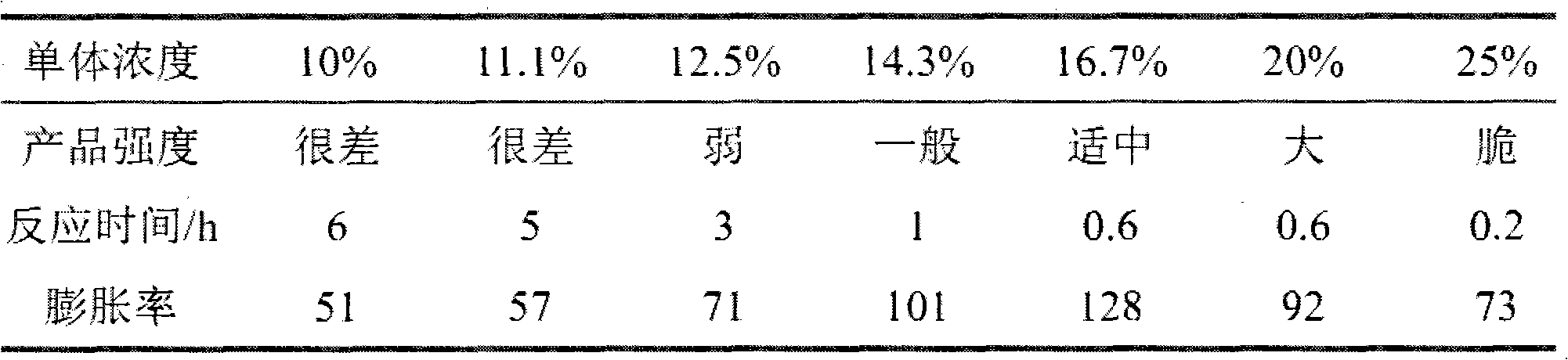

Preparation process of leak protection plugging agent along with drilling based on control of monomer concentration

InactiveCN102993357AImprove performanceIncrease productivityDrilling compositionWater bathsReaction temperature

Owner:倪蕊

Preparation method of 2, 2, 6, 6-tetramethyl-piperidinooxy stearate

InactiveCN103274994AEmission reductionLow priceOrganic chemistryManufacturing technologyWater discharge

Owner:南通市振兴精细化工有限公司

Polyvinyl acetate polymerization method

InactiveCN106008773ANarrow molecular weight distributionQuality improvementPolyvinyl acetateDecomposition

Owner:ANHUI WANWEI UPDATED HIGH TECH MATERIAL CO LTD

Polyurethane-nylon 6 block copolymer, preparation method thereof and polyurethane-nylon 6 elastic fiber

ActiveCN112127007AHigh mechanical strengthImprove wear resistanceMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention provides a polyurethane nylon 6 block copolymer, a preparation method thereof and a polyurethane nylon 6 elastic fiber. The polyurethane nylon 6elastic fiber is obtained by performing melt spinning on the polyurethane nylon 6 block copolymer. The polyurethane nylon 6 block copolymer is an ABA type block copolymer, wherein the block A is an amino-terminated polyamide chain segment, the block B is an isocyanate-terminated polyurethane chain segment, the mass content of the isocyanate-terminated polyurethane chain segment is 20-60wt%, and amino-terminated polyamide and isocyanate-terminated polyurethane are subjected to polymerization reaction according to a molar ratio of 1.2:1 to 1.3:1 by adopting a hydrolytic polymerization method. The molecular structure of the polyurethane-nylon 6 copolymer is designed, so that the copolymer has excellent properties of polyurethane and nylon, copolymer slices meeting melt spinning requirements are obtained, and the polyurethane-nylon 6copolymer elastic fiber with high strength and high resilience is obtained through melt spinning.

Owner:WUHAN TEXTILE UNIV

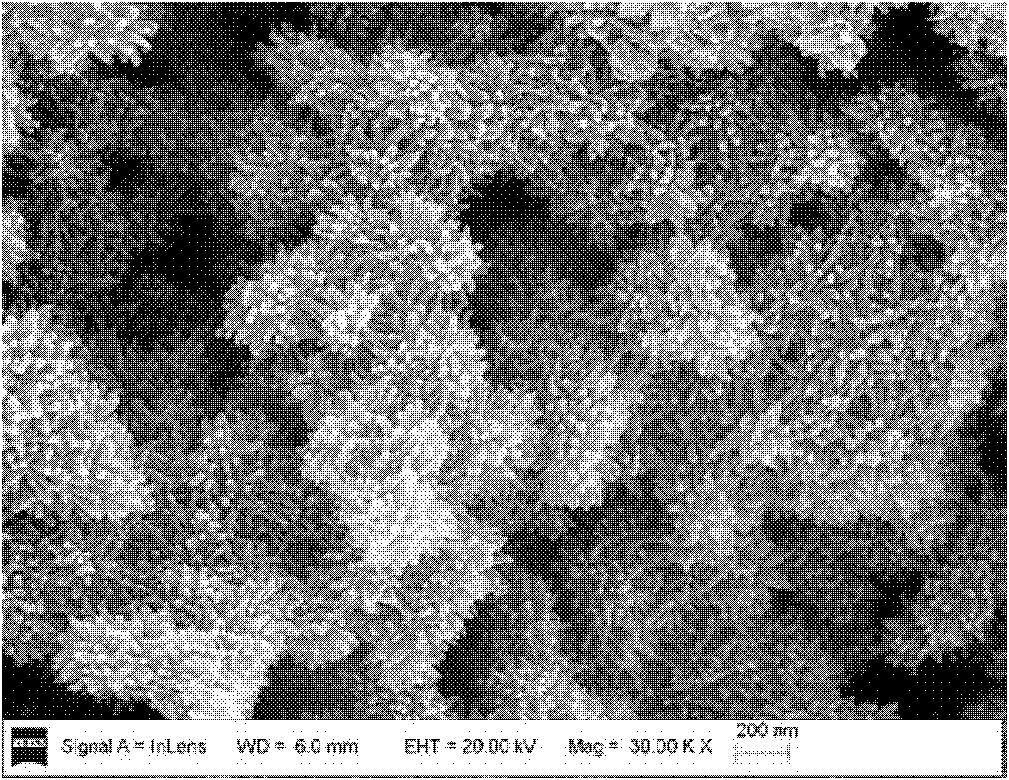

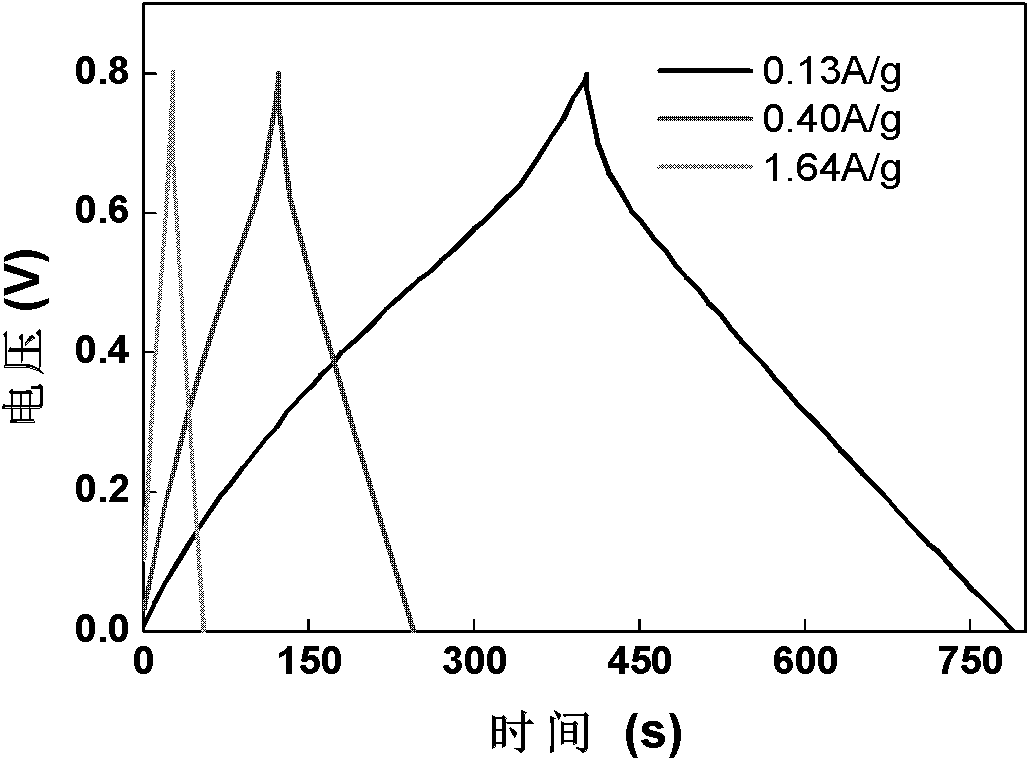

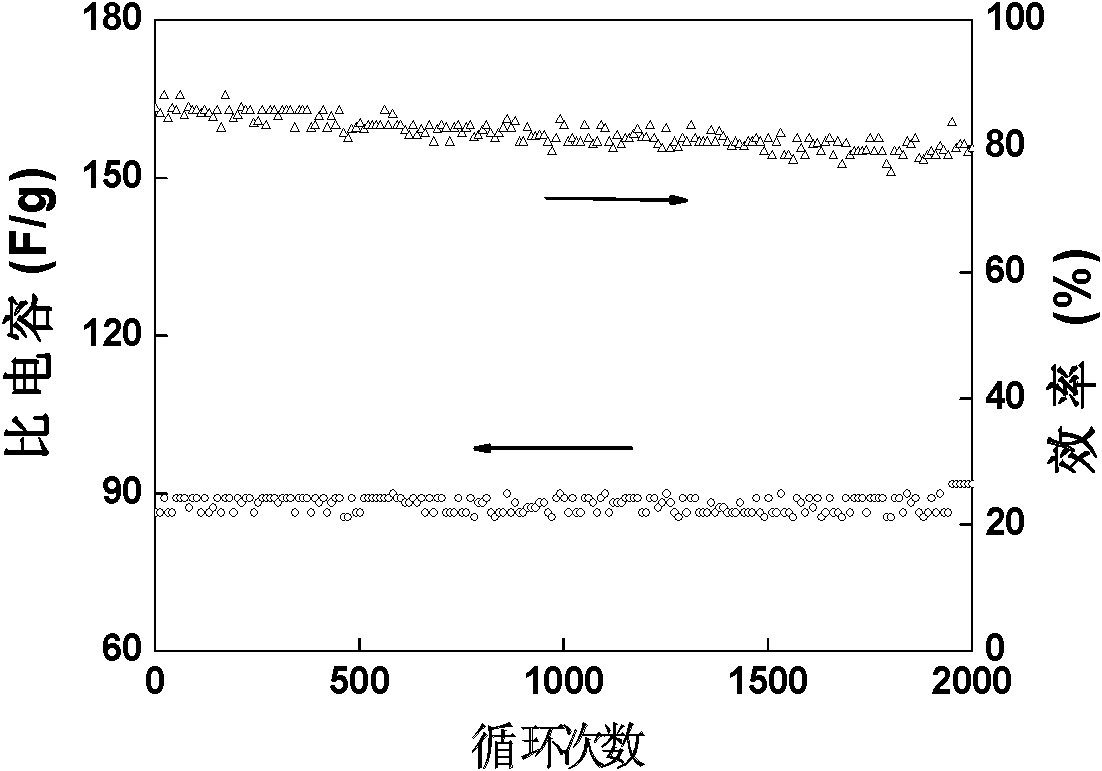

A preparation method of nanometer metatitanic acid doped polyaniline composite electrode material for supercapacitor

ActiveCN102280265AIncrease capacitance densityIncrease energy densityElectrolytic capacitorsCyclic processCapacitance

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Wood wax oil timber modifier and preparation method thereof

InactiveCN105881684AMaintain colorGuaranteed anti-corrosionWood impregnation detailsMoisture absorptionPolymerization

The invention discloses a wood wax oil timber modifier and a preparation method thereof. The modifier comprises the following components by mass percentage: 28-32% of tung oil, 8-12% of camphor wood oil, 17-22% of rosin-modified resin, 9-11% of orange oil, 4-6% of glass powder, and 22-27% of ethanol. The preparation method comprises the following steps: the tung oil, the camphor wood oil, rosin-modified resin, orange oil, and glass powder are placed in a reaction vessel, are subjected to a polymerization at the high temperature of 260-300 DEG C, then cooled to the temperature of 70-90 DEG C, ethyl alcohol is added for being stirred, and then the materials are cooled to the room temperature to obtain the product. The preparation method has simple process, the modifier does not contain toxic components such as triphenyl, formaldehyde and heavy metals, has no pungent smell, can keep original color when used on the timber, has the advantages of anticorrosion, insect resistance, non moisture absorption, non moistening, non deformation, and no influence on glues and paints.

Owner:董学明

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap