High-fidelity durable lightfast UV/UVLED curing coating for note and preparation method thereof

A curing coating, high-fidelity technology, used in polyurea/polyurethane coatings, paper coatings, wax coatings, etc., can solve the problems of yellowing paint color, curing film yellowing, and curing film not fastness to sunlight, etc. The effect of low grade, no yellowing and gloss, excellent adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

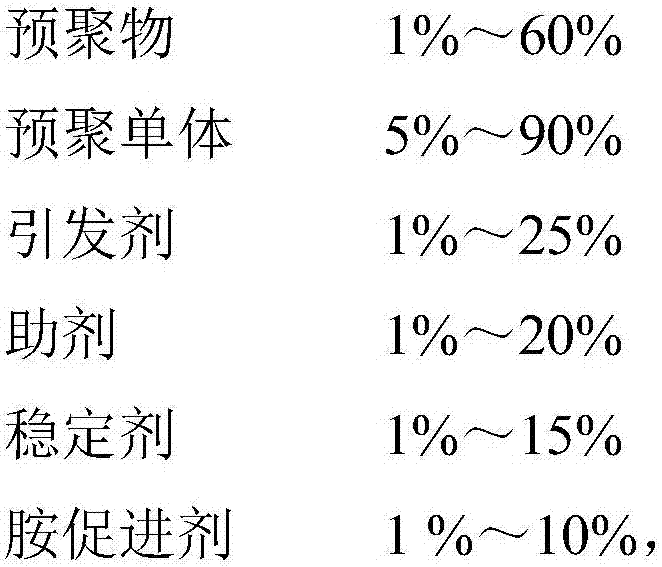

[0056] The mass percentage composition of coating is as follows:

[0057]

[0058] First, weigh aliphatic modified epoxy diacrylate resin, aliphatic polyurethane diacrylate, α, α-dialkylacetophenone DEAP, α-hydroxyalkylphenone 150, p-hydroxyanisole according to the above mass percentage , nano-calcium carbonate, add in the reaction vessel and stir, then roll on a three-roller machine to obtain a base material with a fineness≤15 μm, then weigh cyclotrimethylolpropane acrylate, 4(ethoxylated ) pentaerythritol tetraacrylate, trimethylolpropane triacrylate, and amine accelerator EDB are added to the base material, mixed with the base material, stirred with a high-speed mixer, and the stirring speed is 400 to 1500 rpm, stirring 20 to 60 Minutes, filtered to obtain the target coating with the appearance of a milky white uniform emulsion, the viscosity of the coating was measured to be 200-800mps / 25°C.

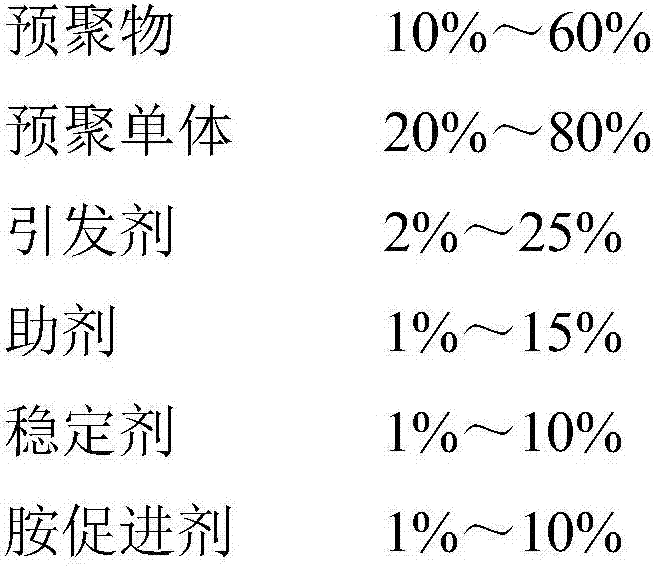

Embodiment 2

[0060]

[0061] First, weigh aliphatic polyurethane nonaacrylate, aliphatic polyurethane tetraacrylate, aliphatic polyurethane triacrylate, α-aminophenones 369, benzophenones CMBB, acyl phosphorus oxides 110, 2 , 6-tert-butylphenol, and polytetrafluoroethylene-modified polyethylene micropowder wax are added to the reaction vessel and stirred, then rolled on a three-roll machine to obtain a base material with a fineness of ≤15 μm, and then weigh the ring according to the above mass percentage. Trimethylolpropane acrylate, dipropylene glycol diacrylate, 4 (ethoxylated) pentaerythritol tetraacrylate, amine accelerator DMB are added in the base material, mixed with the base material, stirred with a high-speed mixer, and the stirring speed is 400-1500 rev / min, stirring for 20-60 minutes, and filtering to obtain the target paint with the appearance of a milky white uniform emulsion. The measured viscosity of the paint is 200-800mps / 25°C.

Embodiment 3

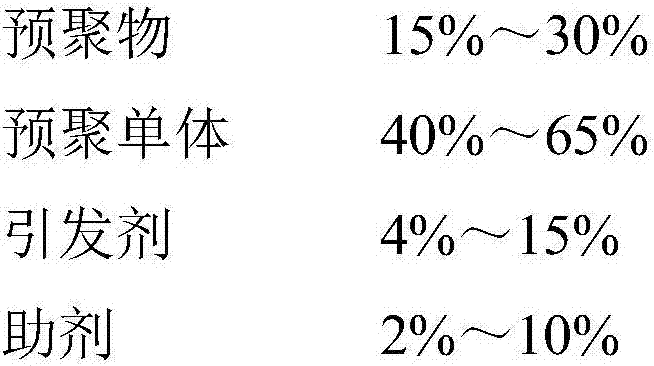

[0063] The mass percentage composition of coating is as follows:

[0064]

[0065] First, weigh modified polyurethane diacrylate, aliphatic polyurethane nonaacrylate, aliphatic polyurethane tetraacrylate, benzophenone PBZ, α,α-dialkylacetophenone 2959, acyl oxide Phosphorous TPO-L, p-hydroxyanisole, and white carbon black are added into the reaction vessel and stirred, then rolled on a three-roll machine to obtain a base material with a fineness of ≤15 μm, and then weigh tripropylene glycol according to the above mass percentage Diacrylate, 4 (ethoxylated) pentaerythritol tetraacrylate, trimethylolpropane tetraacrylate, and amine accelerator PDA are added to the base material, mixed with the base material, and stirred with a high-speed mixer at a stirring speed of 400-1500 rpm, stirred for 20-60 minutes, and filtered to obtain the target paint with the appearance of a milky white uniform emulsion. The measured viscosity of the paint is 200-800mps / 25°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap