Novel moisture-curing flame-retardant polyurethane hot melt adhesive and preparation method thereof

A polyurethane hot-melt adhesive and moisture-curing technology, which is applied in the field of structural adhesives, can solve the problems of reducing the chemical corrosion resistance, heat resistance and aging resistance of polyurethane hot-melt adhesive coatings, and solve the problem of poor wetting performance , Improve compatibility and improve chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

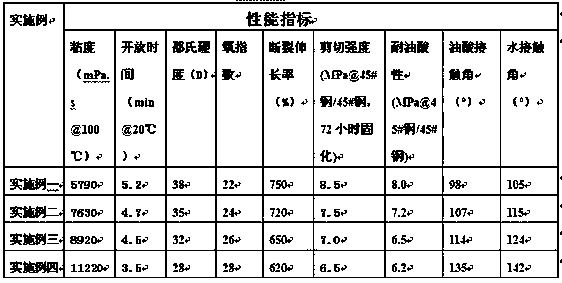

Examples

Embodiment 1

[0027] It is a new type of moisture-cured flame-retardant polyurethane hot-melt adhesive, which is prepared by the following steps:

[0028] Step 1: Synthesis of isocyanate-modified polyacrylic acid fluorosilicone copolymer

[0029] 8 parts of hexafluorobutyl acrylate HFMA, 8 parts of methacryloxypropyl monoblocked dimethylpolysiloxane MAPDMS, 30 parts of methyl acrylate MA and 7 parts of methacrylic acid isocyano Ethyl ICEMA was dissolved in 50 parts of toluene, controlled at 90°C, under the protection of nitrogen, 1.9 parts of thermal initiator tert-amyl peroxide 2-ethylhexanoate was added, the polymerization reaction was 5 hours, and the toluene was removed by rotary evaporation , to obtain isocyanate-modified polyacrylic acid fluorine-silicon copolymer, the chemical structure of isocyanate-modified polyacrylic acid fluorine-silicon copolymer is: poly(hexafluorobutyl acrylate-random-methacryloxypropyl single-capped di Methylpolysiloxane-Atactic-Methyl Acrylate-Atactic-Isocyan

Embodiment 2

[0033] It is a new type of moisture-cured flame-retardant polyurethane hot-melt adhesive, which is prepared by the following steps:

[0034] Step 1: Synthesis of isocyanate-modified polyacrylic acid fluorosilicone copolymer

[0035] 12 parts of hexafluorobutyl acrylate HFMA, 12 parts of methacryloxypropyl monoblocked dimethyl polysiloxane MAPDMS, 35 parts of methyl acrylate MA and 5 parts of methacrylic acid isocyano Ethyl ICEMA was dissolved in 70 parts of toluene, controlled at 100°C, under the protection of nitrogen, 1.2 parts of thermal initiator tert-amyl peroxide 2-ethylhexanoate was added, the polymerization reaction was 6 hours, and the toluene was removed by rotary evaporation , to obtain isocyanate-modified polyacrylic acid fluorine-silicon copolymer, the chemical structure of isocyanate-modified polyacrylic acid fluorine-silicon copolymer is: poly(hexafluorobutyl acrylate-random-methacryloxypropyl single-capped di Methylpolysiloxane-Atactic-Methyl Acrylate-Atactic-Iso

Embodiment 3

[0039] It is a new type of moisture-cured flame-retardant polyurethane hot-melt adhesive, which is prepared by the following steps:

[0040] Step 1: Synthesis of isocyanate-modified polyacrylic acid fluorosilicone copolymer

[0041] 15 parts of hexafluorobutyl acrylate HFMA, 15 parts of methacryloxypropyl monoblocked dimethyl polysiloxane MAPDMS, 40 parts of methyl acrylate MA and 6 parts of methacrylic acid isocyano Ethyl ICEMA was dissolved in 80 parts of toluene, controlled at 95 ° C, under the protection of nitrogen, adding 0.6 parts of thermal initiator tert-amyl peroxide 2-ethylhexanoate, polymerized for 12 hours, and removed toluene by rotary evaporation , to obtain isocyanate-modified polyacrylic acid fluorine-silicon copolymer, the chemical structure of isocyanate-modified polyacrylic acid fluorine-silicon copolymer is: poly(hexafluorobutyl acrylate-random-methacryloxypropyl single-capped di Methylpolysiloxane-Atactic-Methyl Acrylate-Atactic-Isocyanoethyl Methacrylate)

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap