Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Improve flame retardant performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

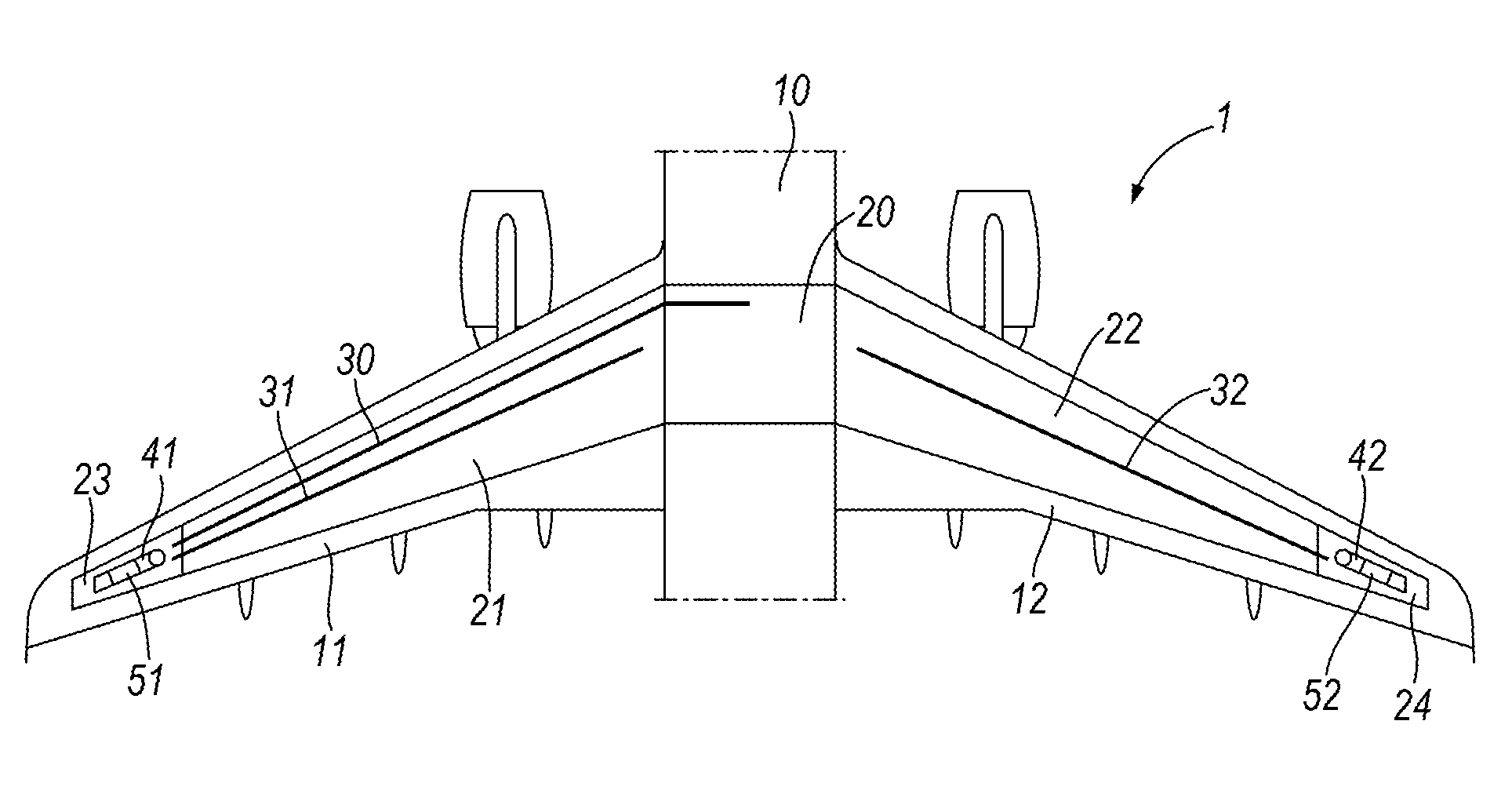

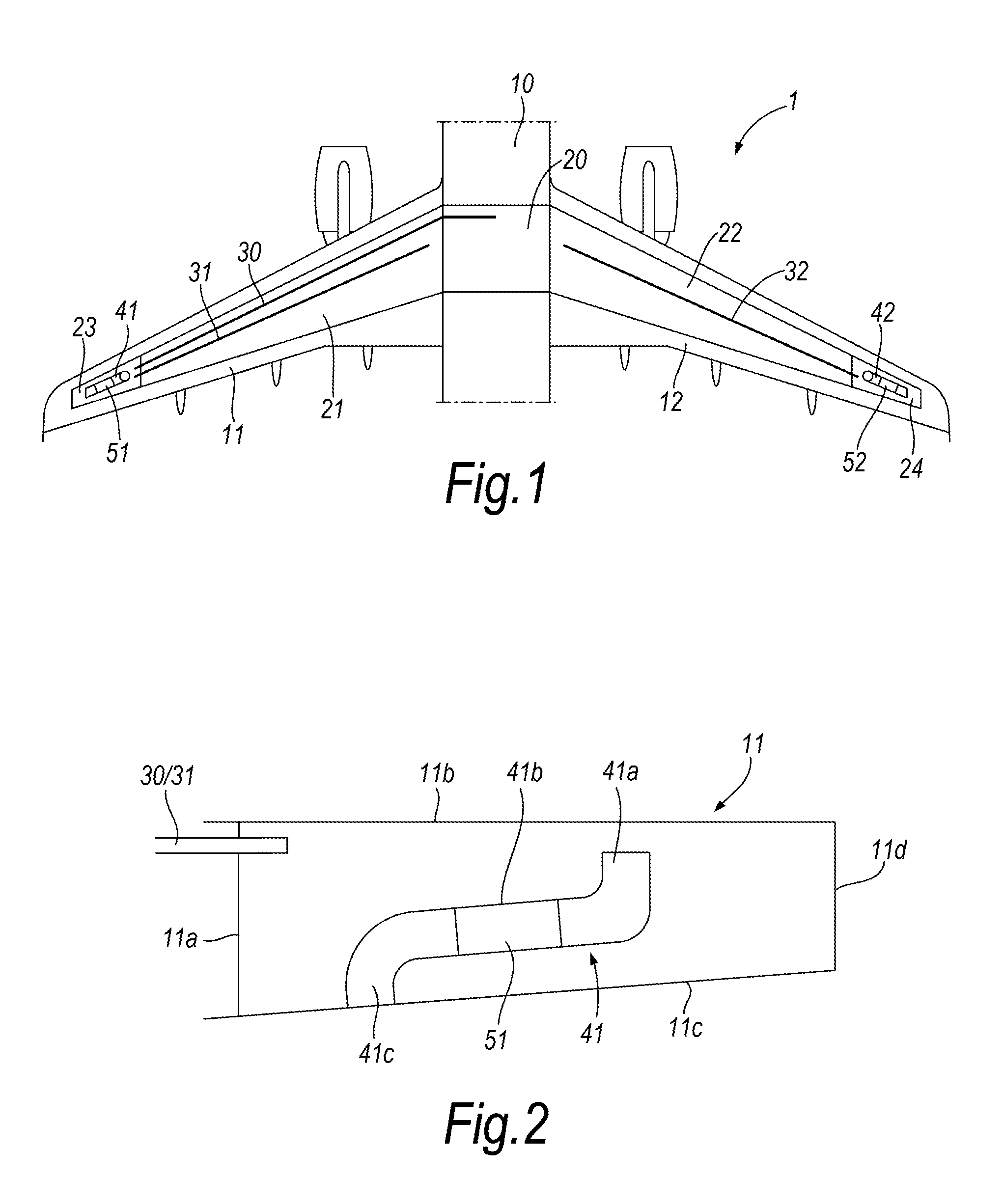

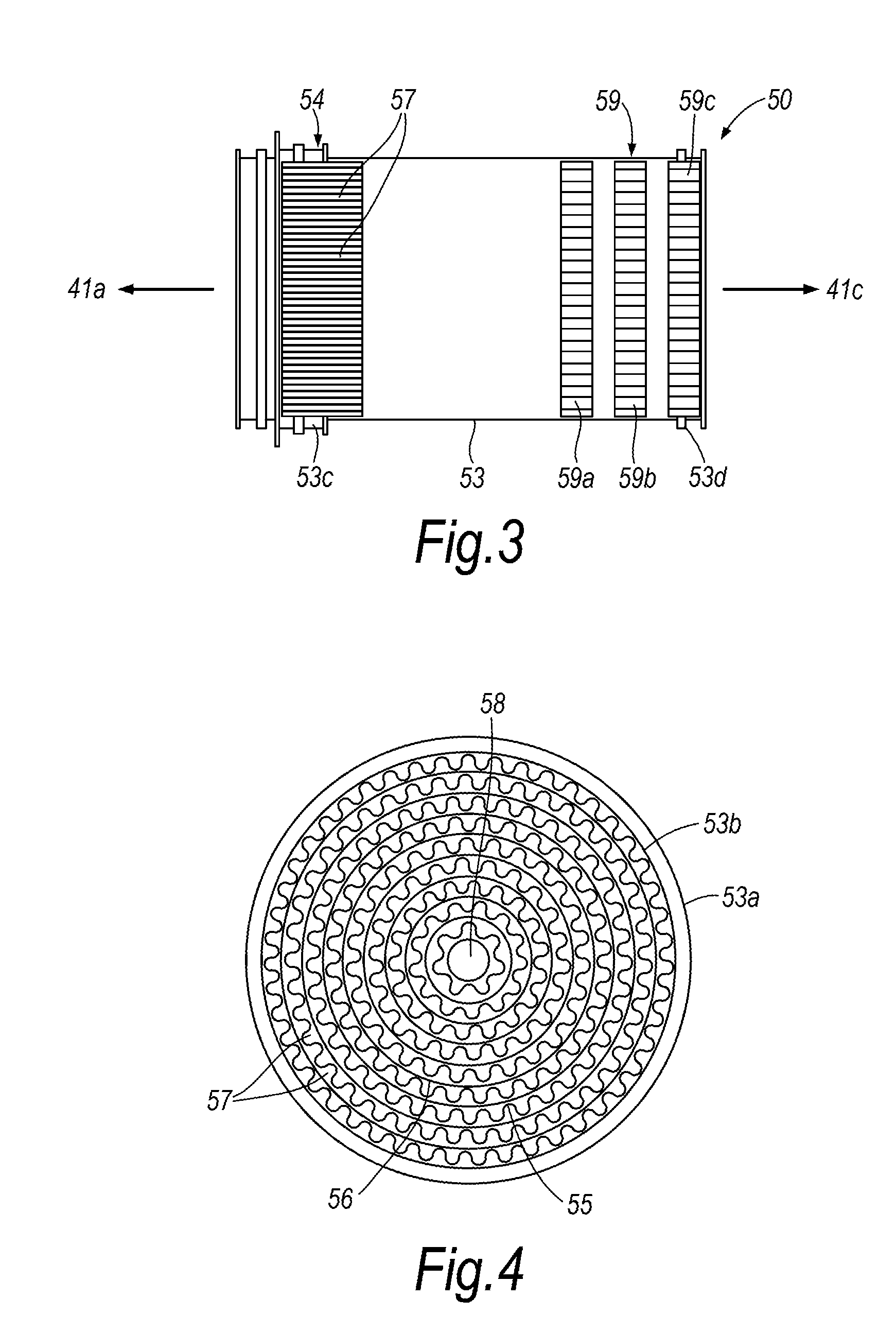

Flame trap cartridge, flame arrestor, method of preventing flame propagation into a fuel tank and method of operating an aircraft

InactiveUS20120273239A1Improve flame retardant performanceProlong foaming timeLiquid fuel feeder/distributionAdditive manufacturing apparatusAirplaneEngineering

Owner:AIRBUS OPERATIONS LTD

Heptatridecafluorooctylpropyl polyhedral oligomeric silsesquioxane and functionalized derivates thereof

The invention provides a preparation method for heptatridecafluorooctylpropyl polyhedral oligomeric silsesquioxane and functionalized derivates thereof. The preparation method comprises the steps as follows: adding tridecafluorooctylpropyl trimethoxy silane into an organic solvent, adding de-ionized water and NaOH, heating, stirring, reacting under reflux condition, washing by a washing solvent, and drying to obtain trisilanol sodium salt of heptatridecafluorooctylpropyl polyhedral oligomeric silsesquioxane; and adding trisilanol sodium salt into an organic reagent, dropwise adding hydrochloric acid, triethylamine and a silane coupling agent, stirring a mixture at normal temperature for reaction, removing generated deposit, carrying out rotary evaporation, removing the solvent, obtaining white crystals, dissolving the crystals in methanol, filtering for collecting insoluble parts, and carrying out vacuum drying to obtain a T8-type monofunctional tridecafluorooctylpropyl POSS (polyhedral oligomeric silsesquioxane) monomer. The preparation method can obtain long branch chain type active fluorine-containing POSS, is simple and easy in process, low in cost, high in yield and higher in product purity, and is suitable for large-scale industrial production.

Owner:HOHAI UNIV

Preparation method of modified polyethylene terephthalate cable sheath tube

InactiveCN102604338AHigh strengthHigh compressive strengthCable installations in underground tubesDiethyl phosphatePolymer science

The invention relates to a preparation method of a modified polyethylene terephthalate cable sheath tube. The preparation method comprises the following steps of: with 62-73 parts by weight of polyethylene terephthalate as a raw material, adding 15-20 parts by weight of propylene-ethylene block copolymer, 5-8 parts by weight of ethylene-acrylic acid ethyl ester copolymer, 6.5-9.0 parts by weight of micro-encapsulation red phosphorus, 0.5-1.0 part by weight of 3, 5-di-tert-butyl-4 hydroxy benzyl diethyl phosphate, drying the mixture, stirring and mixing the mixture at a high speed, extruding and pelletizing the mixture by using a double screw, extruding and forming by using a single screw, and forming the cable sheath tube by using a cooling and setting technology. The cable sheath tube prepared by the method has the advantages that the vicat softening temperature is higher than 153 DEG C, the ring stiffness is greater than 25KN / m<2>, the volume resistivity is greater than 3.0*1011, the creep resistance and flame retardant property are good; and the cable sheath tube is suitable for the fields of buried power cable sheaths and the like.

Owner:FUJIAN NORMAL UNIV +4

Epoxy modified low-dielectric fluorine-containing polyphenyl ether coating and high-frequency high-speed copper-clad plate prepared from same

ActiveCN111363308AGood processabilityImprove flame retardant performanceGlass/slag layered productsLaminationCoatingFire retardant

Owner:SHUNDE POLYTECHNIC

Lightning protected cable for communication base station

ActiveCN103325489ALower the resistance valueSmall short-term calorific valueCommunication cablesInsulated cablesAluminium hydroxideEngineering

The invention belongs to the technical field of cables and relates to a lightning protected cable for a communication base station. The lightning protected cable for the communication base station comprises a cable core, an inner protecting sleeve, an armor layer, an outer protecting sleeve and a ground layer. The lightning protected cable for the communication base station is characterized in that a first protecting layer is arranged outside the cable core, the inner protecting sleeve is arranged outside the first protecting layer, a second protecting layer is arranged outside the inner protecting sleeve, the ground layer is arranged outside the second protecting layer, the armor layer is arranged outside the ground layer, and the armor layer is coated with the outer protecting sleeve; the armor layer is a single-face film covering steel belt and the face, in contact with the ground layer, of the armor layer is a non-film-covering face; the first protecting layer and the second protecting layer are both mica tapes; the outer protecting sleeve comprises, by weight, the following raw materials of 71 parts of polyethylene, one part of anti-oxygen 1010, 12 parts of aluminum hydroxides, 0.5 part of HK-type antistatic agent, 3 parts of ethyl acetate, 1 part of carbon black, 10 parts of zirconium oxide and 1.5 parts of polyethylene wax. The lightning protected cable for the communication base station has the advantages of being simple in manufacturing, high in production speed, capable of enabling the electrical resisting rate of the ground layer to be low, low in maintaining cost, small in dust adsorption, pressure resistant, and good in flame resistance.

Owner:JIANGSU ZHONGLI GRP CO LTD

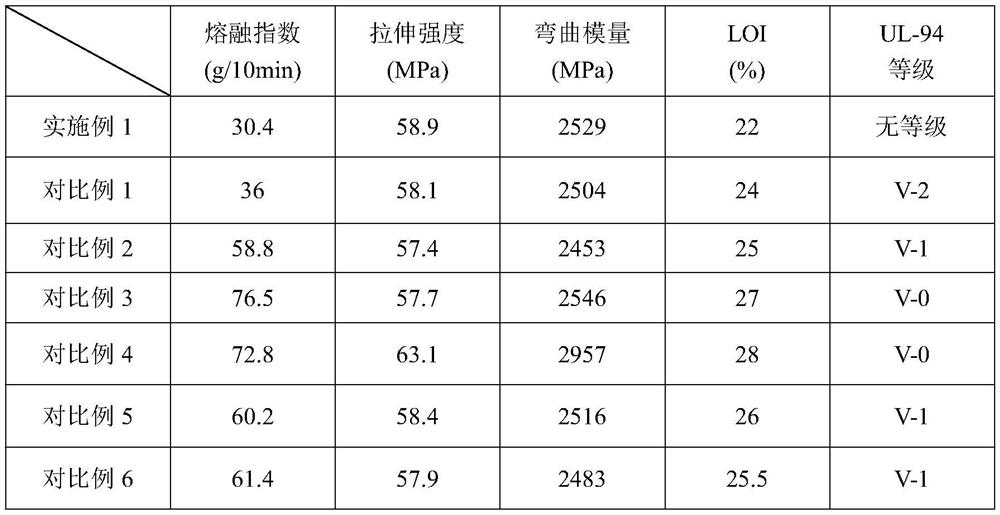

High-fluidity flame-retardant PC/ABS composite material and preparation method thereof

PendingCN113583423AGood molding process and performanceImprove flame retardant performanceAnti oxidantCeramic materials

Owner:广州仕天材料科技有限公司

Mineralized wood materials and methods providing mineralized wood materials

InactiveUS20170043497A1Improve propertiesLimited accessibilityWood treatment detailsPressure impregnationCell wallMaterials science

Owner:SWISS FEDERAL LAB FOR MATERIALS SCI & TECH EMPA

High-strength composite fiber non-woven cloth and preparation method thereof

ActiveCN106427147AFirmly connectedClosely connectedProtective equipmentSynthetic resin layered productsEpoxyAlcohol

The invention discloses high-strength composite fiber non-woven cloth and a preparation method thereof. Ultrahigh-strength high-modulus polyethylene fibers are used as base materials, the polyethylene fiber obtained after fiber placement is subjected to a series of homogenization, parallelization and straight and upright arrangement and placed in a modified epoxy resin solution for sizing treatment in an environment of 60-80 DEG C, then the formed polyethylene fiber layers are subjected to composite lamination, and the non-woven cloth is prepared, wherein the modified epoxy resin solution is prepared by adding and mixing an adhesion agent, a filling agent, an insulating filler, fire retardant, white carbon black and ethyl alcohol, the mass of hydroxyl chemigum accounts for 8-12% of the mass of the modified epoxy resin solution, and the content of vinyl cyanide accounts for 18-30% of the content of hydroxyl chemigum. The non-woven clothes with different thicknesses are prepared by lamination of the polyethylene fiber layers, an antiknock device can be made from different types of non-woven cloths according to explosion sites and use environment, and the non-woven cloths with different thicknesses are different in anti-explosion range so as to sufficiently withstand the impact of a bullet.

Owner:JIANGSU LINRY NEW MSTAR TECH

Environmentally friendly high-flame-retardant foaming material of garbage bin and preparation method of environmentally friendly high-flame-retardant foaming material

InactiveCN106046296AGuarantee personal safetyImprove flame retardant performanceEnvironmental resistanceEnvironmentally friendly

Owner:YANGZHONG TIANZHENG SYNTHETIC MATERIAL RES CENT

Wood (bamboo) powder/ABS/PVC alloy and preparation method thereof

InactiveCN102134357ASmall coefficient of linear expansionImprove flame retardant performancePlasticizerFire retardant

Owner:王广武

High-strength laminated fire-retarding conveyer belt coating rubber, and preparation method thereof

InactiveCN102516617AImprove flame retardant performanceImprove mechanical strengthConveyorsAnti ageingButadiene-styrene rubber

Owner:WUXI BOTON TECH CO LTD

Hydrophobicity-enhanced heat-vulcanized silicone rubber and preparation method thereof

InactiveCN107286671AEnhance internal bondingImprove mechanical propertiesVulcanizationPolymer science

The invention provides hydrophobicity-enhanced heat-vulcanized silicone rubber and a preparation method thereof. The specific preparation method of the silicone rubber comprises steps as follows: divinyltetramethyldisiloxane is mixed with a mixed solution of concentrated hydrochloric acid, deionized water and ethanol, the mixture is mechanically stirred, ethyl orthosilicate is dropwise added, the mixture is subjected to hydrolytic condensation, methylbenzene is added for extraction and layering, methyl vinyl silicone resin is obtained, crosslinked polyethylene particles are added to the methyl vinyl silicone resin, the mixture is stirred uniformly and subjected to molding curing and vacuum heat treatment, and the polyethylene particle crosslinked methyl vinyl silicone resin is obtained; nano-montmorillonite, amorphous alumina and titanium dioxide are added to a polydimethylsiloxane prepolymer, the mixture is mixed and subjected to crosslinking and curing, and a reinforced material coated with organic silicone rubber is obtained; the polyethylene particle crosslinked methyl vinyl silicone resin, the reinforced material coated with organic silicone rubber, 2,4-dichlorobenzoyl peroxide, diphenyl silanediol and octamethylcyclotetrasiloxane are mixed uniformly, left to stand, subjected to open milling and secondary vulcanization, and the hydrophobicity-enhanced heat-vulcanized silicone rubber is obtained.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Flame-retardant PTT

The present invention discloses a flame-retardant PTT, which comprises the following components in mass percentage: 80% to 95% of PTT, 2% to 8% of phosphorus-containing monomers, 1% to 5% of organic montmorillonite, 2% to 6% of aliphatic polyether, 0.1% to 0.5% of trimethyl phosphate, and 0.1% to 0.5% of antioxidant. The phosphorus-containing monomers are composed of 2-carboxyl ethyl alkyl phosphonic acid or 2-carboxyl ethyl phenyl phosphinic acid. The aliphatic polyether is composed of one component selected from polyethylene glycol, polytetrahydrofuran and polypropylene oxide, wherein the molecular weight of the aliphatic polyether is 1000-5000. According to the invention, the phosphorus-containing monomers are added for realizing the flame-retardant modification, and the organic montmorillonite is added for synergistically improving the char-forming characteristics and enhancing the droplet-proof performance. Therefore, the flame-retardant PTT is excellent in halogen-free, droplet-proof and flame-retardant performance, good in spinnability, excellent in mechanical property, simple in preparation process, low in cost and easy in popularization and application.

Owner:王妮娜

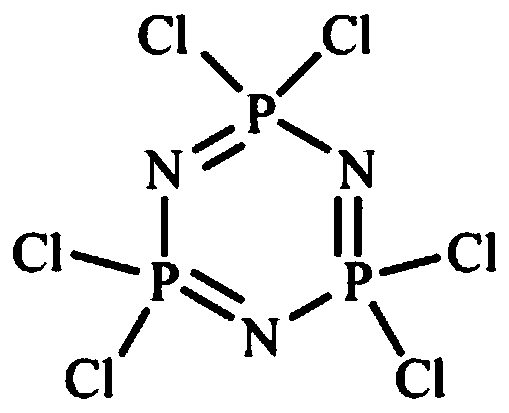

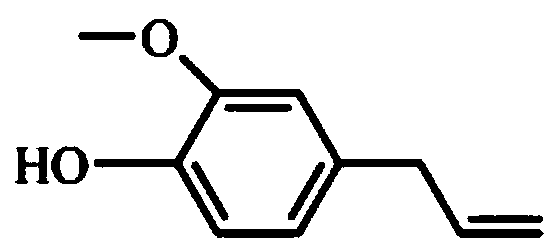

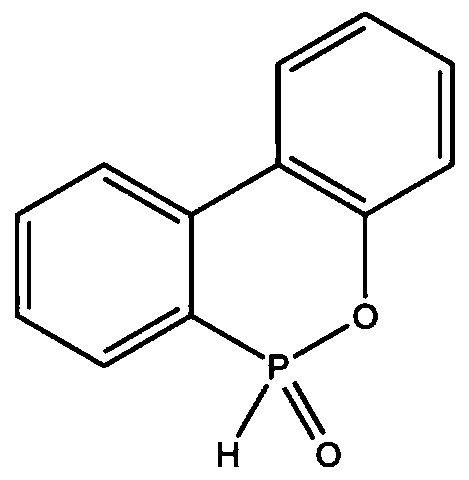

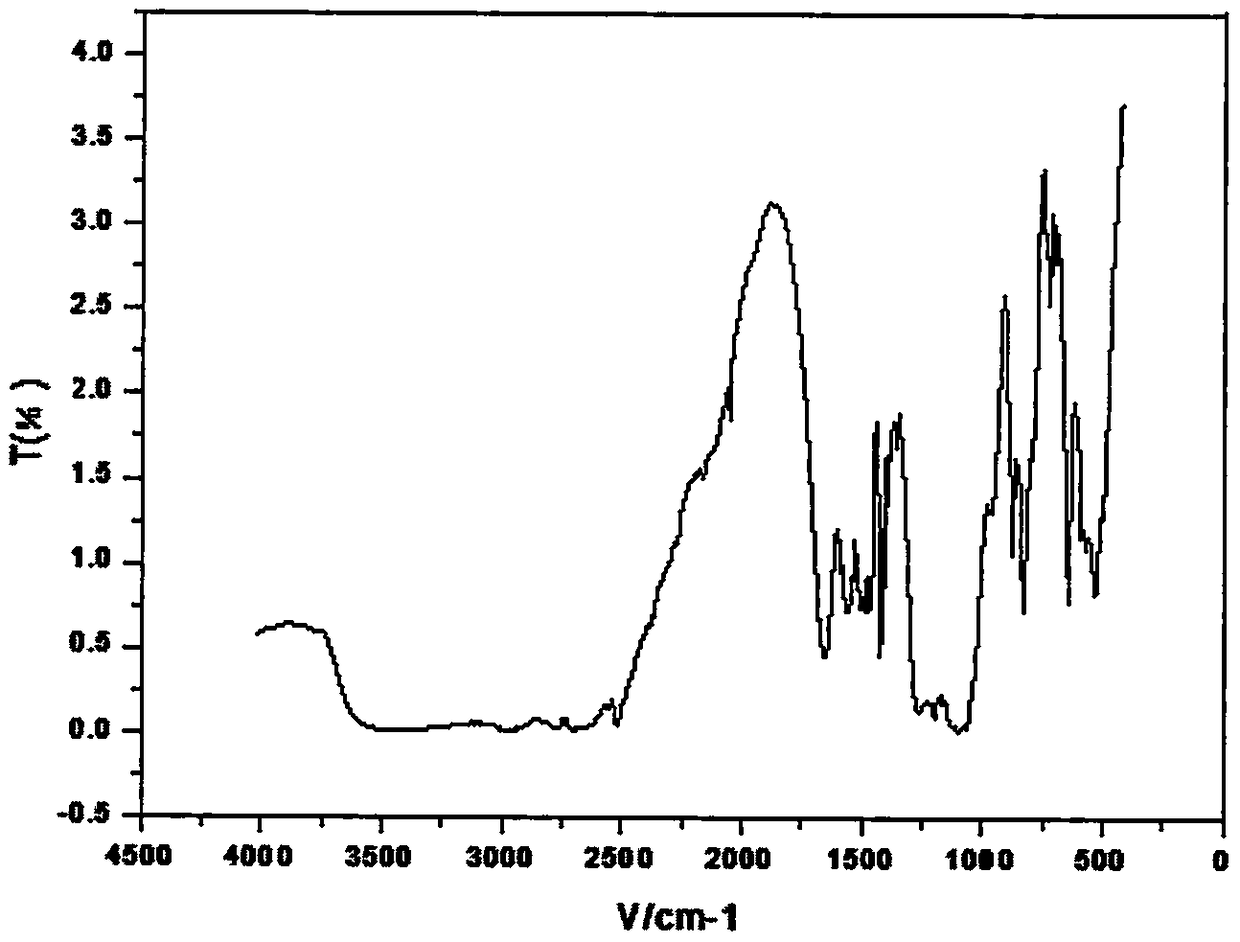

Novel bio-based phosphonitrile epoxy resin monomer and bio-based phosphorous-nitrogen epoxy resin prepared with same

ActiveCN109748935AAbundant raw materialsImprove flame retardant performanceGroup 5/15 element organic compoundsAdductAlkaline catalyst

Owner:GUANGDONG UNIV OF TECH

Piperazine-containing phosphorus-nitrogen type halogen-free flame retardant, and preparation method and use thereof

InactiveCN109608499AGood stabilityImprove flame retardant performanceFireproof paintsFlame-proof filament manufacture1-methylpiperazineCellulose

Owner:TIANJIN POLYTECHNIC UNIV

Special unsaturated polyester resin adhesive for quartz stone sheet material

InactiveCN106753148AImprove impact toughnessHigh bonding strengthNon-macromolecular adhesive additivesGas phasePhosphine oxide

The invention discloses a special unsaturated polyester resin adhesive for a quartz stone sheet material. The special unsaturated polyester resin adhesive is prepared from the following raw materials: unsaturated polyester resin, acrylic acid-2-hydroxyethyl ester, pentaerythritol triacrylate, 2-methyl-1-(4-methylthiophenyl)-2-morpholinyl-1-acetone, biphenyl-(2,4,6-trimethylbenzoyl)phosphine oxide, a flatting agent, a de-foaming agent, a silane coupling agent, gas-phase silicon dioxide, glass microsphere and modified aluminum hydroxide. The special unsaturated polyester resin adhesive for the quartz stone sheet material, provided by the invention, has high binding performance, good impacting toughness and excellent flame-retarding performance.

Owner:ANHUI AIDIBEI BIOLOGICAL CO LTD

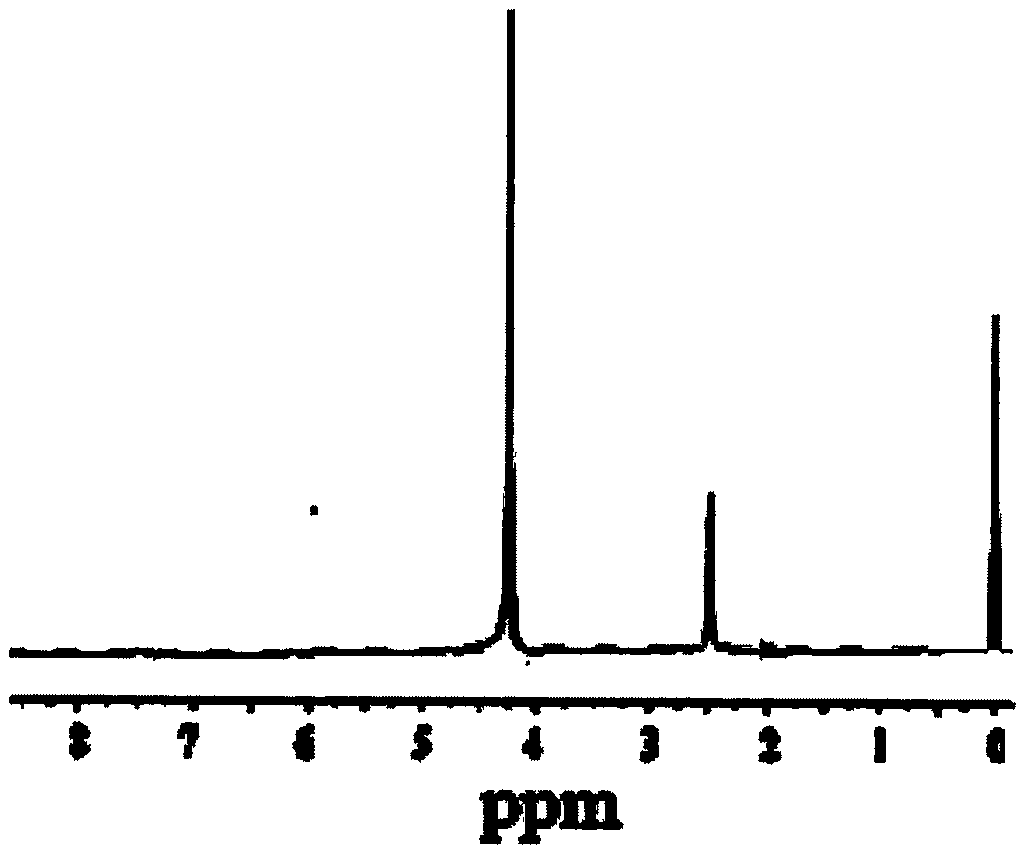

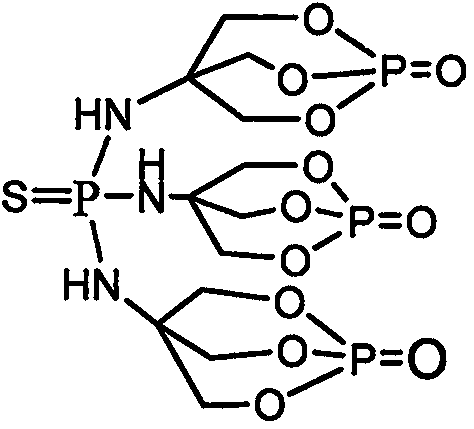

Flame retardant thiophosphoryl-(N,N',N'-tricaged phosphate) triamine compound and preparation method thereof

InactiveCN109232978AHigh mutual synergistic flame retardant performanceHigh decomposition temperatureGroup 5/15 element organic compoundsPolyesterDistillation

The invention relates to a flame retardant thiophosphoryl-(N,N',N'-tricaged phosphate) triamine compound and a preparation method thereof. The compound has a structure as shown in the formula in the specification. The preparation method comprises the following steps: adding amine of caged phosphate and triethylamine, cooling to 10 DEG C, dropwise adding phosphorus trichloride, controlling the dropwise adding temperature to be 10-20 DEG C, heating to 80-110 DEG C after dropwise addition is completed, insulating to react for 3-5 hours, cooling, filtering and drying in vacuum to obtain solid mixture a yellow target product and triethylamine hydrochloride; dissolving the solid mixture with dimethyl sulfoxide, filtering, and drying the filtrate by distillation to obtain the target product thiophosphoryl-(N,N',N'-tricaged phosphate) triamine. The compound is an excellent phosphorus-nitrogen synergistic flame retardant, is suitable for flame retardants of polyester, polyurethane, epoxy resin,unsaturated resin, polyvinyl chloride and other materials, is simple in process and less in equipment investment, and is easy to realize industrial production.

Owner:SUZHOU UNIV OF SCI & TECH

Core-shell type carbon microspheres and preparation method and application thereof

ActiveCN103102509AGood compatibilityImprove flame retardant performancePigment treatment with non-polymer organic compoundsCore shellD-Glucose

Owner:TAIYUAN UNIV OF TECH

Foaming material with modifying filler

InactiveCN103613836AIncrease elasticityStrong sound insulationLinear low-density polyethylenePolyvinyl chloride

The invention discloses a foaming material with modifying filler. The foaming material is characterized by being prepared from the following raw materials in parts by weight: 80-90 parts of linear low density polyethylene, 12-16 parts of SG-5 polyvinyl chloride, 20-24 parts of calcium carbonate powder, 2-3 parts of stearic acid, 2-3 parts of zinc oxide, 4-5 parts of azodicarbonamide, 5-7 parts of chlorinated paraffin, 3-5 parts of polyethylene terephathalate, 4-6 parts of titanium dioxide powder, 2-3 parts of triphenyl phosphite and 6-8 parts of modifying filler. Due to addition of the modifying filler, the foaming material has excellent flame retardant effect, and is further endowed with excellent mechanical property, good rebound resilience and strong sound insulation performance. The polyvinyl chloride foaming material simultaneously has the characteristics of heat insulation, light weight, low water absorption and the like. The foaming material also has the advantages that the operation is simple, the raw materials are easily available, and the cost is low.

Owner:ANHUI AOLO DOOR & WINDOW SYST ENG CO LTD

Impact-resistant conductive polyphenylene sulfide material and preparation method thereof

The invention belongs to the technical field of high polymer materials, and relates to an impact-resistant conductive polyphenylene sulfide material and a preparation method thereof. The impact resistant conductive polyphenylene sulfide material is prepared from the following components in parts by weight: 60-75 parts of PPS, 0.5-1 part of a lubricant, 0.5-0.8 part of epoxy resin, 8-15 parts of a toughening agent, 17-25 parts of carbon black and 0.5-2 parts of a coupling agent. The impact-resistant conductive polyphenylene sulfide material is prepared by using a high-speed pre-mixing dispersion one-step extrusion process. The impact-resistant conductive polyphenylene sulfide material provided by the invention has the characteristics of being good in mechanical property, good in flame retardancy, good in stability, easy to process, good in impact resistance and the like, and is applicable to packages of precise and advanced products of the electronic industry, the war industry and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Fire-resistant flame-retardant thermal conductivity variable material as well as preparation method and application thereof

Owner:SHANGHAI KETER POLYMER MATERIAL

Bromine-carbon flame-retardant type acrylate ester waterproof coating and preparation method thereof

The invention discloses a bromine-carbon flame-retardant type acrylate ester waterproof coating and a preparation method thereof. The bromine-carbon flame-retardant type acrylate ester waterproof coating comprises 40-60 parts of acrylic flame-retardant emulsion, 10-20 parts of organic silicone-modified acrylate ester emulsion, 0.4-1.3 parts of a defoaming agent, 0.1-0.8 parts of a dispersing agent, 20-40 parts of grinding calcite carbonate, 5-20 parts of titanium dioxide, 3-8 parts of chlorinated paraffin and 0.1-0.5 parts of a thickening agent. Through the combined use of the acrylic flame-retardant emulsion, the organic silicone-modified acrylate ester emulsion and other raw materials in the components, the waterproof coating has a synergistic effect, is resistant to high temperature and high in flame retardant performance, can realize long-term flame retardation and possesses high durability. Furthermore, the preparation process is simple and the product is high in security, thereby being worthy of popularization.

Owner:SICHUAN SHUYANG WATERPROOF MATERIAL

Flame-retardant wood-plastic material and preparation method thereof

InactiveCN106009170AImprove flame retardant performanceImprove waterproof performancePlastic materialsMelamine formaldehyde resin

The invention discloses a flame-retardant wood-plastic material, which is composed of the following raw materials in parts by weight: pentaerythritol 1-2, high-density polyethylene 170-200, ammonium polyphosphate 10-16, melamine 2-3, titanium Tetrabutyl acetate 6‑9, methyl triethoxysilane 30‑40, dimethyldiethoxysilane 27‑30, acetylacetone 0.3‑0.4, straw powder 120‑130, tributyl citrate 6‑ 8. Zinc borate hydrate 3‑4, ethylene bisstearamide 0.2‑1. The invention prepares silicon resin containing titanium, and mixes and modifies it with ammonium polyphosphate-coated melamine formaldehyde resin, so that the finished product not only has good flame retardancy, but also has good waterproof and heat resistance.

Owner:刘莹莹

Wear-resistant flame-retardant TPU material and preparation method thereof

The invention relates to the technical field of TPU materials, and particularly discloses a wear-resistant flame-retardant TPU material and a preparation method thereof. The TPU material is prepared from the following raw materials in parts by weight: 60 to 100 parts of polyurethane, 15 to 30 parts of epoxy resin, 3 to 10 parts of di-o-chlorodiphenylamine methane, 20 to 50 parts of polyethylene, 10 to 28 parts of modified calcium sulfate dihydrate whisker, 10 to 28 parts of composite flame retardant and 2 to 6 parts of silicone oil. The preparation method comprises the following steps: uniformly mixing the silicone oil and the modified calcium sulfate dihydrate whisker to obtain a mixture A; uniformly mixing polyurethane, epoxy resin, di-o-chlorodiphenylamine methane and polyethylene to obtain a mixture B; then adding the composite flame retardant into the mixture B, and uniformly stirring to obtain a mixture C; finally, uniformly mixing the mixture A and the mixture C to prepare the wear-resistant and flame-retardant TPU material. The wear-resistant flame-retardant TPU material disclosed by the invention has the advantages of high wear resistance and high flame retardance.

Owner:RONGWEIDA OPTOELECTRONICS (DONGGUAN) CO LTD

Thermal-insulating flame resistant foam material

The invention discloses a thermal-insulating flame resistant foam material. The thermal-insulating flame resistant foam material is characterized by being prepared from the following raw materials in parts by weight: 35-47 parts of acrylonitrile-butadiene-styrene copolymer, 5-21 parts of thiocyanate, 13-21 parts of zinc borate, 10-40 parts of polypropylene, 15-31 parts of ethyl hexyl ester of epoxidized soybean oil, 5-12 parts of dibutyl sebacate, 1-7 parts of molybdenum disulfide, 15-20 parts of aluminum hydroxide, 5-7 parts of red phosphorus, 5-11.5 parts of diacetone salt, 2-10 parts of talcum powder and 10-20 parts of oleic acid. The thermal-insulating flame resistant foam material is enabled to have rare excellent flame retardant efficiency, and simultaneously maintain the advantages such as thermal insulation, low weight and low water absorption.

Owner:QINGDAO HUA CHENG TIAN MACHINERY MFG

Flame-retardant modified silane polyether adhesive

InactiveCN107974229AHigh bonding strengthImprove flame retardant performanceNon-macromolecular adhesive additivesPolyether adhesivesPolymer sciencePlasticizer

The invention provides a flame-retardant modified silane polyether adhesive. The flame-retardant modified silane polyether adhesive disclosed by the invention is prepared from the following raw materials calculated in parts by weight: 10 to 30 parts of modified silane polyether resin 30000 T, 1 to 5 parts of fumed silica, 1 to 5 parts of a silane coupling agent, 1 to 10 parts of a flame-retardantcomplex additive, 60 to 70 parts of powder, 0.1 to 0.5 part of a light stabilizer, 10 to 20 parts of a plasticizer, 0.1 to 0.3 part of a catalyst, and 0.1 to 0.5 part of an oxidant. The flame-retardant modified silane polyether adhesive disclosed by the invention is high in bond strength, and better in elongation and tensile strength and good in flame retardancy, wherein the bond strength is morethan 1.4 MPa, the elongation is more than 550%, the tensile strength is more than 3.6 MPa, and the flame retardancy can reach the levels V-1 and V-0.

Owner:SUZHOU QIYUE NEW MATERIAL TECH CO LTD

Diaphragm for efficient lithium ion secondary battery and preparation method thereof

ActiveCN111341975AImprove flame retardant performanceReduce the risk of explosionSecondary cellsCell component detailsActivated carbonSurface oxidation

The invention discloses a diaphragm for an efficient lithium ion secondary battery. The diaphragm comprises polyethylene microporous layers and a composite material coating. The thickness of each polyethylene microporous layer is 5-10 [mu]m, the pore diameter is 0.03-0.12 [mu]m, and the porosity is 40-50%. The thickness of each composite material coating is 5-10 [mu]m. The material coating comprises the following raw materials in parts by weight: 90-95 parts of organic silicon resin, 5-10 parts of modified activated carbon and 20-30 parts of a curing agent, wherein the water content of the organic silicon resin is 0.5-1%, the modified activated carbon is modified activated carbon obtained by surface oxidation, and the modified activated carbon is nano modified activated carbon. The diaphragm comprises the polyethylene microporous layers and the composite material coating, and is specifically of a polyethylene-composite material-polyethylene layered structure, and organic silicon resinin the composite material layer has good flame retardance, so that the explosion risk of the battery is reduced.

Owner:SICHUAN YOUYUAN NEW ENERGY CO LTD

Flame-retardant reinforced modified PE (polyethylene) composite material and preparation method thereof

InactiveCN103849057AImprove flame retardant performanceHigh mechanical strengthPolymer scienceHeat resistance

The invention discloses a flame-retardant reinforced modified PE (polyethylene) composite material and a preparation method thereof. The flame-retardant reinforced modified PE composite material comprises the following components in percentage by mass: 30-60% of PE, 20-30% of flame retardant, 10-40% of filling reinforcing agent, 0.1-1% of coupling agent, 0.1-1% of antioxidant and 0.1-1% of lubricant. The flame-retardant reinforced modified PE composite material and the preparation method thereof, disclosed by the invention, have the following beneficial effects: compared with the prior art, the PE composite material prepared by the method has the characteristics of high flame retardance, high mechanical strength, high heat resistance, low cost and the like; the flame-retardant property of the PE composite material can reach the UL94V-0 flame retardant grade. The flame-retardant reinforced modified PE composite material provided by the invention is simple in preparation process and convenient in use, and can be used for realizing the industrial automatic production.

Owner:QINGDAO SANLI ZHONGDEMEI WATER EQUIP

Energy-saving and environment-friendly thermal insulation material and preparation method thereof

The invention provides an energy-saving and environment-friendly thermal insulation material and a preparation method thereof. The energy-saving and environment-friendly thermal insulation material comprises the following components in parts by weight: 60 to 80 parts of polystyrene, 2 to 6 parts of nanometer titania, 2 to 4 parts of nano-aluminium hydroxide, 10 to 14 parts of cross-linking agent, 20 to 30 parts of PPF fiber, 15 to 22 parts of mineral waste residue, 10 to 14 parts of epoxy resin, 8 to 16 parts of foaming agent, and 45 to 60 parts of water. The preparation method comprises the steps of uniformly mixing the components, injecting into a mold, extruding in a spacing way, and maintaining for 8 to 12h under sustained pressure. The thermal insulation material has a higher flame retardant property, a lower heat conductivity coefficient and higher breaking strength.

Owner:HEFEI GUANGNENG NEW MATERIAL TECH CO LTD

Halogen-free flame-retardant epoxy resin and preparation method thereof

InactiveCN109467680AImprove flame retardant performanceUniform flame retardant performanceEpoxyHalogen

The invention discloses a halogen-free flame-retardant epoxy resin. The halogen-free flame-retardant epoxy resin is prepared from the following components in parts by weight: 100 to 150 parts of epoxyresin, 15 to 30 parts of a curing agent, 5 to 8 parts of a dispersant, 20 to 30 parts of hydroxylated multi-walled carbon nano-tubes and 5 to 10 parts of a halogen-free flame retardant. The halogen-free flame-retardant epoxy resin does not contain a halogen flame retardant; the flame retarding effect is good and uniform; the oxygen index can reach 30 percent or above.

Owner:SUZHOU SIRGEL RESINS SPECIALTIES CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap