Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

15 results about "Antistatic agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An antistatic agent is a compound used for treatment of materials or their surfaces in order to reduce or eliminate buildup of static electricity. Static charge may be generated by the triboelectric effect or by a non-contact process using a high voltage power source. Static charge may be introduced on a surface as part of an in-mold label printing process.

Antistatic teflon film and preparation thereof

InactiveCN101481483ADoes not affect electrical insulationImprove mechanical propertiesOther chemical processesTetrafluoroethyleneAntistatic agent

Owner:广州市东泓氟塑料股份有限公司

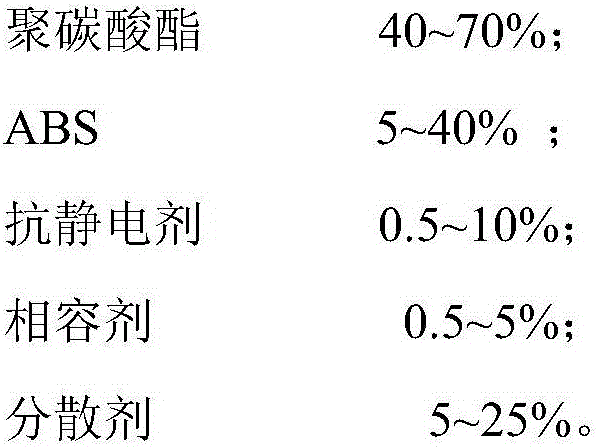

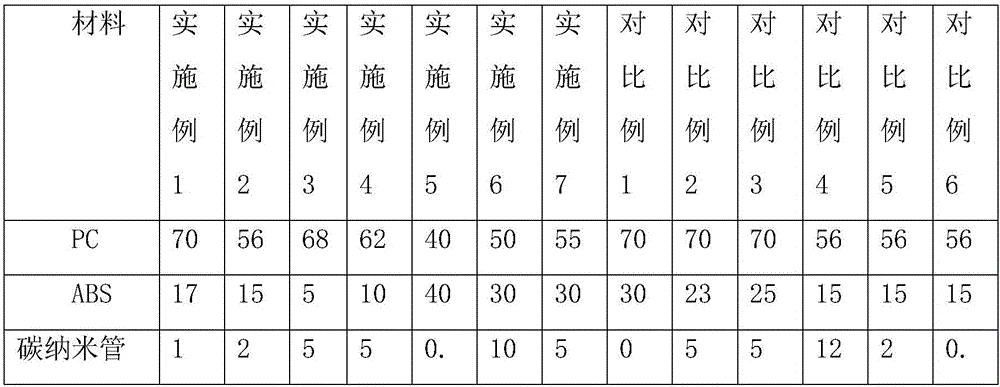

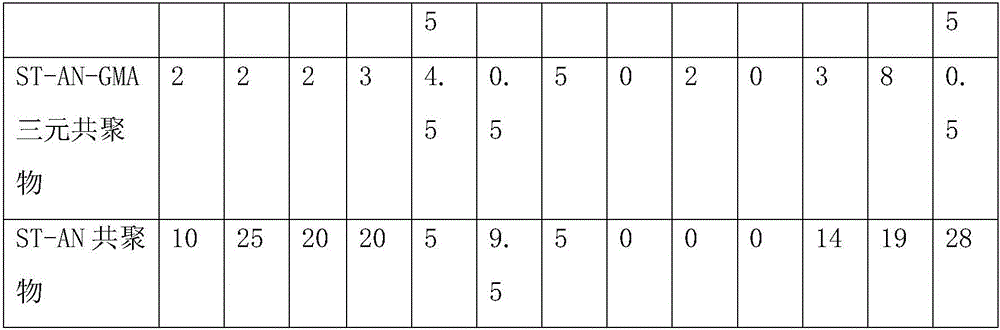

Efficient anti-static PC/ABS (Polycarbonate/Acrylonitrile Butadiene Styrene) composite material and preparation method thereof

Owner:FINE BLEND POLYMER SHANGHAI CO LTD

Highly effective antistatic agglomerate for biaxial tension polypropylene and its preparation method

InactiveCN1765970AAdd lessLong-term stabilityAntistatic agentBiaxial tension

The invention relates to a highly effective antistatic agglomerate for biaxial tension polypropylene and its preparation method, wherein the agglomerate comprises raw materials of the following constituents (by weight proportion): polypropylene 70-90%, antistatic agent 8-30%, grinding agent 0.1-1%, dispersing agent 0.1-2%, anti-oxidant 0.1-1%, inhibiting agent 0.1-0.5%, anti-ageing 0.1-0.5%.

Owner:SHANGHAI SUNNY

Production process of polyester water-resistant emery cloth with high adhesive power

InactiveCN107139087AImprove waterproof performanceLower surface energyNon-macromolecular adhesive additivesLiquid surface applicatorsEpoxyRubber material

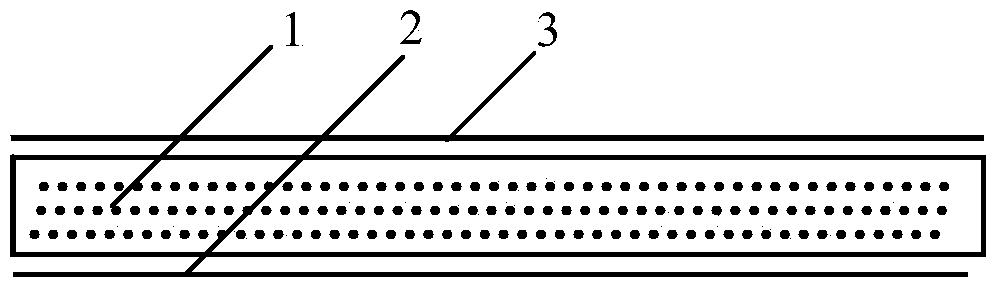

The invention discloses a production process of high-adhesion polyester water-resistant abrasive cloth, which adopts water-resistant sandpaper as a cloth base for production; after scraping the sand-planted surface of the cloth base, corona treatment is performed on the sand-planted surface of the cloth base; Squeegee coating material, base rubber material and re-adhesive compound are all added with heat-dissipating materials and heat-conducting materials; the abrasive used for sand planting is diamond abrasive grain; the diamond abrasive grain layer (3) is coated with a re-adhesive layer (4) , the substrate (1) is a non-woven material; by mass percentage, the components of the primer layer (2) and the contents of each component are: 50% to 75% of epoxy modified phenolic resin, 15% to 15% of softening agent 35%, thickening lubricant 2%~5%, tackifier 8%~15%, the sum of the mass percentages of the above-mentioned components is 100%; by mass percentage, the components and The content of each component is: 60%-75% of water-based epoxy resin, 2%-10% of internal mixed antistatic agent, 15%-35% of auxiliary materials, and the sum of the mass percentages of the above-mentioned components is 100%.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

Antistatic anti-flaming PC/ABS compound material and preparation method thereof

The invention discloses an antistatic and flame-resistant PC / ABS composite material and a preparation method thereof. The composite material comprises 60-80 parts of PC resin; 8-15 parts of ABS resin; 8-12 parts of flame retardant; toughening agent 1-5 parts; antistatic agent 8-25 parts; antioxidant 0.01-2 parts; other additives 0.4-0.8 parts. The present invention selects the preferred antistatic agent, which minimizes the impact on PC performance, and the use of the antistatic agent in conjunction with the emulsion method ABS is beneficial to the antistatic effect of the antistatic agent and can last.

Owner:SHANGHAI KINGFA SCI & TECH +2

Lightning protected cable for communication base station

ActiveCN103325489ALower the resistance valueSmall short-term calorific valueCommunication cablesInsulated cablesAluminium hydroxideEngineering

The invention belongs to the technical field of cables and relates to a lightning protected cable for a communication base station. The lightning protected cable for the communication base station comprises a cable core, an inner protecting sleeve, an armor layer, an outer protecting sleeve and a ground layer. The lightning protected cable for the communication base station is characterized in that a first protecting layer is arranged outside the cable core, the inner protecting sleeve is arranged outside the first protecting layer, a second protecting layer is arranged outside the inner protecting sleeve, the ground layer is arranged outside the second protecting layer, the armor layer is arranged outside the ground layer, and the armor layer is coated with the outer protecting sleeve; the armor layer is a single-face film covering steel belt and the face, in contact with the ground layer, of the armor layer is a non-film-covering face; the first protecting layer and the second protecting layer are both mica tapes; the outer protecting sleeve comprises, by weight, the following raw materials of 71 parts of polyethylene, one part of anti-oxygen 1010, 12 parts of aluminum hydroxides, 0.5 part of HK-type antistatic agent, 3 parts of ethyl acetate, 1 part of carbon black, 10 parts of zirconium oxide and 1.5 parts of polyethylene wax. The lightning protected cable for the communication base station has the advantages of being simple in manufacturing, high in production speed, capable of enabling the electrical resisting rate of the ground layer to be low, low in maintaining cost, small in dust adsorption, pressure resistant, and good in flame resistance.

Owner:JIANGSU ZHONGLI GRP CO LTD

Preparation method and preparation device for PET multi-layer composite sheet

The invention discloses a preparation method of a PET multi-layer composite sheet. The preparation method comprises the following steps: (1) treating a PET raw material and a PETG raw material respectively; (2) mixing the treated PET raw material and PETG raw material by a metering pump; (3) carrying out upper-layer and lower-layer distribution for the two types of raw materials through a material distributor; (4) obtaining a sheet from the raw materials treated by upper and lower layering through a molding die head; (5) cooling and sizing the obtained sheet by water of 30 degrees; (6) coating the sheet with a lubricating agent and an antistatic agent after intermediate sizing by a push coating device; (7) drying the sheet after being coated with the lubricating agent and the antistatic agent; (8) cutting boundary materials of the obtained sheet according to required specifications; and (9) drawing out the sheet with the boundary materials being cut, and then rolling to obtain a finished product. According to the preparation method disclosed by the invention, the PET multi-layer composite sheet can be produced by the device, and the device can be used for changing physical properties of the PET multi-layer composite sheet.

Owner:SHANGHAI KUNYUAN NEW MATERIALS CO LTD

Medical non-woven fabric composite and preparation method and application thereof

InactiveCN106120152AElectroconductive/antistatic filament manufactureMelt spinning methodsChemistryAntistatic agent

Owner:朱小涛

Antistatic geothermal floor

InactiveCN104234374AFast heat conductionImprove the status quo of performance defectsFlooring insulationsWater-setting substance layered productMagnesiumAntistatic agent

The invention relates to an antistatic geothermal floor. The antistatic geothermal floor is characterized by comprising a decorative layer on an upper surface, an antistatic layer on a lower surface, and a core layer sandwiched between the upper surface layer and the lower surface layer, wherein the core layer is a sheet material made of magnesium oxysulfate cement and bamboo fibers. The antistatic geothermal floor has the beneficial benefits that 1, the magnesium oxysulfate cement which has high combination degree with the bamboo fibers and does not corrode the bamboo fibers covers the bamboo fibers to form a floor core layer which meets a fire resistance requirement, the antistatic layer is compounded on the lower surface of the core layer to meet the requirement of a geothermal floor, and the present situation that the existing geothermal floor has defective performance is improved; 2, the sheet material for manufacturing the core layer is made of a mixture in a semi-dry state, and is formed by pressing, maintaining pressure and curing, so that the requirement of high strength of the antistatic geothermal floor is met; 3, the antistatic layer made of a composite material meets an antistatic requirement, and meanwhile, has high heat conductivity, so that the heat conductivity of the floor is improved, the utilization rate of heat is improved, and energy conservation and emission reduction are facilitated.

Owner:NG TERASUN AIR DUCT

Shell plastic for computer display screens and preparation method of shell plastic

InactiveCN107163494AGood acid and alkali resistanceGood high temperature resistancePolyvinyl chlorideEngineering

Owner:HEFEI SIBOT SOFTWARE DEV CO LTD

Antibacterial and anti-static paint and preparation method thereof

InactiveCN106519927AGood dispersionImprove adhesionFireproof paintsAntifouling/underwater paintsEpoxyAntistatic agent

Owner:WUXI BENNIU BIOTECH CO LTD

Thermally developable materials with backside antistatic layer

ActiveUS20070072772A1Good electrical conductivityPhotosensitive materialsAblative recordingAntistatic agentConductive polymer

Owner:CARESTREAM HEALTH INC

Anti-static warning tape base material

InactiveCN103497447AImprove waterproof performanceImprove moisture resistanceFilm/foil adhesivesAntistatic agentPolyvinyl chloride

Owner:SUZHOU HUAZHOU TAPE

Mildew-proofing and antibacterial PVC modified material used for placemats and preparation method of same

InactiveCN107286517AImprove anti-mold and anti-bacterial propertiesImprove anti-static effectWeather resistanceAntistatic agent

Owner:广东祺龙科技有限公司

High-strength food packaging film and manufacturing method thereof

Owner:ANHUI YILIN PLASTIC IND CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap