Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48 results about "Polytetrafluoroethylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene that has numerous applications. The well-known brand name of PTFE-based formulas is Teflon by Chemours. Chemours was a spin-off from DuPont, which originally discovered the compound in 1938. Another popular brand name of PTFE is Syncolon by Synco Chemical Corporation.

Downhole Well Communications Cable

ActiveUS20120031607A1High service temperaturePlastic/resin/waxes insulatorsCommunication cablesVinyl etherTetrafluoroethylene

Owner:THE CHEMOURS CO FC LLC

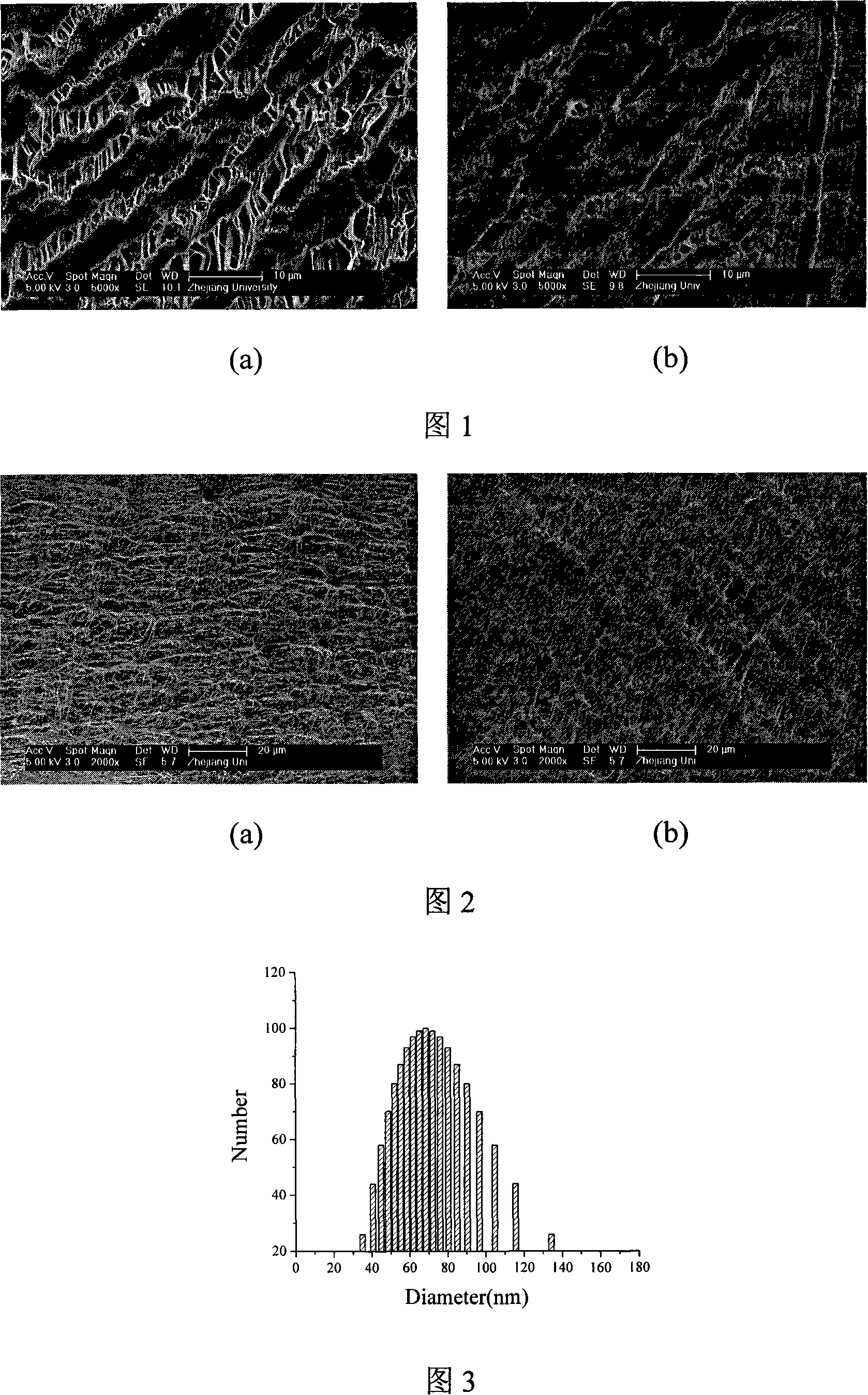

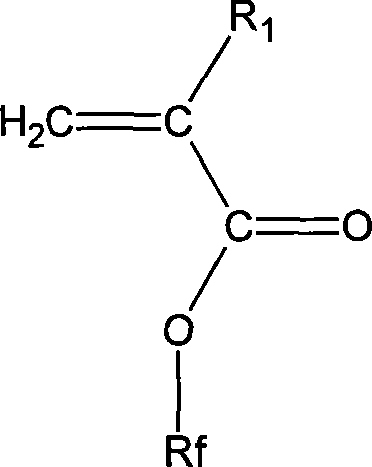

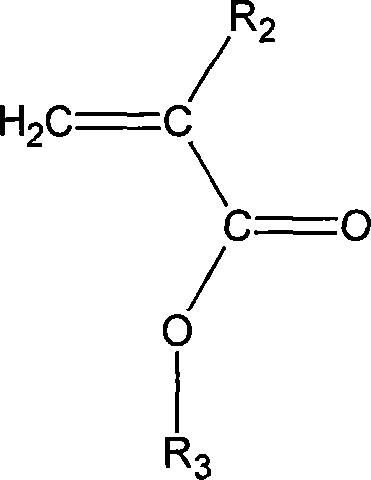

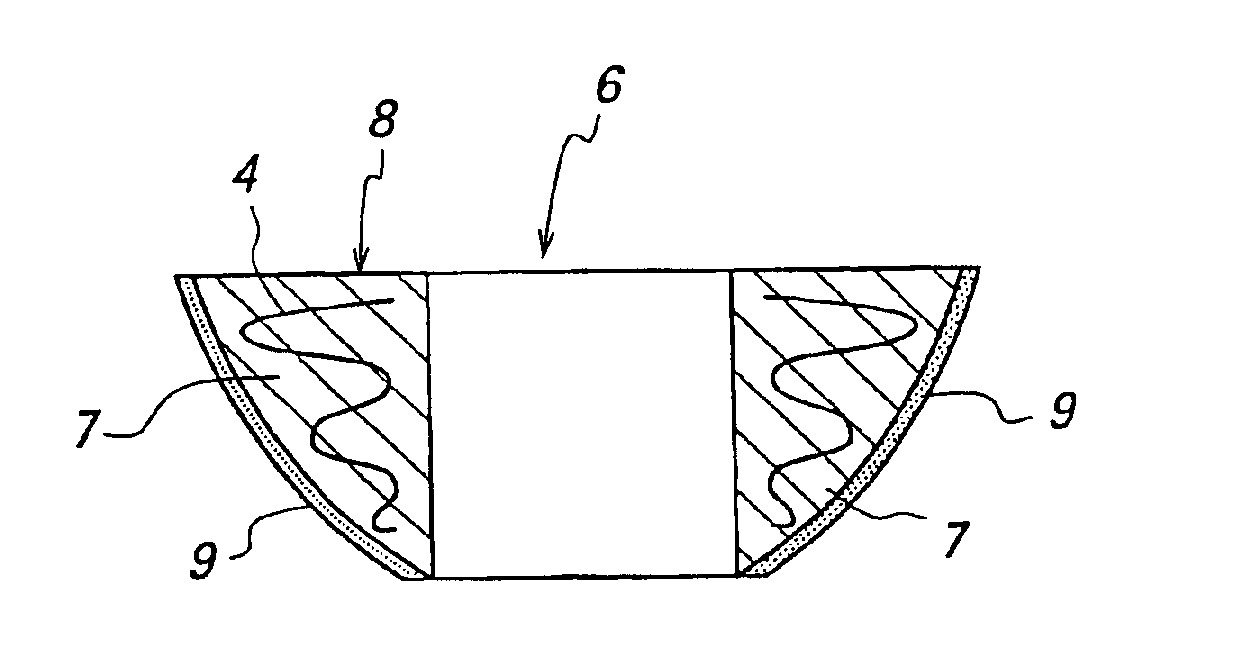

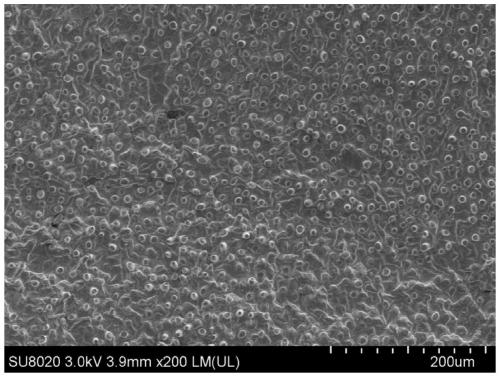

Method of amphipathic nature fluorine-contained copolymer modifying surface of polytetrafluoroethylene porous membrane

InactiveCN101108313AImprove anti-pollution performanceImprove hydrophilic abilitySemi-permeable membranesFiberTetrafluoroethylene

Owner:ZHEJIANG UNIV

Antistatic teflon film and preparation thereof

InactiveCN101481483ADoes not affect electrical insulationImprove mechanical propertiesOther chemical processesTetrafluoroethyleneAntistatic agent

Owner:广州市东泓氟塑料股份有限公司

Polyetrafluoroethylene micropowder compositions

InactiveUS20070100077A1Improve performanceSpecial tyresPigment pastesTetrafluoroethylenePolymer science

A micropowder composition containing a granular PTFE micropowder, a fine powder PTFE micropowder, and a fine powder molding resin provides mixtures with fluoroelastomers containing copolymerized and alternating units of tetrafluoroethylene and propylene that provide molded articles having improved surface smoothness characteristics and tear resistance on molding. Processes for mixing additives with fluoroelastomers by adding or mixing the fluoroelastomer with the additives in the presence of micropowder PTFE compositions.

Owner:AGC CHEM AMERICAS INC

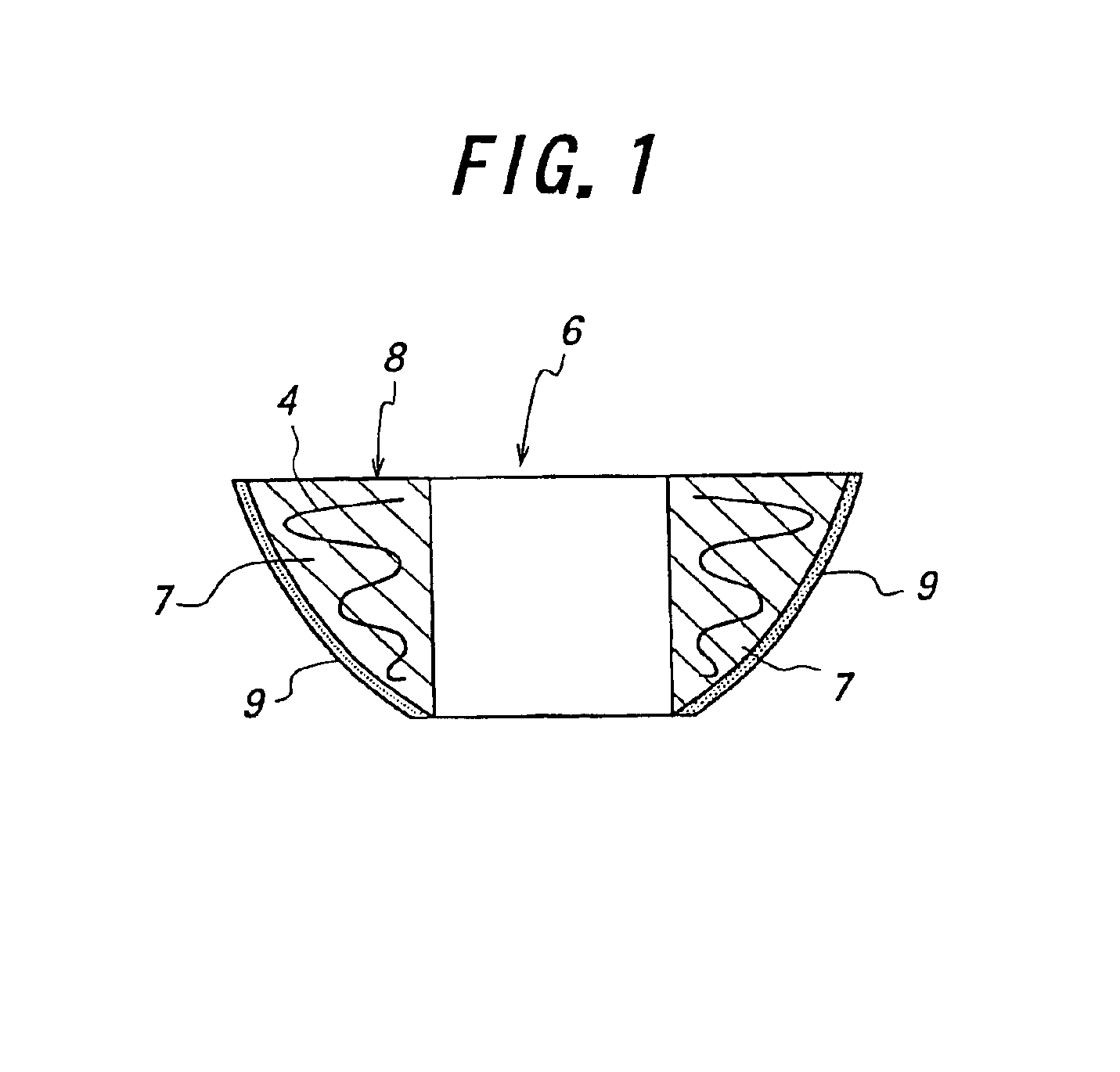

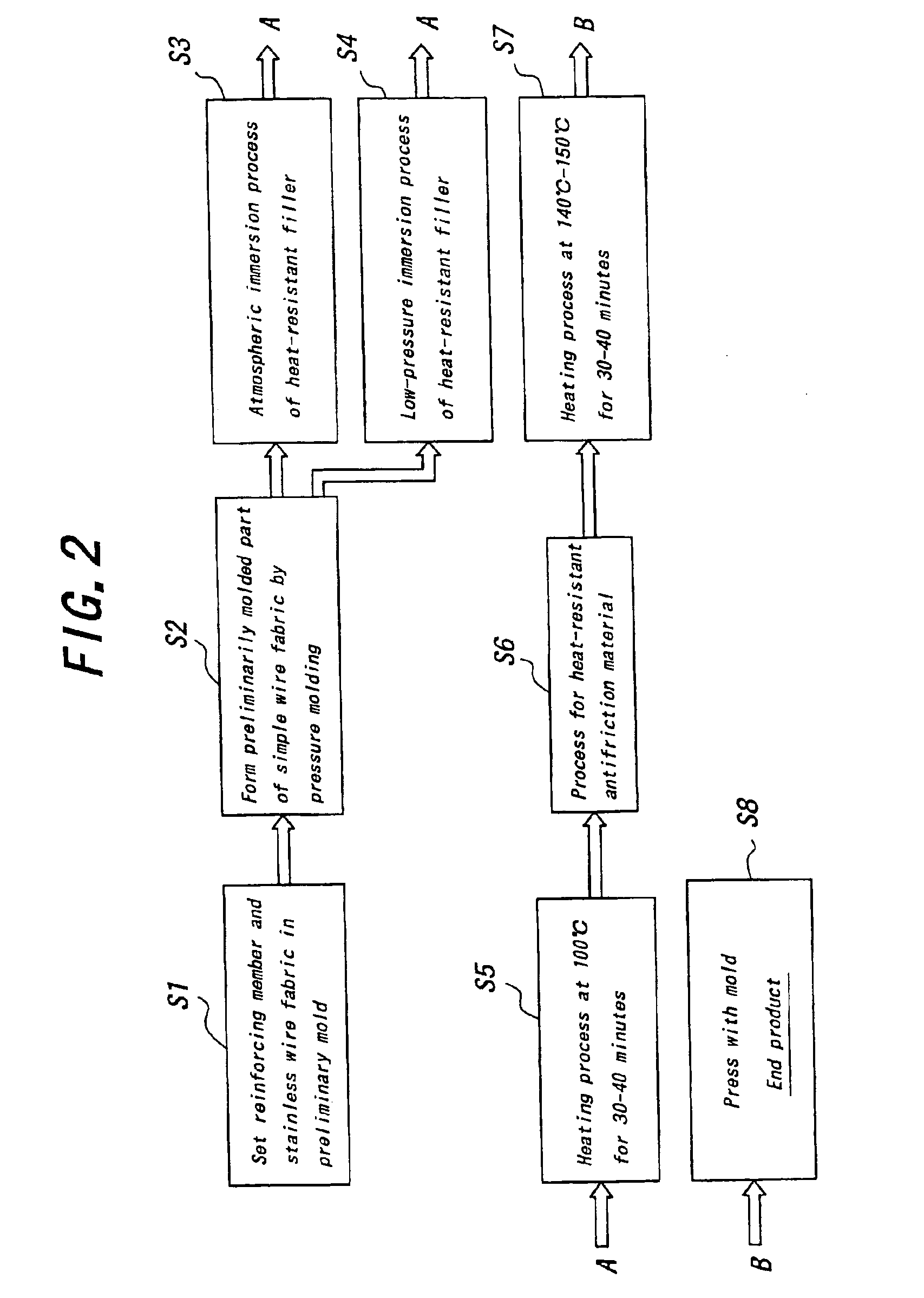

Gasket for high-temperature joint and method of fabricating the same

InactiveUS6889983B2Flowability of solution is reducedHigh strengthEngine sealsFlanged jointsBoron nitridePolytetrafluoroethylene

Owner:HONDA MOTOR CO LTD +1

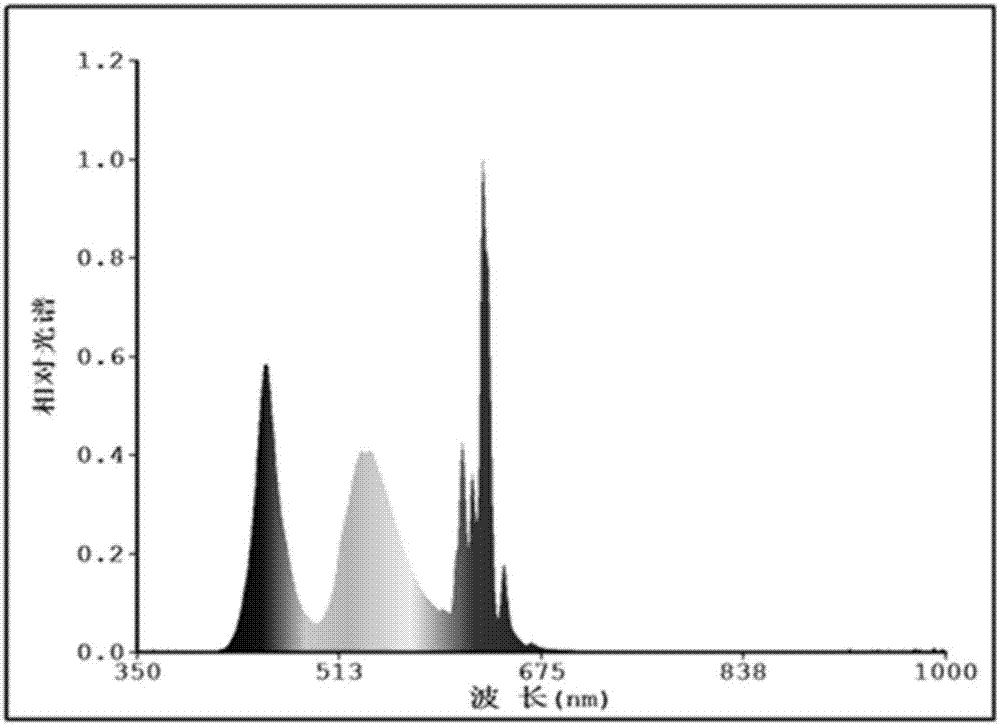

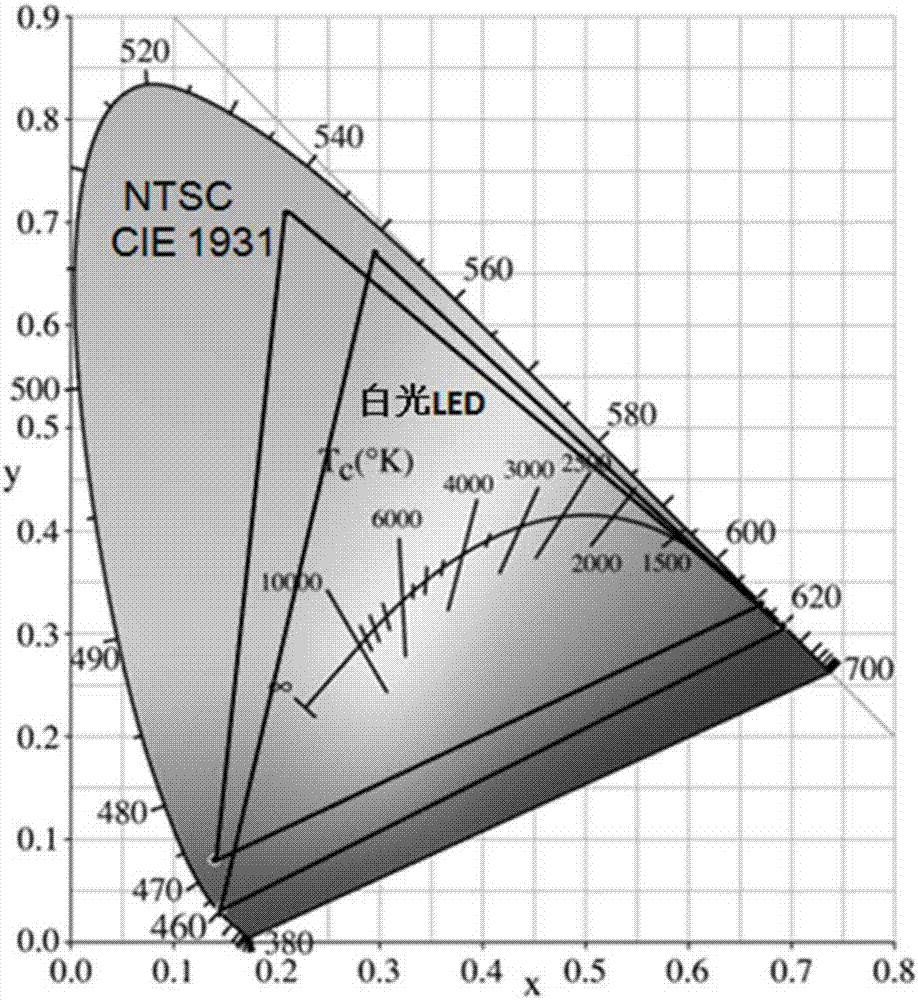

Mn<4+> doped fluoroaluminate red fluorescent powder as well as preparation method and application thereof

InactiveCN107384382ANarrow emission spectrumImprove luminous efficiencyLuminescent compositionsSemiconductor devicesHydrofluoric acidAqueous solution

Owner:HEFEI UNIV OF TECH

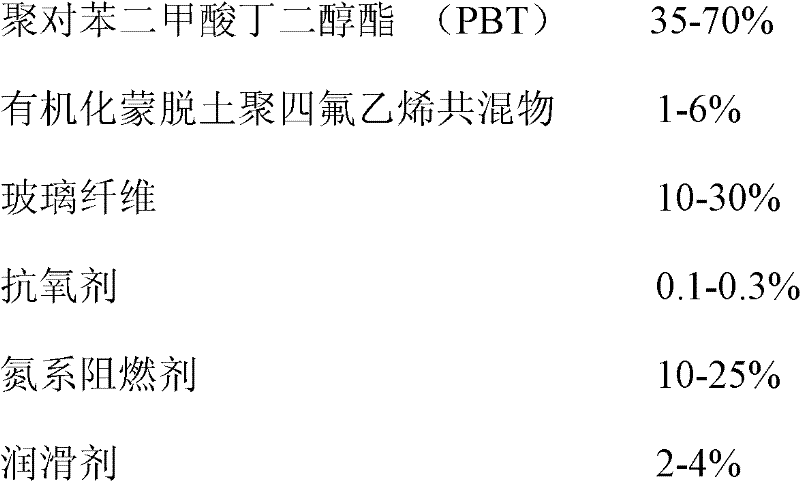

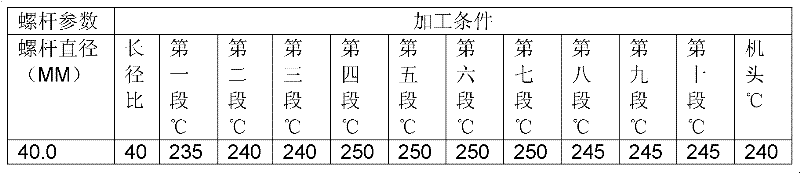

Halogen-free flame-retardant polybutylene terephthalate PBT (polybutylece terephthalate) composite material and preparation method thereof

ActiveCN102391624APhenomenon that limits floating fibersExcellent surface finishPolytetramethylene terephthalateAlkali free

Owner:LONGJAR SHANGHAI IND

Template-free preparation method for double-metal multi-shell yolk-shell nano hollow spheres

InactiveCN108585062AEasy to makeImprove securityZinc oxides/hydroxidesCobalt oxides/hydroxidesYolkGlycerol

The invention discloses a template-free preparation method for double-metal multi-shell yolk-shell nano hollow spheres. The preparation method comprises the following steps: (1) dissolving a metal salt and a terephthalic acid in a mixed solvent consisting of N-N dimethyl formamide and glycerol, and carrying out stirring to form a uniform and transparent solution; (2) moving the material obtained in the step (1) into a reaction kettle having a polytetrafluoroethylene lining, and carrying out a reaction; and (3) carrying out centrifugal washing on the reaction product obtained in the step (2) byusing a polar solvent, then carrying out drying, placing the dried reaction product into a muffle furnace, carrying out heating, and carrying out cooling to obtain the double-metal multi-shell yolk-shell nano hollow spheres. According to the preparation method, templates are not required, the preparation process is simple and is easy to repeat, the safety is high, and the method has a wide application prospect.

Owner:XIAMEN UNIV

Method of synthesizing nano zinc silicate light emitting material by using waste silicon powder by hydrothermal method

InactiveCN104087289ATo achieve the purpose of resource recyclingSimple methodLuminescent compositionsPolytetrafluoroethyleneMaterials science

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Preparation method of graphene quantum dots

ActiveCN110540192AHigh fluorescence yieldImprove stabilityMaterial nanotechnologyGrapheneFluorescenceFiltration

Owner:SHANGHAI SIXTH PEOPLES HOSPITAL

Moisture-proof agent for storage of powder coating for film forming by electrostatic spraying

InactiveCN107337955AReduced hygroscopicityGood moisture resistancePowdery paintsEpoxy resin coatingsPolyglutamic acidPolytetrafluoroethylene

The invention discloses a moisture-proof agent for storage of a powder coating for film forming by electrostatic spraying, and relates to the technical field of powder coatings. The moisture-proof agent is prepared from the raw materials in parts by weight as follows: 10-15 parts of hydrophobic fine silica aerogel, 5-10 parts of glycerol monostearate-polyglutamic acid-dodecanol, 5-10 parts of N-(hydroxymethyl)acrylamide, 1-5 parts of chlorinated polyvinyl chloride, 1-5 parts of ultrafine magnesium oxide, 0.5-2 parts of polytetrafluoroethylene ultrafine powder, 0.5-2 parts of carnauba wax and 50-100 parts of absolute ethanol. After 3%-5% by mass of the moisture-proof agent is added to the powder coating, excellent moisture-proof performance can be developed, the resistivity and dielectric constant of the powder coating are prevented from being affected by agglomeration due to moisture absorption during storage and use, and accordingly, smooth implementation of electrostatic spraying of the powder coating and quality of a formed film are ensured.

Owner:ANHUI ZHIBO NEW MATERIAL TECH CO LTD

Insulated fireproof coating for optical cables

InactiveCN105567024AExcellent physical and chemical propertiesDry fastFireproof paintsEpoxy resin coatingsFiberEpoxy

Owner:FUXIN POWER SUPPLY COMPANY STATE GRID LIAONING ELECTRIC POWER +1

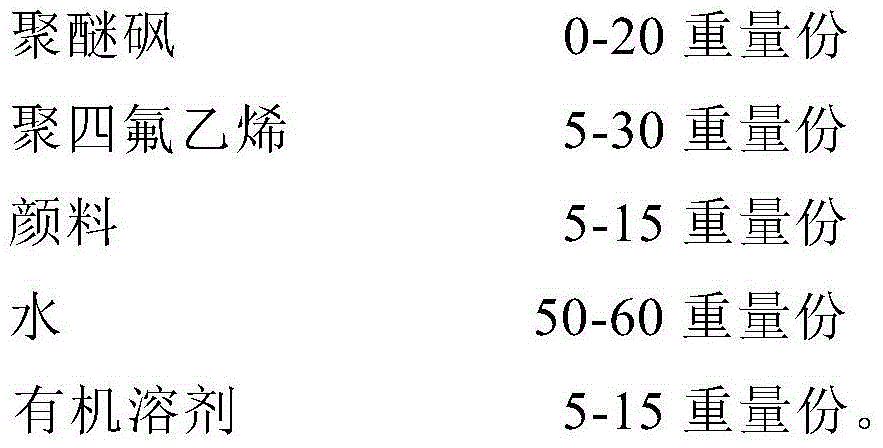

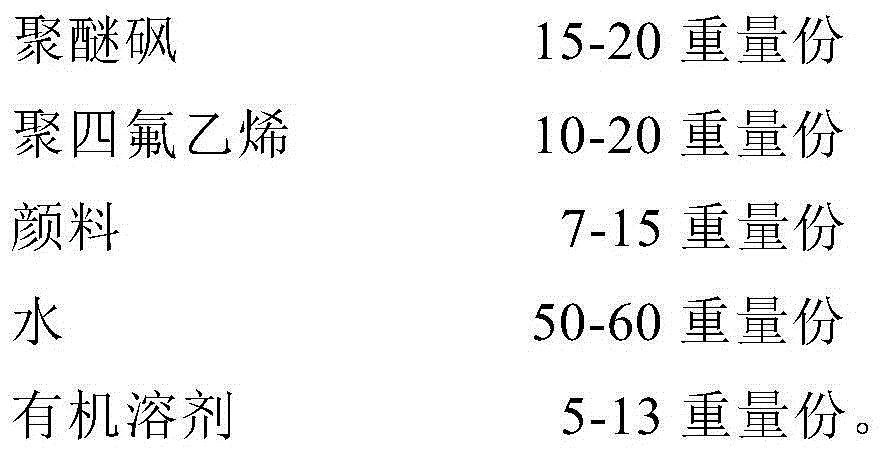

Non-stick coating layer and coating process thereof

InactiveCN111171682ASmall coefficient of static frictionLower coefficient of dynamic frictionPretreated surfacesSpecial surfacesPolymer sciencePapermaking

The invention discloses a non-stick coating layer, which is prepared from the following raw materials in parts by weight: 40 to 50 parts of epoxy acrylate, 25 to 32 parts of polyacrylic acid fluorine-containing ester, 25 to 32 parts of poly (vinylidene fluoride-trifluoroethylene), 10 to 15 parts of polytetrafluoroethylene powder, 2.5 to 4 parts of a suspension dispersing agent, 1 to 1.4 parts of aleveling agent and 1.5 to 2 parts of a curing agent. The non-stick coating layer has excellent lubricating performance and excellent non-stick performance, can completely meet the use requirements ofvarious processing molds (such as various plastic demolding, baking molds and papermaking and textile industries), contains no demolding agent (the production efficiency can be improved), and has excellent durability; in addition, no silicone oil is contained, and the product is prevented from being polluted; the adhesive force with a base material is large, the loading capacity is large, the impact resistance is good, the flexibility is good, the comprehensive performance is good, and the service life is long.

Owner:CHENGRUN (JIAXING) NEW MATERIAL TECH CO LTD

Separation method of waste polyphenylene sulfide and polytetrafluoroethylene blended dust settling pockets

The invention relates to a separation method of waste polyphenylene sulfide and polytetrafluoroethylene blended dust settling pockets. The separation method comprises the steps that the waste polyphenylene sulfide and polytetrafluoroethylene blended dust settling pockets are firstly smashed, then the smashed mixed materials are added into a separating medium with the density between the density of polyphenylene sulfide and the density of polytetrafluoroethylene for centrifugal separation, blended fabric is smashed according to the different densities of two fibers, and the aim of recycling polyphenylene sulfide and polytetrafluoroethylene in the waste dust settling pockets is achieved through centrifugal separation. The purity of polyphenylene sulfide materials obtained after separation reaches 97% or above, the purity of polytetrafluoroethylene materials reaches 91% or above, the material separation purity is high, the separation effect is good, and the recycling value is high.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

Core-shell Au@TiO2 nano-particles and preparation method thereof

InactiveCN105537583ALarge specific surface areaUniform particle sizeMaterial nanotechnologyTransportation and packagingTitanium tetrafluorideNanoparticle

The invention discloses core-shell Au@TiO2 nano-particles and a preparation method thereof. Cores of the nano-particles are made of Au, and shells of the nano-particle are made of TiO2. The preparation method of the core-shell Au@TiO2 nano-particles includes the following steps that (1) 0.3-6 ml of a 0.01M tetrachloroauric acid aqueous solution is prepared; (2) 4.5 ml of a 0.01M sodium citrate aqueous solution is added, and the mixture is stirred for 2 min; (3) 0.3-6 ml of a 0.01M ascorbic acid aqueous solution is added, and the mixture is stirred for 5 min; (4) then 0.5-6 ml of a 0.04M titanium tetrafluoride aqueous solution is added, and the mixture is evenly mixed and then diluted to 80 ml with distilled water added therein; (5) the mixture is transferred to a stainless steel reaction kettle with polytetrafluoroethylene serving as a liner, and the stainless steel reaction kettle is heated for 48 h in an electric furnace and naturally cooled to the room temperature finally; and (6) products are washed with deionized water and dried in a drying oven, so that the Au@TiO2 nano-particles of core-shell structures are obtained. The products obtained by the method are uniform in particle size, large in specific surface area and controllable in shape, and the core-shell structures in different diameters can be obtained.

Owner:HARBIN INST OF TECH

Shell plastic for computer display screens and preparation method of shell plastic

InactiveCN107163494AGood acid and alkali resistanceGood high temperature resistancePolyvinyl chlorideEngineering

Owner:HEFEI SIBOT SOFTWARE DEV CO LTD

High-heat-resisting self-lubricating PVC/NBR composite foam board and preparation method thereof

InactiveCN106221064AGood compatibilityImprove heat resistanceEnvironmental resistancePolymer science

Owner:CHUZHOU HONGYUAN SPRAYING

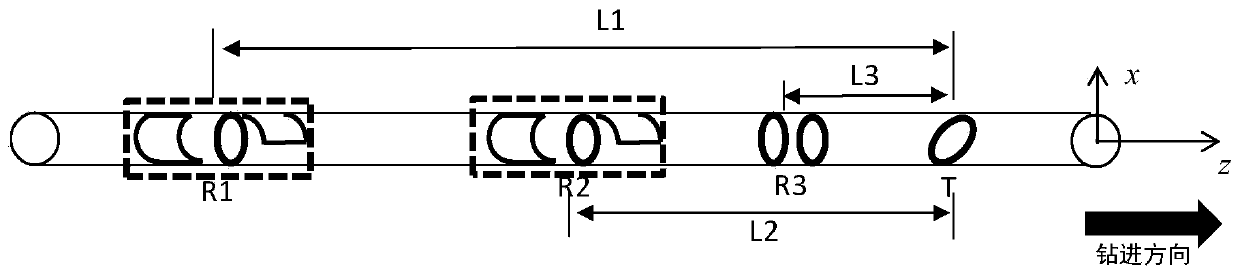

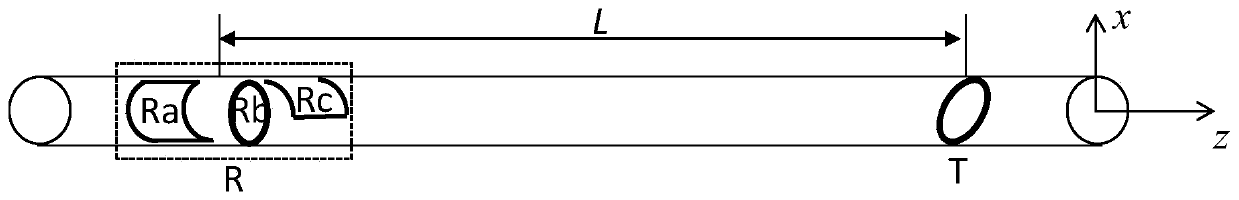

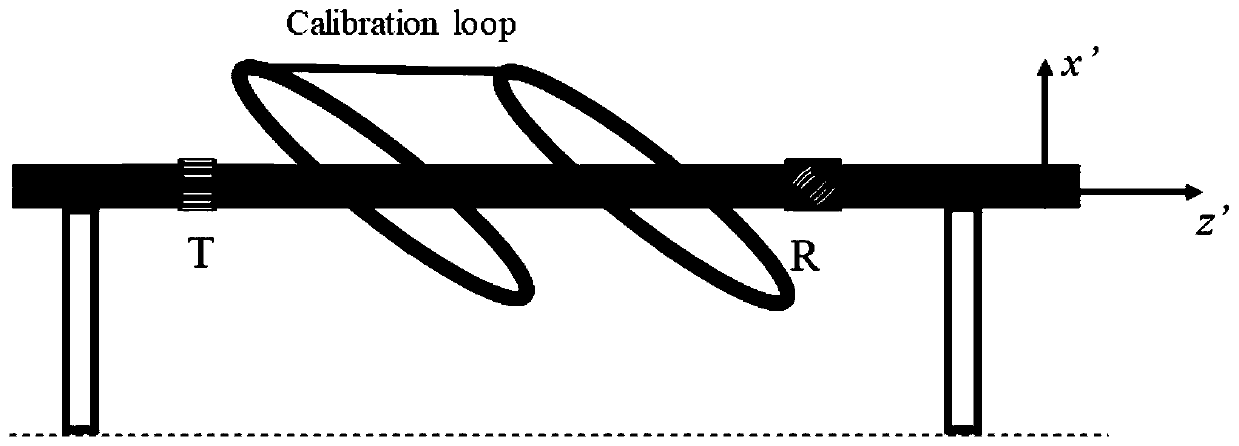

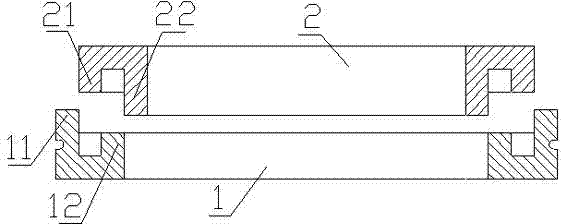

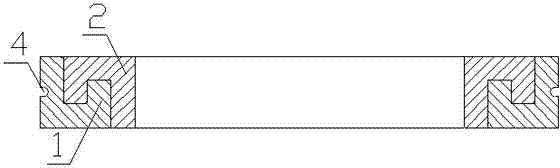

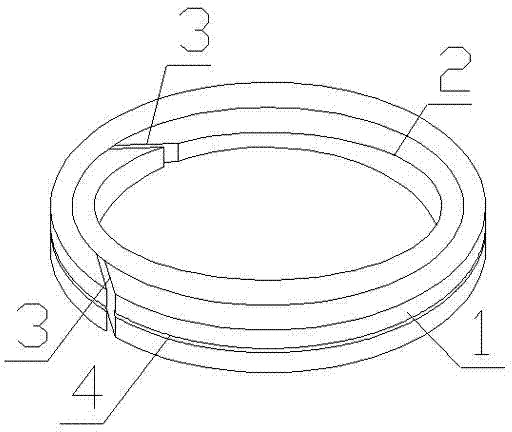

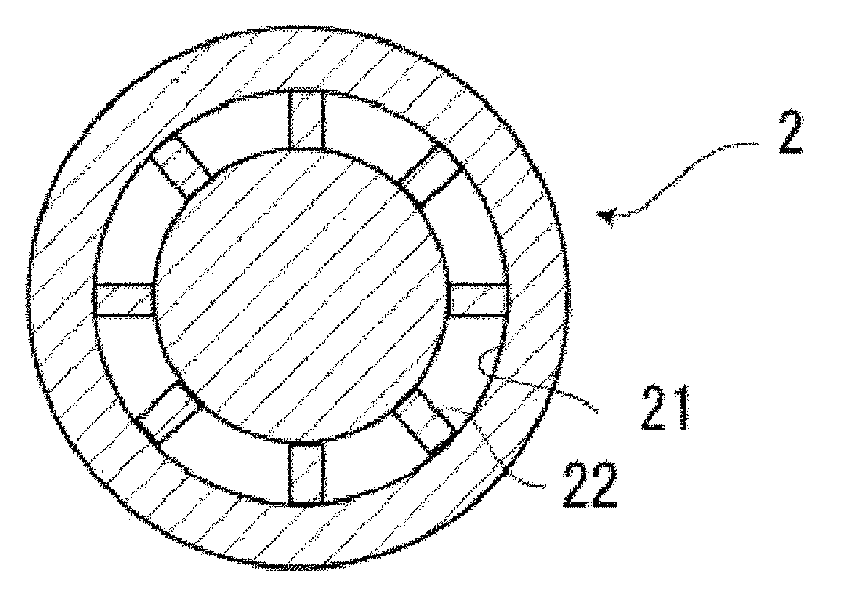

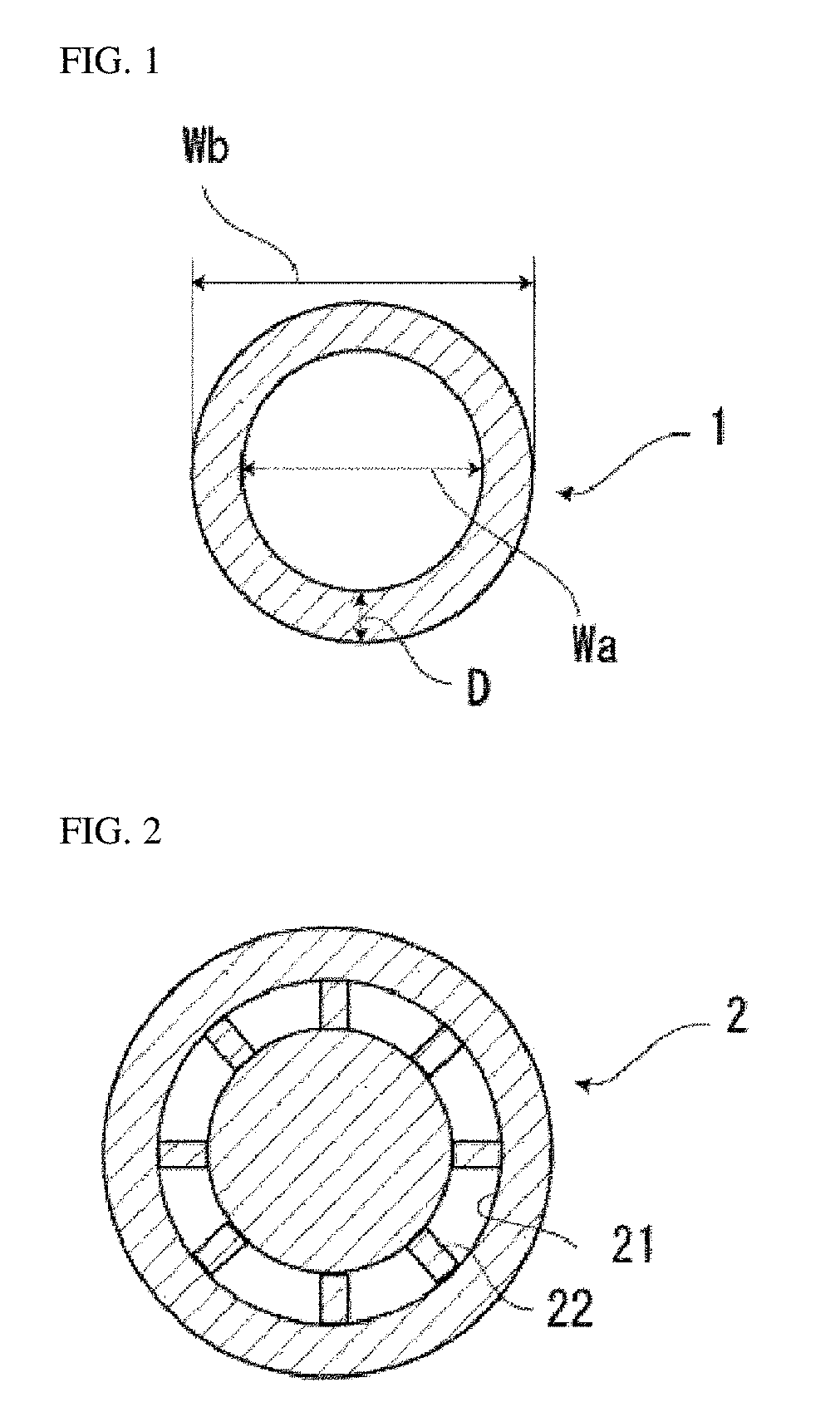

Method and device for calibrating while-drilling remote detection electromagnetic wave resistivity logging instrument

PendingCN111502648AInnovative designEasy to manufactureSurveyDesign optimisation/simulationCircular discCapacitance

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Preparation method and application of Ag2Se/GO nano material with micro-flower structure

InactiveCN109806891AImprove catalytic performanceImprove photocatalytic performancePhysical/chemical process catalystsWater/sewage treatment by irradiationLiquid wasteWastewater

Owner:DONGHUA UNIV

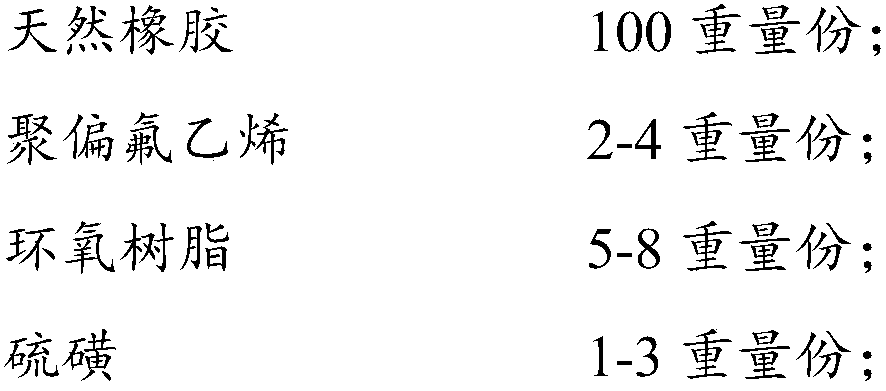

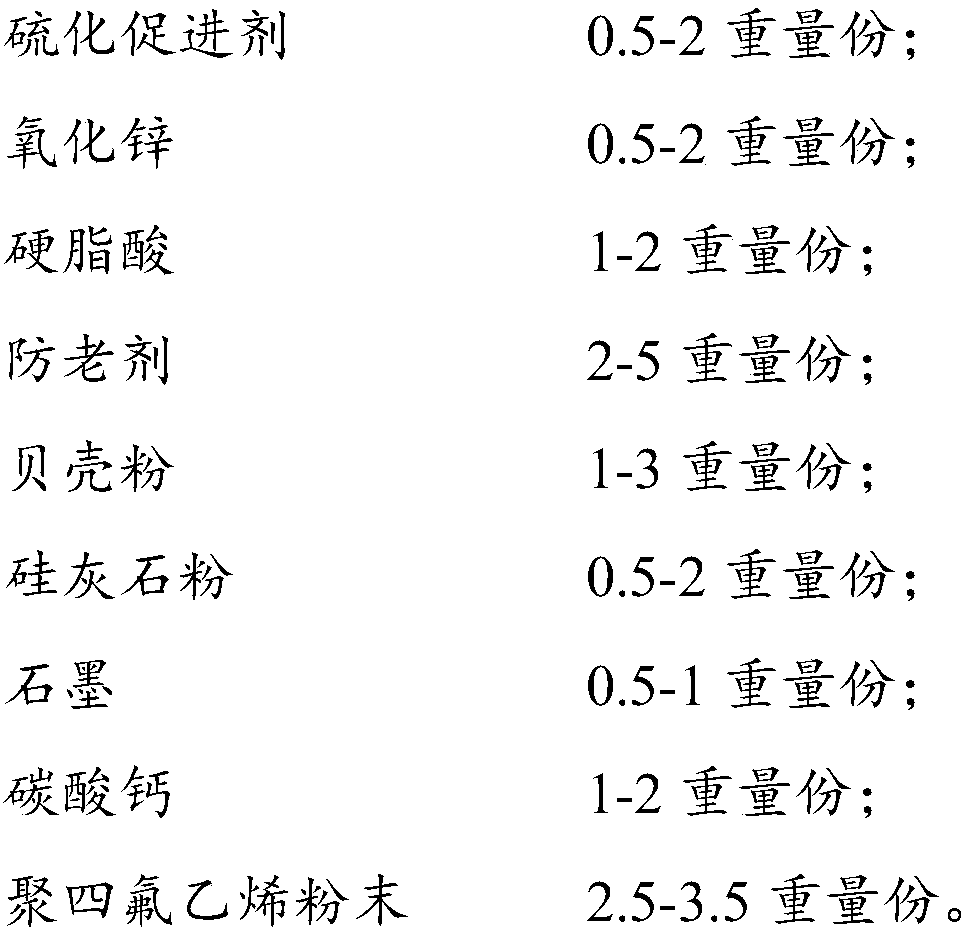

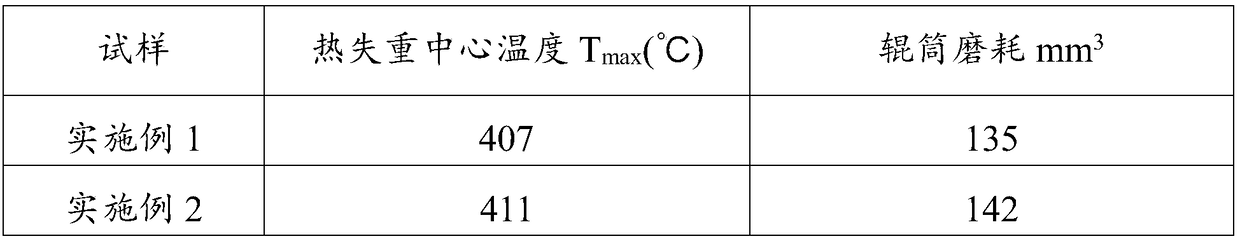

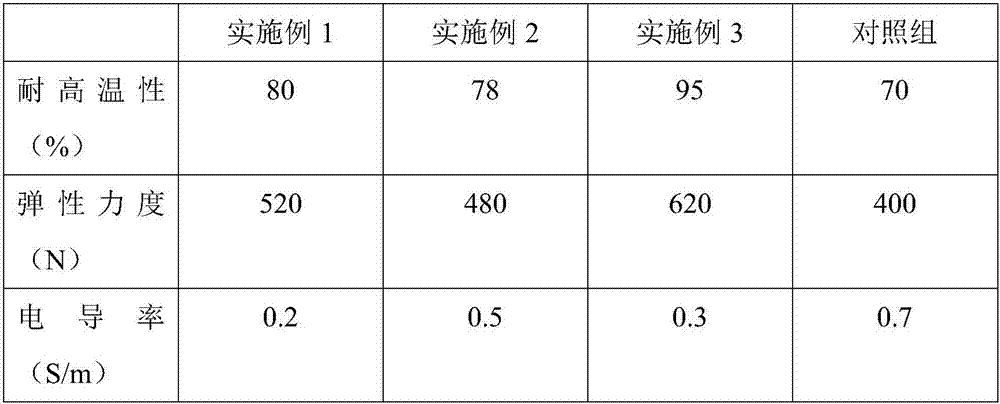

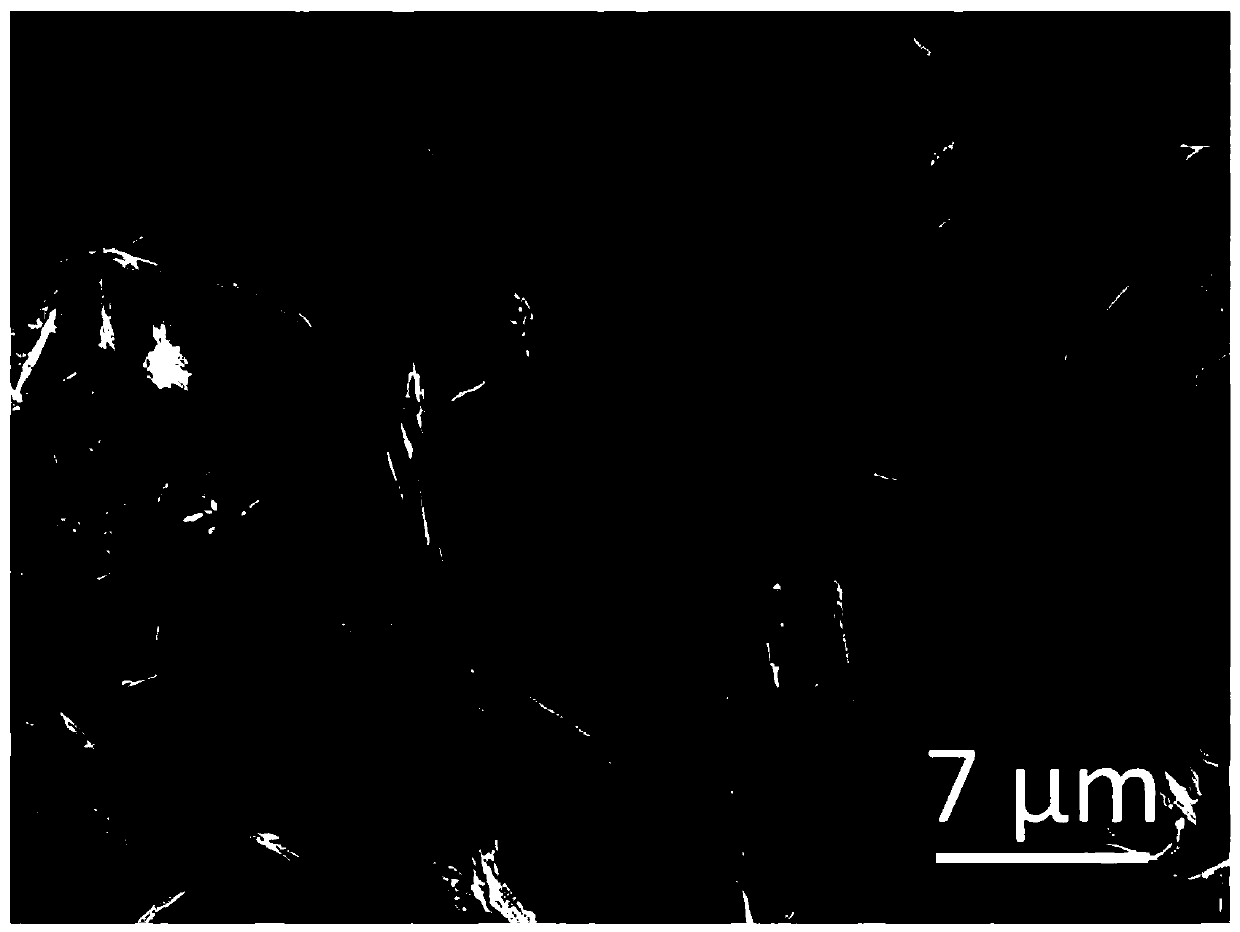

Heat-resistant and wear-resistance natural rubber composite material and preparation method thereof

Owner:长春智享优创科技咨询有限公司

High-temperature-resistant insulation material applied to power equipment and preparation method of high-temperature-resistant insulation material

InactiveCN107189167AGood mechanical propertiesImprove insulation performancePlastic/resin/waxes insulatorsEpoxyAlkali free

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

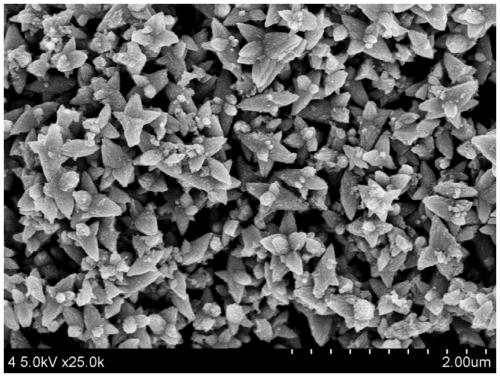

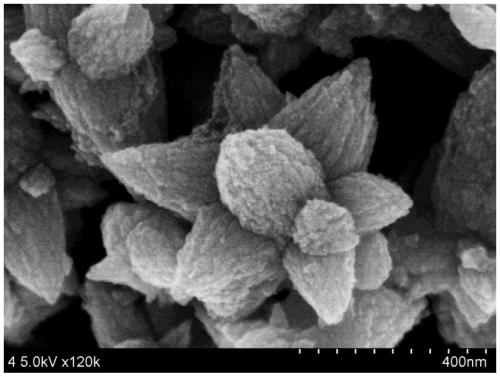

Synthesis method for porous ZnCo2O4 nanosheet and pseudo-cubic micro-nano structure

InactiveCN108033493AReduce manufacturing costSynthesis fastNanotechnologyCobalt compoundsMicro nanoSynthesis methods

Owner:ZHONGBEI UNIV

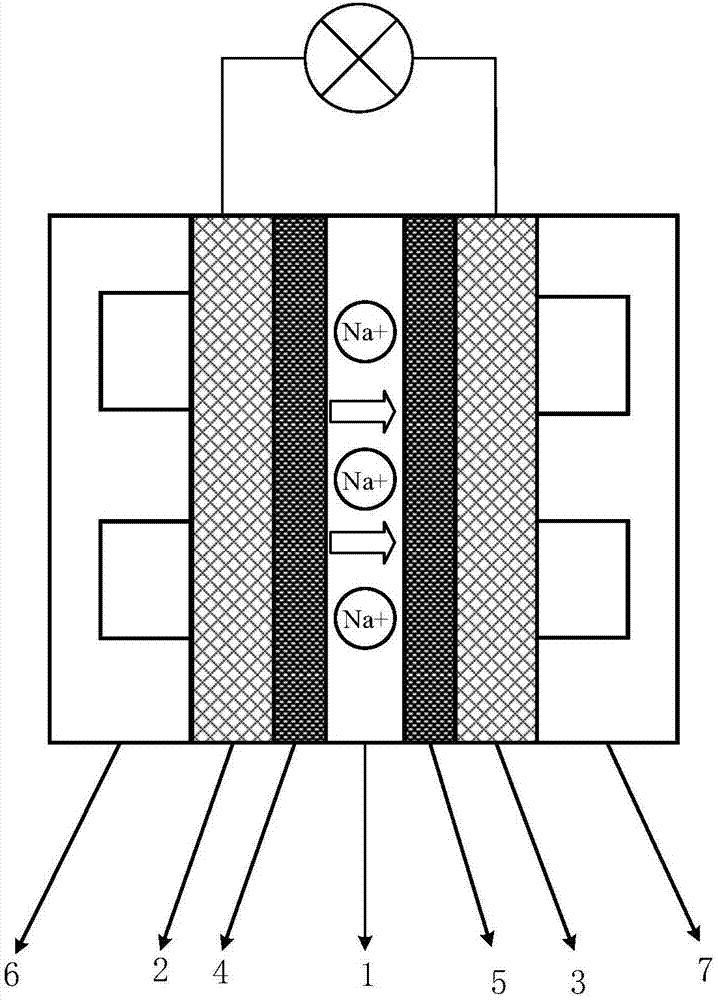

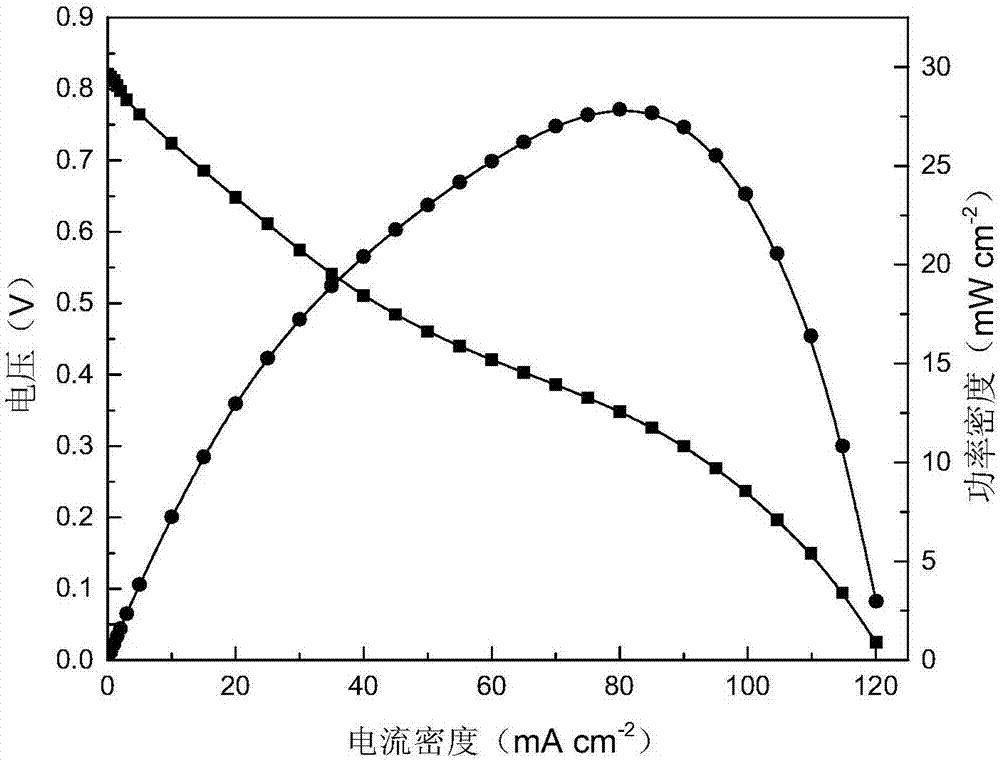

High temperature direct formate fuel cell with electricity and alkali salt co-production

ActiveCN106972176AOvercome stabilityLower internal resistanceCell electrodesFinal product manufactureFormateNon platinum

Owner:XI AN JIAOTONG UNIV

Combined compressor multielement penetration compound layer piston ring

ActiveCN103696939APositive displacement pump componentsPositive-displacement liquid enginesPolytetrafluoroethyleneEngineering

Owner:成都展望能源机械有限公司

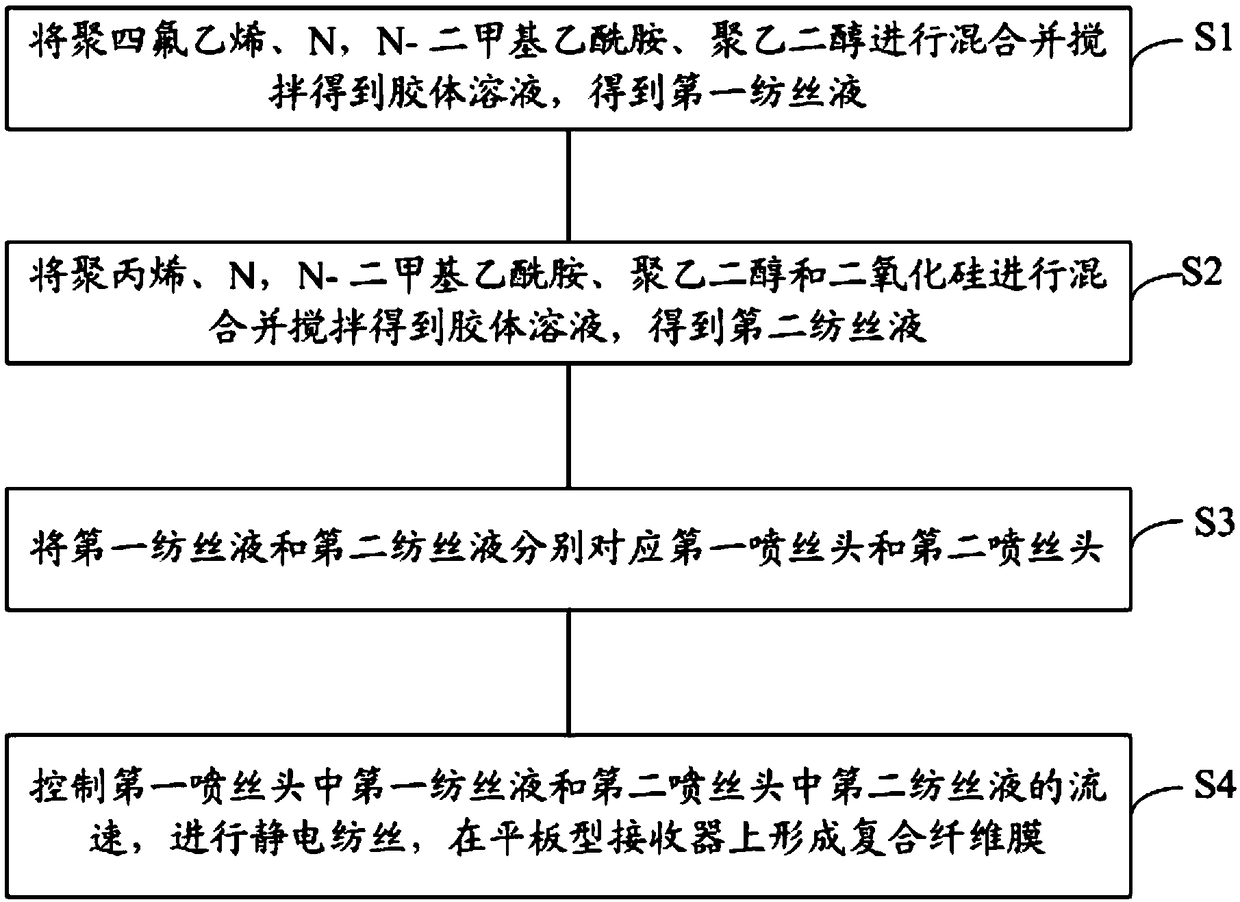

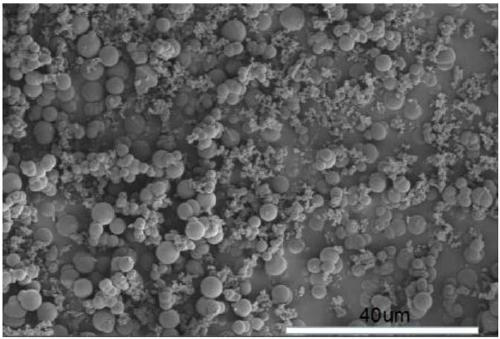

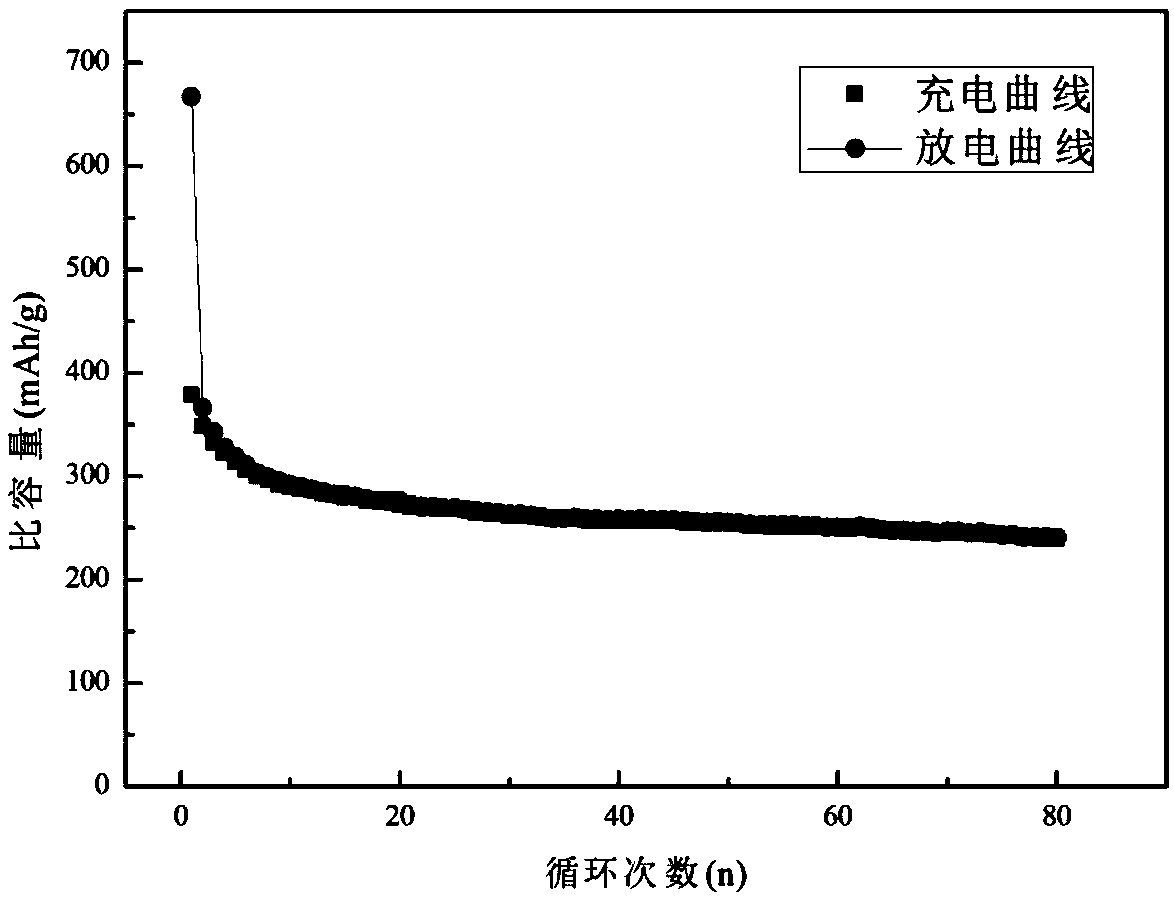

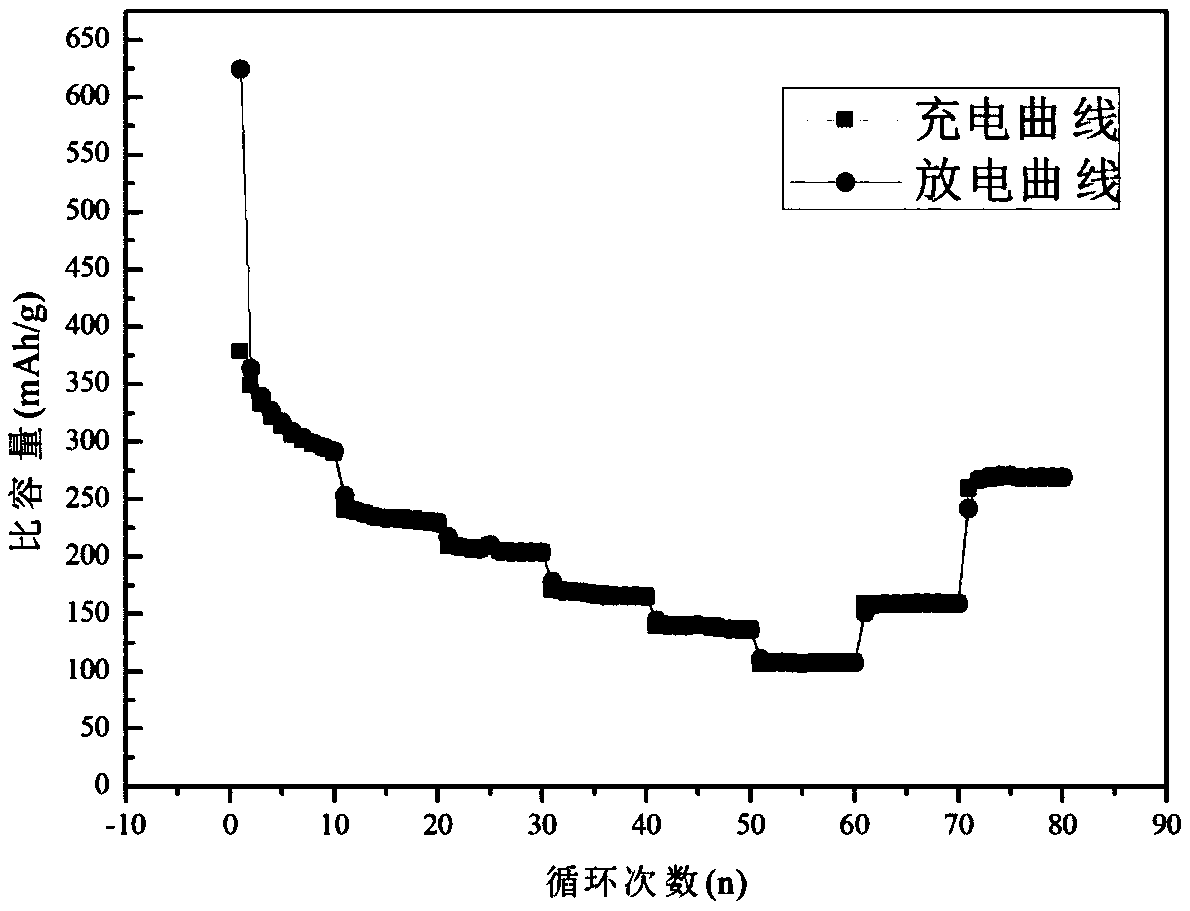

Preparation method of composite fiber membrane with efficient filtration

Owner:江苏弗瑞仕环保科技有限公司

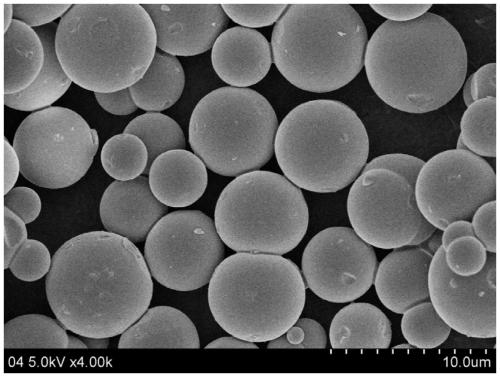

Preparation method of chitosan-based spherical negative lithium ion battery carbon electrode

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH +1

Preparation method of flexible hydrophobic reversible photochromic wood and wood prepared thereby

ActiveCN111319109AEasy to prepareLow costWood treatment detailsSpecial ornamental structuresEpoxyPolymer science

Owner:ZHEJIANG FORESTRY UNIVERSITY

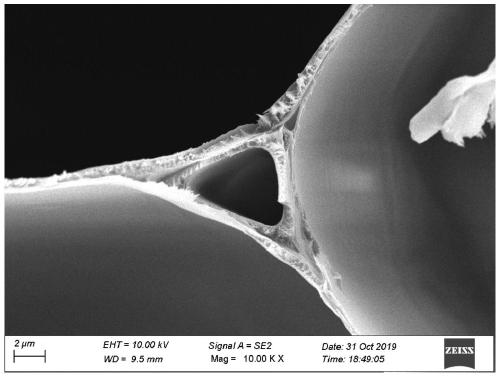

Tearable tube formed from fluororesin

InactiveUS20180281262A1Maintain good propertiesFlexible pipesInsulatorsEngineeringPolytetrafluoroethylene

Owner:GUNZE LTD

Method for preparing CuO@carbon cloth flexible electrode material through one step by regulating and controlling interface cavitation effect

ActiveCN110499646AThe load is easy to controlEasy to implementCarbon fibresUltrasonic/sonic fibre treatmentCavitationProcess conditions

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap