Tearable tube formed from fluororesin

a technology of fluororesin and tearable tubes, which is applied in the direction of flexible pipes, pipes, mechanical equipment, etc., can solve the problems of large tearing force required in the removal of the provisional covering tube from the product, product damage, product inside the covering tube may be scratched, etc., and achieve excellent lengthwise-direction tearing property and inner surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

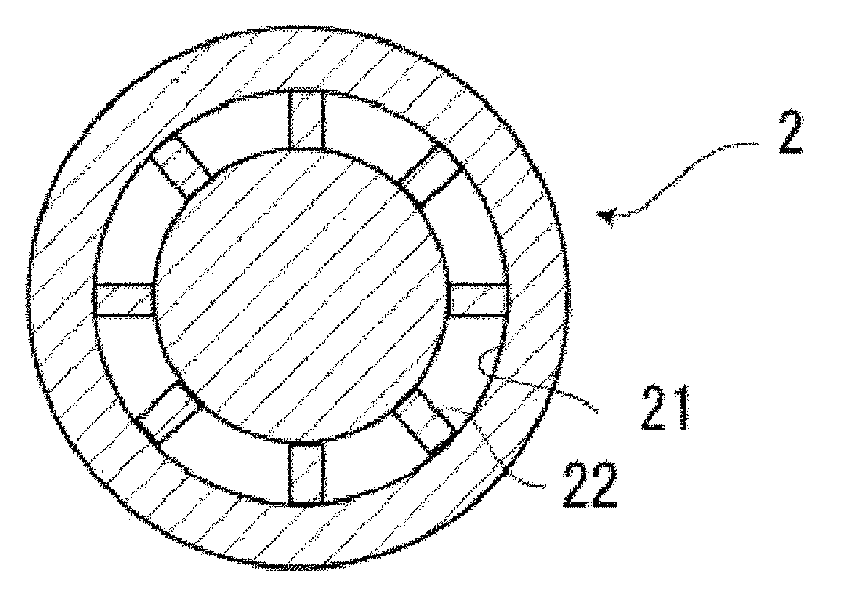

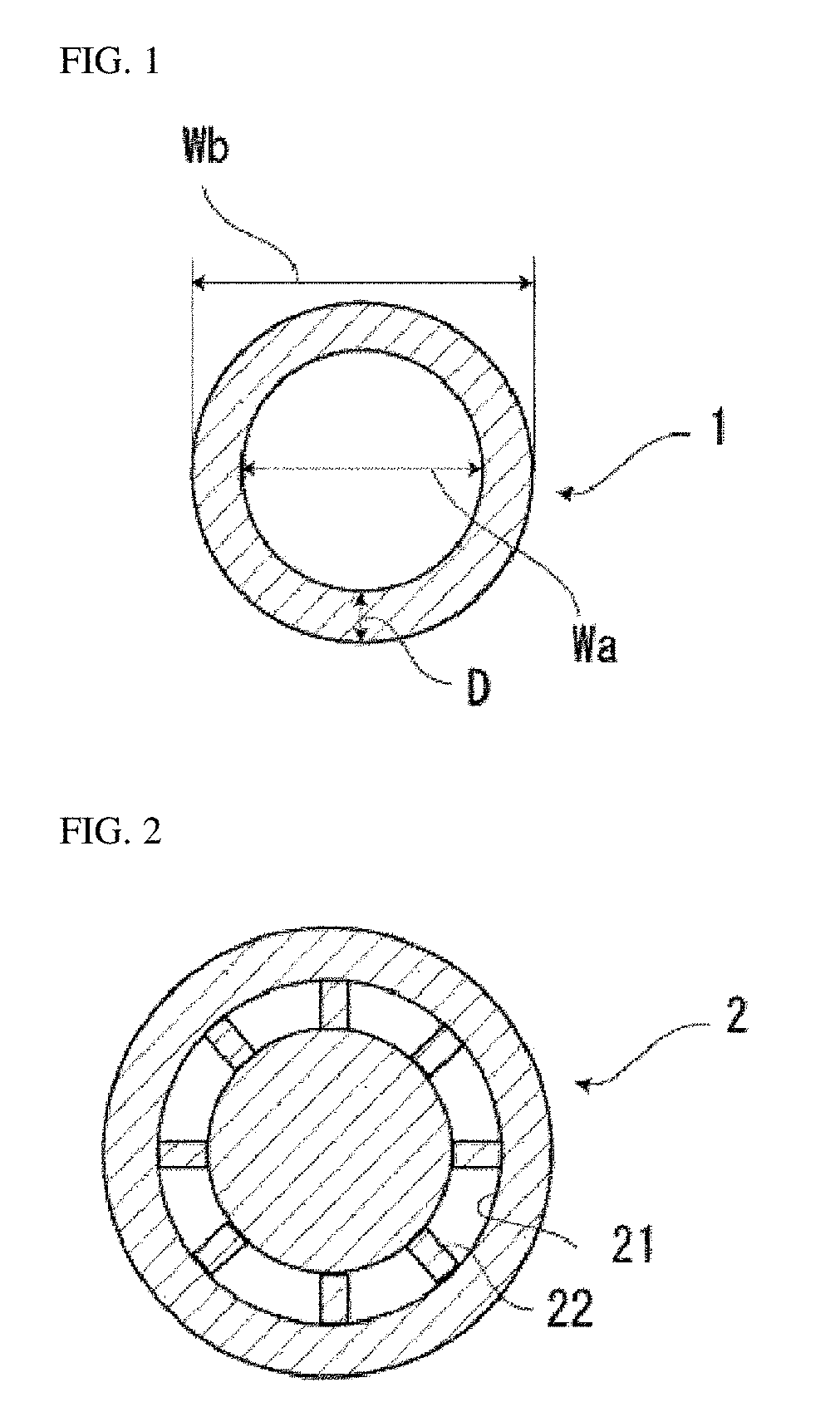

[0061]A fluororesin tube was produced by melt extrusion molding with a tetrafluoroethylene-hexafluoropropylene copolymer (FEP) (FEP-130J manufactured by Du Pont-Mitsui Fluorochemicals Co., Ltd.) used as a fluororesin. In melt extrusion molding, a single screw extruder including a mold and having a cylinder diameter of 30 mm was used to perform tube molding by a sizing plate method at a screw rotation speed of 2.0 rpm and a die temperature of 330° C., thereby preparing a fluororesin tube (original tube) (before expansion) having an inner diameter of 0.5 mm, an outer diameter of 1.2 mm and a wall thickness of 0.35 mm. In the mold that was used, leg portions were provided in a flow path of a molten resin, the leg portions each had a width of 5 mm and length of 10 mm (length of the branched flow path), the number of the leg portions was 8, and the distance between a mold outlet and the leg portion on the molt outlet side was 10 mm.

[0062]Next, the resulting original tube was inserted into a

example 2

[0063]Except that as a fluororesin, a tetrafluoroethylene-perfluoroalkyl vinyl ether copolymer (PFA) (PFA 950 HPplus manufactured by Du Pont-Mitsui Fluorochemicals Co., Ltd.) was used in place of the tetrafluoroethylene-hexafluoropropylene copolymer (FEP), the same procedure as in Example 1 was carried out to prepare a fluororesin tube (original tube) (before expansion). Further, expansion was performed in the same manner as in Example 1 to obtain a fluororesin tube having an inner diameter of 1.25 mm, an outer diameter of 1.65 mm and a wall thickness of 0.2 mm (after expansion).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap