Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64 results about "Ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethers are a class of organic compounds that contain an ether group—an oxygen atom connected to two alkyl or aryl groups, as opposed to esters. They have the general formula R–O–R′, where R and R′ represent the alkyl or aryl groups. Ethers can again be classified into two varieties: if the alkyl groups are the same on both sides of the oxygen atom, then it is a simple or symmetrical ether, whereas if they are different, the ethers are called mixed or unsymmetrical ethers. A typical example of the first group is the solvent and anesthetic diethyl ether, commonly referred to simply as "ether" (CH₃–CH₂–O–CH₂–CH₃). Ethers are common in organic chemistry and even more prevalent in biochemistry, as they are common linkages in carbohydrates and lignin.

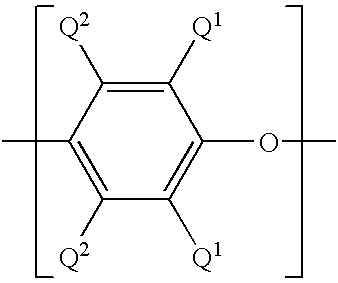

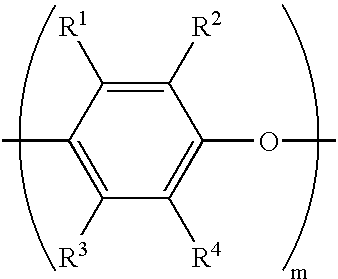

Poly(arylene ether)-containing thermoset composition in powder form, method for the preparation thereof, and articles derived therefrom

Owner:SABIC GLOBAL TECH BV

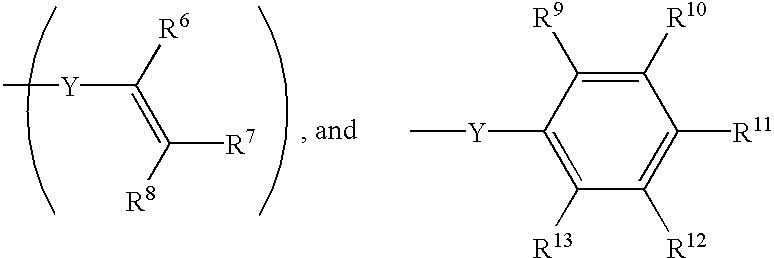

Gas layer formation materials

InactiveCN1735945APlastic/resin/waxes insulatorsSemiconductor/solid-state device detailsAcenaphthyleneMethacrylate

The present invention provides gas layer formation material selected from the group consisting of acenaphthylene homopolymers; acenaphthylene copolymers; poly(arylene ether); polyamide; B-staged multifunctional acrylate / methacrylate; crosslinked styrene divinyl benzene polymers; and copolymers of styrene and divinyl benzene with maleimide or bis-maleimides. The formed gas layers are used in microchips and multichip modules.

Owner:HONEYWELL INT INC

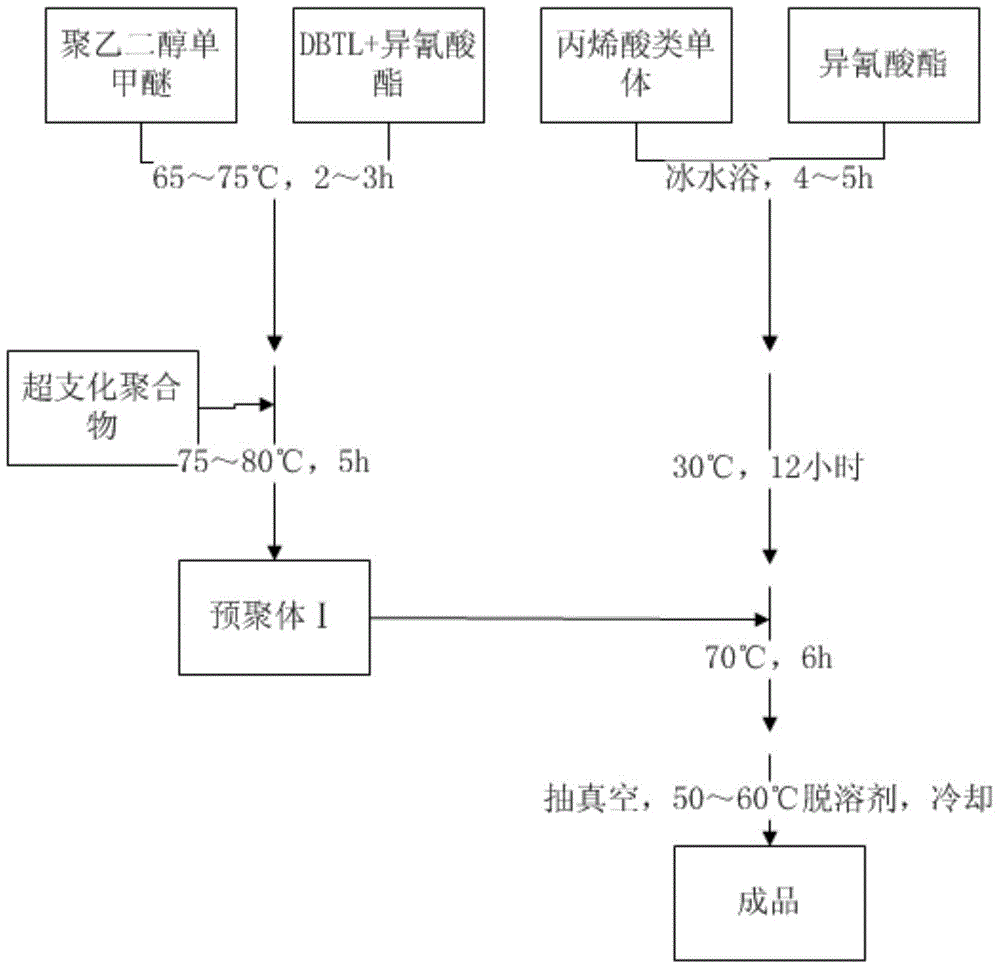

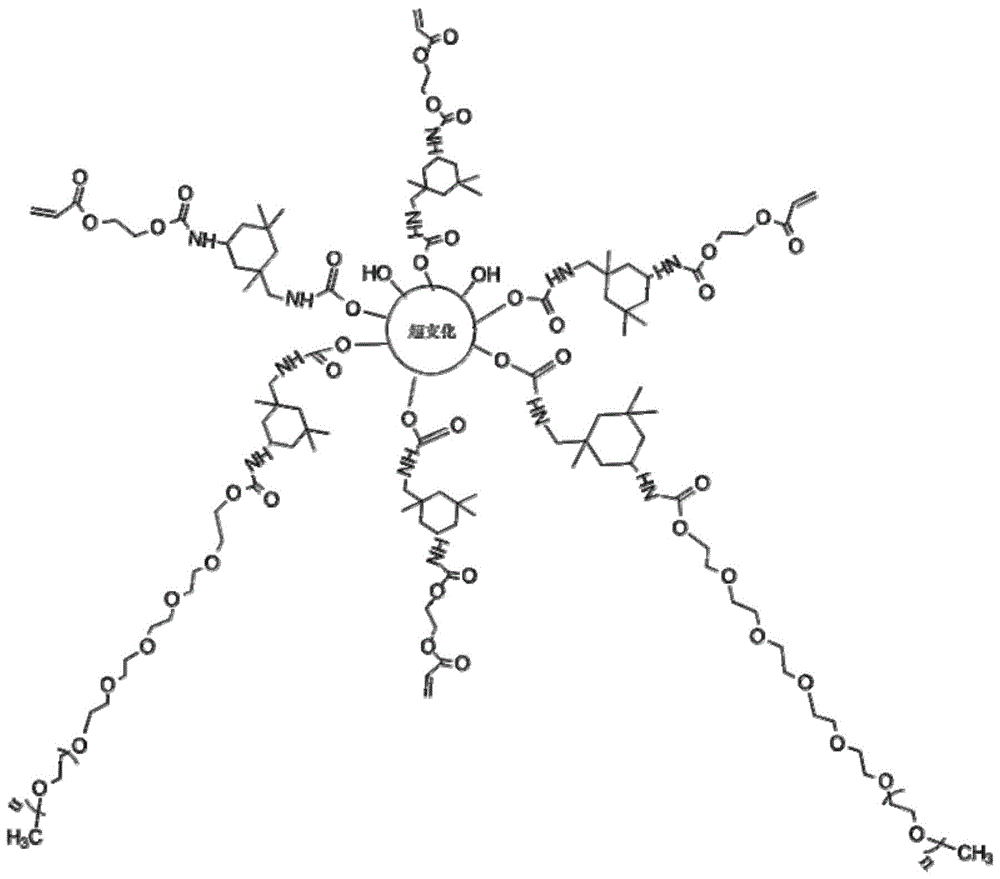

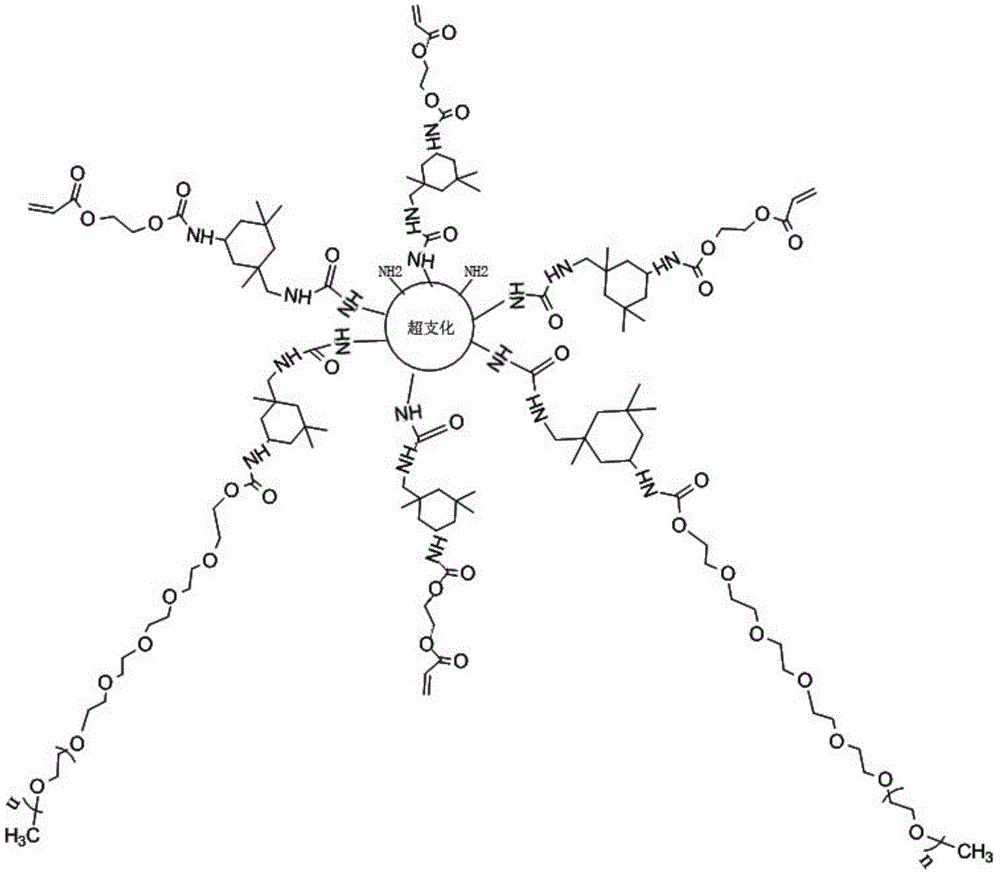

Hydrophilic UV (Ultraviolet) coating hardness assistant and preparation method thereof

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS +1

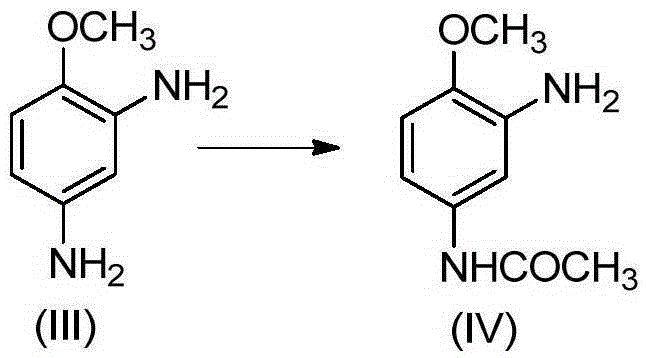

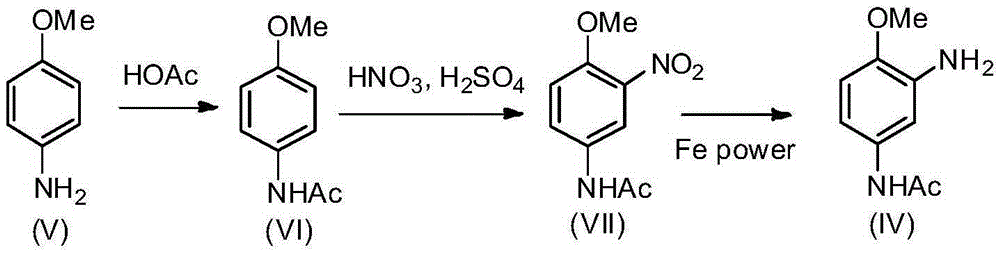

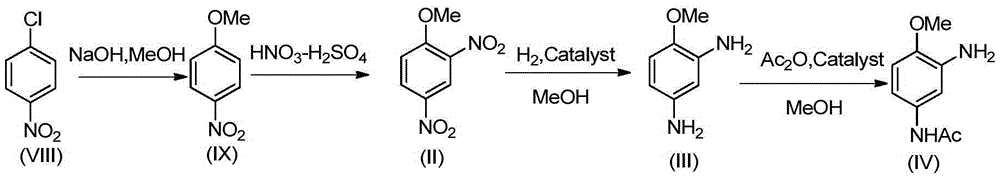

2-amino-4-acetamino anisole synthesis process

InactiveCN105348132AOrganic compound preparationCarboxylic acid amides preparationAcetic anhydrideEther

Owner:安徽奥瑞化工有限公司

Low-temperature electrolyte for lithium iron phosphate battery

InactiveCN106129472AImprove low temperature conductivityReduced solvation radiusSecondary cellsElectrolytesLithium vanadium phosphate batteryTetrafluoroborate

Owner:DONGFENG COMML VEHICLE CO LTD

Flash rust-proof acrylic roof waterproof coating and preparation method thereof

InactiveCN109796825AAnti-rust and waterproof effect lasts for a long timeImprove UV protection effectAnti-corrosive paintsCelluloseUltraviolet

The invention relates to the field of water proofing of metal roofs and particularly discloses a flash rust-proof acrylic roof waterproof coating which is prepared from, by weight, the following raw materials: 30-50 parts of an acrylic emulsion, 25-60 parts of antirust slurry, 1-5 parts of a plasticizer, 0.3-5 parts of a dispersing agent, 0.1-1 part of a defoaming agent, 0.1-1 part of a base material wetting agent, 0.1-2 parts of an anti-flash rust additive, 1-4 parts of a film forming assistant, 3-10 parts of water, 0.01-0.5 part of cellulose ether, 0.1-0.5 part of a bactericide, 0.01-0.5 part of a coupling agent and 0.01-0.5 part of a pH adjusting agent. The flash rust-proof waterproof effect of the roof waterproof coating with a flash rust-proof function is longer lasting than that of acommon metal roof waterproof coating, the anti-ultraviolet effect is good, and the service life of a base material is prolonged. The waterproof coating has high elongation rate, good elasticity, strong base layer deformation resistance, the capability of shielding cracks, water proofing and breathability.

Owner:KESHUN WATERPROOF TECH CO LTD

Ink resin composite used for plastic gravure printing and preparation method thereof

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Hydrochlorofluoroolefin blowing agent compositions

Owner:ARKEMA FRANCE SA

Method of Treating Paper Forming Wire Surface

ActiveUS20120043040A1Non-fibrous pulp additionFats/resins/pitch/waxes removal in pulpPolymer sciencePolyethylene glycol

A method for inhibiting resinous and sticky substances from filling or forming deposits on or within papermaking forming wire, by applying to said wire an effective inhibiting amount of a composition comprising at least one cationic agent selected from the group consisting of (a) cationic polyureas, (b) hydrophobically modified cationic polymers, (c) alkylammonium or / and alkylimidazolium salts, and optionally at least one nonionic amphiphilic copolymer selected from (i) hydrophobically modified polyethylene glycols], (ii) hydrophobically modified cellulose ethers, (iii) copolymers of vinyl alcohol and vinyl alkonate, (iv) polyoxyalkylene block copolymers, and (v) hydrophilically modified polydimethylsiloxanes.

Owner:SOLENIS TECH CAYMAN

Calcium carbonate compound type flame-retardant foaming agent

Owner:新建特阔漂整(南通)有限公司

Method for preparing chloroprene rubber adhesive agent

InactiveCN101781538APromote environmental protectionHigh affinitySolesGraft polymer adhesivesPolymer scienceBenzoyl peroxide

Owner:NANTONG GUANGTAI BIOCHEM PROD

Environmental-friendly foaming plastic and preparing method thereof

Owner:ANHUI GUANGYUAN TECH DEV

Preparation technology of perfluoropolyether for resin

Owner:XUZHOU ZENITH COATING

Super heat insulation coating loaded with nano titanium dioxide and preparation method of super heat insulation coating

InactiveCN104610847ADelay the aging processImprove hydrophilicityEpoxy resin coatingsBulk chemical productionEpoxySilicon dioxide

Owner:WUHU BAOYI AMUSEMENT EQUIP

Waterborne polyester resin and preparation method thereof

InactiveCN106893087AImprove hydrolysis resistanceGood dispersionPolyester coatingsWater dispersibleAdipic acid

The invention discloses waterborne polyester resin, comprising polyols and polyacids; the polyols include 8-12% of trimethylol propane, 12-24% of neopentyl glycol, 6-12% of ethylene glycol, and 8-12% of propylene glycol; the polyacids include 5-15% of purified terephthalic acid, 12-24% of isophthalic acid, 6-12% of phthalic acid, 10-18% of trimellitic anhydride, 6-12% of hexahydro-phthalic acid, 10-20% of maleic anhydride, and 5-10% of adipic acid; the waterborne polyester resin also comprises 0.1-0.3% of p-methoxyphenol, 6-24% of ethylene glycol butyl ether, 8-16% of dimethylethanolamine, and 60-100% of deionized water. The waterborne polyester resin can gain improved hydrolysis resistance, water dispersibility and storage stability, has improved stability of polyester main chain hydrolysis and is widely applicable to waterborne insulating devices, the defects of the prior art can be overcome, and the requirement on actual use can be met.

Owner:CHUZHOU QUAN FENG MATERIALS CO LTD

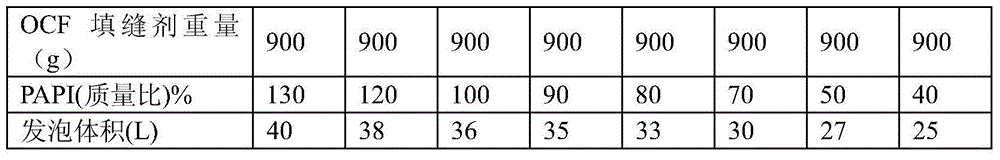

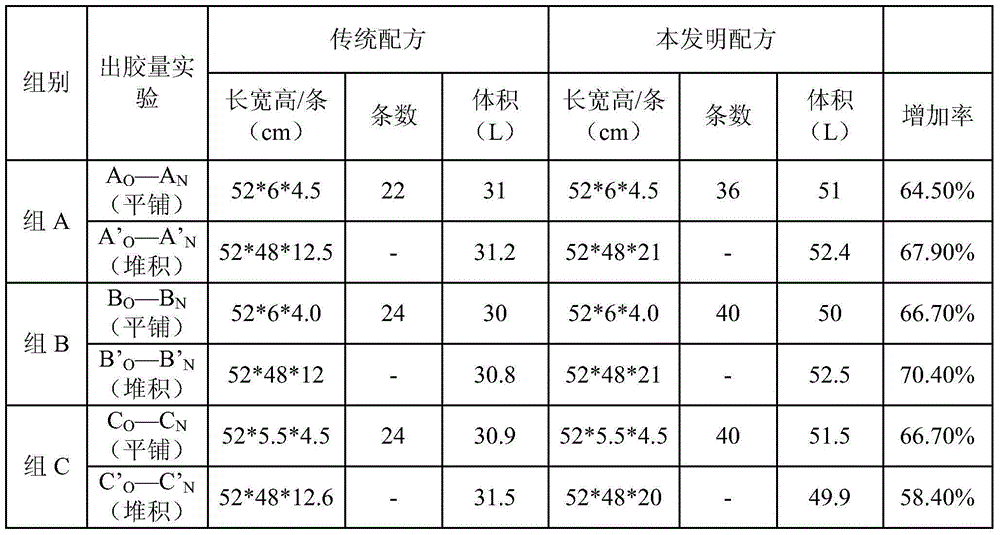

Ultrahigh-foaming amount polyurethane foaming agent

Owner:GUNUO TIANJIN IND

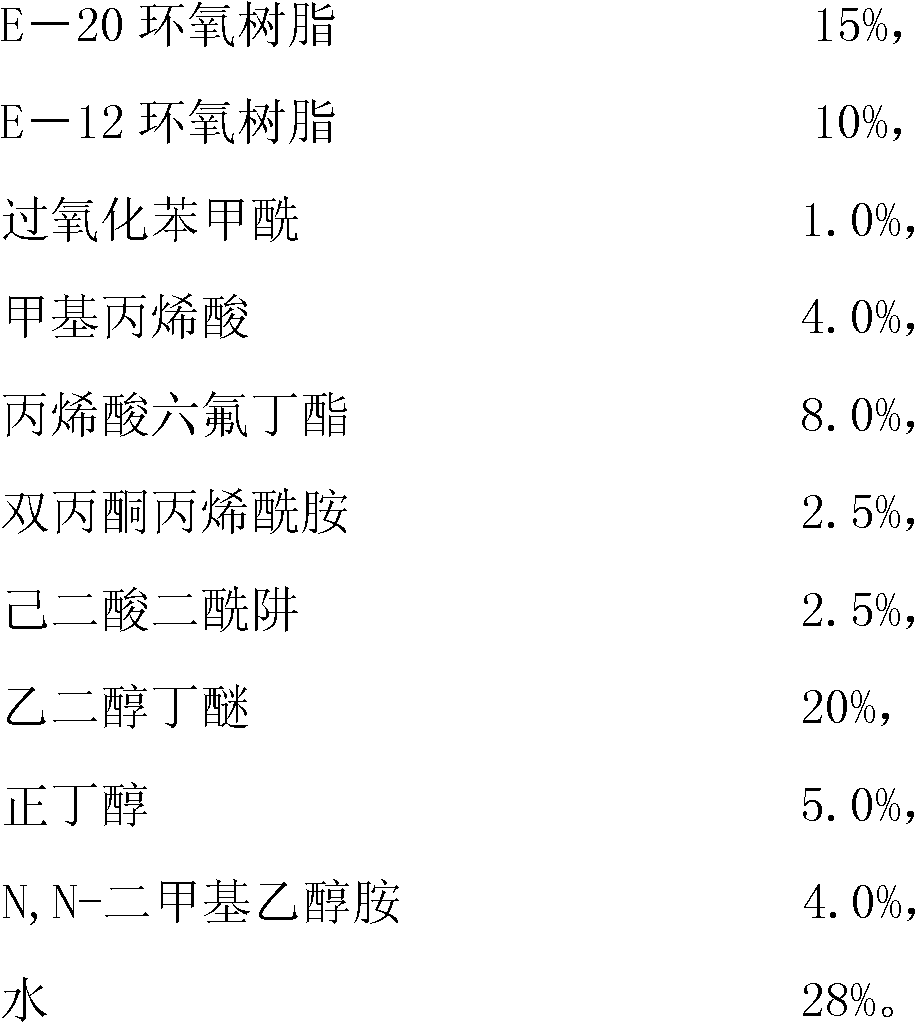

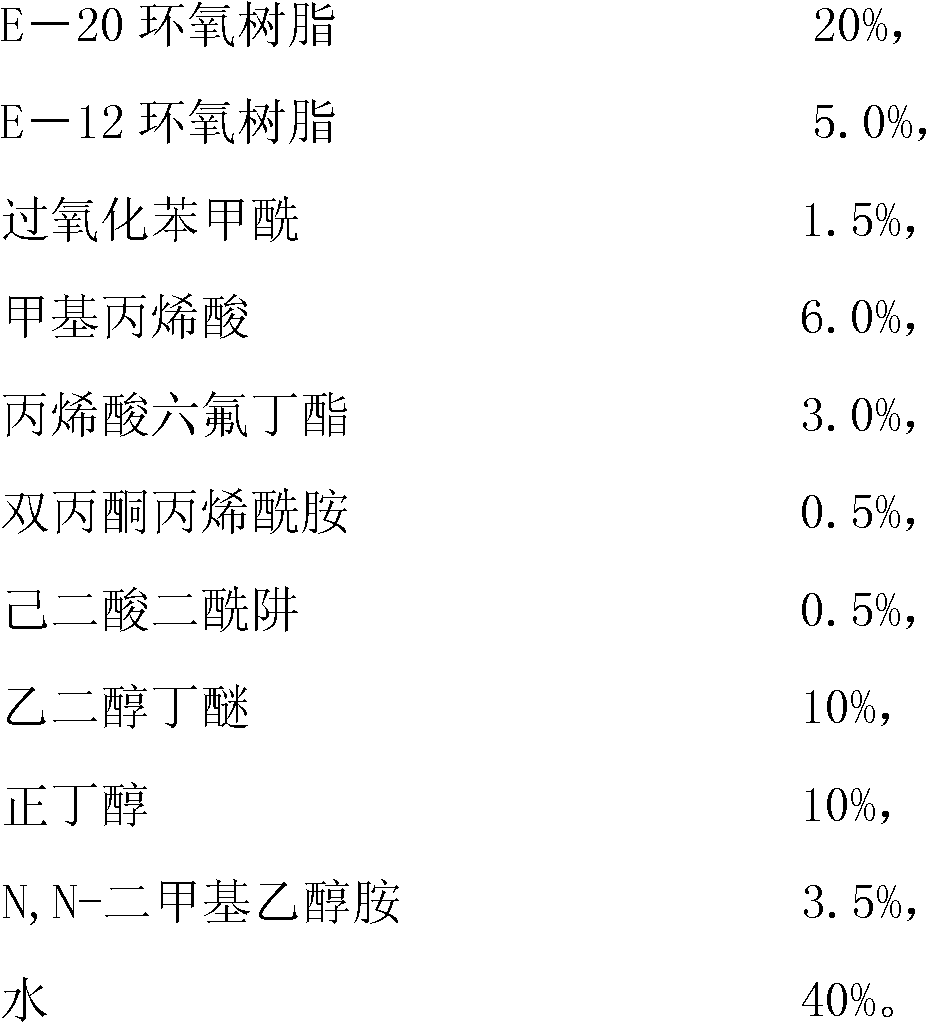

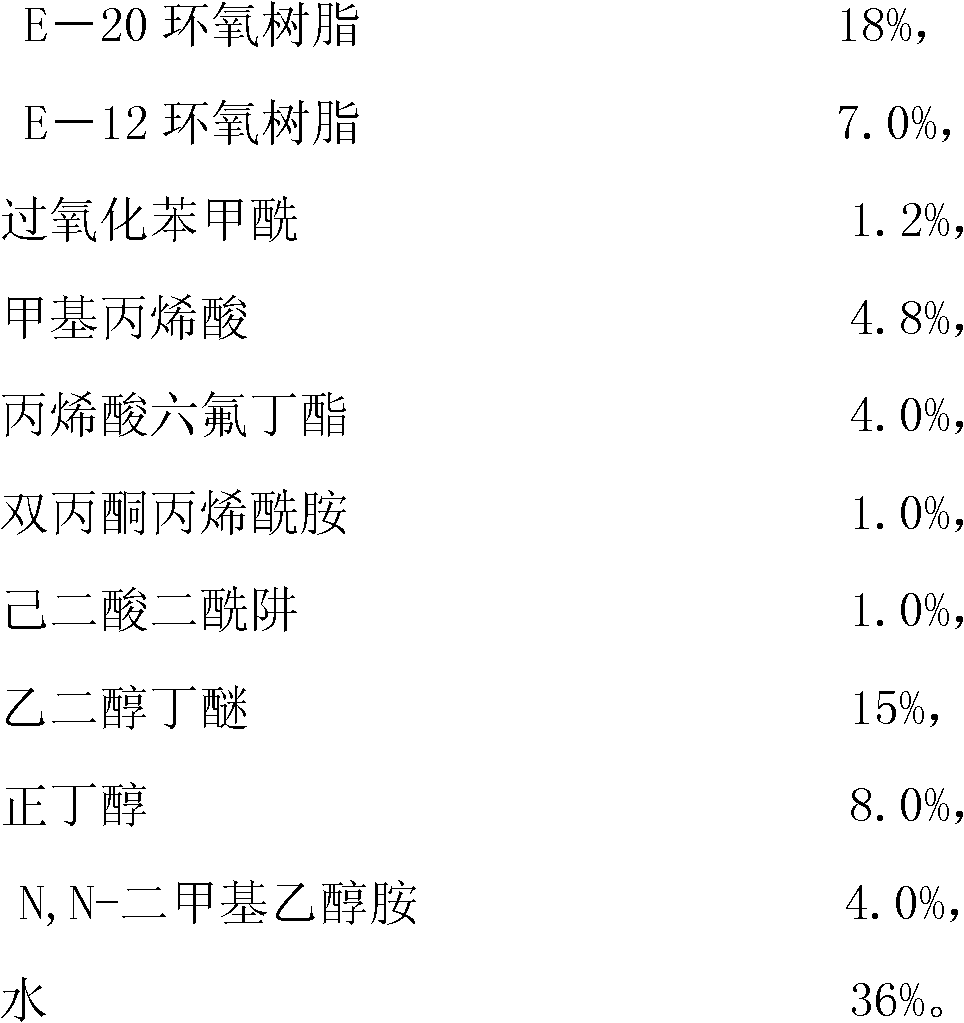

Epoxy emulsion cured at room temperature with high aquosity and weather resistance as well as preparation method of epoxy emulsion

InactiveCN102604047AGood film formingGood physical and mechanical propertiesCoatingsEpoxyBenzoyl peroxide

Owner:JIANGSU UNIV OF SCI & TECH

Impact-resistant composite insulating material and preparing method thereof

The invention discloses an impact-resistant composite insulating material and a preparing method thereof. The insulating material is prepared from 4-10 parts of polyimide resin, 3-6 parts of glass fibers, 5-12 parts of bisphenol-S epoxy resin, 5-15 parts of polycarbonate, 4-8 parts of dodecyl acrylate, 3-7 parts of dodecanol polyethenoxy ether, 2-5 parts of ethylene bis-oleamide, 3-6 parts of styrylphenol polyoxyethylene ether, 4-10 parts of phenolic epoxy vinyl ester resin and 2-5 parts of polyvinyl cinnamate. The preparing method includes the following steps that 1, the components are thrown into a high-speed mixer to be mixed; 2, the insulating material mixture mixed evenly is taken out of the high-speed mixer and extruded through a double-screw extruder; 3, the material extruded in the step 2 is granulated, and the impact-resistant composite insulating material is obtained after the granulated material is cooled to normal temperature.

Owner:SUZHOU YIXINYUAN PHOTOELECTRIC TECH

Preparation method of organic tin-free chlorine ether resin

Owner:HANGZHOU ELECTROCHEM GROUP

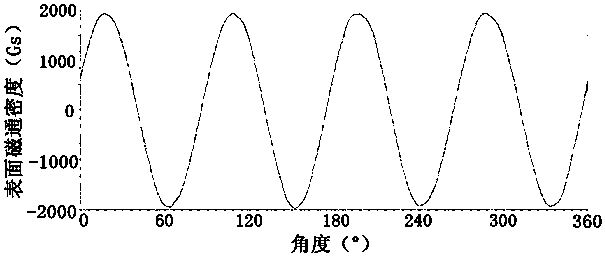

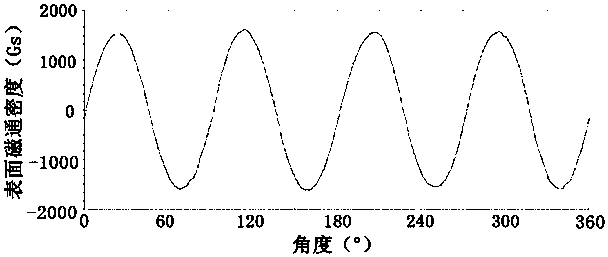

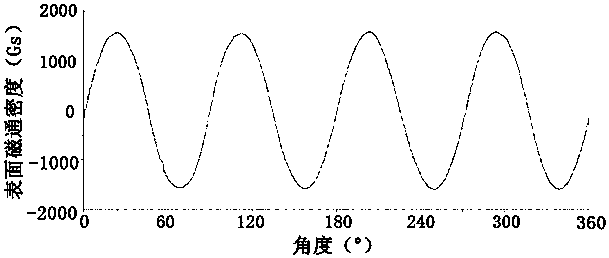

High-surface magnetic flux density dry-pressed permanent ferrite magnet and preparation method thereof

InactiveCN109133900AInorganic material magnetismInductances/transformers/magnets manufactureMagnetic fluxEther

Owner:HUNAN AEROSPACE MAGNET & MAGNETO

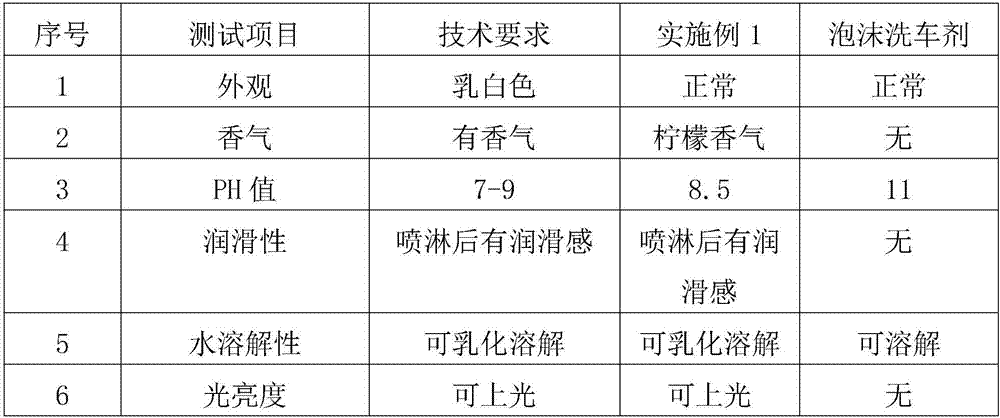

Ultraviolet-proof anhydrous automobile-washing agent and preparation method thereof

InactiveCN106929200AEfficient removalExcellent decontaminationInorganic/elemental detergent compounding agentsCationic surface-active compoundsUltravioletSalicylic acid

Owner:WUHU YANGZHAN NEW MATERIAL TECH SERVICE CO LTD

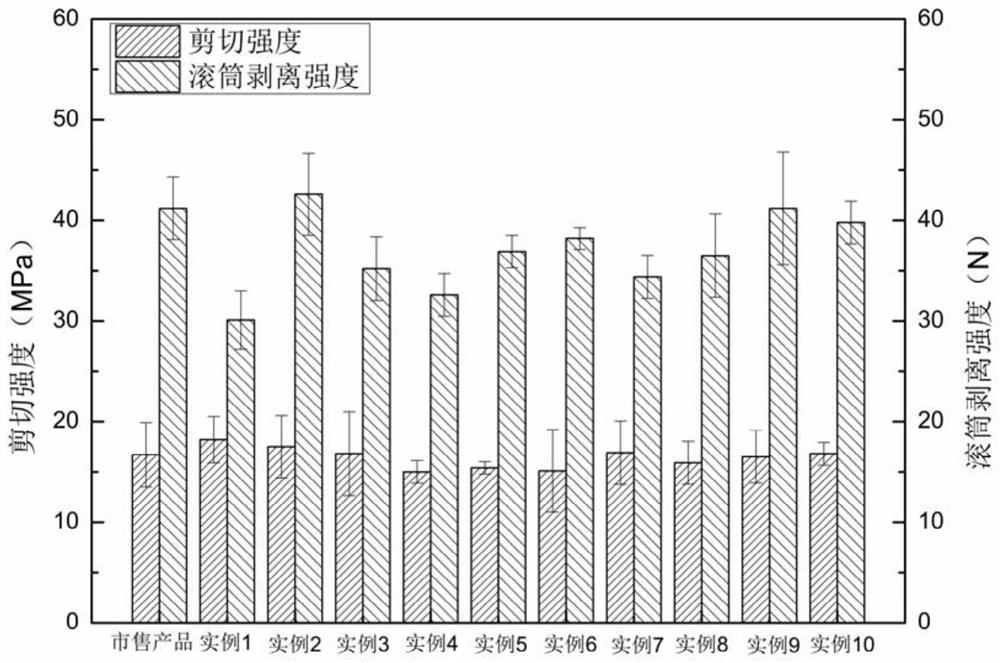

Lightweight high-toughness military shelter structural adhesive and preparation method thereof

InactiveCN111876118AHigh tensile strengthHigh impact strengthMacromolecular adhesive additivesEpoxy resin adhesivesFiberCarbon fibers

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

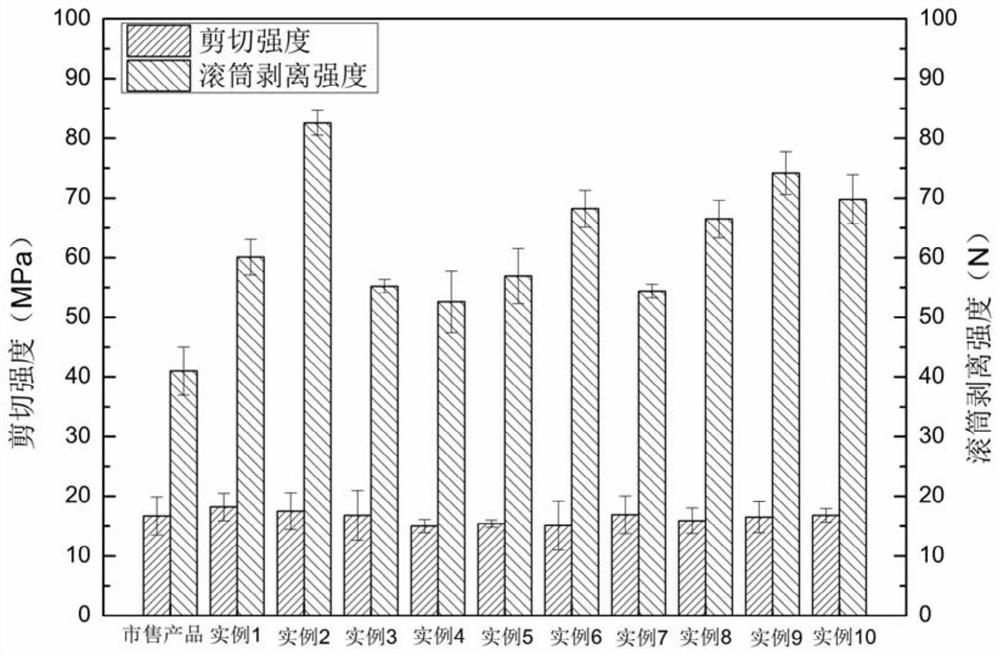

Thermoplastic resin adhesive film

InactiveCN102942878AExtended service lifeImprove long-term stabilityFilm/foil adhesivesPrinted circuit detailsVitrificationDielectric loss

The invention relates to a thermoplastic resin adhesive film and application thereof. The adhesive film comprises symmetrical polyphenylene ether molecules, is not sticky and has low dielectric constant and dielectric loss, and a high-frequency multilayer printed circuit board prepared by the adhesive film has high glass transition temperature, excellent heat resistance and flame resistance and an environmental protection function. The adhesive film serves as a thermally conductive and insulating layer of the high-frequency printed circuit board, so that the printed circuit board has the advantages of high thermal conductivity, quick signal transmission, low loss and the like.

Owner:彭代信

Aluminium powder paint, spraying method of aluminium powder paint and product sprayed by the method

InactiveCN103834247AHigh hardnessImprove alcohol resistancePretreated surfacesCoatingsSurface stressButyl acetate

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Preparation method of composite acrylate emulsion

ActiveCN109369842AImproved rheological propertiesSmall size effectWater bathsSodium bicarbonate

Owner:XUZHOU NORMAL UNIVERSITY

Method for preparing high-purity pristimerin by high-speed countercurrent chromatography

InactiveCN101519420AHigh purityReduces changes in chemical propertiesSolid sorbent liquid separationSteroids preparationStationary phaseCountercurrent chromatography

Owner:SHANGHAI INST OF PHARMA IND

Coating Composition, Solid Preparation Coated Therewith, and Method for Preparing Solid Preparation

Owner:SHIN ETSU CHEM IND CO LTD

Casting paint composition prepared by industrial dust

Owner:GANSU KOCEL CHEM

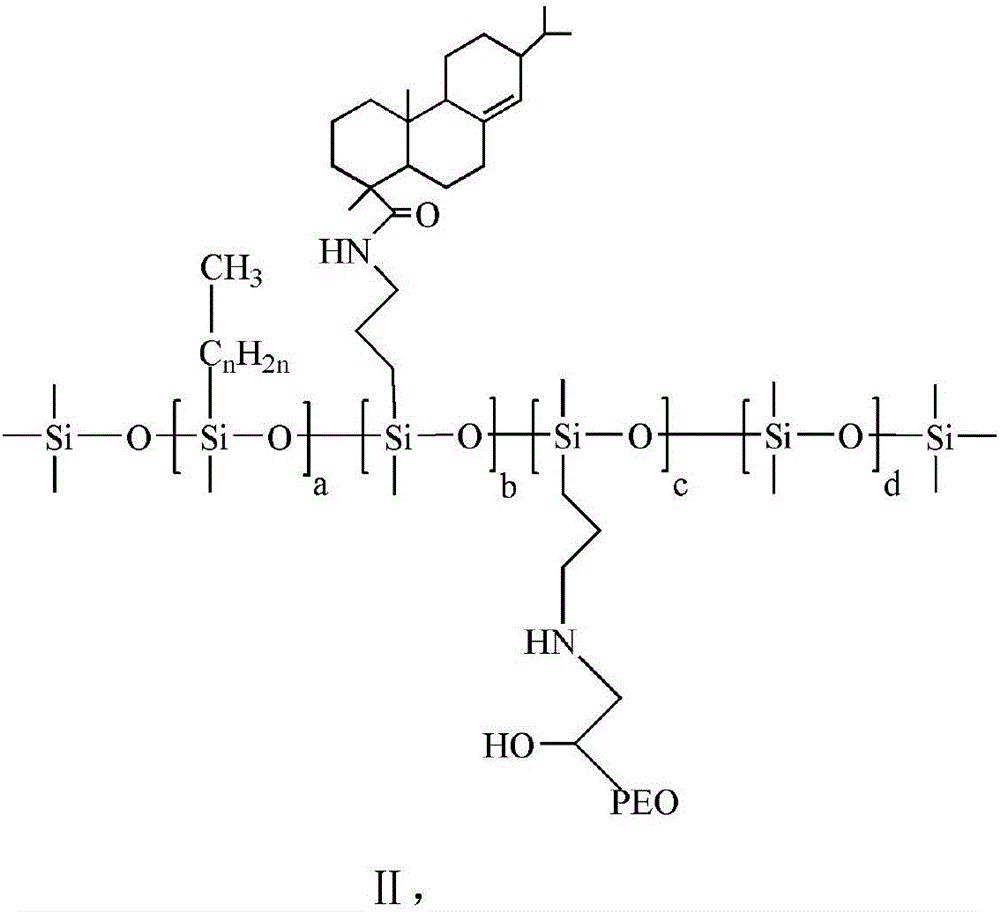

Rosin modified silicon wax and preparing method thereof

Owner:太仓中化环保化工有限公司

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap