Aluminium powder paint, spraying method of aluminium powder paint and product sprayed by the method

A technology of aluminum powder paint and paint film, which is applied in the field of aluminum powder paint, can solve the problems that aluminum powder paint cannot have both hardness and alcohol resistance, and achieve the effect of excellent hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

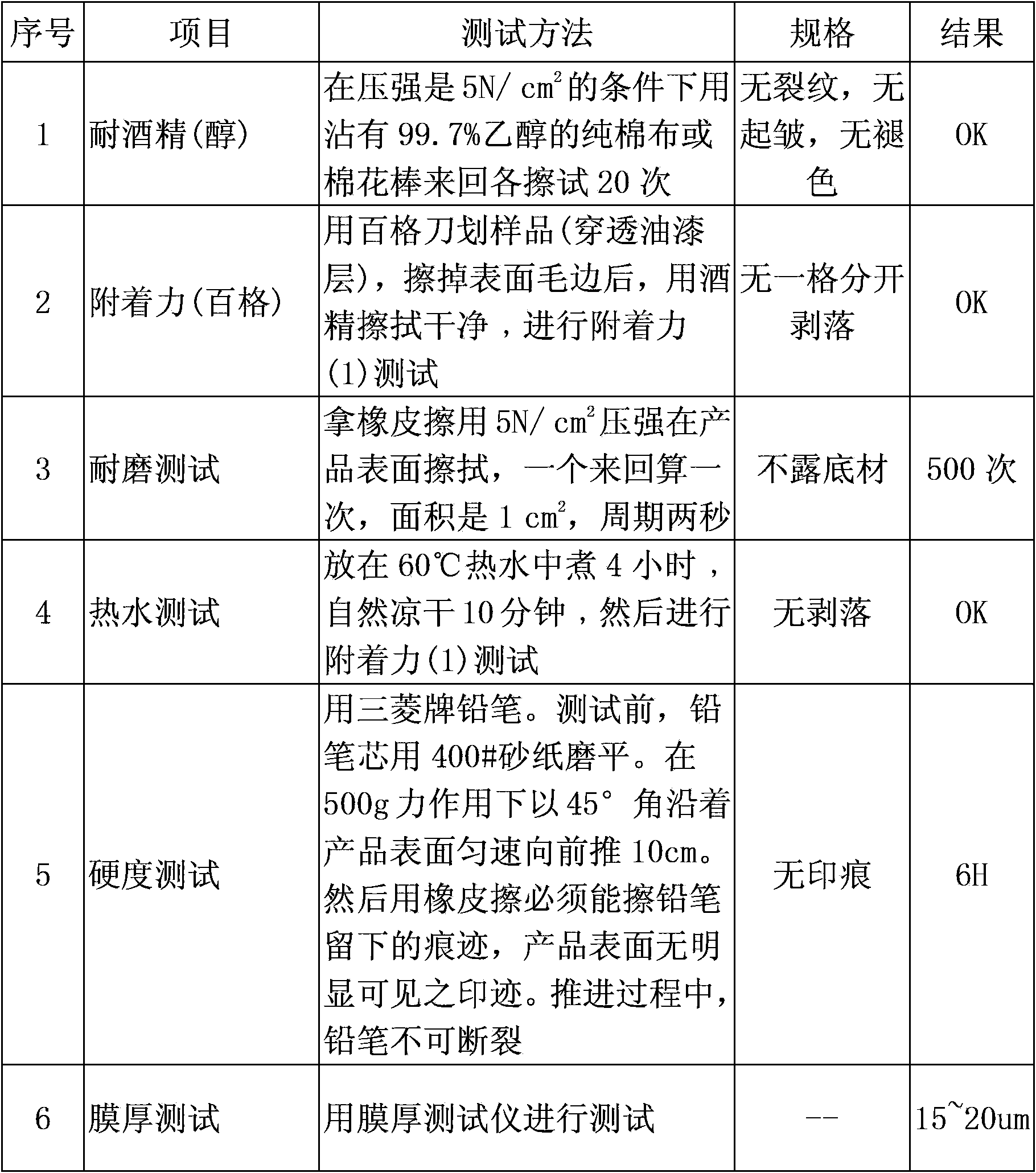

Image

Examples

Embodiment 1

[0043] Described aluminum powder paint, it comprises the following components calculated according to mass fraction:

[0044] K2560 40%;

[0045] 20% CAB381-2 solution 20%;

[0046] BYK333 0.5%;

[0047] Butyl acetate 15%;

[0048] Ethylene glycol butyl ether 5%;

[0049] Xylene 9.5%;

[0050] 40% aluminum powder paste 10%.

[0051] The production method of the aluminum powder paint is, for example, weighing 40g of thermoplastic acrylate resin K2560, adding 15g of butyl acetate and 5g of ethylene glycol butyl ether to dissolve, adding 20% (mass fraction) of CAB381-2 solution and 0.5 g of BYK333, stir evenly, then add 40% (mass fraction) of aluminum powder slurry, add 9.5g of xylene and mix well.

Embodiment 2

[0053] Described aluminum powder paint, it comprises the following components calculated according to mass fraction:

[0054] K2560 30%;

[0055] 20% CAB381-2 solution 18%;

[0056] BYK333 0.5%;

[0057] Butyl acetate 18.5%;

[0058] Ethylene glycol butyl ether 10%;

[0059] Xylene 15%;

[0060] 40% aluminum paste 8%.

[0061] The manufacturing method of embodiment 2 is similar to that of embodiment 1, and will not be repeated here.

Embodiment 3

[0063] Described aluminum powder paint, it comprises the following components calculated according to mass fraction:

[0064] K2560 38.5%;

[0065] 20% CAB381-2 solution 10%;

[0066] BYK333 0.5%;

[0067] Butyl acetate 20%;

[0068] Ethylene glycol butyl ether 8%;

[0069] Xylene 14%;

[0070] 40% aluminum paste 9%.

[0071] The manufacturing method of embodiment 3 is similar to that of embodiment 1, and will not be repeated here.

[0072] The present invention also provides a kind of spraying method of described aluminum powder paint, it comprises the steps:

[0073] Stir the aluminum powder paint and diluent evenly according to a certain mass fraction;

[0074] Spray the diluted aluminum powder paint on the surface of the product by spraying;

[0075] Bake and dry at room temperature or at 50-60°C.

[0076] Wherein, the diluent can include the following components calculated according to mass fraction:

[0077] Ethyl acetate: 70-80%

[0078] Methyl acetate: 10~15%

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap