Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "High hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for enhancing surface of magnesium aluminium alloy by laser remelting

InactiveCN101532134AHigh strengthImprove corrosion resistanceMolten spray coatingSuperimposed coating processOxygenLaser beams

The invention relates to a method for enhancing the surface of magnesium aluminium alloy by laser remelting, aiming at enhancement processing of the surfaces of magnesium aluminium alloy plates and magnesium aluminium alloy rods by the methods of flame spraying of alloyed powder and laser remelting. The method is characterized by cleansing the surface of the magnesium aluminium alloy, carrying out oxy-acetylene flame spraying on the alloyed powder, namely aluminium nickel alloy powder, nickel-chromium-boron-silicon-iron master alloy powder and neodymium powder, carrying out remelting and curing on the surface of the magnesium aluminium alloy on a laser processor, carrying out omnibearing radiation by laser beams according to trace curves set by computer programs so that a nickel base alloy layer is melted and cured on the surface of the magnesium aluminium alloy to form the alloy layer, therefore, the hardness of the surface of magnesium aluminium alloy is greatly improved by 8-10 times as high as that before processing, the wearing resistance and corrosion resistance of the surface of magnesium aluminium alloy are greatly improved respectively by 56% and 56.4%. The method has short process flow, easy realization, safety, stability and reliability and firm solid melting layer, is not easy to fall off and can enhance the surfaces of the magnesium aluminium alloys with various profiles.

Owner:TAIYUAN UNIV OF TECH

Method for casting rotary axis casts of aerogenerators

ActiveCN101618425AImprove yieldReduce manufacturing costFoundry mouldsFoundry coresMetallurgyBlock effect

The invention discloses a method for casting rotary axis casts of aerogenerators, which comprises the steps of mould manufacture, the manufacture of sand moulds and moulding by casting. In the step b of the manufacture of sand moulds, a top sprue (1) is used as an inlet of iron liquor, and is alternately communicated with runners; a bottom runner is communicated with an ingate communicated with a cast mould cavity; the runners are designed into a first runner (3), a second runner (4) and a circular runner (5); the ingate is designed into a plurality of radial runners (6) for communicating the circular runner (5) and the cast mould cavity; filtering apparatuses are arranged on the first runner (3) and the second runner (4), and are also arranged between each radial runner (6) and the circular runner (5); and in the step c of moulding by casting, the casting temperature is controlled from 1310 DEG C to 1350DEG C; and finally, a cast (2) is obtained. The method for casting rotary axis cast of aerogenerator has the advantages of good residue blocking effect and low production cost.

Owner:RIYUE HEAVY IND

Boron-containing semi-high speed steel cold roller and manufacturing method thereof

InactiveCN101407891AReduce manufacturing costReduce the amount addedProcess efficiency improvementElectric furnaceIngotMolten steel

The invention relates to a boron-containing semi high-speed steel cold roller and a manufacturing method thereof and belongs to the field of steel rolling technology. The existing cold rollers have the problems of poor wear-resistance, high production cost and the like. The invention obtains the boron-containing semi high-speed steel cold roller by pouring the molten steel with the compositions of the following weight percentages of 0.30 to 0.45 of C, 3.8 to 4.2 of Cr, 0.2 to 0.6 of Si, 0.2 to 0.6 of Mn, 0.5 to 0.8 of Mo, 0.2 to 0.4 of Ni, 0.3 to 0.6 of Cu, 0.6 to 1.0 of B, 0.3 to 0.7 of V, 0.6 to 0.8 of Ti, 0.1 to 0.3 of Nb, 0.03 to 0.10 of N, 0.25 to 0.45 of Al, less than 0.03 of S, less than 0.04 of P and the residual quantity of Fe into an outer layer of the cold roller and adopting ductile cast iron as a core part or directly pouring the molten steel into ingots. The roller has the advantages of high hardness and intensity, good toughness and wear-resistance, simple production process, low cost, etc.

Owner:BEIJING UNIV OF TECH

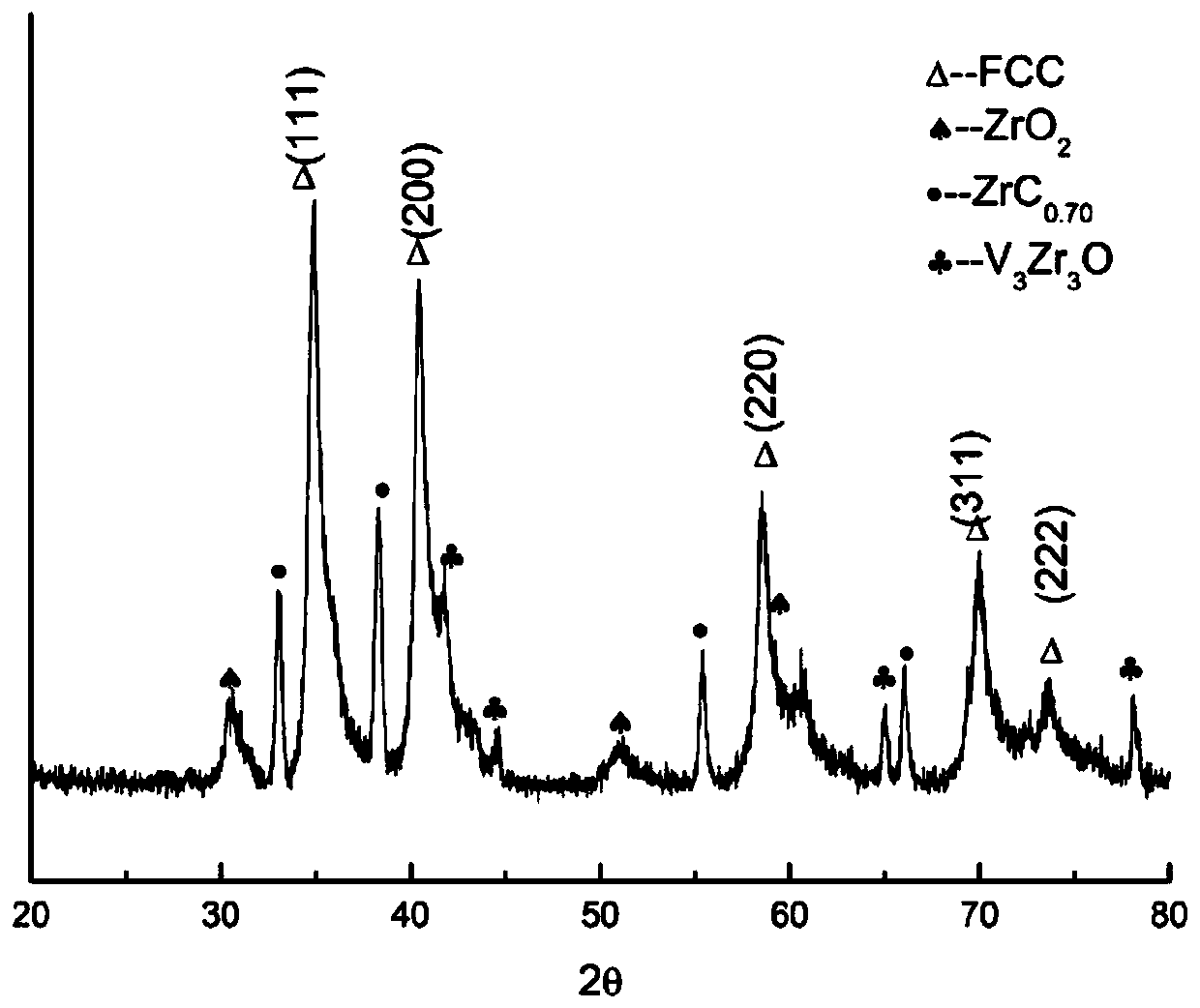

High-hardness and high-elasticity-modulus multi-component nitride coating and preparation method thereof

InactiveCN106835037AIngredient ControlHigh hardnessVacuum evaporation coatingSputtering coatingSputteringAlcohol

The present invention is a multi-component nitride coating with high hardness and high elastic modulus. Its chemical formula is AlCrTiZrNbN, and the atomic ratios of Al, Cr, Ti, Zr, Nb and N are respectively 8-12%: 8-12 %: 8~12%: 8~12%: 8~12%: 48~52%, the thickness of the coating is 2~5μm. The present invention also provides a method for preparing the above-mentioned nitride coating. Firstly, the surface of the substrate is subjected to mirror polishing, then ultrasonically cleaned with acetone and alcohol, and after vacuum ion cleaning, the AlCrTiZrNbN layer is deposited by radio frequency reactive sputtering, wherein AlCrTiZrNbN is mostly The component nitride coating is composed of AlCrTiZrNb alloy target with equiatomic molar ratio in (Ar+N 2 ) atmosphere prepared. The coating of the invention has high hardness and high modulus of elasticity, and can be used as a novel protective coating for various service occasions such as cutting tools and molds.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

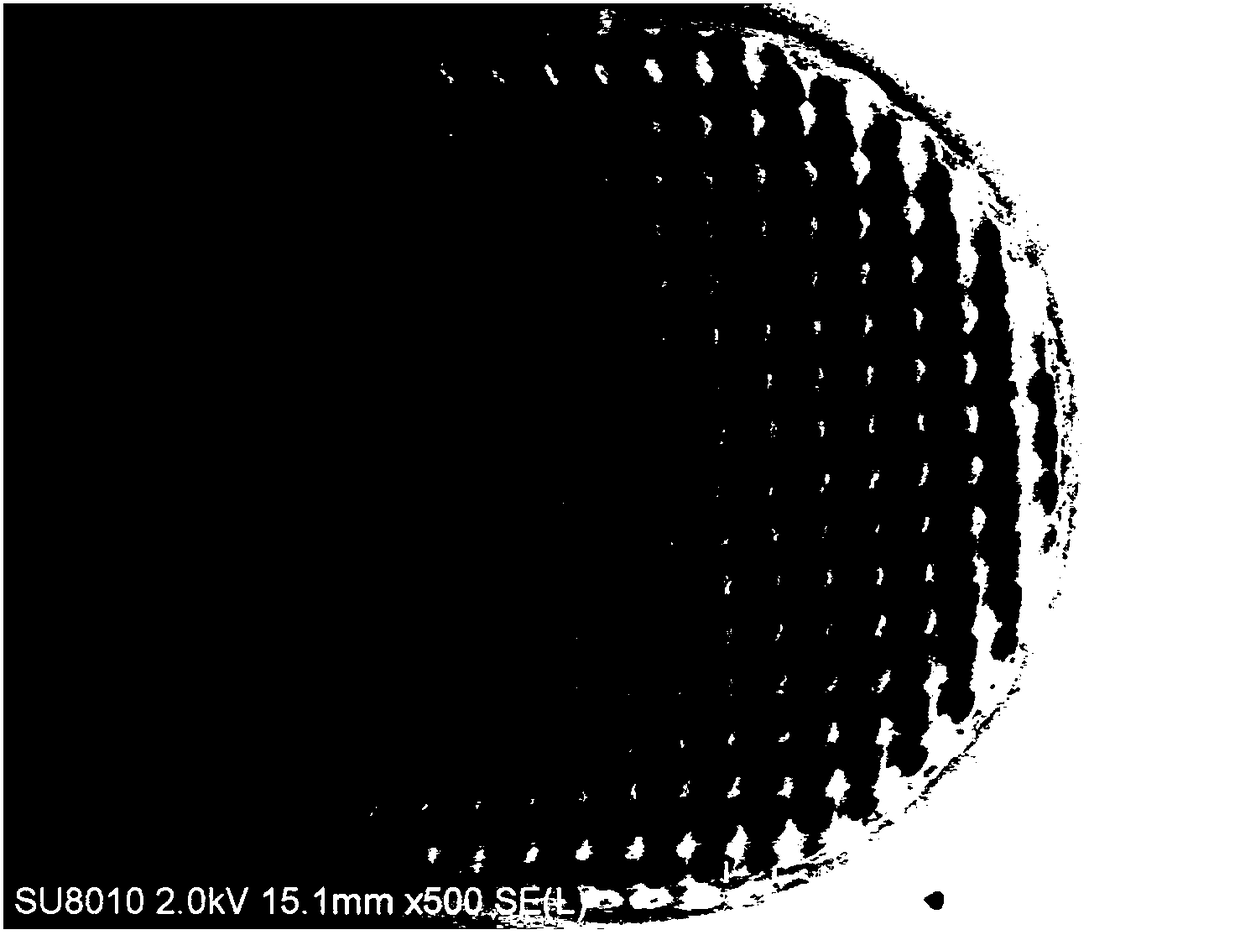

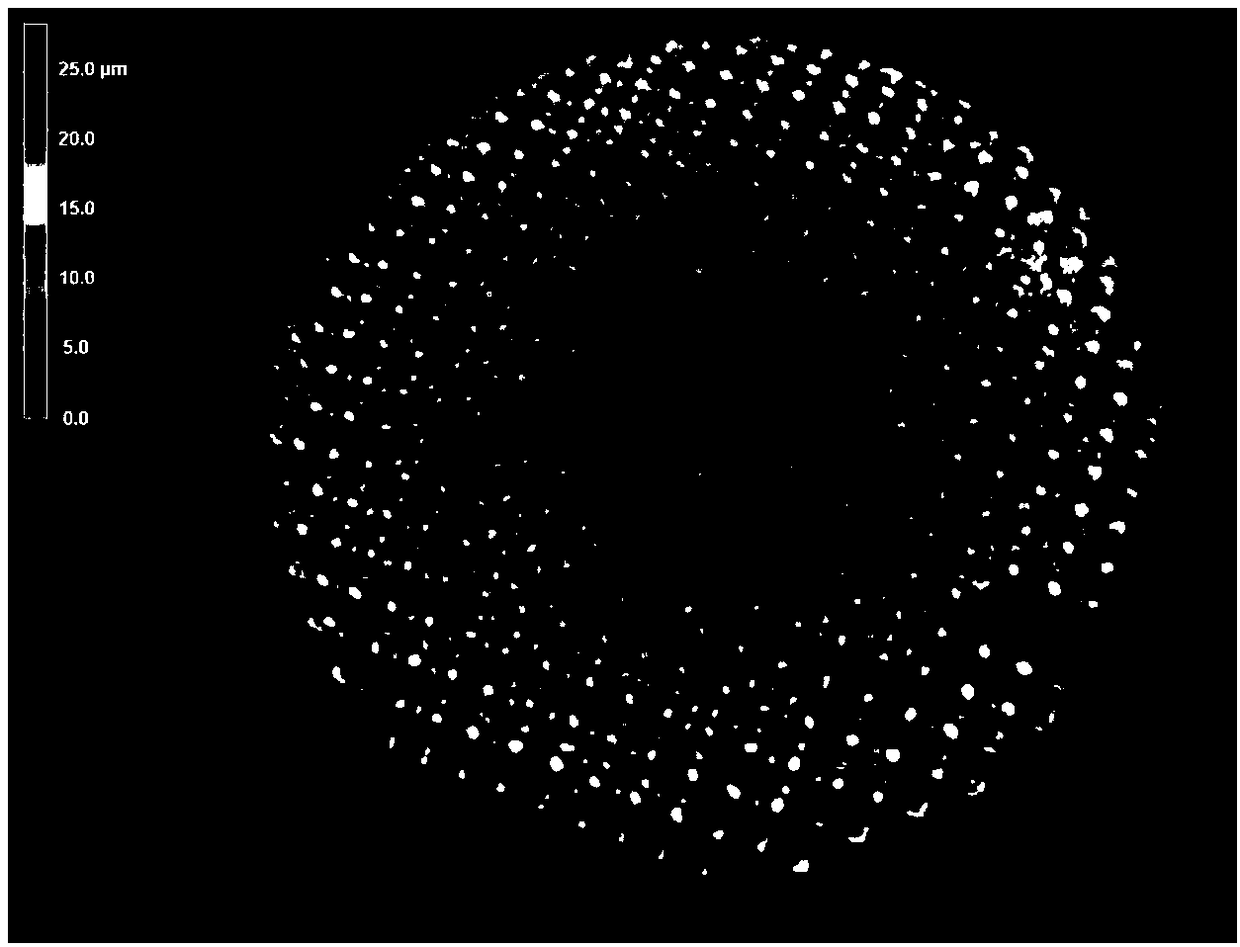

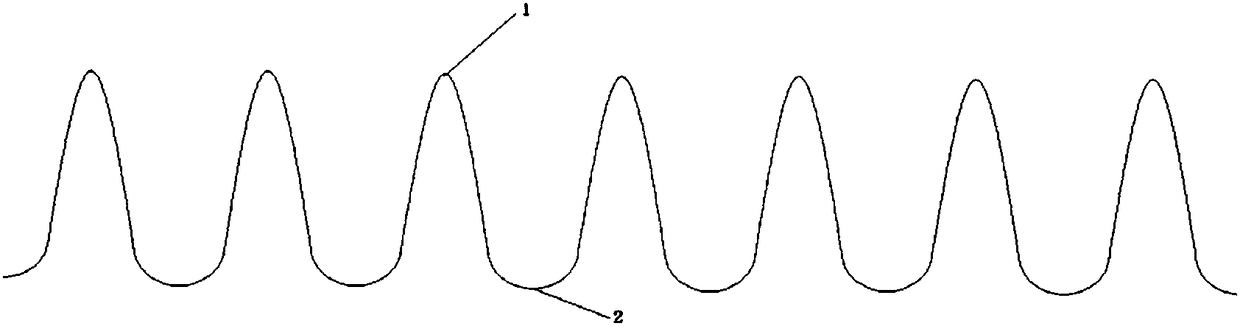

Chopper for improving bonding strength of lead

ActiveCN108389806AImprove bonding performanceImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingWear resistantEngineering

The invention discloses a chopper for improving bonding strength of a lead. The chopper is a welding ceramic chopper and comprises a body, a welding nozzle and a hole, wherein the welding nozzle is arranged at one end of the body, the hole extends along a longitudinal axis of the body and the welding nozzle, and a tip surface of the welding nozzle comprises convex parts and concave parts which arealternatively distributed. By the design of a chopper surface structure, the wear-resistant region of the surface can be expanded, the hardness of the tip surface is improved, the roughness of the surface is improved, and the service lifetime is prolonged; compared with a traditional polishing and thermal processing chopper, the chopper has the advantages of better bonding effect and higher stability; on one hand, the gold reservation degree of a tip is effectively reduced by the design; and on the other hand, the wear-resistant degree of a porcelain nozzle is improved, and thus, the servicelifetime of the porcelain nozzle is prolonged.

Owner:CHAOZHOU THREE CIRCLE GRP

Solar photoelectric photo-thermal integrated assembly and solar combined heat and power generation system thereof

InactiveCN103594538AEliminates the effects of thermal contact resistanceEliminate the effects ofPV power plantsEnergy industryCells panelMetal sheet

The invention relates to a solar photoelectric photo-thermal integrated assembly and a solar combined heat and power generation system of the solar photoelectric photo-thermal integrated assembly. The solar photoelectric photo-thermal integrated assembly is characterized by comprising a photovoltaic cell panel provided with a metal outer frame, a metal sheet type heat exchanger and a heat-preservation material layer, wherein the metal sheet type heat exchanger and the heat-preservation material layer are sequentially arranged on the back surface of the photovoltaic cell panel in parallel and in an overlapped mode, and are rapidly fixed in the metal outer frame of the photovoltaic cell panel through a metal fixing clamp, and the standard photovoltaic cell panel can be rapidly modified into the photoelectric photo-thermal integrated assembly. The photoelectric photo-thermal integrated assembly has the advantages of being compact in structure, high in efficiency, small in pressure loss, light in weight, flexible to install, high in pressure bearing performance, resistant to corrosion, low in cost and the like, further reduces the initial investment and installation space of a medium and low temperature solar thermoelectric system, lowers the operation expenses of the system, and is suitable for civil and industrial occasions requiring for both heat and power.

Owner:SHANGHAI LVJIAN ENERGY TECH

Lightweight cylinder sleeve and preparation process thereof

ActiveCN113719373AFacilitate pouring handling workHigh hardnessCoatingsCylinder headsAlkali soilCylinder block

Owner:ZYNP GRP ANHUI CO LTD

Fluorine-containing aqueous coating composition

InactiveCN1738878AGood chemical resistanceImprove water resistancePolyurea/polyurethane coatingsWater dispersibleSolvent

A fluorine-containing aqueous coating composition composed of (A) an aqueous emulsion of a functional group-containing fluororesin obtained by dispersing, in water, a fluoroolefin copolymer having a functional group that is obtained through solution polymerization and (B) a water-dispersible unblocked isocyanate compound is disclosed. The fluororesin aqueous coating composition can be cured at ordinary temperature, and a coating formed therefrom is excellent in chemical resistance, water resistance, solvent resistance, contamination resistance, hardness, weathering resistance and durability.

Owner:DAIKIN IND LTD

Method of making semiconductor devices having protruding contacts

InactiveUS6107120AHigh hardnessSemiconductor devicesSemiconductor/solid-state device detailsDiffusion barrierElectrode

Owner:PANASONIC CORP

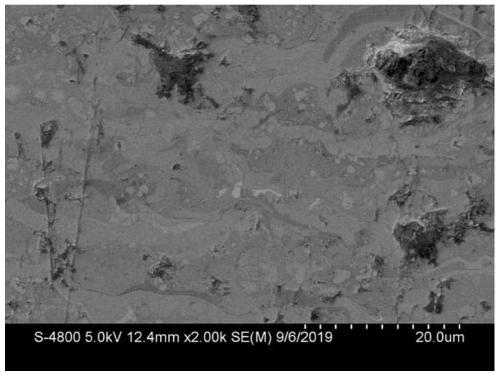

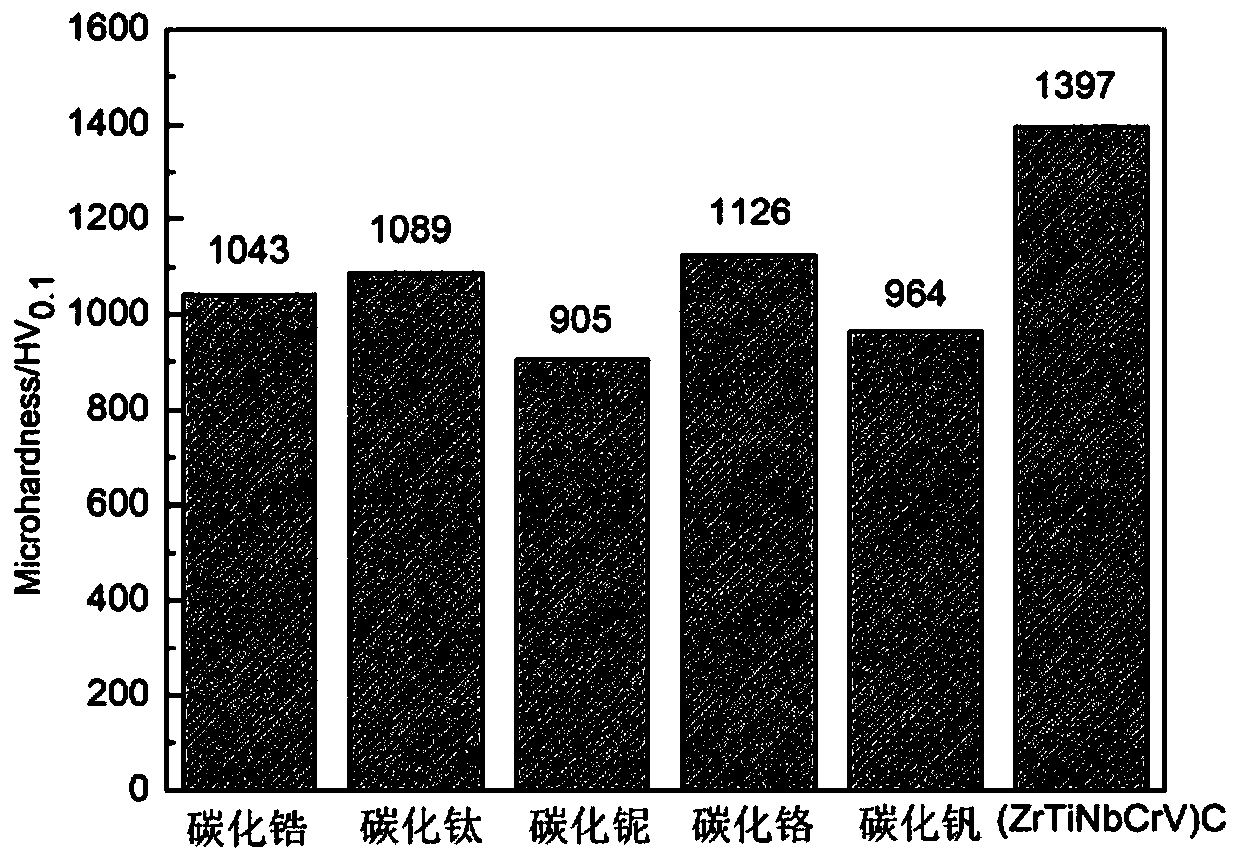

Preparation method of high-entropy ceramic coating

Owner:HEBEI UNIV OF TECH

Superhard non-stick silicon cooker coating prepared by sol-gel hybridization technique

InactiveCN102002268ALower sintering temperatureIncreased durabilityCoatingsSilicic acidCeramic coating

The invention discloses a superhard non-stick silicon cooker coating prepared by a sol-gel hybridization technique. The coating comprises the following components: 30-50% of nanometer silica, 20-40% of silicic acid compound, 5-10% of magnesium-calcium compound, 3-5% of ammonium chloride, 0.5-2.0% of catalyst, 1-4% of accessory ingredient, 0.5-2.0% of silane coupling agent, 15-25% of multielement organosilicon material, 5-10% of absolute ethyl alcohol and 10-20% of distilled water. The preparation method of the coating comprises the following steps: using a sol-gel method to synthesize nano CaO-SiO2 power; replacing Ca by Mg to develop a (Ca, Mg)SiO3 nano power material; introducing low-temperature sintered assistant precursors into sol to reduce the sintering temperature of ceramics; and adding a defined amount of organosilicon material to adjust the hardening temperature of the ceramics to obtain the low-temperature sintering nano ceramic coating at the temperature below 250 DEG C. The superhard non-stick silicon cooker coating has strong adhesive force, high hardness, small possibility of scratch, and impact resistance, is non-toxic and environment-friendly, and can completely replace Teflon non-stick coatings.

Owner:DONGGUAN EONTEC CO LTD

Additive and method for producing 6 micron high-hardness electrolytic copper foil by using additive

The invention relates to an additive. The additive comprises a hardness agent and a brightening agent; the hardness agent is an aqueous solution A containing 1,3-thiazolidin-2-one, DPS and MESS, wherein in the aqueous solution A, the concentration of 1,3-thiazolidin-2-one is 0.5-10 ppm, the concentration of DPS is 10-50 ppm, and the concentration of MESS is 1-20 ppm; and the brightening agent is an aqueous solution B containing SPS and Cl-, wherein in the aqueous solution B, the concentration of SPS is 10-50 ppm, and the concentration of Cl- is 10-30 ppm. According to 6 micron electrolytic copper foil made through the method, a HVS-1000 desktop hardness meter is adopted for detecting a hardness value, hardness is remarkably improved (can reach 120-150 HV), water ripples are greatly relieved, and the added technical value is remarkably improved.

Owner:LINGBAO WASON COPPER FOIL

Hydrophobic scratch-resistant coating on organic polymer surface and preparation method thereof

Owner:SHANGHAI UNIV

Ionic nitriding heat treatment technique of 35CrMoV toothed sleeve or toothed ring for centrifugal compressor

ActiveCN106893822AHigh strengthHigh hardnessFurnace typesSolid state diffusion coatingHardnessUltimate tensile strength

The invention discloses an ionic nitriding heat treatment technique of a 35CrMoV toothed sleeve or toothed ring for a centrifugal compressor and belongs to the technical field of heat treatment techniques. The ionic nitriding heat treatment technique comprises the following steps that (1) normalizing treatment is conducted, specifically, the normalizing temperature is 900 DEG C, the heat preservation time is (effective thickness / 40mm) hours, and then air cooling is conducted; (2) quenching treatment is conducted, specifically, the quenching temperature is 900 DEG C, the heat preservation time is (effective thickness / 40mm) hours, and then oil cooling is conducted; (3) tempering treatment is conducted, specifically, the tempering temperature is 600 DEG C, the heat preservation time with the unit being hour is 1.5 times the quenching heat preservation time, and then air cooling is conducted; and (4) ionic nitriding treatment is conducted, specifically, ionic nitriding is conducted at the temperature of 520 DEG C for 18.0-25.0 h, furnace cooling is conducted till the temperature is lowered to be 200 DEG C, and then a product is moved out of a furnace and subjected to air cooling. The contact-fatigue strength of a workpiece treated through ionic nitriding heat treatment can be greatly improved owing to the fact that the core strength and hardness are improved.

Owner:SHENYANG TURBO MASCH CORP

Cured In Place Pipe Liner With Styrene Barrier

InactiveUS20100243154A1Promote migrationHigh hardnessPipe elementsRecord information storageEngineeringCured-in-place pipe

A liner for repairing damaged pipes, such as underground sewer or gas pipes is disclosed. The liner comprises a TPU coating on fibrous mat of non-woven fabric. The TPU coating contains a barrier layer to retard the migration of styrene from the liner to the media used to force the liner against the damaged pipe and to activate the thermoset resin. The thermoset resin converts the liner from a flexible state to a rigid state as the liner is cured in place inside the pipe.

Owner:LUBRIZOL ADVANCED MATERIALS INC

High-temperature bearing steel and cleaning and homogenizing preparation method thereof

Owner:CENT IRON & STEEL RES INST

Preparation method of TiC ceramic coating

InactiveCN1807700AImprove bindingGuaranteed bondingElectrolytic inorganic material coatingElectrochemical responseCeramic coating

The invention discloses a TiC ceramic coating preparing method, which comprises the following steps: 1) placing block metal Ti electrode(1) and working electrode(4) in coal oil(2); 2) connecting anode of impulsing power source(3) to block metal Ti electrode(1); linking up with cathode of impulsing power source(3) and work electrode(4); 3) making connection with impulsing power source(3); carrying on electrochemical reaction with Ti metallic ion released form metal and C ion ionized from coal oil(2); compounding ceramic coating(5) of ceramic film TiC and depositing on the surface of work electrode. The invention improves the stability of craft and cementing property of basilemma.

Owner:GUANGDONG UNIV OF TECH

Seam binding agent with modified fatty amine as epoxy curing agent resin

ActiveCN102816501AFast shapingEasy constructionNon-macromolecular adhesive additivesEpoxy resin adhesivesCalcium silicateFiber

The invention relates to a seam binding agent with modified fatty amine as epoxy curing agent resin. The agent is suitable for easy-cracking positions in indoor and outdoor decorations. The agent is filled into seams of same or different materials such as wood, brick and stone, gypsum board, calcium silicate, and the like, for providing an excellent anti-cracking effect. The agent can also be used as a binding agent for roof leakage repairing, wood, and plastic. The agent can be used in crack sealing and water proofing of various grouting projects, bridges, and tunnels. According to the invention, a novel nano fiber binding technology is adopted. When the product is cured, nano fibers in the product form a high-molecular high-density net-shaped film at a seam position, wherein the physical density of the film is close to that of wood board or gypsum board. The film can expand or contract synchronically with the board when weather is changed, and has good cracking resistance, adhesive force, and flexibility. The seam binding agent is advantaged in fast shaping, easy construction, and low sagging.

Owner:SKSHU PAINT

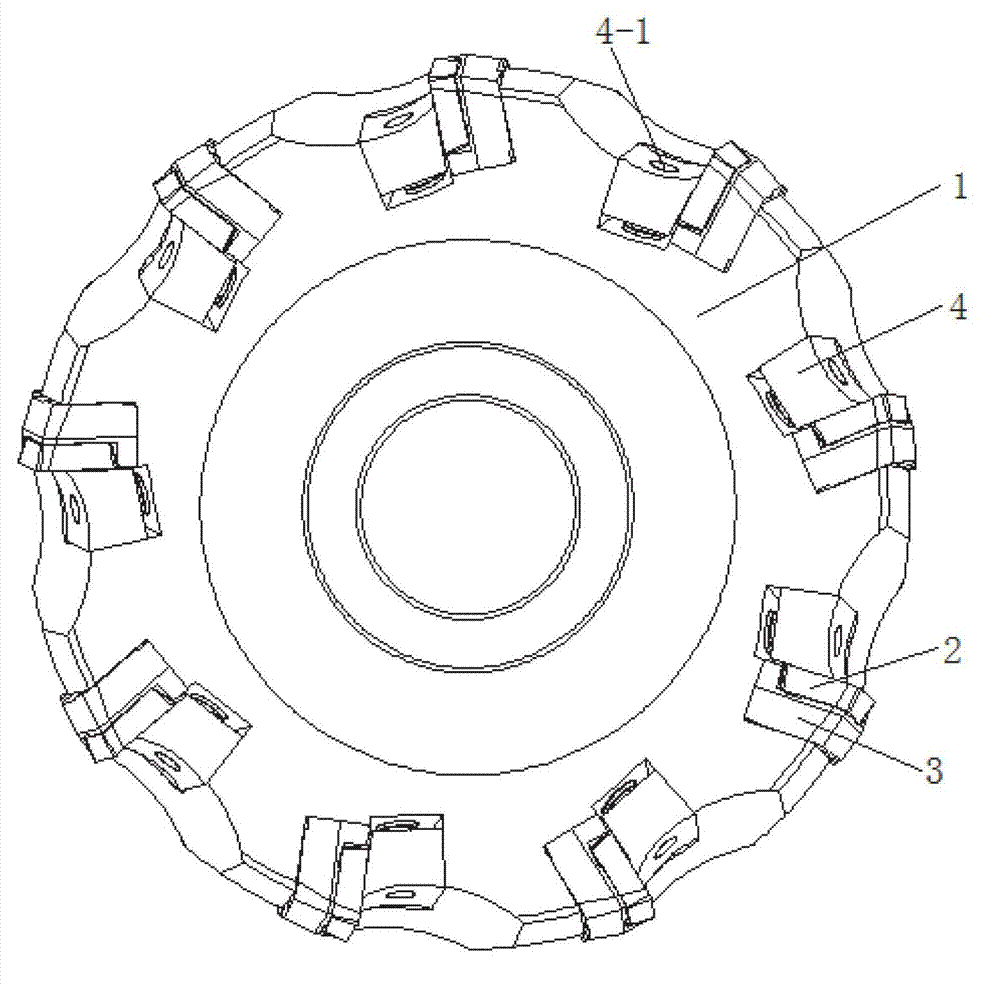

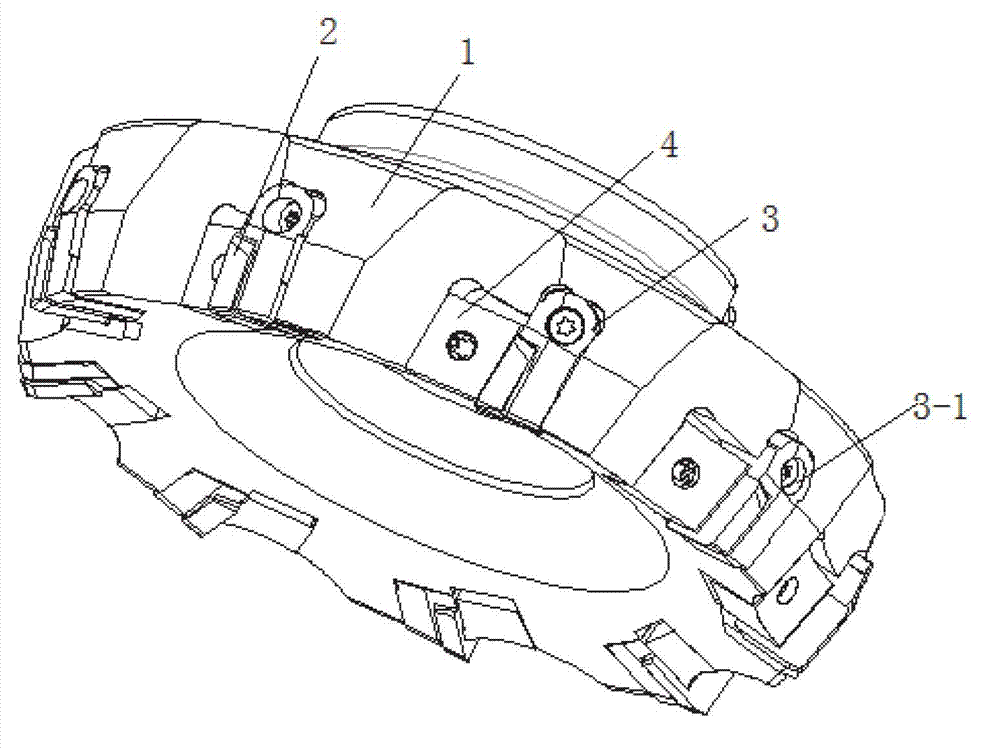

Face milling cutter with indexable inserts and knife pads thereof

The invention discloses a face milling cutter with indexable inserts and knife pads thereof. Each knife pad is provided with a knife pad screw hole and a step groove. The step groove comprises a blade bottom contact face, a blade axial locating face and a blade radial locating face which are connected with each other. A notch with three sides opening is formed in each knife pad. Due to the design of the unique knife pads, blades are not in direct contact with a cutter body, the rigidity of the cutter body is greatly strengthened, the abrasion of the cutter body is reduced, the service life of the cutter is prolonged on the whole, and meanwhile the blades are enabled to be located without the need of being in contact with the cutter body, and the accuracy of repeated locating is high. The service life of the cutter is longer than face milling cutters of other types by more than 50%, the accuracy of processing workpieces is improved by more than one accuracy level, the replacement of the blades is convenient, and the processing cost is reduced greatly.

Owner:常州瑞诺切数控刀具有限公司

Double-membrane seawater desalination process

PendingCN111392934AElevated mineral contentHigh hardnessMultistage water/sewage treatmentSeawater treatmentAqueous solutionCarbon dioxide

Owner:青岛百发海水淡化有限公司

Fluorine-free plasma curing process for porous low-k materials

InactiveUS7011868B2Improving elastic modulusImproving material hardnessSilicaPlastic/resin/waxes insulatorsFluorine freeElastic modulus

Low dielectric constant porous materials with improved elastic modulus and material hardness. The process of making such porous materials involves providing a porous dielectric material and plasma curing the porous dielectric material with a fluorine-free plasma gas to produce a fluorine-free plasma cured porous dielectric material. Fluorine-free plasma curing of the porous dielectric material yields a material with improved modulus and material hardness, and with comparable dielectric constant. The improvement in elastic modulus is typically greater than or about 50%, and more typically greater than or about 100%. The improvement in material hardness is typically greater than or about 50%. It is emphasized that this abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims 37 CFR §1.72(b).

Owner:JSR CORPORATIOON +1

Inorganic ceramic coating for building durability protection

Owner:北京固瑞恩科技有限公司

Structure of motor-mount for electric vehicle

InactiveUS20150069685A1Characteristic be lowHigh hardnessDampers-spring combinationsElectric propulsion mountingElectric motorElectric vehicle

Owner:HYUNDAI MOTOR CO LTD

Thermal insulation daily-use ceramic product and preparation method thereof

InactiveCN109627033AGood insulation performanceHigh hardnessCeramic materials productionClaywaresEmulsionEnvironmentally friendly

Owner:福建省德化县鹏欣陶瓷有限公司

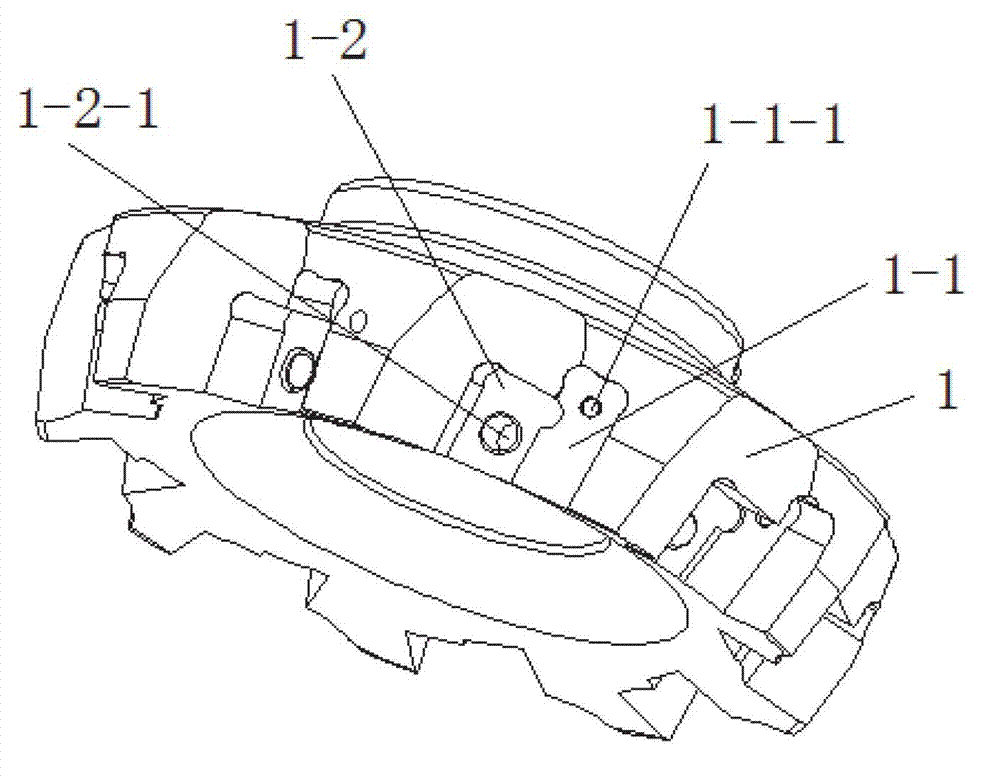

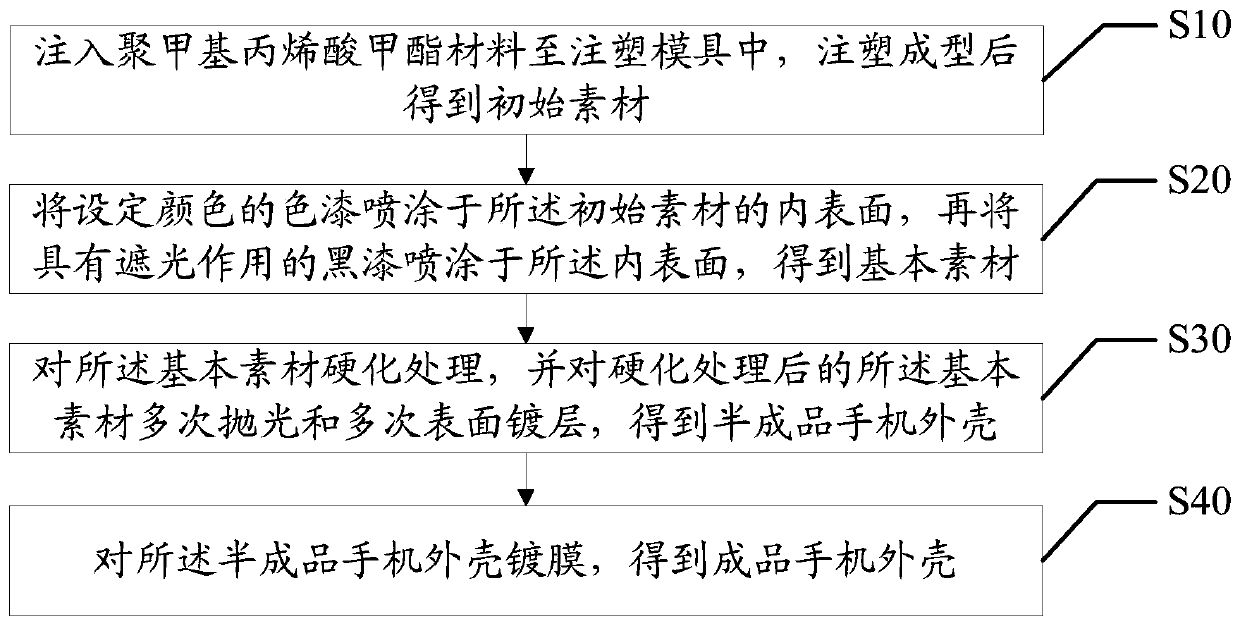

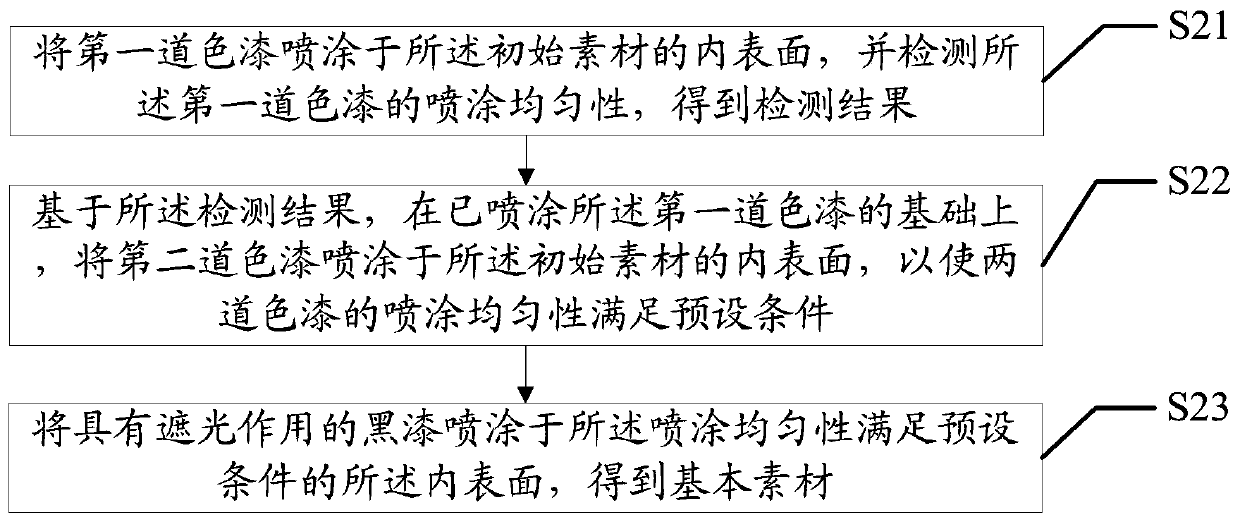

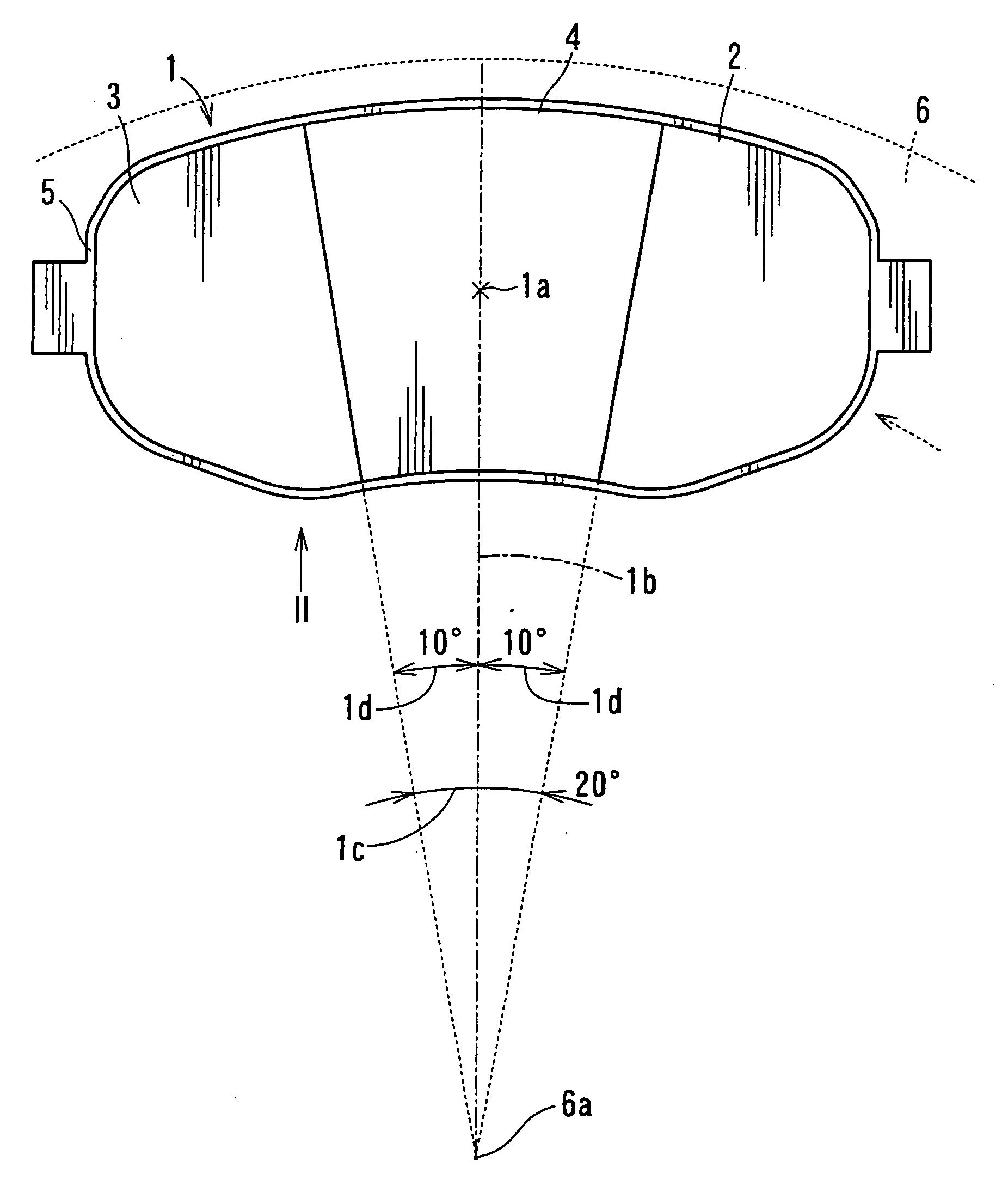

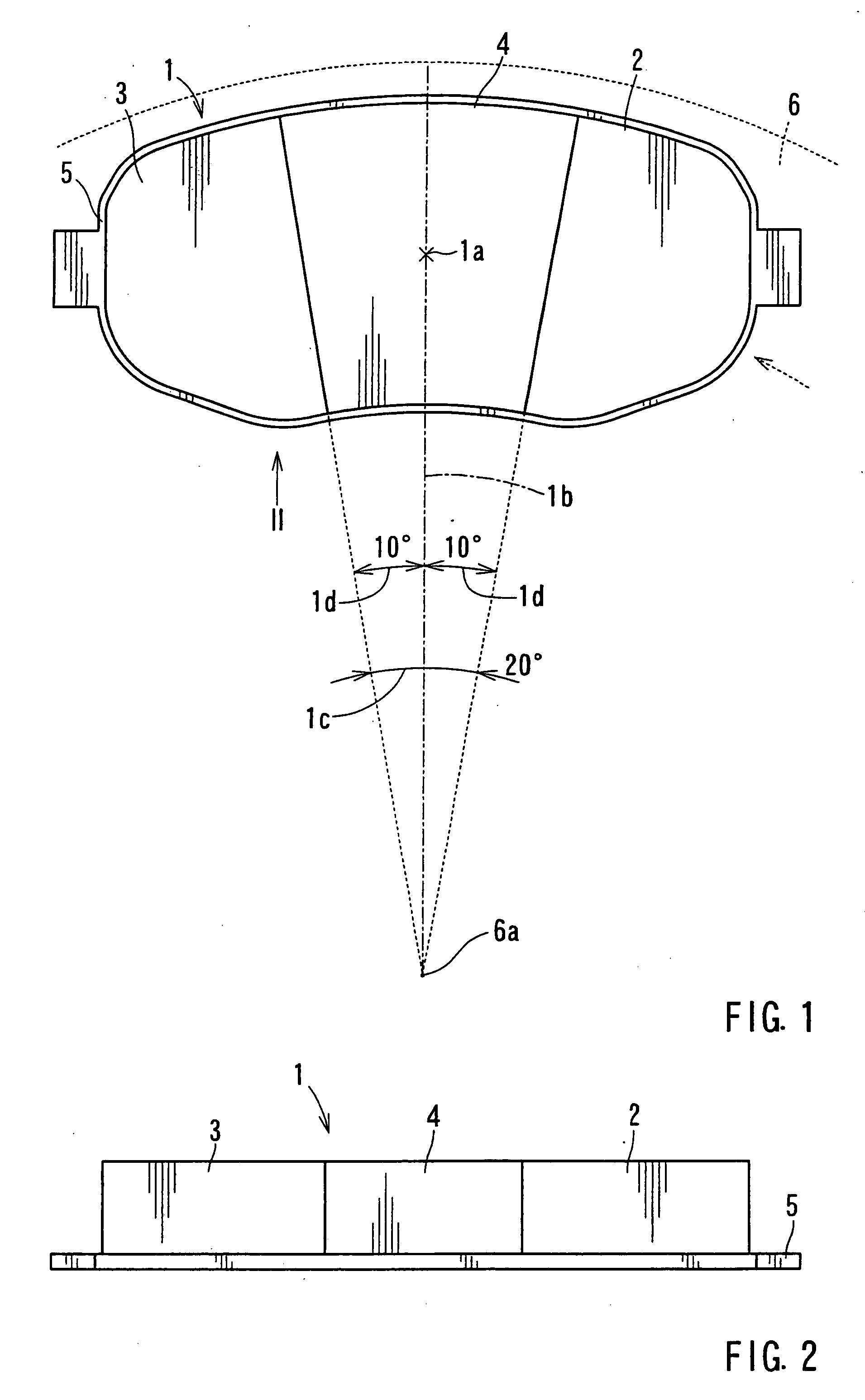

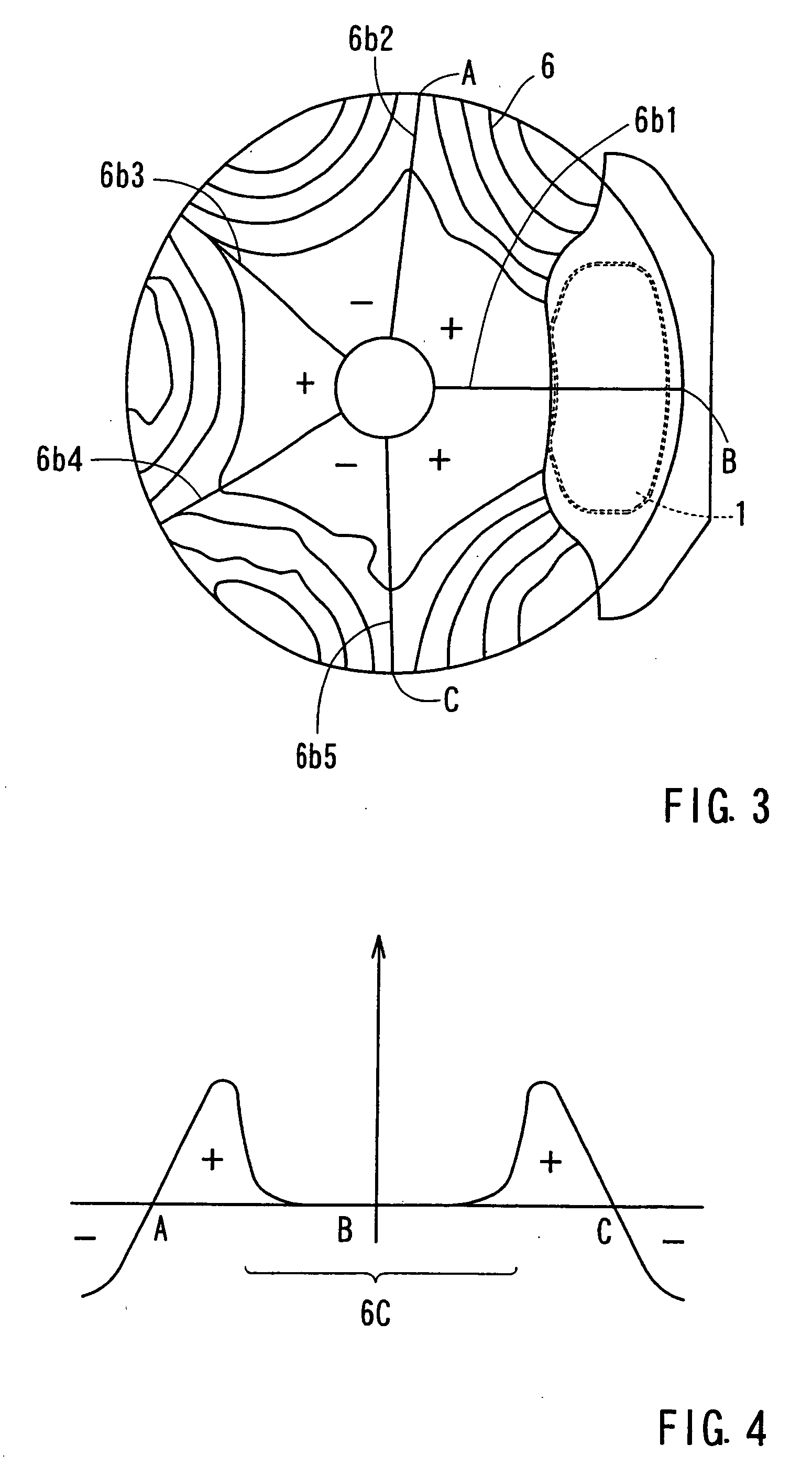

Hybrid pads for disc brakes

Owner:HIROMASA OKAMURA

Polyvinyl Chloride Resin Composition for Automotive Electric Wire, and Ultrathin-Wall Low-Voltage Electric Wire for Automobile

ActiveUS20150240104A1High hardnessPlastic/resin/waxes insulatorsInsulated cablesChemistryPlasticizer

Owner:YAZAKI CORP

Guide and guard roller for guiding steel billet in high speed wire rolling machine and its making process

InactiveCN1847439AGood high temperature wear resistanceHigh hardnessFurnace typesHeat treatment furnacesAlloyChemical composition

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Waterborne polyurethane super wear-resistant finish paint and preparation process thereof

ActiveCN109456690ASmall particle diameterGood dispersionPolyurea/polyurethane coatingsWear resistantWear resistance

The invention discloses waterborne polyurethane super wear-resistant finish paint and a preparation process thereof, and relates to the technical field of preparation of finish paint, aiming at solving the problem that the finish paint is poorer in wear resistance, so that local damage is easily caused in a using process. The finish paint is prepared from a component A and a component B, wherein the component A is prepared from the following raw materials: 50-60 parts of waterborne polyurethane resin AH-1618, 12-18 parts of polyurethane color paste, 0.8-1.2 parts of a leveling agent BYK346, 0.3-0.5 part of an aqueous leveling agent BYK333, 0.3-0.6 part of a polyurethane rheological agent SN612NC, 0.3-0.5 part of a defoaming agent BYK024, 0.08-0.1 part of a defoaming agent Tego901W, 0.8-1.5parts of rutile titanium dioxide, 8-10 parts of wear-resistant ball powder, 0.8-1.5 parts of an aqueous scratch-resistant agent, 1.2-1.6 parts of propylene glycol methyl ether and 12-18 parts of deionized water; the component B is prepared from 95-100 parts of a polyurethane curing agent; the ratio of parts by weight of the component A to parts by weight of the components B is equal to (4-6) to 1. The waterborne polyurethane super wear-resistant finish paint has good wear resistance after being cured.

Owner:SHANGHAI BOGE BUILDING MATERIALS CO LTD

Al2O3-TiC/Al2O3-TiC-CaF2 self-lubricating laminated ceramic drawing die and preparation method thereof

The invention relates to a drawing die and particularly relates to an Al2O3-TiC / Al2O3-TiC-CaF2 self-lubricating laminated ceramic drawing die and also relates to a preparation method of the laminated ceramic drawing die. The technical scheme is as follows: the Al2O3-TiC / Al2O3-TiC-CaF2 self-lubricating laminated ceramic drawing die mainly comprises an Al2O3-TiC layer ceramic material and an Al2O3-TiC-CaF2 layer ceramic material, wherein the Al2O3-TiC layer ceramic material comprises the following components according to the volume ratio: 45% of aluminum oxide, 50% of titanium carbide, 0.5% of molybdenum, 4.5% of nickel and trace magnesium oxide and yttrium oxide; the Al2O3-TiC-CaF2 layer ceramic material comprises the following components according to the volume ratio: 30% of aluminum oxide, 60% of titanium carbide and 10% of calcium fluoride. The Al2O3-TiC layer ceramic material and the Al2O3-TiC-CaF2 layer ceramic material are laminated according to the design requirements of different wire processing sizes for the ceramic drawing die, and the ceramic die obtained after sintering retains higher hardness and strength, meanwhile, the toughness of the die is improved, and in addition, the whole die has a self-lubricating characteristic in the drawing process, so that the wear reducing and resisting effects are remarkable.

Owner:UNIV OF JINAN

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap