Face milling cutter with indexable inserts and knife pads thereof

A face milling cutter and shim technology, which is applied in the field of indexable face milling cutters and shims, can solve the problems of complicated adjustment and adjustment of working time by operators, affecting the service life of the tool, and destroying the slot groove of the blade, so as to achieve enhanced Effects of rigidity, reduction in processing cost, and downsizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

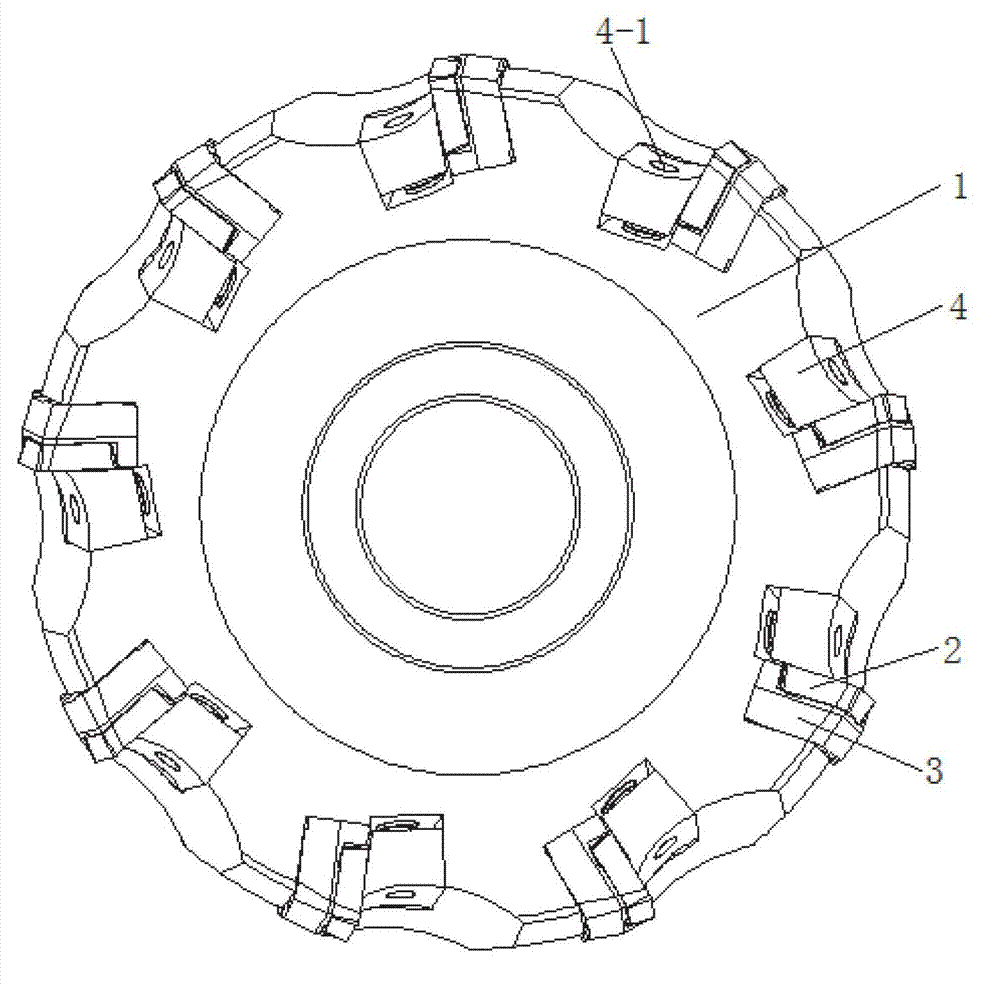

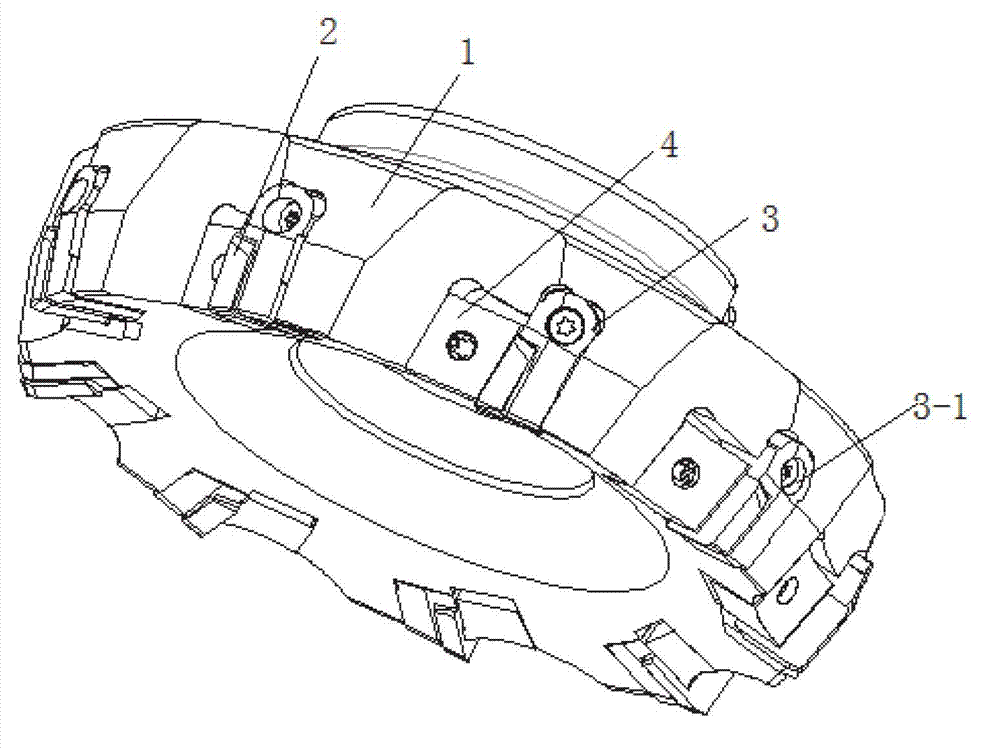

[0030] See Figure 1 to Figure 6 , The indexable face milling cutter of this embodiment includes a cutter body 1, a blade 2, a cutter shim 3, a pressing block 4 and a fixing screw 5.

[0031] The fixing screws 5 include a shim fixing screw 5-1 and a pressing block fixing screw 5-2.

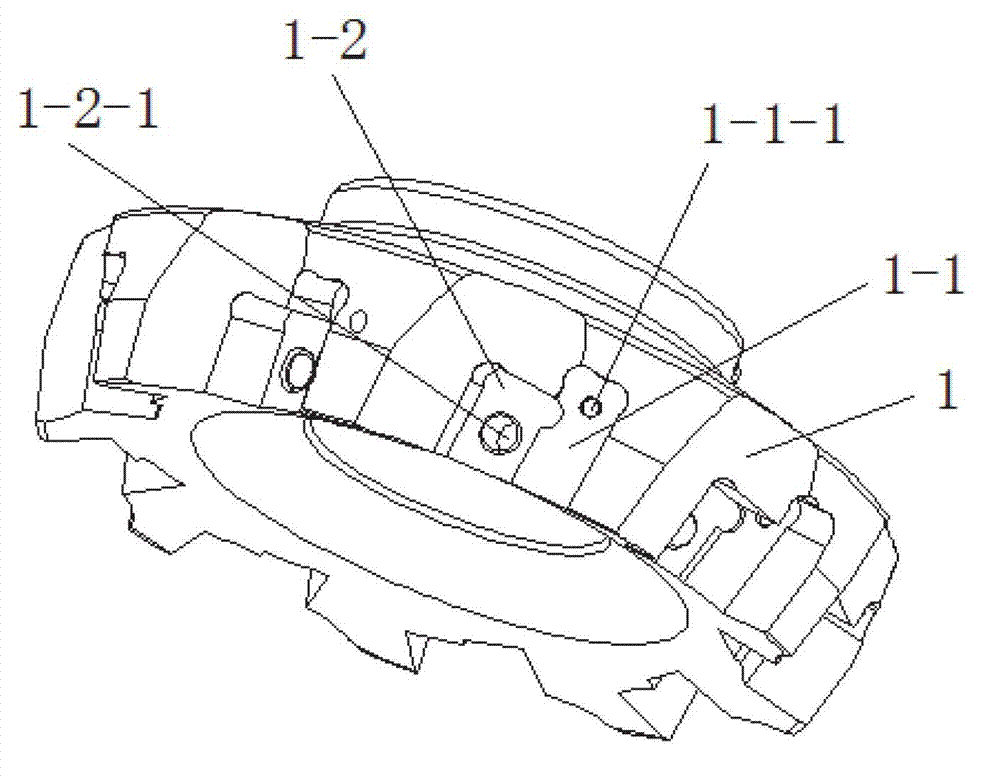

[0032] See image 3 , 9 sets of shim installation grooves 1-1 and pressure block installation grooves 1-2 are evenly distributed on the cutter body 1 along the axial blade inclination angle direction. Each group of shim mounting grooves 1-1 and pressing block mounting grooves 1-2 are connected to each other. The bottom of the shim mounting groove 1-1 is provided with a shim mounting hole 1-1-1. A briquetting mounting hole 1-2-1 is provided on the groove bottom of the briquetting mounting groove 1-2.

[0033] The blade 2 is a blade with 4 cutting edges, and a small hole is arranged in the middle for anti-vibration.

[0034] The shim 3 is set in the shim installation groove 1-1, and the shim sc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap