Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13 results about "Work time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

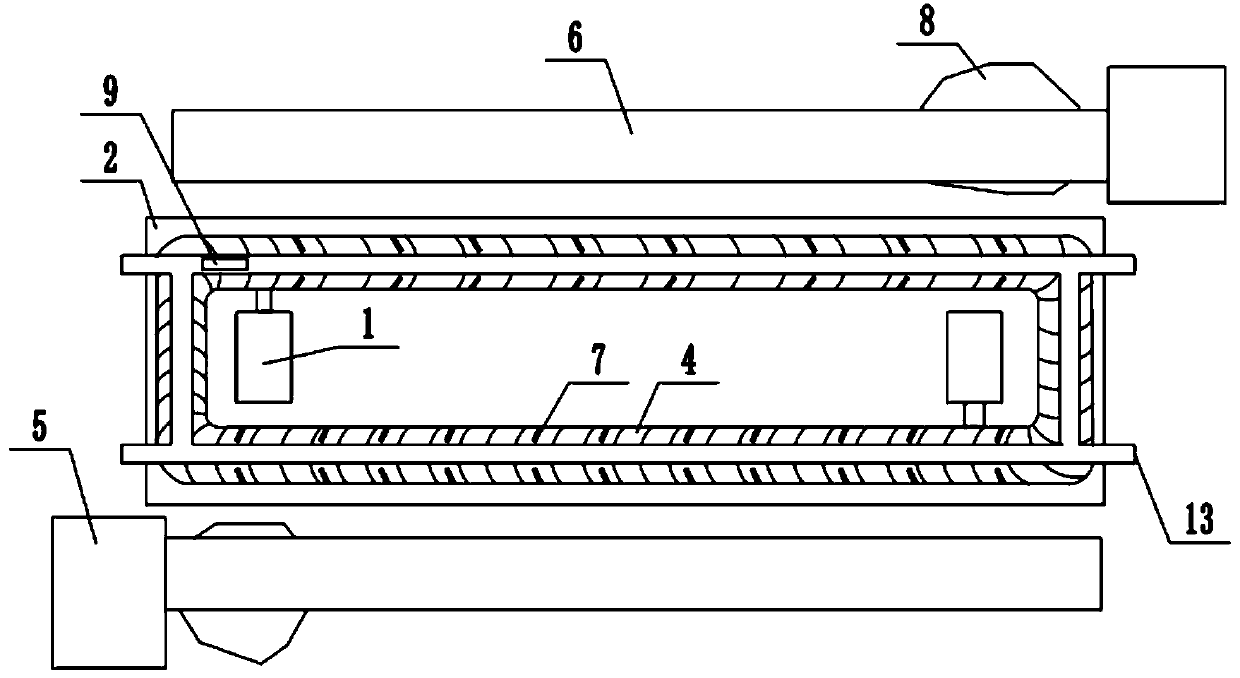

Storage transfer robot group with automatic charging function and wireless automatic charging method thereof

InactiveCN108512272ARealize automatic allocation and chargingImprove transportation efficiencyMobile unit charging stationsElectric powerLogistics managementLogistic management

Owner:LIUZHOU FUNENG ROBOT DEV CO LTD

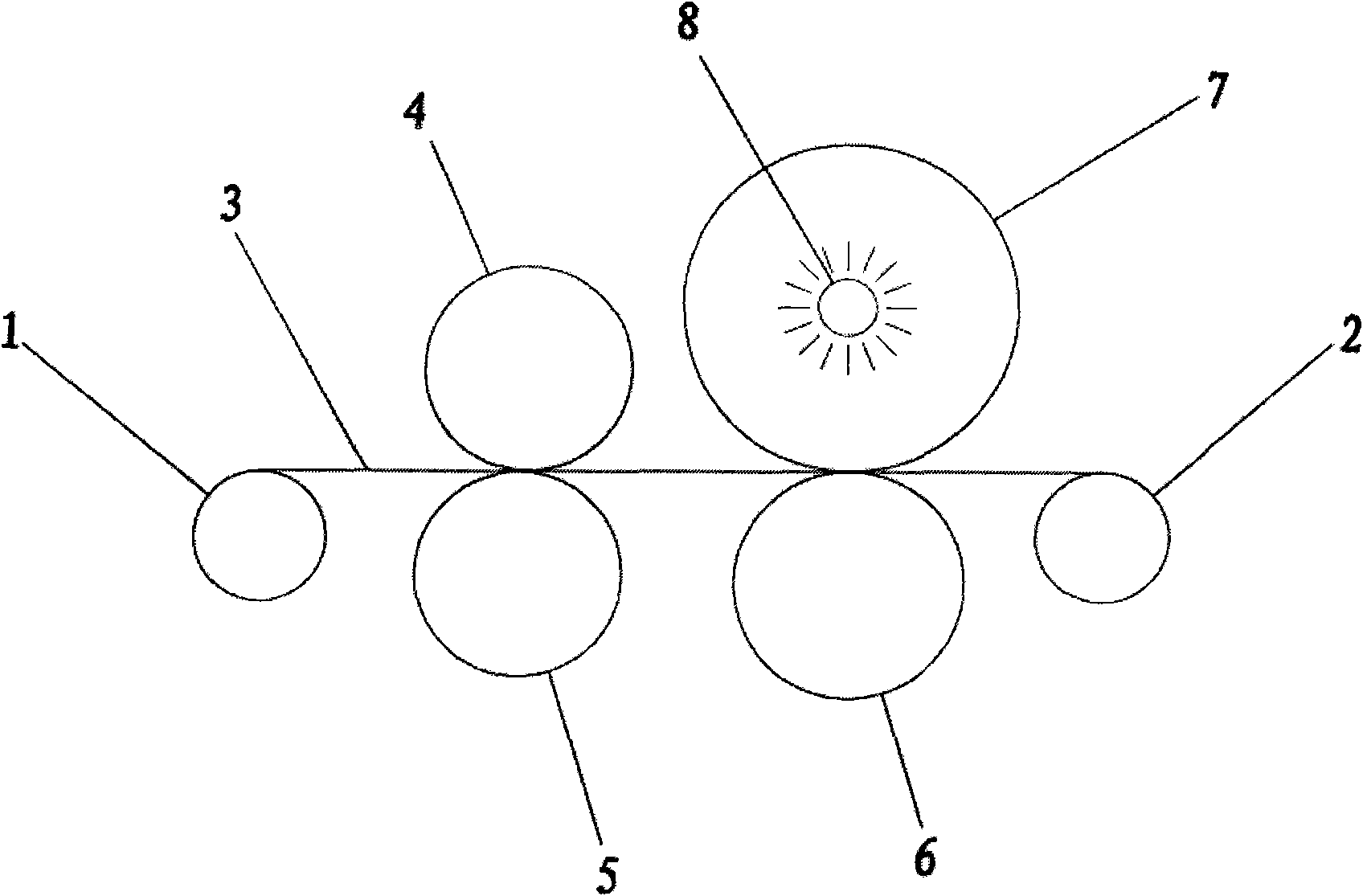

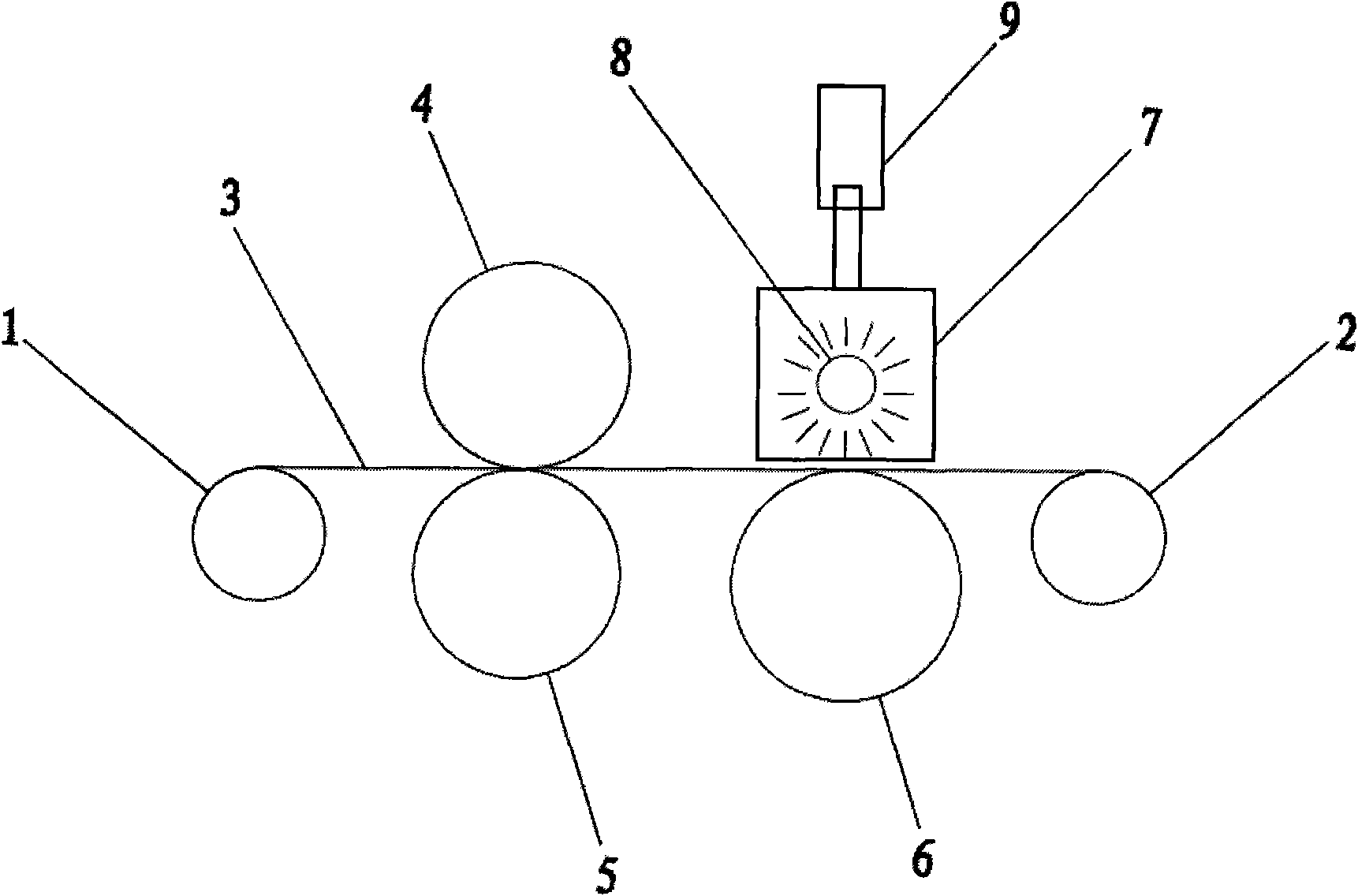

Method and device for obtaining holographic patterns and printing machine with same

InactiveCN101797850AShorten the timePrevent fallingRotary pressesOther printing apparatusEngineeringPrinting press

Owner:BROTECH GRAPHIC

Non-contact synchronous measuring instrument for subgrade and rail vibration

InactiveCN101915603AAvoid the influence of human factorsRealize intelligenceSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansVibration amplitudeStatic random-access memory

The invention relates to a non-contact synchronous measuring instrument for subgrade and rail vibration. A CCD (Charge Coupled Device) drive circuit is respectively connected with a CCD video signal binaryzation processing unit, an A / D and SRAM (Static Random Access Memory) working time sequence controller and an address counter time sequence generator and used for providing a necessary working pulse for a CCD and generating an interface signal between the CCD drive circuit and a data acquisition card; and the output of the CCD video signal binaryzation processing unit and the outputs of the A / D and SRAM working time sequence controller and the address counter time sequence generator are connected with a data acquisition interface circuit based on a parallel interface. By computer control automatic measurement, the invention greatly prevents the influence of human factors, realizes the intellectualization of detection, solves the synchronous problem of two different vibration frequencies and vibration amplitudes by non-contact synchronous measurement and can carry out software calibration at random, thereby preventing precision reduction caused by long-term use. A photoelectric probe is just dedusted regularly without replacing a detecting probe regularly.

Owner:TIANJIN UNIV

Method for testing hearing aid function and voice performance of acoustic generator

InactiveCN102075847APrevent appearanceImprove work efficiencyElectrical apparatusTest efficiencyHearing aid

The invention provides a method for testing a hearing aid function and voice performance of an acoustic generator. The method is realized on the basis of arranging a hearing aid sensor device in a cavity of a test press block, so that when the test press block supplies electrical signal input to the acoustic generator, the hearing aid sensor device arranged in the test press block can acquire a magnetic induction signal of a hearing aid part of the acoustic generator, and the magnetic induction signal is transmitted to a test computer through the test press block; and a voice signal realizes voice conversion through an artificial ear which is connected with the acoustic generator, and the voice performance is tested by the test computer. By the test method, the voice performance and the hearing aid function of the acoustic generator can be simultaneously tested, the working time is saved and the test efficiency is improved.

Owner:AAC TECH PTE LTD

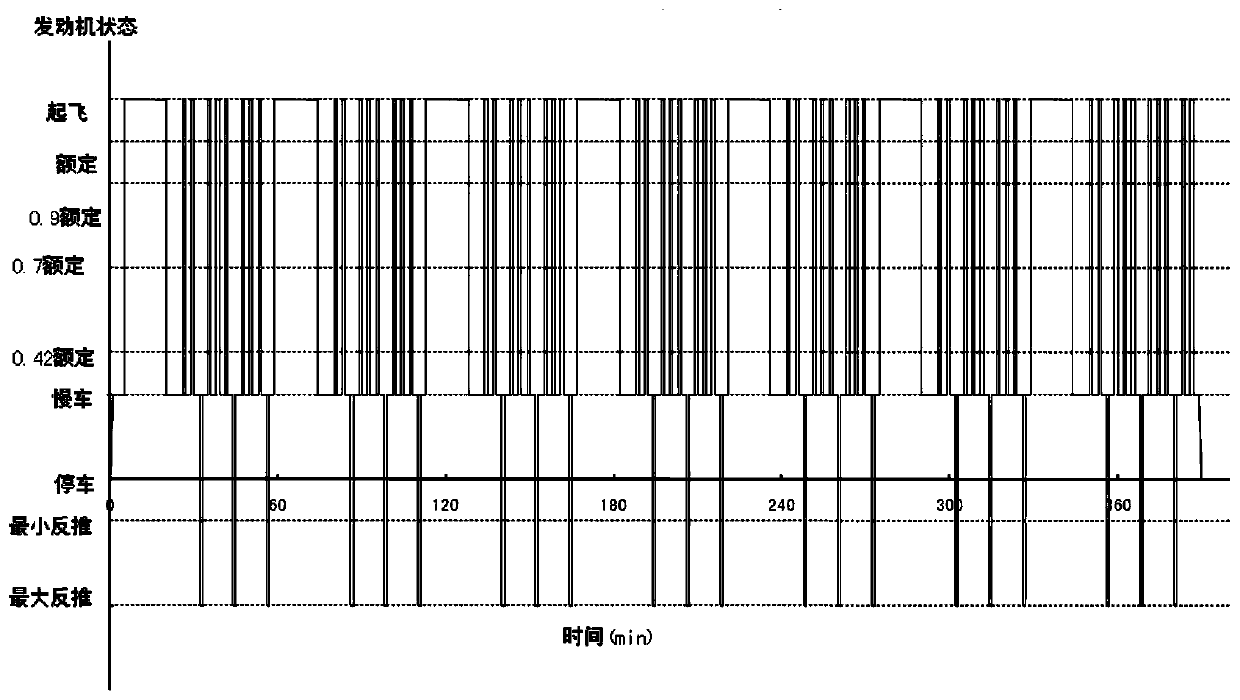

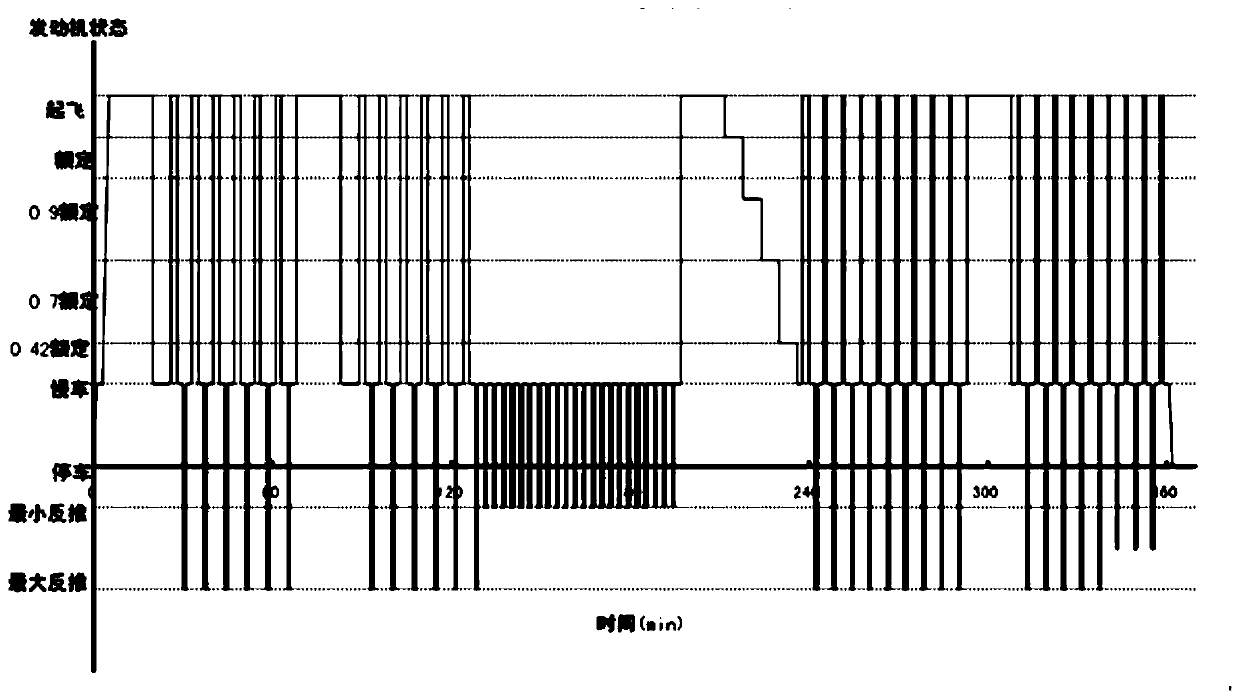

Acceleration equivalence test method of long-service-life aero-engine

Owner:CHENGDU ENGINE GROUP

Transmission device special for municipal waste

Owner:广西大自然再生资源有限公司

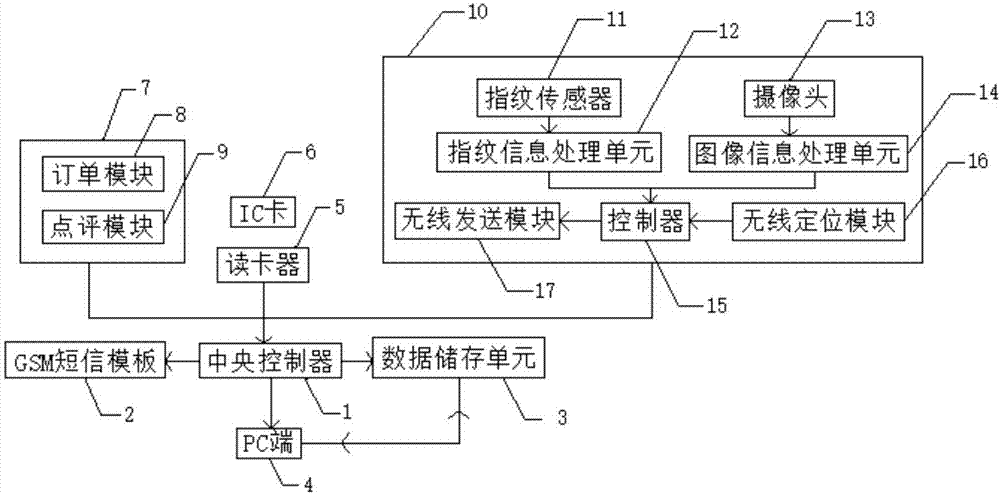

Integrated device for enterprise information management system

InactiveCN107993041AEffective assessmentAccurate assessmentRegistering/indicating time of eventsCharacter and pattern recognitionInformation processingCard reader

Owner:广州源创设计顾问有限公司

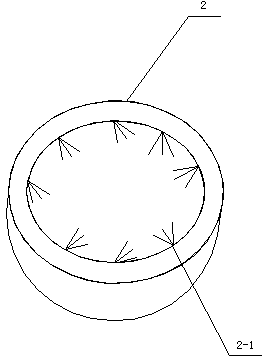

Novel polishing machine

InactiveCN103659557ASave time at workReasonable structural designEdge grinding machinesPolishing machinesVacuum pumpWork time

Owner:KUNSHAN SHANGDAZHI MACHINERY

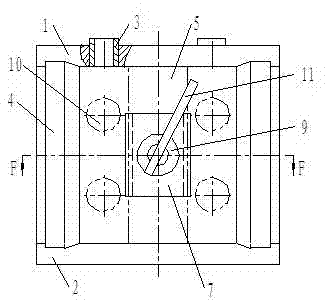

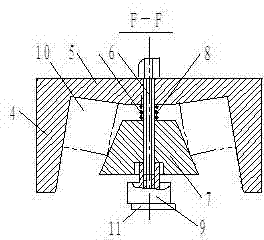

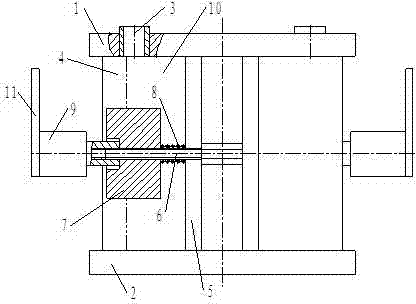

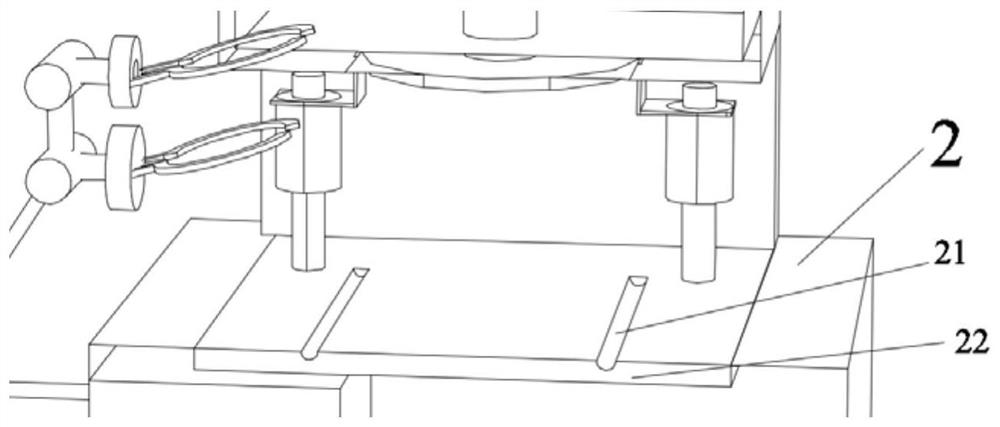

A valve hole processing device for a slice reversing valve

ActiveCN102847975BEasy accessRealize clamping positioningPositioning apparatusBoring/drilling machinesEngineeringMachine

Owner:HUAIAN SHENGJIE HYDRAULIC MACHINERY

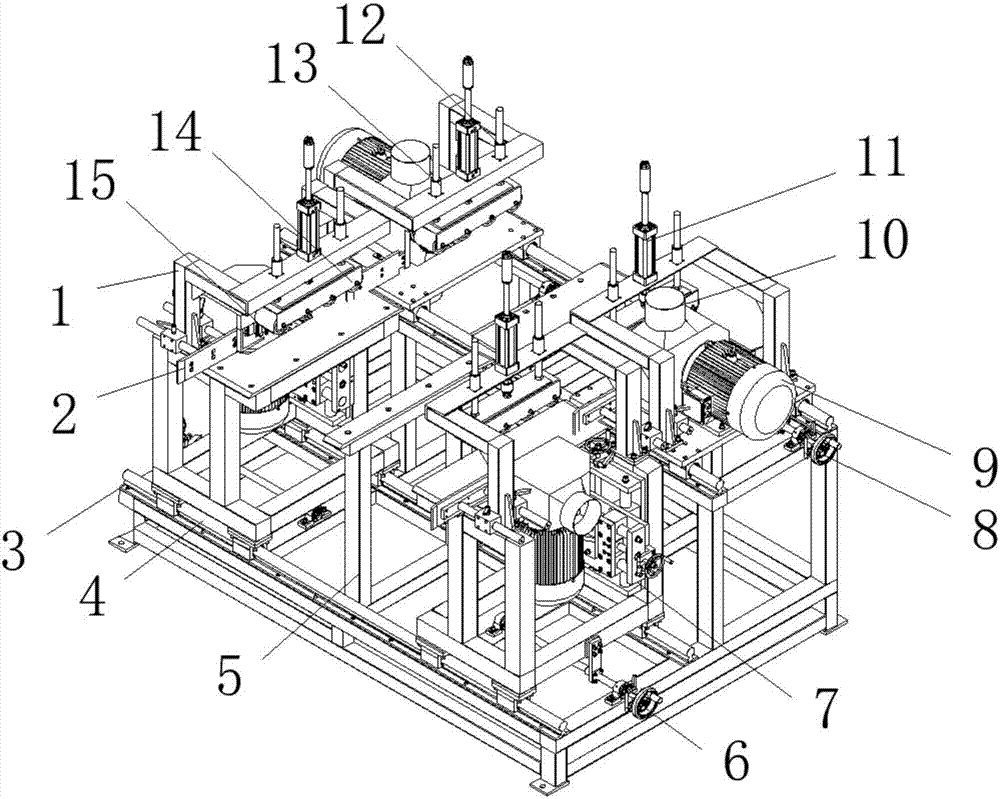

Edge milling and notching integrated machine

PendingCN107538084AIncrease physical strengthReduce consumptionMetal working apparatusPositioning apparatusRotational axisThree phase asynchronous motor

Owner:南京欧格节能环保科技有限公司

Installation joint of steel frame and prefabricated inner partition wall

The invention relates to an installation joint of a steel frame and a prefabricated inner partition wall. The steel frame is provided with a frame edge joint plate (3), a plurality of first bolt holes are distributed in the side faces of all frames of the frame edge joint plate (3), inner clamping grooves (6) used for installing the side faces of all the frames of the frame edge joint plate (3) are formed in the edge of the wall face of one side of the prefabricated inner partition wall, a plurality of second bolt holes are evenly formed in the inner clamping grooves (6) at equal intervals in a penetrating mode, and the set positions of the second bolt holes correspond to the set positions of the first bolt holes. Compared with the prior art, the installation joint has the advantages of shortening the field working time, being convenient to install, higher in adaptability to installation errors and the like.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

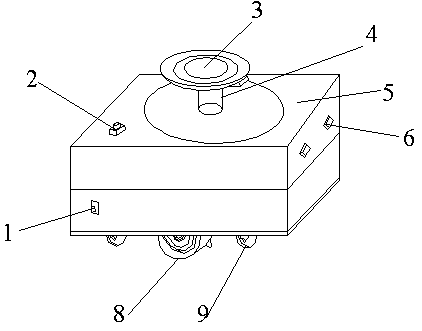

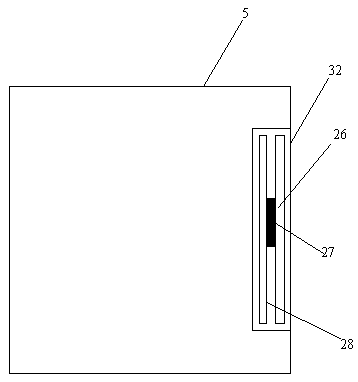

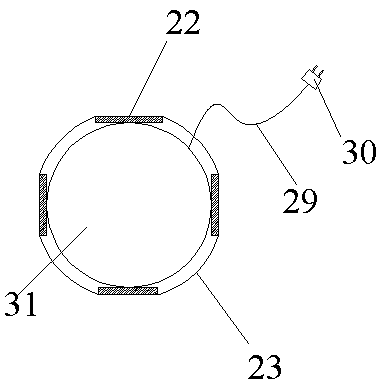

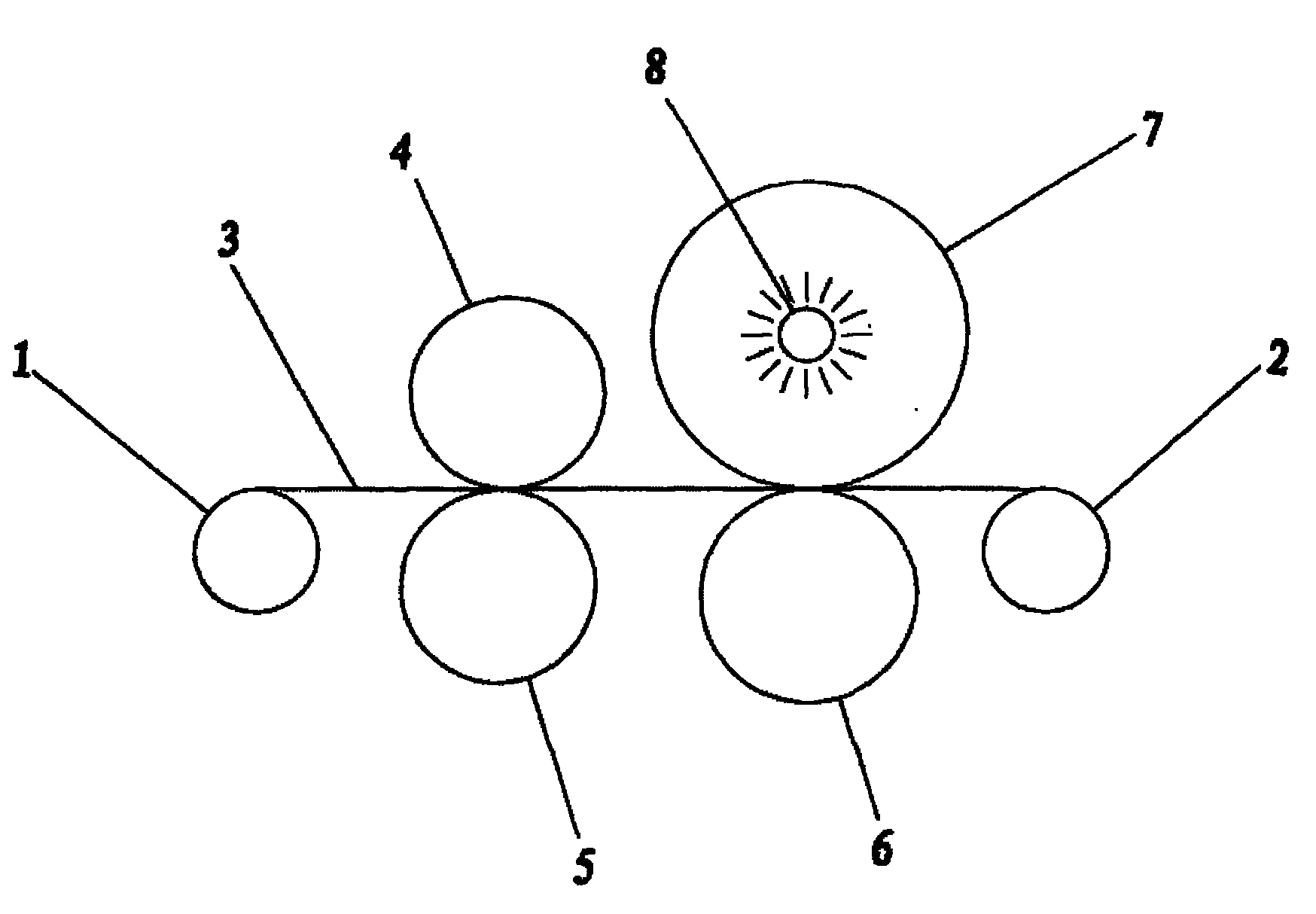

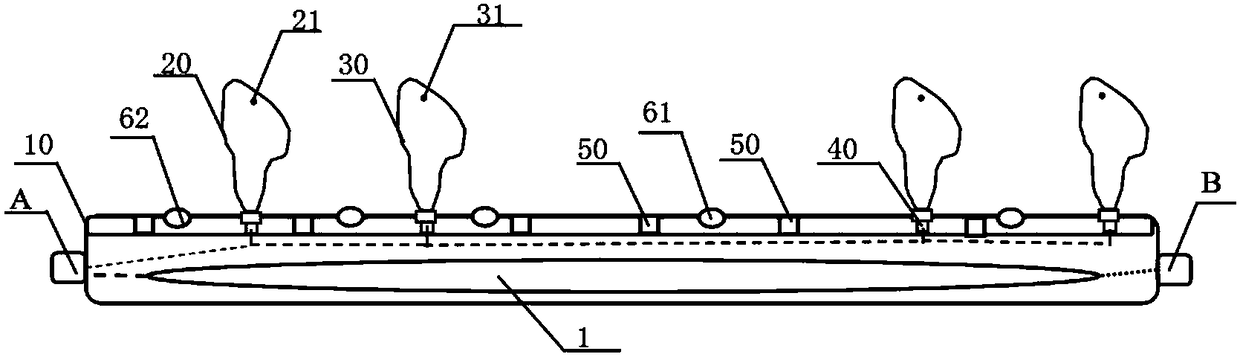

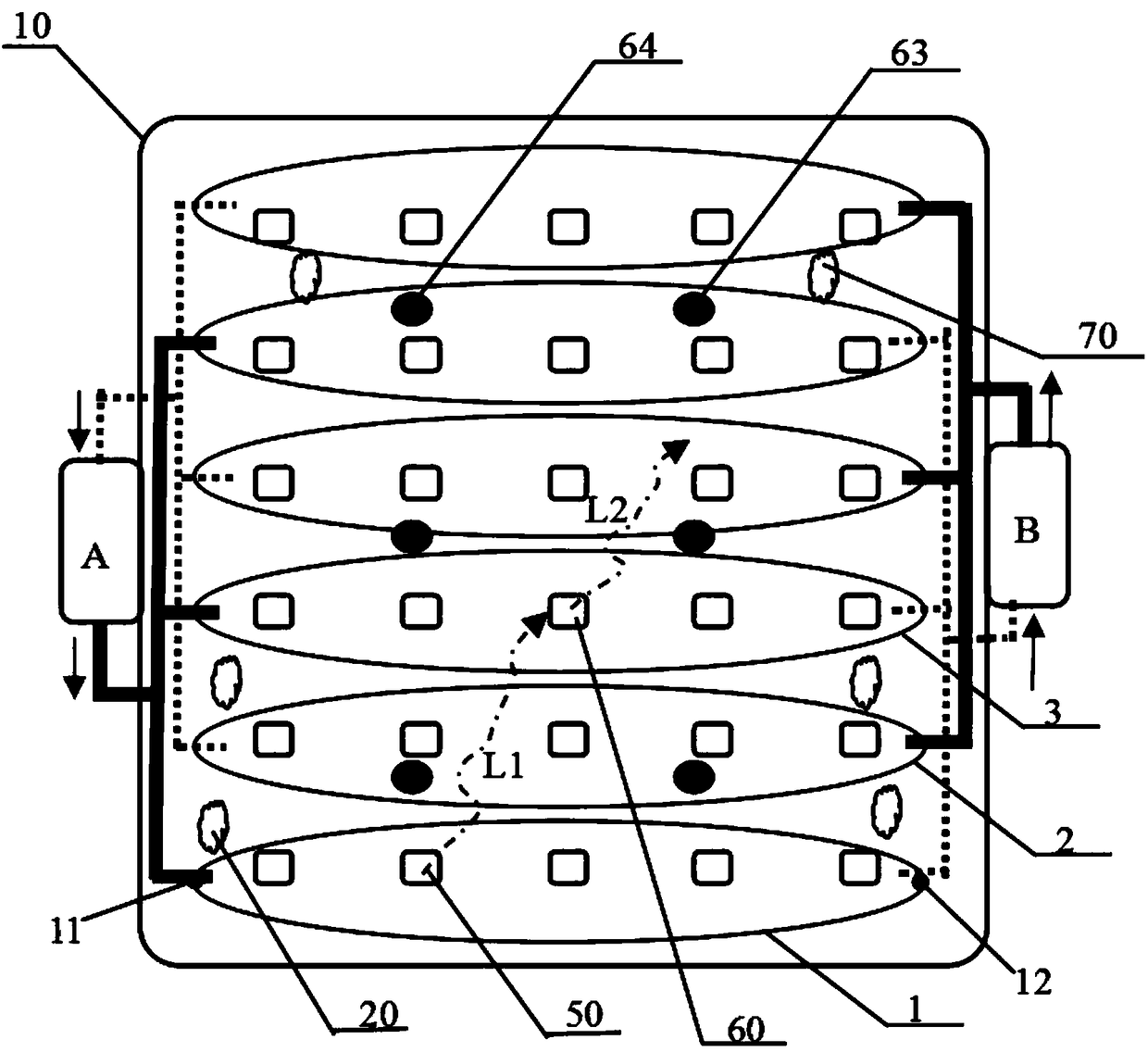

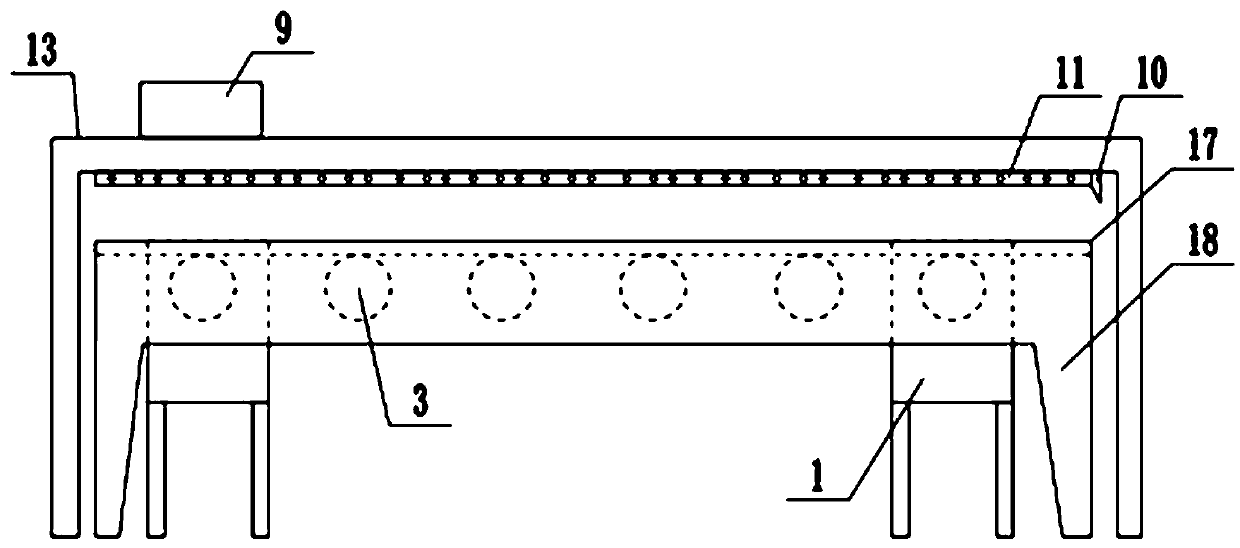

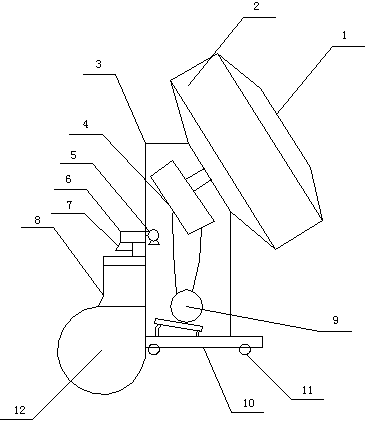

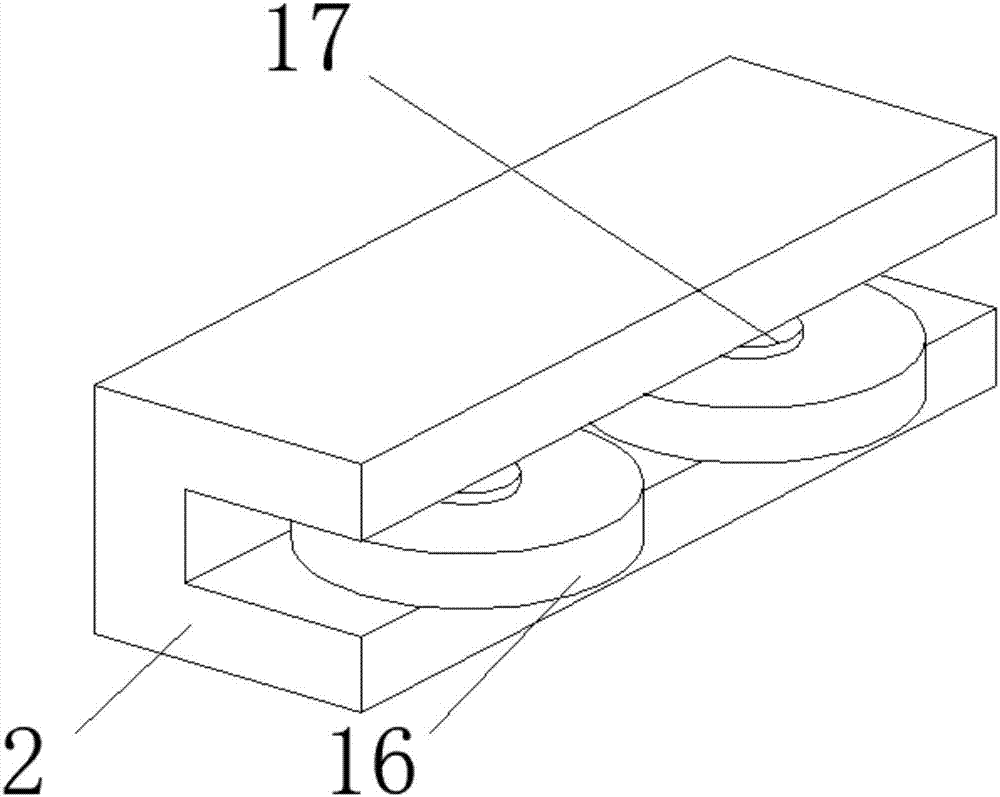

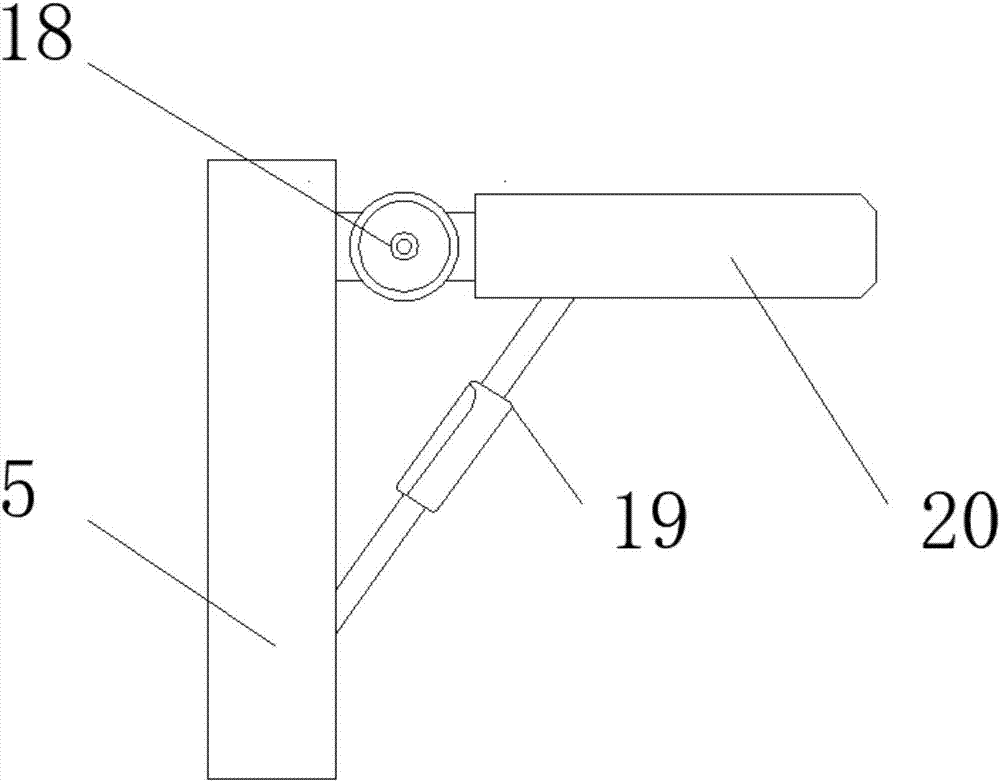

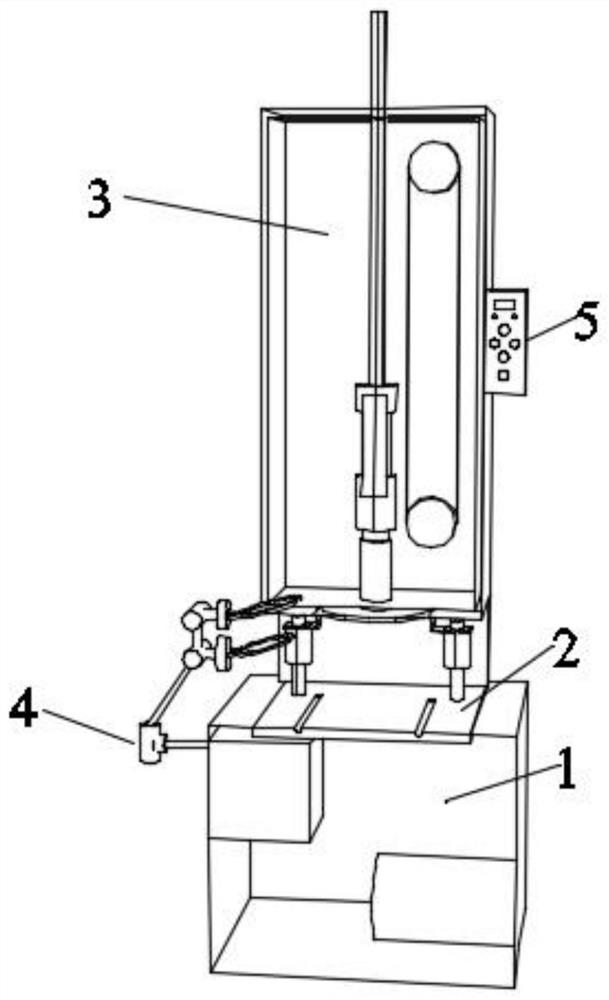

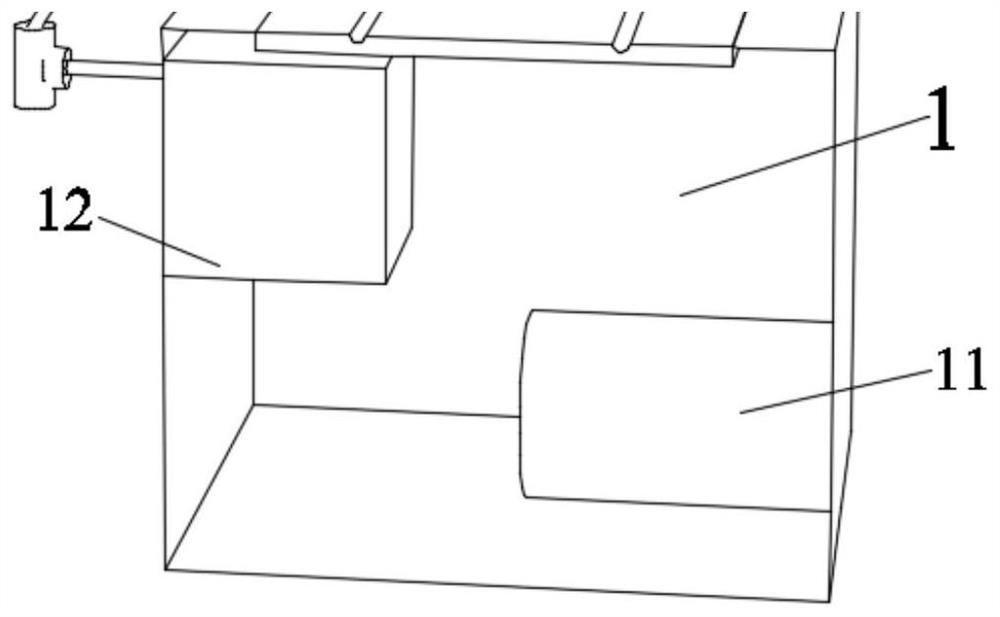

Semi-automatic Marshall compactor

PendingCN112414805ARealize automatic surface changeReduce the risk of being smashed and scaldedPreparing sample for investigationConstruction engineeringElectric machinery

Owner:YANGZHOU UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap