A valve hole processing device for a slice reversing valve

A processing device and reversing valve technology, applied in the direction of positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of time saving, labor saving, energy saving, batch processing of workpieces, etc., and achieve The effect of shortening the processing time, saving production cost and convenient clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

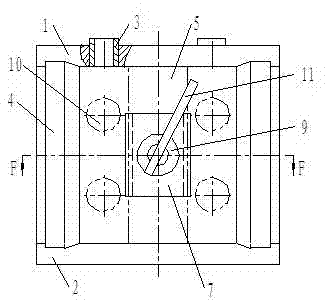

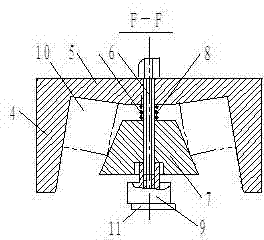

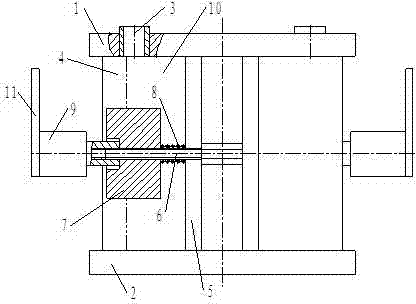

[0011] A valve hole processing device for a slice reversing valve, refer to figure 1 , 2 , the device includes: an upper base plate 1 and a lower base plate 2, the upper base plate 1 is provided with a boring tool feed hole 3, and the lower base plate 2 is installed on the working table of the boring machine. Between the upper base plate 1 and the lower base plate 2, a groove-shaped plate composed of two side plates 4 and a back plate 5 is provided. At both ends of the groove-shaped plate, the inner surfaces of the two side plates 4 are inclined from outside to inside. The width of the groove gradually decreases from outside to inside, and is arranged perpendicular to the inner surface of the back plate 5 . The workpiece 10 enters the two ends of the trough-shaped plate, and its two sides are respectively close to the inner surface of the side plate 4 and the inner surface of the back plate 5 for bonding and positioning. The boring cutter of the boring machine enters through t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap