Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

138results about "Positioning apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

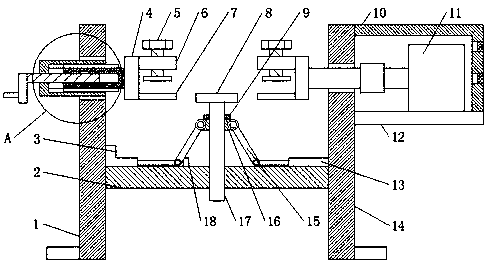

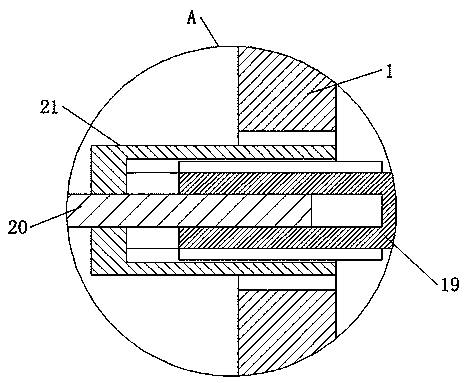

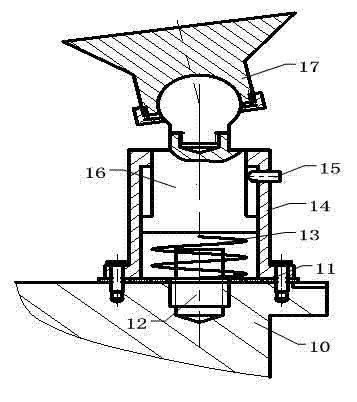

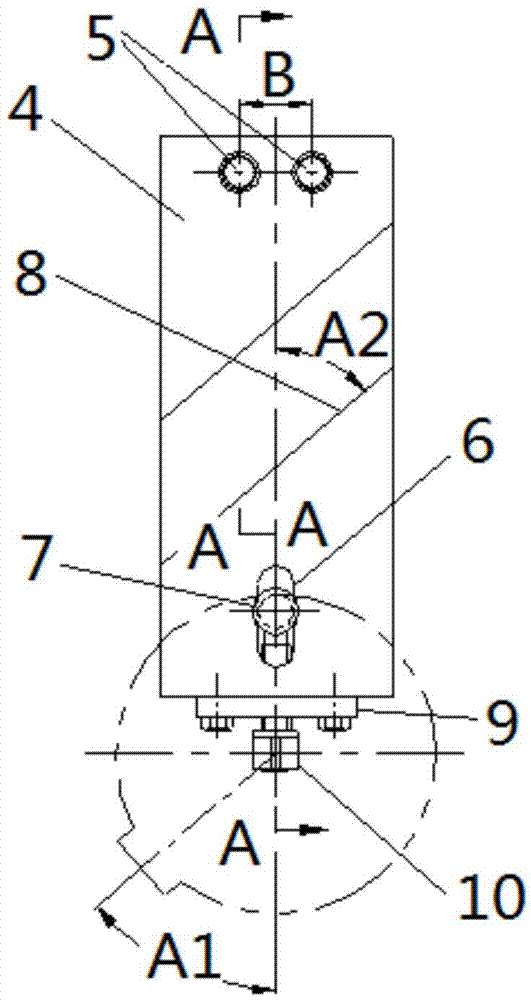

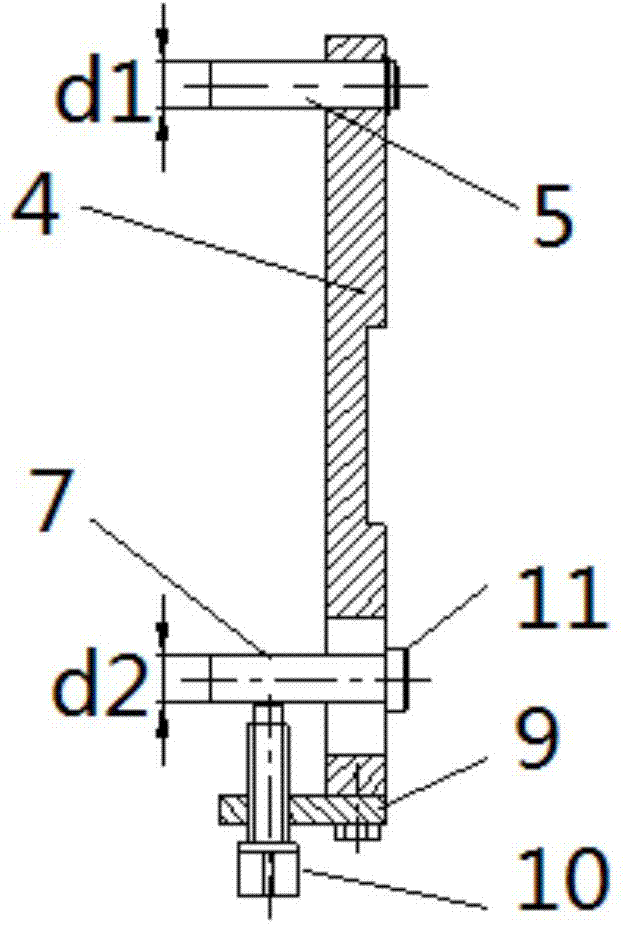

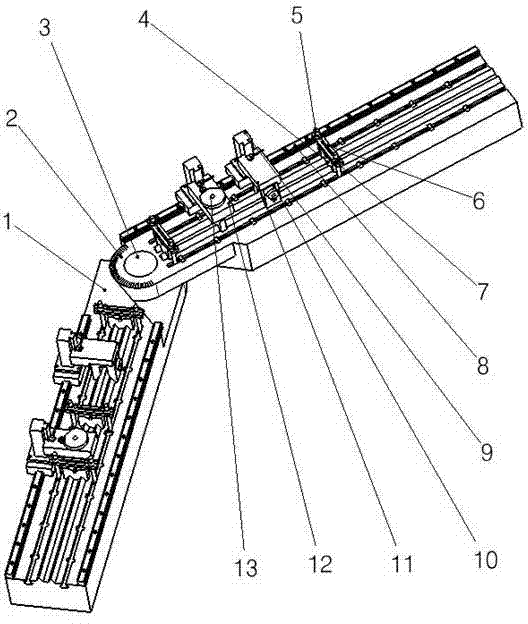

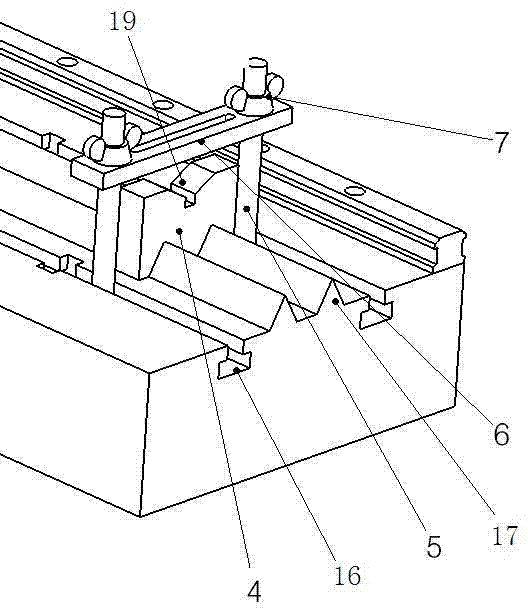

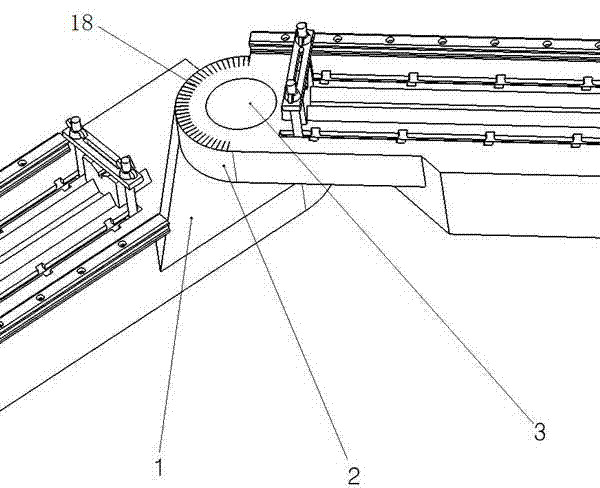

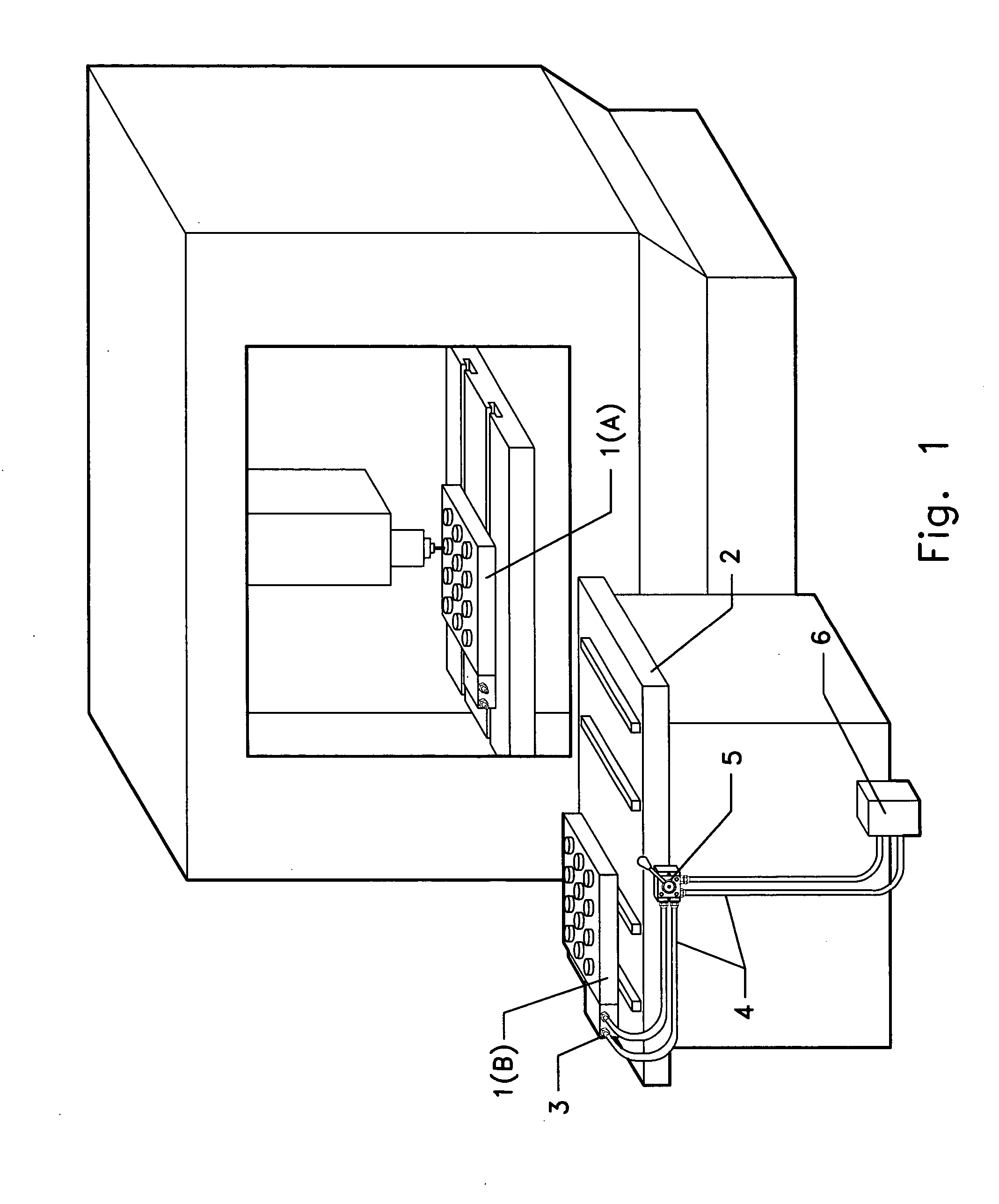

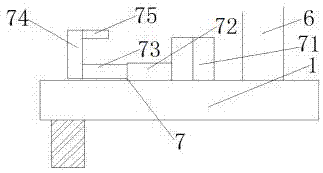

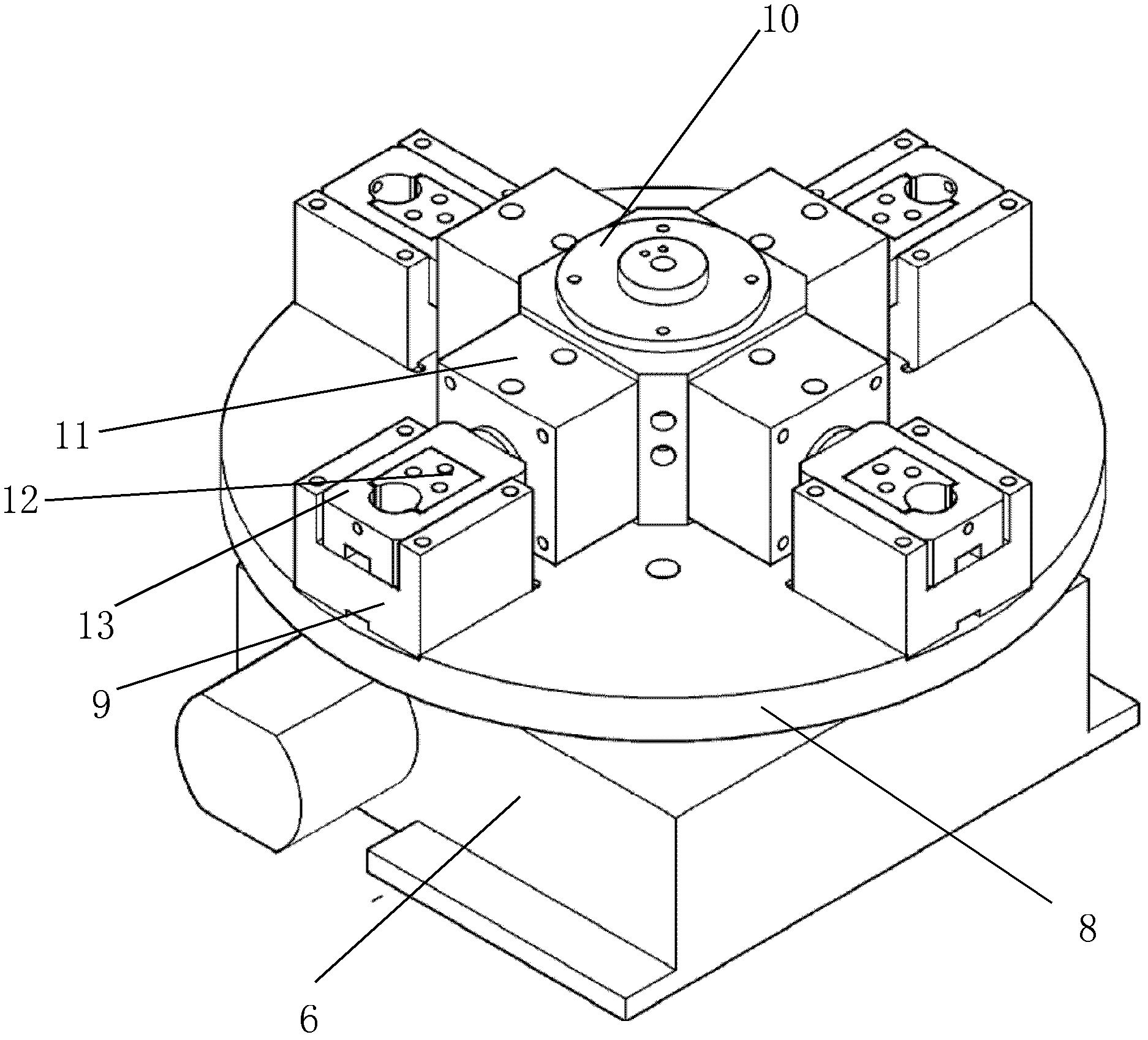

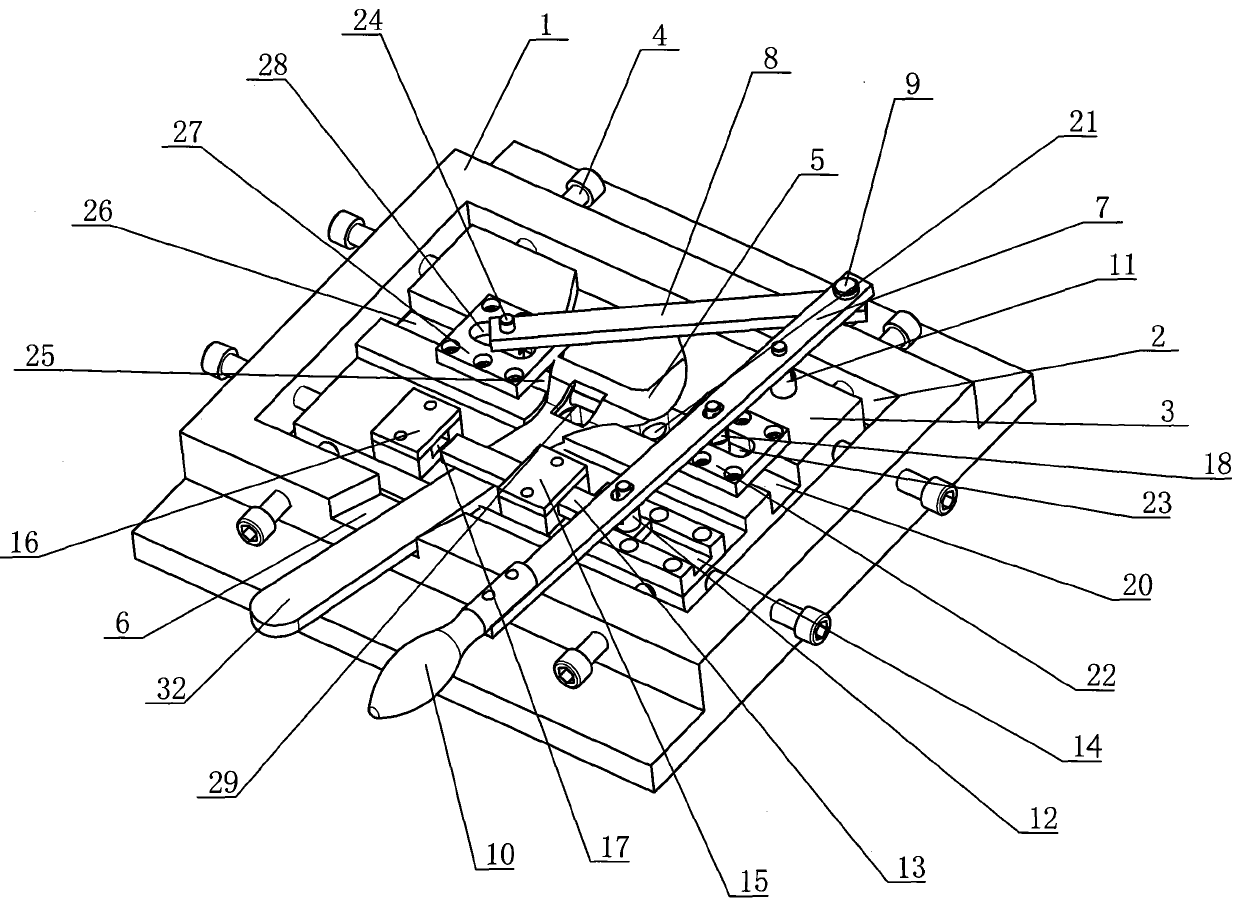

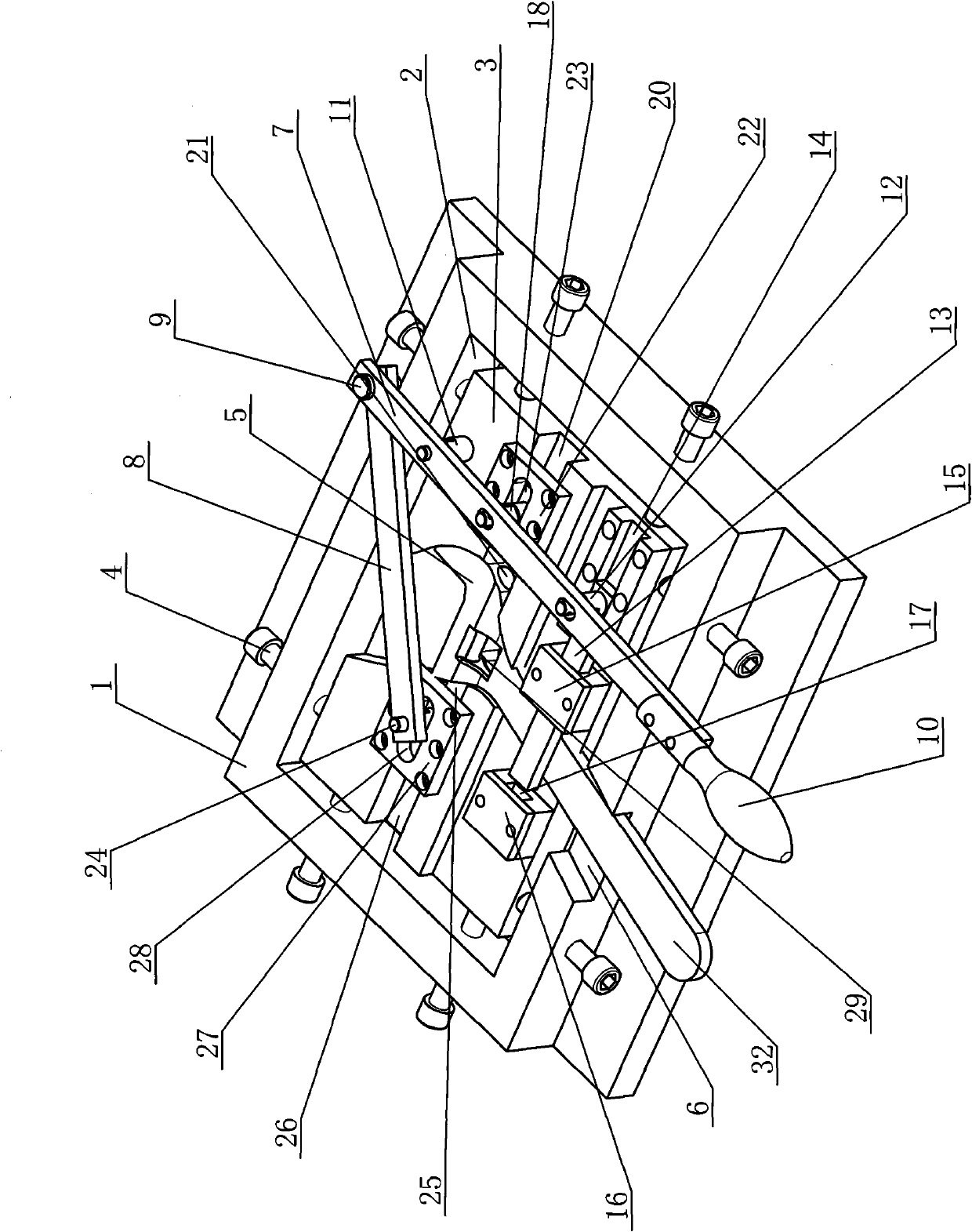

Special fixture for processing inclined conical nozzle steam passage and method thereof

InactiveCN101670527AGuaranteed accuracyImprove operational efficiencyPrecision positioning equipmentPositioning apparatusMilling cutterDrill bit

A special fixture for processing an inclined conical nozzle steam passage and a method thereof relate to a fixture for processing the inclined conical nozzle steam passage and a method thereof. The invention solves the problem that at present, no special fixture for processing the inclined conical nozzle steam passage exists, and when a tapered hole of the nozzle steam passage is processed, a drilling bit is difficult to be centered. An indexing plate of the special fixture is provided with twenty indexing through holes along the periphery direction; the center of a stepped through hole and the center of the indexing through holes are on one periphery; a spotting spindle is mounted on the indexing plate in a plug-in manner; the processing method is as follows: using a milling cutter with diameter of 13mm to feed from a P point so as to process a plane C which is vertical to the central line of the tapered hole to be processed; and stopping feeding when the milling cutter mills to a Q point, wherein the center of a hole pitch circle having diameter of 13mm and milled by the milling cutter is the core-bit of the drilling bit. The special fixture solves the problem that at present, nospecial fixture for processing the inclined conical nozzle steam passage exists; and the inclined conical hole of the nozzle stream passage processed by the method has high position accuracy.

Owner:HARBIN TURBINE

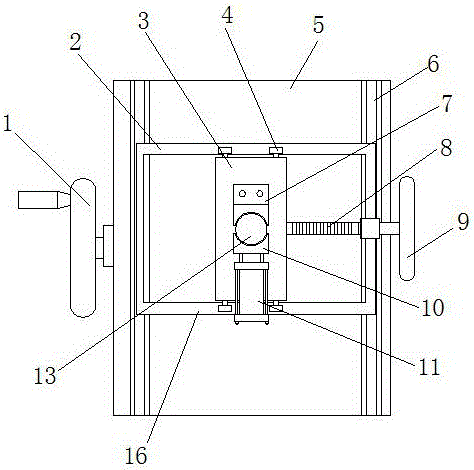

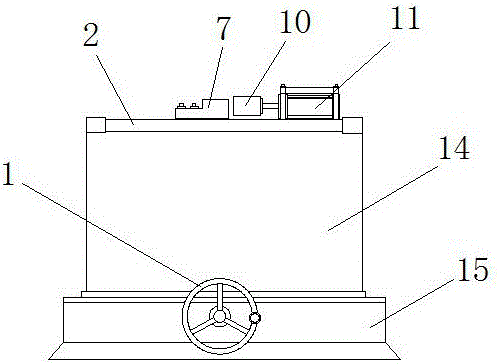

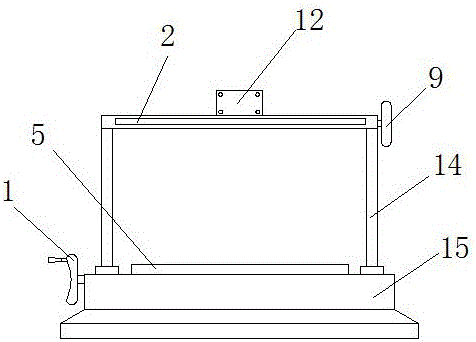

Turnover device for mechanical automatic machining

Owner:QUANZHOU MIAOYI AUTOMATION MACHINERY CO LTD

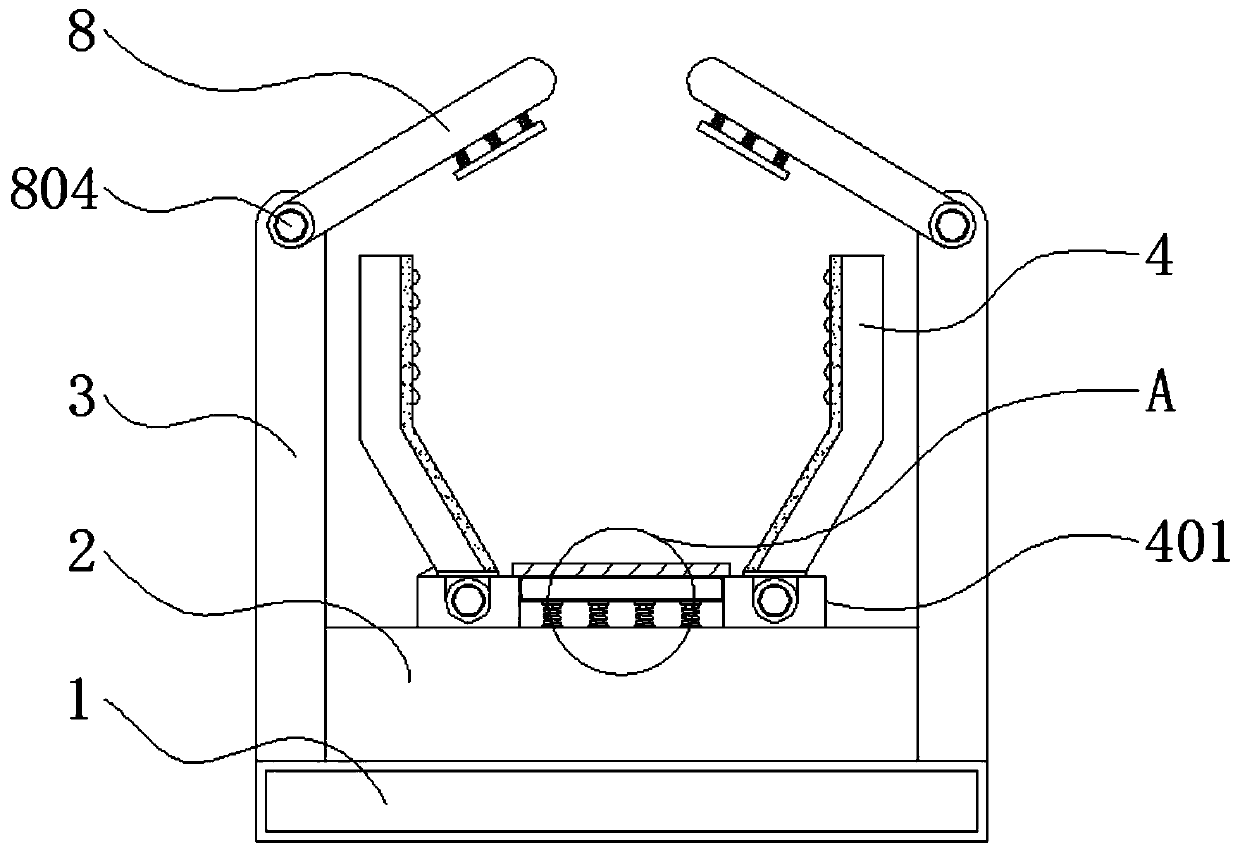

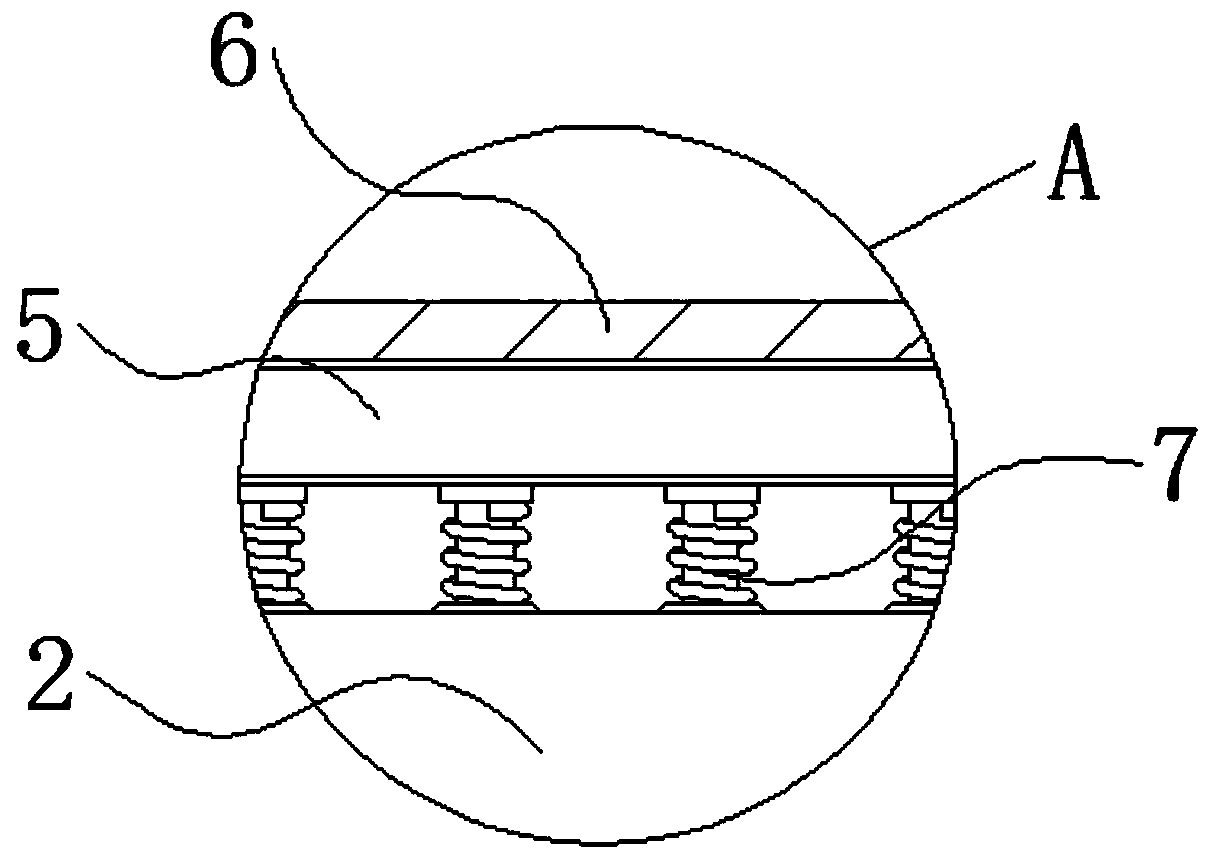

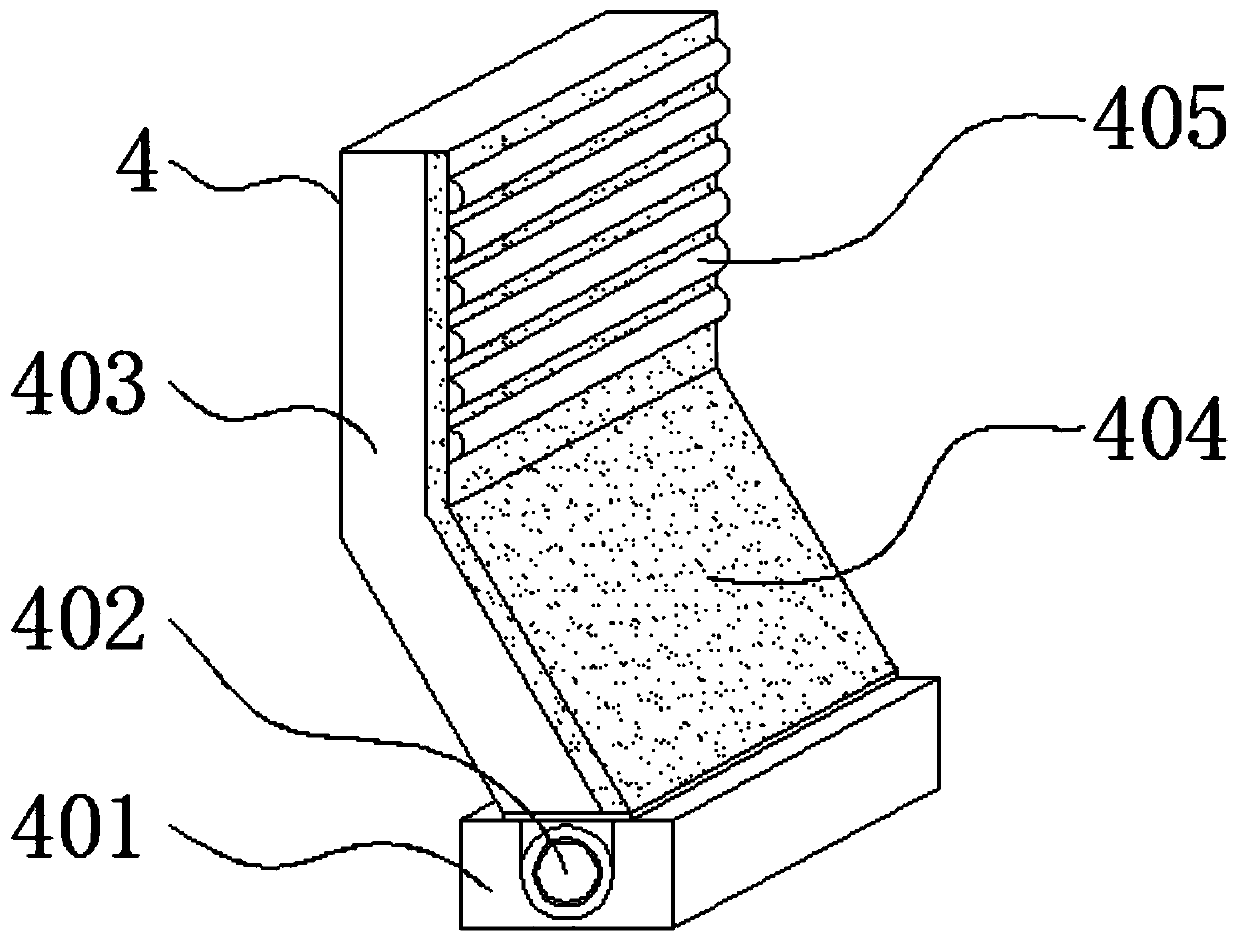

Supporting device and supporting method for machining propeller blade

InactiveCN102886699AIncrease stiffnessStable supportPositioning apparatusMetal-working holdersHydraulic cylinderPropeller

Owner:JIANGSU UNIV OF SCI & TECH

Fixing device for plate processing

Owner:WUXI ZHIGURUITUO TECH SERVICE CO LTD

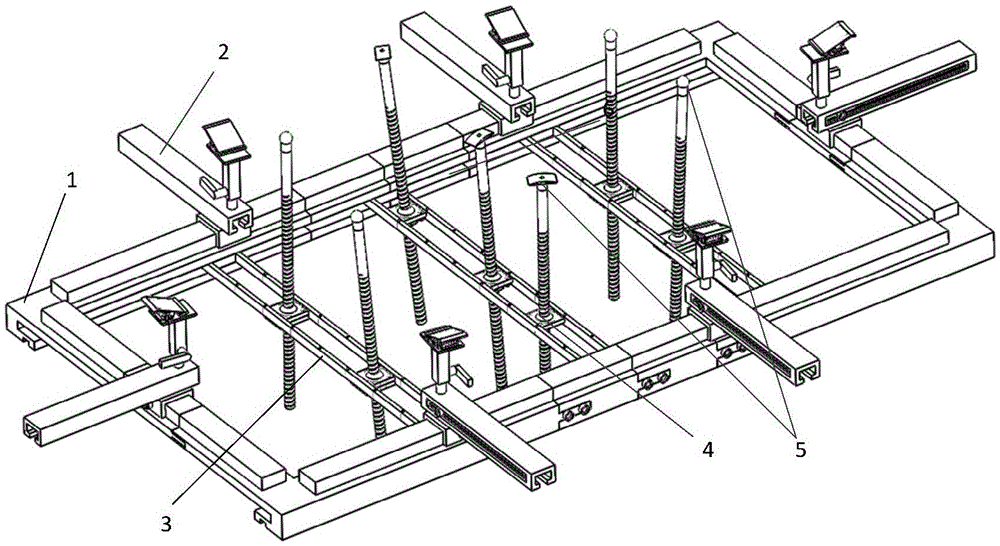

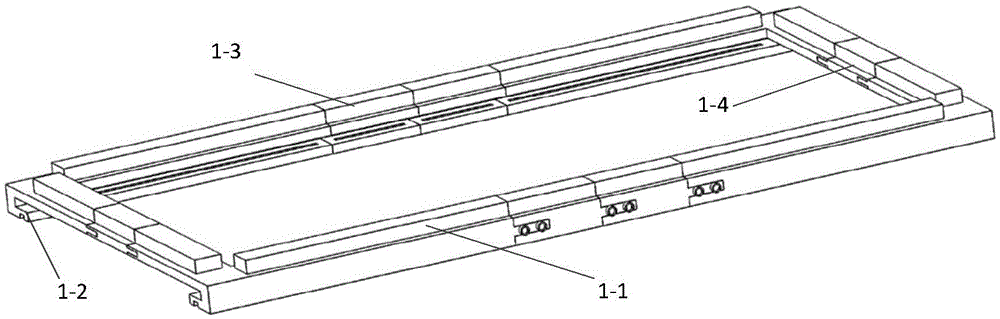

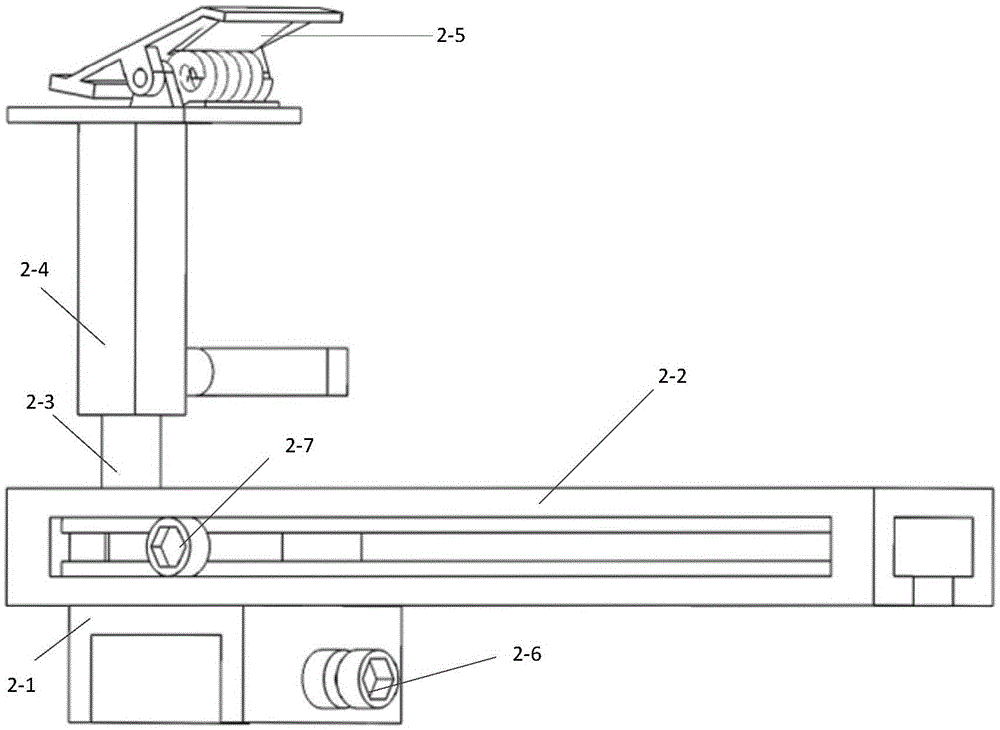

Flexible clamp suitable for positioning and clamping complex curved surfaces of parts

ActiveCN105522420AAdjustable angleImprove flexibilityPositioning apparatusMetal-working holdersMechanical engineering

Owner:NANJING UNIV OF SCI & TECH

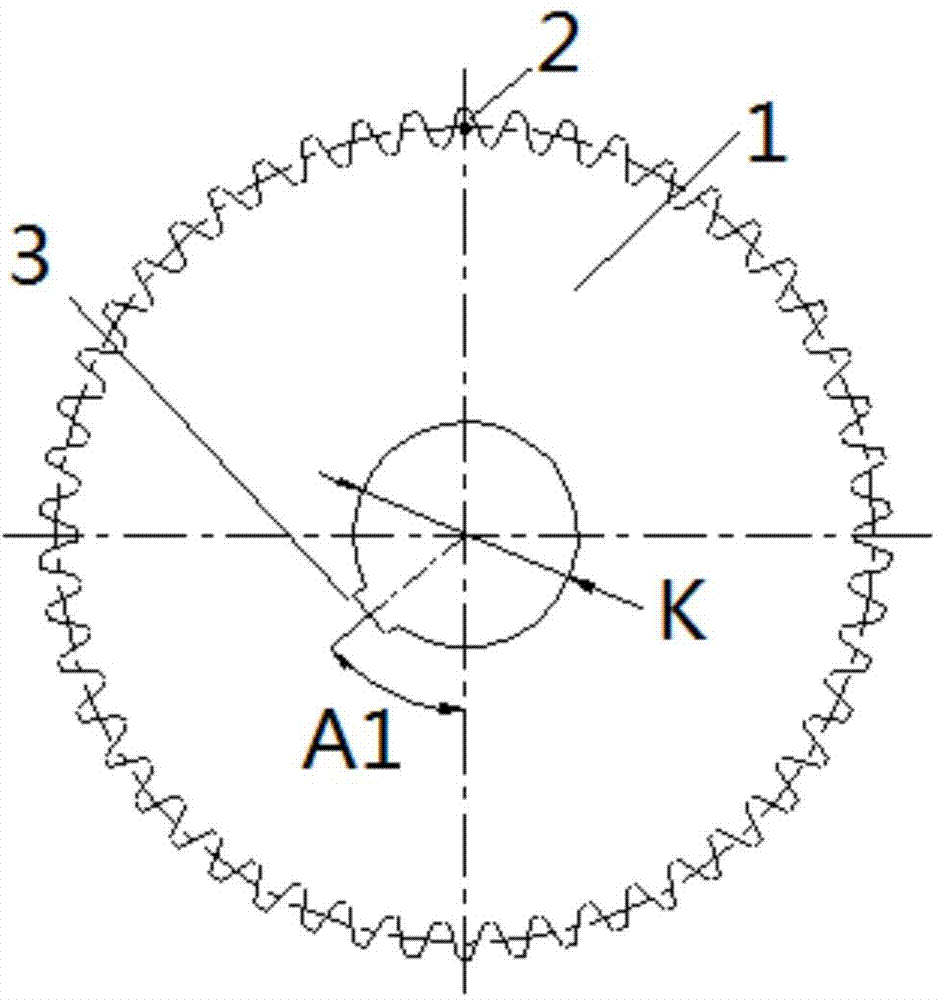

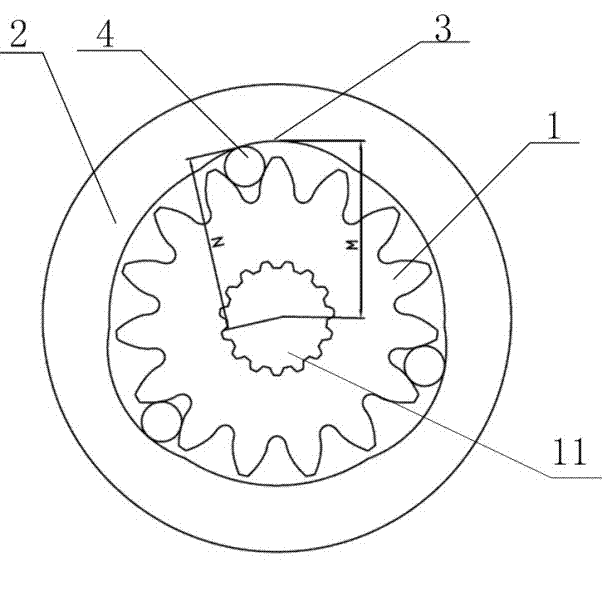

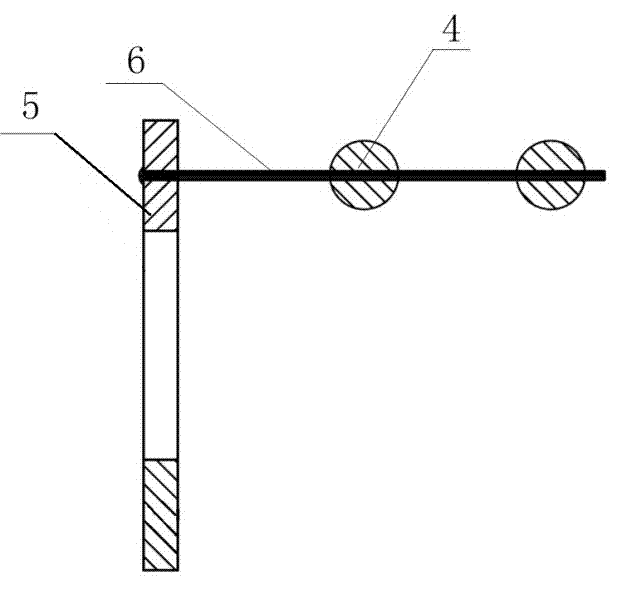

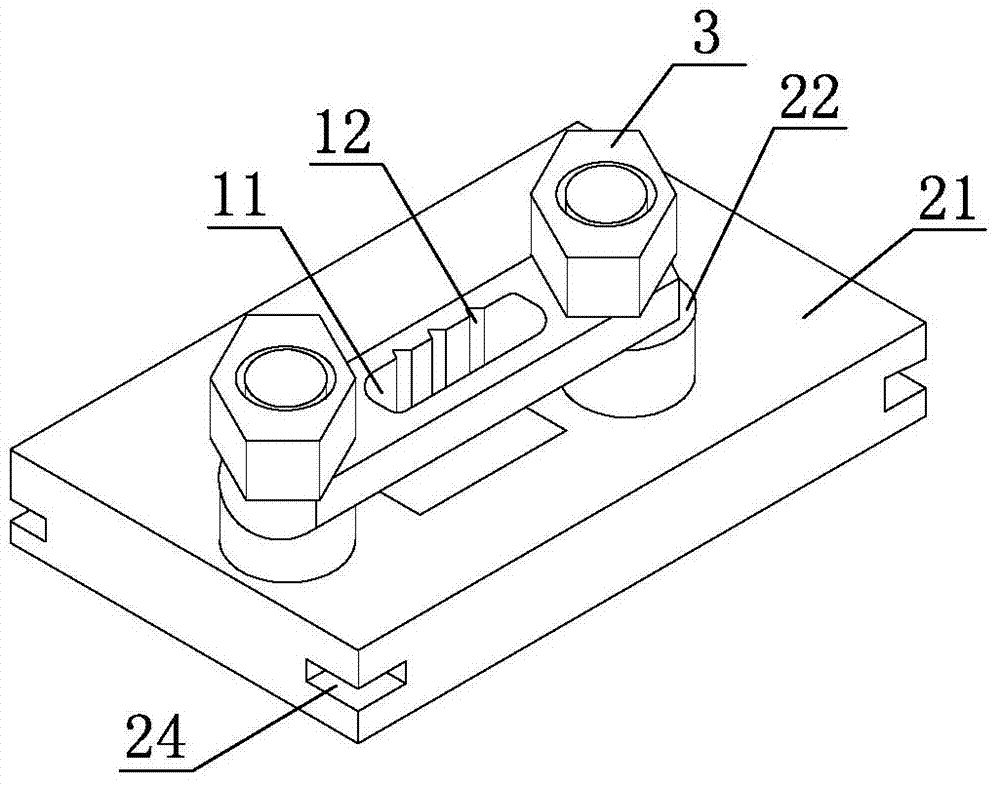

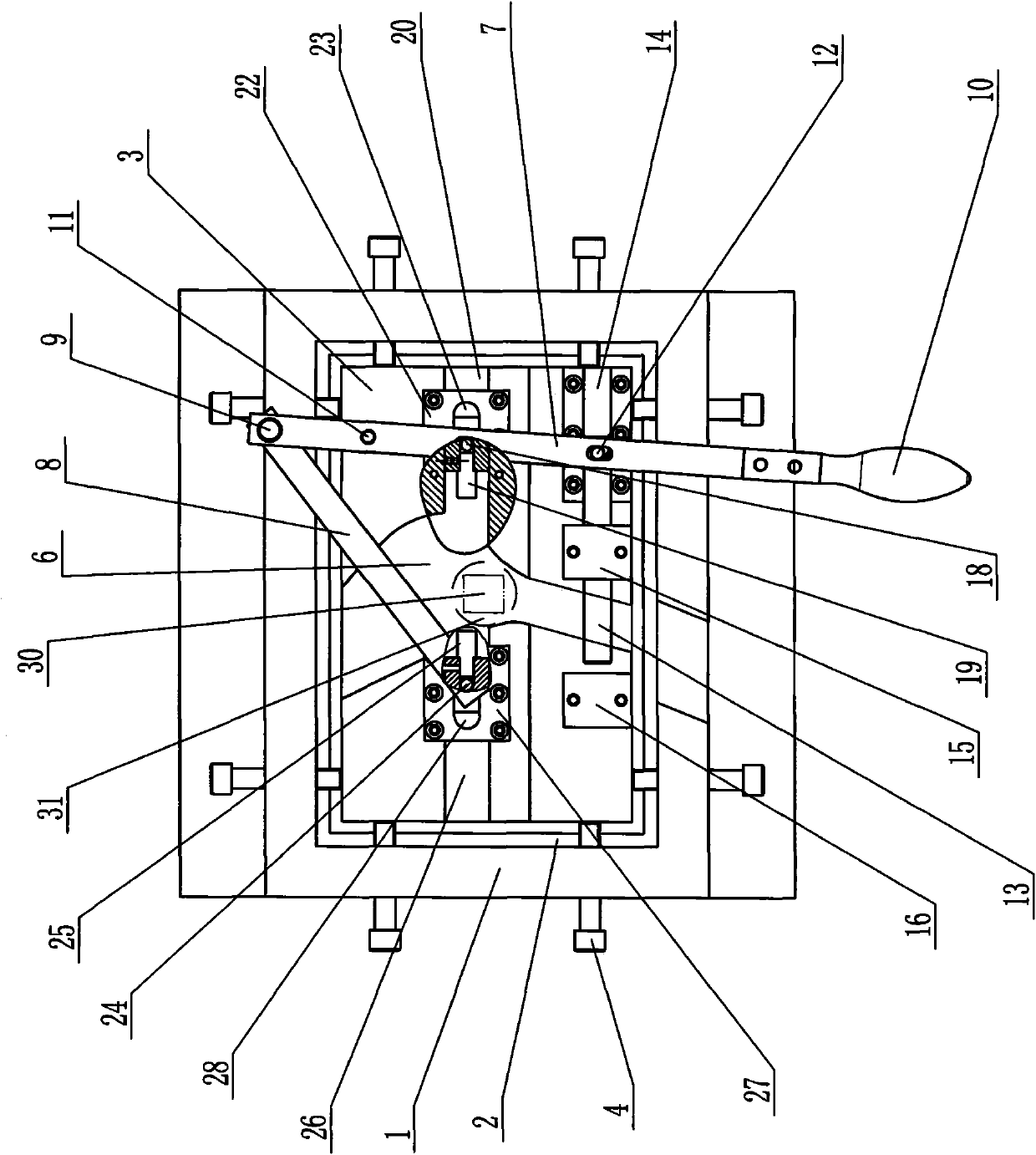

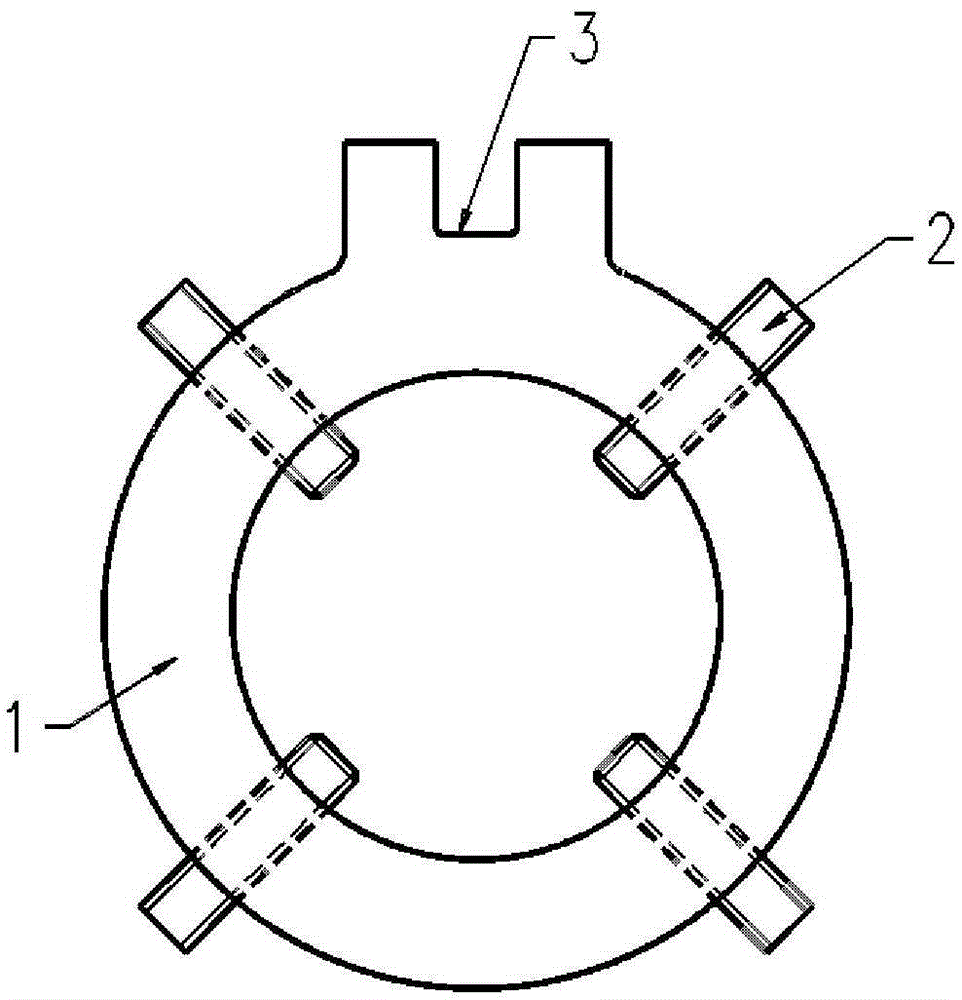

Alignment device and method for machining strict phase-position key groove of gear inner hole

ActiveCN103894861ASimple methodEasy to operatePositioning apparatusMetal-working holdersEngineeringPerpendicular direction

The invention discloses an alignment device for machining a strict phase-position key groove of a gear inner hole. The alignment device is characterized in that two symmetrical installation holes are formed in the inner edge of the outer end of a locating plate along the center line, and a fixed pin is installed in each installation hole; long grooves are machined in the inner edge of the inner end of the locating plate along the center line, movable pins are movably arranged in the long grooves, and the moveable pin ends of the movable pins are hooked on the upper edges of the long grooves; a baffle in the perpendicular direction is fixedly installed on the inner end face of the locating plate, the baffle and the locating plate are buckled through a bolt, an abutting screw is installed in a screw hole formed in the position, corresponding to the center line of the locating plate, of the baffle, and the abutting screw is in contact with the movable pins in an abutting-against mode; an alignment face is machined on the locating plate. The invention further discloses an alignment method for machining the strict phase-position key groove of the gear inner hole. The alignment device and method are simple in structure, easy to operate and high in accuracy.

Owner:MCC SFRE HEAVY IND EQUIP

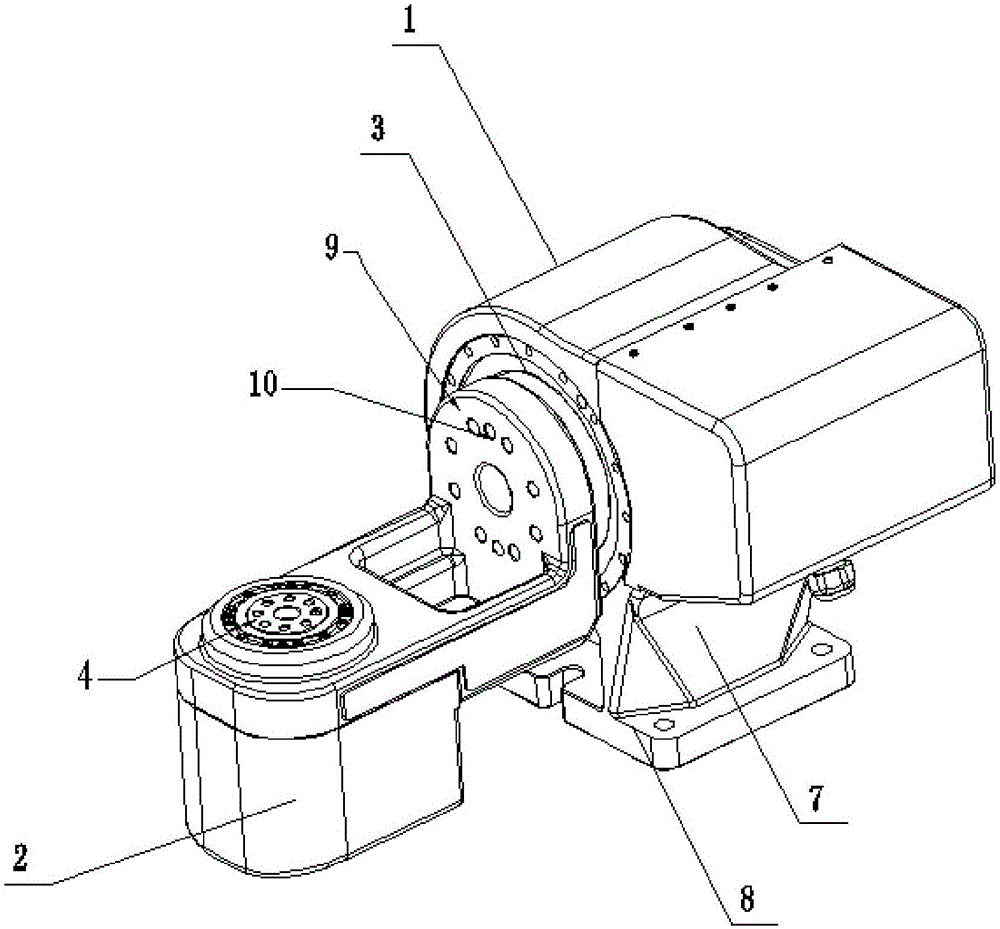

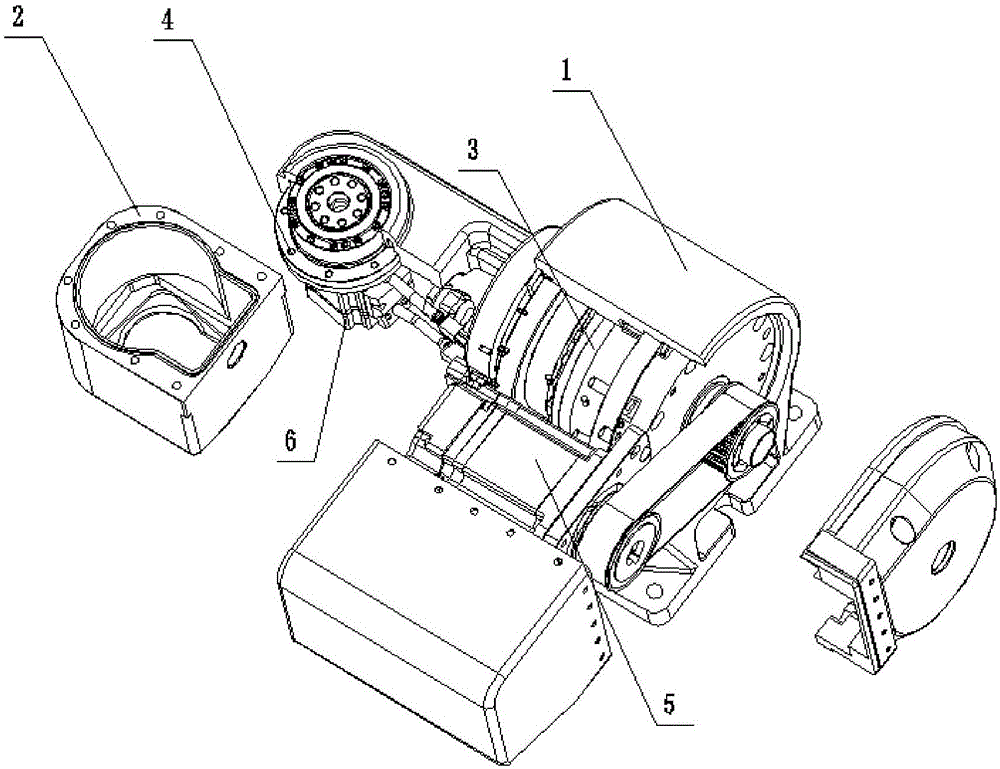

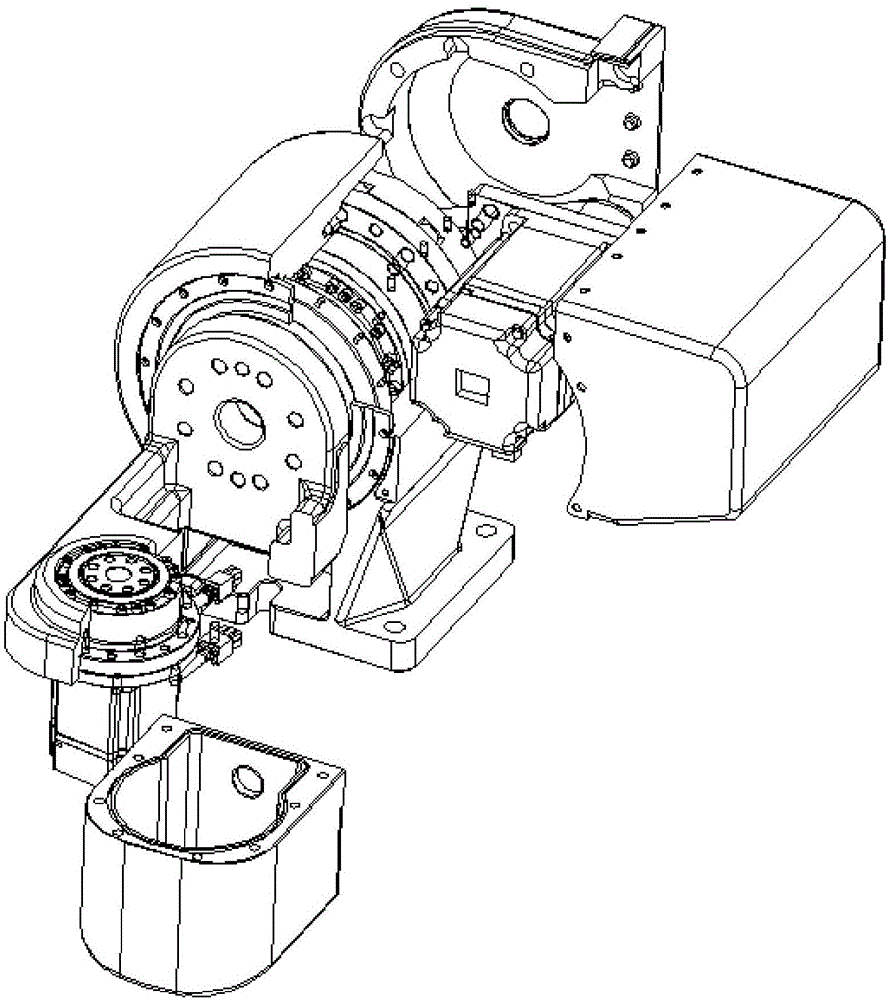

Fourth-axis and fifth-axis clamp

InactiveCN105014439AHigh positioning accuracyHigh repeat positioning accuracyLarge fixed membersPositioning apparatusMechanical engineeringEncoder

Owner:昆山冠品优精密机械有限公司

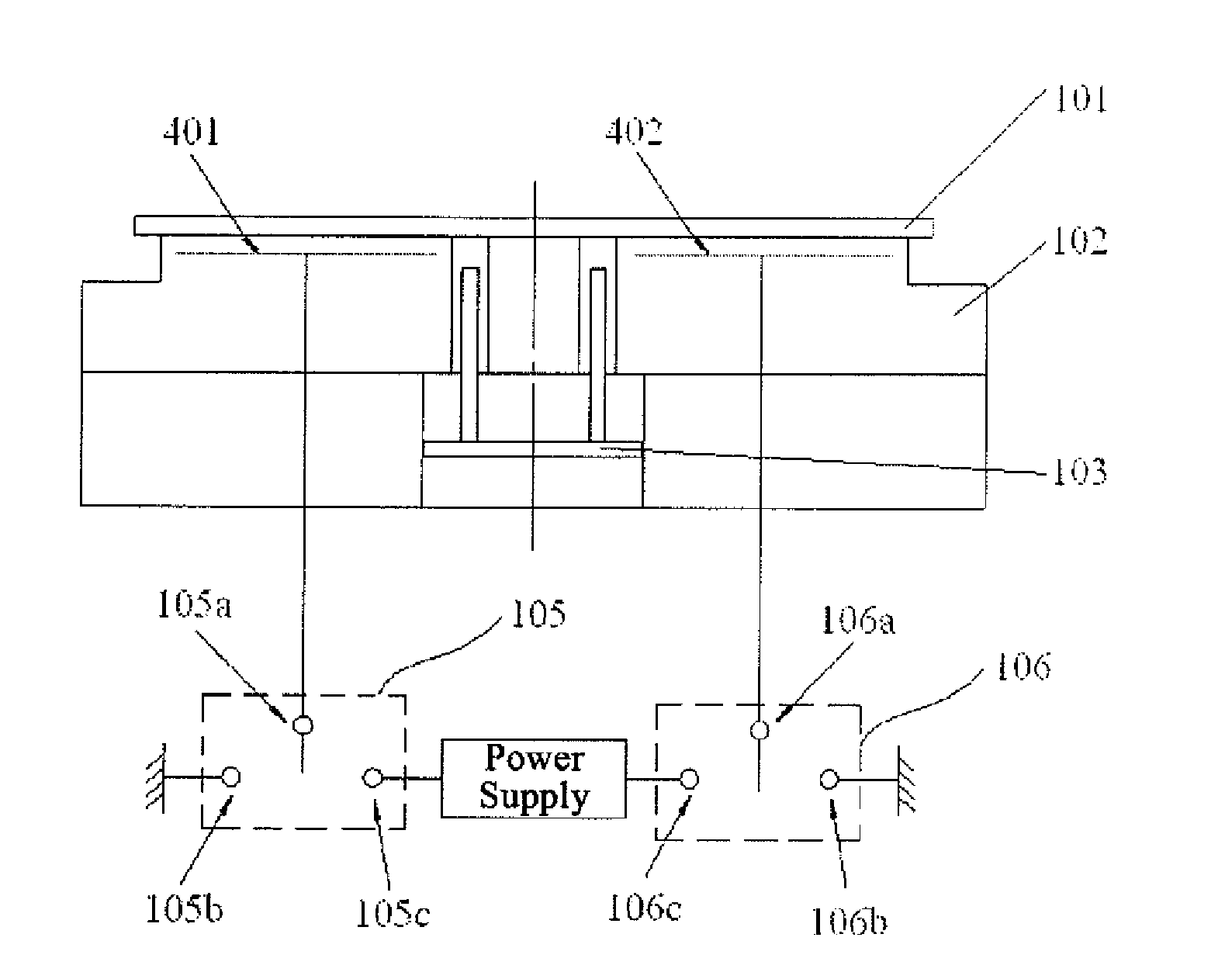

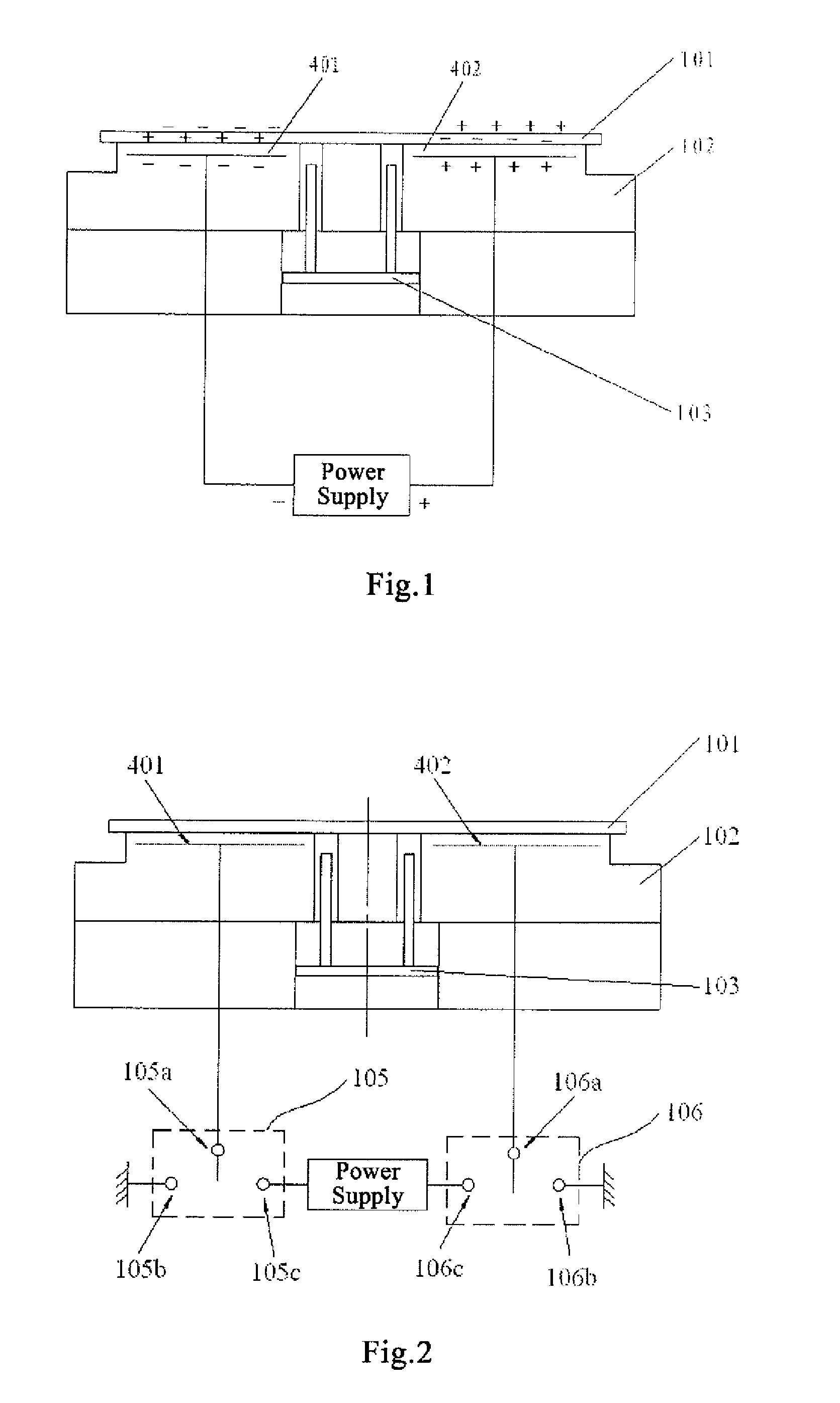

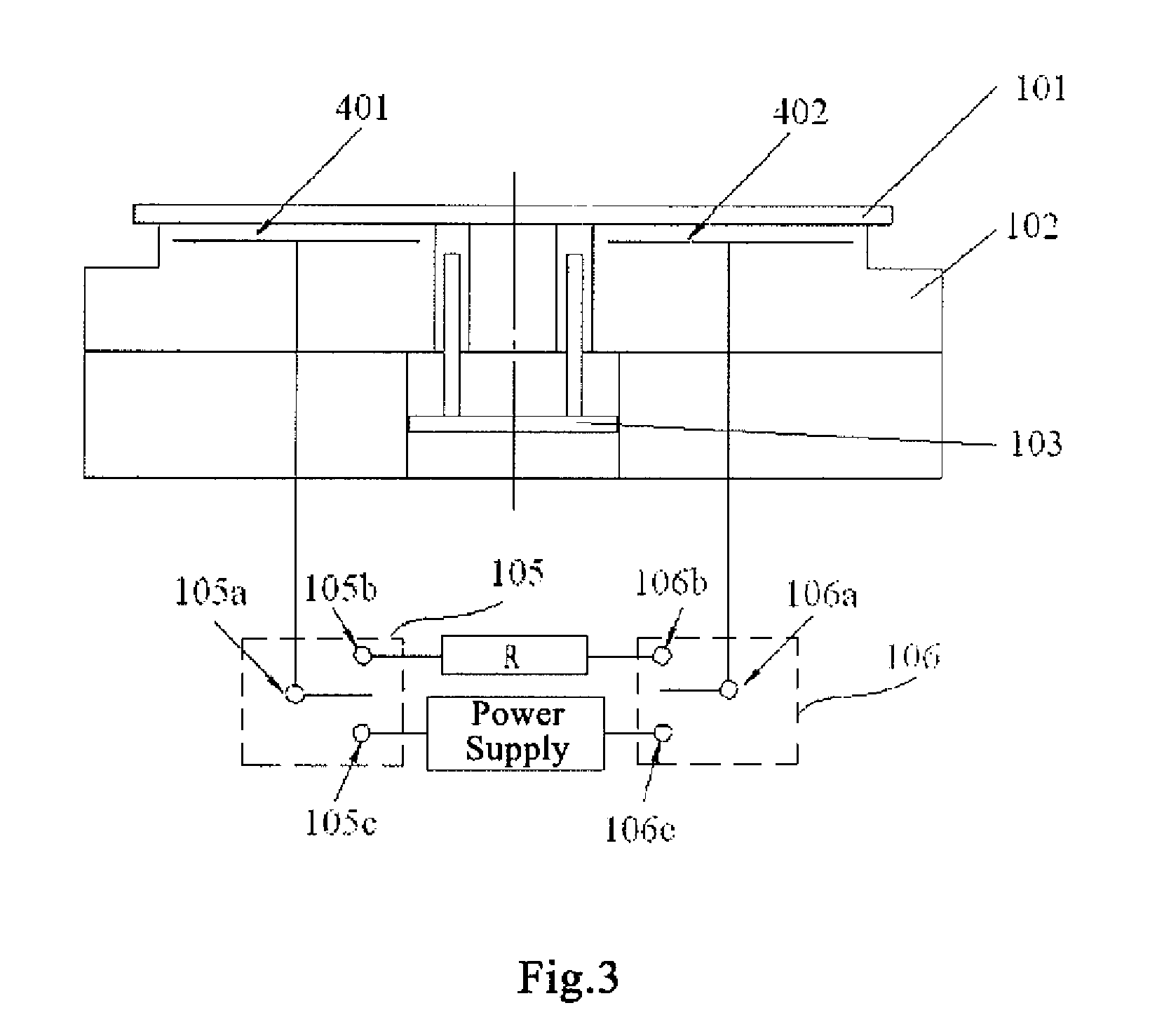

Electrostatic chuck and method for removing remaining charges thereon

InactiveUS20120200981A1Improve reliabilityImprove production yieldEmergency protective arrangement detailsSemiconductor/solid-state device manufacturingElectric energyStatic electricity

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

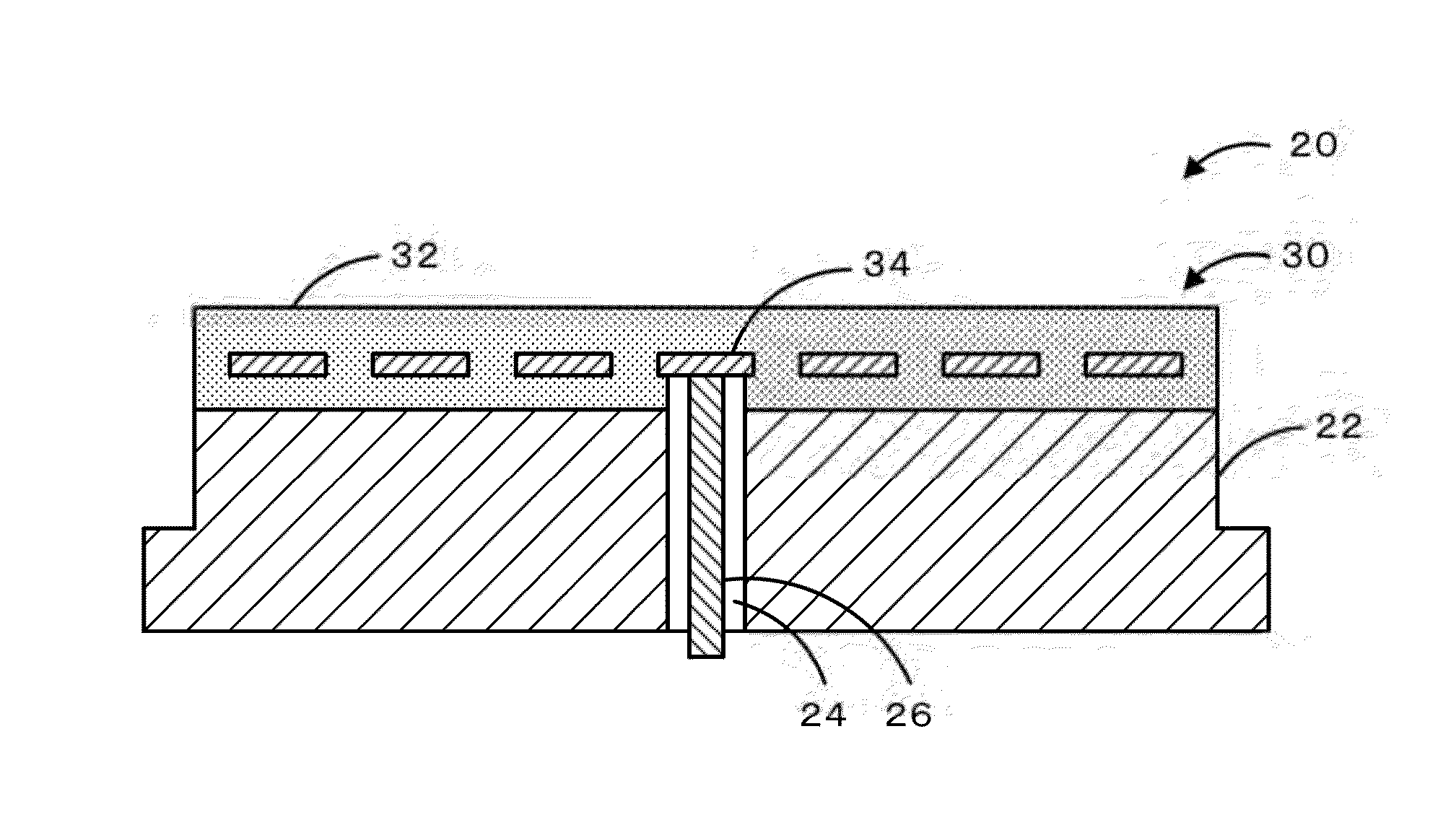

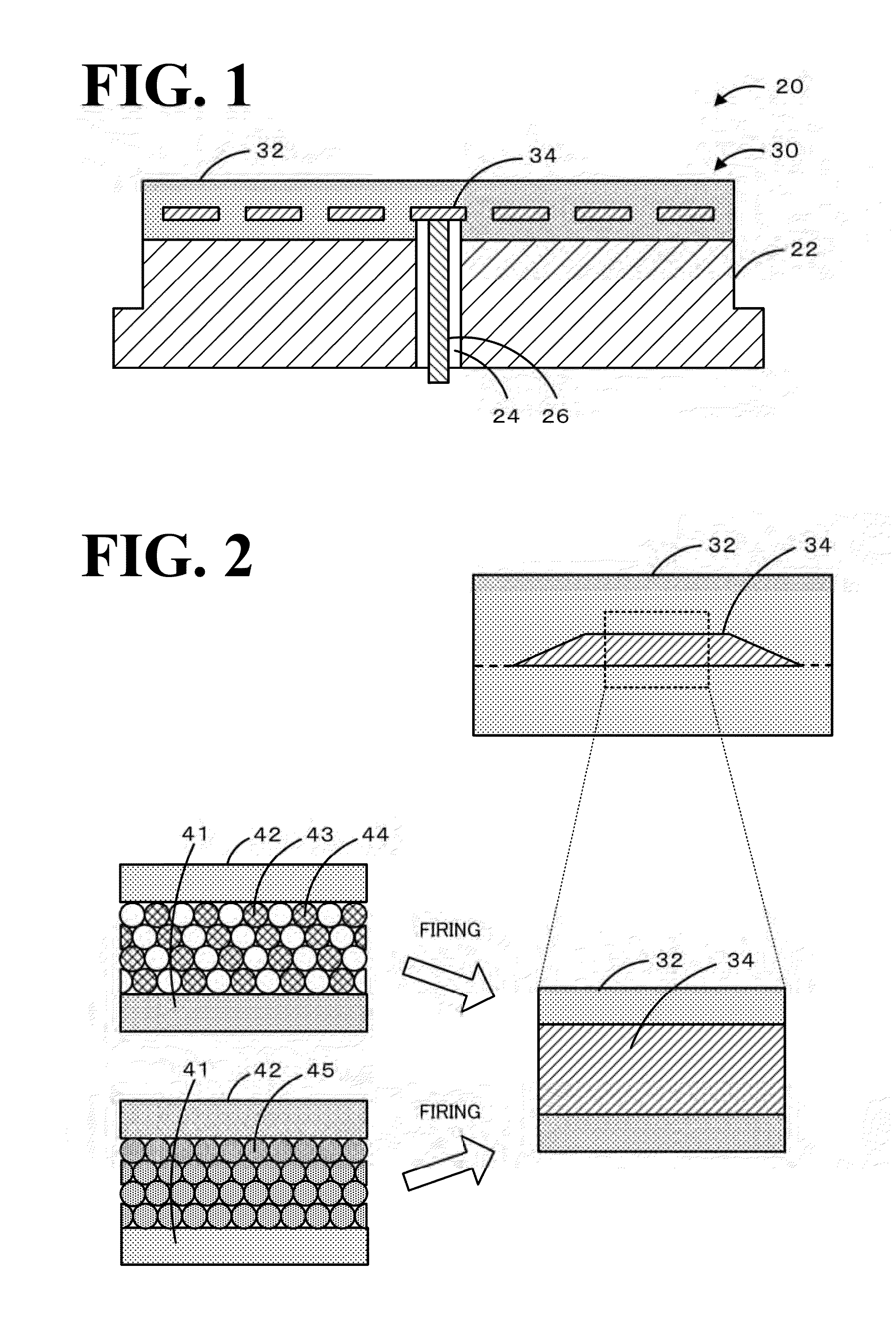

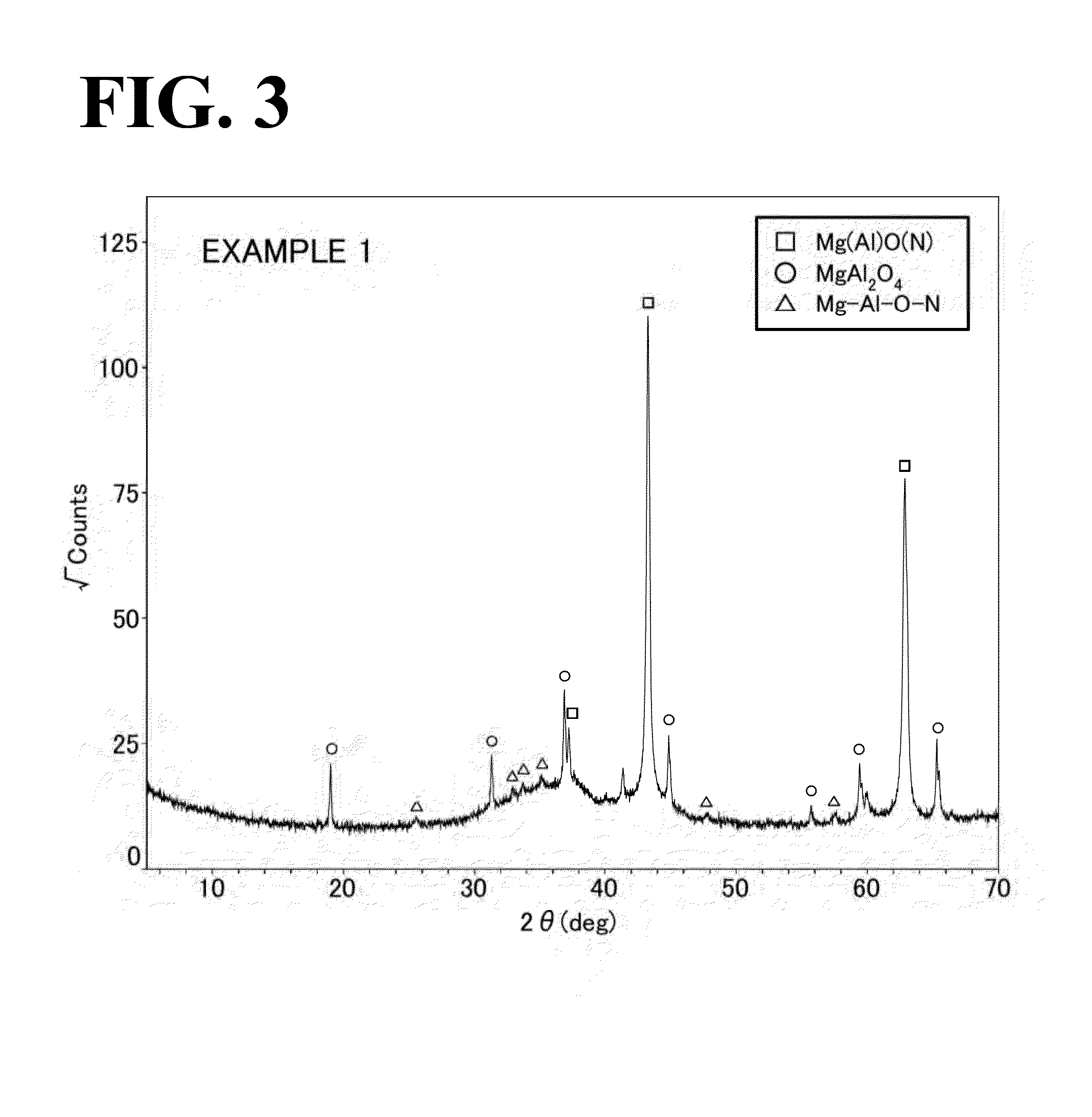

Ceramic member and member for semiconductor manufacturing equipment

ActiveUS20140285943A1Avoid crackingLow resistivitySemiconductor/solid-state device manufacturingPositioning apparatusRutheniumAlloy

Owner:NGK INSULATORS LTD

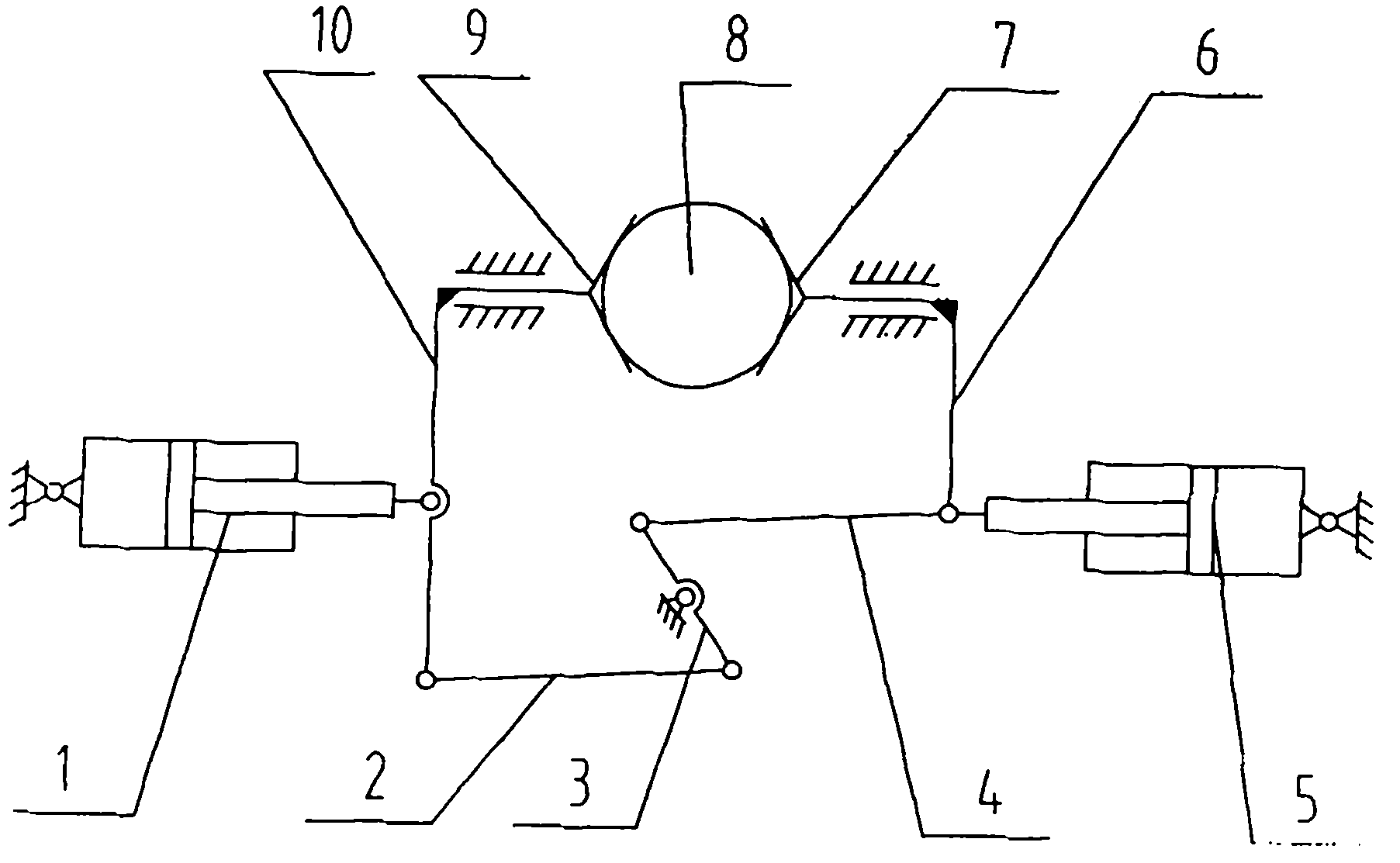

Centering mechanism for clamping device of cutting machine

InactiveCN102000994AEasy to implementReduce center deviationPositioning apparatusMetal-working holdersEngineeringMachine tool

Owner:浙江浙大网新环境工程有限公司

Cylindrical part bending angle measuring and horizontal and vertical surface drilling jig

InactiveCN103692251APrecise positioningConvenient bending angle measurementMeasurement/indication equipmentsPositioning apparatusHorizontal and verticalDrill

Owner:SHENYANG AEROSPACE UNIVERSITY

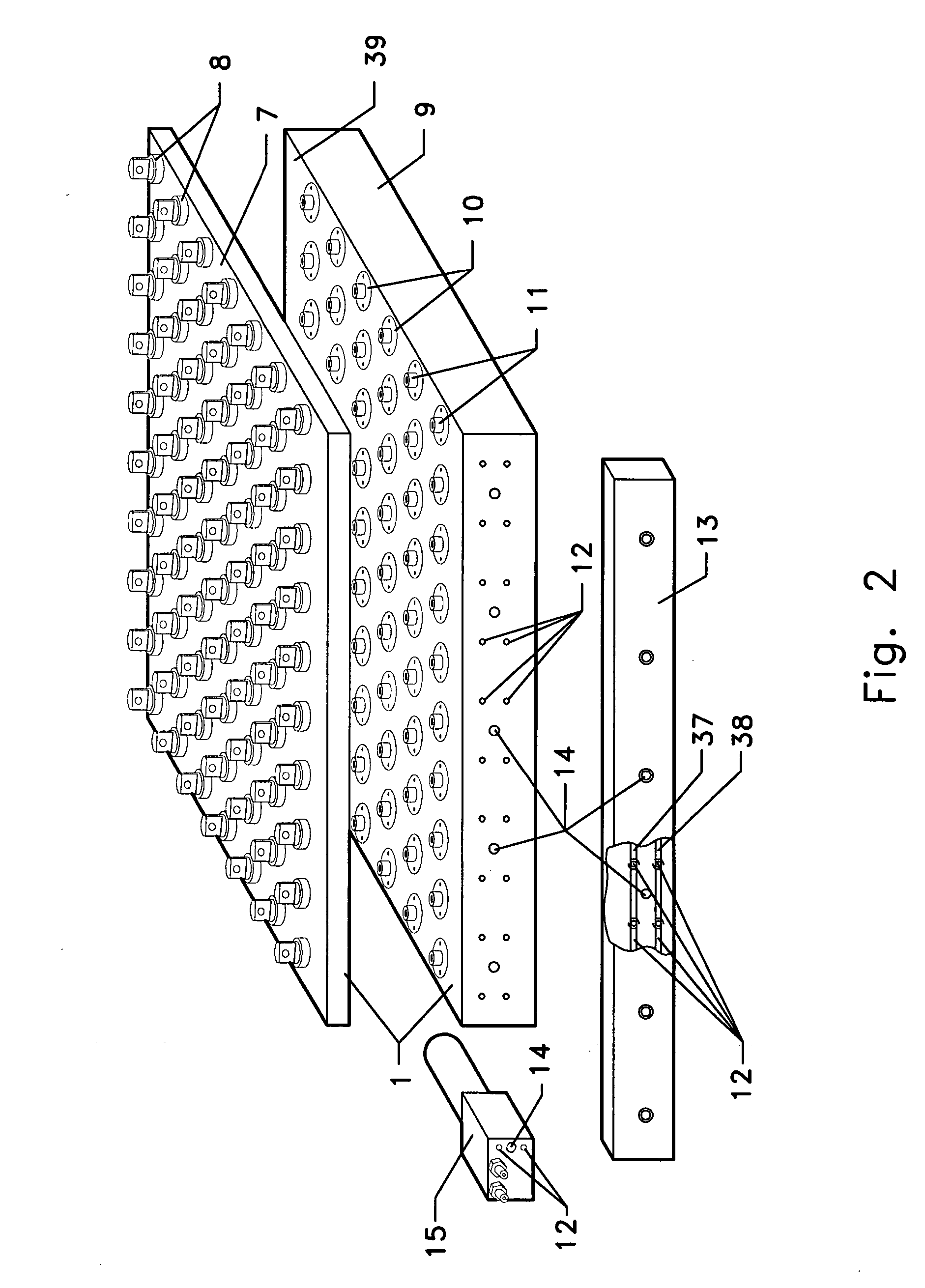

Versatile palletized work holding system

InactiveUS20040113345A1Measurement/indication equipmentsPositioning apparatusPistonMultiple function

Owner:MONTAGUE TOOL & MFG

Special fixed perforating device for automobile aluminum alloy hubs

Owner:TAIZHOU WEIHUA COATING TECH CO LTD

Composite connection type hydraulic knife handle

ActiveCN108907776AHigh strengthPrevent extravasationPositioning apparatusMetal-working holdersConnection typeInterference fit

The invention relates to a composite connection type hydraulic knife handle. The composite connection type hydraulic knife handle comprises a main knife handle body and an elastic thin-wall inner ringarranged in the main knife handle body, wherein a hydraulic oil cavity is arranged between the main knife handle body and the elastic thin-wall inner ring; the elastic thin-wall inner ring is arranged as a barrel thin-wall structure with two thick ends and a thin middle part; and the side outer rings of the two ends of the elastic thin-wall inner ring make contact with the support surfaces of inner holes of the main knife handle body. The main knife handle body and the elastic thin-wall inner ring are fixed in a manner of combining brazed connection and interference fit connection, the effectof stress on the connection performance of the main knife handle body and the elastic thin-wall inner ring is reduced, the joint of the main knife handle body and the elastic thin-wall inner ring isprevented from tear under the high pressure state, and therefore the service life of the hydraulic knife handle is prolonged. Meanwhile, by improving the structure of a piston rod and the structure ofa piston sleeve, the piston sleeve is quickly maintained, the overall sealing performance of a hydraulic access is improved, and the overall strength of the hydraulic knife handle is improved.

Owner:CHENGDU CHENGLIN CNC TOOL CO LTD

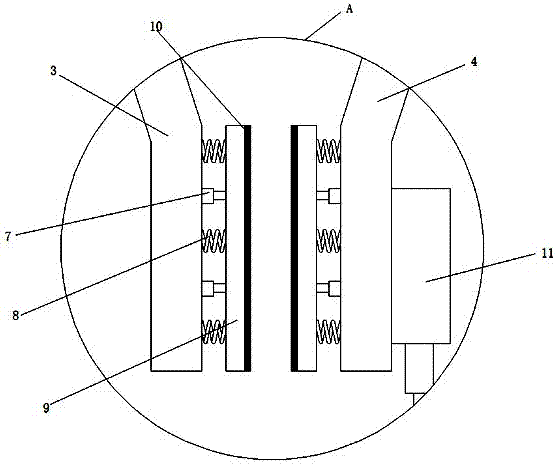

Drilling tool for machining automotive transmission parts

InactiveCN106363439ANot easy to looseImprove drilling accuracyPositioning apparatusMetal-working holdersParallel plateContact position

Owner:合肥齐飞信息技术有限公司

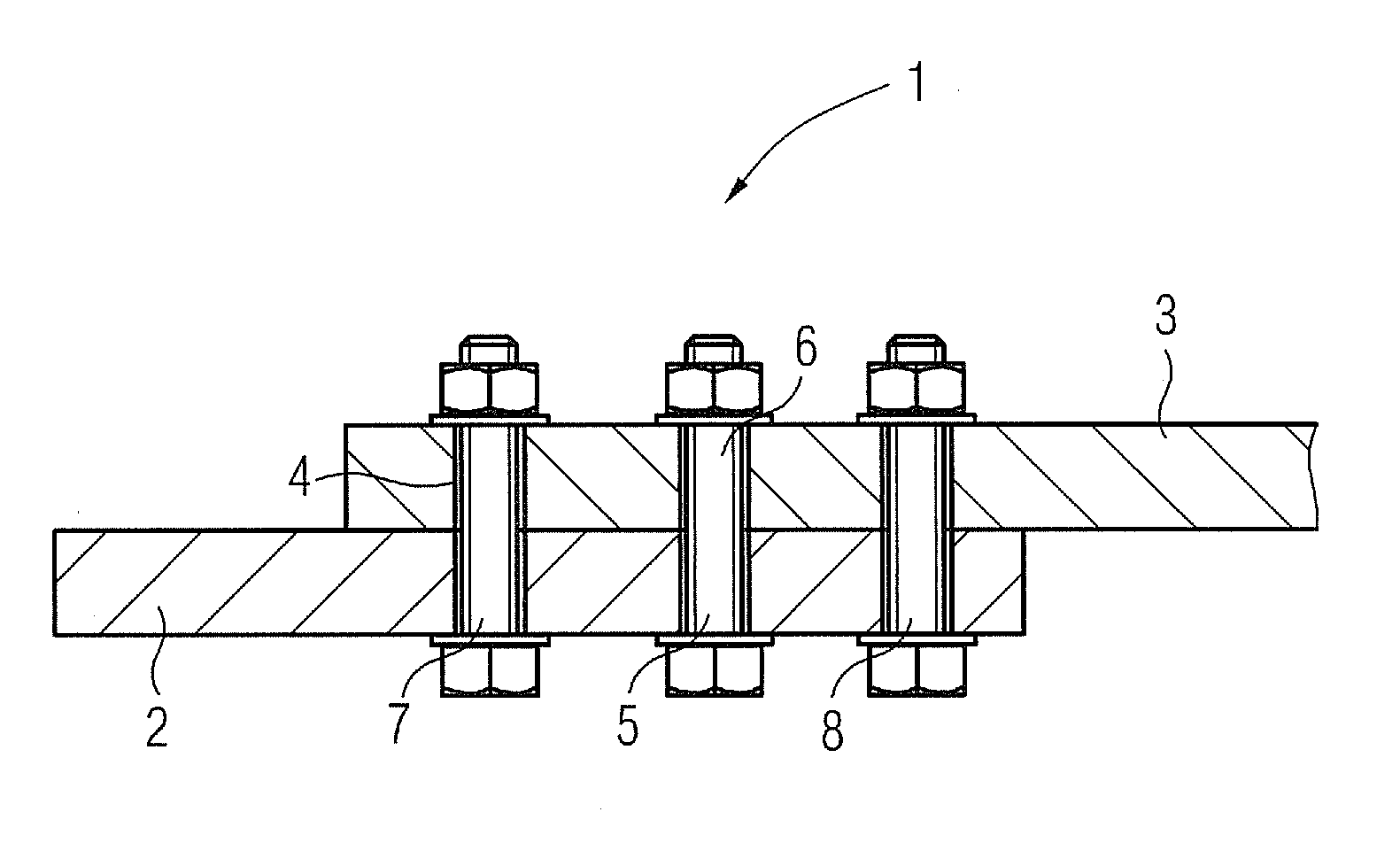

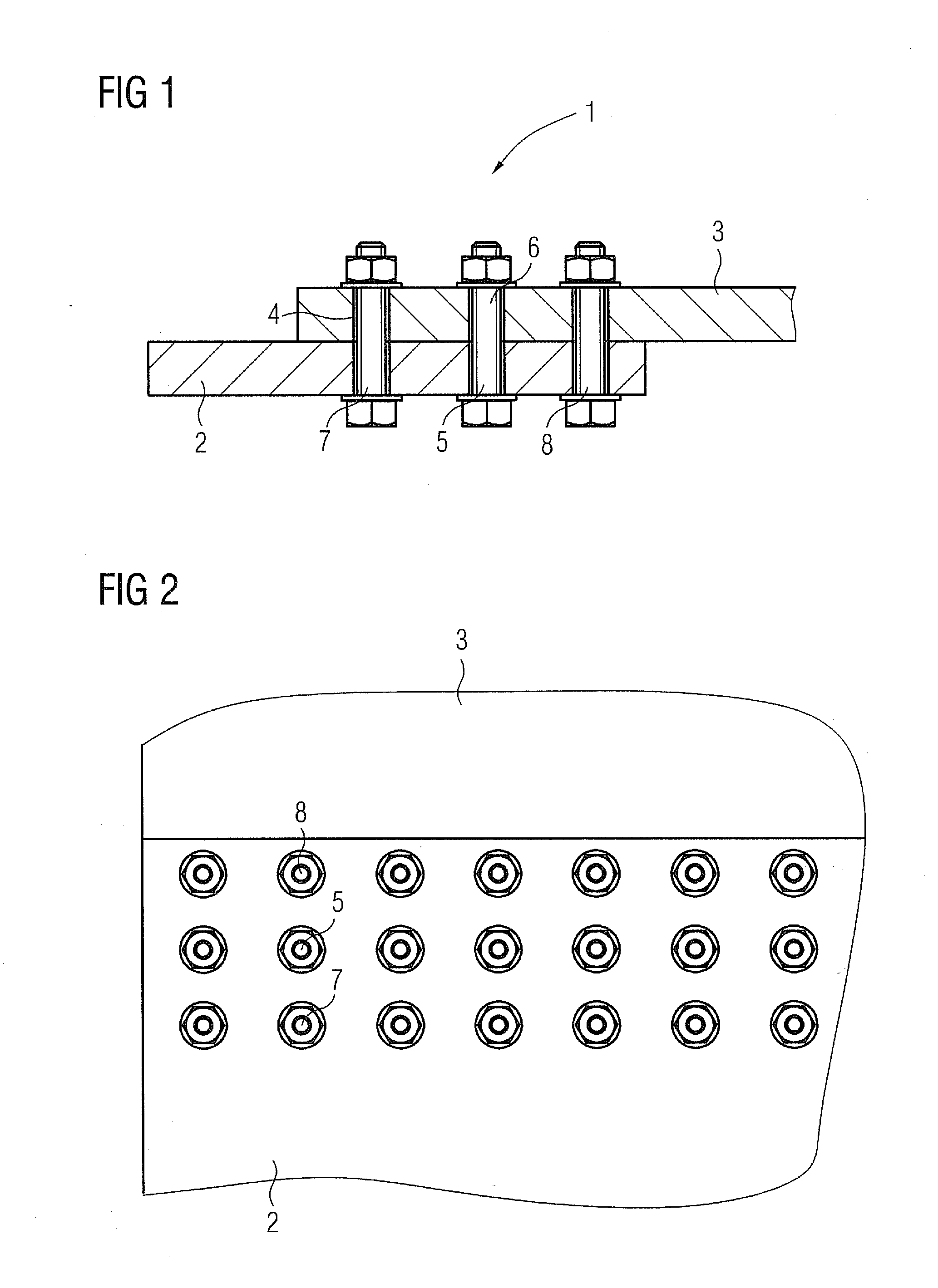

Wind turbine tower

Owner:SIEMENS AG

Power knife turret protection structure, power knife turret system and control method

ActiveCN107350495AStable and reliable structure operationKnow life expectancyTool holdersPositioning apparatusStructural engineeringMechanical engineering

The invention discloses a power knife turret protection structure, a power knife turret system and a control method, and aims to provide the power knife turret which is highly-reliable and safe and stable in operation. The technical scheme of the invention is characterized in that safe locking is performed through a duplex fluted disc, a static gear ring and a movable fluted disc structure; reliability is improved through a pushing spring; a piston-type unlocking function is formed by utilizing an oil cavity; and working stability and reliability are improved by adopting a sealing ring.

Owner:WENLING SANHE CNCEQUIP

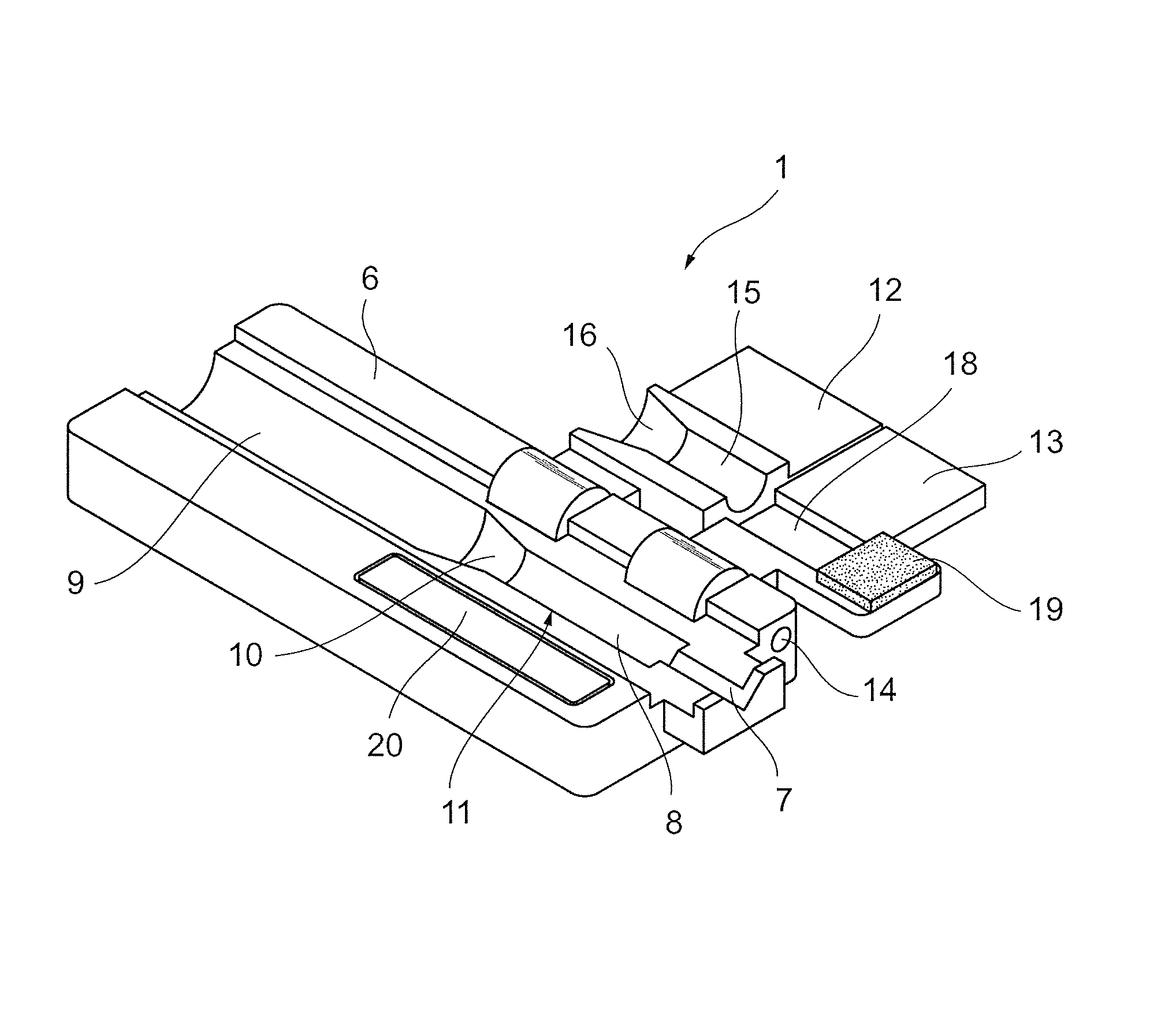

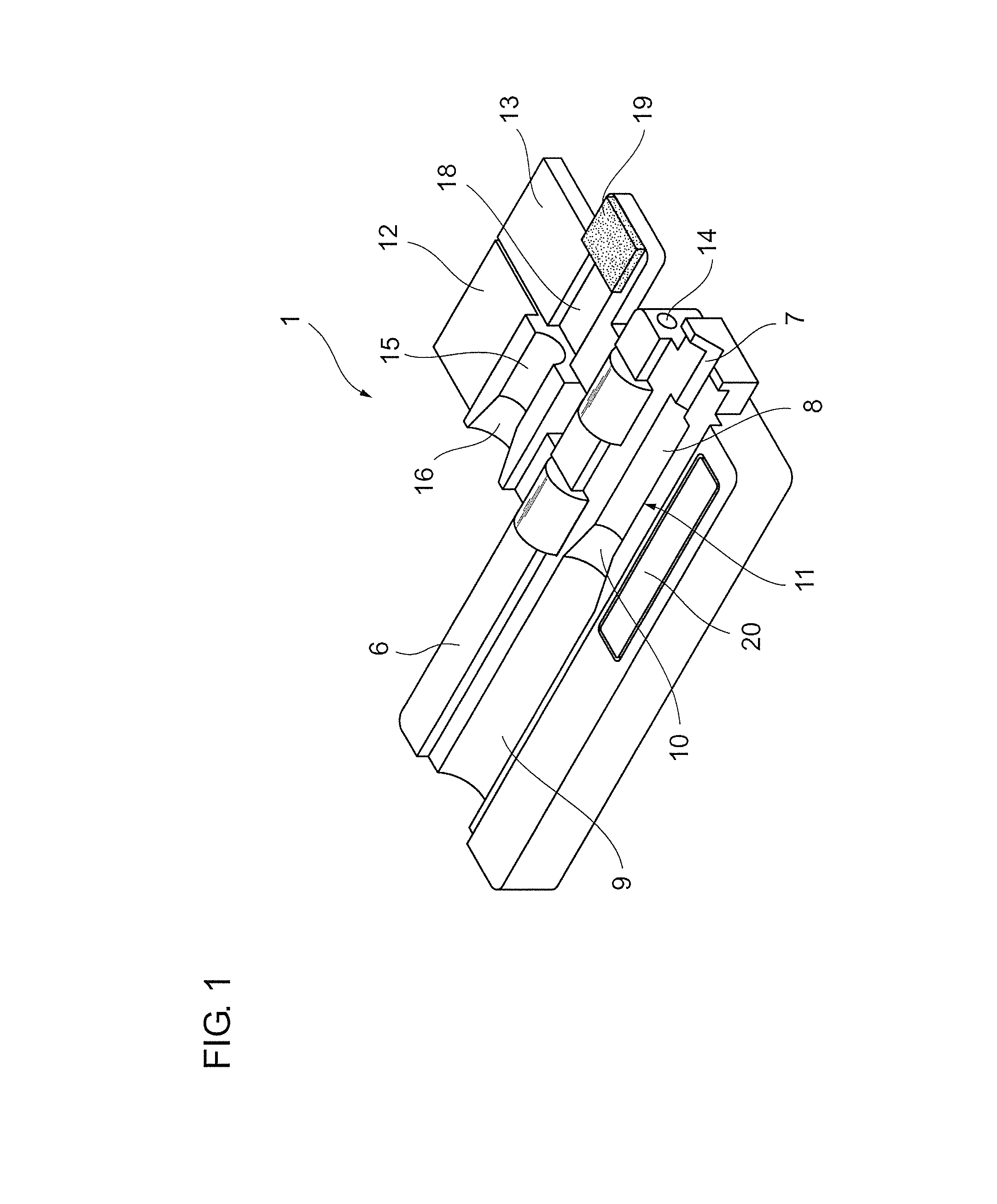

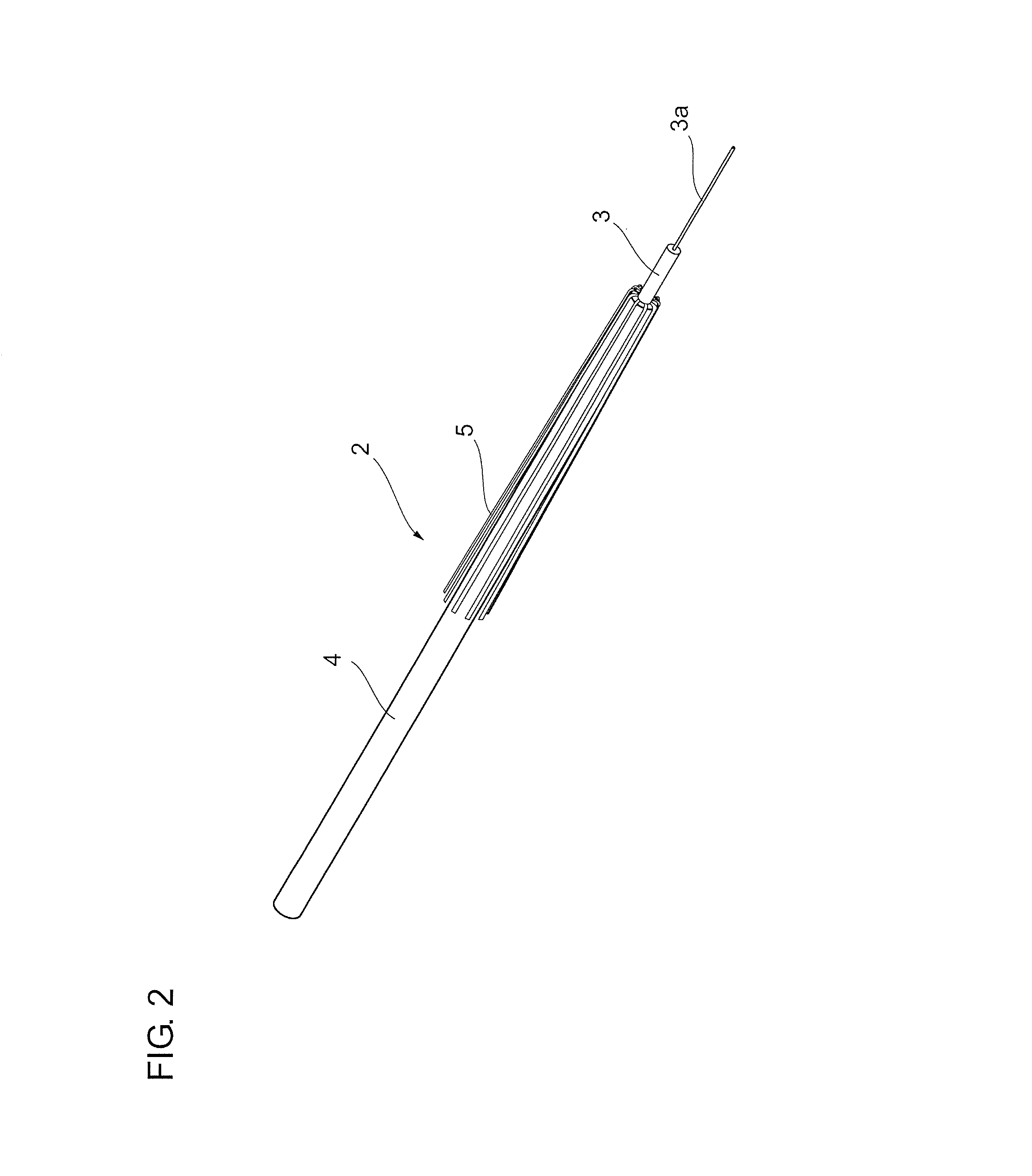

Optical fiber holder and method for holding coated optical fiber

ActiveUS20120251068A1No loss of splicing qualityHigh strengthPositioning apparatusOptical light guidesFiberEngineering

Owner:SUMITOMO ELECTRIC IND LTD

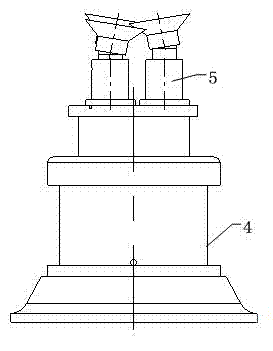

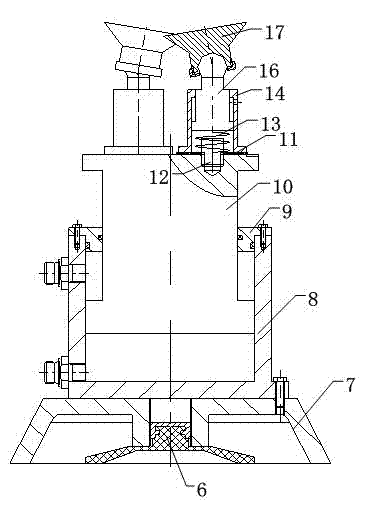

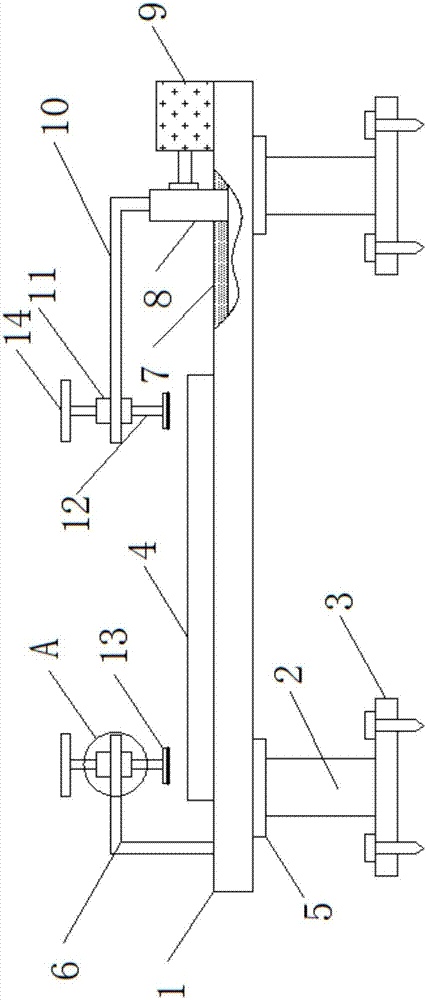

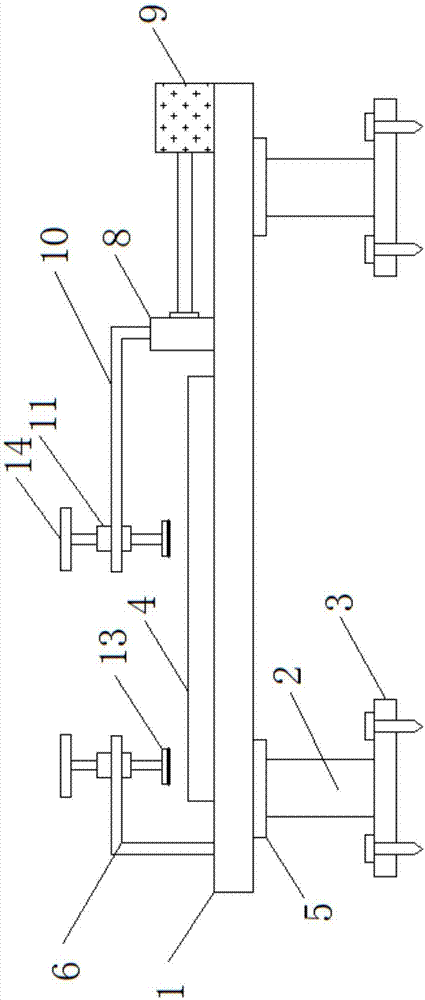

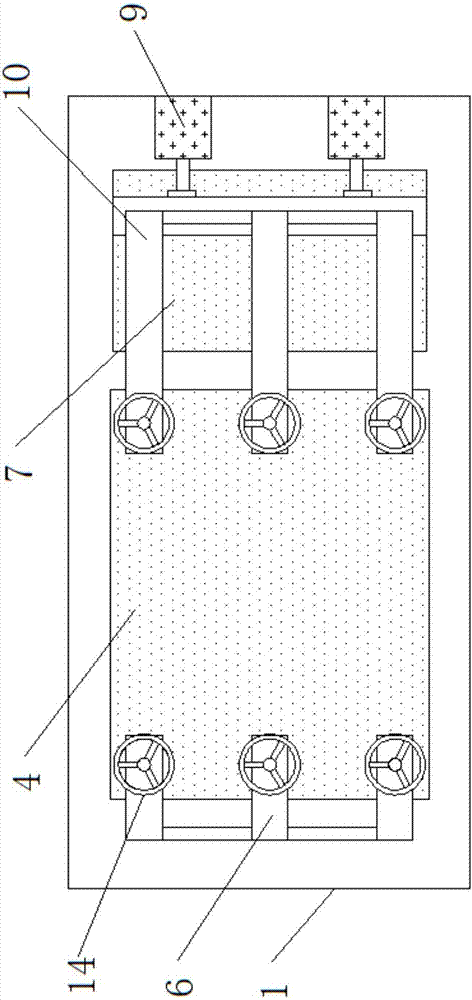

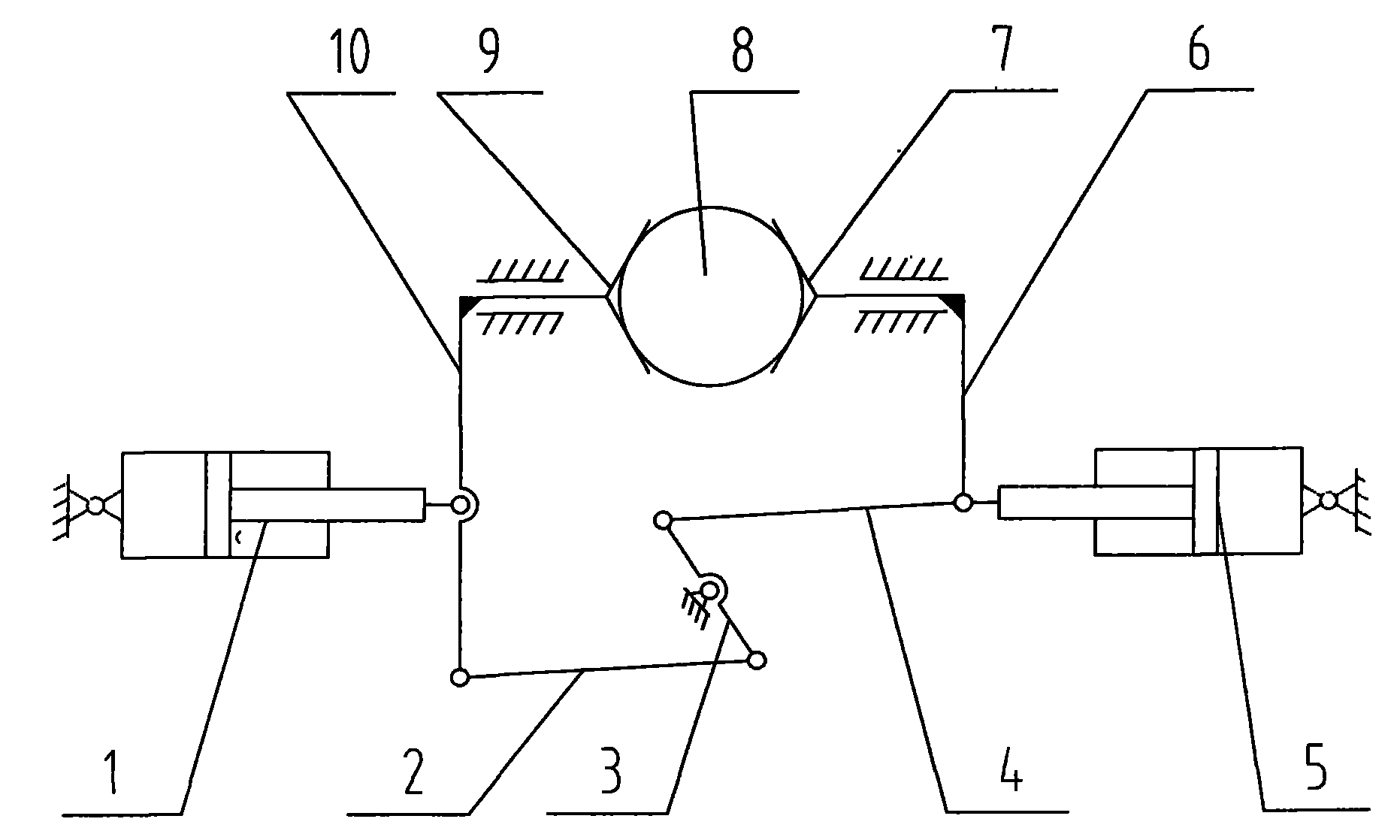

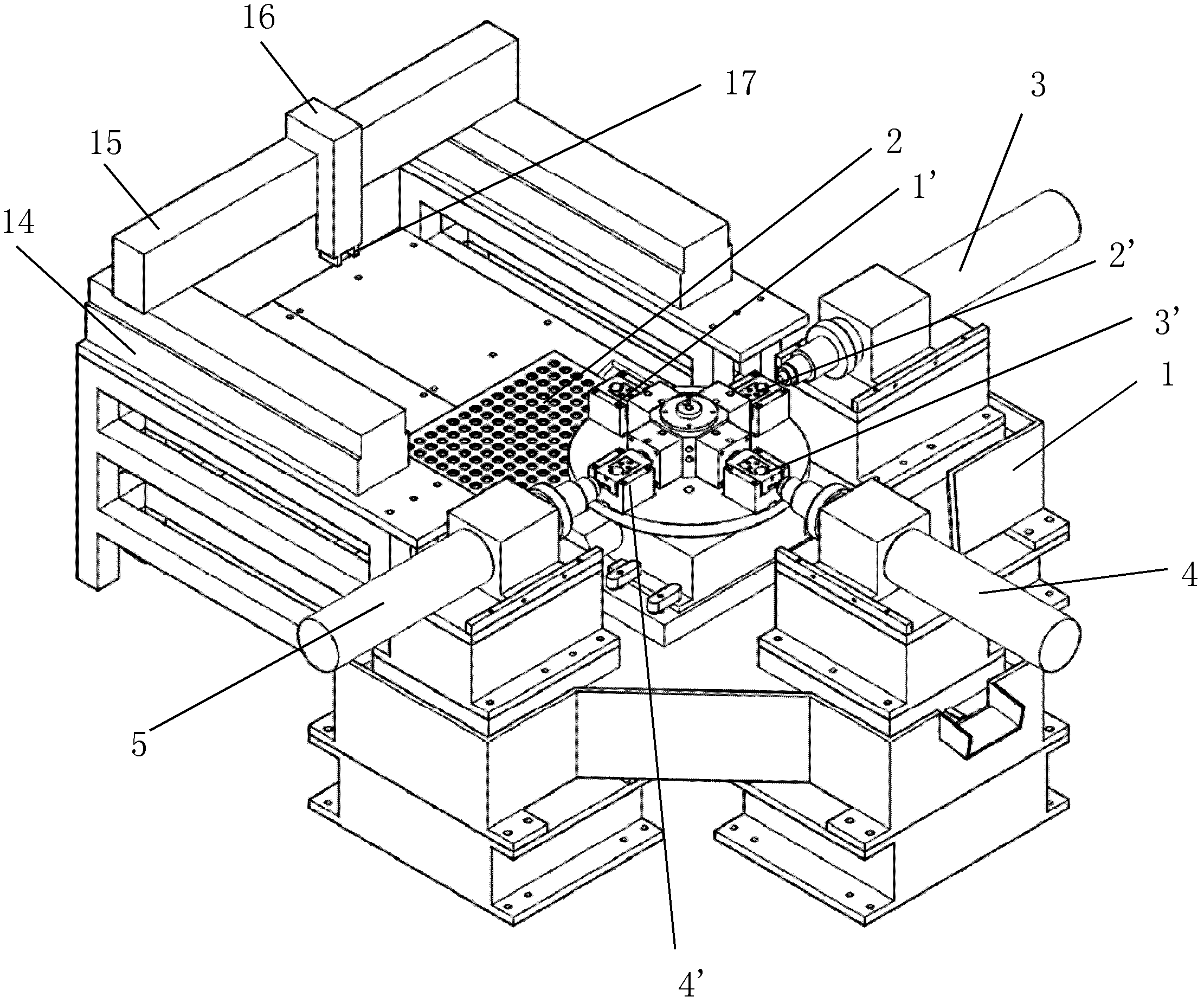

Special four-station machine tool for jackscrew holes of worms

InactiveCN102909554ANot affected by processing qualityFully automatedOther manufacturing equipments/toolsPositioning apparatusTransverse axisDrill hole

The invention relates to a special four-station machine tool for jackscrew holes of worms. The special four-station machine tool is characterized by comprising a tool body, a tray, a chamfering power head, a drilling power head, a tapping power head, a hydraulic turntable and fixtures; the hydraulic turntable is fixedly connected to the center of a working table of the tool body, the chamfering power head and the tapping power head are symmetrically fixedly connected onto the working table of the tool body along the transverse axis of the hydraulic turntable, the drilling power head is fixedly connected to the central position between the chamfering power head and the tapping power head along the radial direction of the hydraulic turntable, and the fixtures for mounting a workpiece are arranged on rotary work stations of the hydraulic turntable. The special four-station machine tool has the advantages that the special four-station machine tool are fully automatic, and labor cost is greatly reduced; various working procedures are centralized and can be carried out simultaneously, and accordingly the efficiency is improved; and influence of skills of operators to the machining quality is avoided, and the special four-station machine tool is stable and reliable.

Owner:天津市中马骏腾精密机械制造有限公司

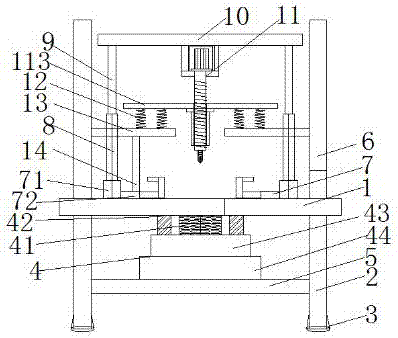

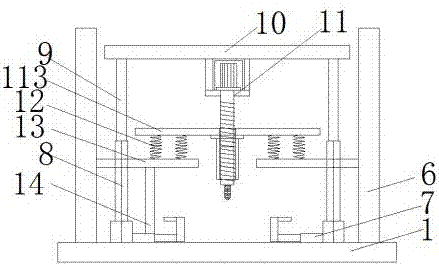

Automatic clamping device for computerized numerical control machine tool

InactiveCN107175343AImprove qualityPrevent fallingMetal working apparatusPositioning apparatusWrinkle skinNumerical control

Owner:张艳

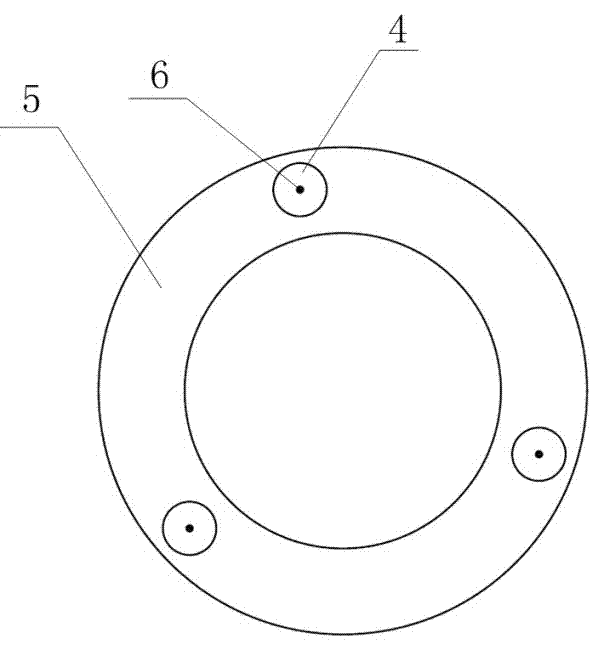

Internal spline gear pitch circle quick positioning device and machining method thereof

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Cycloid rotational indexing-based novel vertical milling machine

ActiveCN106424867AAvoid multiple clampingLow costLarge fixed membersMilling equipment detailsMilling cutterEngineering

The invention relates to vertical milling machines and belongs to the field of machining. A cycloid rotational indexing-based novel vertical milling machine is characterized by comprising a machine body mechanism, a milling head mechanism and a worktable mechanism. The cycloid rotational indexing-based novel vertical milling machine comprises two working modes: rotational indexing machining and milling by an eccentric milling cutter. In the rotational indexing machining mode, the milling cutter in compound movements of rotation and revolution is matched with two-dimensional translation of a to-be-machined workpiece and a vertical movement of the milling head mechanism to form a special movement track of the milling cutter relative to the to-be-machined workpiece so as to machine a special part in a complex shape. The milling mode by the eccentric milling cutter is as follows: the milling cutter is fixed in an expected position relative to the rotary center of a spindle box to form the eccentric milling cutter, and the rotation movement of the eccentric milling cutter is combined with two-dimensional translation of the to-be-machined workpiece and a vertical movement of the milling head mechanism. The cycloid rotational indexing-based novel vertical milling machine provided by the invention retains the functions of a conventional milling machine and increases a mode of efficiently machining the part in the special shape by cycloid rotational indexing. The two modes can be freely switched, so that the cycloid rotational indexing-based novel vertical milling machine is of certain universality.

Owner:SHANGHAI UNIV OF ENG SCI

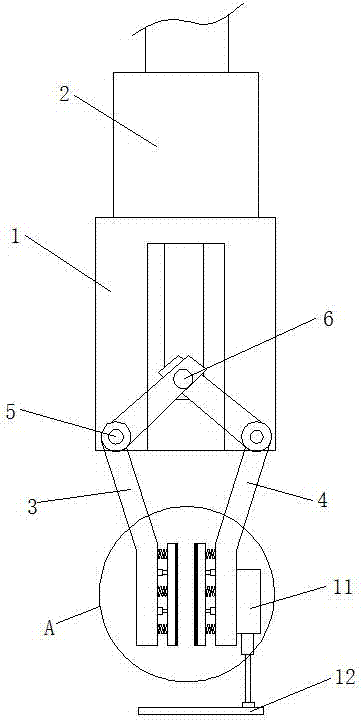

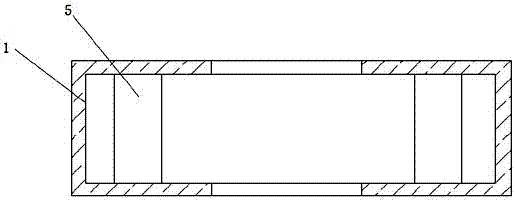

External machining fixture for one-step clamping

InactiveCN103240632AImprove adaptabilitySimple structurePositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention relates to an external machining fixture for one-step clamping. The external machining fixture comprises a body and a sliding tip cone, the sliding tip cone is mounted inside the body and is limited to only axially slide inside the body by a positioning screw, a driving plate is sleeved at the front end of the body, a support lever is arranged at the rear end of the sliding tip cone, a nut is arranged at the front end of the support lever, a hexagonal plug is arranged at the rear end of the support lever, and a Belleville spring is arranged on the support lever and is compressed inside the body by the hexagonal plug. According to the external machining fixture for one-step clamping, the sliding tip cone and driving teeth are used for double positioning support, and external machining can be realized by one-step clamping. A plurality of oil cavities are further arranged on the fixture to adapt to workpieces with different end faces, and adaptability of the fixture is improved. By means of practical machining and use, the fixture is simple in structure, high in machining precision and remarkable in implementation effect.

Owner:TONGLING NONFERROUS XINGTONG ELECTROMECHANICAL MFG CO LTD

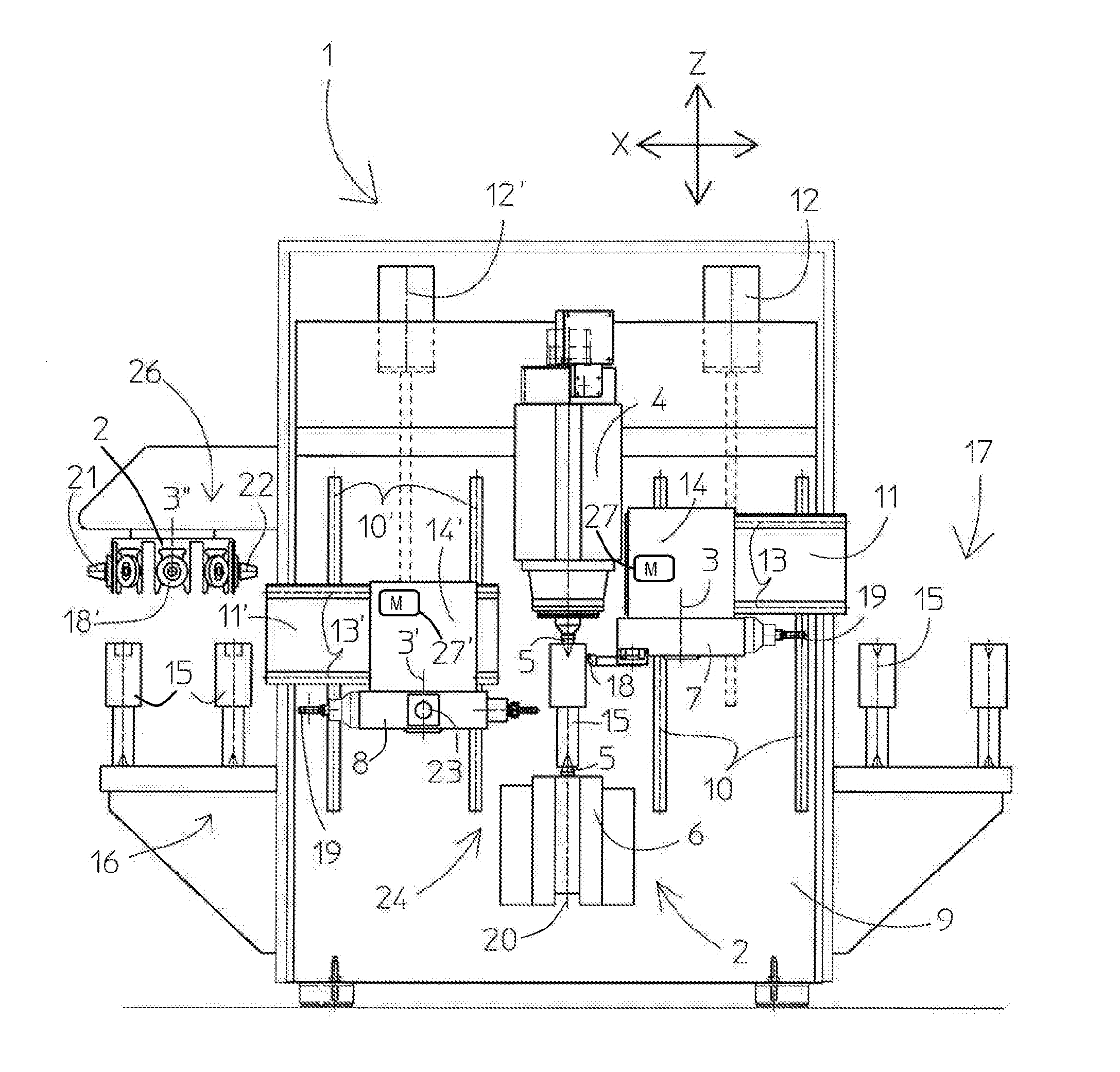

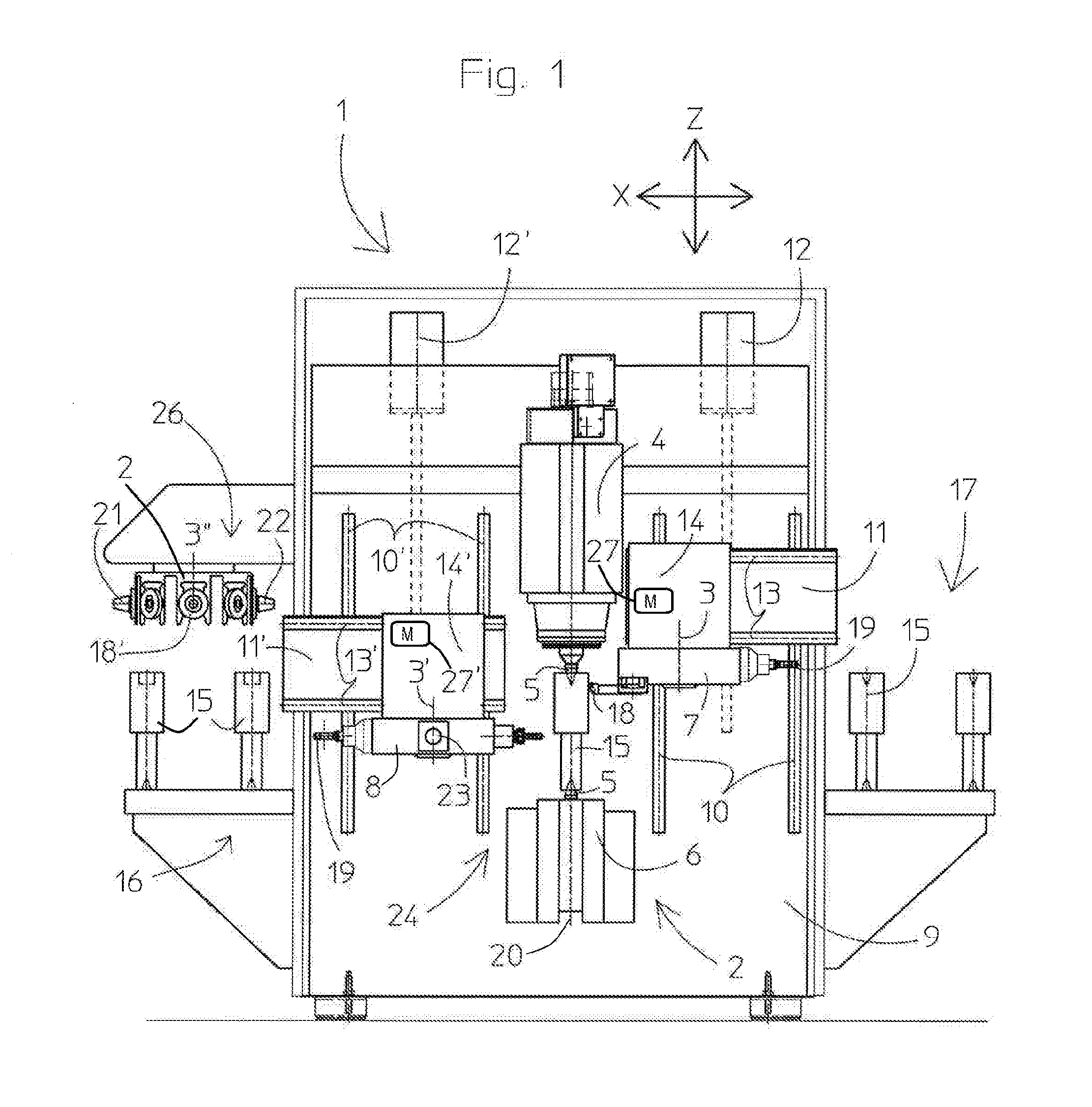

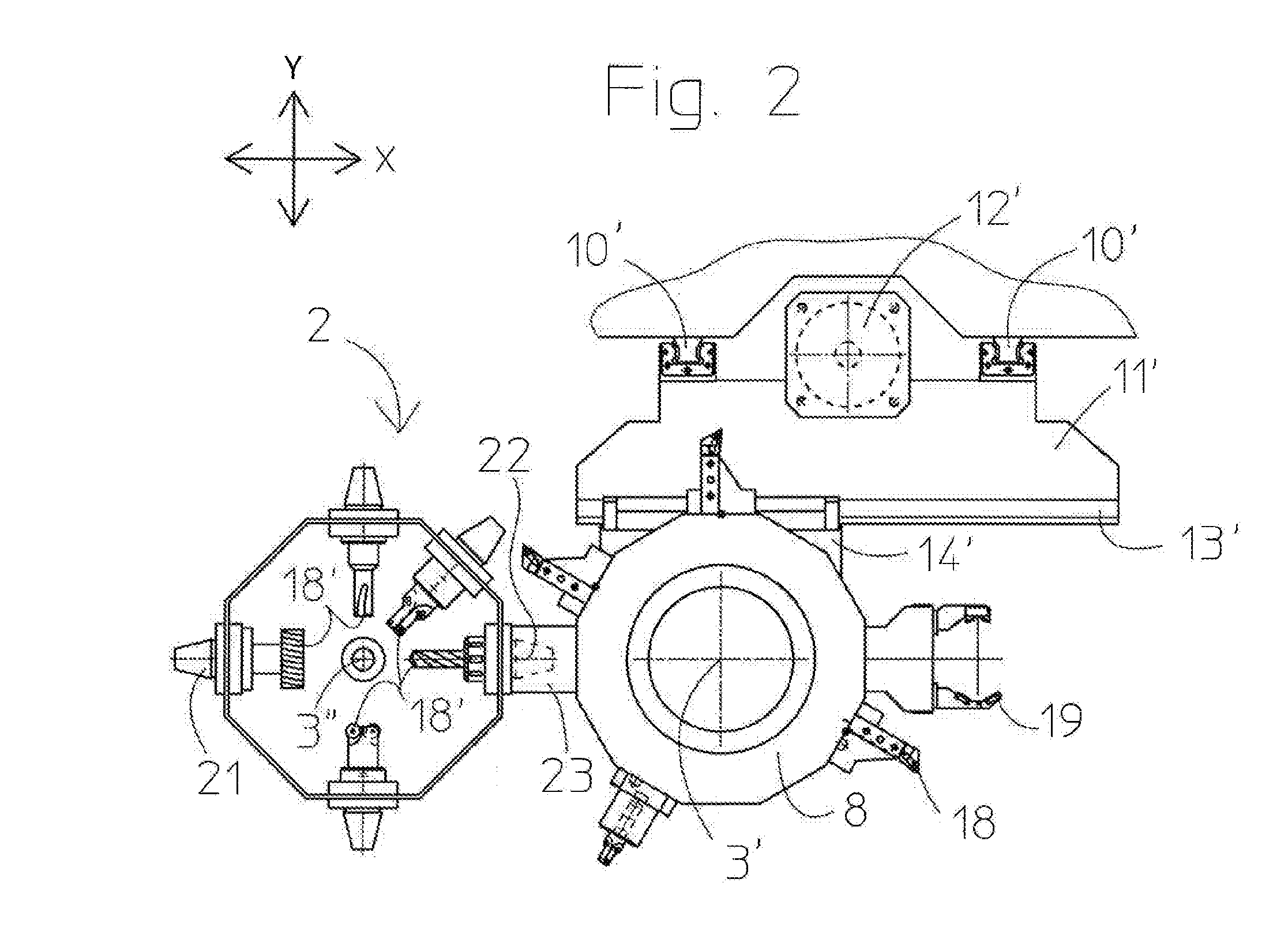

Machining apparatus

ActiveUS20140157559A1Simple mechanismEasy to controlAutomatic/semiautomatic turning machinesTurret lathesTool bitVertical plane

Owner:EMAG HLDG GMBH

Auto component tooling fixture

Owner:重庆永今汽车零部件有限公司

Use method of linear cutting and positioning fixture

Owner:WUXI CITY SHENGFENG FORGING

Quick linkage clamping device

PendingCN111331396ASet stableEasy to adjustPositioning apparatusMetal-working holdersAdhesiveClassical mechanics

Owner:SUZHOU KSC PRECISE MACHINERY

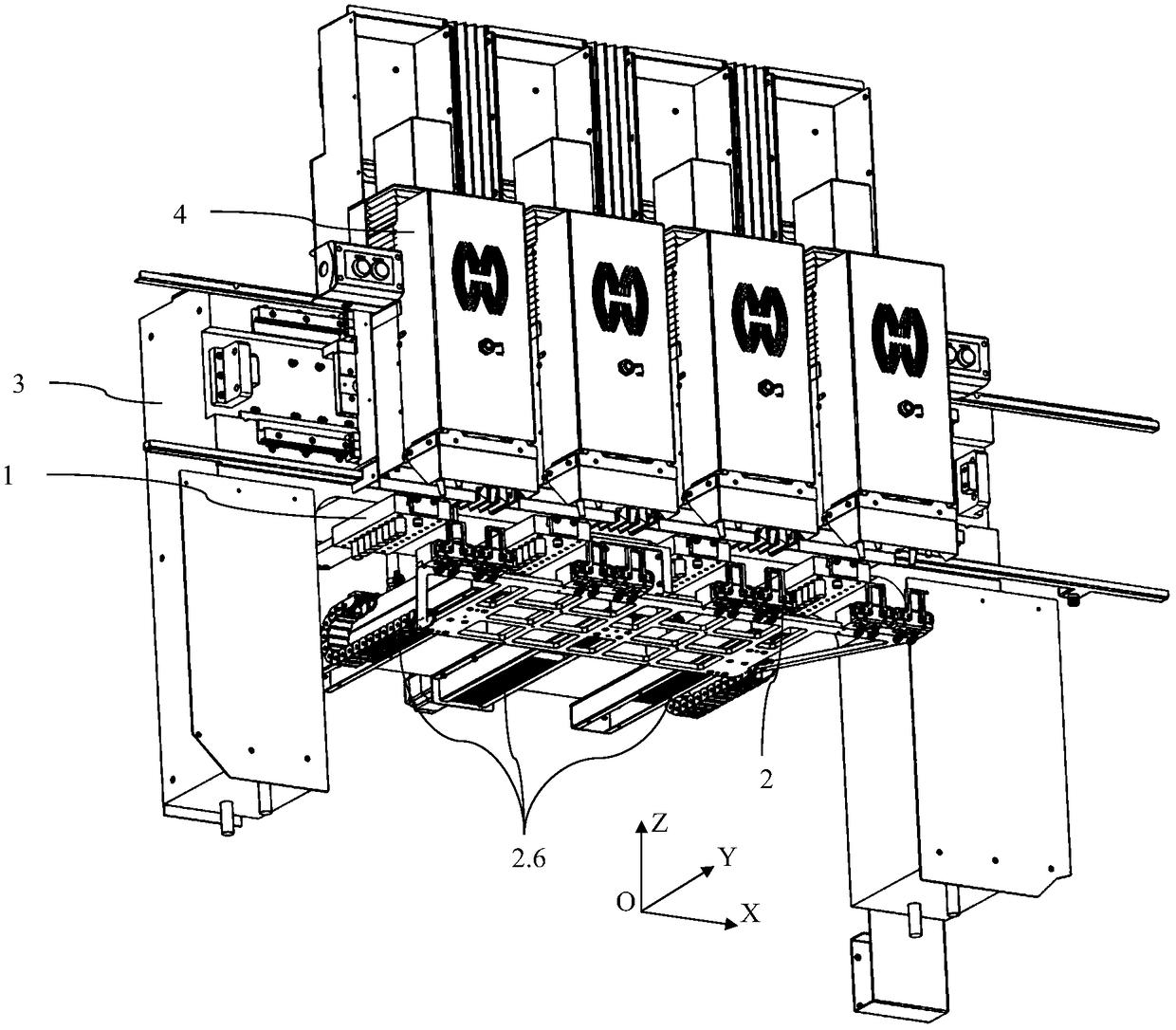

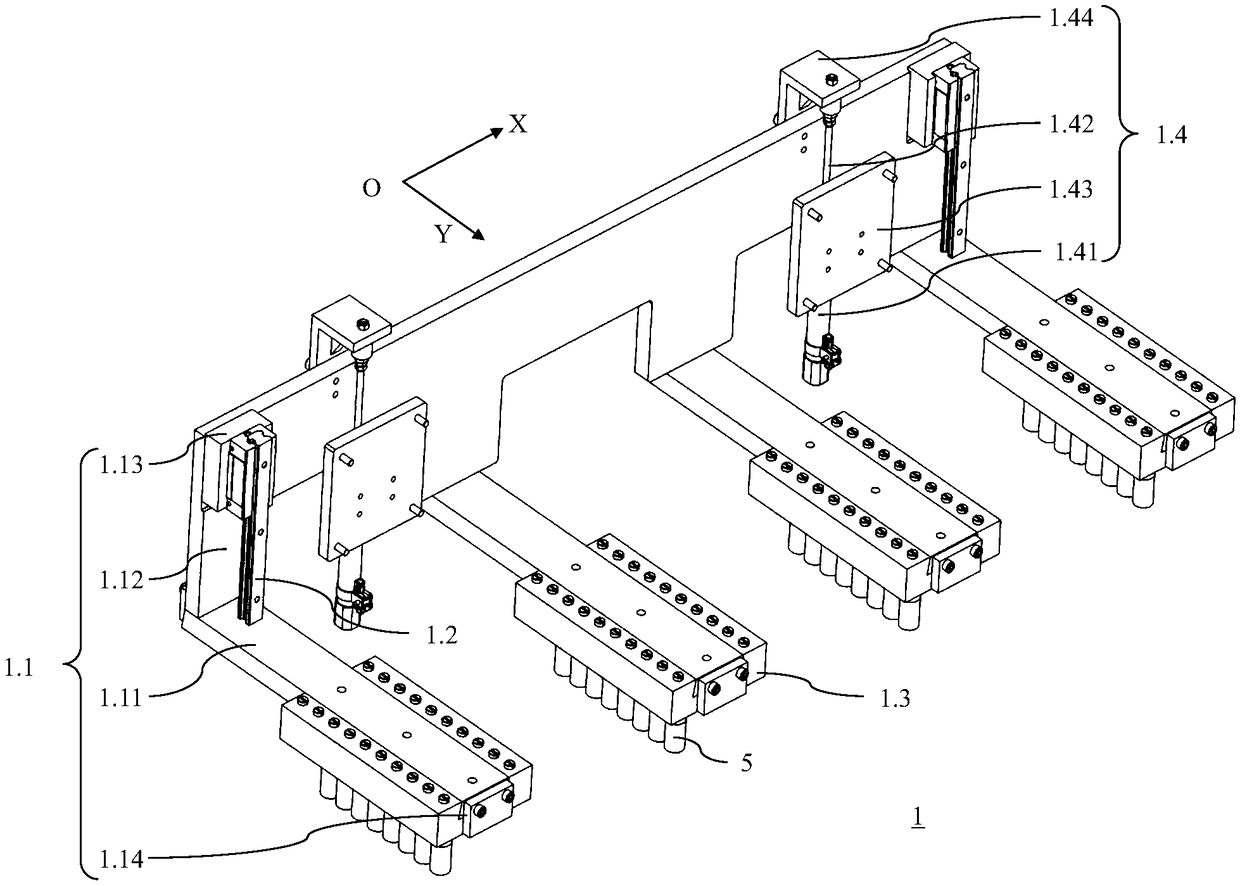

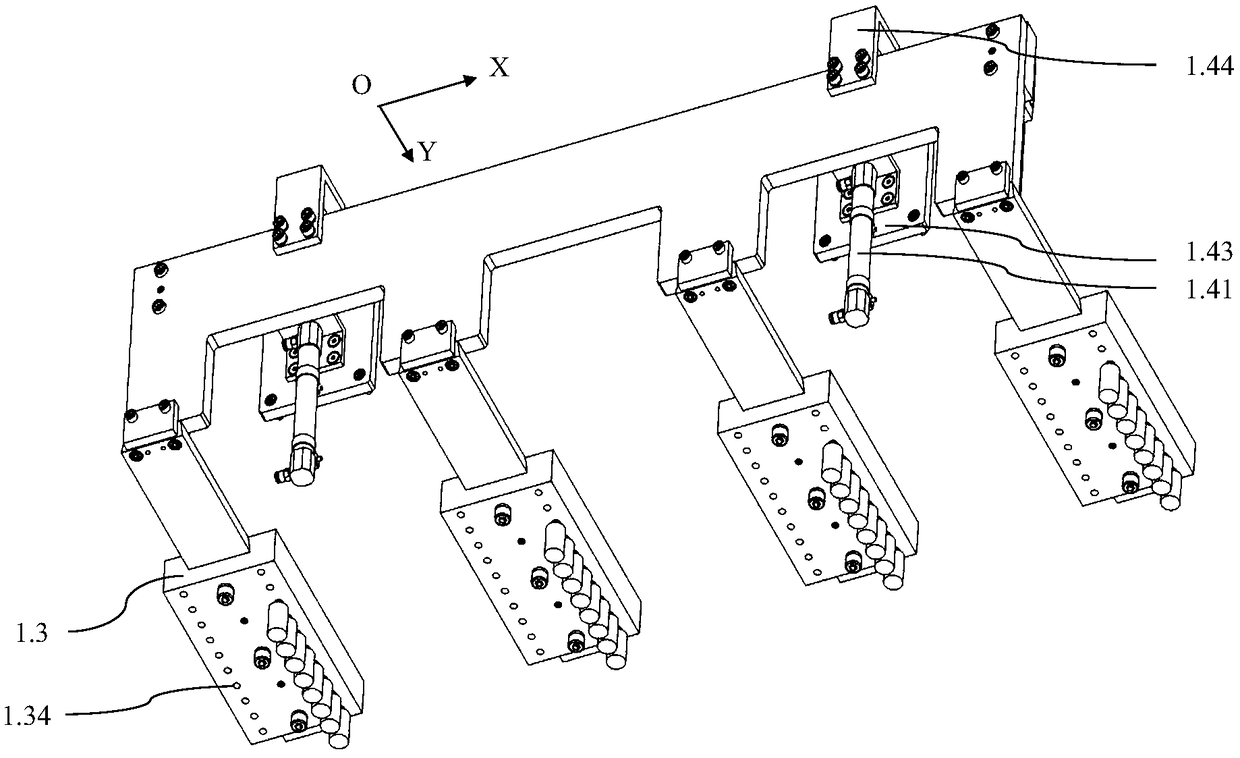

Tool magazine, tool changing mechanism and multi-spindle machining center

Owner:江西衡源智能装备股份有限公司

Square hole pulling clamp of adjustable spanner

InactiveCN101905426AEasy to clamp and fixImprove machining accuracyPositioning apparatusMetal-working holdersProcessing accuracyWrench

Owner:ZHANGJIAGANG YUCHENG MASCH C0 LTD

External thread secondary fitting fixture and clamping method

InactiveCN105397538ASimple clamping methodSafe clamping methodPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention provides a fixture for repeatedly turning and repairing an external thread by using a horizontal lathe simply, safely and precisely and a clamping method thereof. A poking disc fixture consists of four ejecting bolts and a U-shaped groove; a poking disc tool is fixed on a workpiece through the four ejecting bolts; the workpiece is supported by lathe head and lathe tail tips in the workpiece clamping; and the poking disc tool is connected to one clamping jaw of the lathe for transferring a torque through the U-shaped groove. After a thread of the workpiece is roughly machined, a horizontal turning chuck is locked to link with a tool post; and the workpiece and the poking disc fixture are dismounted from equipment for premounting. When the workpiece is horizontally turned again, the workpiece is also fixed by the horizontal turning lathe head and lathe tail tips; and the clamping jaw used in the first clamping process is adjusted to enter the U-shaped groove of the poking disc tool to finish the second clamping process; and the second fitting of the thread can be directly performed without alignment for a workpiece thread machining initial angle after clamping.

Owner:HARBIN ELECTRIC MASCH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap