Use method of linear cutting and positioning fixture

A positioning fixture and wire cutting technology, applied in the field of fixtures, can solve the problem that the V-shaped groove cannot be processed by turning or milling, and achieve the effect of simple structure, high processing precision and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

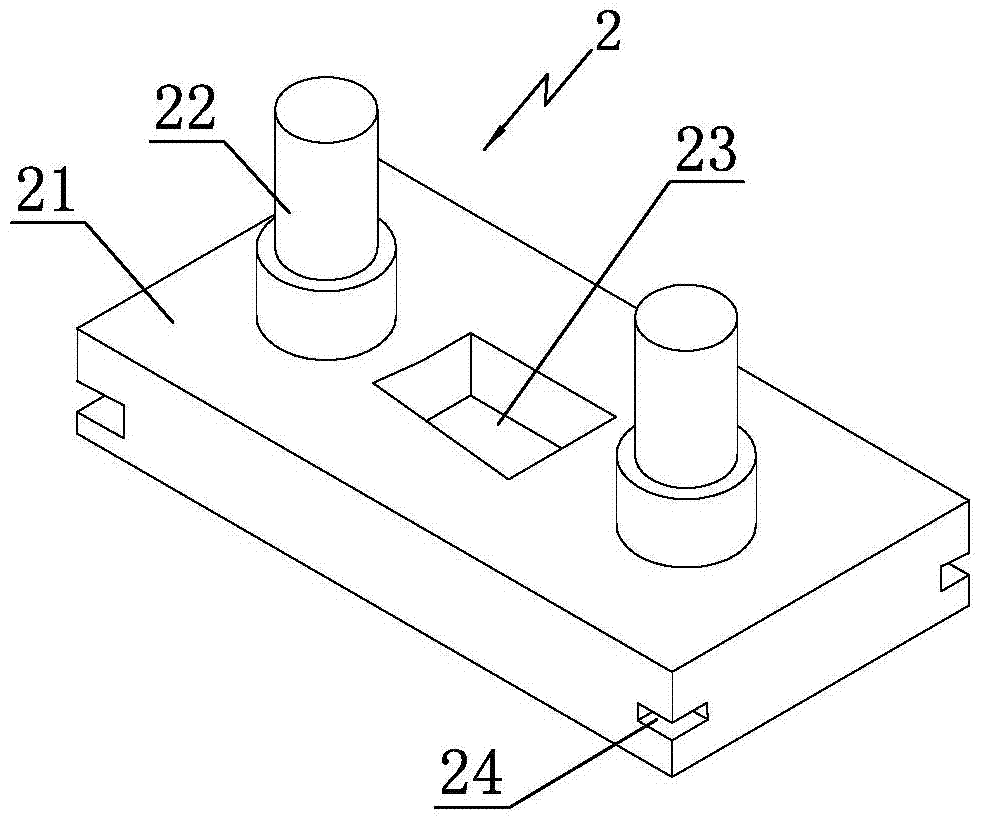

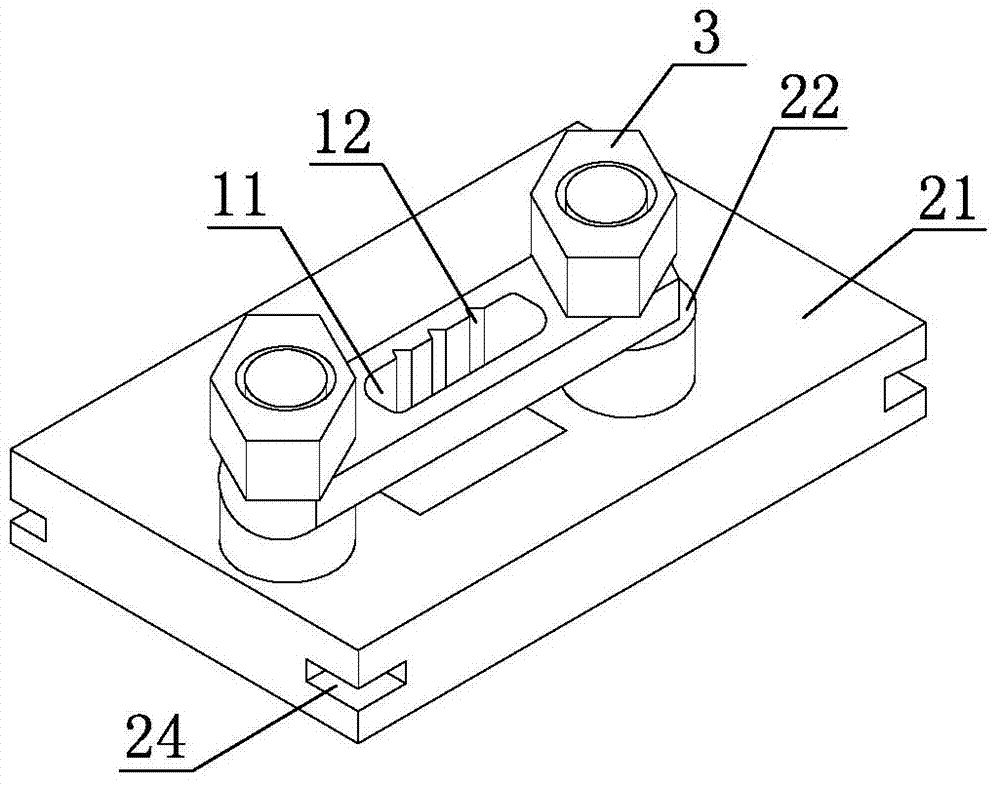

[0015] like Figure 1 to Figure 3 As shown, the present invention includes a positioning seat 2, the base plate 21 of the positioning seat 2 has a square through hole 23, the through hole 23 is a threading hole, and the workpiece 1 is wire-cut through the through hole 23, and the base plate 21 is located on the Both sides of the through hole 23 are provided with a positioning screw 22, the positioning screw 22 is symmetrical about the through hole 23, the positioning holes 12 at both ends of the workpiece 1 are set on the screw 22, and the positioning nut 3 is installed on the screw 22 to compress and position the workpiece 1. The elongated hole 11 on the workpiece 1 is directly above the through hole 23 on the base plate 21, which can ensure smooth processing of the V-shaped groove 13 on the side wall of the elongated hole 11; the four corne

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap