Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

11 results about "Pitch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pitch is a viscoelastic polymer which can be natural or manufactured, derived from petroleum, coal tar, or plants. Various forms of pitch may also be called tar, bitumen, or asphalt. Pitch produced from plants is also known as resin. Some products made from plant resin are also known as rosin.

Solid waste-based baking-free environment-friendly hollow brick and preparation method thereof

Owner:SHANDONG UNIV +1

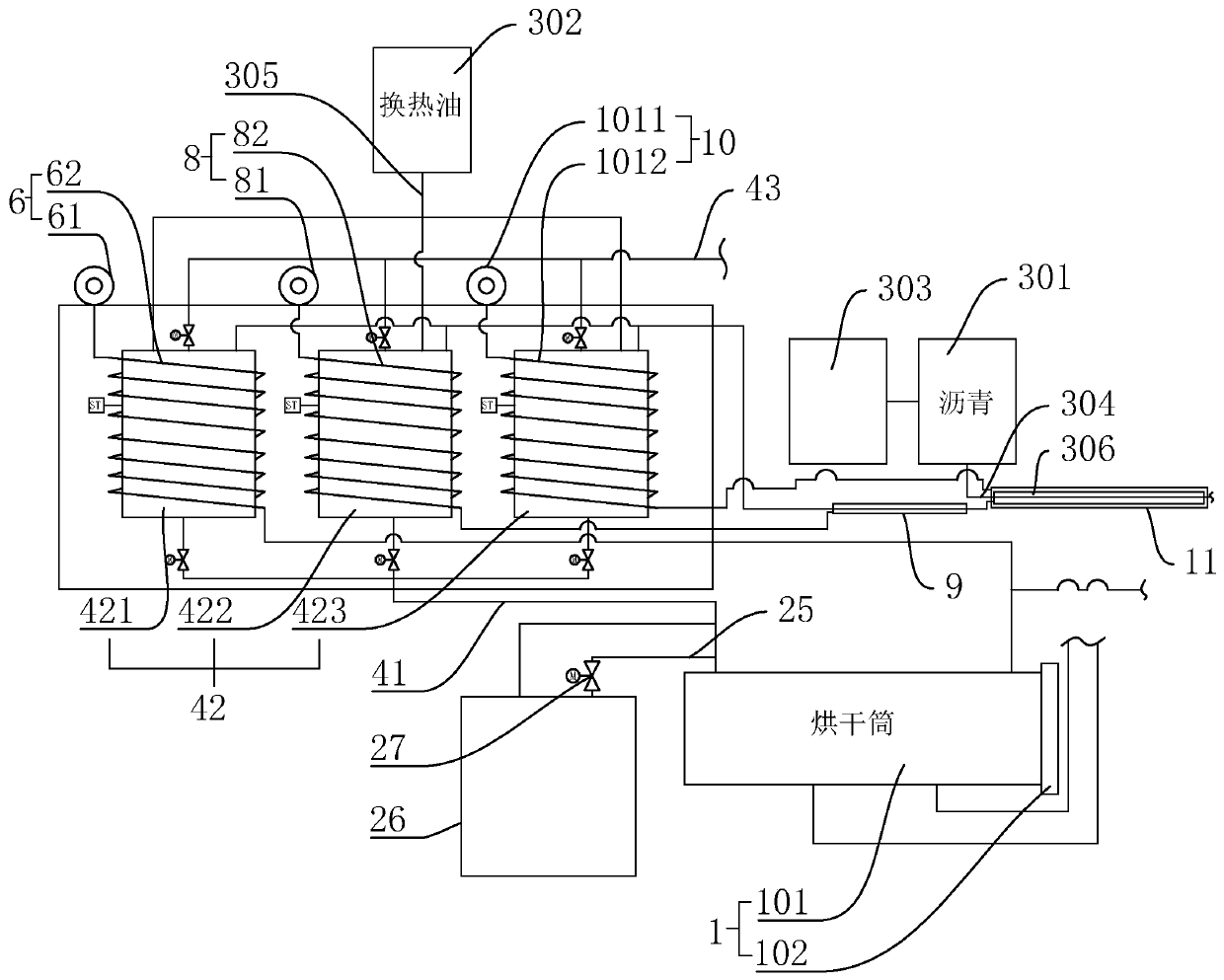

Device and process for purifying and treating tar tail gas and asphalt fume

ActiveCN110425550ASolve the problem that it is difficult to purify asphalt fumeImprove thermal efficiencyIncinerator apparatusChimneysCombustion chamberEnvironmental geology

The invention relates to a device and process for purifying and treating tar tail gas and asphalt fume. The device comprises an incinerator and a chimney, wherein the incinerator is composed of a first combustion chamber, a second combustion chamber, a first heat storage chamber and a second heat storage chamber, the first combustion chamber is arranged below the second combustion chamber, and thefirst combustion chamber and the second combustion chamber communicates with each other; the two ends of the first combustion chamber communicates with the top of the first heat storage chamber and the top of the second heat storage chamber respectively, a first combustor is arranged inside the first combustion chamber, a second combustor is arranged inside the second combustion chamber, and a heat accumulator is arranged inside the first heat storage chamber and the second heat storage chamber. By adopting a process combining a heat storage type incinerator and a direct combustion type incinerator, the tar tail gas and the asphalt fume can be purified at the same time, the problem that the heat storage type incinerator is difficult to purify the asphalt fume and the direct combustion type incinerator is low in heat efficiency is solved, meanwhile, waste gas waste heat is recycled, the operation cost of the incinerator is reduced, and the purposes of energy conservation and environmental protection are achieved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Anti-aging SEBS modified asphalt and preparation method thereof

The invention relates to the field of road engineering, particularly to anti-aging SEBS modified asphalt and a preparation method thereof, wherein the raw materials of the anti-aging SEBS modified asphalt can comprise matrix asphalt, a styrene-ethylene / butylene-styrene block copolymer, triphenyl phosphite, a terpene resin and sulfur. According to the invention, a styrene-ethylene / butylene-styreneblock copolymer is introduced into matrix asphalt, and an anti-aging agent triphenyl phosphite, a terpene resin and a stabilizer sulfur are further added, so that the hardening of the matrix asphalt is slowed down while the degradation of SEBS is delayed; and the anti-aging SEBS modified asphalt can reduce the aging degree of modified asphalt under the action of thermal oxygen, and significantly improve the aging resistance of asphalt.

Owner:TONGJI UNIV

Amorphous alpha-olefin copolymer improved paper-based friction material and preparation method thereof

ActiveCN112855811AEasy to processImprove high temperature stabilityOther chemical processesFriction liningFiberPolymer science

Owner:NORTHWESTERN POLYTECHNICAL UNIV

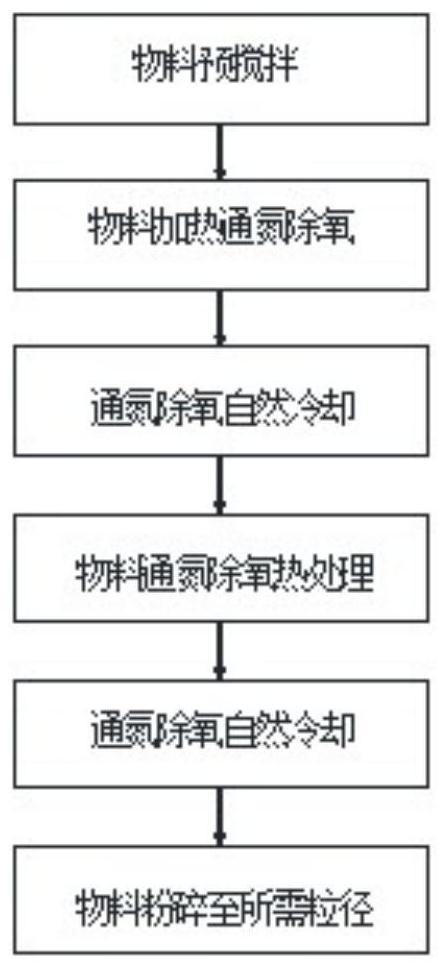

Low-nitrogen recarburizer processing technology

ActiveCN110804686AGuaranteed performanceReduce manufacturing costRotary stirring mixersTransportation and packagingDrive shaftProcess engineering

Owner:丹晟实业(上海)有限公司

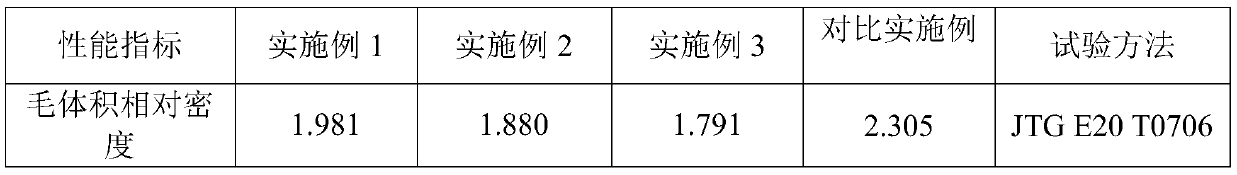

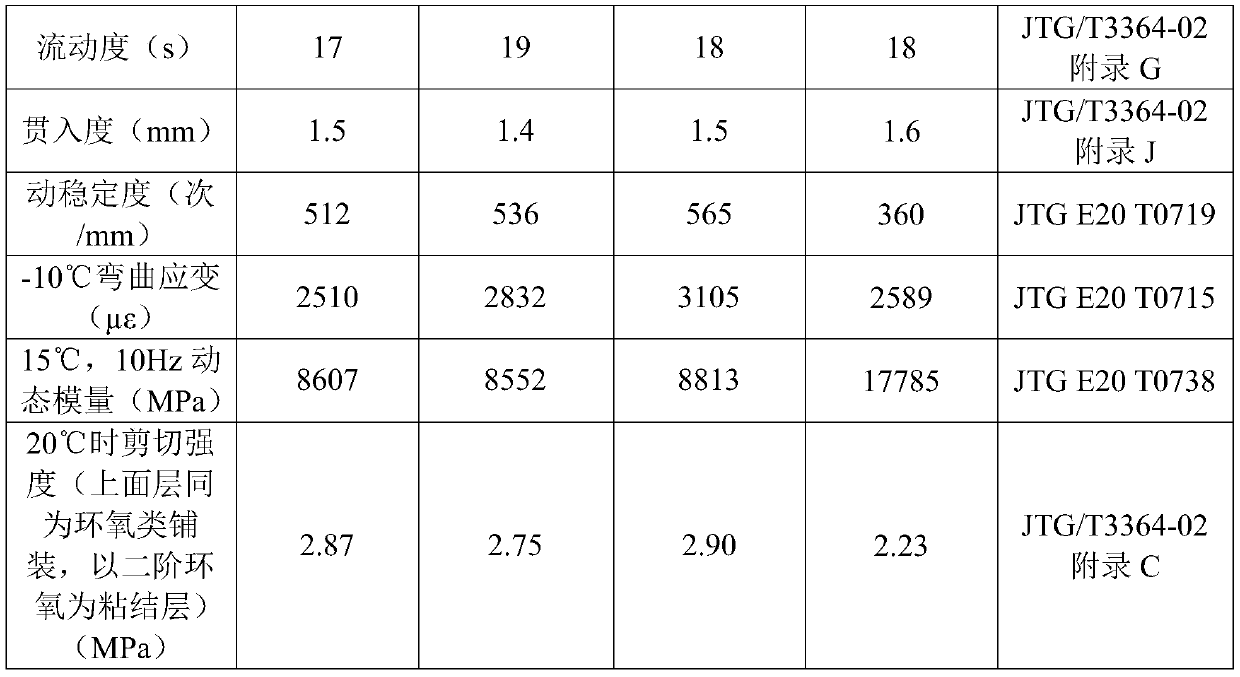

Gradient functional bridge deck pavement material and preparation method thereof

Owner:JIANGSU SINOROAD ENG TECH RES INST CO LTD

Preparation method of lithium ion battery negative electrode composite material

InactiveCN111785935AAvoid Match SelectivityReduce consumptionCell electrodesSecondary cellsCarbon coatingBattery cell

Owner:江苏载驰科技股份有限公司

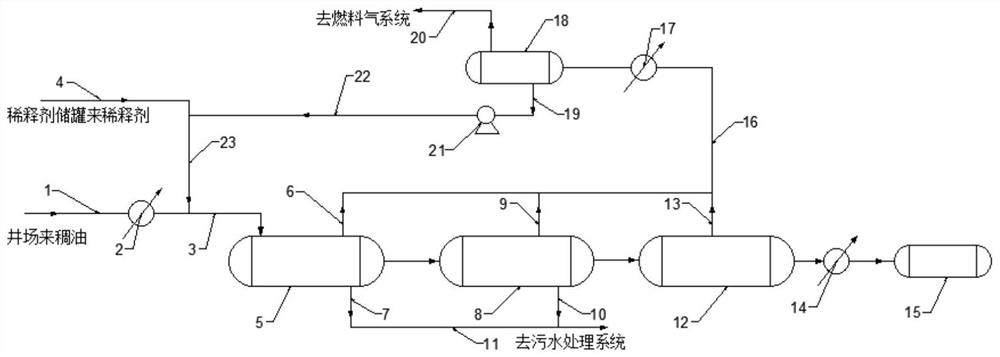

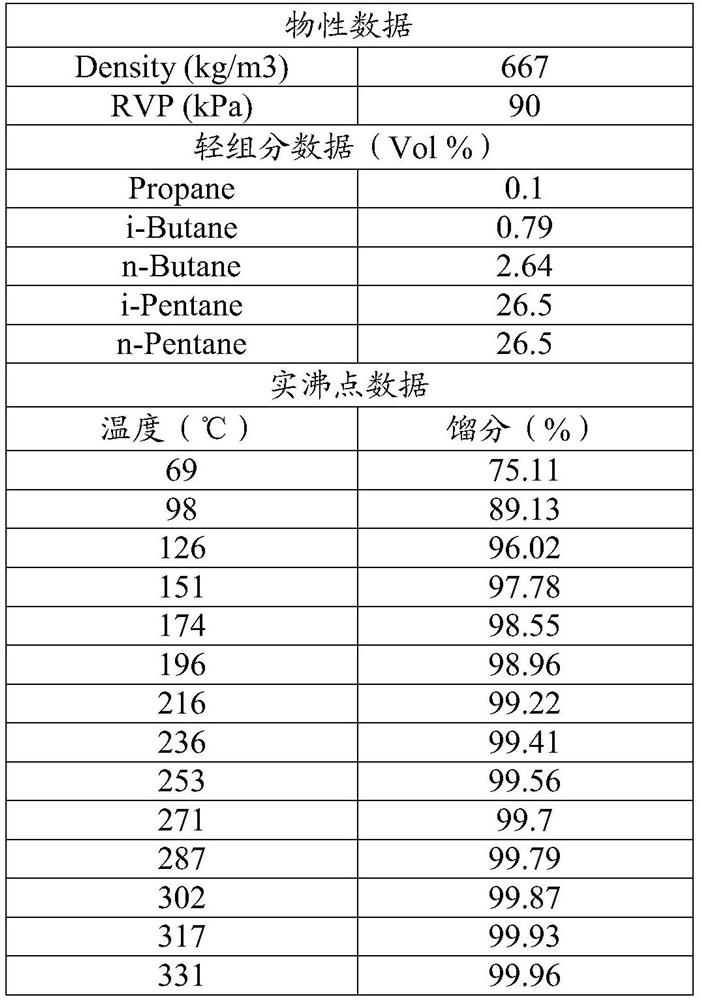

SAGD (steam assisted gravity drainage) thick oil dehydration method

InactiveCN113025373AReduce lossMeet the developmentDewatering/demulsification with chemical meansDiluentOil water

Owner:CHINA NAT OFFSHORE OIL CORP +1

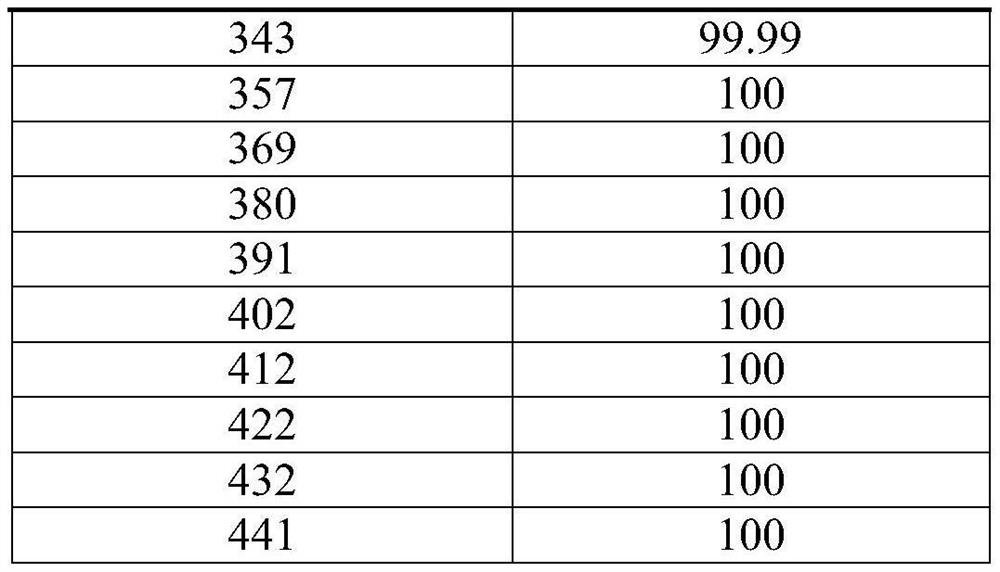

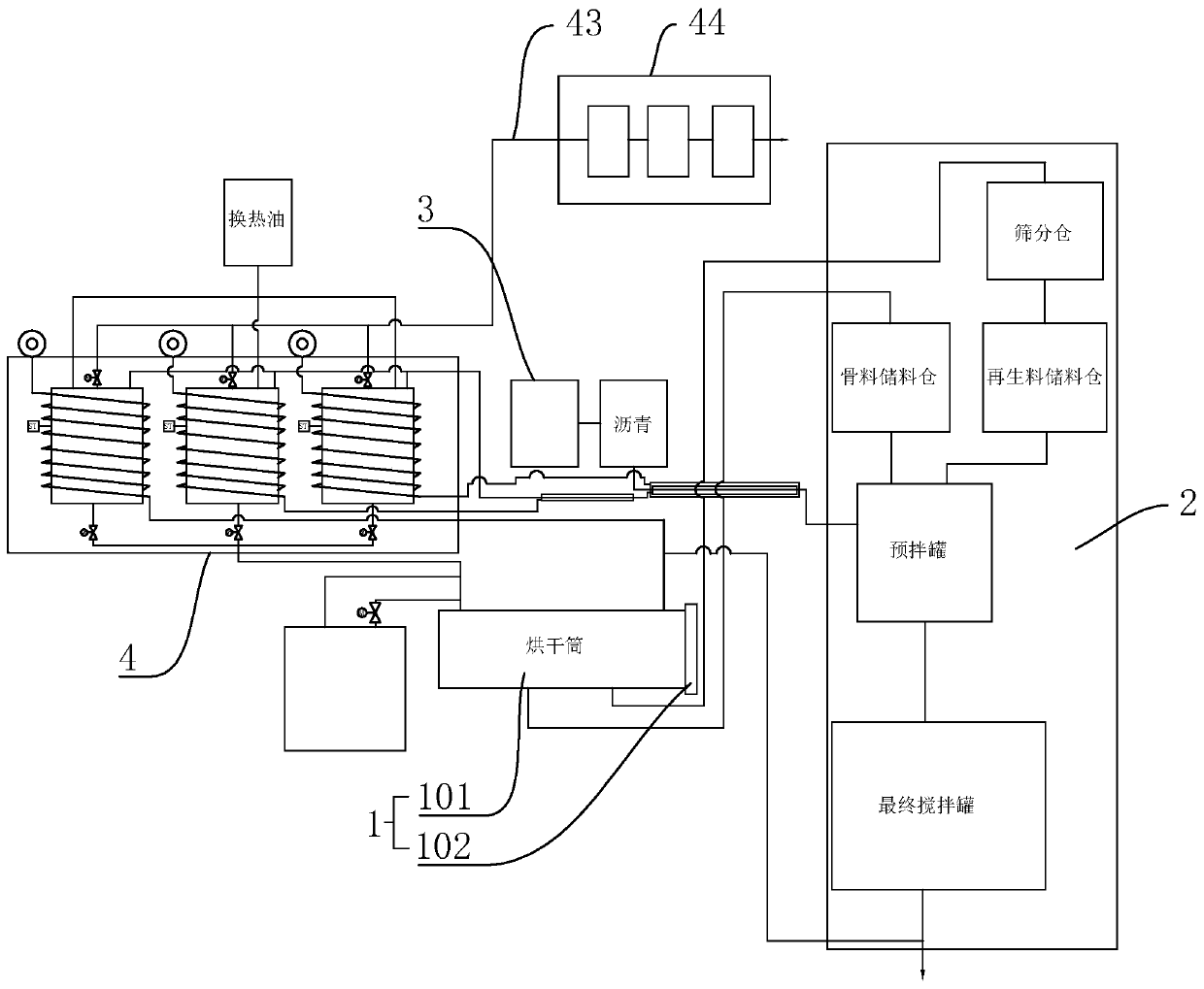

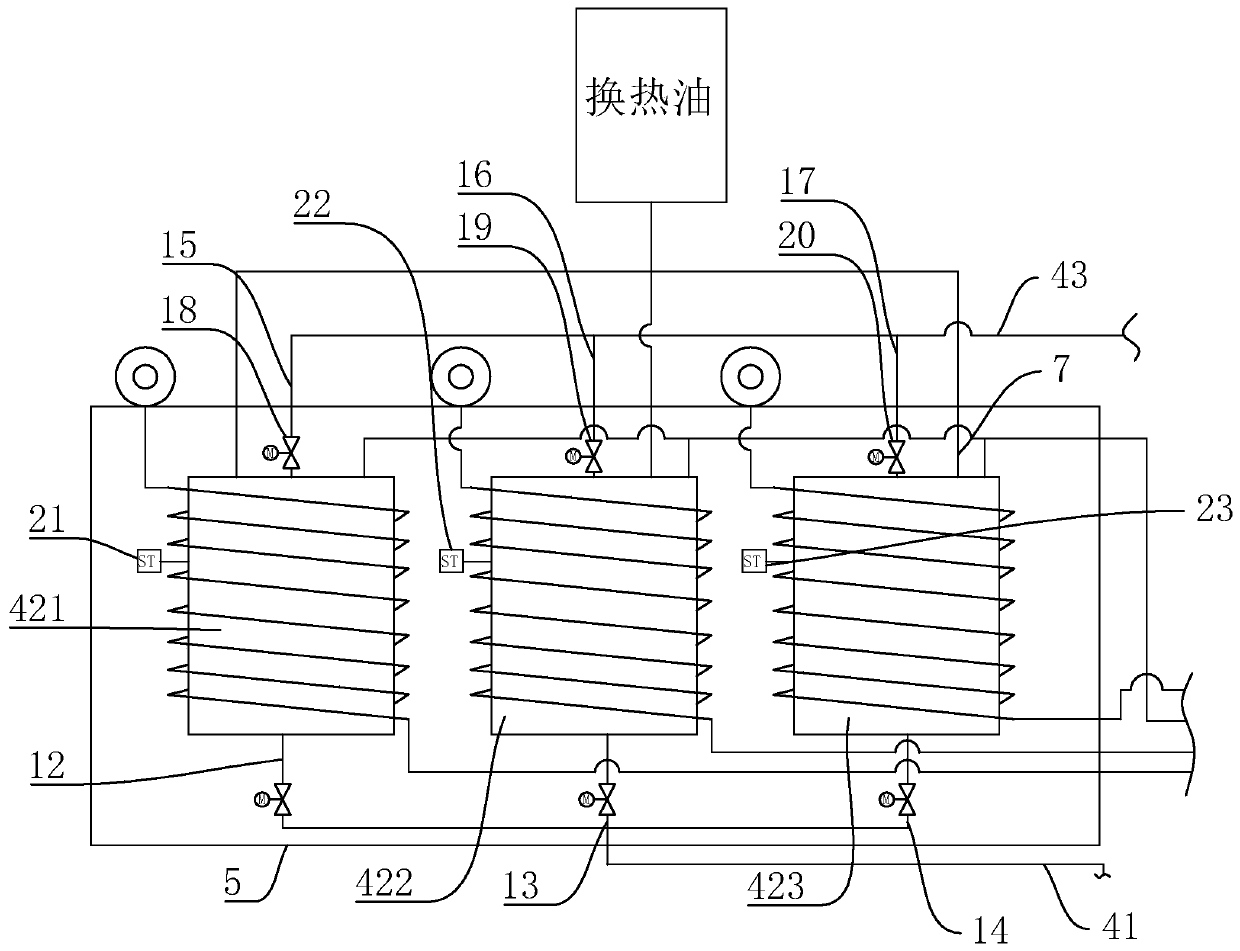

Flue gas heat energy recycling system applied in production process of bituminous concrete

InactiveCN111578743ATake advantage ofAvoid wastingHeat storage plantsDrying gas arrangementsOil canThermodynamics

Owner:江苏盛达飞建筑材料有限公司

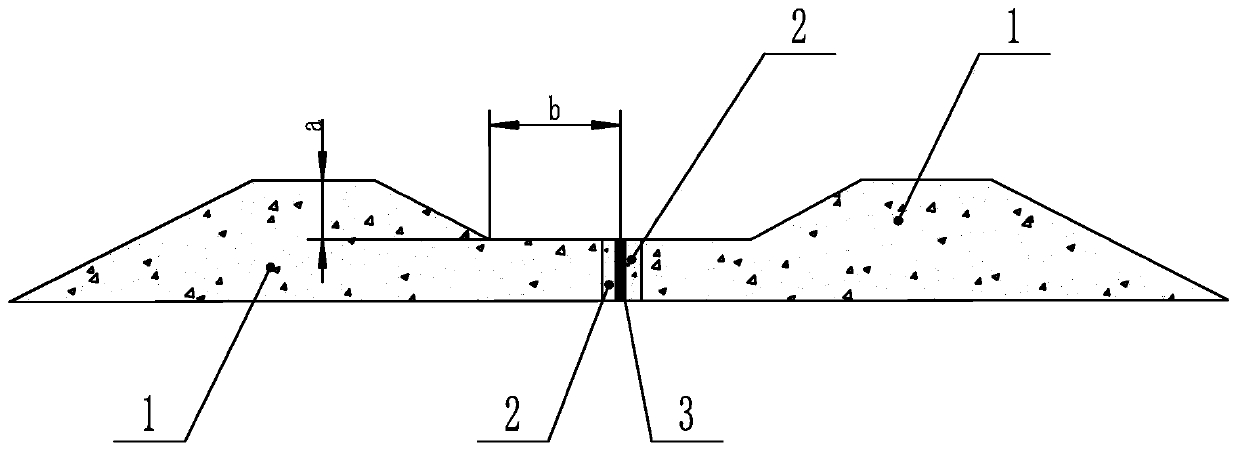

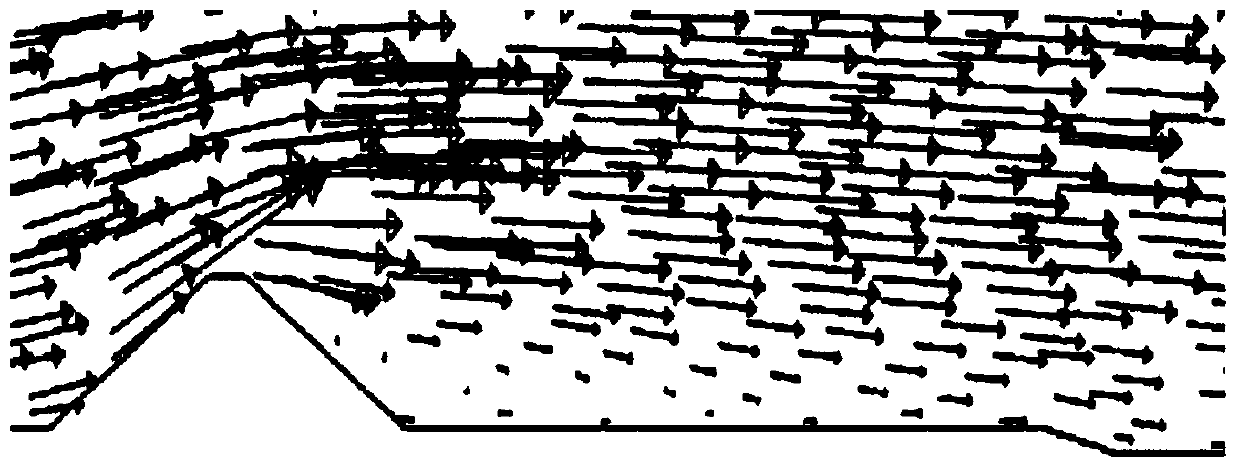

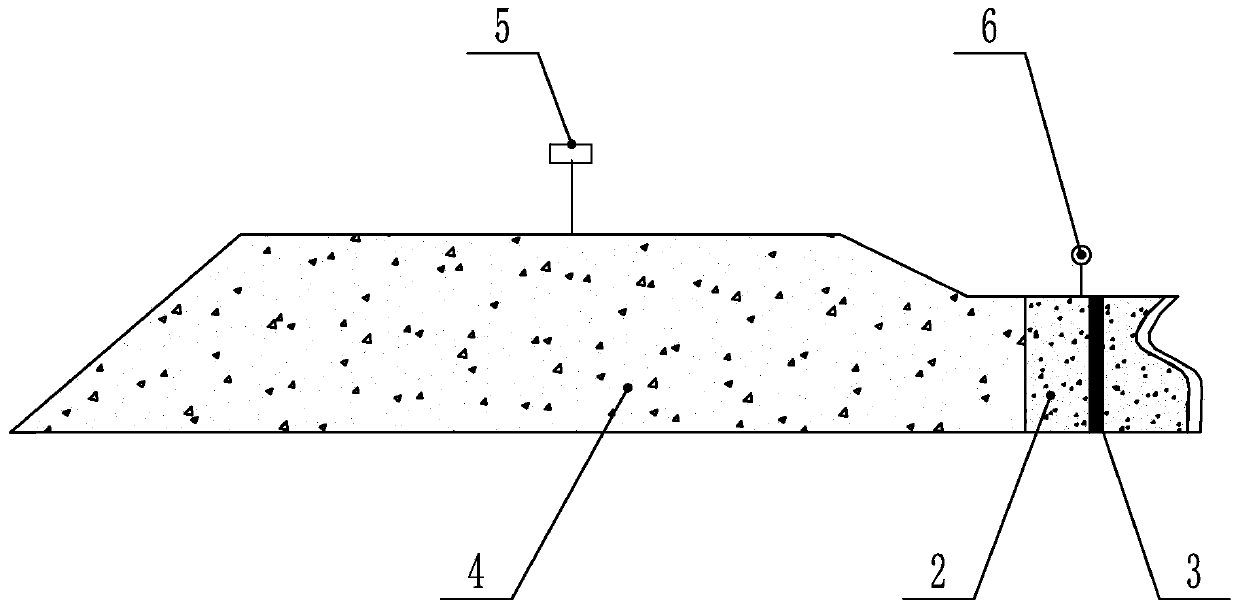

Asphalt concrete construction method for preventing wind and sand by utilizing filling height difference between dam body and core wall

InactiveCN111364301AConvenient for continuous constructionAchieve windproof effectRoadwaysProtective constructionStructural engineeringAsphalt concrete

Owner:XINJIANG AGRI UNIV

Asphalt mortar and aggregate adhesion evaluation method

PendingCN113945512AMaterial strength using tensile/compressive forcesUsing mechanical meansAsphalt mortarPitch

Owner:同路达(泰州)生态科技有限公司 +2

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap