SAGD (steam assisted gravity drainage) thick oil dehydration method

A technology of heavy oil and electric dehydrator, which is applied in the fields of dehydration/demulsification of hydrocarbon oil, dehydration/demulsification of chemical method, petroleum industry, etc. Loss of dehydration effect and other issues, to achieve the effect of small footprint, airtight process, high dehydration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

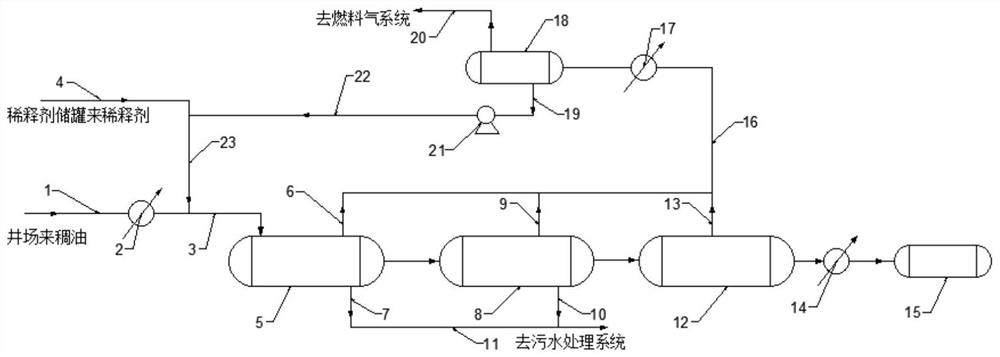

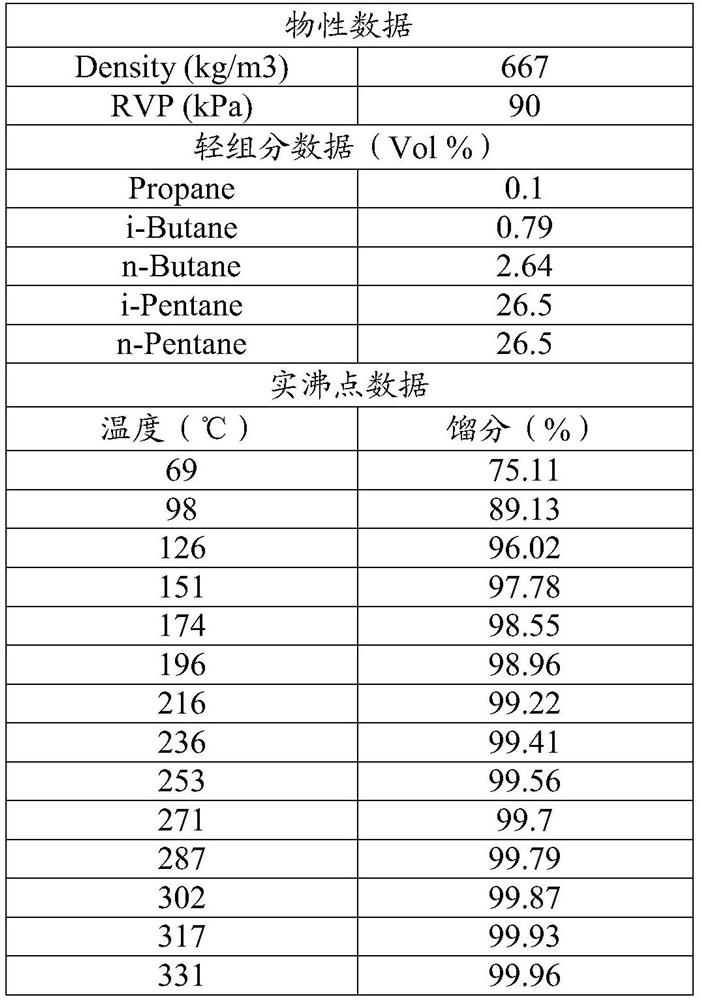

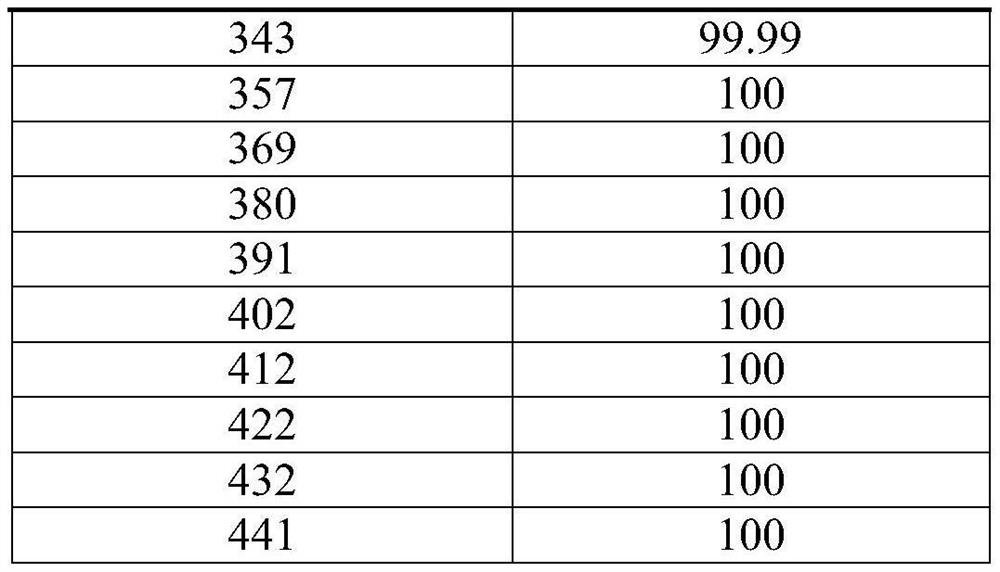

[0037]Water-containing heavy oil (1.45MPaG, 197°C) from the well site is cooled to 135°C by the crude oil / ethylene glycol heat exchanger, mixed with the diluent from the diluent storage tank, and then enters the three-phase separator for oil-gas separation and thermochemical Dehydration, the operating pressure of the thermochemical three-phase separator is 1.15MPaG, the operating temperature is 125°C, and the liquid phase residence time is 40min. 0.90MPaG, the operating temperature is 120°C, and the residence time is 90min. After degassing, the qualified crude oil (water content≤0.5%) enters the flash tank for degassing. The operating pressure of the flash tank is 0.30MPaG, and the operating temperature is 94°C. Meet the requirements of saturated vapor pressure. The qualified crude oil after degassing passes through the qualified crude oil / ethylene glycol heat exchanger and enters the crude oil storage tank for storage; the natural gas extracted from the thermochemical three-

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap