Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Dehydration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Excessive loss of fluid from the body

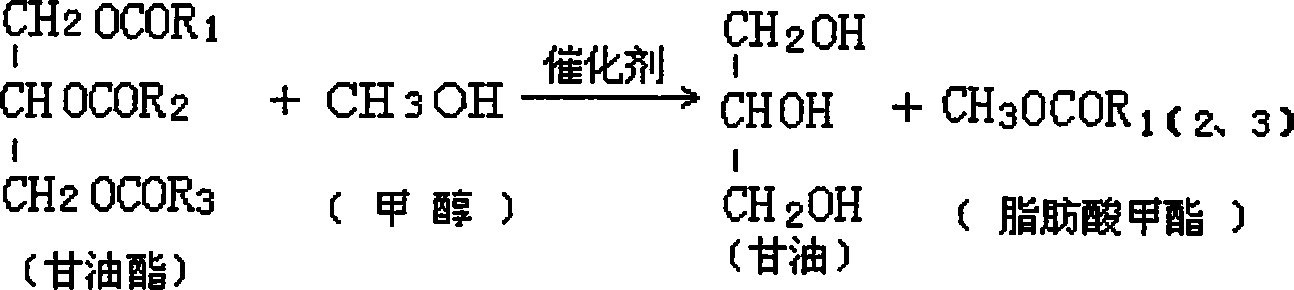

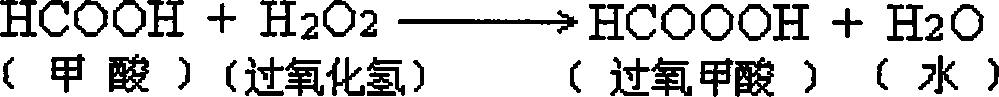

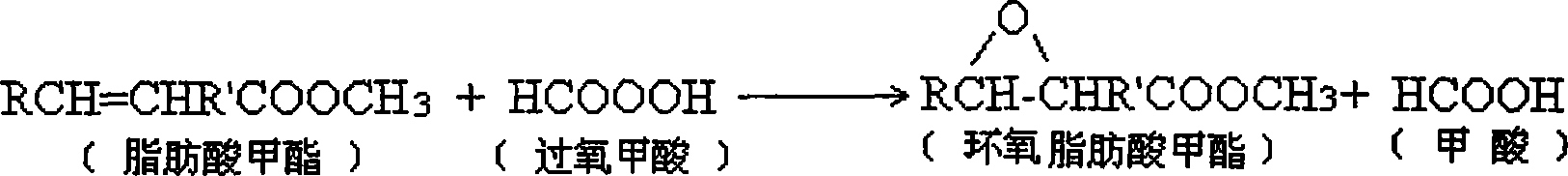

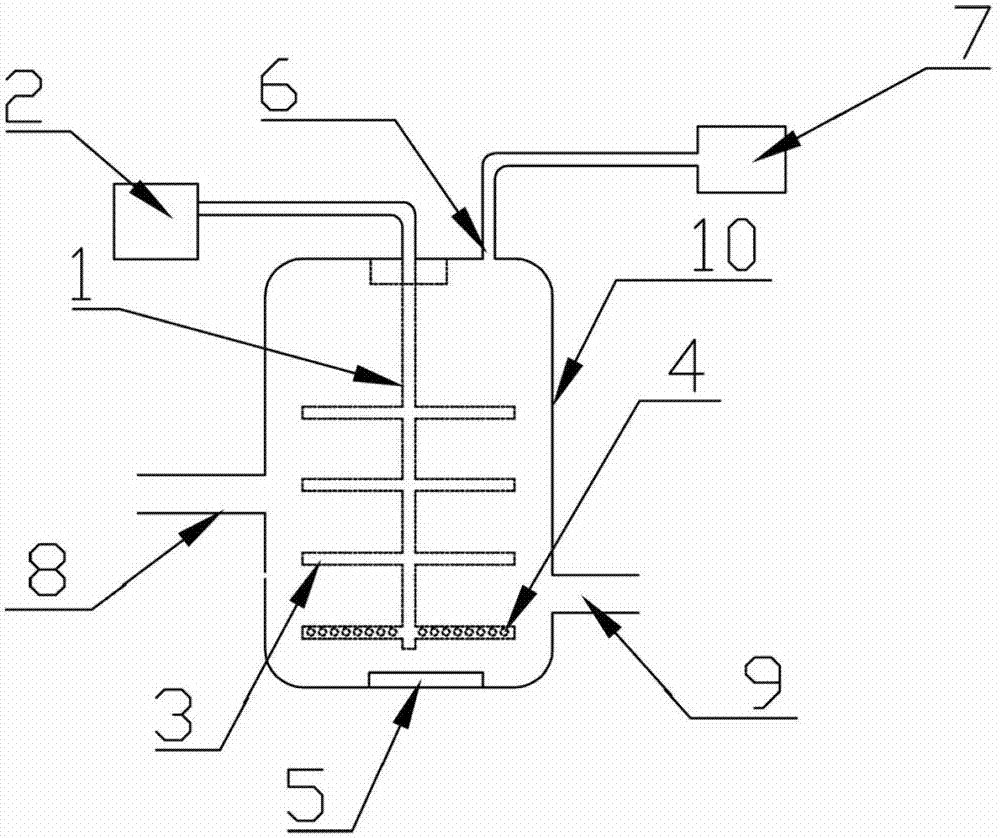

Method for producing epoxy plasticizer using waste grease

InactiveCN101070510AHarm reductionReduce dosageFatty oils/acids recovery from wasteFatty acid esterificationEpoxyDistillation

Owner:江苏向阳科技有限公司

Dehydration process

ActiveUS20160229779A1Organic compound preparationPreparation by aldehyde oxidation-reductionMethacroleinOrganic chemistry

A process for preparing dry methacrolein, and a process for producing methyl methacrylate are disclosed.

Owner:ROHM & HAAS CO

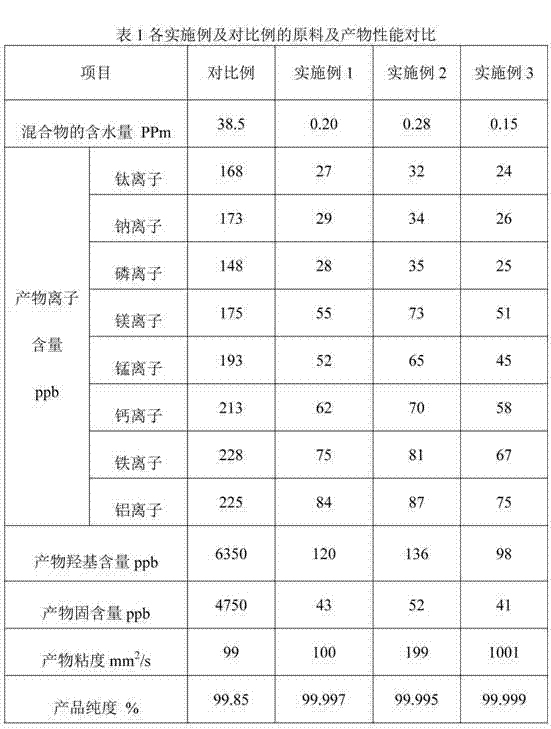

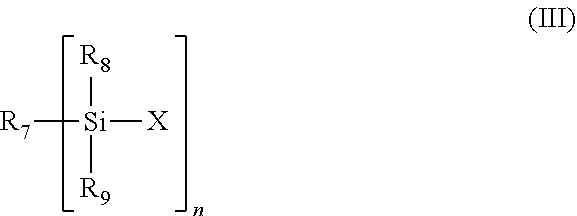

Continuous preparation technology of high-purity low-viscosity dimethicone

ActiveCN103073722AHigh purityMaintain catalytic activityChemical recyclingPtru catalystSilicone fluid

Owner:YICHANG COLLIN SILICON MATERIAL CO LTD

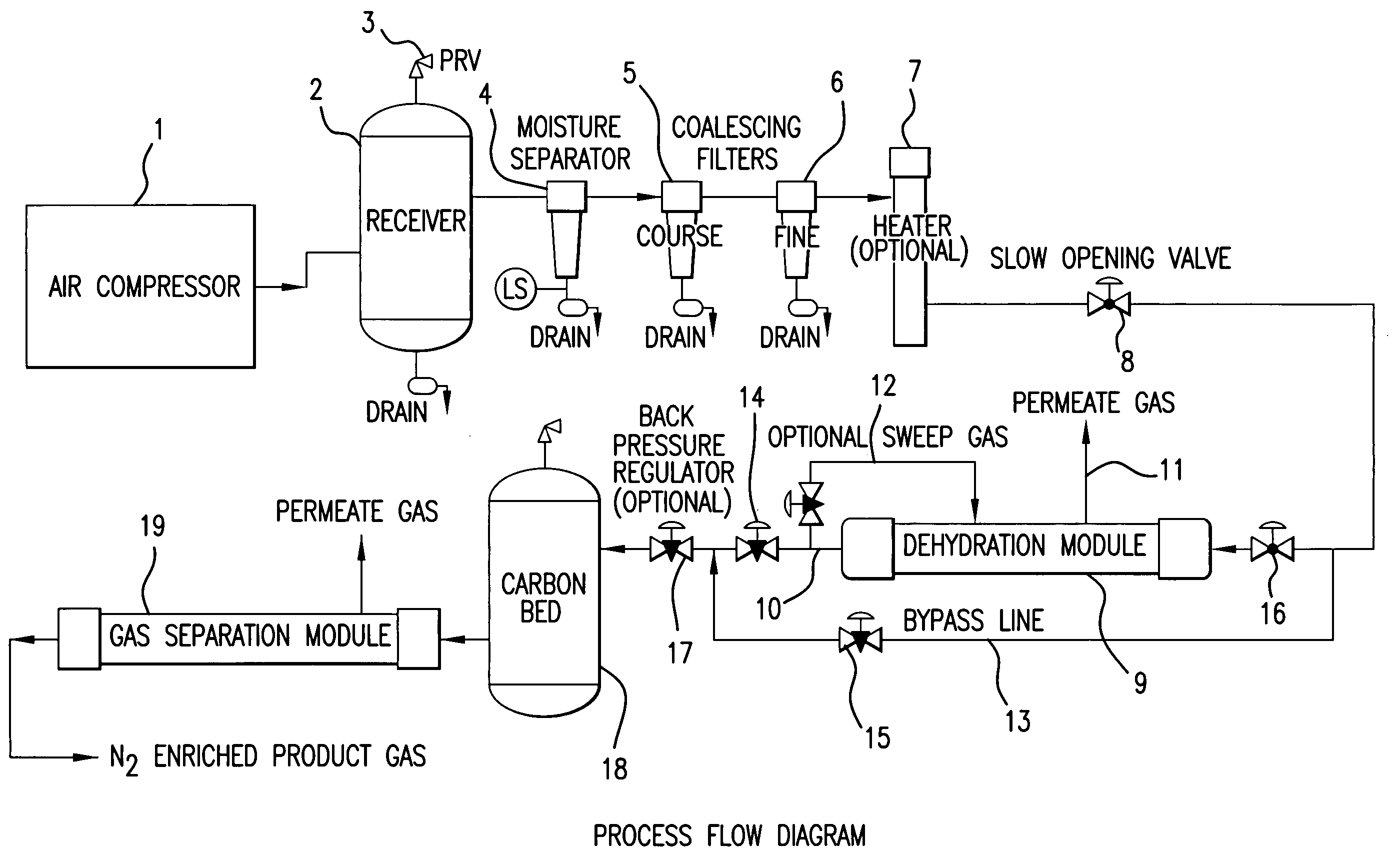

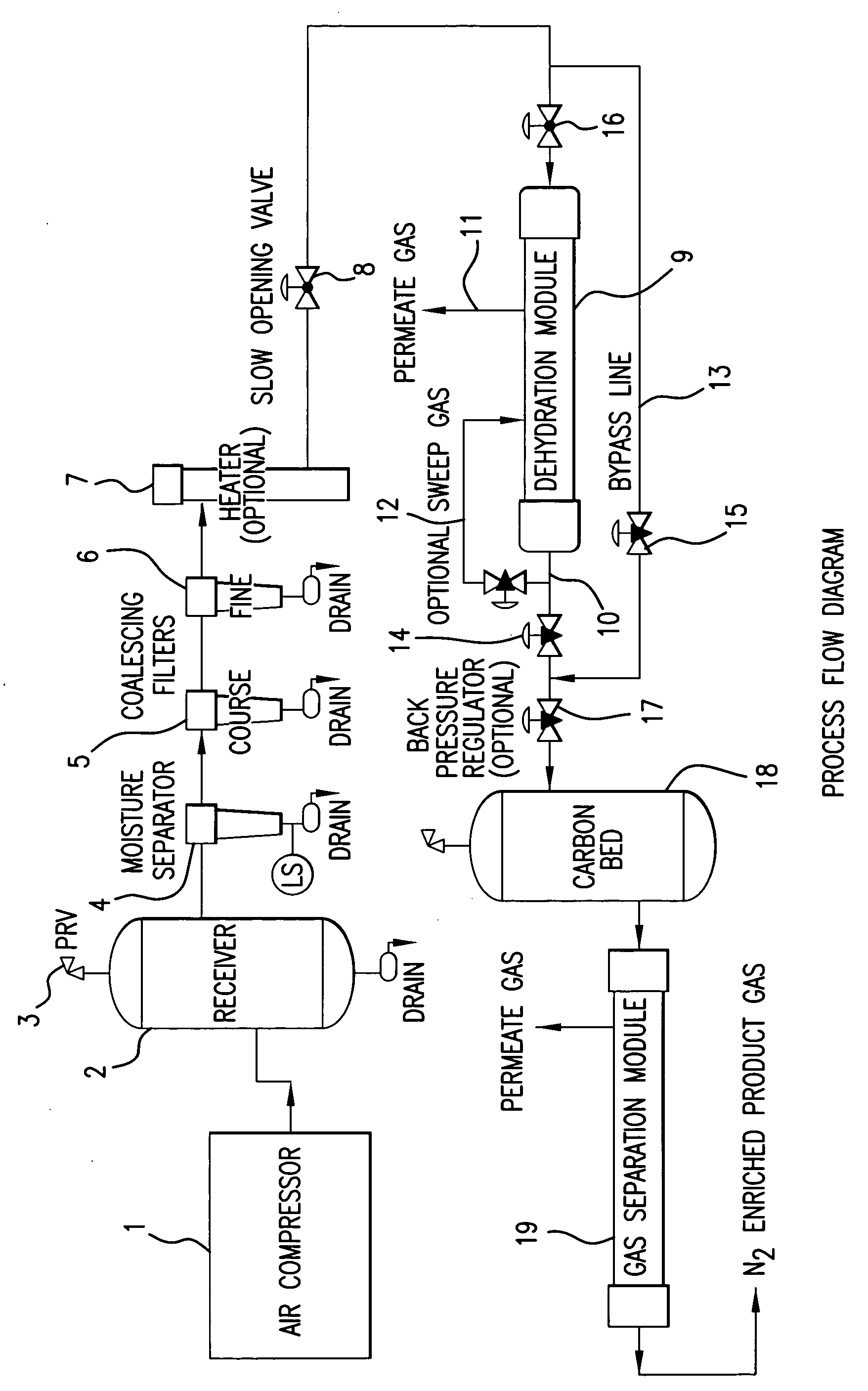

Air separation system using dehydration membrane for pretreatment of compressed air

Owner:GENERON IGS

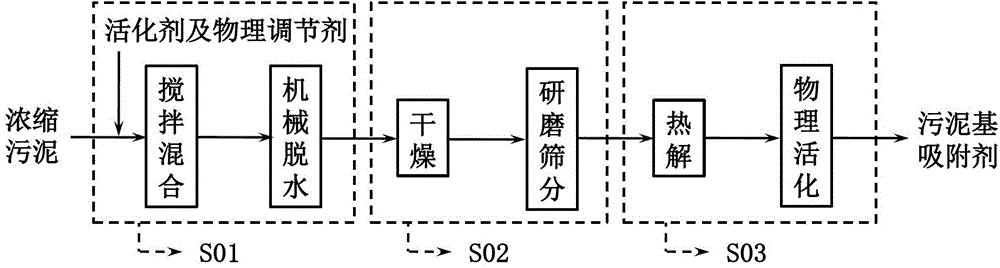

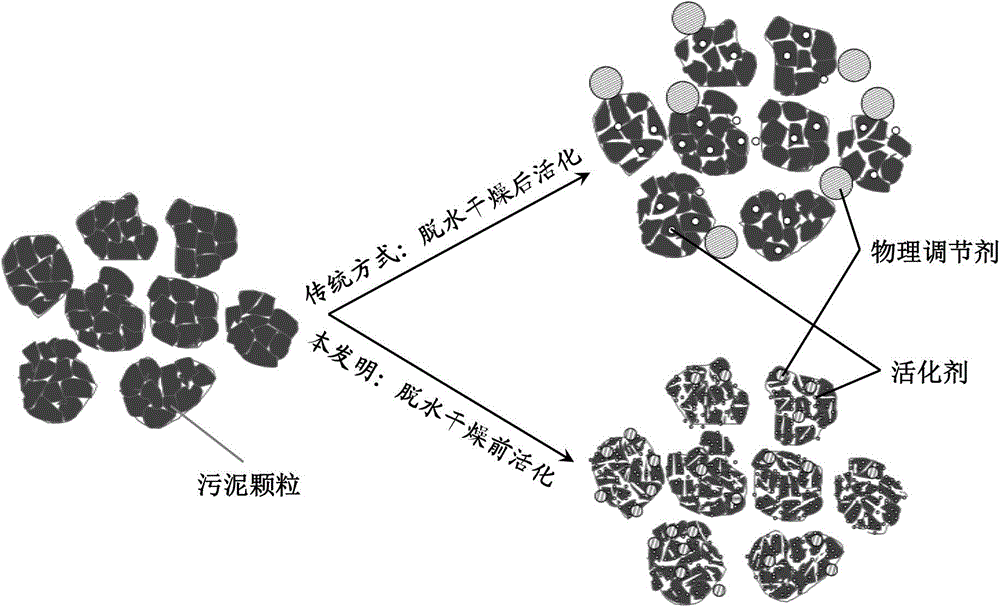

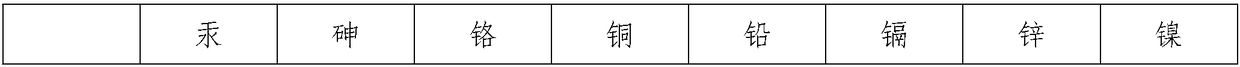

Sludge-based adsorbent used for desulfurization and demercuration of flue-gas and preparation method thereof

ActiveCN102745879AHigh porosityHigh adsorption activitySludge treatment by de-watering/drying/thickeningOther chemical processesSludge cakePhysical conditioning

Owner:HUAZHONG UNIV OF SCI & TECH

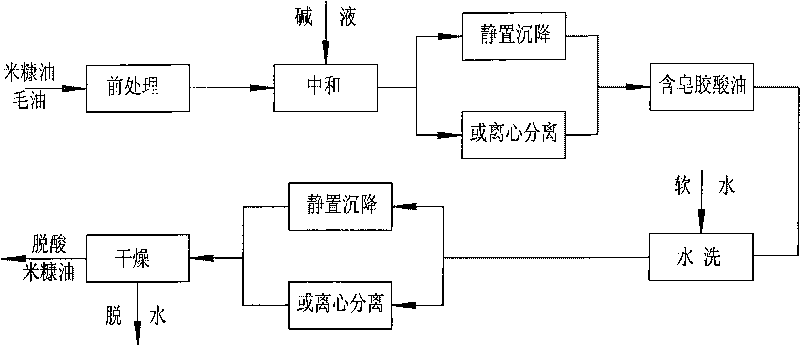

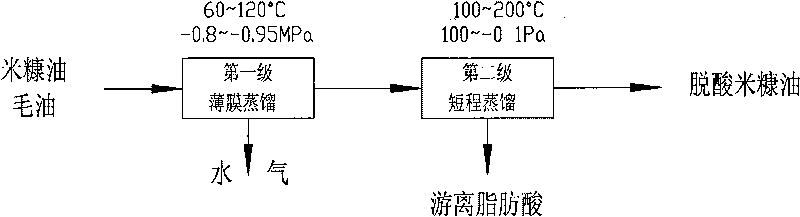

Method for refining rice bran oil by using short distance distillation

InactiveCN101705148ANo effectNo pollution in the processFatty-oils/fats refiningDistillationOleic Acid Triglyceride

Owner:SOUTH CHINA UNIV OF TECH

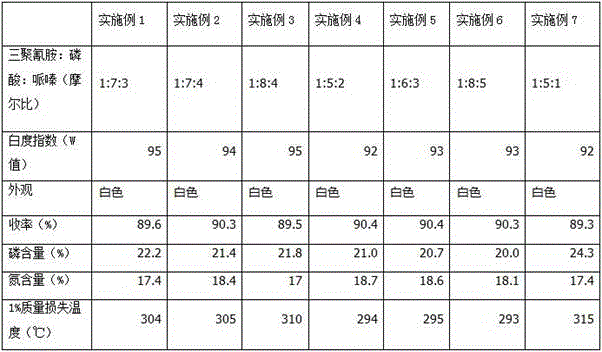

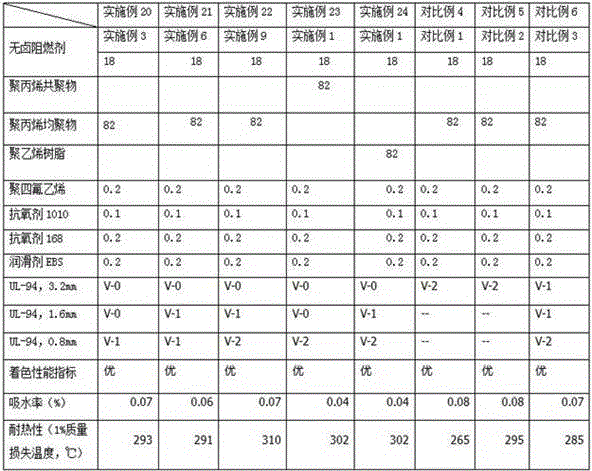

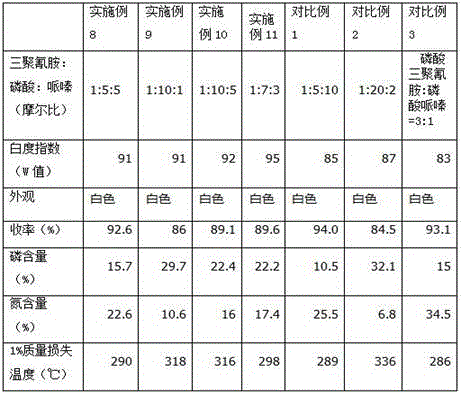

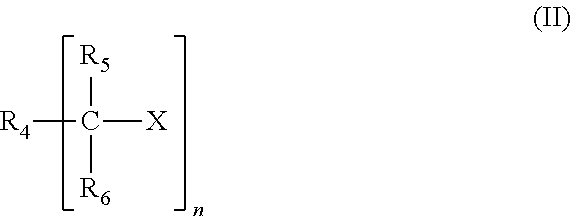

Halogen-free flame retardant and preparation method thereof and flame-retardant polyolefin composition composed of same

ActiveCN105837855AImprove thermal stabilityThe content of functional components is flexible and adjustableOrganic chemistryPolymer sciencePolyolefin

Owner:KINGFA SCI & TECH CO LTD

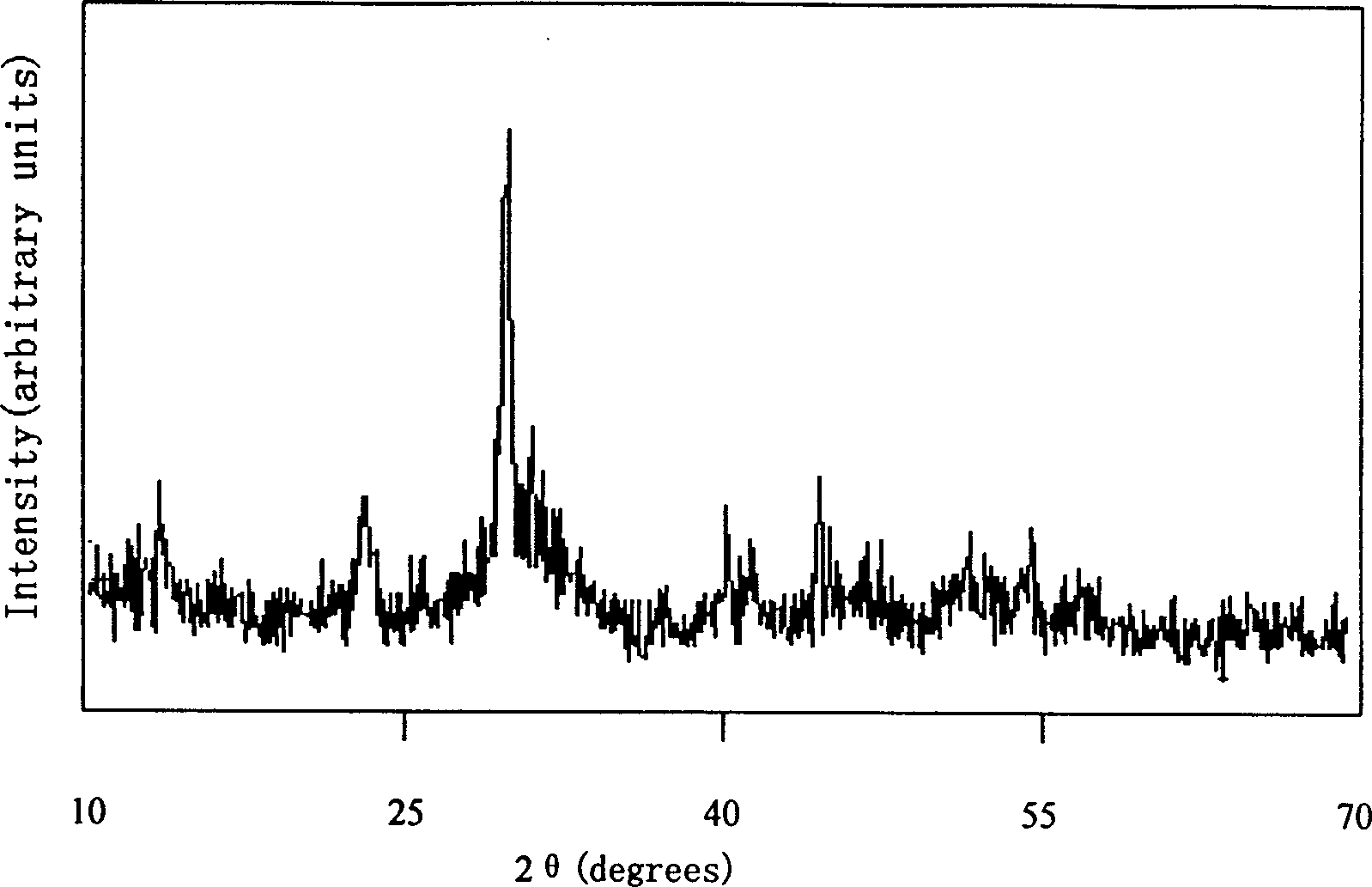

Nano-grade lanthanum titanium compound oxide, its preparation method and application

InactiveCN1394680AReduce viscosityReduce the temperatureCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsOligomerLactide

Owner:CHONGQING UNIV

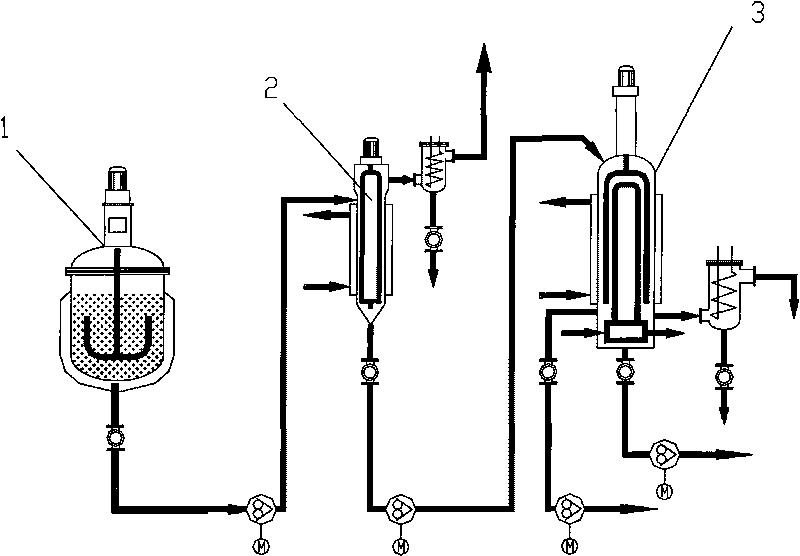

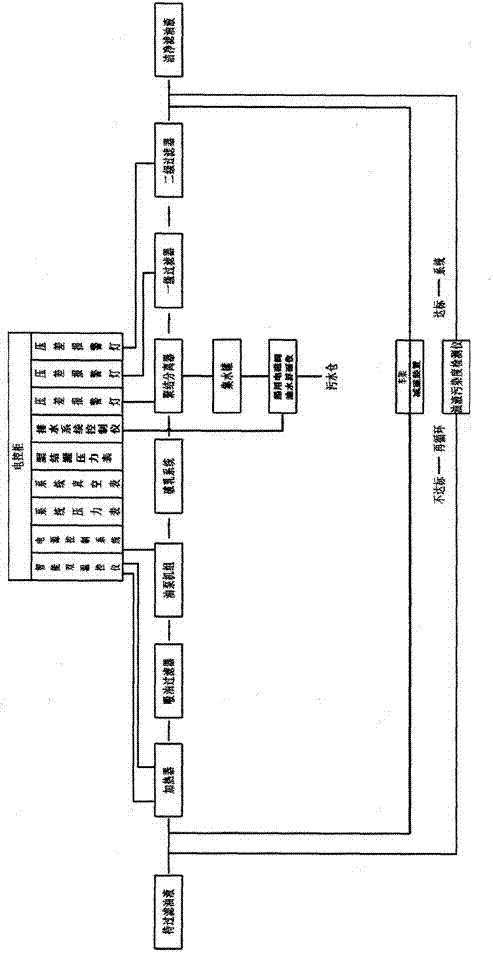

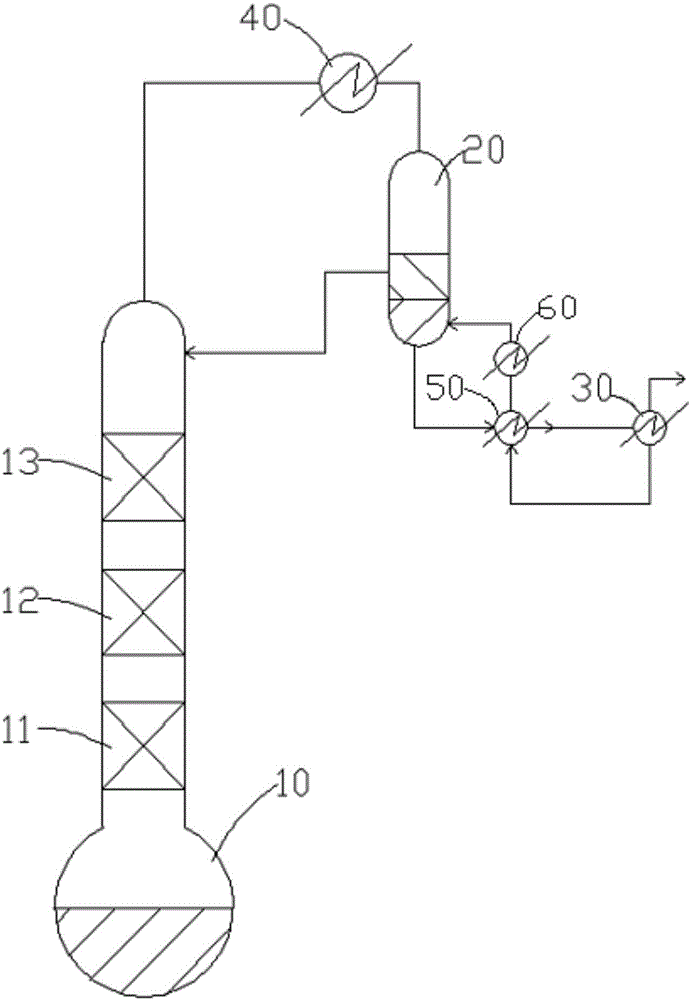

Method and equipment thereof for synthesizing methyl isobuthl ketone with acetone two-step method

ActiveCN108002995AReduce the problem of high DAA contentReduce generationOrganic compound preparationEnergy inputHydrogenMethyl isobutyl ketone

The invention discloses a method and equipment thereof for synthesizing methyl isobuthl ketone with an acetone two-step method. The method includes the steps that a, DAA and MSO are generated by condensation and dehydration of the raw material of acetone in a catalytic distillation column, products rich in MSO and water are side taken off from the catalytic distillation column; b, a material containing DAA is side taken off from the catalytic distillation column, and put into a DAA decomposition reactor, DAA in the material is transformed into acetone and MSO, the products are separated by flash evaporation to obtain a gas phase rich in acetone and a liquid phase rich in MSO and water, the gas phase and the liquid phase are respectively circulated back to the column; c, the liquid phase products in the step a are cooled and divided into phases, an organic phase rich in MSO and a water phase containing small amounts of organic matter are obtained, the water phase enters into a recoverytower to recycle organic matter; d, MIBK is generated by the hydrogenation of the organic phase in the step c, after hydrogen gas is recycled by flash evaporation, then enters into an MIBK refining tower, and a MIBK product is side taken off. The total conversion rate of acetone is 99.0%, and the product MIBK purify is up to 99.5%.

Owner:CHANGCHENG NEW ENERGY CO LTD +1

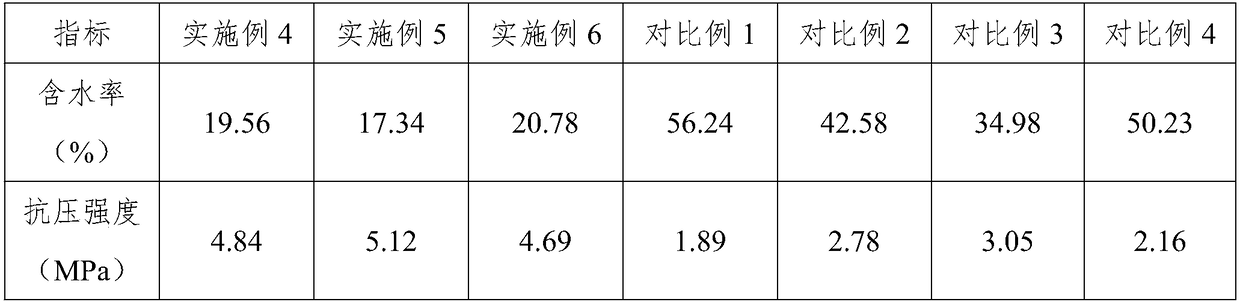

Sludge solidifier and preparation method thereof

ActiveCN108314280AImprove water qualityReduce pollutionFixation/solidifcation sludge treatmentSulfateSludge

Owner:GUANGZHOU WATER CONSERVANCY & HYDROPOWER STATION CONSTR ENG

Method and system for treating human excrement

InactiveCN108218480AAvoid pollutionLimit churnBio-organic fraction processingClimate change adaptationHuman wasteLiquid storage tank

The invention discloses a method for treating human excrement. The method comprises the steps as follows: (1) a liquid in the human excrement is discharged into an original liquid storage tank, and solids are dehydrated; (2) solids obtained after dehydration treatment in the step (1) are subjected to aerobic fermentation after being crushed; (3) secondary fermentation is performed; (4) materials obtained after the secondary fermentation are used as solid fertilizer. The invention also discloses a system adopting the method. The system comprises impurity removal equipment A, a dewatering deviceA, the original liquid storage tank, a crusher A, a distributor A, a full-closed fermentation tank A, an oxygen generator and the like. The method and the system for treating the human excrement havethe advantages as follows: a complete production process is provided for recycling of human excrement, a scheme is provided for urban emission reduction and sewage treatment plant pressure reduction,waste can be reused, and sustainable development can be realized really.

Owner:石伟

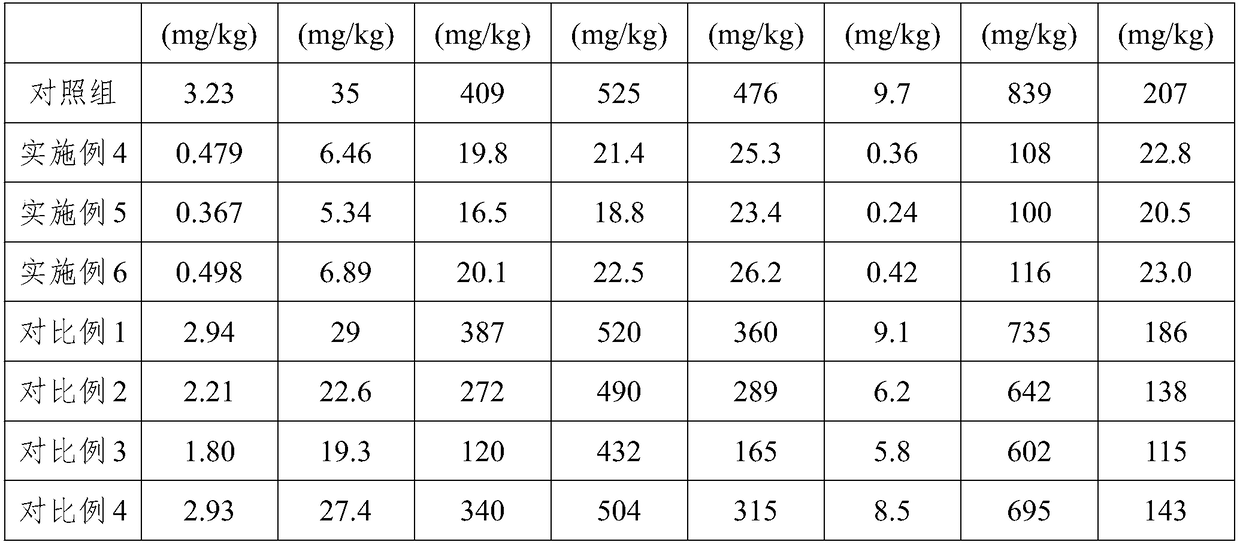

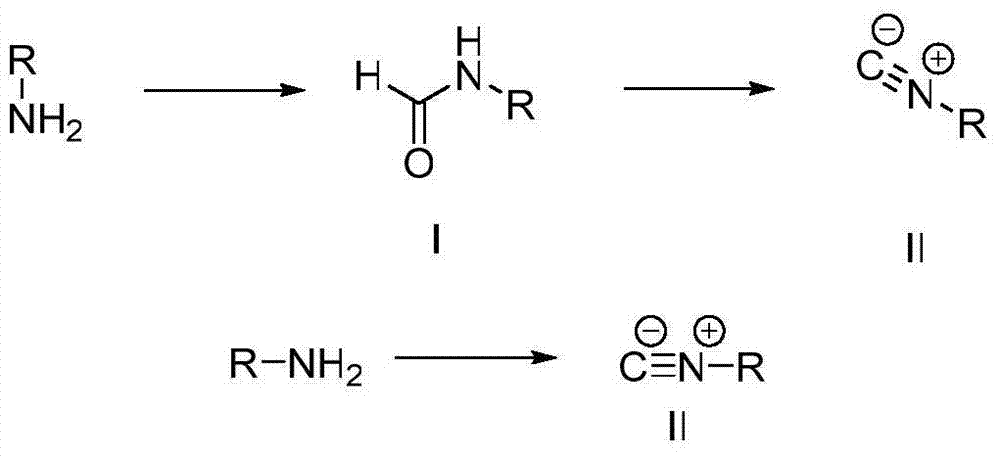

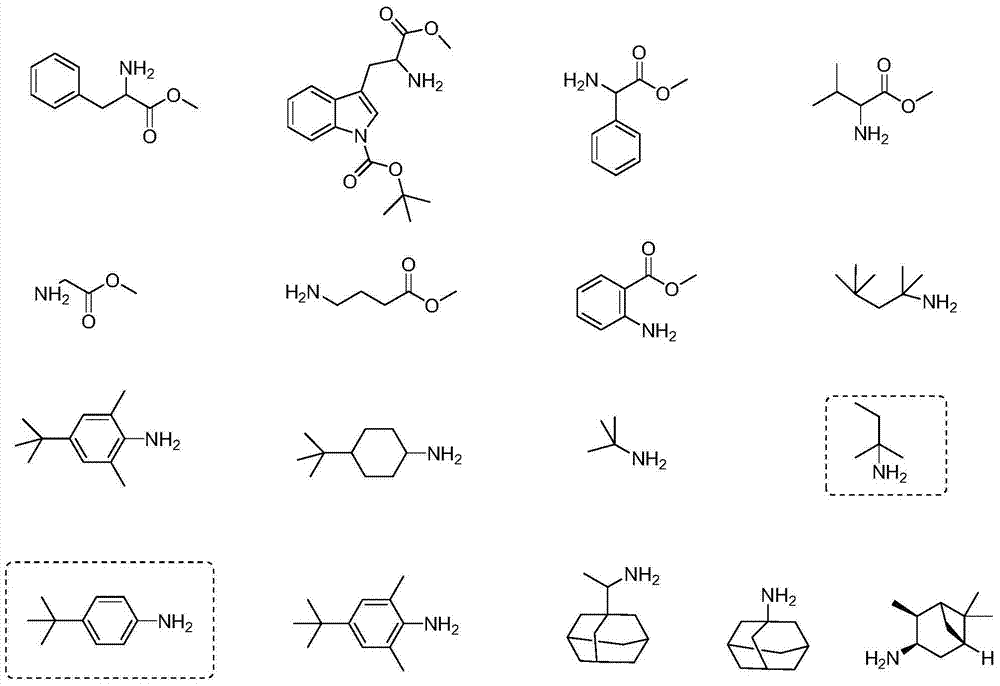

Formamide and isonitrile compounds serving as influenza A virus inhibitors and preparation and application thereof

InactiveCN103922966AAvoid drug resistanceHigh activityOrganic compound preparationAntiviralsFormamideStructural formula

Owner:WUHAN UNIV

Water dividing oil purifier for lubricating oil used by ship

PendingCN107158750AChange physical and chemical propertiesExtended service lifeLiquid separation auxillary apparatusPropulsion power plantsControl systemFiltration

Owner:XINXIANG RIXIN PURIFY EQUIP

Processing method of high-oryzanol rice bran oil

InactiveCN107474942ASpeed up extractionImprove oil yieldFatty-oils/fats refiningFatty-oils/fats productionWater vaporRice Bran Extract

Owner:衢州刘家香食品有限公司

Method for producing clostridium butyricum by using pichia pastoris fermentation bacterial sludge

InactiveCN106544293AIncrease profitSolve high-volume processing challengesBacteriaMicroorganism based processesPichia pastorisSludge

The invention provides a method for producing clostridium butyricum by using pichia pastoris fermentation bacterial sludge, wherein the method comprises the following steps: 1) diluting the pichia pastoris fermentation bacterial sludge into a yeast suspension; 2) placing the yeast suspension in a stirring reactor, and stirring and mixing evenly; 3) carrying out spray drying dehydration treatment of the evenly-mixed yeast suspension, to obtain a yeast powder; 4) adding the yeast powder instead of an organic nitrogen source to a clostridium butyricum culture medium, and carrying out anaerobic fermentation, to obtain a clostridium butyricum fermentation liquid; and 5) concentrating the clostridium butyricum fermentation liquid, and carrying out spray drying treatment, to obtain a clostridium butyricum powder preparation. The method can solve the problem of processing of the pichia pastoris fermentation bacterial sludge, reduces environmental pressure, achieves low emission of industrial production, also enables the nitrogen source required for clostridium butyricum culture to be replaced, reduces the production cost of enterprises, and has good market application prospects.

Owner:SUNHY TECH (HUBEI) CO LTD +2

Preparation method of inorganic polymeric water purifier

InactiveCN107445265AFast water purificationGood water purification speedWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionSludgePollution

Owner:如皋市康利化工有限公司

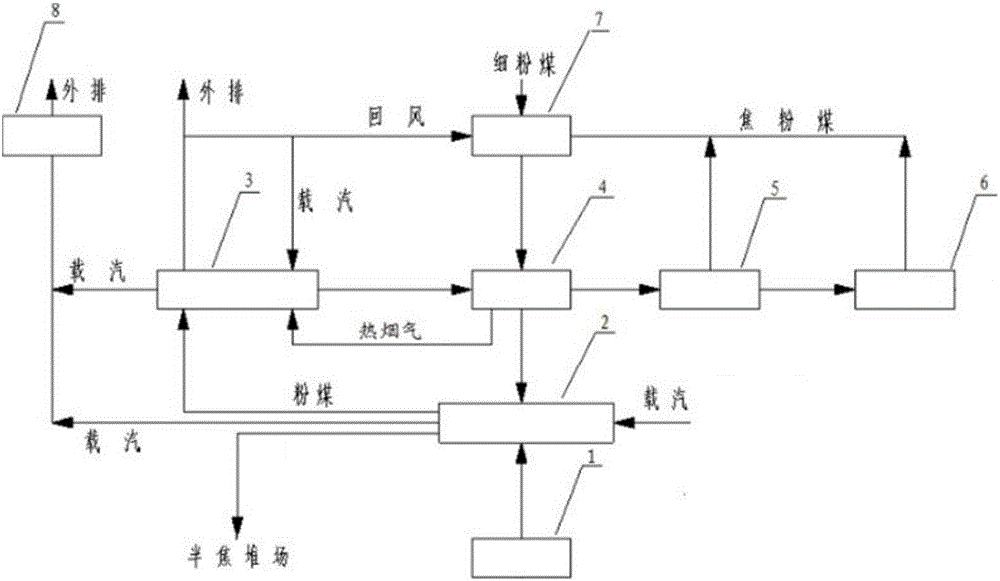

Pyrolytic process method for directly drying pulverized coal through semicoke

InactiveCN106190205AReduced risk of cloggingSimple processEnergy inputSpecial form destructive distillationProcess engineeringHeat energy

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

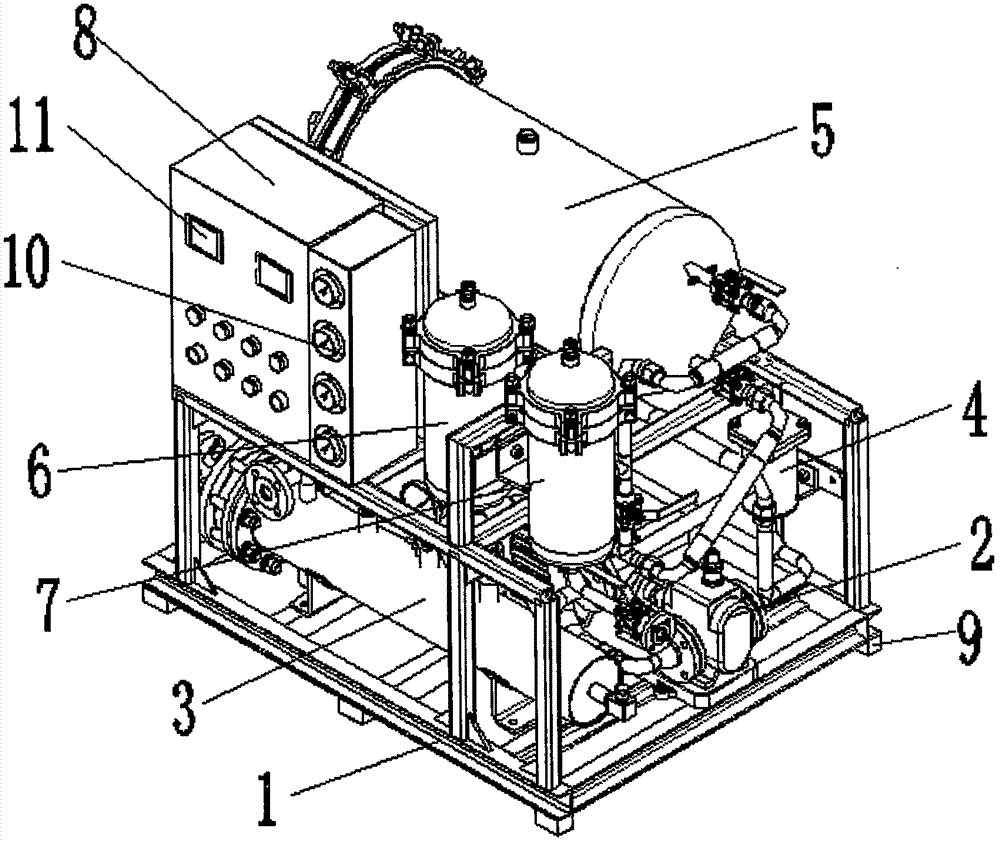

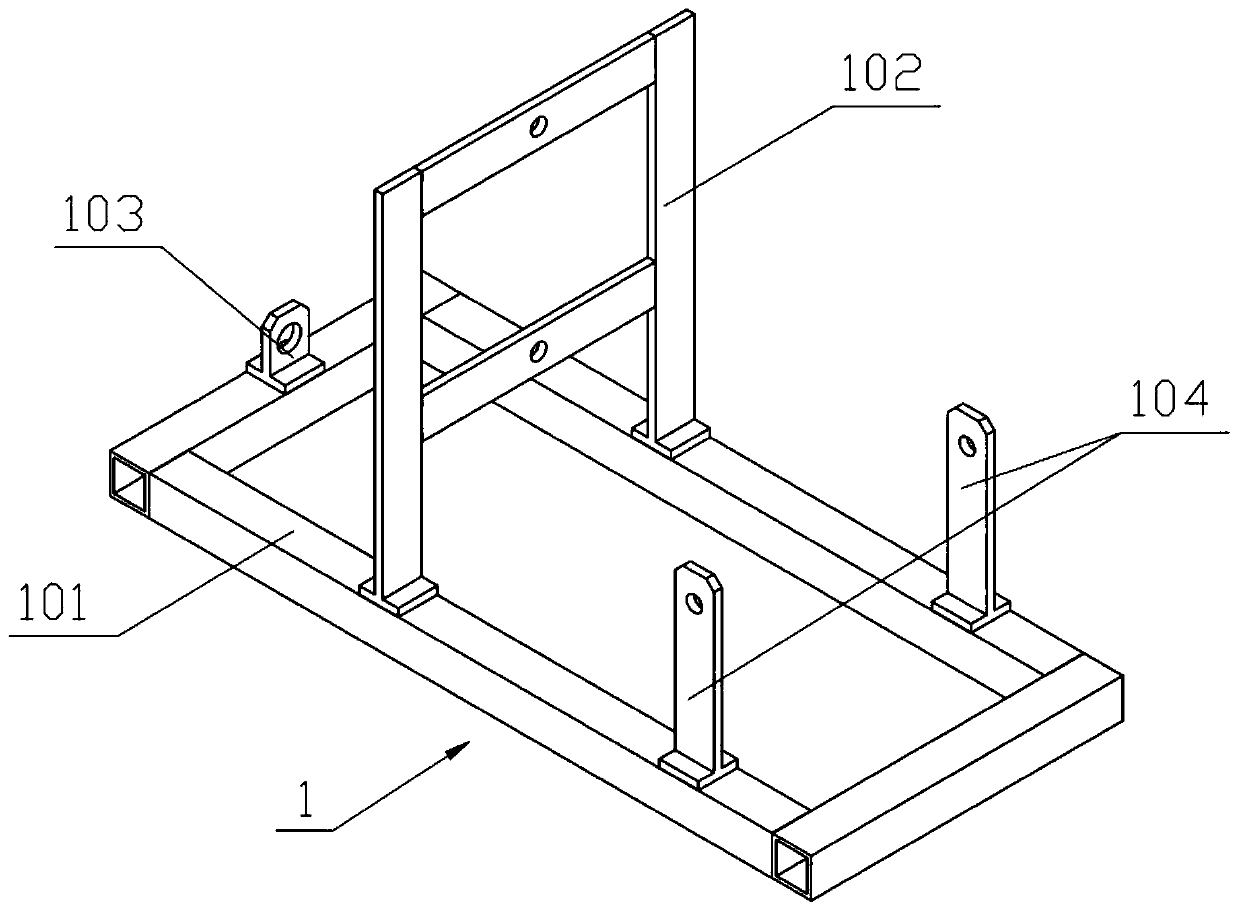

Well-drilling waste mud treatment equipment

InactiveCN108726839AMade quicklyImprove efficiencySludge treatment by de-watering/drying/thickeningFlocculationWell drilling

The invention discloses well-drilling waste mud treatment equipment. The well-drilling waste mud treatment equipment comprises a dilution mechanism, a flocculation mechanism and a drying mechanism, wherein the dilution mechanism is connected with the flocculation mechanism; the flocculation mechanism is connected with the drying mechanism; the dilution mechanism is used for adding water into thickwaste mud and diluting the waste mud, so that flocculation treatment is conveniently carried out on the waste mud; the flocculation mechanism is used for carrying out dehydration treatment on the diluted waste mud to realize solid-liquid separation; the drying mechanism is used for carrying out drying and shaping treatment on separated solids so that generated mud blocks are convenient to transport and treat. By adopting the structure, the waste mud can be very effectively treated into the small mud blocks and the efficiency of preparing the mud blocks from the waste mud is improved; meanwhile, the transportation efficiency of the waste mud is also improved.

Owner:崔九香

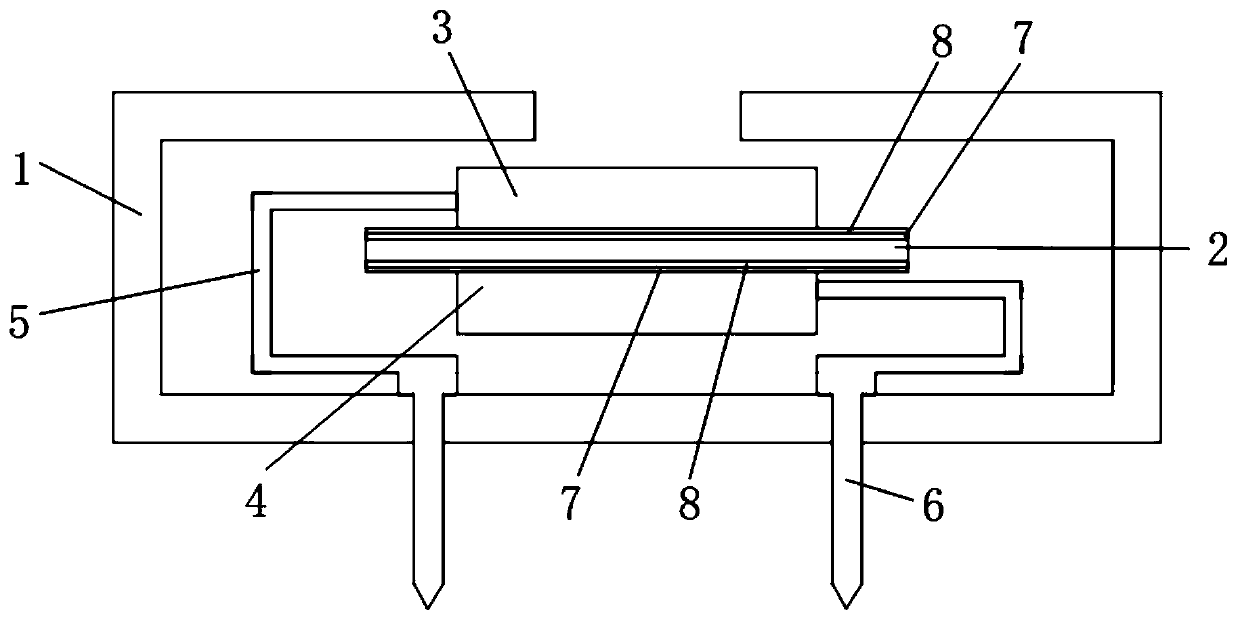

Salting-out-rectification coupling-method dehydration method and device

Owner:JIANGSU HUAYI TECH

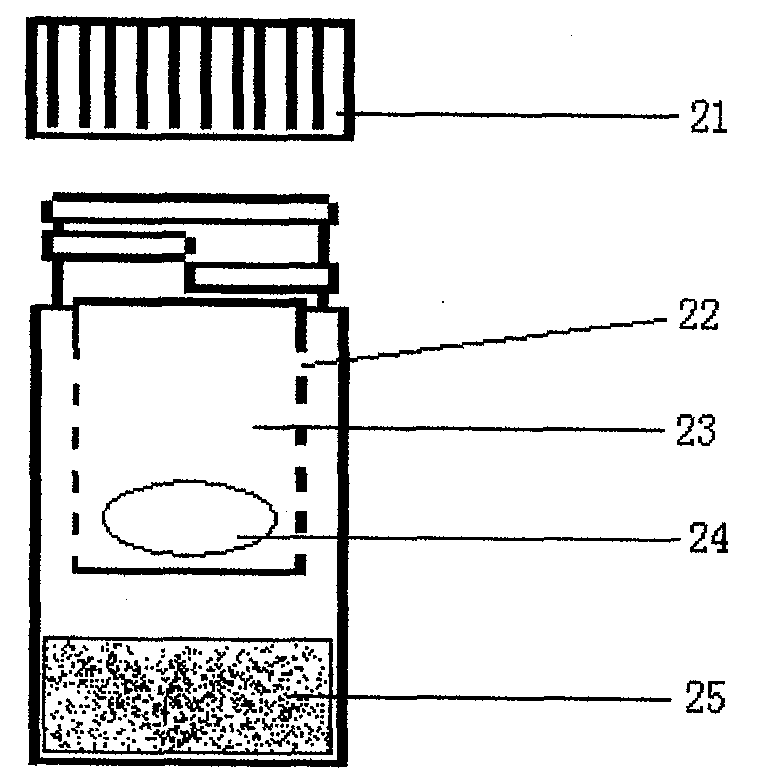

Device for rapid dehydration and of fixing biological molecule detection sample and method

Owner:银丰低温医学科技有限公司

Drying-free granulation treatment medicament for wet coal slime

InactiveCN110791343AImprove viscous-wetting propertiesAchieve dryingSolid fuelsCombustionExhaust gas emissions

The invention belongs to the technical field of coal separation, and discloses a drying-free granulation treatment medicament for wet coal slime. The drying-free granulation treatment medicament for wet coal slime comprises a water-absorbent resin, a dehydration aid, a drying aid, and a powder flow aid, and the mass ratio of the water-absorbent resin, the dehydration aid, the drying aid, and the powder flow aid is (5 to 10):(0.5 to 5):(0.5 to 5):(0.3 to 5). The drying-free granulation treatment medicament for wet coal slime is added to the wet coal slime and thoroughly mixed and crushed, so that the wet coal slime can lose water and become embrittlement, and the purpose of removing stickiness is achieved, the medicament is non-toxic and has no irritating odor, usage is less, safety is high, energy saving and efficient effects are achieved, no exhaust gas is emitted, all-weather using is possible, after the coal slime treatment is completed, the coal slime can be directly used as thermal coal for combustion after being screened by a screening system.

Owner:PINGDINGSHAN TIANAN COAL MINING +1

Method for preparing feed ingredients from kitchen wastes

InactiveCN106071044ASolve processing problemsRealize resource utilizationAnimal feeding stuffAdditive ingredientOil water

The invention discloses a method for preparing feed ingredients from kitchen wastes. The method comprises the following steps: (1) solid-liquid separation: performing solid-liquid separation on the kitchen wastes through a filter device, performing oil-water separation treatment on liquid obtained by solid-liquid separation, and performing solid-solid separation on a solid mixture obtained by solid-liquid separation, wherein the solid mixture contains plastic products, metal products and food residues at the same time; (2) solid-solid separation: putting the plastic products and the metal products which are subjected to separation into the solid kitchen waste retreatment procedure, and putting the separated solid food residues into the dehydration treatment procedure; (3) dehydration treatment procedure: dehydrating and deoiling the solid food residues until the moisture content is below 60 percent, putting the treated solid food residues into the drying treatment procedure, and performing oil-water separation treatment on liquid collected by squeezing; (4) drying treatment procedure: drying the solid food residues at high temperature to obtain the feed ingredients. The process is simple and controllable; the industrial chain of production is complete, so that the problem of incomplete treatment is solved.

Owner:HOPE TECH (TIANJIN) CO LTD

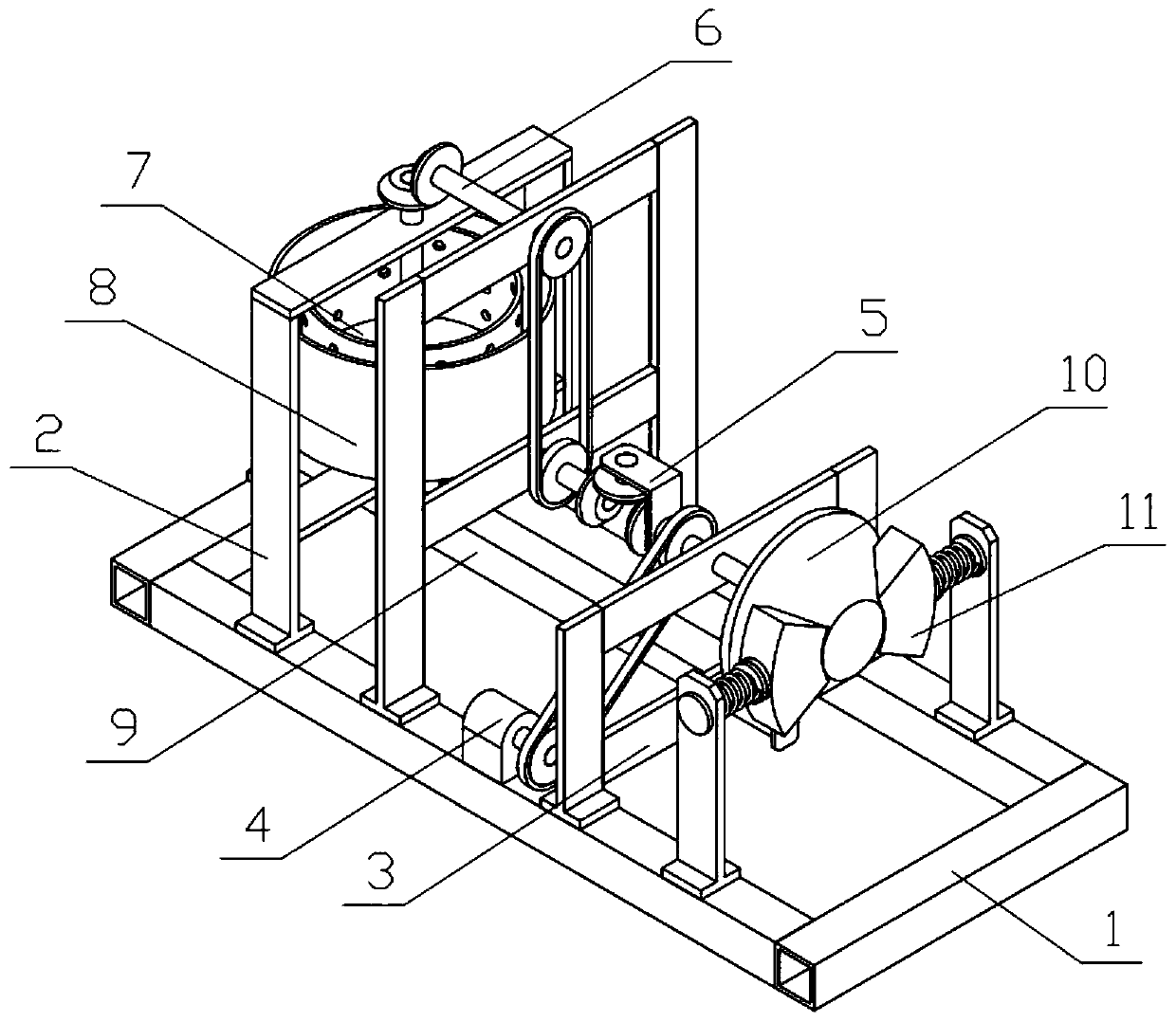

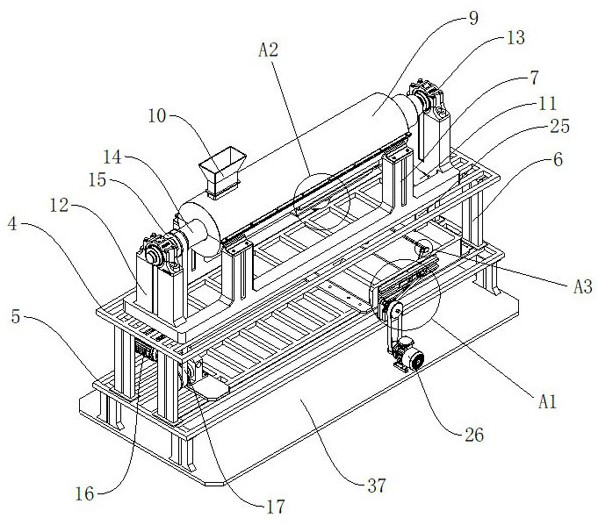

Screw propelling type high-pressure solid-liquid separation machine

PendingCN110667163AAvoid stuck conditionsSimple processing technologyPressesMechanical engineeringDehydration

The invention puts forward a screw propelling type high-pressure solid-liquid separation machine. A screw extrusion propelling rod is longitudinally mounted in a protection cover of the separation machine; a screen is mounted on the periphery of the screw extrusion propelling rod; the screen is fixedly connected with the protection cover through a screen reinforcing frame; the screw extrusion propelling rod is divided into two discontinuous sections; a through shaft of the screw extrusion propelling rod is sleeved with a plurality of replaceable loose-joint shaft sleeves; and a secondary extrusion section of the screw extrusion propelling rod and the plurality of replaceable loose-joint shaft sleeves can be taken down from the through shaft to change positions. The problems that blockage of materials is caused easily due to the fact that the section of the screw extrusion propelling rod and the section of the protection cover are changed from big to small, the equipment loss is high during extrusion, the damage caused by the materials to the screen is high during extrusion and equipment is required to be maintained frequently in the prior art are solved. According to the screw propelling type high-pressure solid-liquid separation machine, the screw extrusion propelling rod and the protection cover adopt the non-variable-section design, a separation zone is designed for buffering, thus the energy consumption is lower, and the dehydration process is smoother.

Owner:HARBIN HUAMEI YIFENG COMPOUND MATERIALS

Novel formaldehyde sensor

InactiveCN110208340ASmall form factorAvoid exceptionMaterial electrochemical variablesInternal resistanceProton

Owner:深圳市安诺意环境技术有限公司

Flue gas catalytic desulfurization solid-liquid separation system

InactiveCN111195448AAutomatically adjust the spin speedMoving filtering element filtersThermodynamicsFlue gas

Owner:海积(北京)科技有限公司 +1

Cationic polymerization of olefins using green acids

ActiveUS20190330395A1Organic sulfonic acidIndium

Owner:LEWIS STEWART P

Circulating automatic mopping and sweeping integrated machine

InactiveCN107969996APowerfulImprove cleaning efficiencyMachine detailsFloor sweeping machinesEngineeringMechanical engineering

The invention discloses a circulating automatic mopping and sweeping integrated machine. The machine comprises a box, a cloth driving belt, a rolling wheel movable frame, front rolling wheels, bottomrolling wheels, a control connecting rod, a control handle, control handle heads, a support plate, a water tank, rotating rolling wheels, support rolling wheels, soaking rolling wheels, dehydration rolling wheels, a handle frame, water, ground, a water inlet, a water outlet and an air dryer; the support plate is arranged in the box, the water tank is arranged on the upper portion of the support plate, the dehydration rolling wheels are arranged above the sides of the rotating rolling wheels, the soaking rolling wheels are arranged at the bottom of the water tank, the support rolling wheels arearranged on the portions, on the two sides of the lower portion of the water tank, of the box, the bottom rolling wheels are arranged on the inner side of the bottom of the box, and the rolling wheelmovable frame is arranged in the front of the box. Accordingly, the bottom of furniture is cleaned through the front rolling wheels, cleaning of the small area is achieved through adjustment of the rolling wheel movable frame, the cleaned ground is air-dried through the air dryer, the function of the product is powerful, the cleaning efficiency is higher, and the cleaned ground is drier and safer.

Owner:HENAN XINZHIXIANG EDUCATION TECH CO LTD

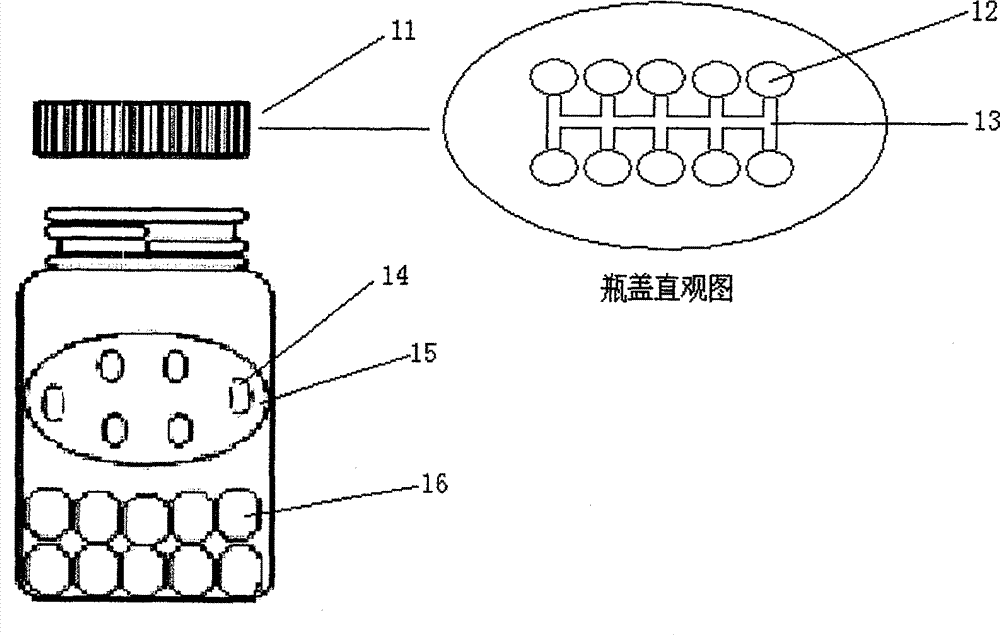

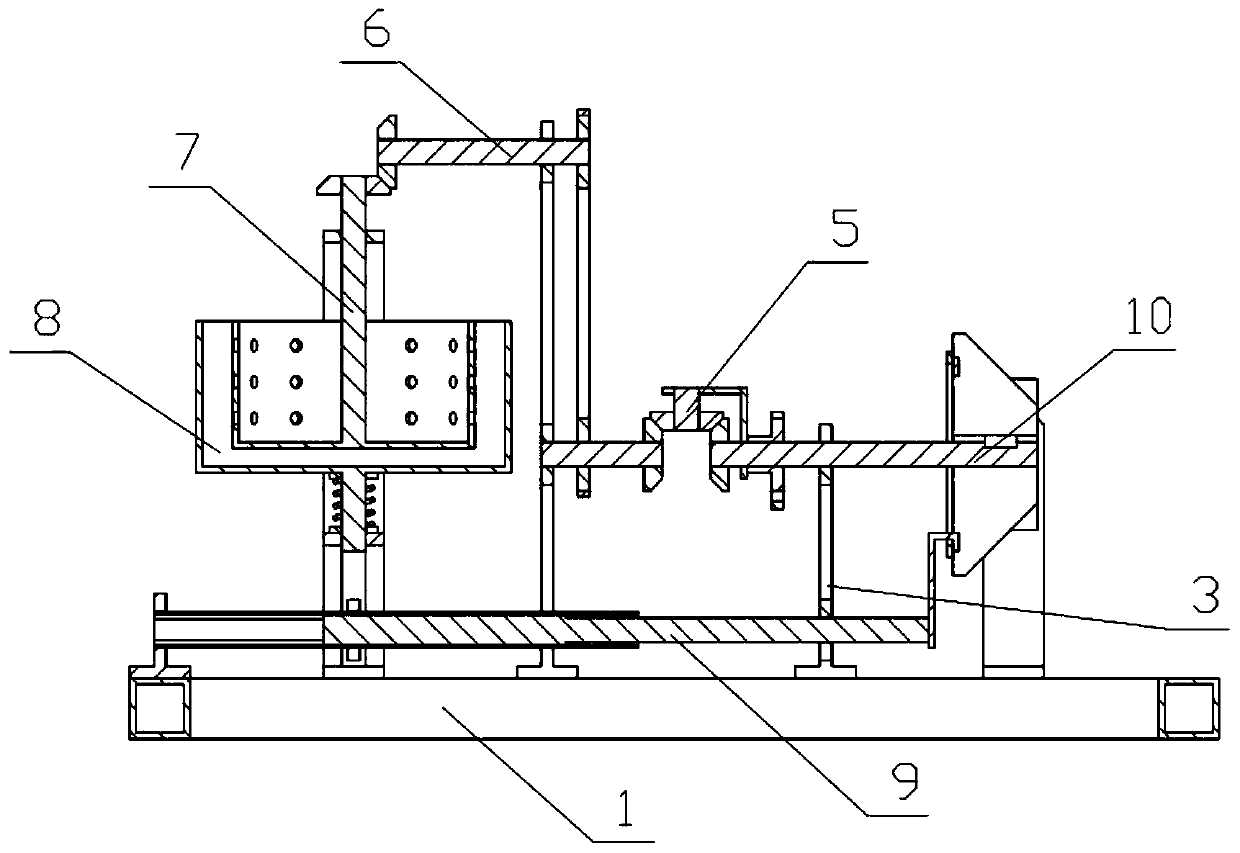

Dehydration device for pea starch production

ActiveCN114801289ATroubleshoot blocky appearanceImprove dehydration efficiencyGrain treatmentsPressesWater filterSpiral blade

Owner:优承生物科技(烟台)有限公司

Non-fermented composite organic grease fertilizer and preparation method thereof

InactiveCN110563501AIncrease enzyme activityImprove fertilizer efficiencyCalcareous fertilisersExcrement fertilisersPhosphateDecomposition

Owner:佛山市嘉实和生物科技有限公司

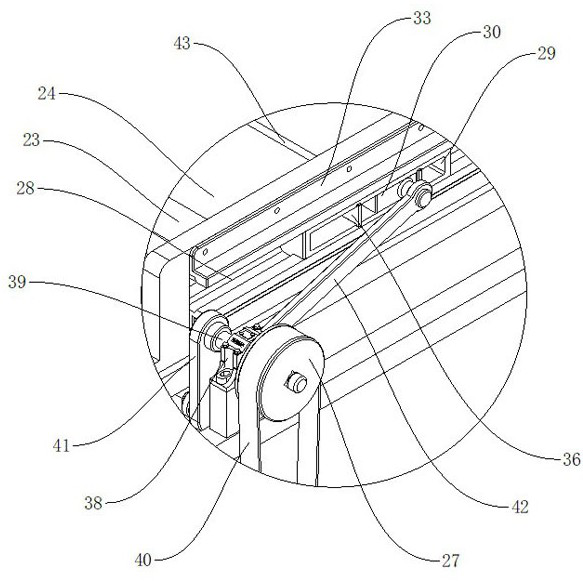

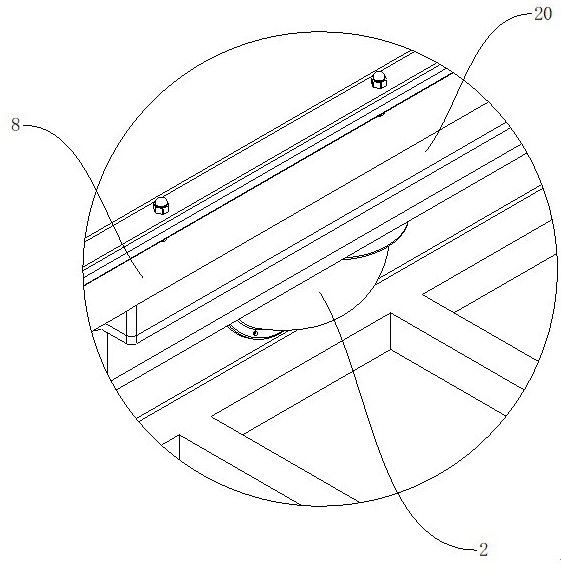

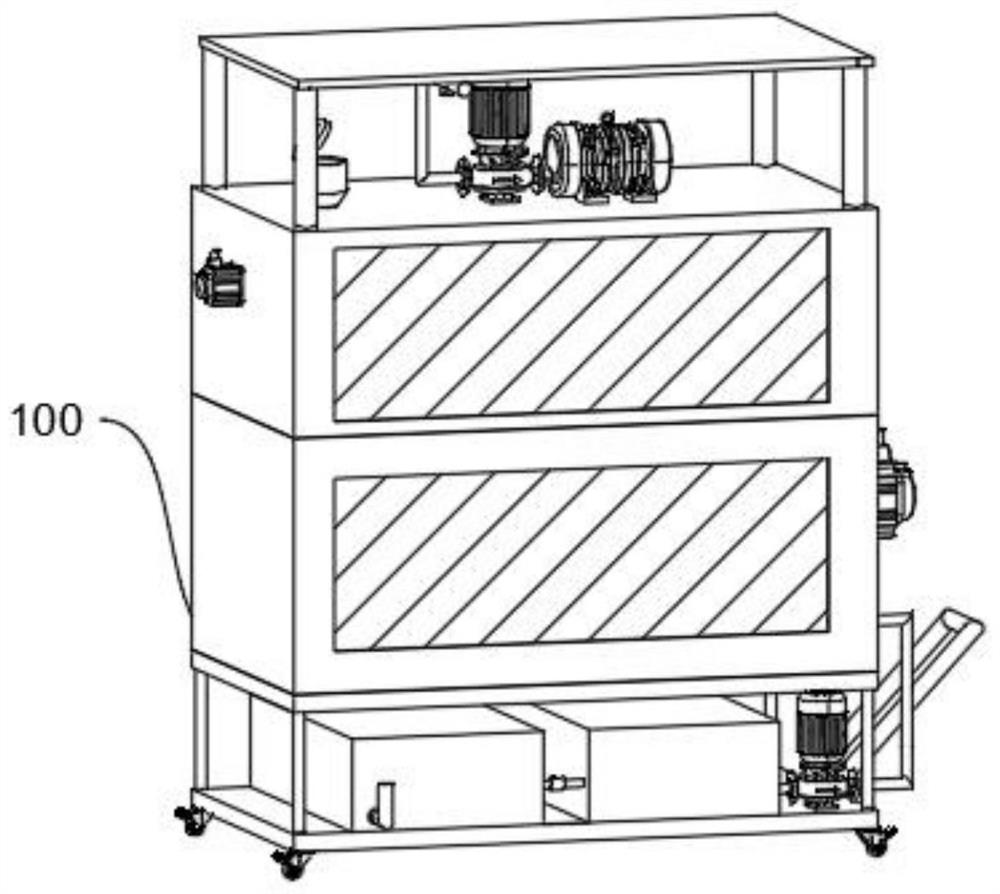

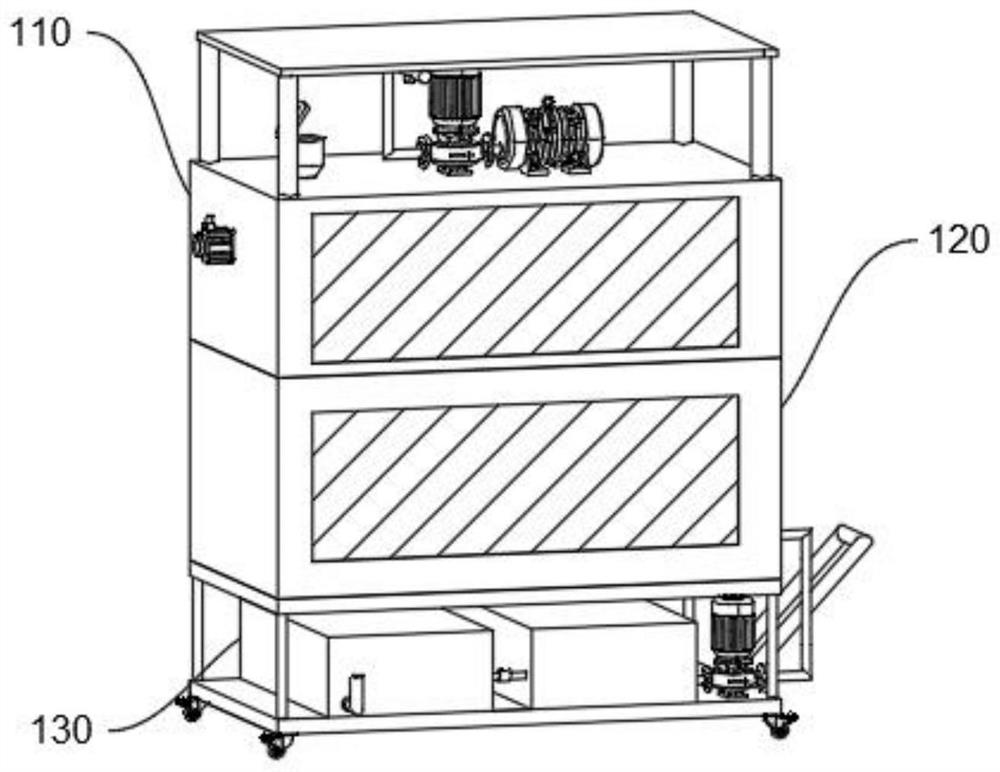

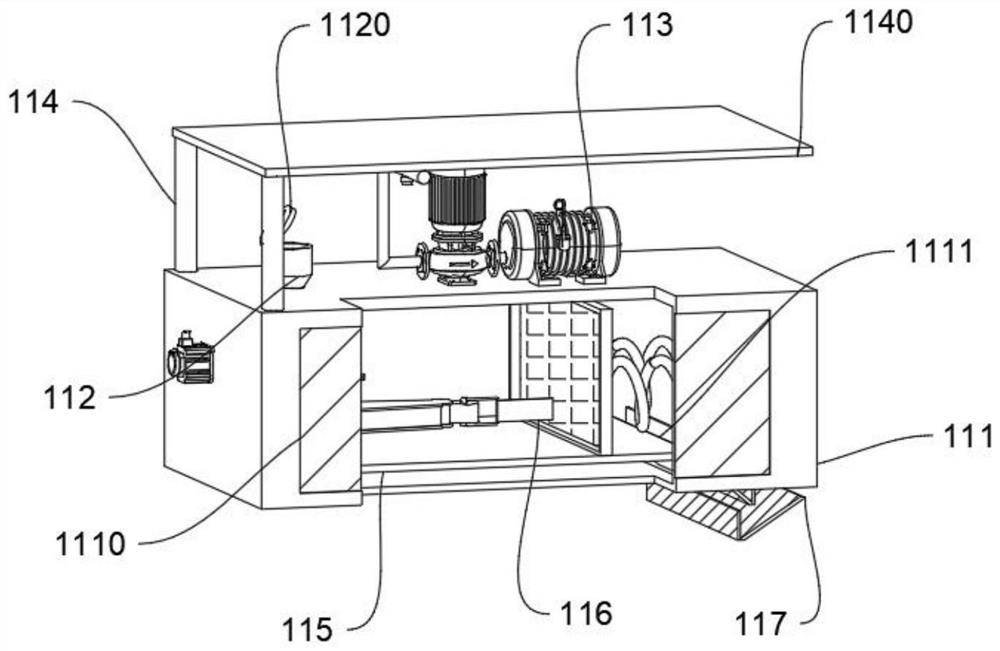

Waste mineral oil dehydration and impurity removal equipment based on pretreatment

InactiveCN112791464APrevent the formation of precipitatesNot easy to filter outCentrifugal force sediment separationDrive wheelDrive shaft

Owner:湖南两山环境科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap