Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about "Presses" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Press

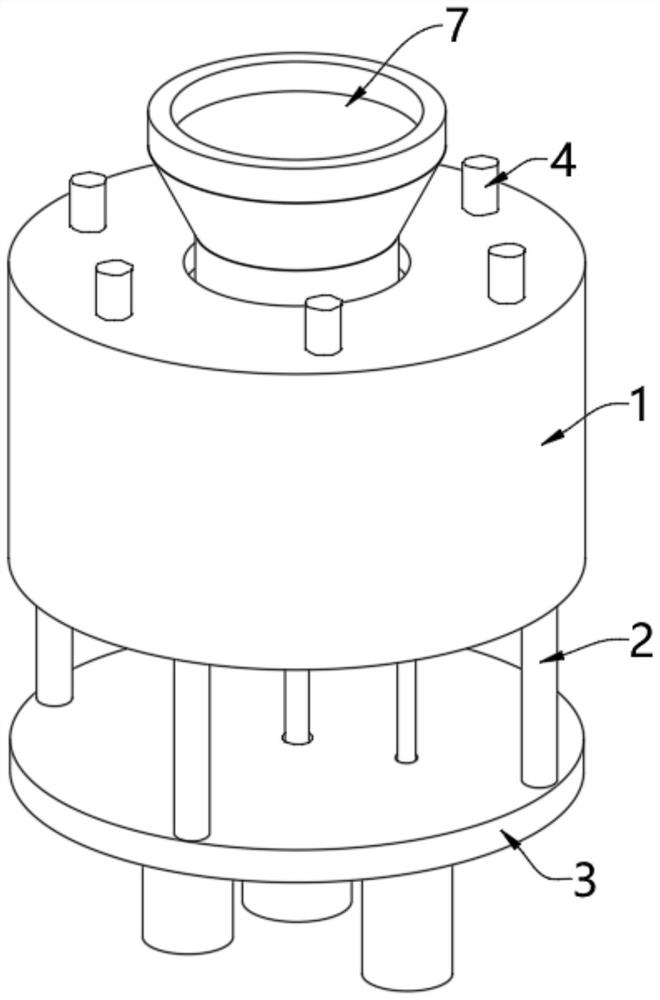

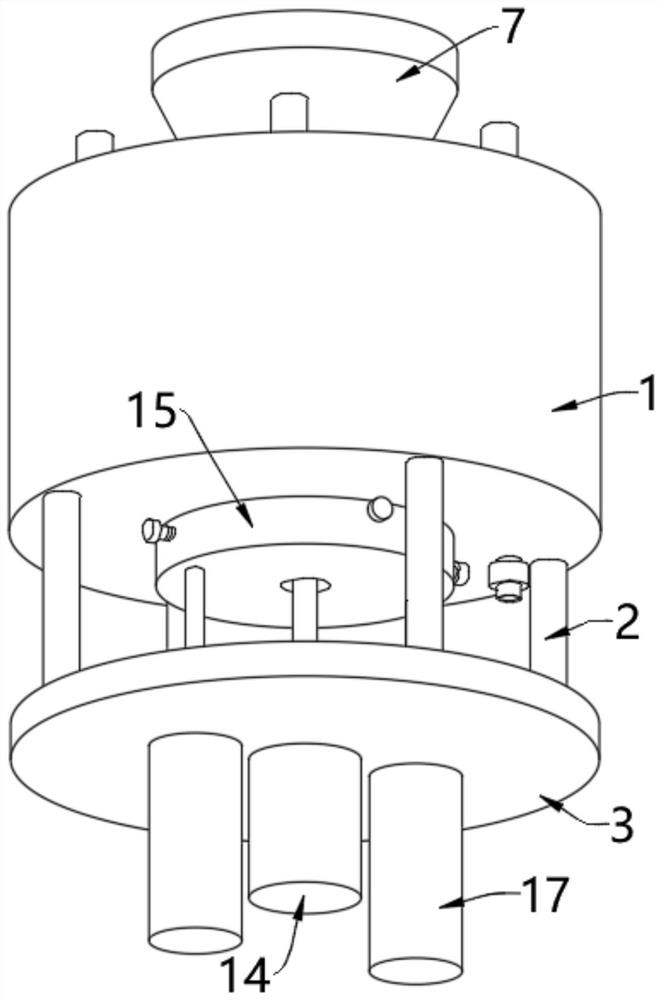

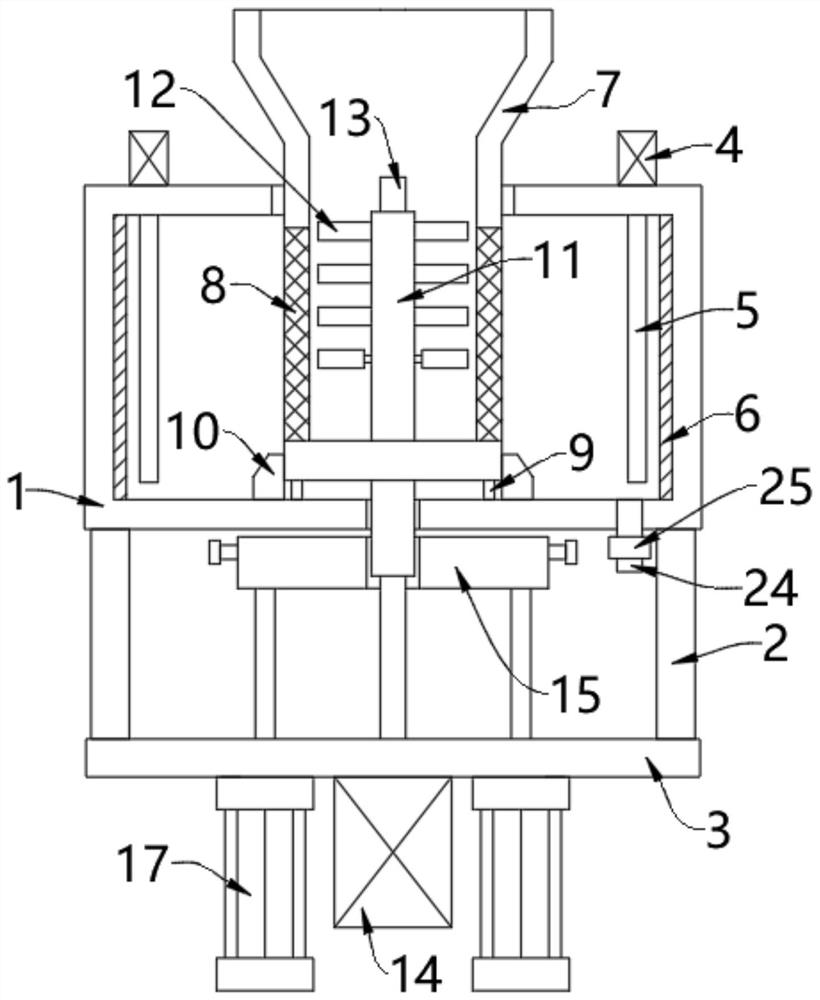

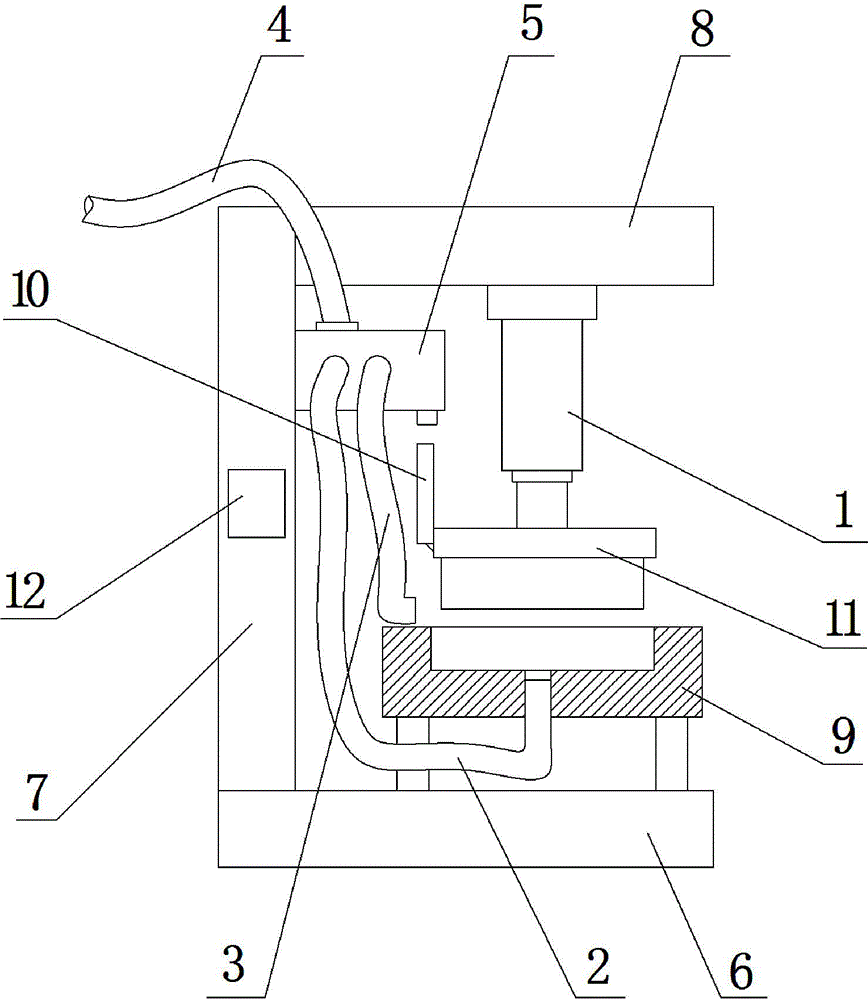

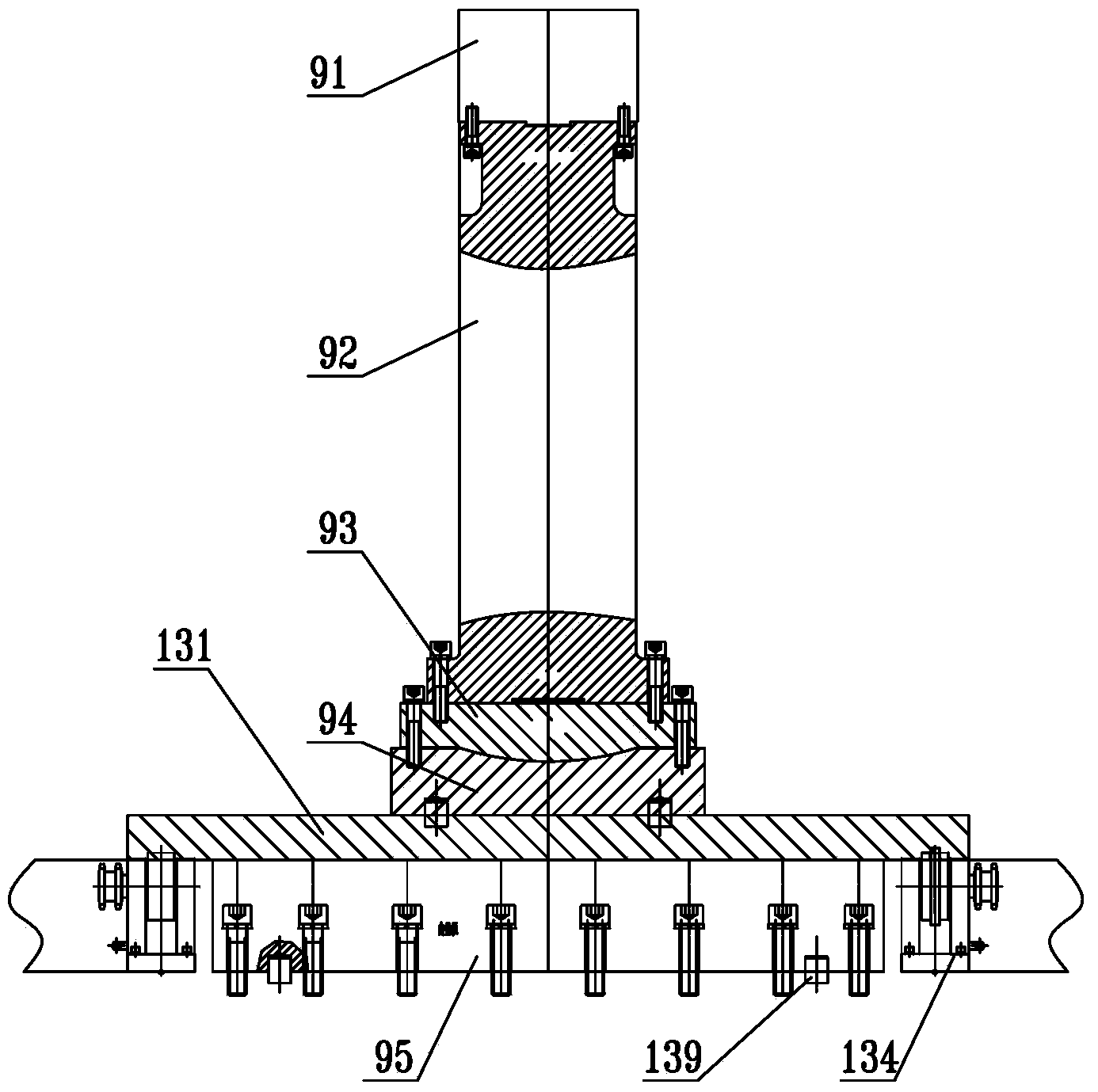

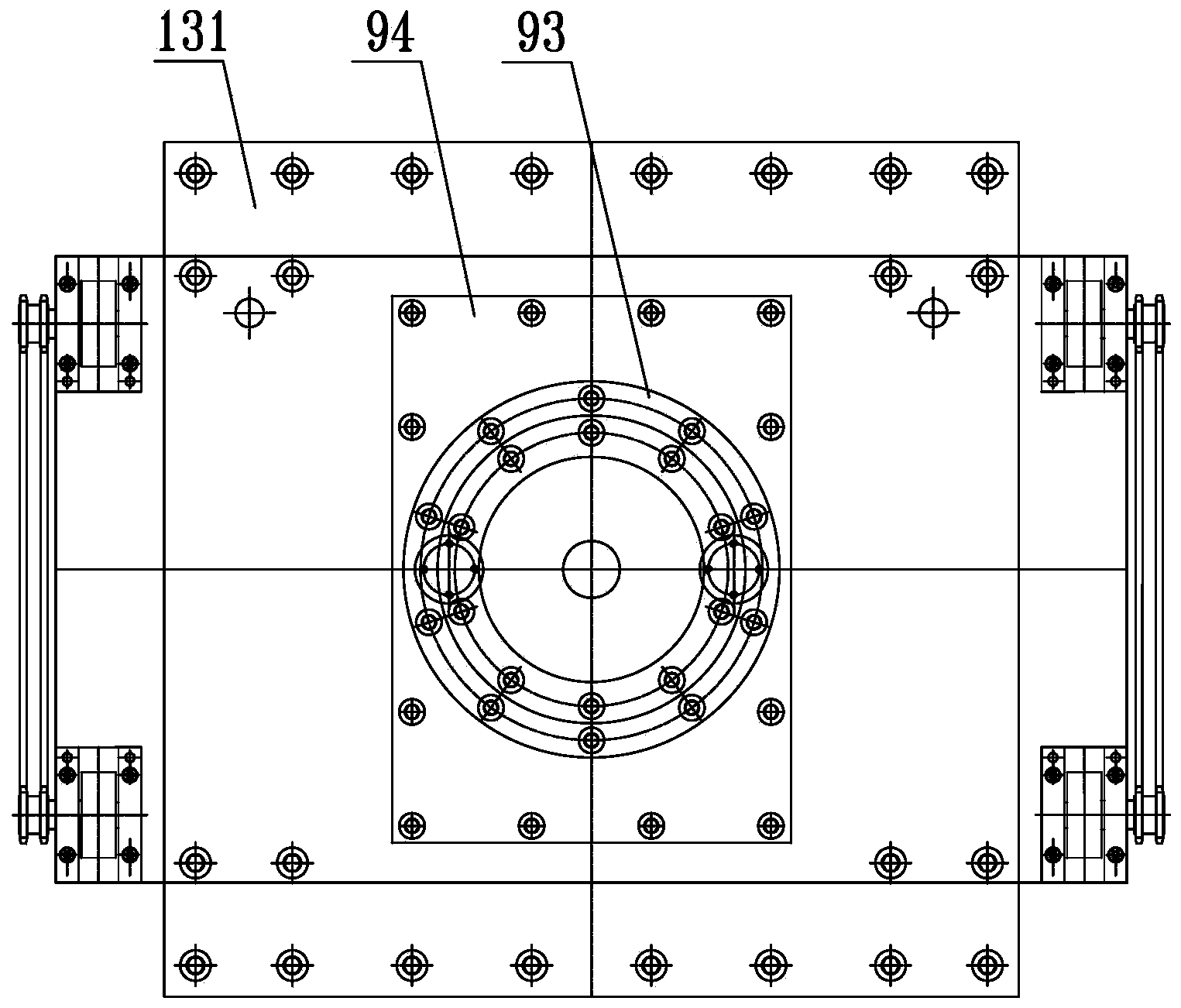

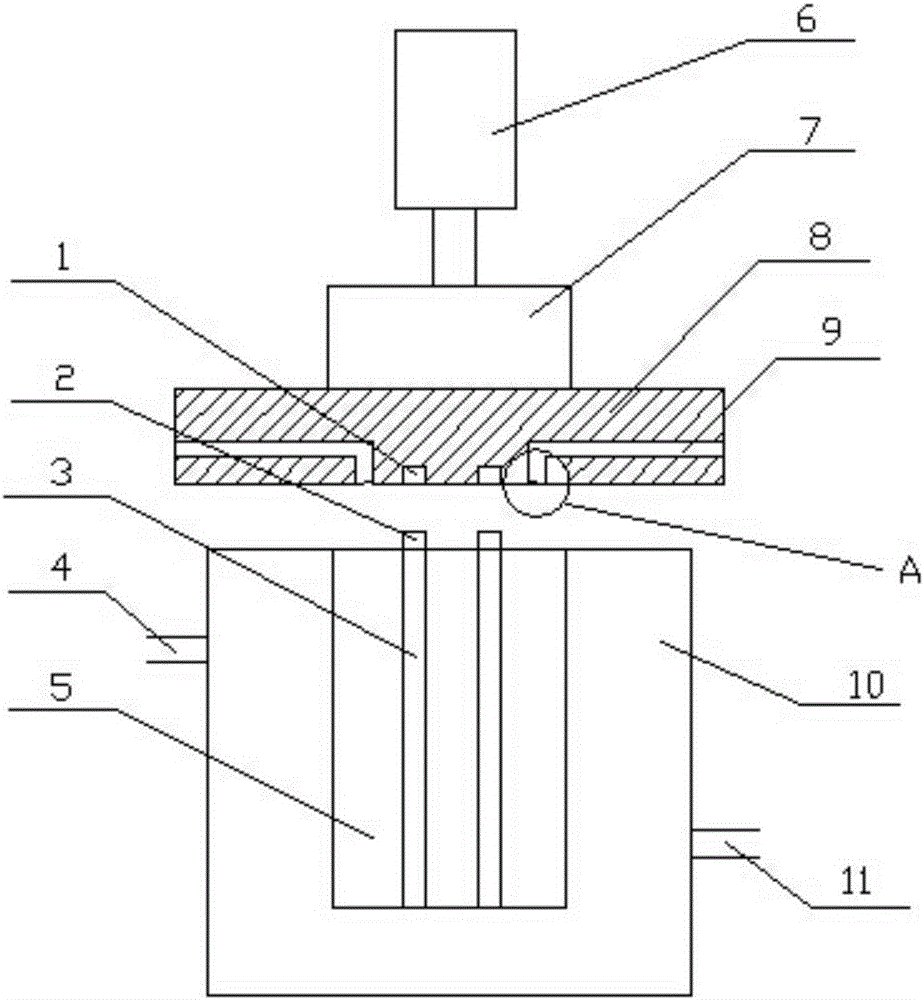

InactiveUS20130276505A1Improve production efficiencyShorten the timePressesMechanical engineeringVertical axis

A press including a number of pairs of dies each clamped by a driving source to press set work pieces in a vertical direction, and a revolver holding the pairs of dies and rotatable around a vertical axis, wherein the revolver by rotating moves any pair of dies to a pressing position where pressing process is performed.

Owner:KOJIMA PRESS IND CO LTD

Single-screw extruder

Owner:NANNING SUGAR INDUSTRY CO LTD

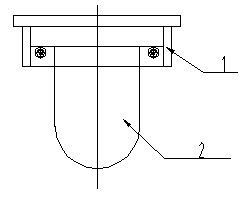

Laminated plate and end treatment method of the laminated plate

ActiveUS20100021675A1Welding/cutting auxillary devicesHollow wall articlesEngineeringMechanical engineering

A manufacturing method of a laminated plate (19) includes: a first step of supporting, by a support member (9), a thermoplastic resin-made laminated material (1) in which a pair of plate-like members (3, 4) are laminated to each other while interposing a longitudinal wall portion (2b) so that a peripheral edge portion (1a) of the laminated material (1) can be exposed, and heating and softening the peripheral edge portion (1a) by blowing a hot air to the peripheral edge portion (1a); and a second step of pressing the plate-like member (4) as one of the pair of plate-like members (3, 4) against other plate-like member (3) by thrusting a cutting blade (17a) of a cutting die (17) against the heated and softened peripheral edge portion (1a), thereby bringing the pair of plate-like members (3, 4) into contact with each other and welding the plate-like members (3, 4) to each other, and then cutting the laminated plate (19) out of the laminated material (1).

Owner:MEIWA IND CO LTD

Rapeseed oil squeezing device capable of collecting rapeseed oil conveniently

Owner:安徽茗峰机械制造股份有限公司

Traditional Chinese medicine extraction stirring device facilitating residue-liquid separation

ActiveCN113144672AEasy to separateEasy extractionRotary stirring mixersTransportation and packagingMedicinal herbsEngineering

Owner:XUCHANG UNIV

Sewage treatment integrated equipment

ActiveCN109876599AEasy dischargeEasy to collectDispersed particle separationWater/sewage treatmentFixed frameEngineering

The invention discloses sewage treatment integrated equipment, which structurally comprises a compression tank device, a controller, a wire, a hydraulic rod, a compressor and a supporting frame. Sewage is guided onto an odor-backflow-preventing device, a floating block is pushed through buoyancy of the sewage to move upwards, and then a flow-stop block is driven to move upwards to open a sewage discharging channel to discharge the sewage; after no sewage flows into the channel, the flow-stop block and a semicircular connecting block are connected to close the channel so as to avoid backflow ofodor in the sewage; when the compressor is pressed to the compression tank device, a movable plate extrudes an airbag to guide an air flow into a pneumatic rod, thus the pneumatic rod pushes a deodorization filter net device to rotate around a return rod, and the air flow is blown onto a deodorization filter net to be deodorized; and when the compressor moves upwards, a fixing frame is provided with restoration power by arranging a return spring in the return rod, and the compressor moves upwards and makes contact with the fixing frame to provide the fixing frame restoration power.

Owner:ANHUI BAIBANG ENVIRONMENTAL ENG CO LTD

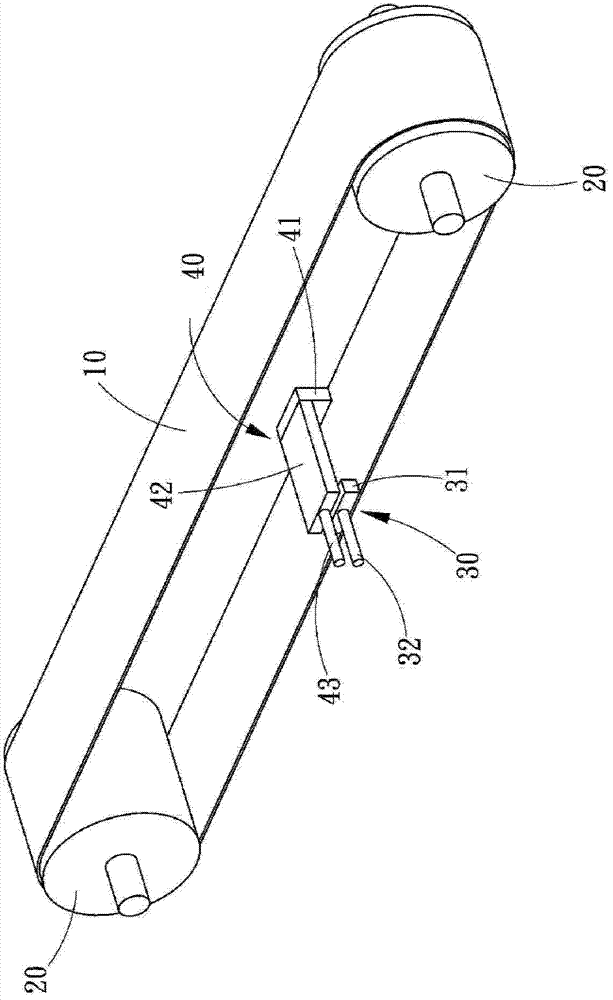

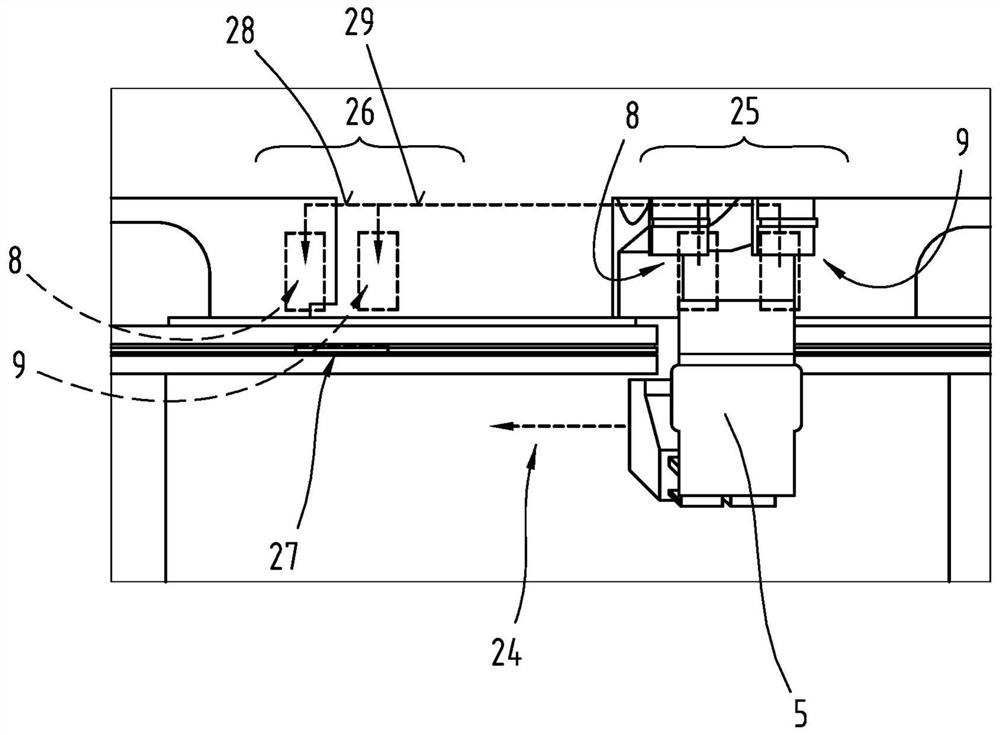

Pneumatic cylinder with safety device

InactiveUS6997102B2Considerable kinetic energySafe catching of the pistonCylindersFluid-pressure actuatorsEngineeringPiston

A pneumatic force-generating device, for example, a pneumatic cylinder for balancing the ram weight on a press, is provided with an impact or catching device having an impact plate (24) for catching the piston (18) upon discharge of the weight. The deformable impact plate (24) is securely clamped along its edge or held by a clamping device (31), that permits a controlled slipping through. The impacting piston (18) deforms the impact plate (24) to absorb the kinetic energy produced if this piston is released as a result of damage and is accelerated by the existing gas bolster and thrown against the impact plate (24).

Owner:SCHULER PRESSEN GMBH & CO KG

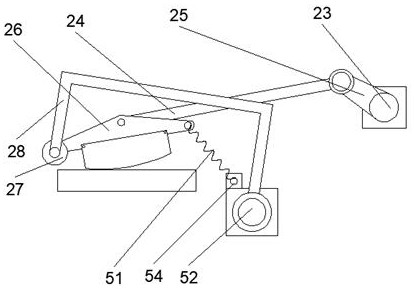

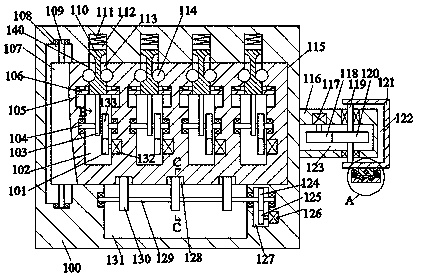

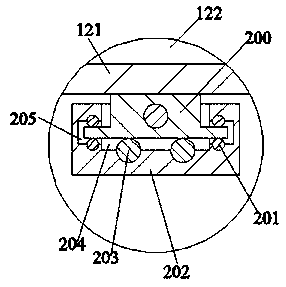

Novel equipment for processing box-shaped electronic elements

InactiveCN104128417AReduce laborIncrease productivityShaping toolsPressesEngineeringElectronic component

Owner:成都丽元电器有限公司

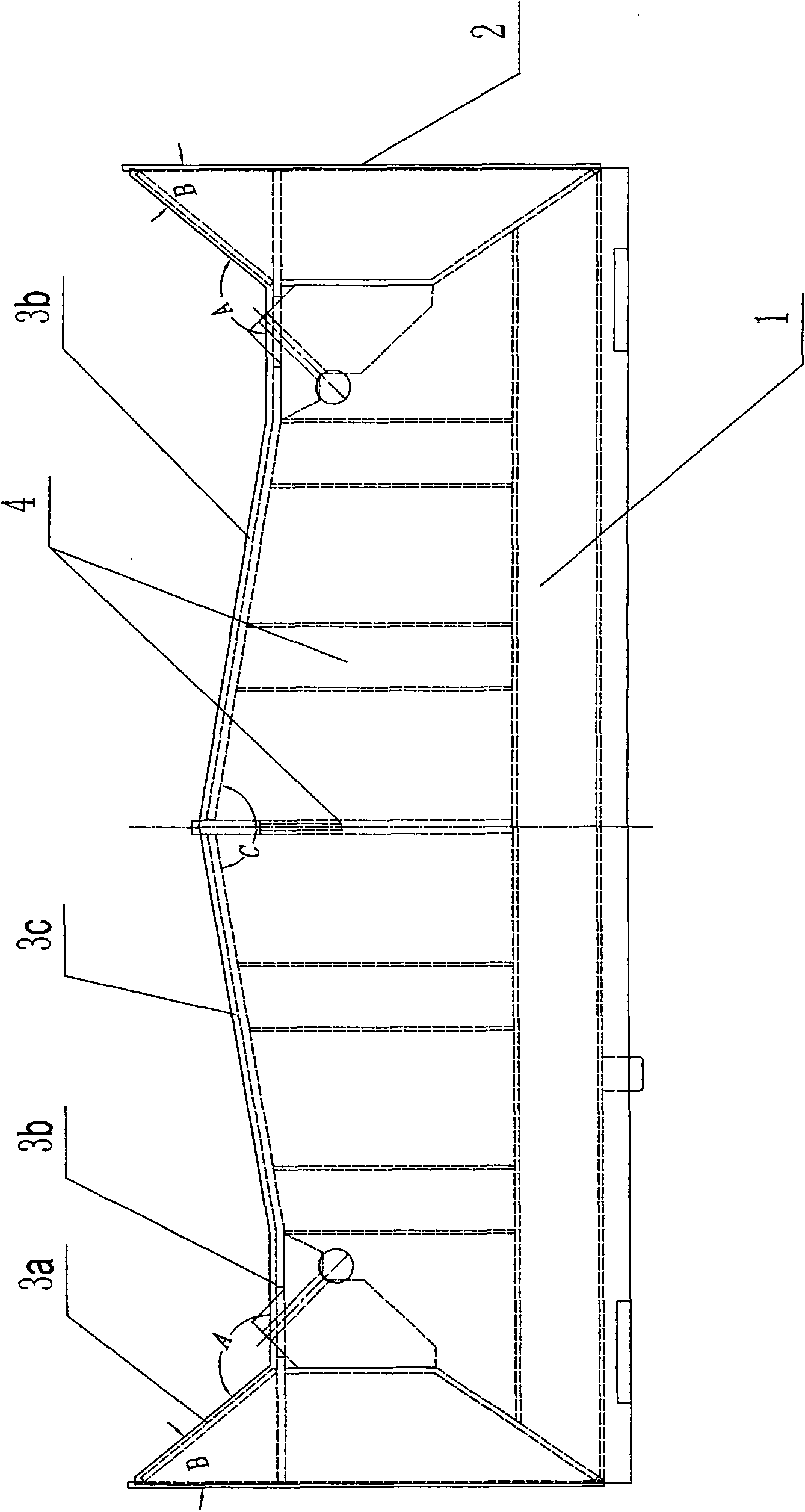

Compressing head of trash compressing box

ActiveCN101676094AReasonable distribution of stress pointsEven by forceRefuse transferringStorage devicesRear quarterEngineering

Owner:YANGZHOU JINWEI ENVIRONMENTAL PROTECTION TECH CO LTD

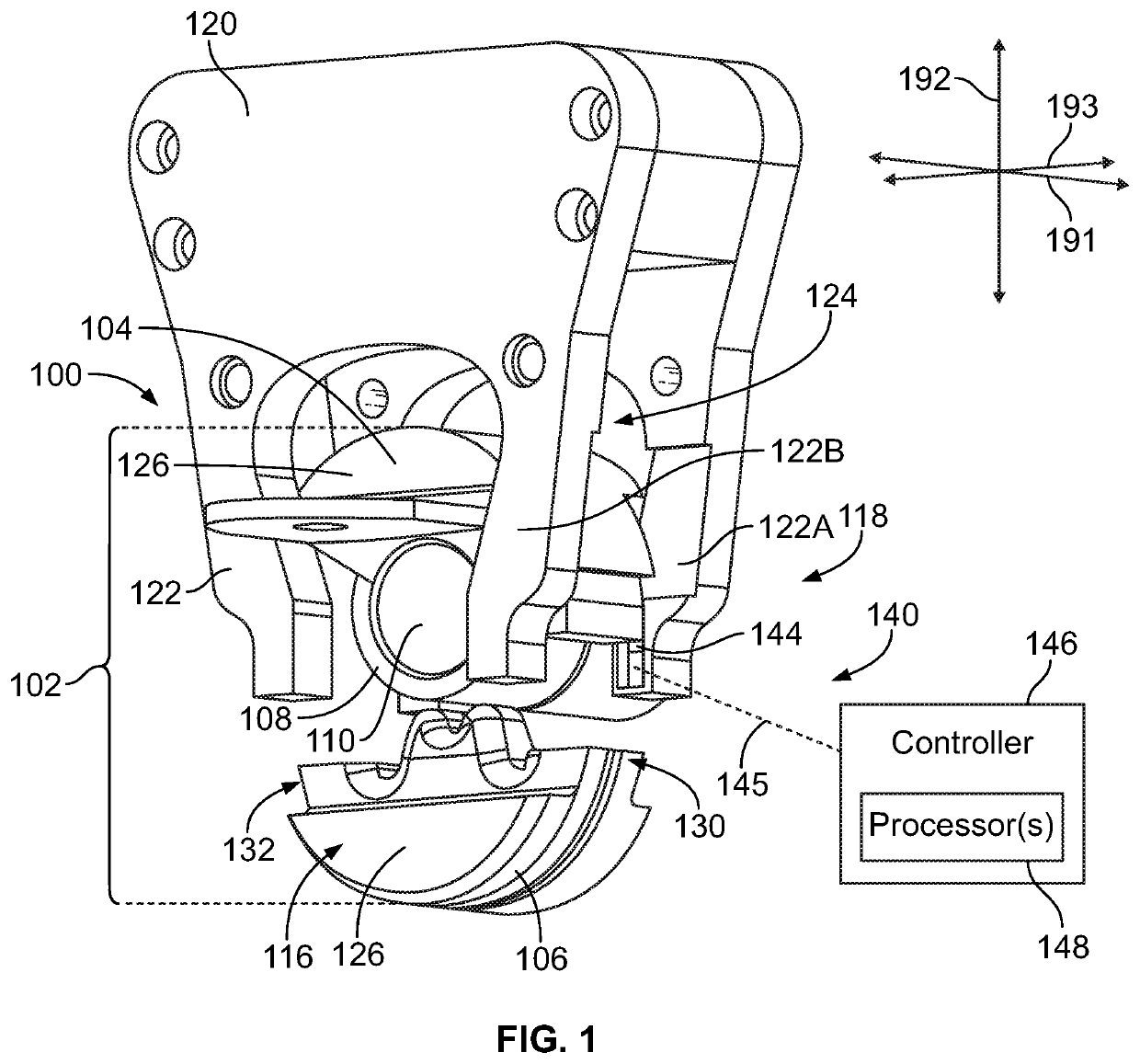

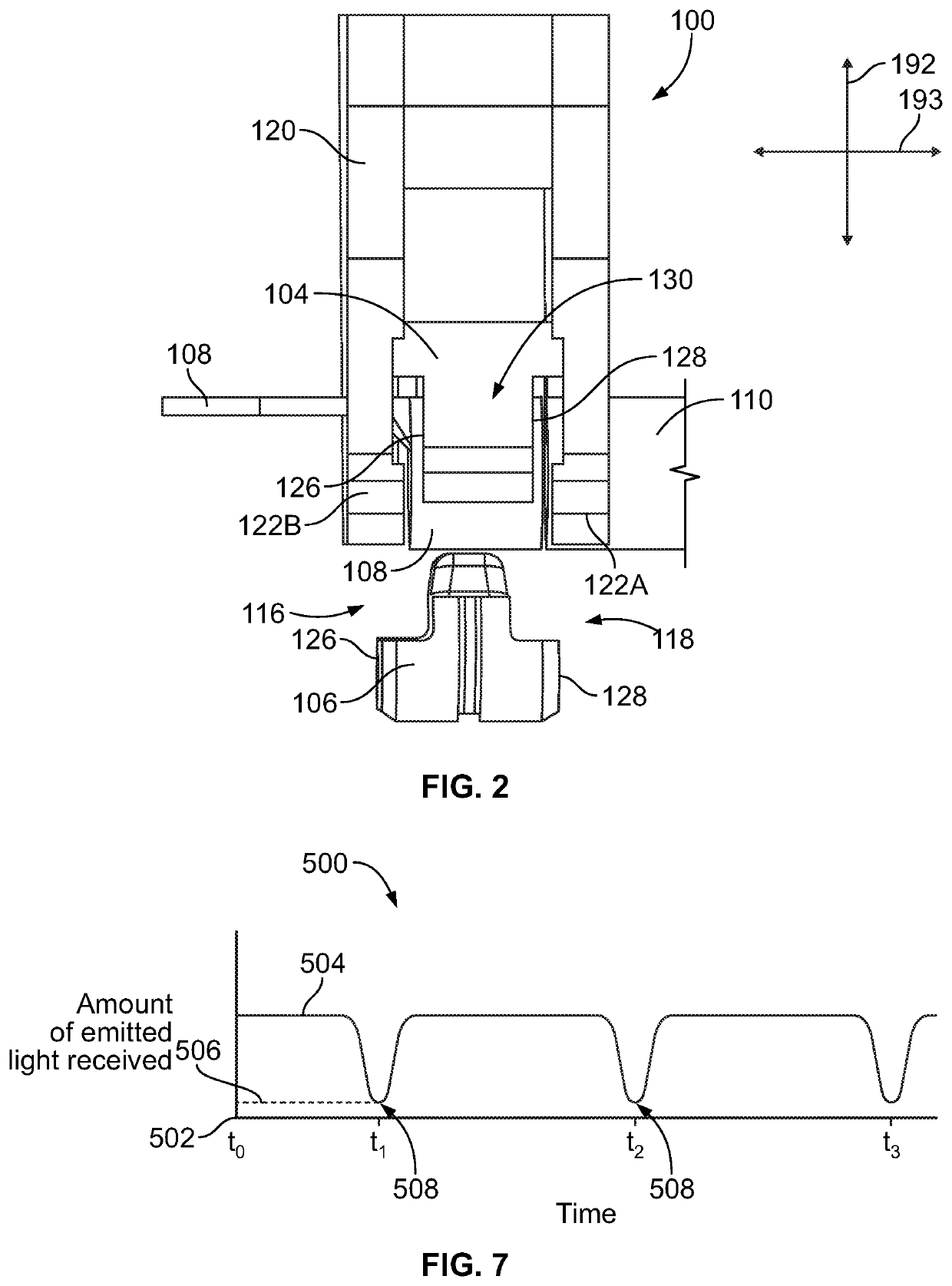

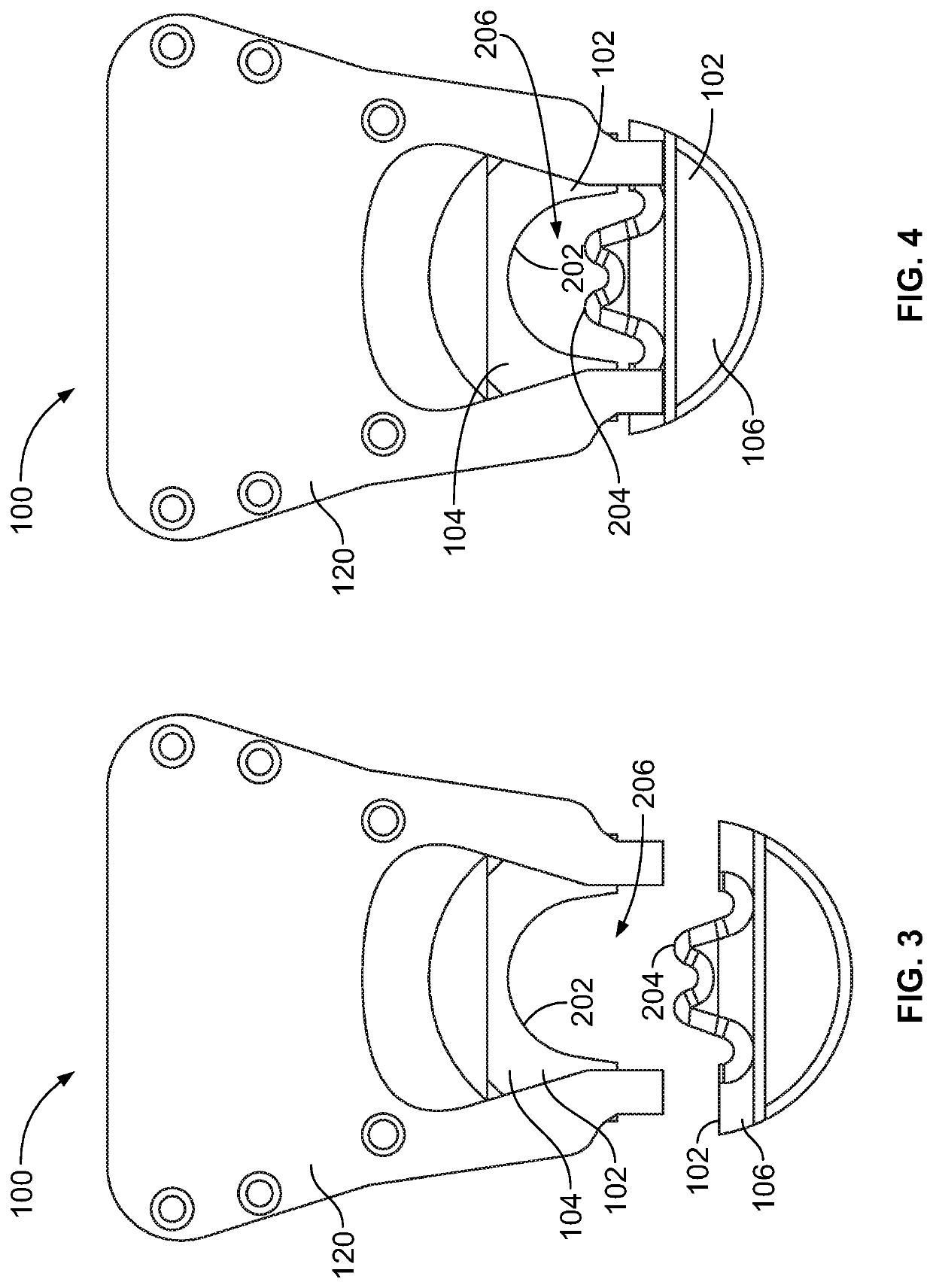

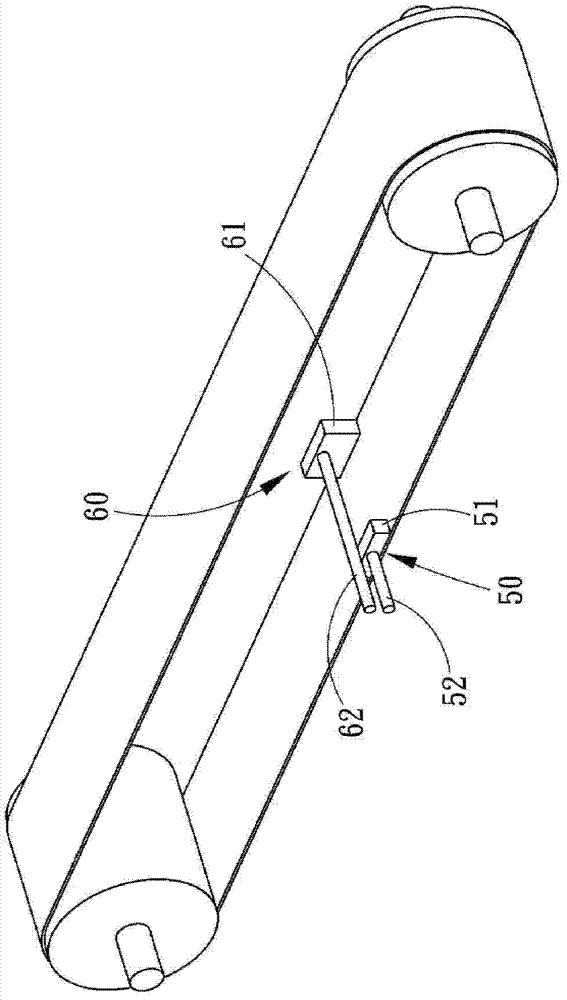

Die clearance monitoring system for a crimping device

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

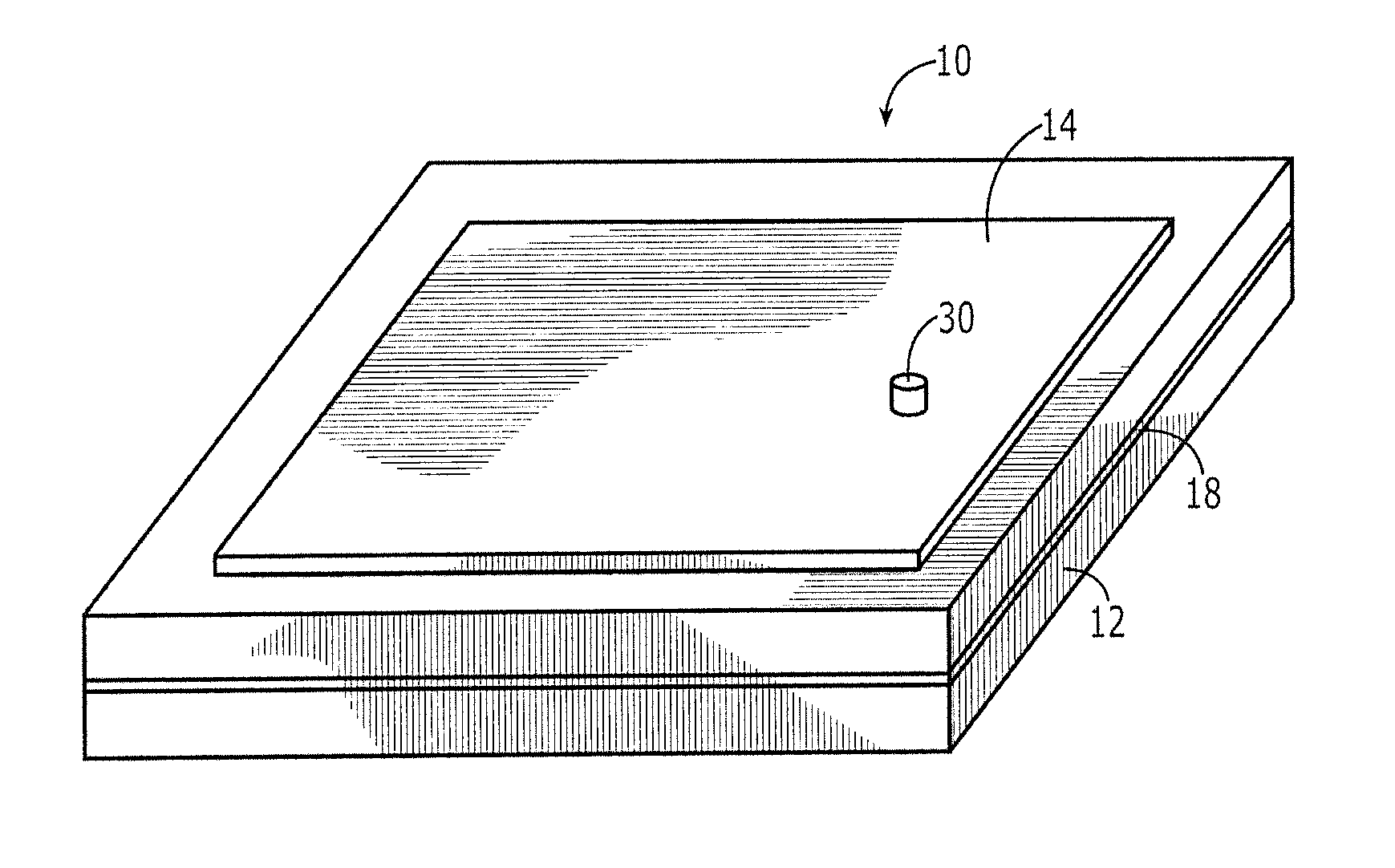

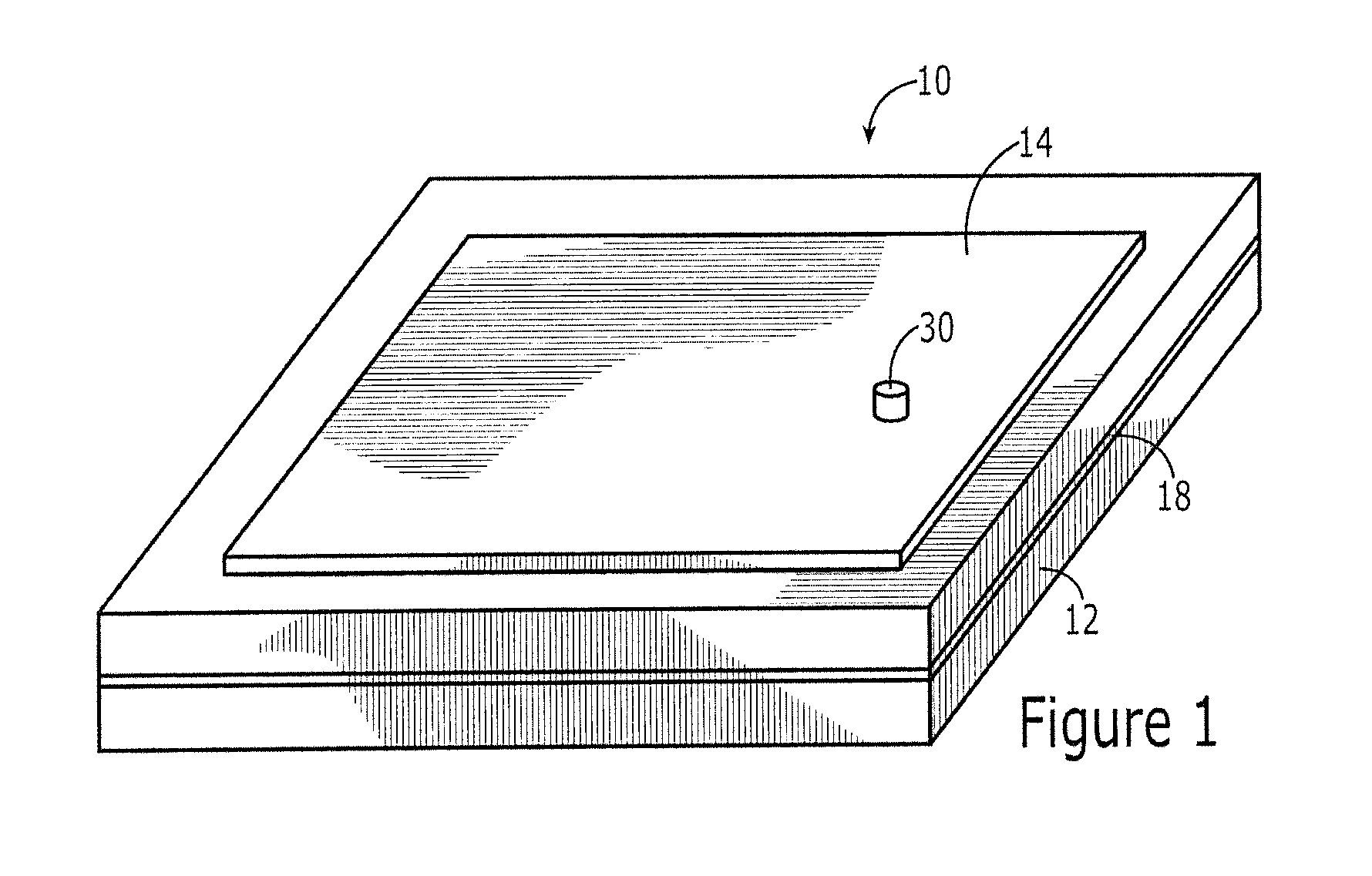

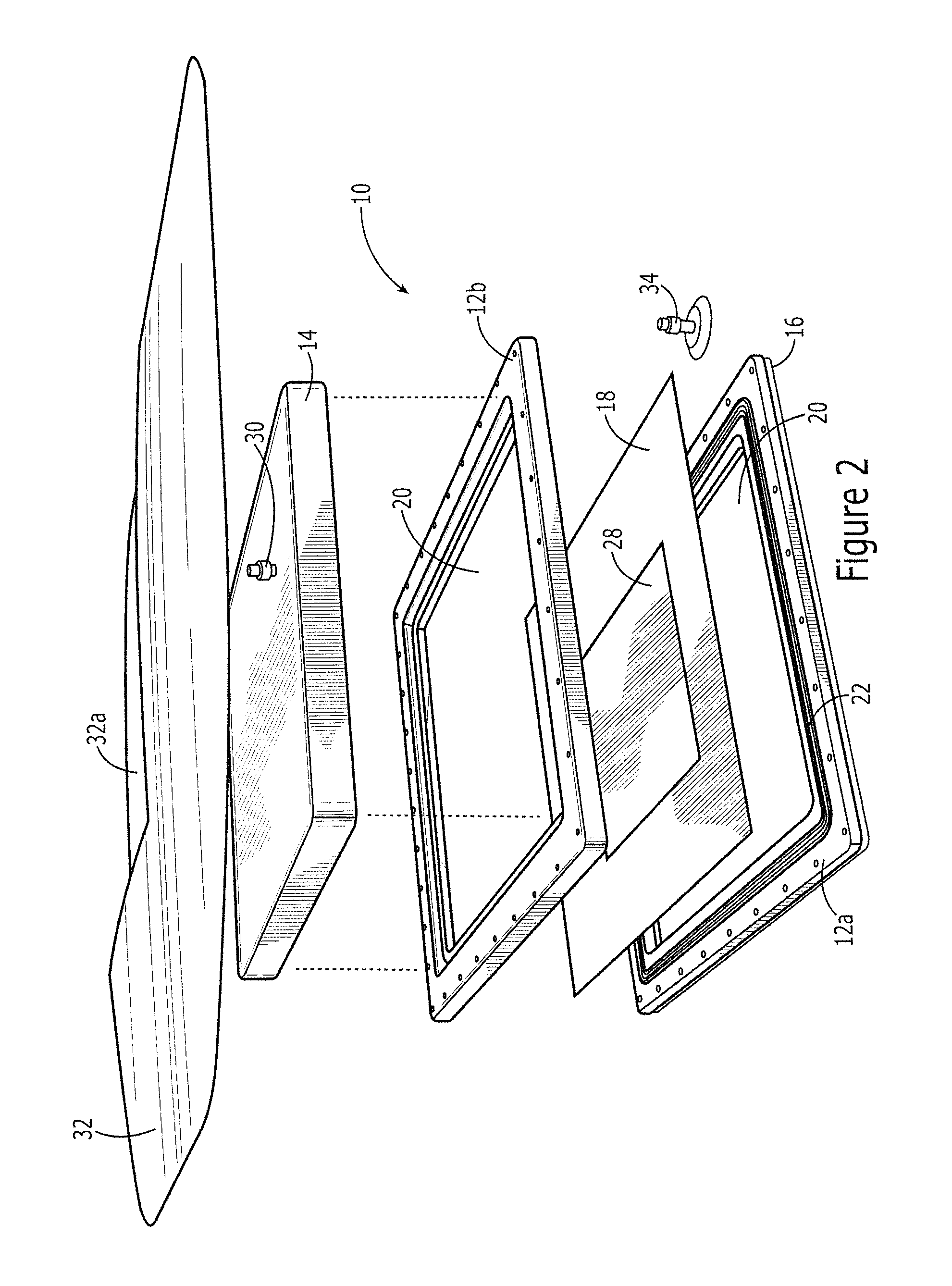

Installation tool and associated method for applying a patch to a surface

Owner:THE BOEING CO

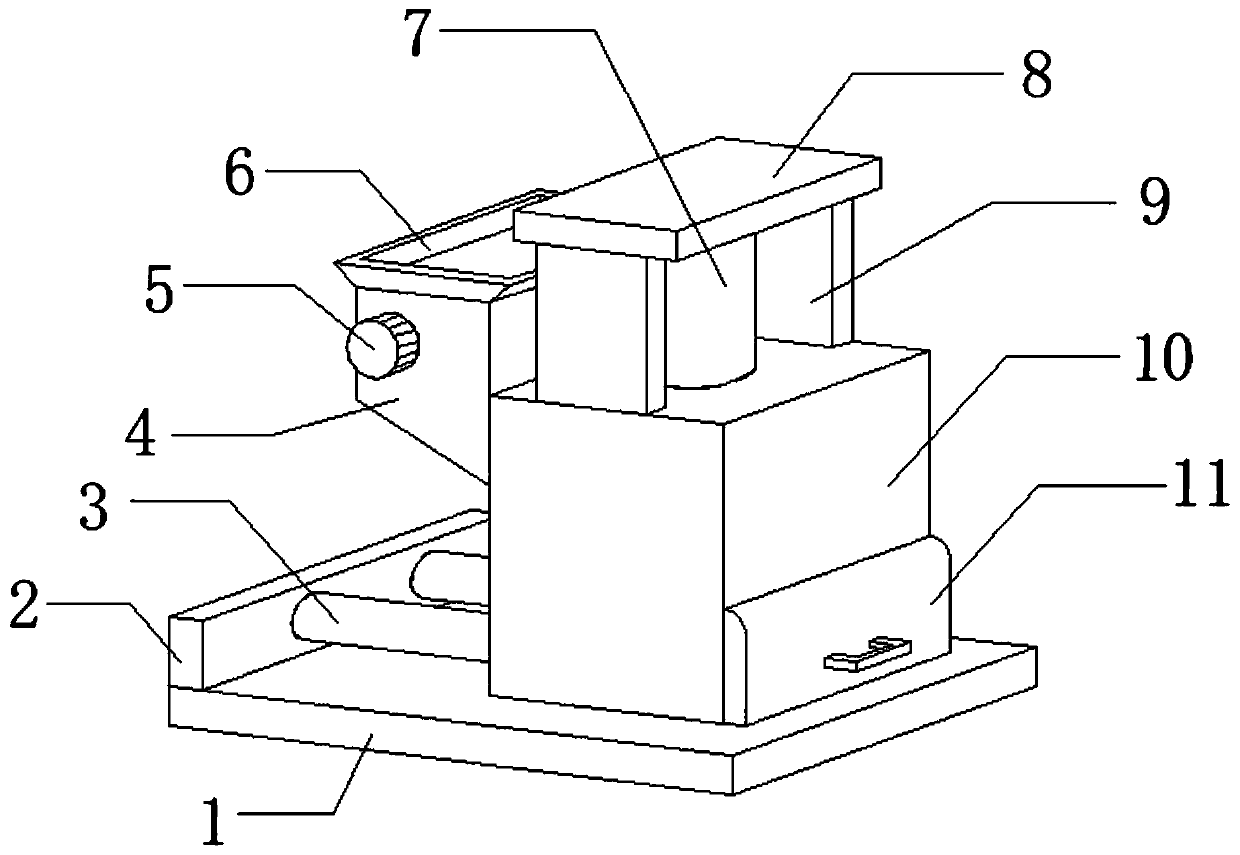

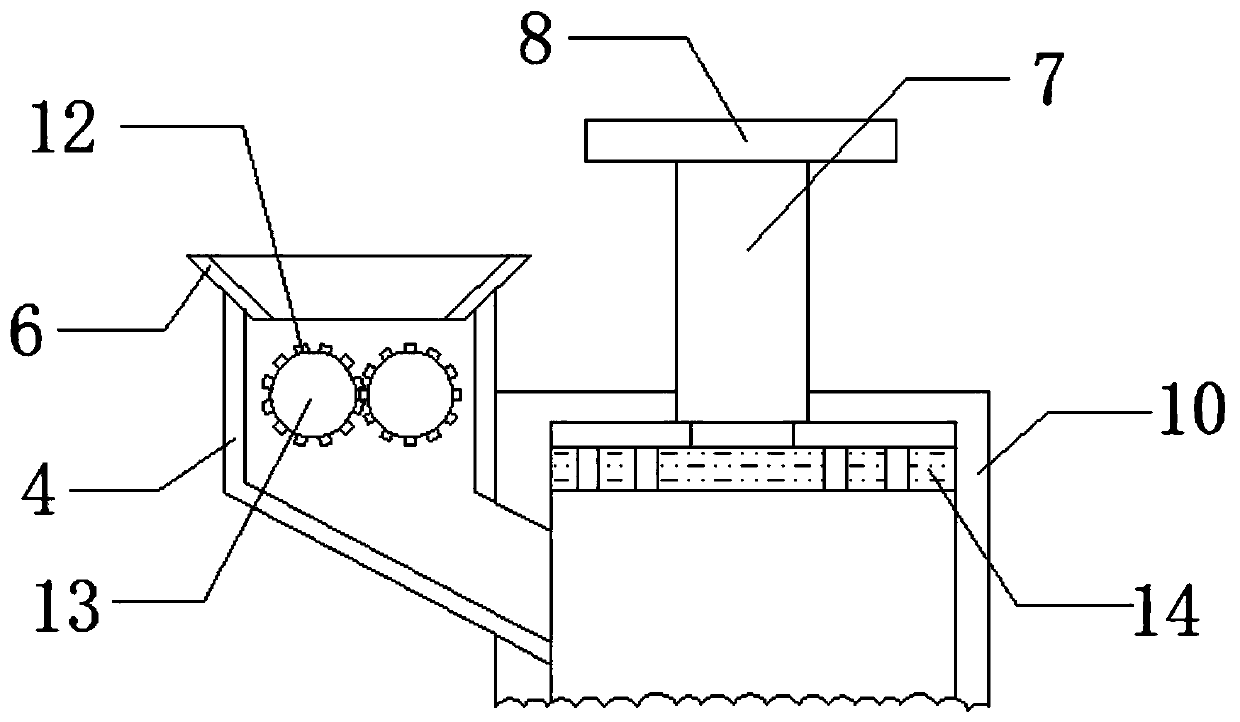

Fruit wine production crusher

ActiveCN113102031AAdjustable spacingImprove crushing efficiencyJuice extractionGrain treatmentsFruit wineAgricultural engineering

The invention discloses a fruit wine production crusher which comprises a crushing bin, a juice filtering bin and a juice squeezing bin. The bottom end of the crushing bin communicates with an inner cavity of the juice filtering bin; a self-flowing juice box fixedly installed in the inner cavity of the juice filtering bin is arranged below the crushing bin; a filtering plate is arranged between the self-flowing juice box and the crushing bin; the higher end of the filtering plate is installed on the side wall of the inner cavity of the juice filtering bin through a first rotating shaft; the lower end of the filtering plate is connected with the top end of the side wall of one side of the self-flowing juice box through a plurality of springs; a screen is installed in the center of the filtering plate; a discharging hopper is installed on one side of the bottom of the inner cavity of the juice filtering bin; and the bottom end of the discharging hopper communicates with the inner cavity of the juice squeezing bin. According to the fruit wine production crusher provided by the invention, the distance between a first crushing roller and a second crushing roller can be adjusted to meet the crushing requirements of different types of fruits, so that the fruit crushing efficiency and the fruit crushing quality are improved; and self-flowing juice and squeezed juice can be separated so as to be prevented from being mixed in the follow-up process, so that the quality of brewed fruit wine is improved, and fruit resources are fully utilized.

Owner:JIANGXI VALLEY SPRING WINE ECOLOGICAL AGRI DEV CO LTD

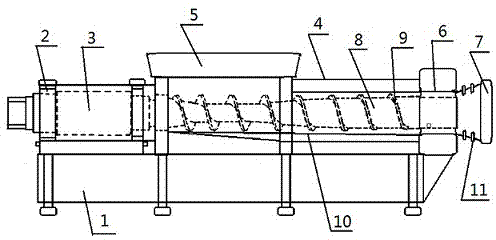

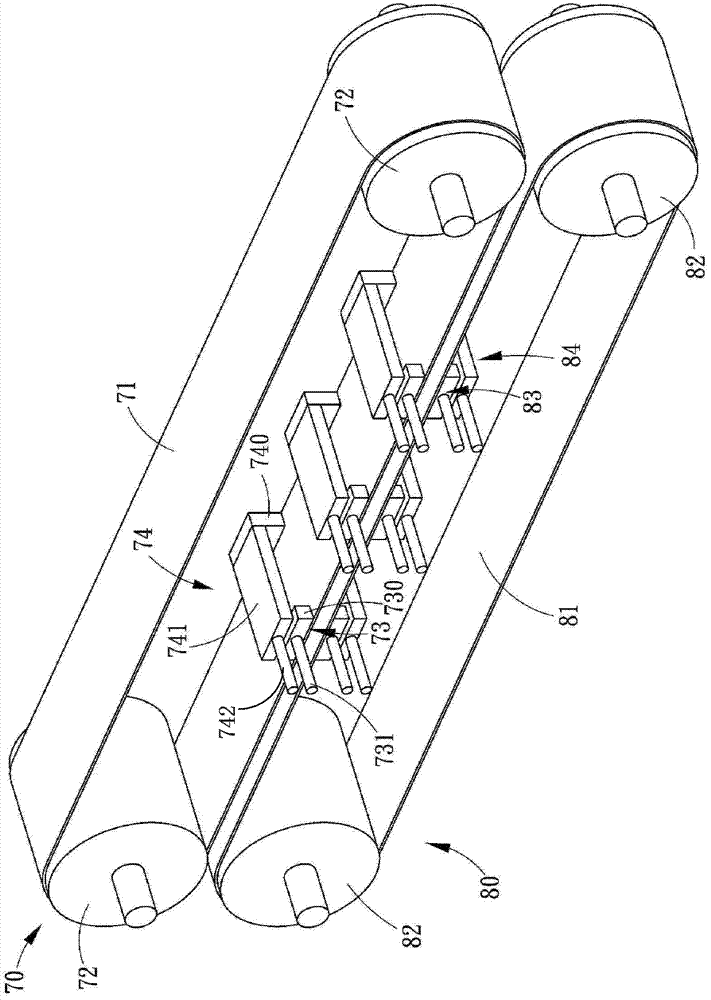

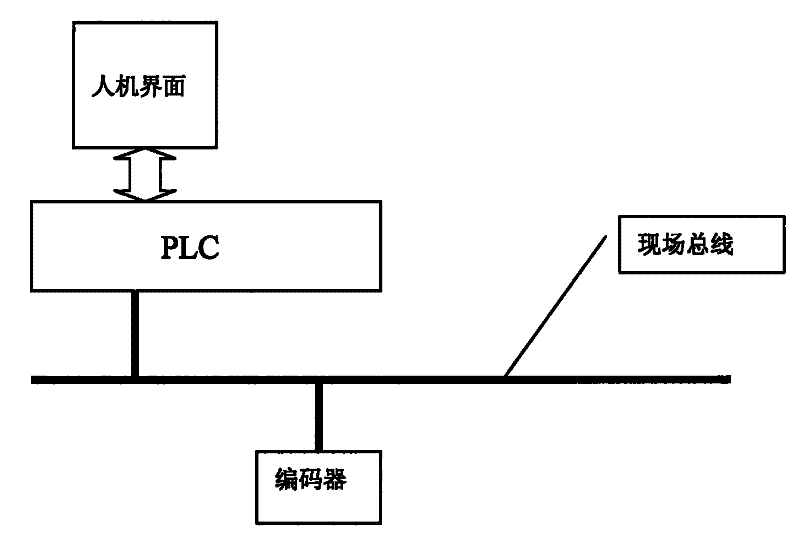

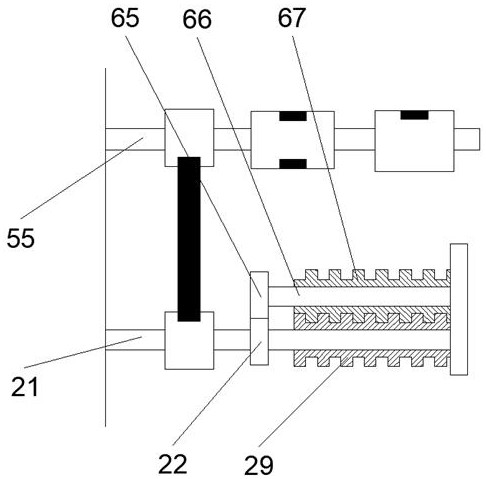

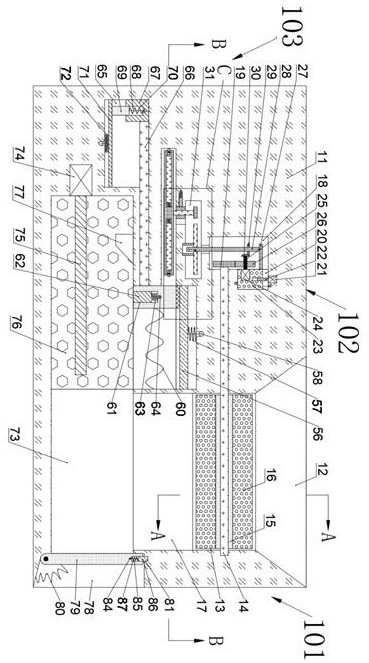

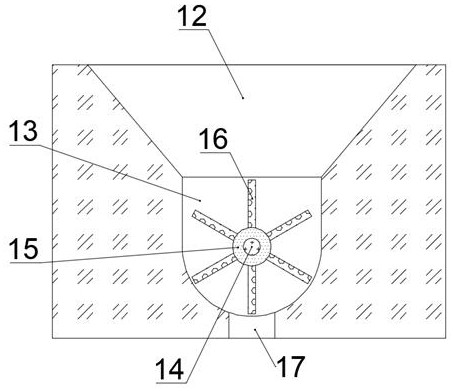

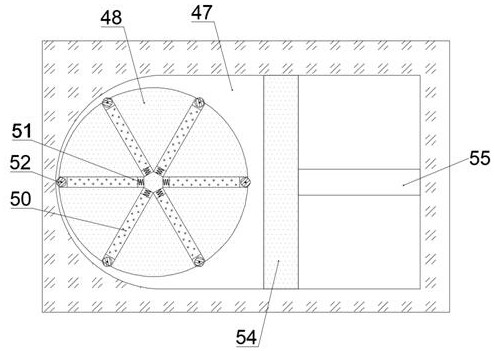

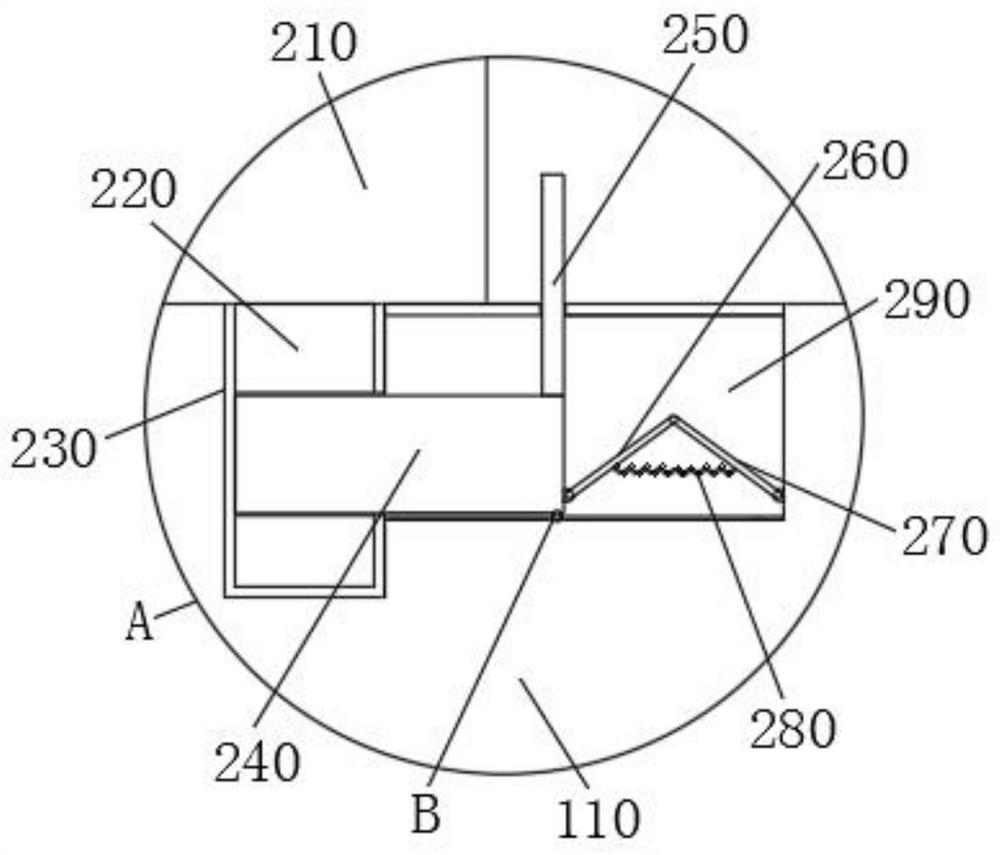

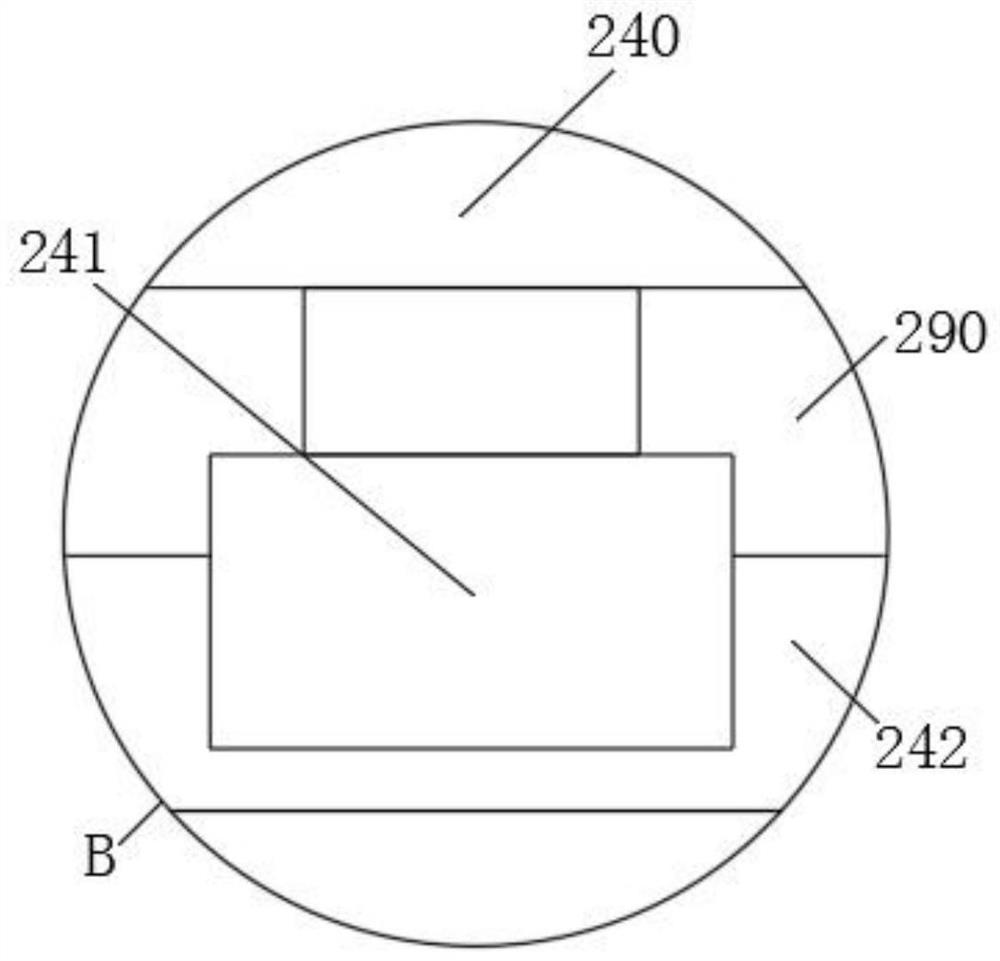

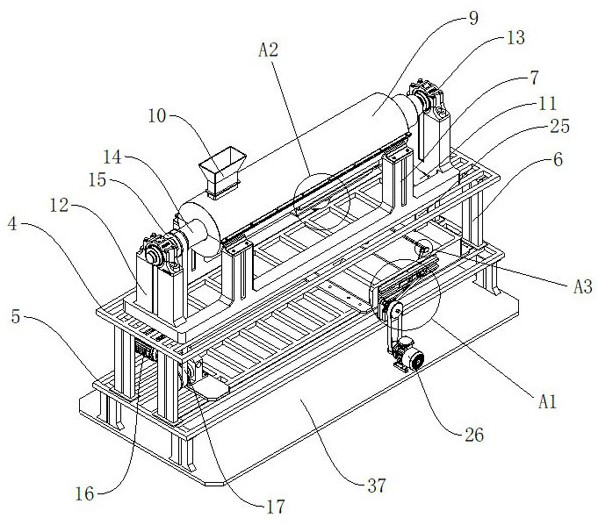

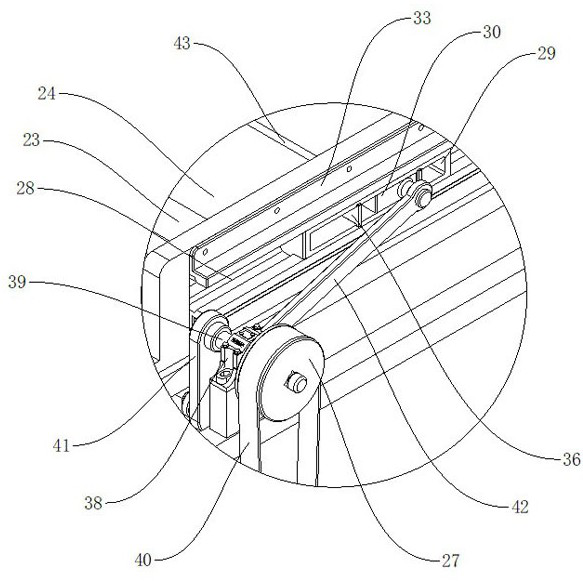

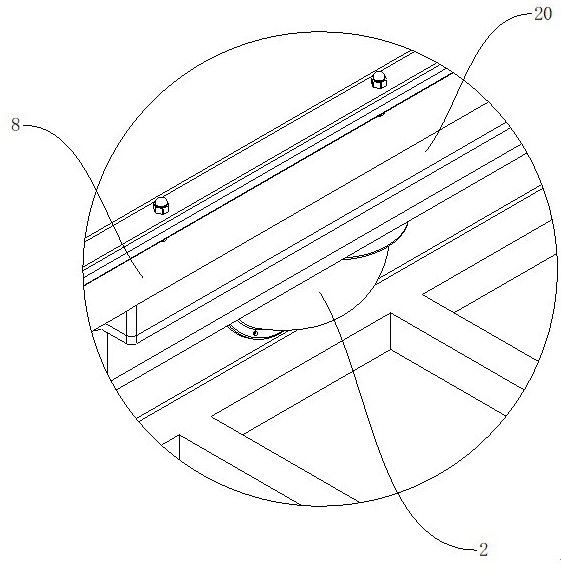

Intelligent continuous type oil press

PendingCN110328884AAutomatic and precise thickness adjustmentLow solidsFatty-oils/fats productionPressesUltrasonic sensorContinuous type

The invention discloses an intelligent continuous type oil press comprising a feeding mechanism, a pressing cage, a screw shaft, a cake correcting mechanism, an oil-refuse separating mechanism, a PLCcontrol cabinet and a machine frame. The material outlet end of the feeding mechanism communicates with a feeding opening of the pressing cage. The screw shaft is composed of a plurality of pressing bolts. The screw shaft is matched with the pressing cage. One end of the screw shaft is connected with a drive device, and the other end of the screw shaft is connected with the cake correcting mechanism. The oil-refuse separating mechanism is located below the pressing cage and provided with a vertical conveyer communicating with the feeding opening on the pressing cage. The pressing cage, the screw shaft and the oil-refuse separating mechanism are installed on the machine frame. The feeding mechanism, the transmission device, the cake correcting mechanism and the oil-refuse separating mechanism are all connected with the PLC control cabinet. The intelligent continuous type oil press has the beneficial effects that the functions of automatic feeding, automatic spiral pressing, automatic cake adjusting and automatic back pressing are integrated; the feeding mechanism is composed of a material suction machine, an ultrasonic sensor and an atomizer, automatic feeding and material stoppingcan be achieved, and the humidity and temperature of oil materials can be adjusted.

Owner:OIL CROPS RES INST CHINESE ACAD OF AGRI SCI

High-frequency electric-heating rolling strip

InactiveCN103369742AOvercome methodOvercome structureOhmic-resistance electrodesPressesEngineeringAlternating current

Owner:KUNSHAN YURONG ELECTRONICS +1

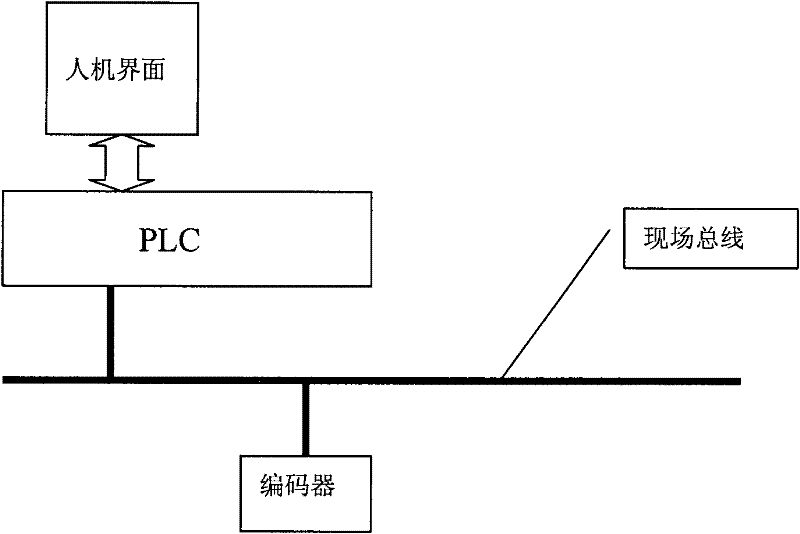

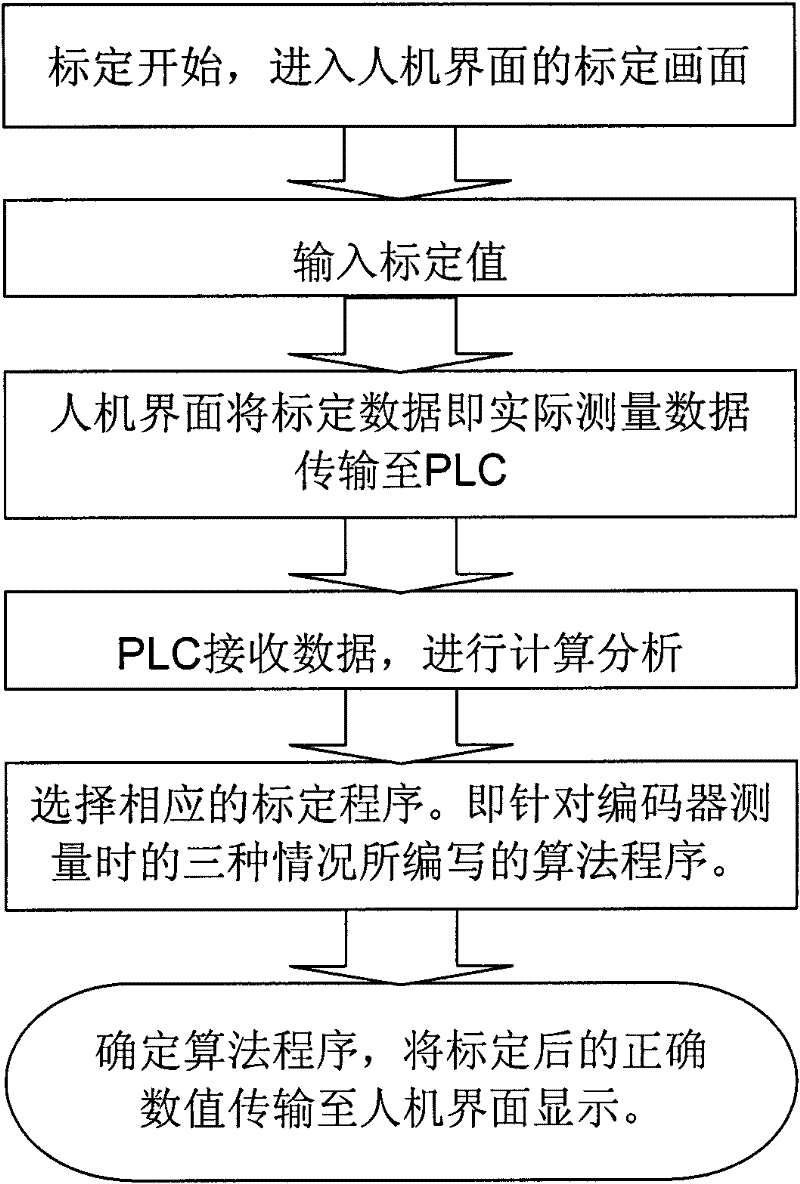

Mold feeding height measurement calibration method of pressing machine

Owner:YANGLI GRP CORP LTD

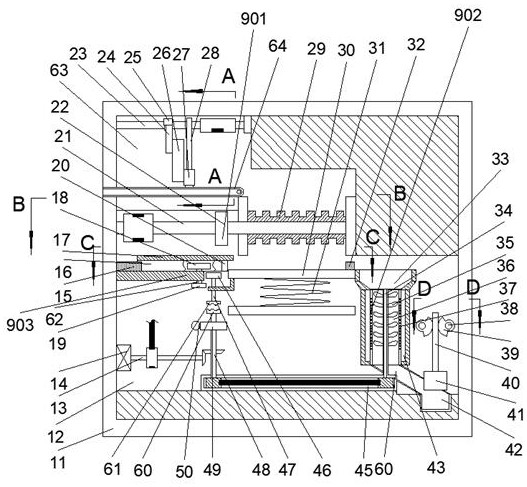

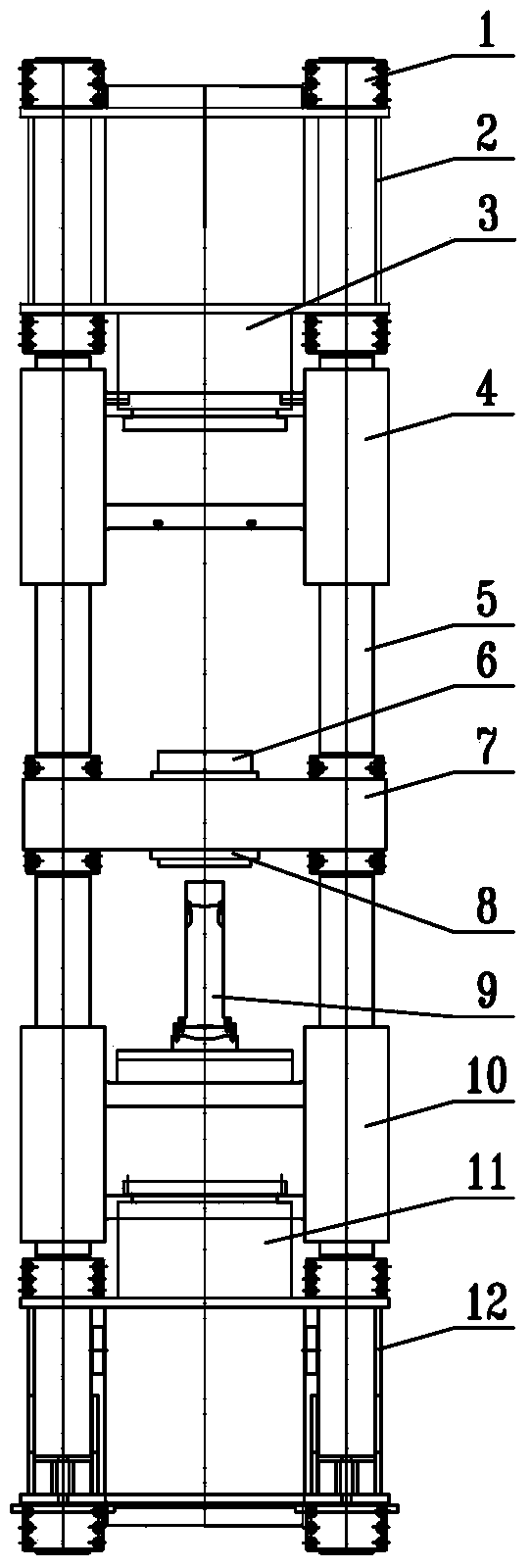

Exhaust gas discharge device for hydraulic press for interior part of high-speed multiple unit train

InactiveCN109228495AAvoid pollutionEasy to switchDirt cleaningPressesHydraulic cylinderControl engineering

The invention belongs to the technical field of high-speed multiple unit train interior-part hydraulic presses, and discloses an exhaust gas discharge device for a hydraulic press for an interior partof a high-speed multiple unit train. The device includes an exhaust hood and four baffles, the exhaust hood is installed at the upper end of a hot press body through a bracket, the hot press body includes a lower cross beam and an upper cross beam, the lower cross beam and the upper cross beam are fixedly connected through four sets of symmetrically arranged stand columns, a hydraulic cylinder isarranged on the upper cross beam, one end of a piston rod of the hydraulic cylinder is fixedly connected with the symcenter of the upper end of an upper die body, an operation platform is arranged onthe upper portion of the lower cross beam, the four baffles are symmetrically arranged on the outer sides of the hot press body, the upper ends of the baffles are hinged to one side of the upper cross beam, the lower ends of the baffles are provided with operation doors, and the upper end of the exhaust hood is symmetrically provided with two first air pipes.

Owner:HEFEI HAIDE HYDRAULIC PRESS

Garbage compressing method for environmental protection

InactiveCN110978596AImprove sufficiencyImprove convenienceDispersed particle separationGrain treatmentsHydraulic cylinderElectric machine

Owner:天门市怡田饮品科技有限公司

Device capable of separating and recycling metal filings and cutting oil

InactiveCN111992291AFully processedTake advantage ofSolid waste disposalGrain treatmentsMetal stripsThermodynamics

Owner:SHANGYU ZHONGTAI MEDICAL TECH

Stamping process for large-table-board stamping device of metal sheet stamping and cutting automation equipment

Owner:LUOYANG YOUNENG AUTOMATION EQUIP CO LTD

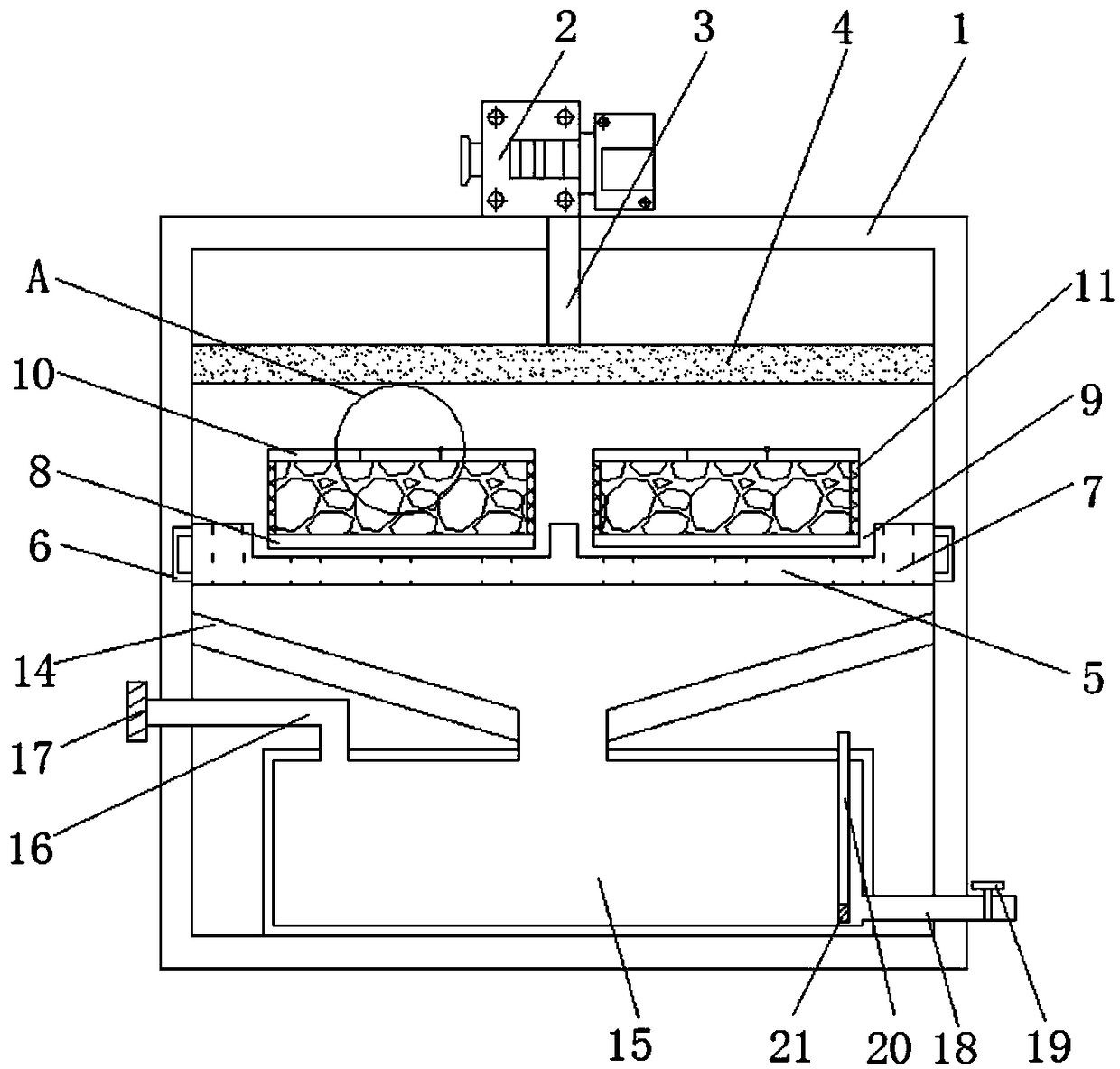

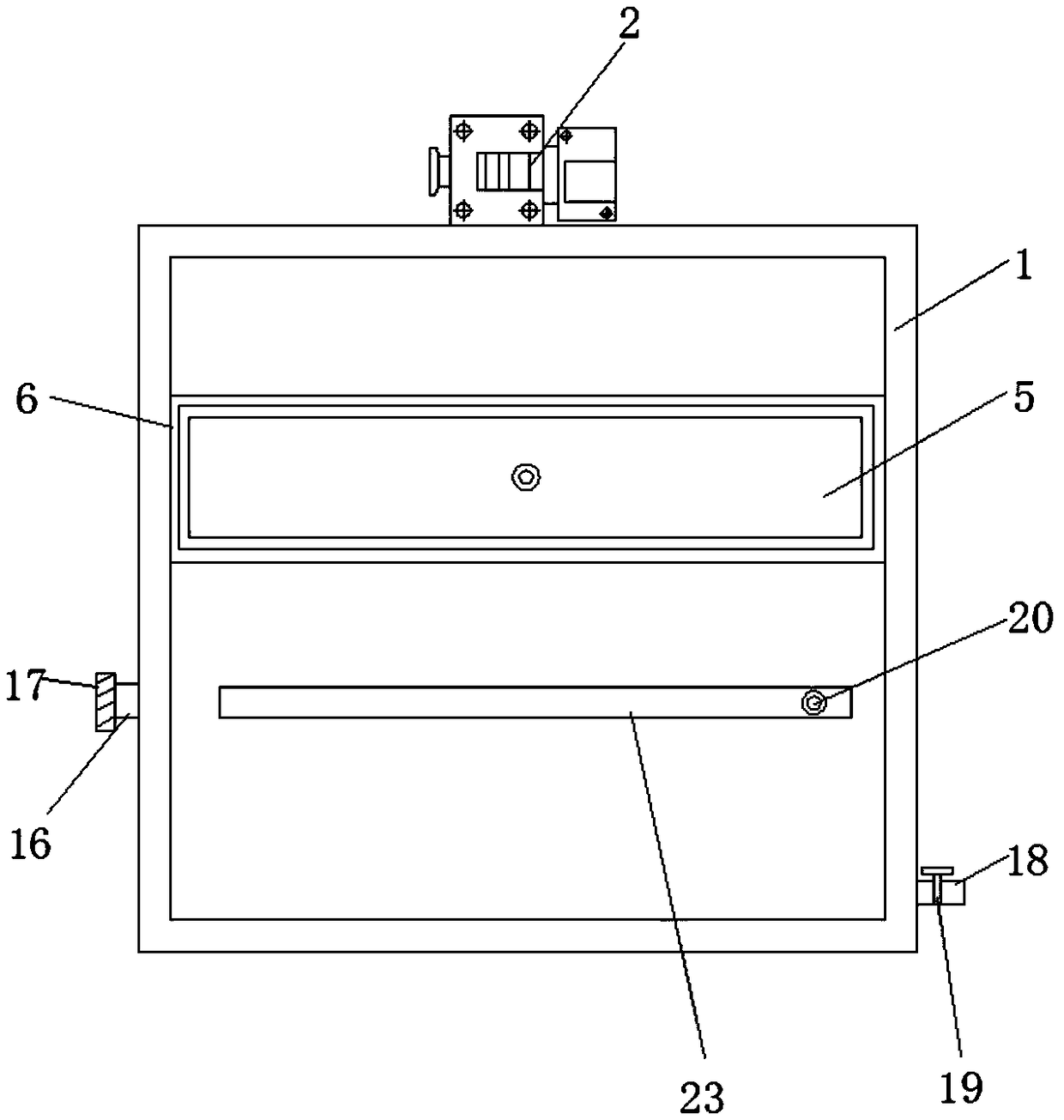

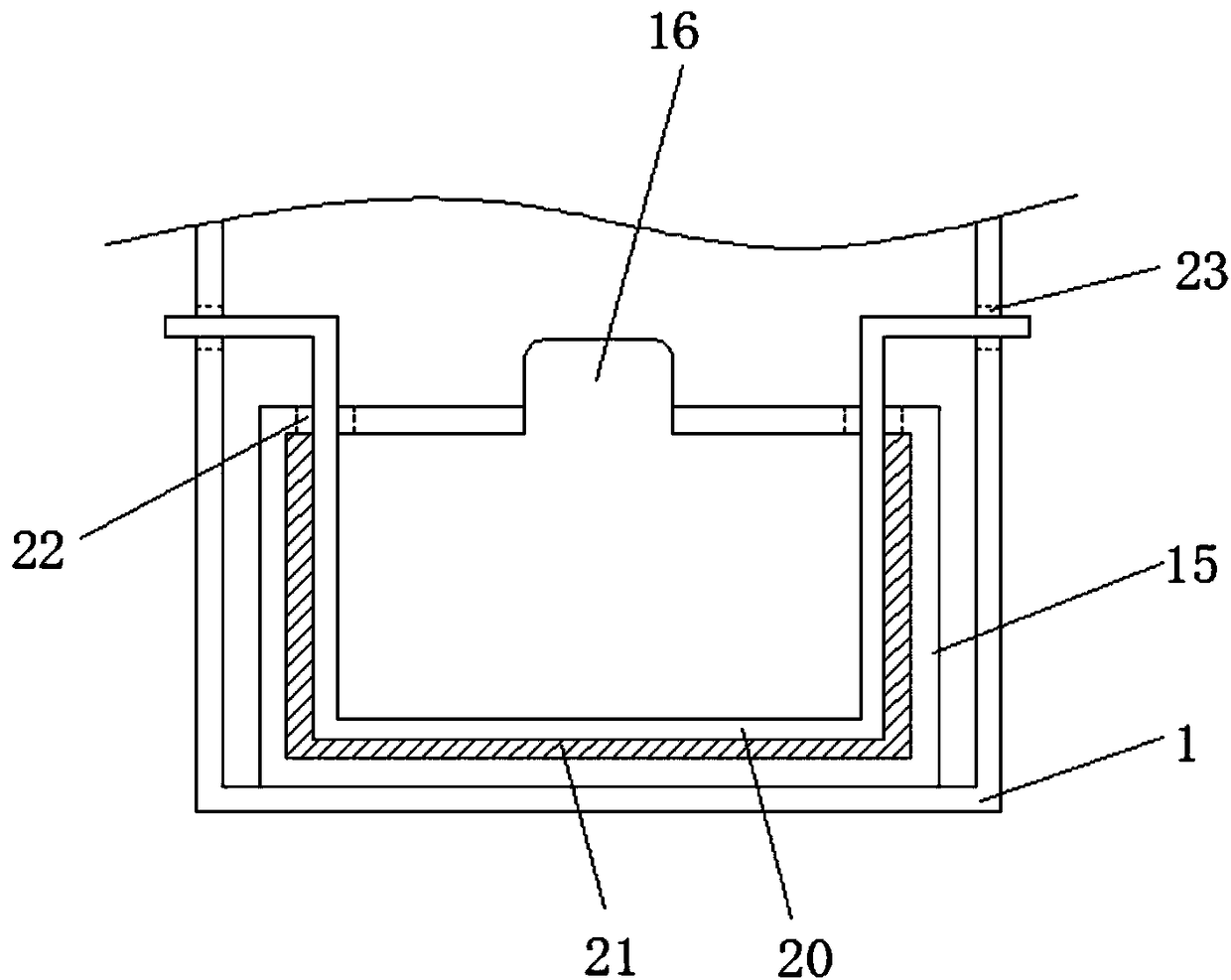

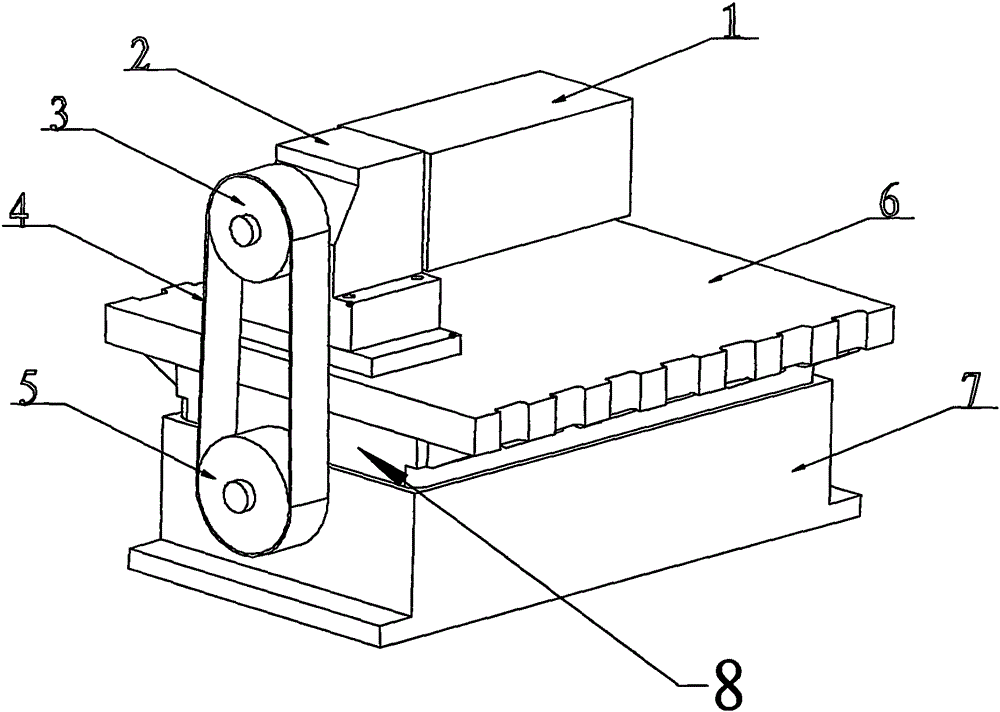

Screw propelling type high-pressure solid-liquid separation machine

PendingCN110667163AAvoid stuck conditionsSimple processing technologyPressesMechanical engineeringDehydration

The invention puts forward a screw propelling type high-pressure solid-liquid separation machine. A screw extrusion propelling rod is longitudinally mounted in a protection cover of the separation machine; a screen is mounted on the periphery of the screw extrusion propelling rod; the screen is fixedly connected with the protection cover through a screen reinforcing frame; the screw extrusion propelling rod is divided into two discontinuous sections; a through shaft of the screw extrusion propelling rod is sleeved with a plurality of replaceable loose-joint shaft sleeves; and a secondary extrusion section of the screw extrusion propelling rod and the plurality of replaceable loose-joint shaft sleeves can be taken down from the through shaft to change positions. The problems that blockage of materials is caused easily due to the fact that the section of the screw extrusion propelling rod and the section of the protection cover are changed from big to small, the equipment loss is high during extrusion, the damage caused by the materials to the screen is high during extrusion and equipment is required to be maintained frequently in the prior art are solved. According to the screw propelling type high-pressure solid-liquid separation machine, the screw extrusion propelling rod and the protection cover adopt the non-variable-section design, a separation zone is designed for buffering, thus the energy consumption is lower, and the dehydration process is smoother.

Owner:HARBIN HUAMEI YIFENG COMPOUND MATERIALS

Die changing device of five-beam-four-column power press equipment lower punch

Owner:HEFEI METALFORMING MACHINE TOOL

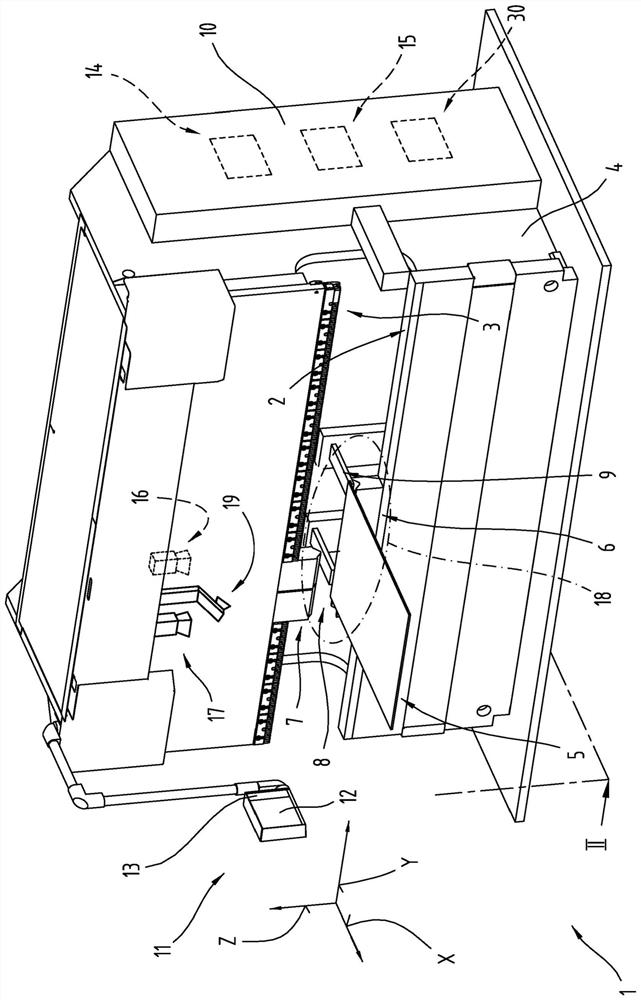

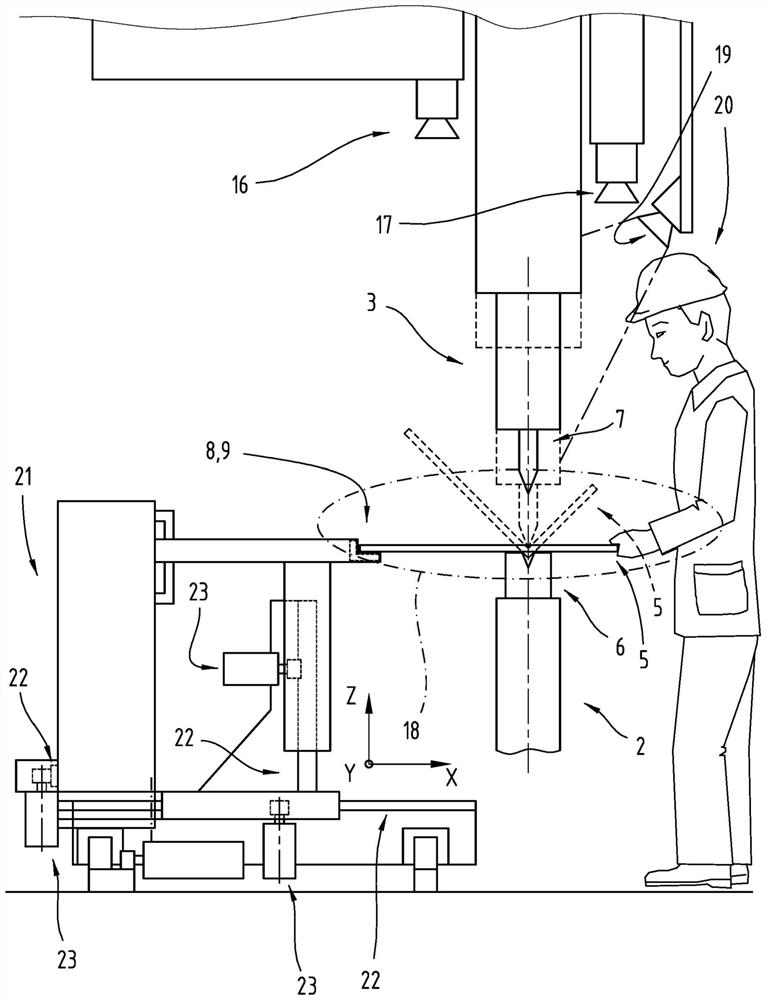

Method for operating a bending machine

Owner:TRUMPF MASCHEN AUSTRIA

Upper die for oil press

Owner:无锡国电华新起重运输设备有限公司

Extruding machine facilitating adjusting compression strength

Owner:PUJIANG JISHU MASCH TECH CO LTD

Combined mold for producing electric wire rack

Owner:天津帅通科技发展有限公司

Waste chip recovery lathe for practice teaching

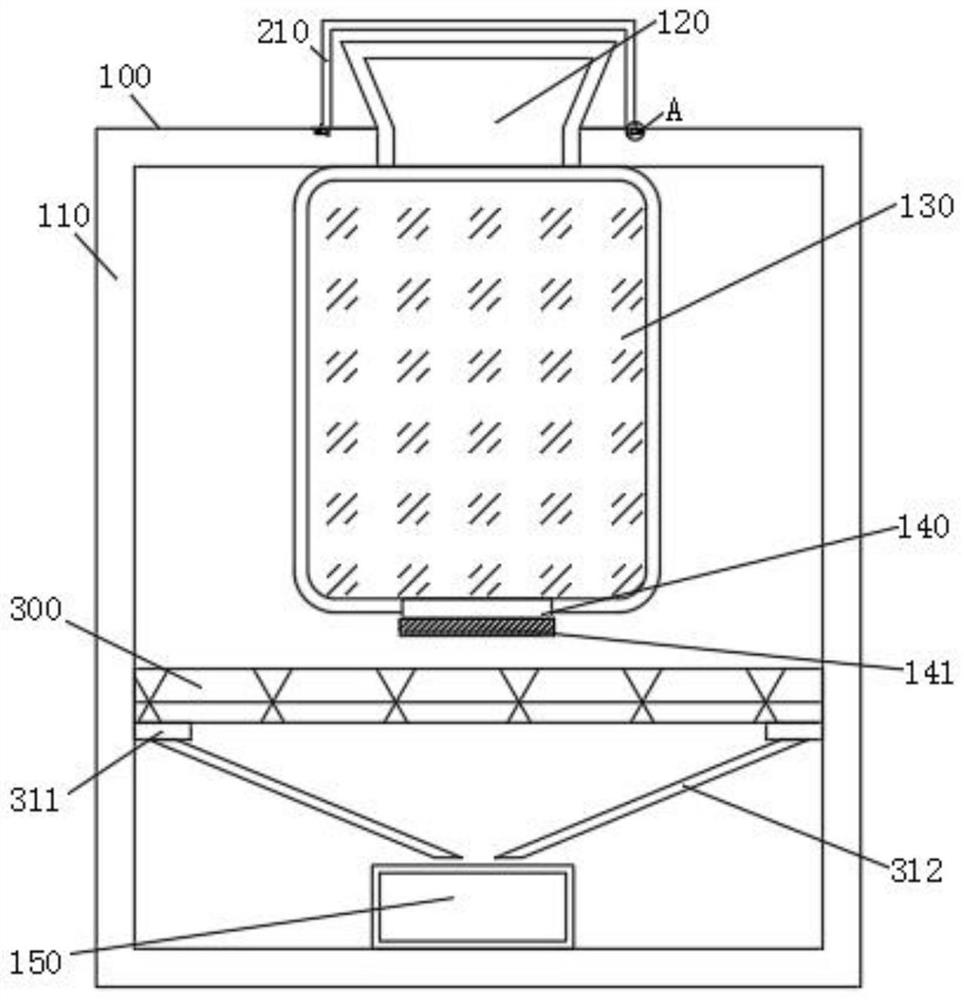

InactiveCN111805295AProtect personal safetyHands-on sessions are convenient and safeMaintainance and safety accessoriesPressesStructural engineeringCoursework

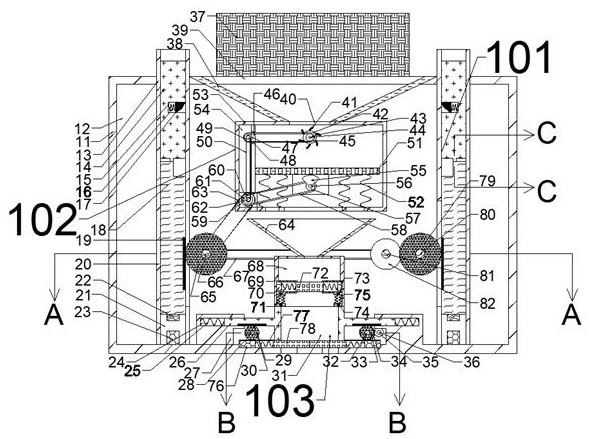

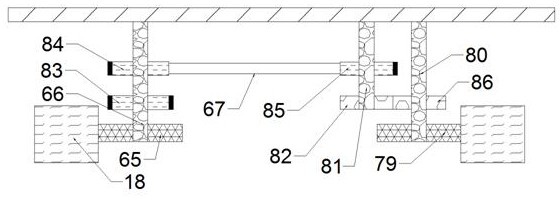

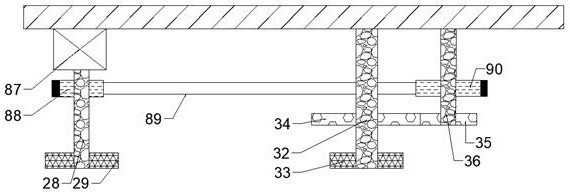

The invention discloses a waste chip recovery lathe for practice teaching. The waste chip recovery lathe for practice teaching comprises a box body, an empty bin is arranged in the box body, a safetyguarantee mechanism is arranged in the empty bin, the safety guarantee mechanism comprises two safety boxes, the two safety boxes are symmetrical left and right by taking the center line of the emptybin as the center, the safety boxes are fixedly connected to the inner wall of the lower side of the empty bin, and the upper ends of the safety boxes extend to the outer space. According to the wastechip recovery lathe for practice teaching, when a student carries out lathe machining practice, a barrier can be unfolded to protect the student, waste chips are prevented from flying into the eyes of the student or scalding the skin of the student, and the personal safety of the student is guaranteed; and the novel lathe can automatically collect the waste chips generated in the lathe machiningprocess and conduct packaging treatment, so that cleaning machining of the lathe is improved, and then a practice course of the student is more convenient and safer.

Owner:福州鼓楼卓穆尼奥科技有限公司

Metal punching equipment

Owner:骆婧怡 +4

Dust treatment device for machining

InactiveCN112387752AEasy to handleEasy to filterRotary stirring mixersSolid waste disposalElectric machineEngineering

The invention relates to the field of machining, in particular to a dust treatment device for machining. The dust treatment device comprises a stirring cavity, wherein a stirring motor is mounted on the front side of the stirring cavity, a stirring shaft is mounted on the rear side of the stirring motor, first stirring pieces are arranged at the upper end and the lower end of the stirring shaft, adischarge tube is mounted on the lower side of the stirring cavity and arranged in a filter cavity; a filter screen plate is mounted at the bottom of the filter cavity, mounting plates are mounted onthe upper side of the filter cavity, a bidirectional threaded rod is arranged between the mounting plates, slide plates are connected to the left and right ends of the bidirectional threaded rod, a first connecting rod is arranged on the lower side of the slide plate, a spray head is arranged at the lower side of the first connecting rod, a connecting slide slot is formed outside the first connecting rod; a second one-way threaded rod is mounted inside the connecting slide slot, a slide block is in threaded connection to the second one-way threaded rod, the lower side of the slide block is connected to the connecting groove through a second connecting rod, and an extrusion plate is arranged on the inner side of the connecting groove. The dust treatment device can conveniently perform extrusion molding treatment on dust, and is convenient for use of the equipment.

Owner:李存贺

Vegetable oil squeezing device with dustproof structure

PendingCN111844880AImprove cleanlinessPress work fastFouling preventionPressesVegetable oilAgricultural engineering

Owner:湖南省康多利油脂有限公司

Dehydration device for pea starch production

ActiveCN114801289ATroubleshoot blocky appearanceImprove dehydration efficiencyGrain treatmentsPressesWater filterSpiral blade

Owner:优承生物科技(烟台)有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap