Device capable of separating and recycling metal filings and cutting oil

A technology of cutting oil and metal shavings, which is applied in the removal of solid waste, presses, grain processing, etc., can solve the problems of economic loss of cutting oil and high price of cutting oil, and achieve the goal of reducing economic loss and fully utilizing resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

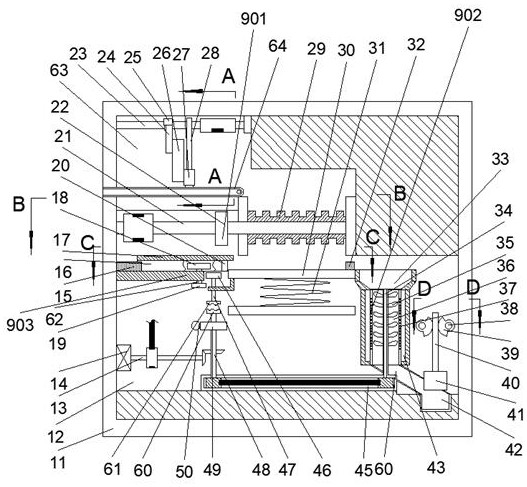

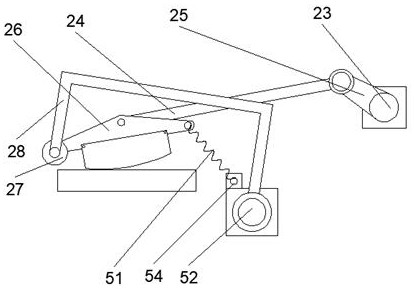

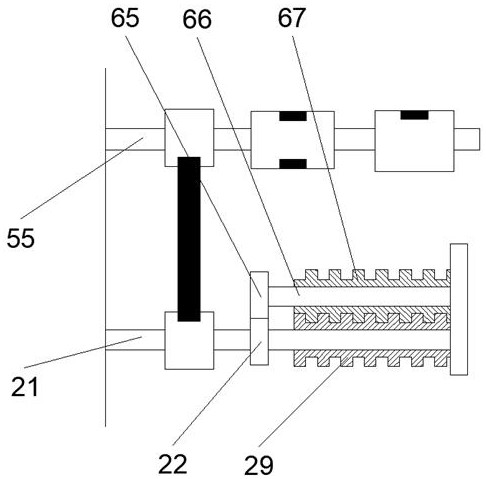

[0015] Combine below Figure 1-Figure 5 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0016] The invention relates to a device capable of separating and recovering metal scraps from cutting oil, which is mainly used for separating and recycling metal scraps from cutting oil. The invention will be further described below in conjunction with the drawings of the invention: a device described in the invention A device capable of separating and recovering metal shavings from cutting oil, comprising a housing 11, the housing 11 is provided with a connecting chamber 12, and the upper side of the connecting chamber 12 is provided with a working chamber 63 communicating with it. A horizontal transmission shaft 21 is rotatably connected to the inner wall on the left side of th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap