Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

179 results about "Thermodynamics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermodynamics is the branch of physics that deals with heat and temperature, and their relation to energy, work, radiation, and properties of matter. The behavior of these quantities is governed by the four laws of thermodynamics which convey a quantitative description using measurable macroscopic physical quantities, but may be explained in terms of microscopic constituents by statistical mechanics. Thermodynamics applies to a wide variety of topics in science and engineering, especially physical chemistry, chemical engineering and mechanical engineering, but also in fields as complex as meteorology.

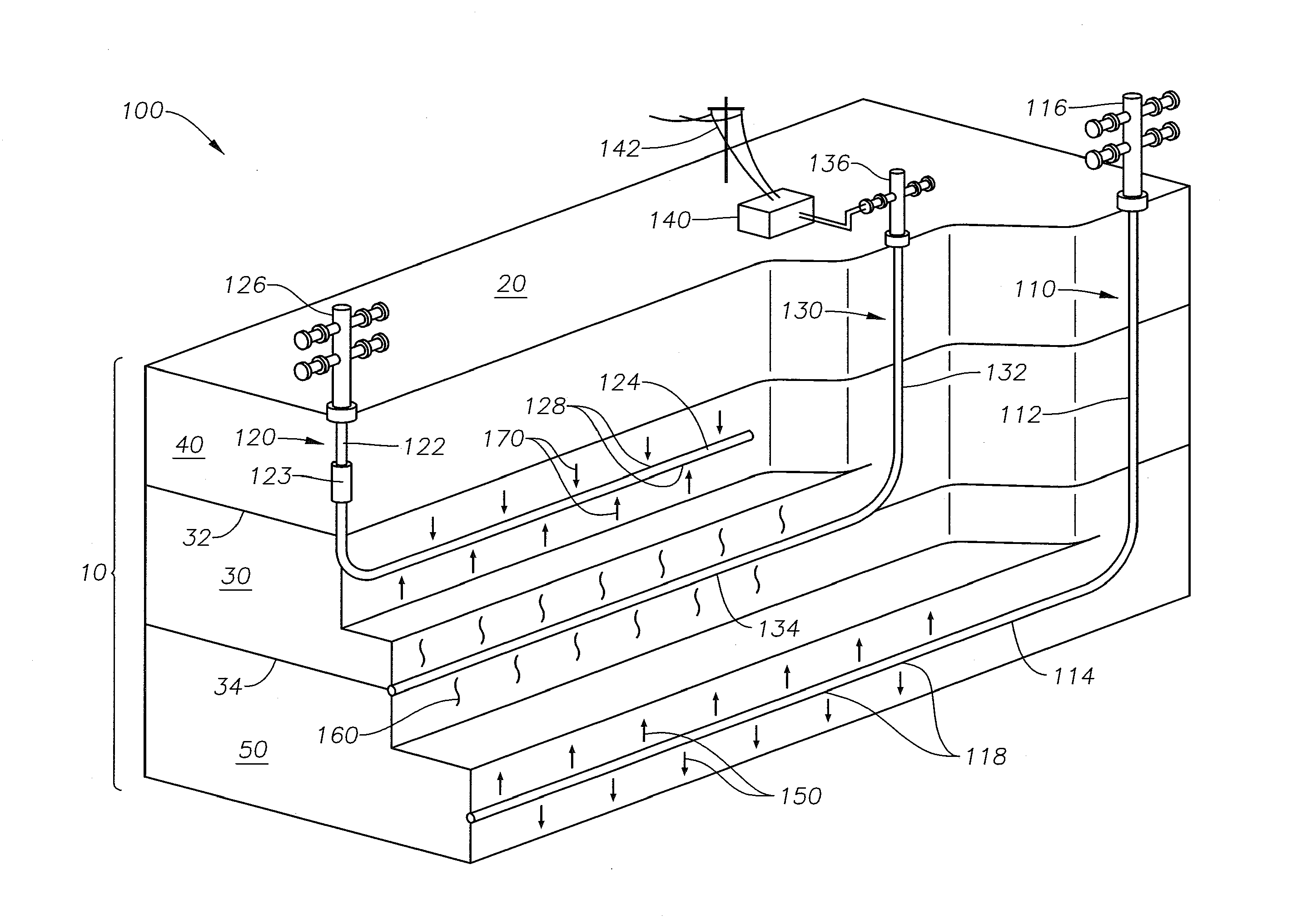

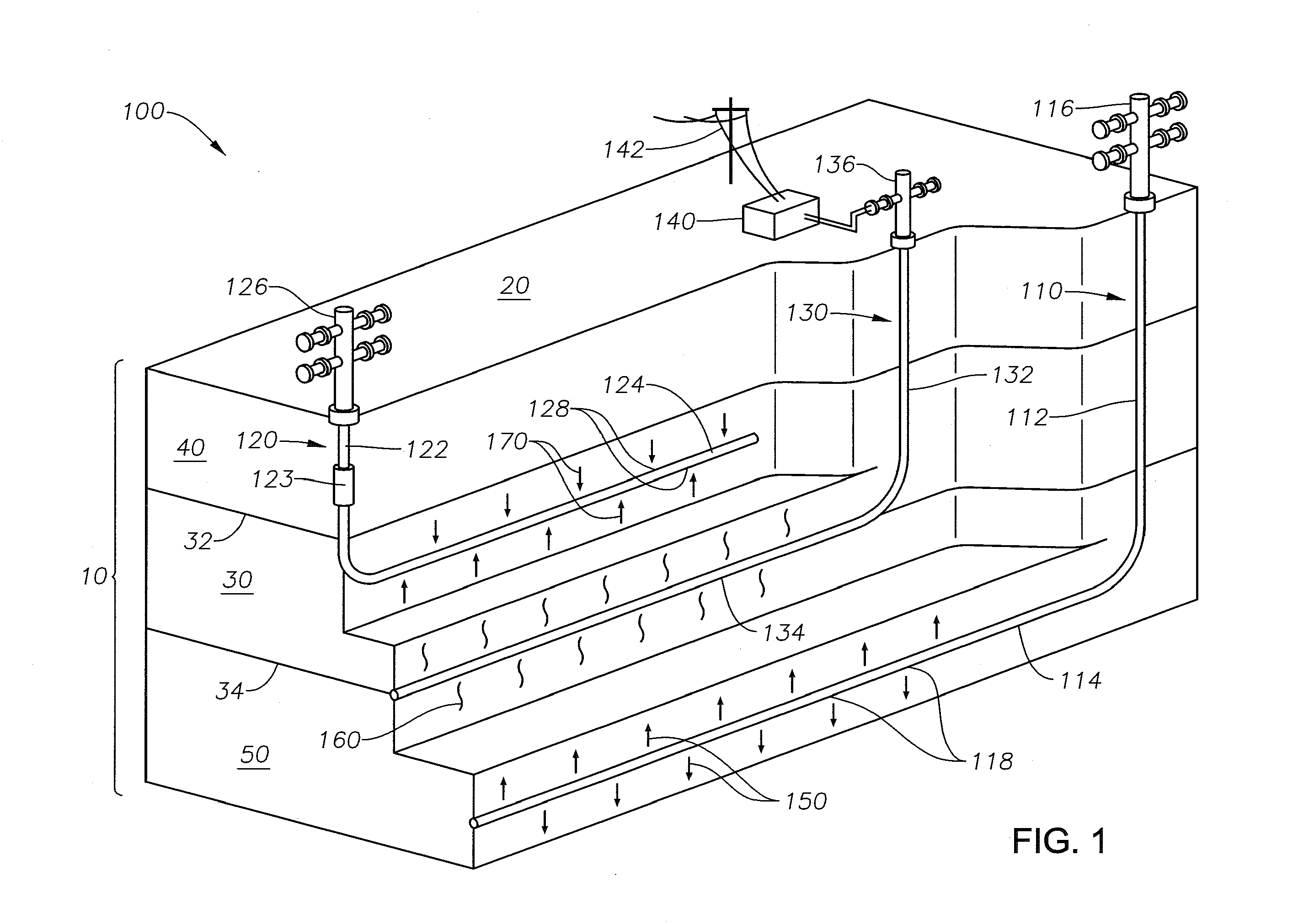

Utilization of microwave technology in enhanced oil recovery process for deep and shallow applications

ActiveUS20140027109A1Promote recoveryFluid removalDrilling compositionThermodynamicsHorizontal wells

Owner:SAUDI ARABIAN OIL CO

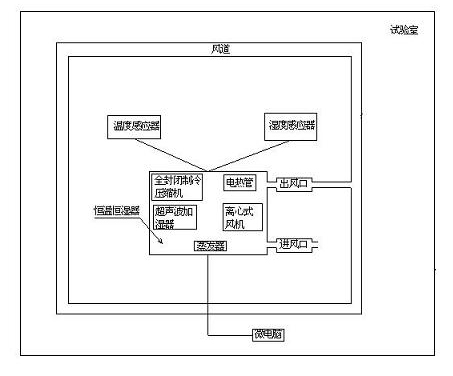

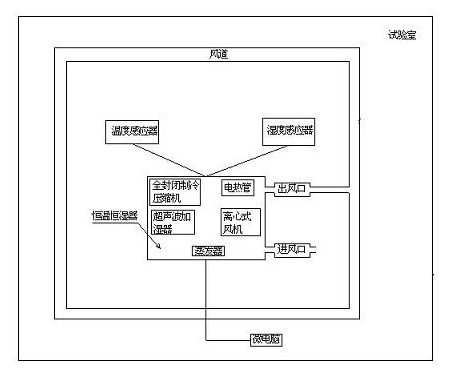

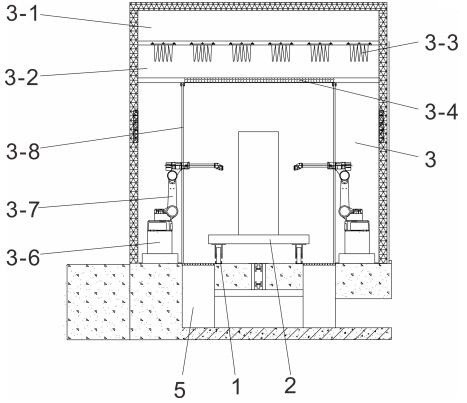

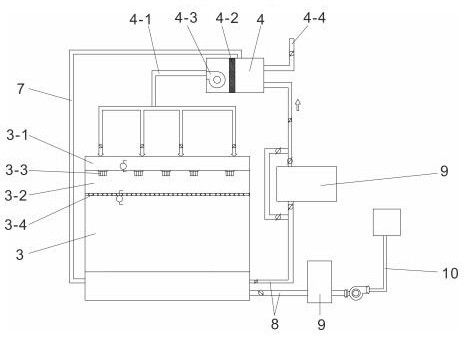

Concrete sample curing room

ActiveCN101947810AUniform temperatureUniform humidityCeramic shaping apparatusMicrocomputerThermodynamics

Owner:JSTI GRP INSPECTION & CERTIFICATION CO LTD

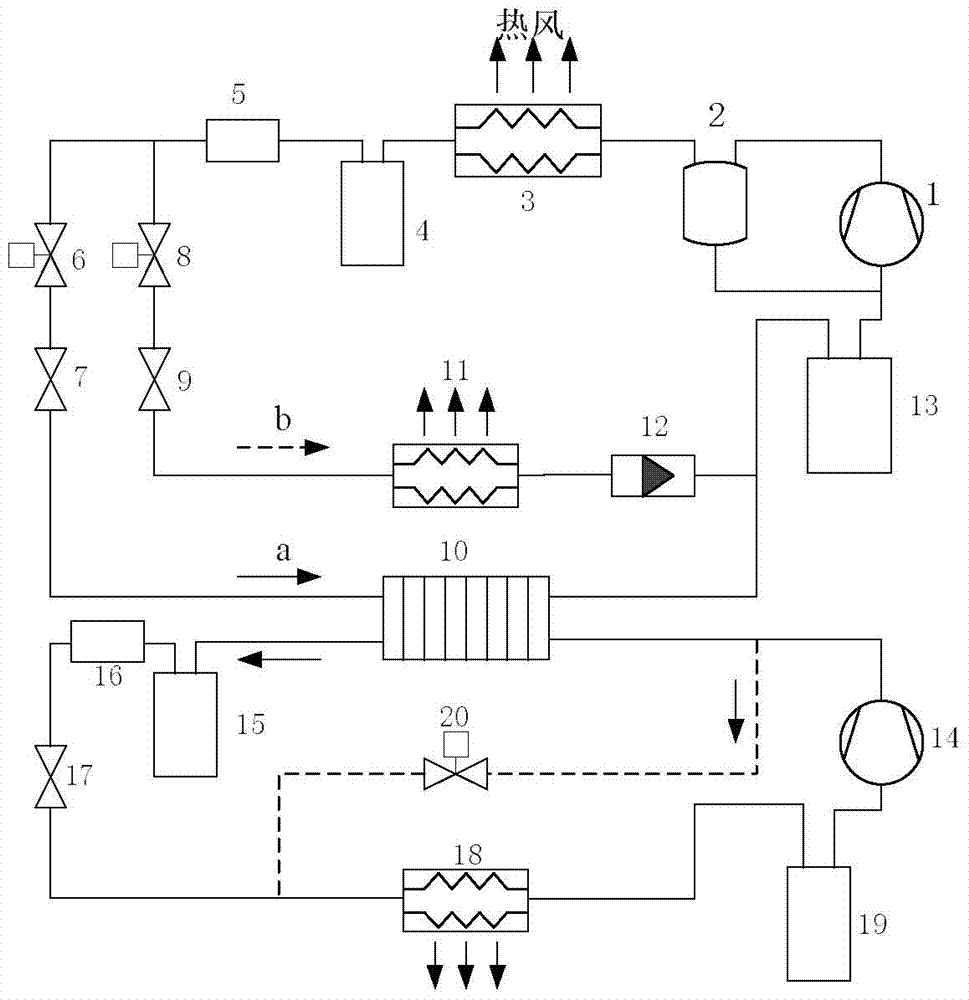

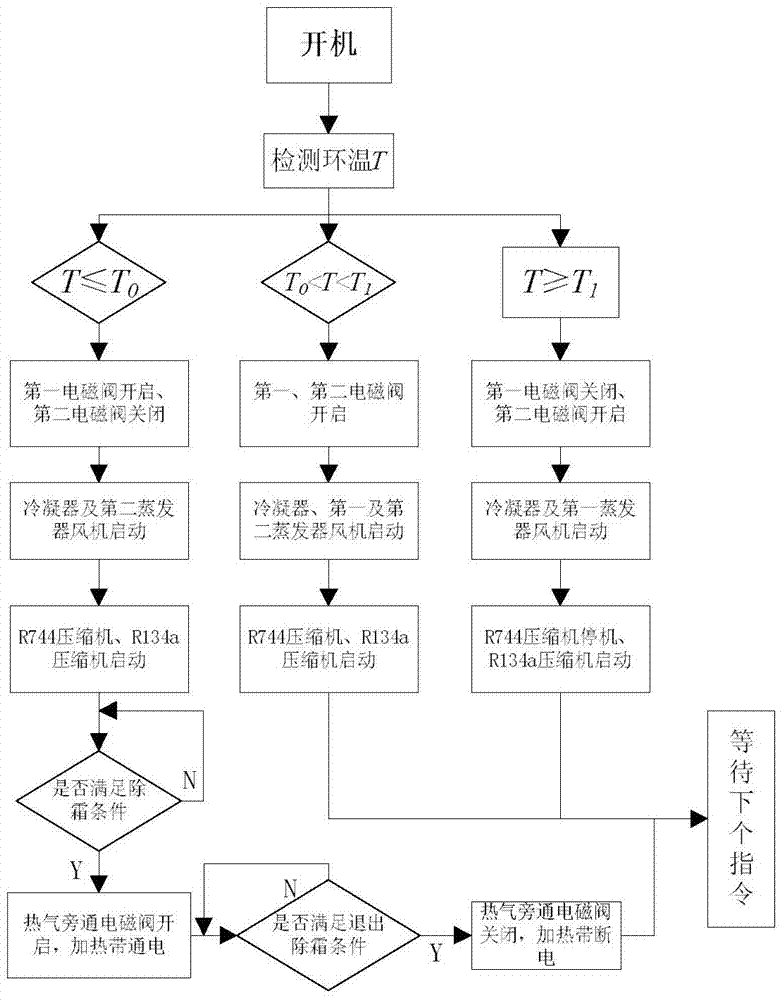

Cascade heat pump drying system and control method thereof

ActiveCN103940156AControl operationFulfil requirementsMechanical apparatusFluid circulation arrangementThermodynamicsRefrigerant

Owner:JIANGSU SUJING GROUP +1

Steam device and operation and use method thereof

PendingCN111472156ANormal use workIncrease flexibilityBatteries circuit arrangementsIroning apparatusThermodynamicsLiquid medium

The invention discloses a steam device and an operation and use method thereof. The method comprises the steps that a steam brush and a power supply seat are connected; the power supply seat suppliespower to a steam generator in the steam brush and heats the steam generator; meanwhile, a lithium battery in the steam brush is charged through the power supply seat; an indicating lamp indicates thatthe steam generator reaches prese temperature; the steam brush is taken off from the power supply seat and disconnected with the power supply seat; and a switch element on the steam brush is closed,power is supplied to a water pump in the steam brush through the lithium battery, a liquid medium is conveyed into the steam generator through the water pump, and the liquid medium is heated into steam through the steam generator. Due to the fact that the lithium battery is arranged in the steam brush, after the steam generator is heated to certain temperature, the steam brush can be divorced fromdependence on electric supply to complete normal use work, and the use flexibility is improved.

Owner:CUORI ELECTRICAL APPLIANCES GRP

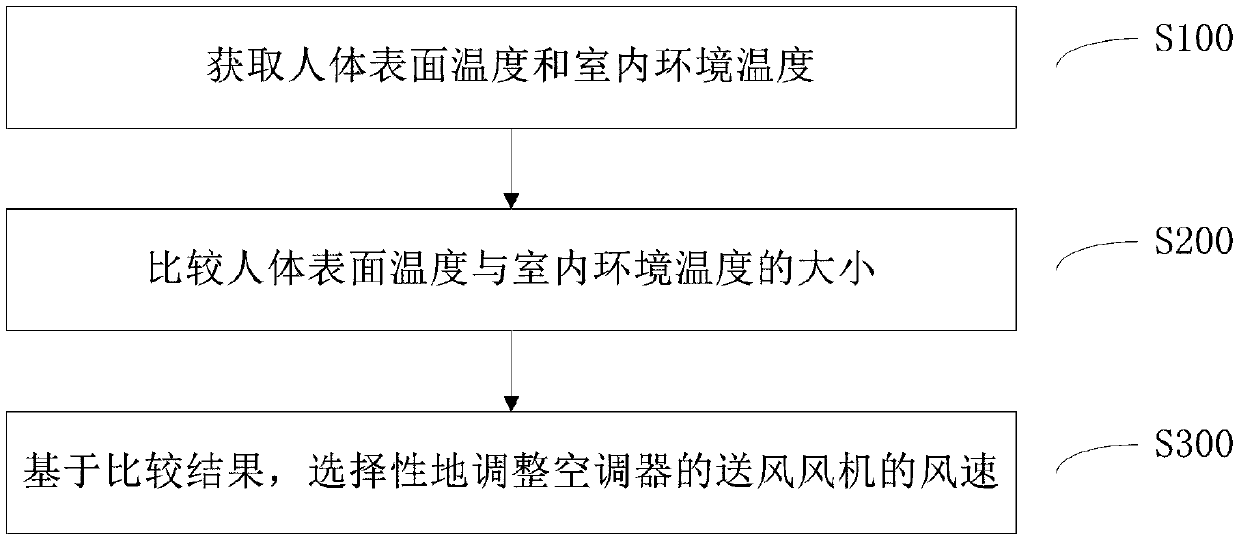

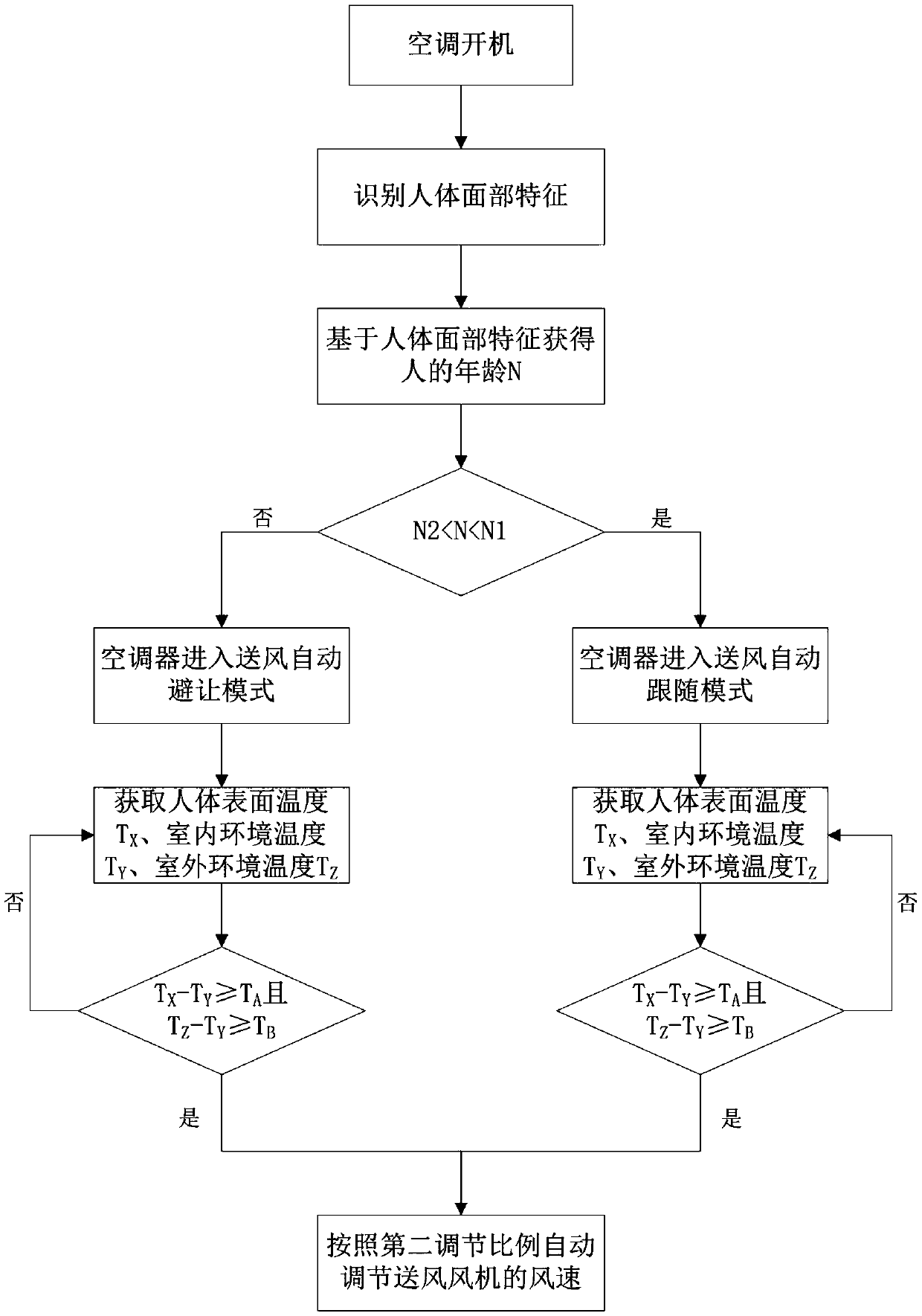

Control method of air conditioner and air conditioner

ActiveCN110887174AAdjust the wind speedImprove user experienceMechanical apparatusLighting and heating apparatusThermodynamicsAir velocity

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

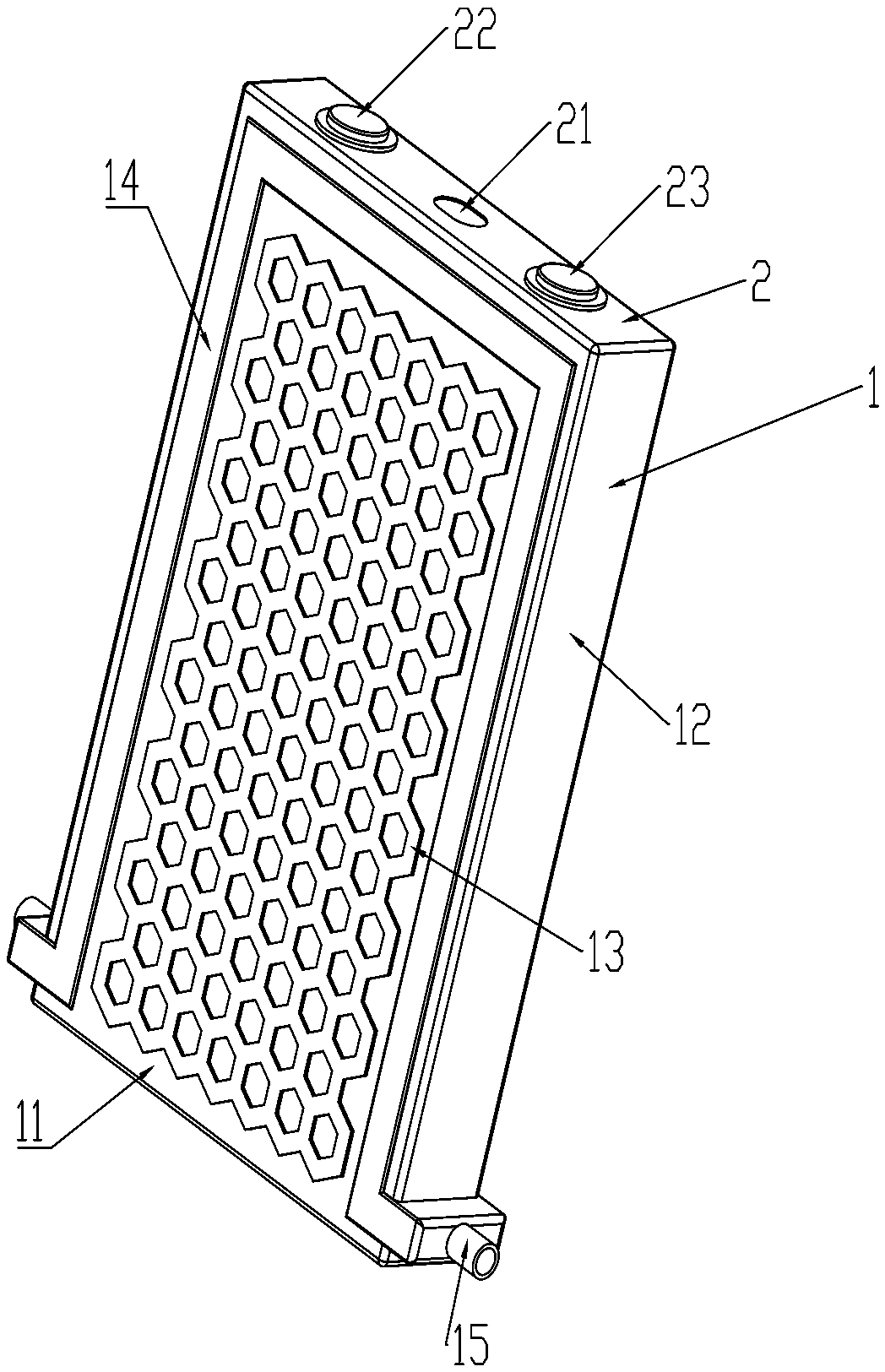

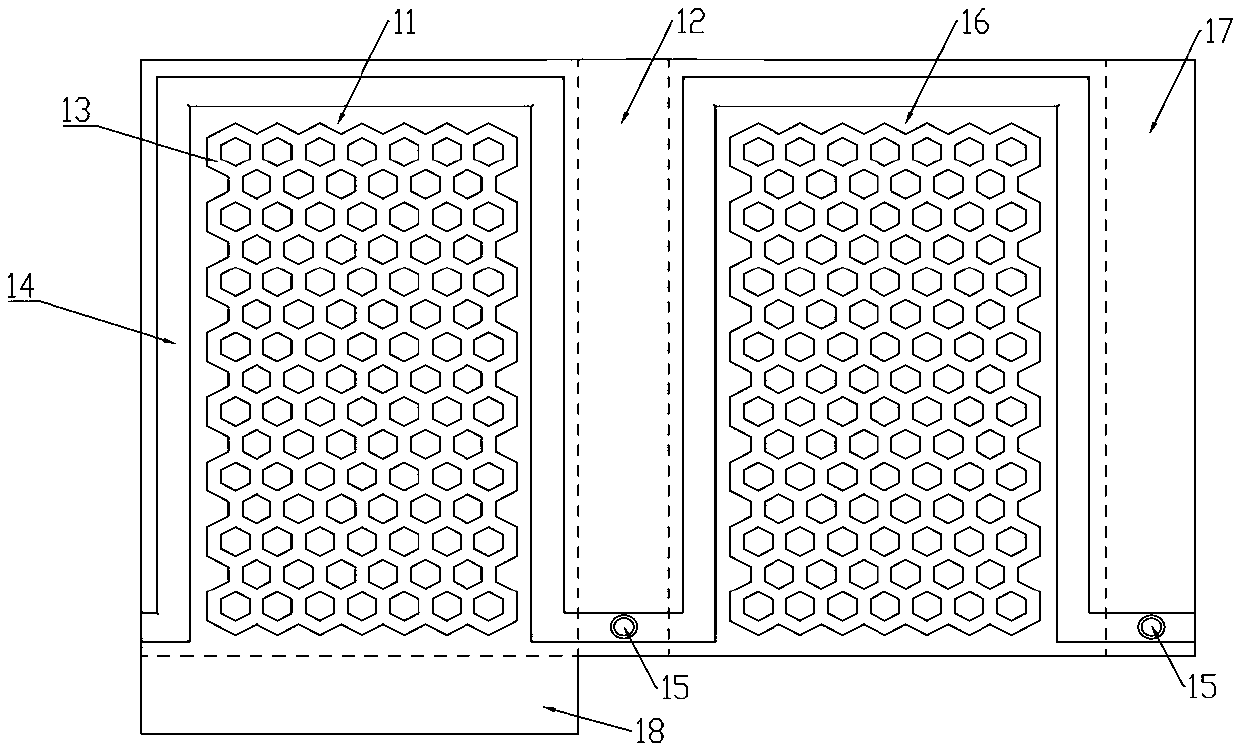

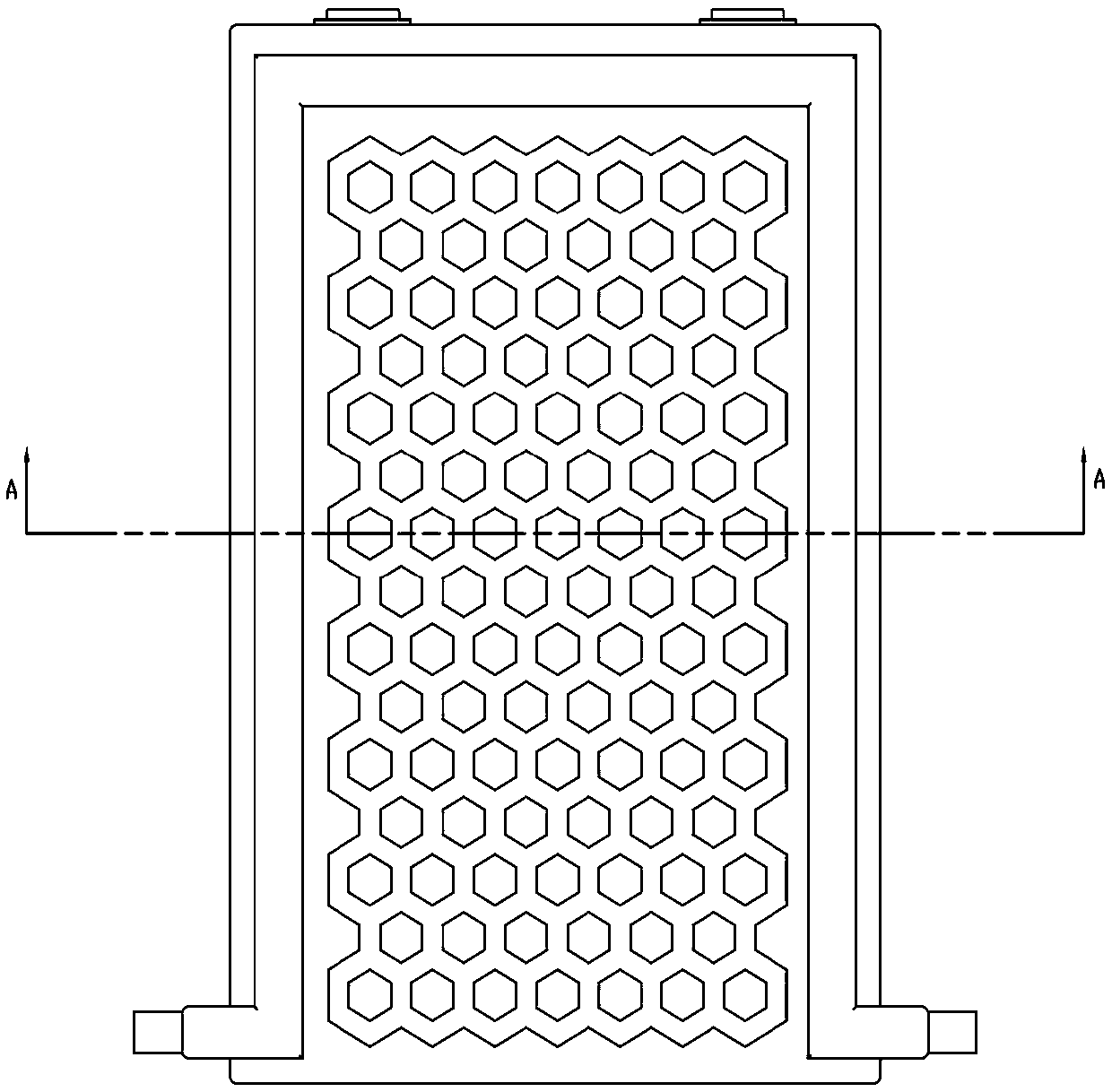

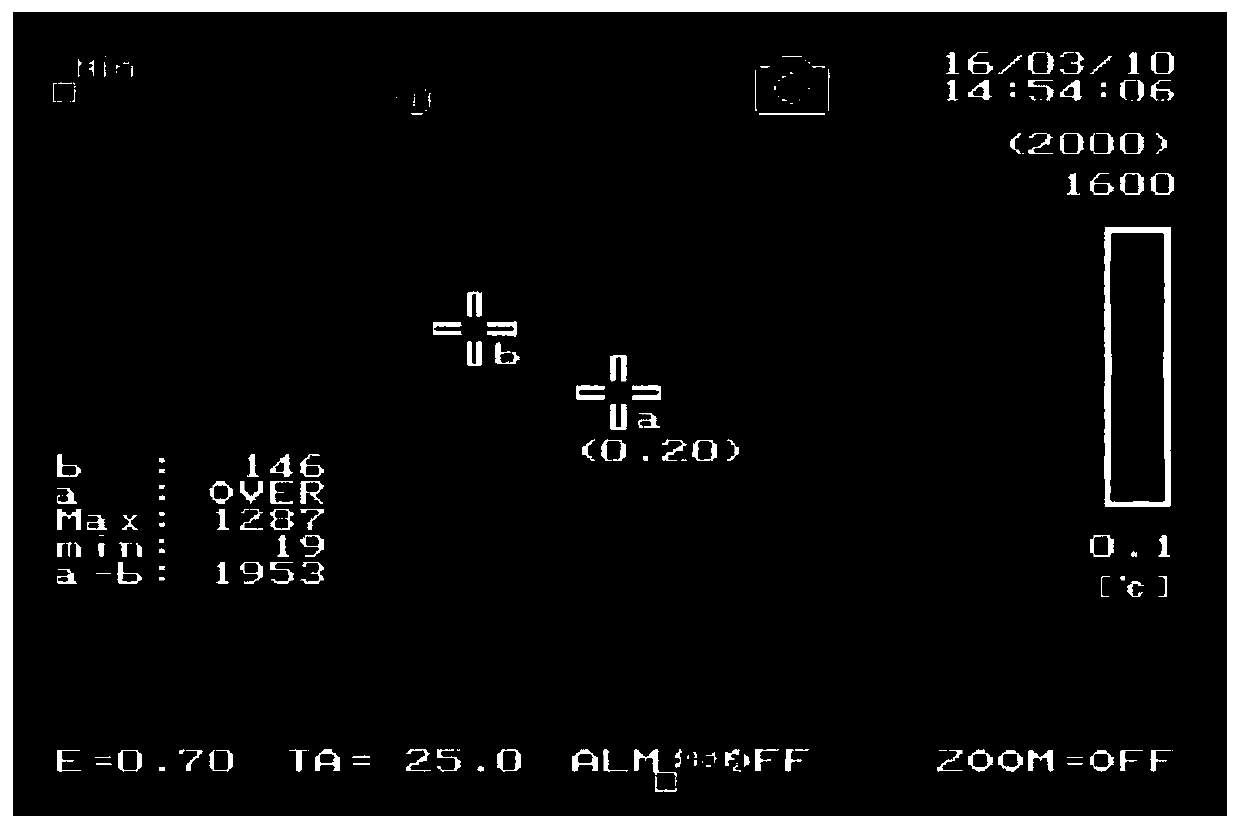

Lithium battery and lithium battery packaging housing

PendingCN111490186AMeet heat dissipation requirementsMeet the needs of efficient heat controlSecondary cellsJackets/cases materialsThermodynamicsEngineering

Owner:ZHEJIANG JIAXI TECH CO LTD

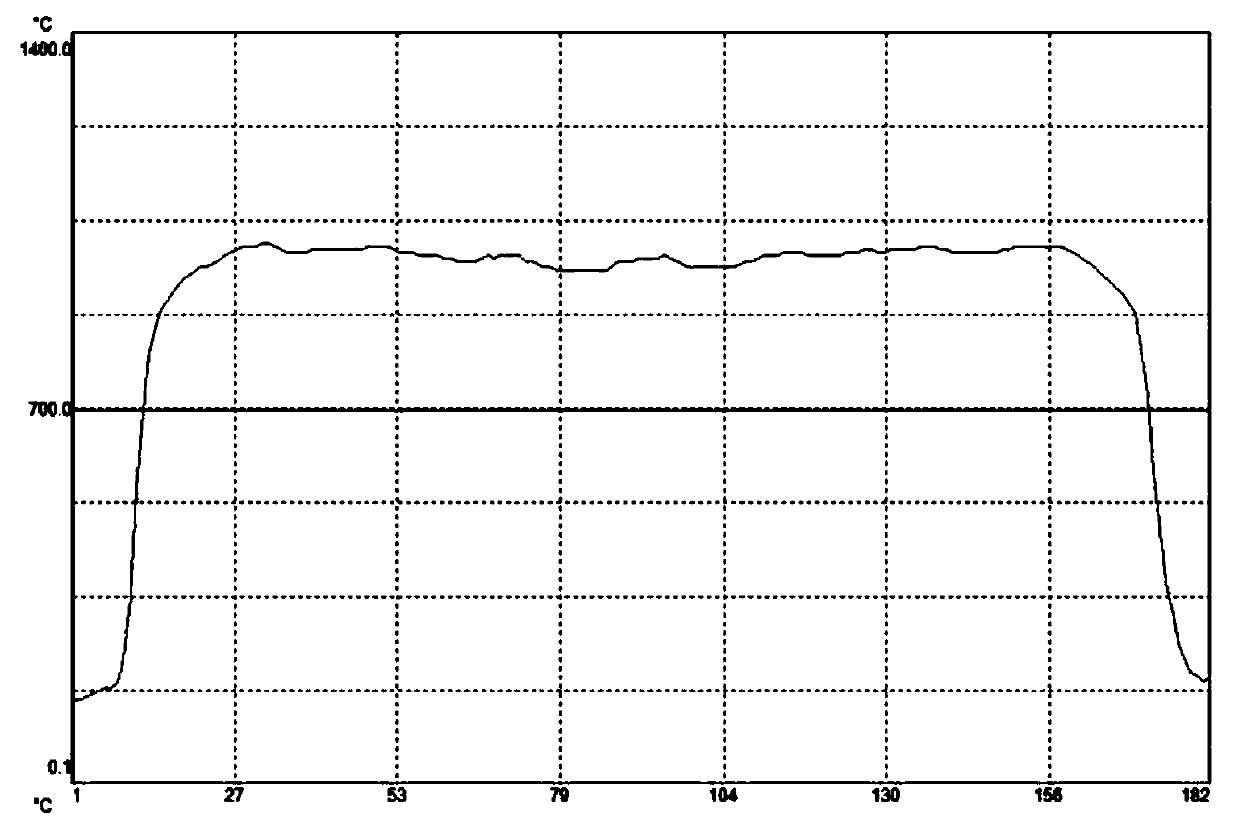

Method for evaluating temperature uniformity in width direction of hot-rolled strip steel intermediate billet

Owner:MAANSHAN IRON & STEEL CO LTD

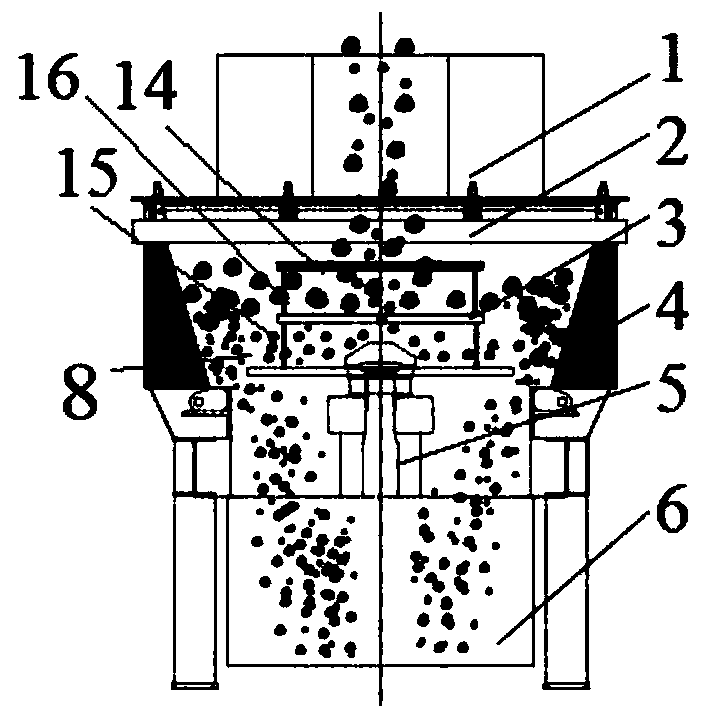

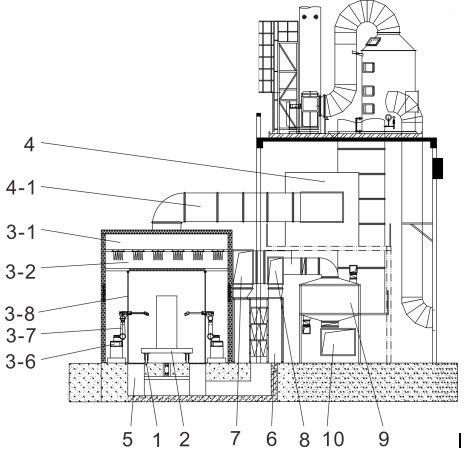

Open type absorption heat pump-MVR technology coupled closed cycle drying system

ActiveCN111947443AReduce trafficReduce the risk of entrainmentEnergy efficient heating/coolingClimate change adaptationThermodynamicsEngineering

The invention discloses an open type absorption heat pump-MVR technology coupled closed cycle drying system which comprises an open type absorption heat pump system and a mechanical compression heat pump cycle system. An outlet of a mechanical heat pump compressor is divided into two paths, one path is in pipeline connection with a hot channel inlet of a heat removal device through a hot channel of a condenser, and the other path is in pipeline connection with the hot channel inlet of the heat removal device through a 2# heat and mass exchanger; and a hot channel outlet of the heat removal device is connected with an expansion valve through a pipeline, an outlet of the expansion valve is divided into two paths, one path is in pipeline connection with an inlet of the mechanical heat pump compressor through a 1# heat and mass exchanger, the other path is in pipeline connection with the inlet of the mechanical heat pump compressor through a cold channel of an evaporator, and a mechanicalcompression type heat pump cycle system is formed. According to the open type absorption heat pump-MVR technology coupled closed cycle drying system, absorbed heat is used for regenerating a dilute solution through the mechanical compression type heat pump cycle system, regenerated steam is used for heating dry gas after the grade of the regenerated steam is improved through an MVR technology; andby means of the open type absorption heat pump-MVR technology coupled closed cycle drying system, a large amount of latent heat in damp and hot gas exhausted by a dryer can be reasonably utilized.

Owner:ZHEJIANG UNIV OF TECH +1

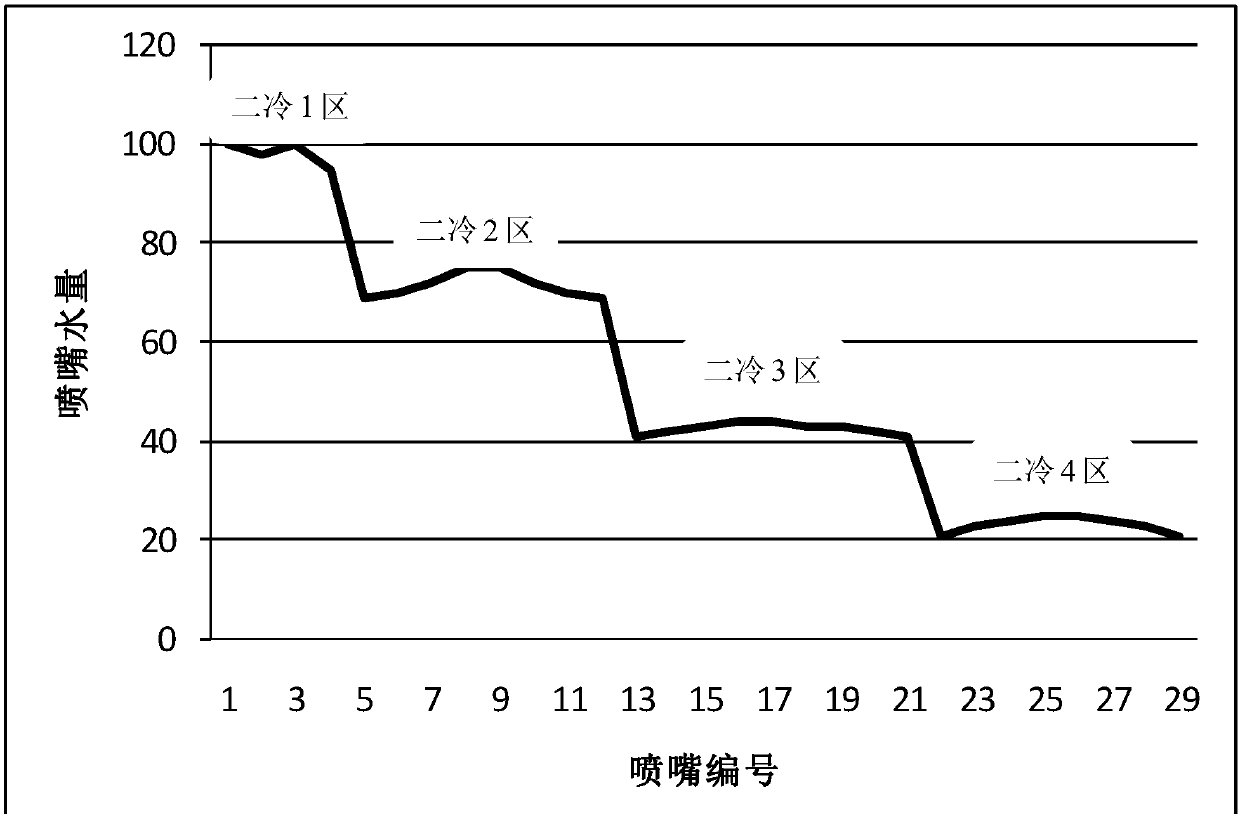

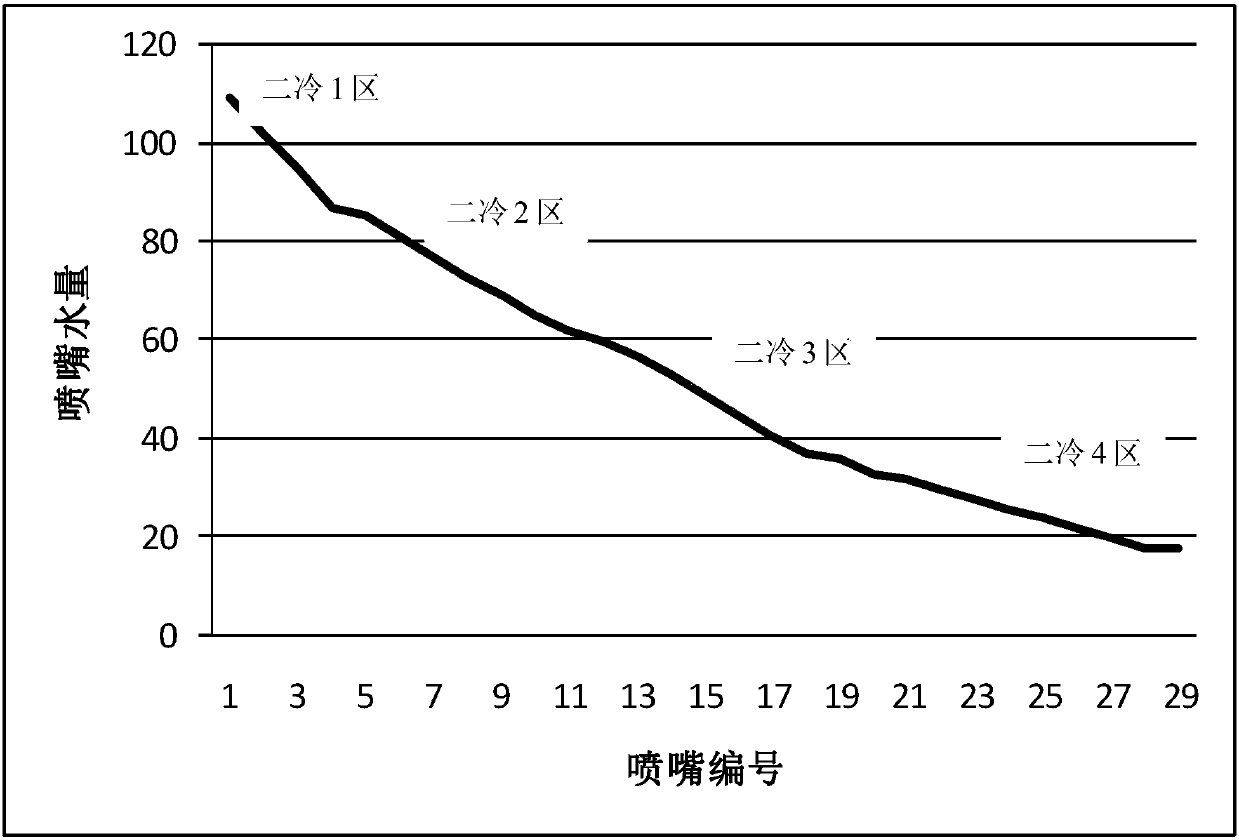

Secondary cooling method and device for continuous casting machine

PendingCN107737896AControl and regulate outflow flowImprove cooling uniformityThermodynamicsSpray nozzle

Owner:CISDI ENG CO LTD +1

Portable electric heating steam cleaning machine

ActiveCN111001604AWide range of cleaningImprove cleaning efficiencyCleaning using liquidsThermodynamicsProcess engineering

Owner:ZIBO JIAMING ENVIRONMENTAL SCI & TECHCO

Hydraulic power balance adjusting method and system for cells of heating unit

ActiveCN111811016ASame return water temperatureScientific and reasonable dynamic adjustment abilityData processing applicationsLighting and heating apparatusThermodynamicsEngineering

The invention discloses a hydraulic power balance adjusting method and system for cells of a heating unit. The return water temperature of the cells of the heating unit at the next moment is obtainedby carrying out deep learning training on historical sample data of the heating unit. By predicting the return water temperature of the cells of the heating unit at the next moment, the valve openingdegree of each cell can be adjusted in advance, so that the return water temperature of the cells is kept consistent, and the problems in the prior art that experts and field personnel need to carry out calculation and adjustment, and the valve opening degree of each cell cannot be adjusted in advance to enable the return water temperature of the cells to be kept consistent are solved. The returnwater temperature of each cell can be predicted in advance, the valve opening degree of each cell is adjusted in advance, the return water temperature of the cells are kept consistent, more scientificand reasonable dynamic adjusting capacity is provided, and the problem that normal production and life of a user are influenced by heat waste or insufficient heat supply due to unreasonable calculation and delayed adjustment is avoided.

Owner:RUINA INTELLIGENT EQUIP CO LTD

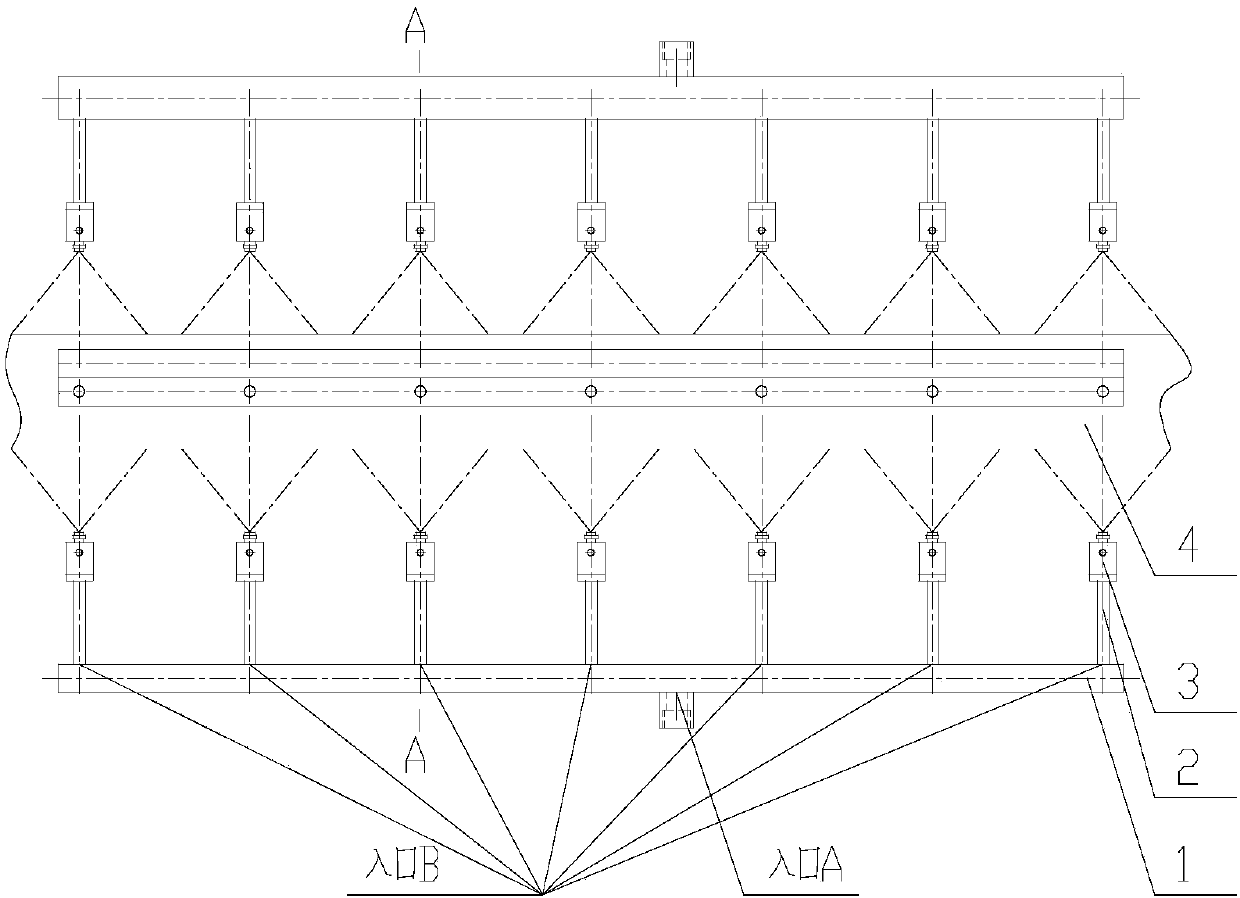

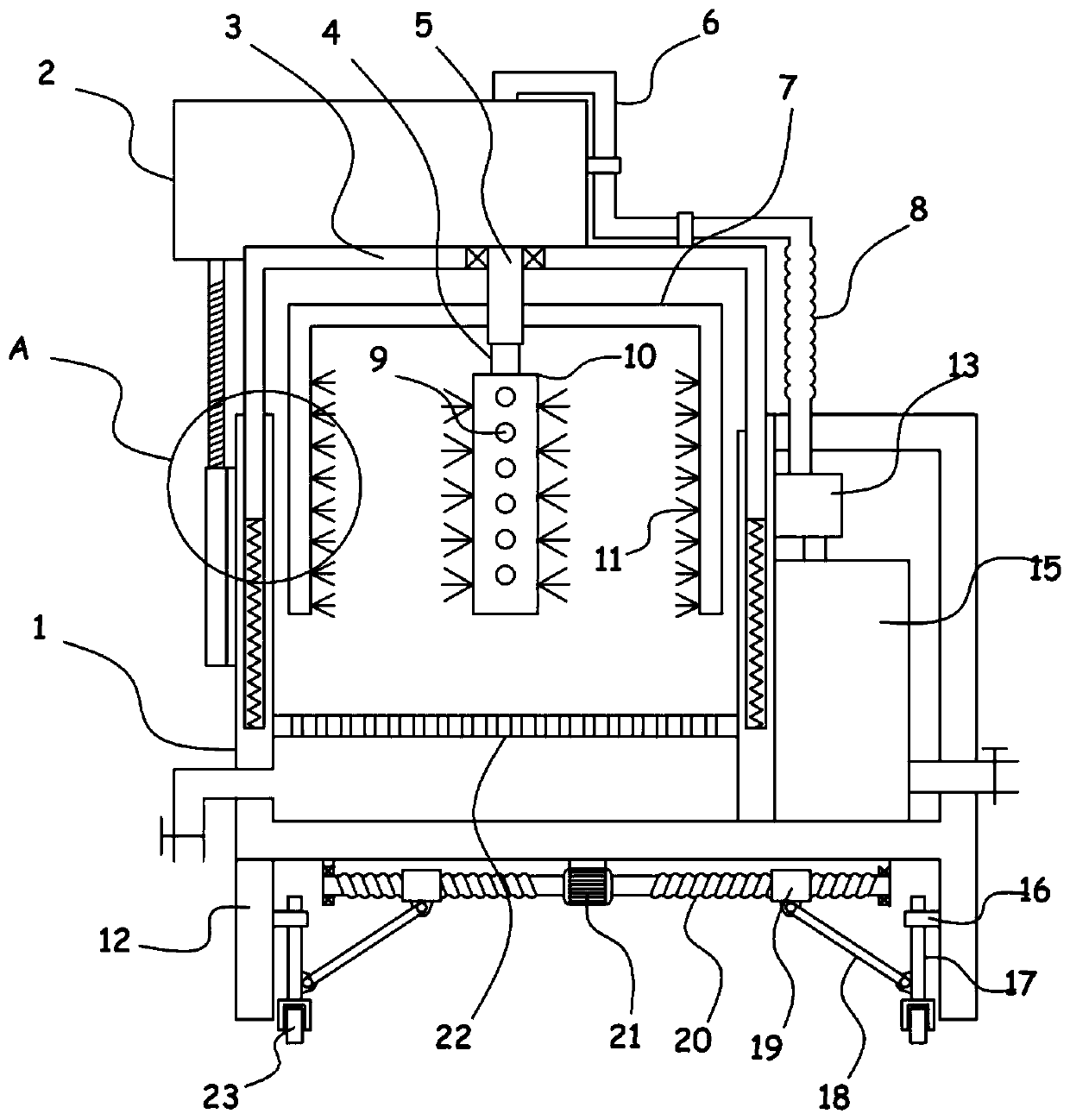

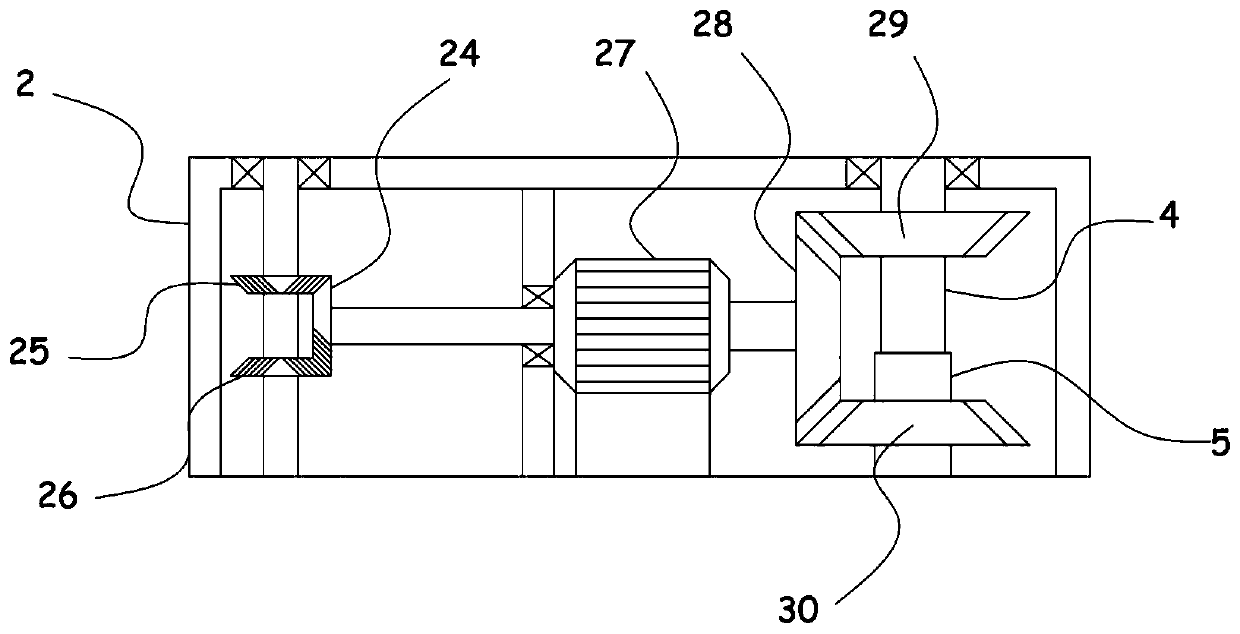

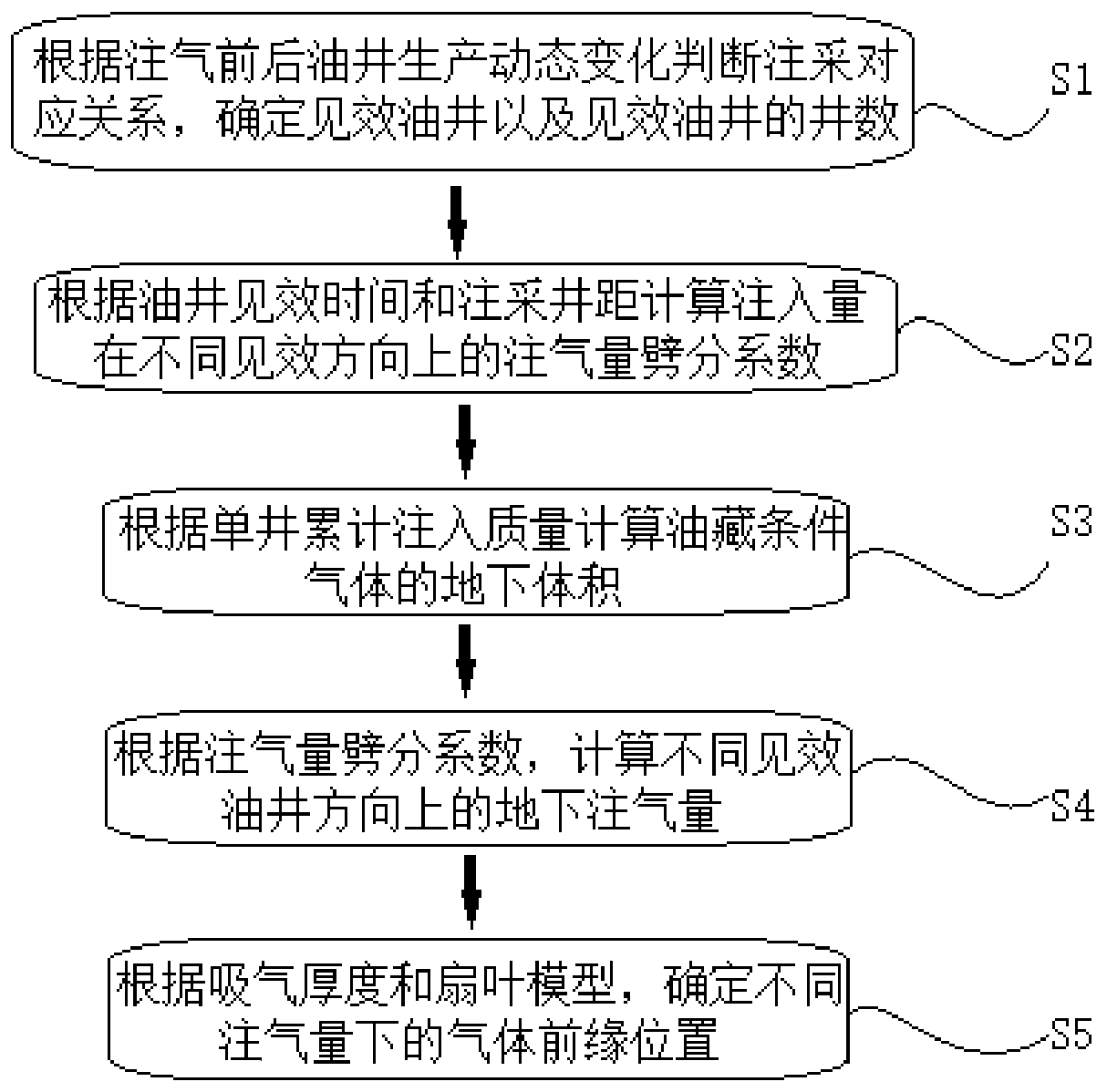

Carbon dioxide flooding gas front edge dynamic change prediction method

ActiveCN110863806AEasy to collectSimple processing capacityFluid removalDesign optimisation/simulationThermodynamicsSoil science

Owner:XI'AN PETROLEUM UNIVERSITY

Gas burner and gas stove

PendingCN107091476AGuaranteed service lifeUniform energy supplyCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelThermodynamicsEngineering

Owner:YANTAI ZHONGDE ENVIRONMENTAL PROTECTION EQUIPTECH

Home appliance with supplemental combustion air supply apparatus

ActiveUS20140305424A1Increasing burner efficiencyImprove efficiencyAir supply regulationDomestic stoves or rangesThermodynamicsCombustor

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Waste gas treatment device for garbage storing workshop of cement kiln co-processing domestic garbage system and treatment method thereof

PendingCN107716505AGuaranteed not to leakRealize harmless treatmentDirt cleaningIncinerator apparatusCombustion systemThermodynamics

Owner:ANHUI CONCH DESIGN & RES INST OF BUILDING MATERIALS CO LTD

Pipe valve shell casting cooling device

The invention relates to a pipe valve shell casting cooling device. The device comprises a bearing table, a cooling cavity used for cooling a pouring bottom die, a water tank used for transferring andstoring cooling water, a water inlet chamber used for storing the cooling water and a water outlet chamber used for collecting residual water. The cooling cavity, the water tank, the water inlet chamber and the water outlet chamber are all erected on the bearing table, wherein the number of the cooling cavities is at least one, and a pouring bottom die is installed in the cooling cavity. The device can be applied to the casting process of a pipe valve shell; the cooling water circulation is adopted for cooling treatment, so the continuous cooling state of the cooling cavity can be ensured. According to the invention, the modes of pre-cooling, total conveying, graded conveying and residual water recycling are adopted for cooling the pouring bottom die which is produced at the same time, thereby guaranteeing that a casting part can be rapidly cooled, demolding treatment can be conveniently conducted on the casting part, and the production efficiency of casting of the pipe valve shell isimproved.

Owner:HUBEI FANCHAO AUTOMOTIVE IND

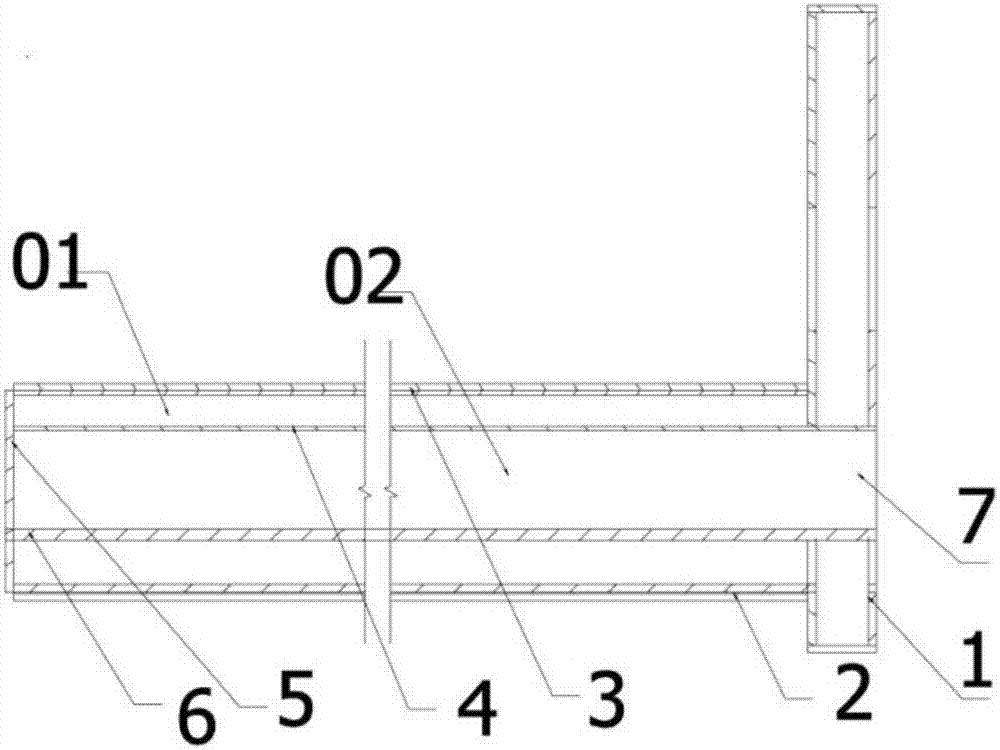

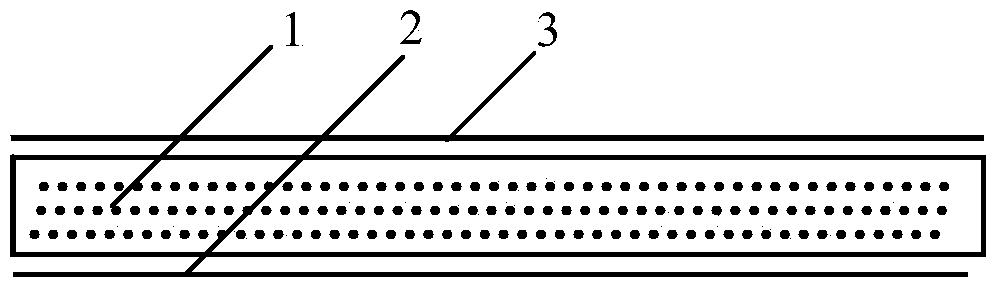

Antistatic geothermal floor

InactiveCN104234374AFast heat conductionImprove the status quo of performance defectsFlooring insulationsWater-setting substance layered productMagnesiumAntistatic agent

The invention relates to an antistatic geothermal floor. The antistatic geothermal floor is characterized by comprising a decorative layer on an upper surface, an antistatic layer on a lower surface, and a core layer sandwiched between the upper surface layer and the lower surface layer, wherein the core layer is a sheet material made of magnesium oxysulfate cement and bamboo fibers. The antistatic geothermal floor has the beneficial benefits that 1, the magnesium oxysulfate cement which has high combination degree with the bamboo fibers and does not corrode the bamboo fibers covers the bamboo fibers to form a floor core layer which meets a fire resistance requirement, the antistatic layer is compounded on the lower surface of the core layer to meet the requirement of a geothermal floor, and the present situation that the existing geothermal floor has defective performance is improved; 2, the sheet material for manufacturing the core layer is made of a mixture in a semi-dry state, and is formed by pressing, maintaining pressure and curing, so that the requirement of high strength of the antistatic geothermal floor is met; 3, the antistatic layer made of a composite material meets an antistatic requirement, and meanwhile, has high heat conductivity, so that the heat conductivity of the floor is improved, the utilization rate of heat is improved, and energy conservation and emission reduction are facilitated.

Owner:NG TERASUN AIR DUCT

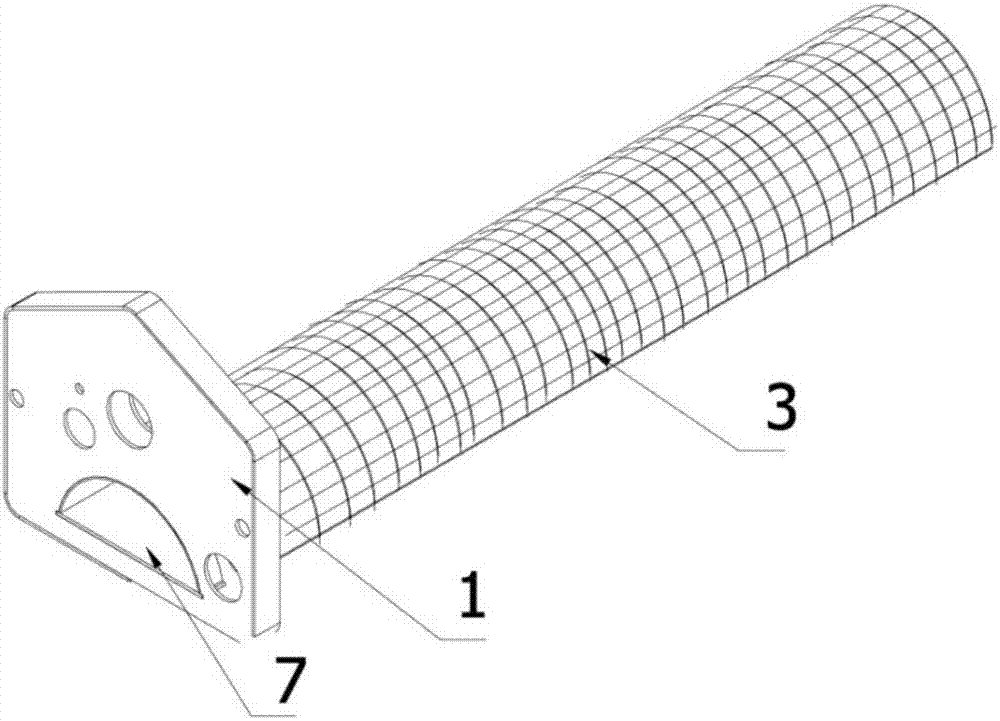

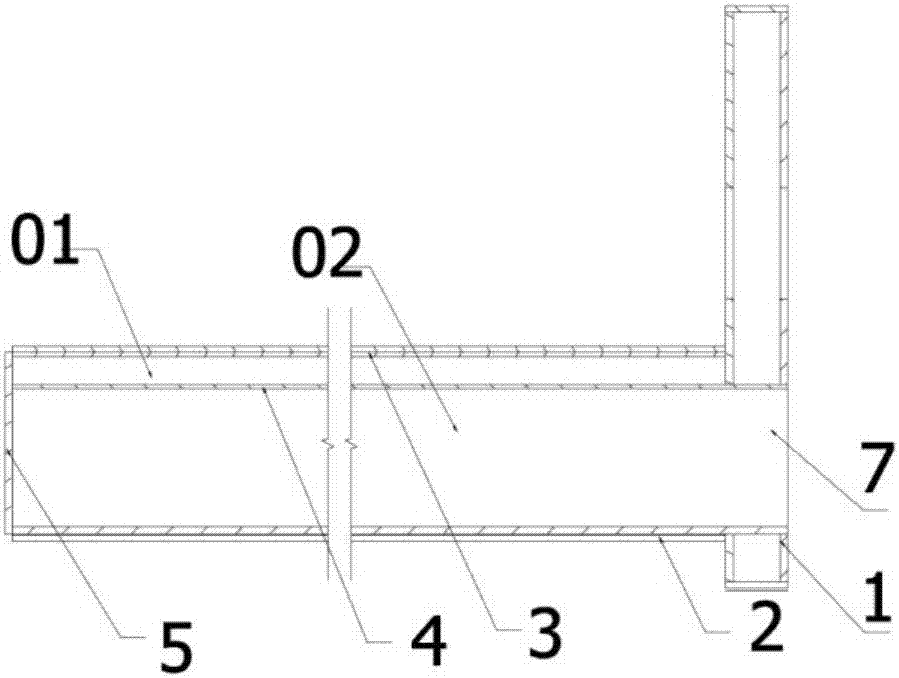

Transverse heating body atomizer

The invention discloses a transverse heating body atomizer. The transverse heating body atomizer comprises an oil storage bin (1), a silica gel piece (3), an oil absorption piece (4) and a base (6), the oil absorption piece (4) comprises a heating wire (5) wound on the outer wall, a body of the silica gel piece (3) is provided with a through hole (301), the oil absorption piece (4) is transversely installed in the silica gel piece (3), the two ends of the body are located below the through hole (301), the silica gel piece (3) is located in the base (6), and the base (6) is installed in a bottom opening of the oil storage bin (1). Tobacco tar in the oil storage bin (1) enters the oil suction piece (4) from the through hole (301), and the heating wire (5) can heat the tobacco tar to generate smoke during working, and the smoke is sucked from a top opening of the oil storage bin (1).

Owner:SHENZHEN EIGATE TECH CO LTD

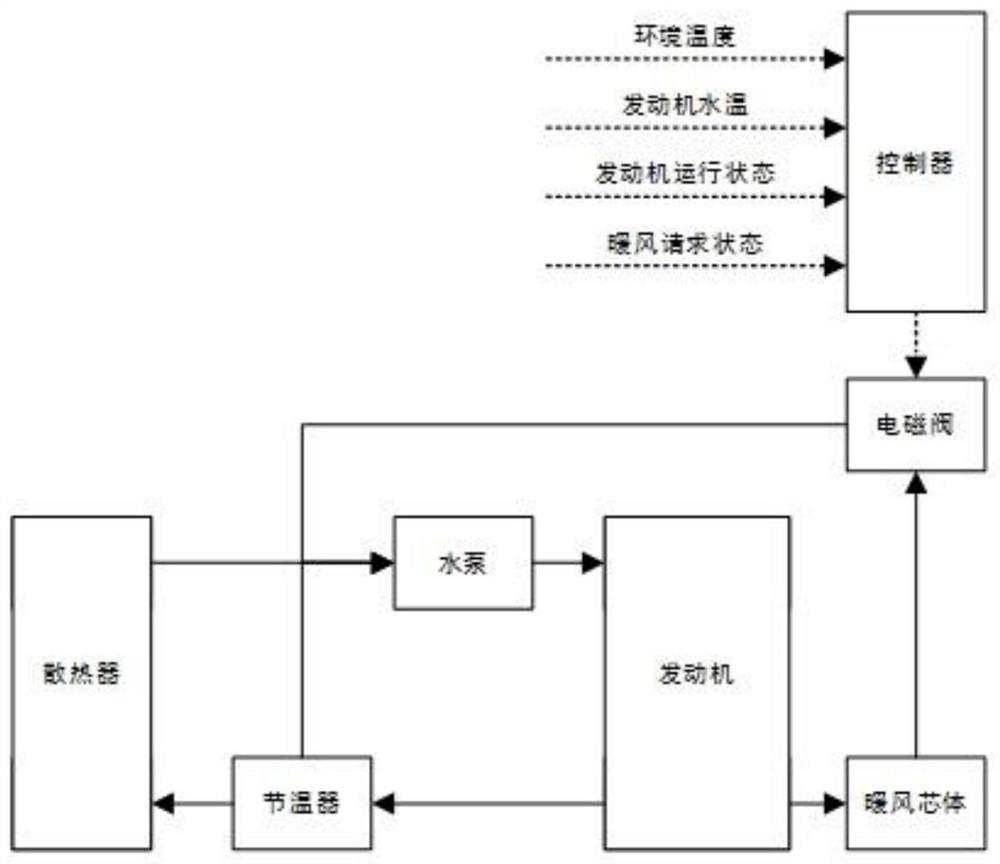

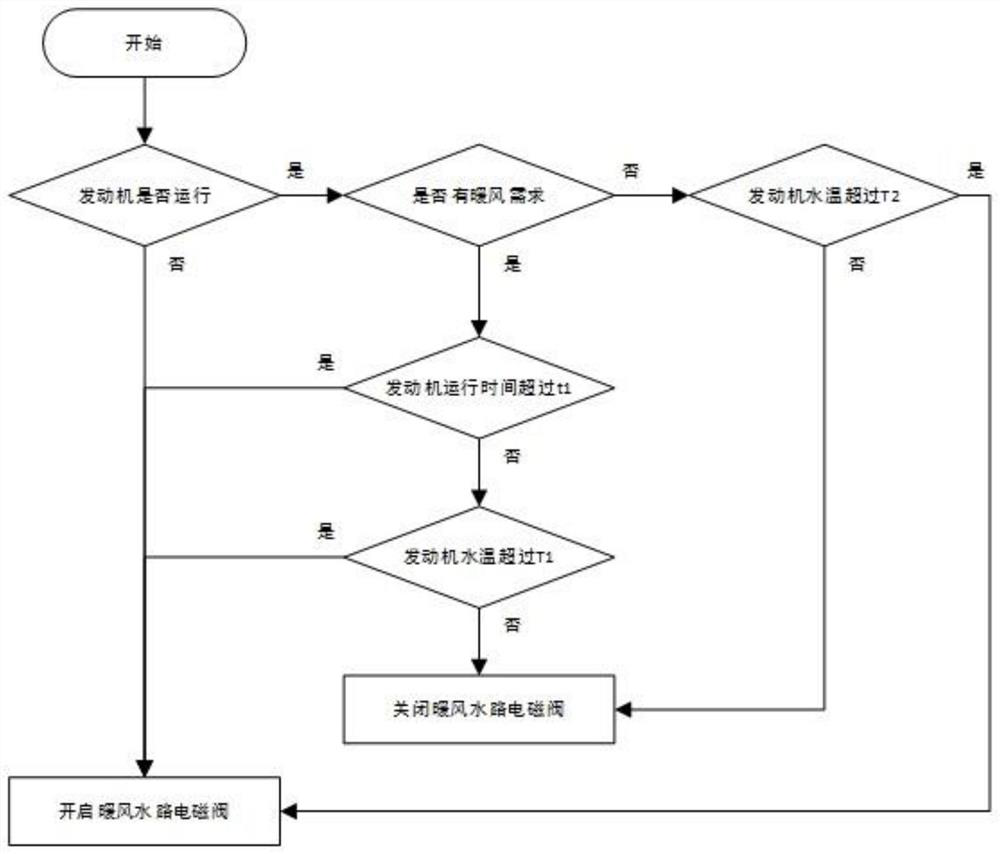

Control method and system for warm air water circulation of oil-fueled automobile and storage medium

ActiveCN112177754AReduce cooling costsIncrease temperatureCoolant flow controlAir-treating devicesThermodynamicsEngineering

Owner:DONGFENG MOTOR CORP HUBEI

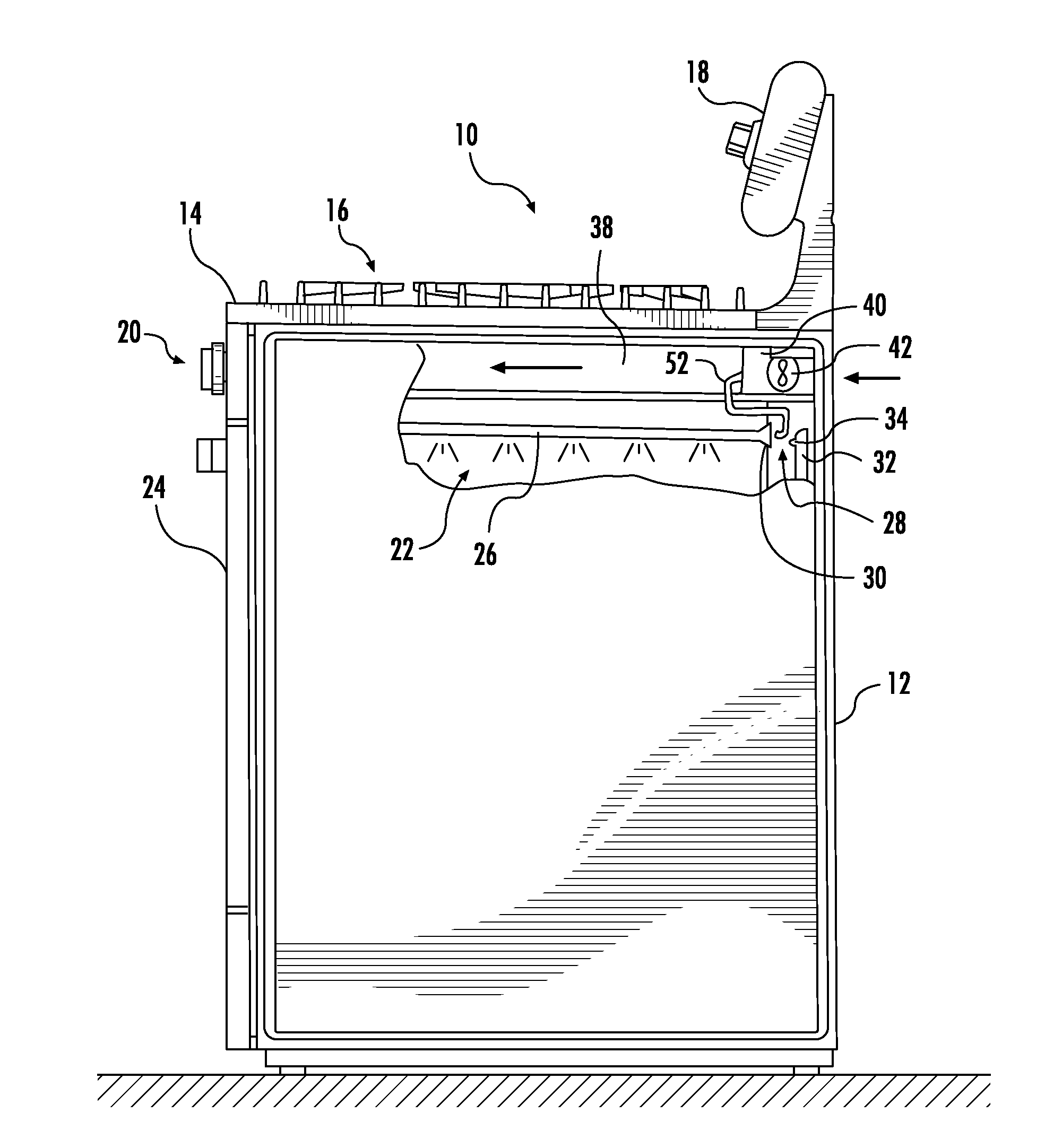

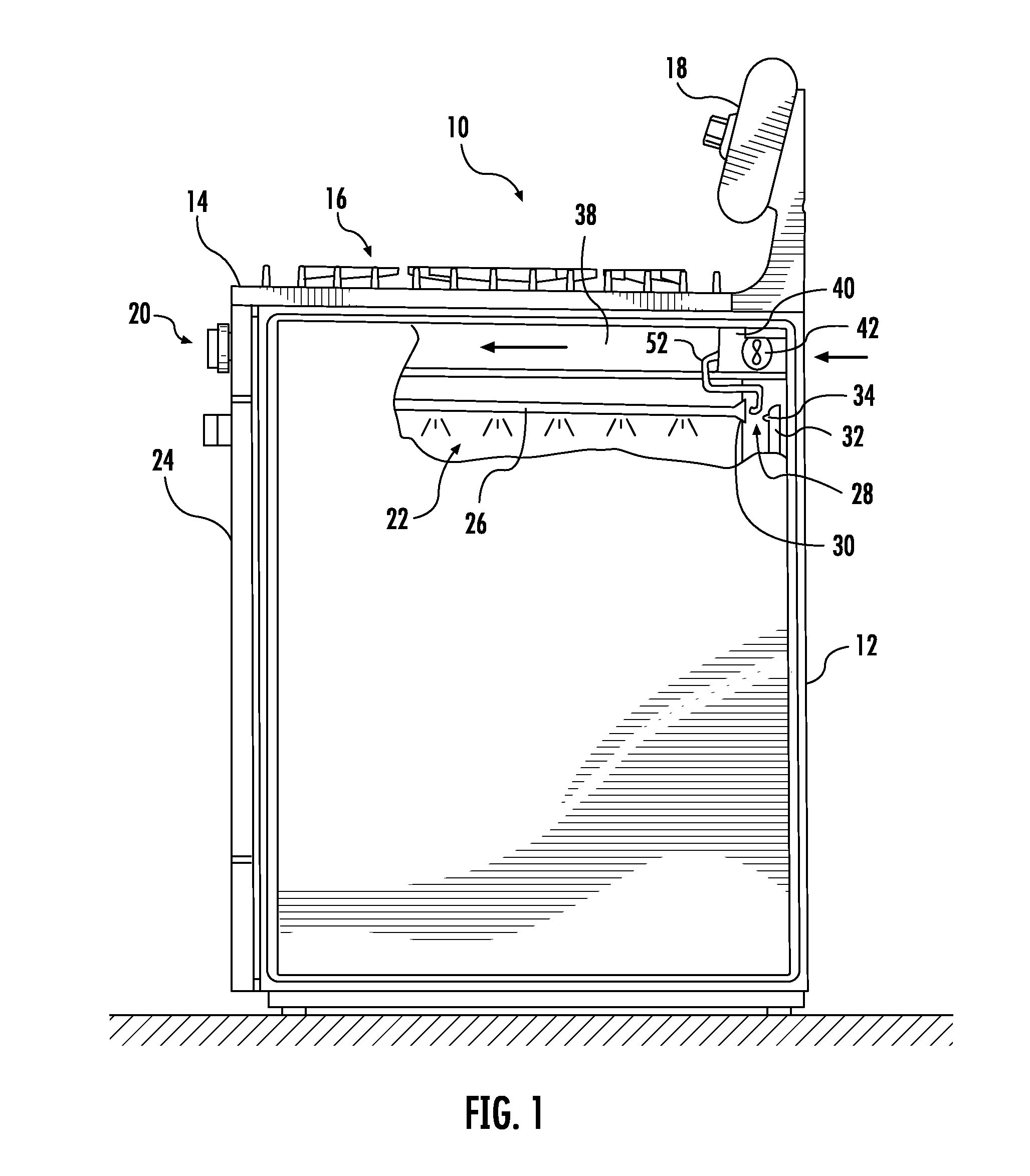

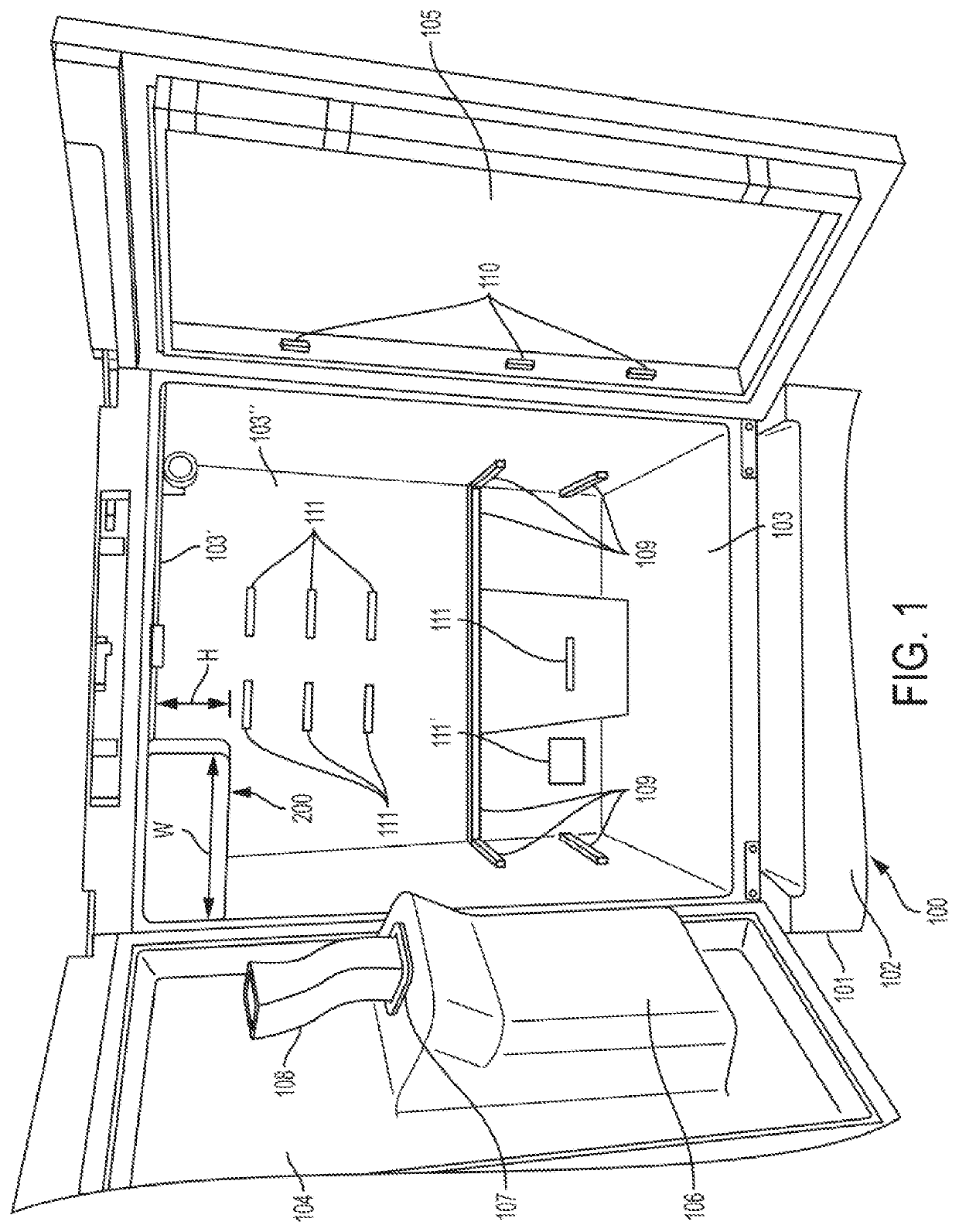

Method for drying laundry in a laundry treating appliance

A method of drying laundry in a laundry treating appliance having a treating chamber in which the laundry is received for drying comprises moving the treating chamber to redistribute the laundry, supplying air to the treating chamber to define a supply air flow, exhausting the supplied air from the treating chamber to define an exhaust air flow, heating the air supplied to the treating chamber by actuating a heater at full output to define a first heating phase and then cycling the heater ON / OFF to define a second heating phase.

Owner:WHIRLPOOL CORP

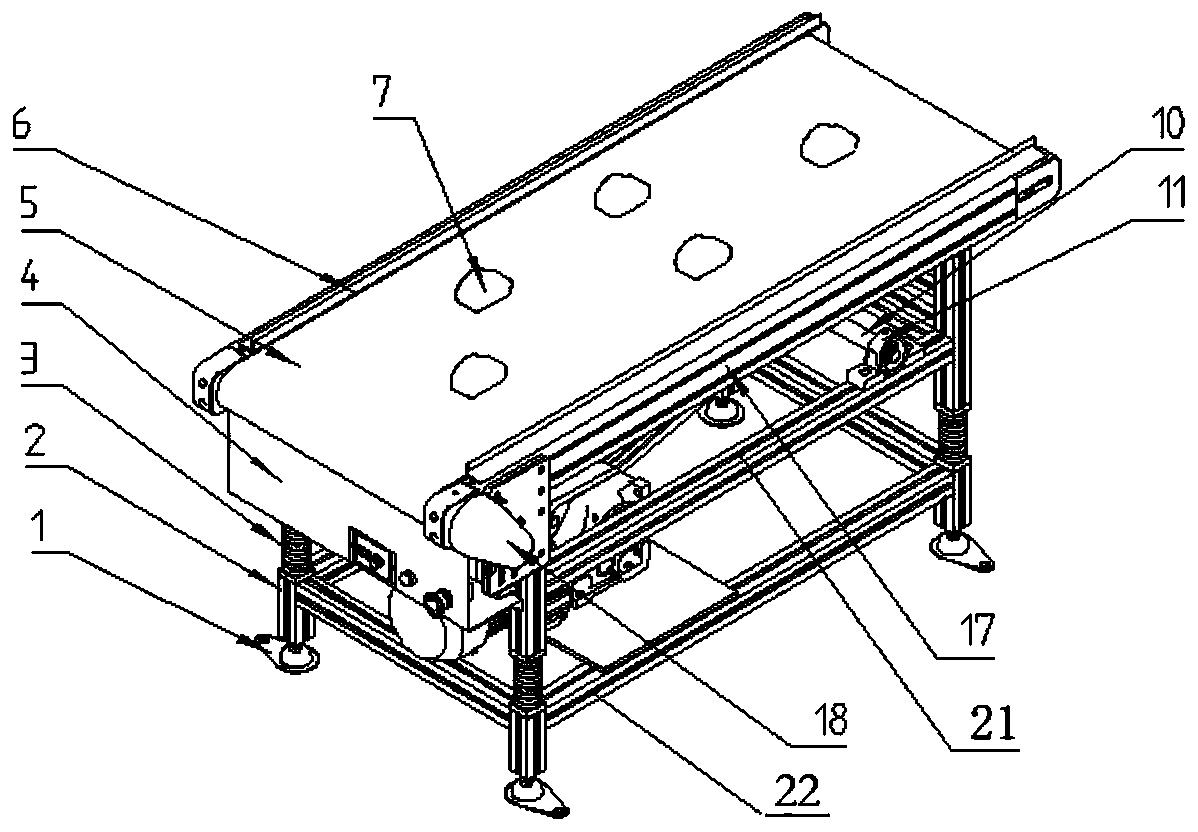

Coal gangue conveying vibration device

Owner:PINGDINGSHAN TIANAN COAL MINING +2

Marine diesel lubricating composition

The invention provides a method of lubricating a 2-stroke marine diesel cylinder liner with a lubricating composition having a total base number of 10 to 25 mg KOH / g. The invention further provides a lubricating composition for lubricating the 2-stroke marine diesel cylinder liner.

Owner:THE LUBRIZOL CORP

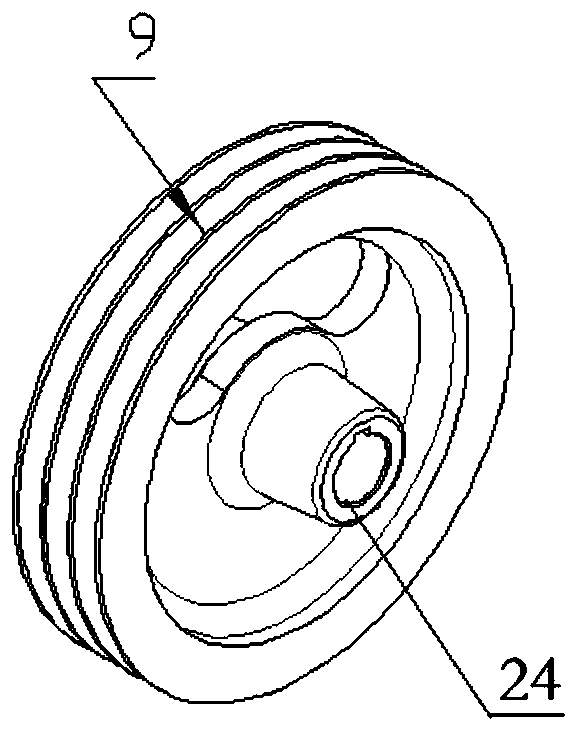

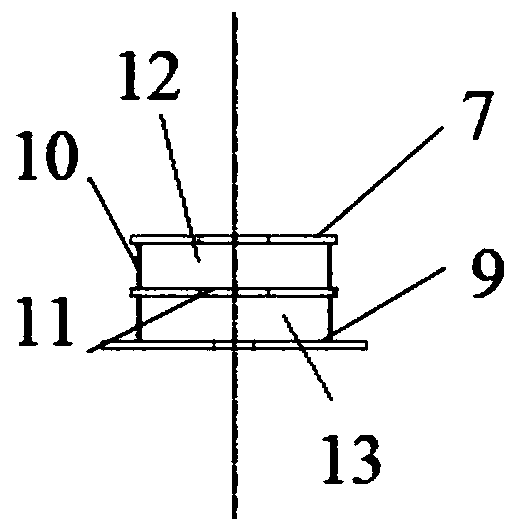

Rotor of sand making machine and sand making machine

ActiveCN111318347AReduce kinetic energy differenceShrinker says broken energy is poorGrain treatmentsThermodynamicsEngineering

Owner:CHINA RAILWAY CONSTR HEAVY IND

Paint spraying and drying integrated room for robot operation

Owner:苏州金迈驰航空智能科技有限公司

Multi-cycle vertical type drying method and device

ActiveCN103994636AEfficient use ofAvoid wastingDrying solid materials with heatDrying gas arrangementsMolecular sieveThermodynamics

The invention discloses a multi-cycle vertical type drying method and device. According to the method, hot gas with carbon molecular sieve raw materials enters a vertical type drying pipeline, so that when the hot gas rises in the vertical type drying pipeline, the hot gas and the carbon molecular sieve raw materials are fully mixed in a contacting mode, and the carbon molecular sieve raw materials after preliminary drying are dried again. According to the method, a plurality of sections of expanding pipes are arranged on a pipe body of the vertical type drying pipeline, the hot gas with the carbon molecular sieve raw materials enters the expanding pipes, then the flow speed of the hot gas is suddenly decreased, when the hot gas with the carbon molecular sieve raw materials flows out of the expanding pipes, the flow speed is suddenly increased, during flow speed changing, the hot gas and the carbon molecular sieve raw materials are in full contact, and accordingly the carbon molecular sieve raw materials are better dried. According to the method, a heat exchanging layer is arranged in an environment-protecting energy-saving burning device, air enters the heat exchanging layer for heat exchanging, hot gas is formed, and then the hot gas enters the vertical type drying pipeline to dry the carbon molecular sieve raw materials.

Owner:HUZHOU QIANGDA MOLECULAR SIEVE TECH CO LTD

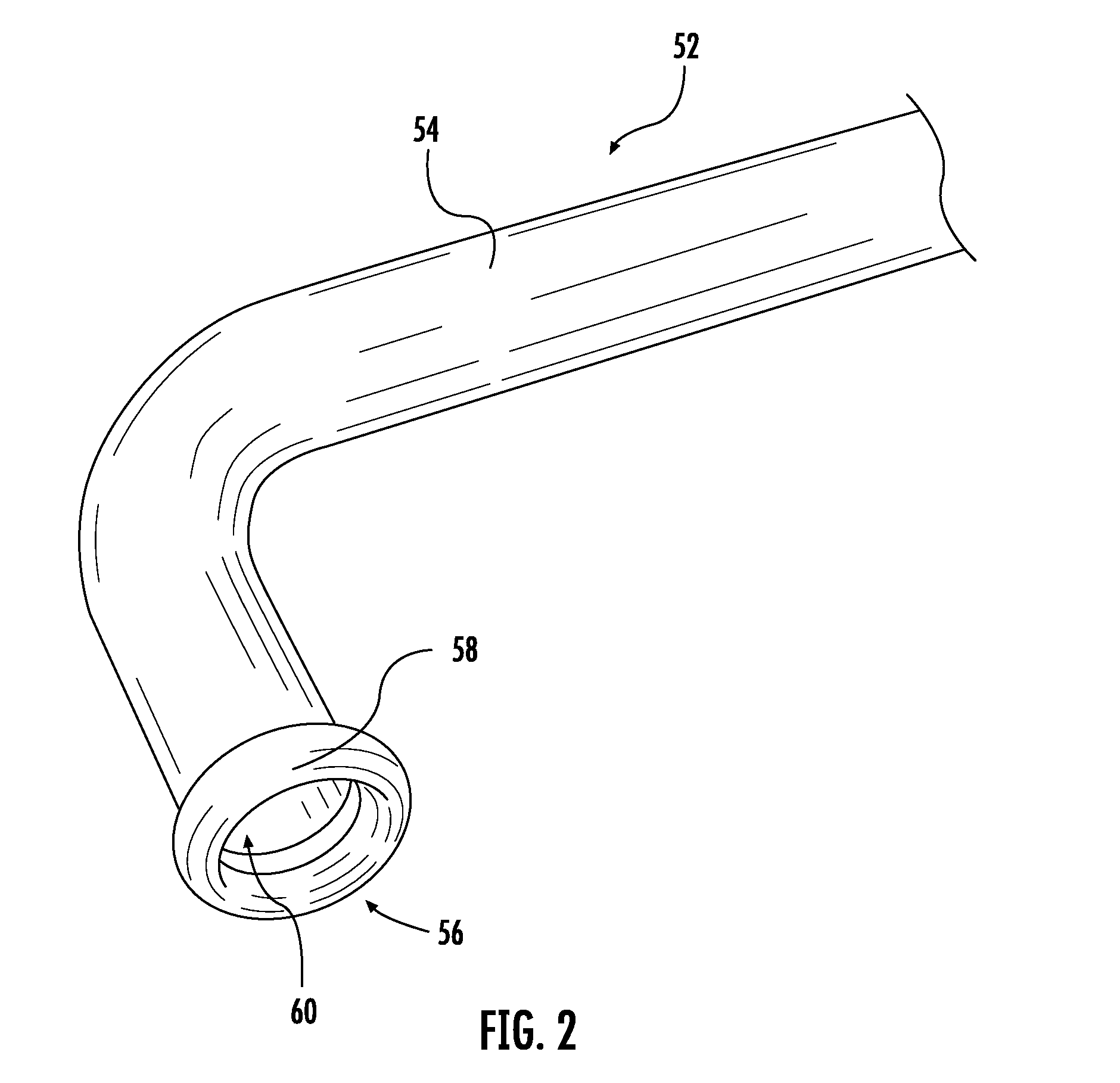

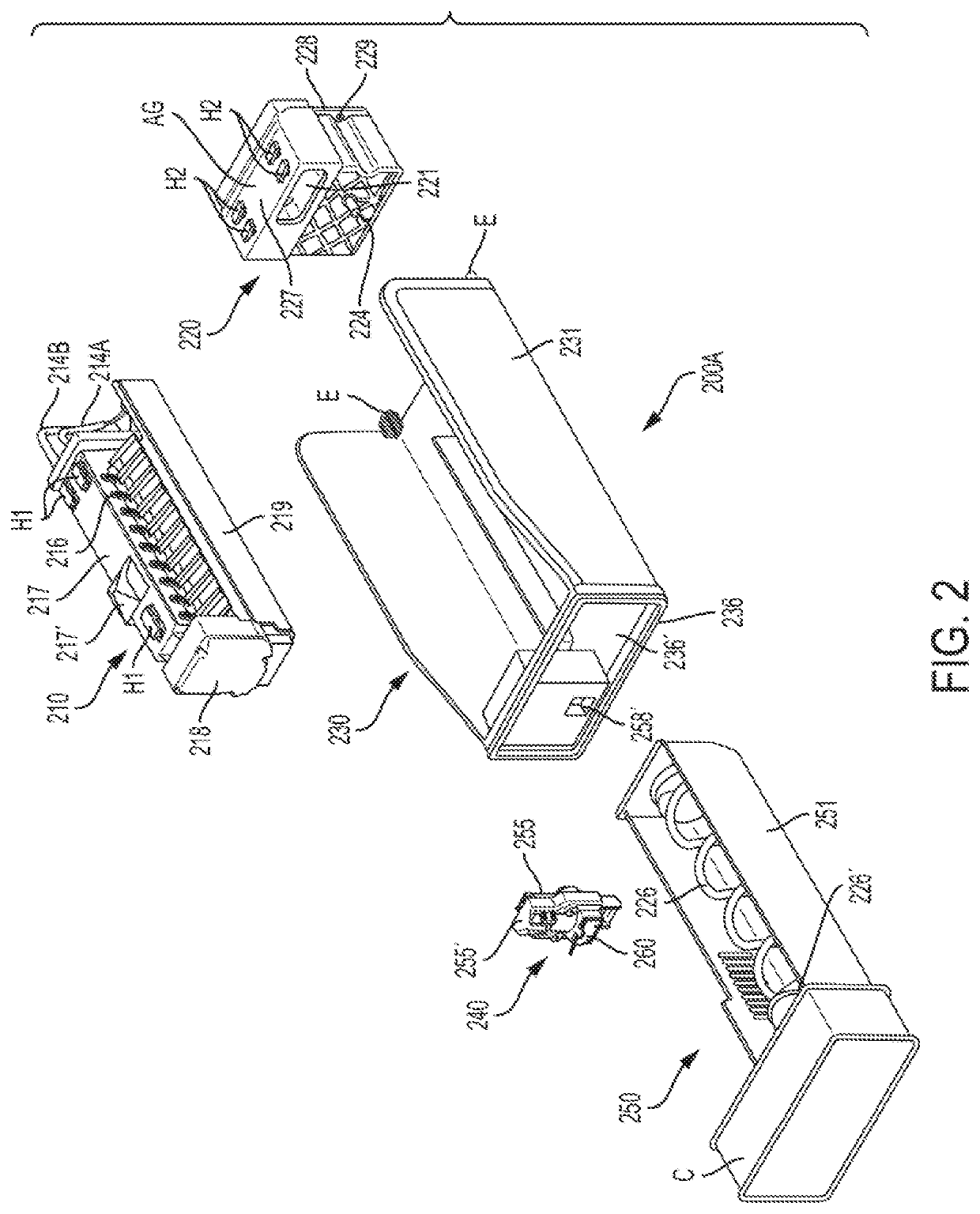

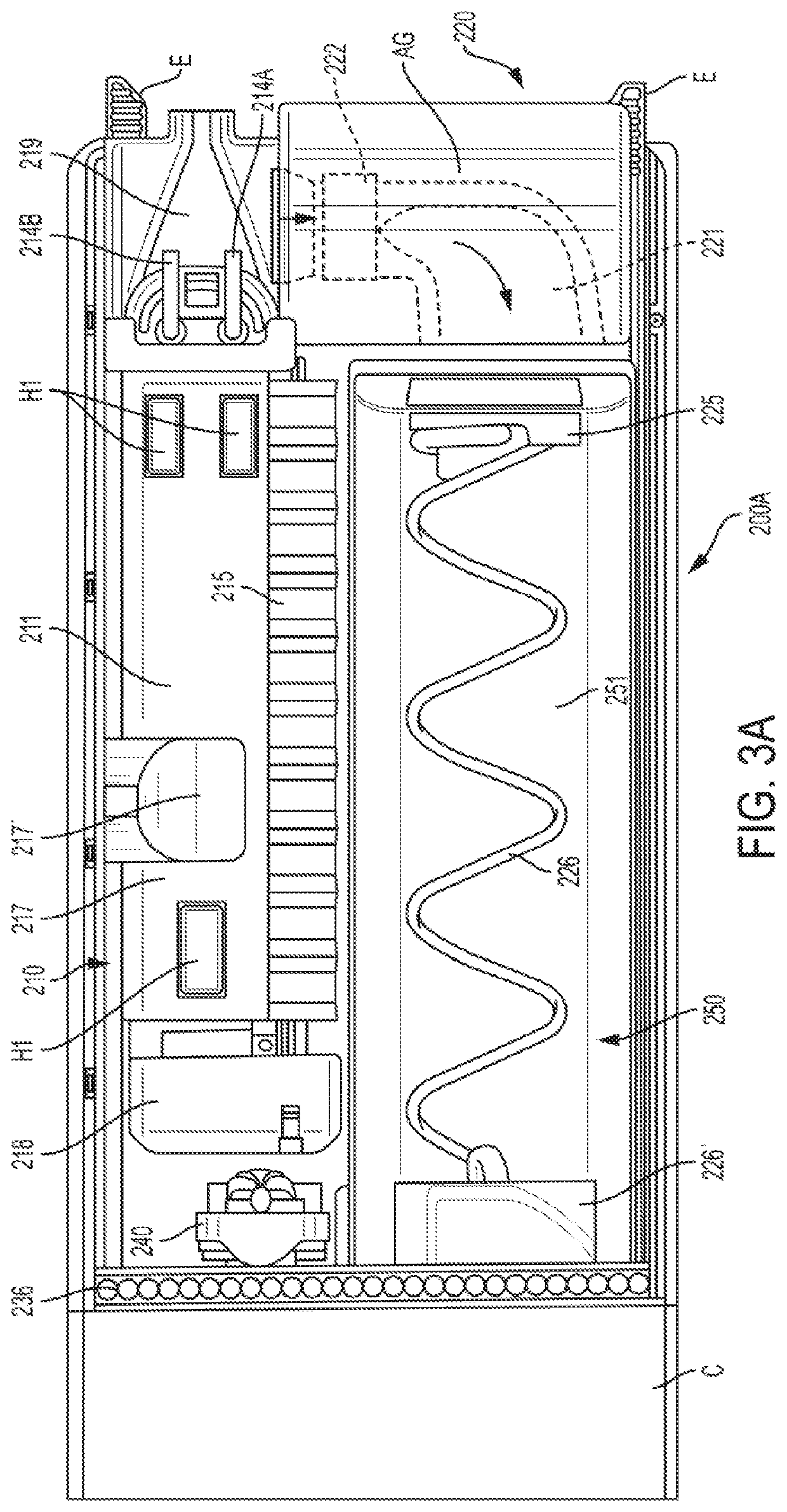

Compact ice making system for slimline ice compartment

ActiveUS20200033040A1Small volumeFaster ice productionLighting and heating apparatusIce productionThermodynamicsIcebox

Owner:BSH HOME APPLIANCES CORP +1

Control method for uniform preheating of powder bed and additive manufacturing device

InactiveCN114850498AConsistent temperature gradientImprove stabilityAdditive manufacturing apparatusIncreasing energy efficiencyThermodynamicsEngineering

Owner:西安赛隆增材技术股份有限公司

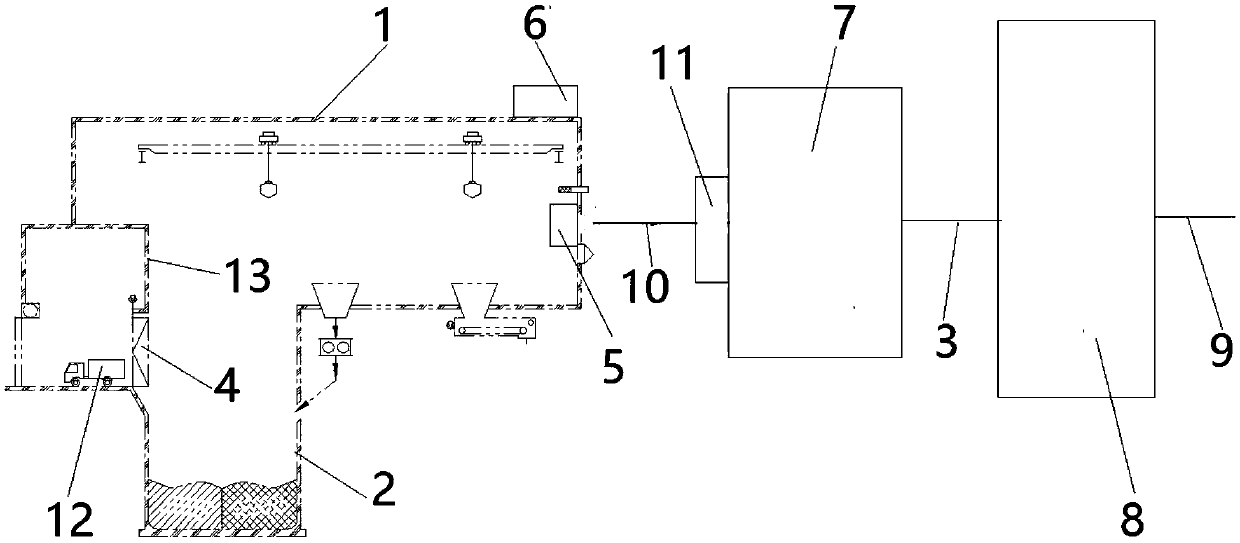

Internal and external heating type medium and low temperature powdered coal temperature division dry distillation system and method

ActiveCN105505422AEfficient dehydrationImprove thermal distillation efficiencyIndirect and direct heating destructive distillationSpecial form destructive distillationThermodynamicsCombustion chamber

The invention discloses an internal and external heating type medium and low temperature powdered coal temperature division dry distillation system and method. The system comprises a spiral pushing medium and low temperature external heating dry distillation device and a low temperature internal heating rotary kiln dry distillation device, wherein a spiral pushing dry distillation chamber in the spiral pushing medium and low temperature external heating dry distillation device is arranged in a combustion chamber of the spiral pushing medium and low temperature external heating dry distillation device, combustion smoke in the combustion chamber is directly supplied to the interior of a rotary kiln cylinder, and solid materials in the rotary kiln cylinder are supplied to the interior of the spiral pushing dry distillation chamber. Dry distillation of coal is divided into two or more phases according to temperature and is achieved through organic combination of the internal heating rotary kiln dry distillation device and the spiral pushing external heating dry distillation device, winnowing and dust removal, preheating and drying and dehydration are conducted on raw coal by means of a rotary kiln, high-efficiency medium and low temperature dry distillation and high-calorific-value raw gas and tar product precipitation are achieved by means of the spiral pushing external heating dry distillation device, the advantages of the internal heating dry distillation device and the external heating dry distillation are fully combined, dry distillation efficiency, heat utilization efficiency and the quality of dry distillation products are improved greatly, and marketing prospects are broad.

Owner:王崇峰

Method for calculating thermoelectric peak shaving capacity of solar gas combined cycle unit

PendingCN112234650ALower heating costsReduce consumptionFrom solar energySingle network parallel feeding arrangementsThermodynamicsProcess engineering

The invention discloses a method for calculating the peak shaving capacity of a solar gas-steam combined cycle combined heat and power generation system. The method comprises the following steps of: adding solar energy into a gas-steam combined cycle unit; determining the flow of heat conduction oil supplied to a gas unit by a solar loop and determining the minimum peak regulation output conditionand the maximum peak regulation output improvement of a heat supply unit under the same heat supply load requirement. The method can be applied to calculation and evaluation of the peak regulation maximum and minimum output conditions of a new system after the solar loop is added to the gas-steam combined cycle unit for transformation, and therefore important reference data are provided for the unit peak regulation capacity change conditions and the transformation scheme after solar energy is applied to the gas combined cycle combined heat and power generation unit.

Owner:CECEP GUOJI UNITED POWER (NINGXIA) CO LTD

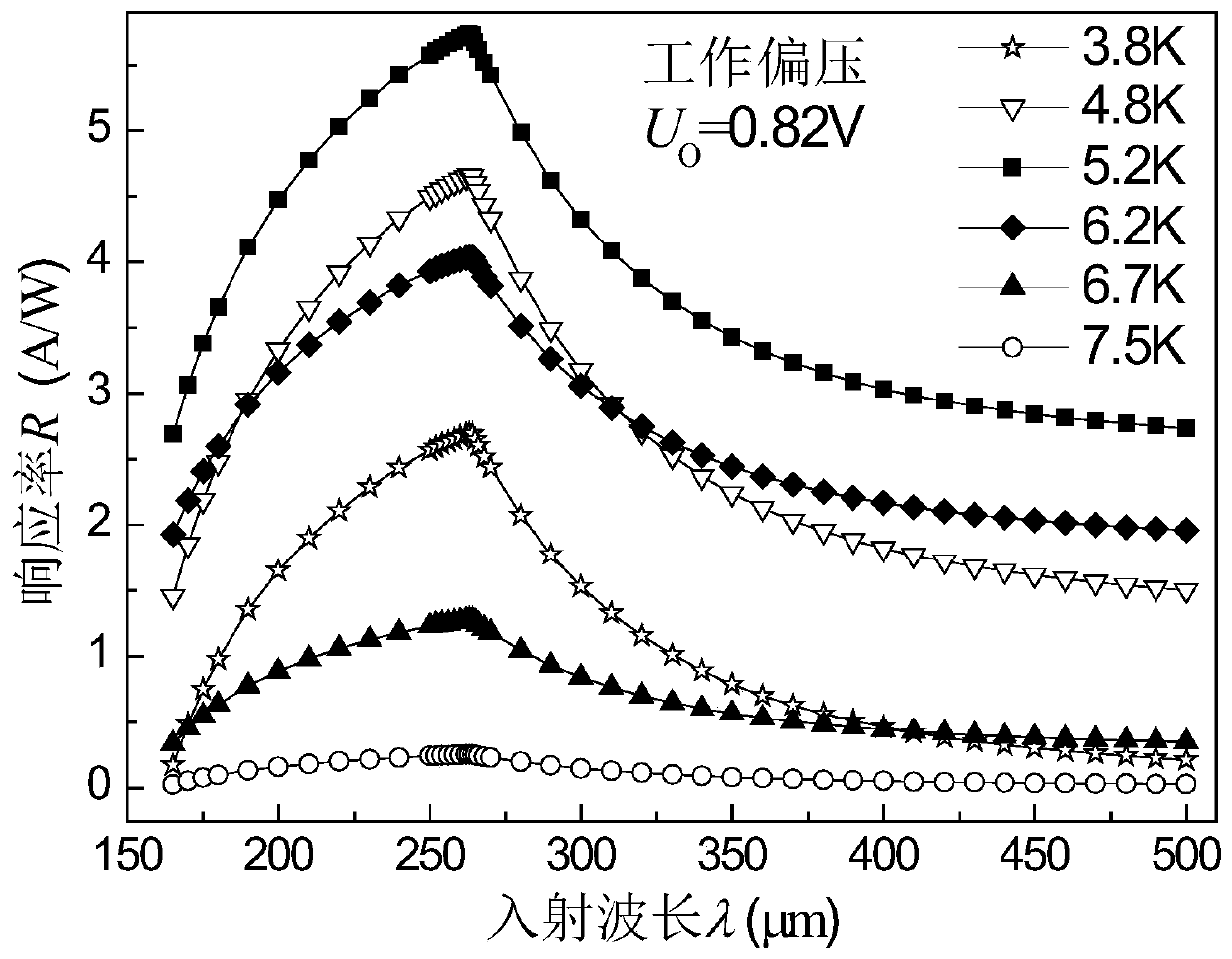

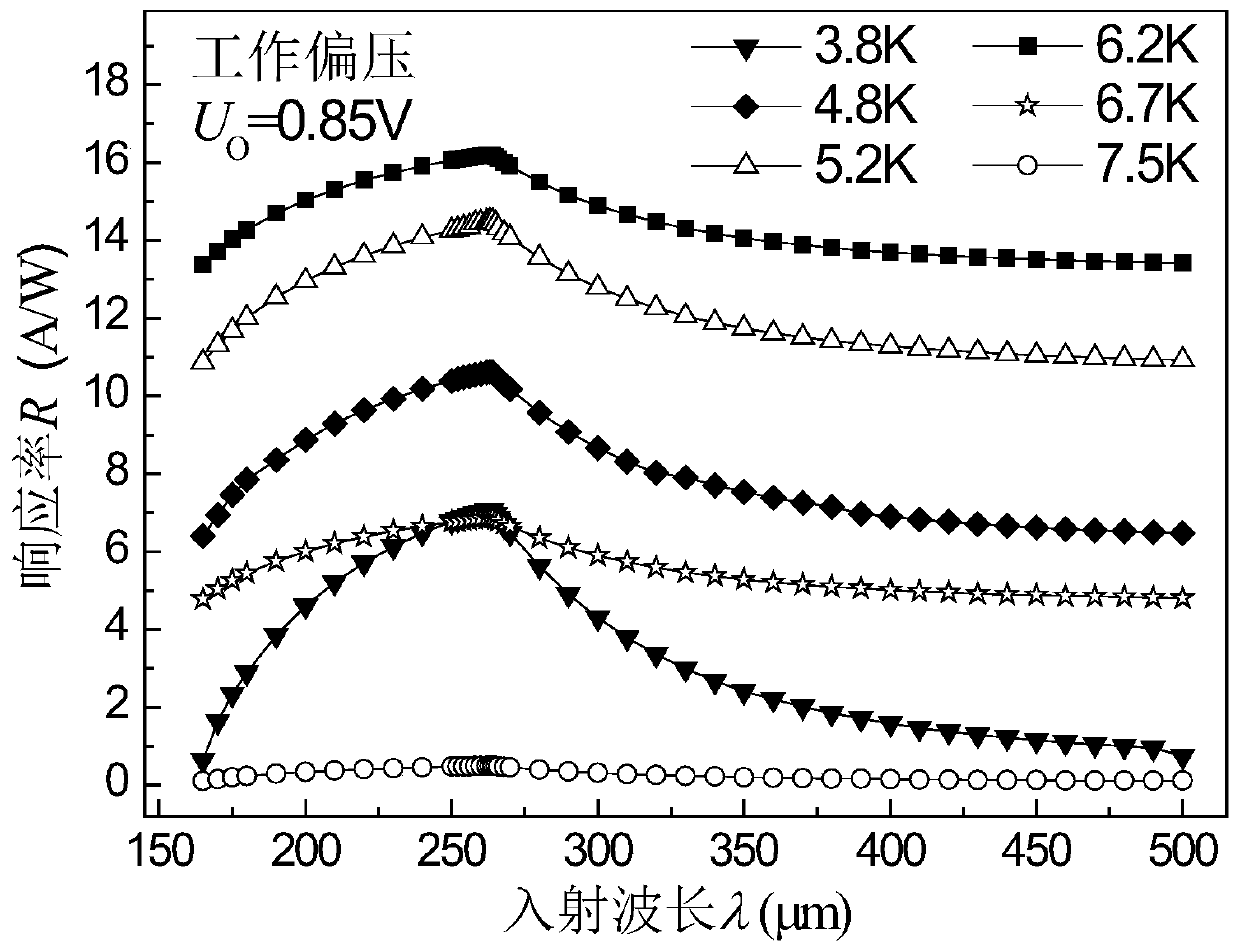

Method for optimizing responsivity of BIB detector, and BIB detector

ActiveCN111191403AImprove response rateIncrease working temperatureFinal product manufactureCAD circuit designThermodynamicsResponsivity

Owner:上海微波技术研究所(中国电子科技集团公司第五十研究所)

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap