Method for evaluating temperature uniformity in width direction of hot-rolled strip steel intermediate billet

A technology of hot-rolled strip steel, uniformity, applied in the field of steel rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In an embodiment of the present invention: a method for evaluating the temperature uniformity in the width direction of a hot-rolled strip intermediate slab is provided, comprising the following steps:

[0030] The first step: Use a thermal imager to measure the temperature of the intermediate billet during the hot rolling process, and import the captured thermal image into the computer;

[0031] The second step: use the thermal imaging analysis software to process the image data;

[0032] Step 3: Use Photoshop software to fill the cross grid on the thermal imaging image, divide the image into multiple squares, and mainly analyze the edge temperature drop value of the intermediate billet and the width value of the edge temperature drop area through the grid.

[0033] In the above embodiment, it also includes adding temperature measurement line and generating temperature line graph, Photoshop filling grid, calculation of unit length of temperature line graph, determining th

Embodiment , Embodiment 2

[0041] Taking the thin-gauge high-strength steel QStE500TM-P produced by a steel factory as an example, the size of the intermediate billet is 38.7×1290mm, and the size of the finished product is 5×1250mm; , and the five parts of the tail were measured respectively to obtain five sets of data, and a thermal image was taken in the length direction of the head and tail, and the length of the low temperature zone of the head and tail was calculated. The calculated data are shown in Table 1 and Table 2:

[0042] Table 1 Data of temperature drop at edge in width direction

[0043]

[0044] Table 2 Temperature drop data at head and tail positions

[0045]

[0046]

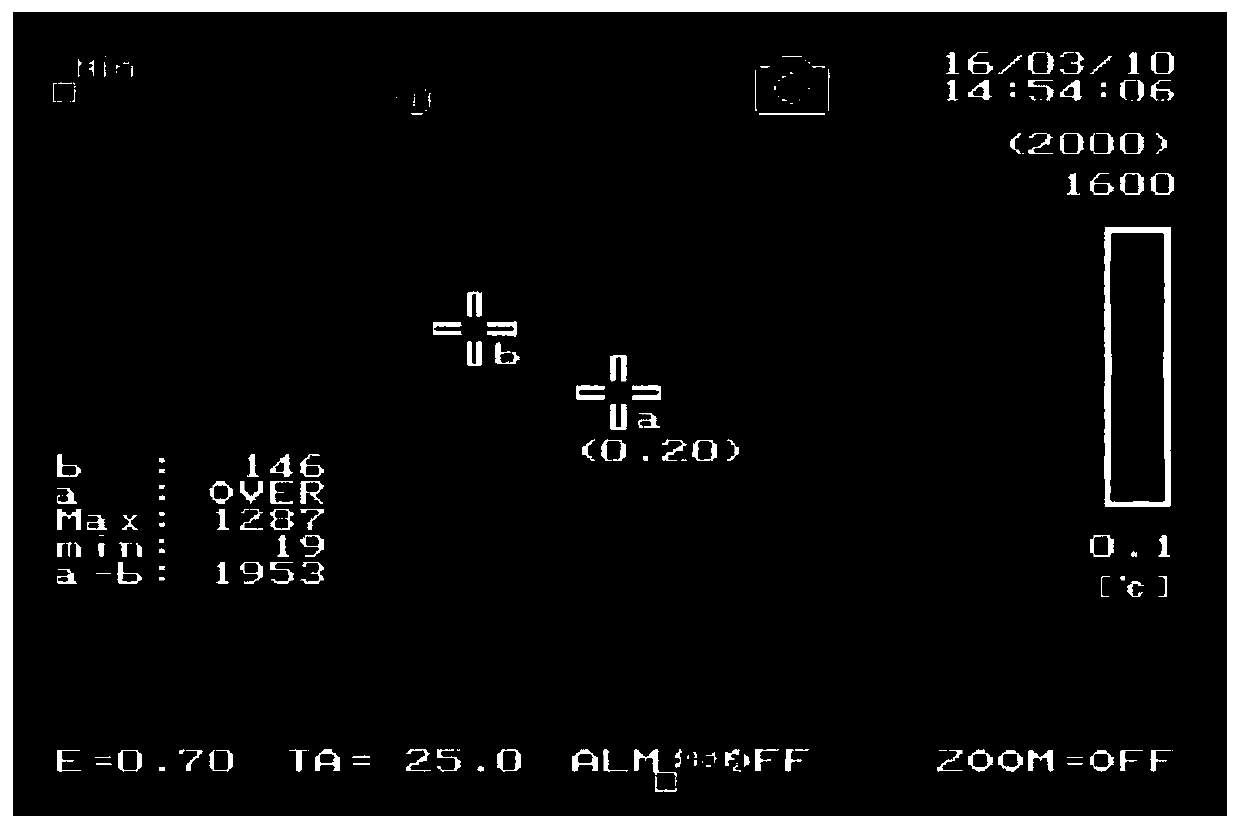

[0047] see figure 1 , importing the temperature image taken by the thermal imager into the computer;

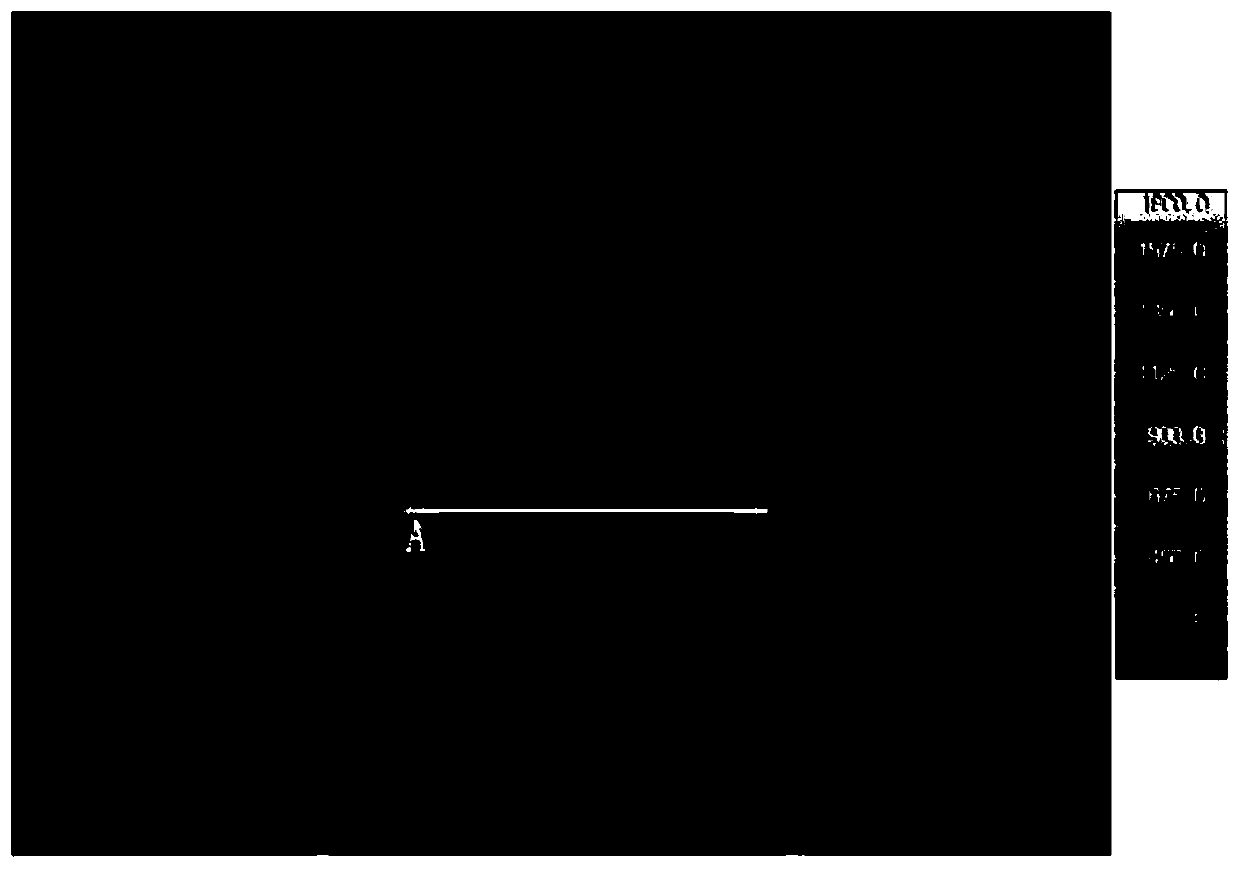

[0048] see figure 2, take the temperature measurement line A in the width direction of the intermediate billet to be measured;

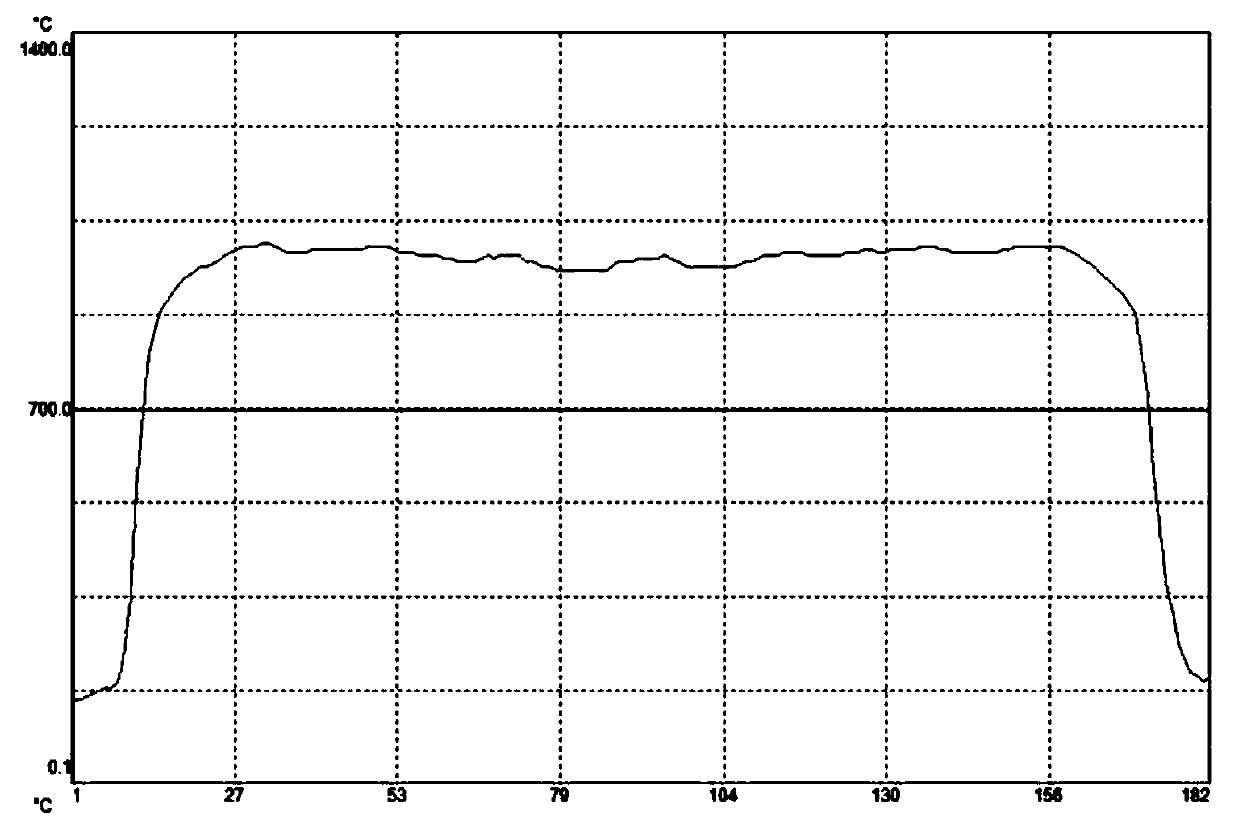

[0049] see image 3 , the temperature line graph of line A is generated in the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap