Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

197 results about "Mechanics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mechanics (Greek μηχανική) is the area of science concerned with the behavior of physical bodies when subjected to forces or displacements, and the subsequent effects of the bodies on their environment. The scientific discipline has its origins in Ancient Greece with the writings of Aristotle and Archimedes (see History of classical mechanics and Timeline of classical mechanics). During the early modern period, scientists such as Galileo, Kepler, and Newton laid the foundation for what is now known as classical mechanics. It is a branch of classical physics that deals with particles that are either at rest or are moving with velocities significantly less than the speed of light. It can also be defined as a branch of science which deals with the motion of and forces on objects. The field is yet less widely understood in terms of quantum theory.

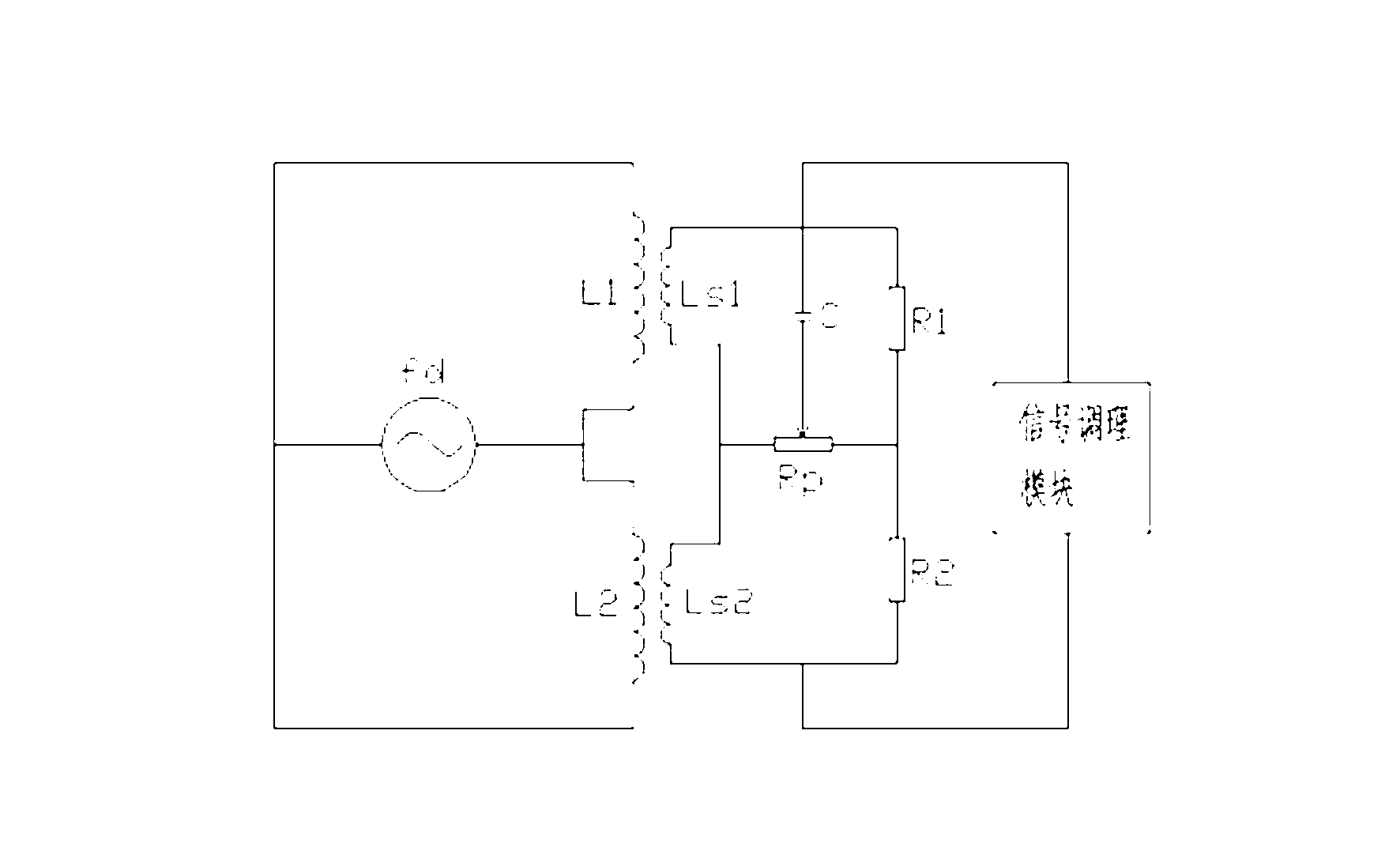

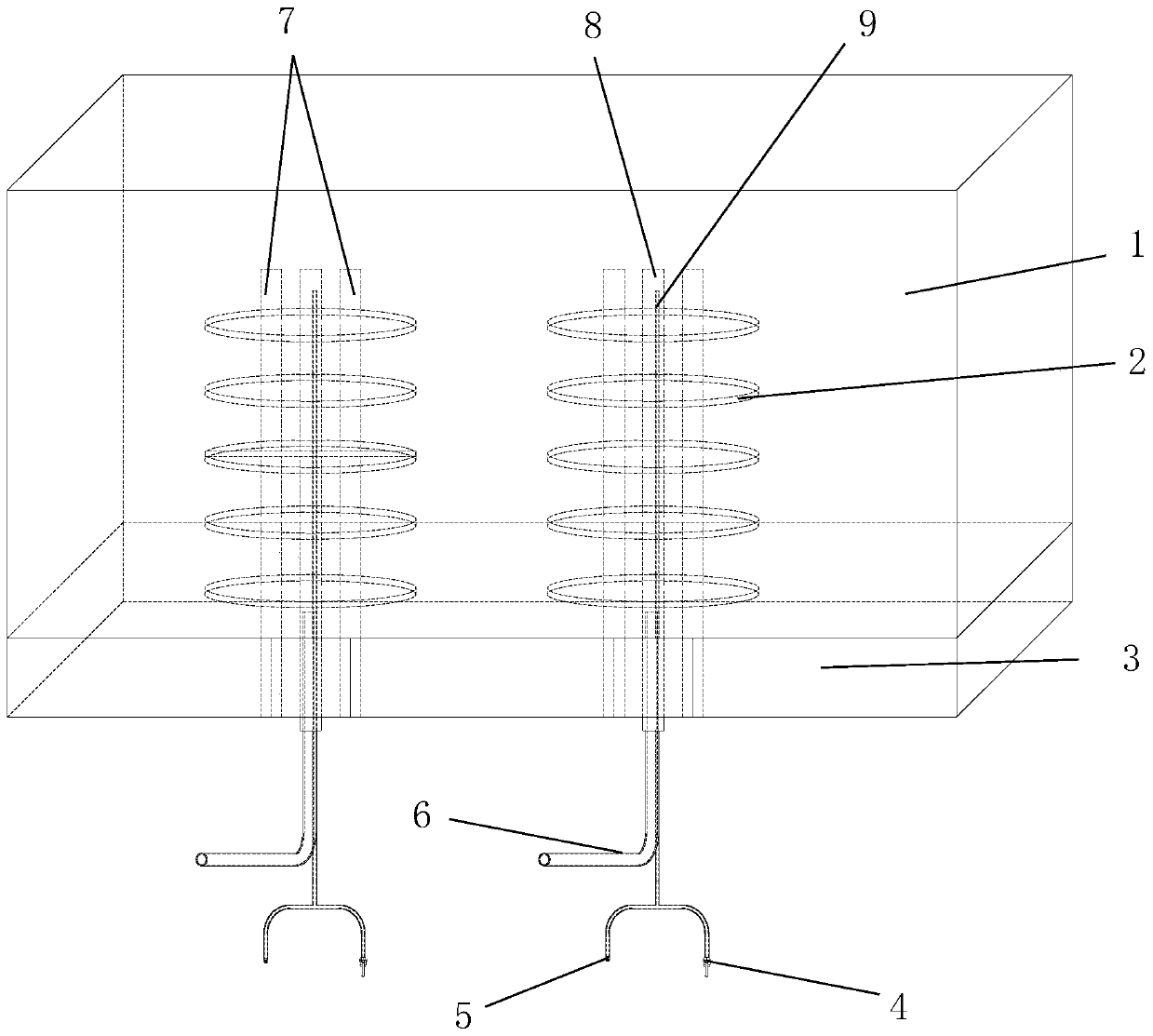

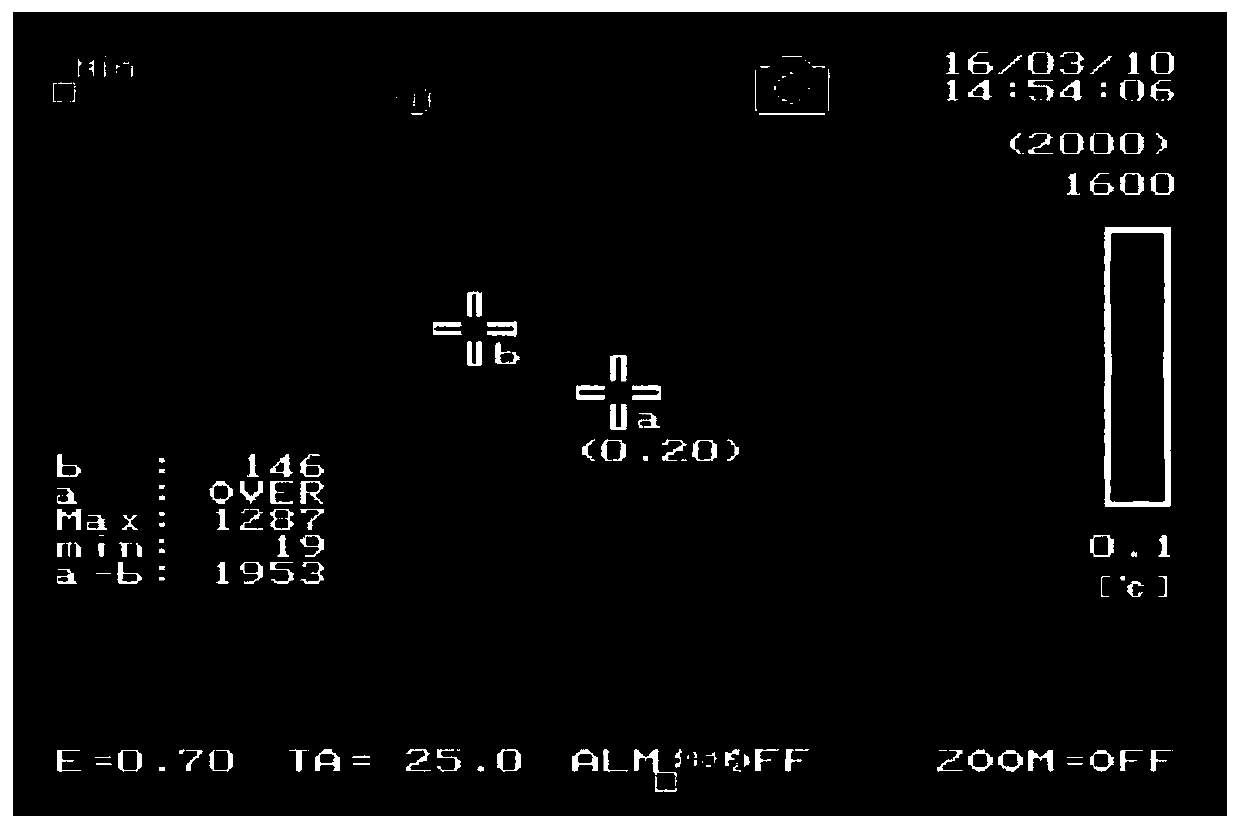

Sensor for monitoring metal abrasive particles in oil liquid on line and application method for sensor

InactiveCN103308431AReasonable structureHigh sensitivityMaterial analysisMechanical equipmentLinearity

Owner:GUILIN UNIV OF ELECTRONIC TECH

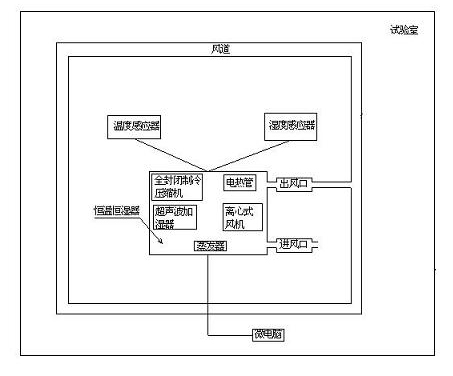

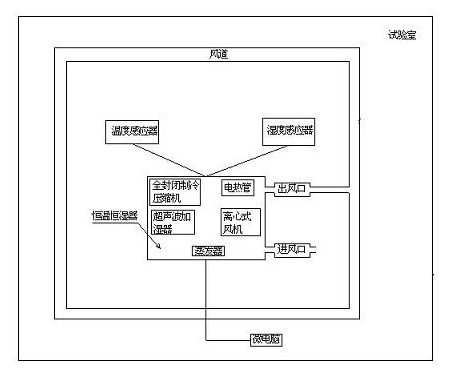

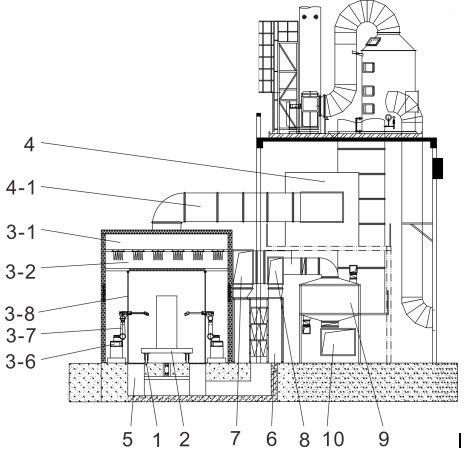

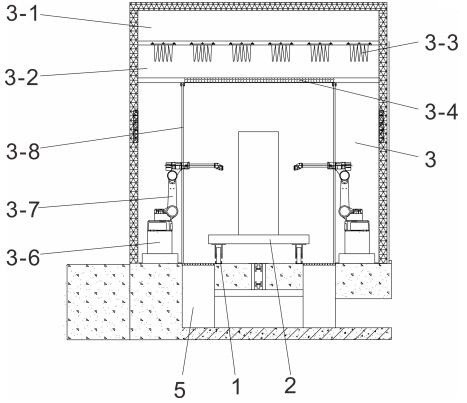

Concrete sample curing room

ActiveCN101947810AUniform temperatureUniform humidityCeramic shaping apparatusMicrocomputerThermodynamics

Owner:JSTI GRP INSPECTION & CERTIFICATION CO LTD

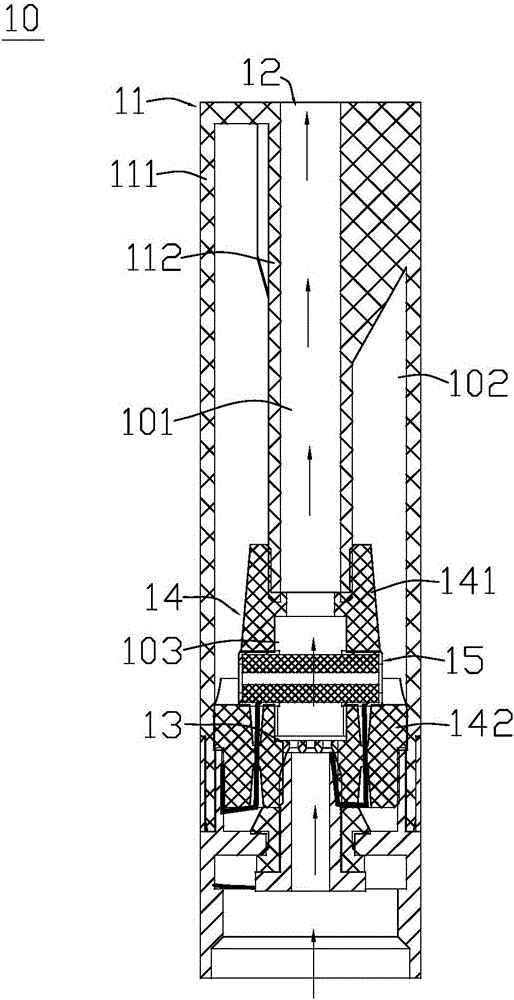

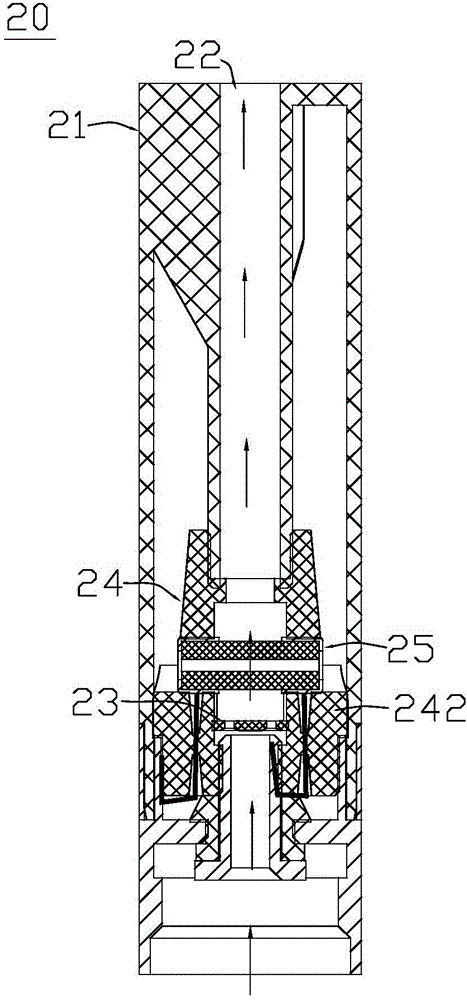

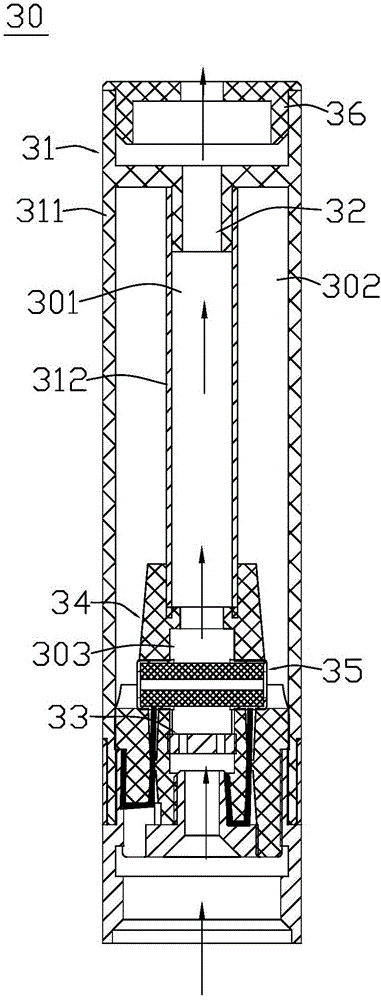

E-cigarette leak-proof device

Owner:O NET AUTOMATION TECH SHENZHEN

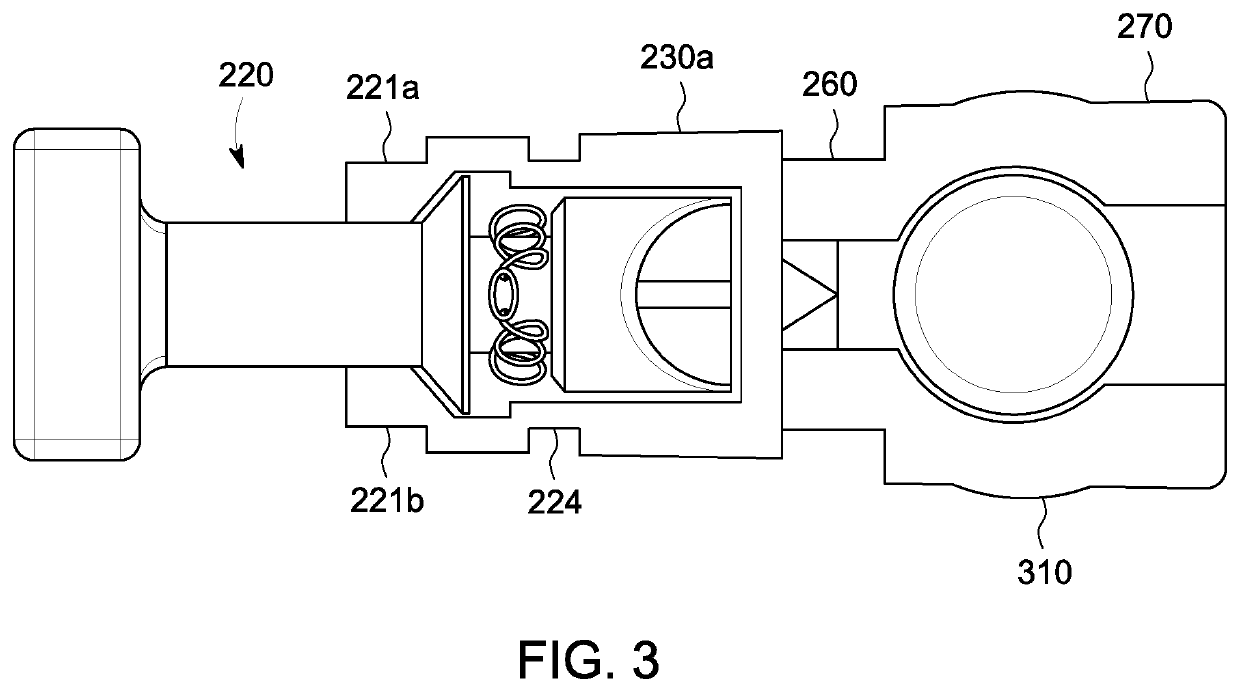

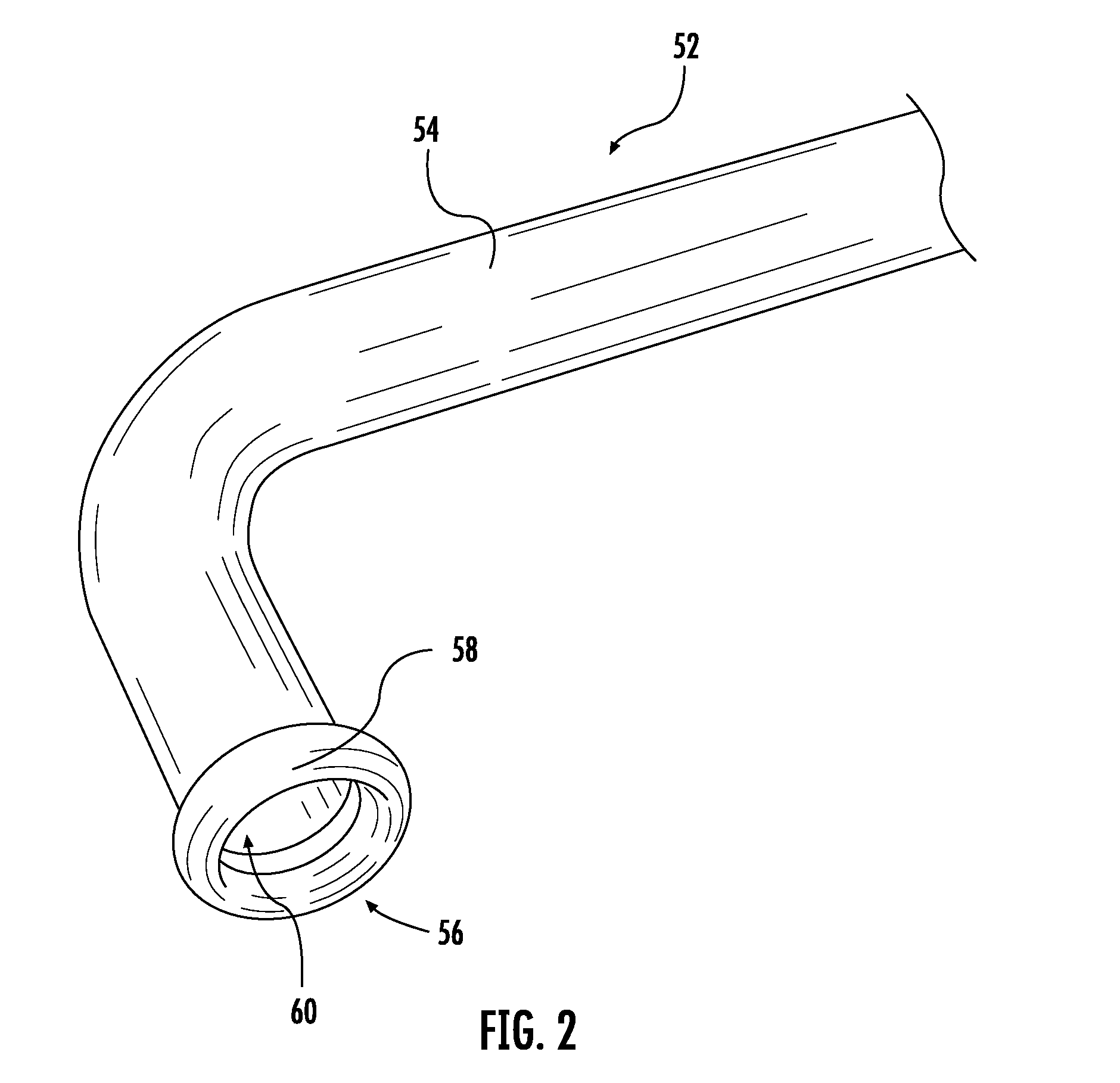

Purge and trap concentrator with sparge vessel

InactiveUS7803635B1Optimize volumeAnalysing fluids using sonic/ultrasonic/infrasonic wavesComponent separationEngineeringOptical transducers

A purge and trap concentrator system that includes a sparge vessel, and includes a variable gas flow valve for controlling the gas pressure in an analytic trap or the sparge vessel; a sensor that detects both a foaming sample state and a high liquid level in the sparge vessel, using one optical sensor; a control scheme that re-directs the purge gases to a second inlet of the sparge vessel during a foaming condition; a control scheme that uses a split flow to enhance the quantity of sample gases passed from an analytic trap; an electrically powered thermal energy source with a fan raising the sparge vessel temperature via thermal convection.

Owner:PROFESSIONAL TECHN SERVICES

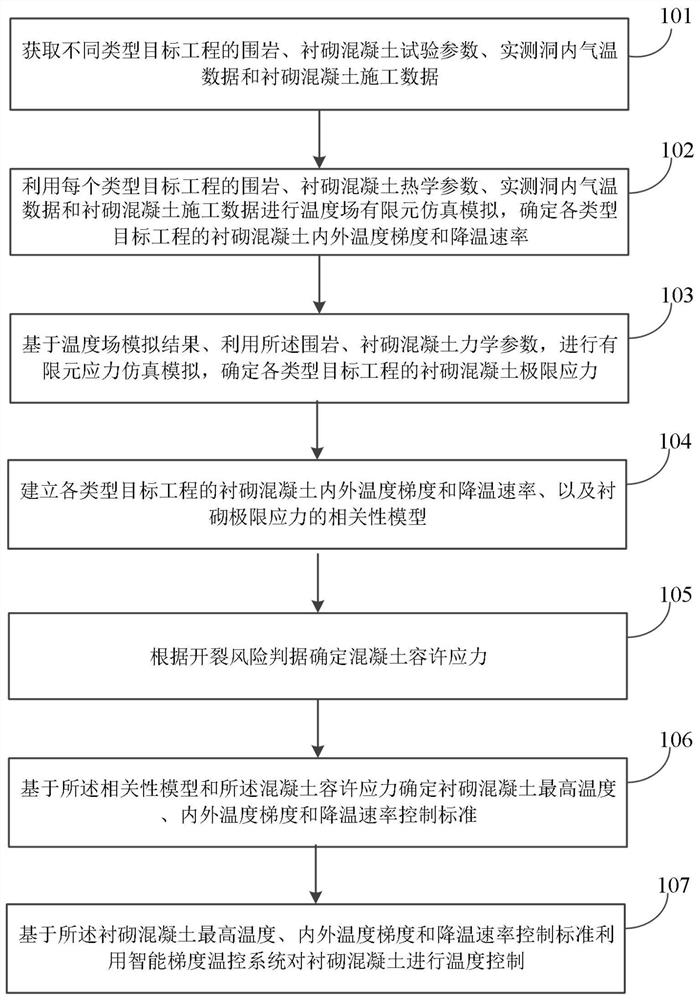

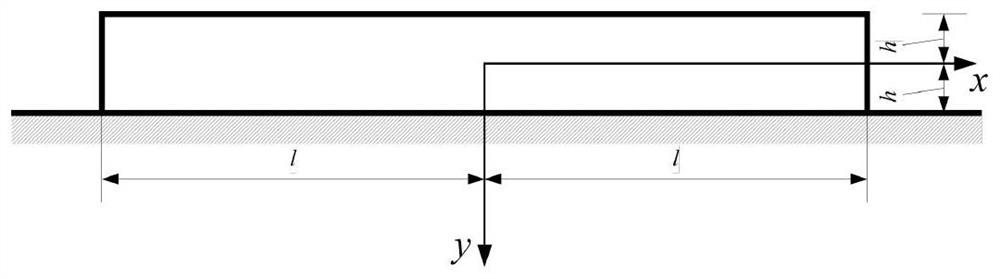

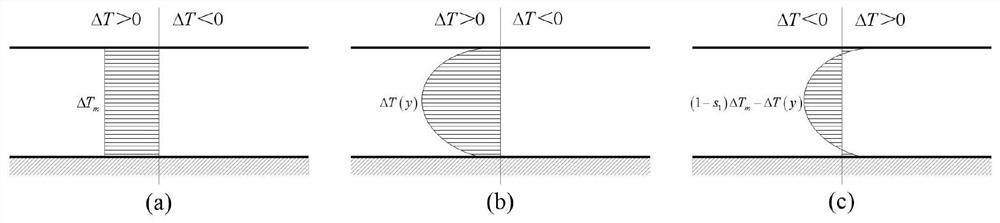

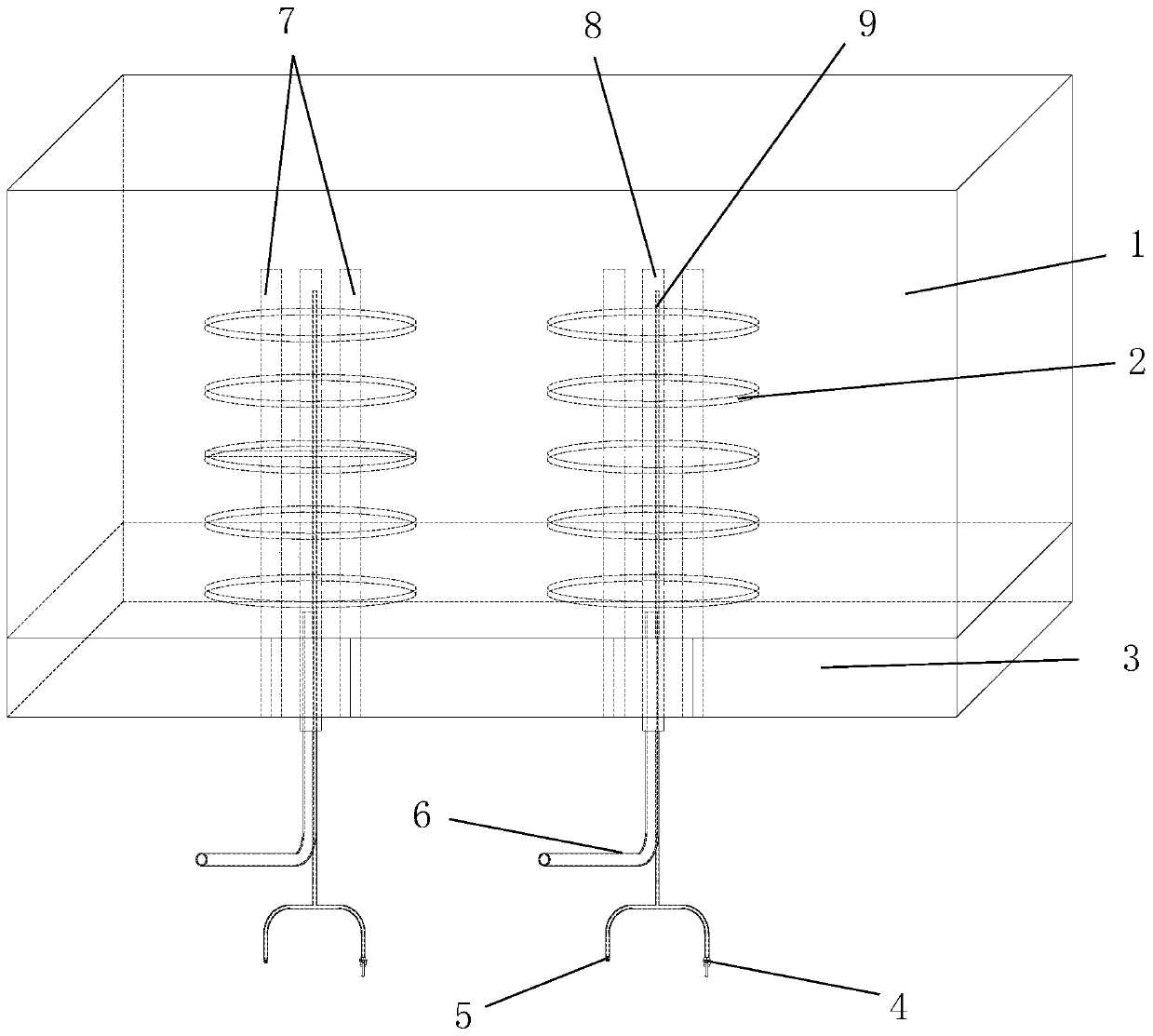

Intelligent gradient temperature control method, system and device and readable storage medium

ActiveCN112113875ARealize temperature control and crack preventionMaterial thermal analysisStrength propertiesStructural engineeringMechanics

The embodiment of the invention discloses an intelligent gradient temperature control method, system and device and a readable storage medium. The method comprises steps of temperature field finite element analogue simulation being conducted by means of surrounding rock, lining concrete thermal parameters, actually-measured in-tunnel temperature data and lining concrete construction data of each type of target engineering; carrying out finite element stress analogue simulation; establishing a correlation model of lining concrete internal and external temperature gradient and cooling rate of each type of target engineering and lining ultimate stress; determining concrete allowable stress according to the cracking risk criterion; determining the highest temperature, the internal and externaltemperature gradient and the cooling rate control standard of the lining concrete based on the correlation model and the concrete allowable stress; and performing temperature control on the lining concrete by utilizing an intelligent gradient temperature control system based on the maximum temperature of the lining concrete, the internal and external temperature gradient and the cooling rate control standard; and the temperature control anti-cracking of the lining concrete construction in the whole period being realized.

Owner:TSINGHUA UNIV +1

Coal seam anti-reflection method for circular damage by using cold shock of liquid nitrogen and phase change gas

ActiveCN111119829AGood cracking and anti-reflection effectFast injectionDrilling rodsFluid removalEngineeringNitrogen gas

Owner:CHINA UNIV OF MINING & TECH

Dual-air-duct air conditioner and dehumidification method and system thereof

ActiveCN110736144AEnsure normal dehumidificationExpand coverage areaMechanical apparatusLighting and heating apparatusAir cycleEngineering

The invention relates to the field of refrigeration equipment, and discloses a dual-air-duct air conditioner and a dehumidification method and system thereof. By obtaining target temperature Ts and target relative humidity [phi]s set by a user and obtaining indoor ambient temperature Tin, outdoor ambient temperature Tout and indoor relative humidity phi in real time, whether the air conditioner meets parameter conditions for entering into an ultralow-sensible-heat high-latent-heat load area dehumidification mode, a low-sensible-heat high-latent-heat load area dehumidification mode and a medium-high-sensible-heat load area dehumidification mode or not is judged, the rotating speed of an upper fan and the rotating speed of a lower fan are controlled under certain dehumidification mode, thusthe three dehumidification modes can be switched, especially when the dual-air-duct air conditioner operates in the ultralow-sensible-heat high-latent-heat load area dehumidification mode, the upper fan is controlled to operate in a low-air gear to be mainly used for promoting air circulation, the lower fan is controlled to operate at the lowest reliable fan rotating speed to be mainly used for dehumidification, latent heat output of a compressor during low-frequency operation is improved while sensible heat output is lowered, and constant-temperature dehumidification is achieved.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

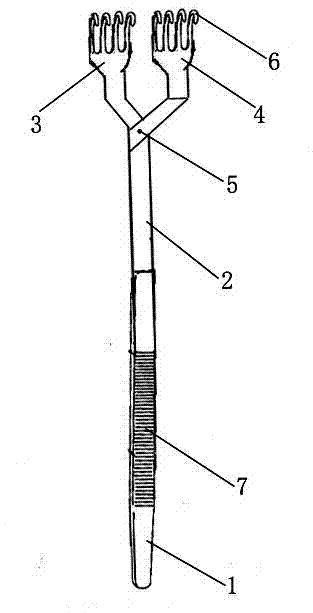

Double-head thyroid drag hook

Owner:NANJING QINHUAI HOSPITAL

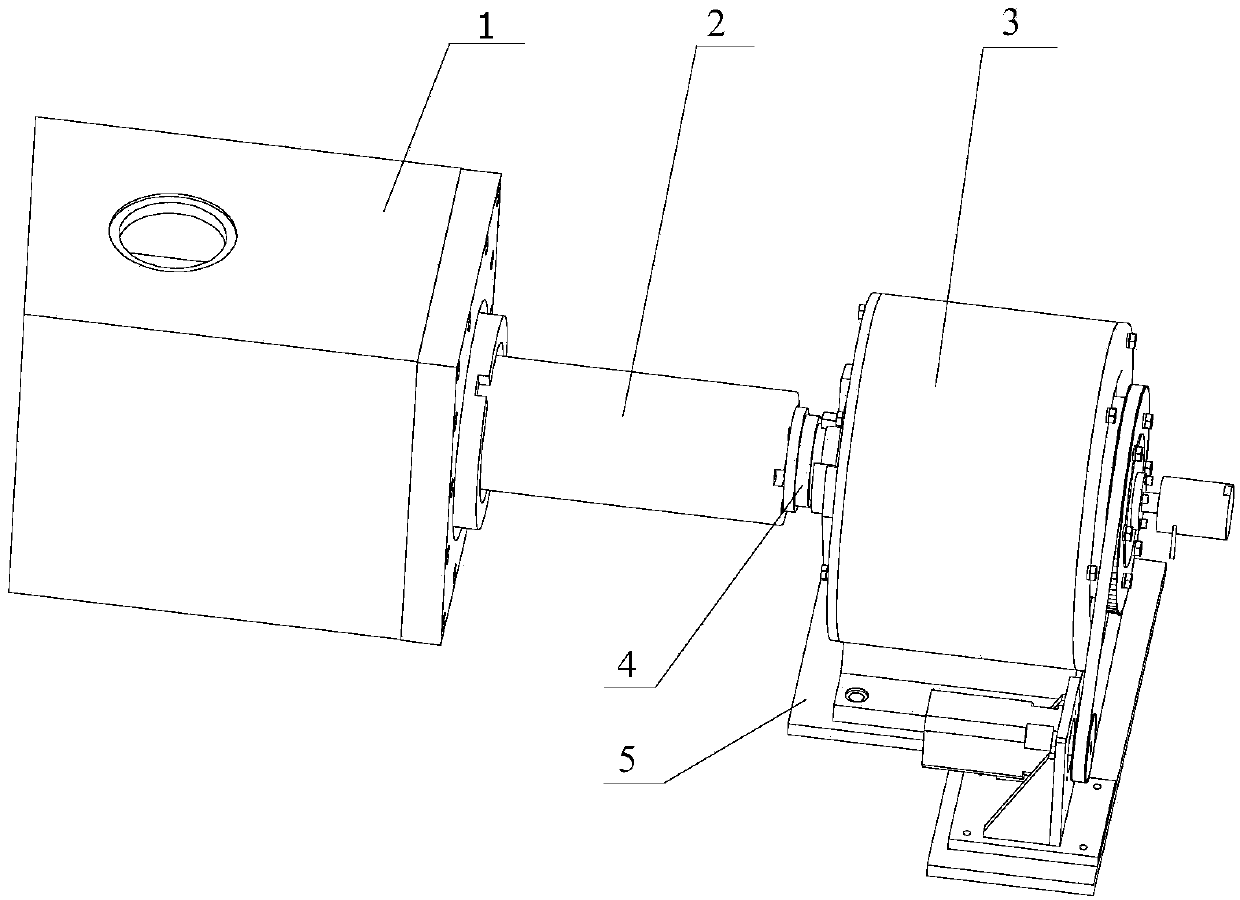

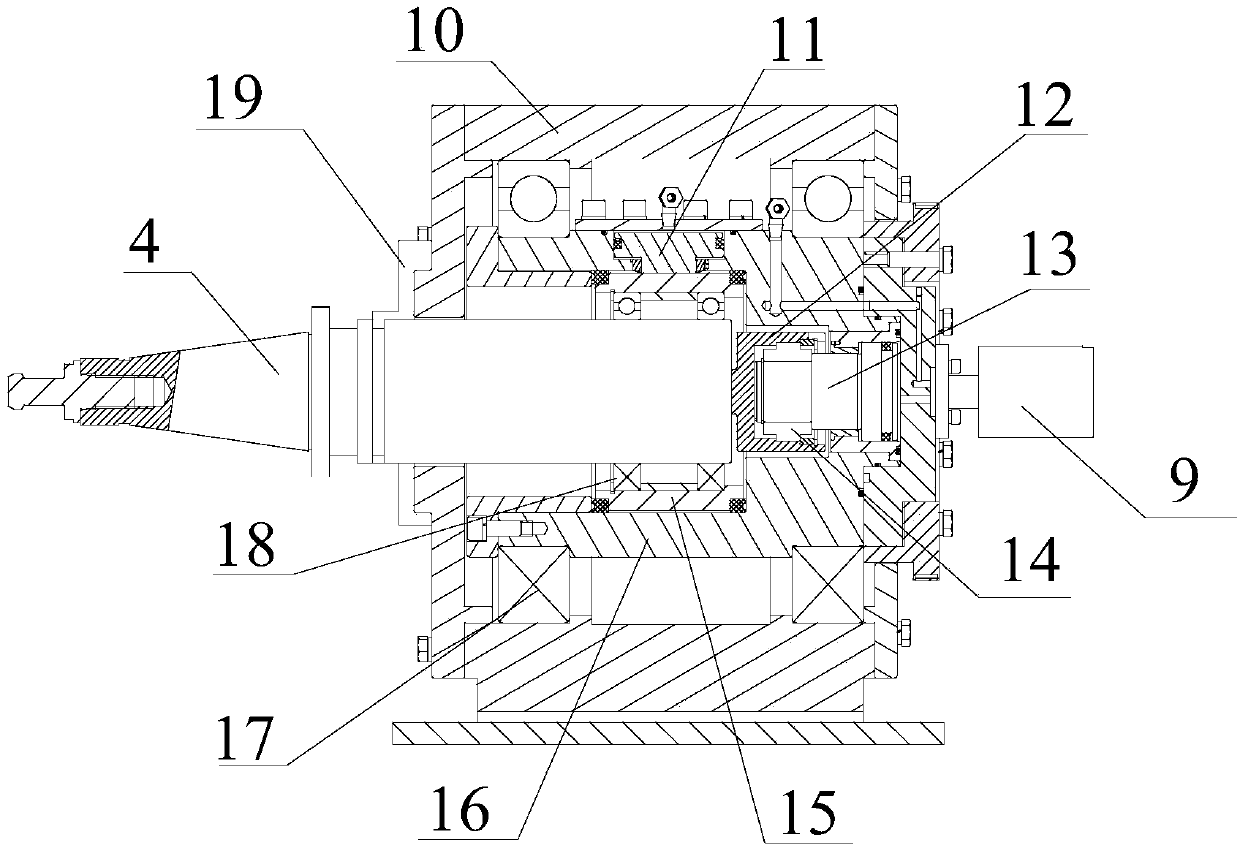

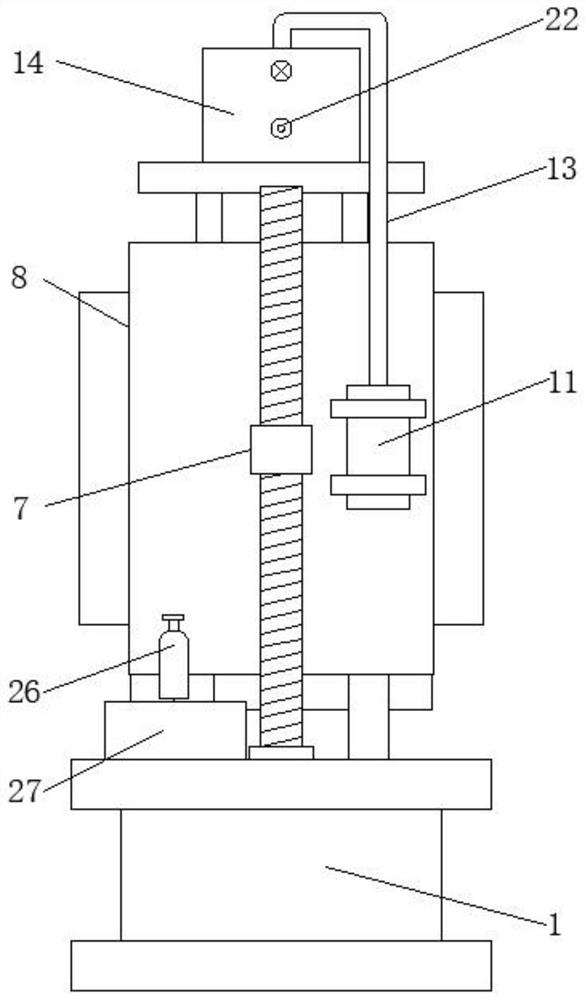

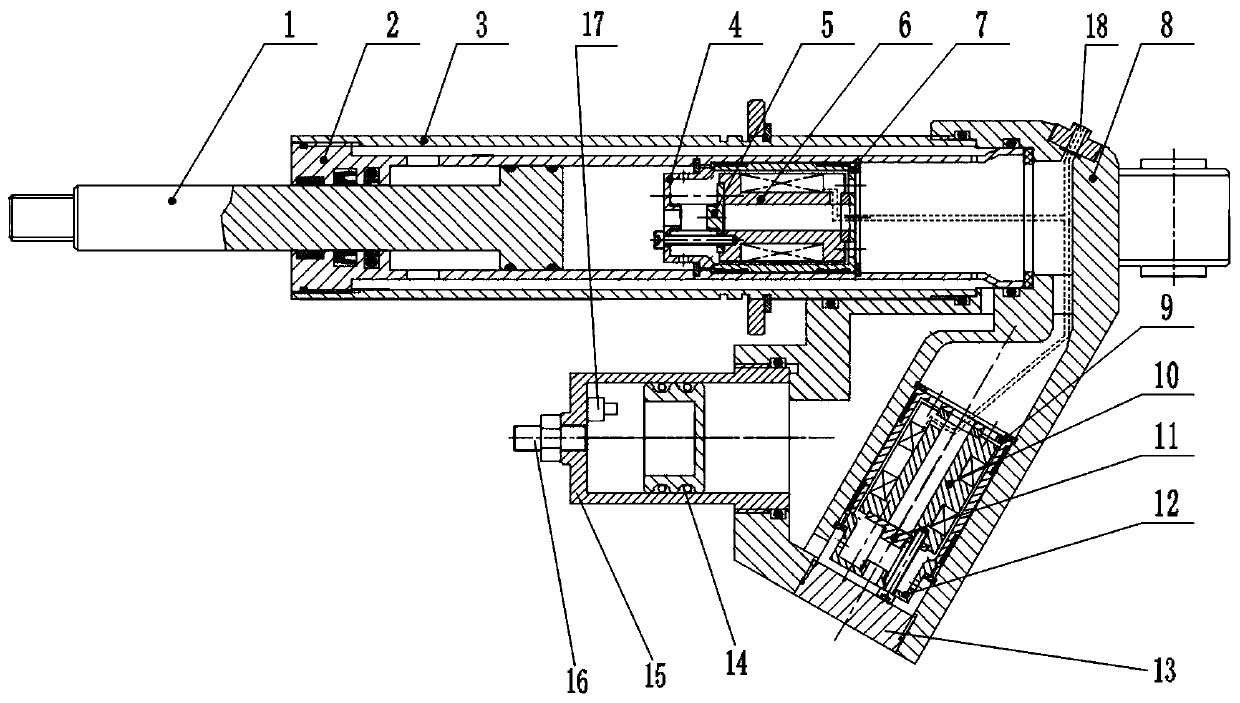

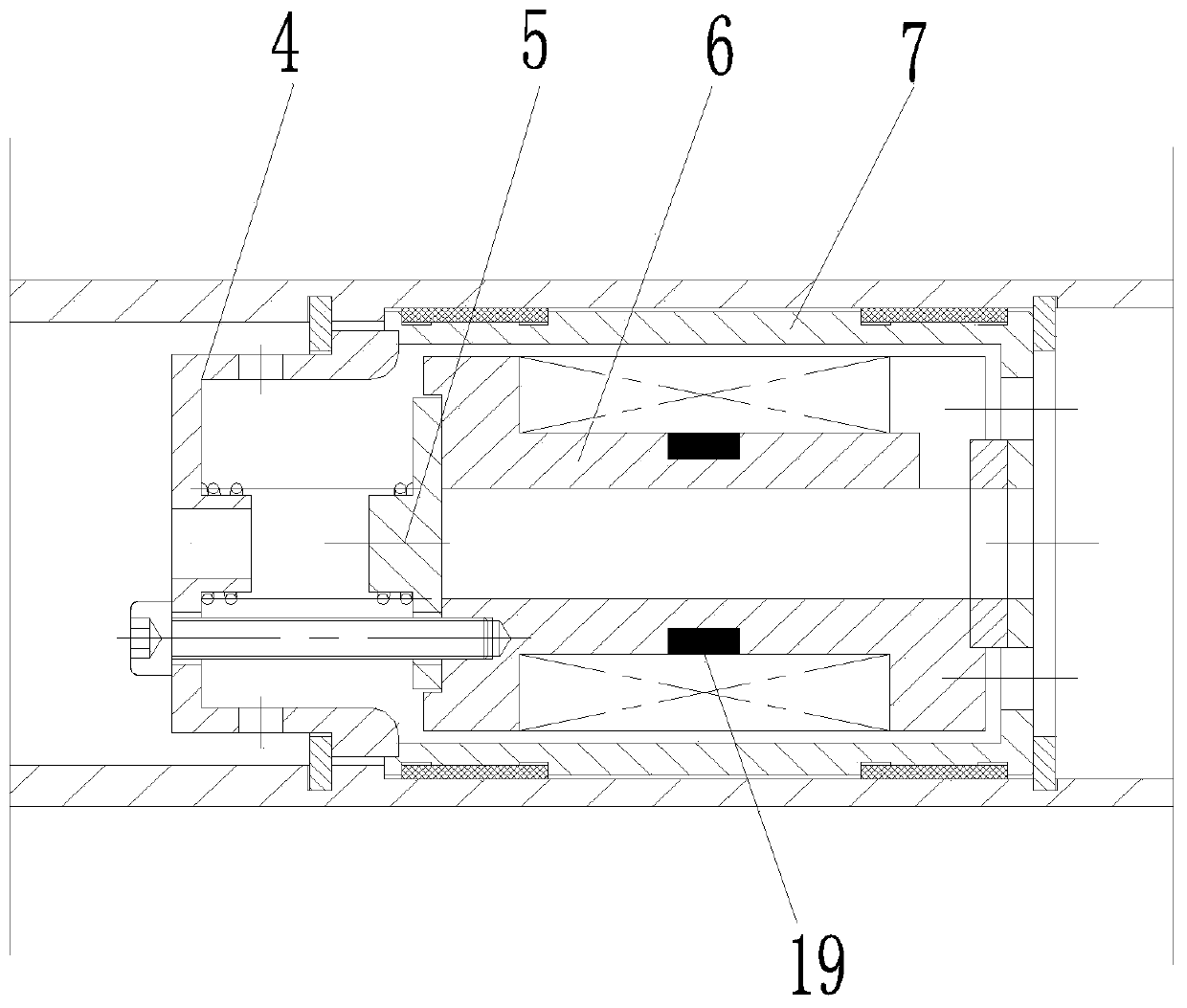

Machine tool cutting force simulation loading device

ActiveCN103737431AHigh simulationSimple structureProgramme controlMeasurement/indication equipmentsNumerical controlHydraulic cylinder

Owner:通用技术齐齐哈尔二机床有限责任公司

Central grading lean oil premixed low-pollution combustion chamber

ActiveCN111174233ABroaden the boundaries of workPromote atomizationContinuous combustion chamberSpontaneous combustionCombustion chamber

Owner:NORTHWESTERN POLYTECHNICAL UNIV

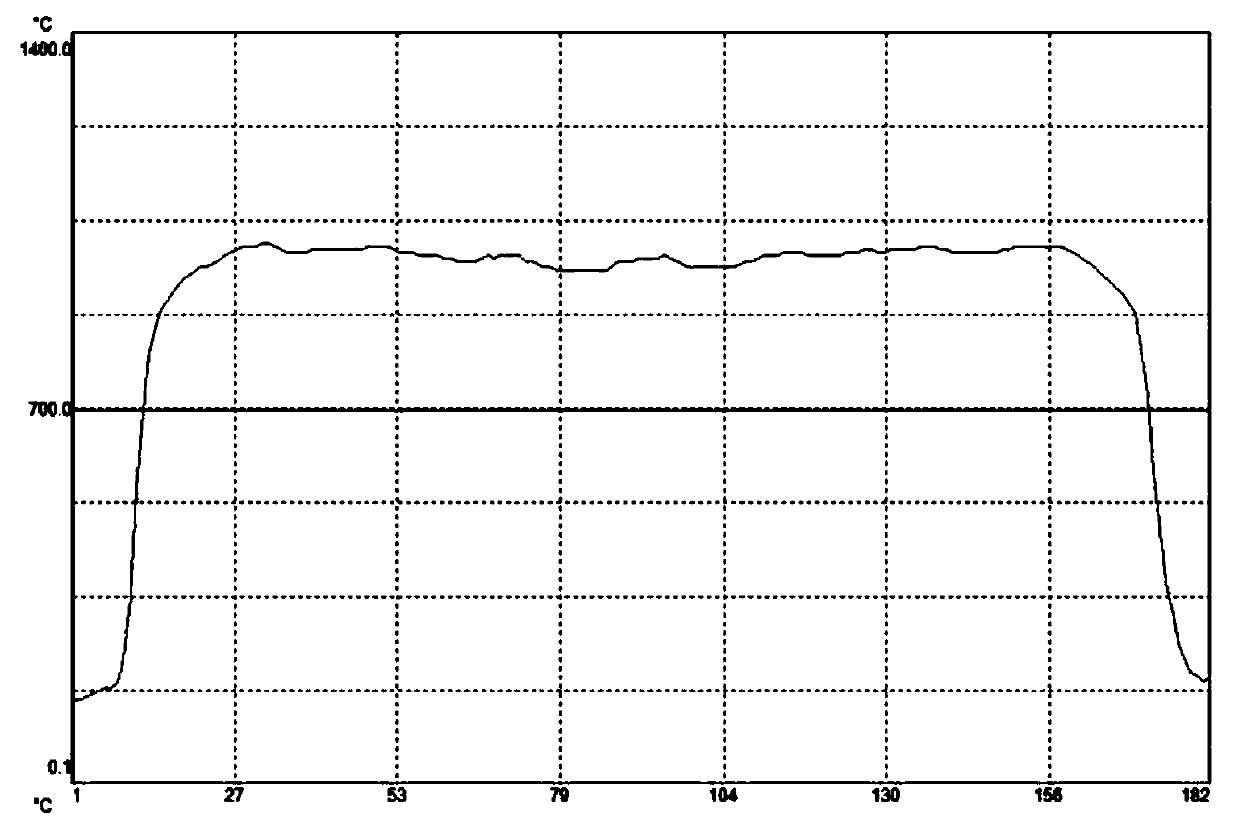

Method for evaluating temperature uniformity in width direction of hot-rolled strip steel intermediate billet

Owner:MAANSHAN IRON & STEEL CO LTD

Hydraulic power balance adjusting method and system for cells of heating unit

ActiveCN111811016ASame return water temperatureScientific and reasonable dynamic adjustment abilityData processing applicationsLighting and heating apparatusThermodynamicsEngineering

The invention discloses a hydraulic power balance adjusting method and system for cells of a heating unit. The return water temperature of the cells of the heating unit at the next moment is obtainedby carrying out deep learning training on historical sample data of the heating unit. By predicting the return water temperature of the cells of the heating unit at the next moment, the valve openingdegree of each cell can be adjusted in advance, so that the return water temperature of the cells is kept consistent, and the problems in the prior art that experts and field personnel need to carry out calculation and adjustment, and the valve opening degree of each cell cannot be adjusted in advance to enable the return water temperature of the cells to be kept consistent are solved. The returnwater temperature of each cell can be predicted in advance, the valve opening degree of each cell is adjusted in advance, the return water temperature of the cells are kept consistent, more scientificand reasonable dynamic adjusting capacity is provided, and the problem that normal production and life of a user are influenced by heat waste or insufficient heat supply due to unreasonable calculation and delayed adjustment is avoided.

Owner:RUINA INTELLIGENT EQUIP CO LTD

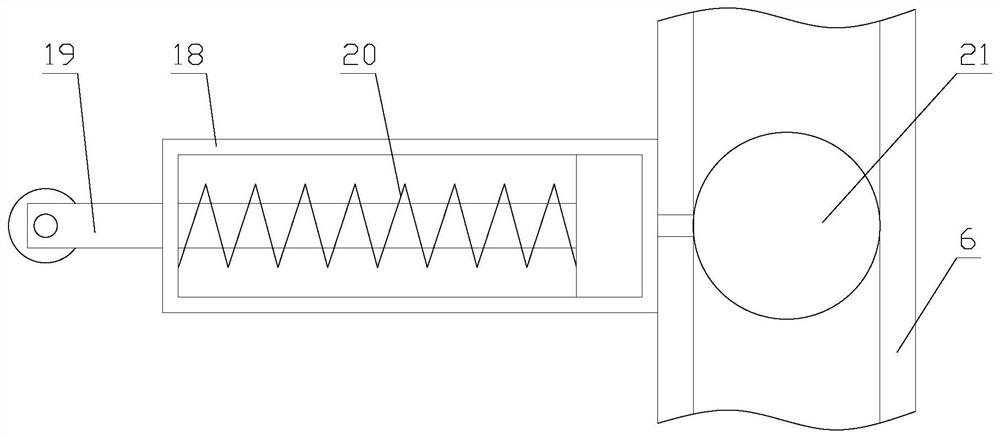

Hydraulic external line-up clamp for steel gas pipeline

InactiveCN111112935AGood adjustment functionEasy alignmentWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderStructural engineering

The invention relates to the technical field of welding auxiliary tools, in particular to a hydraulic external line-up clamp for a steel gas pipeline. The hydraulic external line-up clamp comprises apositioning plate, a central positioning element, lateral positioning elements and a synchronous feeding mechanism, wherein the central positioning element comprises two symmetric middle half rings and a first hydraulic cylinder; the two middle half rings are hinged; the articulated shafts of the two middle half rings are arranged on the upper surface of the positioning plate; the first hydrauliccylinder can drive the two middle half rings to be tightly abutted; the two lateral positioning elements are symmetrically arranged on two sides of an axial line direction of each middle half ring; the positioning plate is fixedly provided with spacing rods; the two spacing rods are independently positioned on two sides of the central positioning element and are positioned on lateral sides of theaxial line direction of lateral half rings; and the synchronous feeding mechanism can drive the two lateral positioning elements to synchronously move to a direction near or far away from the centralpositioning element relative to the positioning plate. According to the hydraulic external line-up clamp, a function that a worker can conveniently regulate a welding line between two pipelines is realized.

Owner:SHANGHAI ANHONG CONSTR ENG CO LTD

Vapor compression refrigeration system and method of operating such a system

ActiveUS20210254864A1Eliminate orMitigate such drawbackMechanical apparatusCompression machines with non-reversible cycleEngineeringGas cooler

A vapor compression refrigeration system has a main refrigerant circuit having a primary compressor group, a gas cooler or condenser, an expansion device, a liquid receiver, and at least one evaporator. An emergency circulation duct fluidically connects the liquid receiver to the main circuit to allow a flow of refrigerant from the liquid receiver to the gas cooler. An emergency compressor group in the emergency circulation duct is activatable when pressure inside the liquid receiver or in the duct upstream of the emergency compressor group meets or exceeds a predefined emergency pressure threshold. An uninterruptible power supply powers the emergency compressor group and expansion device during a shutdown of the refrigeration system. When pressure inside the liquid receiver or in the duct upstream of the emergency compressor group equals or exceeds the predefined emergency pressure threshold, an emergency circulation of refrigerant fluid is activated through the emergency circulation duct.

Owner:EPTA

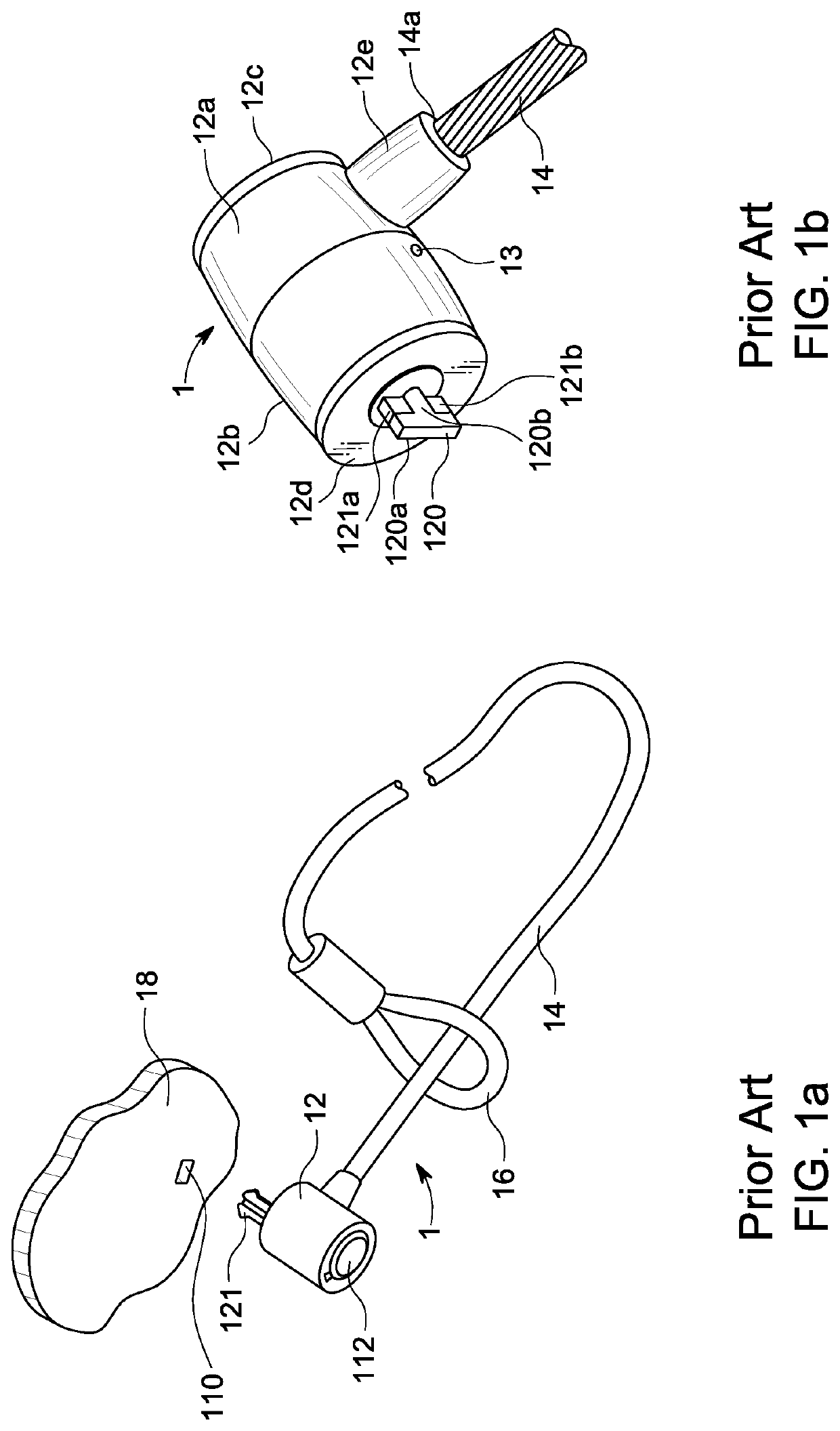

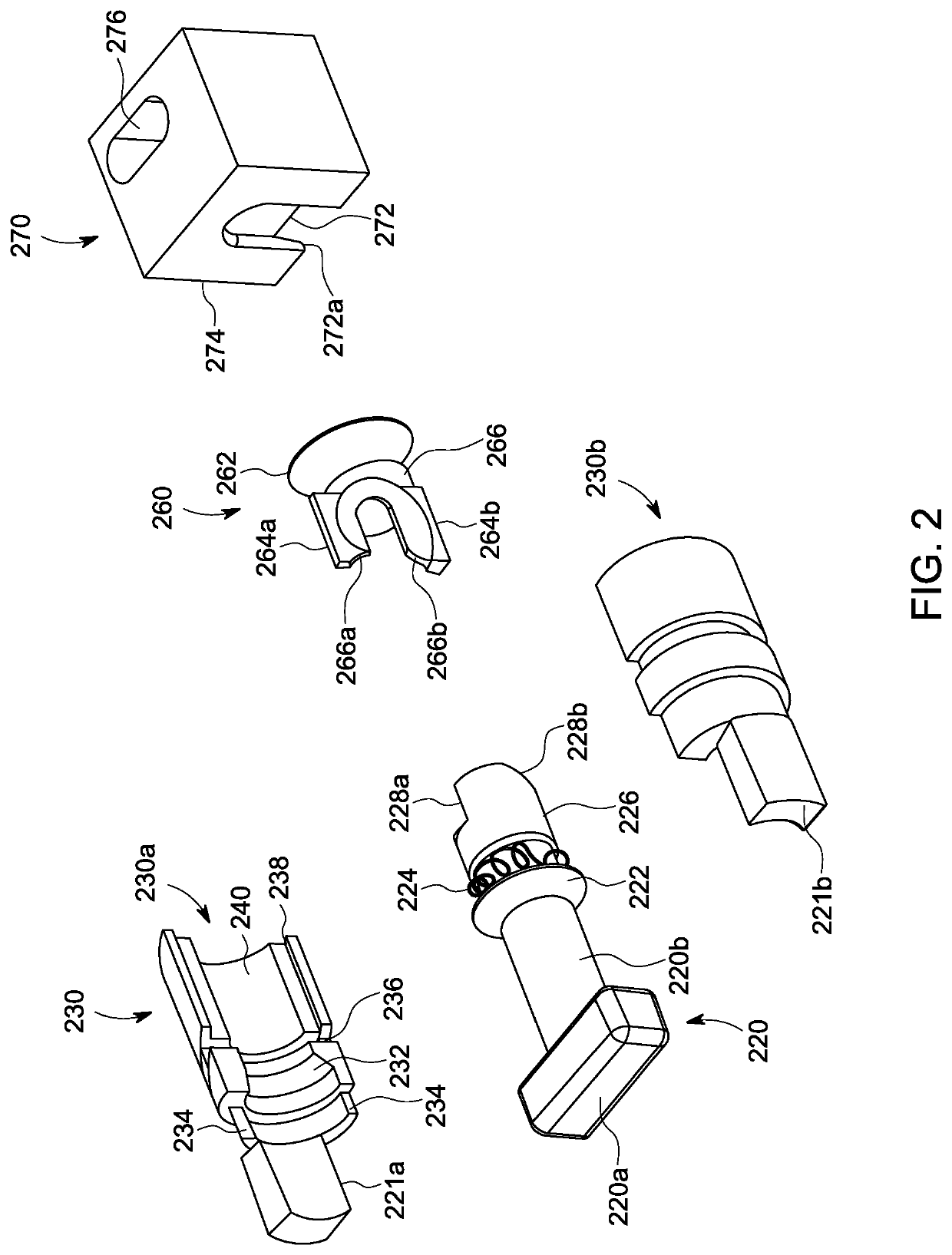

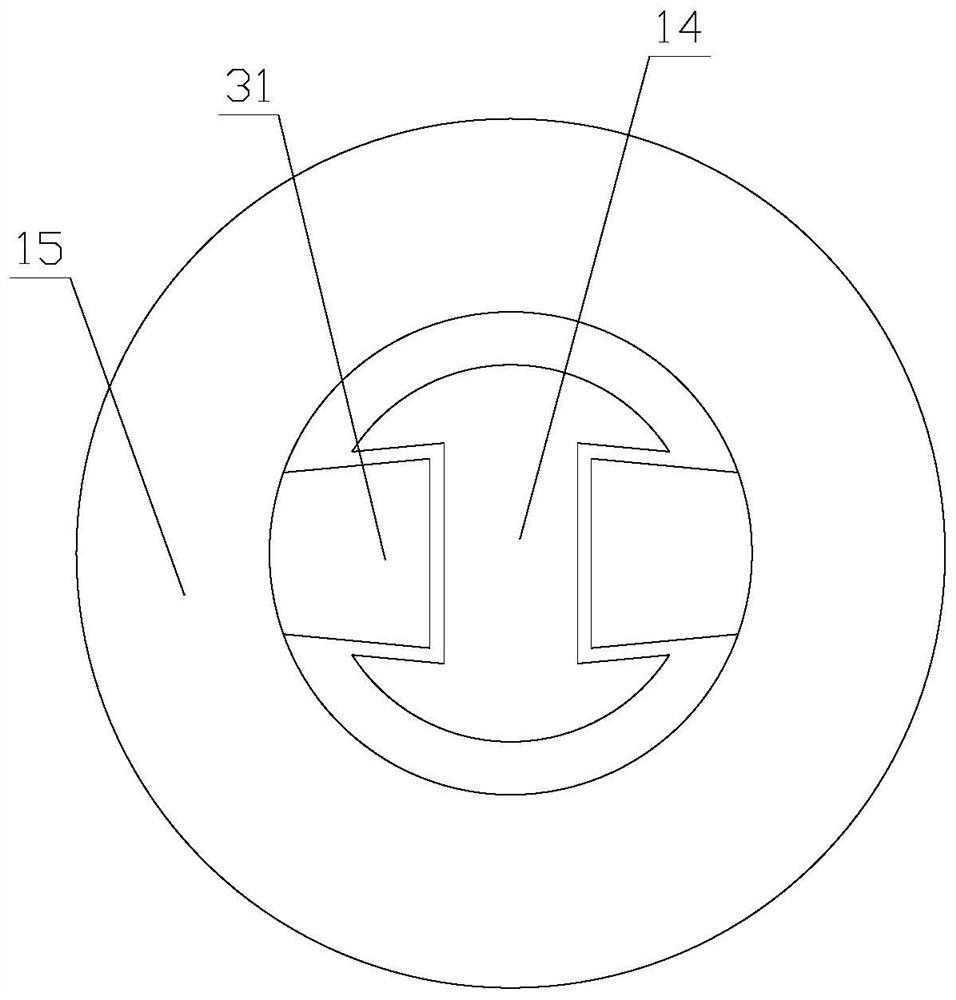

Corner-mounted lock head for computer security

ActiveUS20200173201A1Sacrificing strengthSacrificing usabilityLocks for portable objectsStructural engineeringMechanical engineering

Owner:AVGANIM MEIR

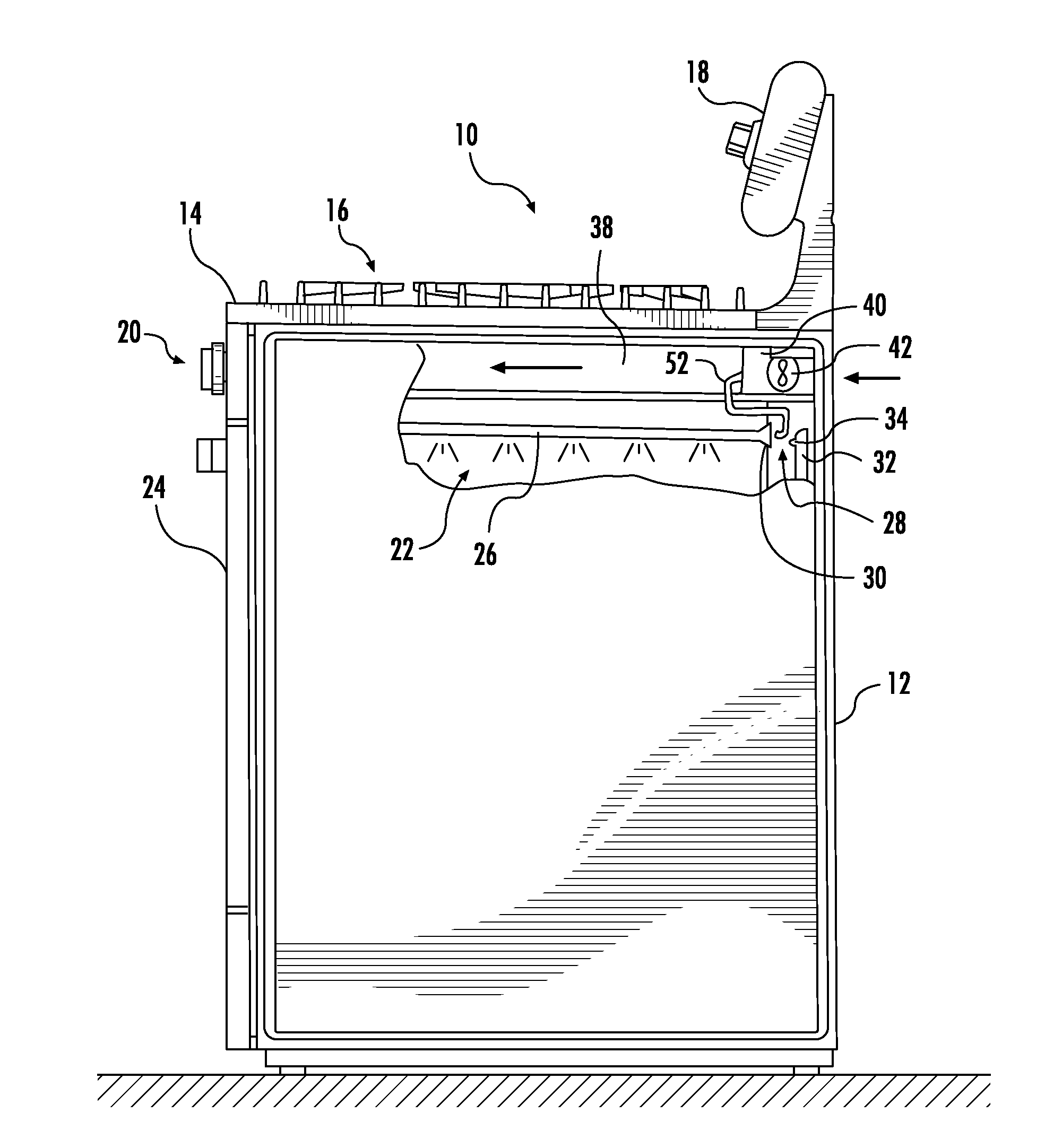

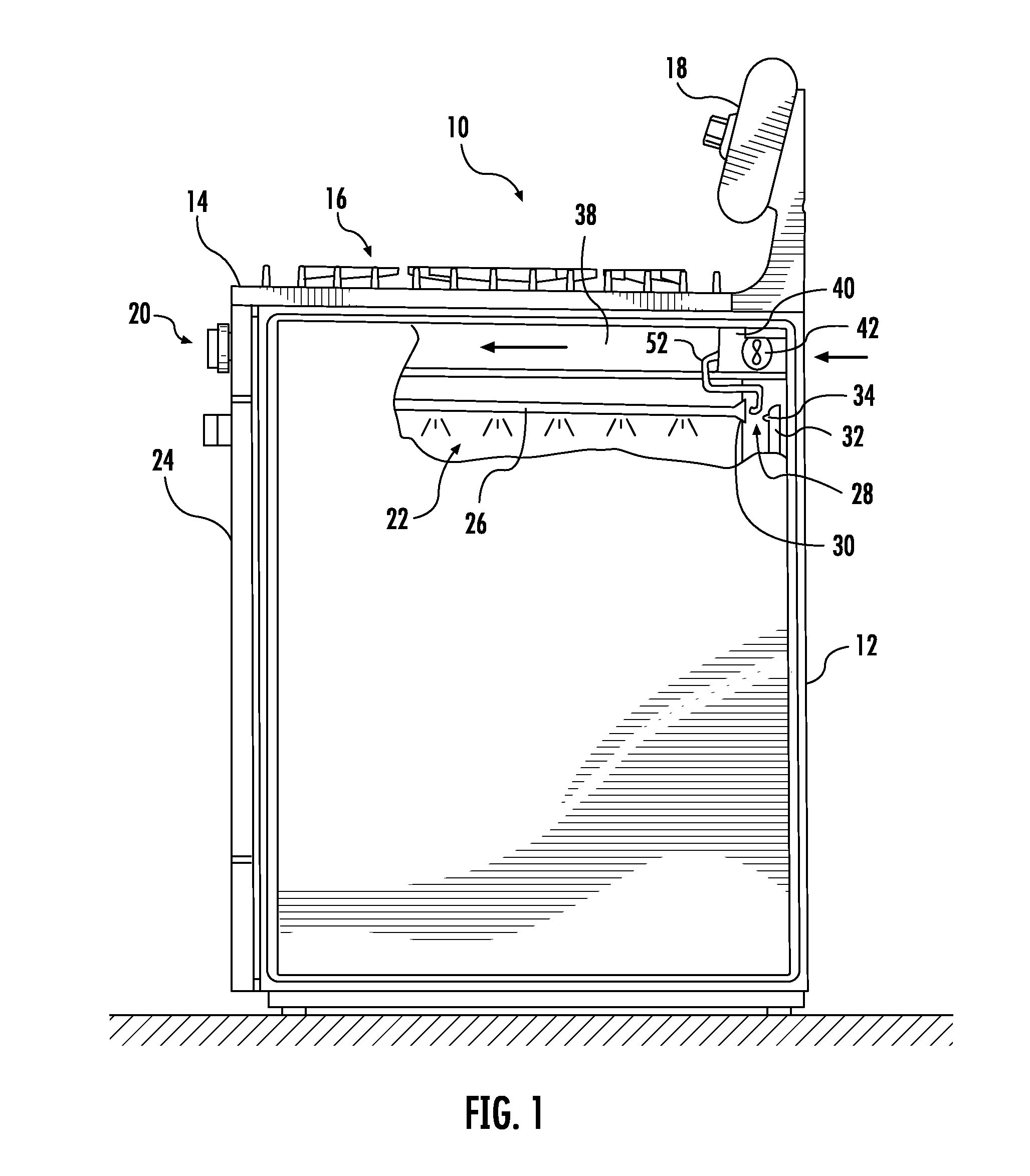

Home appliance with supplemental combustion air supply apparatus

ActiveUS20140305424A1Increasing burner efficiencyImprove efficiencyAir supply regulationDomestic stoves or rangesThermodynamicsCombustor

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

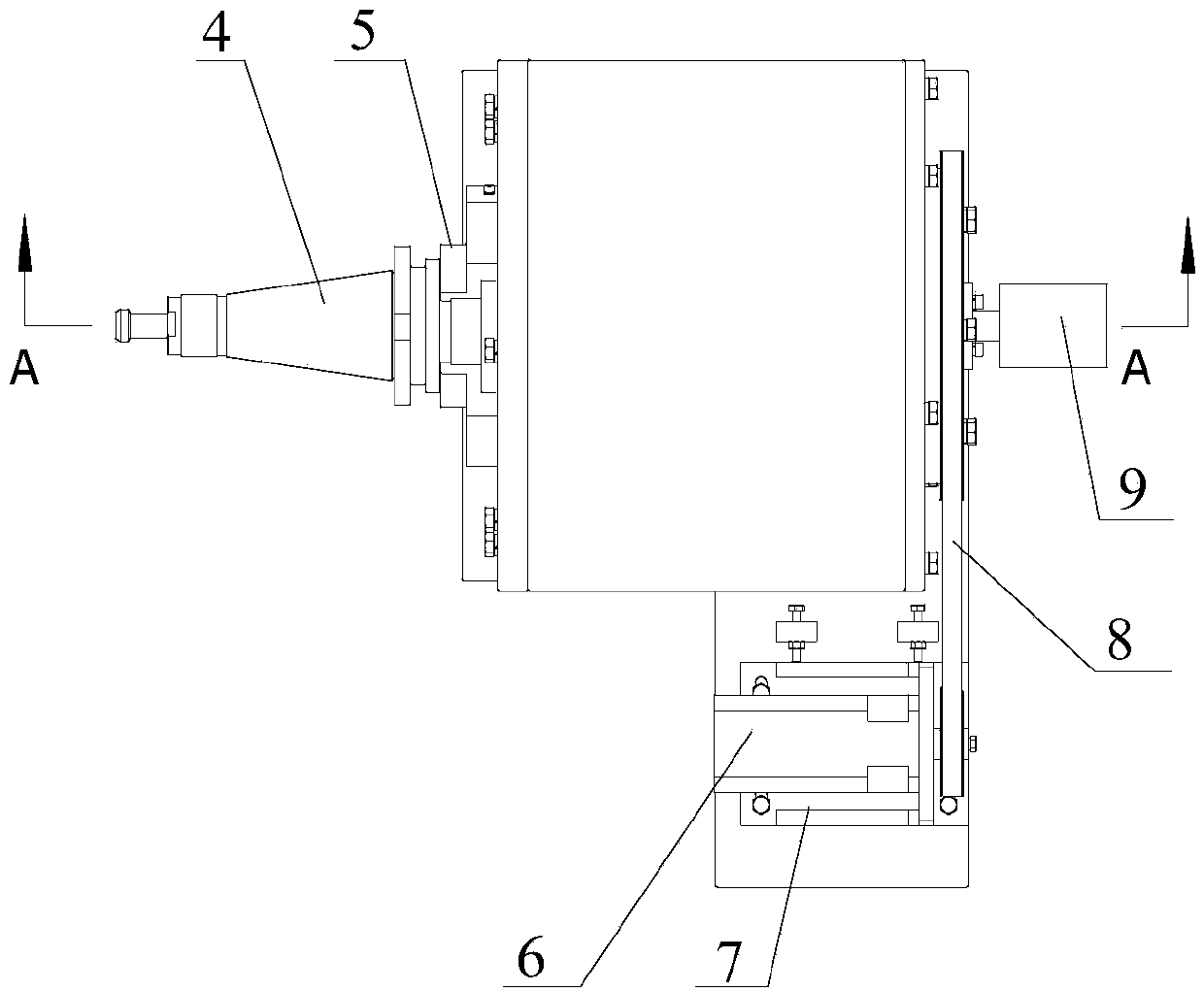

Front-back parallel three-joint double-support attack angle mechanism and control method thereof

InactiveCN111579198ARealize the function of changing the angle of attackEasy to operate and controlAerodynamic testingInlet channelAerodynamic load

The invention relates to the technical field of wind tunnel experiments and discloses a three-joint double-support attack angle mechanism. The three-joint double-support attack angle mechanism comprises a front support and a rear support which are installed at the bottom of an air inlet channel model, wherein one end of the front support is fixed to a front end of the bottom of the air inlet channel model, the other end of the front support is hinged to a fixing rod through a first movable joint, the fixing rod is fixed to a wall plate at the bottom of a wind tunnel, one end of the rear support is fixed to a rear end of the bottom of the air inlet model, and the other end of the rear support is hinged to a connecting rod through a second movable joint, and an end of the connecting rod is hinged with a push-pull rod driven by a driving mechanism to move up and down. The three-joint double-support attack angle mechanism is advantaged in that the driving mechanism is used for pushing thepush-pull rod to move up and down to drive an air inlet model to change an attack angle with a first movable joint as the rotating center, the air inlet model can be supported, the attack angle changing function of the air inlet model can be achieved, and an existing attack angle mechanism of a wind tunnel is completely or partially replaced, operation control is simple, cost is low, and a problemthat a traditional attack angle mechanism for the outflow test is easily damaged due to overlarge aerodynamic load of the inflow test model is avoided.

Owner:CHINA AERODYNAMICS RES & DEV CENT

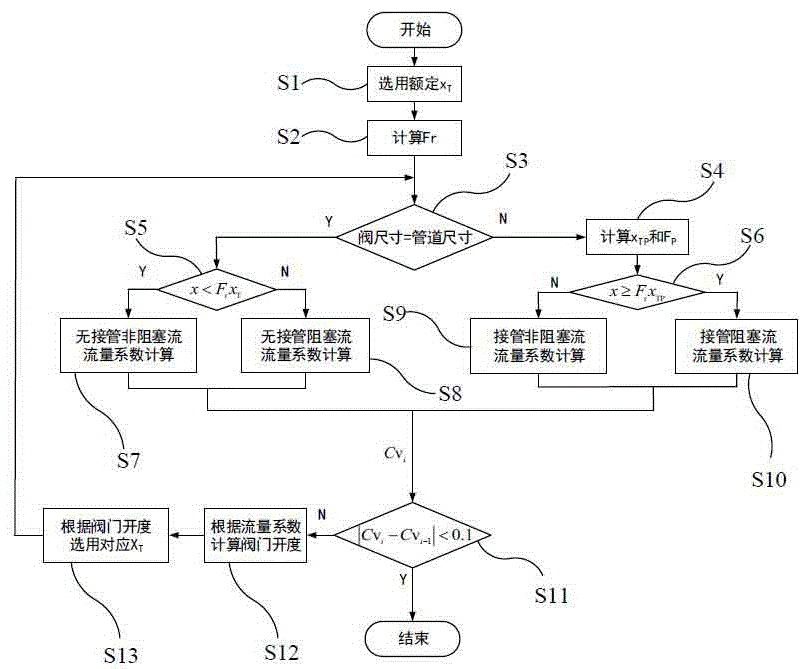

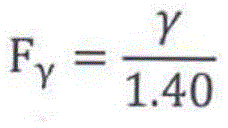

High-precision gas medium regulating valve selection calculation method

The invention discloses a high-precision gas medium regulating valve selection calculation method, which comprises the following steps of after obtaining an initial flow coefficient through selecting a differential pressure ratio coefficient when a valve is fully opened, considering the characteristic of the differential pressure ratio coefficient changing along the valve opening, repetitively iterative calculating, and finally obtaining an accurate flow coefficient of the valve under a given operation condition. According to the high-precision gas medium regulating valve selection calculation method provided by the invention, a calculating process is improved based on a gas medium flow coefficient calculation part in ANSI / ISA-75.01.01(IEC60534-2-1 Mod)-2007, the corresponding differential pressure ratio coefficient is selected according to the change of the valve opening, and the flow coefficient is iteratively operated, so that the selection calculation result of the gas medium regulating valve is more accurate, and the actual use requirement is met.

Owner:JIANGSU SHENTONG VALVE

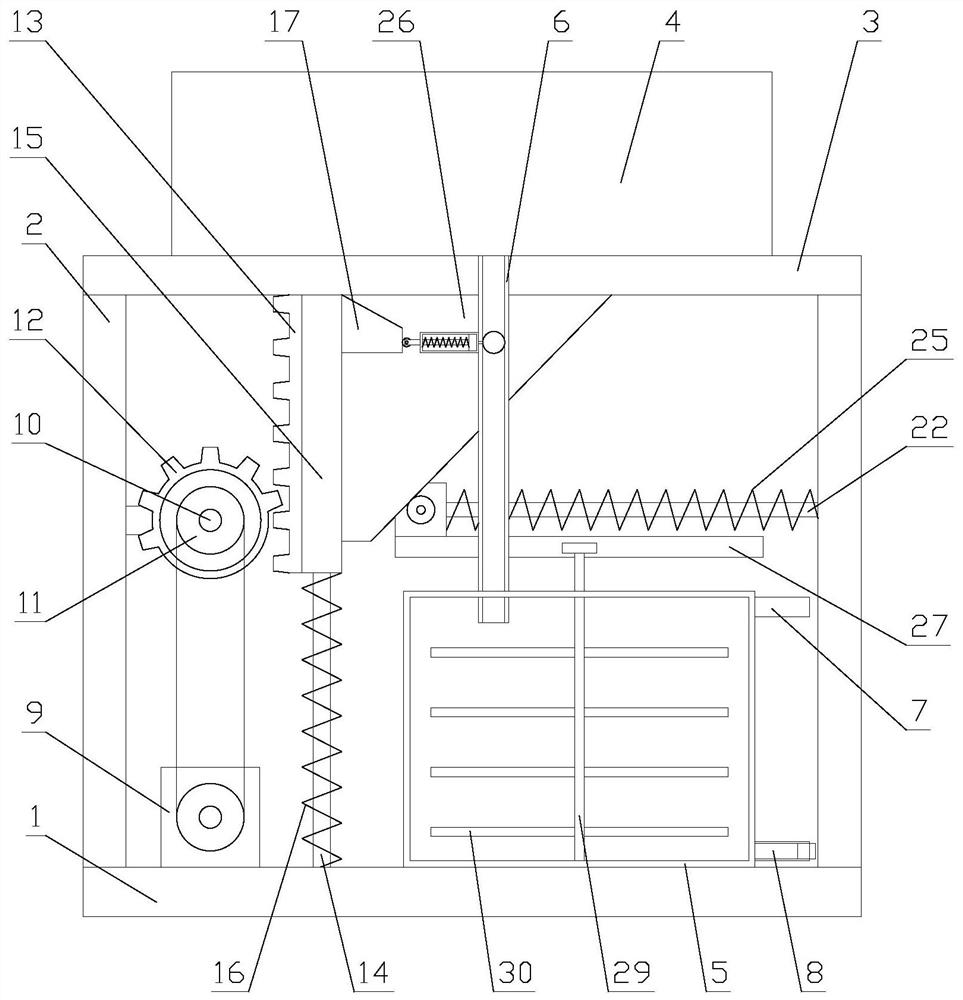

Extrusion granulation device for zinc fertilizerpreparation

InactiveCN112125763AGranulation by pressingSolid/semi-solid fertilisersElectric machineAgricultural engineering

The invention discloses an extrusion granulation device for zinc fertilizer preparation. The device comprises a granulation mechanism for zinc fertilizer extrusion granulation, a conveying mechanism,a rolling mechanism, a support frame and a processing box; the processing box is mounted at the upper end of the support frame; the rolling mechanism is arranged in the middle of the interior of the processing box; the support frame is mounted at the lower end of the processing box; the granulation mechanism is arranged on the lower side of the interior of the processing box; the rolling mechanismis located above the granulation mechanism; and the conveying mechanism is arranged at the lower end of the inner side of the support frame. The granulation device further comprises a stirring mechanism and a recycling mechanism. A stirring roller in the processing box is driven by a gear motor to rotate; a powdery fertilizer is supported by an overturning plate, a supporting seat and a telescopic cylinder during stirring, so that the powdery zinc fertilizer raw material is stirred into a flocculent state; incomplete zinc fertilizer particles obtained after extrusion granulation are screenedand sucked away by the recycling mechanism, and therefore, the incomplete zinc fertilizer is put into a granulation box again to be granulated again.

Owner:HUAXING ZINC CHEM CO LTD

W-shaped elastic strip parametric modeling method

ActiveCN110765684AAccurately establishedGuaranteed accuracyGeometric CADDesign optimisation/simulationElement modelModelSim

The invention discloses a W-shaped elastic strip parametric modeling method which comprises the following steps: A, acquiring design parameters in a front view and an expanded view of an elastic strip; B, calculating an elastic strip front view curvilinear equation and an elastic strip expansion graph curvilinear equation; C, based on the symmetrical structure of the elastic strip, obtaining an elastic strip overall axis space curve equation;C, compiling a parameterized modeling program by utilizing Matlab software, wherein the parameterized modeling program has the function of quickly obtaining an elastic strip axis space curve equation based on elastic strip design parameters; and E, inputting the diameter D of the elastic strip, and finishing modeling by utilizing finite element software. The method has the beneficial effects that the elastic strip axis space curve equation can be obtained through a parameterized modeling program only by acquiring basic parameters of the elastic strip structure, namely, the formula, and the precision, and the corresponding finite element model can be quickly and accurately established by utilizing finite element software on the basis of the equation and the diameter D of the elastic strip.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

Ammonia low-nitrogen multi-stage rotational-flow burner

ActiveCN112963833AWell mixedUniform heat loadAir supply regulationGaseous fuel burnerCombustorThermal radiation

Owner:XI AN JIAOTONG UNIV

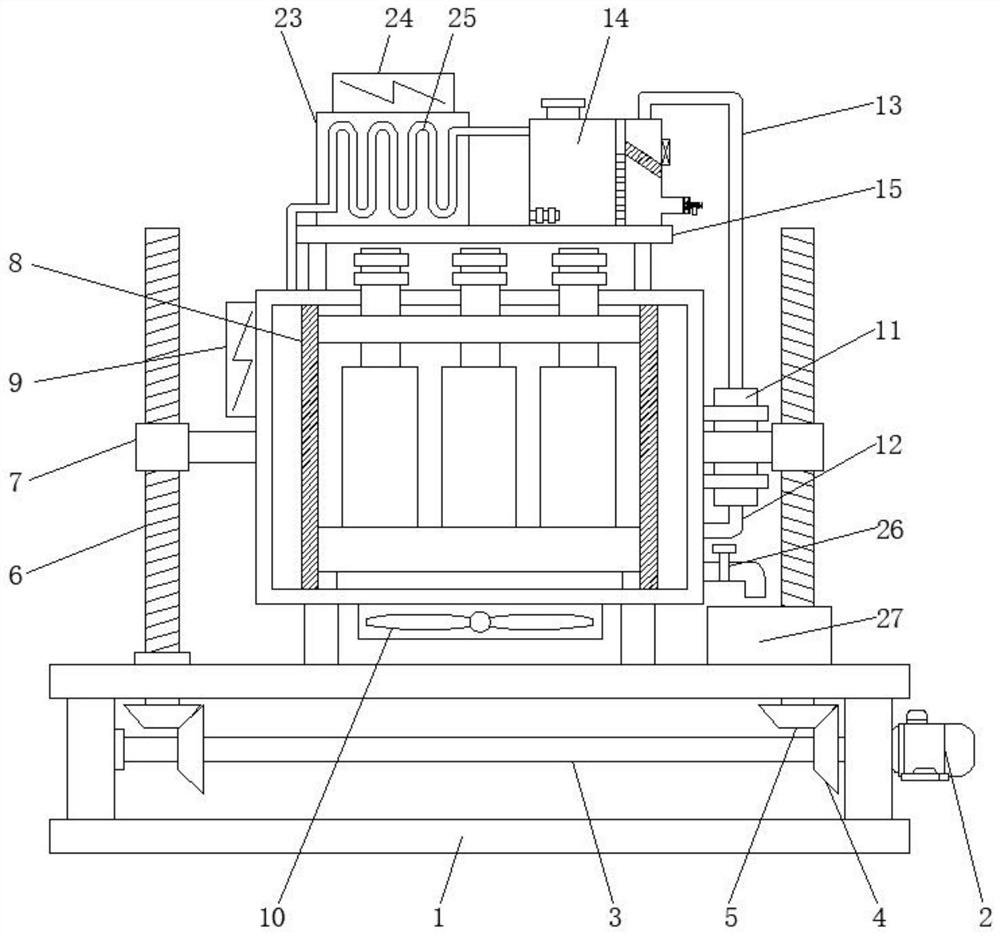

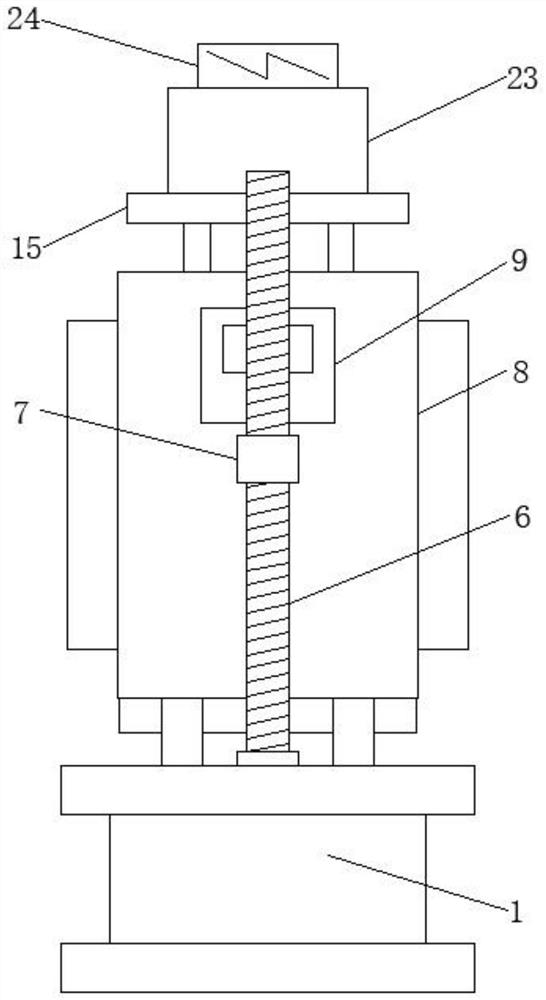

Oil-immersed transformer capable of cleaning impurities

InactiveCN112466616AEasy to check and maintainIncrease heightTransformers/reacts mounting/support/suspensionTransformers/inductances coolingElectric machineTransformer oil

Owner:江苏永刚电力设备有限公司

Hydraulic Block for a Hydraulic Assembly of a Slip Control System of a Hydraulic Vehicle Brake System

ActiveUS20200094800A1Vented more easilyEasy to ventServomotor componentsVehicle sub-unit featuresControl systemClassical mechanics

A hydraulic block of a slip control system of a hydraulic vehicle brake system includes receptacles for the hydraulic accumulator and receptacles for outlet valves arranged on opposite sides of each other in the hydraulic block. The sides of the hydraulic block, which comprise the receptacles for the outlet valves and the hydraulic accumulators, are connected to one another by bores perpendicular thereto.

Owner:ROBERT BOSCH GMBH

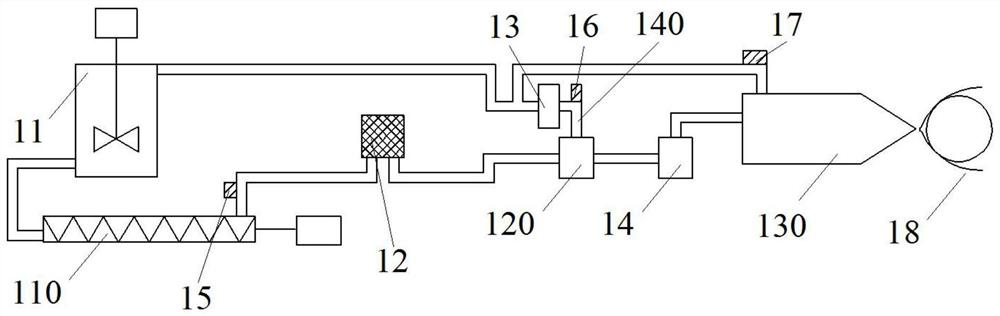

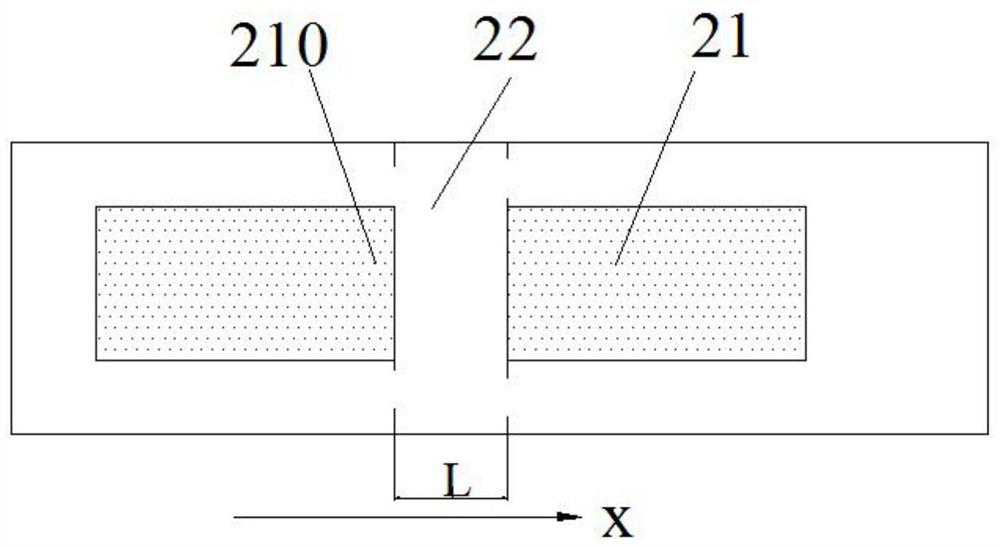

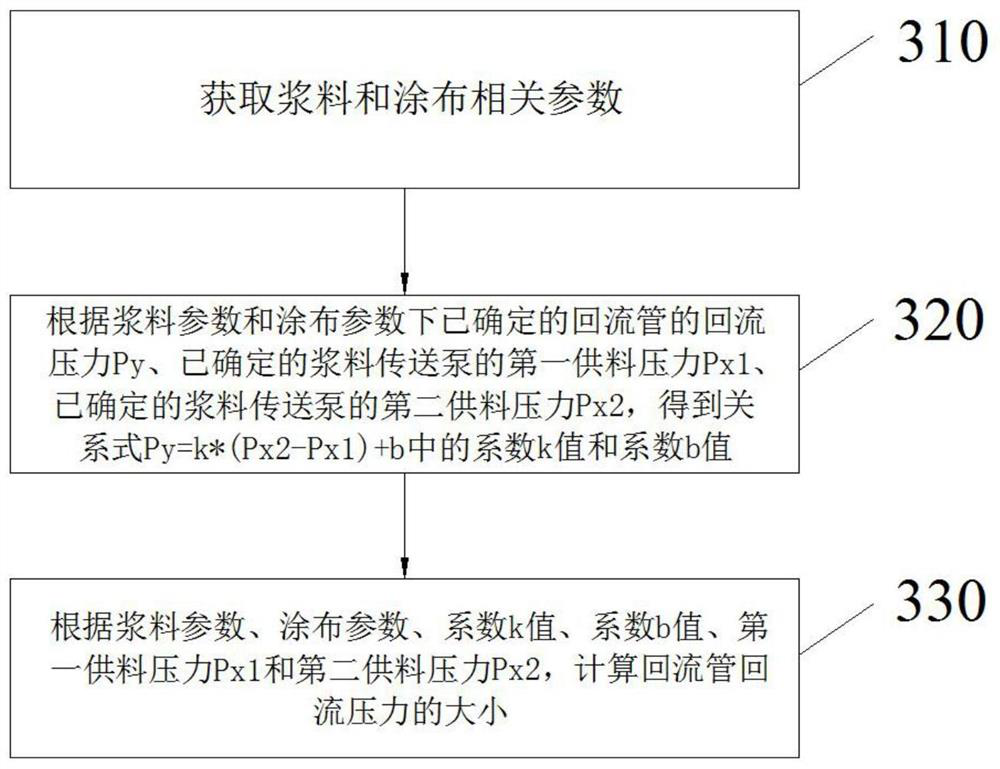

Method and device for calculating backflow pressure of extrusion type coating machine, and storage medium

Owner:东莞维科电池有限公司

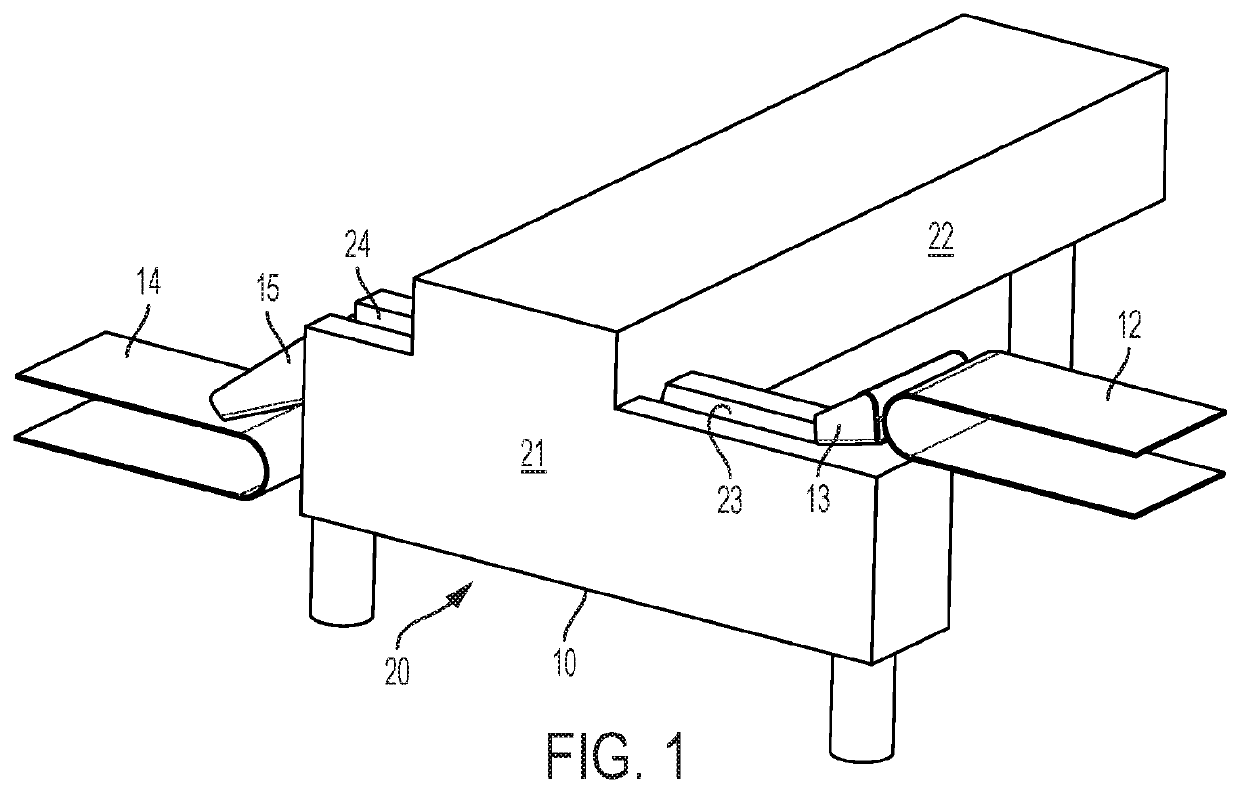

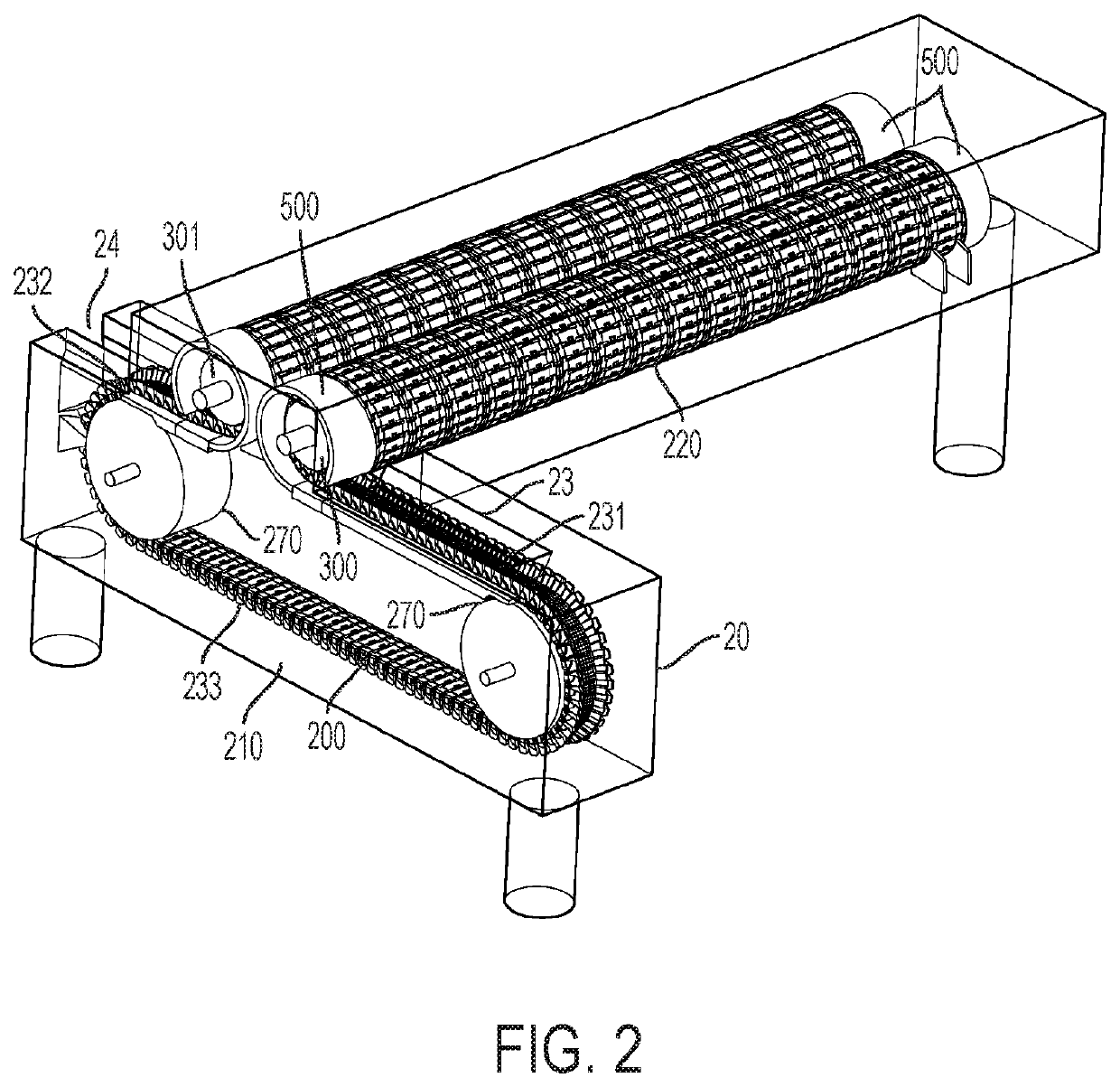

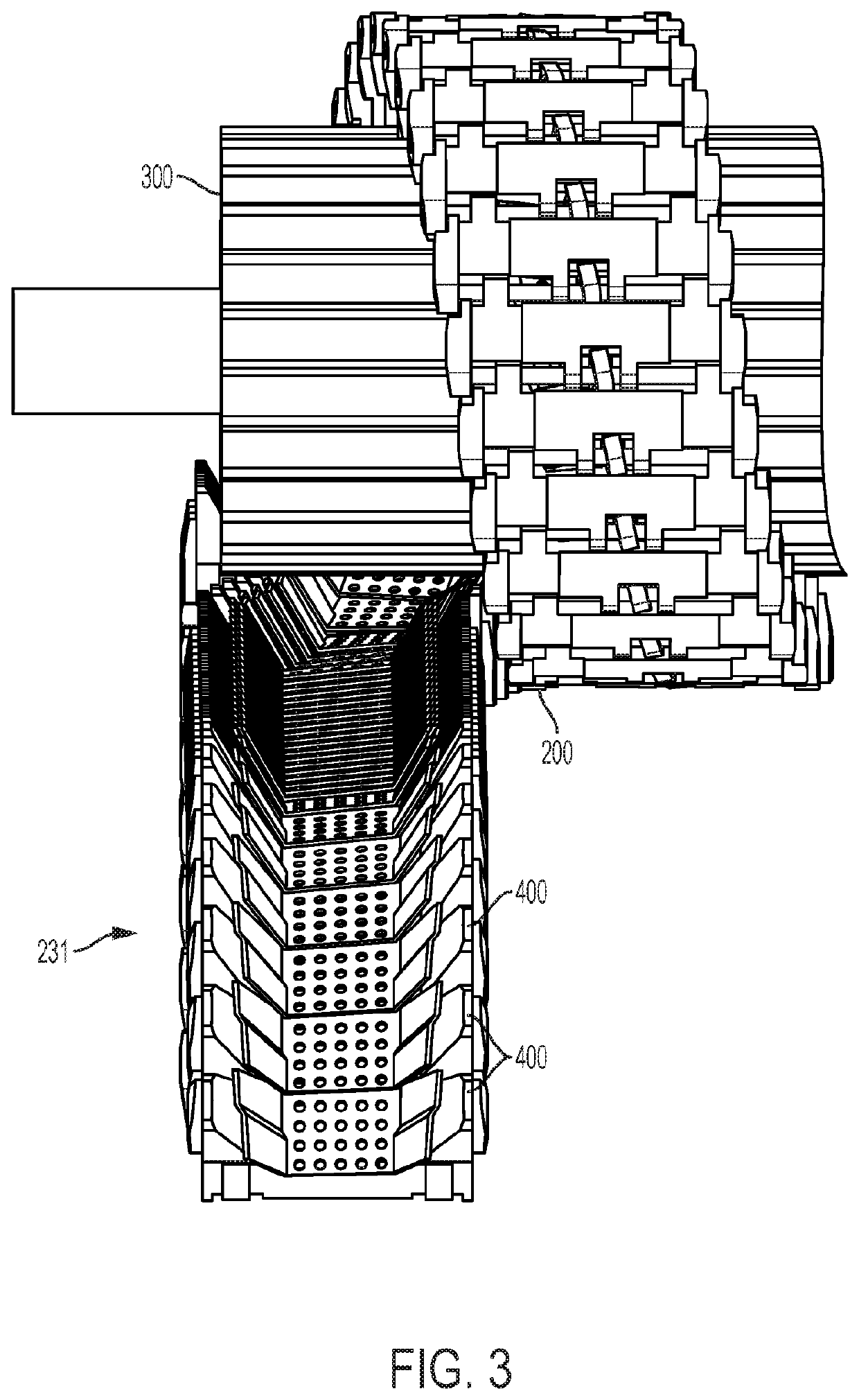

Centrifugal dewatering conveyor system

ActiveUS20200062510A1Promote formationConveyorsDrying solid materials without heatEngineeringStructural engineering

Owner:LAITRAM LLC

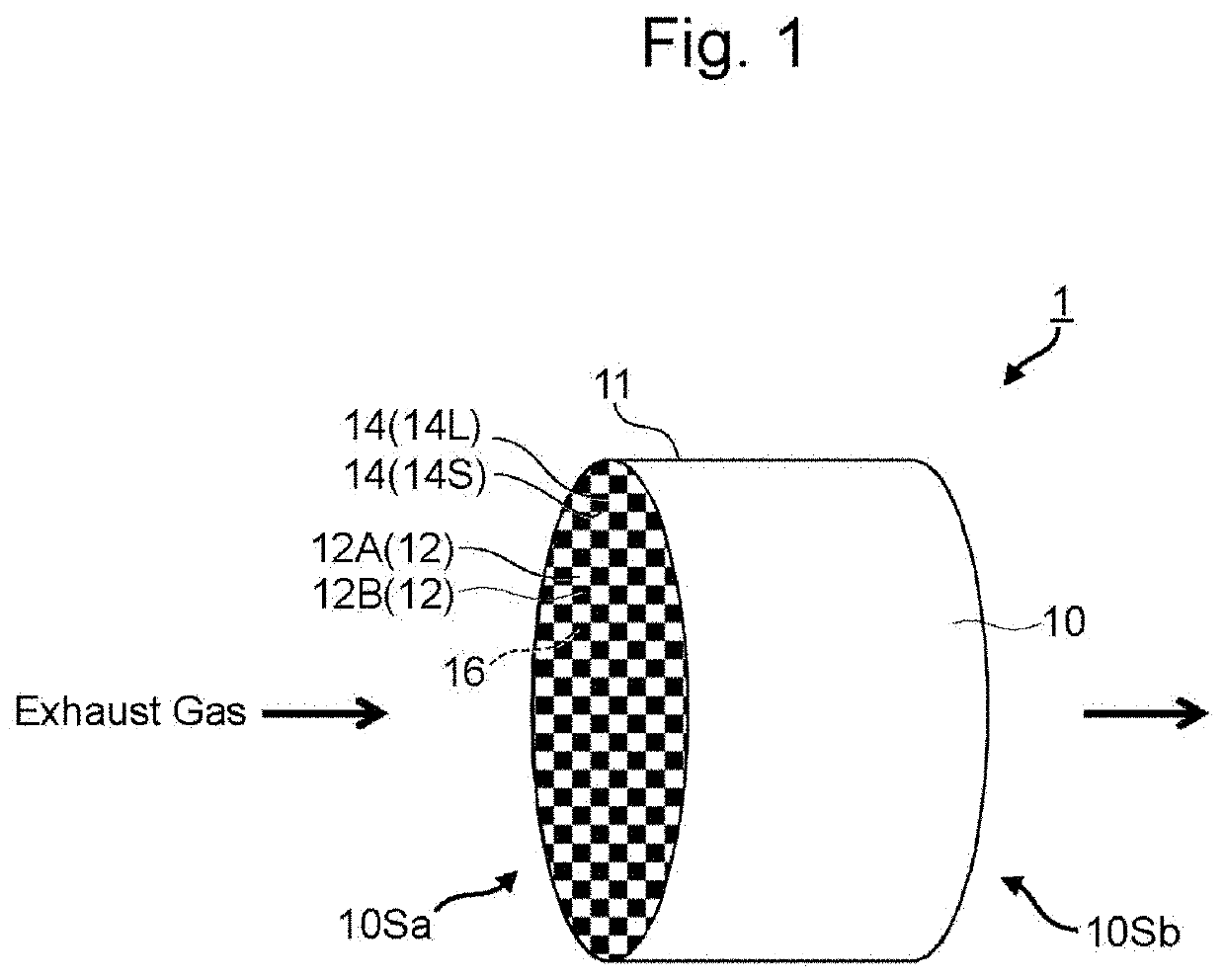

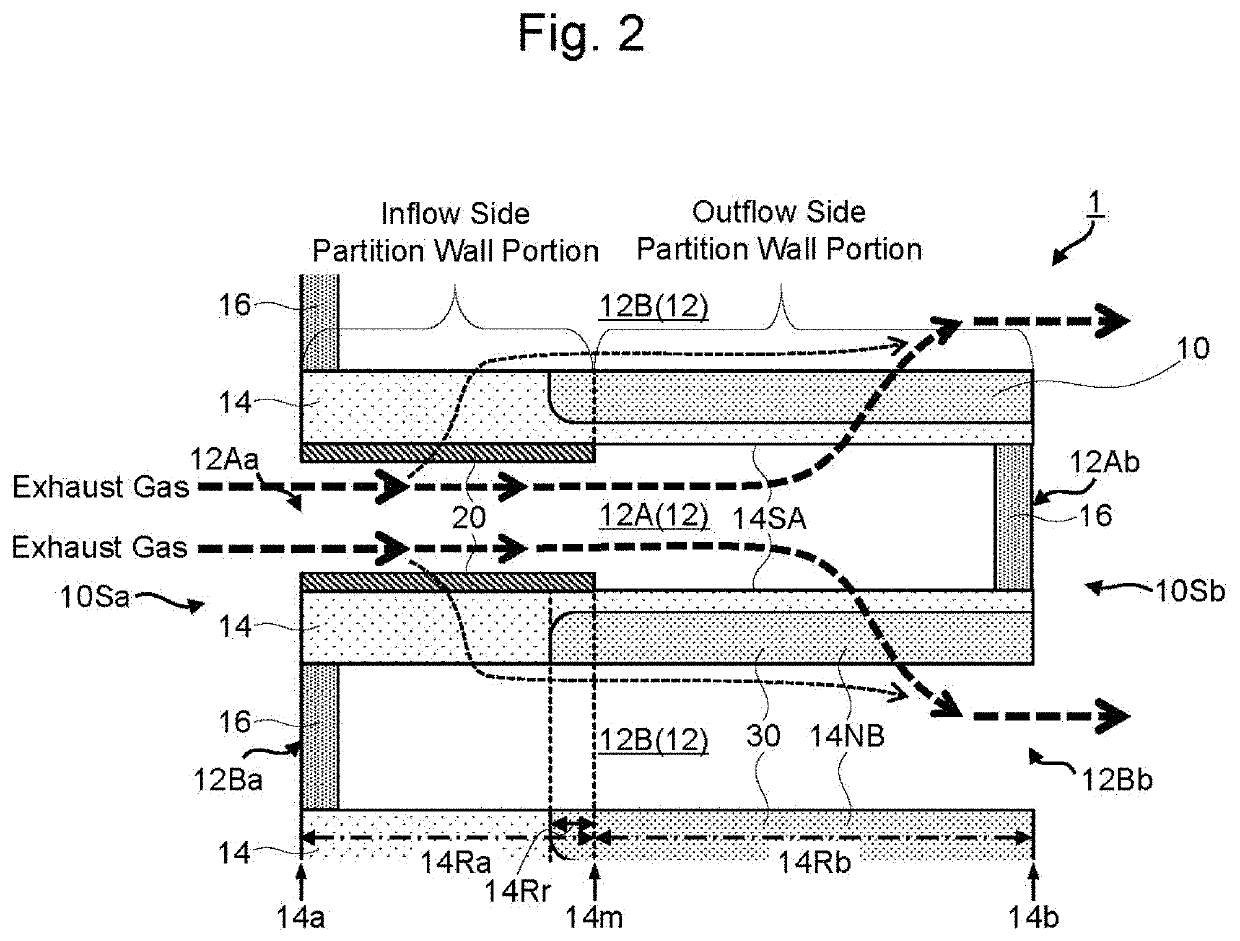

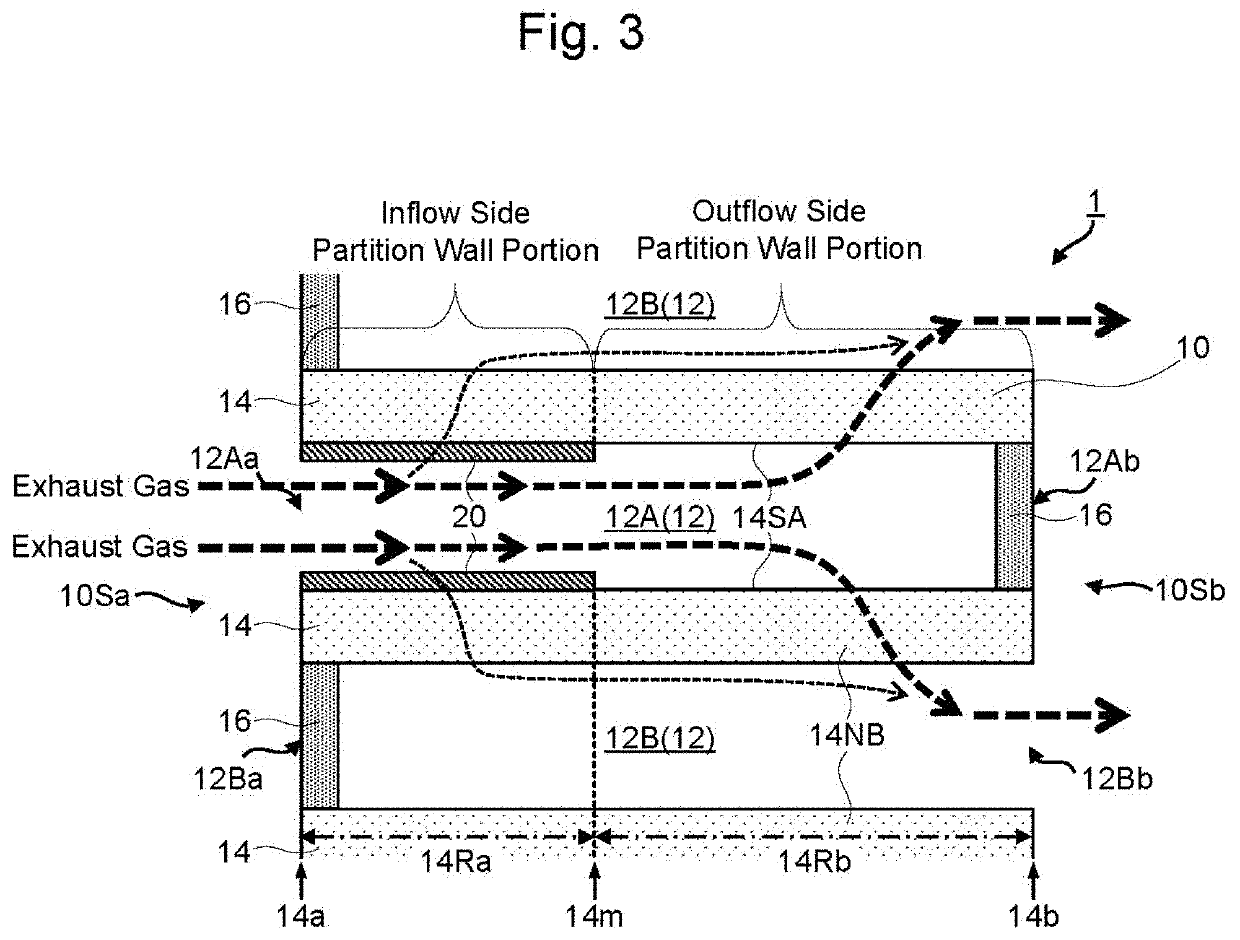

Exhaust gas purification device

ActiveUS20210283589A1Improve purification effectSuppress pressure lossGas treatmentInternal combustion piston enginesPtru catalystExhaust fumes

Owner:TOYOTA JIDOSHA KK +1

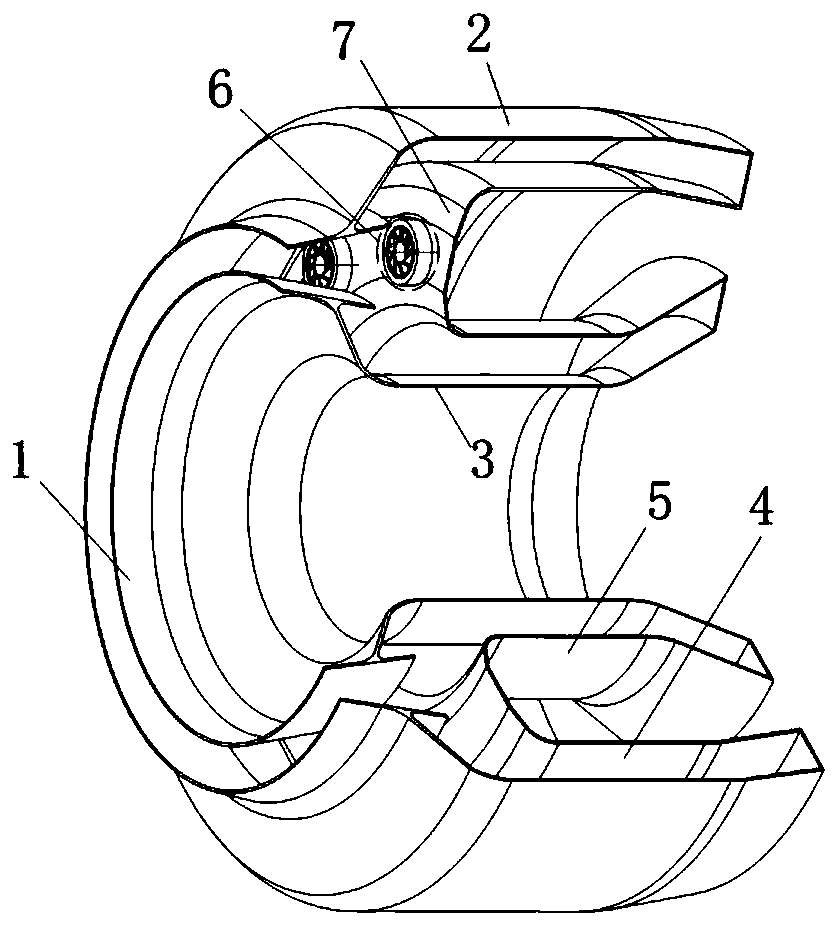

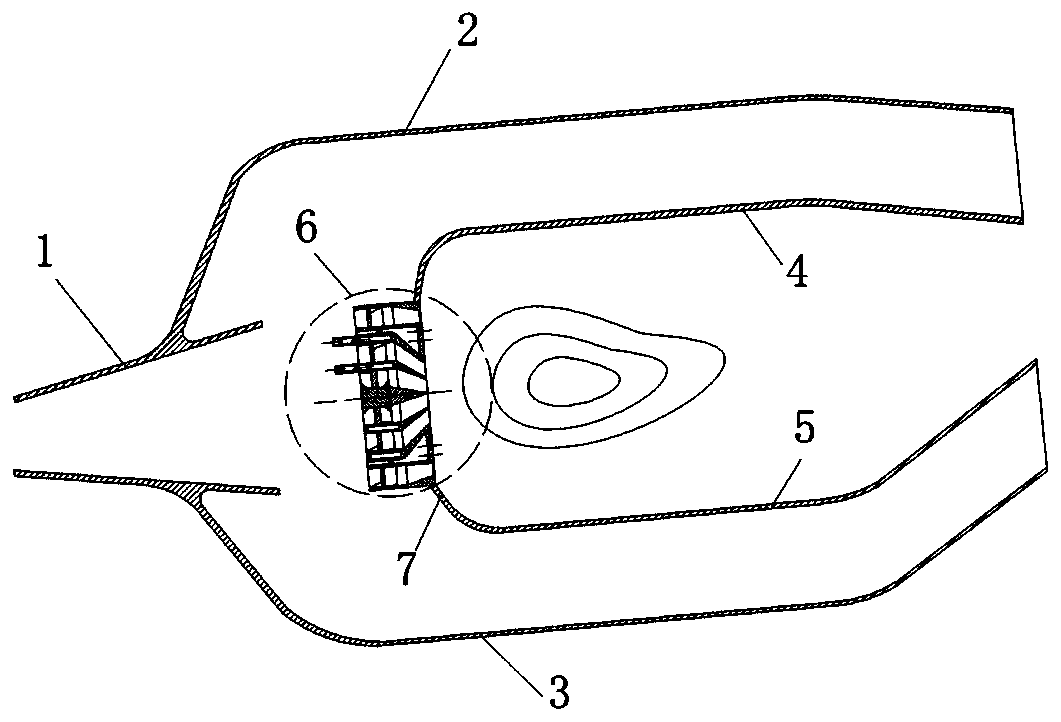

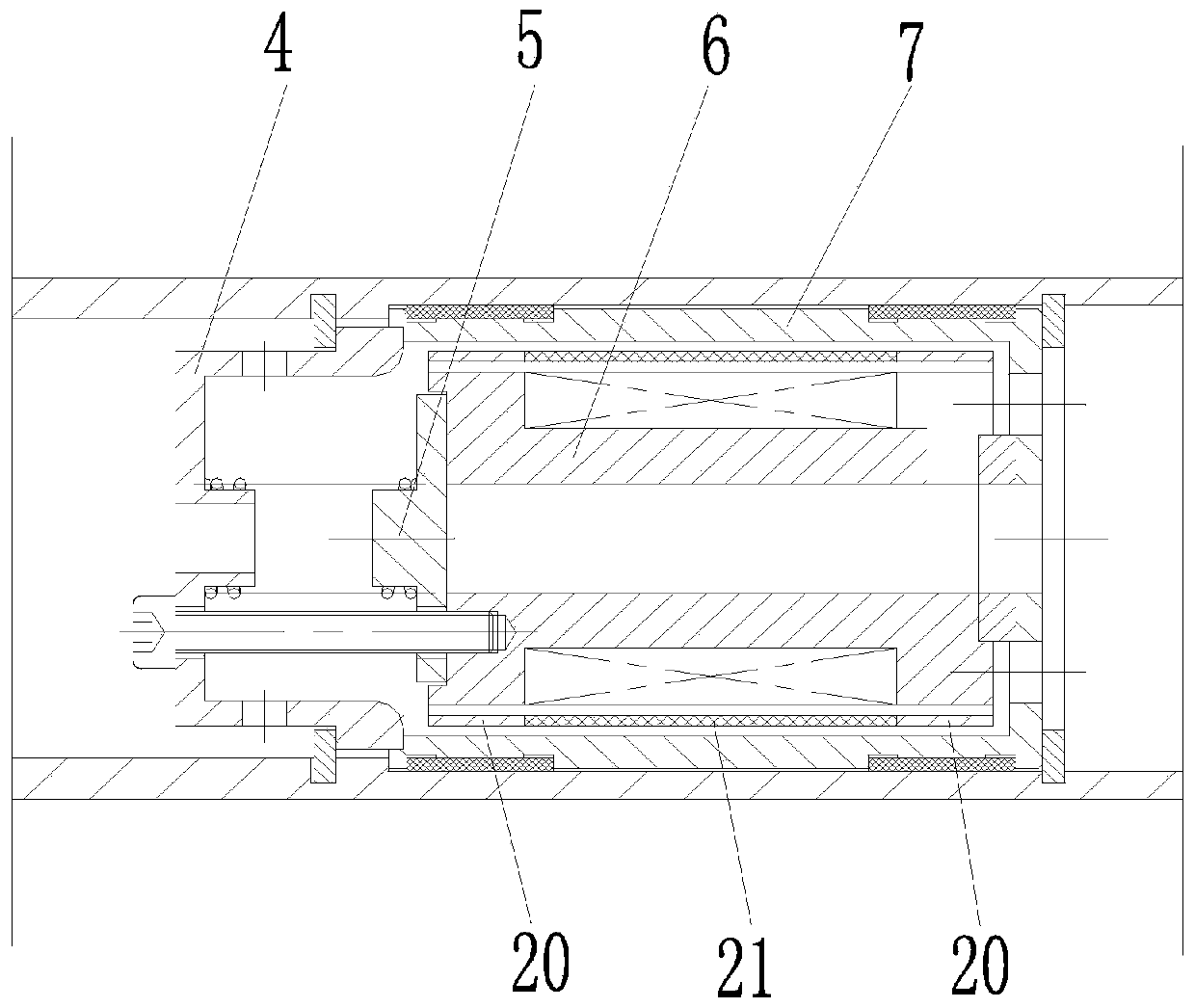

Separated double-cylinder magnetorheological damper

ActiveCN110822009AExtensive controlWide rangeSpringsNon-rotating vibration suppressionReciprocating motionEngineering

Owner:CHONGQING UNIV

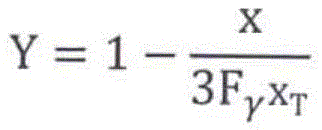

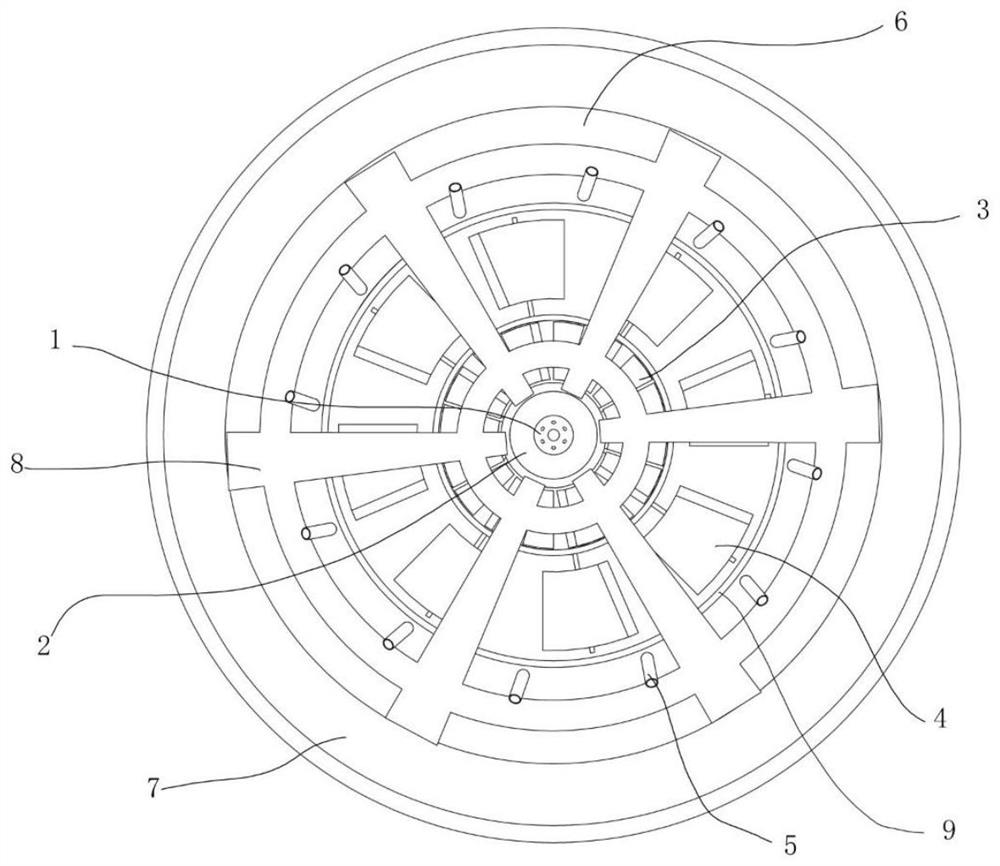

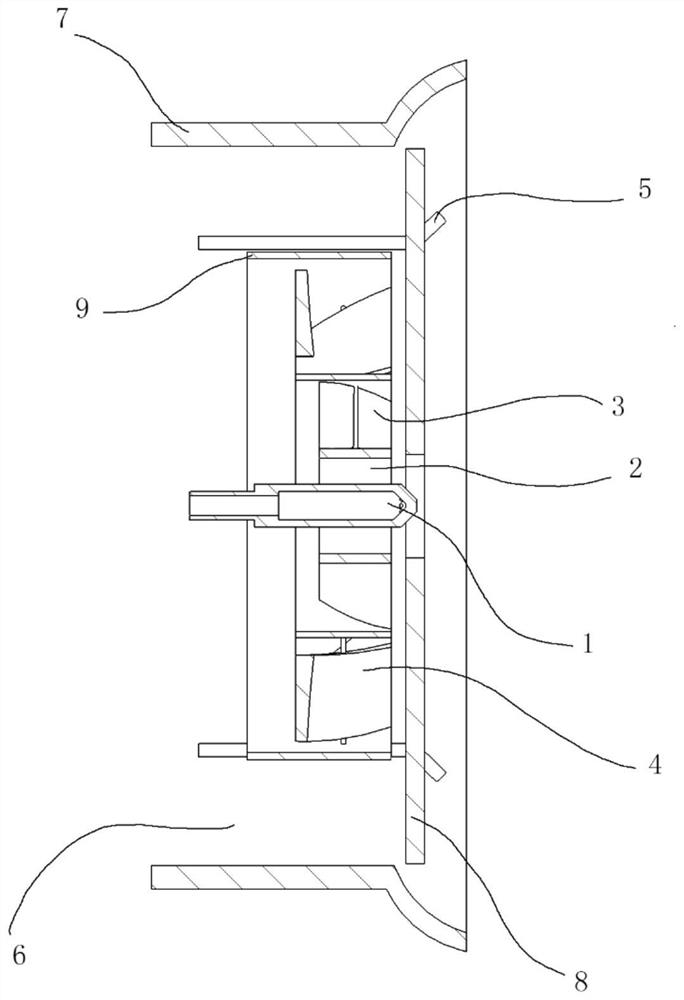

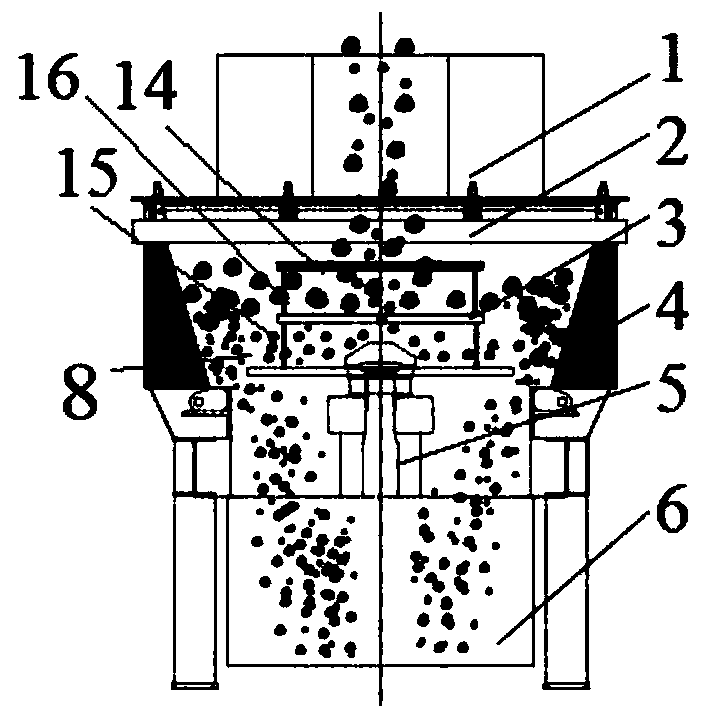

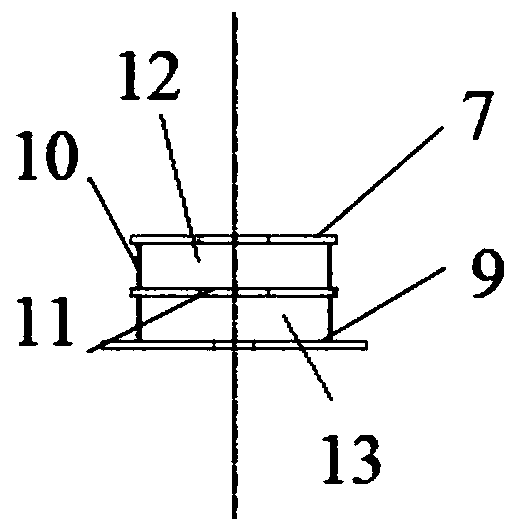

Rotor of sand making machine and sand making machine

ActiveCN111318347AReduce kinetic energy differenceShrinker says broken energy is poorGrain treatmentsThermodynamicsEngineering

Owner:CHINA RAILWAY CONSTR HEAVY IND

Pesticide mixing device with good effect

InactiveCN112999918ARealize quantitative inflowRealize online stirring and mixingRotary stirring mixersTransportation and packagingEngineeringBiology

Owner:深圳市俊达通办公智能科技有限公司

Paint spraying and drying integrated room for robot operation

Owner:苏州金迈驰航空智能科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap